Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

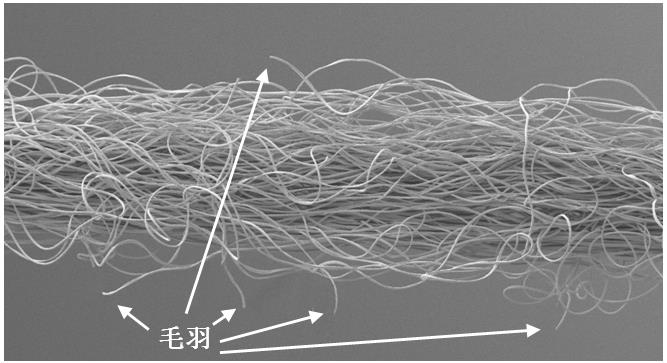

47results about How to "Less hairiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impregnating compound special for single-filament plastic coated yarn and preparation method thereof

The invention relates to an impregnating compound special for single-filament plastic coated yarn and a preparation method thereof. The impregnating compound is prepared mainly by a main film former including water-solubility polyurethane and epoxy resin emulsion, and an assistant film former including water-solubility epoxy resin, as well as a coupling agent, a lubricating agent, a pH value adjusting agent and deionized water. The preparation method comprises the following steps: hydrolyzing the coupling agent in the deionized water; diluting the lubricating agent, and adding the diluted lubricating agent into the hydrolyzed coupling agent for stirring; adding the water-solubility polyurethane, the epoxy resin emulsion and the water-solubility epoxy resin for continuously stirring; and adding the deionized water and stirring uniformly. In the invention, the water-solubility polyurethane and the epoxy resin emulsion are taken as the film formers, so that the impregnating compound has the advantages of simple preparation process and low cost; and glass fiber yarn produced by the impregnating compound has extremely high breakage resistance and smaller fur containing amount, and the strength and the production efficiency of products are improved greatly, so that the impregnating compound is more suitable for promotion and application.

Owner:SHANDONG FIBERGLASS GRP

Alkali-containing glass fiber direct roving sizing agent for spinning

The invention provides an alkali-containing glass fiber direct roving sizing agent for spinning, and relates to a formula of a sizing agent. The formula consists of a coupling agent, a lubricant A, a lubricant B, epoxy resin emulsion, modified polyester resin emulsion, an auxiliary filmogen, a special additive, an antistatic agent and deionized water. By the sizing agent, the performance of alkali-containing glass fiber direct roving can be improved, a small quantity of feathers are generated in weaving, the breaking tenacity of the direct roving is high, and the production performance and application performance are high.

Owner:江西大华新材料股份有限公司

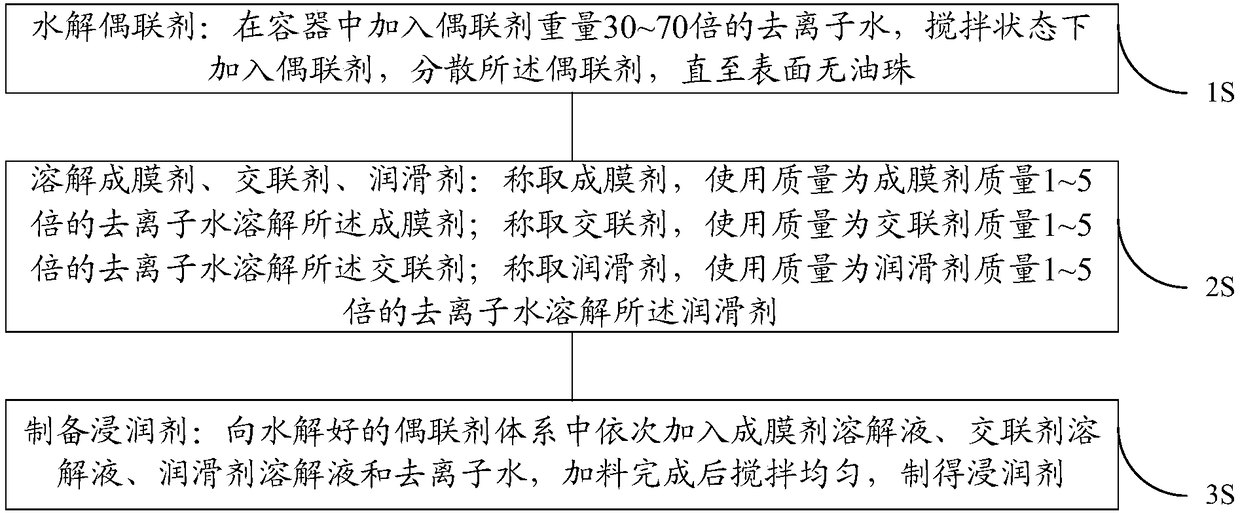

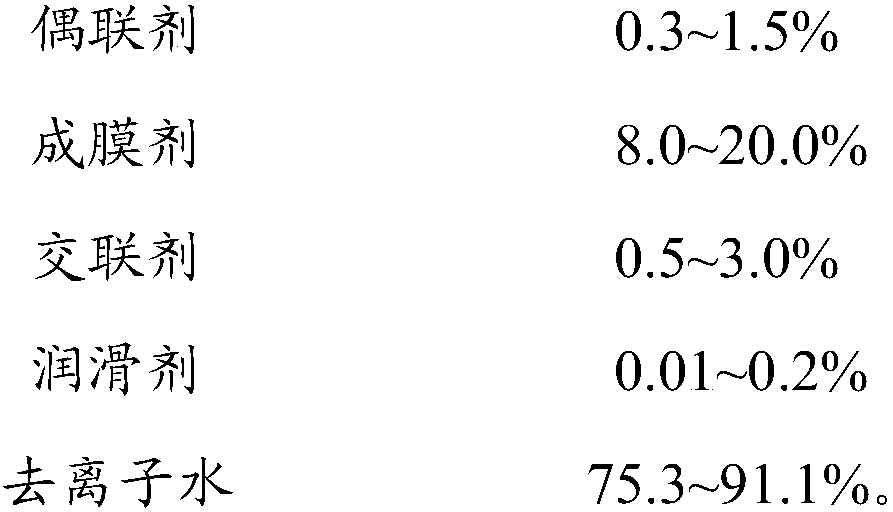

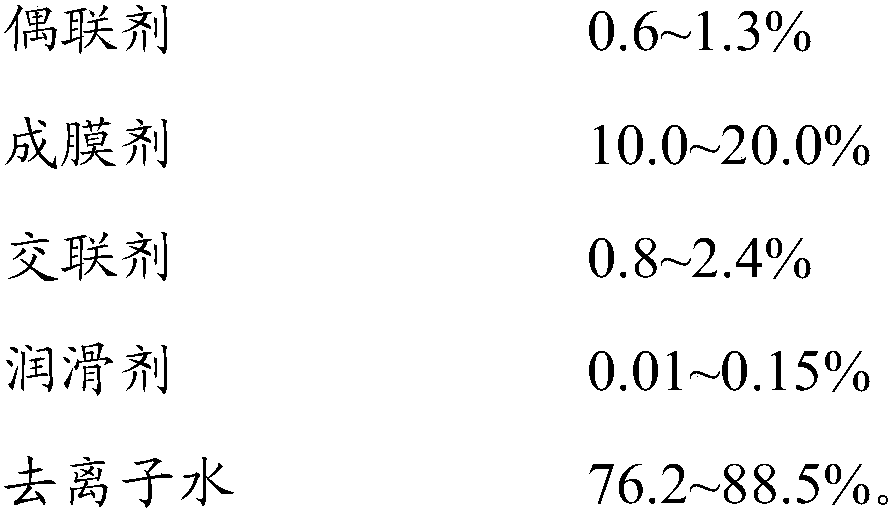

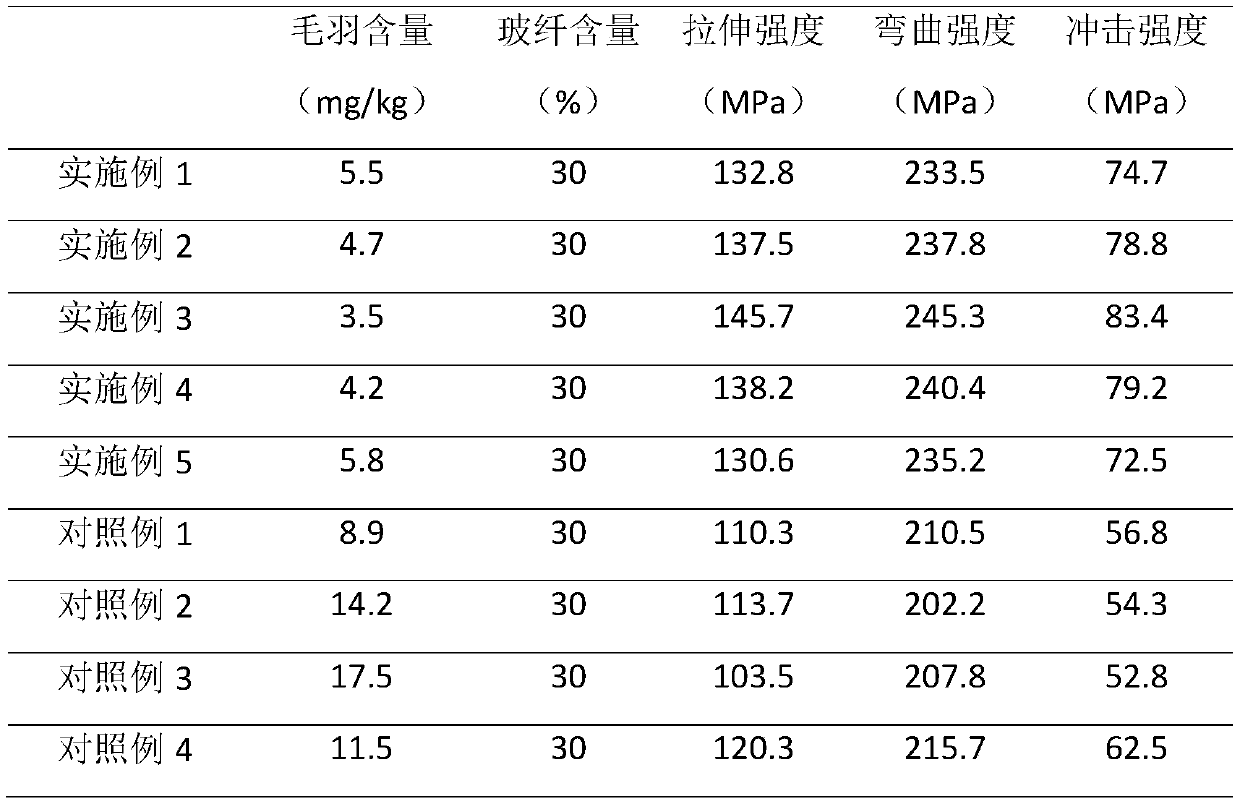

Impregnating agent for reinforced nylon resin glass fibers and preparation method thereof

The invention provides an impregnating agent for reinforced nylon resin glass fibers. The impregnating agent compress a coupling agent, a film forming agent, a crosslinking agent, a lubricating agentand deionized water, wherein the coupling agent is a silane coupling agent; the film forming agent is polyurethane emulsion. According to the impregnating agent, the components are matched with each other to prepare the impregnating agent for the reinforced nylon resin glass fibers, particularly an impregnating agent for chopped reinforced nylon resin glass fibers. The invention also provides a preparation method for preparing the impregnating agent. The glass fibers prepared through the impregnating agent are high in collection property, small in fuzz amount, outstanding in processing performance, and high in compatibility relative to nylon resin; and the prepared composite material is outstanding in mechanical performance.

Owner:JUSHI GRP CO

Quartz glass fiber reinforced textile size

The invention relates to a quartz glass fiber reinforced textile size which belongs to the technical field of glass fiber surface treatment. The size is prepared by physically mixing the following raw materials by weight percent: 1-30% of water-soluble epoxy resin, 0.1-10% of modified epoxy resin, 0.1-2.0% of cation surfactant, 0.1-2.0 nonionic surfactant, 0.1-2.0% of silane coupling agent, 0.1-10% of water-based inorganic additive, 0.1-2% of plasticizer, 0.05-0.5% of pH regulator and 20-95% of deionized water and then stirring evenly. The quartz glass fiber has favorable production process performance, favorable textile performance, high breaking strength and low hairiness amount and is capable of fully exploiting the excellent performance, so that the quartz glass fiber can be better applied to the fields of aerospace, war industry, heat insulation and the like so as to satisfy the demands of national economy and defense-related science and technology.

