Patents

Literature

117 results about "Acetylenic alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetylenic alcohols are produced by ethinylation of carbonyl compounds, especially ketones, in the presence of an alkaline reagent and a solvent. Alkaline reagents used in this process include potassium hydroxide, alkali metal alcoholates, alkali metals, and alkaline earth metal amides. Commonly used bases are alkali amides.

Certain silicone polyethers, methods for making them and uses

InactiveUS6987157B2Reduce surface tensionCosmetic preparationsSilicon organic compoundsPolymer scienceAlcohol

There are disclosed silicone polyether compositions, methods for making them and their uses. The compositions are based on polyethers initiated by non-isomerizing alkenyl or alkynyl alcohols.

Owner:DOW SILICONES CORP

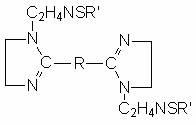

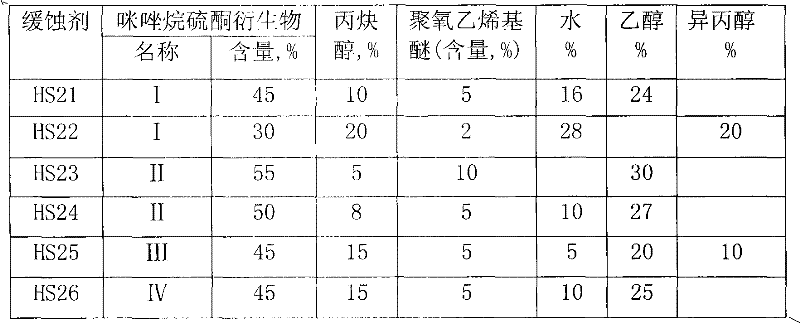

Sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and preparation method thereof

InactiveCN102321463AImprove protectionGood water solubilityOrganic chemistryBorehole/well accessoriesCarbon dioxide corrosionActive agent

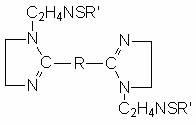

The invention discloses a sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and a preparation method thereof. The corrosion inhibitor comprises the following components in percentage by weight: 20-50 percent of sulfur-containing bis-imidazoline quaternary ammonium salt, 1-5 percent of nonionic surfactant, 40-70 percent of low molecular alcohol solvent and 5-10 percent of alkynol, wherein a sulfur-containing bis-imidazoline compound has a general formula of a structure which is shown in the specification; the number of carbon atoms in R of the formula is 5 or 8; the nonionic surfactant is fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylate; the low molecular alcohol solvent is methanol, ethanol, isopropanol or ethylene glycol; and the alkynol is propargyl alcohol or hexynol. In the invention, the sulfur-containing bis-imidazoline compound which is generated through dehydration between dicarboxylic acid and polyamine molecule, dehydration reaction in the molecule and further reaction with the sulfur-containing compound is adopted; the molecule contains a plurality of active adsorption centers such as two diazo five-membered heterocyclic rings, a sulfur-containing group and the like; and a formed organic adsorption membrane has better protection effect on carbon steel.

