Secondary sizing slurry for electronic glass fiber cloth and preparation method thereof

A technology of glass fiber cloth and slurry, applied in the direction of fiber type, fiber treatment, textile and paper making, etc., can solve the problem of impregnation of electronic glass fiber cloth, macular or dark spots on glass fiber cloth, hindering the combination of glass fiber and resin and other problems, to achieve the effect of reducing the desizing time, good adhesion and easy desizing

Pending Publication Date: 2021-11-05

GLOTECH ELECTRONICS SUZHOU

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

To achieve a better desizing effect, it is necessary to increase the desizing temperature or prolong the desizing time, and these measures will greatly increase energy consumption

Moreover, prolonging the desizing time or temperature will lead to the loss of the strength of the electronic cloth, and it is easy to tear and break the cloth in subsequent production

[0006] At present, the size used for warp yarn sizing is mainly polyvinyl alcohol size, which has stable viscosity, tough size film, good wear resistance and buckling resistance, but at the same time, it is difficult to desizing, and the size is in the process of smoldering. Insufficient combustion often occurs in the process, resulting in yellow spots or black spots on the produced glass fiber cloth, which seriously affects the appearance of the product. The residual slurry on the surface will also affect the impregnation of the electronic glass fiber cloth, hindering the glass fiber and resin. The combination of the influence of product quality

At the same time, in order to achieve a better desizing effect, the amount of fuel is increased to increase the furnace temperature and the cost is very high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment l

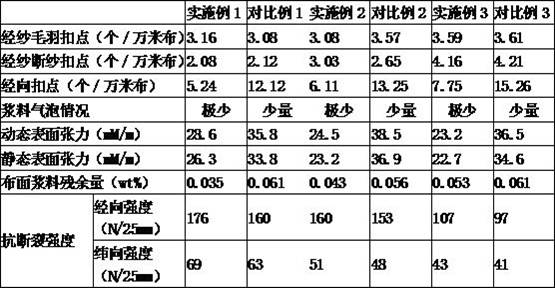

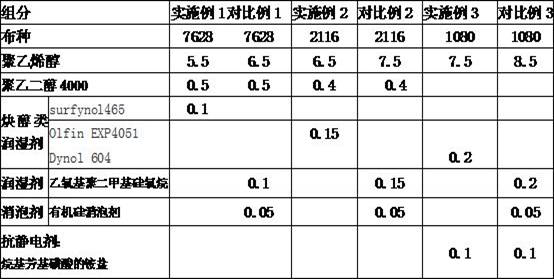

[0032] Prepare new electronic grade glass fiber cloth slurry according to the ratio in Table 1.

Embodiment 2

[0034] Prepare new electronic grade glass fiber cloth slurry according to the ratio in Table 1.

Embodiment 3

[0036] Prepare new electronic grade glass fiber cloth slurry according to the ratio in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a secondary sizing slurry for electronic glass fiber cloth and a preparation method thereof. The slurry comprises the following components in percentage by mass: 3 to 15 percent of polyvinyl alcohol, 0 to 10percent of polyethylene glycol, 0.02 to 2percent of a wetting agent, 0 to 0.5percent of an antistatic agent and the balance of pure water, wherein the wetting agent is an acetylenic ethylene glycol surfactant or an acetylenic alcohol surfactant. According to the secondary sizing slurry for the electronic glass fiber cloth and the preparation method thereof provided by the invention, the dynamic surface tension and the static surface tension of the slurry are less than 30 mM / m, even the dynamic surface tension and the static surface tension are less than 25 mM / m, the viscosity is determined to be less than or equal to 35 mPa.s at the temperature of 25 DEG C, and the low foam effect can be achieved without adding a defoaming agent to the slurry.

Description

technical field [0001] The invention relates to a secondary sizing slurry for electronic glass fiber cloth and a preparation method thereof, belonging to the technical field of electronic glass fiber cloth. Background technique [0002] Electronic-grade glass fiber yarn is an inorganic non-metallic material. Its manufacturing process is to uniformly pulverize silica sand, limestone, borax and other ores, mix and melt them in a high-temperature furnace to form a co-melt, and then rapidly cool them through the bushing at high speed. Dozens to hundreds of glass fiber filaments are wound on the cake, dried and twisted by a twisting machine to make bobbins for weaving glass fiber cloth. In the spinning process, a size is required to prevent the yarn from breaking and hairiness during the spinning process. The slurry coated in the spinning process is the "primary slurry". [0003] Electronic glass fiber cloth is a plain weave fabric in which the warp and weft yarns are interlace...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06M15/333D06M15/53D06M13/148

CPCD06M15/333D06M15/53D06M13/148D06M2200/40

Inventor 俞绍玫李健

Owner GLOTECH ELECTRONICS SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com