Patents

Literature

52results about How to "Short hydrolysis time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification

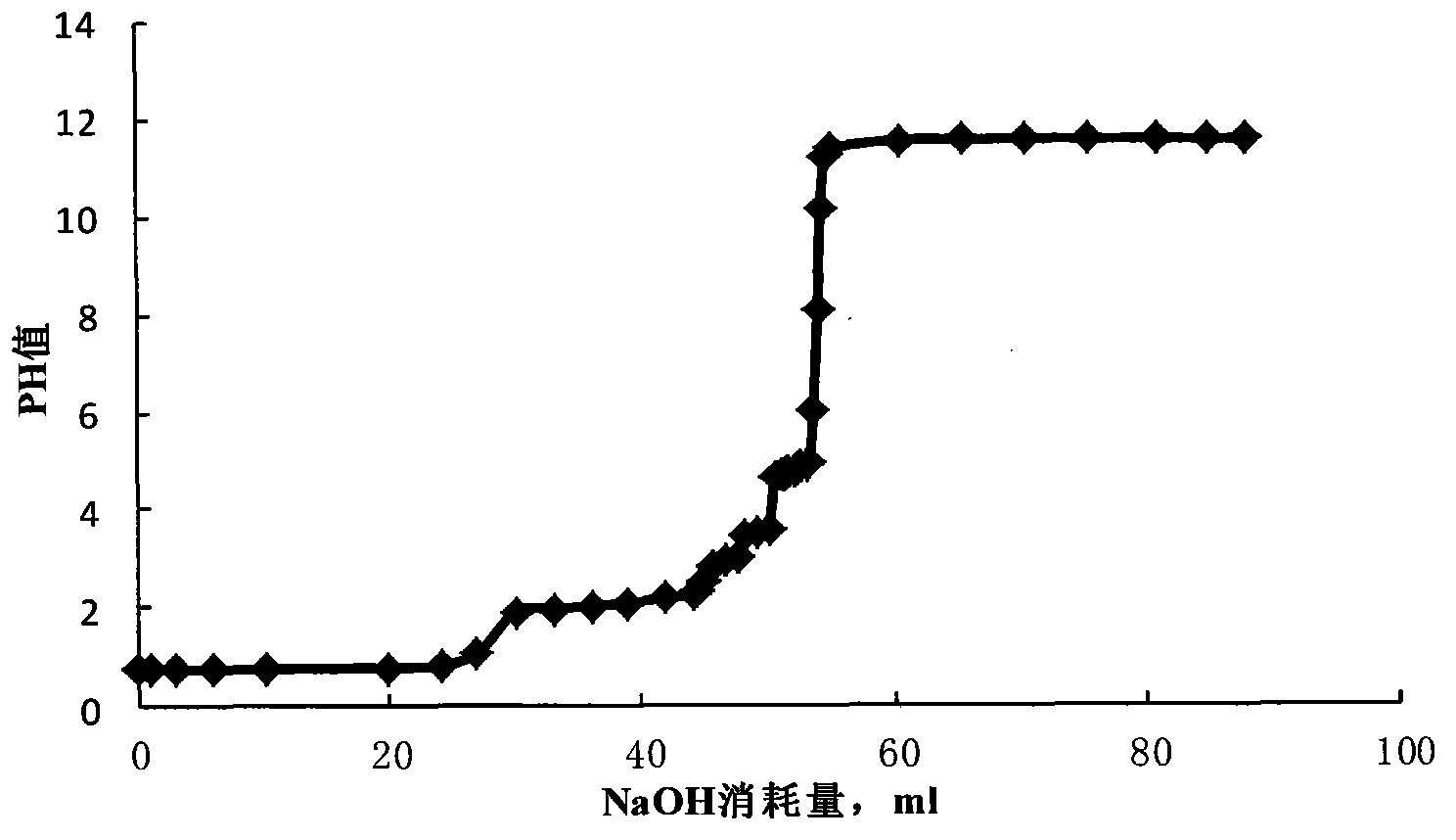

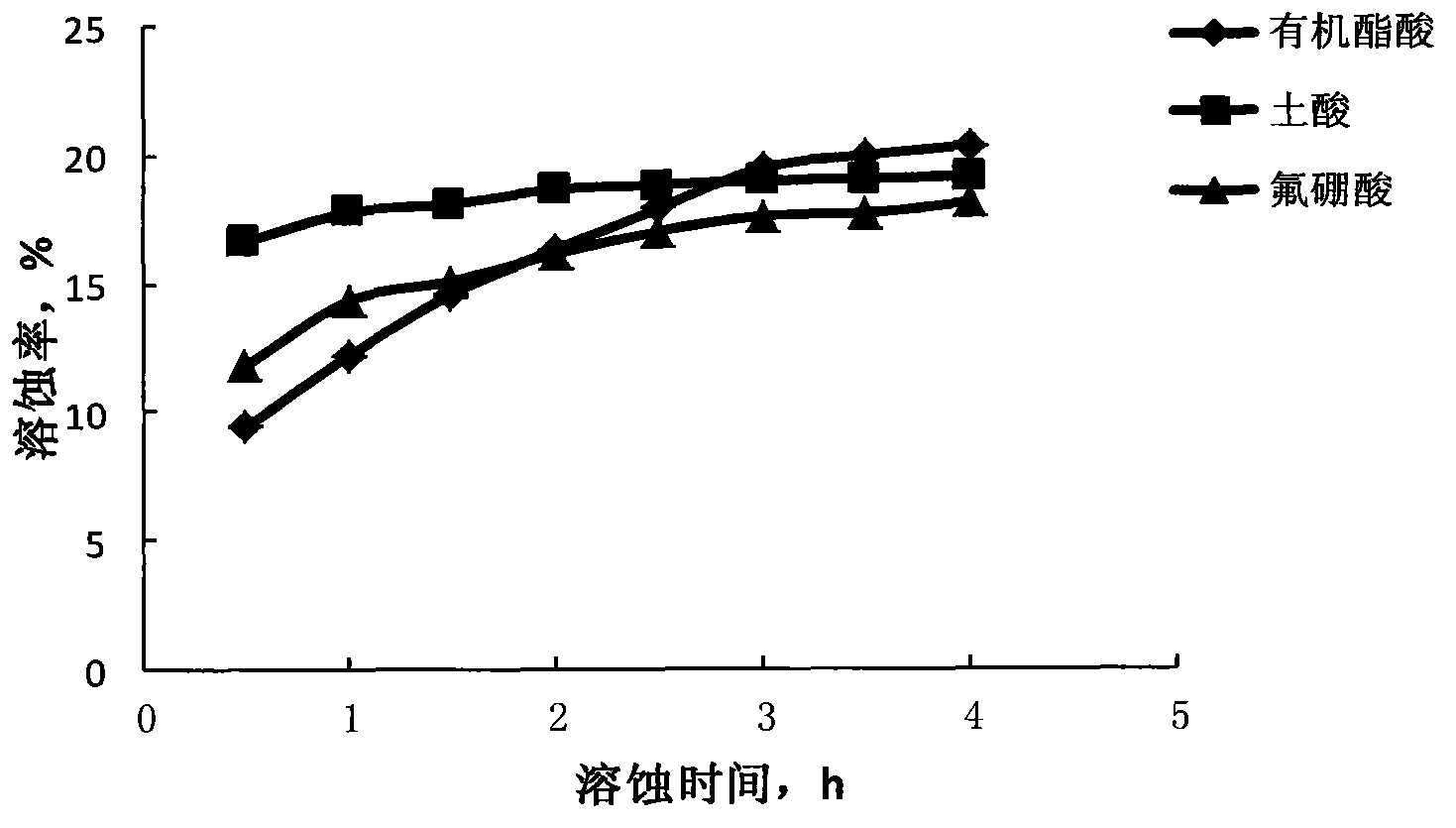

The present invention discloses a retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification. The acid solution system is suitable for acidification modification of high temperature deep well, particularly condensate gas reservoir, and comprises the following components, by weight, 0.5-3 parts of hydrofluoric acid or 6-12 parts of fluoroboric acid, 8-10 parts of an organic ester, 0.01-0.05 part of a catalyst, 0.1-1 part of a corrosion inhibitor, 0.1-1 part of an iron ion stabilizer, 0.1-1 part of a clay stabilizer, 1-2 parts of a cleanup additive, and 80-100 parts of water. According to the present invention, effects of retardance and corrosion inhibition of the acid solution system can be well achieved at a high temperature, and water blocking can be released and acid solution backflow can be easily achieved with the finally produced methanol and the carbon dioxide.

Owner:SOUTHWEST PETROLEUM UNIV

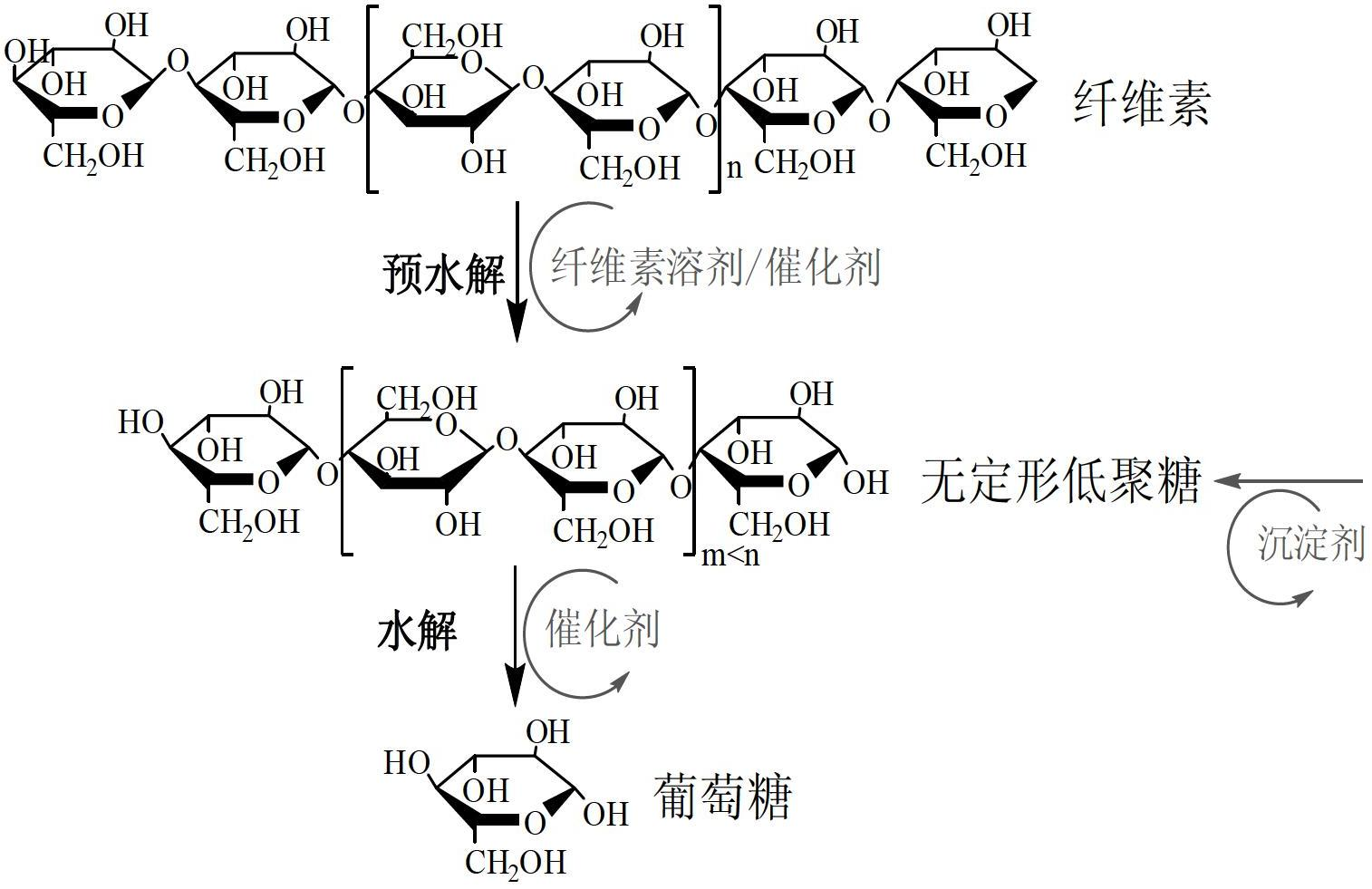

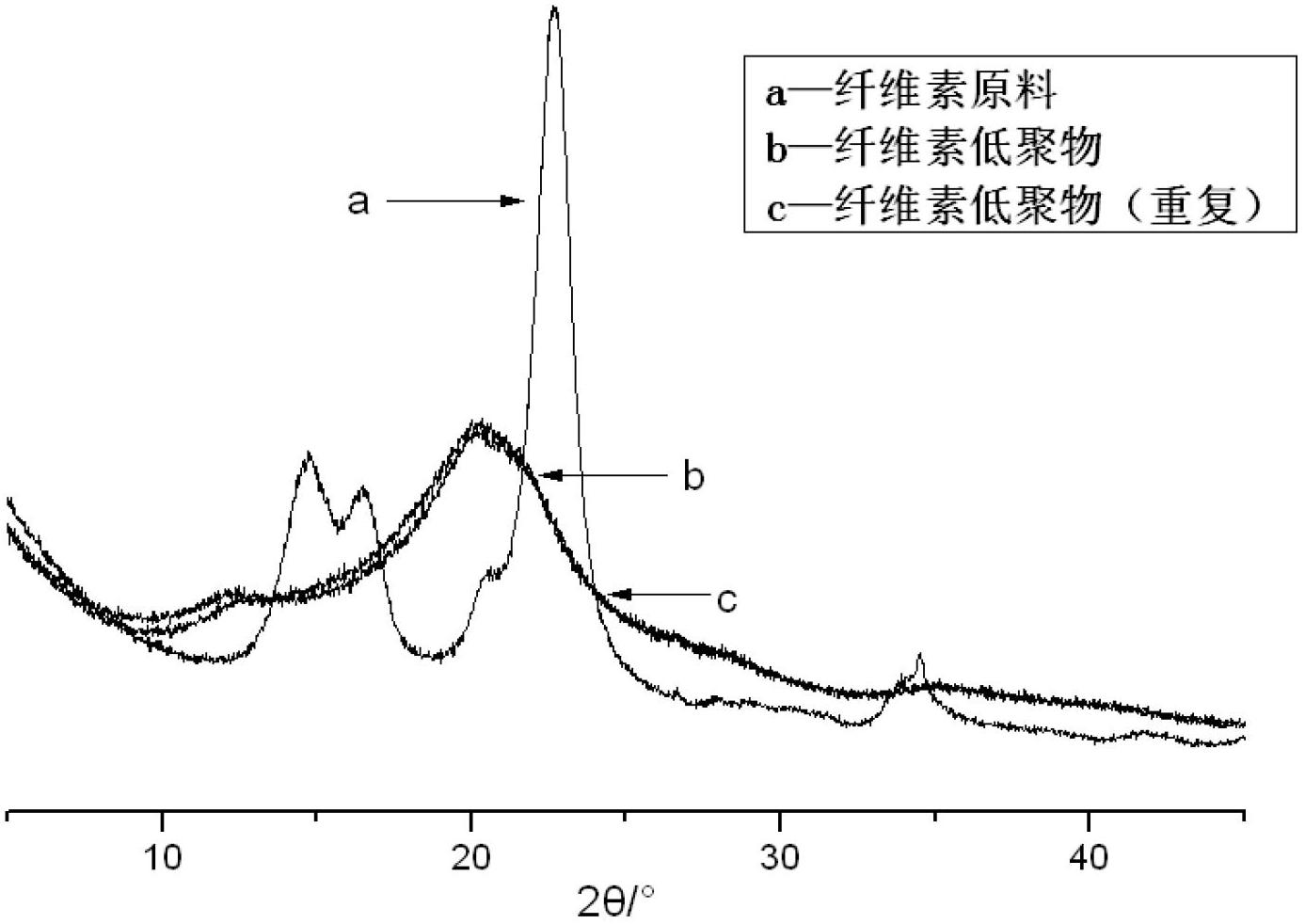

Two-step hydrolysis method for preparing reducing sugars with cellulose

ActiveCN102690897AEffective separation and reuseReduce dosageGlucose productionCelluloseIndustrial fermentation

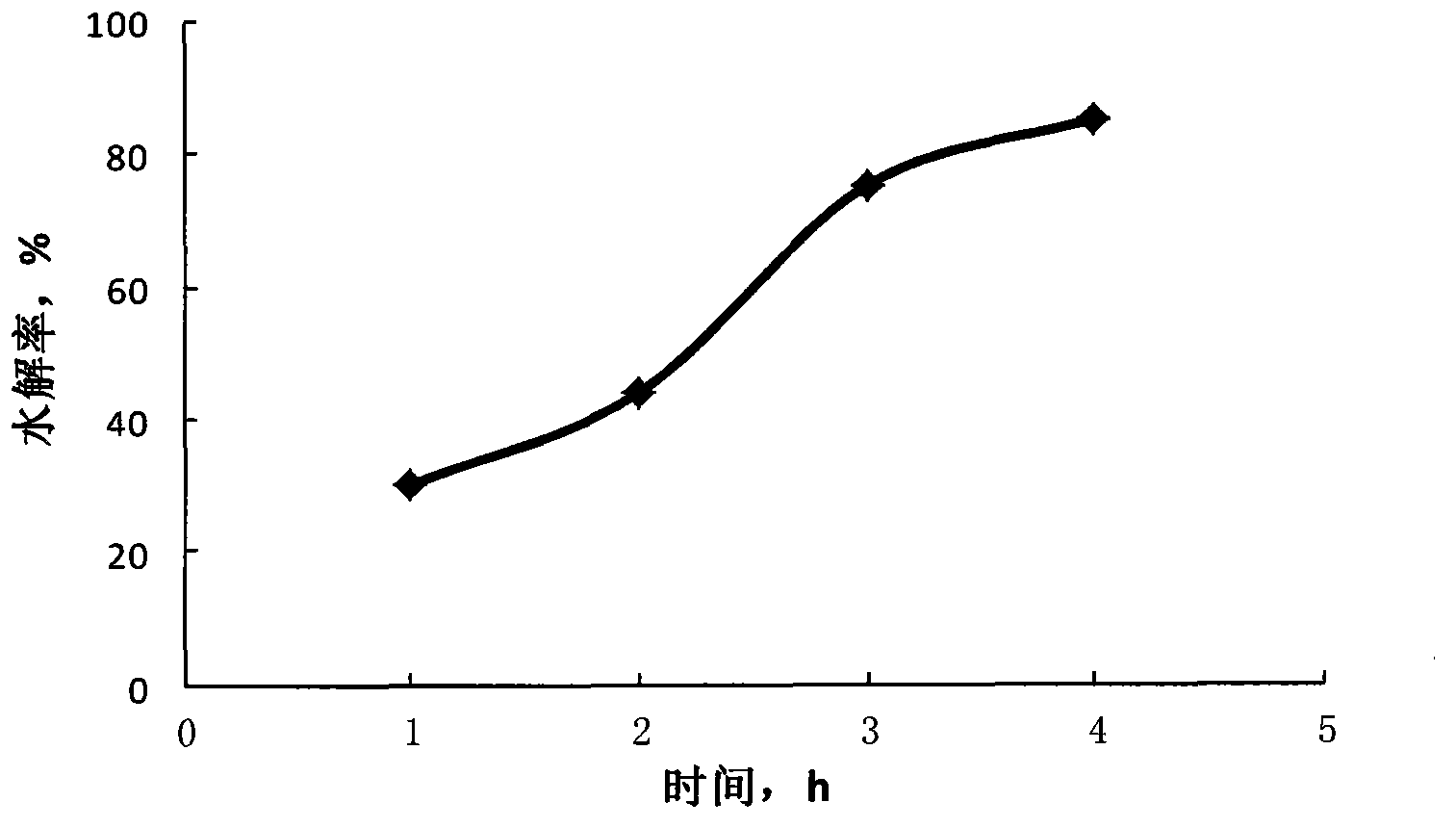

The invention discloses a two-step hydrolysis method for preparing reducing sugars with cellulose, comprising the following steps: step (1) of dissolving the cellulose into a solvent to obtain a cellulose solution; in the cellulose solution, enabling the cellulose to contact water by the action of a first catalyst to perform a first-step hydrolysis and obtain hydrolysate; adding a precipitator into the hydrolysate, and separating after precipitating to obtain precipitate; step (2) of adding a second catalyst in the precipitate obtained in the step (1) by utilizing water as a medium to perform a second-step hydrolysis and obtain the reducing sugars, wherein productivity of the reducing sugars reaches 40-85%. The invention further discloses application of the two-step hydrolysis method for preparing reducing sugars with cellulose in fermentation and preparation for compounds such as ethanol, lactic acid and so on in the carbohydrate industry. Cellulose solvent, catalyst and precipitator utilized by the invention can effectively separated and used repeatedly; hydrolysis condition is relatively mild; dosage of acid catalysts is less; and the method is featured with simple operation, low energy consumption, fast reaction and high productivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

