Concrete polishing system

a concrete and concrete technology, applied in the direction of grinding heads, manufacturing tools, grinding machines, etc., can solve the problems of uneven concrete floors, unsightly concrete floors with polished portions and other parts rough, and high cost of time and material for the polishing or grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

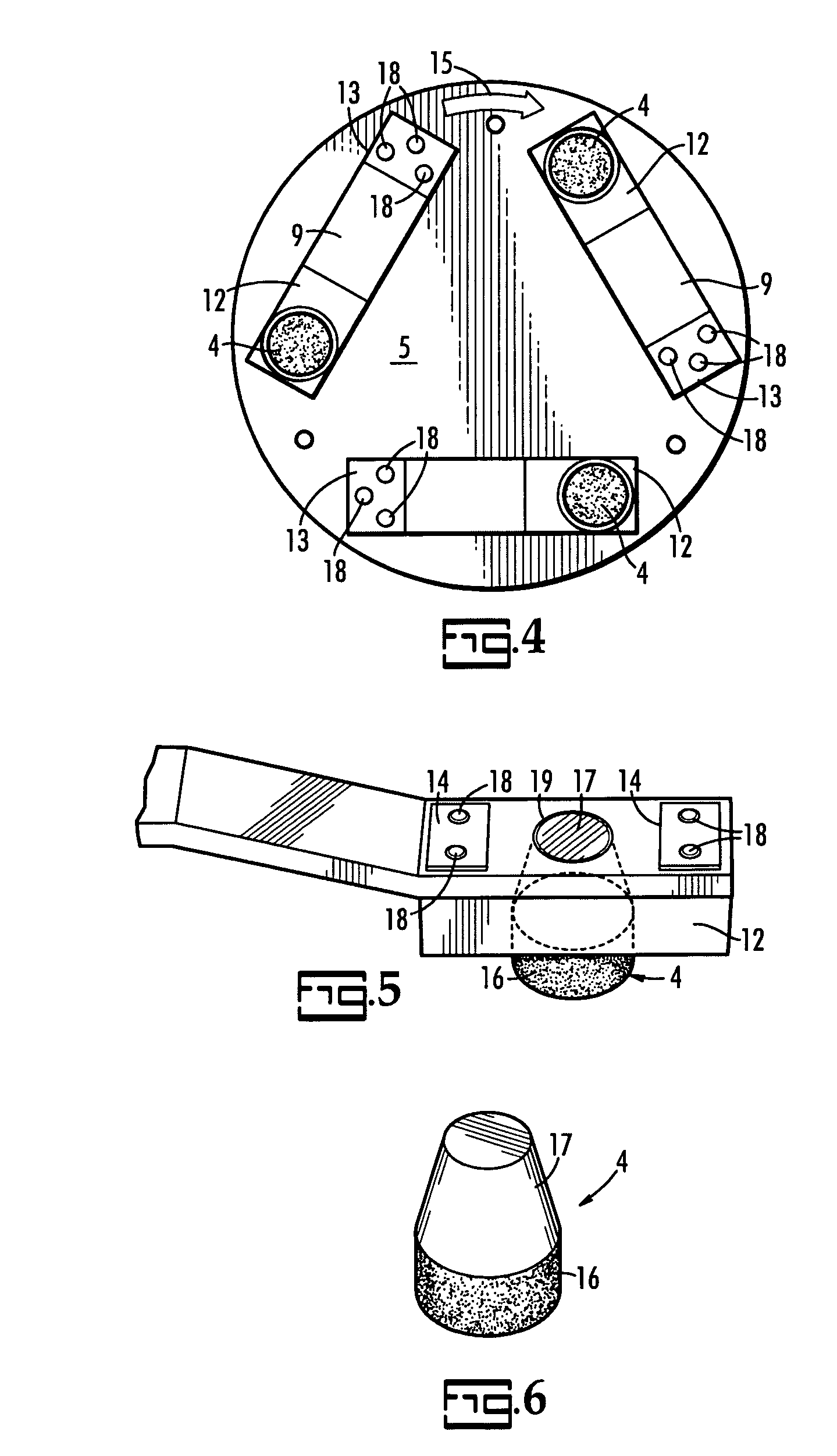

[0029] The invention will be described with reference to the various figures. The figures represent part of the present disclosure but are not intended to limit the scope of the invention. Within the various figures similar elements will be numbered accordingly.

