Patents

Literature

125results about How to "Good high speed performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

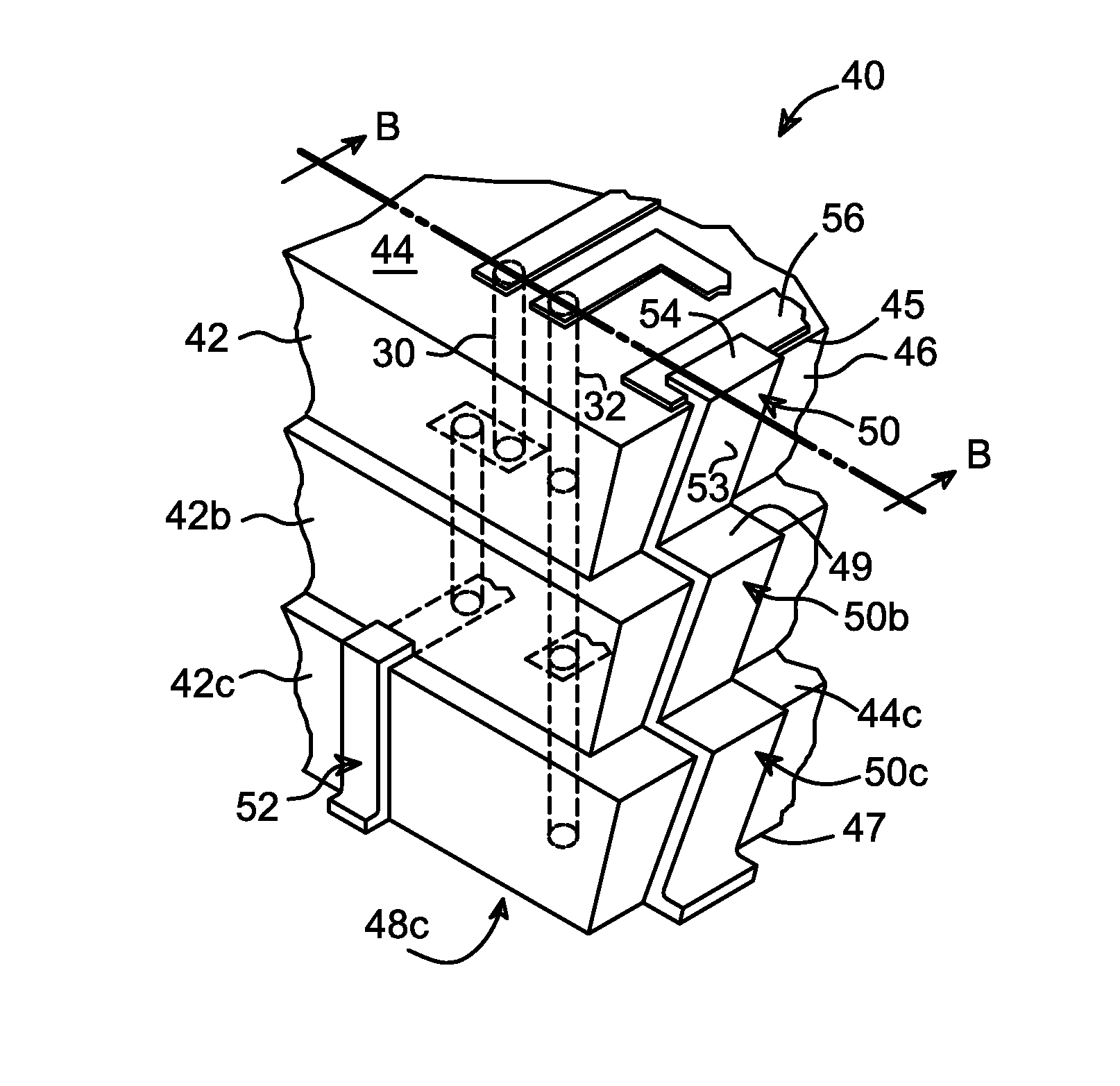

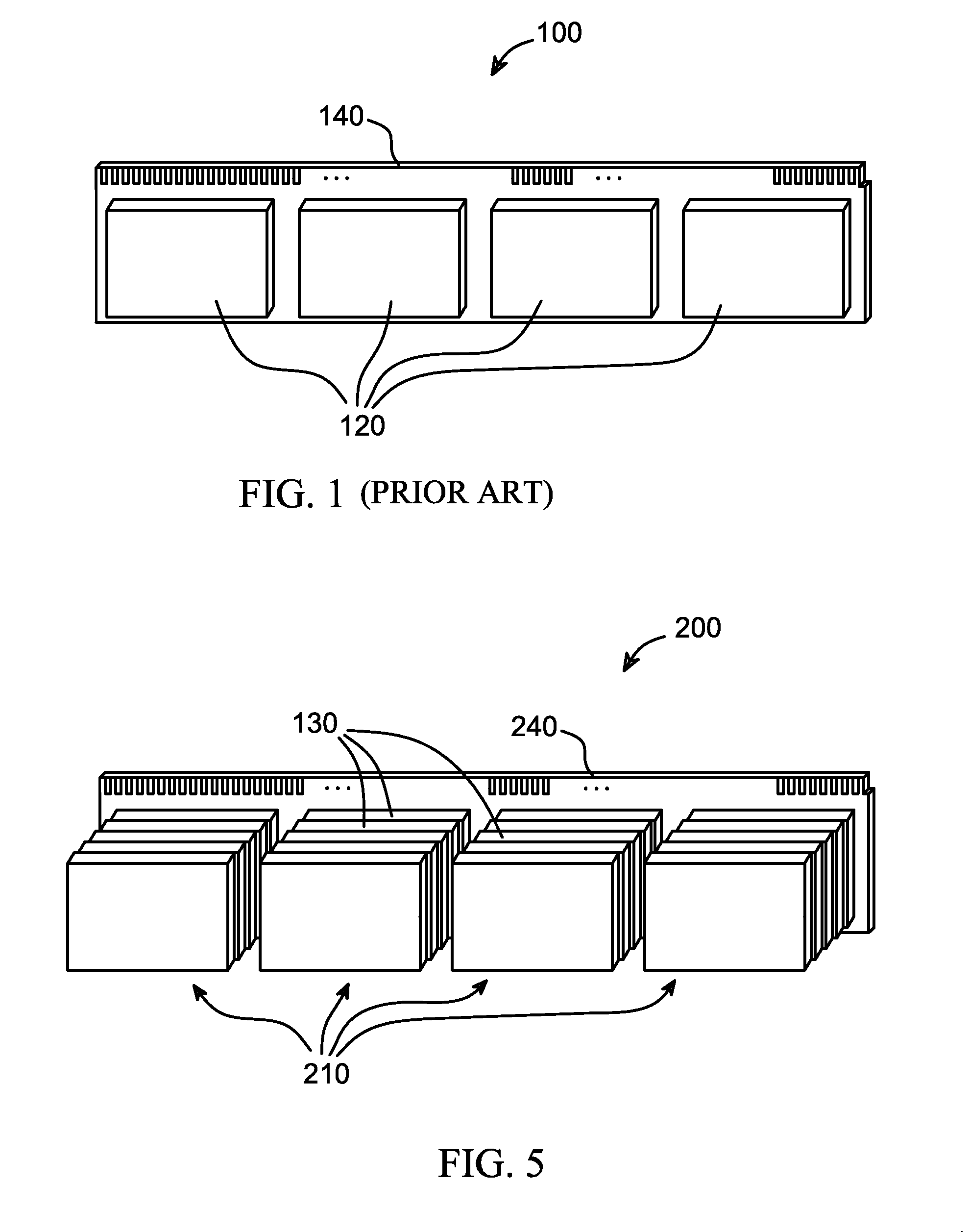

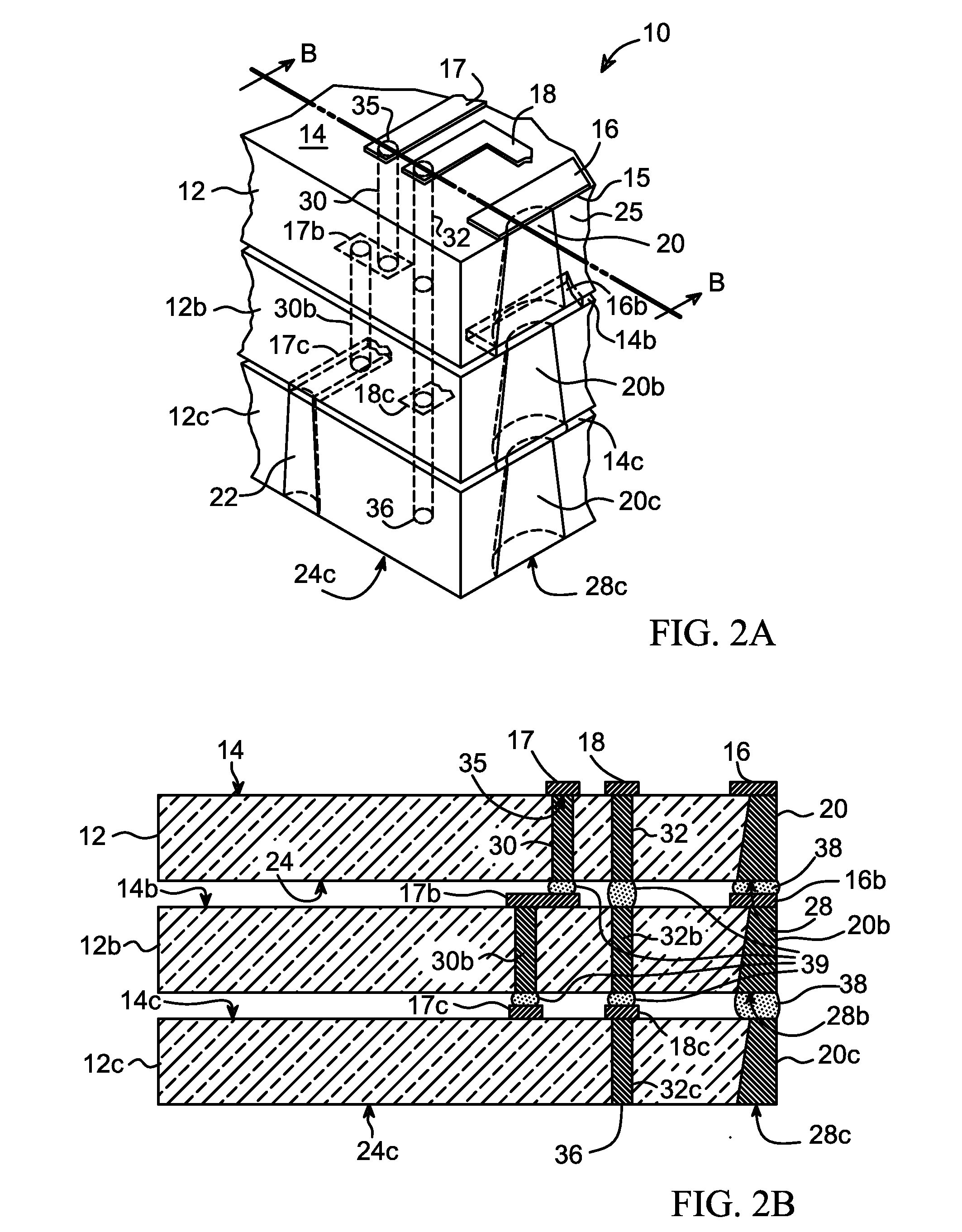