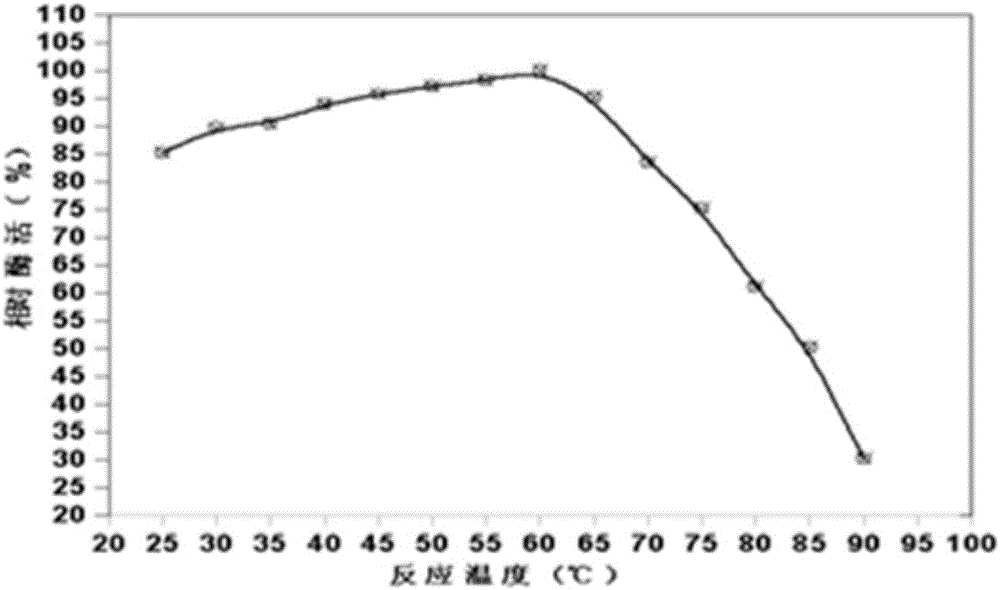

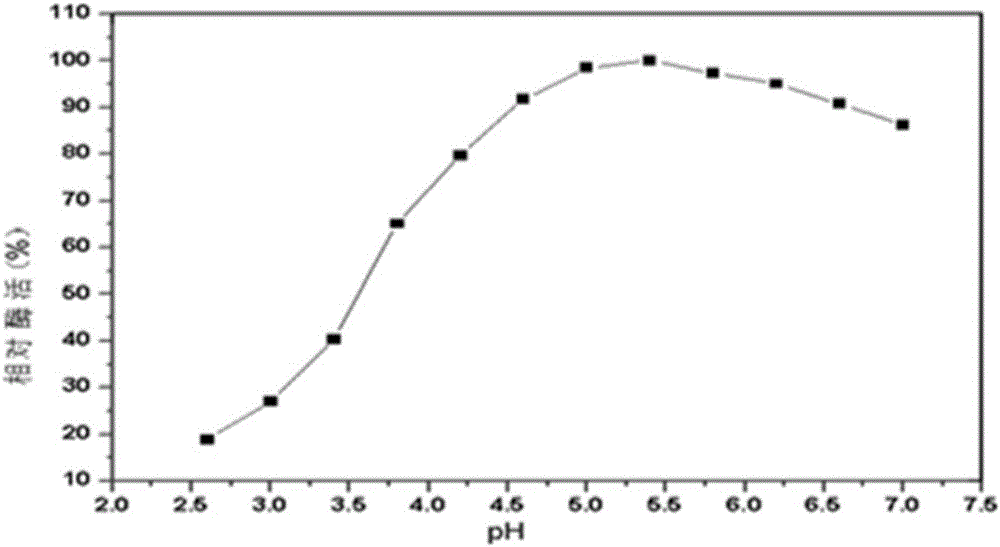

Method of utilizing acidic mannase to hydrolyze refined konjac powder to prepare konjac oligosaccharide

The invention relates to a method of utilizing acidic mannase to hydrolyze refined konjac powder to prepare konjac oligosaccharide and belongs to the technical field of food processing. The method includes: utilizing beta-mannase to pre-prepare an enzyme solution, wherein 200-300IU of enzyme is added for each gram of konjac powder; hydrolyzing the refined konjac powder under conditions of 40-60 DEG C and pH 4.5-7.0 to form konjac mannan oligosaccharide suspension; hydrolyzing a mannan oligosaccharide water solution through immobilized yeast technology to remove monosaccharide to form a water solution mainly containing oligosaccharide; obtaining a clarified oligosaccharide solution after being treated by filtering and membrane technology; finally utilizing high-speed centrifugal spraying and drying equipment to spray and dry at the temperature of 180-210 DEG C to obtain a konjac oligosaccharide powder product. The method is short in hydrolysis time and low in energy consumption, yield of prepared konjac obligosaccharide is higher than 70%, and the product is high in purity, low in monosaccharide, good in healthcare effect and suitable for industrialized production.

Owner:LIJIANG YUYUAN FOOD +1

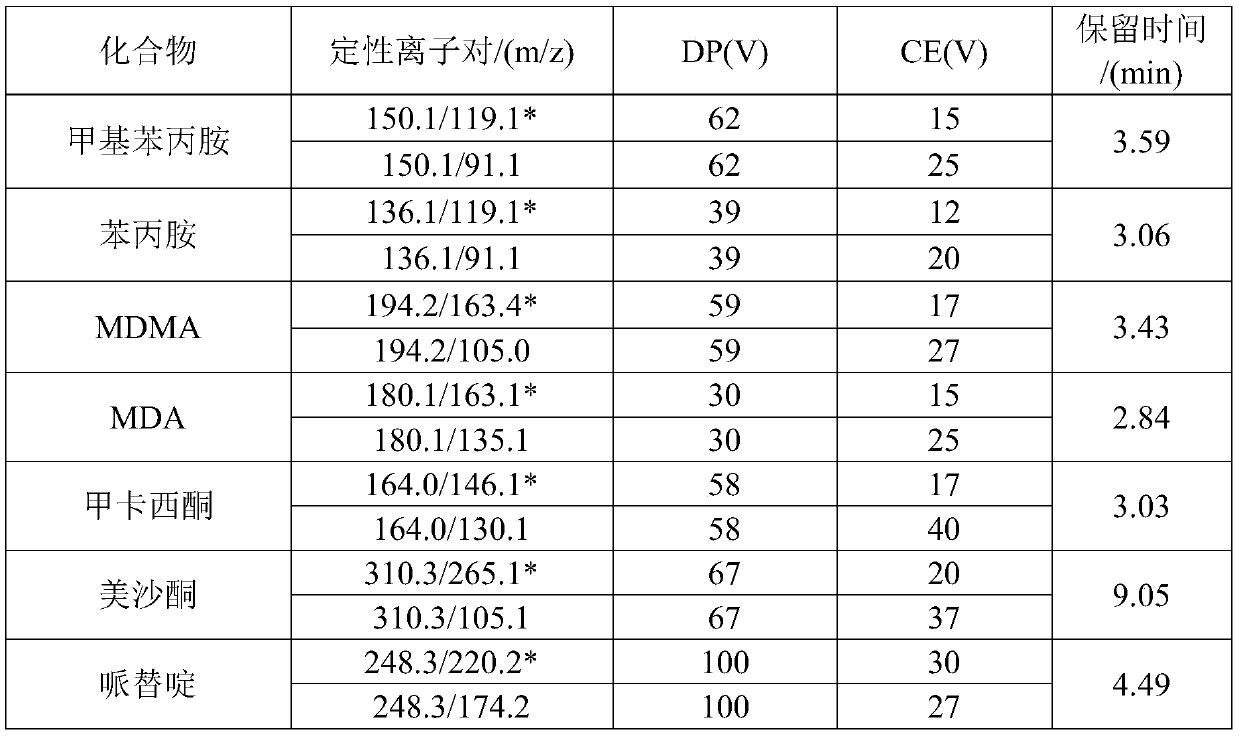

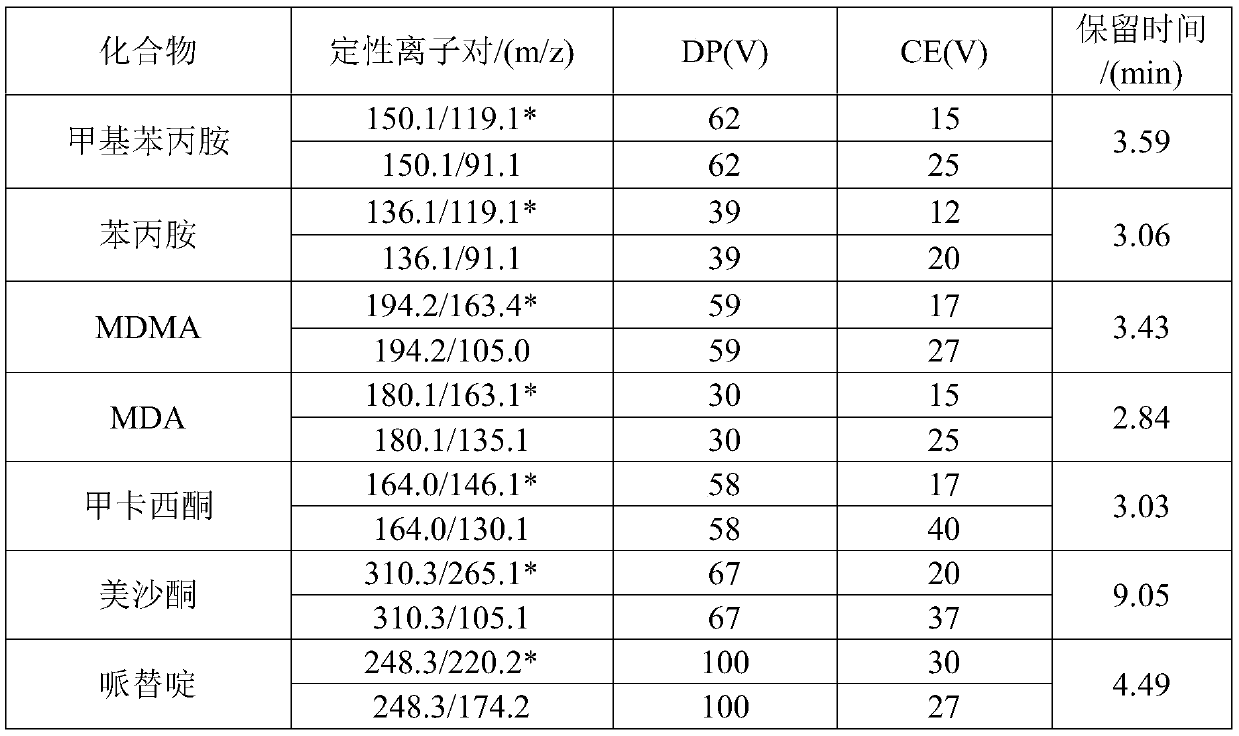

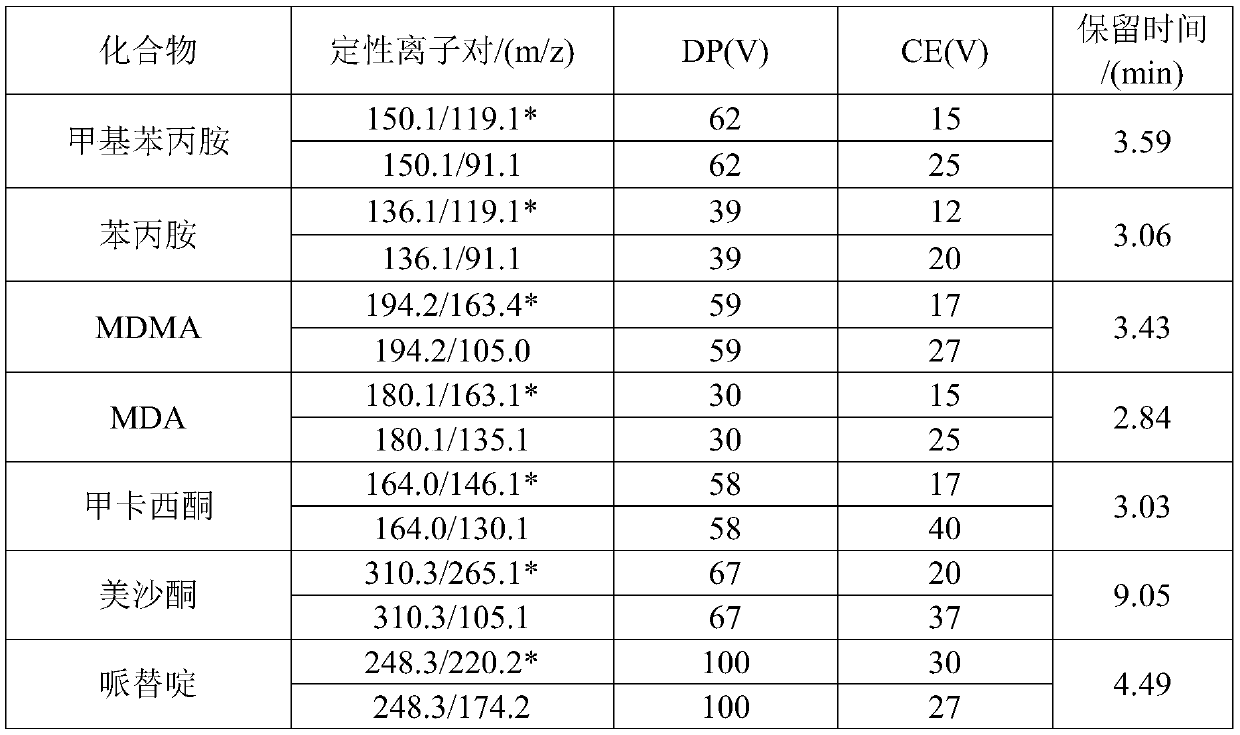

Extraction kit, extraction method and detection method for drugs in hair

ActiveCN110044670AShort hydrolysis timeEasy to operateComponent separationPreparing sample for investigationSolventHydrolysis

The invention relates to an extraction kit, an extraction method and a detection method for drugs in hair. The extraction kit comprises a composite extract containing a disulfide bond reducing agent,a hydrogen bond blocker, a hair expansion agent and a solvent, wherein the composite extract is alkaline and has a pH of 8.5 to 10. The extraction kit for drugs in hair hydrolyzes the hair by using areduction method with no need of special pulverizing equipment and extraction equipment during the pretreatment and with short hydrolysis time and simple operation of the whole extraction process, andthe reduction method is more suitable for the requirements of rapid detection of laboratory forensic identification compared with the conventional methods such as acid methods, alkali methods, methanol solvent methods, buffer salt solution methods and enzymatic methods. Furthermore, the reagents used in the composite extract in the extraction kit are all water-soluble reagents, which are easy tobe extracted by the organic reagent liquid, so that the solution to be detected can be quickly separated. And the reagents used are basically pollution-free to the environment, non-toxic to the operator, easily removed without residue, and basically damage-free to instruments and equipment.