Owner:UNIV OF SCI & TECH BEIJING

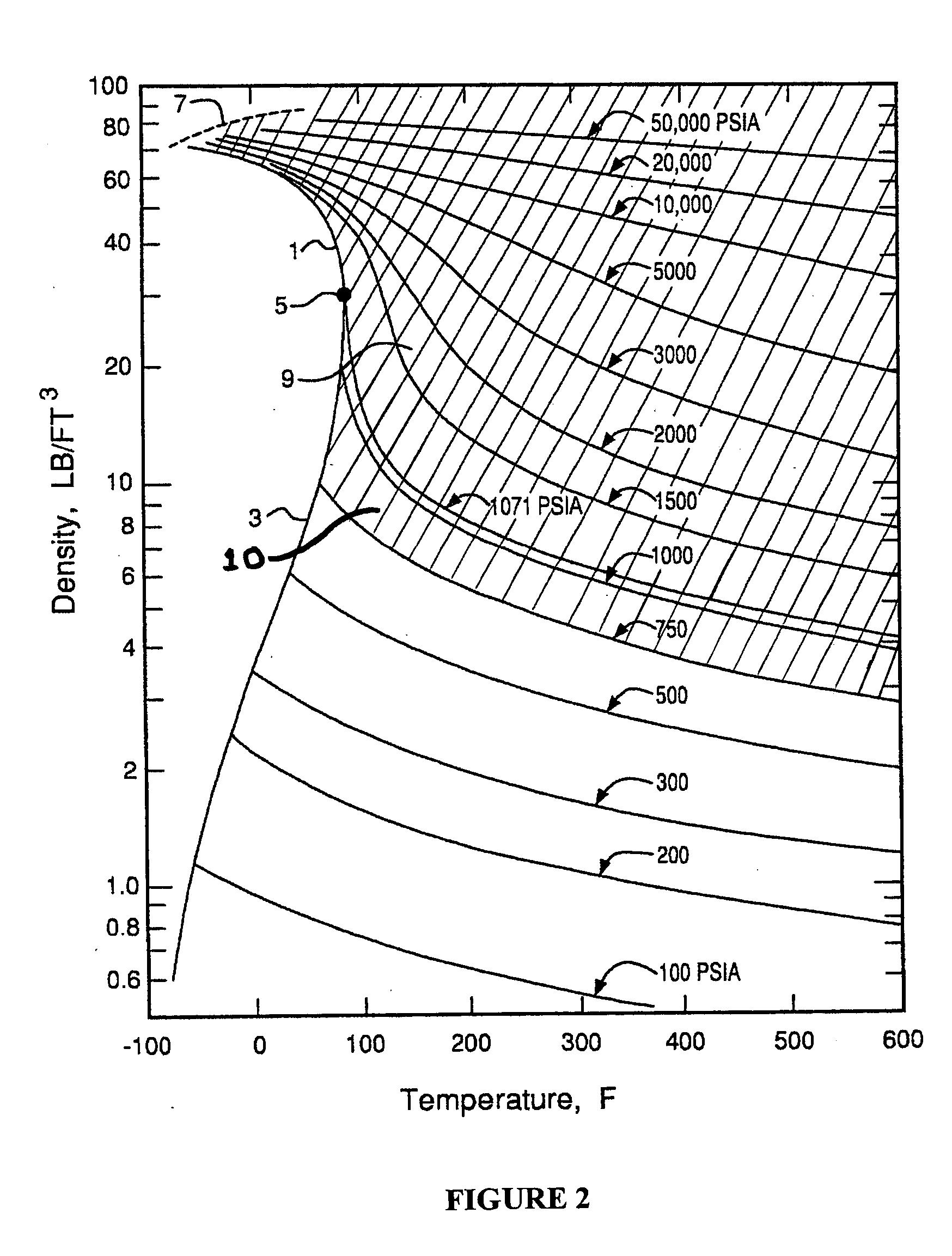

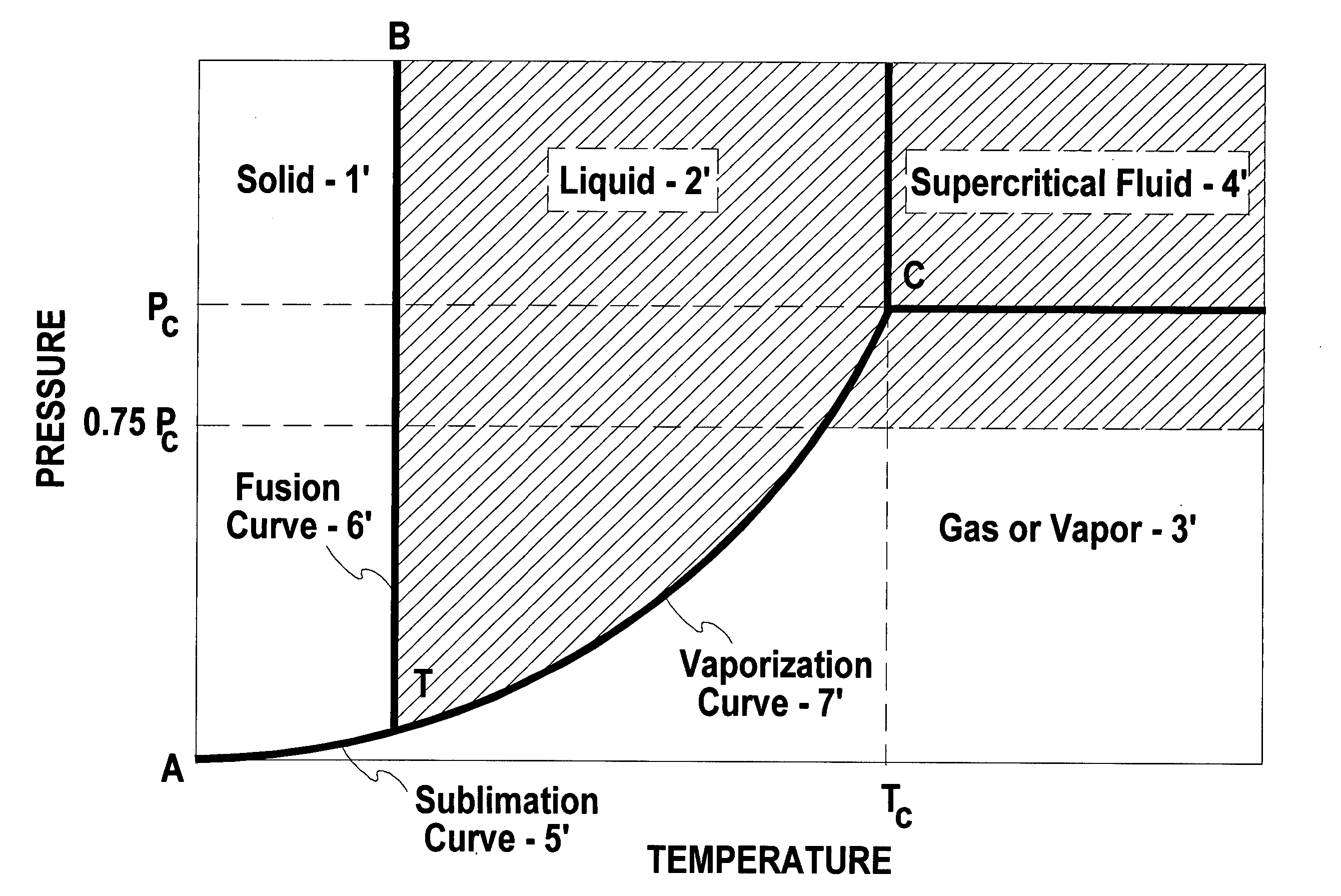

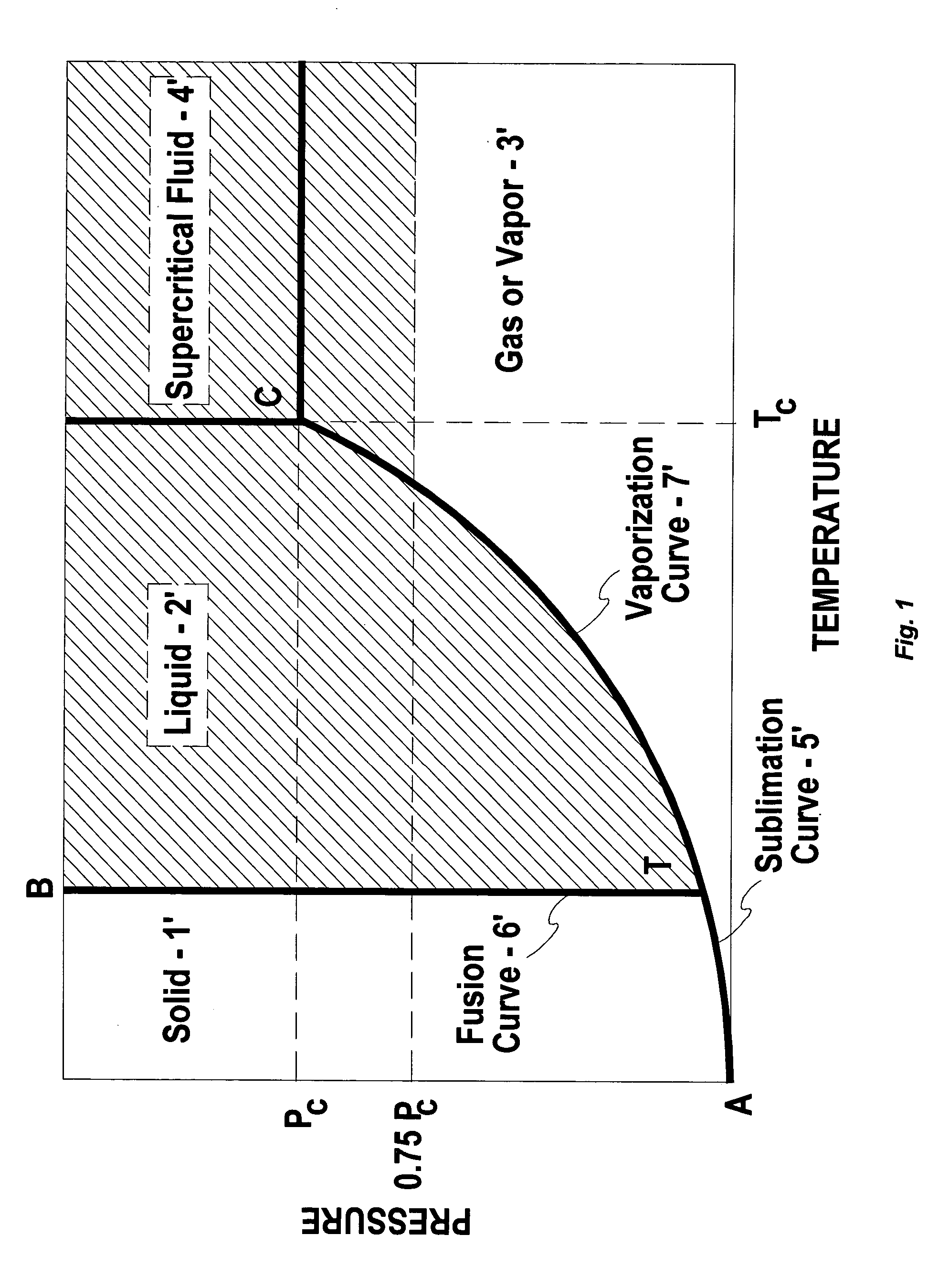

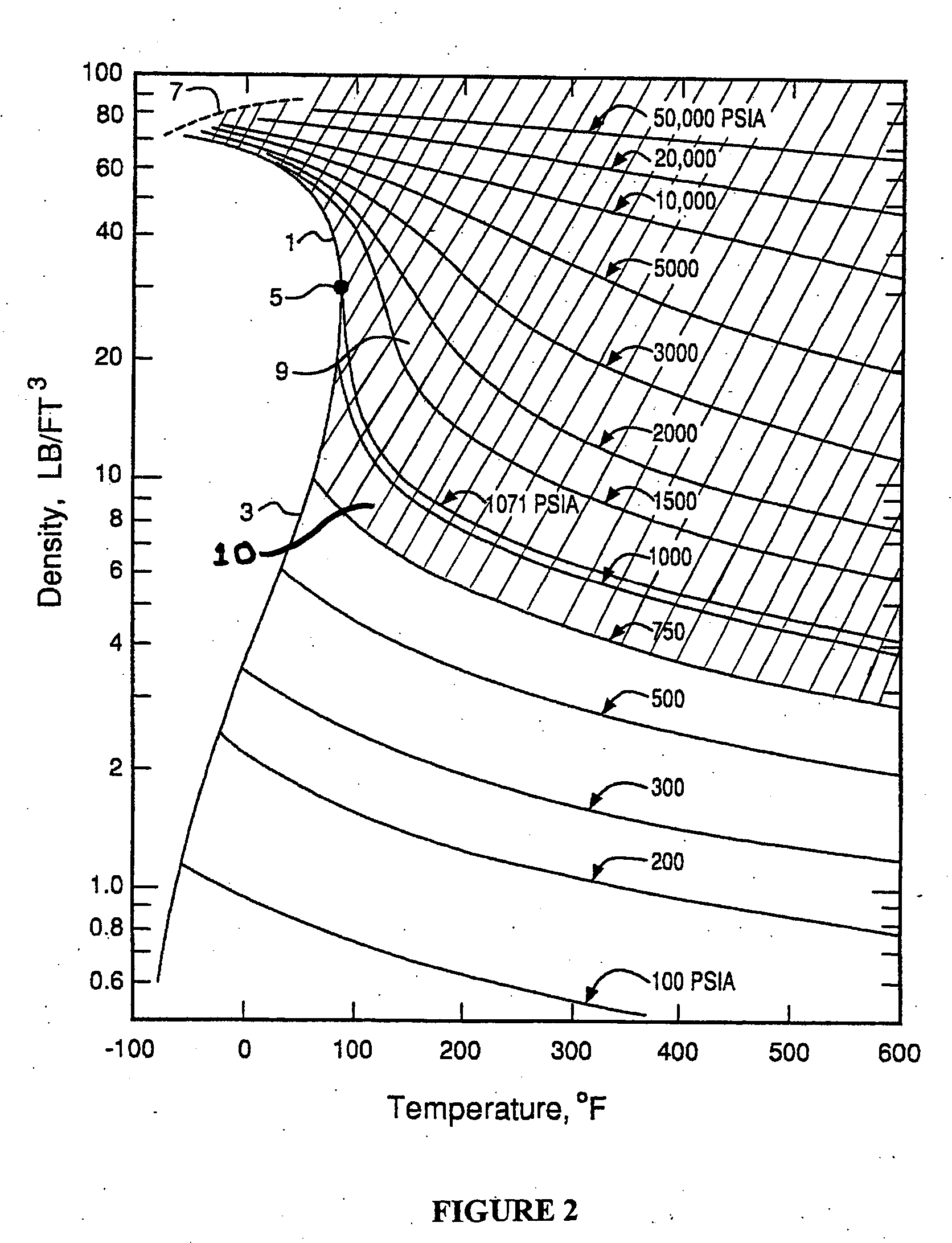

Processing of semiconductor substrates with dense fluids comprising acetylenic diols and/or alcohols

InactiveUS20050029492A1Organic detergent compounding agentsSurface-active detergent compositionsActive agentAcetylenic alcohol

A dense cleaning fluid for removing contaminants from an substrate and a method comprising same is disclosed herein. In one embodiment of the present invention, the dense cleaning fluid comprises a dense fluid and at least one acetylenic diol or acetylenic alcohol surfactant.

Owner:VERSUM MATERIALS US LLC

Transparent anti-fog anti-splash coating compositions

The present invention is directed to an anti-fogging / anti-splash composition that can be used for anti-fog / anti-splash applications. When applied to the surface of a transparent or reflective substrate, the composition dries relatively clear and comprises a solution of a non-toxic, fast drying solvent or alcohol and a surface active agent containing sodium lauryl ether sulfate, and either a block ethylene oxide / polyethylene oxide copolymer, an ethoxylated amine, an ethoxylated acetylenic alcohol, sodium sulfosuccinate, ethoxylated sorbitan ester, random EO / PO polymers on butyl alcohol, or mixtures thereof. When applied to the surface of a substrate, the present invention provides a coating of high transparency which cures rapidly, is sufficiently surface active to be an anti-fog agent when "dry", will persist when "wet" under water spray conditions (such as on a dental mirror) for a period substantial enough to be practicable, and will provide anti-splash benefits throughout the use cycle.

Owner:MACHSON ROGER

Method and composition for controlling corrosion in high density brines

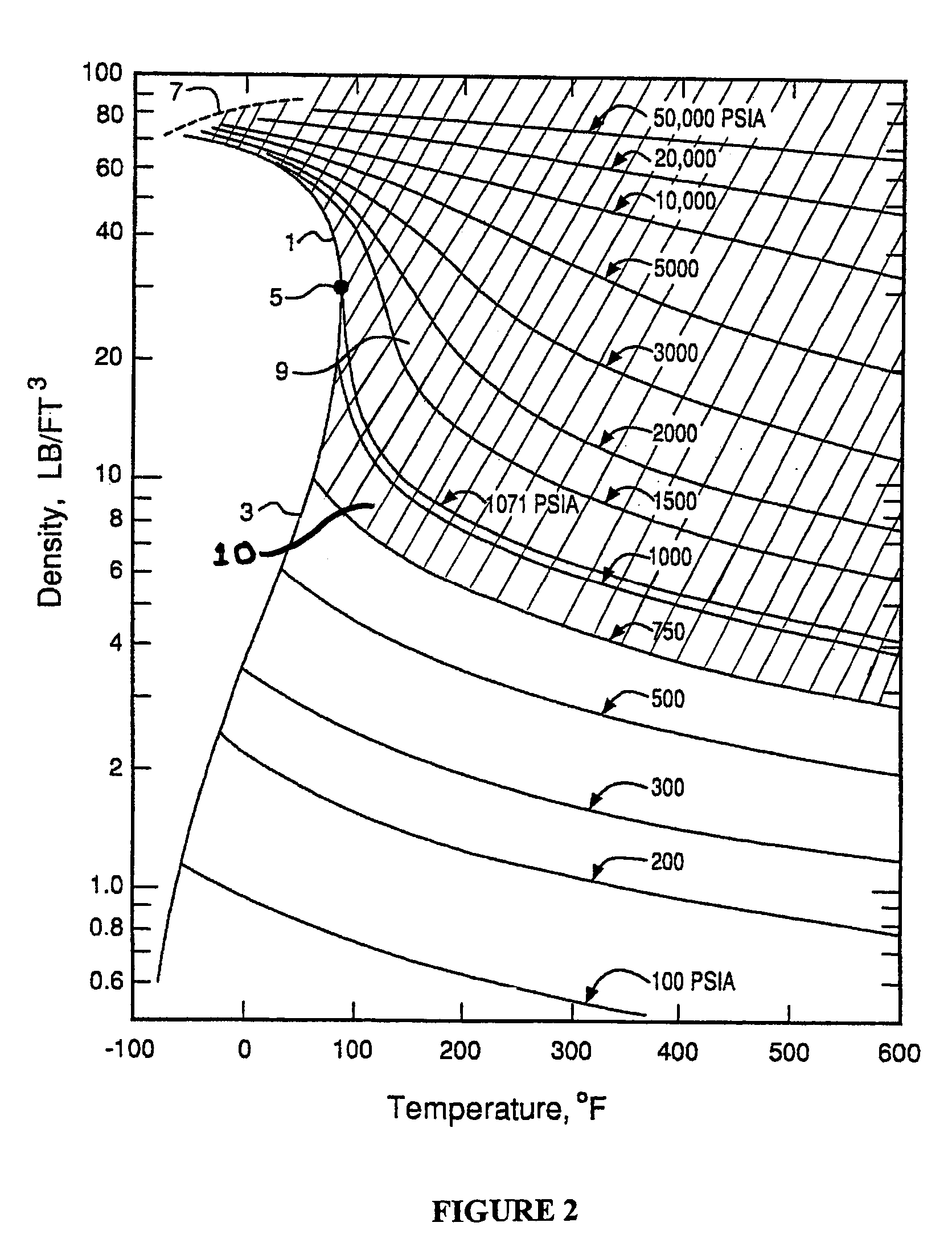

A corrosion inhibitor package containing an acetylenic amine or acetylenic alcohol enables a sulfur-free method for protecting metal tubulars and equipment. The package has particular applicability in the protection of carbon steel tubulars in high density brines at elevated temperatures. The corrosion inhibitor package may contain a transition metal oxide as a corrosion inhibitor intensifier.

