Retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification

An oil and gas reservoir and retarding technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reducing acidification effect, poor compatibility, long hydrolysis time, etc., achieve long effective action time, small environmental pollution, The effect of short hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

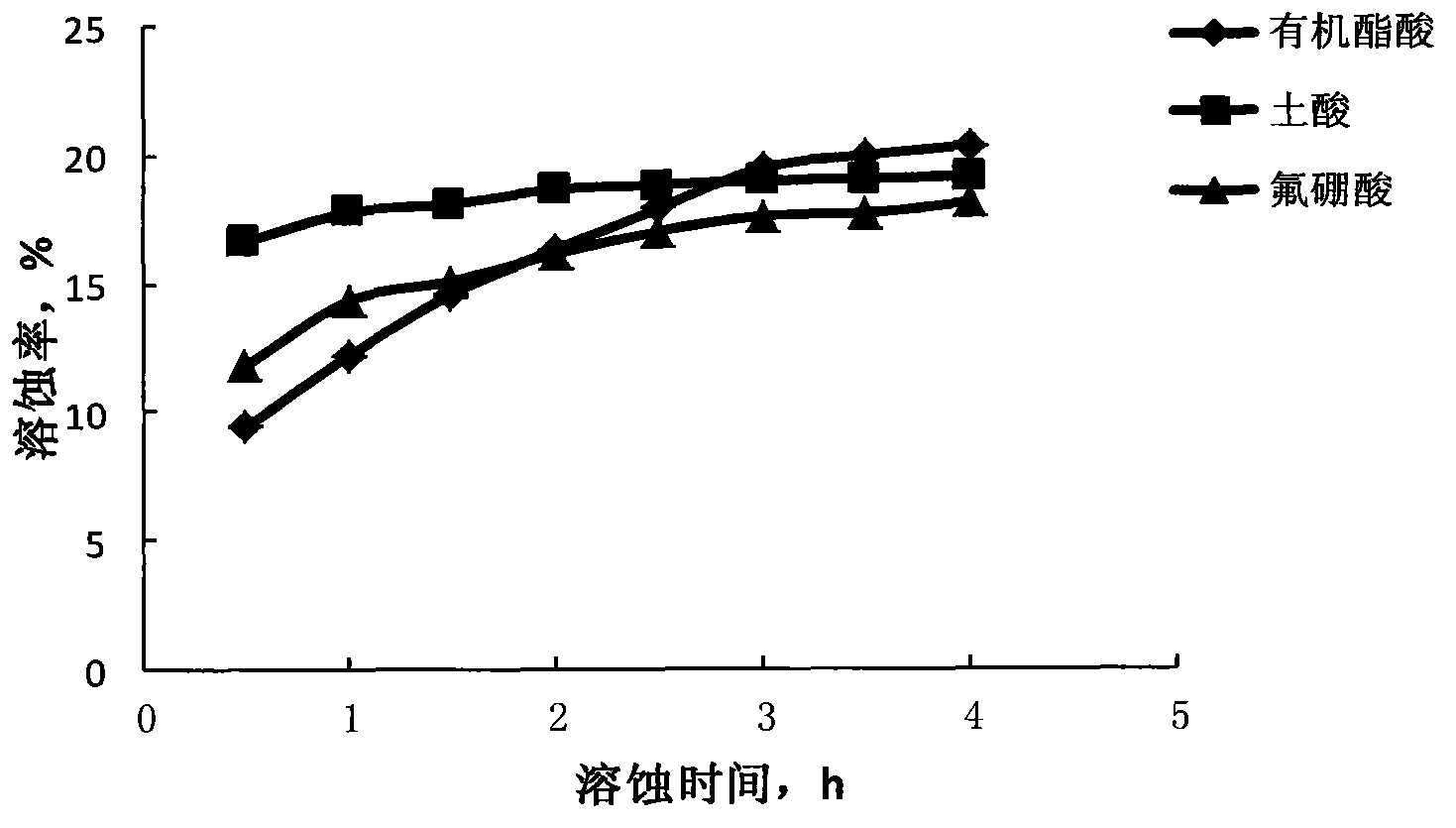

[0025] Weigh 10 parts by weight of dimethyl carbonate, 0.5-3 parts by weight of hydrofluoric acid, 0.05 parts by weight of N-methyldiethanolamine, 1 part by weight of nonylphenol polyoxyethylene ether corrosion inhibitor, and 1 part by weight of hydroxylamine hydrochloride iron ion Stabilizer, 1 part by weight of organic cationic quaternary ammonium salt polymer clay stabilizer, 2 parts by weight of dodecyltrimethylammonium chloride drainage aid, 80-82 parts by weight of water, stirring rapidly at room temperature until fully mixed, Configured as an acidified formula system.