Owner:GUANGZHOU SHENGXIN BIOTECH CO LTD

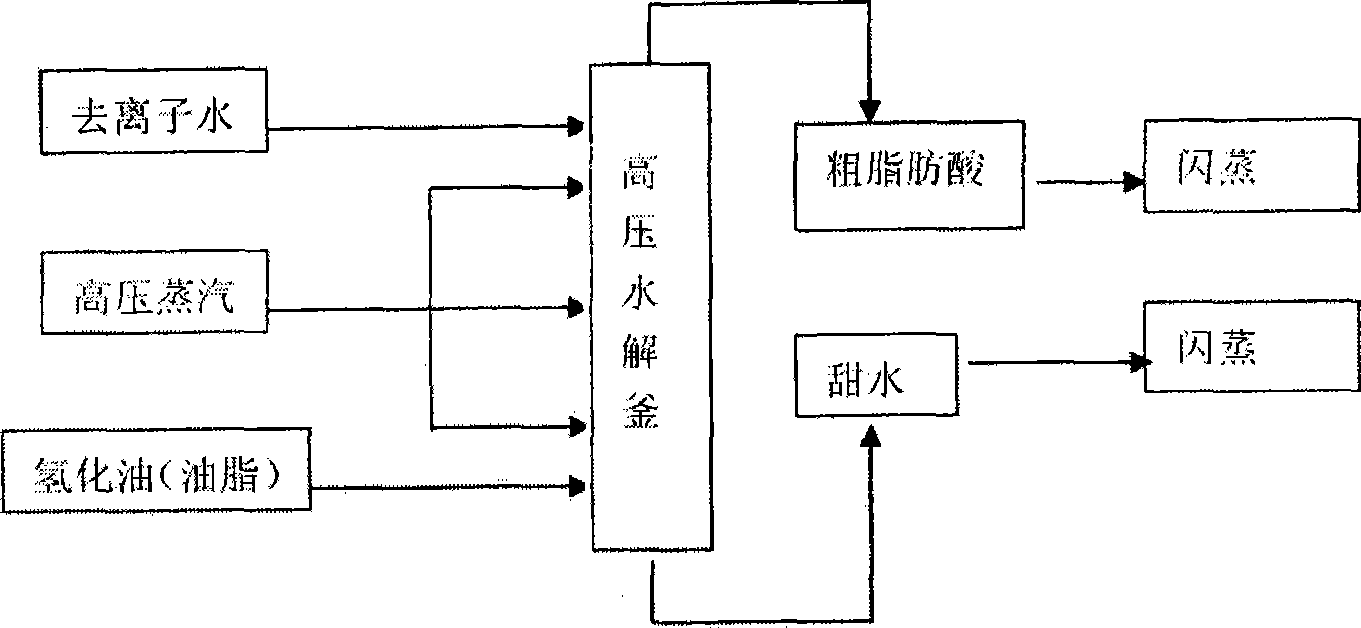

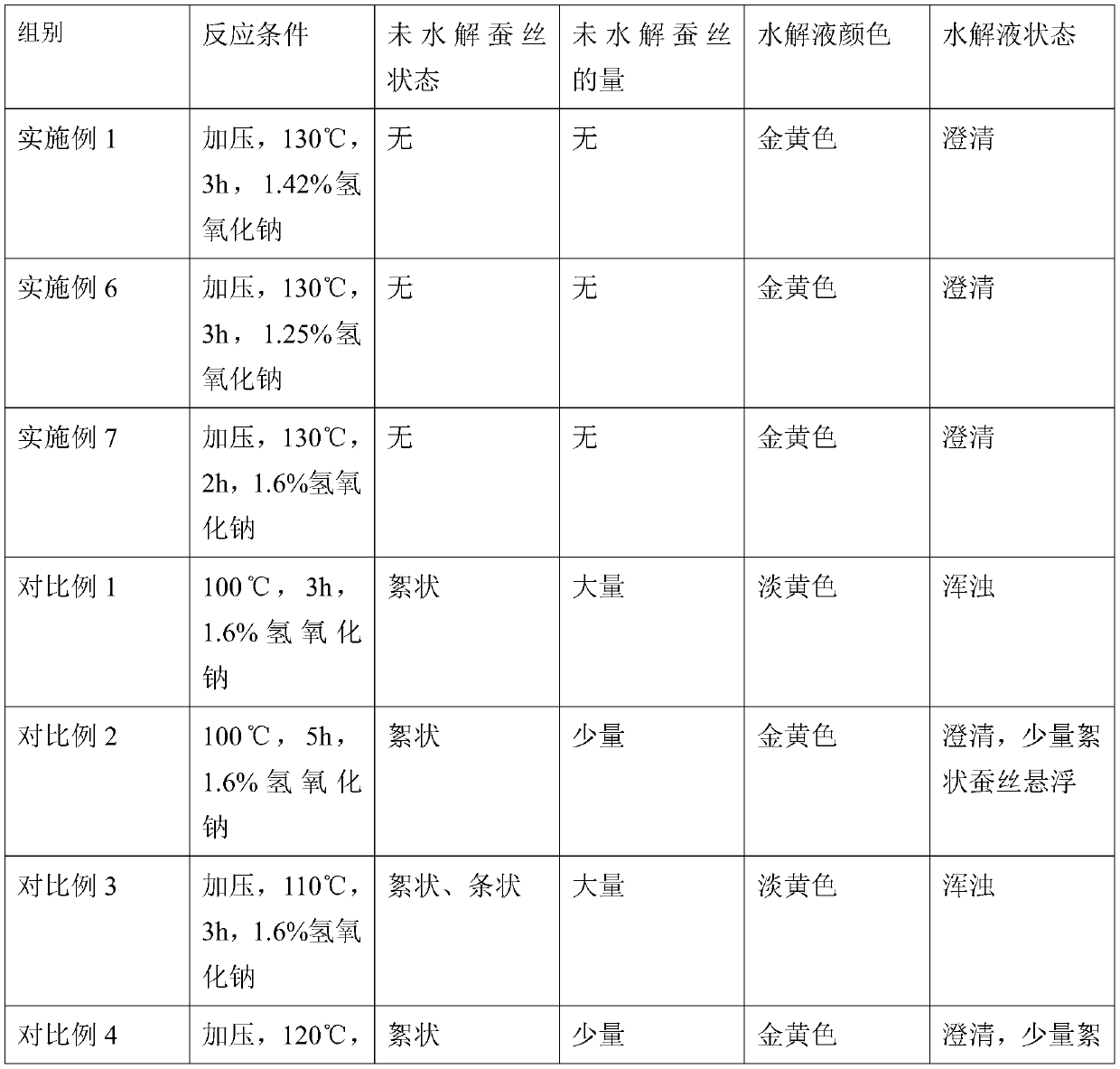

High pressure continuous hydrolysis technology for grease

InactiveCN101386809ALess coloringReduce consumptionOxygen-containing compound preparationFatty acids production/refiningAutomatic controlHigh pressure

The invention discloses a grease high-pressure continuous hydrolysis process, wherein raw grease reacts in a reaction tower at certain temperature and pressure and then is subjected to hydrolysis. The grease high-pressure continuous hydrolysis process has the advantages of easy continuous control, stable product quality, capability of reaching the degree of slight colouration or no colouration for the produced fatty acid, high hydrolysis pressure, short production period, high hydrolysis percentage which is generally more than 95 percent, simple and convenient operation, and capability of realizing automatic control and mass production.

Owner:RUGAO SHUANGMA CHEM

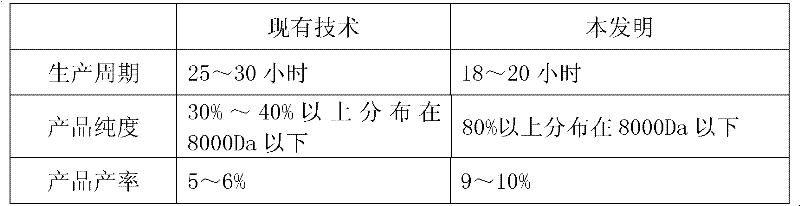

Method for separation and extraction of active peptide from domestic fungus by-products

InactiveCN102199647AIncrease profitHigh yieldPeptide preparation methodsChemical recyclingSeparation technologyFiltration

The invention aims to prepare domestic fungus active peptide by a method combining composite enzyme enzymolysis with membrane separation technology. The method is characterized by mild reaction and simple process. And products of the method contain abundant peptide. The method comprises the steps of: pretreating domestic fungus by-products like golden mushroom, pleurotus eryngii, mushroom and the like, adding alkali protease, papain and trypsin in a ratio of 1-1.2:1-1.2:1-1.2 by weight, performing enzymolysis to the composite enzyme for 3-5 hours, killing enzyme, filtering and centrifuging the enzymolyzed liquid, conducting membrane separation to the obtained crude extract from last step, under a filtration pressure of 0.15-0.2 MPa implementing fine filtration to primary filtrate with an acetate fiber organic membrane with an intercepting particle size of 0.1-0.2 micrometers, under a filtration pressure of 0.15-0.25 MPa performing hyperfiltration to fine filtrate with an aromatic polyamide organic composite membrane with a cut-off molecular weight less than 8000 Da so as to get peptide liquid with a molecular weight less than 8000 Da, conducting vacuum concentration and spray drying to the peptide liquid, thus obtaining extracted domestic fungus active peptide.

Owner:梅跃明

Hydrolytic agent for treating wastewater containing tetrafluoroborate and application thereof

ActiveCN102336460AImprove hydrolysis effectWide range of application conditionsWater contaminantsWater/sewage treatmentAluminium chlorideCerium nitrate

The invention provides a hydrolytic agent for treating wastewater containing tetrafluoroborate and application thereof. The hydrolytic agent consists of at least one aluminum salt and at least one water-soluble cerate. The aluminum salt is selected from alum, aluminum chloride or hydrate of the aluminum chloride, aluminum sulfate or hydrate of the aluminum sulfate, and preferable the alum; and the water-soluble cerat is selected from cerium nitrate, cerous sulfate and cerium chloride, and the preferable the cerium chloride. The hydrolytic agent disclosed by the invention is used for treating the wastewater containing tetrafluoroborate, thus the consumption of the aluminum salt contained in the hydrolytic agent can be reduced on the one hand and the concentration of the tetrafluoroborate in the hydrated wastewater can be reduced on the other hand, which provide advantages for subsequent treatment. After the wastewater is continuously precipitated by lime milk or CaOH2, the concentration of the tetrafluoroborate and the concentration of fluorinion are respectively reduced and reach the discharge stand, and thus the etrafluoroborate and the fluorinion can be directly discharged and further the subsequent treatment flow is shortened.

Owner:CHINA PETROLEUM & CHEM CORP

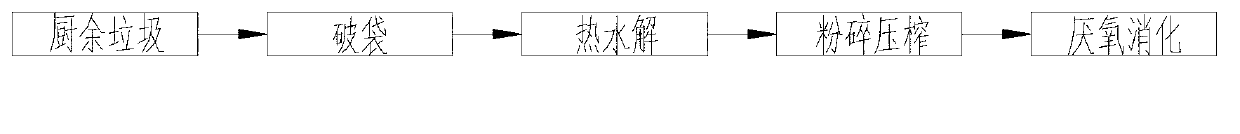

Processing method of kitchen garbage

The invention discloses a processing method of kitchen garbage. The processing method comprises the following steps of: transferring the kitchen garbage to hydrolyze in a hydrolyzing tank, transferring the hydrolyzed clinker aggregate to a crush presser to crush and squeeze, transferring the squeezed slurry body to an anaerobic digestion reactor for anaerobic digestion so as to finish the treatment on the kitchen garbage. The processing method provided by the invention can efficiently realize stabilization, harmlessness and minimization of the kitchen garbage, the unstable organic substance is fully stabilized, methane and water and the like are formed so as not to generate secondary pollution, and the minimization of organic matter in the garbage is effectively realized through a biogas slurry and biogas residue processing system; and generated methane after anaerobic digestion is used as a high-quality clean energy, and fixed material after crushing and squeezing is treated reasonably according to specific circumstances.

Owner:北京洁绿环境科技股份有限公司

Preparation of zirconia superfine powder by hydrolysis method

The invention discloses a superfine zirconium oxide powder production in a water decomposing method. The tech is by low temperature low pressure drying and burning the zirconium oxide wet gelatin composed in water decomposing method, obtaining superfine zirconium oxide powder. By adopting the method the sphere particle zirconium oxide superfine powder with small particle diameter and narrow particle size distribution can be obtained and applied on fine ceramic composing, catalyzer and other fields.

Owner:HARBIN ENG UNIV

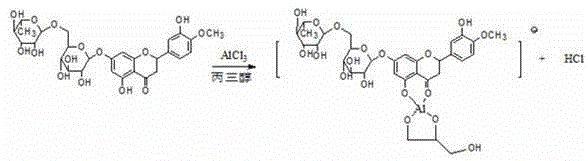

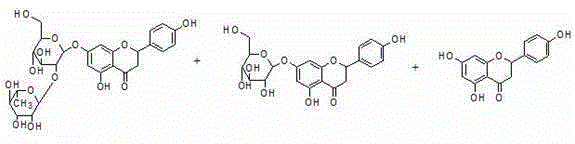

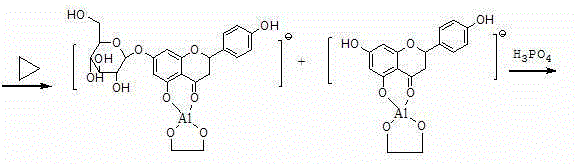

Preparation method of flavone aglycone or monoglycoside from aluminum-salt-flavonoid-glycoside complex through hydrolysis

InactiveCN105481916ASimple methodShort hydrolysis timeSugar derivativesSugar derivatives preparationO-Phosphoric AcidPhosphate

Disclosed is a preparation method of flavone aglycone or monoglycoside from aluminum-salt-flavonoid-glycoside complex through hydrolysis. The problems that flavonoid glycosides neither dissolve in water nor are hard to dissolve in a common organic alcohol solution, and flavone aglycone prepared from hydrolysis has slow hydrolysis speed, needs a large amount of an organic solvent, and cannot be totally hydrolyzed are solved. A complex product from complexation of aluminum salt and flavonoid glycosides is easy to dissolve in alcohol, hydrogen chloride generated by the complex product is utilized with addition of hydrochloric acid or sulfuric acid, and hydrolysis is carried out at a certain temperature to prepare aglycone or a mixture of aglycone and monoglycoside. After the reaction is over, phosphoric acid or phosphate is added to break complexation of aluminum ions and flavone to obtain flavone aglycone, or the mixture of flavone aglycone and flavone monoglycoside, or a mixture of flavone aglycone, flavone monoglycoside, and flavonoid glycoside. The method is simple and easy to operate, relatively high in yield and purity, and extremely low in cost, and is suitable for massive industrial production of flavone aglycone or the mixture of flavone aglycone and flavone monoglycoside.

Owner:闻永举

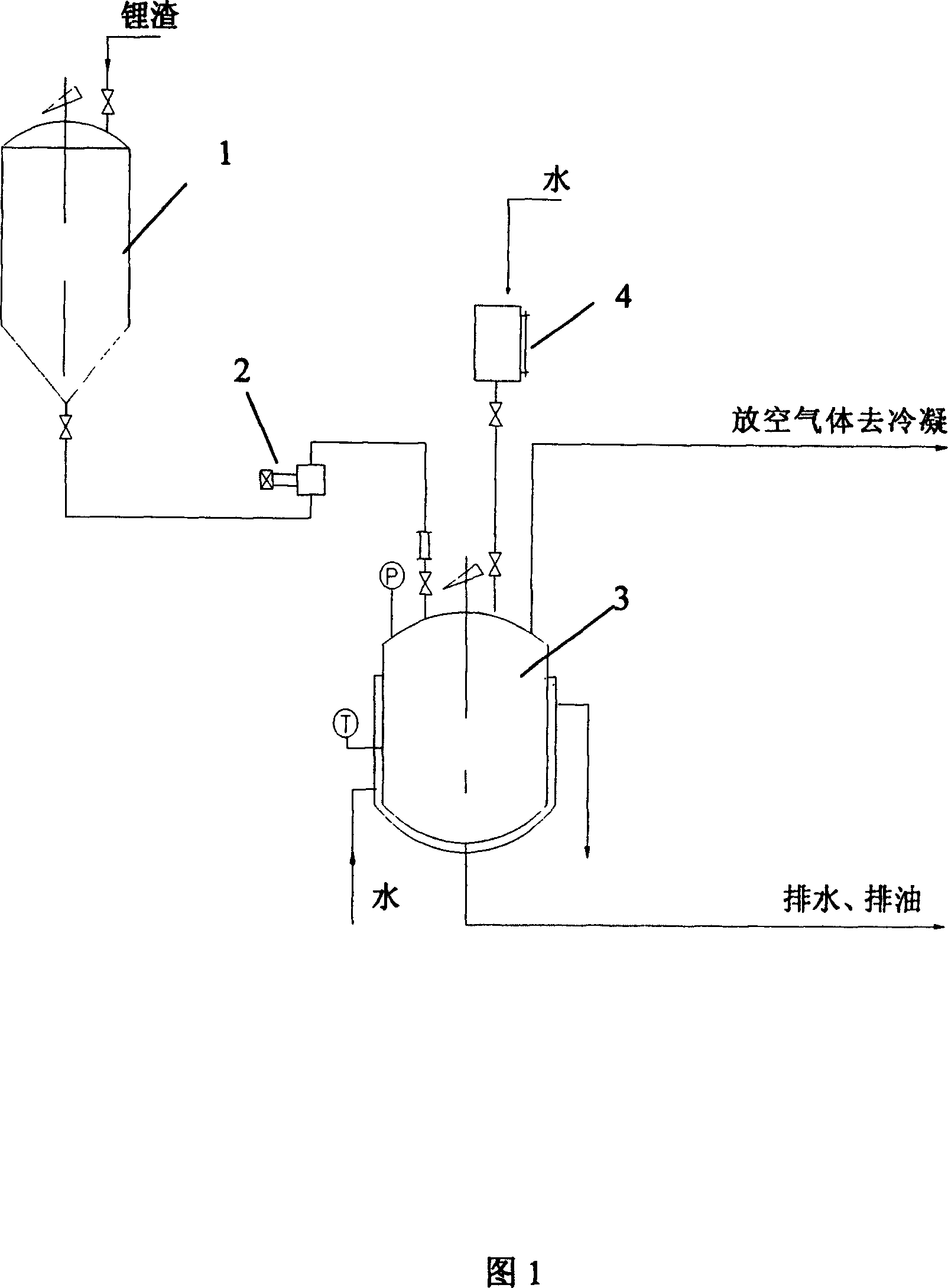

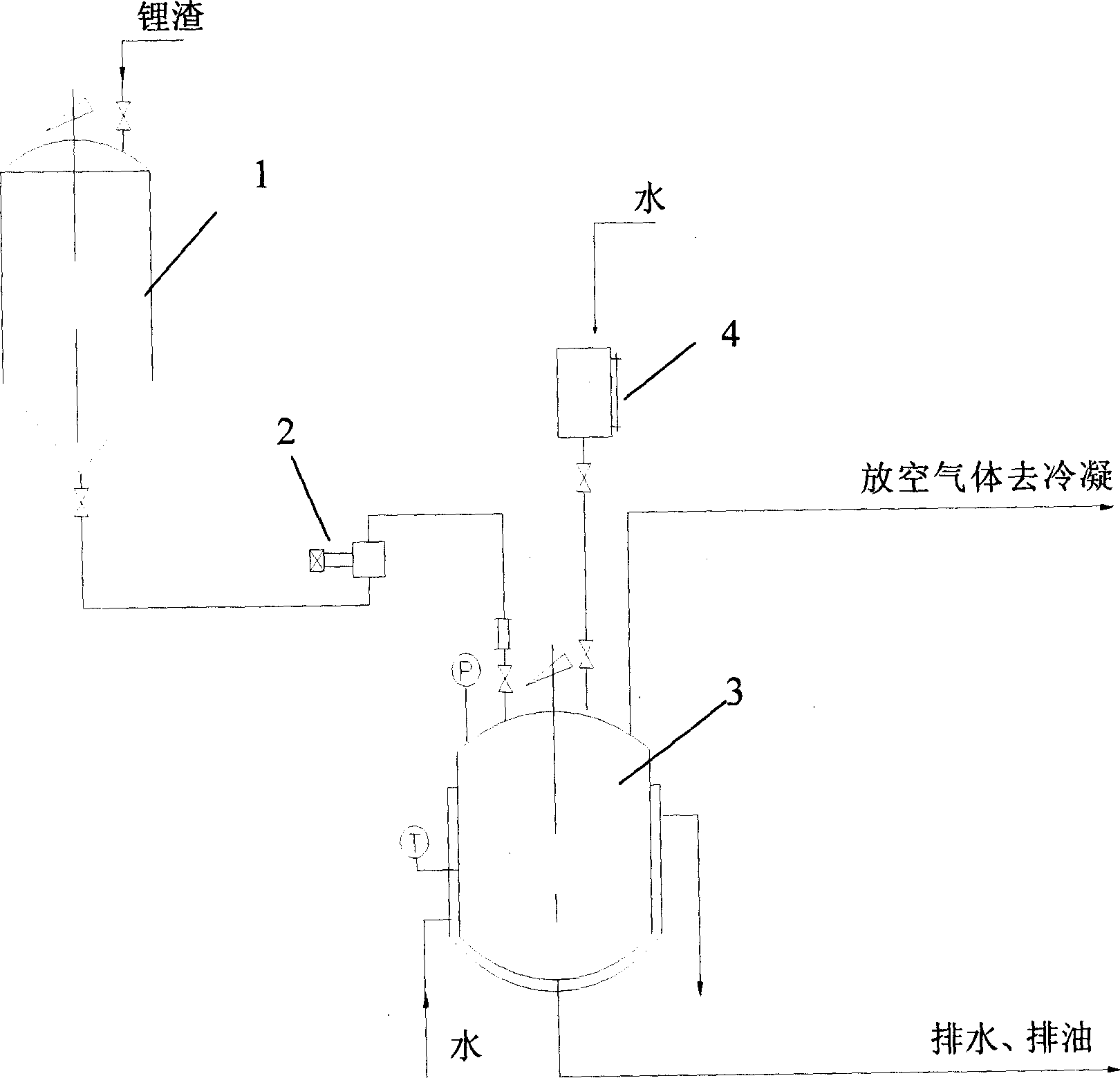

Hydrolysis method for lithium slag from lithium alkyl synthesis

ActiveCN1326640CHydrolysis process safetyThe hydrolysis process is stableSolid waste disposalLithiumAutomatic control