Owner:BAKER HUGHES INC

Acid inhibitor compositions for metal cleaning and/or pickling

ActiveUS20090032057A1Trend downImprove protectionDetergent mixture composition preparationDetergent compounding agentsHexamethylenetetramineFatty amine

An acid inhibitor concentrate is provided which contains water, at least one polyamino-aldehyde resin such as a quaternized polyethylenepolyamine-glyoxal resin, and at least one compound selected from the group consisting of acetylenic alcohols, ethoxylated fatty amines, ethoxylated fatty amine salts, and aldehyde-releasing compounds (such as hexamethylenetetramine). Such concentrates form useful metal cleaning and pickling solutions when combined with aqueous acid, wherein such solutions, when contacted with a metal surface, are effective in removing scale, smut and other deposits from the metal surface but exhibit a reduced tendency for the aqueous acid to attack or etch the metal itself.

Owner:HENKEL KGAA

Processing of substrates with dense fluids comprising acetylenic diols and/or alcohols

InactiveUS20050029490A1Organic detergent compounding agentsSurface-active detergent compositionsAlcoholAcetylenic alcohol

A dense cleaning fluid for removing contaminants from a substrate and a method comprising same is disclosed herein. In one embodiment of the present invention, the dense cleaning fluid comprises a dense fluid and at least one acetylenic diol or acetylenic alcohol surfactant.

Owner:VERSUM MATERIALS US LLC

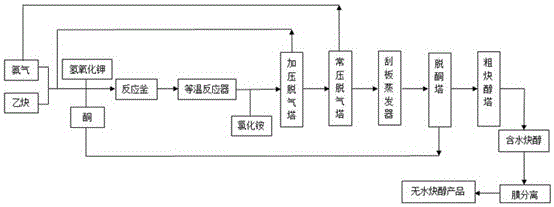

Novel process for synthesizing alkynol from acetylene and ketone compounds

ActiveCN106117010AIn line with the characteristics of reaction kineticsHigh reaction yieldOrganic compound preparationHydroxy compound separation/purificationInorganic saltsAcetylenic alcohol

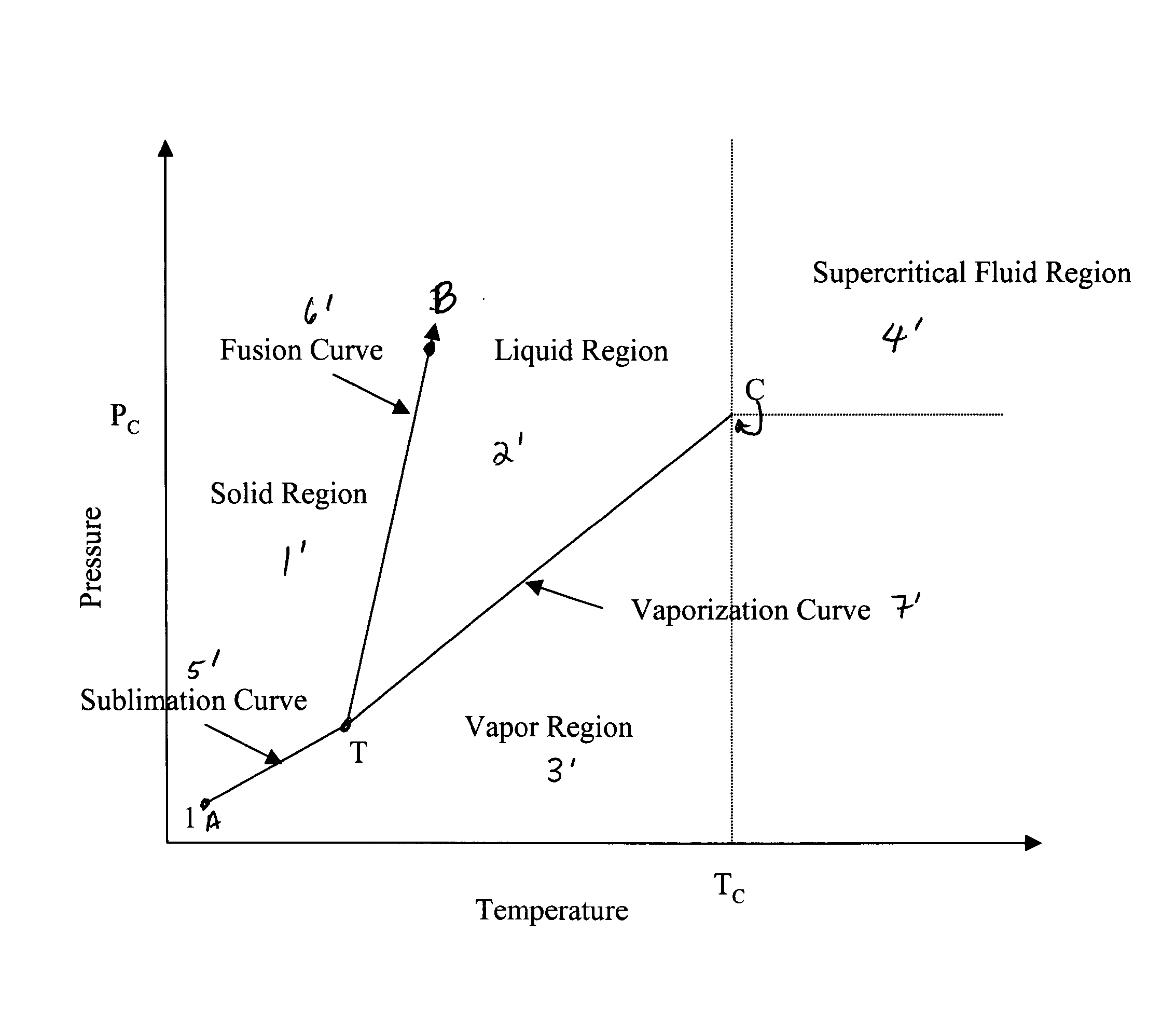

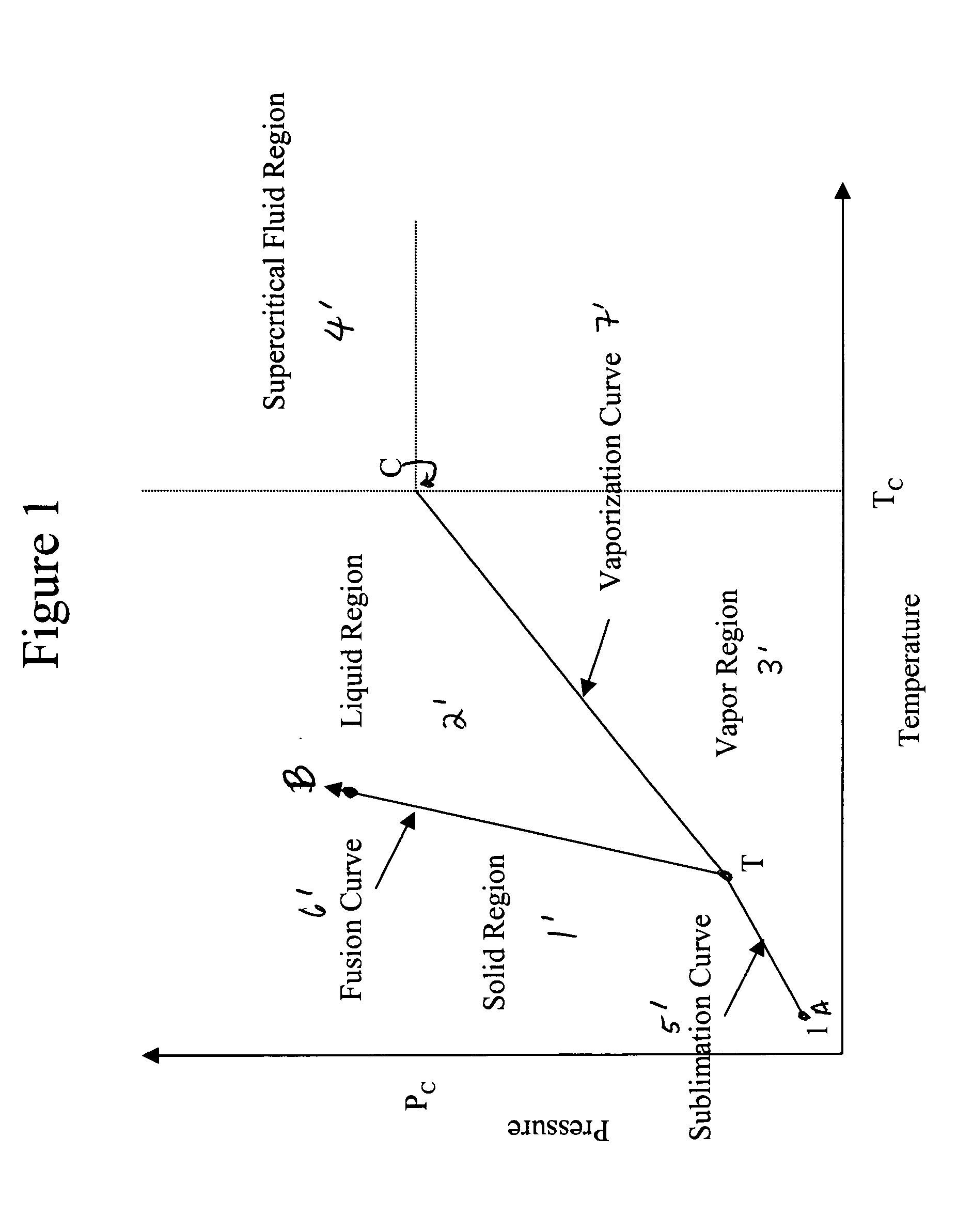

The invention relates to a novel process for synthesizing alkynol from acetylene and ketone compounds. The novel process comprises the following steps: acetylene and a solvent ammonia gas are mixed and compressed, the ketone compounds and a potassium hydroxide catalyst are added, an ethynylation reaction is completed in a reactor, and ammonium chloride is added to terminate the reaction; unconsumed acetylene from the reaction system and 2-5 times of ammonia are output in a liquid form in a pressurized degassing tower, and the condition that a material in the tower contains no acetylene is guaranteed; ammonia in the system is all output in an atmospheric degassing tower with an ammonia self-cooling technology, and the condition that the material in the tower contains no ammonia is guaranteed; inorganic salt in the system is removed by a scraper evaporator; the ketone compounds are output from the top of a ketone removal tower and recycled to the reaction system; alkynol-containing products are obtained in a crude alkynol tower; water is further removed through membrane separation, and anhydrous alkynol products are finally obtained. The novel process has the advantages of high product yield, low energy consumption and little wastewater discharge.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