Owner:HUBEI FEILIHUA QUARTZ GLASS

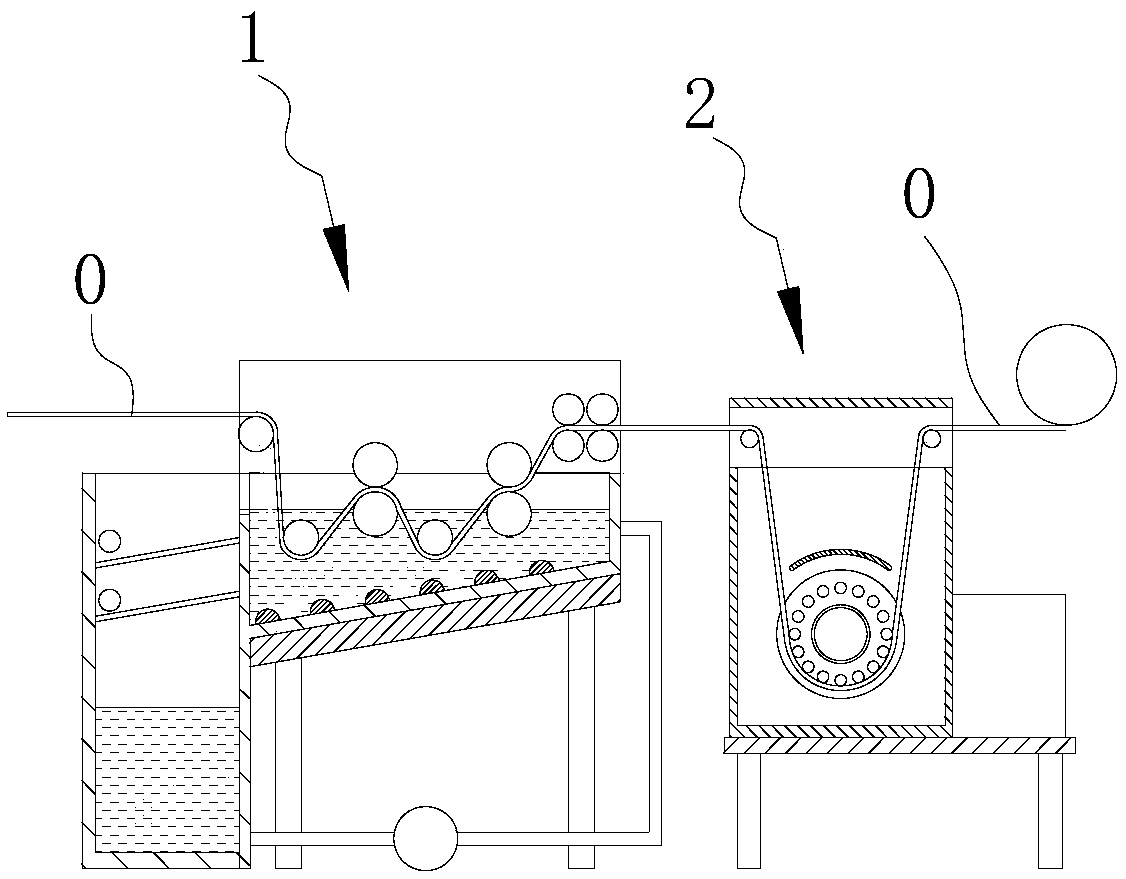

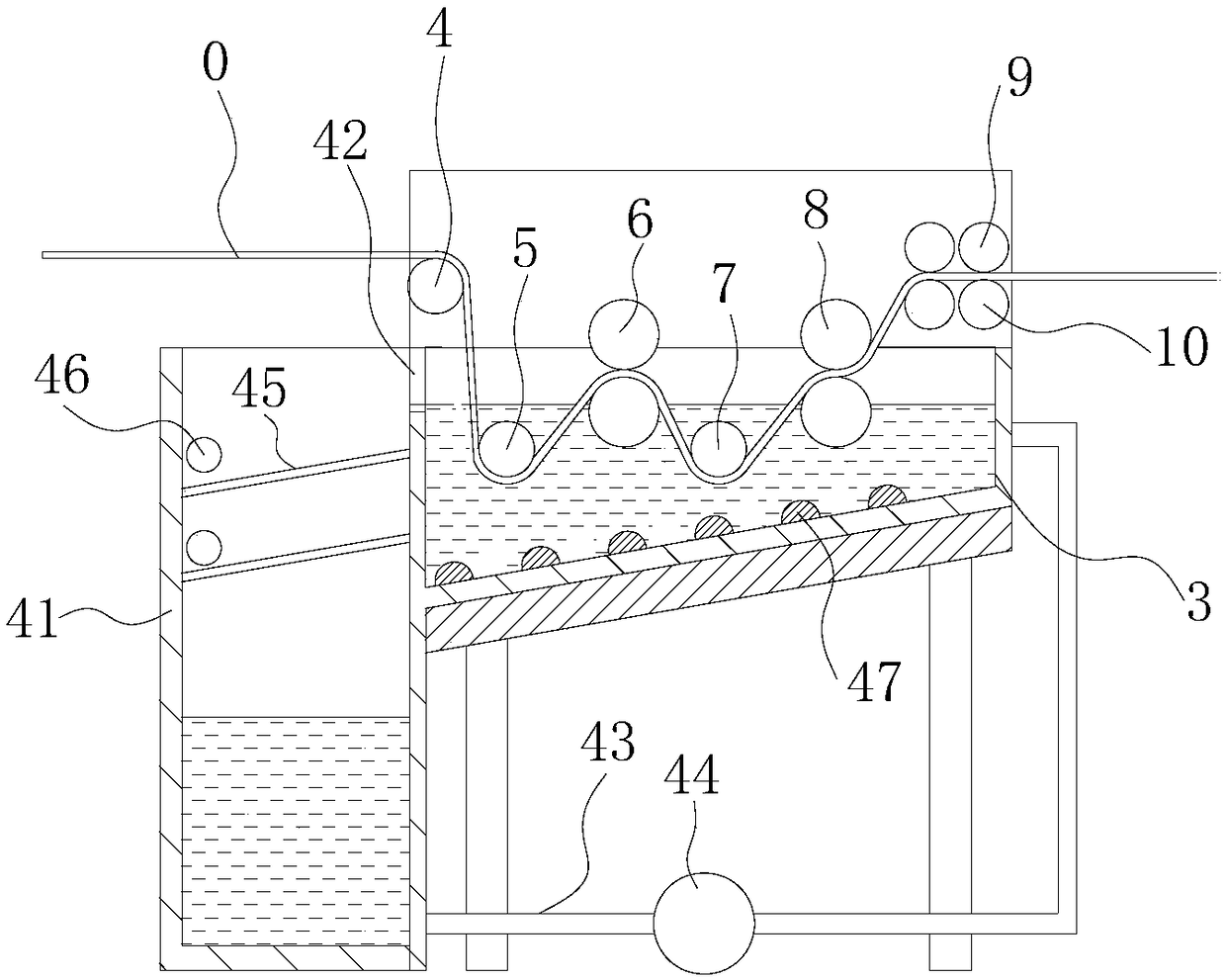

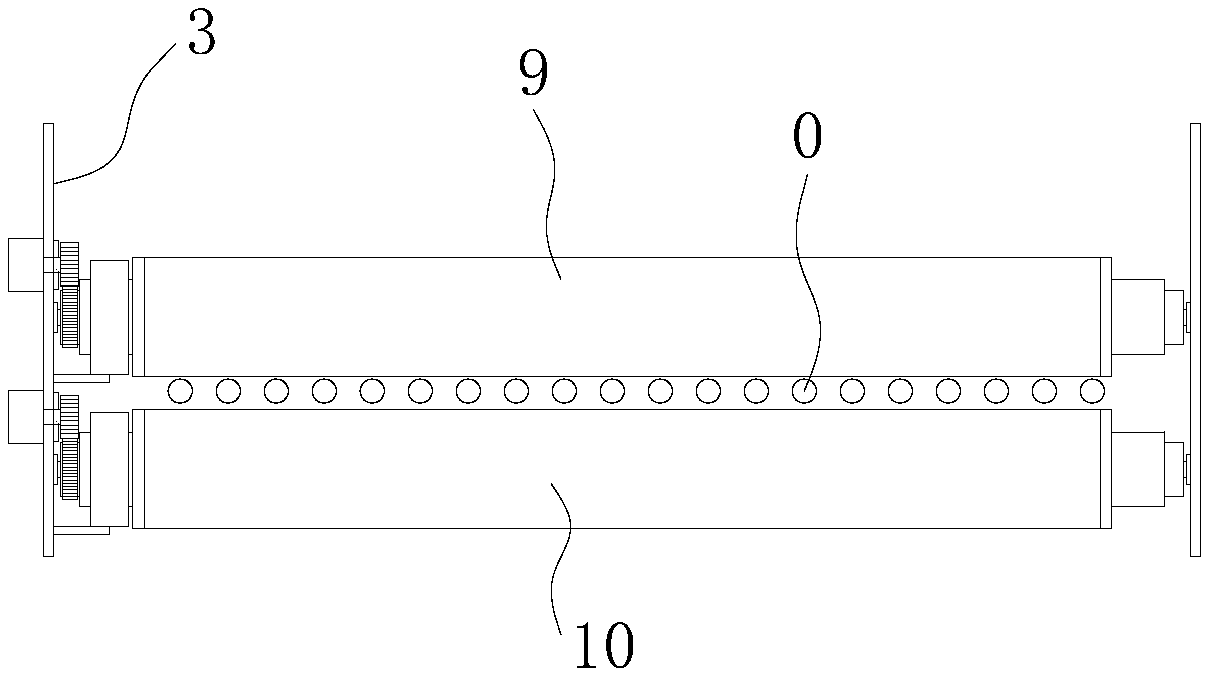

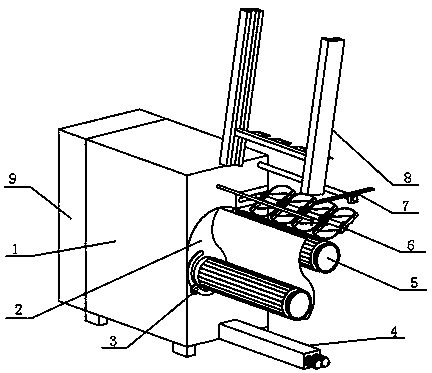

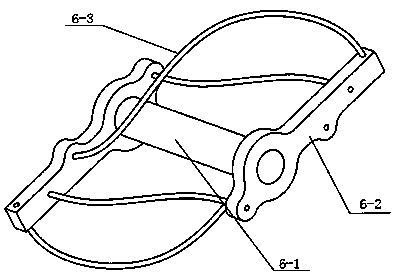

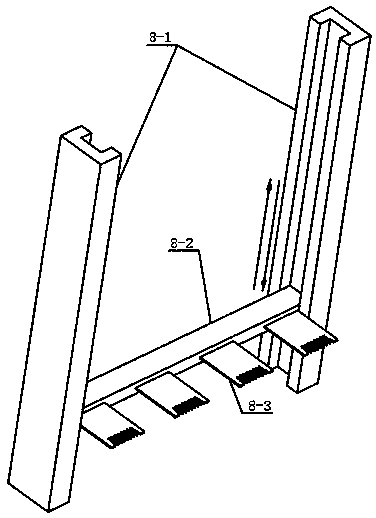

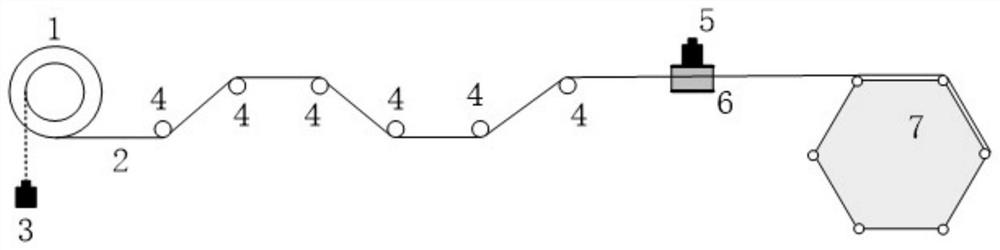

High-performance sizing machine

ActiveCN109440334AEfficient removalQuality improvementLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionYarnEngineering

The invention relates to the technical field of textile, and aims to provide a high-performance sizing machine capable of improving yarn performances. The technical scheme includes that the high-performance sizing machine comprises a sizing machine body and a drying box which are sequentially arranged along the conveying direction of yarns, the sizing machine body comprises a stock tank and a return tank, a sizing mechanism is arranged on the stock tank, the return tank is positioned on one side, close to the incoming direction of the yarns, of the stock tank, an overflow port is formed in thetop of a tank plate between the stock tank and the return tank, redundant slurry in the stock tank can flow towards the return tank, the bottom of the return tank is communicated with the stock tankthrough a circulating pipe, a circulating pump is arranged on the circulating pipe, and a cleaning filter screen is arranged on the inner upper portion of the return tank and positioned on the lower portion of the overflow port. Impurities in the slurry can be effectively removed, the quality of the slurry is improved, the hairiness quantity of the yarns is decreased, and yarn quality is improved.

Owner:叶江波

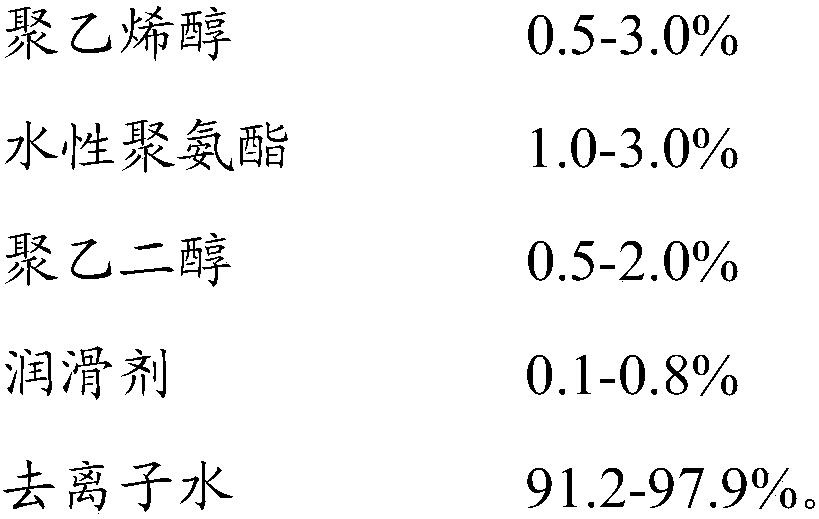

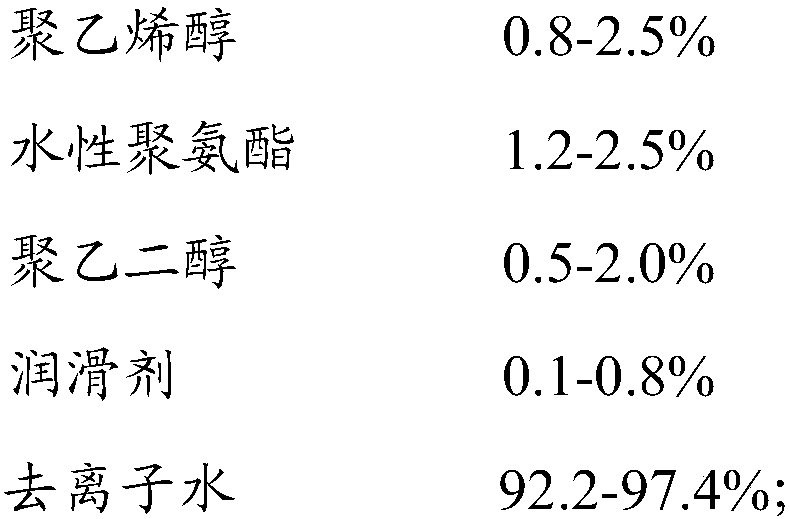

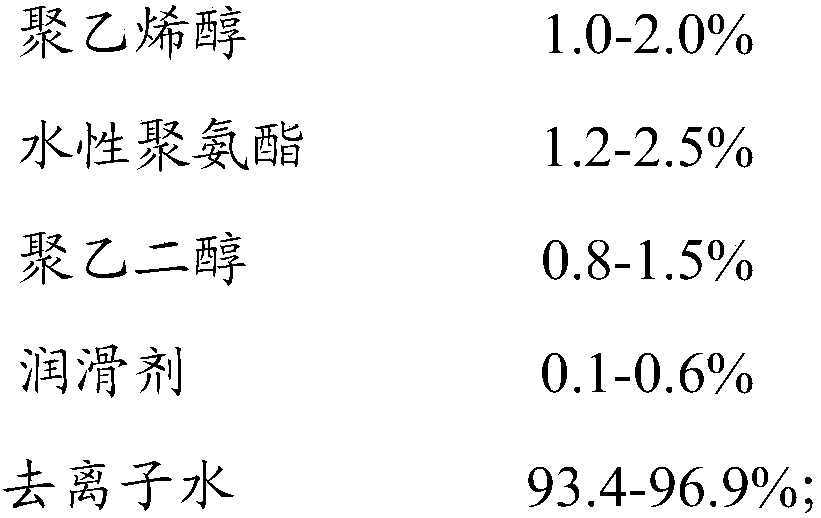

Electronic-grade glass fiber yarn secondary slurry, glass fiber yarn covered with secondary slurry and corresponding glass fiber cloth