Embodiment 2

[0027] Weigh 10 parts by weight of dimethyl carbonate, 6-12 parts by weight of fluoroboric acid, 0.05 parts by weight of N-methyldiethanolamine, 1 part by weight of nonylphenol polyoxyethylene ether corrosion inhibitor, and 1 part by weight of hydroxylamine hydrochloride for iron ion stabilization Agent, 1 part by weight of organic cationic quaternary ammonium salt polymer clay stabilizer, 2 parts by weight of dodecyltrimethylammonium chloride drainage aid, 80-82 parts by weight of water, stir rapidly at room temperature until fully mixed, and configure into an acidified formula system.

Embodiment 3

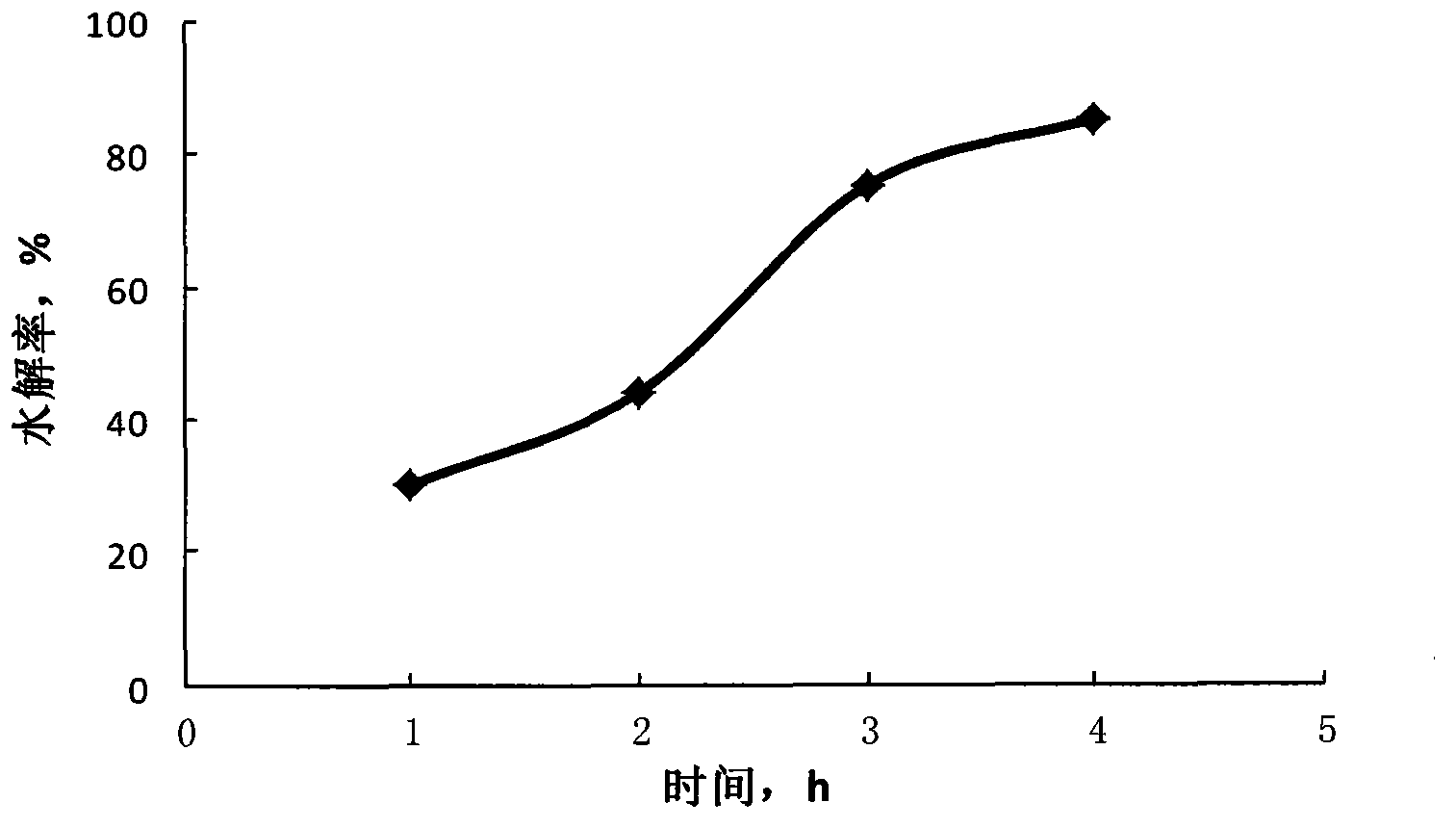

[0029] Weigh 10 parts by weight of dimethyl carbonate and 0.05 parts by weight of N-methyldiethanolamine, and at 140°C, the hydrolysis effect can be seen figure 1 , The hydrolysis rate reaches 80% within 4 hours, and can produce 8% equivalent of methanol and 5% equivalent of carbon dioxide, which helps to relieve the water lock damage of condensate oil and gas reservoirs and promote acid flowback.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com