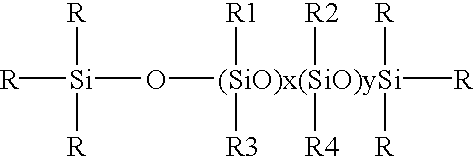

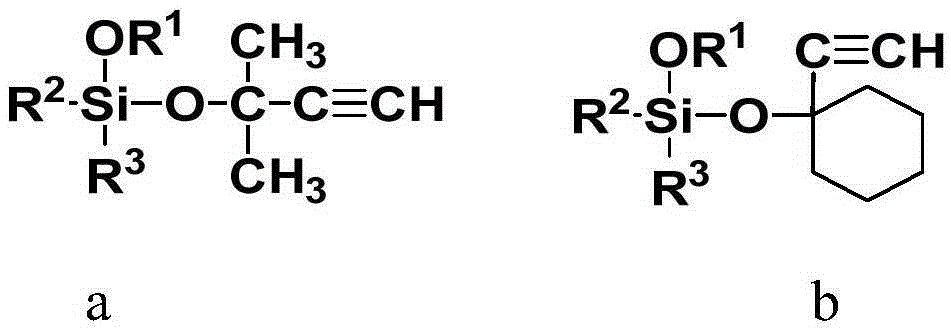

Alkoxy silane acetylenic silicon hydrogen addition inhibitor and preparation method thereof

The invention relates to an alkoxy silane acetylenic silicon hydrogen addition inhibitor and a preparation method thereof. The alkoxy silane acetylenic silicon hydrogen addition inhibitor uses alkynol and alkoxy silane as main materials, and an inhibitor which is added through alkoxy silane acetylenic silicon hydrogen is generated under the action of a catalyst. The method for preparing the alkoxy silane acetylenic silicon hydrogen addition inhibitor is simple, the alkoxy silane acetylenic silicon hydrogen addition inhibitor which is obtained through the method for preparing the alkoxy silane acetylenic silicon hydrogen addition inhibitor can overcome the defects that alkynol inhibitors and base glue are poor in compatibility, are easy to volatilize and residue has toxicity and the like. The alkoxy silane acetylenic silicon hydrogen addition inhibitor can prolong storage life in room temperature by being used in additional liquid silicone rubbers, enables the surfaces of the additional liquid silicone rubbers to be smooth after being solidified, can improve bonding with base materials through organic groups which are connected with the inhibitor, and gives better bonding force to glue.

Owner:WUHAN UNIV

Aqueous emulsion non-silicon defoamer and preparation method thereof

ActiveCN101780383BImprove surface activityEnhanced defoamingTransportation and packagingMixingWater basedEmulsion

The invention discloses an aqueous emulsion non-silicon defoamer and a preparation method thereof. The defoamer consists of a material with defoaming activity, an emulsifying material and a dispersion medium, wherein the material with defoaming activity consist of alkynol, higher aliphatic alcohol and glyceryl polyether; the emulsifying material consists of anionic emulsifier and non-ionic emulsifier; and the dispersion medium consists of water and glycol. The defoamer of the invention has excellent defoaming and anti-foaming functions and high wettability and stability and is particular suitable for water-based paint, oil ink and other systems.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

A method for purification and enhanced stability of alkynol compounds

InactiveCN102701911AImprove stabilityOrganic compound preparationHydroxy compound preparationAcetylenic alcoholSodium bisulfite

The invention relates to a method for purification and enhanced stability of alkynol compounds. The invention is characterized by including the following steps successively: adding potassium tert-butoxide to tetrahydrofuran, feeding acetylene gas after cooling to obtain potassium acetylide, adding ketone dropwise, pouring the reaction solution into water and getting the alkynol by hydrolyzing, removing the unreacted ketone in the crude alkynol with sodium bisulfite, distilling to obtain a product with purity over 99%, and adding a polymerization inhibitor to the qualified alkynol product to enhance the stability. The method help to solve the problems that the alkynol products produced in the prior art are low in purity, unqualified in appearance, and low in additional value.

Owner:河北百灵威超精细材料有限公司

Aqueous alkaline cleaning compositions and methods of their use

ActiveUS20130157919A1Easy to handleEasy to prepareInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsOrganic solventAcetylenic alcohol

Aqueous alkaline cleaning composition free from organic solvents and metal ion-free silicates, the said compositions comprising (A) a thioamino acid having at least one primary amino group and at least one mercapto group, (B) a quaternary ammonium hydroxide, (C) a chelating and / or corrosion inhibiting agent selected from the group consisting of aliphatic and cycloaliphatic amines having at least two primary amino groups, and aliphatic and cycloaliphatic amines having at least one hydroxy group, (D) a nonionic surfactant selected from the group of acetylenic alcohols, alkyloxylated acetylenic alcohols and alkyloxylated sorbitan monocarboxylic acid mono esters; the use of the alkaline cleaning composition for the processing of substrates useful for fabricating electrical and optical devices; and a method for processing substrates useful for fabricating electrical and optical devices making use of the said aqueous alkaline cleaning composition.

Owner:BASF AG

Propargyl alcohol type quaternary ammonium salt surfactant and preparation method thereof

InactiveCN102049213AGood corrosion inhibitionHigh temperature resistanceOrganic chemistryTransportation and packagingQuaternary ammonium cationOrtho position

The invention relates to a propargyl alcohol type quaternary ammonium salt surfactant and a preparation method thereof, and the structural formula of quaternary ammonium salt is as follows: n is equal to 8, 10, 12, 14 or 16, and X is Cl or Br; and a substituent is positioned in the ortho-position, interposition or para-position. The preparation method is as follows: (1) adding 3-5g of NaH into a reactor, introducing nitrogen, adding 60-90ml of THF (tetrahydrofuran), stirring at room temperature, dropping 4-6g of propiolic alcohol, further slowly dropping 10-15g of chloromethylpyridine, stirring for 15-30h, separating water phase from organic phase, washing, drying, performing column chromatography, and then getting pyridyl-2-butynol; and (2) adding the pyridyl-2-butynol and alkyl halide into the reactor according to the molar ratio of 1: 1.5-1: 4, further adding 10ml-15ml of acetonitrile, refluxing and stirring for 20-30h at the temperature of 50-80 DEG C, washing, performing the column chromatography, and then getting the alkynol type quaternary ammonium salt surfactant. The series of the propargyl alcohol type quaternary ammonium salt surfactants have very high surface activity and very strong corrosion inhibition performance, the preparation method is simple and feasible, the operation is easy, the yield is higher, and the environmental pollution can be avoided.

Owner:CHINA WEST NORMAL UNIVERSITY

Aqueous marking ink composition

ActiveCN102762675AHigh shieldingImprove fixation effectInksOriginals for photomechanical treatmentAcetylenic alcoholSolvent

Provided is an aqueous marking ink composition with which it is possible to write smoothly with low viscosity on non-absorbent surfaces, such as metals and resins, that are greased with oil, such as cutting oil and lubricating oil, while having suitable and favorable wettability and without being repelled; with which it is possible to draw lines having excellent masking characteristics and excellent adherence; in which the masking agent can be re-dispersed easily by a simple stirring operation even if the masking agent settles out over time; which has excellent masking characteristics and stability; and especially which can be stirred easily even with a stirring element having a low specific gravity. The disclosed aqueous marking ink composition contains at least: 1-20% by mass of a water-soluble resin having a hydrophobic moiety in a molecule thereof; a coloring agent containing at least 5-30% by mass of titanium oxide; 0.05-2% by mass of at least one compound selected from acetylenic glycols, acetylenic alcohols, and derivatives thereof; 1-20% by mass of a water-soluble solvent having a vapor pressure of at most 5 mmHg at 25 DEG C; and water.