The invention provides electronic-grade glass fiber yarn secondary slurry. Polyvinyl alcohol, waterborne polyurethane, polyethylene glycol and a lubricating agent are matched to be used and researched, so that the prepared secondary slurry not only can protect warps and meet a high-speed weaving technology requirement, but also has the characteristics of easiness in desizing, small residual fat content after thermal burning off and the like. The invention further provides an electronic-grade glass fiber yarn treated by the secondary slurry and an electronic-grade glass fiber cloth woven by thesized yarn.

Owner:JUSHI GRP CO

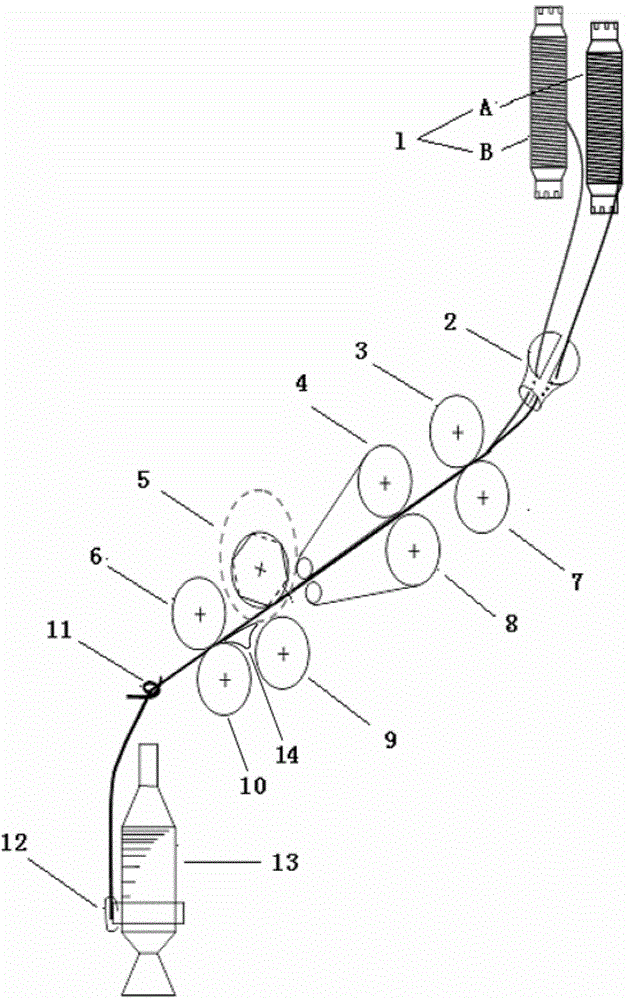

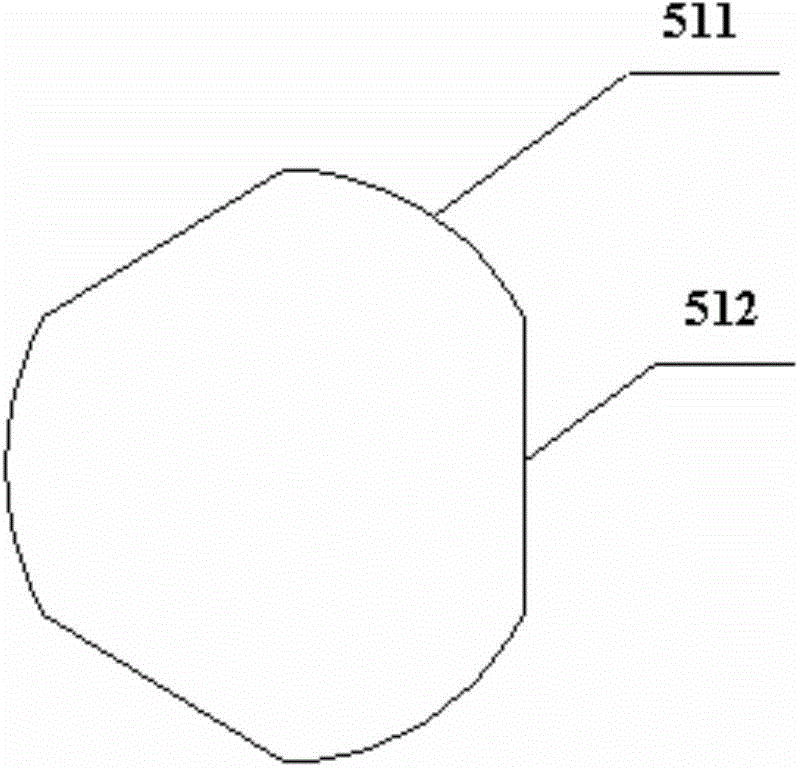

Novel colored spun yarn production method

InactiveCN104153058AHas a scaly appearanceAchieve intermittent draftingDrafting machinesContinuous wound-up machinesYarnColored

The invention discloses a novel colored spun yarn production method. The method includes in the procedures of Siro compact fine spinning, feeding a rough yarn A and a rough yarn B into a left hole and a right hole of a double-hole horn of a Siro compact spinning machine to reel on a fine yarn pipe via a rear roller, a middle roller, a front roller, a concentrating roller, a yarn hook and a steel ring sequentially. The front roller comprises a portion a and a portion b axially, the length of the portion a takes 30% to 50% of that of the front roller, the cross sections of the portion a are almost hexagonal consistently, the edges of the almost hexagon are formed by arcs and lines connected alternately, and the central angle of each edge of the almost hexagon is in 60 degrees; the portion b is in a cylindrical structure, and the radius of the arcs of the portion a is the same as that of the cylinder of the portion b. Yarns produced by the production method is capable of weaving colored spun fabrics with the ripple effect and can be widely applied to garment fabrics of knitwear and sweaters.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Glass fiber impregnating compound for polyurethane pultrusion composite material and preparation method of glass fiber impregnating compound

The invention discloses a glass fiber impregnating compound for a polyurethane pultrusion composite material and belongs to the technical field of polyurethane pultrusion processes. The glass fiber impregnating compound comprises the following components in percentage: 0.2-0.6wt% of a silane coupling agent A, 0.4-0.8wt% of a silane coupling agent B, 6.2-8.2wt% of a film-forming agent, 0.3-0.7wt% of a lubricant A, 0.2-0.8wt% of a lubricant B, 0.2-0.6wt% of an auxiliary agent, 0.2-0.4wt% of a pH regulator and the balance of water. The glass fiber impregnating compound disclosed by the inventionis high in compatibility with a polyurethane pultrusion composite material, can enable glass fiber yarn to be good in bundling property and small in hairiness amount, and can improve mechanical properties of a glass fiber reinforced polyurethane composite material.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Novel forming and winding apparatus of glass fiber

PendingCN109989139AImprove product qualityReasonable structureContinuous wound-up machinesYarnGlass fiber

The invention relates to a novel forming and winding apparatus of glass fiber. Strand cake of glass fiber plied yarns produced via the novel forming and winding apparatus of glass fiber has the advantages of uniform tension, good strand integrity, low hairiness, high splitting rate and the like; finished rovings that are plied have higher quality level than most of products in the current market.The quality of the strand cake is improved, so that production efficiency and yield of subsequent steps can be increased, and production cost is reduced for enterprises. An auto-loading device and anauto-unloading device help improve labor efficiency and save manpower resources. The novel forming and winding apparatus of glass fiber is provided, which is reasonable in structure and convenient tooperate and helps effectively improve the product quality.

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

Organosilicone impregnating compound for quartz glass fibers and preparation method for organosilicone impregnating compound

The invention discloses an organosilicone impregnating compound for quartz glass fibers and a preparation method for the organosilicone impregnating compound and relates to the field of quartz glass fiber impregnating compounds. The impregnating compound contains the ingredients in parts by mass: 4-10 parts of silicone resin, 4-10 parts of silicone oil, 0.1-2.0 parts of antistatic agent, 0.1-2.0 parts of viscosity regulator and 78-90 parts of diluent, wherein the diluent is ethyl acetate or butyl acetate. According to the organosilicone impregnating compound for the quartz glass fibers and the preparation method for the organosilicone impregnating compound, the condition that electrical insulation properties of the quartz glass fibers are not affected can be guaranteed, meanwhile, quartz glass fiber yarn treated by using the organosilicone impregnating compound is low in hair feather volume and relatively high in fracture tensile strength.

Owner:武汉鑫友泰光电科技有限公司

Beam sizing process of high-count color yarn

The invention discloses a beam sizing process of high-count color yarn. A size mixing formula comprises modified starch, polyvinyl alcohol, acrylic acid, wax sheets and a penetrant. The formula is sized by a double-size sizing machine, and the sizing process parameters of the double-size sizing machine are as follows: the sizing speed is 40-60 m / min-1, the size tank temperature is 95-98 DEG C, thesize viscosity is 6-8 s, the size solid content is 10%-12%, the moisture regain is 4%-5%, the sizing percentage is 10%-15%, the main size press force is 18-24 kN and the auxiliary size press force is8-12 kN. The size formula is simple, high in permeability and high in sizing percentage, the sizing quality is easy to control, the prepared size has high strength, low elongation reduction rate andlittle hairness, and the process is simple, applicable to sizing of high-count pure cotton color yarn and sizing of blended yarn taking cotton yarn as a main material and has very great significance in development of yarn-dyed pure cotton high-count and high-density products.

Owner:南通科沃纺织有限公司 +1

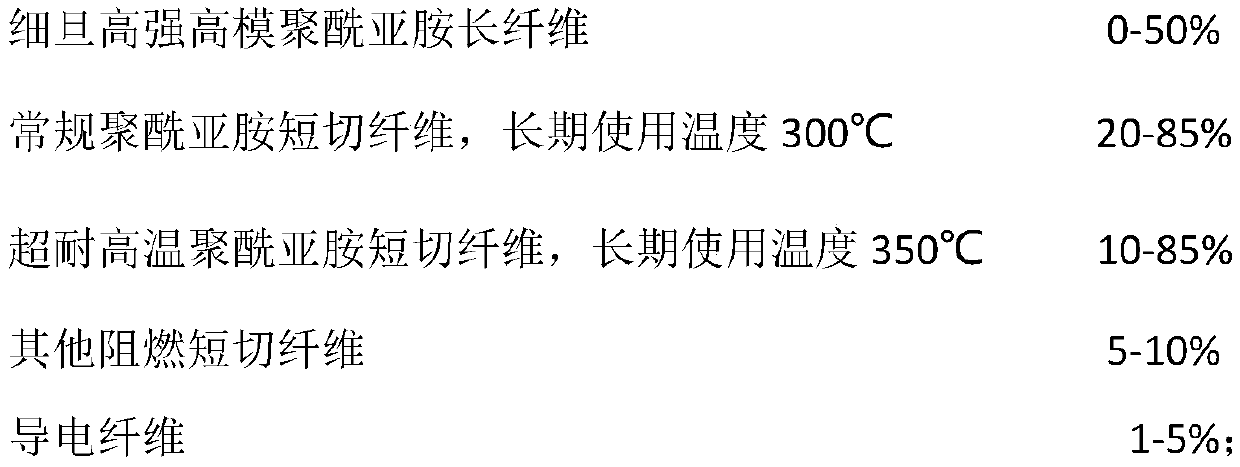

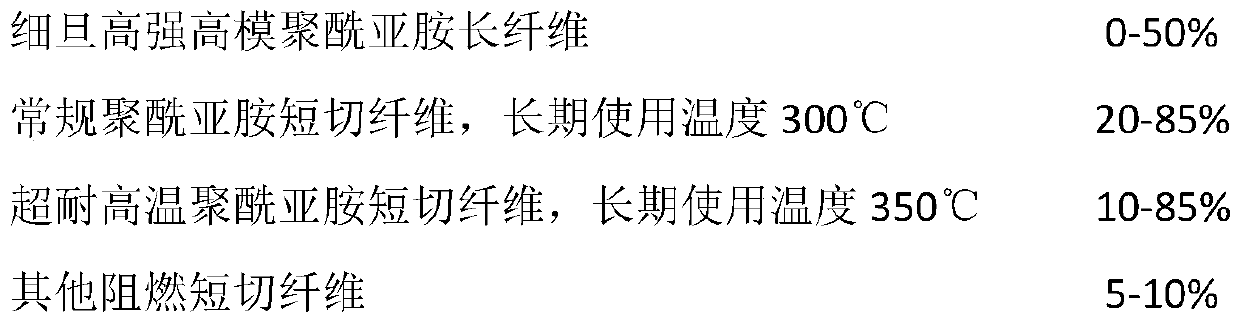

High-strength, flame-retardant and high-temperature-resistant polyimide yarn and manufacturing method thereof

