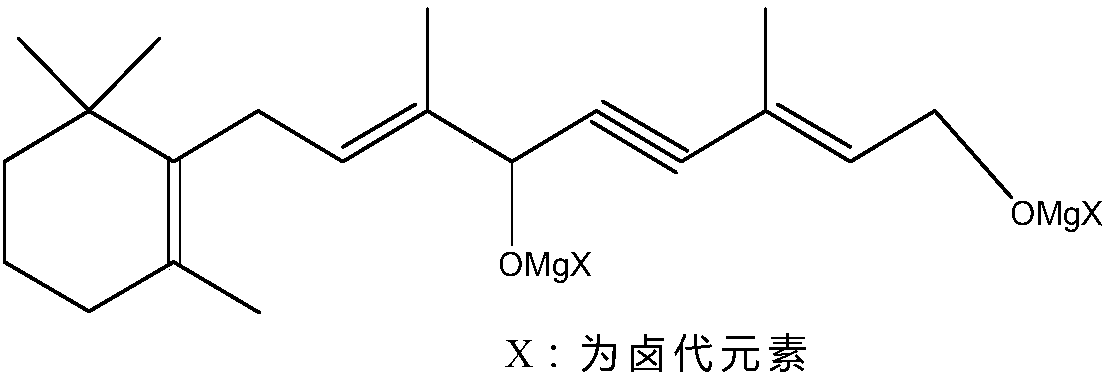

A method and device for continuous hydrolysis and neutralization of vitamin A intermediate double Grignard condensate

A technology of double Grignard condensates and intermediates, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of difficulty in purification, difficulty in precise control, and difficulty in operation, etc. Achieve the effect of improving production efficiency and equipment utilization, avoiding manual errors, high purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A straight tube reactor is adopted, and the filler section in the pipeline is made of quartz sand, and the length ratio of the filler section to the blank section is 1:1.

[0049] Preparation concentration is the diethyl ether solution of 0.8mol / L magnesium dichloride condensate, forms material 1; Preparation [H + ] Concentration is 1.6mol / L hydrochloric acid aqueous solution, forms material 2; Preparation sodium bicarbonate concentration is 0.5mol / L alkali aqueous solution, forms material 3.

[0050] At the same time, the material 1 and the material 2 are pumped into the tubular reactor through the feed port 1 and the feed port 2 at a ratio of 1:1.1 per unit time, and the hydrolysis temperature is controlled at 25°C, and the hydrolysis time is 20 seconds; After that, the material 3 is pumped into the tubular reactor through the feed port 3, the volume ratio of material 1 and material 3 per unit time is 1:0.6, the neutralization reaction temperature is controlled at 25°...

Embodiment 2

[0052] A U-shaped tubular reactor is used, and the filler section in the pipeline is made of quartz sand, and the length ratio of the filler section to the blank section is 1:0.5.

[0053] Preparation concentration is the tetrahydrofuran solution of 1.2mol / L magnesium dichloride condensate, forms material 1; Preparation concentration is 1.8mol / L ammonium chloride aqueous solution, forms material 2; Preparation sodium bicarbonate concentration is 0.1mol / L alkali aqueous solution, forms Material 3.

[0054] At the same time, the material 1 and the material 2 are pumped into the tubular reactor through the feed port 1 and the feed port 2 at a ratio of 1:1.4 per unit time, and the hydrolysis temperature is controlled at 45°C, and the hydrolysis time is 80 seconds; the hydrolysis time After that, the material 3 is pumped into the tubular reactor through the feed port 3, the volume ratio of material 1 and material 3 per unit time is 1:2, the neutralization reaction temperature is co...