Owner:MITSUBISHI PENCIL CO LTD

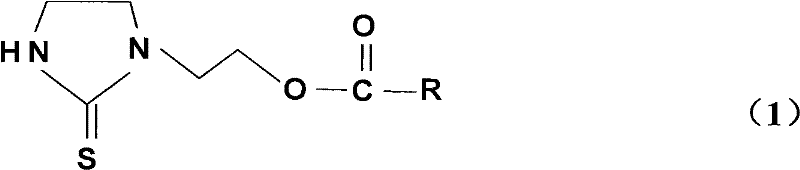

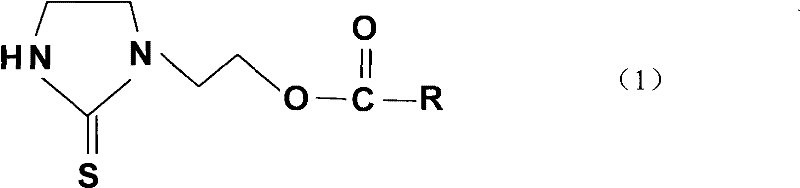

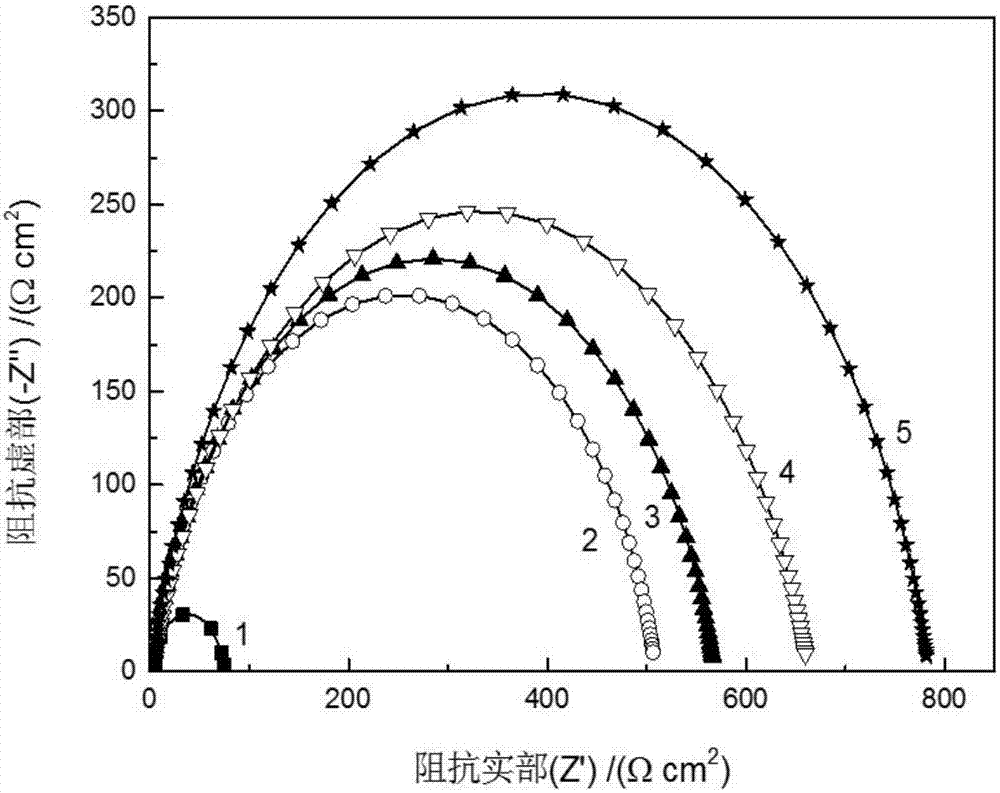

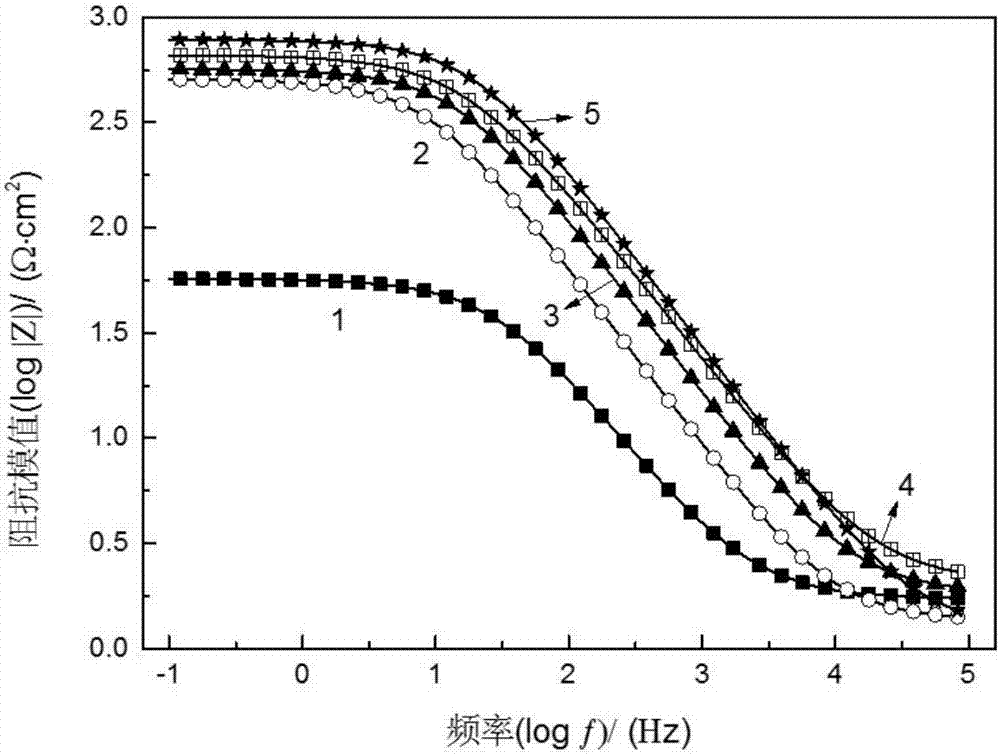

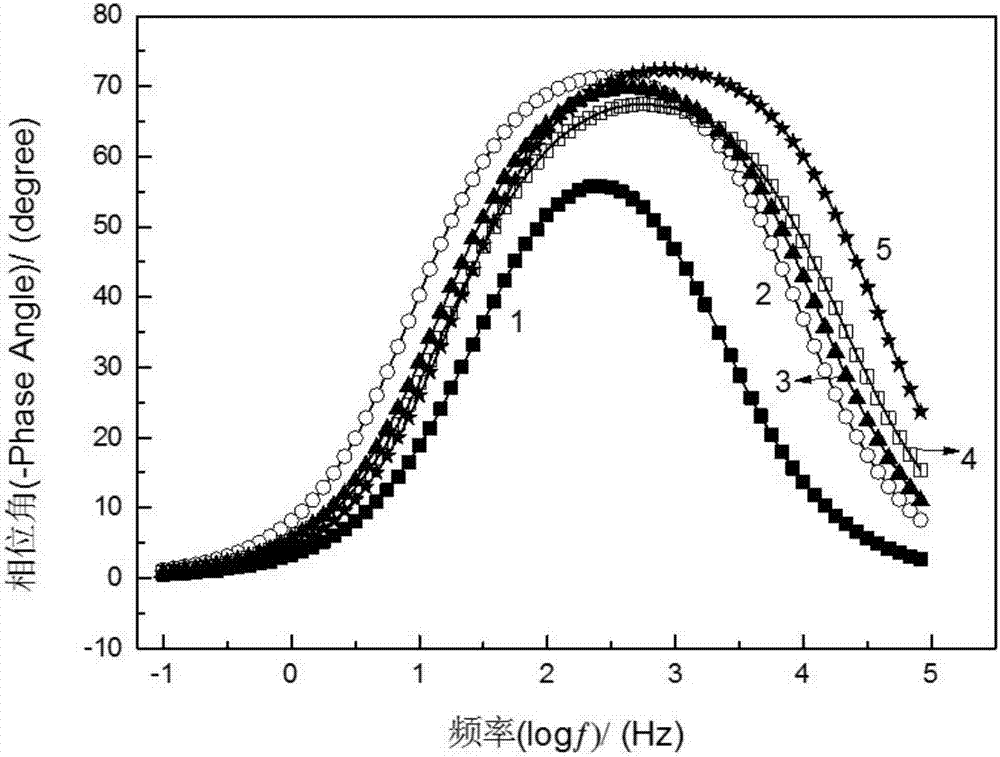

A kind of corrosion inhibitor for suppressing h2s/co2 corrosion and preparation method thereof

InactiveCN102268677AEffective corrosion controlBorehole/well accessoriesEthylene diamineImidazolidine

The invention discloses a corrosion inhibitor for inhibiting H2S / CO2 corrosion and a preparation method thereof. The corrosion inhibitor is a composition, and its composition and content are: (A) imidazolidinethione derivative 20% by weight to 60% by weight %; (B) acetylene alcohol 5% by weight to 20% by weight; (C) surfactant 1% by weight to 10% by weight; (D) solvent 20% by weight to 50% by weight, wherein the preparation of imidazolidinethione derivatives The raw materials are thiourea, β-hydroxyethylethylenediamine and fatty acids. The corrosion inhibitor is especially suitable for inhibiting H2S / CO2 corrosion in oil fields.

Owner:CHINA PETROCHEMICAL CORP +1

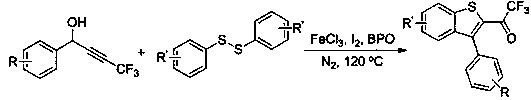

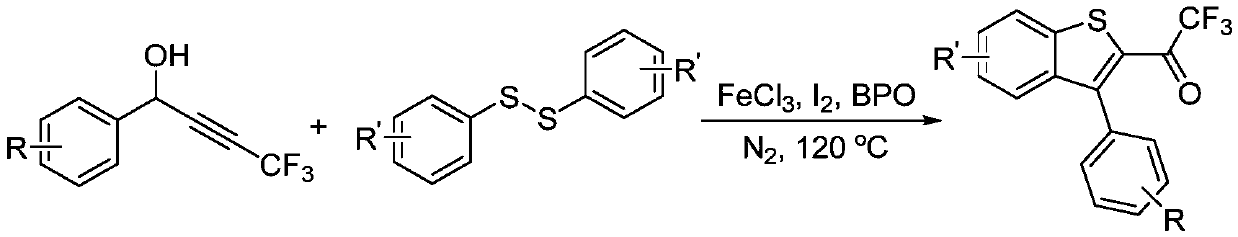

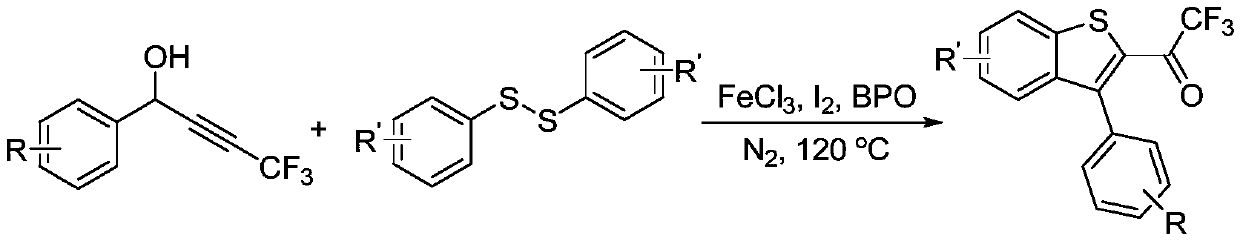

Preparation method for trifluoromethyl benzothiophene derivative and purification method for product of preparation method

The invention discloses a preparation method for a trifluoromethyl benzothiophene derivative and a purification method for a product of the preparation method. The preparation method comprises the steps that an alkynol compound containing methyl fluoride building blocks or a derivative of the alkynol compound is taken as a substrate, disulfide is added into the substrate, and a crude product is prepared through a heating reaction under the nitrogen atmosphere of an elementary substance iodine, benzoyl peroxide and an iron catalyst by taking a nitromethane solution as solvent. The crude product is purified through the steps that filtering, iodine removing and solvent removing are performed on the crude product to obtain residua; chromatography is performed on the residua by adopting a silicagel column, elution is performed through eluent, and effluent is collected; the effluent containing the product is merged; concentrating and solvent removing are performed on the merged effluent, and vacuum drying is performed to obtain the target product. The preparation method and the purification method have the advantages of being simple in technological process, low in cost and high in yield.

Owner:WENZHOU UNIVERSITY

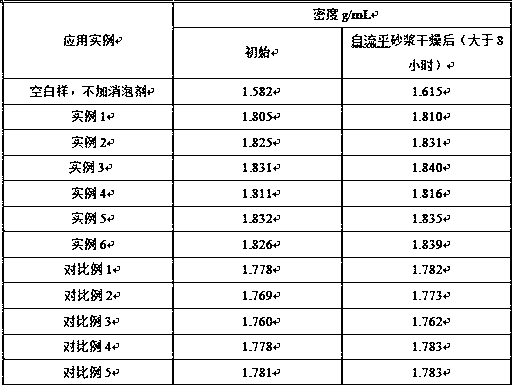

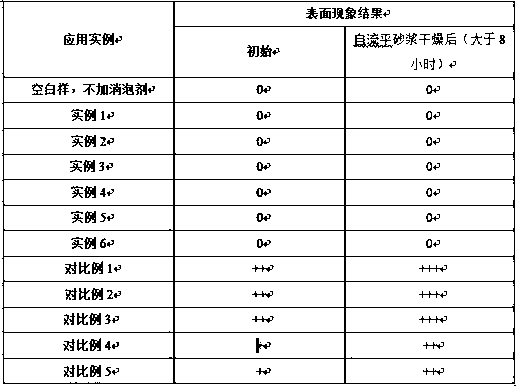

Defoaming agent applied to thin-layer self-leveling mortar and preparation method of defoaming agent

The invention provides a defoaming agent applied to thin-layer self-leveling mortar and a preparation method of the defoaming agent. The defoaming agent comprises the components: white carbon black, polyether, fatty alcohol and alkynol silicon polyether. The preparation method comprises the steps: (1) firstly, mixing and stirring fatty alcohol and part of white carbon black to form a dispersoid M1; (2) preparing alkynol silicon polyether, then adding the dispersoid M1 and polyether, and mixing to obtain a dispersoid M2; and (3) slowly spraying the dispersoid M2 onto A2 through a metering pumpunder certain temperature and rotating speed conditions, and mixing to obtain M3; and finally, screening the M3 to obtain the solid defoaming agent. The solid defoamer prepared by the method is specially used for solving the problems of surface cracking and hollowing of thin-layer self-leveling mortar, and compared with a traditional defoaming agent, the defoaming agent disclosed by the inventionhas the advantages of simple preparation method, good defoaming and foam inhibition performances, no influence on the stability of a self-leveling mortar system and capability of remarkably improvingthe surface performance of the self-leveling mortar.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD +1

Triphenylamine aldehyde derivative and amino acid compound corrosion inhibitor and use method thereof

The invention discloses a triphenylamine aldehyde derivative and amino acid compound corrosion inhibitor and a use method thereof. The triphenylamine aldehyde derivative and amino acid compound corrosion inhibitor comprises components including, by weight percent, 2 to 20% of triphenylamine aldehyde derivatives, 3 to 15% of amino acid, 4 to 10% of acetylenic alcohol, 6 to 30% of corrosive pitting inhibitor and 25 to 60% of low mass molecule alcohol. A use method of the compound corrosion inhibitor comprises the steps that the compound corrosion inhibitor with components mixed and prepared according to the proportion is added into an acid solution corrosion medium making contact with metal, 0.005 to 1.0g of compound corrosion inhibitor is added into 1L of the acid solution, and the immersion temperature ranges from 0 DEG C to 80 DEG C. The corrosion inhibitor has the good corrosion inhibiting effect on metal in the acid media, the corrosion inhibiting rate can reach 92%, the beneficial effects of being little in use amount, high in efficiency and the like are achieved, and the corrosion inhibitor can be suitable for acid pickling and corrosion protection of the metal in the petroleum chemical industry.