Disclosed are a high-strength, flame-retardant and high-temperature-resistant polyimide yarn and a manufacturing method thereof. The manufacturing method includes the following steps: (a) pre-treating polyimide chopped mixed fibers; (b) carrying out opening and picking, carding, drawing and roving; (c) directly preparing rove into a spun yarn, or twisting and winding the spun yarn and a fine-denier high-strength high-modulus polyimide fiber at a front jaw of a spinning frame into a core spun yarn; (d) sizing the prepared polyimide yarn for post-treatment. The prepared polyimide yarn has low hairiness, excellent mechanical properties and high flame retardancy, and the temperature can exceed 350 DEG C after long-term use.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

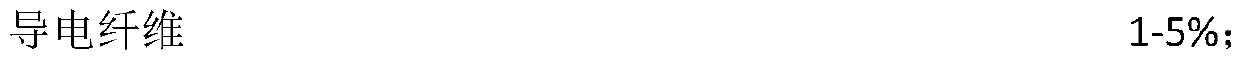

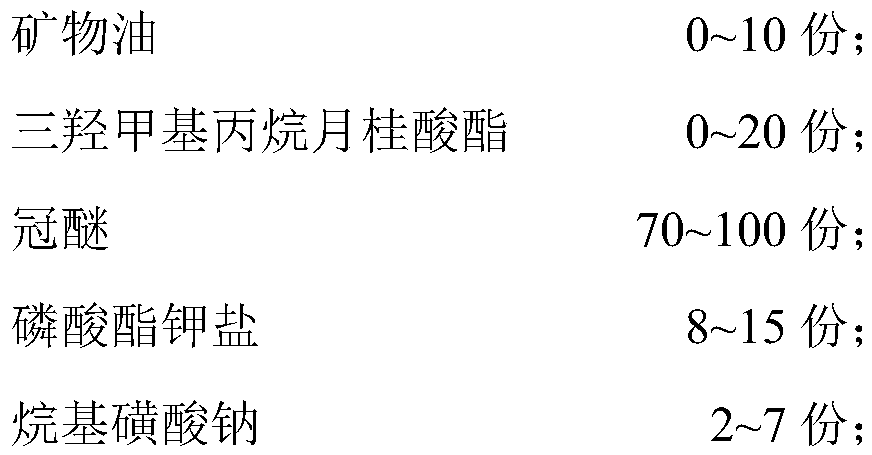

PTFE (Polytetrafluoroethylene) material for glass fiber coating and bundling device and preparation method thereof

ActiveCN109593306AHydrophilic and lipophilicHydrophilic and lipophilic reductionGlass fiberPolytetrafluoroethylene

The invention discloses a PTFE (Polytetrafluoroethylene) material for a glass fiber coating and bundling device. The PTFE material is prepared from the following components in parts by mass: 70 to 100parts of polytetrafluoroethylene (PTFE), 0 to 30 parts of modified polytetrafluoroethylene, 1 to 60 parts of wear-resisting filler and 1 to 60 parts of high-temperature-resisting resin. The PTFE material disclosed by the invention has the advantages of abrasion resistance, high temperature resistance, low friction coefficient, hydrophilic and lipophilic performance, corrosion resistance and the like. Compared with original graphitic oil coating roller and bundling wheel, the abrasion of a product can be reduced, the service life of the product is prolonged and the pollution, caused by the product, to glass fibers is reduced; and the hairiness generated in a glass fiber production process is reduced and the quality of the glass fibers is improved. Being different from other PTFE surface hydrophilic modification methods, an inner material of an oil coating roller product prepared from the PTFE material still has very good hydrophilic performance under the condition that a surface material is abraded, and the coating uniformity of an impregnating agent in a working process is ensured.

Owner:ZHEJIANG JUHUA NEW MATERIALS RES INST CO LTD

D450 electronic yarn impregnating agent and preparation method thereof

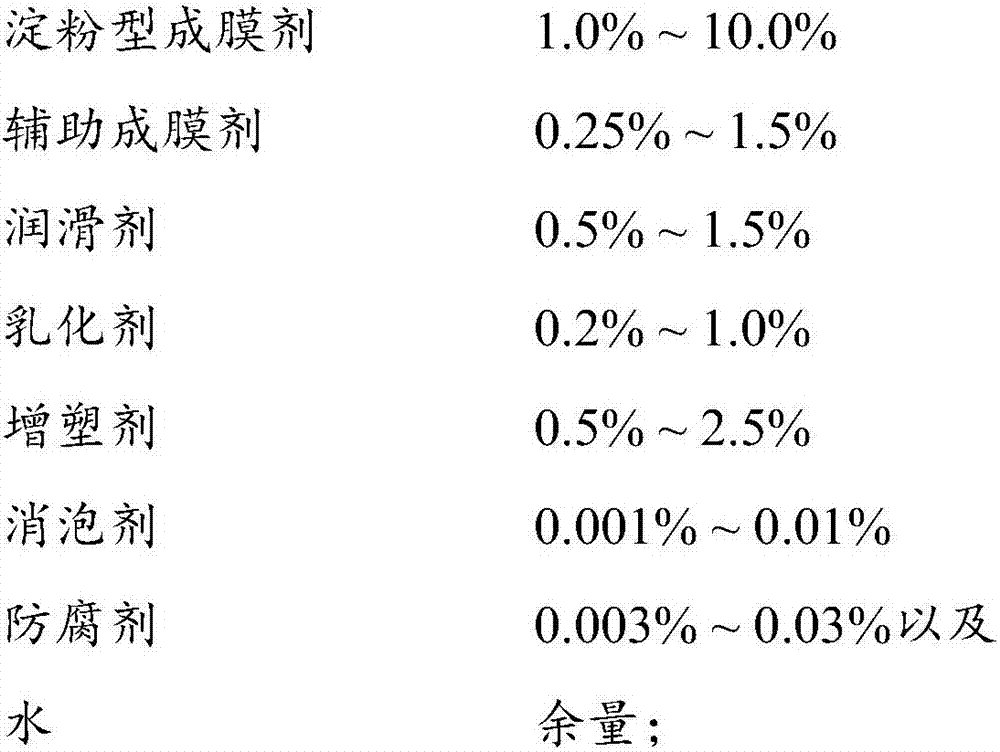

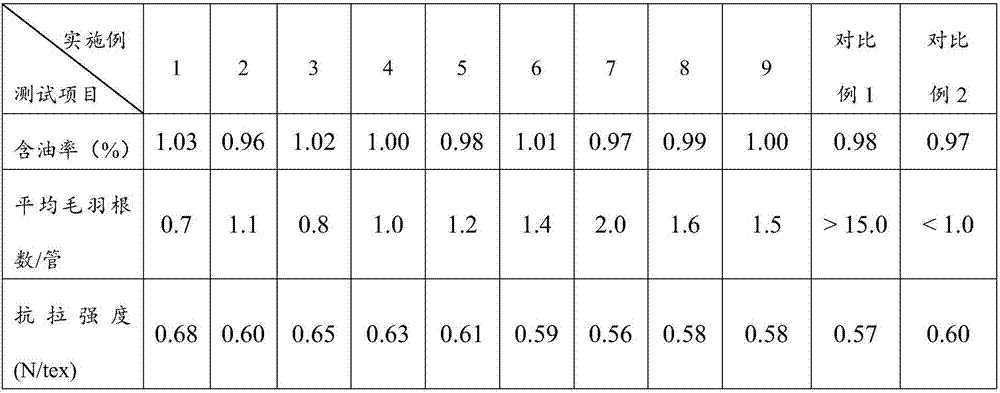

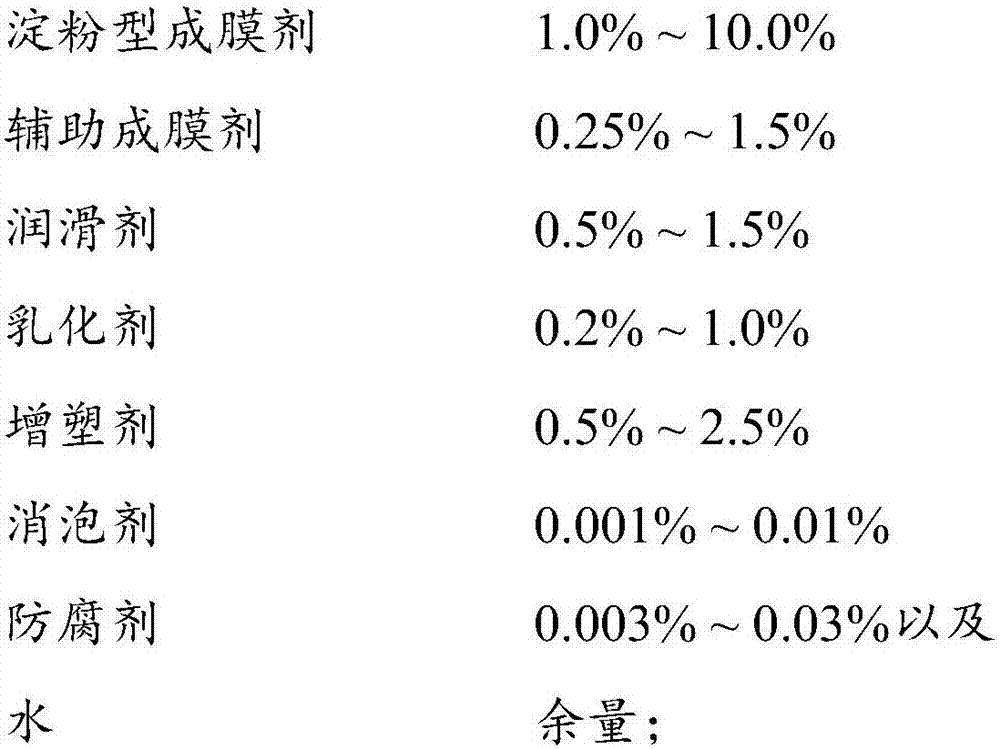

The invention relates to a D450 electronic yarn impregnating agent and a preparation method thereof. The D450 electronic yarn impregnating agent is prepared from, by mass, 1.0%-10.0% of starch-type film-forming agent, 0.25%-1.5% of auxiliary film-forming agent, 0.5%-1.5% of lubricant, 0.2%-1.0% emulsifier, 0.5%-2.5% of plasticizer, 0.001%-0.01% of defoamer, 0.003%-0.03% of preservative and the balance water. In the D450 electronic yarn manufacturing technology process, the D450 electronic yarn impregnating agent is coated to glass fiber to form an impregnating agent film, abrasion of glass fiber tows can be effectively reduced, hairiness is effectively reduced, meanwhile the D450 electronic yarn impregnating agent also has higher mechanical strength, and the surface properties of electronic base cloth are ensured.

Owner:广东志广生物科技有限公司

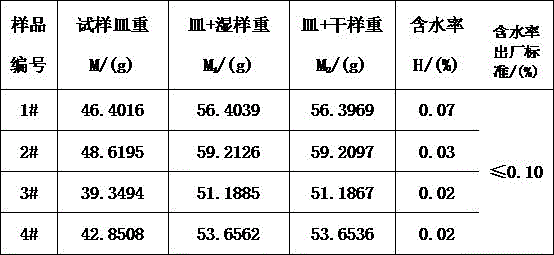

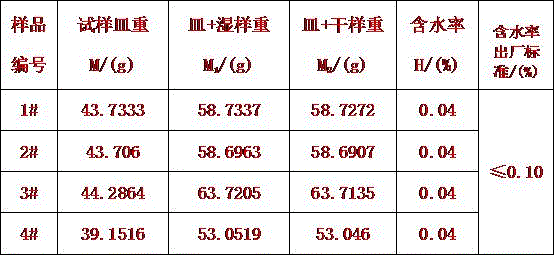

Method for testing internal moisture of high-frequency baked glass fiber yarns

The invention discloses a method for testing internal moisture of high-frequency baked glass fiber yarns. The testing method is implemented in an environment under the temperature of 20-26 DEG C and the humidity of 55-75%, and comprises the following steps: (1) selecting to-be-sampled yarns; (2) removing outer ring yarns of the to-be-sampled yarns; (3) determining sample removing positions; (4) removing test samples; (5) testing the moisture content; and (6) performing data analysis. The needed tools and equipment comprise a yarn cutter, a stainless rule, a signing-pen, a sealing bag, an electronic scale (accurate to 0.1mg), a drying oven, a sample dish and a dryer. According to the method, the internal moisture content of the high-frequency baked yarns can be timely measured, the quality problem caused by incomplete baking is effectively solved, the popularization and application of a high-frequency drying oven can be facilitated, the advantages of a high-frequency baking process, such as small product hairiness quantity, high baking speed and the like can be fully exerted, and the product quality and yield can be effectively improved.