Embodiment 3

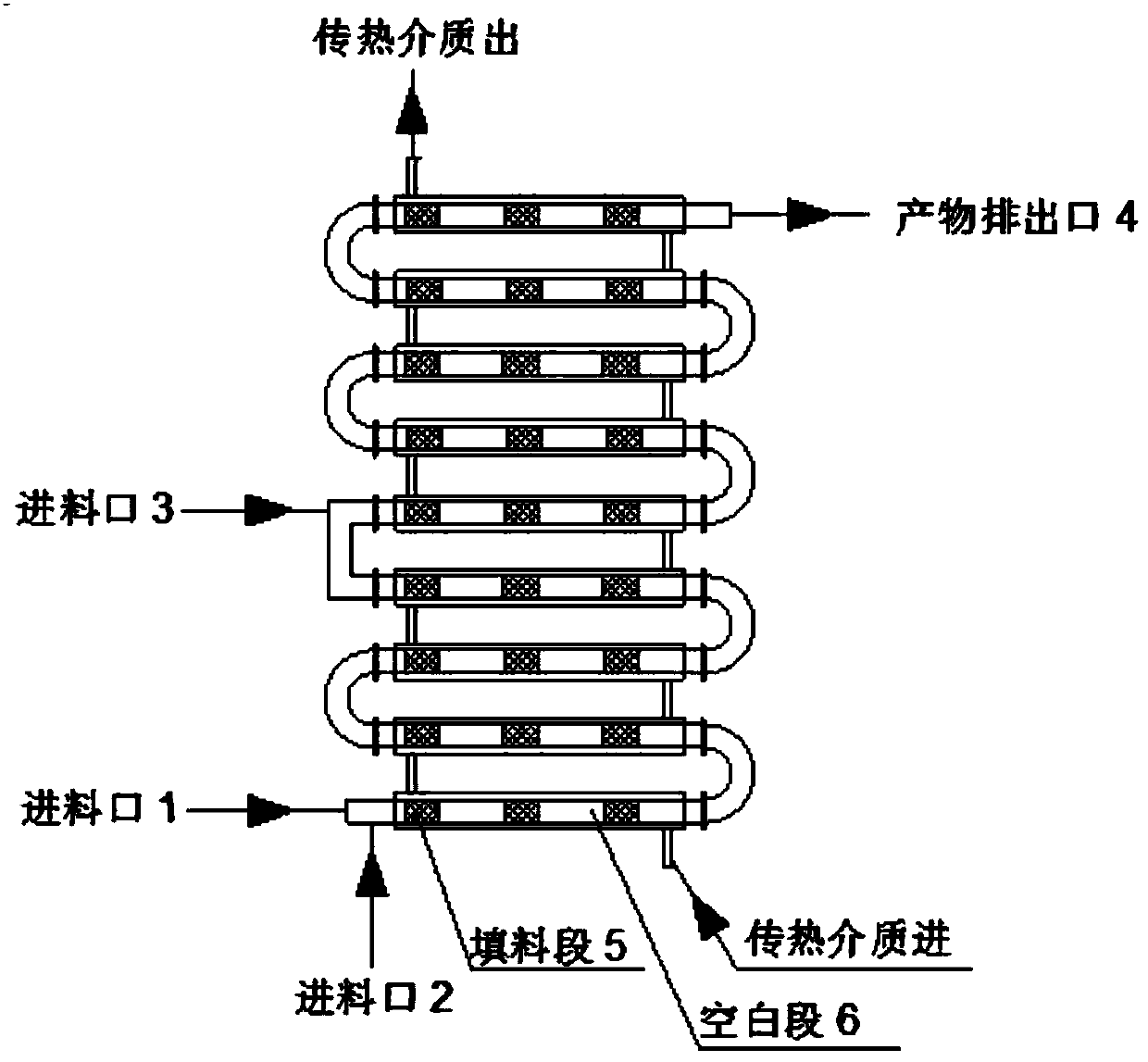

[0056] A coil-type tubular reactor is used, and Raschig rings are used for the packing section in the pipeline, and the length ratio of the packing section to the blank section is 1:1.5. structure see figure 1 shown.

[0057] Preparation concentration is the diethyl ether solution of 1.0mol / L magnesium dichloride condensate, forms material 1; Preparation [H + ] Concentration is 1.4mol / L sulfuric acid aqueous solution, forms material 2; Preparation sodium bicarbonate concentration is 0.1mol / L alkali aqueous solution, forms material 3.

[0058] At the same time, the material 1 and the material 2 are pumped into the tubular reactor through the feed port 1 and the feed port 2 at a ratio of 1:1.5 per unit time, and the hydrolysis temperature is controlled at 35°C, and the hydrolysis time is 30 seconds; the hydrolysis time After that, the material 3 is pumped into the tubular reactor through the feed port 3, the volume ratio of material 1 and material 3 per unit time is 1:1.5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com