Owner:SOUTHWEST PETROLEUM UNIV

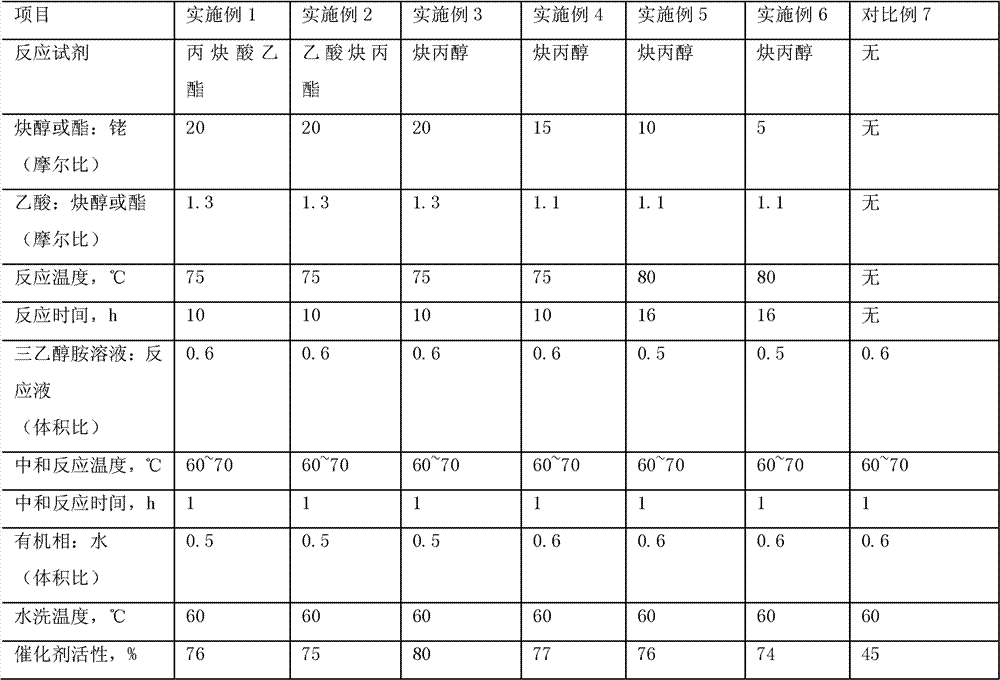

Regeneration method for inactivated rh-p (rhodium-phosphine) complex catalyst for carbonylation reaction

ActiveCN102950028AReduce dosageHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsAcetylenic alcoholCarboxylic acid

The invention relates to a regeneration method for inactivated rh-p (rhodium-phosphine) complex catalyst for carbonylation reaction, which comprises the following steps of: firstly, carrying out hybrid reaction on inactivated rh complex catalyst reaction liquid with 3-6 carbon atom containing alkynol or ester and a carboxylic acid; then, adding a tertiary alkanolamine aqueous solution into the obtained reaction liquid, so that unreacted carboxylic acids or halides are neutralized, and then a water soluble salt is generated; carrying out settling separation on the water soluble salt so as to obtain a rh-p complex catalyst containing organic phase; and washing the separated organic phase with water so as to obtain a rh complex catalyst containing solution which has higher catalytic activity in comparison with the inactivated rh complex catalyst. According to the regeneration method provided by the invention, the application amount of an expensive-price and large-toxicity regenerated reaction reagent (3-6 carbon atom containing alkynol or ester) can be greatly reduced; the reaction conditions are moderate, so that the online regeneration of catalysts can be performed under the condition of not stopping the continuous carbonylation reaction; and the technological process is simple, and the activity of the catalyst subjected to regeneration is high, thereby solving the problem that the regeneration cost of the catalyst is high.

Owner:CHINA PETROLEUM & CHEM CORP

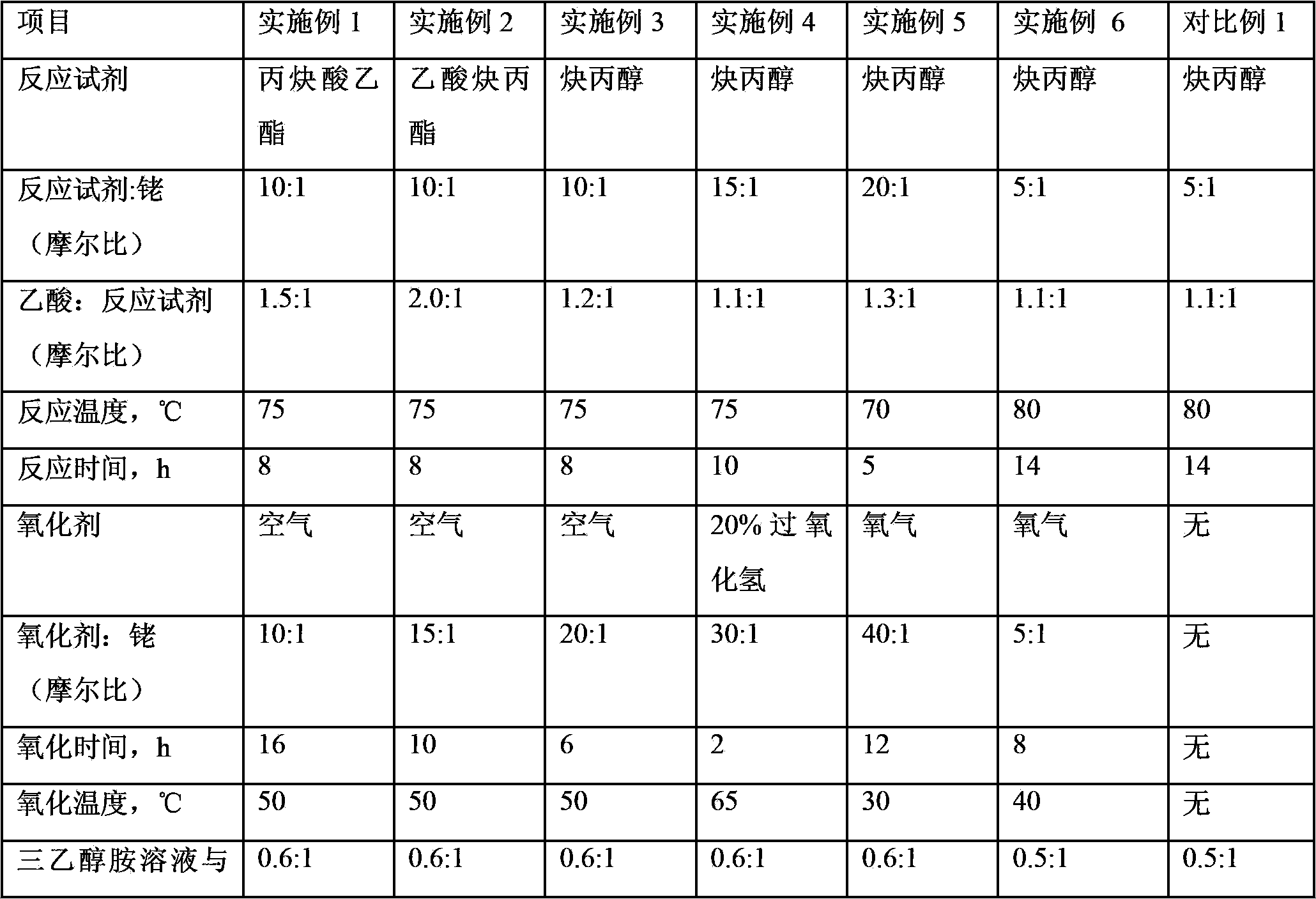

Treatment method of inactivated rhodium-phosphine catalyst

ActiveCN103506167AReduce dosageReduce processing costsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationAcetylenic alcoholCarboxylic acid

The invention belongs to the technical field of treatment of catalysts and particularly relates to a treatment method of an inactivated or partially inactivated rhodium-phosphine catalyst by carbonylation. The treatment method comprises the following steps: firstly mixing a reaction solution containing the inactivated or partially inactivated rhodium-phosphine catalyst with alkynol containing 3-6 carbon atoms or ester and carboxylic acid with the chemical formula of RCOOH for performing activation reaction; then performing oxidation reaction in the presence of an oxidant, and adding a water solution of tertiary alkanolamine into the obtained reaction solution and generating a water-soluble salt; and performing settling separation so as to obtain an organic phase containing a rhodium-phosphine complex catalyst, washing the organic phase with water and obtaining a solution containing the rhodium-phosphine complex catalyst, which has catalytic activity higher than that of the inactivated rhodium-phosphine catalyst. According to the treatment method, the inactivated rhodium-phosphine catalyst is treated by a combined process method of activation and oxidation, so that the inactivation of the catalyst, which is mainly caused by the formation of a rhodium cluster compound is obviously improved, and the activity of the treated rhodium-phosphine catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP

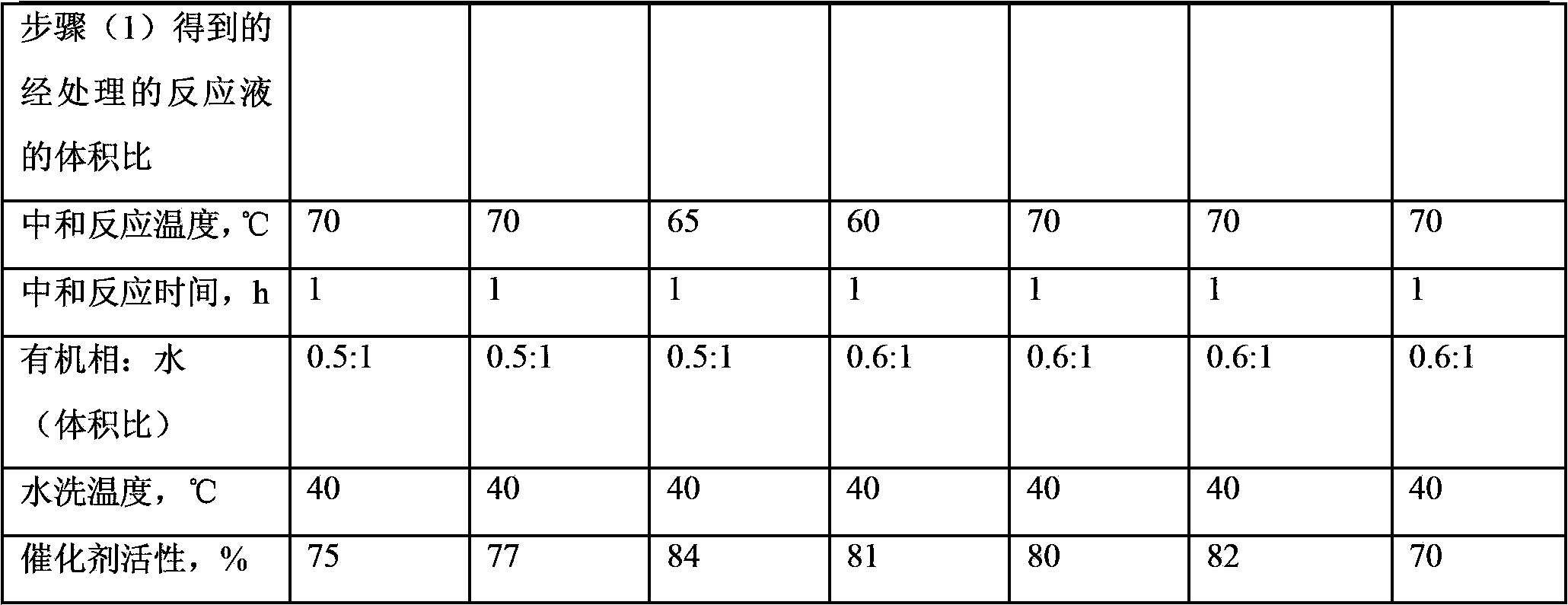

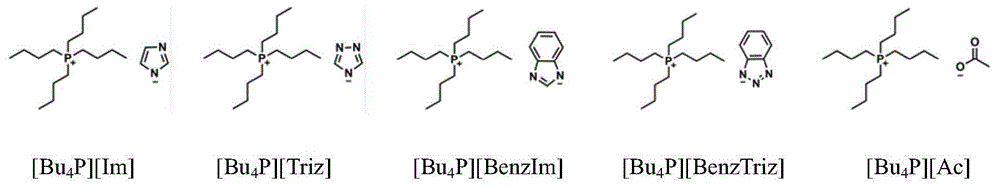

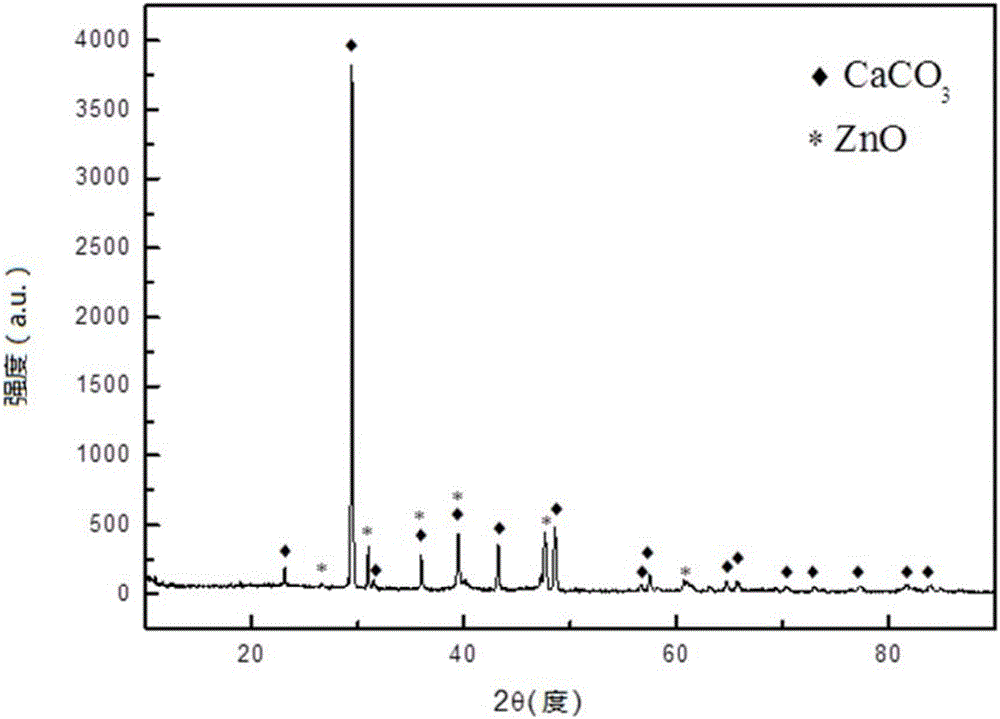

Catalytic system for synthesizing alpha-hydroxy ketone by alkynol hydration reaction

ActiveCN104437621AHigh catalytic activityWide applicabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by C-C triple bond hydrationHydration reactionAcetylenic alcohol

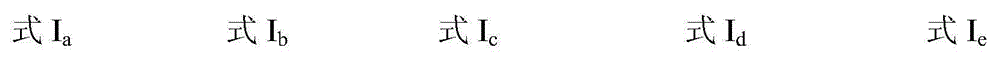

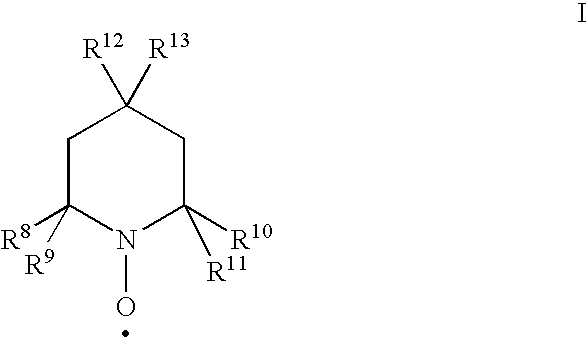

The invention discloses a catalytic system for synthesizing alpha-hydroxy ketone by alkynol hydration reaction. The catalytic system consists of an ionic liquid and a CO2 gas, wherein the ionic liquid is selected from at least one of ionic liquids as shown in formulas Ia-Ie described in the specification. In the catalytic system, the amount of substances of the ionic liquid is 0.01-0.5mol, and the pressure of the gas is 0.1-8MPa. The invention further provides a method of preparing alpha-hydroxy ketone compounds by utilizing the catalytic system. The catalytic system is suitable for a reaction system for catalyzing alkynol hydration reaction to synthesize alpha-hydroxy ketone compounds. The catalytic system is relatively high in catalytic activity, mild in reaction condition, and free of metals. The main catalyst ionic liquid is easy to synthesize and recycle, and has a relatively strong application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Processing of substrates with dense fluids comprising acetylenic diols and/or alcohols

InactiveUS7211553B2Organic detergent compounding agentsSurface-active detergent compositionsAlcoholAcetylenic alcohol

A dense cleaning fluid for removing contaminants from a substrate and a method comprising same is disclosed herein. In one embodiment of the present invention, the dense cleaning fluid comprises a dense fluid and at least one acetylenic diol or acetylenic alcohol surfactant.

Owner:VERSUM MATERIALS US LLC

One-component, solvent-free organosiloxane composition

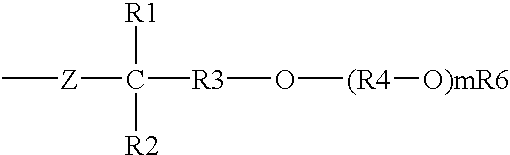

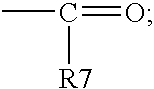

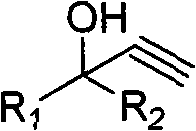

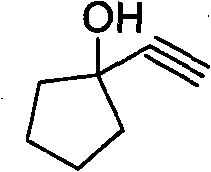

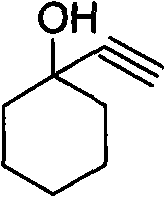

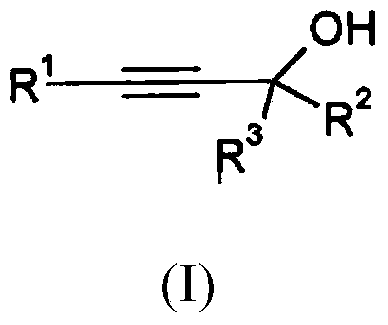

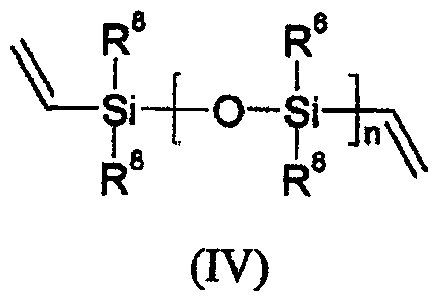

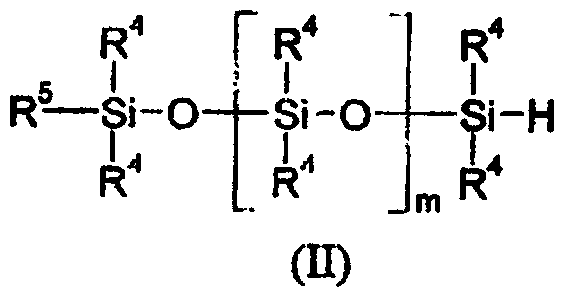

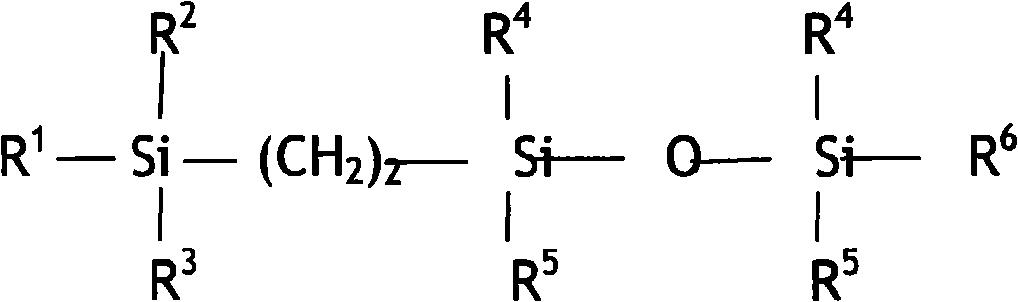

One-component, solvent-free organosiloxane composition comprising a) a linear or branched polyorganosiloxane containing at least two alkenyl or alkynyl groups, as component A; b) a linear or branched polyorganosiloxane containing at least 3 Si-H groups, as component B; c) a hydrosilylation catalyst as component C; d) an alkynol of the general formula (I) wherein R1, R2, R3 are selected independently of one another from H, C1-C6-alkyl and substituted or unsubstituted C3-C6-alkyl; or R1 is selected from H, C1-C6-alkyl and substituted or unsubstituted C3-C6-cycloalkyl, and R2, R3 are bonded together and form a 3- to 8-membered ring which can be substituted by one or more C1-C3-alkyl groups, as component D; and e) a fumed silica as component E; and f)0-89.79989wt% one or more other components selected from F, G, H and I, wherein the total of components A to I is 100%wt.

Owner:ELANTAS

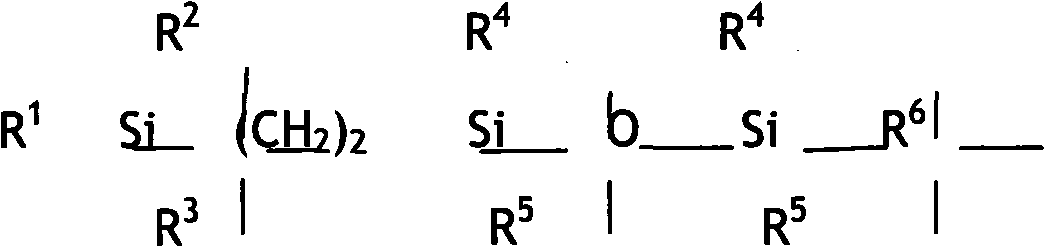

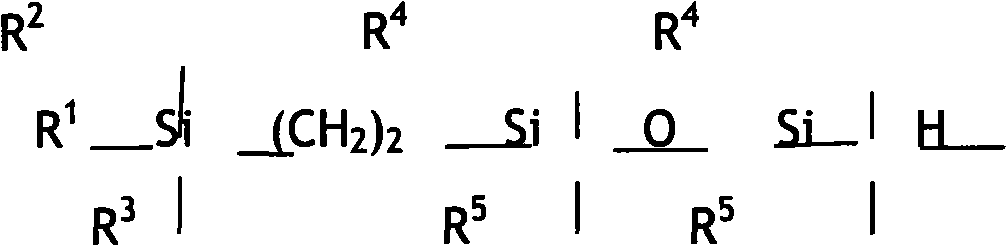

Disiloxane compound terminated by trialkyl silica ethyl and alkyne enol and method for preparing same

The invention discloses a disiloxane compound terminated by trialkyl silicon ethyl and alkyne enol and a method for preparing the same. The method comprises the following steps: synthesizing a siloxane hydride intermediate from dihydro-terminated disiloxane and vinylsilane by the molar ratio of (1:1) in the presence of the Wilkinson's catalyst under the condition of hydrosilylation, wherein, the amount of the Wilkinson's catalyst is 200ppm of the mass of the dihydro-terminated disiloxane as the reactant; and synthesizing the alkyne-enol-terminated disiloxane compound from the siloxane hydrideintermediate and alkynyl-containing alkynol by the molar ratio of (1:1) in the presence of the Speier's catalyst, wherein, the amount of the Speier's catalyst is 50ppm to 1,000ppm of the total mass ofthe reactant. The disiloxane compound of the invention is alkynol-modified siloxane with the pH value range of resisting acid / alkali decomposition being 2 to 12; and the retention rate with the molarfraction being more than or equal to 50% exceeds far beyond 24 hours, wherein, the retention rate of 20% of the invention with the molar fraction being more than or equal to 50% exceeds 1 year underthe equivalent conditions.