Owner:JUSHI GRP JIUJIANG

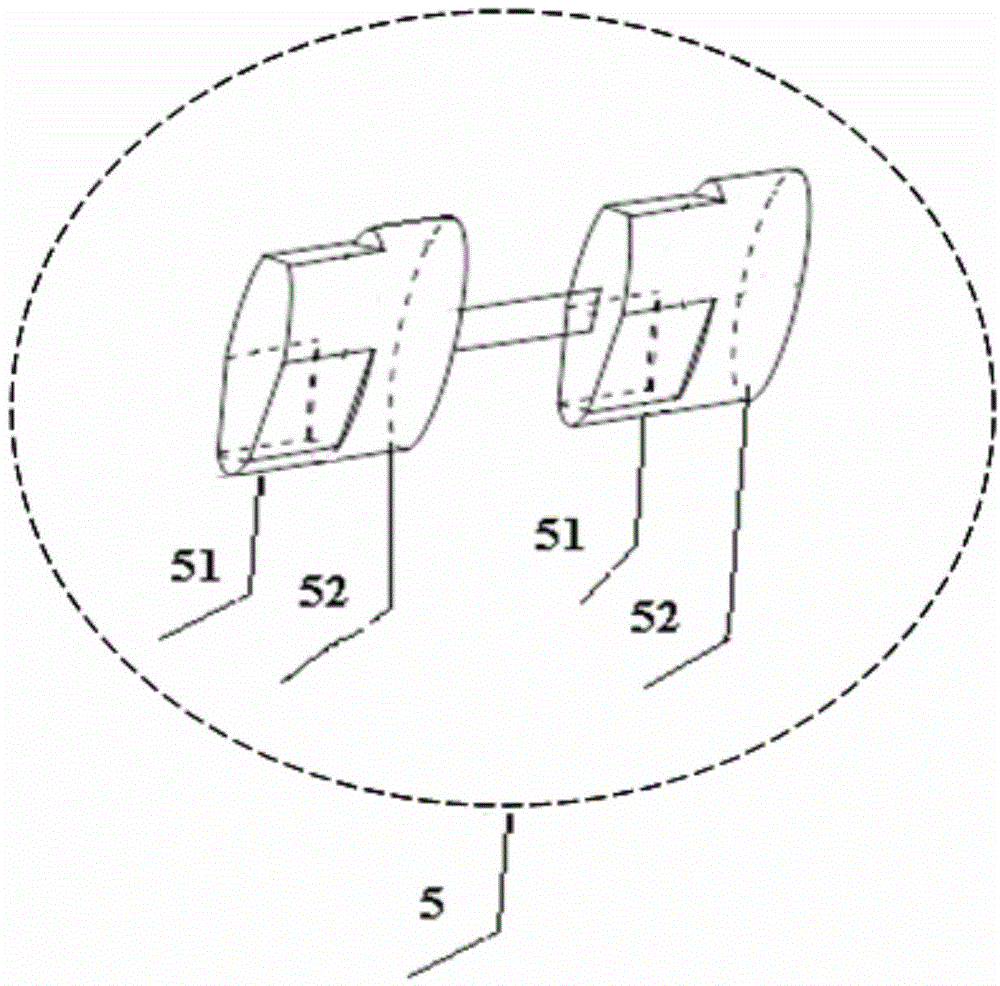

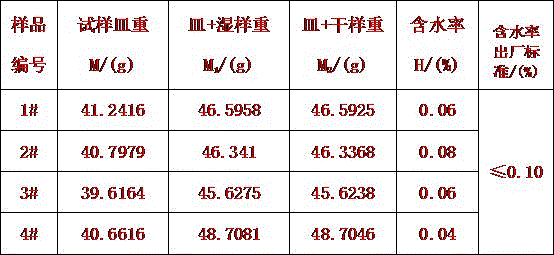

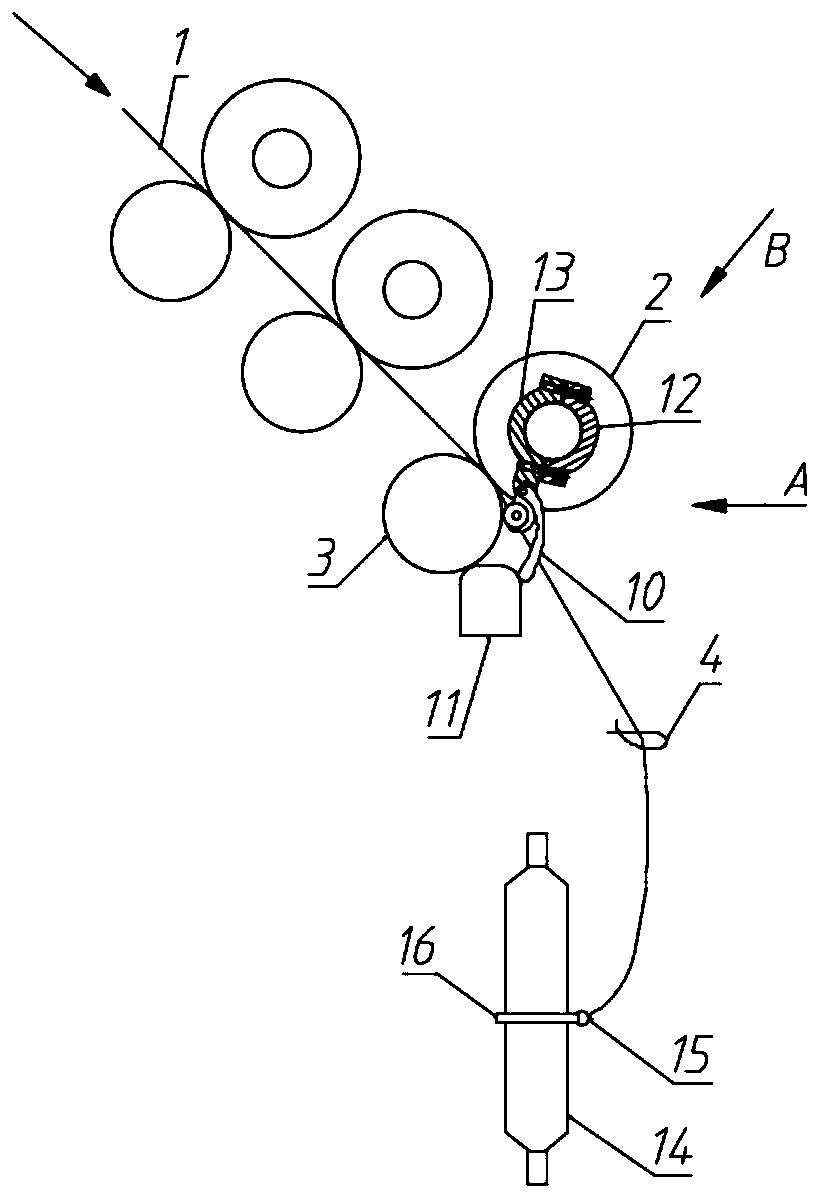

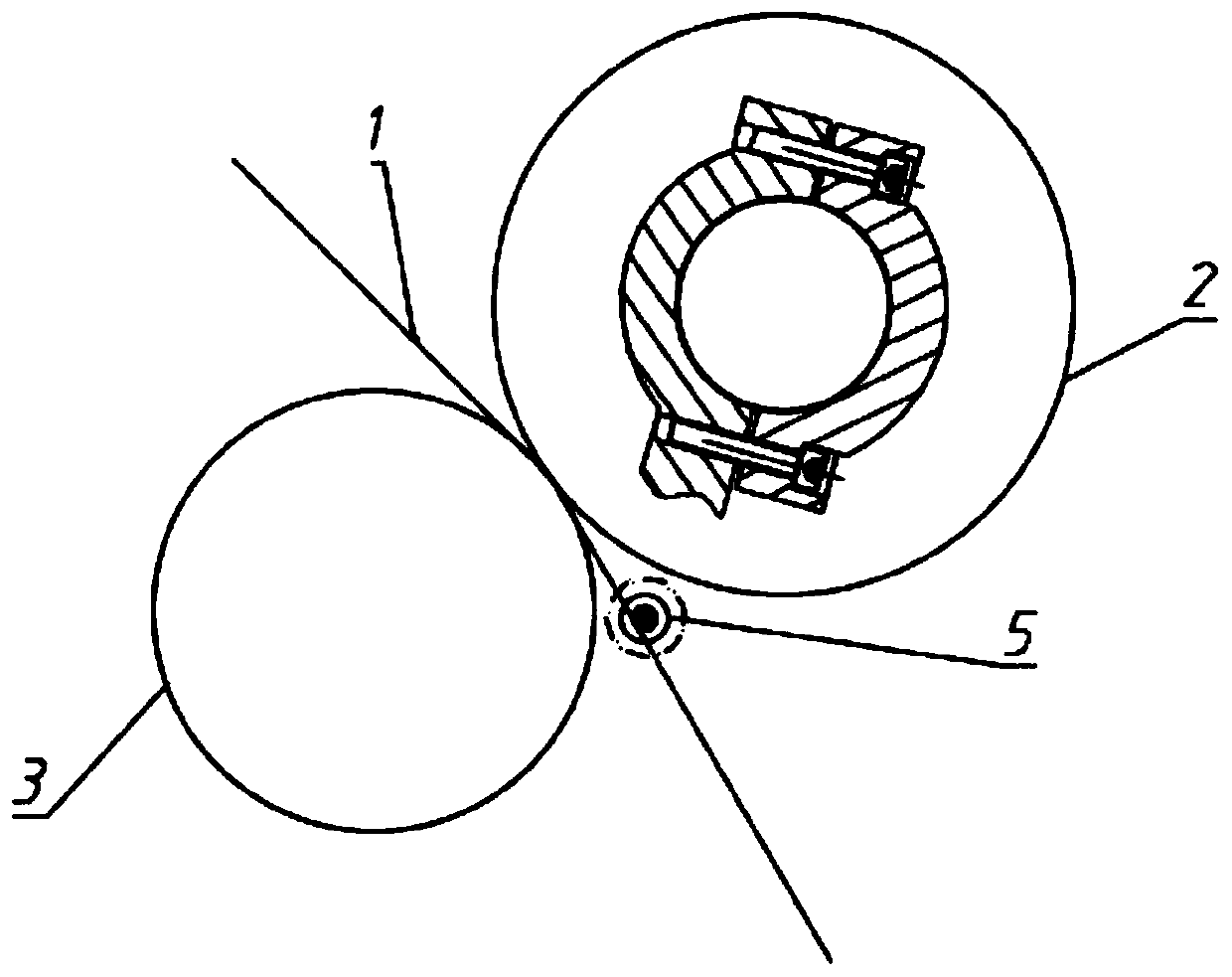

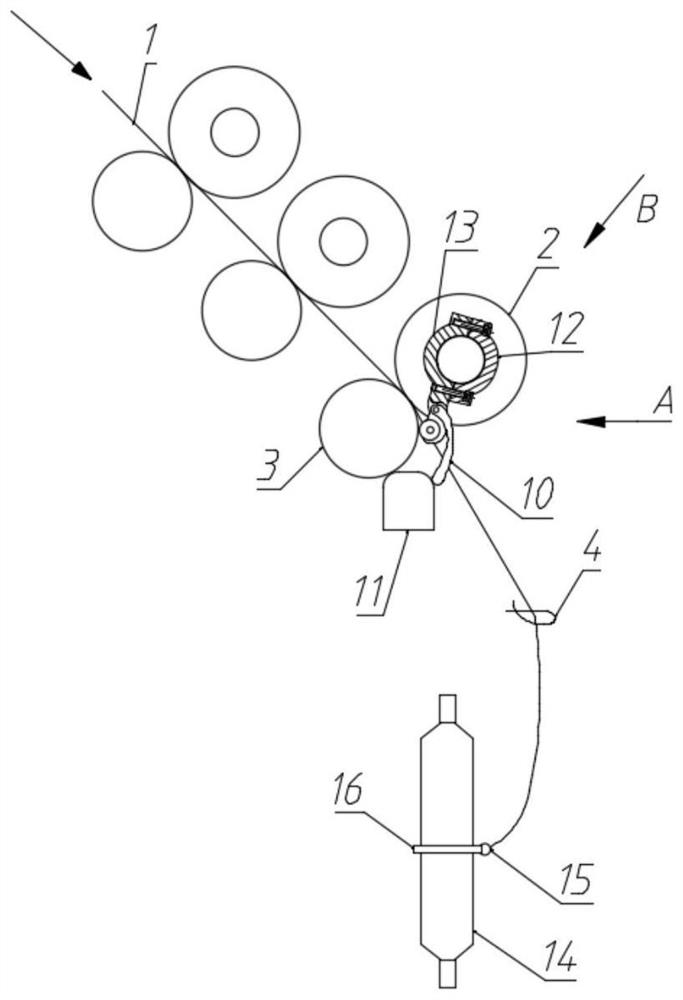

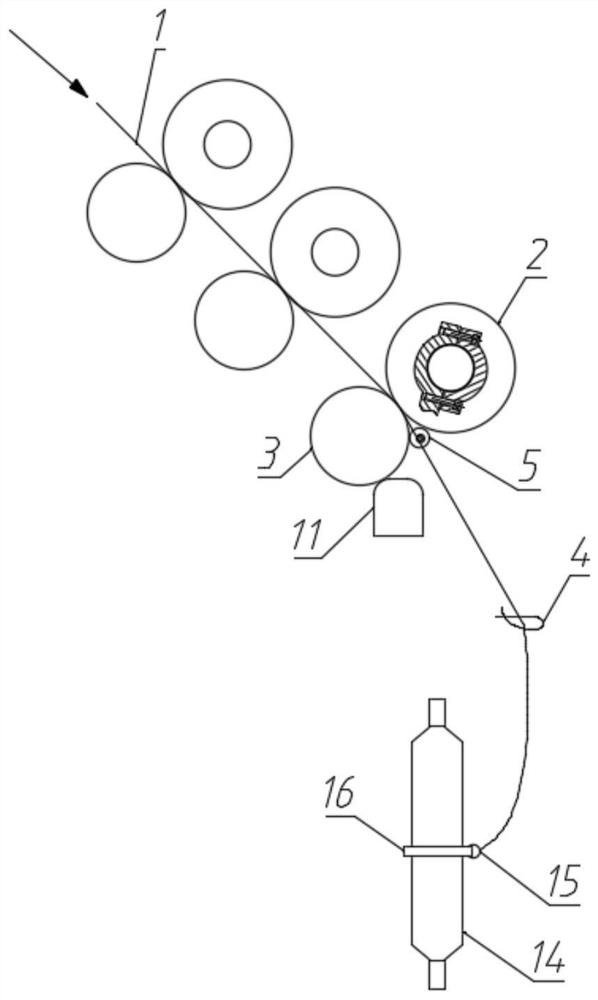

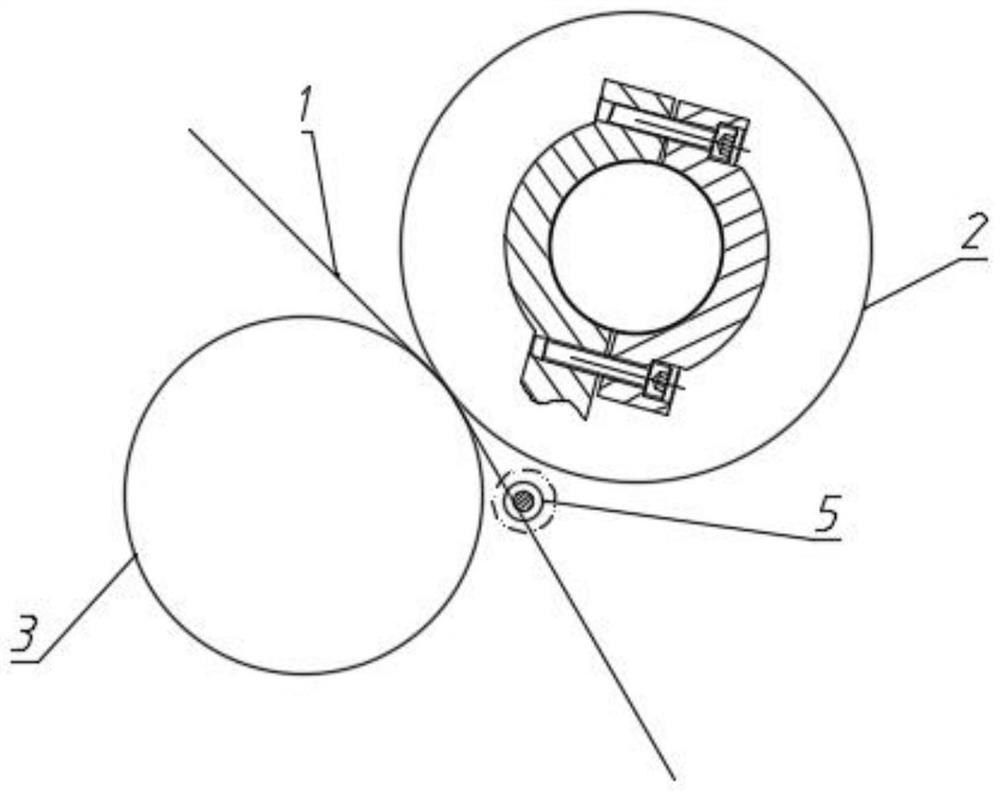

Siro spinning fiber removing device

The invention discloses a siro spinning fiber removing device. A fiber removing roller which rotates freely around a central axis is arranged in a jaw region formed by a front leather roller and a front roller; the fiber removing roller is particularly arranged between the front leather roller and a convergence point and is close to the jaw region as much as possible; two guide grooves are formedin the outer circumferential surface of the fiber removing roller, and two single-strand yarns fall into two guide grooves respectively, wherein the guide grooves collect and gather the edges of the single-strand yarns, so that the fibers extending out of the surfaces of the single-strand yarns are rotated to wrap around the surfaces of the single-strand yarns along with the twisting rotation of the single-strand yarns, and after passing through the convergence point, the two single-strand yarns are twisted and wound together, and the fibers wrapped around the surfaces of the single-strand yarns are wrapped in the yarn, and therefore the fibers on the surface of the yarn is reduced, and the function of further reducing the fibers of the siro-spun yarn is achieved.

Owner:WUHAN TEXTILE UNIV

Preparation and application of composite sizing agent for high-count cotton yarn sizing and desizing method

ActiveCN105671957AHigh extraction rateReduce extraction timeTextile treatment machine arrangementsDry-cleaning apparatus for textilesYarnFiltration

The invention relates to preparation and application of a composite sizing agent for high-count cotton yarn sizing and a desizing method. The preparation and application comprise the following steps: (1) using brewer's grains as a raw material for preparation of the composite sizing agent, putting the above materials into a sodium hydroxide solution, heating at constant temperature of 50-90 DEG C for 30-90 min, centrifuging or carrying out suction filtration to remove undissolved residue, and using a supernatant to prepare the composite sizing agent for high-count cotton yarn sizing; and (2) carrying out sizing process of cotton yarn by the use of a single-yarn sizing machine, adopting a double soak and press mode with temperature of sizing box being 40-70 DEG C, dying room temperature being 50-80 DEG C and sizing speed being 10-50 m / min, controlling permeation and coating ratio of the size in the yarn according to pressure adjustment, and carrying out coordination control of sizing percentage by sizing agent concentration and pressure. The prepared composite sizing agent is low-cost, has good sizing performance, is suitable for cotton yarn sizing, is easy to desize, contains no hardly degradable substance or substances harmful to the environment, and is clean and environmentally friendly.

Owner:SUQIAN YUANYANG BIOTECH

A siro spinning hair removal device

The invention discloses a siro spinning hair removal device. A hair removal roller freely rotating around a central axis is arranged in the nip area formed by a front top roller and a front roller; the hair removal roller is specifically arranged between the front top roller and the convergence between the points, and as close as possible to the nip area; two guide grooves are arranged on the outer peripheral surface of the de-hairing roller, and the two single-ply yarns fall into the two guide grooves respectively, and the guide grooves are opposite to the edges of the single-ply yarns. Gathering is carried out, so that the fibers protruding from the surface of the single-ply yarn are rotated and wrapped around the surface of the single-ply yarn with the twisting and rotation of the single-ply yarn. After passing through the convergence point, the two single-ply yarns are twisted and coiled together. And the fiber that has been wrapped on the surface of the single-ply yarn is clamped inside the yarn to reduce the hairiness on the surface of the yarn, realizing the function of further reducing the hairiness for siro spinning.

