Hairiness color-mixed false-twist processed yarn as well as preparation method and application thereof

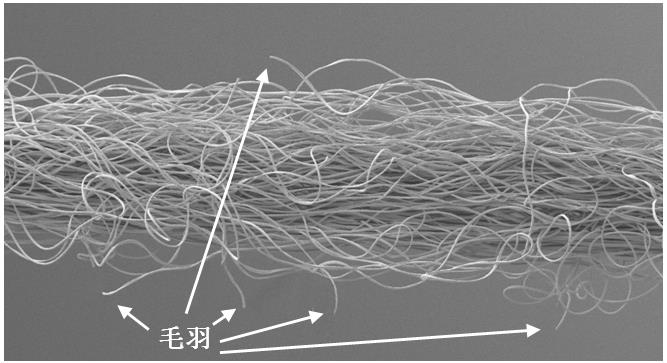

A color mixing and false twisting technology, applied in textiles, papermaking, yarn and other directions, can solve the problems of easy pilling, difficult to control the length of hairiness, affecting the visual effect, etc., and achieve the effect of good anti-pilling effect and good color mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

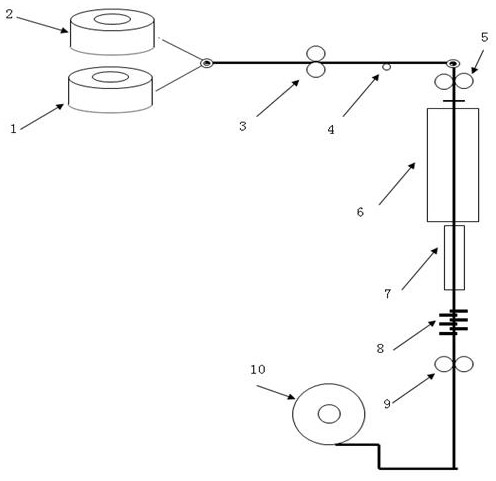

Method used

Image

Examples

Embodiment 1

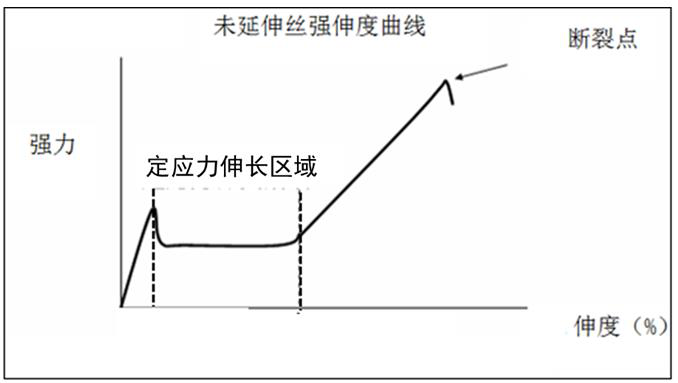

[0044]The ordinary polyester PET (SD) filament POY with a monofilament fineness of 0.89dtex and the cationic dyeable polyester (CD) filament with a monofilament fineness of 1.96dtex are merged and fed to the first roller, and then stretched by hot needles. The elongation ratio is 1.162, and then passes through the second roller, and then enters the hot box for heating. The temperature of the first hot box (1HT) is 175°C. It is cooled by the cooling plate, and then enters the false twisting disc for false twisting deformation, where the untwisting tension is the same as The ratio of twisting tension is 0.53, and then it passes through the nozzle for intertwining and then winding forming. Among the mixed filament yarns obtained by winding, the measured number of hairiness lengths of 1 mm or more was 813 pieces / 1000 meters, and the measured number of hairiness lengths of 2 mm or more was 29 pieces / 1000 meters. After dyeing the fabric made from the hairiness melange false-twisted ...

Embodiment 2

[0046] The ordinary polyester PET (SD) filament POY with a monofilament fineness of 1.96dtex and the cationic dyeable polyester (CD) filament with a monofilament fineness of 0.89dtex are combined and fed to the first roller, and then stretched by hot needles. The elongation ratio is 1.162, and then passes through the second roller, and then enters the hot box for heating. The temperature of the first hot box (1HT) is 175°C, and it is cooled by the cooling plate, and then enters the false twisting disc for false twisting deformation, where the untwisting tension is the same as The ratio of twisting tension is 0.53, and then it passes through the nozzle for intertwining and then winding forming. Among the mixed filament yarns obtained by winding, the number of measured hairiness lengths of 1 mm or more was 900 pieces / 1000 m, and the number of measurement numbers of hairiness lengths of 2 mm or more was 35 pieces / 1000 m. After dyeing the fabric made from the hairiness melange fal...

Embodiment 3

[0048] The ordinary polyester PET (SD) filament POY with a monofilament fineness of 0.89dtex and the cationic dyeable polyester (CD) filament with a monofilament fineness of 1.96dtex are merged and fed to the first roller, and then stretched by hot needles. The elongation ratio is 1.162, and then passes through the second roller, and then enters the hot box for heating. The temperature of the first hot box (1HT) is 175°C, and it is cooled by the cooling plate, and then enters the false twisting disc for false twisting deformation, where the untwisting tension is the same as The ratio of twisting tension is 0.30, and then it passes through the nozzle for intertwining and then winding forming. In the mixed fiber yarn obtained by winding, the measured number of hairiness length 1mm or more was 350 pieces / 1000m, and the measurement number of hairiness length 2mm or more was 15 pieces / 1000m. After dyeing the fabric made from the hairiness melange false-twisted processed yarn, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com