Quick polishing equipment for steel pipe surfaces for industry

An industrial and steel pipe technology, which is applied in the field of rapid polishing equipment for industrial steel pipe surfaces, can solve the problems of low polishing quality, time-consuming and labor-intensive polishing process, and high risk of polishing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

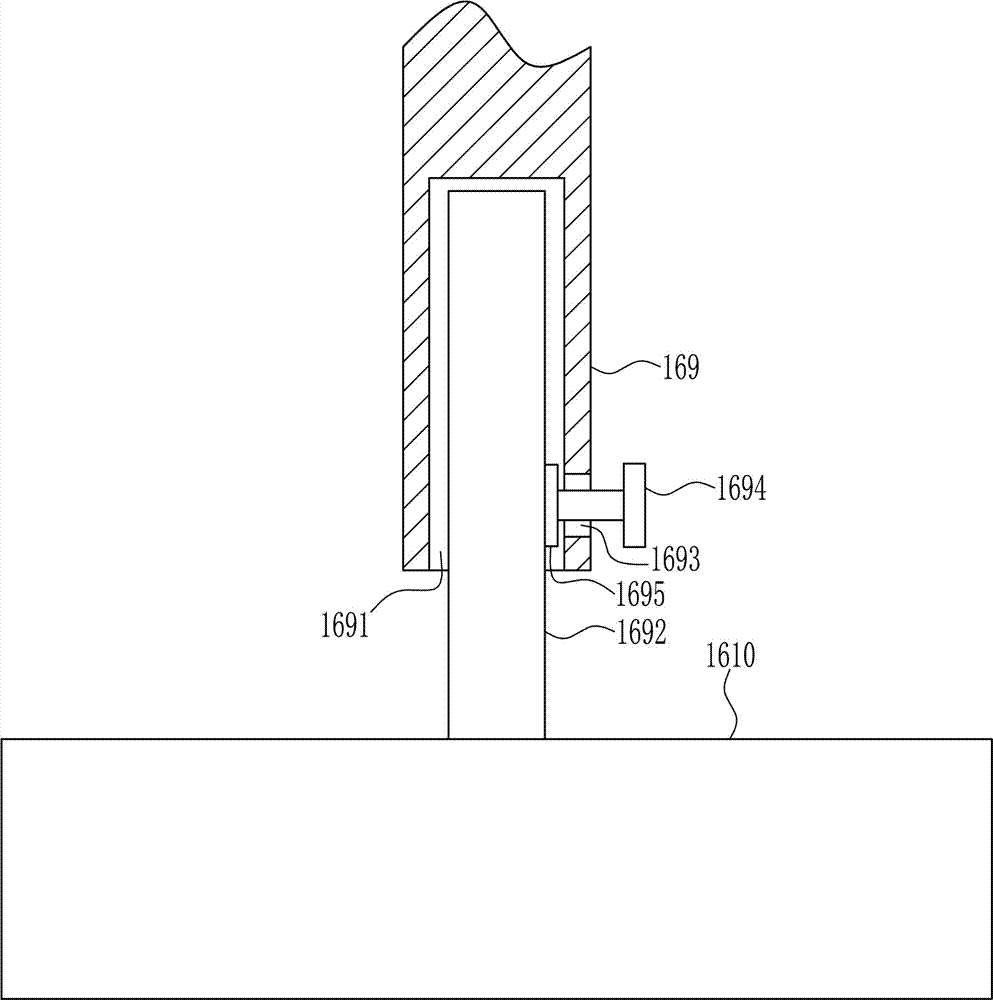

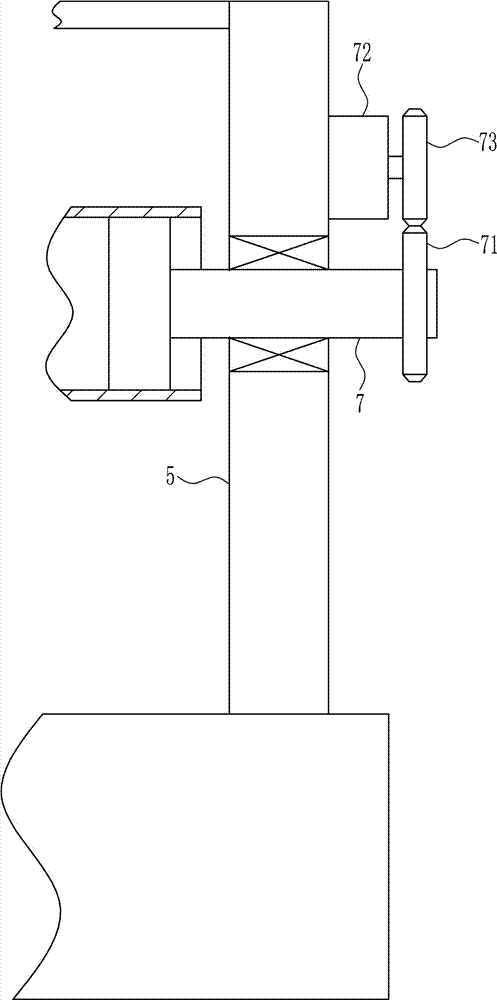

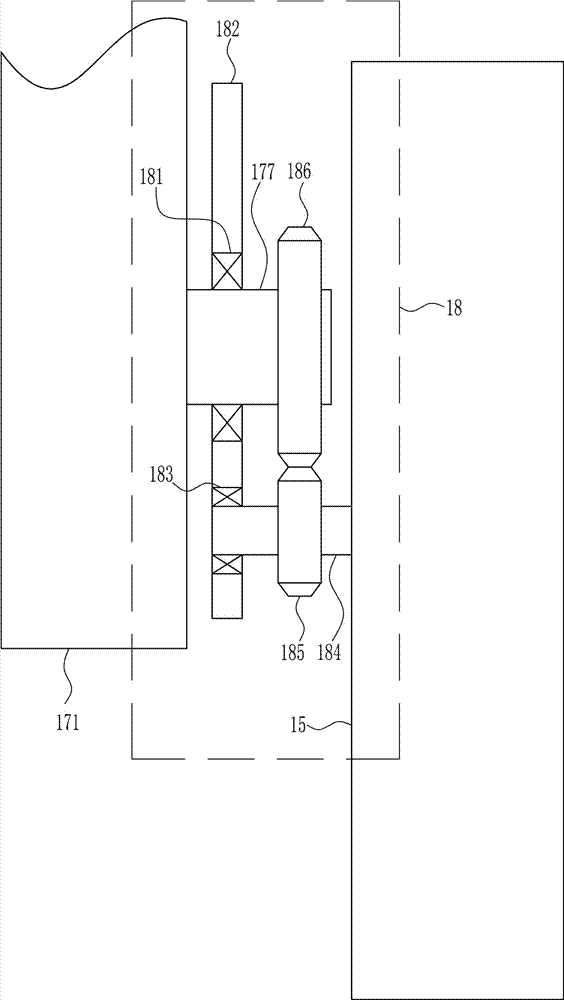

[0038] A kind of rapid polishing equipment for industrial steel pipe surface, such as Figure 1-8 As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, a moving plate 4, a fixed plate 5, a first bearing seat 6, a rotating rod 7, a fixed block 8, a handle 9, a guide rail 11, a moving Block 12, the first motor 14 and the polishing wheel 15, the left side of the base plate 1 is equipped with the first slide rail 2 by means of bolt connection, the first slide rail 2 is slidably connected with the first slide block 3, the first slide block 3 The upper end is installed with a moving plate 4 by welding, the upper right side of the bottom plate 1 is installed with a fixed plate 5 by welding, and the middle parts of the moving plate 4 and the fixed plate 5 are respectively installed with a first bearing seat 6 by bolt connection , the rotating rod 7 is installed in the first bearing seat 6 through an interference connection, the fixed block 8 is installed on t...

Embodiment 2

