Patents

Literature

3083 results about "Warp knitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

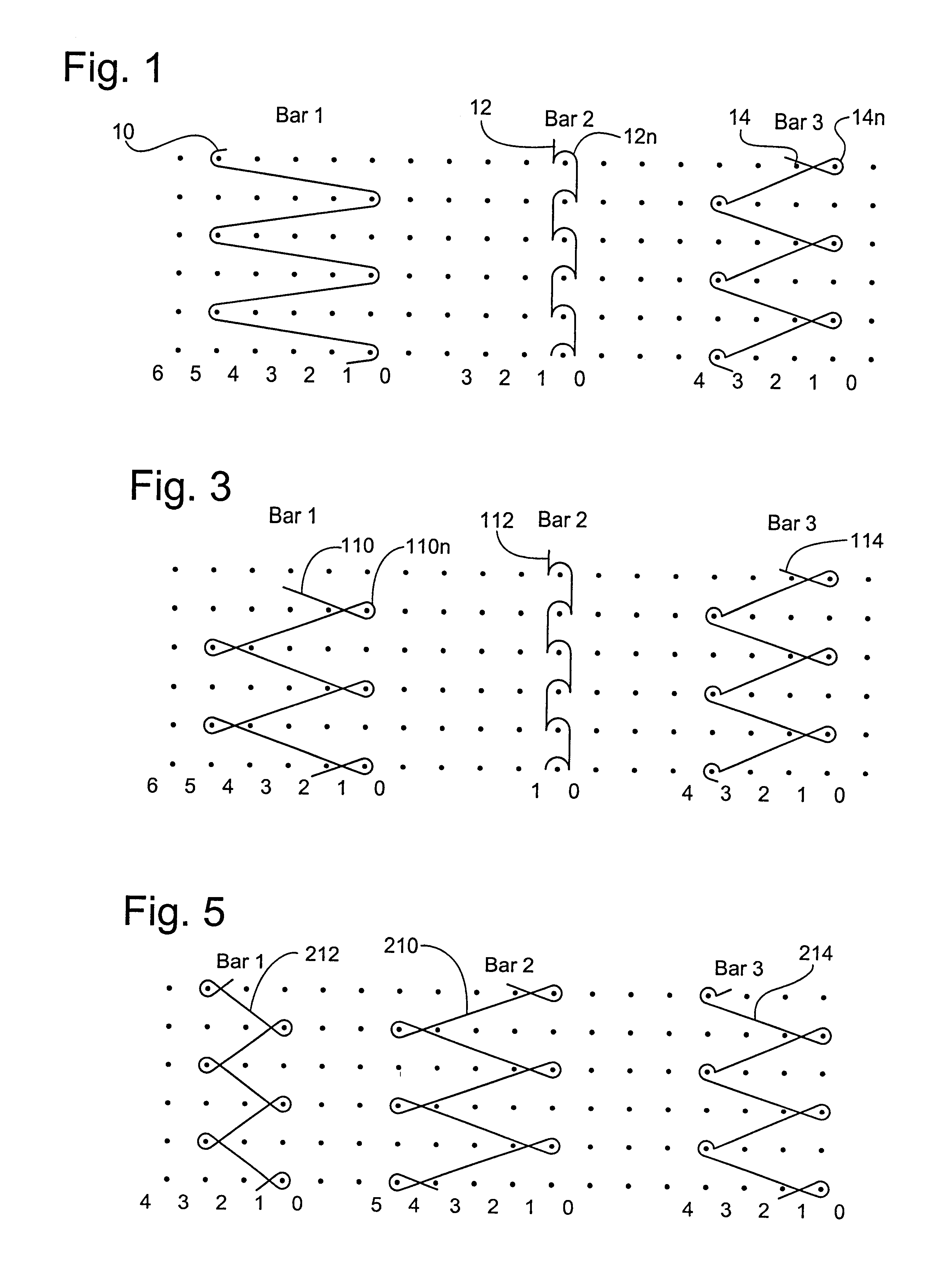

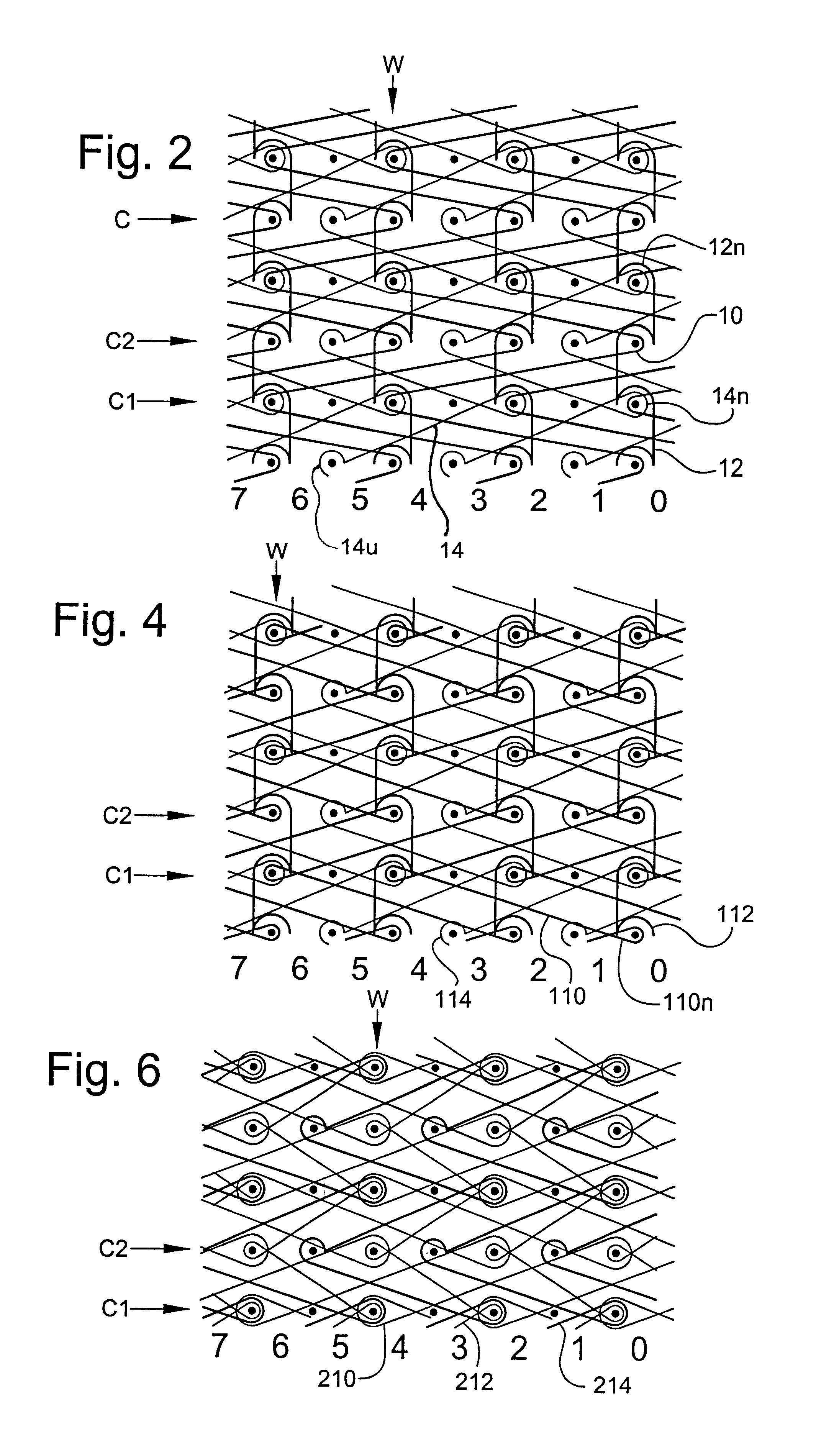

Warp knitting is a family of knitting methods in which the yarn zigzags along the length of the fabric; i.e., following adjacent columns, or wales, of knitting, rather than a single row, or course. For comparison, knitting across the width of the fabric is called weft knitting.

