Cotton/chinlon FDY high count yarn for warp knitting and spinning method thereof

A high-count yarn, nylon technology, applied in the field of textile processing, can solve the problems of broken yarn weaving, unsatisfactory cotton yarn strength, flying flowers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

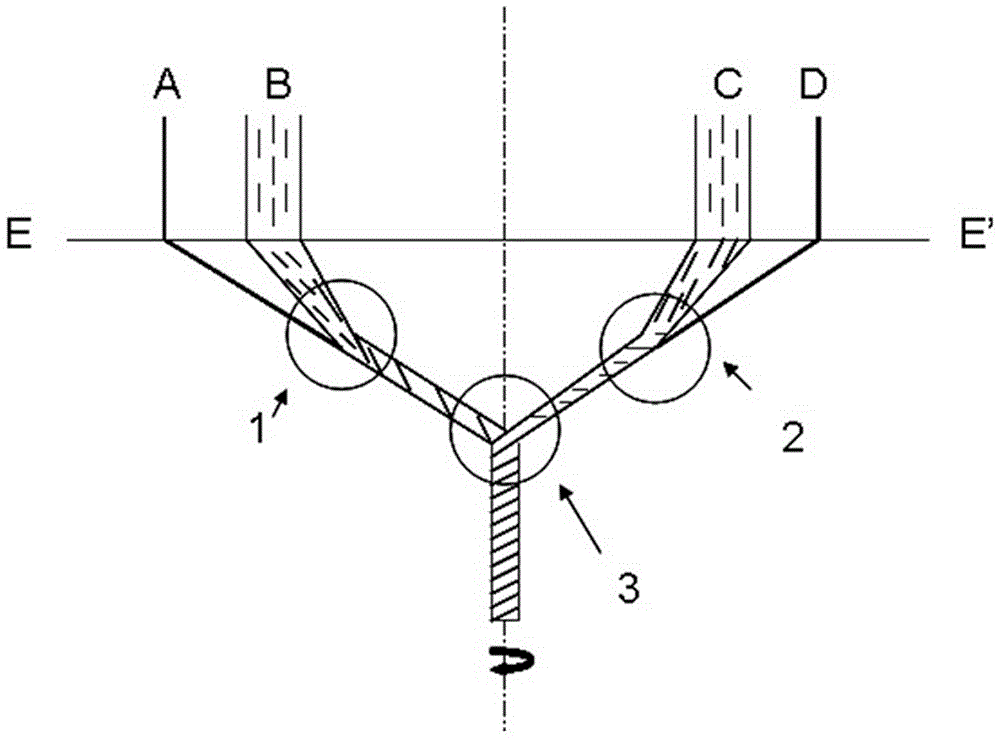

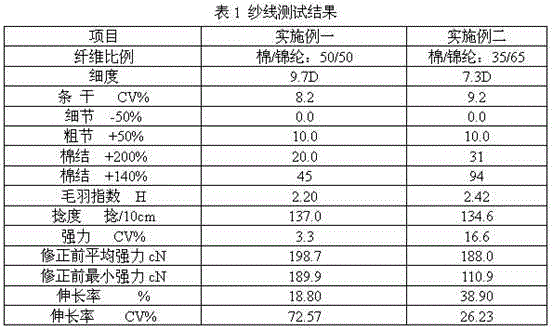

[0021] According to the above process steps: select 2.25g / 10m 100% long-staple cotton roving and 10D / 6F nylon filament yarn as spinning raw materials, set two long-staple cotton rovings in the middle positions B and C, and two nylon long yarns Silk yarns are arranged at positions A and D on both sides. Set twisting triangle one 1; 2——twisting triangle two 2; twisting triangle three 3 air negative pressure range is set at 0.15Mpa, and the yarn test results obtained after spinning on spinning frame are shown in Table 1.

Embodiment 2

[0023] According to the above process steps: select 2.25g / 10m 100% long-staple cotton roving and 15D / 3F nylon filament yarn as spinning raw materials, set two long-staple cotton rovings in the middle positions B and C, and two nylon long yarns Silk yarns are arranged at positions A and D on both sides. Set twisting triangle one 1; 2——twisting triangle two 2; twisting triangle three 3 air negative pressure range is set at 0.15Mpa, and the yarn test results obtained after spinning on spinning frame are shown in Table 1.

[0024]

[0025] The test results show that the yarn strength of the finished yarn spun by the present invention can meet the requirements of the warp knitting yarn, and the hairiness index is low at the same time. Because the fineness of the nylon FDY filament yarn used is small, and there are many cotton fibers on the surface, the warp knitted fabric made of this yarn has an obvious cotton feeling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com