Owner:WUHAN TEXTILE UNIV

Silicone type sizing agent for quartz glass fiber and preparation method thereof

The invention discloses an organosilicone impregnating compound for quartz glass fibers and a preparation method for the organosilicone impregnating compound and relates to the field of quartz glass fiber impregnating compounds. The impregnating compound contains the ingredients in parts by mass: 4-10 parts of silicone resin, 4-10 parts of silicone oil, 0.1-2.0 parts of antistatic agent, 0.1-2.0 parts of viscosity regulator and 78-90 parts of diluent, wherein the diluent is ethyl acetate or butyl acetate. According to the organosilicone impregnating compound for the quartz glass fibers and the preparation method for the organosilicone impregnating compound, the condition that electrical insulation properties of the quartz glass fibers are not affected can be guaranteed, meanwhile, quartz glass fiber yarn treated by using the organosilicone impregnating compound is low in hair feather volume and relatively high in fracture tensile strength.

Owner:武汉鑫友泰光电科技有限公司

Preparation method of sizing agent for pure cotton yarn sizing

The invention discloses a preparation method of a sizing agent for pure cotton yarn sizing. The method comprises the following steps that (1) beer distiller's dried grain is added into water, whereinthe bath ratio is (1:5)-(1:30); cleaning and filtering are performed; rest soluble sugar in the brewer's grain is filtered away; (2) the brewer's grain subjected to sugar removal is dried and is smashed into powder being 30 mesh; (3) protein type soluble substances in the smashed beer distiller's dried grain are extracted by a sodium hydroxide water solution; (4) a brewer's grain mixed solution issubjected to solid-liquid separation; the centrifugal rotating speed is 5000 to 10000rmp; the centrifugation time is 10 to 30min; (5) an acrylamide water solution and butyl acrylate are sequentiallyand dropwise added; after the dropwise adding is completed, continuous heat insulation and stirring are performed for certain time; the sizing agent is obtained. The viscosity of the prepared sizing agent is small; serous fluid can be favorably and better permeated through the inside of pure cotton yarns, so that the sizing efficiency is improved; meanwhile, the per se contains various substances;the size film property is excellent; the hairiness quantity of the pure cotton yarns can be obviously reduced; the wear-resisting property of the yarns is improved.

Owner:SUQIAN YUANYANG BIOTECH

A kind of gf/pp composite fiber sizing agent and its application

ActiveCN112647300BEasy to divergeImprove clusteringLight resistant fibresGrip property fibresPolymer scienceAnoxomer

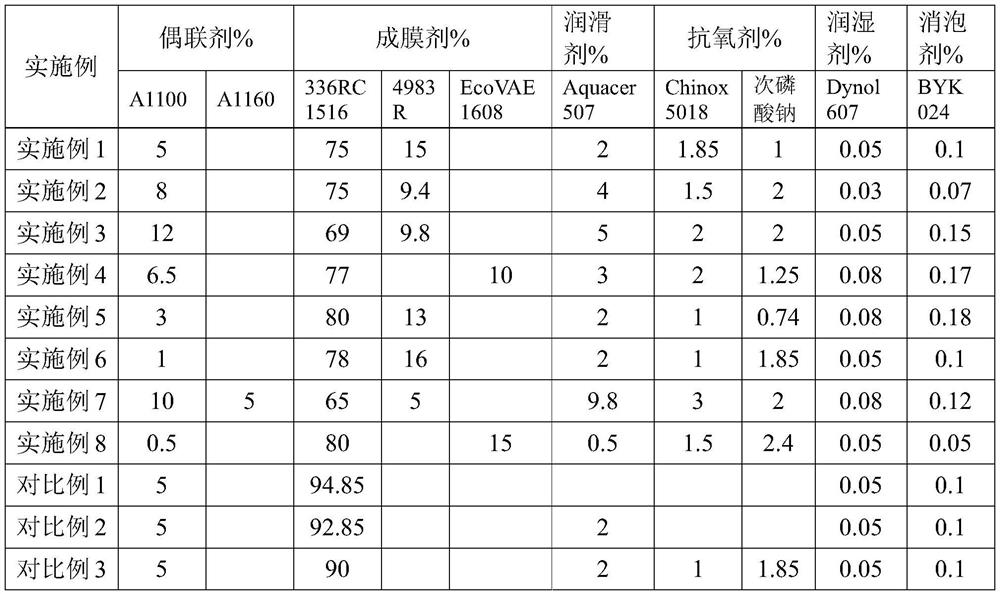

The present invention provides a GF / PP composite fiber sizing agent and its application. The percentages of each component in the sizing agent and the solid mass of each component to the total solid mass of the sizing agent are: coupling agent 0.5% to 15%, Film-forming agent 70-98%, lubricant 0.1-10%, antioxidant 0.5-5%, wetting agent ≤ 0.2%, defoamer ≤ 0.5%; The GF / PP composite yarn coated with the sizing agent has good wear resistance, which effectively solves the problems of downtime and decreased weaving efficiency caused by frequent weft yarn breakage during the weaving process; and the sizing agent of the present invention is used After drying, the coated GF / PP composite yarn will not cause yellow spots on the end face of the yarn cluster due to the migration of the sizing agent. The composite material product made of the composite yarn has a uniform surface color and good mechanical properties, which can satisfy customers. requirements.