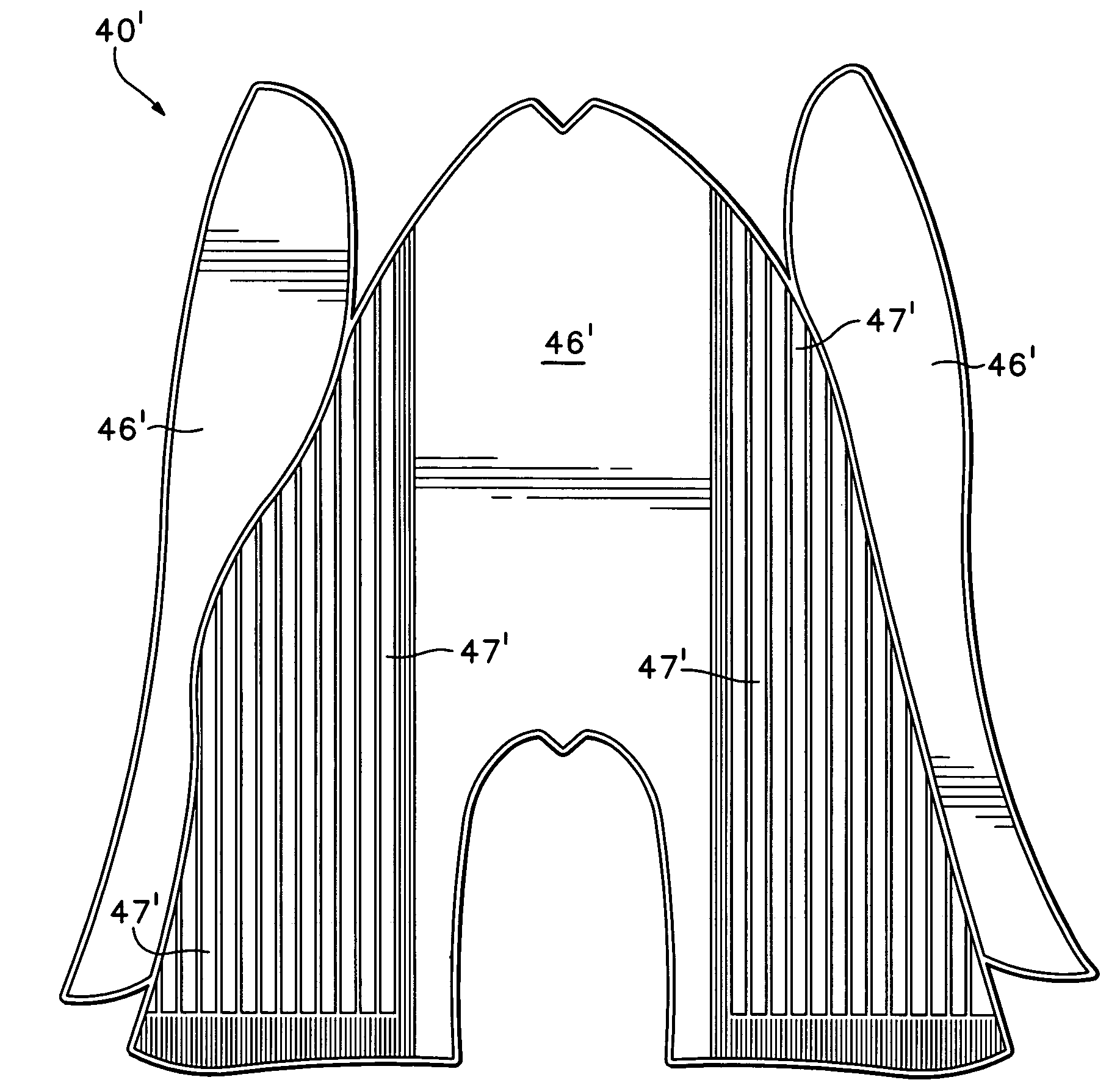

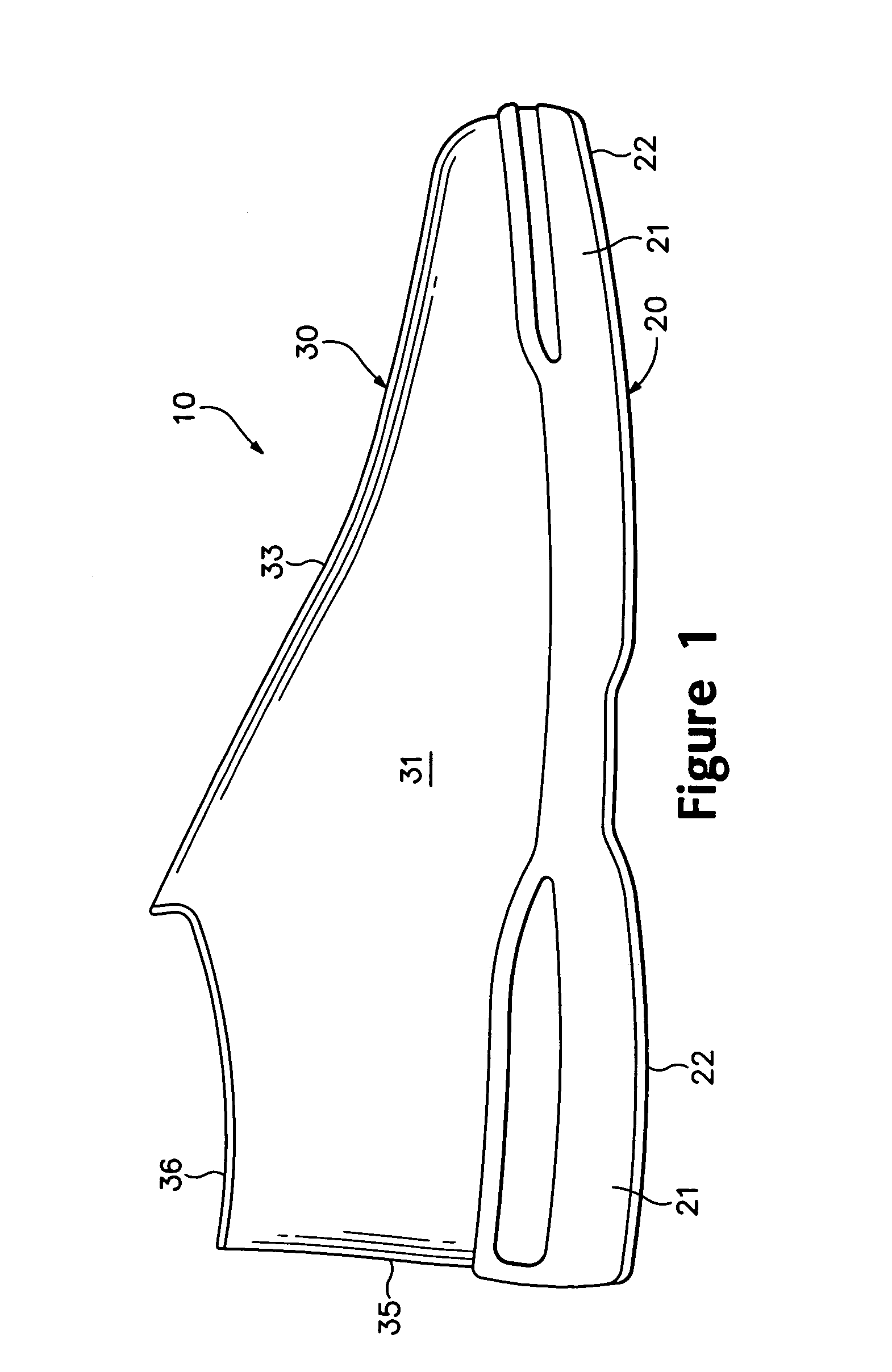

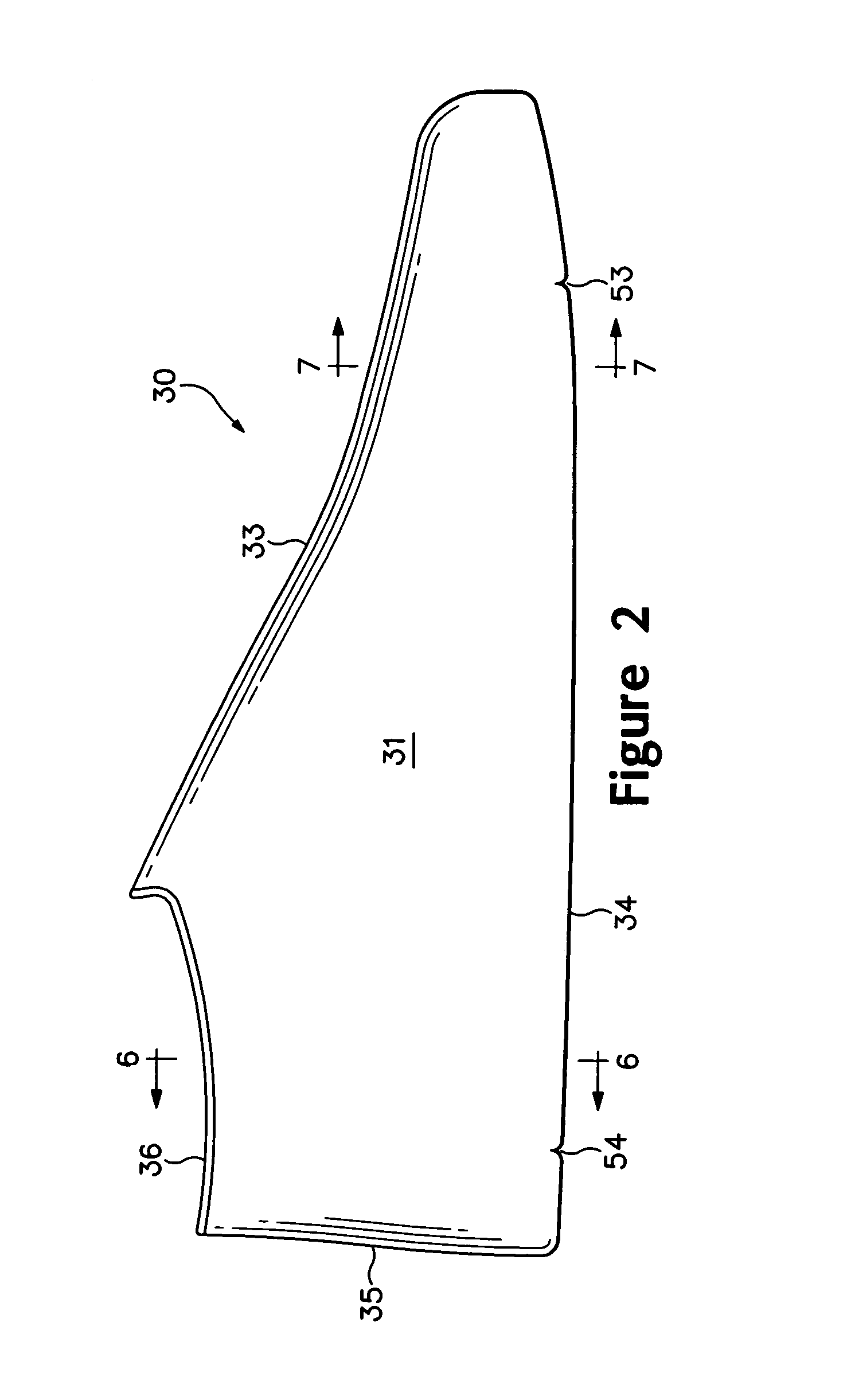

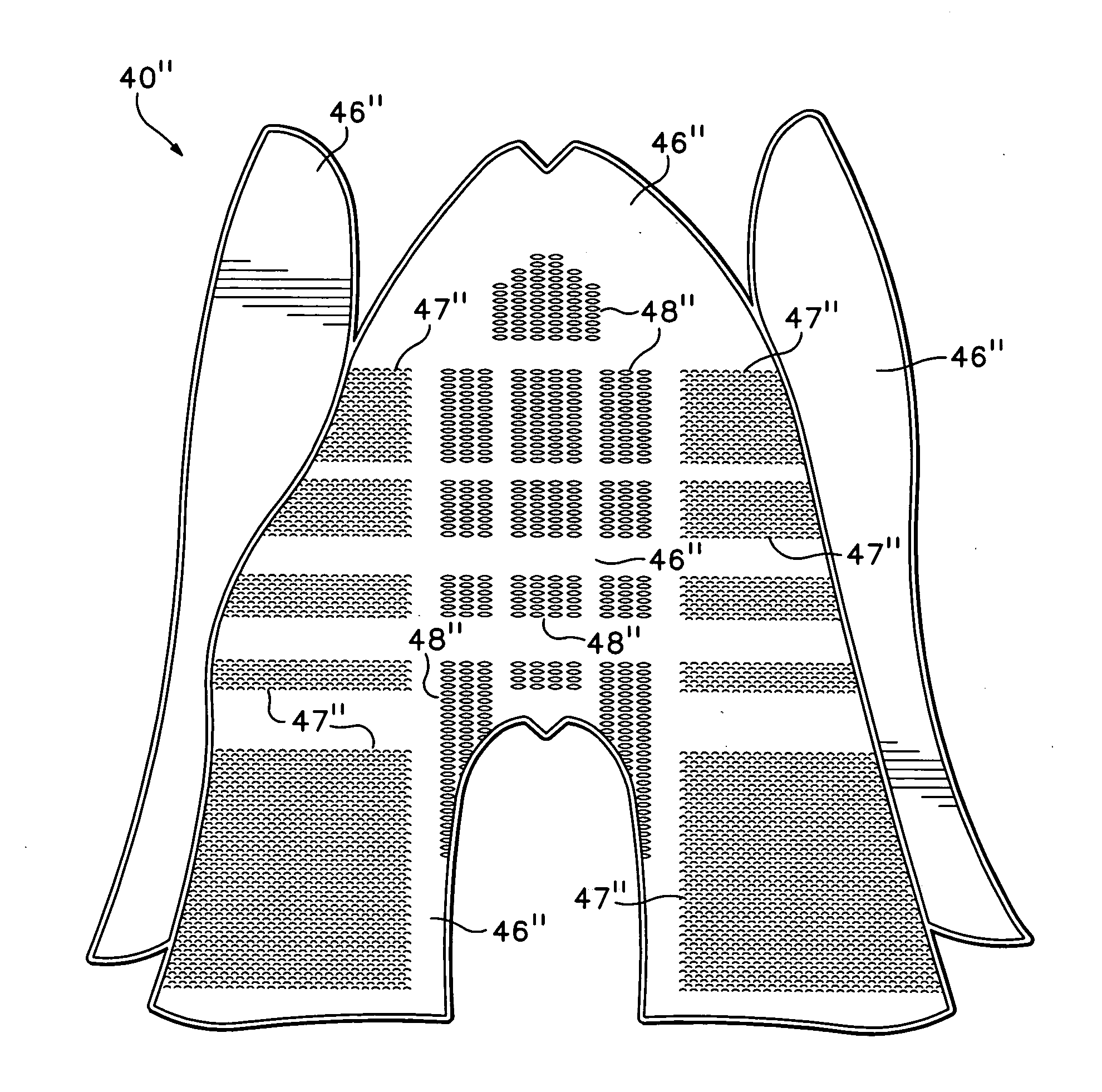

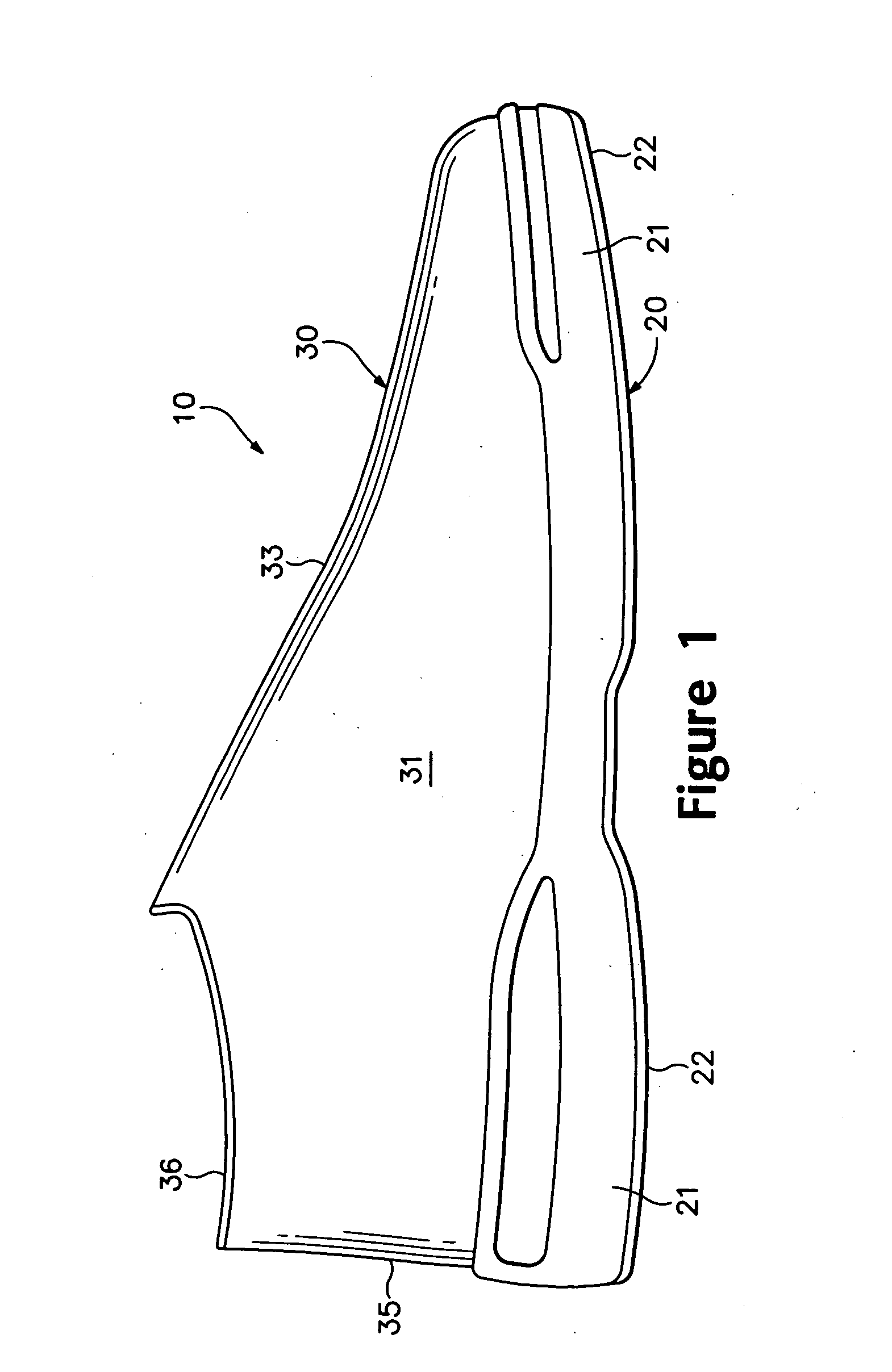

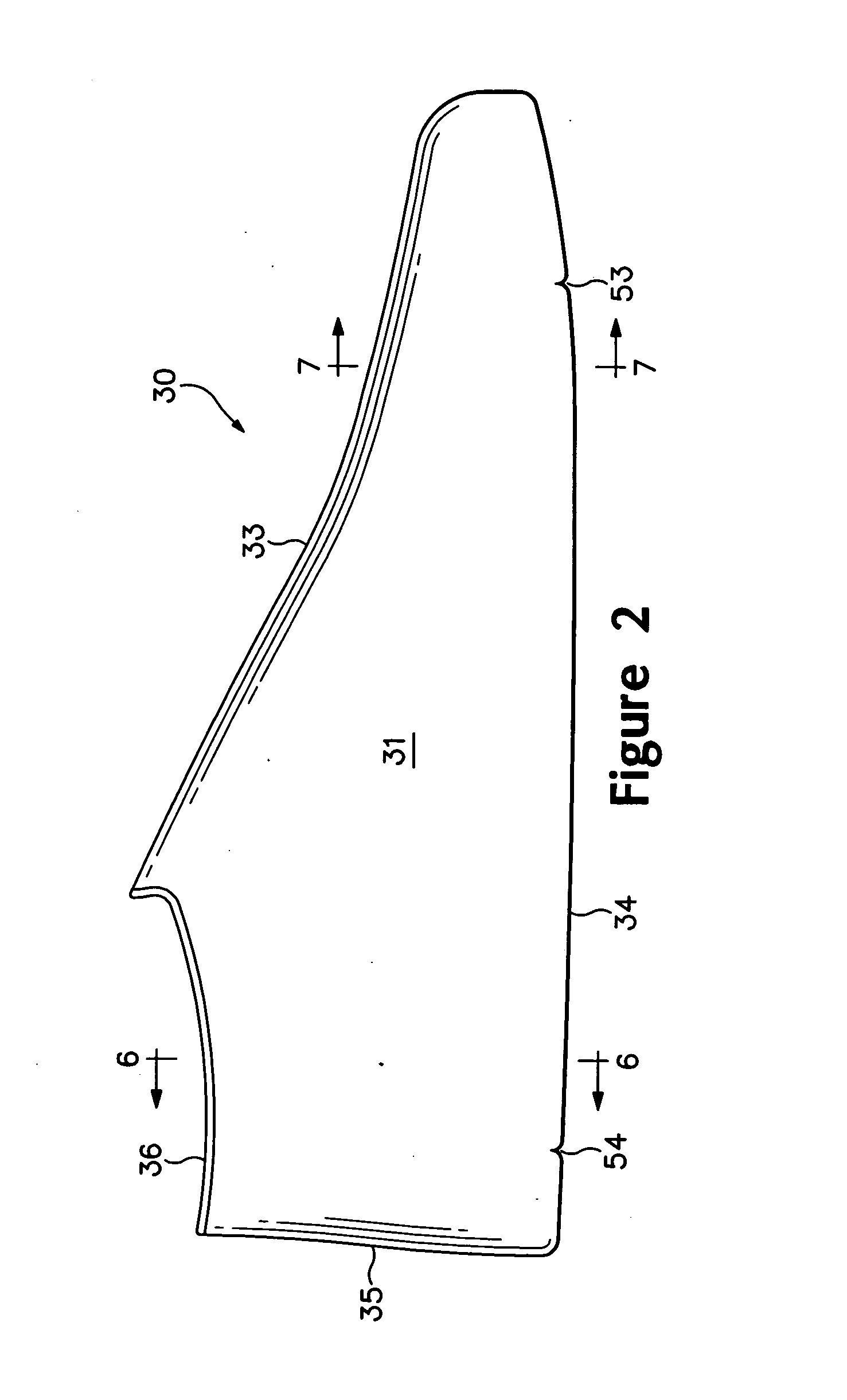

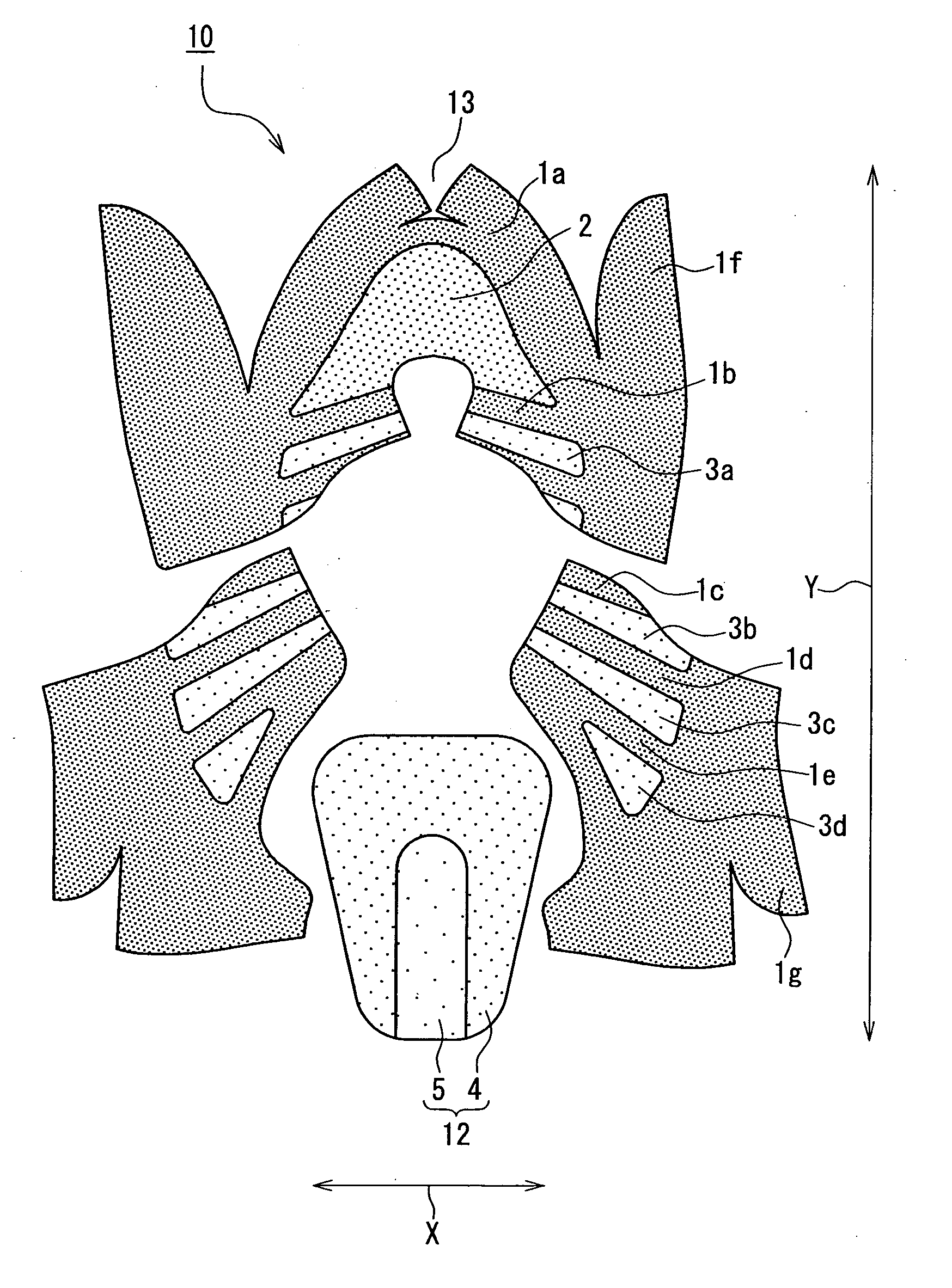

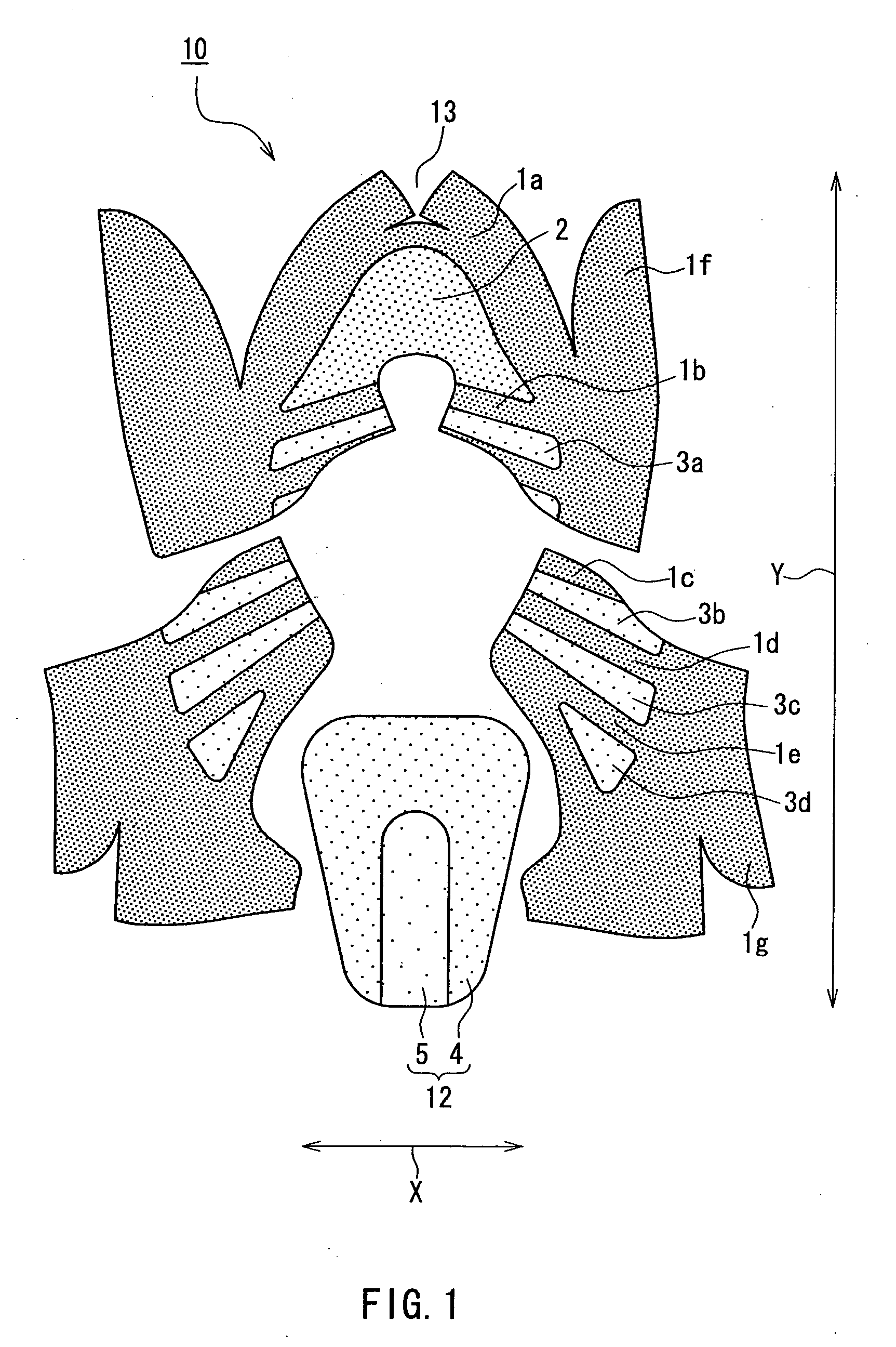

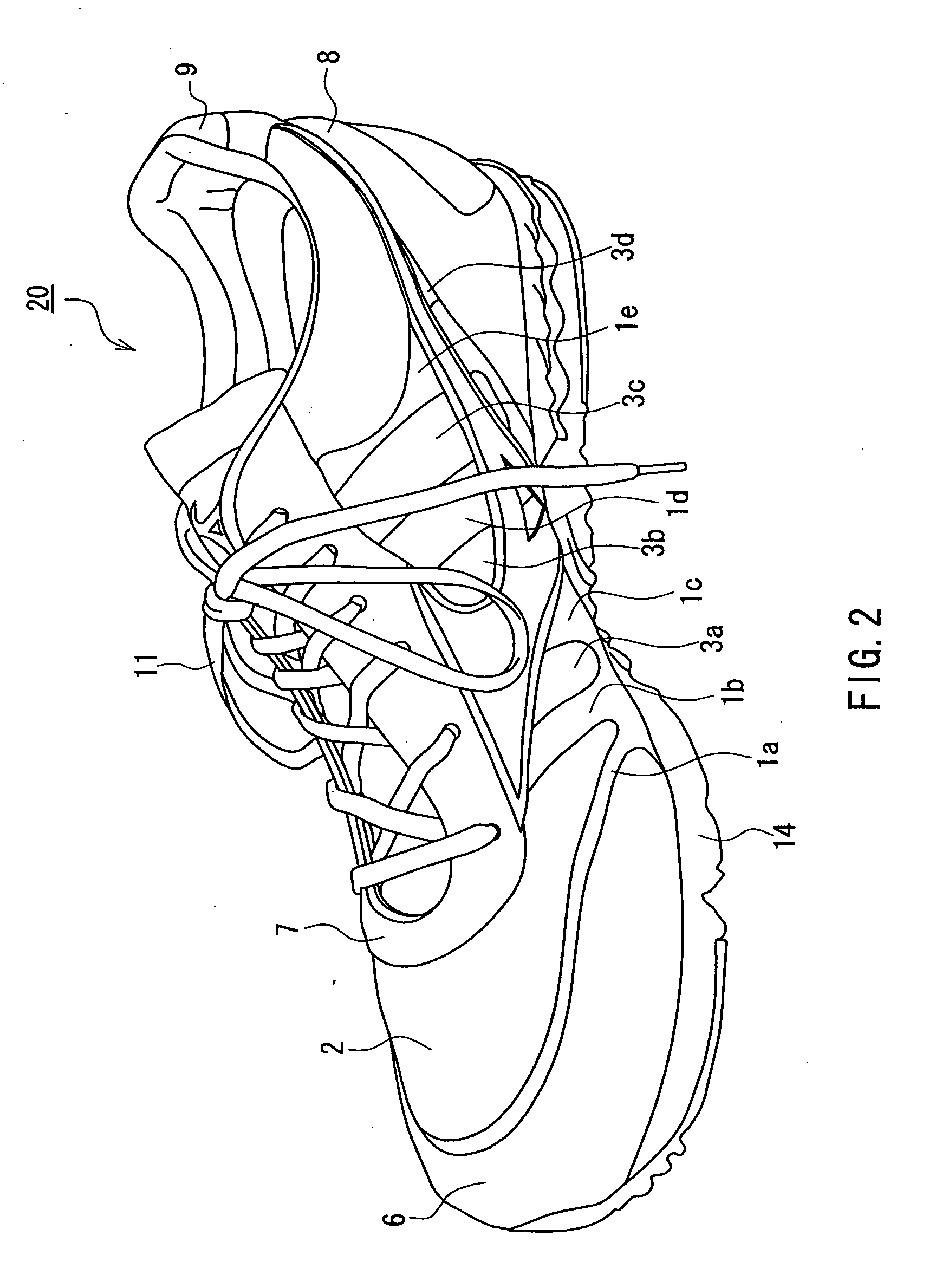

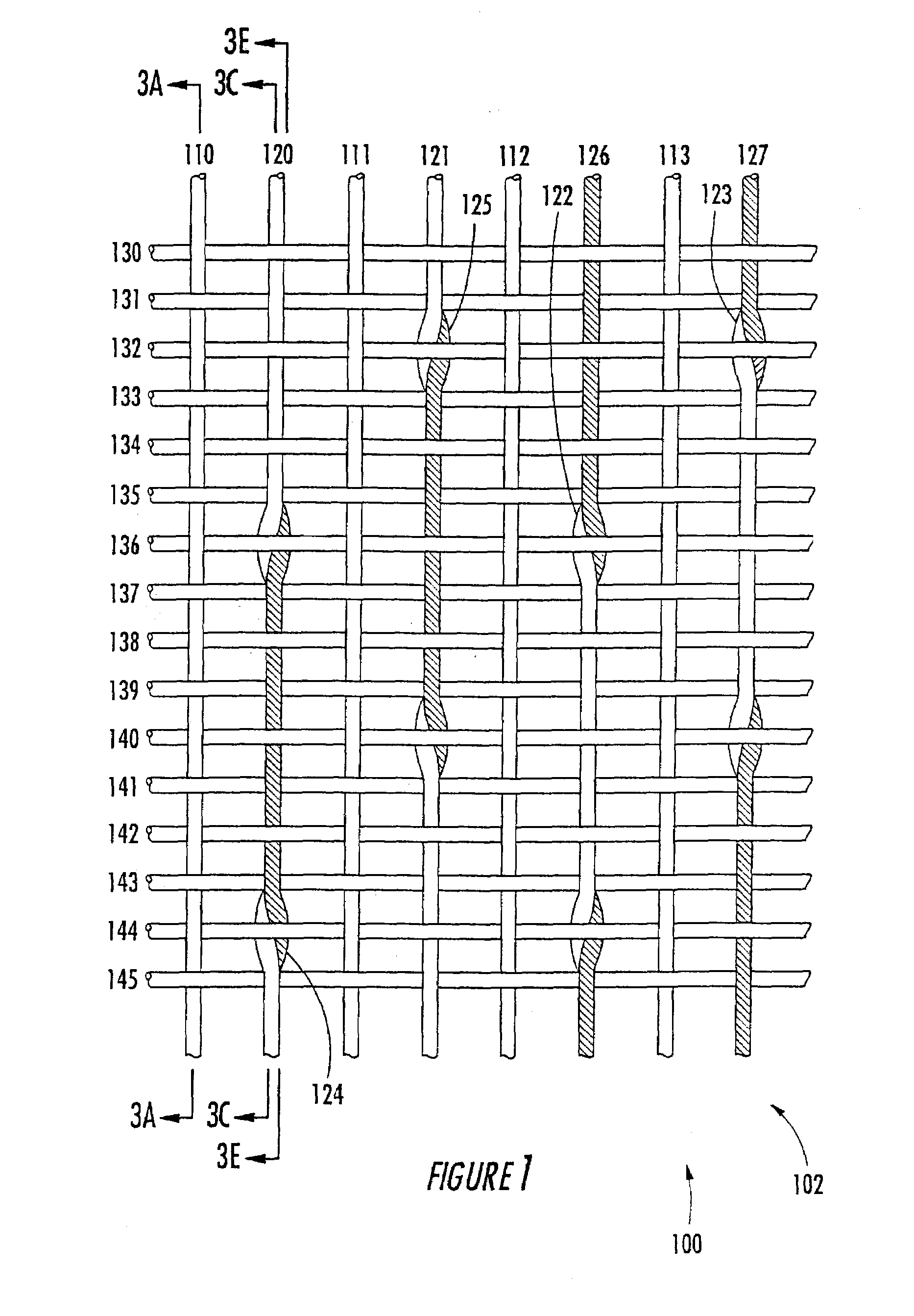

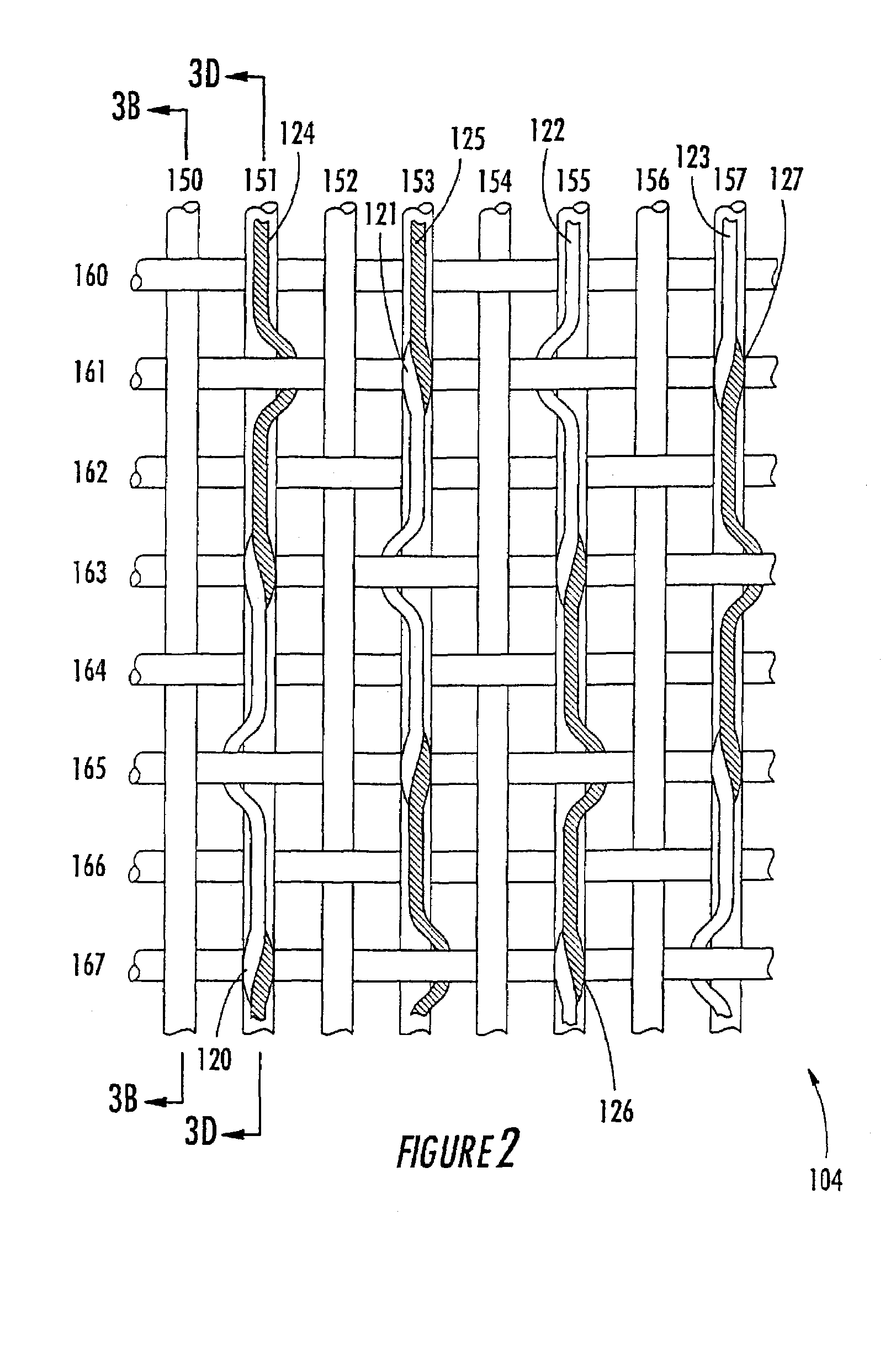

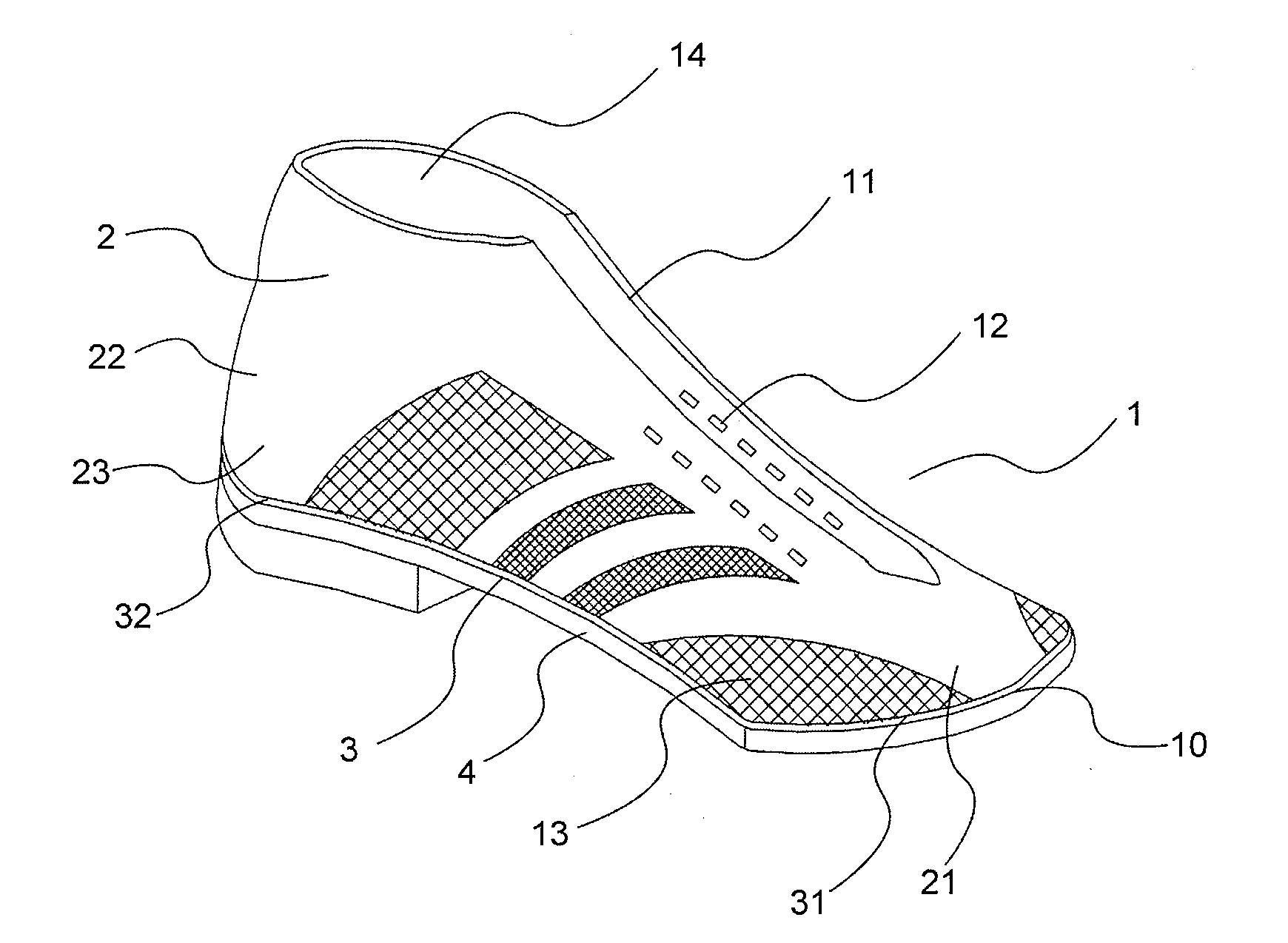

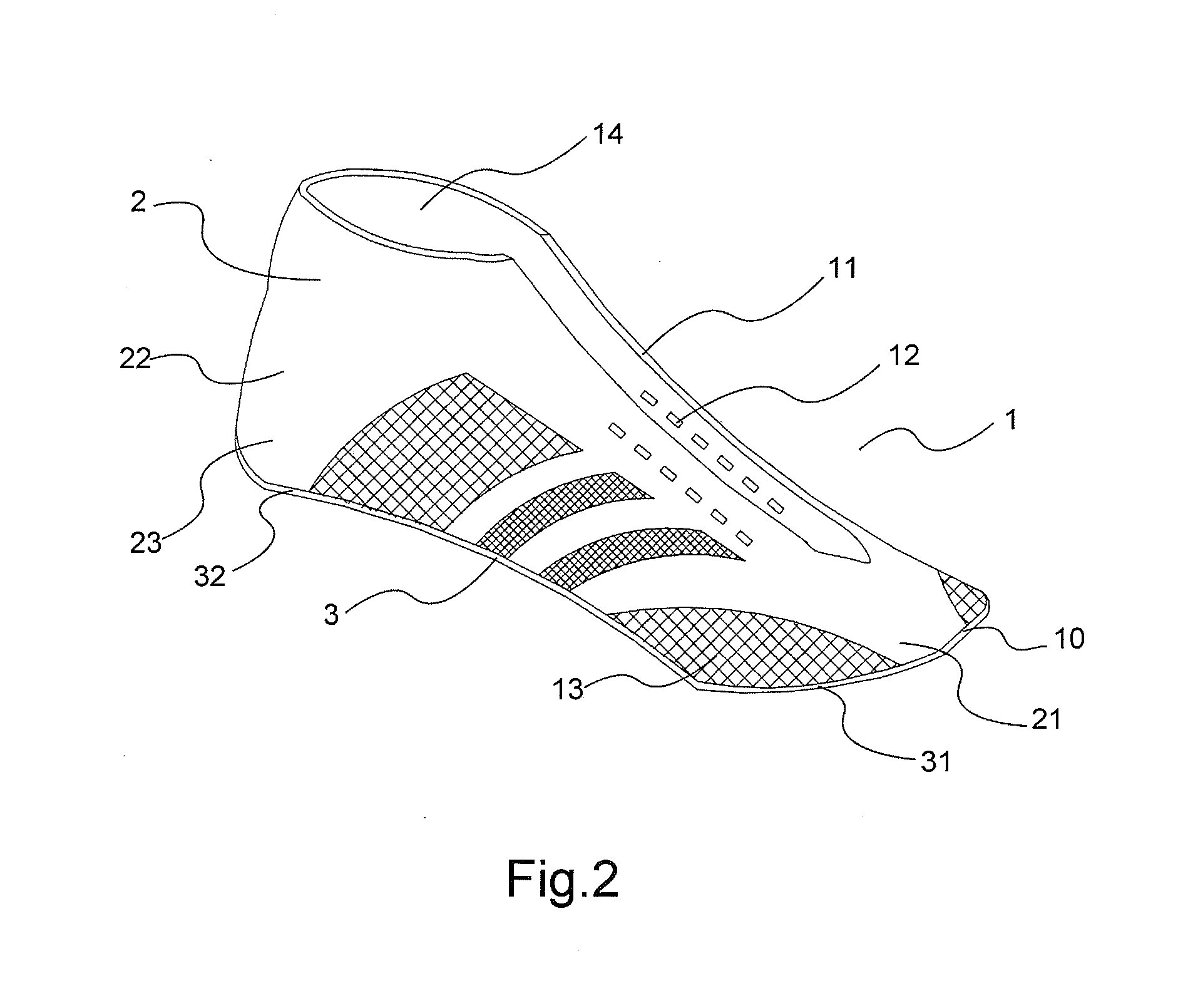

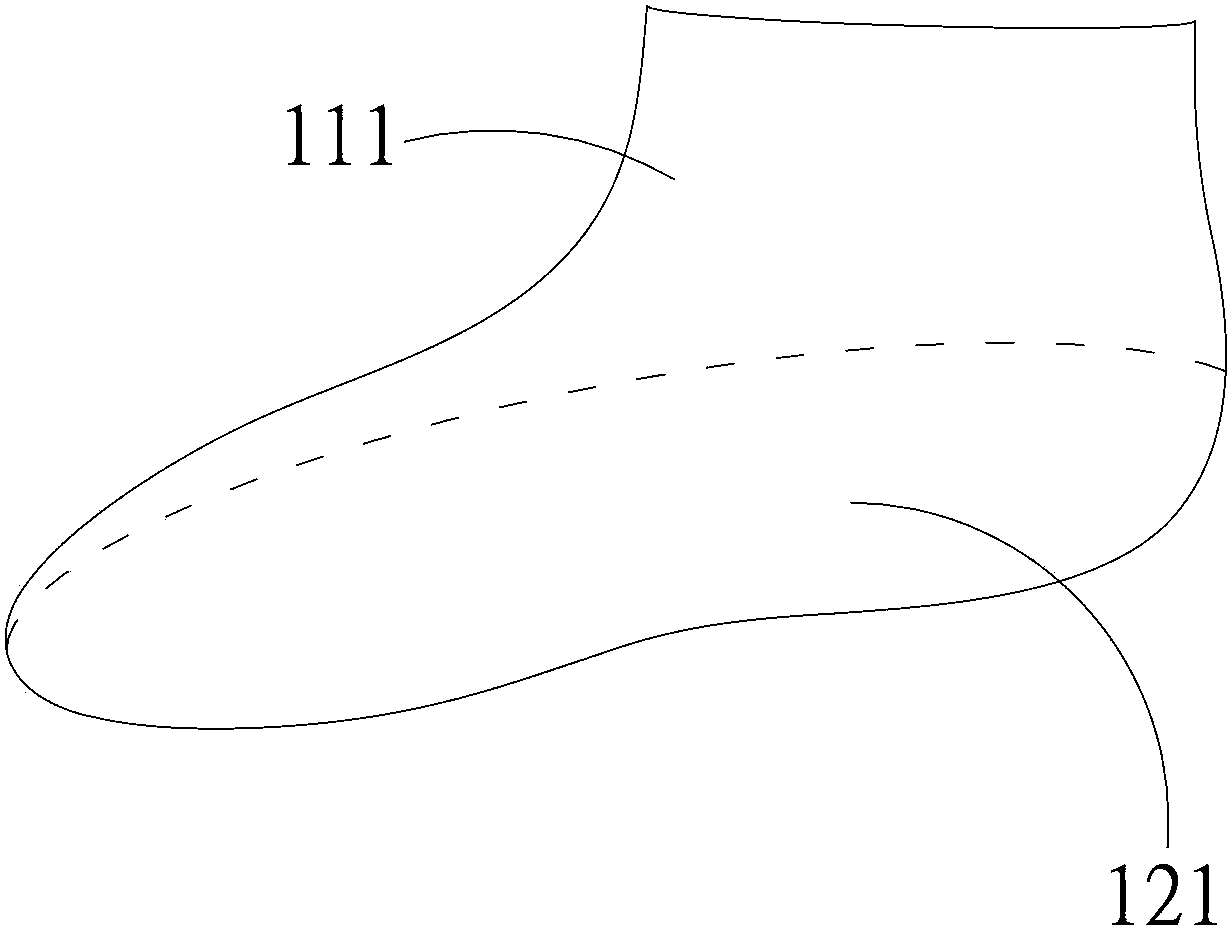

Article of footwear having a textile upper

An article of footwear and a method of manufacturing the article of footwear are disclosed. The footwear may include an upper and a sole structure. The upper incorporates a textile element with edges that are joined together to define at least a portion of a void for receiving a foot. The textile element may also have a first area and a second area with a unitary construction. The first area is formed of a first stitch configuration, and the second area is formed of a second stitch configuration that is different from the first stitch configuration to impart varying textures to a surface of the textile element. Various warp knitting or weft knitting processes may be utilized to form the textile element.

Owner:NIKE INC

Article of footwear having a textile upper

ActiveUS20050193592A1Improve understandingShoemaking devicesWeft knittingEngineeringMechanical engineering

An article of footwear and a method of manufacturing the article of footwear are disclosed. The footwear may include an upper and a sole structure. The upper incorporates a textile element with edges that are joined together to define at least a portion of a void for receiving a foot. The textile element may also have a first area and a second area with a unitary construction. The first area is formed of a first stitch configuration, and the second area is formed of a second stitch configuration that is different from the first stitch configuration to impart varying textures to a surface of the textile element. Various warp knitting or weft knitting processes may be utilized to form the textile element.