Owner:BALING PETRO CHEM CO LTD SINOPEC

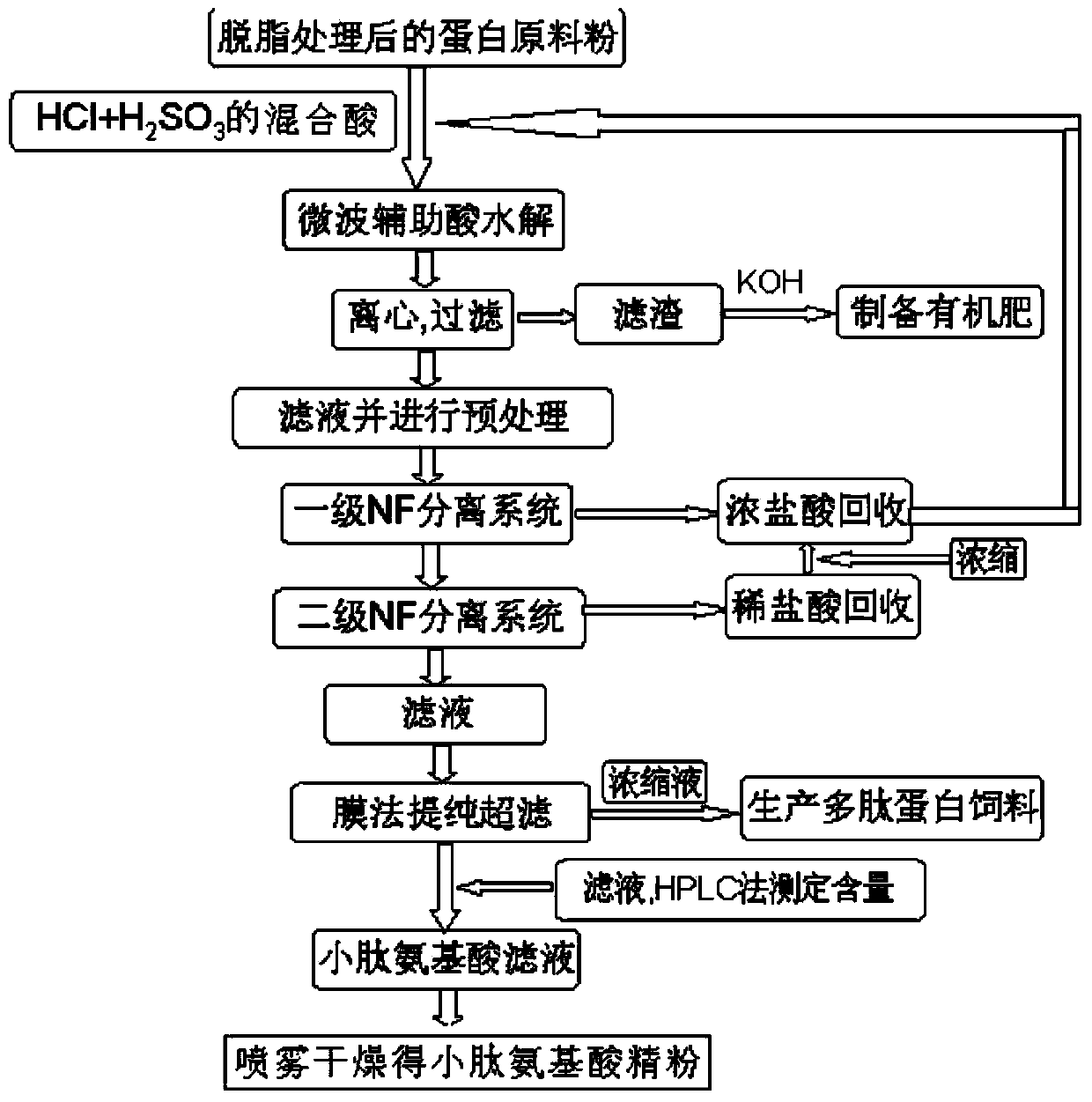

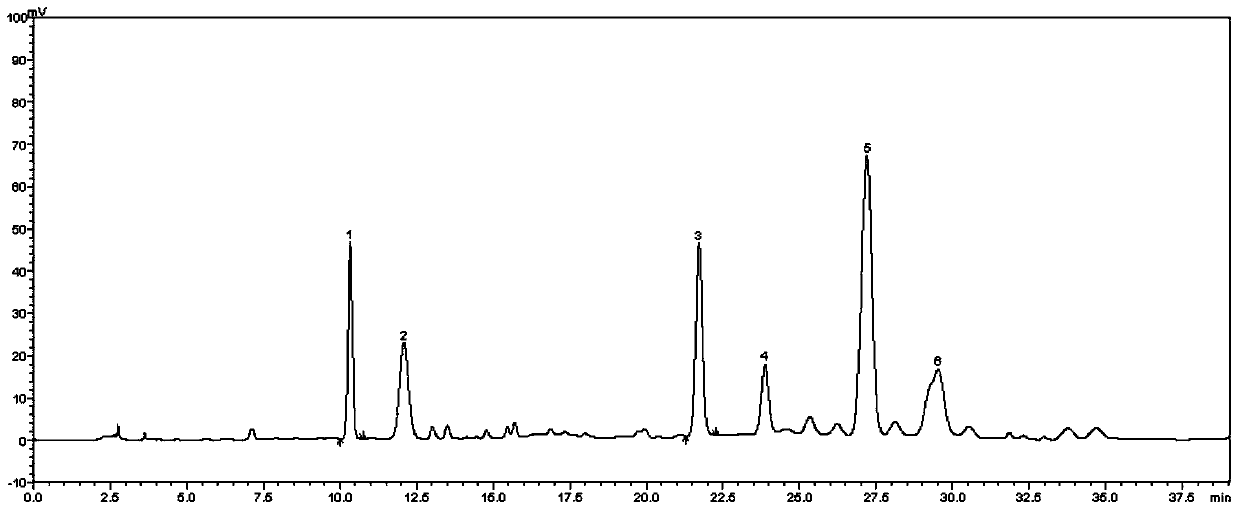

Method for rapidly preparing small peptide amino acids by microwave-assisted protein acid hydrolysis

InactiveCN103739663ALow hydrolysis efficiencyImprove hydrolysis efficiencyPeptide preparation methodsUltrafiltrationAmino acid

The invention discloses a method for rapidly preparing small peptide amino acids by microwave-assisted protein acid hydrolysis. The method comprises: in the microwave environment, performing hydrolysis on a mixed solution of a denatured protein raw material and hydrochloric acid and sulfurous acid, and performing centrifugation filtering, nanofiltration membrane deacidification and ultrafiltration separation to obtain small peptide amino acids with different molecular weight. The preparation method is mild in reaction conditions, short in production period, low in production cost and high in product recovery rate, realizes "three wastes (waste gas, waste water and industrial residue)" zero discharge, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

Hydrolytic agent for treating wastewater containing tetrafluoroborate and application thereof

ActiveCN102336460BImprove hydrolysis effectWide range of application conditionsWater contaminantsWater/sewage treatmentAluminium chlorideTetrafluoroborate

Owner:CHINA PETROLEUM & CHEM CORP

Method for synthesizing glyoxylic acid by means of ozonizing maleic anhydride and mixed solvents

ActiveCN106431885ASimple production processThe method is simpleOrganic compound preparationPreparation from carboxylic acid anhydridesGlyoxylic acidDistillation

The invention relates to a method for synthesizing glyoxylic acid by means of ozonizing maleic anhydride and mixed solvents, and belongs to the field of technologies for preparing glyoxylic acid. The method for synthesizing the glyoxylic acid by means of ozonizing the maleic anhydride and the mixed solvents is low in cost. The method includes steps of carrying out hydrolysis, ozone oxidation, reduction, reduced-pressure distillation, crystallization and the like on the inexpensive maleic anhydride in the mixed solvents to ultimately obtain glyoxylic acid solid. The method has the advantages that the glyoxylic acid solid with high purity can be directly obtained by the aid of the method, and products are high in quality and wide in application; the method is easy to implement and high in glyoxylic acid yield, the maleic anhydride can be converted into the glyoxylic acid at a low price, the method can be used for industrial large-scale production, and certain contribution can be made for solving the problem of situation of excessive maleic anhydride; optimization of the traditional processes for producing the glyoxylic acid and elimination of backward processes can be stimulated, environment-friendly oxidizing agents are adopted, and accordingly huge contribution can be made for environmental protection.

Owner:PANZHIHUA UNIV

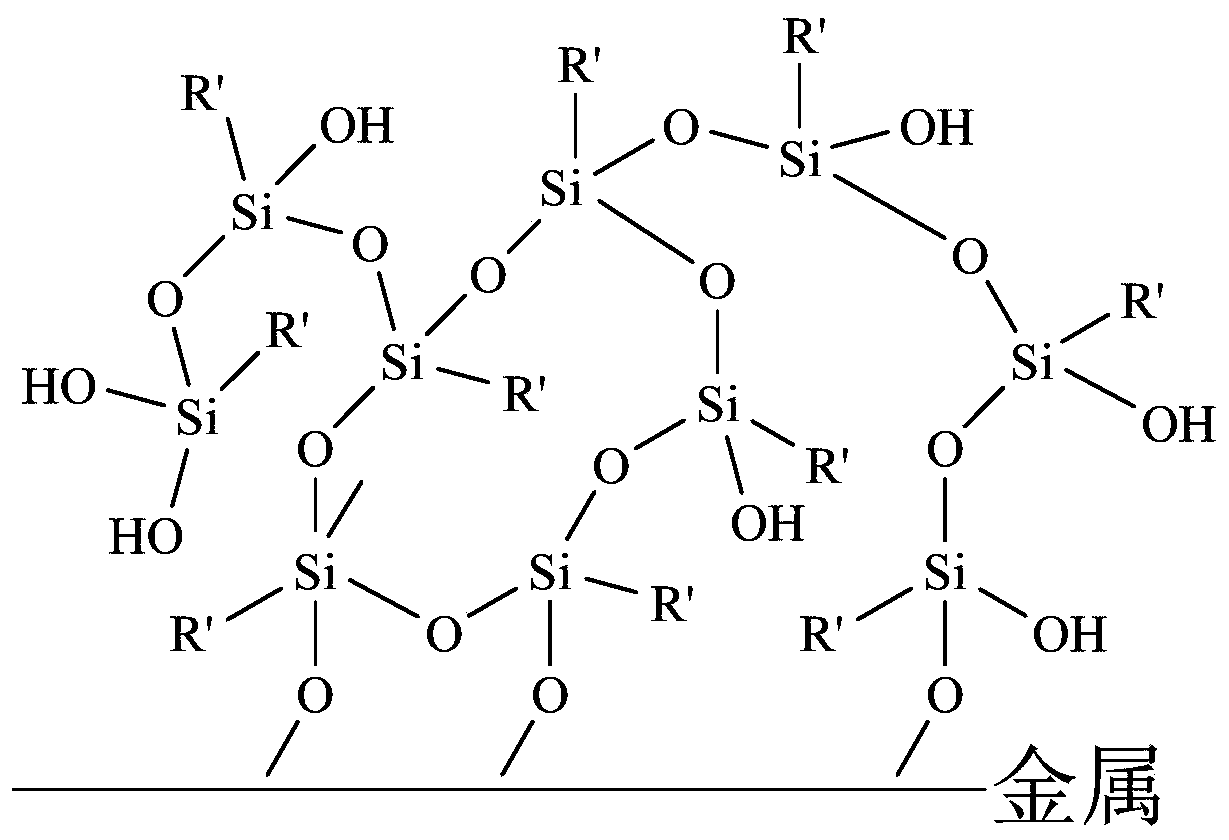

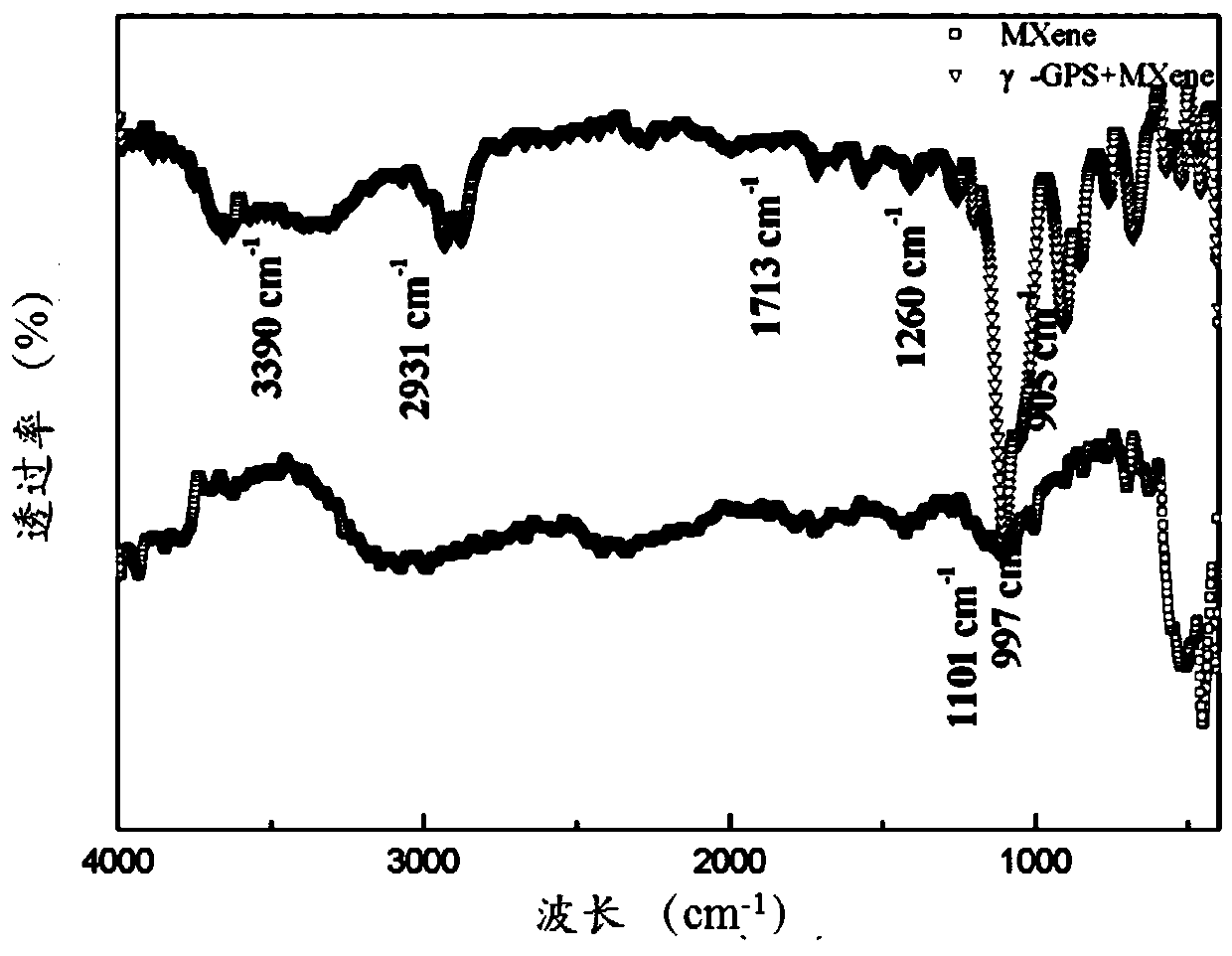

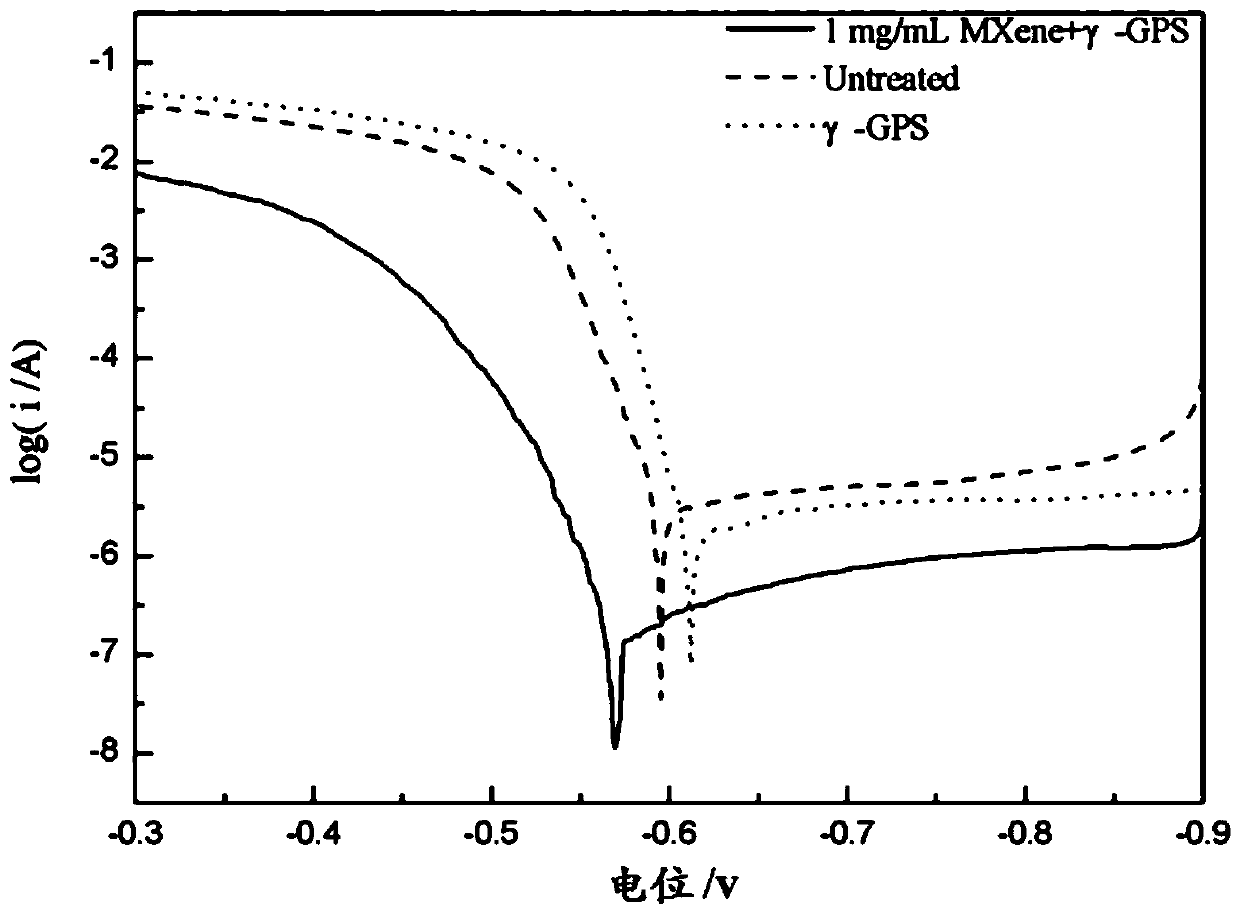

Application of MXene/silane surface composite silane film in metal corrosion protection

ActiveCN110527995ASimplify process stepsShort hydrolysis timeMetallic material coating processesCorrosion resistantSurface finishing

The invention belongs to the field of metal corrosion protection, and particularly relates to application of an MXene / silane surface composite silane film in metal corrosion protection. The method comprises the following steps: preparing and hydrolyzing an MXene / silane mixed solution, carrying out surface treatment on a metal sample, dipping the metal sample in a mixed silane hydrolysate, and curing to form a film. The MXene / silane surface composite silane film protective surface treatment technology is adopted, the defect that a single silane film is not compact is overcome, the operation iseasy, safety and environmental protection are achieved, diffusion of a corrosive medium can be effectively hindered by doping the MXene, and the corrosion resistance of the silane film is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Hydrolysis method for lithium slag from lithium alkyl synthesis

ActiveCN1754630AHydrolysis process safetyThe hydrolysis process is stableSolid waste disposalLithiumAutomatic control

This invention provides one hydrolysis method to synthesize lithium alkyl, which comprises the following steps: containing the lithium powder filtered by lithium alkyl into its buffer tar; then pressing the lithium powder into hydrolysis tar through lithium powder metering pump to react with large amount of water under temperature of sixty degrees to control lithium powder quantative through hydrolysis temperature; the reaction temperature can be taken away by cooling water and thehydrocarbon solvent sent out are recycled by air condensation device. The method can prevent super heat without large range wave to realize the industry automatic control.