Owner:TAISHAN FIBERGLASS INC

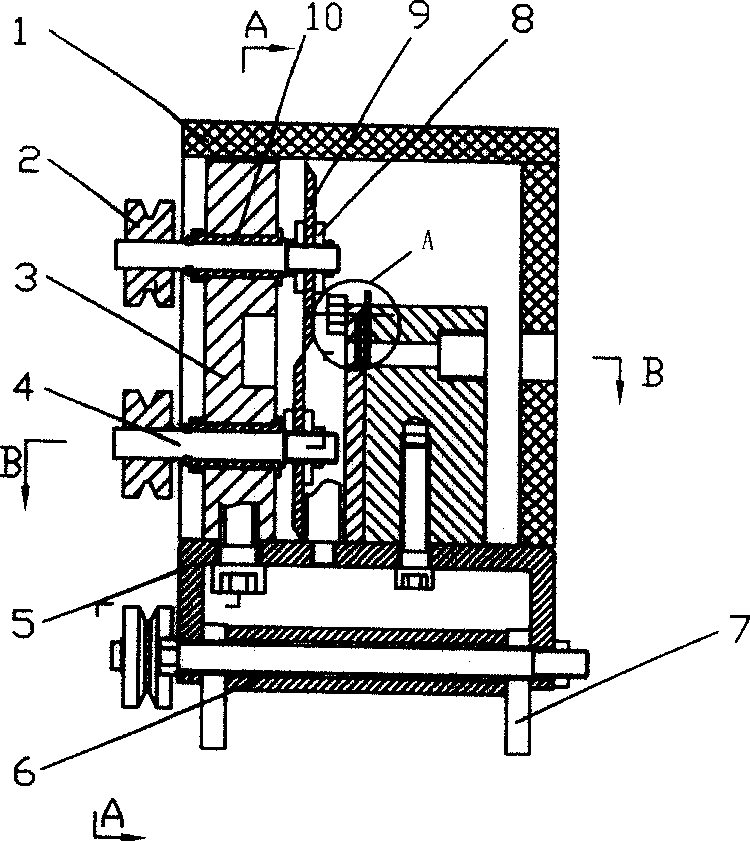

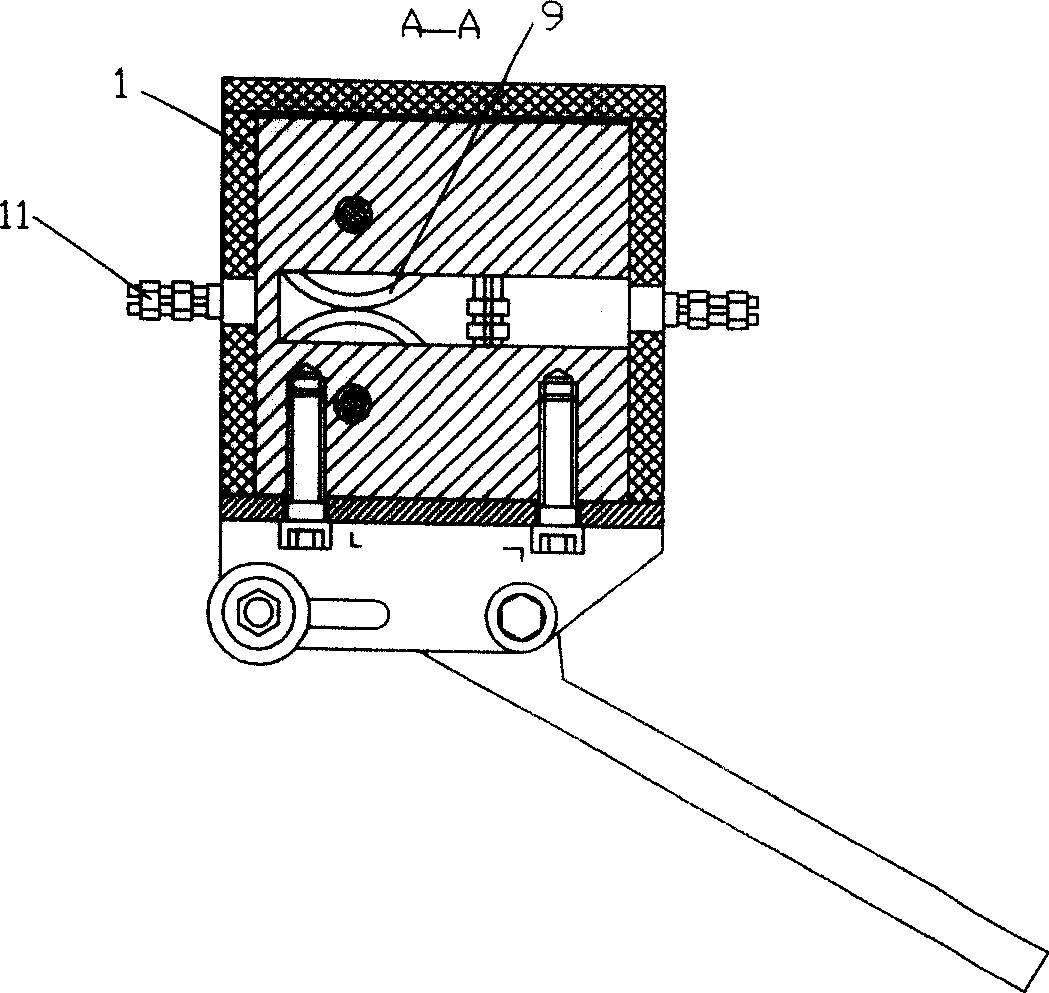

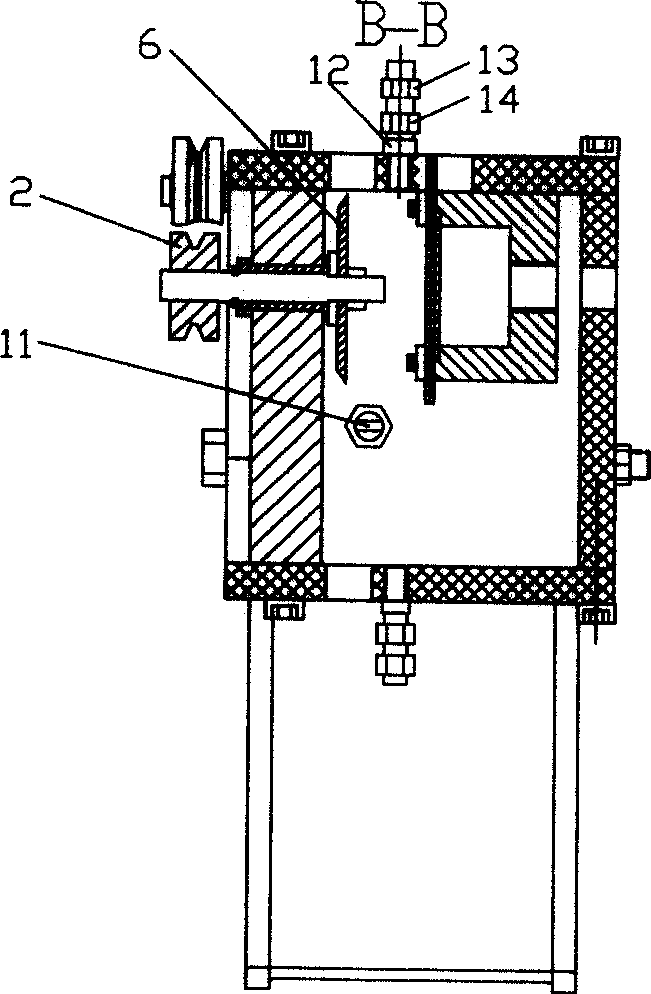

Yarn hair eliminator

InactiveCN100503918CLess hairyImprove other quality indicatorsTextiles and paperYarnPulp and paper industry

The invention belongs to a special mechanical device for textiles, and in particular relates to a novel yarn hairiness reduction device, which differs in that it includes a box plate, a support, a rotary blade set, an air jet device, a transmission device, and a yarn The adjusting device and the transmission device are connected with the rotary blade group, the air jet device is arranged on one side of the rotary blade group and connected with the support, and the yarn adjusting device makes the yarn pass through one side of the blade group. The beneficial effects of the present invention are: (1) the hairiness of the yarn passing through the device is greatly reduced, and other quality indicators of the yarn are improved; (2) the device fully utilizes the electromechanical integration technology, and the structure is simple, easy to operate and install The maintenance is convenient, the hairiness reduction rate is high, and it is easy to popularize and apply; (3) It can not only effectively reduce the amount of hairiness on the yarn, but also adjust the yarn well to realize the control of the hairiness removal amount.

Owner:张建钢 +2

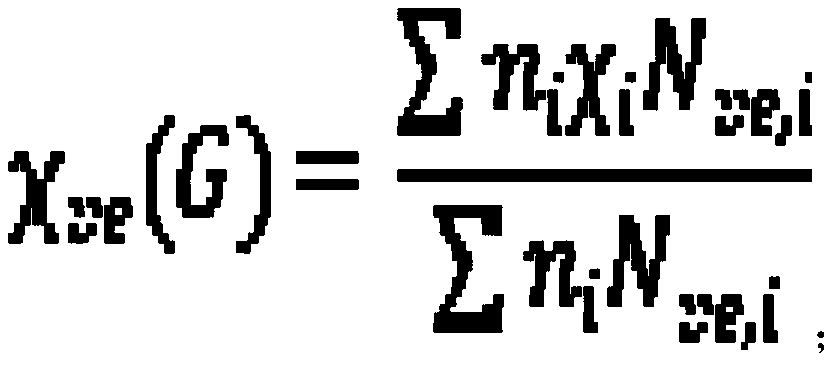

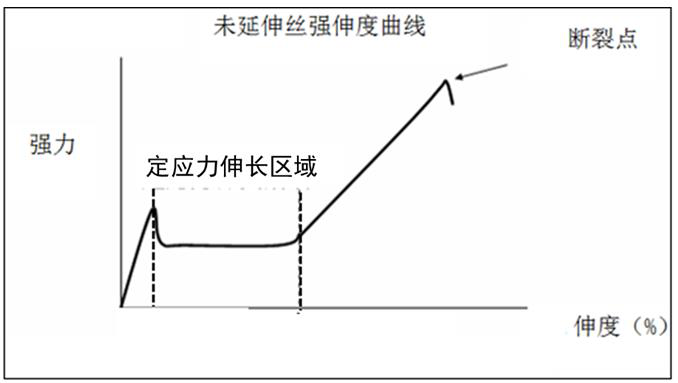

A Method for Reducing Hairiness of Polyester Yarn

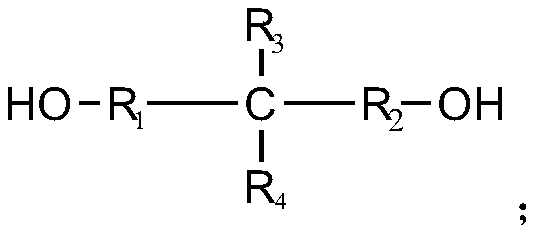

The invention relates to a method for reducing polyester yarn hairness. According to the method, modified polyester is adopted, and polyester yarns are prepared by polyester fiber of an oil agent withthe crown ether content being 67.3 to 85.58 percent by weight used in the oiling link in the spinning process, wherein the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a diol chain segment with branched chains; the structure of the diol chain segment with the branched chains is as follows: (the formula is shown as the description); and in the formula, R1 and R2 are independently selected from straight chain alkylene with the carbon atom number being 2 to 5, R3 is selected from alkyl with the carbon atom number being 1 to 5,and R 4 is selected from alkyl with the carbon atom number being 2 to 5. The method for reducing the polyester yarn hairness, which is provided by the invention, is simple and reasonable, the number of the prepared polyester yarn hairness is 1.8 to 2.1 pieces / 10 km, the number of the prepared polyester yarn hairness is obviously reduced, the advantages of high uniformity, little hairness and highquality are achieved and great application prospect is achieved.

Owner:JIANGSU HENGLI CHEM FIBER

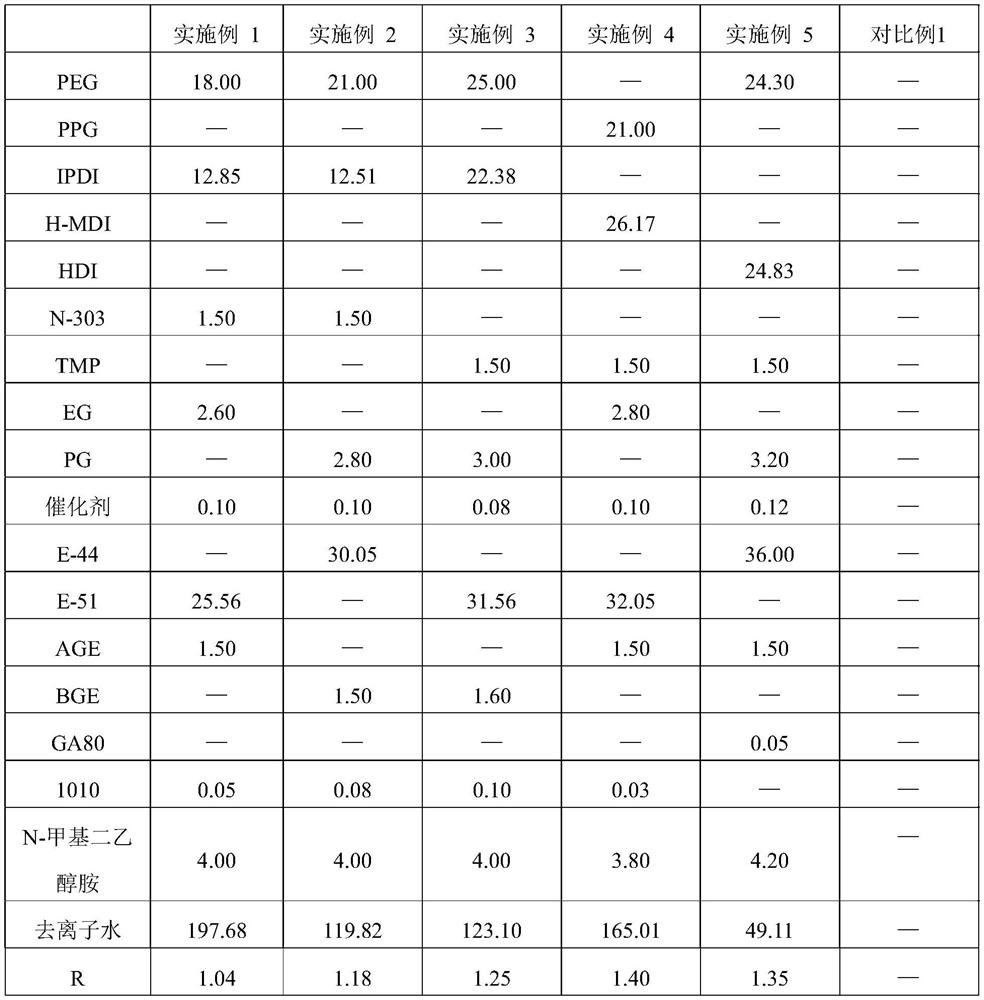

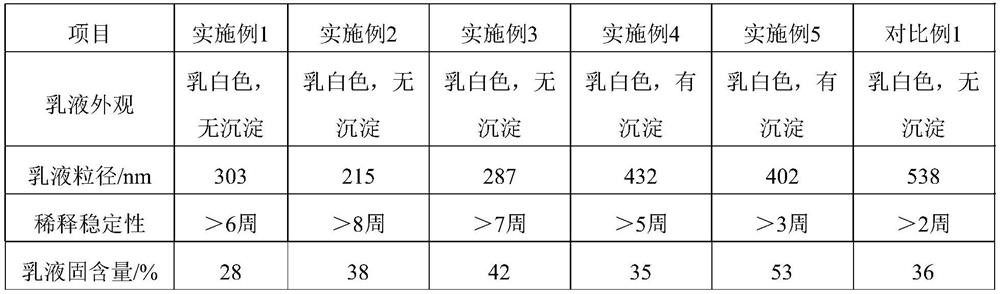

Polyurethane prepolymer modified epoxy resin emulsion as well as preparation method and application thereof

PendingCN114369225AImprove wettabilityImprove clusteringCarbon fibresAbrasion resistant fibresEpoxyFiber

The invention relates to a polyurethane prepolymer modified epoxy resin emulsion as well as a preparation method and application thereof. The preparation method comprises the following steps: enabling polyether polyol to react with aliphatic polyisocyanate, so as to obtain a polyurethane prepolymer reaction product; adding a chain extender, a cross-linking agent, an organic solvent and a catalyst into the polyurethane prepolymer reaction product for chain extension and cross-linking reaction to obtain a cross-linking reaction product; adding epoxy resin, a diluent, an antioxidant, an emulsifier and an organic solvent into the cross-linking reaction product, and carrying out graft modification on the epoxy resin by the polyurethane prepolymer with the cross-linking network structure to obtain a modified reaction product; and carrying out post-treatment on the modified reaction product to obtain the polyurethane prepolymer modified epoxy resin emulsion. The preparation method is used for preparing the polyurethane prepolymer modified epoxy resin emulsion, the polyurethane prepolymer modified epoxy resin emulsion can be used as a sizing agent for carbon fibers, and the wettability, the bundling property and the wear resistance of the carbon fibers can be effectively improved on the basis that the strength of the original carbon fibers is not reduced.

