Siro spinning fiber removing device

A technology of siro spinning, plied yarn, applied in spinning machine, textile and paper making, continuous winding spinning machine, etc., can solve the problems of eliminating hairiness, losing reuniting effect, losing siro spun yarn style, etc. , to achieve the effect of reducing the amount of hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

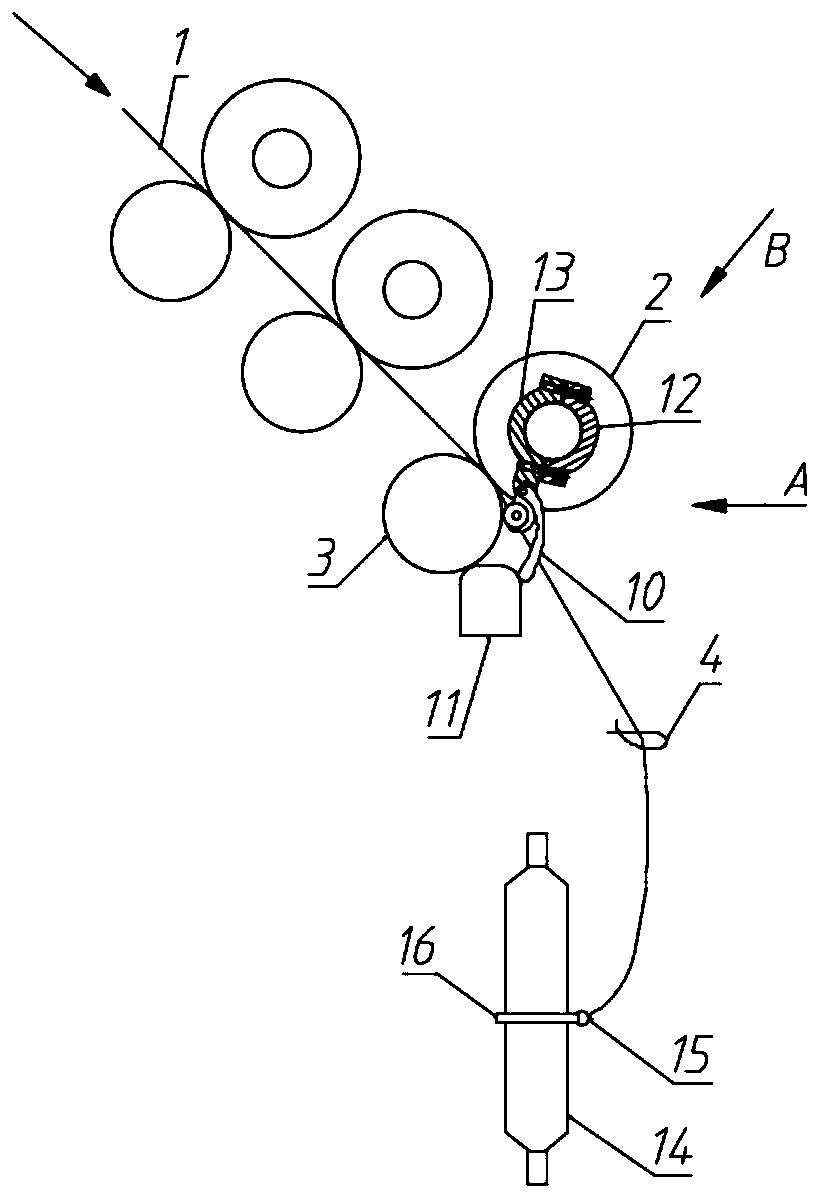

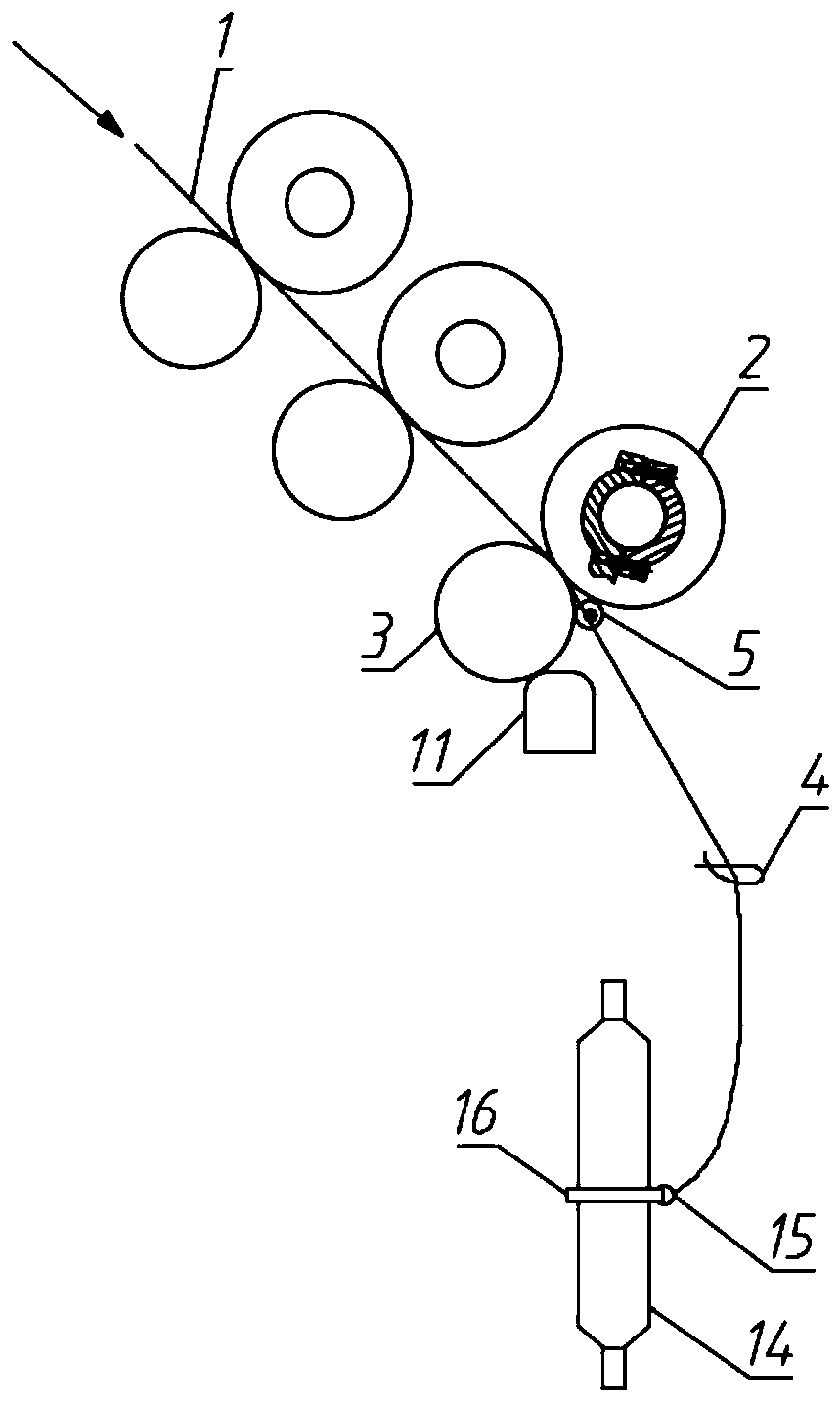

[0034] The two strands 1 are drawn out by the front top roller 2 and the front roller 3, and the distance between the two strands 1 is 3.5mm. Nipper area, so the strand 1 forms a twisting triangle 6, after the twisting triangle 6, the strand 1 obtains the twist passed from the convergence point 7 and becomes a single yarn 17;

[0035] After two single-ply yarns 17 are merged, they are further twisted into yarns similar to plying. When two single-ply yarns 17 are combined, they form a convergence point 7. At the convergence point 7, two single-ply yarns 17 single-ply yarns The included angle is 25 degrees.