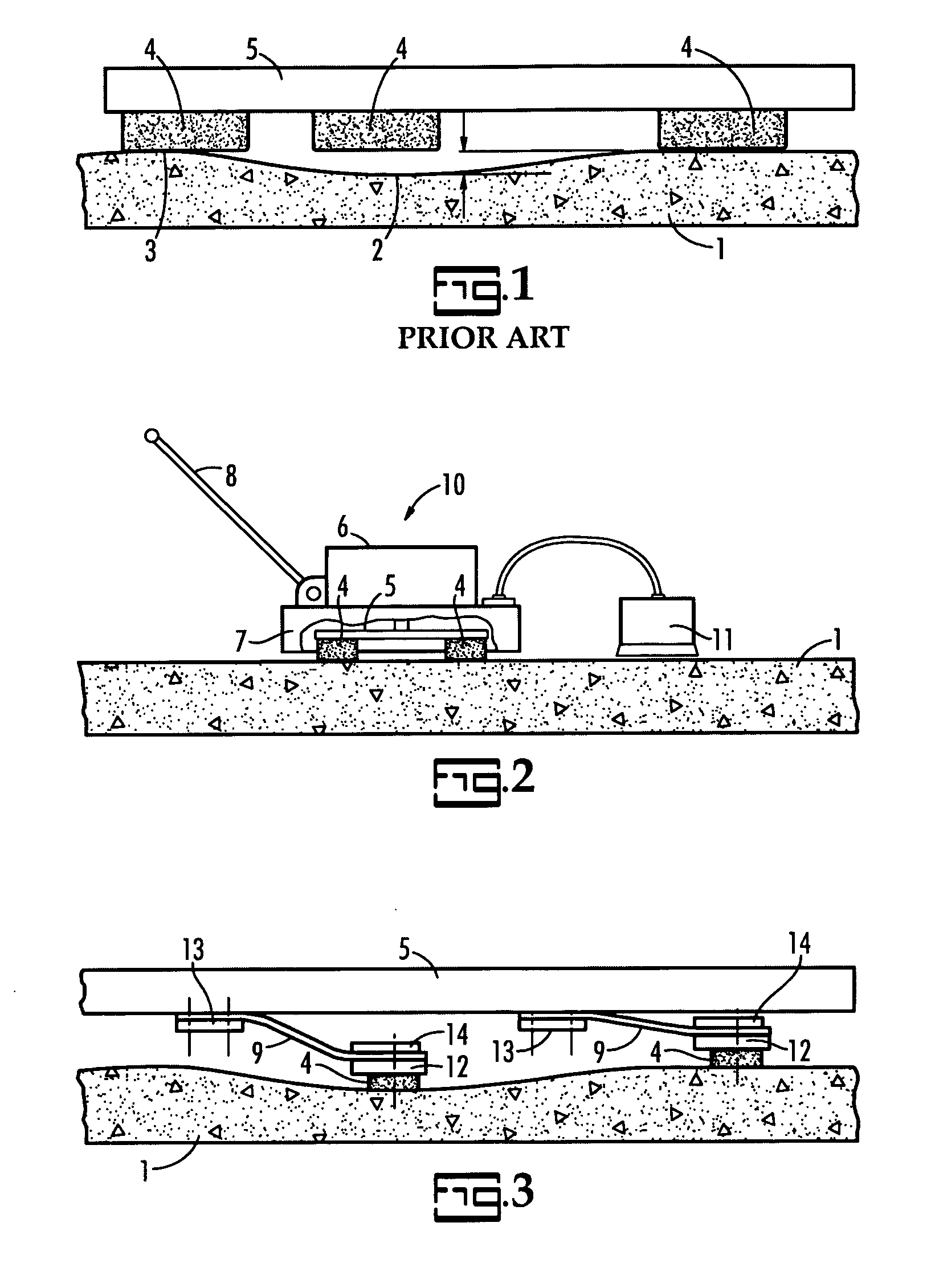

[0030] A floor polisher is illustrated in FIG. 2. In FIG. 2, the floor polisher, 10, comprises abrasive units, 4, mounted on a plate, 5. A motor, 6, rotates the plate, 5. An operator then moves the floor polisher, 10, across the floor by grasping the handle, 8. The combination of the rotating plate and movement of the floor polisher allows the entire surface area to be polished. An optional