Owner:NIKE INC

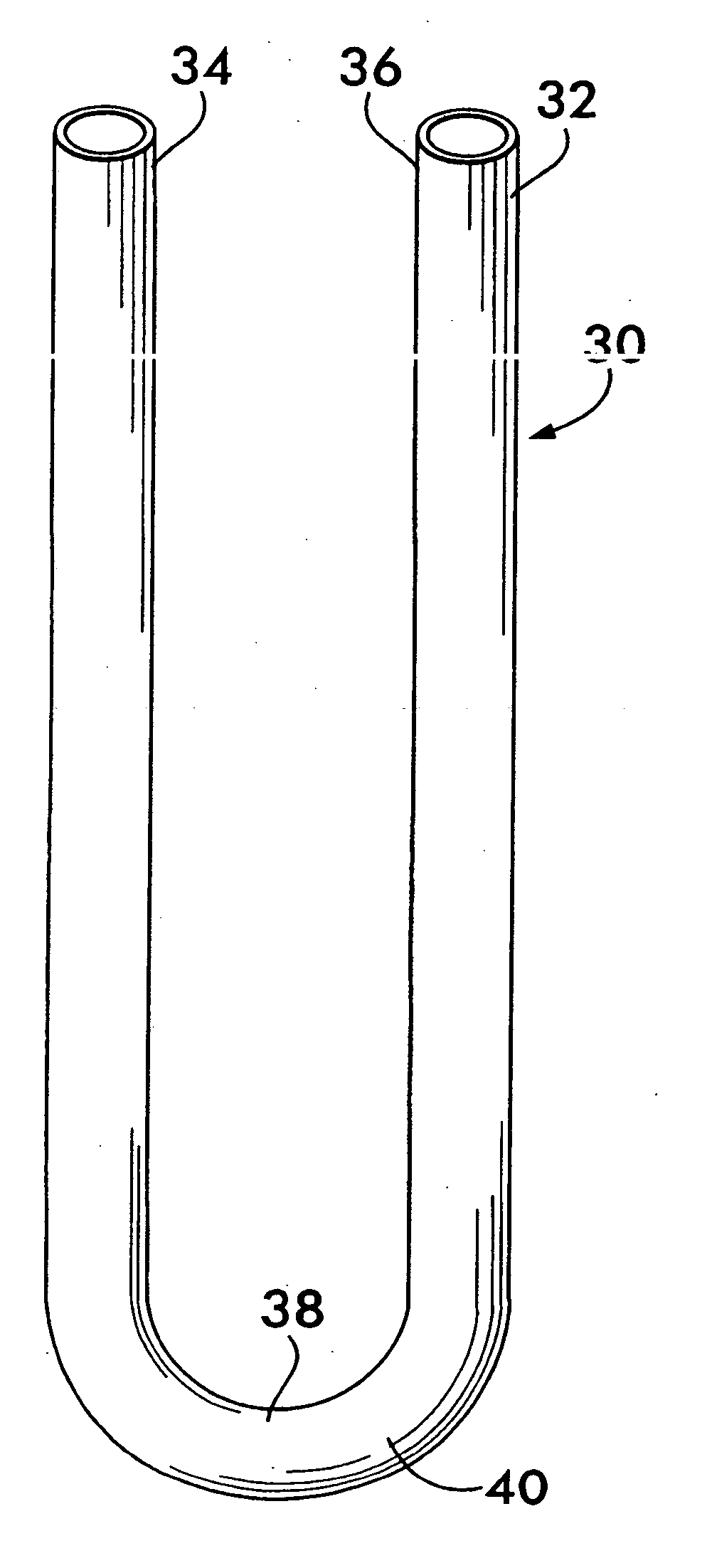

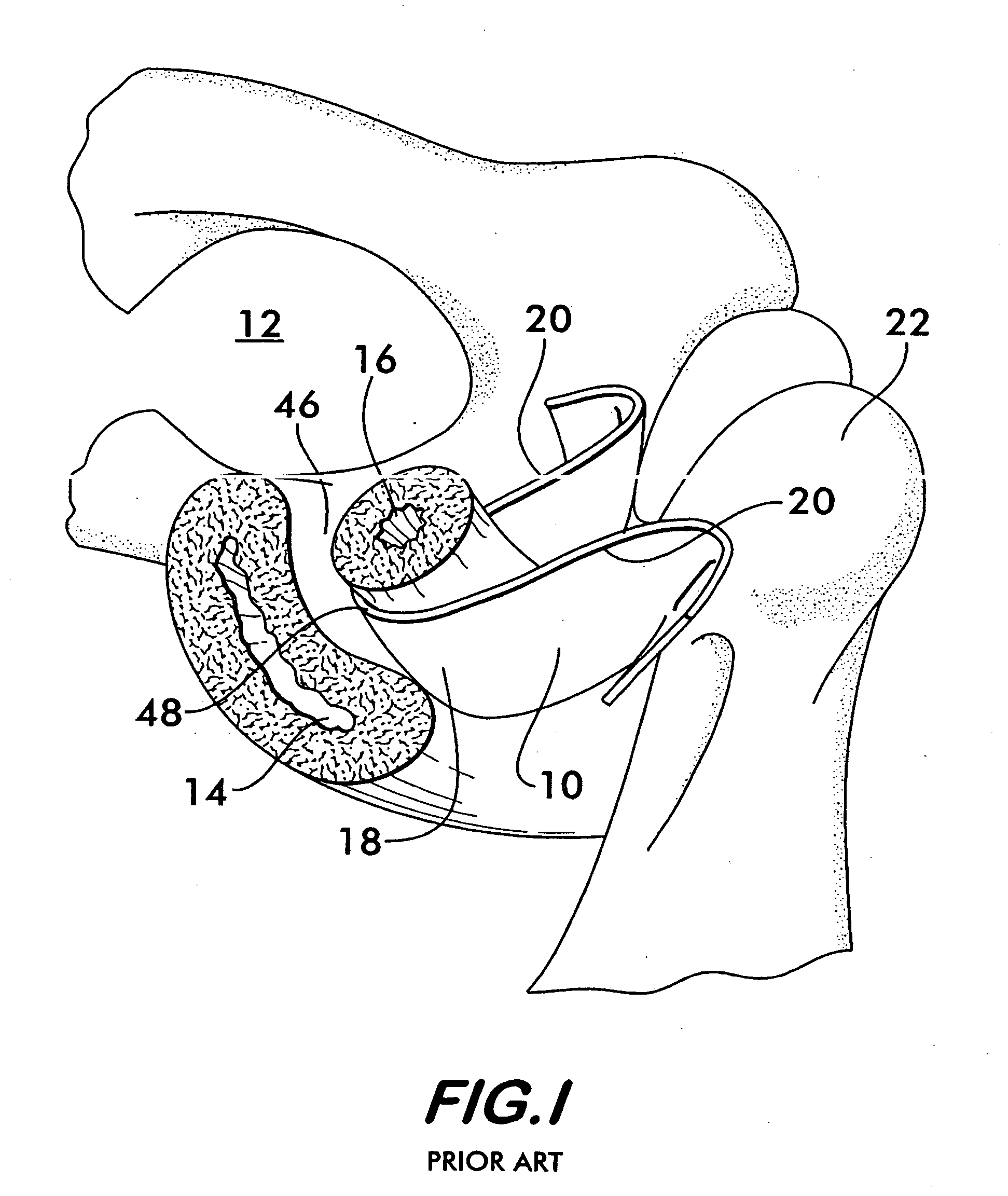

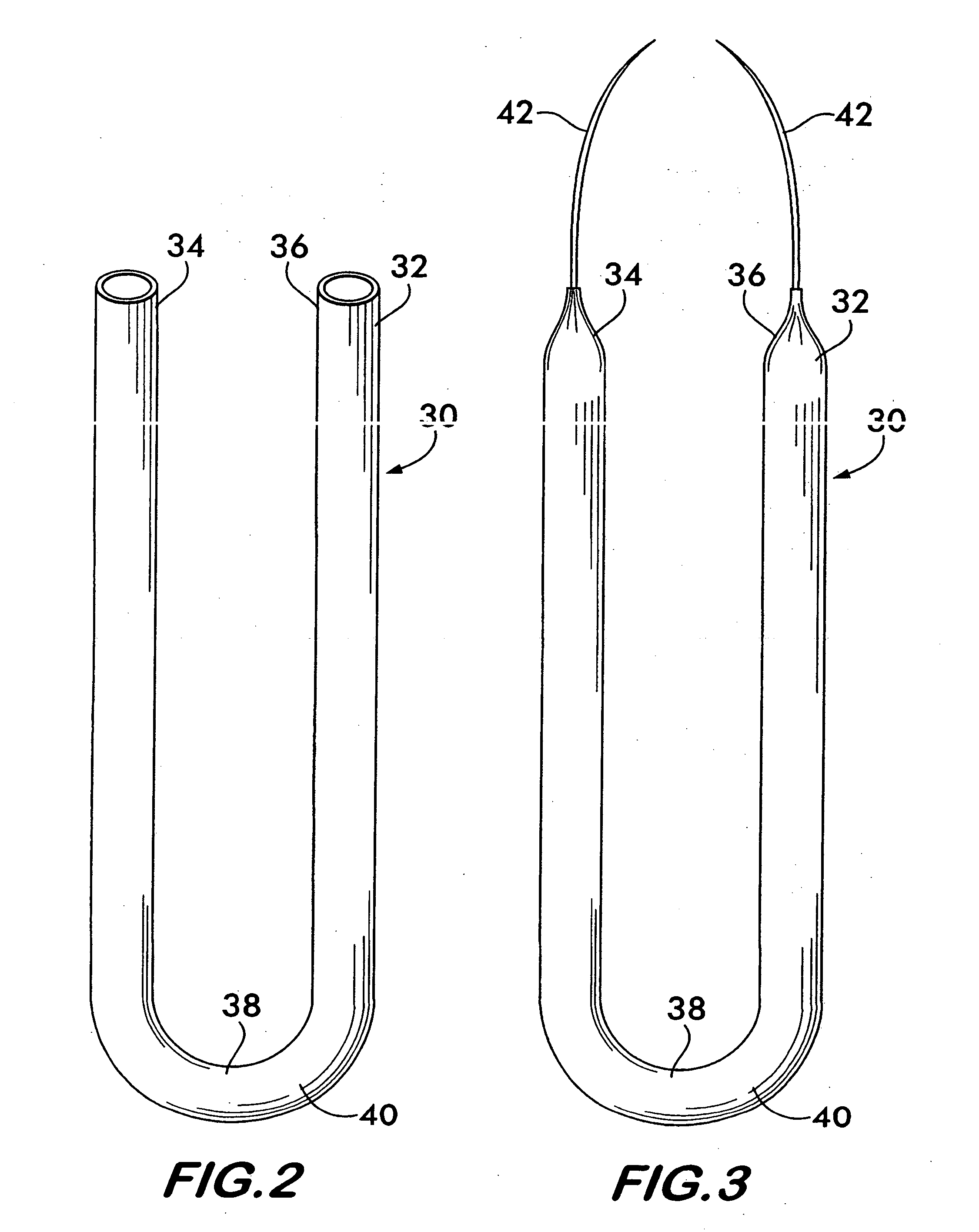

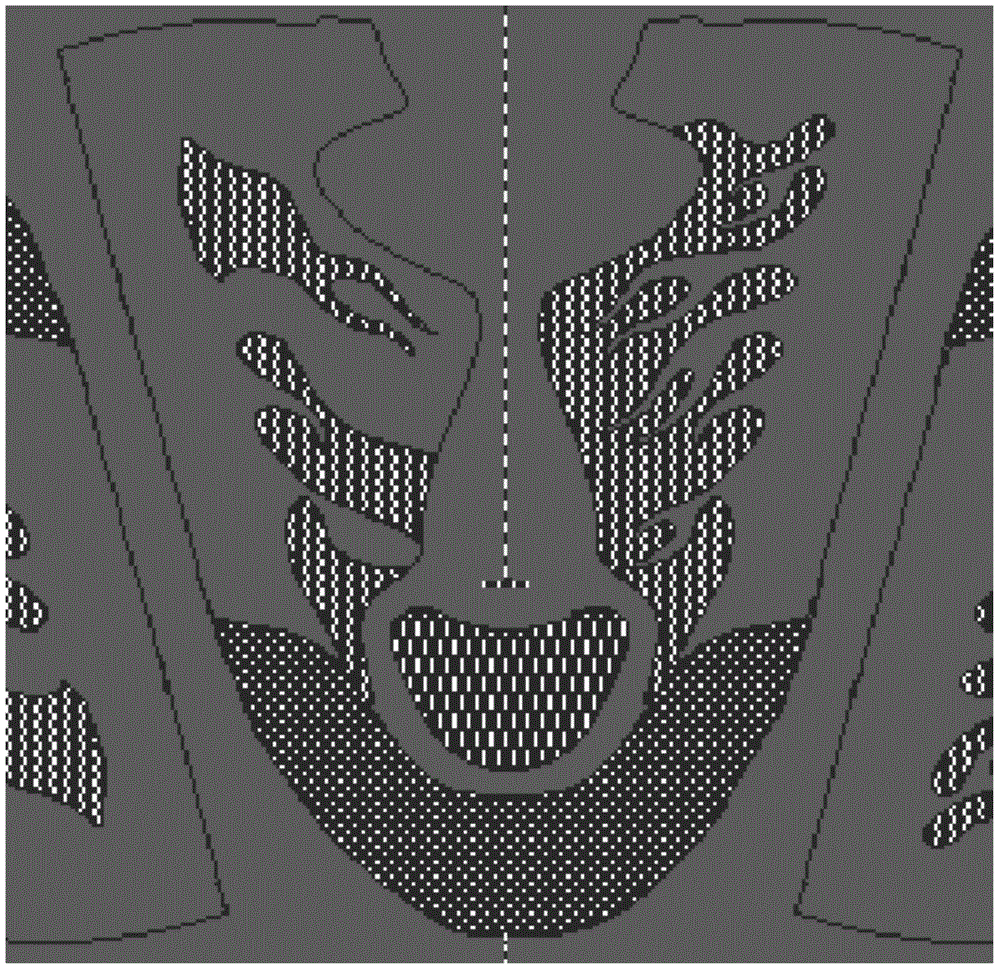

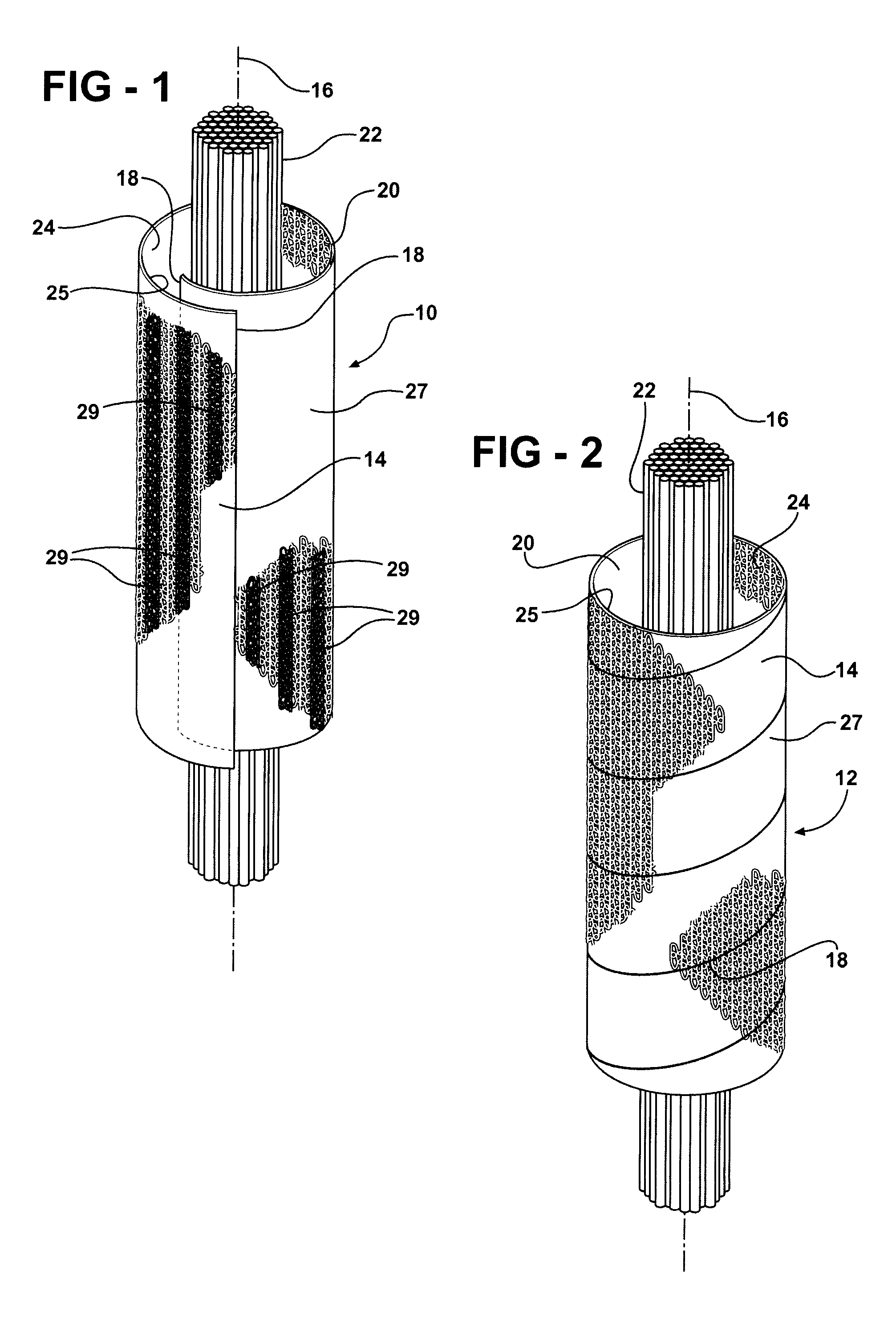

Incontinence sling

A sling for controlling urinary incontinence is disclosed. The sling is formed from a tube having substantially lengthwise inextensible end portions and an elastically lengthwise extensible intermediate portion between the end portions. The intermediate portion has a U-shape which cradles the urethra. The end portions extend through the abdominal tissue to anchor the intermediate portion in position. The sling places the urethra under a transverse compressive load to hold it closed and prevent inadvertent urination. The tube is formed from interlaced filamentary members. Interlacing may be by warp knitting, weaving using a leno weave or braiding using a tri-axial braid structure. The end portions have a rough texture to facilitate anchoring in the tissue of the abdominal wall. The intermediate portion is smooth and soft to prevent tissue erosion.

Owner:STOUT MEDICAL GROUP

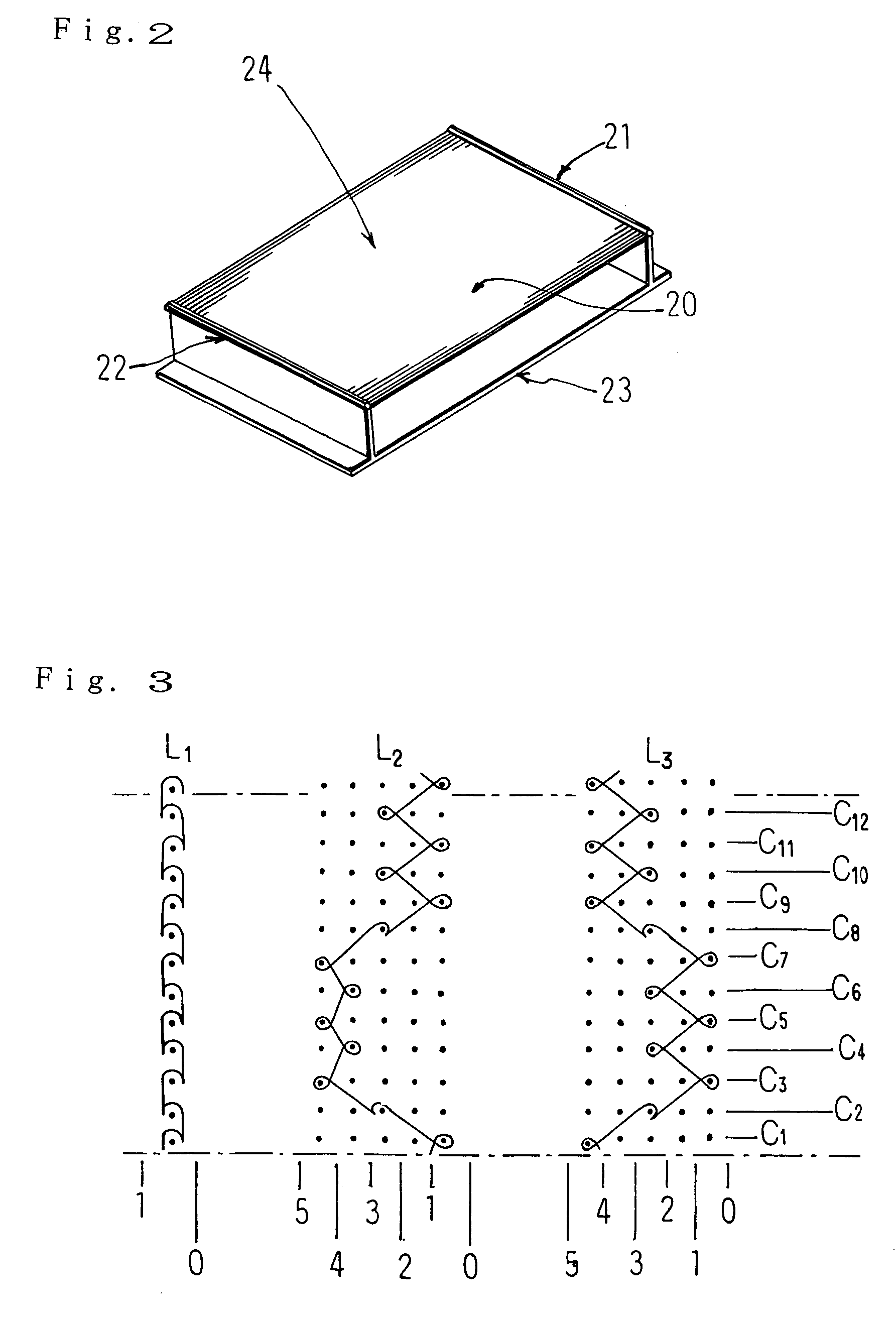

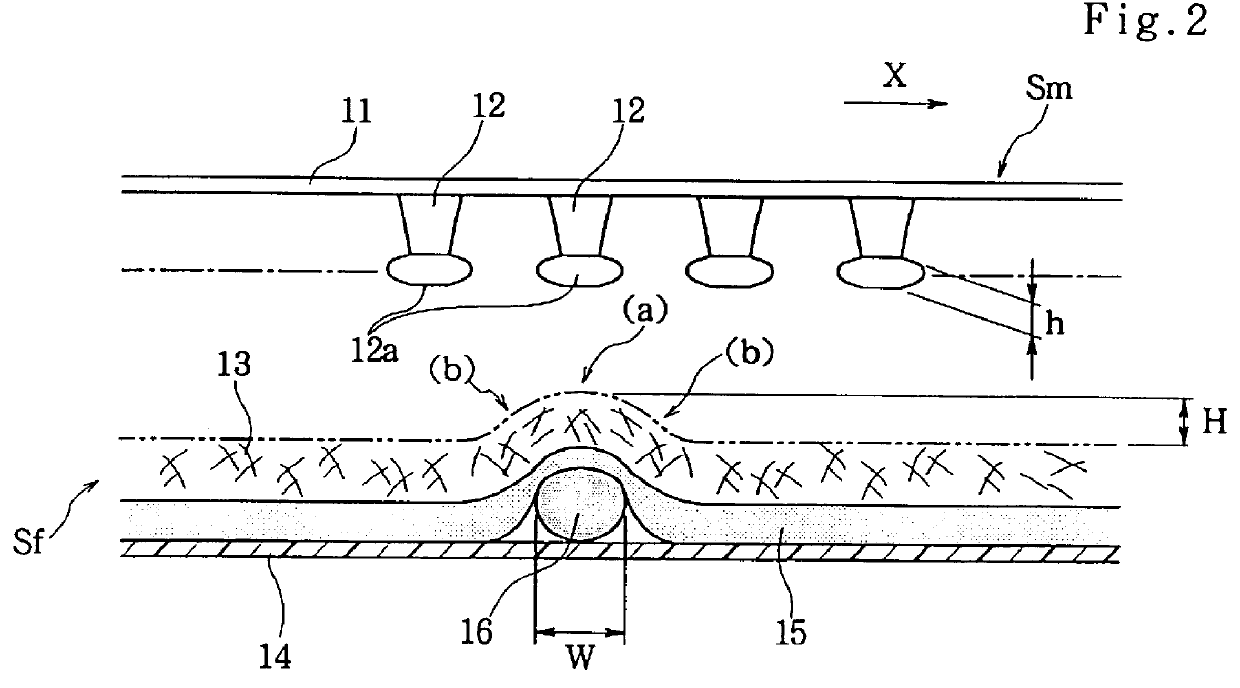

Light weight shoes

ActiveUS20050081402A1Increased durabilityOrnamental textile articlesWarp knittingBursting strengthEngineering

A shoe including an upper material using a double raschel warp knitted fabric is provided. The upper material includes a first surface having a non-mesh structure and a second surface having a non-mesh structure part (A) and mesh structure parts (B, C). The burst strengths burst strengths A, B and C of the parts (A, B and C) satisfy the relationship: A>B>C. The non-mesh structure part (A) is disposed in a part surrounding the tiptoe, a part connecting to a shoe sole and disposed in both sides of the foot for example, in a stripe. The mesh structure part (B) is disposed in the vicinity of the surface of the toe and the mesh structure part (C) is disposed in the both sides of the foot for example, in a stripe. Thus, a shoe having lightweight, air permeability and durability and a double raschel knitted fabric used for the shoe are provided.

Owner:MIZUNO CORPORATION

Warp-stitched multilayer papermaker's fabrics

InactiveUS7059357B2Easy to drainImprove joint strengthCellulosic pulp after-treatmentNon-fibrous pulp additionWeft yarnWarp knitting

A warp-stitched multilayer papermaker's fabric has a set of bottom warp yarns, a set of bottom weft yarns, a set of top weft yarns and a set of warp stitching yarn pairs. The bottom warp yarns are interwoven with the bottom weft yarns. The stitching warp yarns interweave with both the bottom weft yarns and the top weft yarns, and are woven such that at locations where the first of the stitching warp yarns in a pair weaves in the top fabric layer, the second stitching warp yarn in the pair drops below the top fabric layer to interweave with one or more bottom weft yarns to bind the top fabric layer and the bottom fabric layer together. The first stitching warp yarn of the stitching warp yarn pair may weave on a first side of one of the bottom warp yarns while the second stitching warp yarn of each stitching yarn pair may weave on the other side of that bottom warp yarn. Each stitching yarn pair may be substantially stacked above a bottom warp yarn. The fabric may further include a set of top warp yarns that interweave with the top weft yarns in the top fabric layer. The set of top warp yarns may be woven from a first warp beam, the set of bottom warp yarns may be woven from a second warp beam and the set of stitching warp yarns may be woven from a third warp beam.

Owner:WEAVEXX

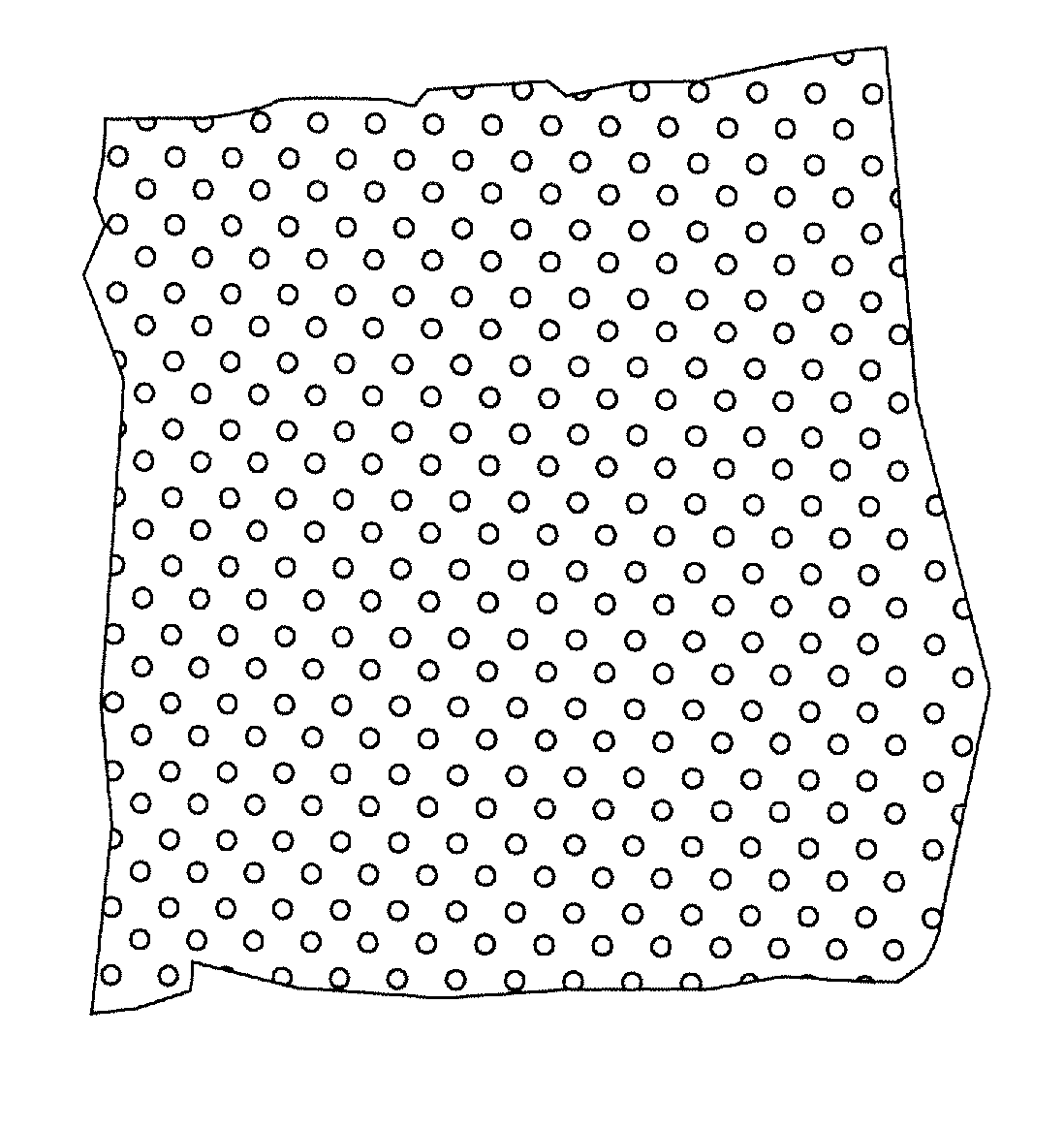

Elastic warp-knit fabric

InactiveUS7201024B2Reduce light reflectionImprove propertiesUpholsteryFlat warp knitting machinesBiomedical engineeringWarp knitting

A fabric article useful for the cushioning surface of a car seat and like items is formed from thick main elastic yarn which is thicker than main stitch yarn, and main inserted yarn which is more bulky and thicker than the main elastic yarn in apparent thickness, are knitted in line in the knitting width direction or in the knitting length direction of a mesh-like base knitted fabric which is knitted up with main stitch yarns by using a warp knitting machine and which have openings which are larger than the needle loops formed from the stitch yarn and extend over plural knitting courses.

Owner:KAWASHIMA SELKON TEXTILES

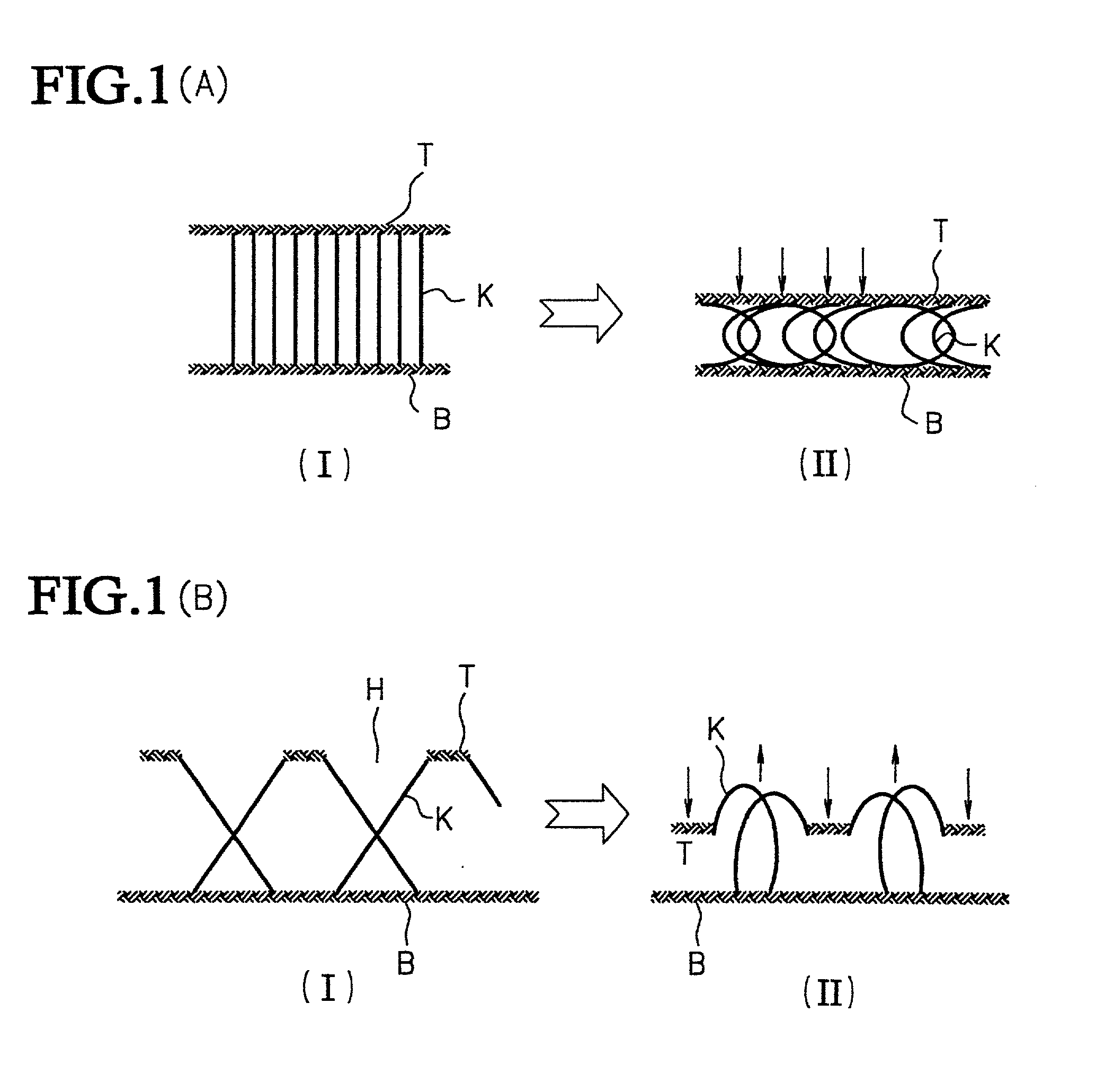

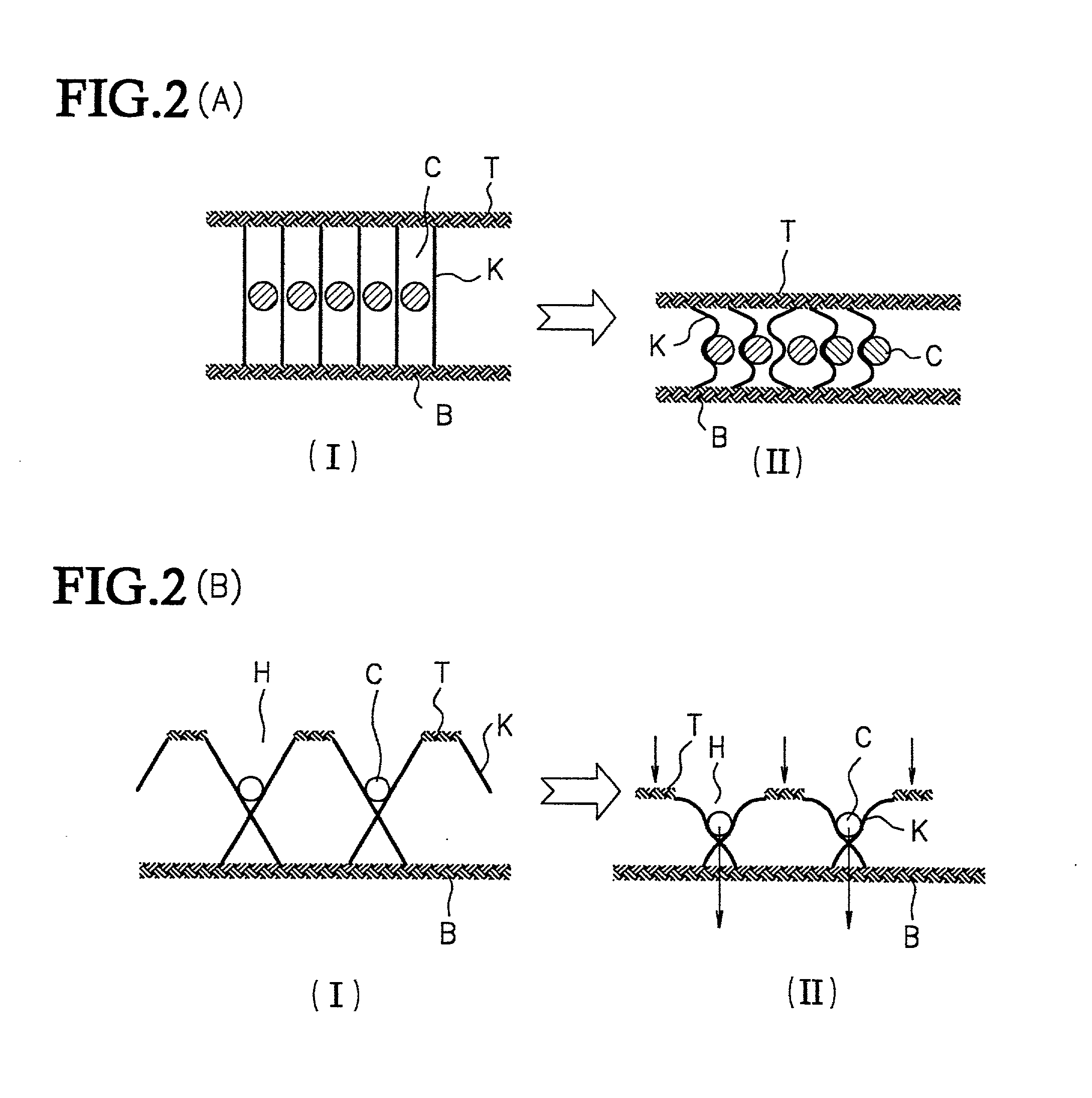

Retaining fastener and diaper using the fastener

InactiveUS6027485AHigh holding strengthOptimization rangeSnap fastenersGarmentsEngineeringUltimate tensile strength

Medium members such as thread are provided between woven fabric sheet such as warp knitting serving as the other sheet and base member, forming linear raised portions in the woven fabric sheet. The density of woven fabric sheet at the inclined portions to either side of these raised portions becomes coarse and the gaps between fine filaments on the woven fabric sheet spread, so that retaining heads of one sheet can easily enter and so that the fine filaments easily become hooked to the base portion of the retaining heads. Consequently, the retaining of the one sheet and the other sheet in strengthened, and the peeling strength is improved.