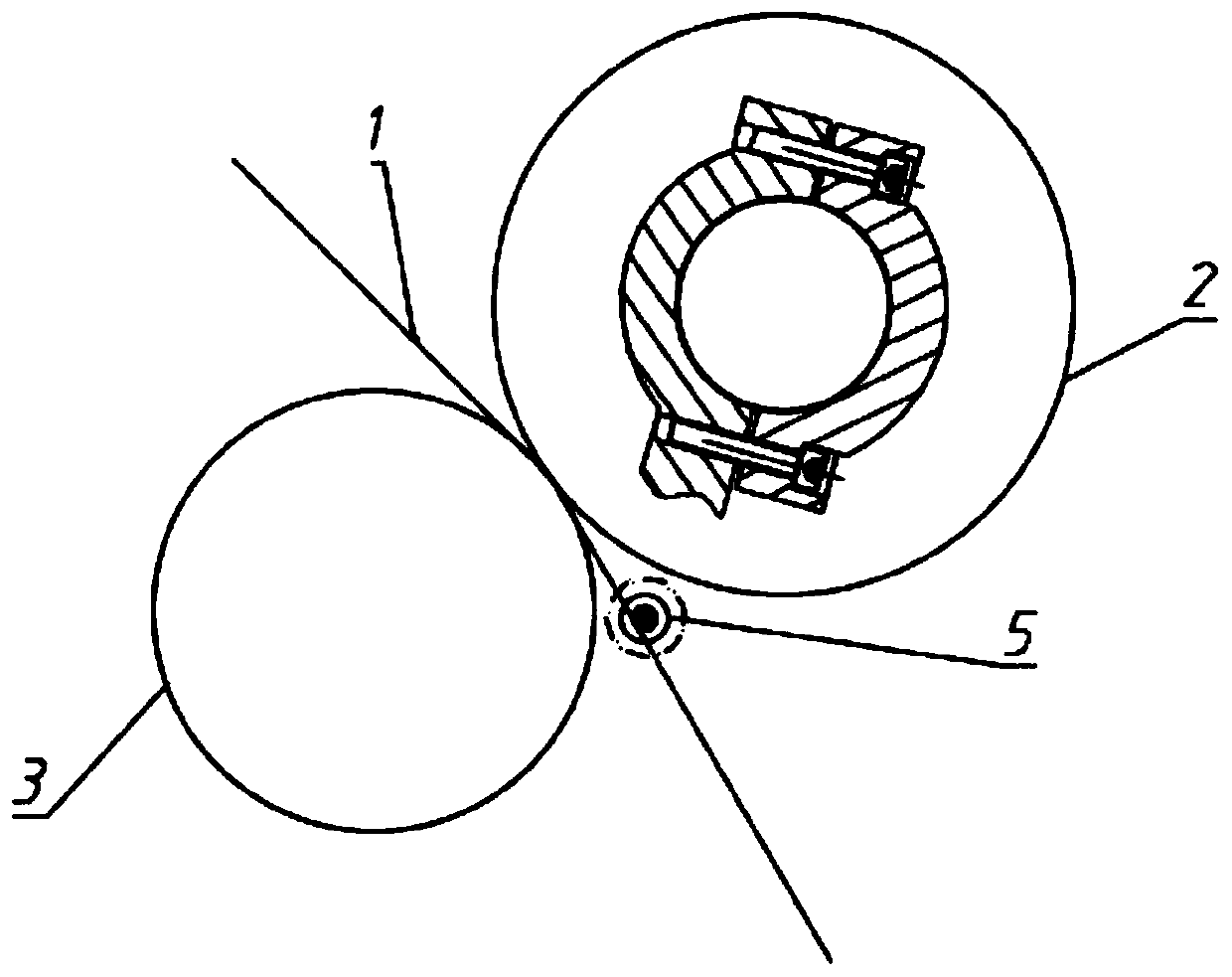

[0036] Such as Figure 1 to Figure 7 As shown, a siro spinning depilation device includes a depilation roller 5 arranged in the nip area formed by the front top roller 2 and the front roller 3, and the depilation roller 5 is free to rotate around the central axis.

[0037] The de-hairing roller 5 is specifically arranged between the front top roller 2 and the convergence po...

Embodiment 2

[0065] Such as Figure 8 As shown, in the present embodiment, the guide groove 9 on the de-hairing roller 5 is a V-shaped groove;

[0066] Preferably, the depth of the V-shaped groove is 0.5mm;

[0067] Preferably, the width of the upper end of the V-shaped groove is 0.8mm;

[0068] Preferably, the center distance between the two V-shaped grooves is 1.8mm;

[0069] Both sides of the V-shaped groove are provided with chamfers to make the yarn fall into the V-shaped groove smoothly.

[0070] The yarn enters the V-shaped groove. Since the V-shaped structure has a better binding effect on the yarn, the fibers protruding from the surface of the single-ply yarn 17 can be better rotated with the twisting and rotation of the single-ply yarn 17. Wrapped to the surface of the single yarn 17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com