Polishing solution for electrochemical polishing of nickel-titanium alloy and application

A nickel-titanium alloy and polishing liquid technology, applied in the chemical industry, can solve problems such as unstable quality, poor operating environment, and environmental pollution, and achieve the effects of good composition stability, low cost, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

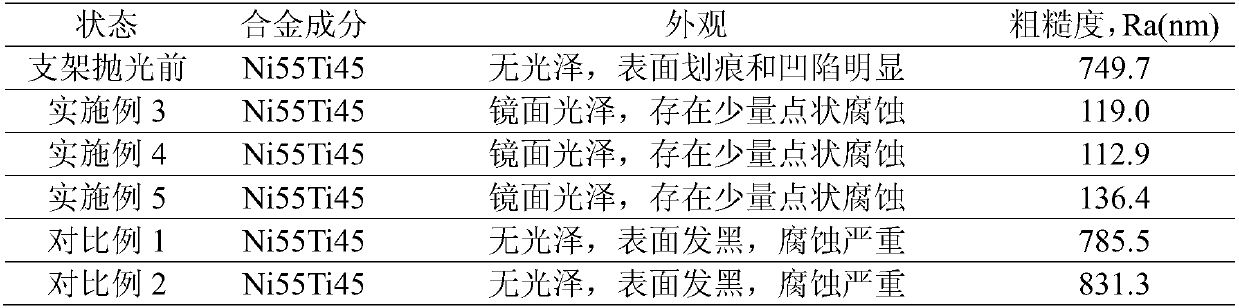

[0030] Preparation, characterization and measuring instruments used in the present invention:

[0031] Quanta FEG450 scanning electron microscope (SEM) with X-ray energy spectrometer (EDS), American FEI company;

[0032] TAYLOR HOBOSN roughness profiler;

[0033] CHI660E electrochemical workstation, Shanghai Chenhua.

Embodiment 1

[0035] The electrolytic polishing solution and polishing method for a nickel-titanium alloy device involved in the present invention have an external diameter of 2 mm, a wall thickness of 0.1 mm, and a length of 10 mm for a nickel-titanium alloy pipe material Ni55Ti45, which is polished to make it appear mirror luster, specifically Proceed as follows:

[0036] Step 1: ultrasonically clean a nickel-titanium alloy pipe with an outer diameter of 2 mm, a wall thickness of 0.1 mm, and a length of 10 mm in acetone, purified water, and absolute ethanol for 10 minutes;

[0037] Step 2: Measure 210mL of concentrated sulfuric acid, 510mL of ethylene glycol, and 280mL of purified water in a fume hood with a graduated cylinder, add the concentrated sulfuric acid into the purified water and stir evenly, then add it to ethylene glycol after dilution, and stir for 10 minutes to mix well;

[0038] Step 3: Use the nickel-titanium alloy tube as the anode and the stainless steel as the cathode, ...

Embodiment 2

[0042] The electrolytic polishing solution and polishing method for a nickel-titanium alloy device involved in the present invention have an external diameter of 2 mm, a wall thickness of 0.1 mm, and a length of 10 mm for a nickel-titanium alloy pipe material Ni55Ti45, which is polished to make it appear mirror luster, specifically Proceed as follows:

[0043]Step 1: ultrasonically clean a nickel-titanium alloy pipe with an outer diameter of 2 mm, a wall thickness of 0.1 mm, and a length of 10 mm in acetone, purified water, and absolute ethanol for 10 minutes;

[0044] Step 2: Measure 430mL of concentrated sulfuric acid, 370mL of ethylene glycol, and 200mL of purified water in a fume hood with a graduated cylinder, add the concentrated sulfuric acid into the purified water and stir evenly, then add it to ethylene glycol after dilution, and stir for 10 minutes to mix well;

[0045] Step 3: Use the nickel-titanium alloy tube as the anode and the stainless steel as the cathode, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com