Surface Grinding Machine and Grinding Head Therefor

a surface grinding machine and grinding head technology, applied in the direction of grinding heads, gear teeth, gear teeth, etc., can solve the problems of excessive grinding disks, energy and manpower, and low spots of floor surfaces that cannot be effectively ground and polished

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

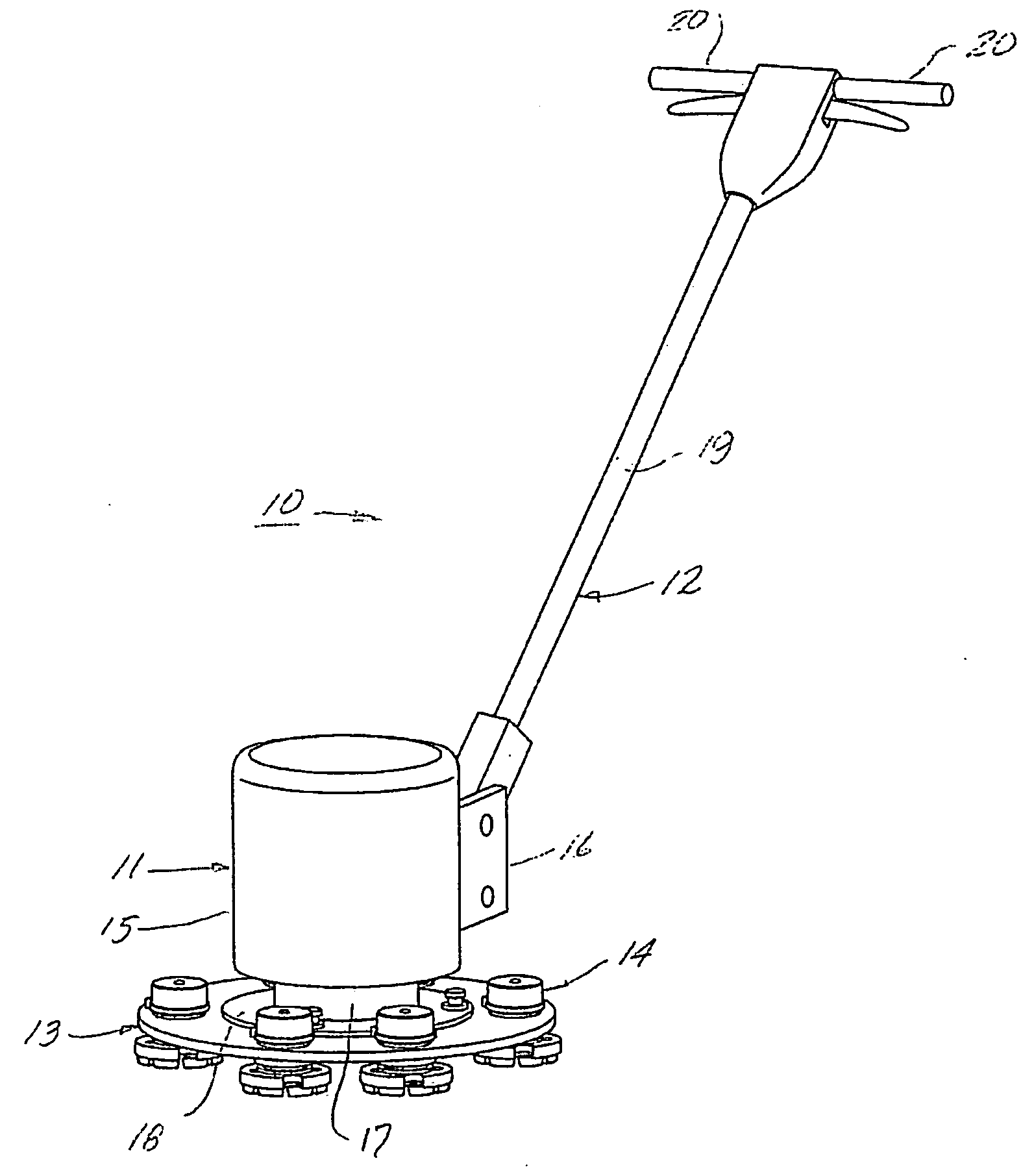

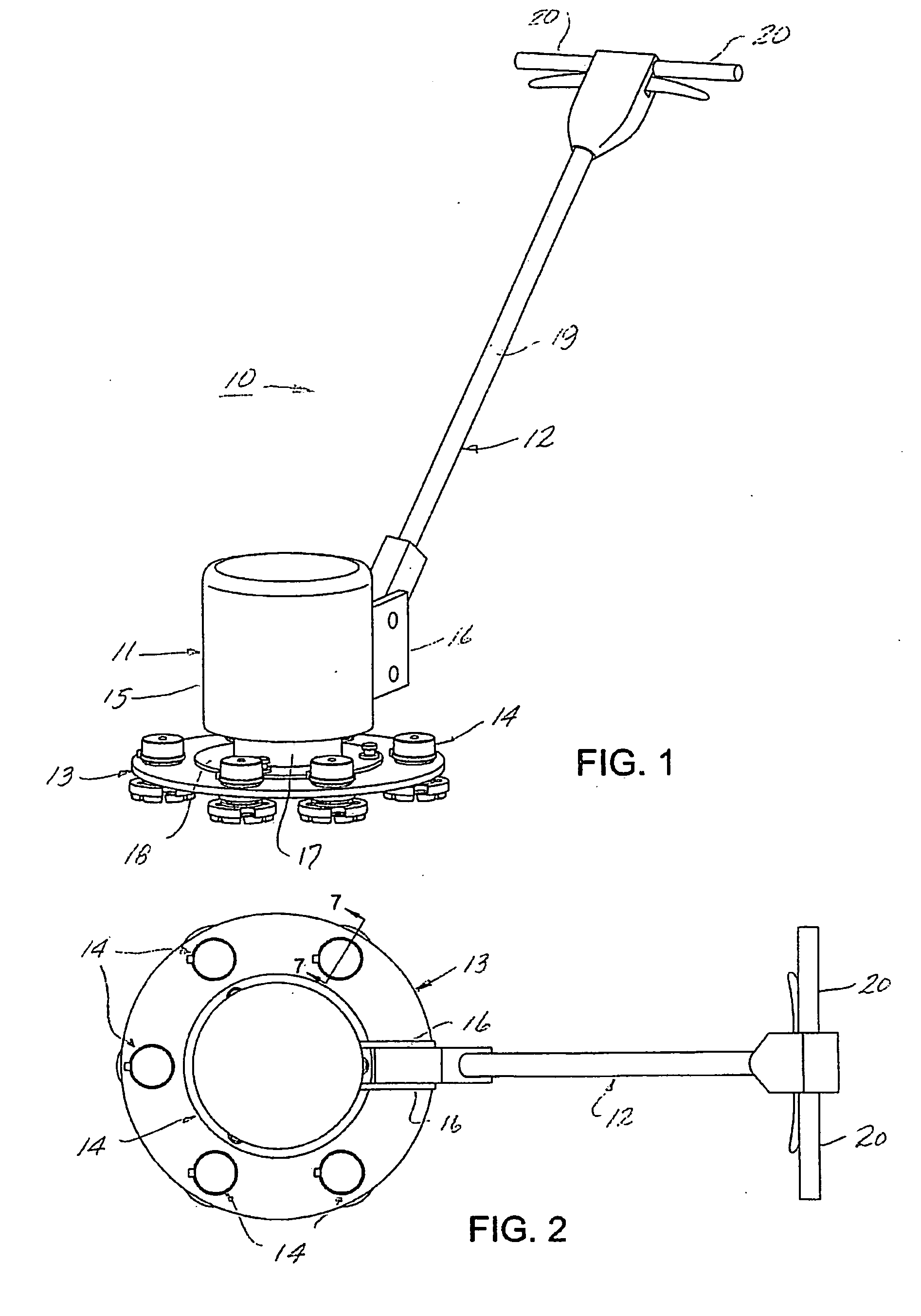

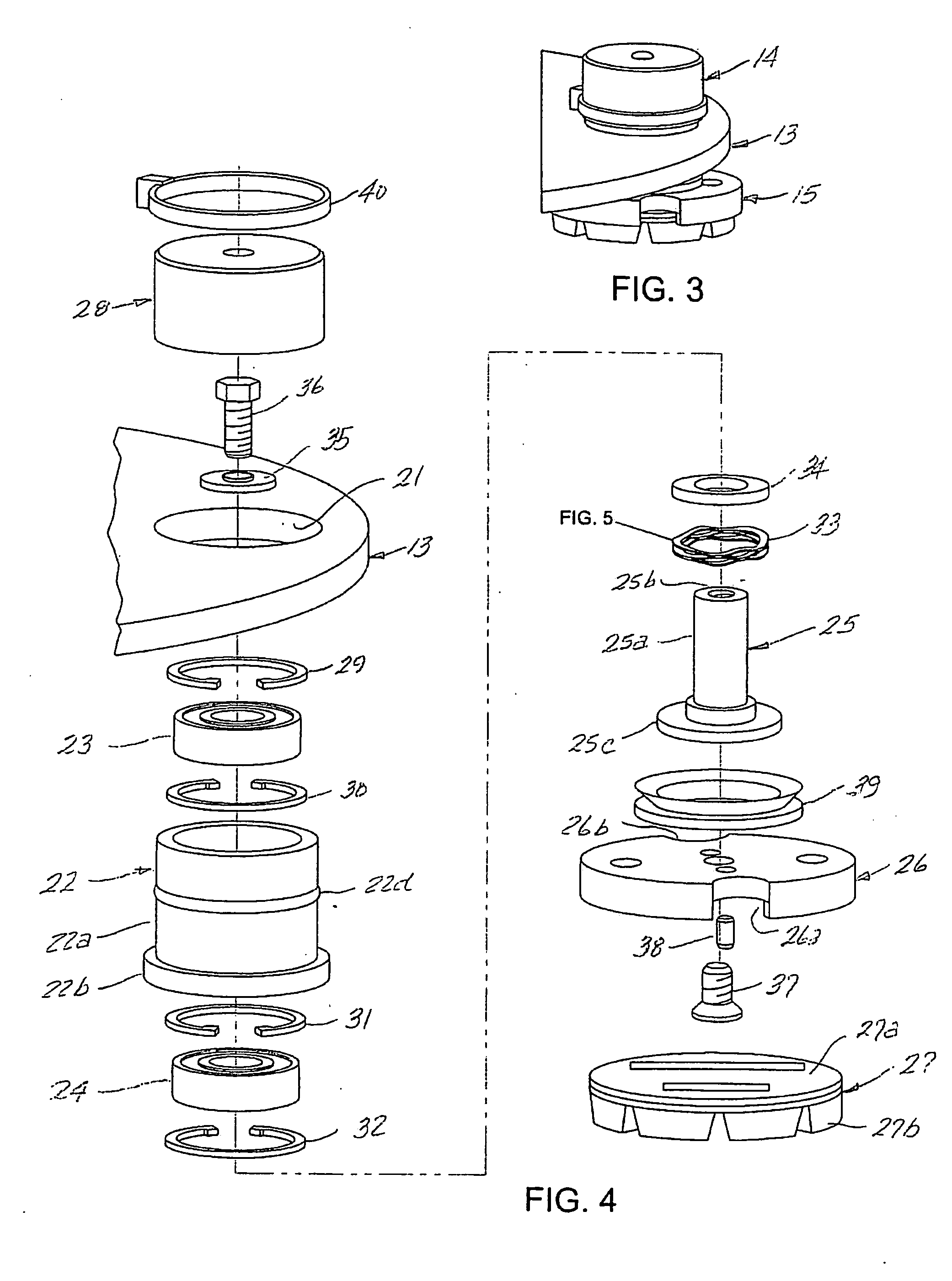

[0012]Referring to FIGS. 1 and 2 of the drawings, there is illustrated a floor grinding machine 10 embodying the present invention which generally includes a motor assembly 11, a handle assembly 12, a planetary disk 13 and a plurality of grinding head units 14. Motor assembly 11 includes a motor mounted within a housing 15 provided with a set of brackets 16, 16, having a depending output shaft. Mounted on the end of the output shaft is a carrier member 17 provided with an annular flange 18. Handle assembly 12 includes an elongated member 19 having a lower end received within and pivotally connected to brackets 16, 16, and a pair of handles 20, 20 disposed at an upper, free end thereof which may be gripped by an operator to guide the machine over a floor surface to be worked. The motor of the machine may be either an internal combustion engine or an electric motor and may be operated in the conventional manner with controls mounted on the handle assembly adjacent handles 20, 20.

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com