Owner:山西钢科碳材料有限公司

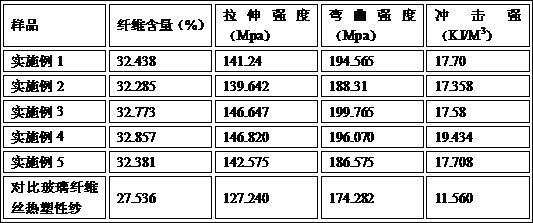

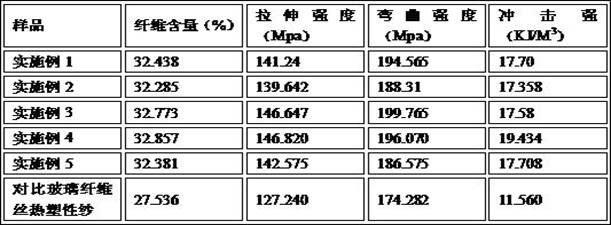

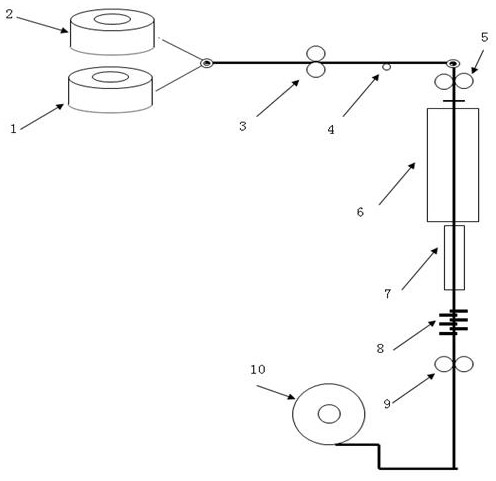

Method for producing thermoplastic chopped strands after modification of glass fiber filaments

ActiveCN113060946BImprove bindingExcellent performance such as bending resistance and impact resistanceGlass making apparatusThermoplasticGlass fiber

The invention relates to the technical field of production technology of thermoplastic chopped strands, in particular to a method for producing thermoplastic chopped strands after modification of glass fiber filaments. The process waste produced in the glass fiber production process of the present invention is short-cut by a Humen guillotine, granulated by a granulator, then sprayed with a self-developed infiltration agent, then dedusted by a dust removal device, and finally enters a vibration fluidization The bed is dried to produce thermoplastic-reinforced chopped strands. The sizing agent is composed of the following raw materials in weight percentage: coupling agent 0.3‑1%, film forming agent A1‑15%, film forming agent B1‑16%, lubricant 0.6‑2%, crosslinking agent 0.050.01‑0.3% , 0.05‑0.2% of antistatic agent and the balance of deionized water, and optimize the preparation method of wetting agent. The treatment process of the invention is simple and reasonable, and the final product is clean and of good quality.

Owner:山东墨匠新材料科技有限公司 +1

Impregnating compound special for single-filament plastic coated yarn and preparation method thereof

The invention relates to an impregnating compound special for single-filament plastic coated yarn and a preparation method thereof. The impregnating compound is prepared mainly by a main film former including water-solubility polyurethane and epoxy resin emulsion, and an assistant film former including water-solubility epoxy resin, as well as a coupling agent, a lubricating agent, a pH value adjusting agent and deionized water. The preparation method comprises the following steps: hydrolyzing the coupling agent in the deionized water; diluting the lubricating agent, and adding the diluted lubricating agent into the hydrolyzed coupling agent for stirring; adding the water-solubility polyurethane, the epoxy resin emulsion and the water-solubility epoxy resin for continuously stirring; and adding the deionized water and stirring uniformly. In the invention, the water-solubility polyurethane and the epoxy resin emulsion are taken as the film formers, so that the impregnating compound has the advantages of simple preparation process and low cost; and glass fiber yarn produced by the impregnating compound has extremely high breakage resistance and smaller fur containing amount, and the strength and the production efficiency of products are improved greatly, so that the impregnating compound is more suitable for promotion and application.

Owner:SHANDONG FIBERGLASS GRP

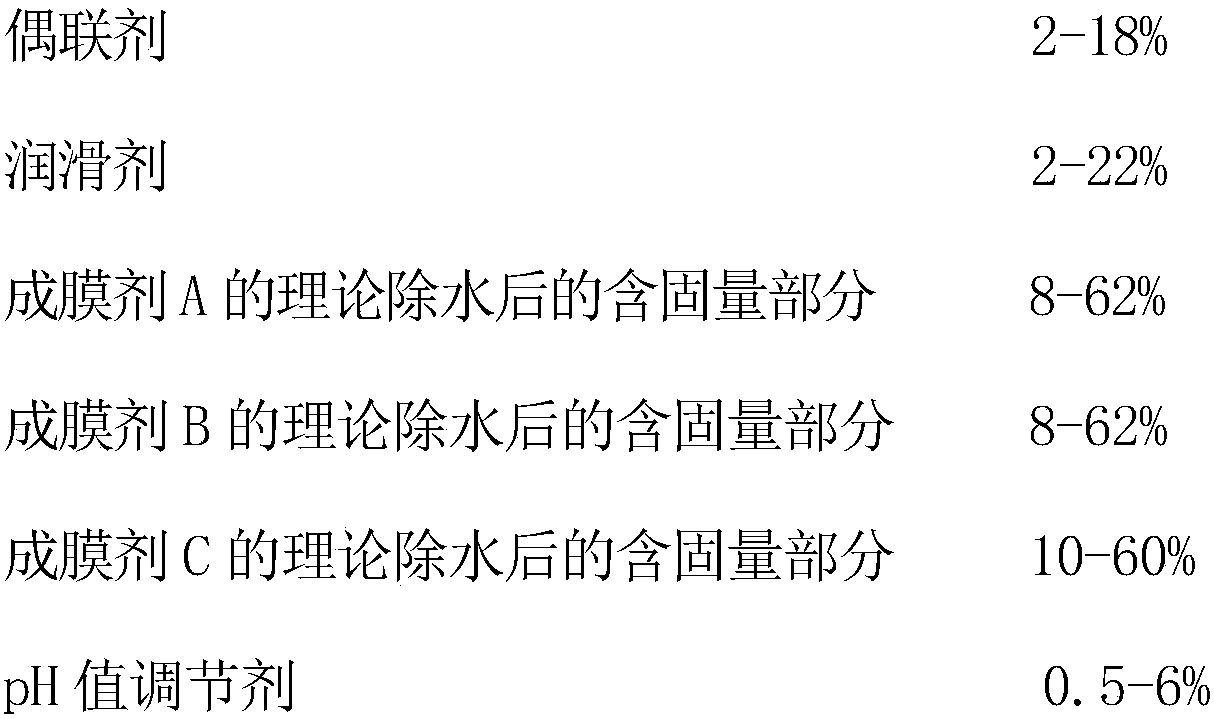

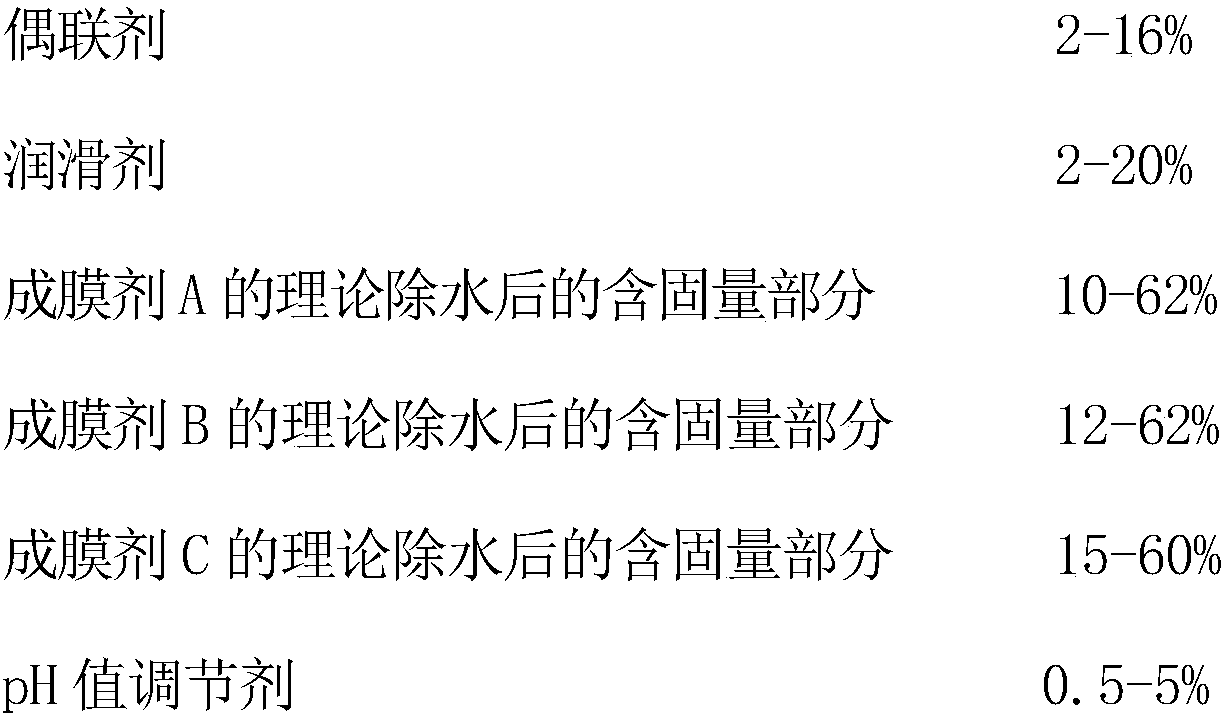

Wetting agent for glass fiber twisted yarn of glass-fiber reinforced polypropylene needled mat

The invention provides a wetting agent for a glass fiber twisted yarn of a glass-fiber reinforced polypropylene needled mat and a preparation method thereof. The wetting agent is prepared from a coupling agent, a lubricating agent, a film-forming agent A, a film-forming agent B, a film-forming agent C, a pH regulator and water, wherein the pH value is 3-9; the coupling agent is selected from a silane coupling agent; the lubricating agent is selected from cation ammonium salt lubricating agent or nonionic lubricating agent; the film-forming agent A is selected from waterborne polyurethane resin; the film-forming agent B is selected from acrylic emulsion; the film-forming agent C is selected from PVAC emulsion; the pH regulator is an acid. Compared with the prior art, the wetting agent has the characteristics of high compatibility with polypropylene resin, excellent yarn dispersibility, low felt contractibility, applicability for hard and soft use, high product strength, and the like, and can meet the market requirement.

Owner:SHANDONG FIBERGLASS GRP

Impregnating compound for thermoplastic chopped yarn production, preparation method of impregnating compound and method for producing thermoplastic chopped yarn after modification of glass fiber filaments

ActiveCN113060946AImprove bindingExcellent performance such as bending resistance and impact resistanceGlass making apparatusYarnThermoplastic

The invention relates to the technical field of thermoplastic chopped yarn production processes, and in particular, relates to an impregnating compound for thermoplastic chopped yarn production, a preparation method of the impregnating compound and a method for producing the thermoplastic chopped yarn after modification of the glass fiber filaments. Process waste generated in the glass fiber production process is chopped by a tiger's guillotine, granulated by a granulator, sprayed with the independently developed impregnating compound, dedusted by a dedusting device, finally enters a vibrated fluidized bed and is dried to finally produce the reinforced thermoplastic chopped yarn. The impregnating compound is prepared from the following raw materials in percentage by weight: 0.3-1% of a coupling agent, 1-15% of a film-forming agent A, 1-16% of a film-forming agent B, 0.6-2% of a lubricating agent, 0.05-0.3% of a cross-linking agent, 0.05-0.2% of an antistatic agent and the balance being deionized water. The preparation method of the impregnating compound is optimized. The treatment process is simple and reasonable, and the final product is clean and good in quality.

Owner:山东墨匠新材料科技有限公司 +1

Hairiness color-mixed false-twist processed yarn as well as preparation method and application thereof

The invention discloses a hairiness color-mixed false-twist processed yarn which comprises polyester filaments A and polyester filaments B. The polyester filaments A and / or the polyester filaments B are / is of a slub structure, and part of slubs in the slub structure are cut off to form hairiness. The number of hairiness with the diameter larger than 2 mm is 100 / 1000 m or below. The anti-pilling effect of the hairiness color-mixed false-twist processed yarn is good. Meanwhile, after being dyed, the fabric made of the false twist processed yarn has natural stripe feelings with different colors, and the color mixing effect is good.

Owner:TORAY FIBER RES INST(CHINA) CO LTD +1

Method for producing vertical bar flat cut towel product

ActiveCN101818402BReduce manufacturing costImprove weaving processWoven fabricsTexture designVertical bar

The invention discloses a method for producing a vertical bar flat cut towel product, which comprises the following steps of: 1) spinning, namely performing spinning by adopting ply yarns as towel yarns, wherein the yarn count of single yarns is British 8 to 10s and the twist of the ply yarns is 28 to 35 twists per 10 centimeters; and 2) weaving, namely weaving the yarns to obtain towel gray fabric, wherein during weaving, the warp density is more than or equal to No. 56 in portie, and the weft density is more than or equal to 200 yarns per 10 centimeters. The method effectively improves the conventional weaving process, obtains the vertical bar flat cut towel product by changing the towel texture design, and breaks through the appearance limitation of the primary cut pile products. Compared with the primary cut pile products, the obtained product has the advantages that: the hairiness amount is relatively reduced, and the appearance of the obtained product is obviously improved after washing and is unique.

Owner:LOFTEX CHINA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com