Owner:UNI CHARM CORP

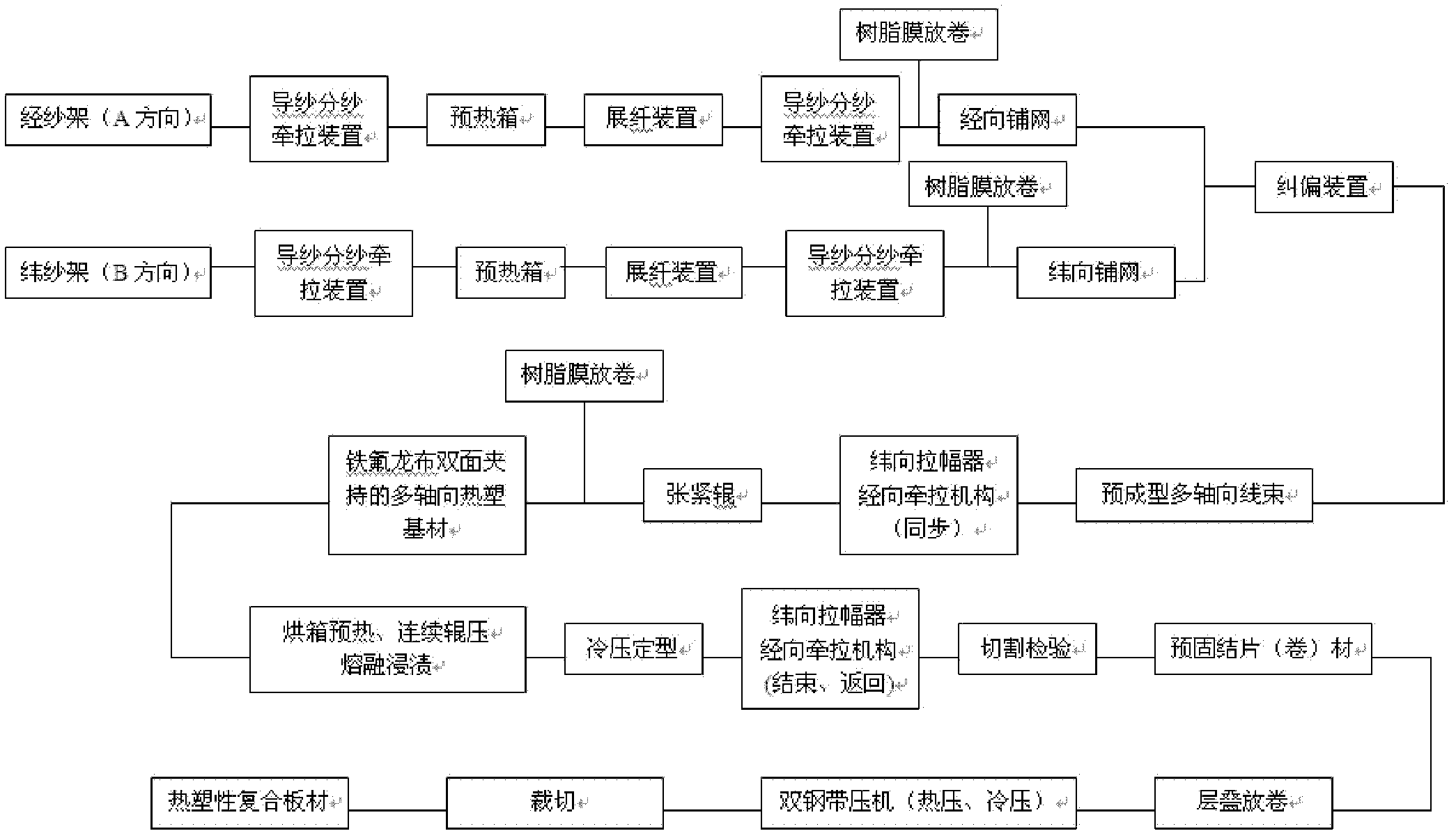

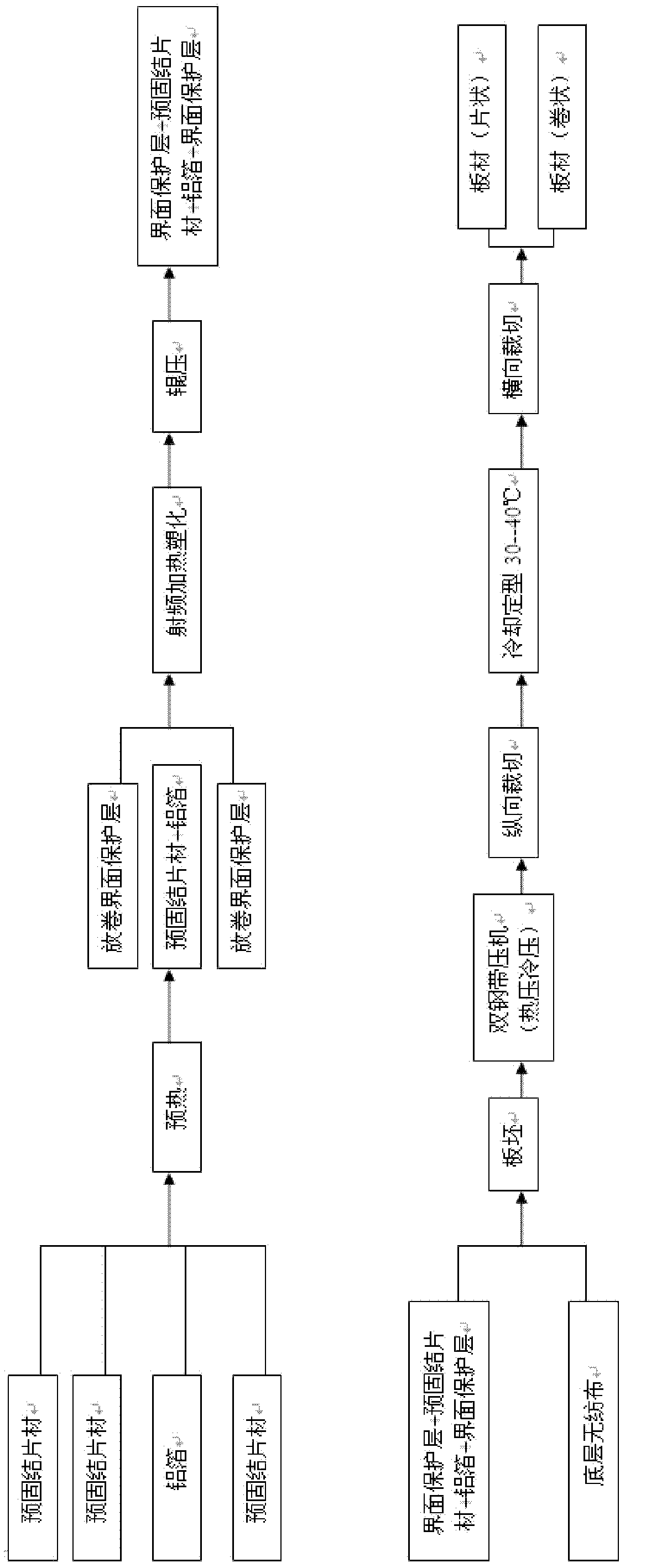

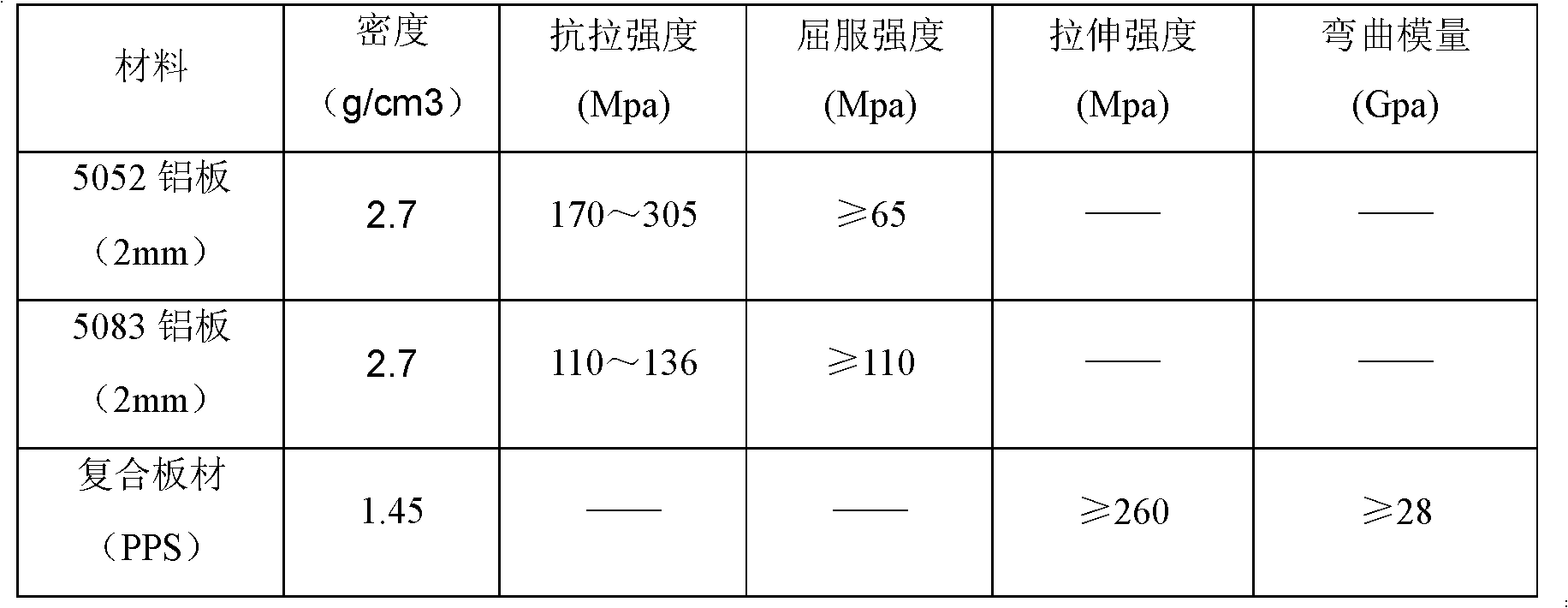

Method for preparing continuous fiber multiaxial fabric reinforced thermoplastic composite material

InactiveCN102218828AGuaranteed to be straightAvoid breakingSynthetic resin layered productsLaminationAviationHoneycomb

The invention discloses a method for preparing a continuous fiber multiaxial fabric reinforced thermoplastic composite material. The prepared continuous fiber multiaxial reinforced thermoplastic preconsolidating material is taken as a base material of the composite board, and combined with other functional materials for forming a novel material system which can be used for producing multiaxial fabric reinforced thermoplastic composite materials for different industries and solving the technical bottleneck that different materials have different composite bonding difficulties. According to the invention, the prepared composite material is constructed by continuous fiber multiaxial direaction; materials have the characteristics of resilience and uniform stressing on different directions. In addition, light sandwich panel formed by a honeycomb core material provides higher impact strength of materials, which is suitable for preparing structural parts and interior decorative parts in the field of railway car containers of navigation and aviation. The product of light-weight flame retardant can be recovered and used, and is more suitable for industrialization scale production of the warp knitting industry organization.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

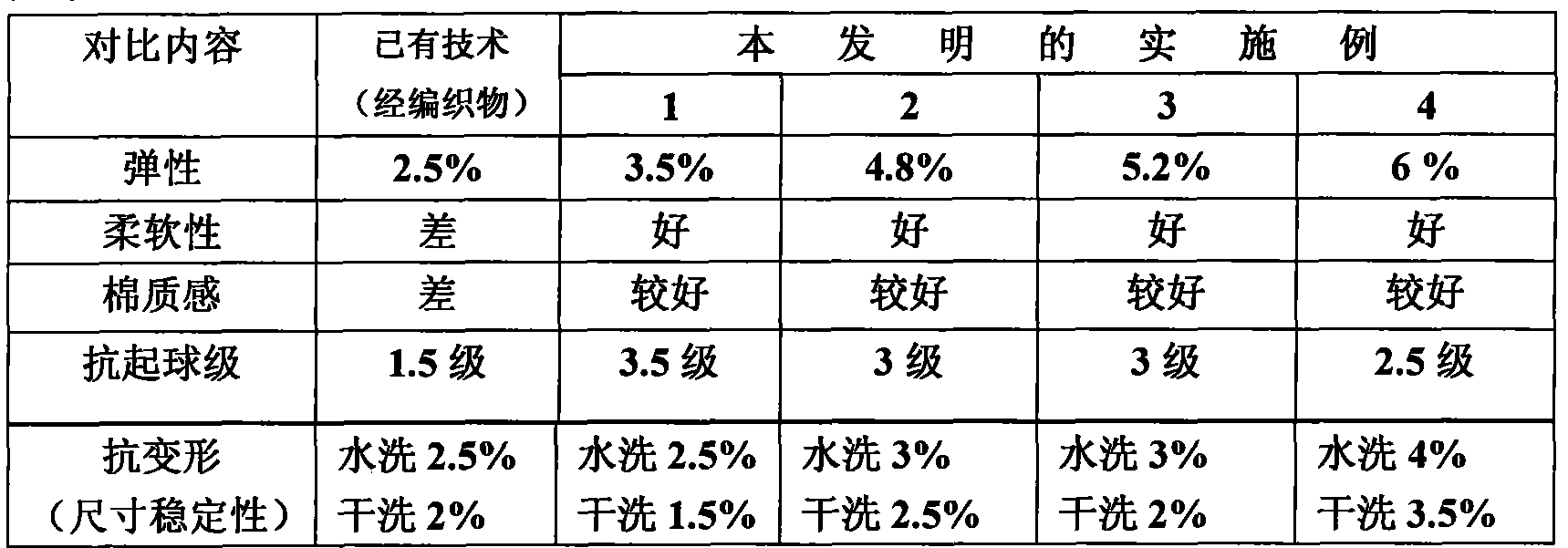

Polyester knitwear fabric and method of processing the same

InactiveCN101435130ACotton soft touchSoft touchWeft knittingHeating/cooling textile fabricsPolyesterFiber

The invention relates to a knitted polyester fabric and a processing method thereof. The fabric comprises covering weave and bottom weave, the raw material of the covering weave is polyester superfine denier fiber, and the raw material of the bottom weave is polyester fiber, wherein, the content of the polyester superfine denier fiber is 60-80 percent of the total ingredients, and the content of the polyester fiber is 20-40 percent of the total ingredients. The invention has the advantages that: as the polyester superfine denier fiber is used as the covering weave and the polyester fiber is used as the bottom weave, the polyester superfine denier fiber can effectively control the rate of retraction, after opening fiber, the fabric has soft cotton handfeel and good temperature suction, elasticity and resistance to deformation and excellent warmth retention and air permeability, and is skin-friendly; and the processing method adopts weft knitting weaving which has short process, small raw material loss, and no parking bars on the fabrics compared with the warp knitting weaving.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

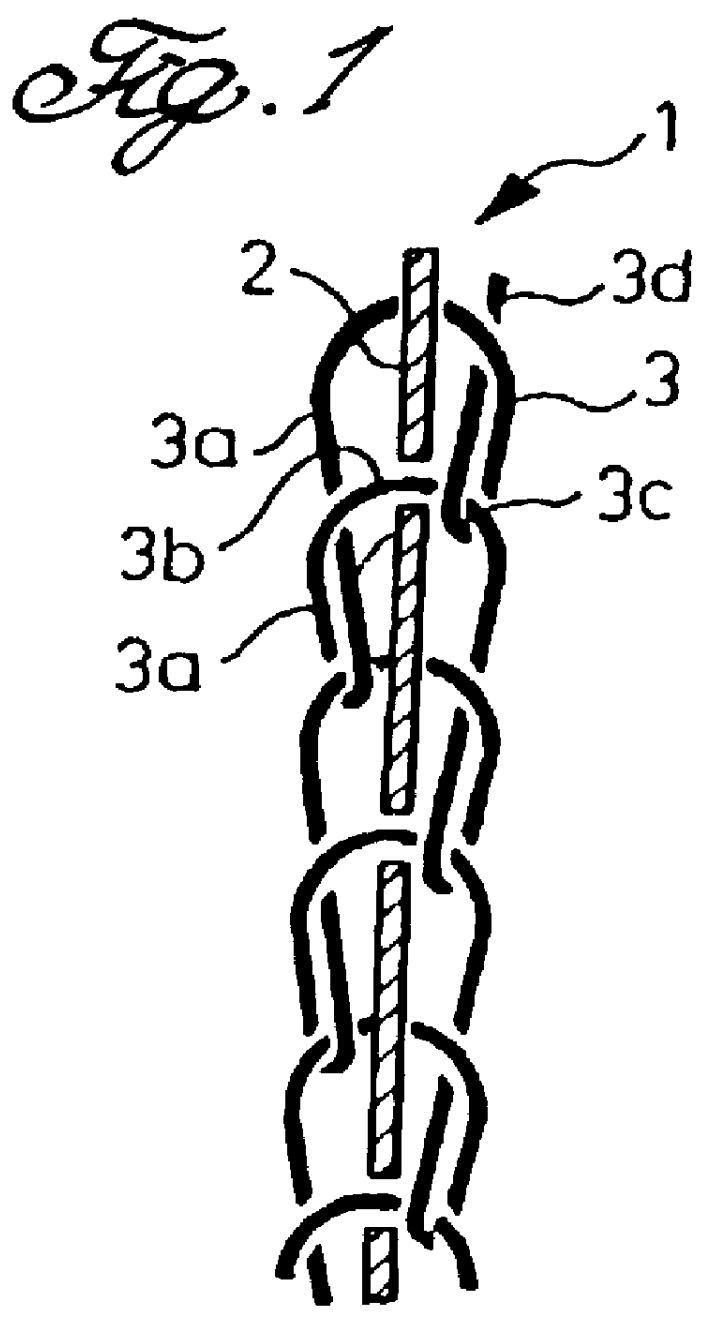

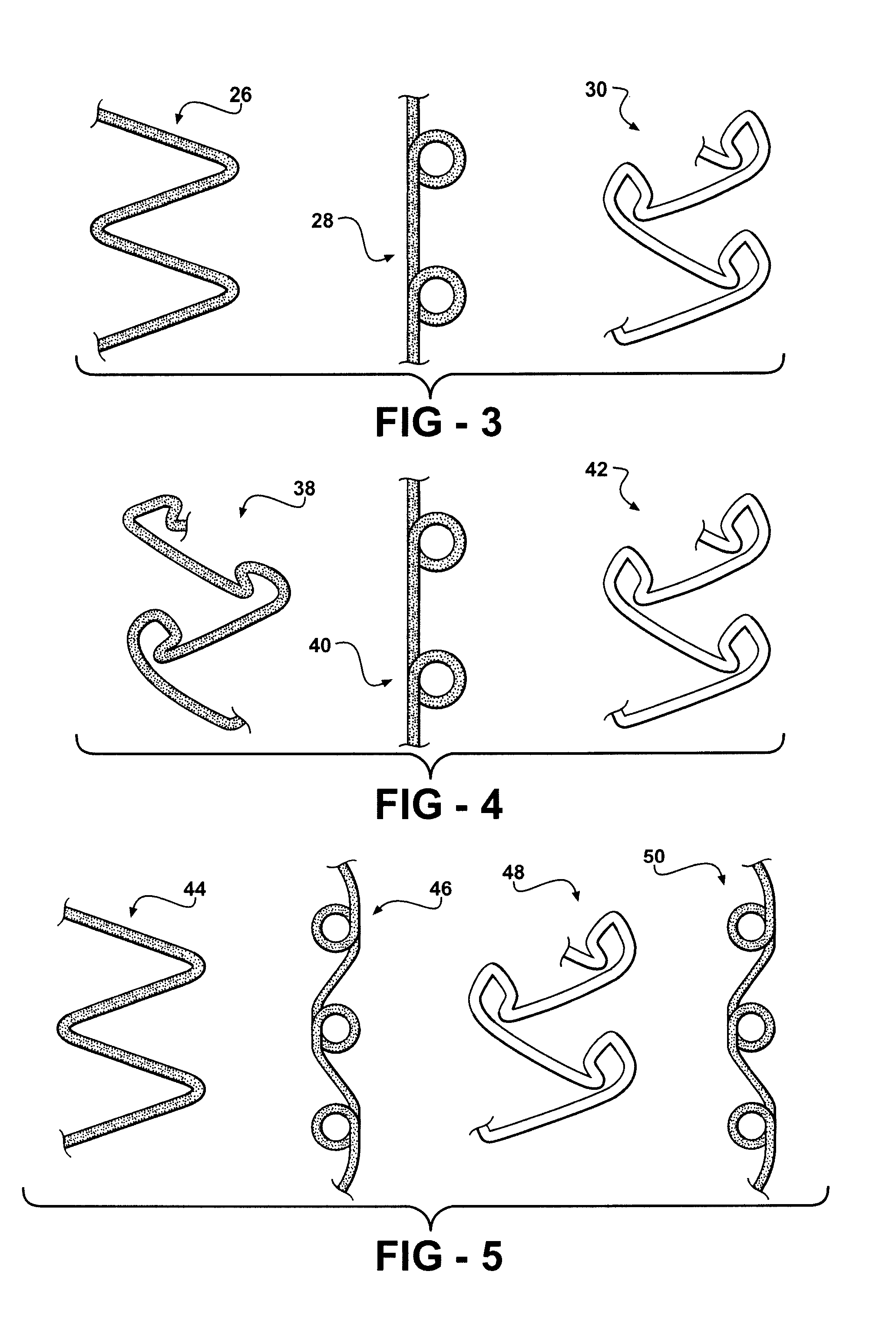

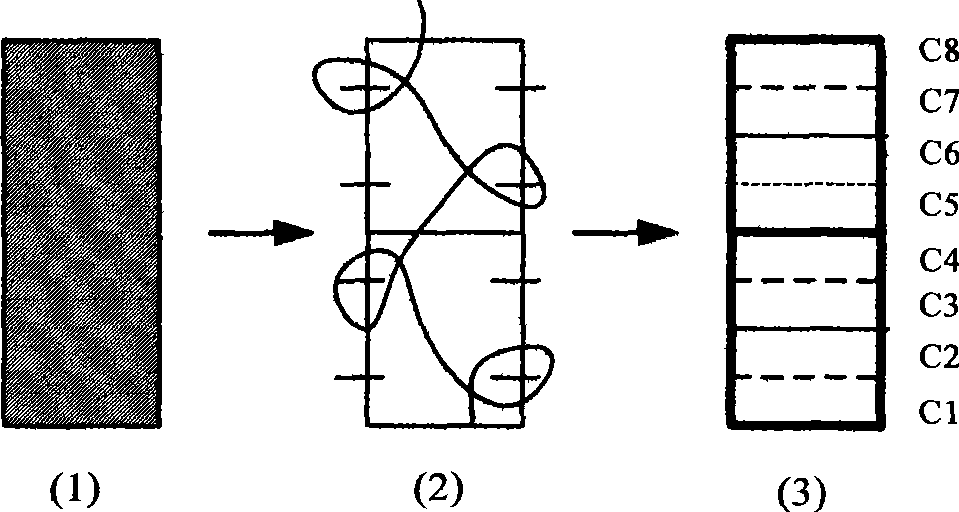

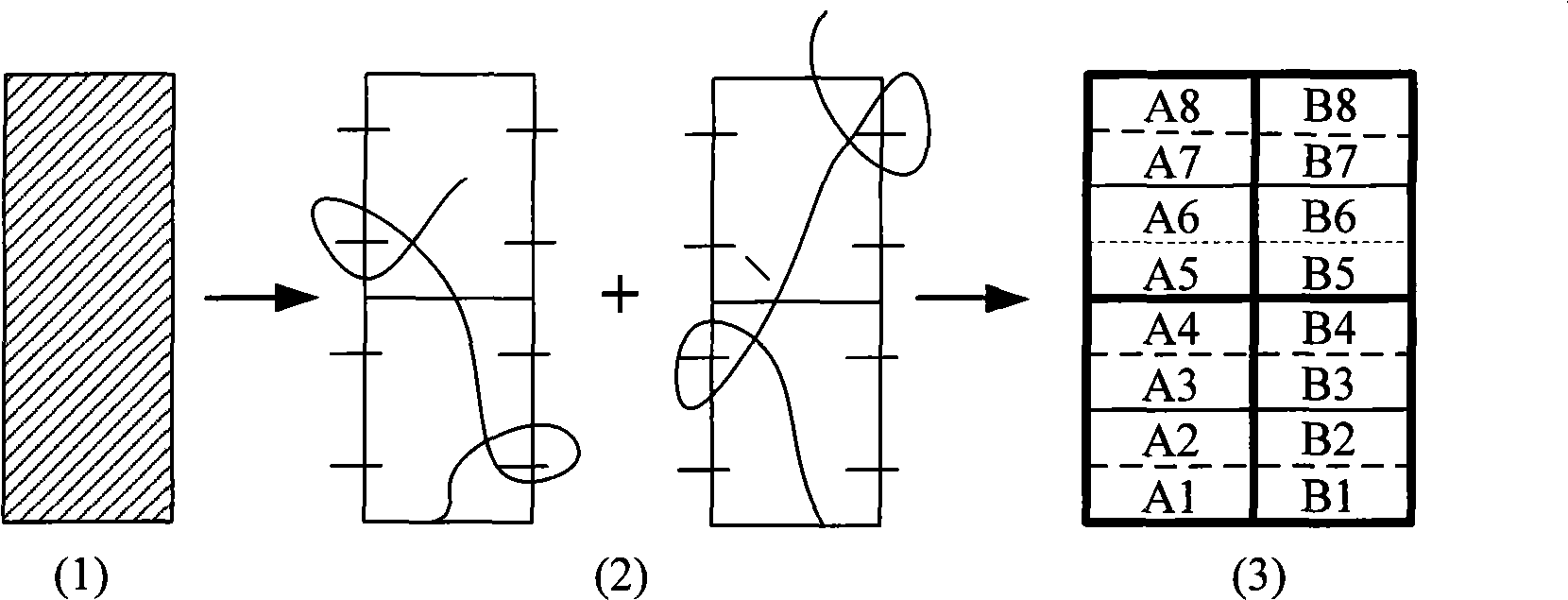

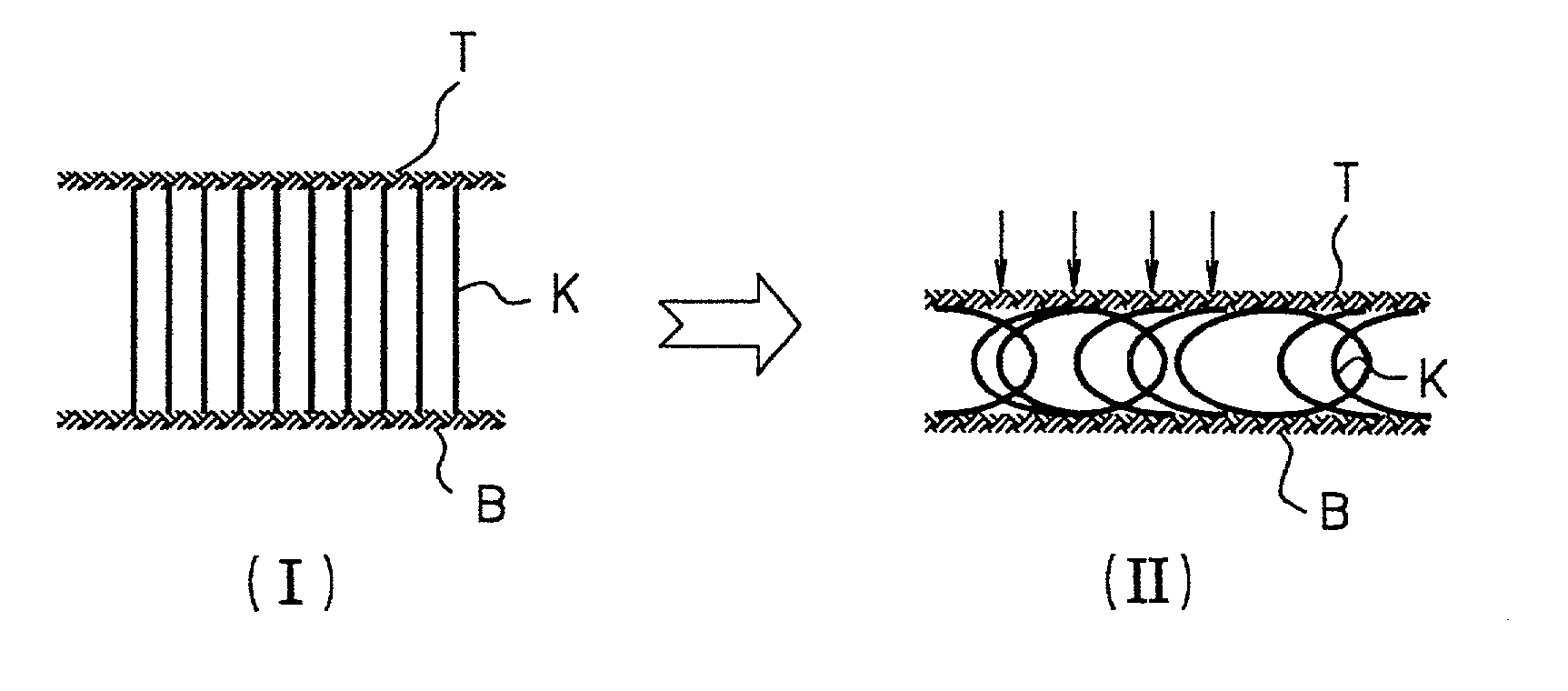

Composite yarn comprised of chain stitch yarn and inlay yarn

PCT No. PCT / JP95 / 00745 Sec. 371 Date Oct. 18, 1996 Sec. 102(e) Date Oct. 18, 1996 PCT Filed Apr. 17, 1995 PCT Pub. No. WO95 / 29278 PCT Pub. Date Nov. 2, 1995A composite yarn comprised of a chain stitch yarn knitted from a yarn A and at least an inlay yarn of a yarn B inserted into the chain stitch yarn along a longitudinal direction thereof. Since the chain stitch yarn and the inlay yarn are surely interlaced with each other in the composite yarn, there is little chance that the chain stitch yarn and the inlay yarn are separated in use. A preferable apparatus for manufacturing the composite yarn in accordance with the present invention may include individual winding mechanisms downstream of each knitting station in a warp knitting machine.

Owner:FUASUTAA

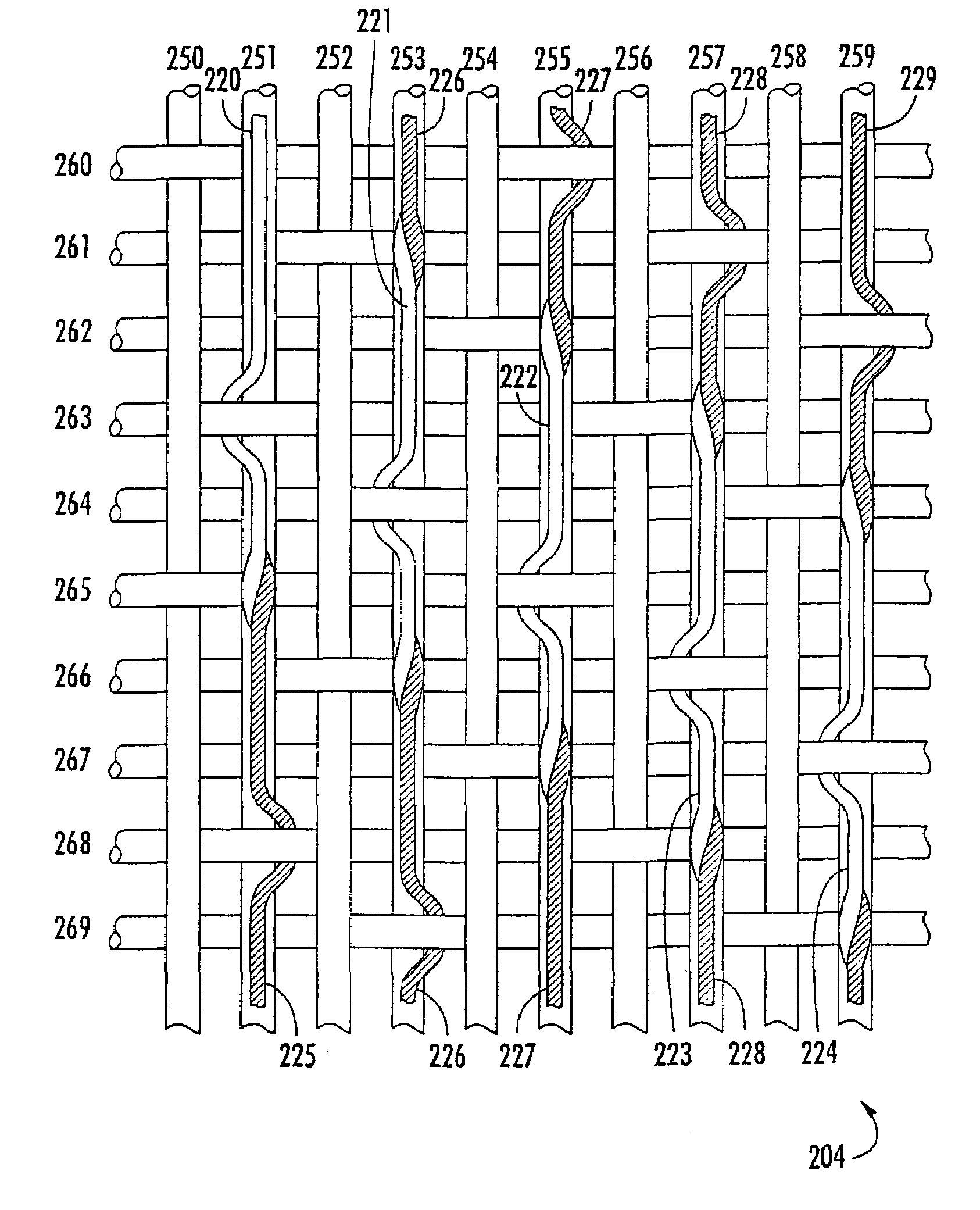

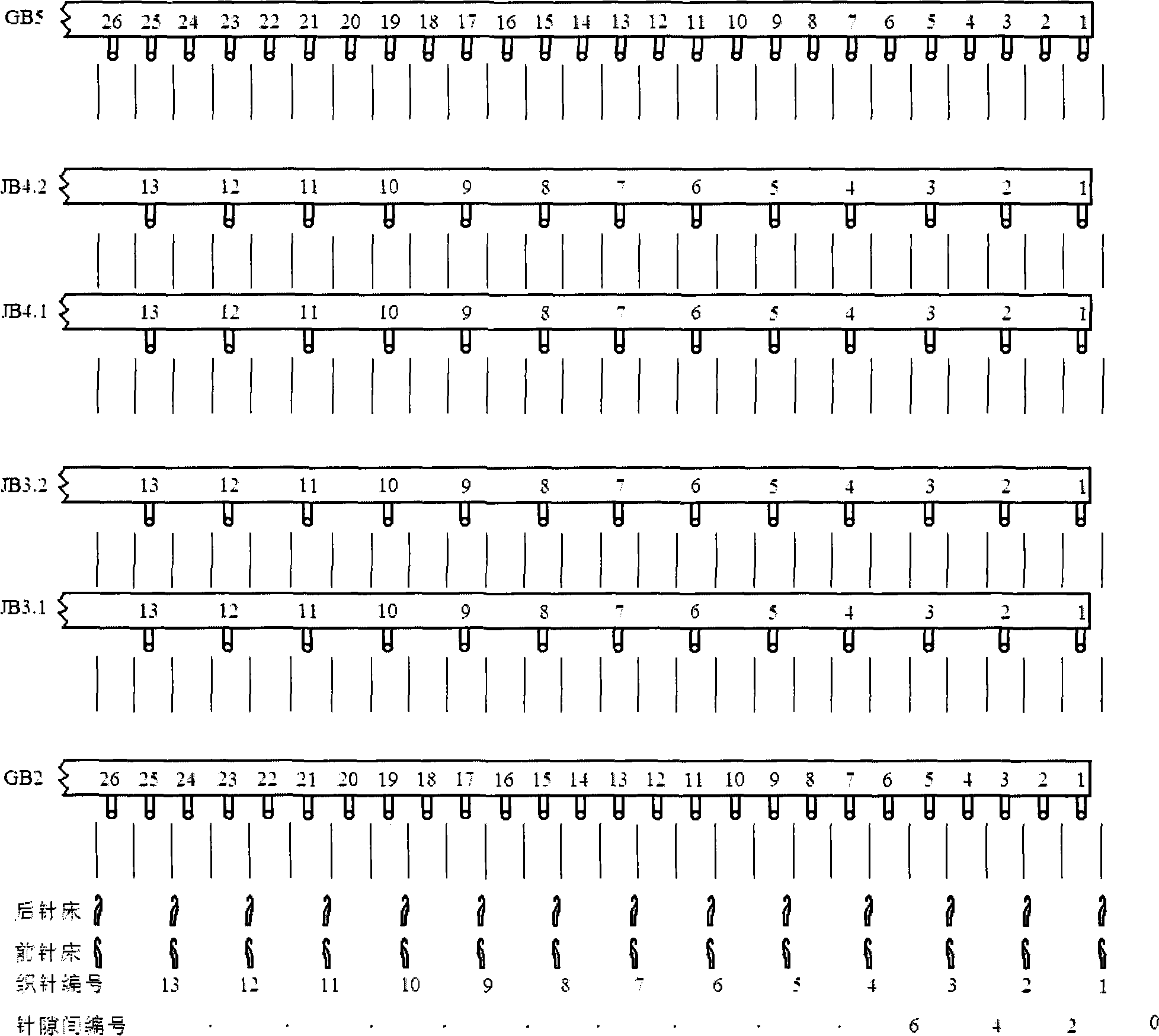

Single-color or multicolor double-layer warp-knitted spacer jacquard fabric and knitting method thereof

ActiveCN103556384ABreathableHave healthOrnamental textile articlesWarp knittingSurface layerEngineering

The invention discloses a knitting method for a single-color or multicolor double-layer warp-knitted spacer jacquard fabric. The knitting method comprises the following steps: (1) designing jacquard patterns of the warp-knitted fabric by using a computer; (2) preparing for knitting; (3) inputting parameters on a jacquard warp knitting machine, and knitting through the warp knitting machine, so as to obtain a double-layer spacer jacquard fabric with preset patterns. The knitting method adopted in the invention is unique, theamount of warp run-in of each yarn is controlled reasonably, the obtained single-color or multicolor double-layer warp-knitted spacer jacquard fabric comprises a surface layer and a bottom layer, the surface layer and the bottom layer are knitted by adopting an irregular knitting method, the surface layer and the bottom layer are connected through yarns or connected in such way that yarns are arranged on the connection part of the surface layer and the bottom layer at intervals, and a gap layer is formed at the connection part without the yarns; the gap can be filled with elastic materials such as cotton wool, plush or sponge, so that the gap part is bulged. Therefore, the knitted fabric integrally has different layered effects.

Owner:莆田华青日用品有限公司

Self-curling knitted sleeve and method of fabrication

InactiveUS20070163305A1Facilitate imparting biasWeft knittingOrnamental textile articlesBuilding constructionCivil engineering

A warp knit self-curling fabric and methods of construction thereof provides an elongate sleeve having overlapping edges for protecting elongate members. The fabric includes warp stitches and a plurality of weft stitches. The fabric comprises at least three yarns warp knit together, wherein one of the weft stitches is knit using a tricot stitch of a monofilament under tension to bias the fabric into a self-curled configuration about a central space. The monofilament forms an inner surface of the sleeve.