Owner:BALING PETRO CHEM CO LTD SINOPEC

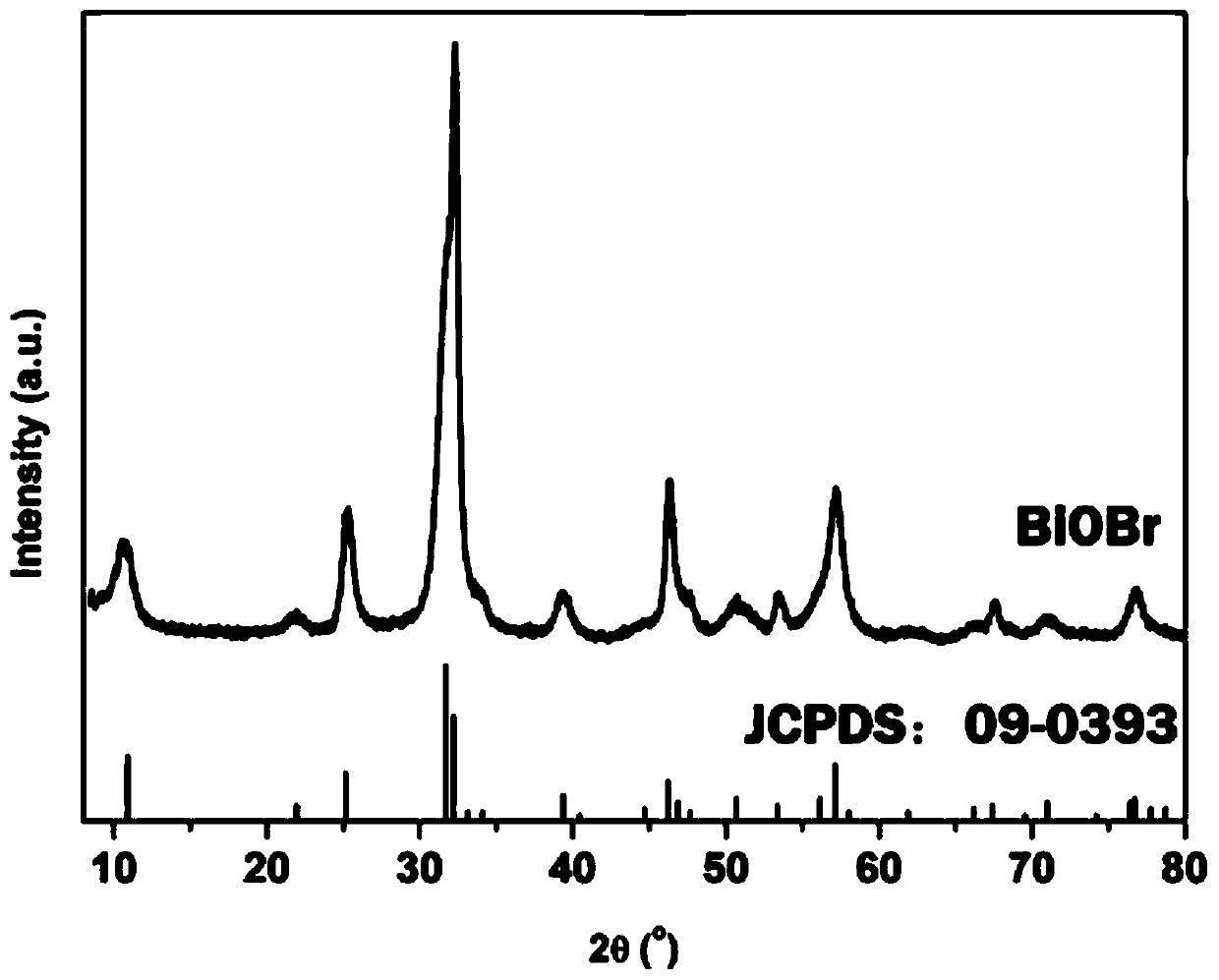

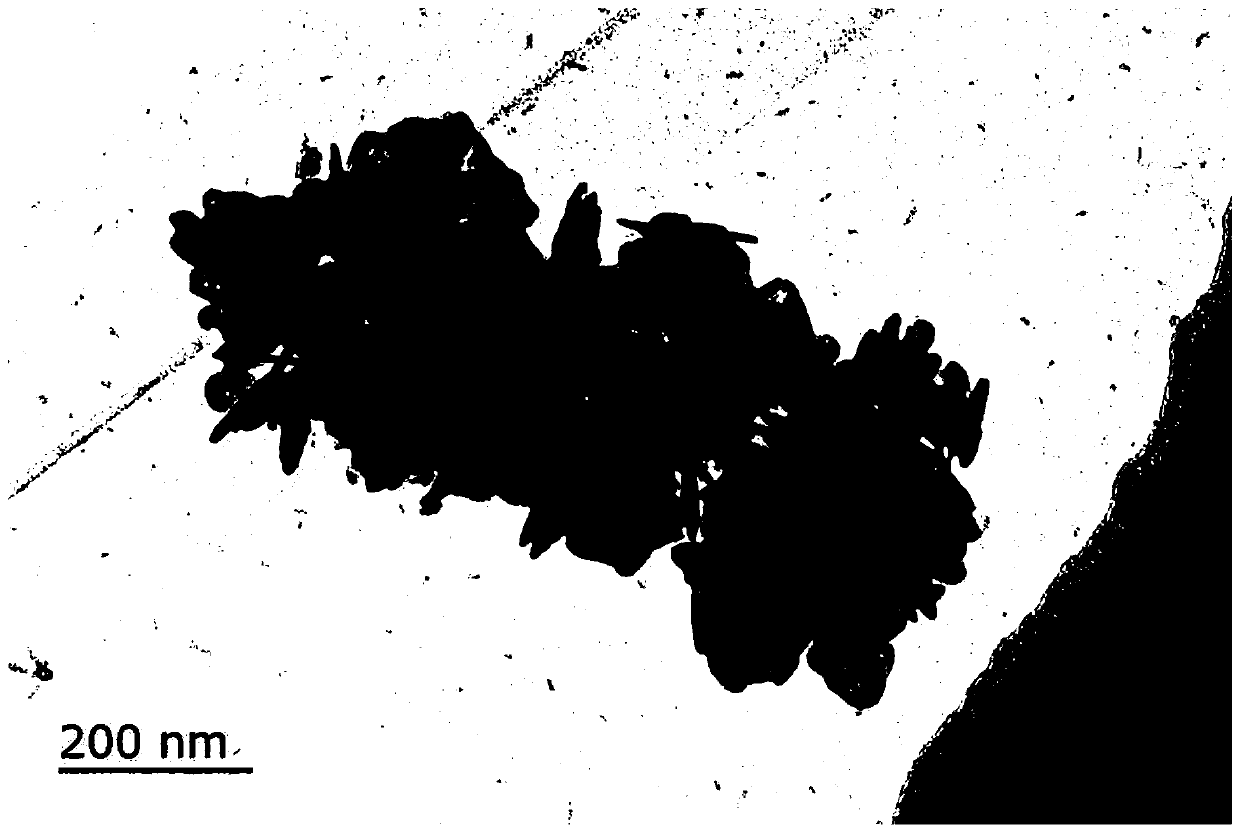

Method for rapidly preparing BiOBr nanoflowers with assistance of water and application of BiOBr nanoflowers

PendingCN110560098AHigh temperature reaction time is shortShort hydrolysis timePhysical/chemical process catalystsWater/sewage treatment by irradiationAlcoholTwo step

The invention discloses a method for rapidly preparing BiOBr nanoflowers with the assistance of water and application of the BiOBr nanoflowers, belonging to the field of synthesis of nanomaterials. The invention aims to solve the technical problems that conventional methods for preparing BiOBr is complex in process, high in cost, tedious in post-treatment and unfavorable for expanded production. According to the method, the BiOBr is rapidly prepared by adopting a two-step method with the assistance of water. The method comprises the following steps: adding bismuth nitrate pentahydrate into organic alcohol, carrying out sufficient stirring, adding a bromine source, continuing sufficient stirring, performing cooling after a solvothermal reaction to obtain a clear and transparent solution, then adding water to allow a white solid to quickly appear, filtering the obtained white solid, and cleaning and drying the white solid so as to obtain the BiOBr nanoflowers. The method has the advantages of simple preparation process, short reaction time, no need for addition of a surfactant, easiness in industrial production and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method of producing acid hydrolyzed casein

ActiveCN101095457AShort hydrolysis timeSimple processAnimal proteins working-upPhosphoric acidHydrolysis

The invention discloses a method for producing acid-hydrolytic casein, which takes milk coarse protein that is used to extract butter as raw material, and comprises following steps: selecting, disintegrating, dissolving, filtering, acidifying, washing, dewatering, drying, purifying and getting casein, hydrolyzing with 4-12mol / l hydrochloride or sulfate or phosphoric acid at 90-100 Deg. C for 2-4 hours, condensing and washing repeatedly for 1-3 times, de-coloring with active carbon, exchanging with weak alkali or weak anion resin, spray drying at 120-160 Deg . C, and getting acid-hydrolytic casein. The invention is characterized by short hydrolysis time, simple process, short time for whole process of about 8-10 hours, reduced production period and cost, and suitability for mass industrial production.

Owner:临夏州华安生物制品有限责任公司

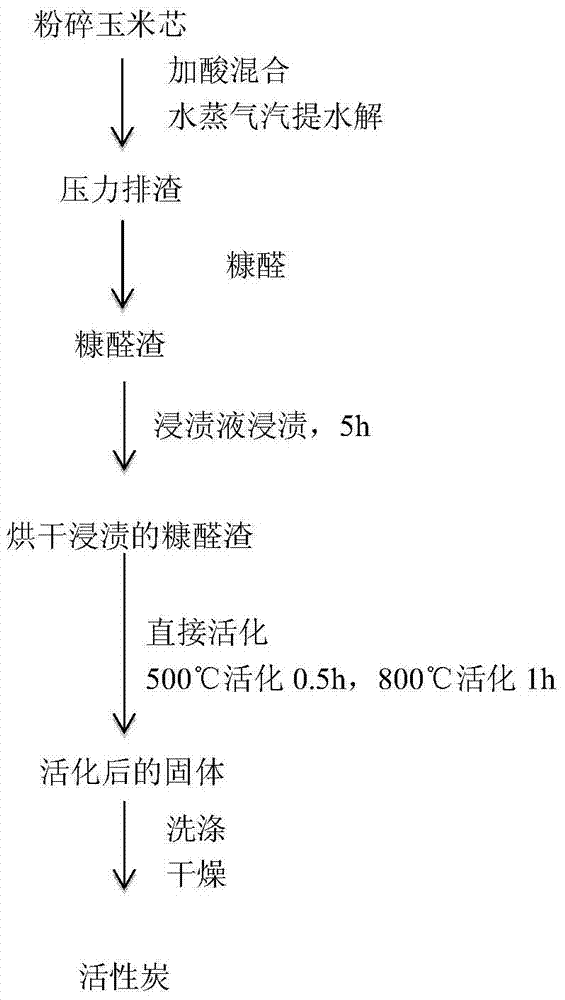

A method for preparing activated carbon and furfural from corn cobs

ActiveCN105174254BAvoid condensationHigh yieldOrganic chemistryCarbon compoundsActivated carbonWater vapor

The invention provides a method for preparing activated carbon and furfural by taking corncob as a raw material. The method for preparing the activated carbon and furfural by taking the corncob as the raw material comprises the following steps: 1) smashing the corncob until particle size is 15-20mm; 2) mixing the corncob with sulphuric acid solution; 3) carrying out steam stripping and hydrolysis, namely enabling steam to be contacted with the corncob for carrying out hydrolysis; 4) collecting gas during steam stripping, hydrolysis and pressure deslagging, condensing, and distilling, so as to obtain a furfural product; 5) impregnating furfural residue, namely mixing KOH solution with the furfural residue, and impregnating at room temperature; 6) drying to a free-water-less state; and 7) directly activating, namely activating the dried furfural in two stages. The method provided by the invention has the advantages that the corncob is taken as the raw material for cooperatively producing furfural and activated carbon products, so that economic benefit of furfural production can be greatly improved; high hydrolysis temperature and short hydrolysis time are adopted, so that furfural condensation is avoided during production, and yield of furfural is increased; and the furfural residue is adopted for preparing the activated carbon, so that waste residue in a furfural production process can be effectively utilized, and environmental pollution is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