[0040] A kind of rapid polishing equipment for industrial steel pipe surface, such as Figure 1-8 As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, a moving plate 4, a fixed plate 5, a first bearing seat 6, a rotating rod 7, a fixed block 8, a handle 9, a guide rail 11, a moving Block 12, the first motor 14 and the polishing wheel 15, the left side of the base plate 1 is equipped with the first slide rail 2 by means of bolt connection, the first slide rail 2 is slidably connected with the first slide block 3, the first slide block 3 The upper end is installed with a moving plate 4 by welding, the upper right side of the bottom plate 1 is installed with a fixed plate 5 by welding, and the middle parts of the moving plate 4 and the fixed plate 5 are respectively installed with a first bearing seat 6 by bolt connection , the rotating rod 7 is installed in the first bearing seat 6 through an interference connection, the fixed block 8 is installed on t...

Embodiment 3

[0043] A kind of rapid polishing equipment for industrial steel pipe surface, such as Figure 1-8As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, a moving plate 4, a fixed plate 5, a first bearing seat 6, a rotating rod 7, a fixed block 8, a handle 9, a guide rail 11, a moving Block 12, the first motor 14 and the polishing wheel 15, the left side of the base plate 1 is equipped with the first slide rail 2 by means of bolt connection, the first slide rail 2 is slidably connected with the first slide block 3, the first slide block 3 The upper end is installed with a moving plate 4 by welding, the upper right side of the bottom plate 1 is installed with a fixed plate 5 by welding, and the middle parts of the moving plate 4 and the fixed plate 5 are respectively installed with a first bearing seat 6 by bolt connection , the rotating rod 7 is installed in the first bearing seat 6 through an interference connection, the fixed block 8 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com