Owner:FEDERAL MOGUL CORP

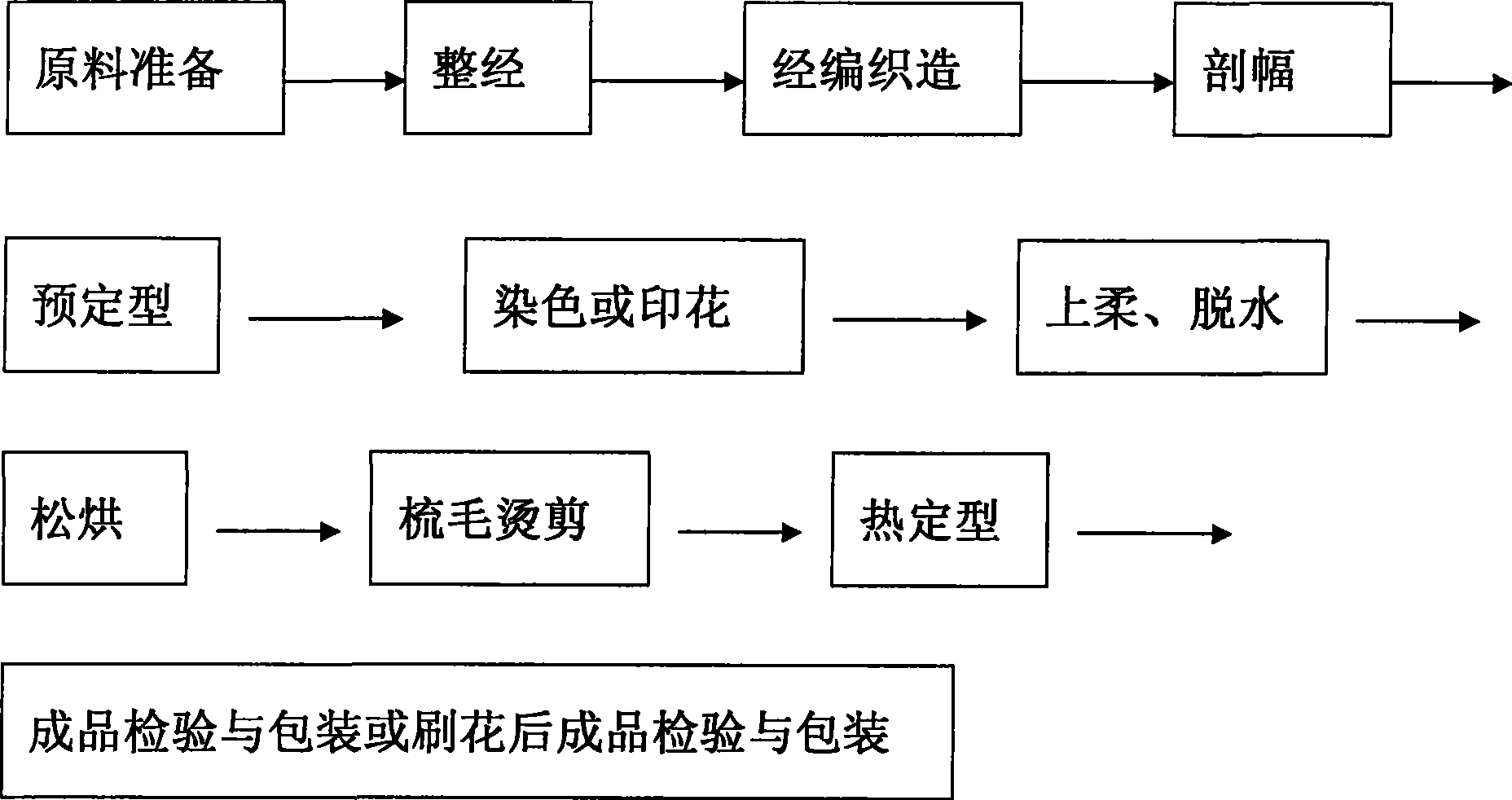

Processing method for full-cleansing woollen plush face fabric

InactiveCN101429703AHigh structural densitySoft feelWarp knittingHeating/cooling textile fabricsProduct inspectionPolyester

The invention relates to a processing method for a polyester plush fabric, which comprises the following processing steps: preparing raw materials; warping; warp knitting and weaving; slitting; pre-setting; dyeing or printing; lustring and dehydrating; baking; combing, scalding and shearing; heat shaping; and product inspection and packing, or product inspection and packing after pattern brushing, wherein the setting temperature for the pre-setting is between 190 and 230 DEG C; and in the pre-setting process, the tension of grey cloth is controlled, and the progression speed of controlling the grey cloth is 35 to 45 meters per minute, and the rotating speed of a blower is 1, 750 to 1, 900 revolutions per minute. The processing method has the advantages that the height of plush is increased to 5 to 30 millimeters, the plush is long and inflexible, and the plush surface is smooth and subtle, and the plush is soft and has good hand feel; the plush is straighter and can comb floating plush at the bottom; at the same time, resetting resulted from difference of fabric width and style caused by high-temperature ironing and cutting is reduced; by adopting warp knitting and weaving, a bottom tissue structure has high density and a bottom fabric tissue has good stability; and the step of pattern brushing makes patterns flexible and the fabrics extend from single toy fabrics to clothing fabrics.

Owner:CHANGSHU YATAIYA TEXTILE ADORN

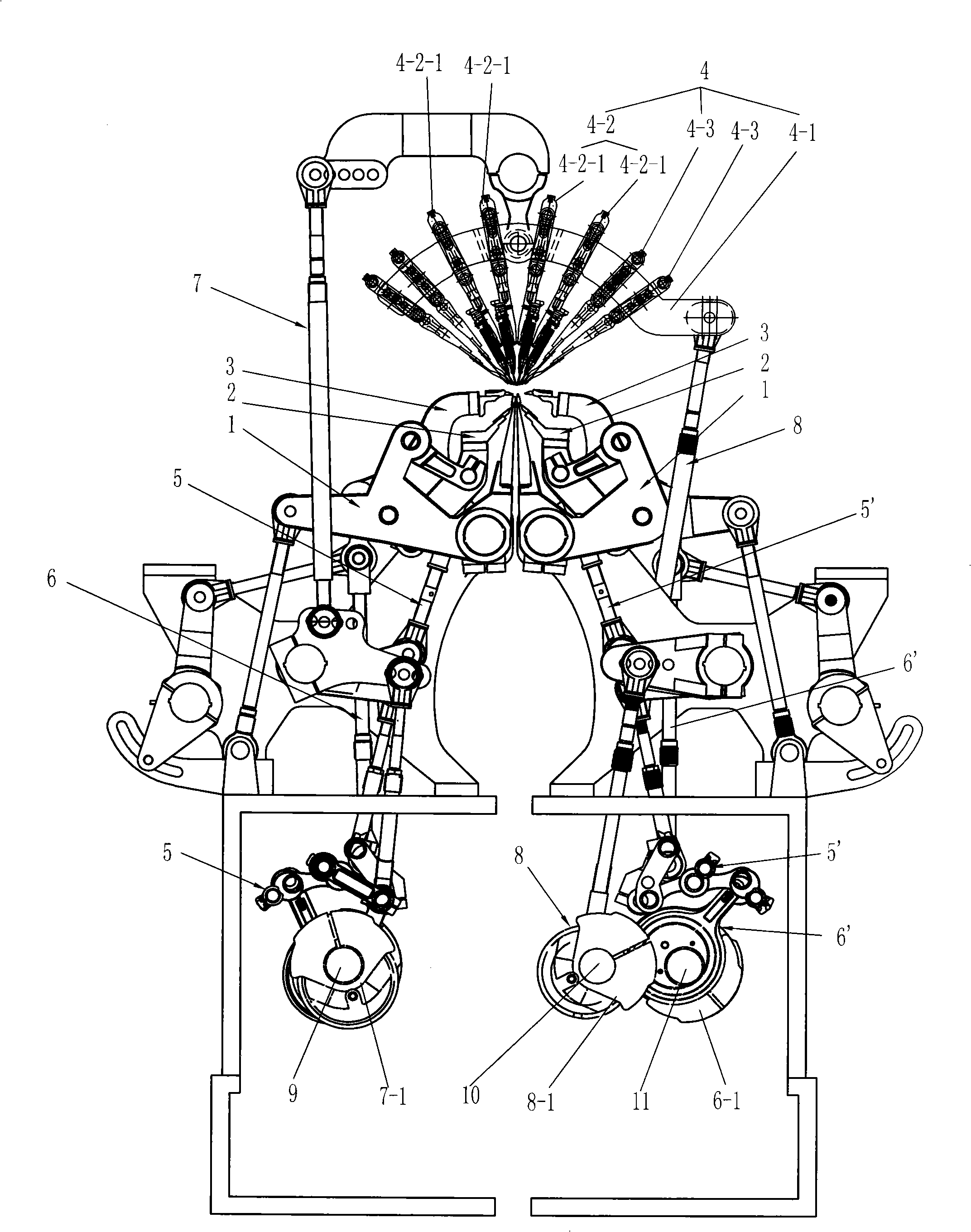

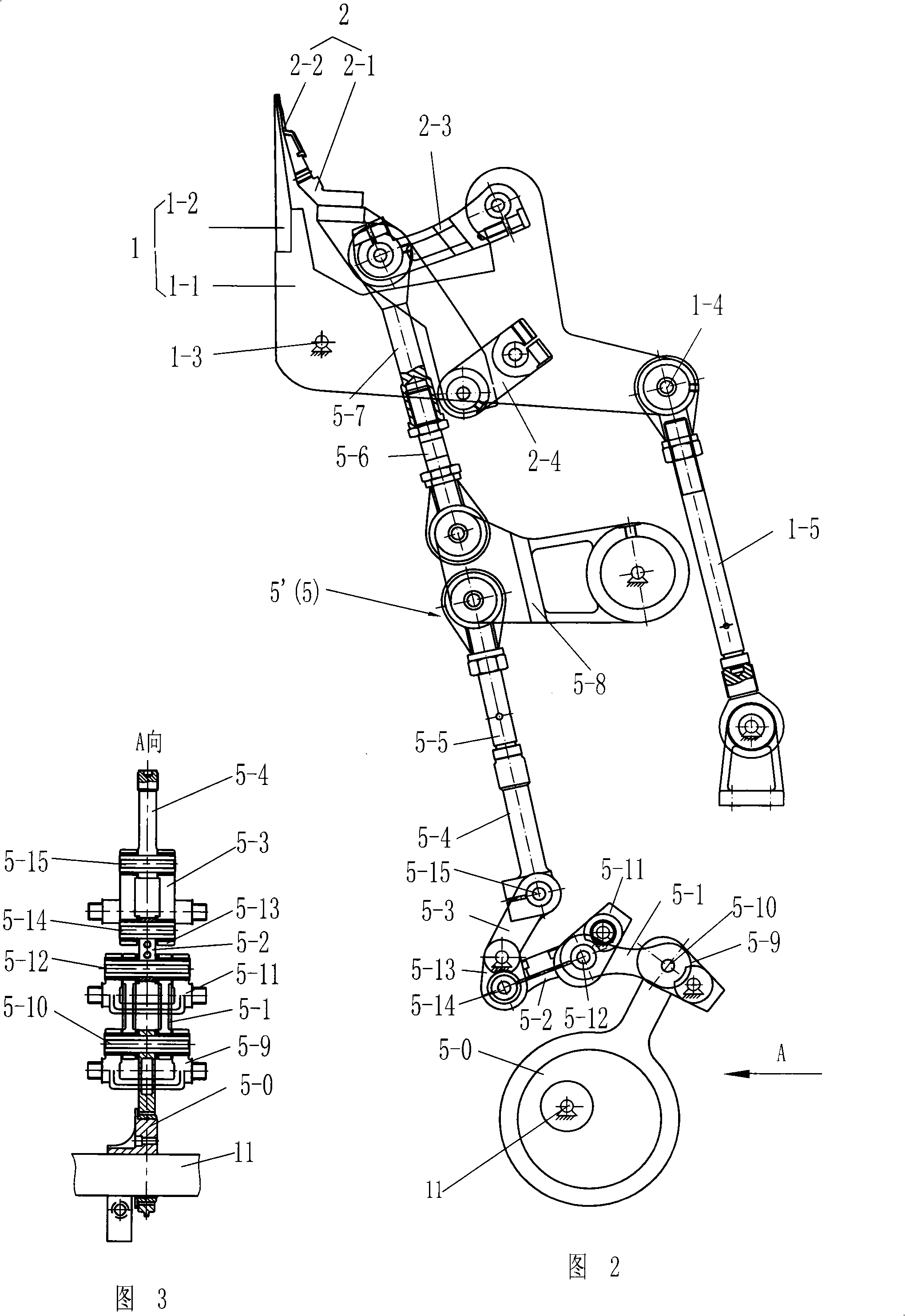

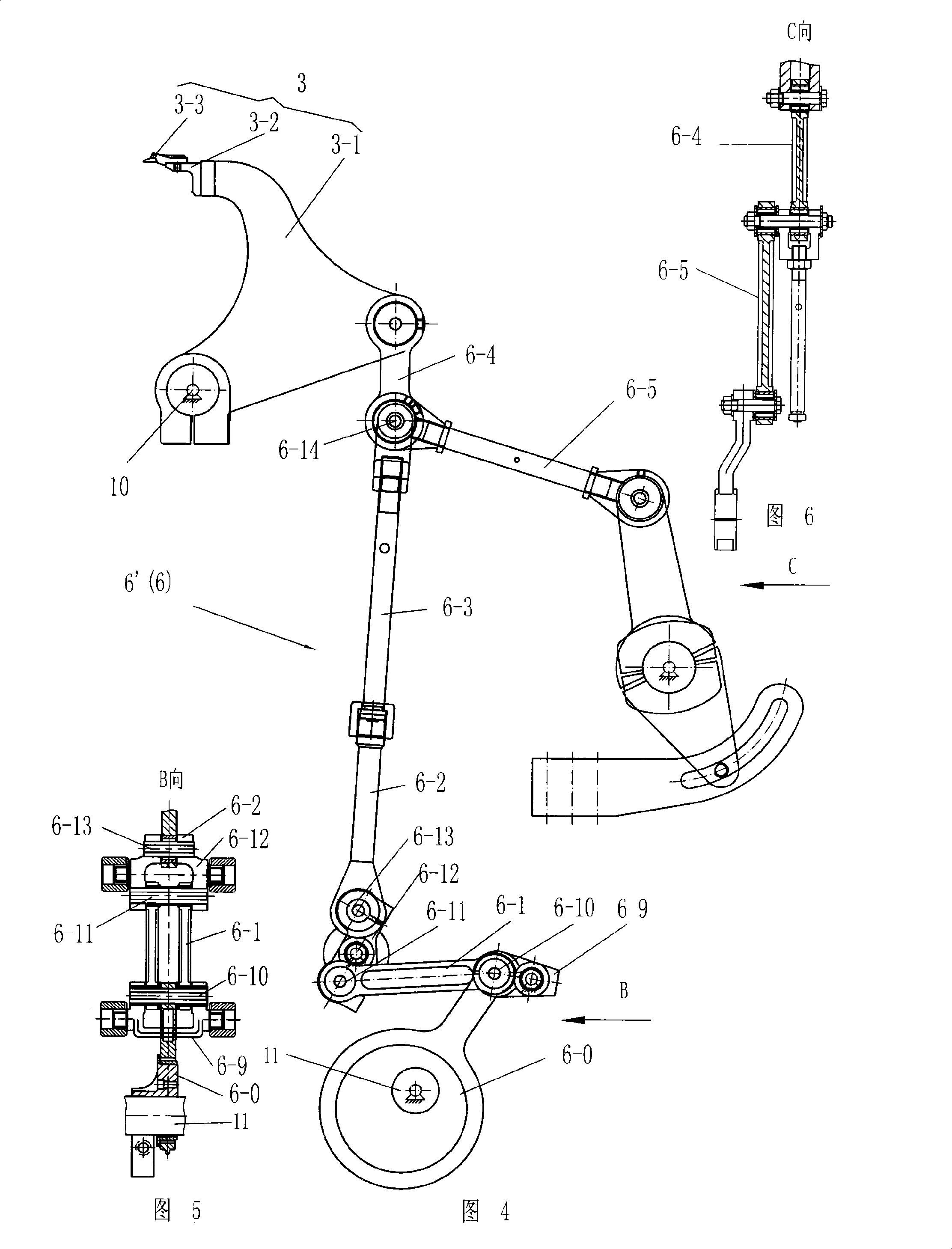

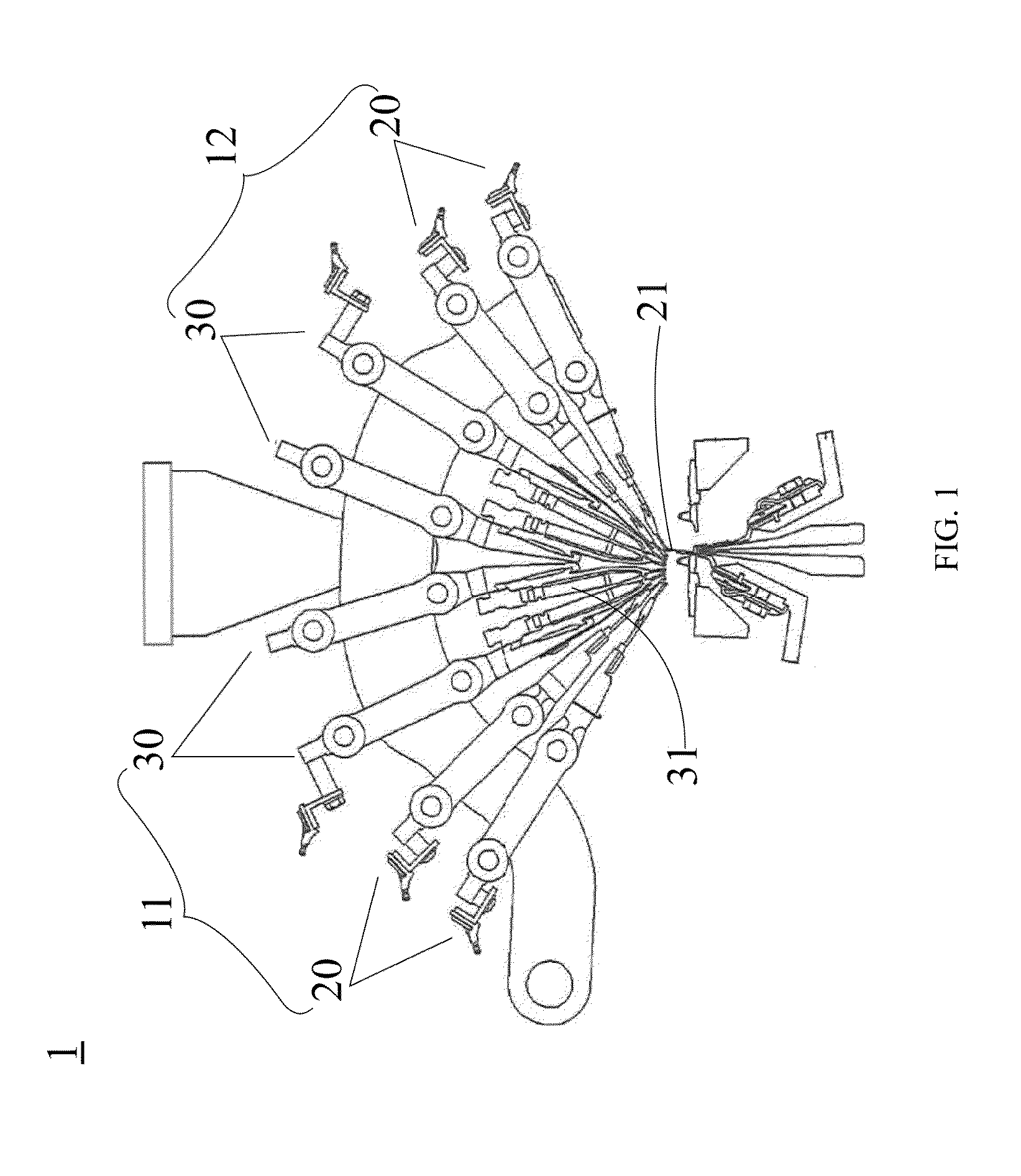

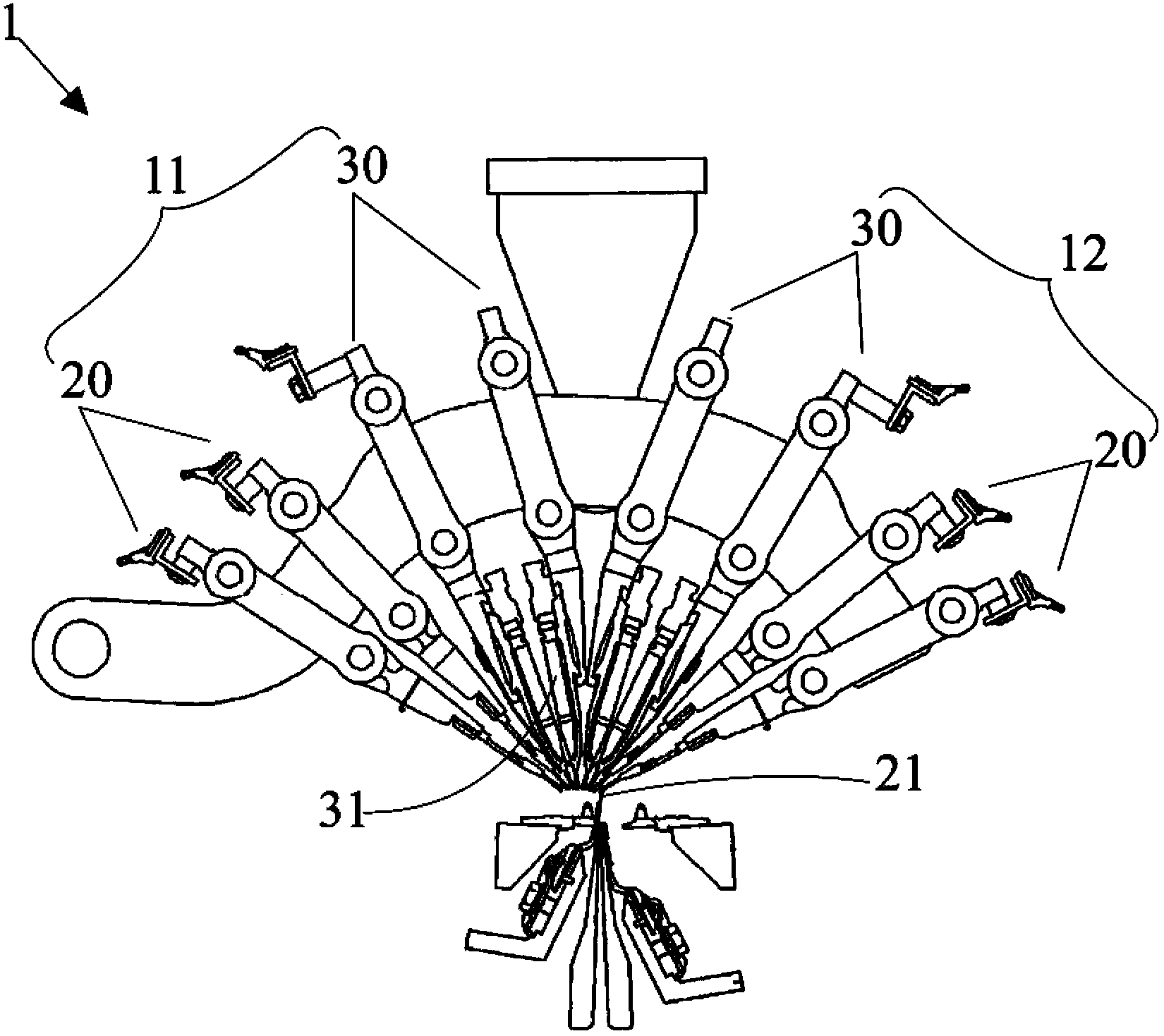

Two-needle bar electronic Jacquard warp knitting machine

A double needle bar electronic jacquard warp-knitting machine comprises a looping device, a guide bar assembly and a transmission device. The guide bar assembly is provided with at least a piezoelectric ceramic jacquard guide bar; the front needle bar transmission mechanism and the rear needle bar transmission mechanism, the front deposition transmission mechanism and the rear deposition transmission mechanism, the guide chase comb upper pendulum transmission mechanism and the guide chase comb lower pendulum transmission mechanism in the transmission device are all eccentric wheel linkage transmission mechanism. Due to the adoption of the piezoelectric ceramic jacquard guide bar needle, the warp-knitting machine provided by the present invention can weave more complicated patterns, conveniently change patterns and simplify the structure. All transmission structures of the present invention adopt the eccentric linkage mechanism. Compared with the original cam linkage mechanism, the eccentric linkage mechanism has more complicated moving track, large moving traverse, high precision and more suitability for more complicated patterns. The rotation speed of the machine can be further increased, which is conducive to increasing the production efficiency.