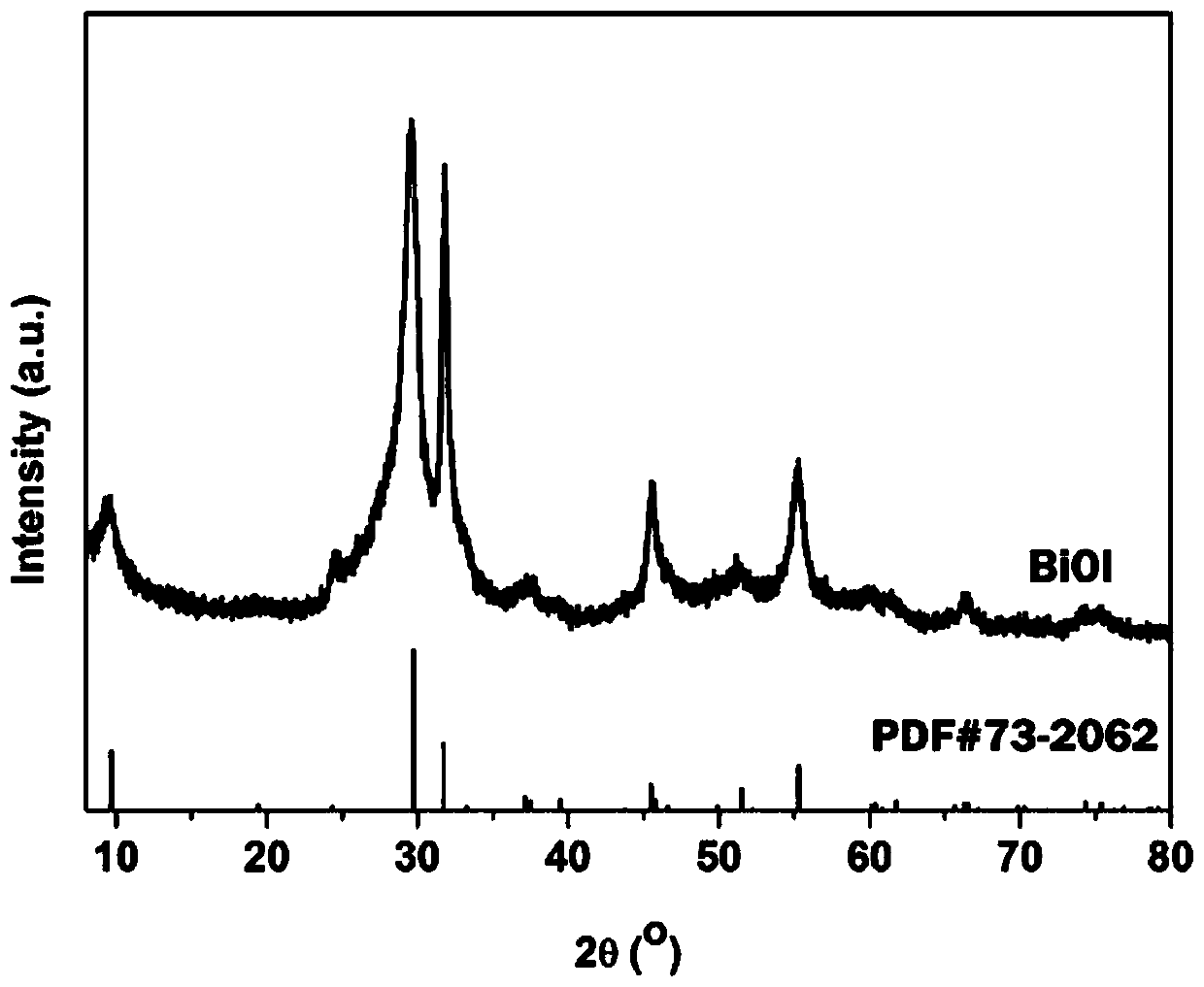

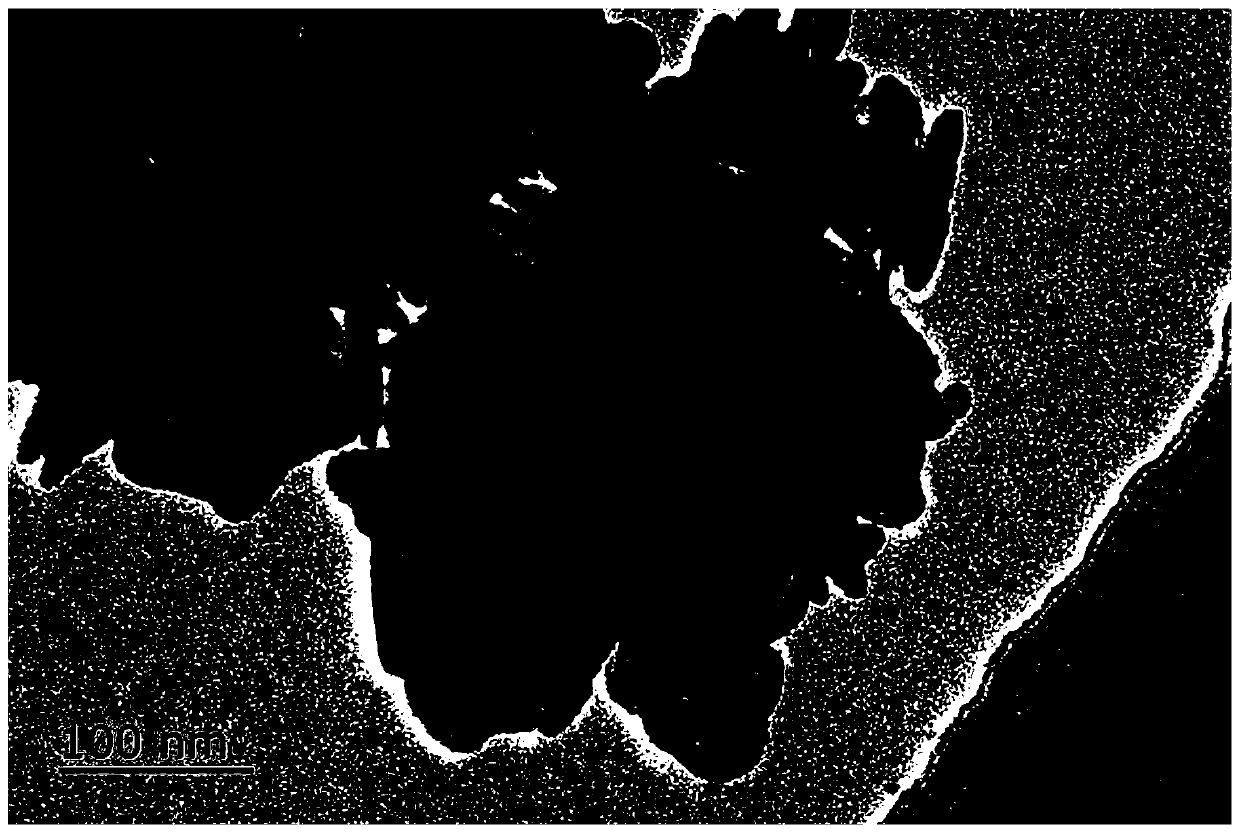

Preparation method and application of BiOI nanoflower with three-dimensional layered structure

PendingCN110560099AShort hydrolysis timeShort reaction cyclePhysical/chemical process catalystsWater/sewage treatment by irradiationSolventReaction timing

The invention discloses a preparation method and application of a BiOI nanoflower with a three-dimensional layered structure, belonging to the field of nanomaterial synthesis. The invention aims to overcome the defects of relatively complex operation conditions, relatively tedious process, difficulty in control of reaction conditions, high cost, tedious post-treatment, inconvenience in expanded production and the like in traditional BiOI preparation methods. The preparation method disclosed by the invention comprises the following steps: adding bismuth nitrate pentahydrate into organic alcohol, carrying out uniform mixing under stirring, adding HI with equal molar weight, continuing stirring for a certain period of time, carrying out a solvothermal reaction to obtain a clear transparent solution, adding a proper amount of water to quickly generate yellow solid, filtering the obtained yellow solid, and carrying out cleaning and drying to obtain the BiOI nanoflower. The method has the advantages of simple preparation process, short reaction time, no need for a surfactant, easiness in industrial large-scale production and the like. The BiOI nanoflower disclosed by the invention is used as a photocatalyst.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

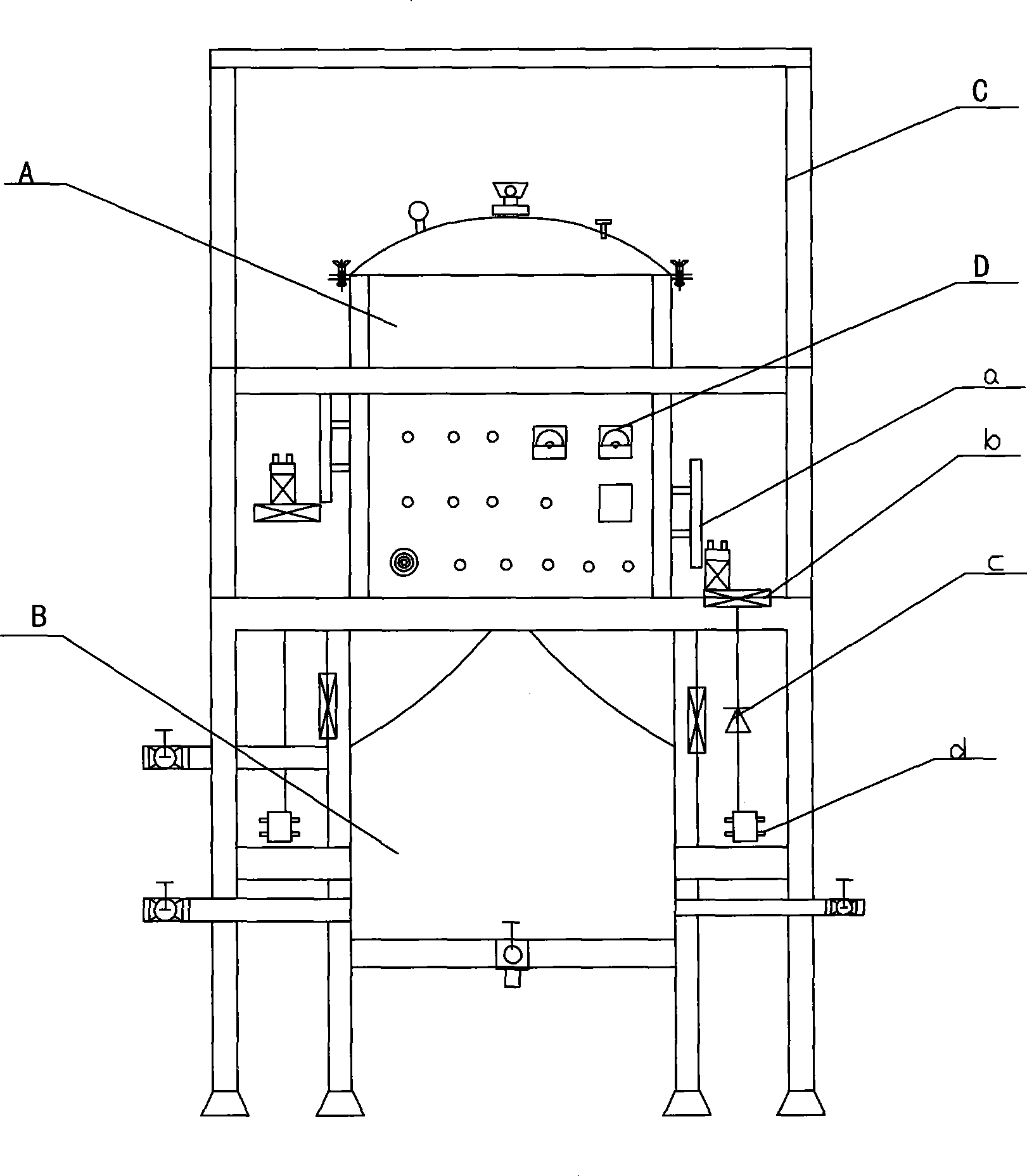

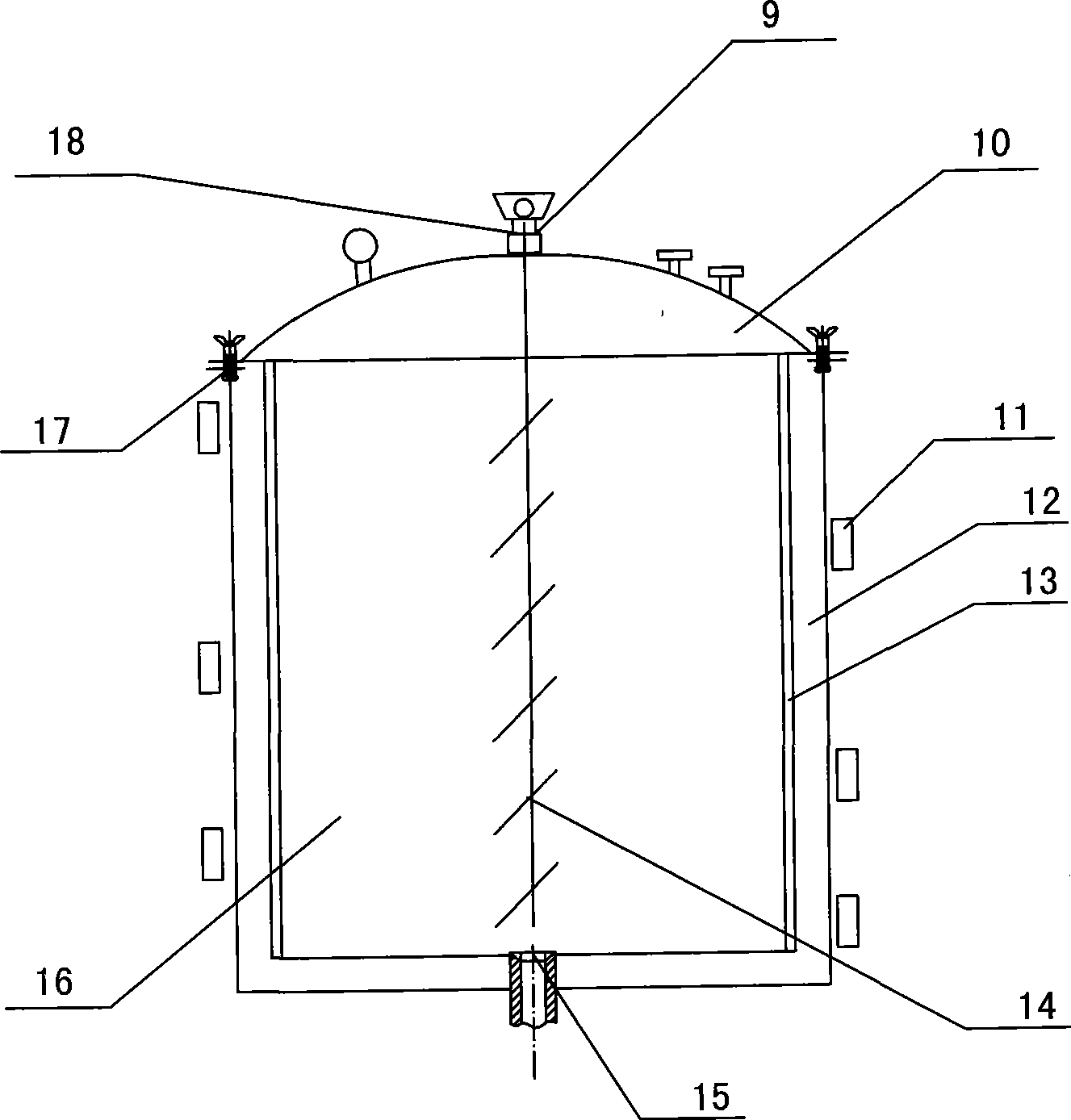

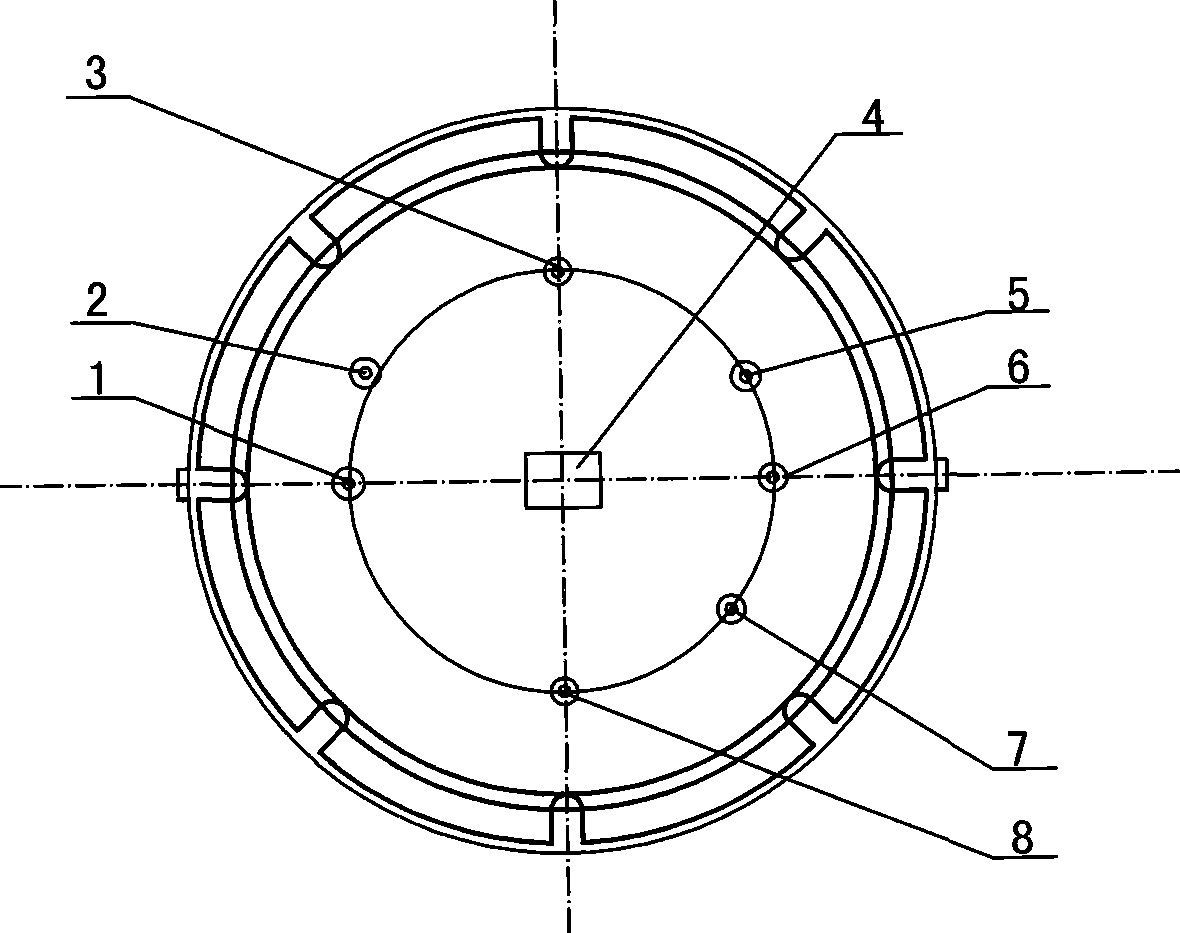

Microwave hydrolysis device

InactiveCN101502781AShort hydrolysis timeRapid hydrolysisEnergy based chemical/physical/physico-chemical processesOrganic compoundMicrowave

The invention relates to a microwave hydrolyzer, comprising a hydrolysis tank, a washing tank, a stander and an instrument panel. The hydrolysis tank comprises a tank body, a tank cover, microwave generators and a blender. The microwave hydrolyzer is characterized in that microwave generators are arranged at the periphery of the tank body of the hydrolysis tank in a spiral way, the hydrolysis tank and the washing tank are connected by a valve and respectively arranged on the stander. The device has simple operation, low energy consumption, comparatively reduced acid amount, short hydrolysis time, high yield and little pollution. When microwave irradiates, connecting keys among molecules under 24 billion times of oscillation are liable to relaxation, another material polar molecule is oscillated by microwave at high speed to generate heat, steam generated from heat in an airtight vessel accumulates to generate pressure, organic compound is hydrolyzed rapidly and thoroughly under the combined action of microwave, weak acid and pressure.