shroud, 7, assists in decreasing the dust emanating from under the floor polisher. An optional vacuum dust collection system, 11, can be employed as known in the art.

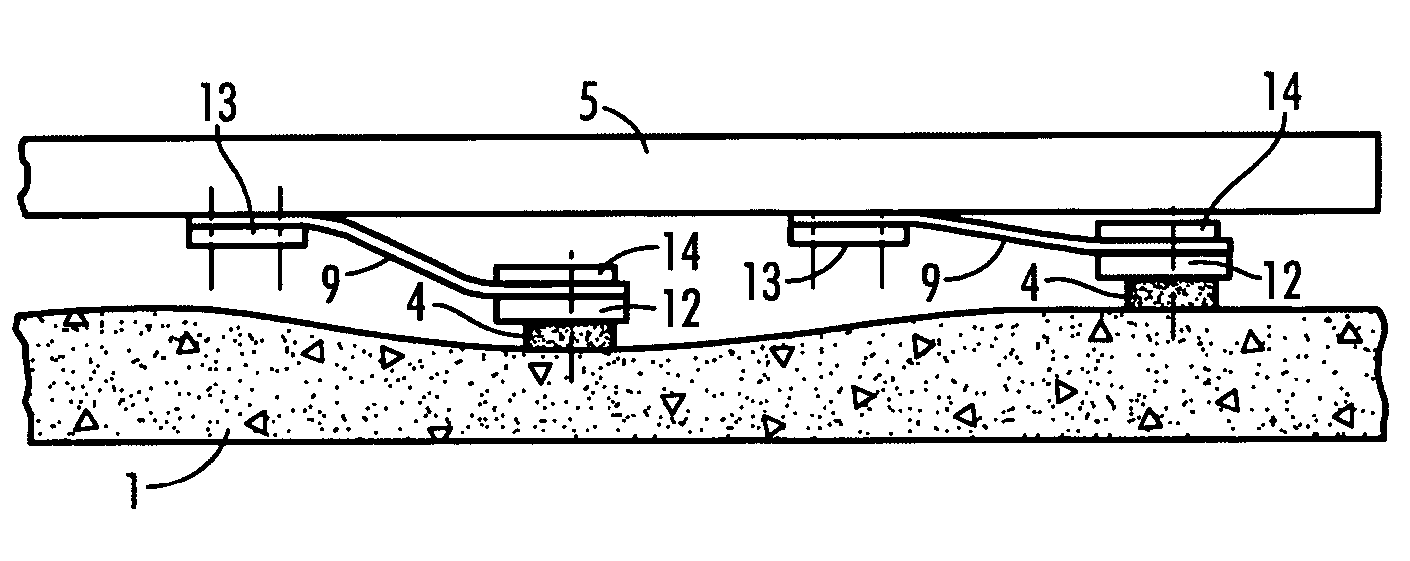

[0031]FIG. 3 is a partial side view of the present invention. In FIG. 3, the plate, 5, has mounted thereon a multiplicity of variable vertical displacement mounting devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com