Owner:孙嘉良

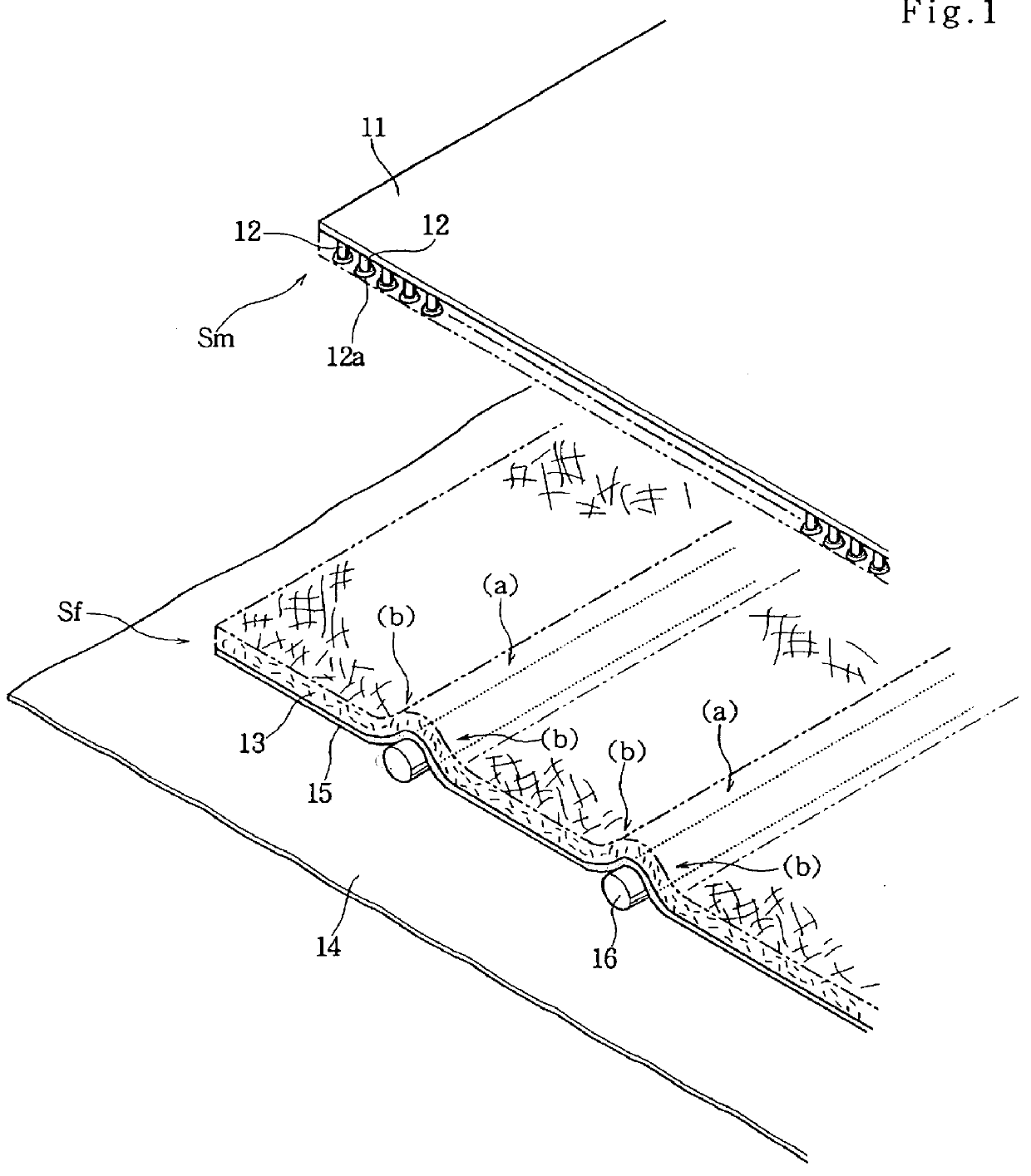

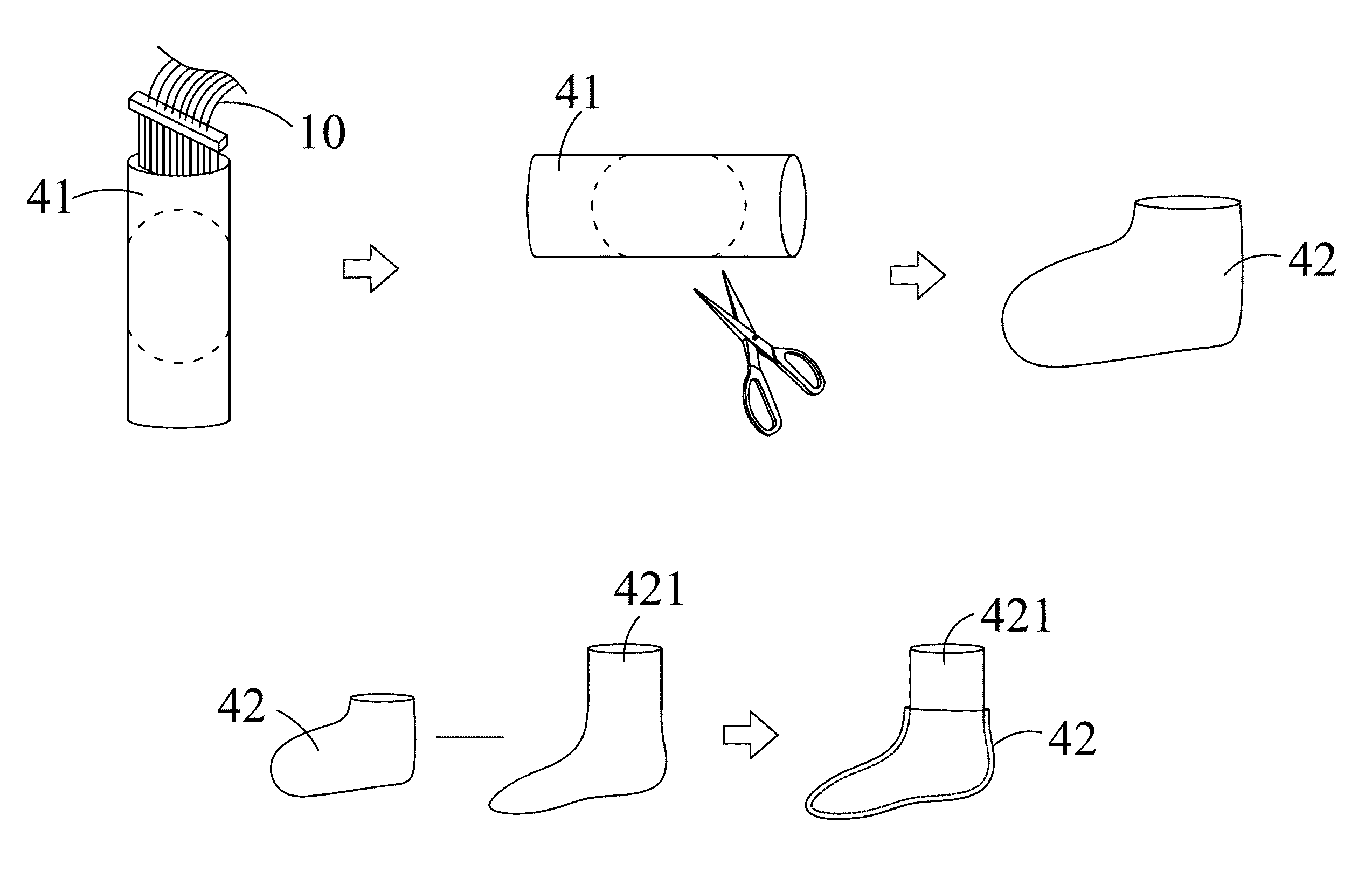

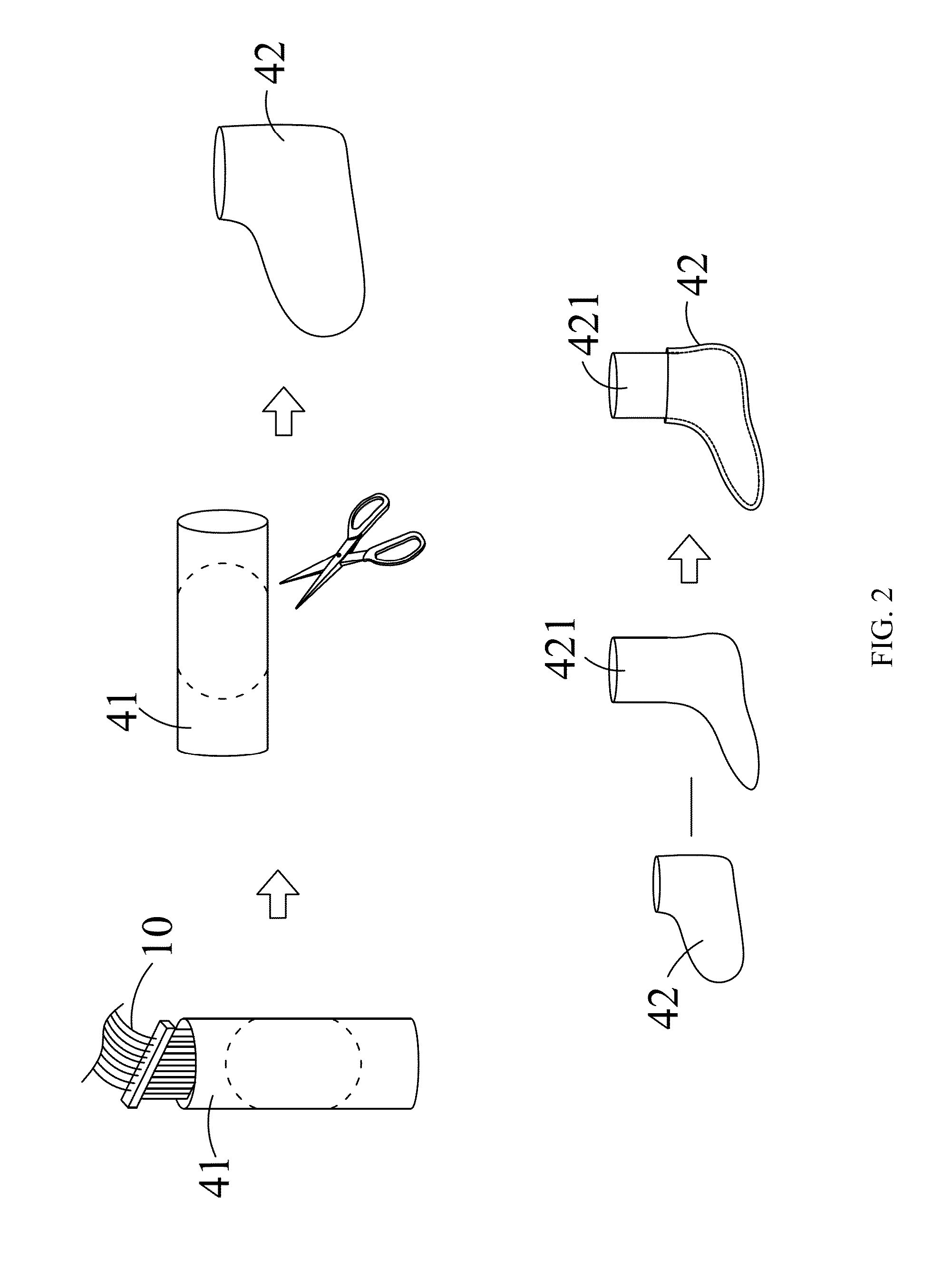

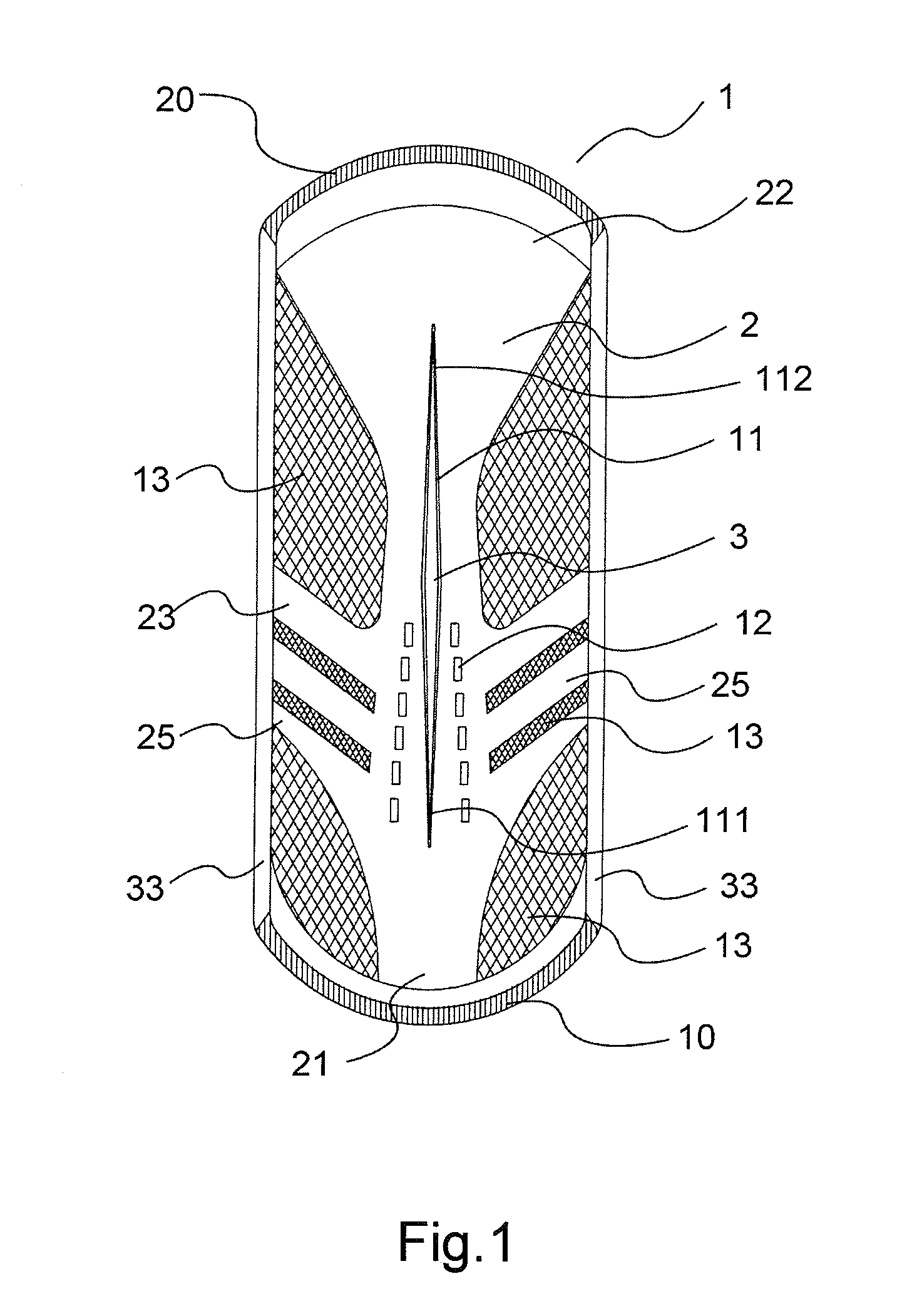

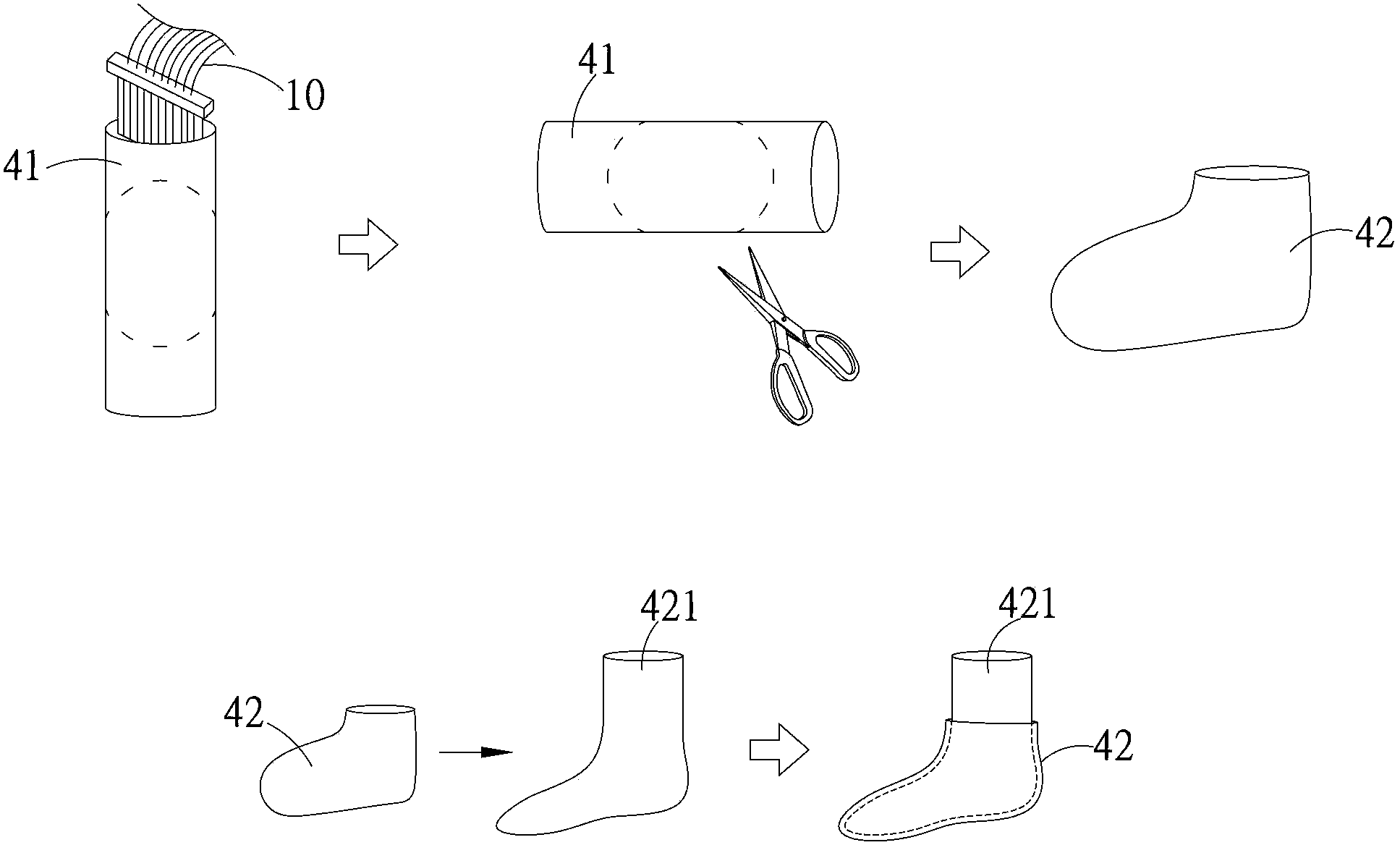

Weaving Method of Three-Dimensional Vamp

ActiveUS20140082905A1Increase labor costEliminate needMechanical cleaningPressure cleaningEngineeringHot melt

A weaving method of a three-dimensional vamp includes the steps of: weaving yarn by a warp-knitting machine to form a top vamp by a first part needle bar of the warp-knitting machine which is interactively woven with a bottom vamp formed by a second part needle bar of the warp-knitting machine so as to form a tube-shaped fabric; cutting the tube-shaped fabric to form a sock-shaped fabric; disposing the sock-shaped fabric on a shoe last; and heating the sock-shaped fabric to tighten the sock-shaped fabric in order to seal the shoe last and consequently obtain the three-dimensional vamp. The heat shrinkable and irreversible properties of a high shrinkage yarn or hot melt yarn are used to seal the sock-shaped fabric with the shoe last, thereby achieving the substantial physical properties. The turner cost and the fabric flotsam can be reduced by the process of manufacturing the integrally formed vamp.

Owner:LONG JOHN TSUNG RIGHT IND

Knit elastic mesh loop pile fabric for orthopedic and other devices

InactiveUS20080072629A1Increase air circulationImprove moisture managementOrnamental textile articlesStraight-bar knitting machinesOrthopedic devicesMuscle tone

An improved fabric for orthopedic devices is provided, being a knitted fabric produced on either a warp or weft knit system and utilizing a filament yarn selected from nylon and polyester as well as spandex. The fabric enhances freedom of movement while stimulating blood flow and muscle tone. The fabric has an elasticity that enables closure of orthopedic and other devices by placing the hook component of a Velcro (®) strip at any convenient point rather than aligning it with the loop component of the Velcro (®). The fabric is more convenient, faster and easier for many incapacitated persons, enhancing wearing comfort. Its mesh structure makes it more porous, which enhances the air circulation and the moisture management in creating a cooling effect on the wearer's skin and ready evaporation of perspiration, while still providing therapeutic warmth without heat buildup.

Owner:GEHRING TEXTILES

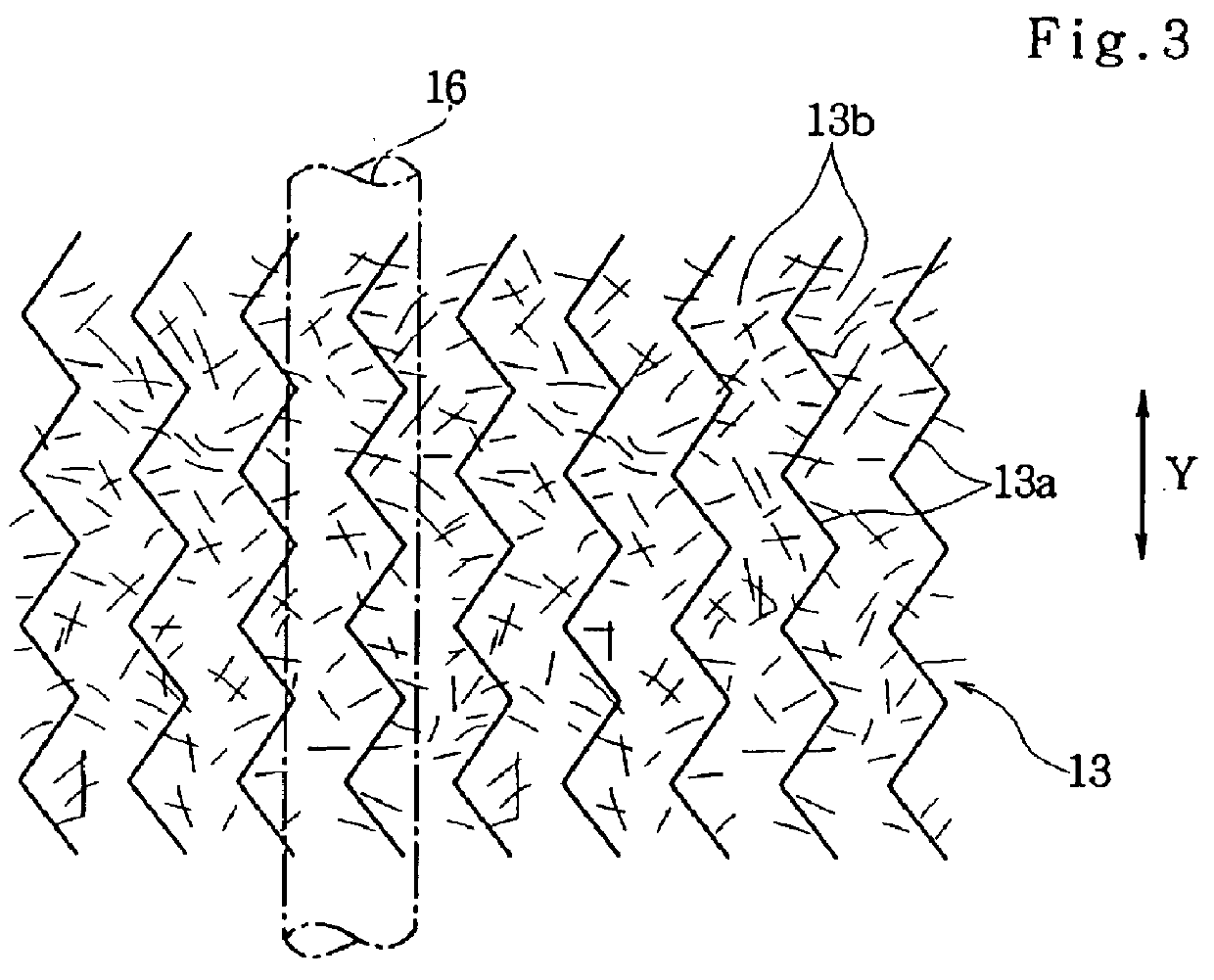

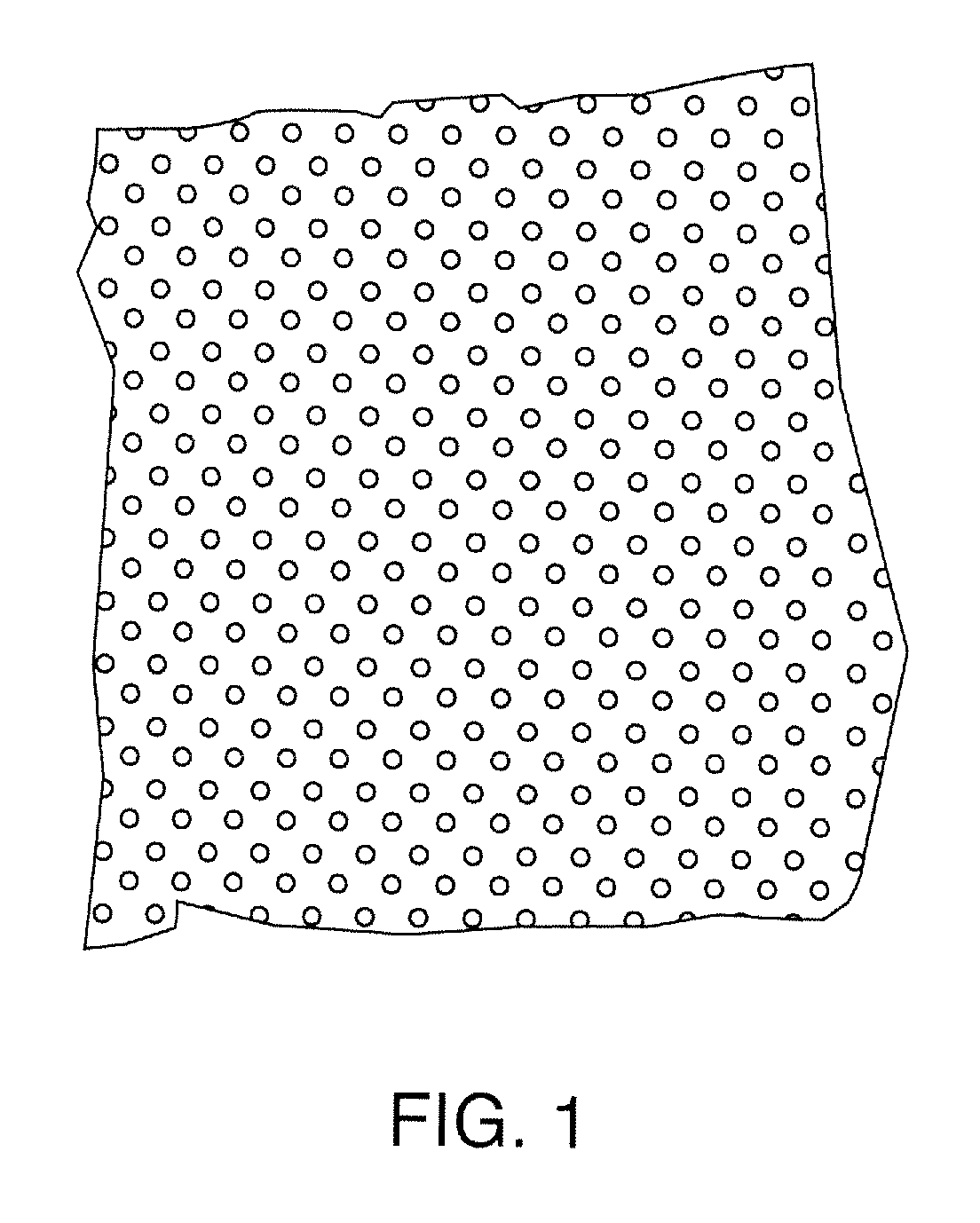

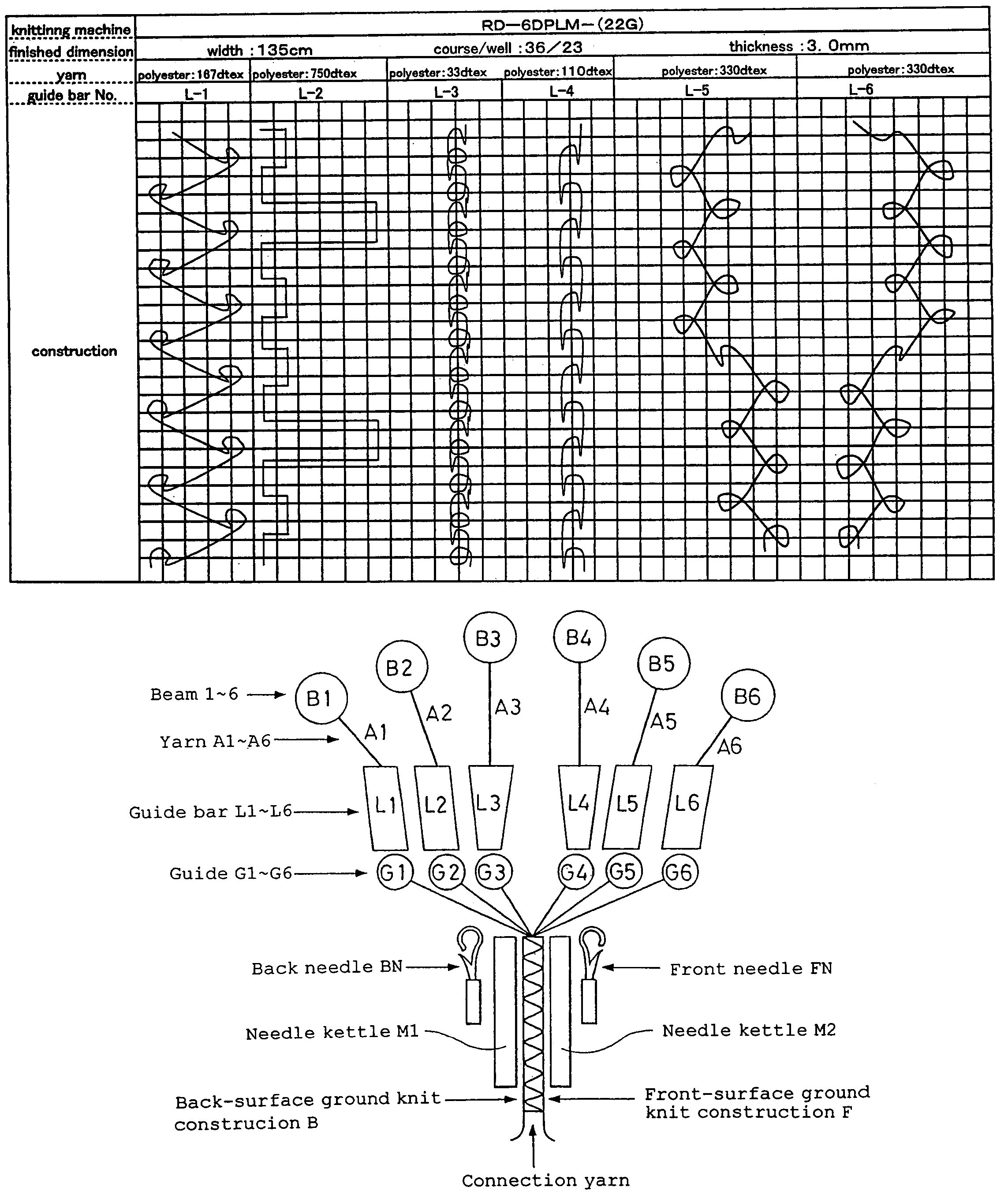

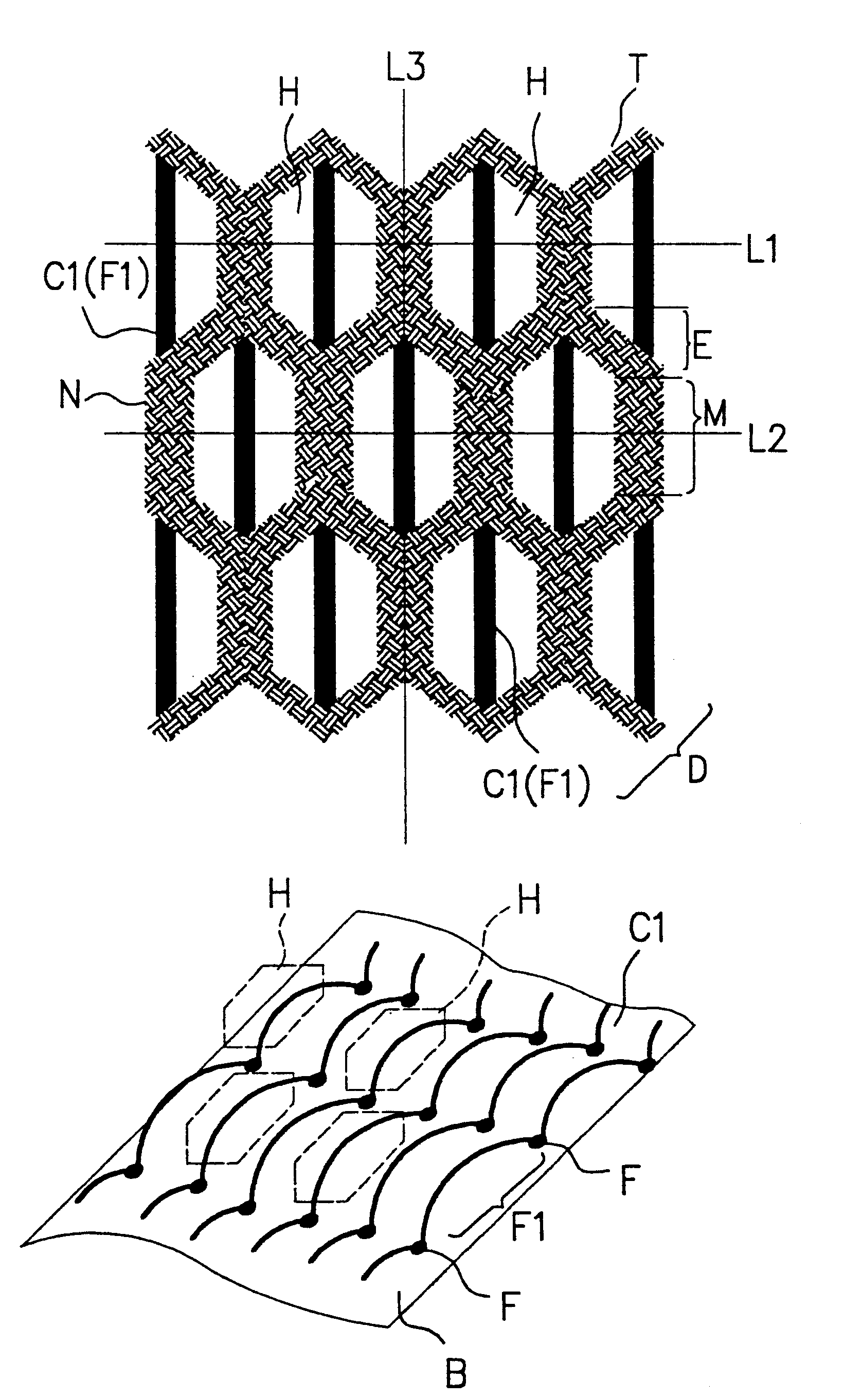

Three-dimensionally constructed warp knit fabric with slippage-preventive yarns

InactiveUS7213421B2Improve stress resistanceWithout impairing cloth flexibilityOrnamental textile articlesCircular knitting machinesEngineeringBuilding construction

A three-dimensionally constructed warp knit fabric formed to include front-surface and back-surface ground knit constructions and connection yarns interconnecting the front-surface and back-surface ground knit constructions has insertion yarns between the connection yarns, in which the insertion yarn is fixed along the inner side of the back-surface ground knit construction. Further, the insertion yarn is fixed by a fixing yarn to the back-surface ground knit construction.

Owner:SEIREN CO LTD

Shoe Upper Structure

A shoe upper structure includes an upper layer and a lower layer. The upper layer includes a slot and a plurality of shoelace holes. The upper layer further includes a plurality of blocks having patterns thereon. The lower layer is engaged with an inner surface of the upper layer and can be connected with a shoe sole. Front ends of the lower and upper layers are associated to form a front closing edge, and rear ends of the lower and upper layers are associated to form a rear closing edge. Two sides of the lower layer are spaced from two sides of the upper layer so that the upper layer can be stretched up, and a rear section of the slot can form a heel opening. The upper and lower layers and the front and rear closing edges are integrally formed with elastomeric yarns by a warp knitting machine.

Owner:HSIAO CHENG TUNG

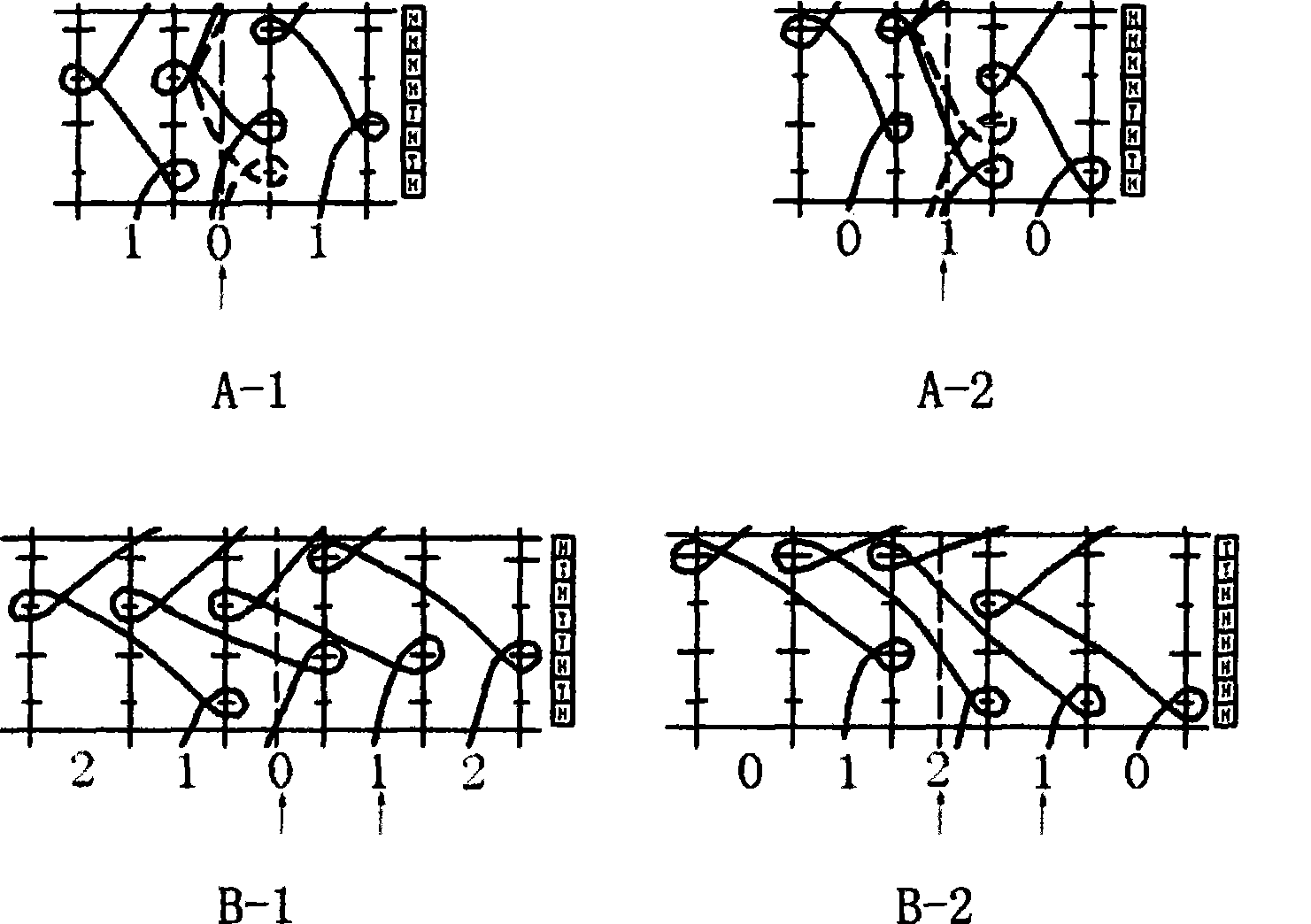

Knitting method for warp-knitting jacquard seamless fabric

InactiveCN101487164ARich organizational structurePattern effect is goodWarp knittingEngineeringMechanical engineering

The invention discloses a method for knitting warp-knitting jacquard-weave seamless textile, comprising the specific process flows as follows: firstly, a basic knitting process is determined; as for the general warp-knitting seamless jacquard-weave textile, a front needle bed and a rear needle bed respectively uses a guide bar to knit base fabric and respectively uses a jacquard weave guide bar to knit main jacquard weave patterns and tissues for connecting front sheets and rear sheets; secondly, information of main jacquard lapping movement and corresponding jacquard needle movement formed by the jacquard weave guide bar is determined; and finally, information of the lapping movement and jacquard weave needle action at the edge of the front garment piece and the rear garment piece is determined. The method utilizes specific process to lead certain needles at the jacquard weave guide bar to knit the edge connecting tissue and lead other jacquard weave needles to knit main patterns, thus forming the textile with natural connection and rich patterns; furthermore, additional guide bars are not used for connecting the edge, thus greatly simplifying the knitting method and improving the design efficiency and production benefits radically.