Owner:丁敏

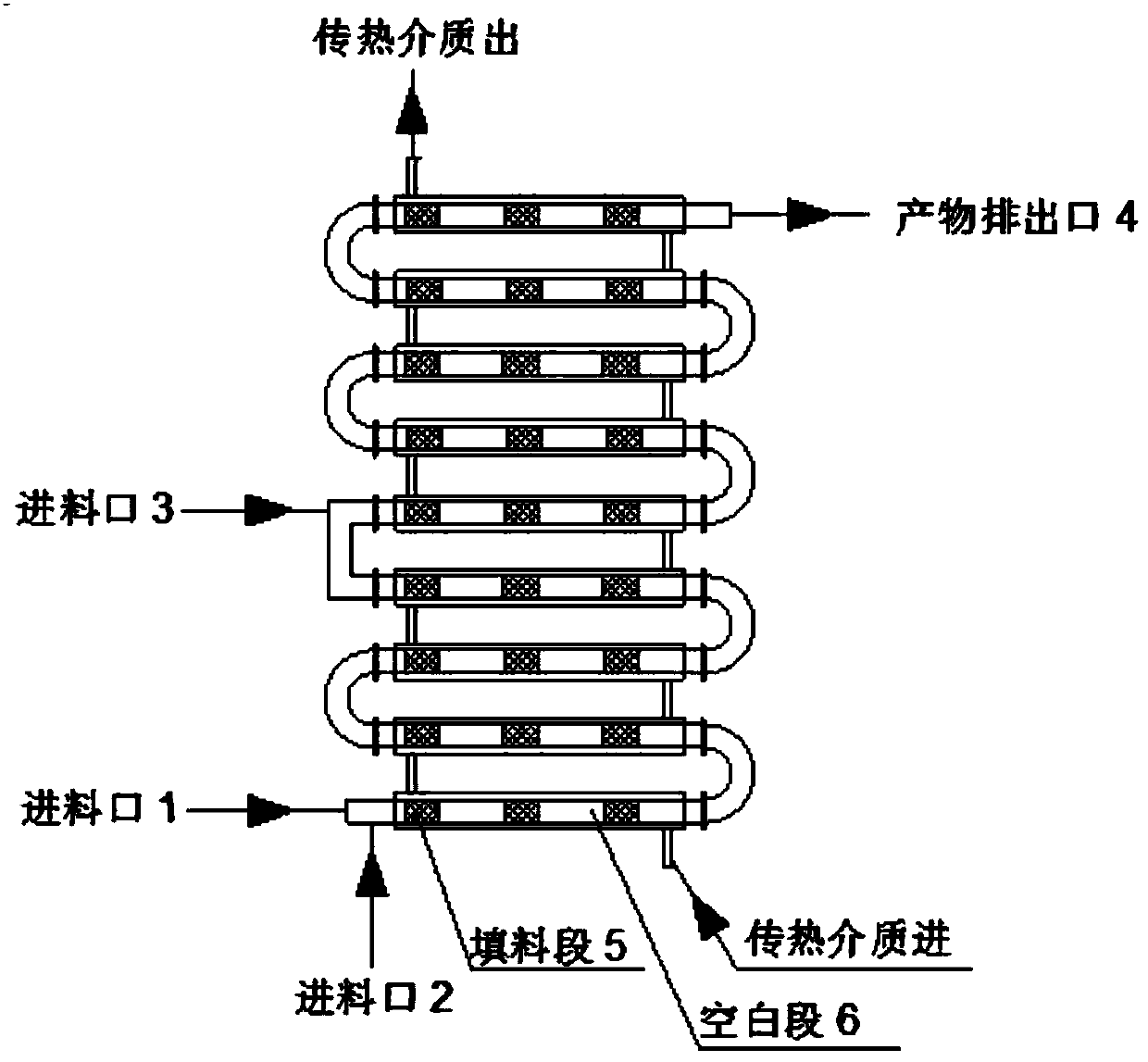

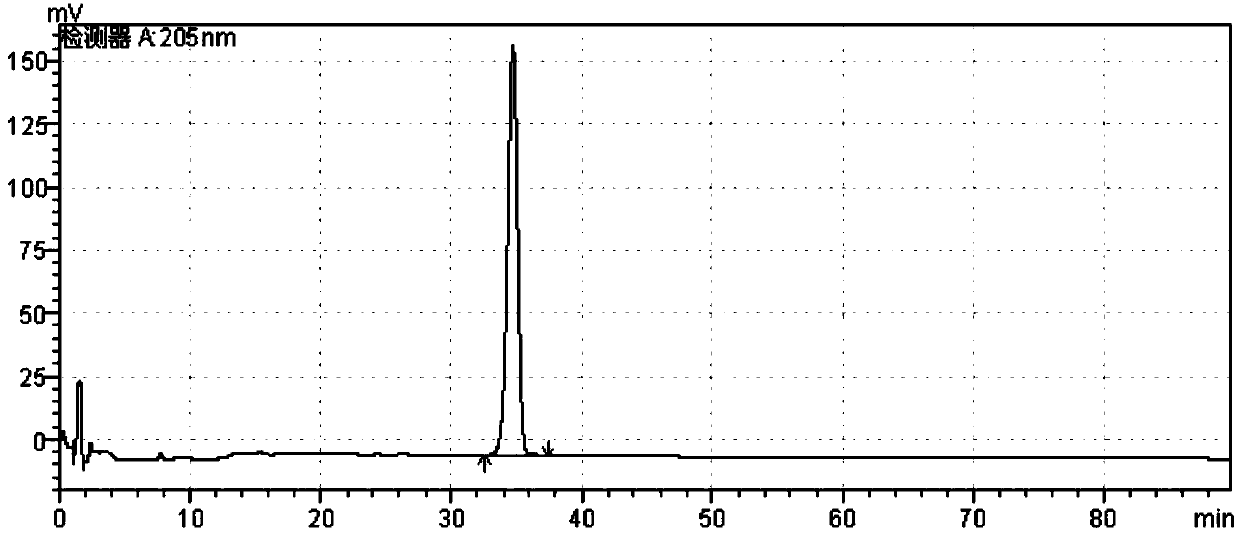

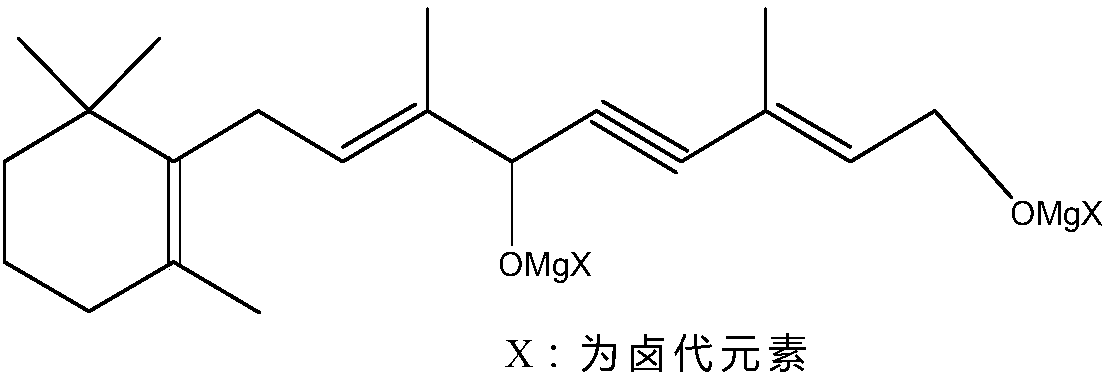

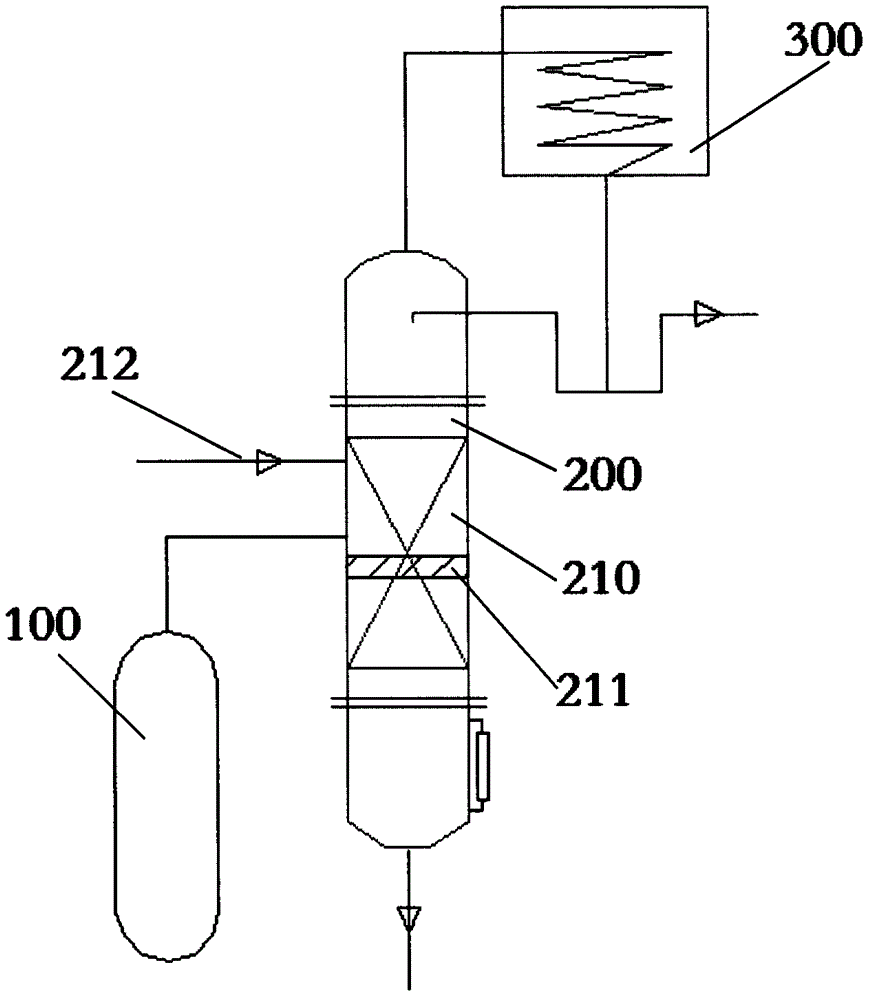

A method and device for continuous hydrolysis and neutralization of vitamin A intermediate double Grignard condensate

ActiveCN106748943BHigh purityHigh yieldOrganic chemistryChemical/physical/physico-chemical stationary reactorsAlkaline waterAcid water

The invention discloses a method and a device for continuous hydrolysis and neutralization of a vitamin A intermediate double Grignard condensate. Steps are as follows: an ether solution and acid water containing the vitamin A intermediate double Grignard condensate are respectively pumped into a tubular reactor, and fully mixed by the tubular reactor for continuous hydrolysis to obtain a hydrolysis liquid; alkaline water is pumped into the tubular reactor by another feeding port of the tubular reactor for continuous neutralization with the hydrolysis liquid in the tubular reactor to obtain a neutralization solution; the neutralization solution is discharged from a product discharging port of the tubular reactor, and is layered into a water phase and an organic phase, the water phase is removed, the organic phase is washed with water to neutral, then an organic solvent is recovered by evaporation, and the vitamin A intermediate double Grignard condensate is obtained. The method has the advantages of high mixing efficiency and short time, the product has high purity and yield, high content and high pure-converting yield. At the same time, continuous operation can be realized, the device is safe and reliable, working environment of production workers is improved, and production efficiency and equipment utilization are improved.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

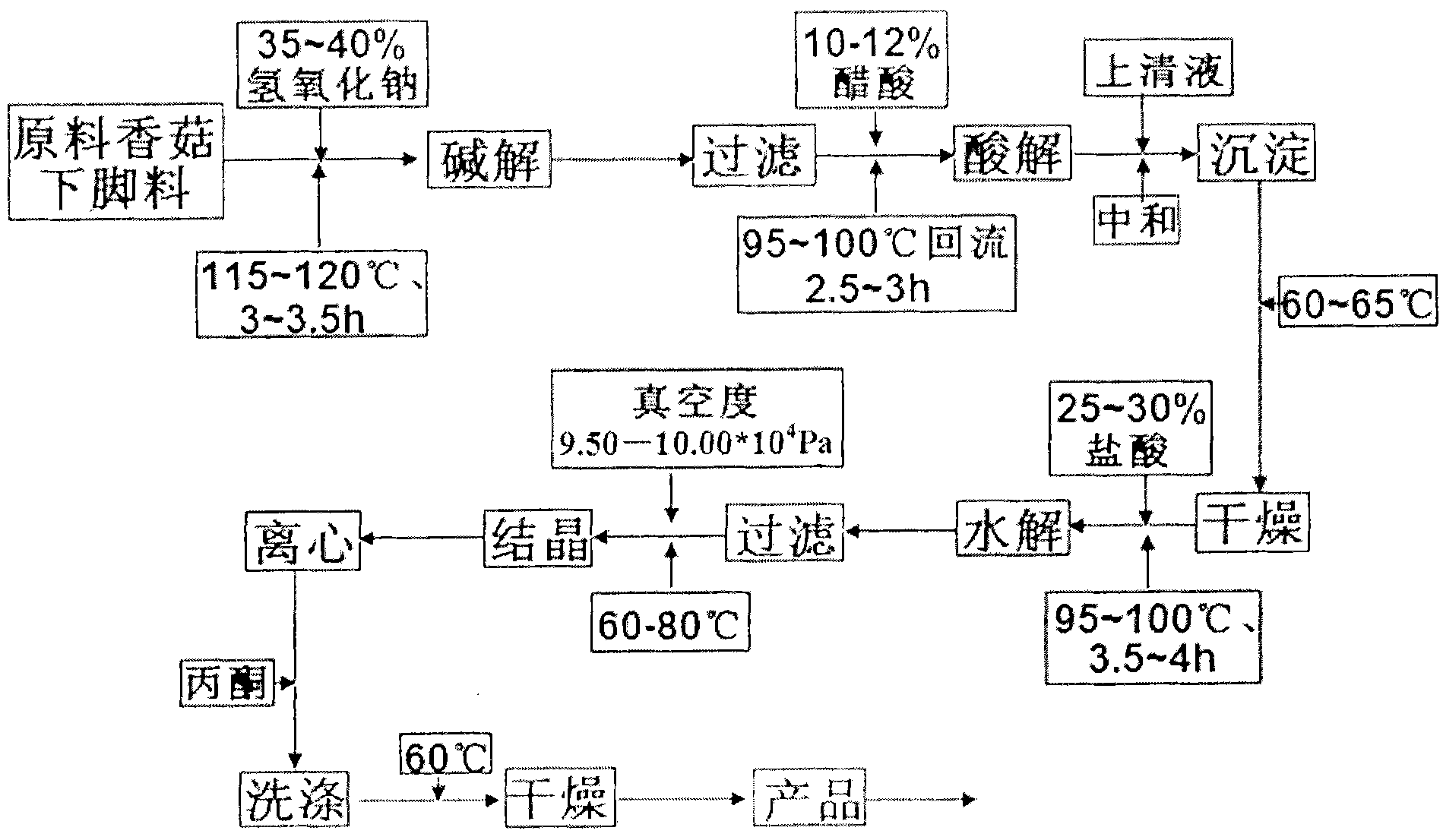

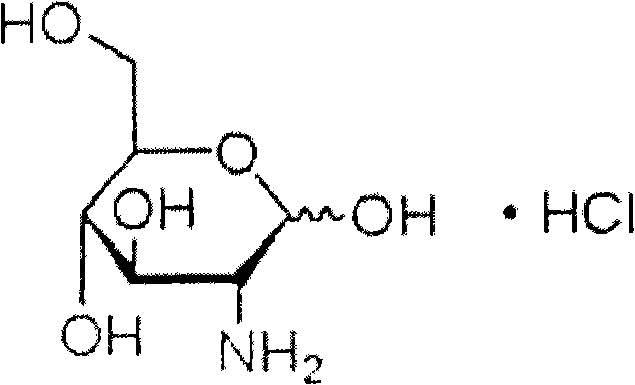

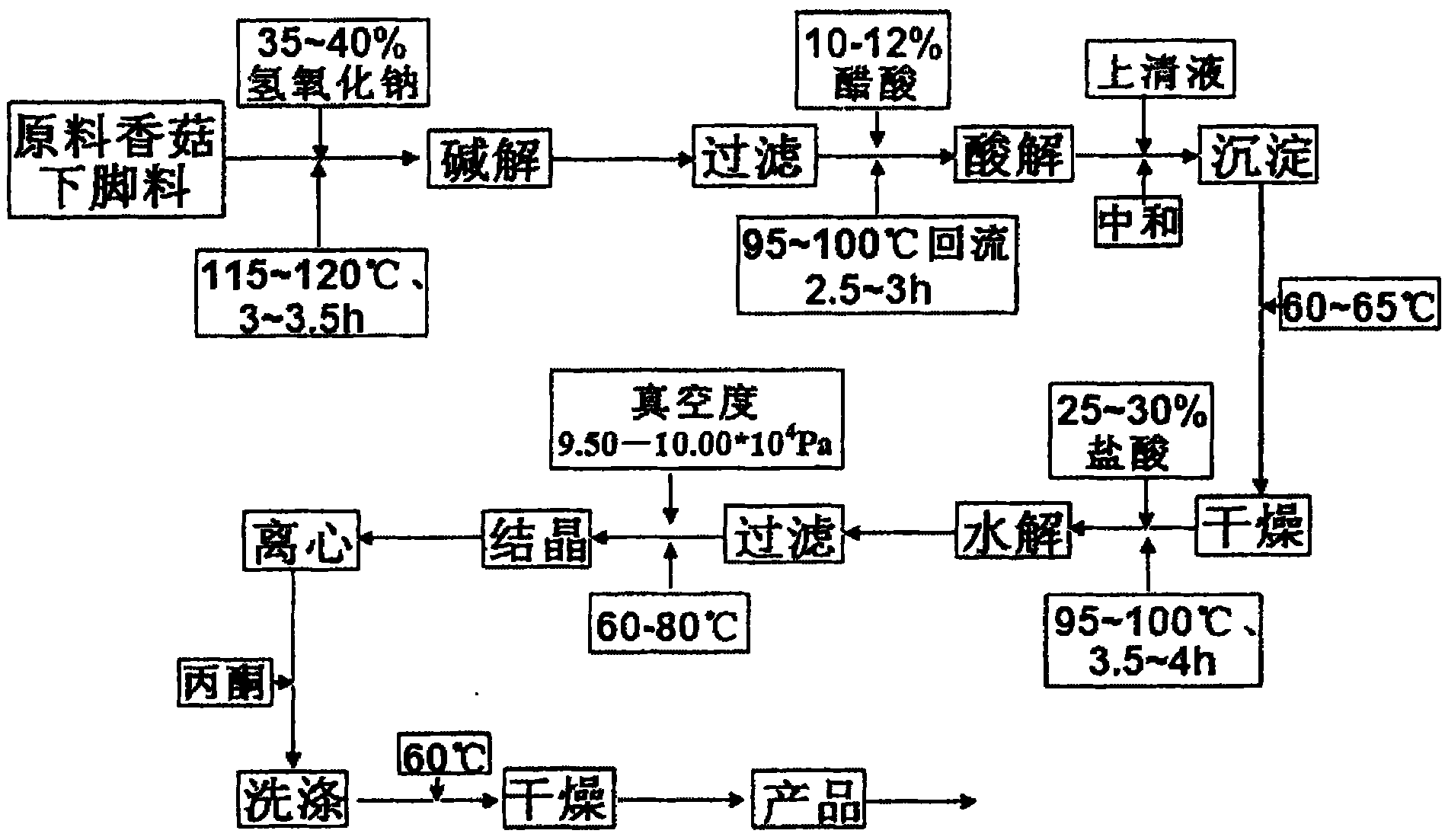

Method for separating glucosamine hydrochloride from Lentinus edodes leftovers

InactiveCN102079762AGood repeatabilityHigh yieldSugar derivativesSugar derivatives preparationSlagFreeze-drying

The invention relates to a method for separating glucosamine hydrochloride from Lentinus edodes leftovers, which comprises the following steps: sequentially hydrolyzing dried Lentinus edodes stipes with sodium hydroxide, and filtering; heating the precipitate under reflux with acetic acid, and centrifugating; and precipitating the supernatant with sodium hydroxide, hydrolyzing with hydrochloric acid, filtering, carrying out vacuum concentration, crystallizing, centrifugating, and carrying out freeze-drying to obtain the glucosamine hydrochloride. The invention has the following advantages: (1) plant-derived mushrooms are used as the raw material, thereby avoiding the defects of the product anaphylaxis, seasonal restrictions to the raw material, incapability of eating for the vegetarianisms and the like in the glucosamine hydrochloride which is made from shrimp and crab shell chitin by the traditional method; (2) the method does not need the pretreatment with acid or alkali, and the raw material dried citric acid slag is directly hydrolyzed, thereby avoiding the problem of sewage caused by pretreatment with acid and alkali; and (3) the hydrolysis time is short, and is only 2.5-3 hours.

