Wetting agent for glass fiber twisted yarn of glass-fiber reinforced polypropylene needled mat

An alkali-free glass fiber and sizing technology, used in fiber processing, textiles and papermaking, etc., can solve the problem that glass fibers cannot meet customer performance requirements for products, and achieve outstanding mechanical and mechanical properties. Small, low hairiness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is specifically described below through specific examples, but the protection scope of the present invention is not restricted by the following examples.

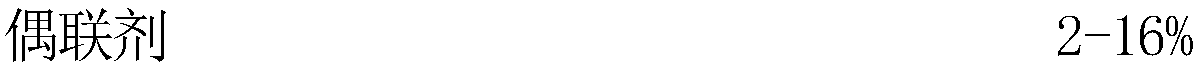

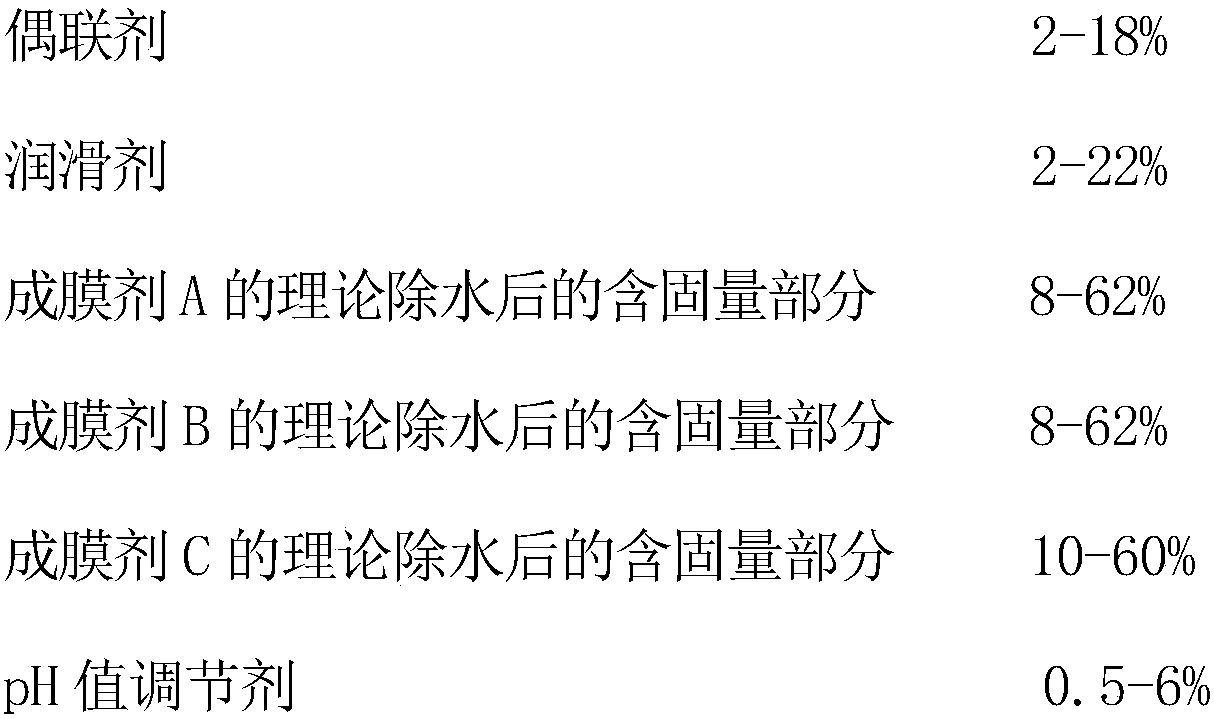

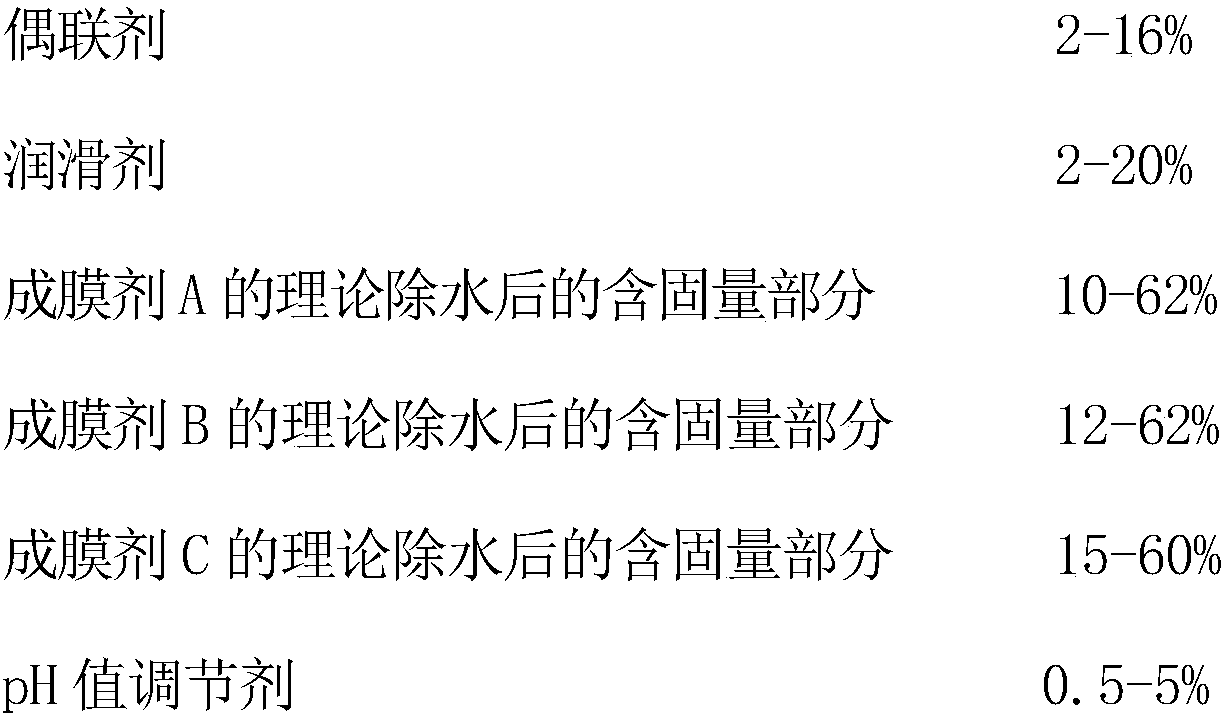

[0023] The components of the wetting agent used in the embodiments of the present invention are as follows:

[0024] The coupling agent is an aminosilane coupling agent produced by Shanghai Guandu Industrial Co., Ltd., and the product grades are A-174 and A-1100 respectively;

[0025] The lubricant is a cationic ammonium salt lubricant, Kekai, and the product grades are 1106, 1107;

[0026] Described film-forming agent A is polyurethane resin emulsion, Nanjing Yi Shengchang, product name is mn088;

[0027] The film-forming agent B is an acrylic emulsion emulsion, which was purchased from Jiangsu Zhonghe Chemical Co., Ltd.

[0028] The film-forming agent C is PVAC emulsion, Jiangsu Zhonghe Chemical Co., Ltd.

[0029] The pH adjuster is a mixture of acetic acid and citric acid, the mass ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com