Owner:JIANGNAN UNIV

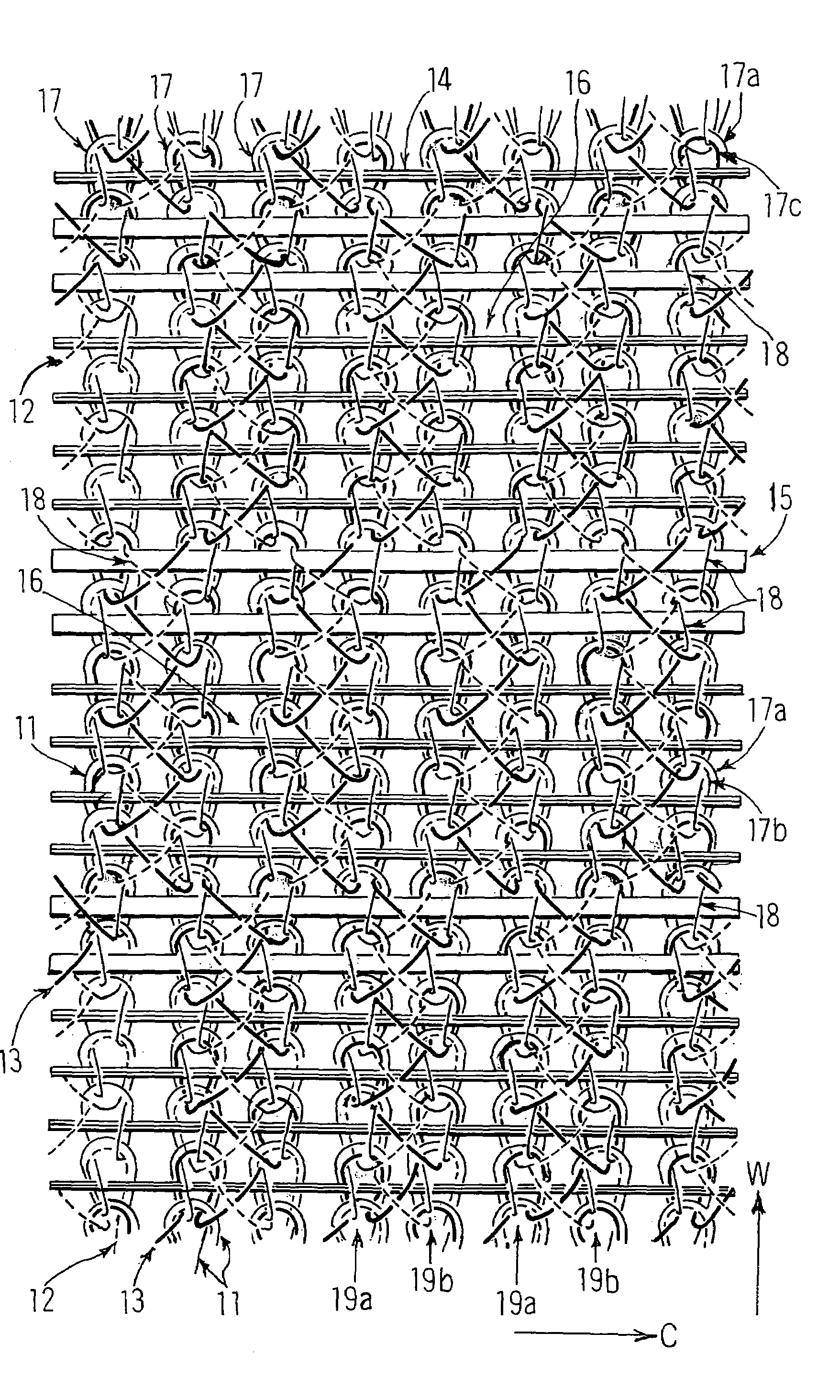

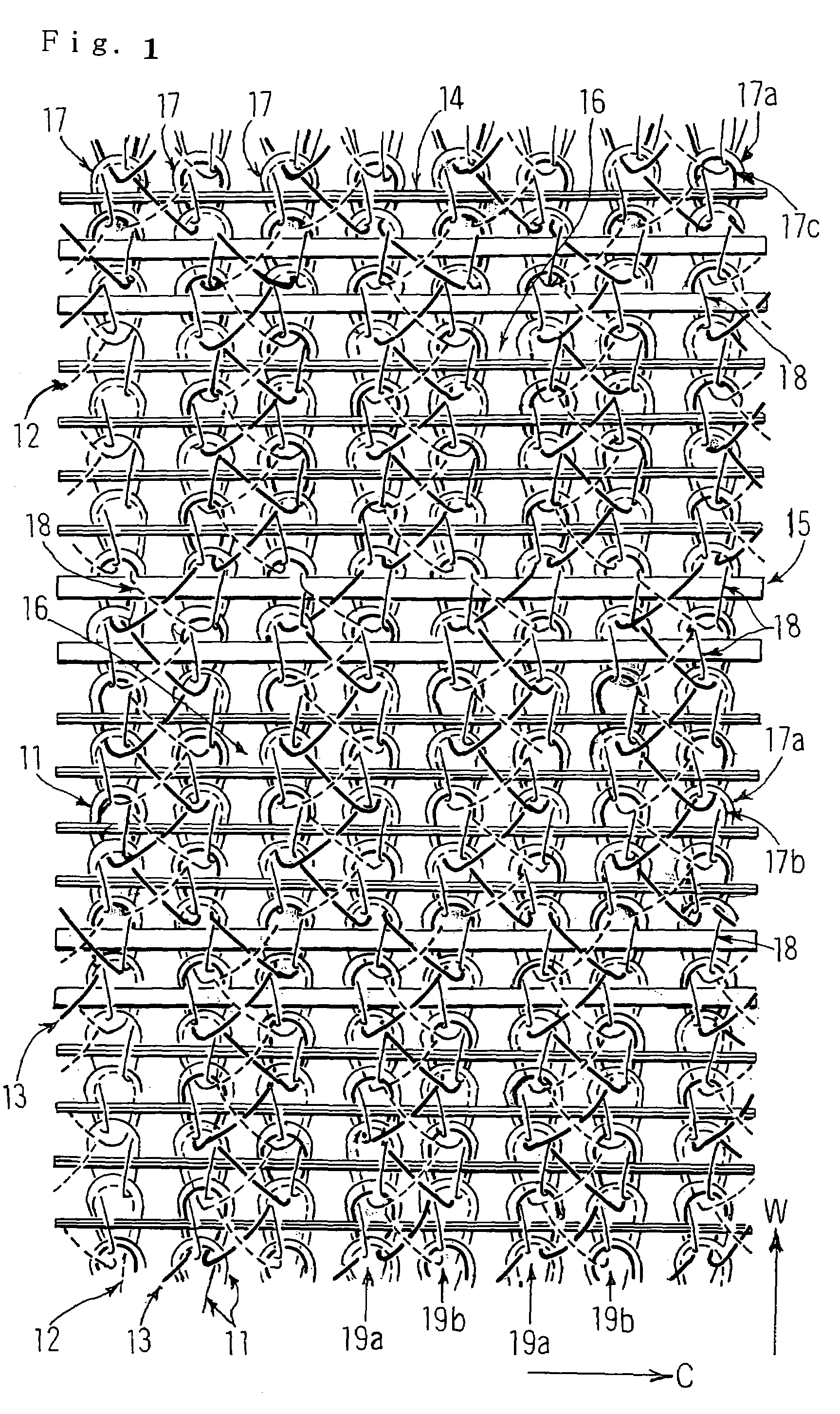

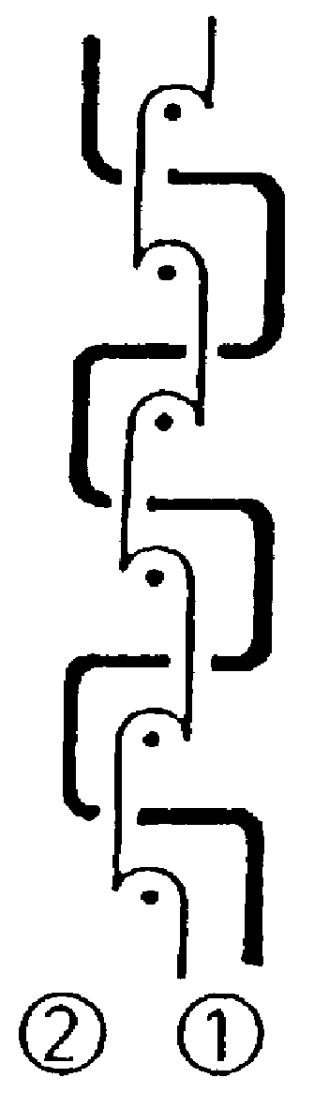

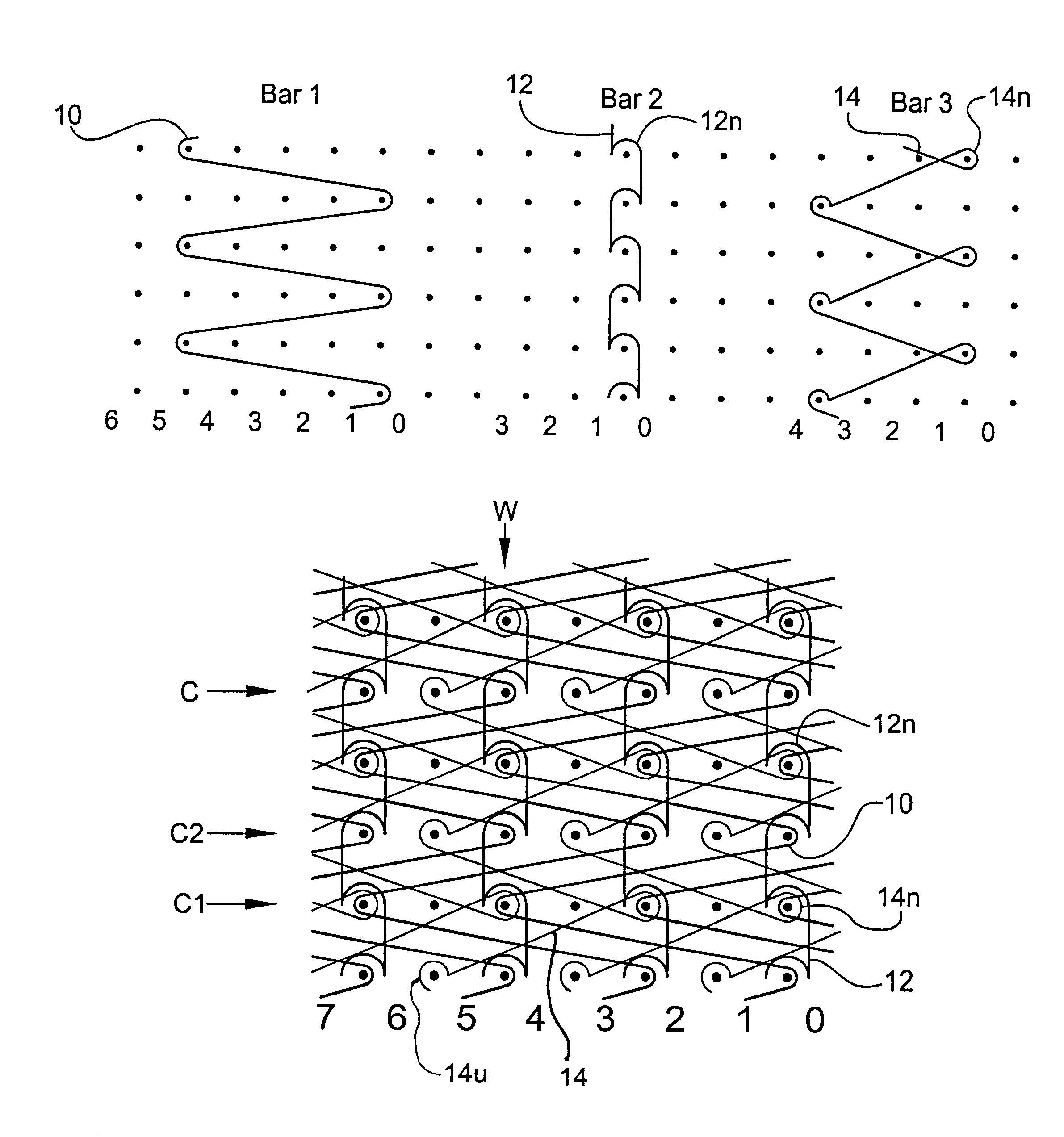

Stretchable loop-type warp knitted textile fastener fabric and method of producing same

A warp knitted textile fabric and a method of producing such a fabric, characterized by a resiliently stretchable three-bar stitch construction, one fabric surface of which presents outwardly extending knitted loops adapted to serve as the loop component in a hook-and-loop fastener system. The fabric is knitted on a warp knitting machine by interknitting ground, elastic and loop-forming yarns together in knitted stitches on spaced needles in spaced fabric courses and interknitting stitches of the ground and elastic yarns on the same spaced needles in intervening courses while forming loops of the loop-forning yarns on inactive intervening needles to be cast off without integration into the ground structure of the fabric so as to form outwardly extending pile loops on one fabric surface. The pile loops do not require brushing or napping to render the fabric suitable for use in a hook-and-loop fastener system.

Owner:GFD FABRICS +1

Printing method of different patterns of double surfaces of warp knitting plush single-layer blanket

ActiveCN103741364AAnti-stickingFeel smooth and plumpWarp knittingHeating/cooling textile fabricsRough surfaceEngineering

Provided is a printing method of different patterns of double surfaces of a warp knitting plush single-layer blanket. Appropriate raw materials are selected to be woven to form grey cloth, secondary removing presetting is conducted, and then pre-processing is conducted; after reverse-side napping tidying is conducted on the warp knitting plush grey cloth in a pre-processing procedure, various printing parameters are regulated according to gram weights and plush heights of the warp knitting plush single-layer blanket, the front side is printed firstly, then the reverse side is printed, and a semi-finished plush single-layer blanket with the different patterns on the front side and the reverse side is obtained; brushing, ironing, shearing, cloth cutting and edge covering are conducted on the front side and the reserve side of the semi-finished plush single-layer blanket, and the finished plush single-layer blanket is obtained. The printing method is reasonable in technology, the blanket with the different patterns on the front side and the reverse side can be obtained, product diversity is improved, the printing effect is good, white plush can not occur on the surface of the warp knitting plush single-layer blanket, the rough surface is glossy and bright, the plush surface is tidy, relatively elastic, and soft and smooth in hand feeling, and the warp knitting plush single-layer blanket achieves quality of a top-grade blanket.

Owner:连云港飞雁毛毯有限责任公司

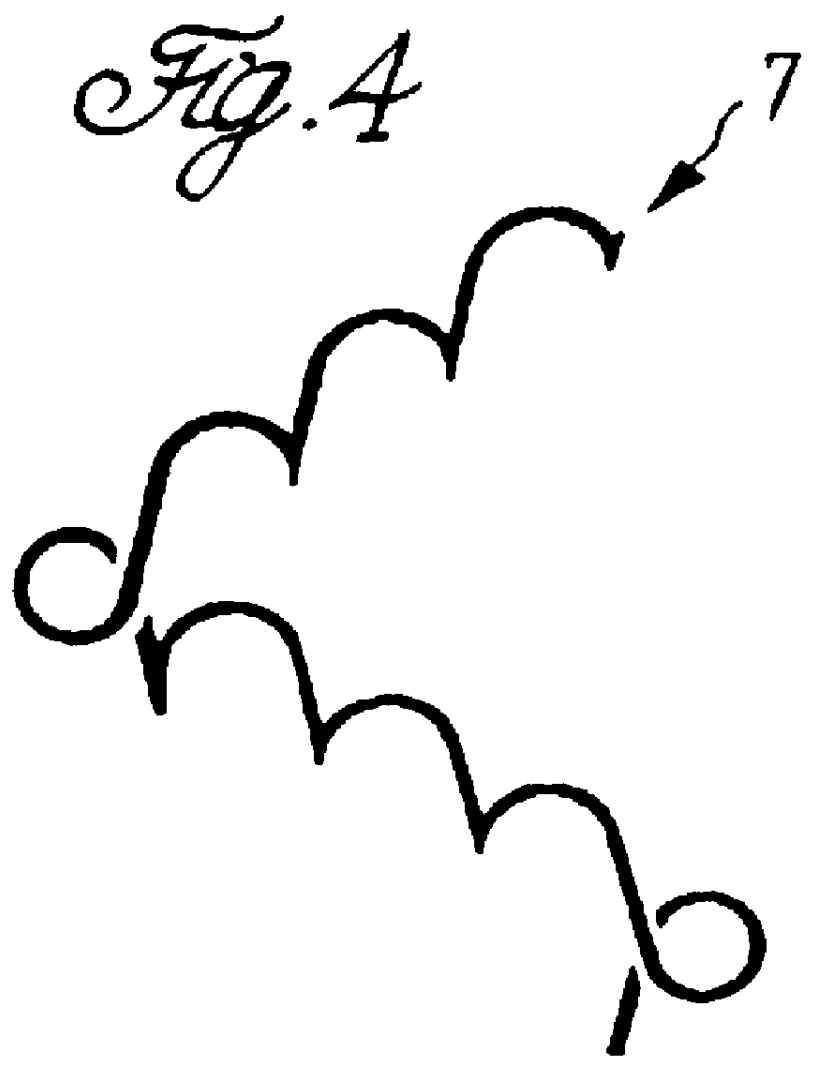

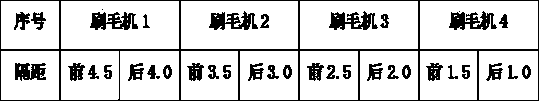

Processing method of warp knitting plush fabrics with burning out printing terylens

InactiveCN101876121AImprove the three-dimensional effectIdeal embossing effectPattern makingHeating/cooling textile fabricsPolyesterEngineering

The invention relates to a processing method of warp knitting plush fabrics with burning out printing terylens. The processing method comprises the following steps of: materials selection: selecting DTY (Draw Textured Yarn) terylen low stretch yarns from 75 D to 150 D as felted yarn materials and selecting FDY (Fully Drawn Yarn) semi-dull polyester yarns from 50 D to 100 D as ground yarn materials, wherein the DTY terylen low stretch yarns account for 60-80% of the fabrics by weight percent, and the FDY semi-dull polyester yarns account for 20-40% of the fabrics by weight percent; weaving or slitting after weaving; thermally forming or pretreating after thermally forming; brushing and cropping the front surface or brushing and cropping the back surface, cropping the back surface and pilling; post-forming; burning out printing: carrying out burning out printing on grey fabrics subjected to the post-forming by using a burning out printing alkali slurry; steaming; post-treating; and forming a finished product. By the technical scheme, the fabrics can achieve the advantages of strong third dimension of patterns, ideal sculptured pattern effects and favorable shininess, residues does not generate in the weaving process, which is beneficial to protecting warp knitting machines.

Owner:CHANGSHU XINXIN WARP & KNITTING

Method for weaving stereoscopic vamp

The invention provides a method for weaving a stereoscopic vamp. The method includes the following steps that yarn knitting is carried out through a warp knitting machine, yarn is knitted to form an upper vamp body through a first needle bed of the warp knitting machine, the upper vamp body and a lower vamp body are interwoven to form a cylindrical fabric, and the lower vamp body is formed through weaving yarn through a second needle bed of the warp knitting machine; the cylindrical fabric is cut to form a sock-shaped fabric; a last is sleeved with the sock-shaped fabric; the sock-shaped fabric is heated at a high temperature, so that the sock-shaped fabric shrinks and is attached to the last, and accordingly the stereoscopic vamp is obtained. The heat shrinkable and irreversible features of high-shrinkage yarn or hot-melt yarn are used, so that the sock-shaped fabric is attached to the last, and the yarn has enough physical property. By means of the manufacturing processes, the vamp is formed at a time, and the effects of reducing worker cost and reducing waste fabrics can be achieved.

Owner:LONG JOHN TSUNG RIGHT IND

A warp knitting method for double-color jacquard seamless fabric

The invention discloses a warp knitting method for double-color jacquard seamless fabric. The concrete process is as follows: first, determining basic knitting process; each of front and back needle bed uses one ground guide bar for knitting base cloth and two jacquard guide bar for knitting main jacquard pattern and connection tissue for front and back sheet; second, determining overlap of main pattern formed by jacquard comb and corresponding motion information of jacquard needle, combines corresponding basic motion information of jacquard needle; finally, determining overlap of edge of front and back sheets and motion information of jacquard needle by adopting superposition method. The invention adopts special machine configuration and specific process, knits double-color seamless fabric, completes warp knitting jacquard seamless fabric with concurrent structural effect and color effect. The seamless fabric of the inventive method has a solid pattern and outstanding layers, rich color, variable structural effect, massive thickness, thereby largely promoting market competitive force of seamless fabric.

Owner:JIANGNAN UNIV

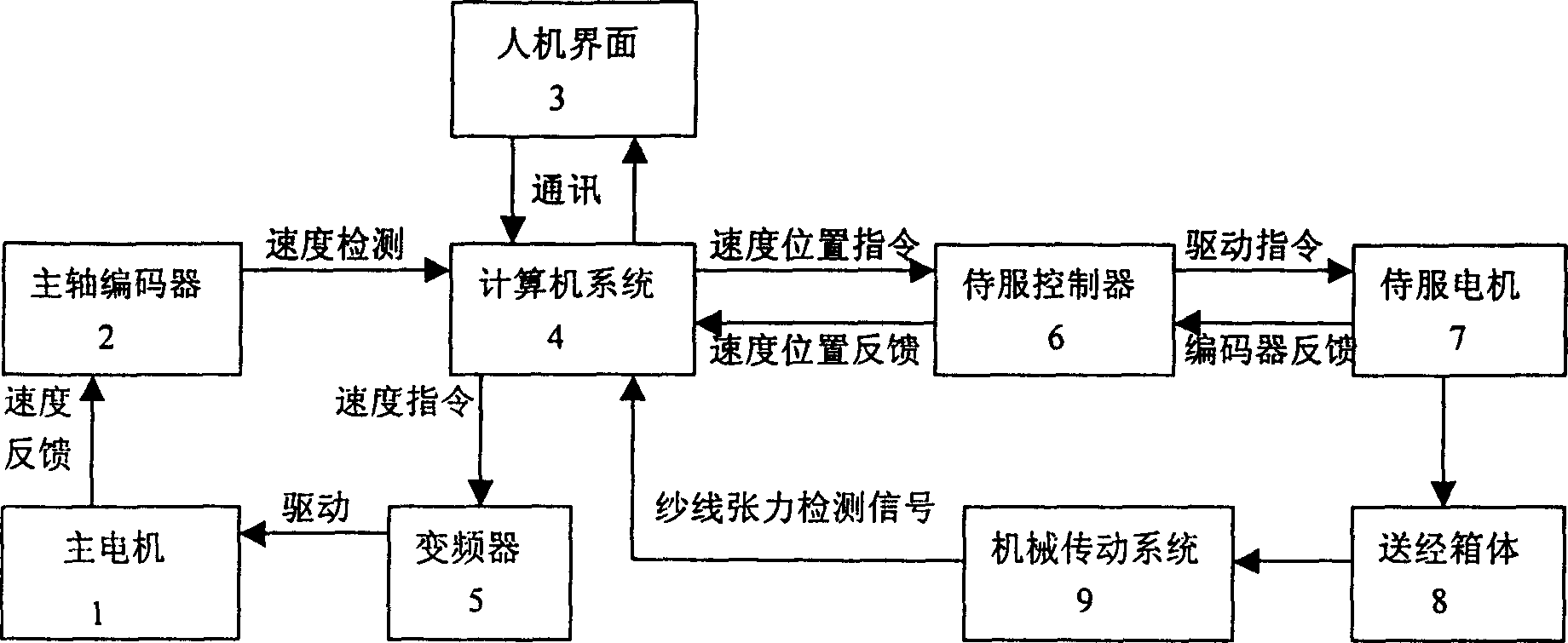

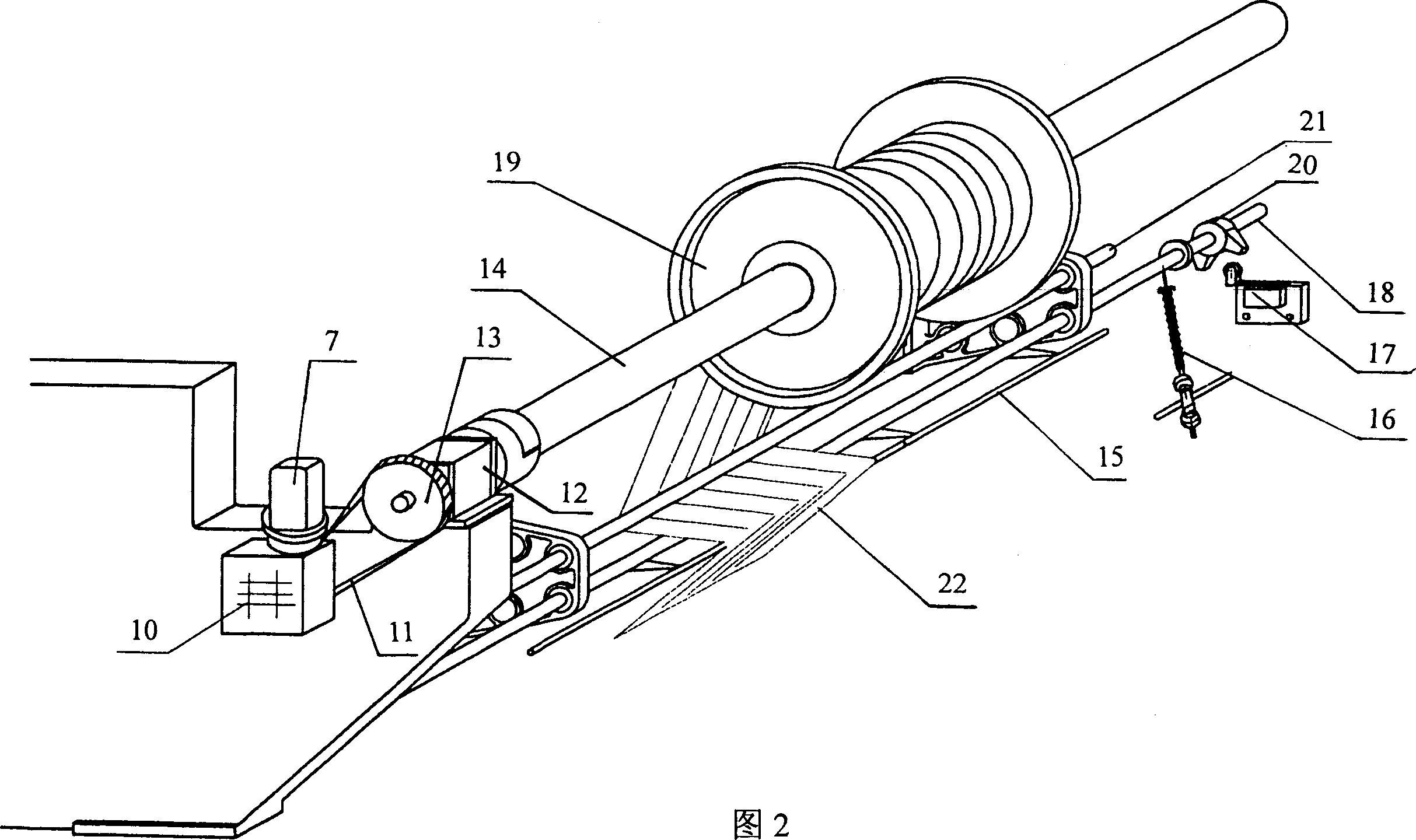

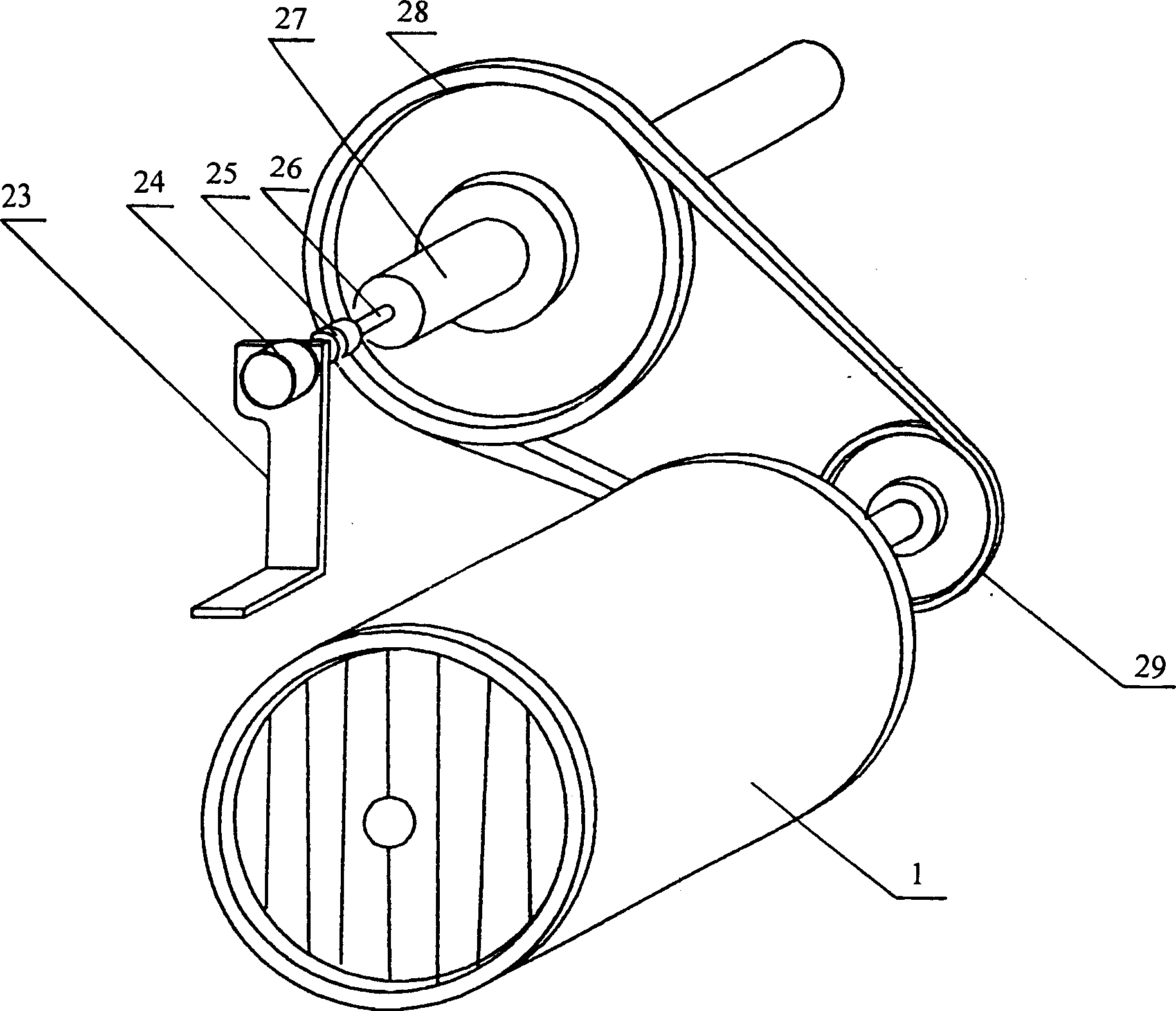

Electronic warp feeding system of warp knitting machine

InactiveCN1827886AGood high speed performanceStable and accurate let-offWarp knittingComputerized systemElectric machinery

The invention relates the warp knitting machine electronic let-off system, comprising main motor(1), chief axis encoder(2), computer system(4), converter(5), controller(6), motor(7), warp let-off box(8) and mechanical gearing system(9). The computer system (4) controls the main motor by converter (5). On the base of real-time rotary speed detection signal, the computer enters processing parameter and sends active instruction. The invention has the advantages of high-speed property, exact and steady warp run-in, easy adjustment, short operation processing time, and adopting multiple speed and position reaction to realize optimum dynamic adjustment.

Owner:康盘方

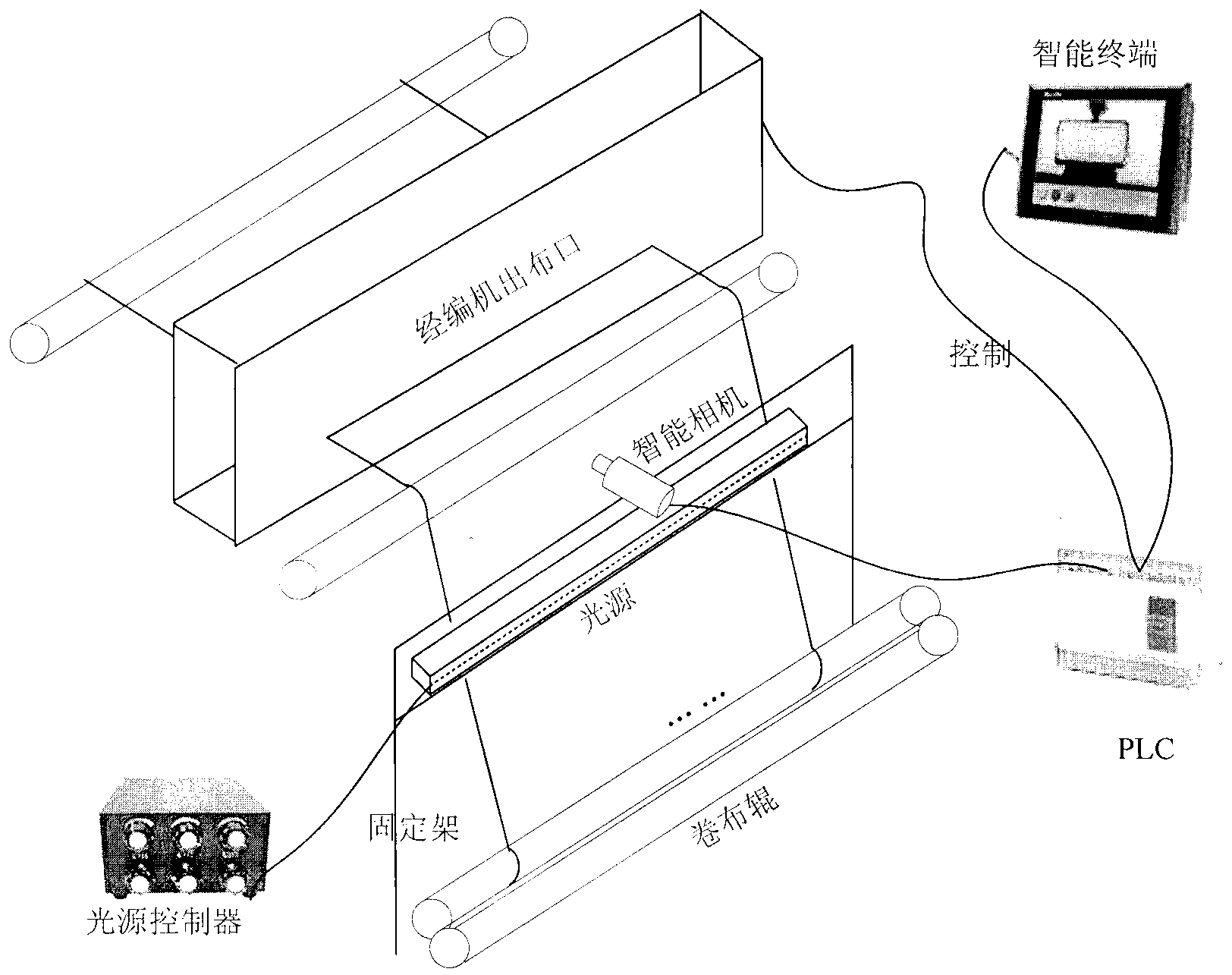

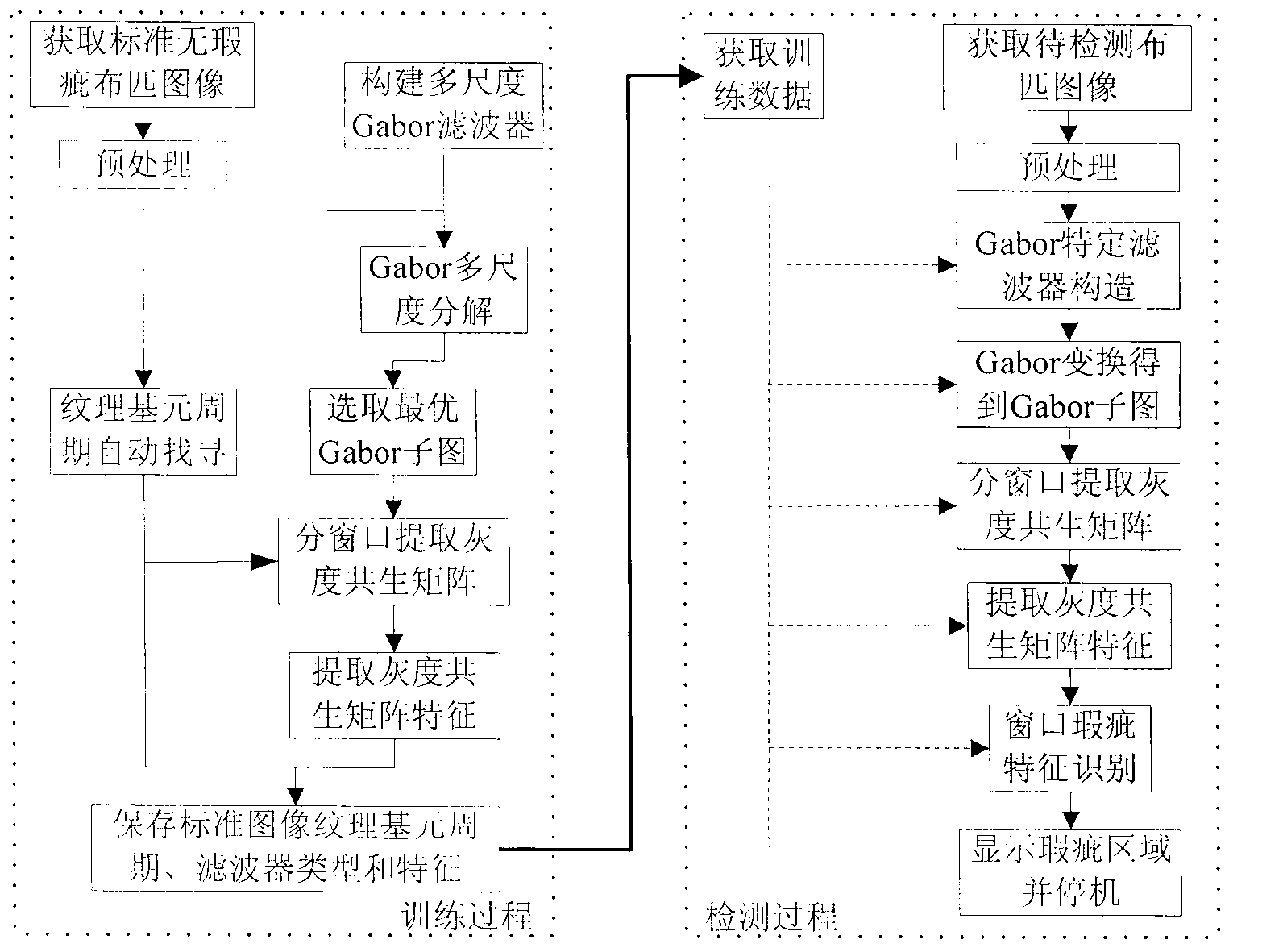

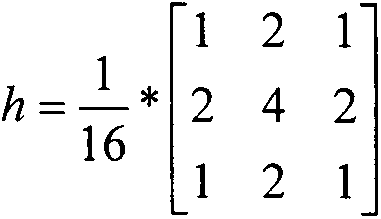

Warp knitting machine cloth flaw on-line visual inspection method based on Gabor transformation

ActiveCN103234976AEliminate computationally expensiveEliminate the disadvantages of data redundancyOptically investigating flaws/contaminationWarp knittingFeature extraction

The invention provides a warp knitting machine cloth flaw on-line visual inspection method comprising Gabor transformation, character extraction, and flaw identification. With the method, warp knitting machine cloth real-time monitoring and machine stopping on detecting flaw can be realized. With the method, defects such as large data calculation amount and information redundancy when traditional Gabor multi-scale decomposition-fusion is used in the field of flaw detection can be solved. Texton cycle is automatically searched, such that window automatic separation can be carried out by the system, characteristic extraction is facilitated, and non-precision caused by different object manual window size input is avoided. With an offline detection algorithm, fast Gabor transformation, fast characteristic extraction and flaw identification can be realized under the guidance of the offline data. Therefore, requirements of high timeliness and high accuracy of warp knitting machine cloth flaw on-line detection can be completely satisfied.

