Warp knitting machine cloth flaw on-line visual inspection method based on Gabor transformation

A visual inspection and warp knitting machine technology, which is applied in the direction of optical testing for flaws/defects, can solve problems such as false detection, easy fatigue, slow speed, etc., and achieve the effect of eliminating large amount of calculation, high real-time performance, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

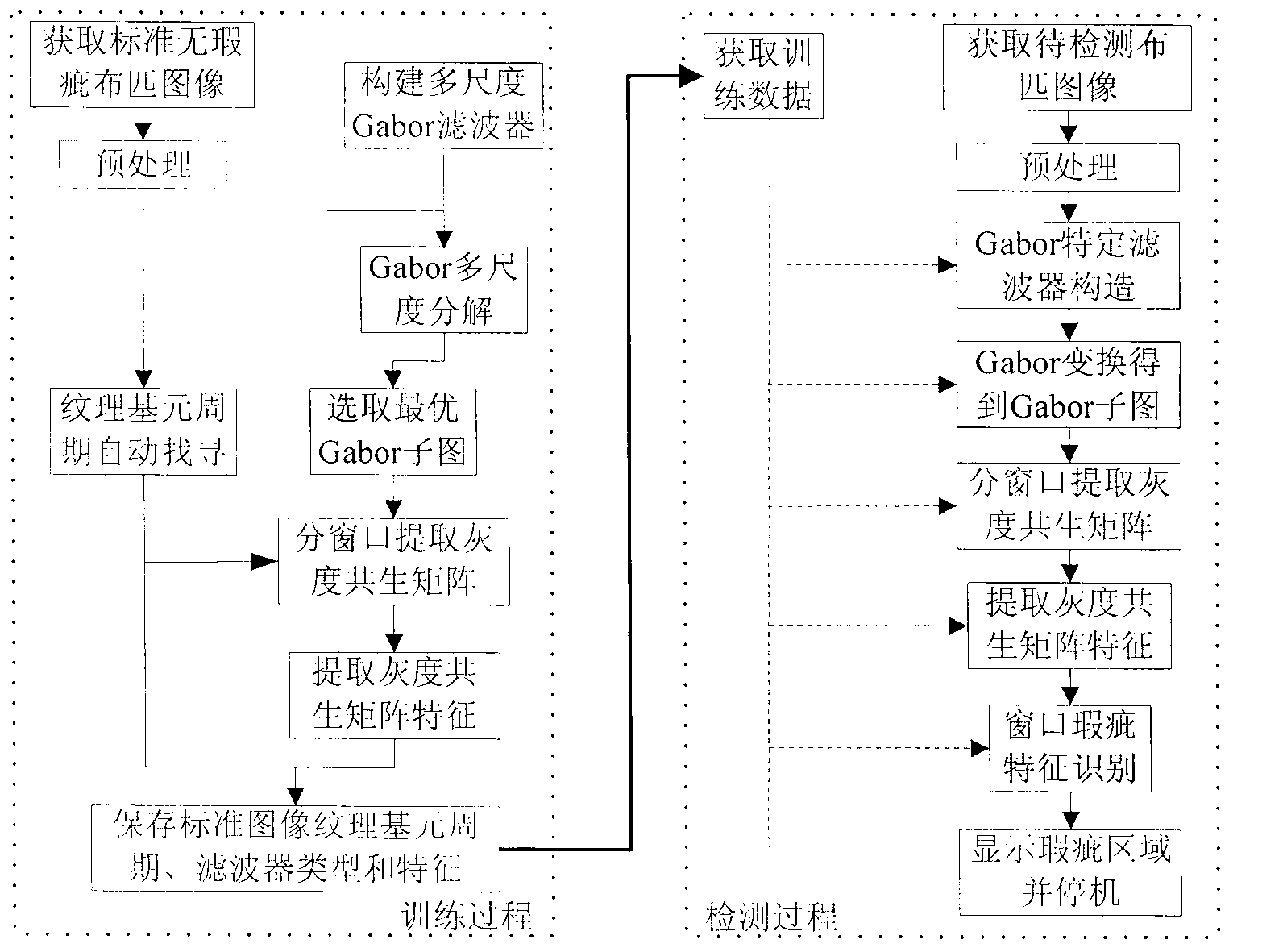

[0022] Such as figure 2 Shown is the overall flowchart of the algorithm of the present invention.