Owner:LANGFANG NORMAL UNIV

Method for Synthesizing Glyoxylic Acid by Ozonation of Maleic Anhydride Mixed Solvent

ActiveCN106431885BSimple production processThe method is simpleOrganic compound preparationPreparation from carboxylic acid anhydridesGlyoxylic acidBiochemical engineering

Owner:PANZHIHUA UNIV

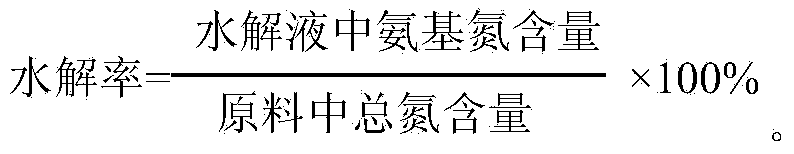

Process for producing amino acid from blood of slaughtered livestock and poultry

The invention discloses a process for producing amino acid from blood of slaughtered livestock and poultry and belongs to the technical field of biochemistry. The process comprises the following steps: (1) filling blood in a storage tank under normal temperature and normal pressure, and transporting or intensively storing the blood; (2) treating the raw material of the blood, mixing coagulated plasma with water according to a ratio of 8 to (1.5-3), stirring for more than 20 minutes by using an OH radical multistage pump, wherein the OH radical can effectively break blood cell membranes; (3) filtering the raw material via a filter net, feeding the raw material into a reaction tank for carrying out hydrolysis reaction under the reaction temperature of 45-60 DEG C, mixing the raw materials with water according to a ratio of 7 to (2.5-3.5), stirring at a pH value of 7.3-7.6, and carrying out hydrolysis reaction for 5-7 hours via 0.3-0.5% by mass of protein hydrolase; (4) forming amino acid after enzymatic hydrolysis reaction, and filtering foreign matters in the amino acid for twice via a 200-250-mesh filter net; (5) carrying out sterilization treatment; and (6) feeding the amino acid into the storage tank for storing, and packaging. The process for producing amino acid from blood of slaughtered livestock and poultry has the advantages that the pollution is completely avoided, the blood nutrition is not lost, the amino acid is not broken, the hydrolysis time is short, the investment is low, and the production cost is low; therefore, the process is simple and efficient.

Owner:金光一

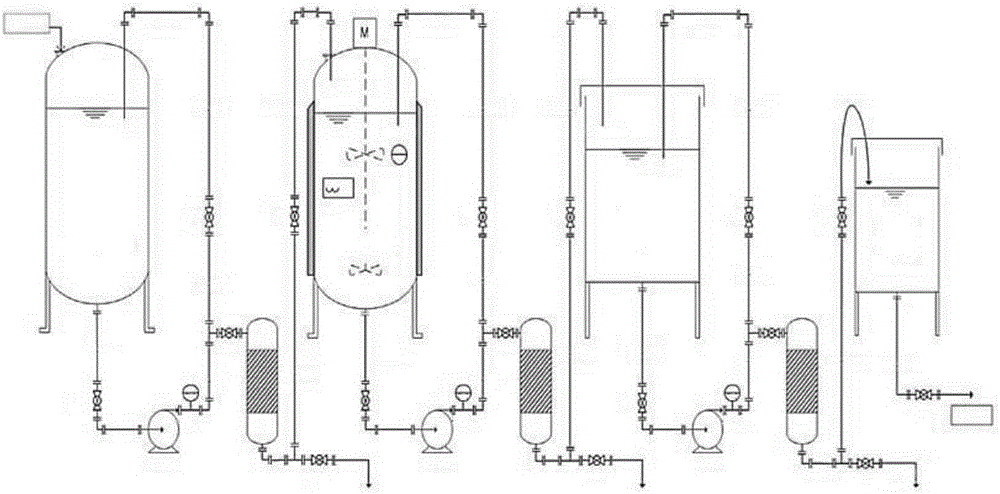

Continuous hydrolyzing device

InactiveCN106278813AShort hydrolysis timeShorten the hydrolysis timeOrganic compound preparationPreparation from carboxylic acid esters/lactonesReboilerSmall footprint

The invention provides a continuous hydrolyzing device. The continuous hydrolyzing device comprises a reboiler, a rectifying tower and a condenser. A catalyzing section is arranged in the rectifying tower and provided with a sold acid catalyst, a material feeding port is formed in the catalyzing section on the rectifying tower, the reboiler is communicated to the catalyzing section, and the condenser is communicated to the top of the rectifying tower. The continuous hydrolyzing device has the advantages of being capable of carrying out continuous reactions, small in occupied area, short in hydrolyzing time, capable of reducing energy consumption and reducing potential safety hazards and the like.

Owner:DAFENG YUELONG CHEM

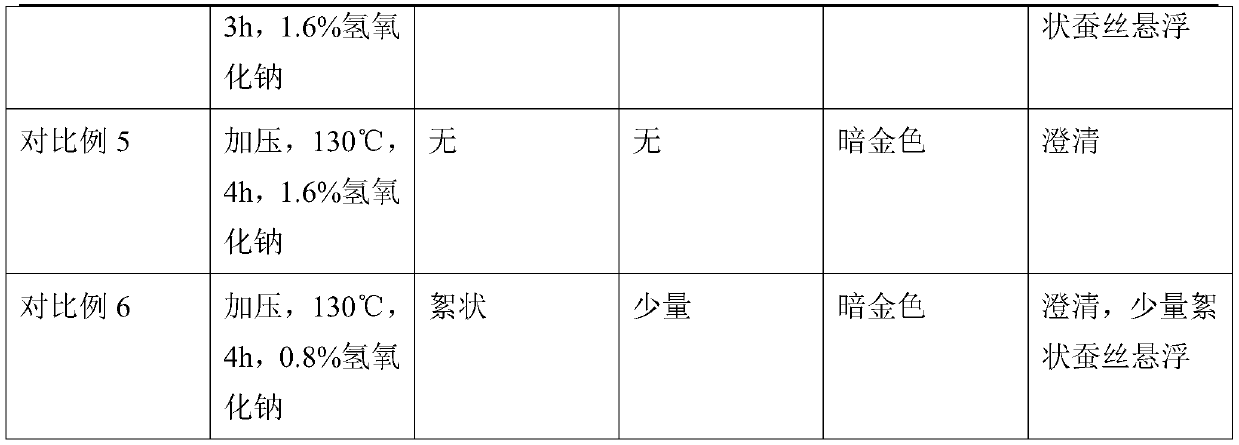

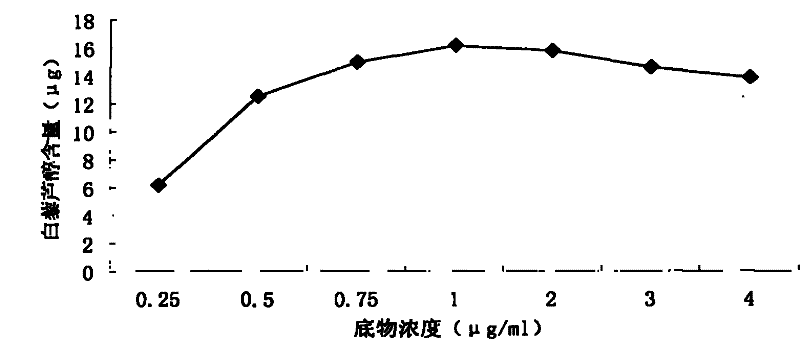

Silk protein mask liquid and preparation method thereof

ActiveCN110840793AGood moisturizing effectFade fine linesCosmetic preparationsToilet preparationsBiotechnologyButanediol

The invention belongs to the technical field of cosmetics, and provides a silk protein mask liquid and a preparation method thereof. The silk protein mask liquid comprises, by weight, 30-50 parts of silk protein hydrolysate, 5-13 parts of pomegranate peel extract, 3-8 parts of manyflower gueldenstaedtia herb extract, 1-5 parts of Japanese felt fern leaf extract, 1-5 parts of leatherleaf mahonia stem extract, 0.5-2 parts of olive oil, 0.5-1.5 parts of diisostearyl malate, 0.1-0.5 part of decyl oleate, 0.1-0.6 part of triethanolamine and 0.1-0.5 part of 1,2-hexanediol, 0.5-2 parts of butanedioland 25-40 parts of water, wherein a preparation method of the silk protein hydrolysate comprises boiling silk in sodium carbonate aqueous solution for degumming, and performing pressure hydrolysis onthe degummed silk in sodium hydroxide solution to obtain the silk protein hydrolysate. The silk protein mask liquid and the preparation method thereof help to solve the problem that the mask liquid containing silk protein in the prior art easily spoils due to proneness to microorganism growth.

Owner:广州微肽生物科技有限公司

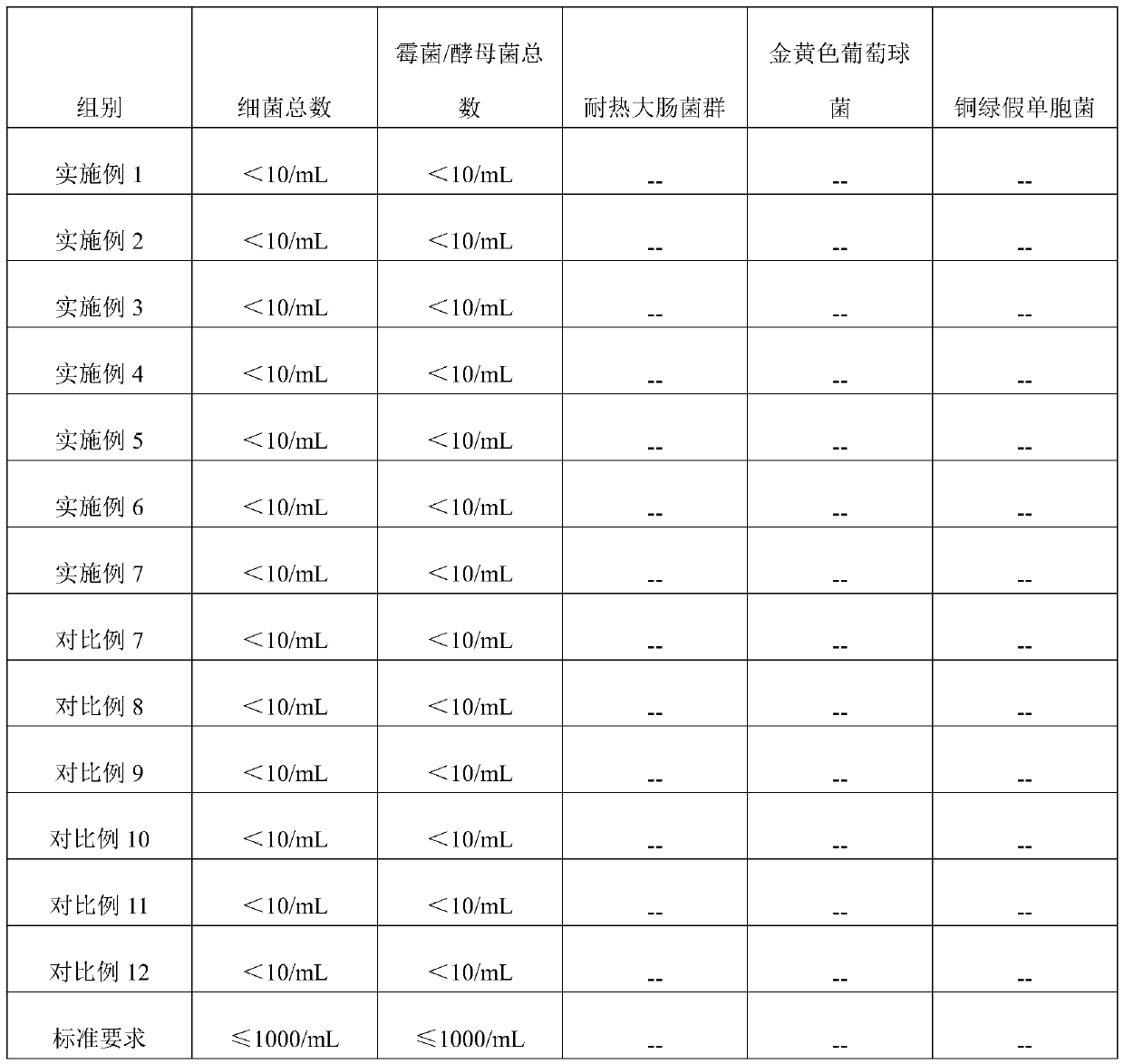

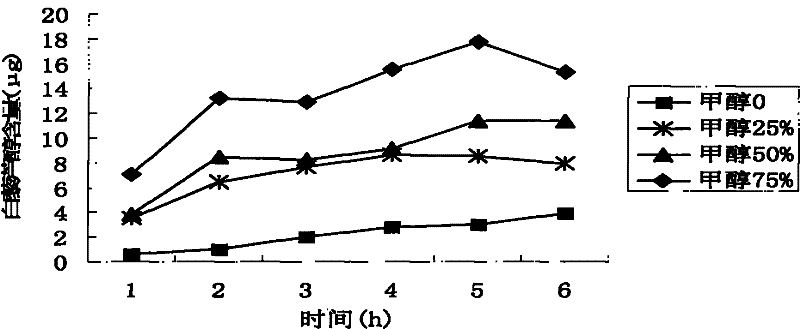

Method for preparaing trans-resveratrol by hydrolyzing trans-polydatin

InactiveCN101519343BImprove conversion rateShort hydrolysis timeOrganic chemistryOrganic compound preparationAcid hydrolysisWhite powder

Owner:ANHUI AGRICULTURAL UNIVERSITY

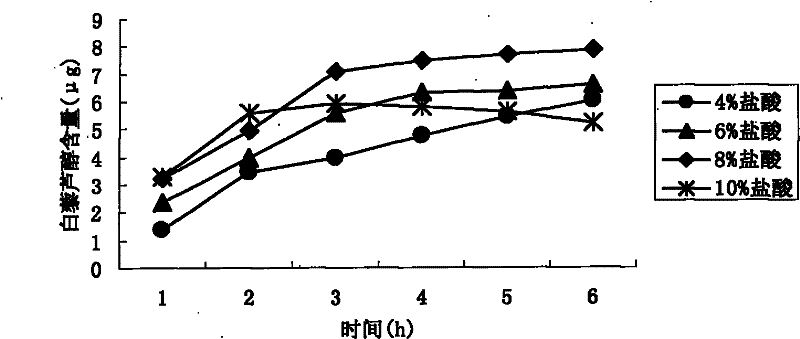

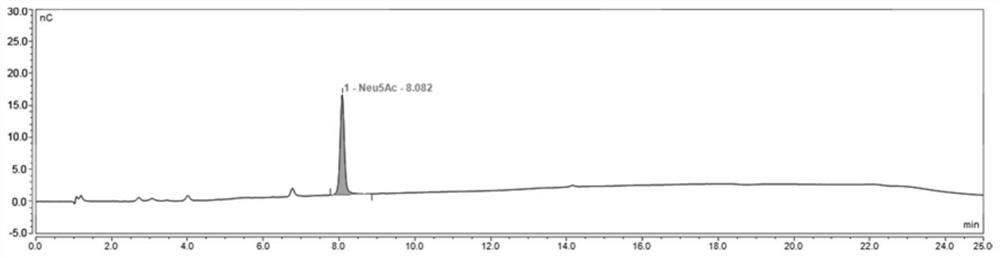

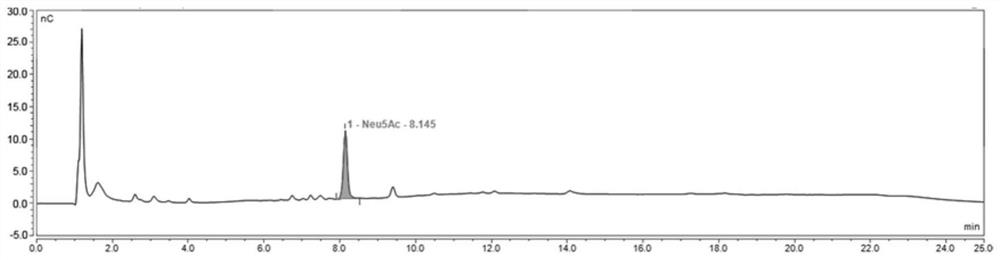

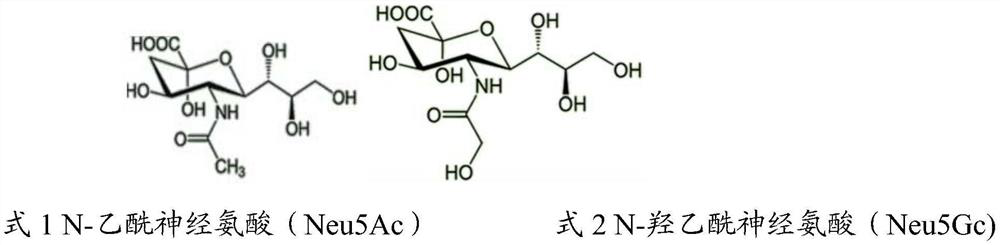

Method for detecting content of sialic acid in milk powder or whey powder

PendingCN114487255AQualitatively accurateAccurate quantitative analysisComponent separationElectrochemical detectorSialic acid

The invention provides a method for detecting the content of sialic acid in milk powder or whey powder, which comprises the following steps: dissolving milk powder or whey powder in water to obtain an aqueous solution; adding an acid solution to the aqueous solution to obtain a milk powder acid solution or a whey powder acid solution; heating the milk powder acid solution or the whey powder acid solution for hydrolysis to obtain milk powder hydrolysate or whey powder hydrolysate; performing centrifugal separation on the milk powder hydrolysate or whey powder hydrolysate to obtain a milk powder supernatant or a whey powder supernatant; diluting the whey powder supernatant, and filtering to obtain whey powder filtrate; or carrying out solid-phase extraction on the milk powder supernatant, leaching with water, eluting with a sodium chloride solution, and collecting to obtain a milk powder eluent; diluting and filtering the whey powder filtrate or the milk powder eluent to obtain filtrate; and determining the filtrate by using a high performance anion exchange chromatography-electrochemical detector. The method disclosed by the invention is simple to operate, and can be used for accurately, qualitatively and quantitatively analyzing N-acetylneuraminic acid in whey powder and milk powder.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Method for preparing glycyrrhetinic acid

The invention relates to a method for preparing glycyrrhetinic acid, and the method comprises the following steps of: (1) sequentially adding n-butyl alcohol and concentrated sulphuric acid into glycyrrhizic acid powder, and filtering after stirring and dissolving so as to obtain filtrate A; (2) heating and hydrolyzing the filtrate A and reducing temperature to be 20-40 DEG C, and filtering to obtain filtrate B; (3) carrying out reduced-pressure concentration on the filtrate B to recycle n-butyl alcohol until volume of the filtrate B is 10% of the original volume of n-butyl alcohol, adding water equivoluminal with recycled n-butyl alcohol, continuing concentrating until no n-butyl alcohol exists, and filtering to obtain precipitate; (4) washing the precipitate to be neutral, adding sodiumhydroxide solution, and filtering after the precipitate is dissolved so as to obtain filtrate C; and (5) adding hydrochloric acid into the filtrate C to regulate pH value to be 4-6, washing the precipitate obtained by regulating the pH value with water until the pH value is equal to 7, and then carrying out vacuum drying so as to obtain glycyrrhetinic acid. Glycyrrhetinic acid provided by the invention can be hydrolyzed at normal pressure and has high hydrolysis temperature, short hydrolysis time and high hydrolysis efficiency.

Owner:GANSU YALAN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com