Owner:JIANGNAN UNIV +1

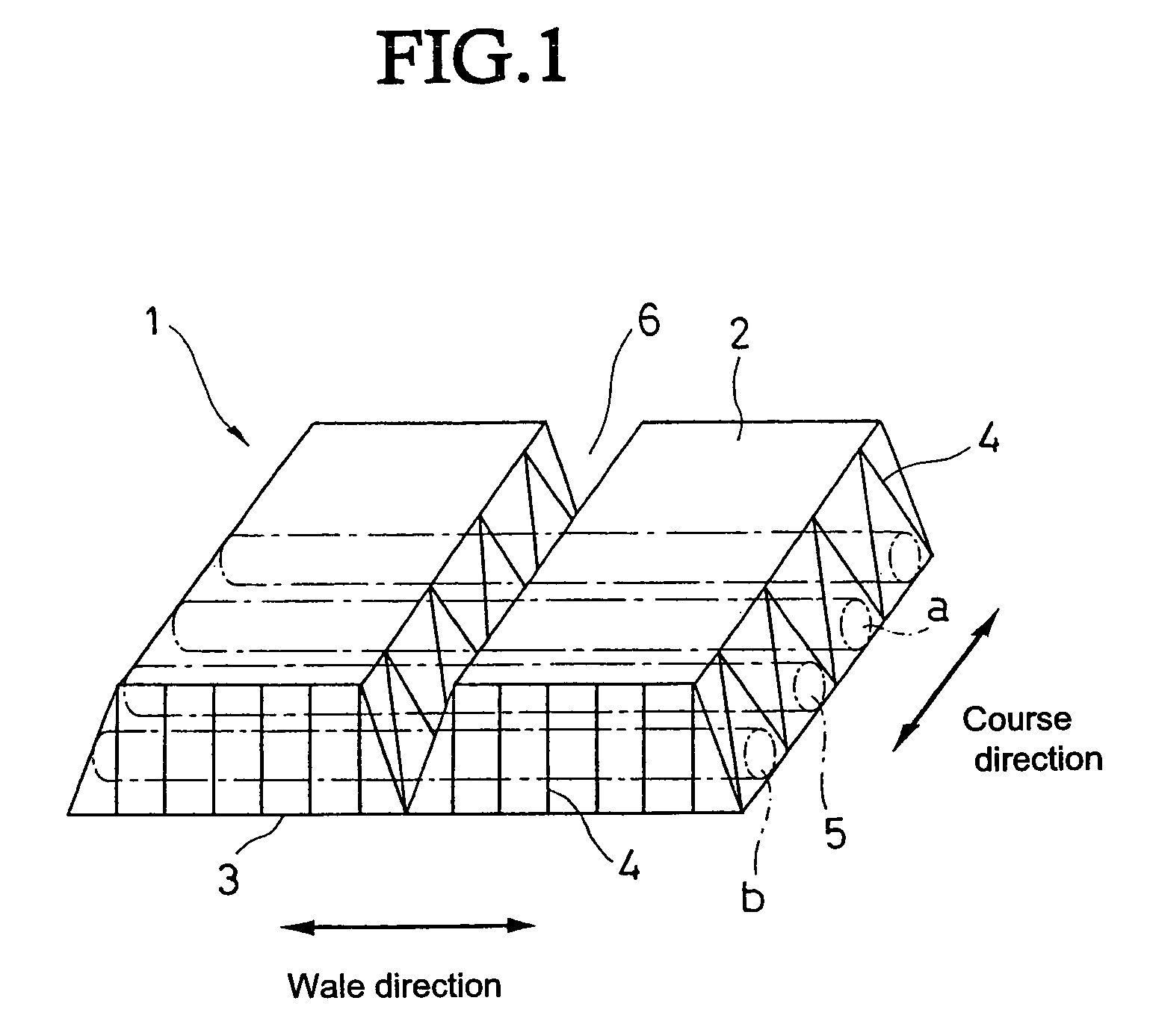

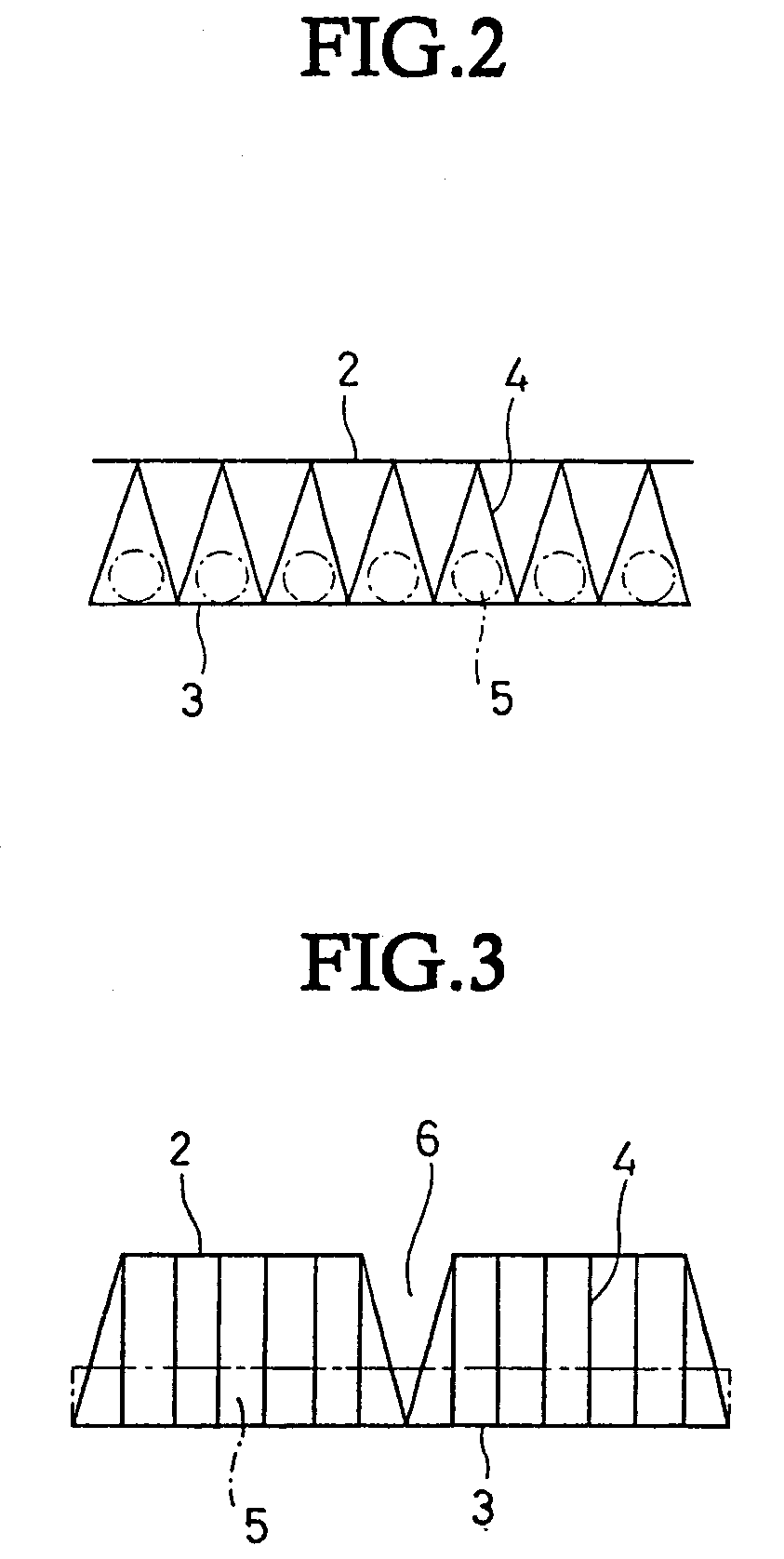

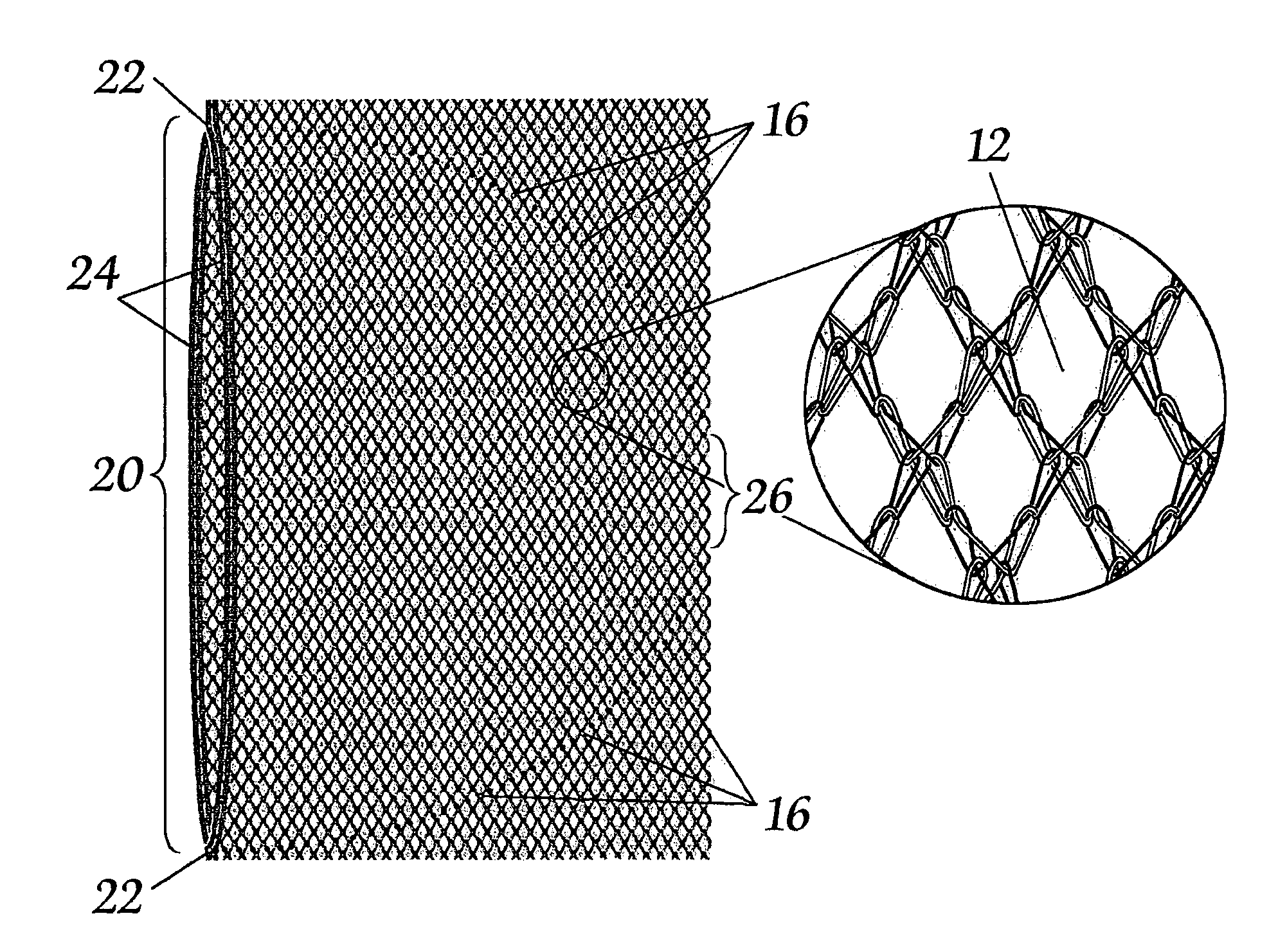

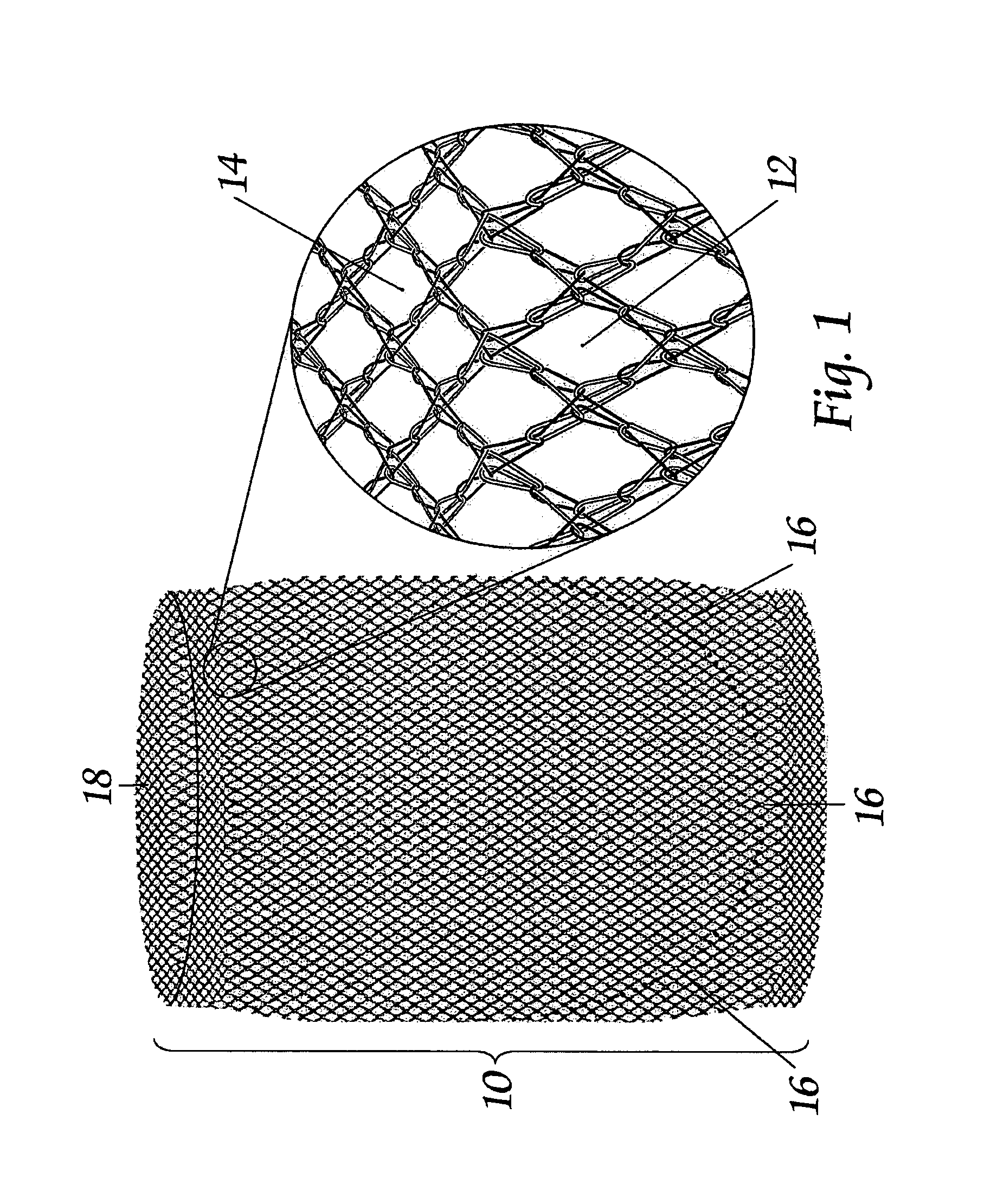

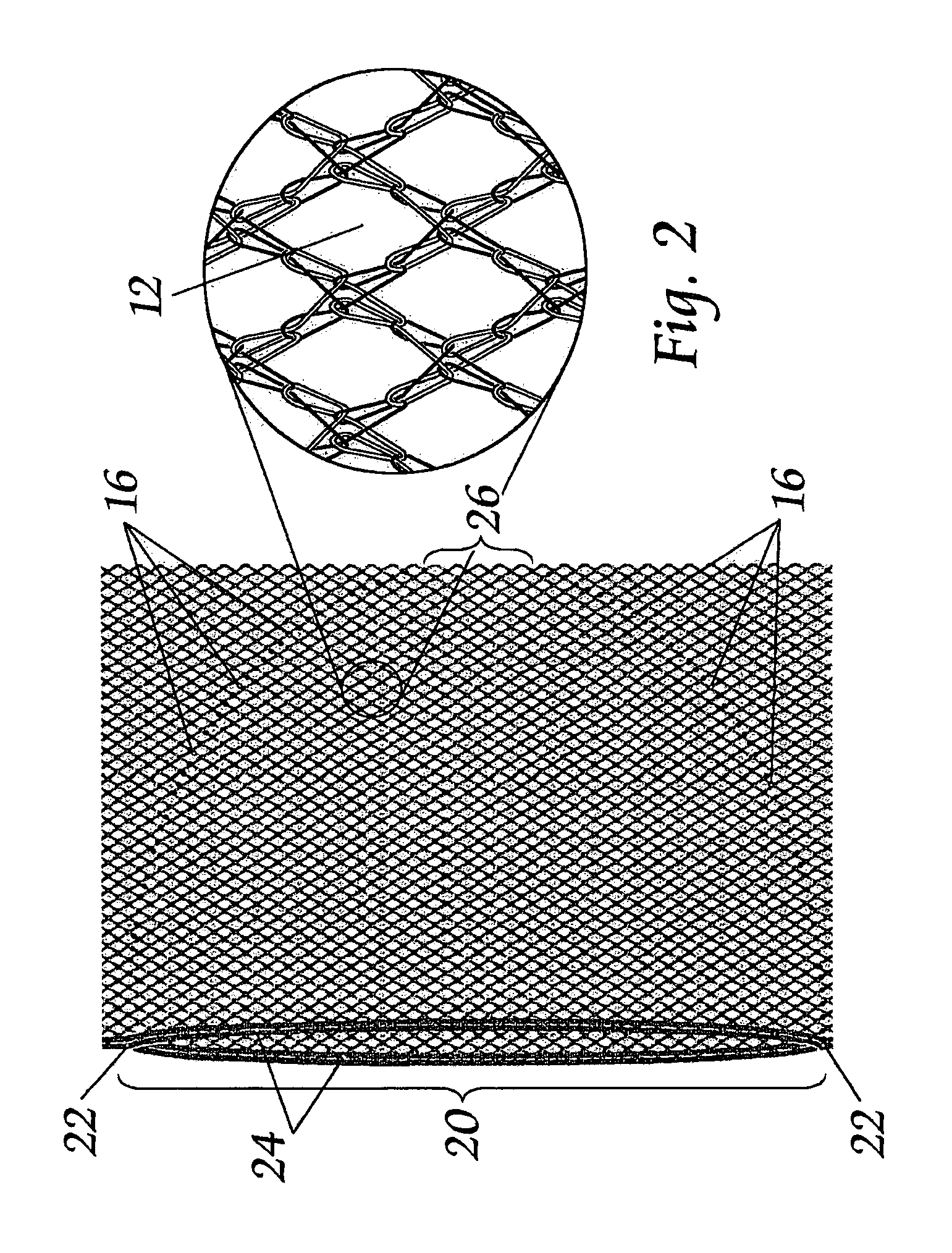

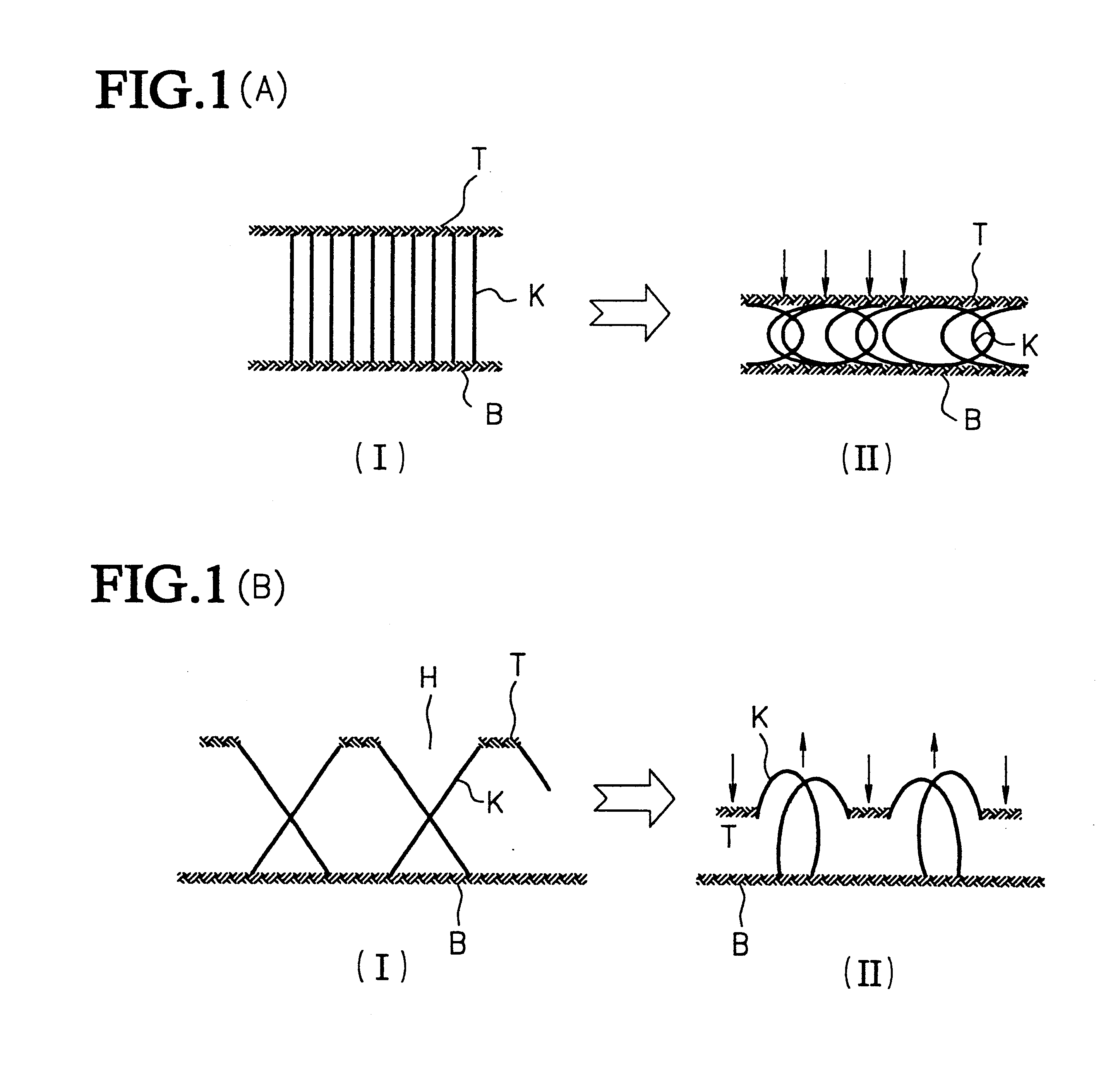

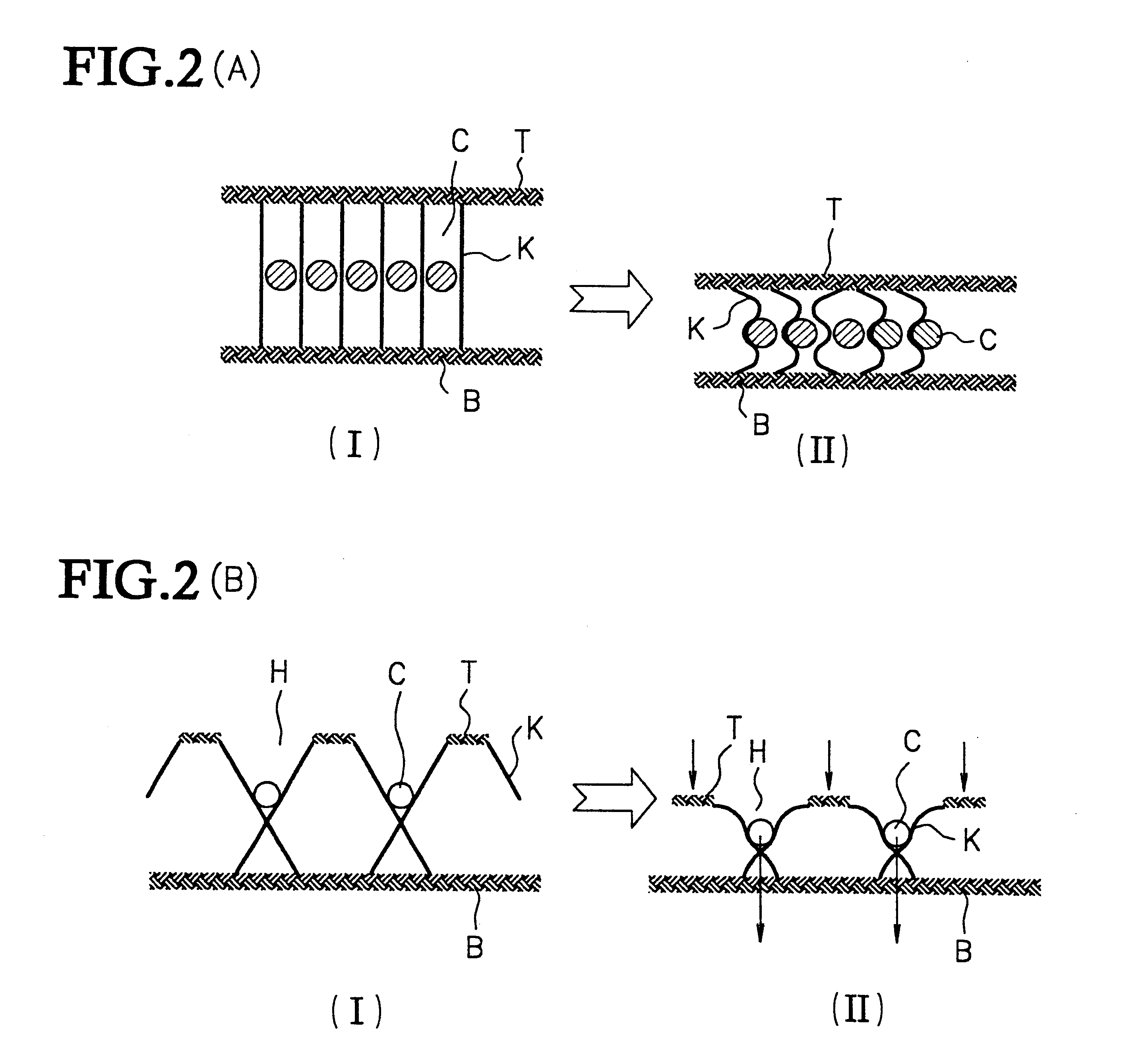

Three-dimensionally structured warp knitted fabric

InactiveUS20020104335A1Minimize bendingDeterioration in its resiliencyOrnamental textile articlesWarp knittingCompressibilityEngineering

It is an object of the present invention to provide a three-dimensionally structured warp knitted fabric which has higher compressibility and resiliency than its conventionally available counterpart, as well as enhanced abrasion resistance to prevent its fuzzing. A three-dimensionally structured warp knitted fabric consisting of a top substructure and a bottom substructure, either of which is a net texture, the other being a plain texture, and yarns connecting said two substructures with a plurality of yarns present between said two substructures and between said substructure connecting yarns adjacent to each other to control the substructure connecting yarns by handling, separating and holding them, said connecting yarn controlling yarns comprising points at which they are stitched into said plain texture side of the top or bottom substructure and portions where they are floating between the top and bottom substructures.

Owner:SEIREN CO LTD

New-type bamboo charcoal fibre blanket and manufacturing method thereof

InactiveCN101603241AImprove breathabilityGood moisture absorptionFibre treatmentWarp knittingPolyesterYarn

The invention relates to a new-type bamboo charcoal fibre blanket, belonging to the technical field of blanket processing. The blanket material comprises surface silk and base silk; the surface silk is 0.39dtex-2.7dtex DTY polyester yarn which is added by bamboo charcoal female particles while base silk is 50D-200DFDY polyester yarn, wherein, the surface silk is 60-75% of material weight while base silk is 40-25% of material weight. The manufacturing process comprises the following steps in turn: sorting, knitting and weaving, slitting, pre-dyeing treatment, heat setting dyeing, dyed fabric after treatment, napping, shaking and erecting, and natural luster finishing (shearing) finished product finalizing. The product in the invention has the advantages of bright color, superior adsorbability, antibiosis, bacteriostat and health care properties, satisfies the pursuit of 'ecological, healthy and environmental' of consumers and is an ideal home textile in modern household life.

Owner:徐建平

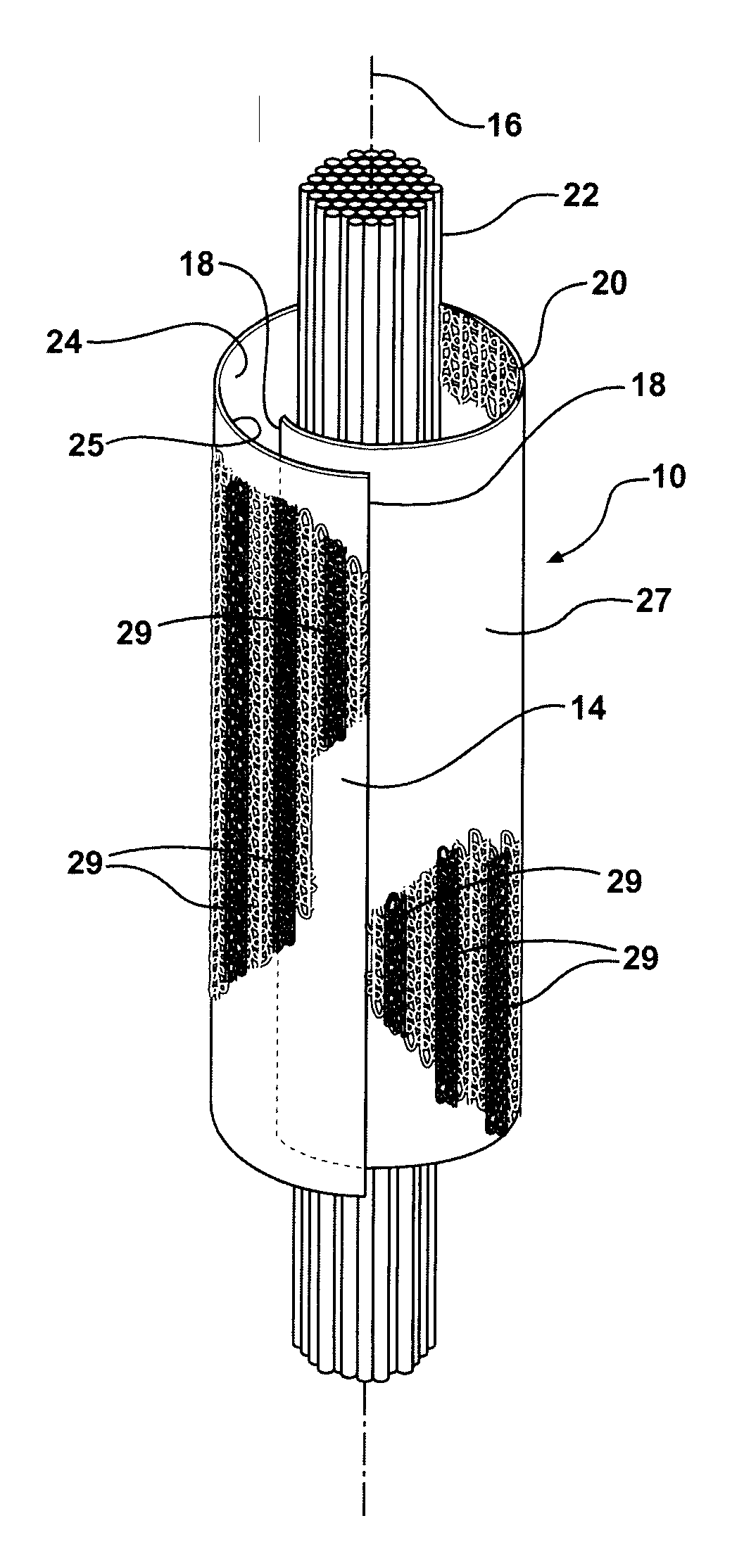

Warp knit fabrics useful for medical articles and methods of making same

ActiveUS7293433B1Easy to fixConstrain congestive heart failure related expansionHeart valvesMedical devicesHeart diseaseBiomedical engineering

Owner:ATEX TECH INC

Three-dimensionally structured warp knitted fabric

InactiveUS6758068B2Minimize bendingDeterioration in its resiliencyOrnamental textile articlesWarp knittingEngineeringCompressibility

A three-dimensionally structured warp knitted fabric has a higher compressibility and resiliency than its conventionally available counterpart, as well as enhanced abrasion resistance to prevent fuzzing. The three-dimensionally structured warp knitted fabric includes a top substructure and a bottom substructure, either of which is a net texture, the other being a plain texture. Substructure connecting yarns connect the two substructures. A plurality of connecting yarn controlling yarns are present between the two substructures and between the substructure connecting yarns. The connecting yarn controlling yarns control the substructure connecting yarns by handling, separating and holding them. The connecting yarn controlling yarns include portions which are stitched into the plain texture side of the top or bottom substructure and portions which are floating between the top and bottom substructures.

Owner:SEIREN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com