[0023] The algorithm is divided into offline testing and online testing process, the specific steps are as follows:

[0024] Offline testing process

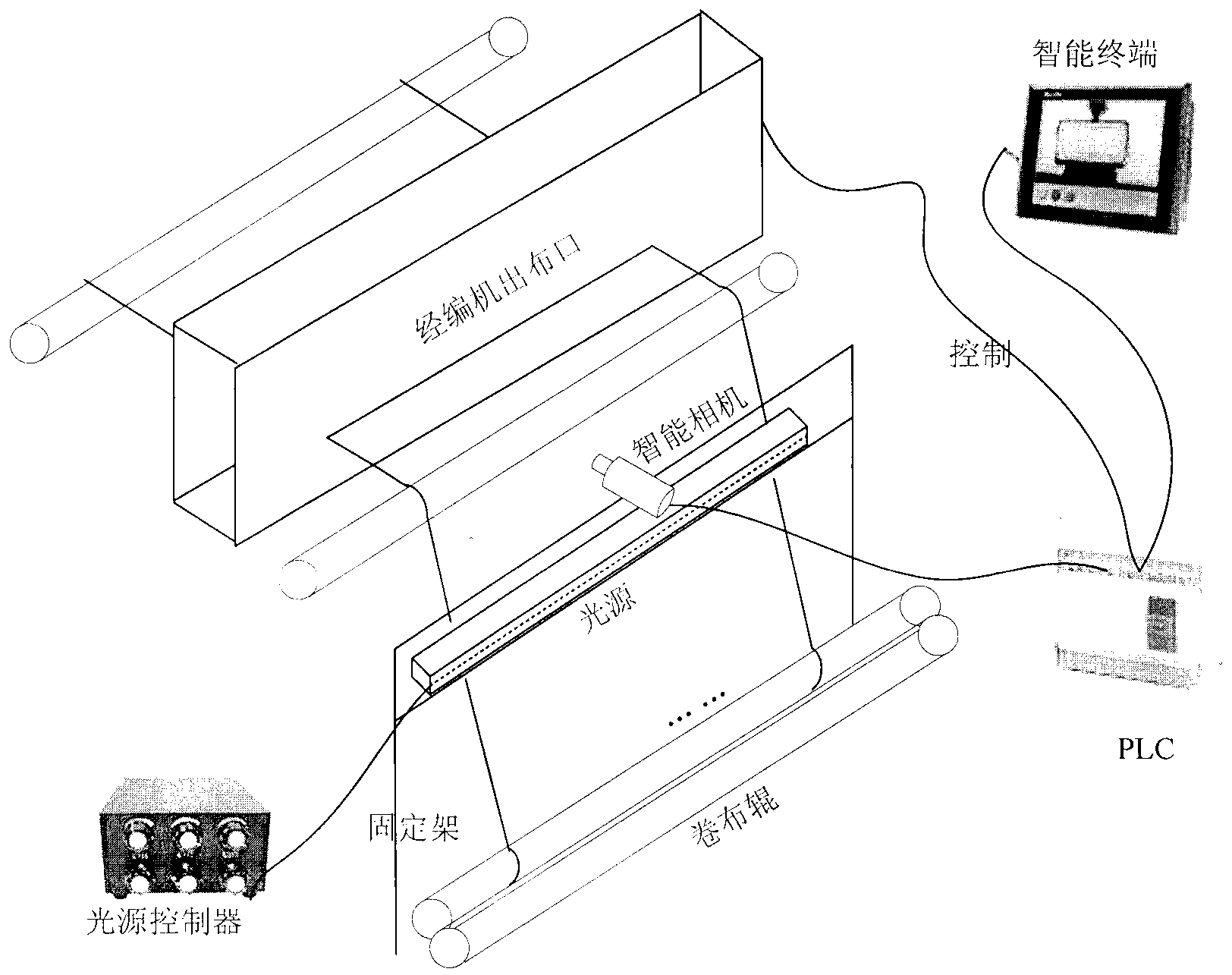

[0025] Step 1: Obtain the image of the flawless cloth of the warp knitting machine in real time, take pictures at about 5cm from the cloth outlet of the warp knitting machine, and obtain the image sequence of the warp knitting machine in real time.

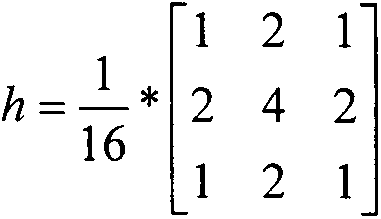

[0026] Step 2: Preprocess the acquired flawless cloth image, remove image interference points through Gaussian filtering; stretch the image through histogram equalization, enhance contrast, and highlight image texture.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com