Owner:HUAIAN KAIYUE TECH DEV

Process for preparing alkynecarboxylic acids by oxidation of alkyne alcohols

InactiveUS7173149B2Avoid disadvantagesOrganic compound preparationOrganic chemistry methodsAlcoholAcetylenic alcohol

A process for preparing alkynecarboxylic acids includes the oxidation of an alkyne alcohol with a hypohalite in the presence of a nitroxyl compound at a pH of greater than 7 with continual addition of the alkyne alcohol and of the hypohalite to the reaction mixture.

Owner:WACKER CHEM GMBH

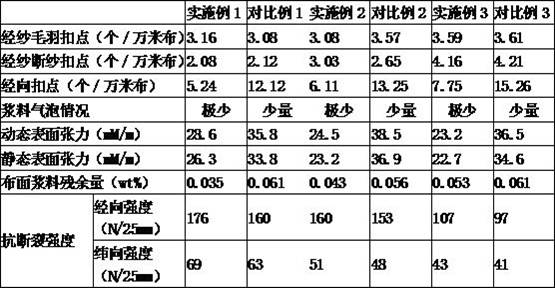

Secondary sizing slurry for electronic glass fiber cloth and preparation method thereof

The invention discloses a secondary sizing slurry for electronic glass fiber cloth and a preparation method thereof. The slurry comprises the following components in percentage by mass: 3 to 15 percent of polyvinyl alcohol, 0 to 10percent of polyethylene glycol, 0.02 to 2percent of a wetting agent, 0 to 0.5percent of an antistatic agent and the balance of pure water, wherein the wetting agent is an acetylenic ethylene glycol surfactant or an acetylenic alcohol surfactant. According to the secondary sizing slurry for the electronic glass fiber cloth and the preparation method thereof provided by the invention, the dynamic surface tension and the static surface tension of the slurry are less than 30 mM / m, even the dynamic surface tension and the static surface tension are less than 25 mM / m, the viscosity is determined to be less than or equal to 35 mPa.s at the temperature of 25 DEG C, and the low foam effect can be achieved without adding a defoaming agent to the slurry.

Owner:GLOTECH ELECTRONICS SUZHOU

Corrosion inhibitors

InactiveUS20100167966A1Excellent corrosion protectionImprove protectionOther chemical processesFluid removalAntimony compoundsMorpholine

Provided is an anticorrosive composition for use in aqueous salt solutions. The composition contains an antimony compound and at least two other components selected from morpholine derivatives, acetylenic alcohols, ascorbic acid derivatives, and selenium compounds. The composition is particularly useful for inhibiting corrosion of metallic surfaces of drilling devices or refrigeration systems that are in contact with salt brines at elevated temperatures.

Owner:BROMINE COMPOUNDS

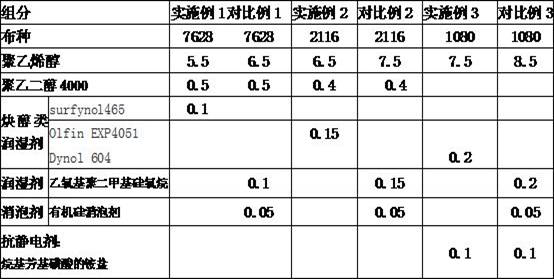

Triple bond partial hydrogenation method and catalyst thereof

PendingCN113788737AEasy to makeEasy to operatePreparation by hydrogenationCatalyst activation/preparationPtru catalystPartial hydrogenation

The invention provides a triple bond partial hydrogenation method and a catalyst thereof. The catalyst comprises a carrier, and a main catalyst metal palladium, an auxiliary agent metal and a poisoning agent which are loaded on the carrier; the carrier is calcium carbonate, barium sulfate, aluminum oxide and silicon oxide; the auxiliary metal is tungsten, molybdenum and manganese metal simple substances; and the poisoning agent is lead salt, zinc salt and chromium salt. The catalyst in the hydrogenation method provided by the invention has excellent partial hydrogenation activity and selectivity, and can realize partial hydrogenation of carbon-carbon triple bonds at high yield to obtain an olefin product. In the reaction process, carbon dioxide and a small amount of alcohol amine are introduced into the reaction system, so that the occurrence of dimerization side reaction of the raw material alkynol is reduced, and the selectivity of partial hydrogenation reaction is further improved.

Owner:WANHUA CHEM GRP CO LTD

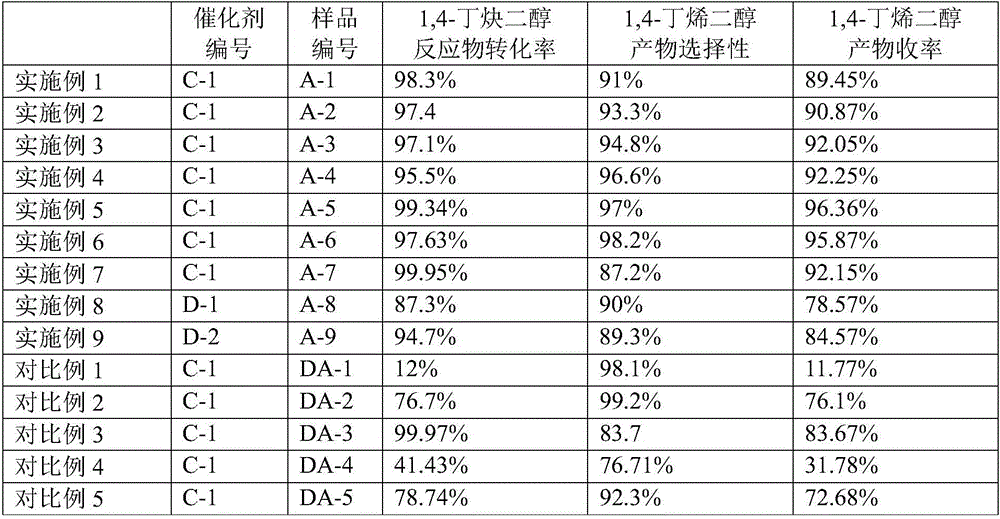

Method for preparing enol by semi-hydrogenating alkynol

InactiveCN106748658ALower H

<sup>+</sup>

concentrationReduce electron deficiency characteristicsOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydrogenationAcetylenic alcoholControllability

The invention provides a method for preparing 1,4-butenediol by semi-hydrogenating 1,4-butynediol. The method comprises the following steps: pre-treating raw materials by utilizing an alkaline solution; and realizing the controllability of a hydrogenating step by adopting a gradient stirring method in the presence of a catalyst. According to the method, the liquid-solid ratio of 1,4-alkynediol to the catalyst is (80-200) to 1, and the operation temperature (30 DEG C-115 DEG C) and the pressure (0.3MP-1MPa) are relatively low; and the conversion ratio of the 1,4-butynediol reaches 99.9% and the selectivity and yield of the 1,4-butenediol reach 98.2% and 95.87%. According to the method provided by the invention, the charge density of the raw material is changed and the controllability of a hydrogenating process is realized in the presence of the catalyst through adjusting a stirring speed by gradient, and a relatively good semi-hydrogenating performance is represented; and the method has a good industrial application value.

Owner:CHONGQING JIANFENG INDAL GROUP

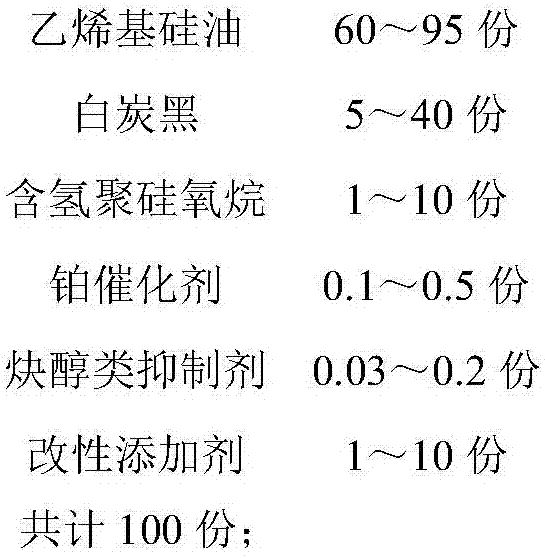

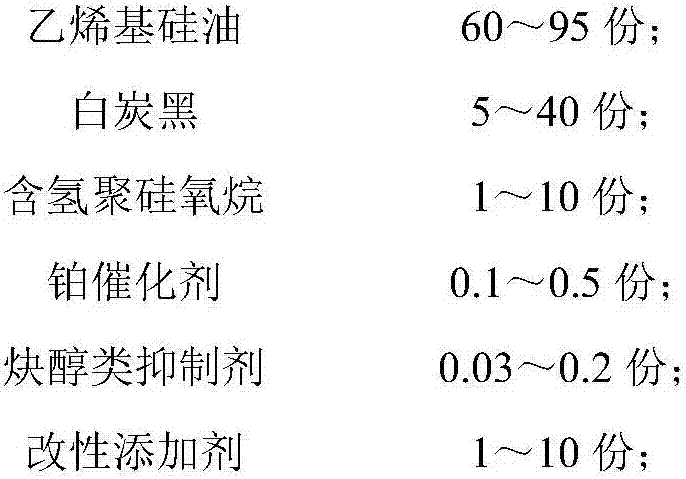

A kind of one-component addition type liquid silicone rubber and preparation method thereof

The invention discloses a one-component addition type liquid silicone rubber with high tear strength and a preparation method thereof. The components of the liquid silicone rubber are calculated in percent by weight: 60-95 parts of vinyl silicone oil; 5-40 parts of white carbon black; 1-10 parts of hydrogen-containing polysiloxane; 0.1-0.5 parts of platinum catalyst; 0.03-0.2 parts of acetylenic alcohol inhibitors; 1-10 parts of modified additives; wherein the hydrogen-containing polysiloxane is a hydrogen-terminated polysiloxane with a hydrogen content of 0.05-0.3% and a hydrogen content of 0.4-0. 0.8% mixture of pendant hydropolysiloxanes. The invention also discloses a preparation method of the liquid silicone rubber. The prepared one-component addition-type liquid silicone rubber has the characteristics of good mechanical properties, high tear resistance, low viscosity and the like.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com