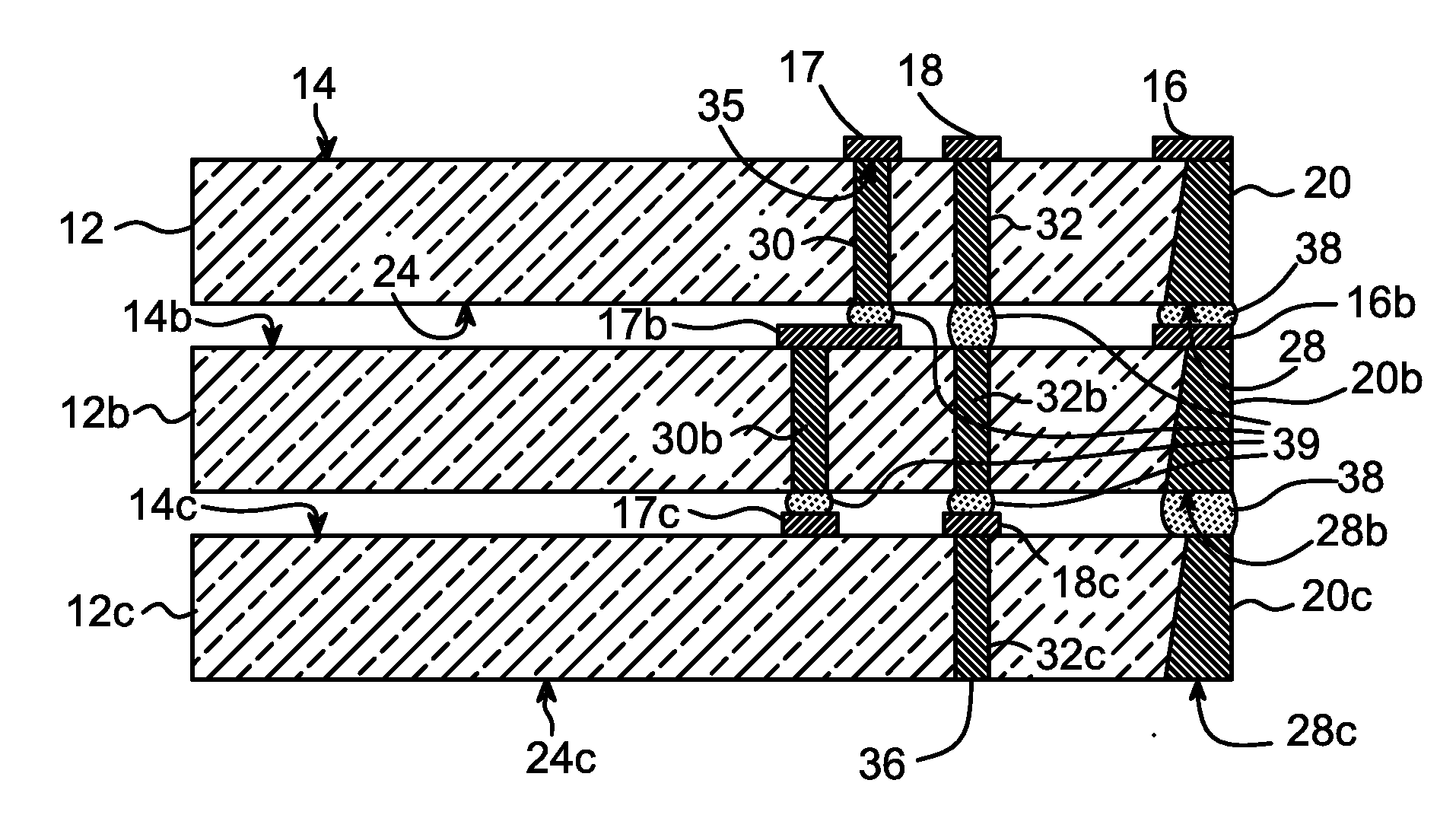

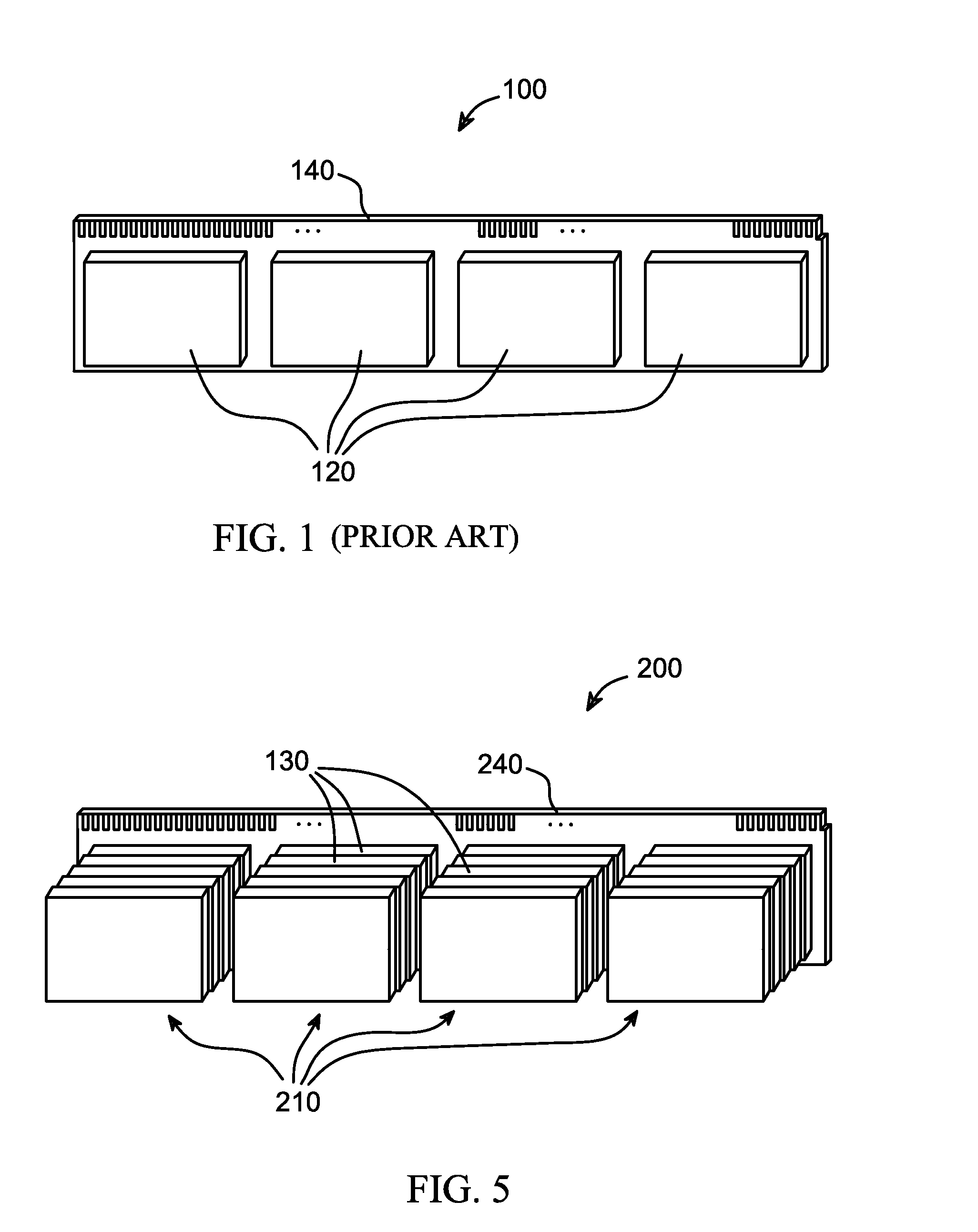

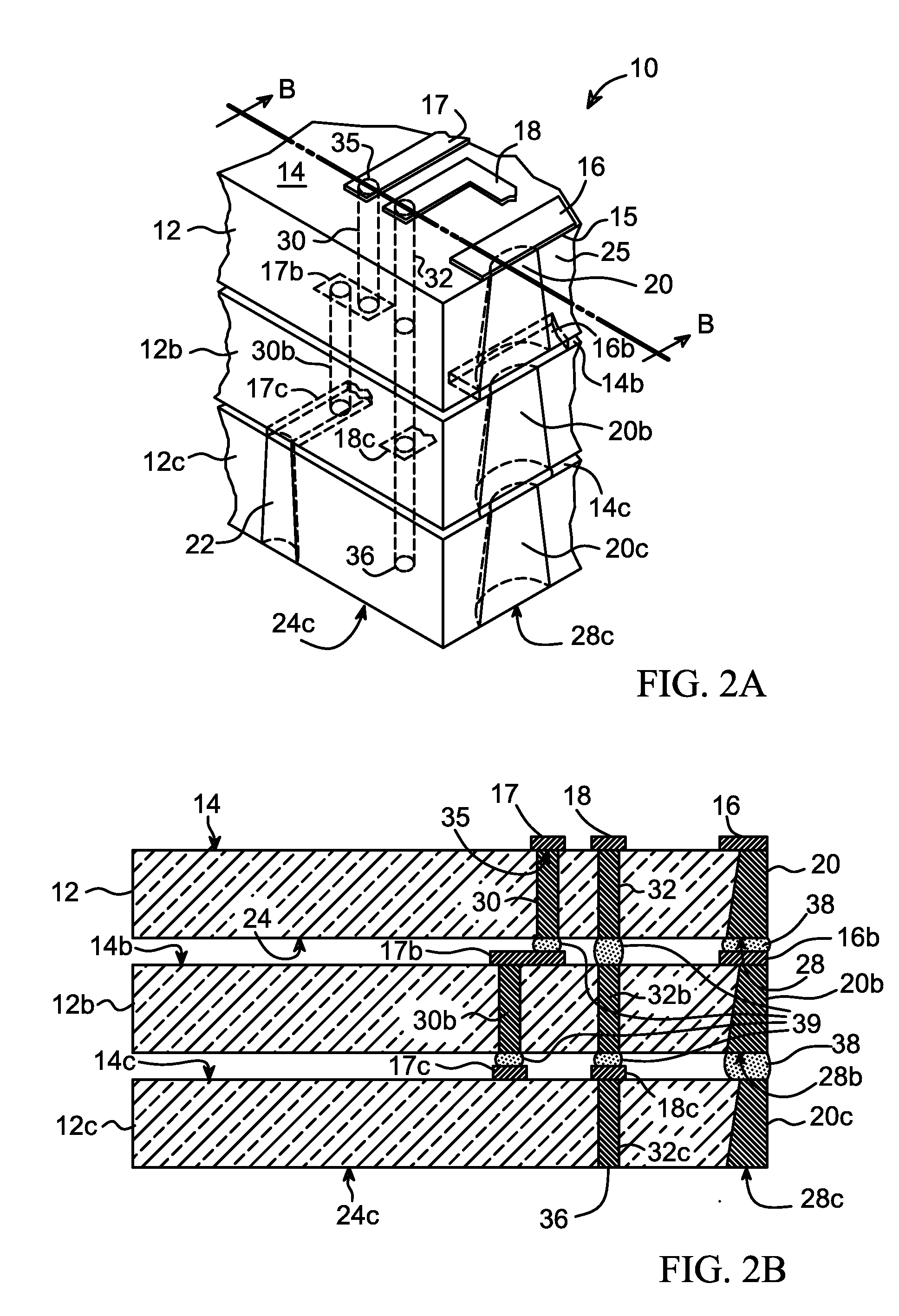

Dual Interconnection in Stacked Memory and Controller Module

InactiveUS20100270668A1High capacity memoryLess spaceSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringSlow speed

A chip package transmitting slow speed signals via edge connectors and high speed signals by means of through-silicon-vias. The edge connectors are formed in recesses formed in the sidewalls of the package.

Owner:WAFER LEVEL PACKAGING PORTFOLIO

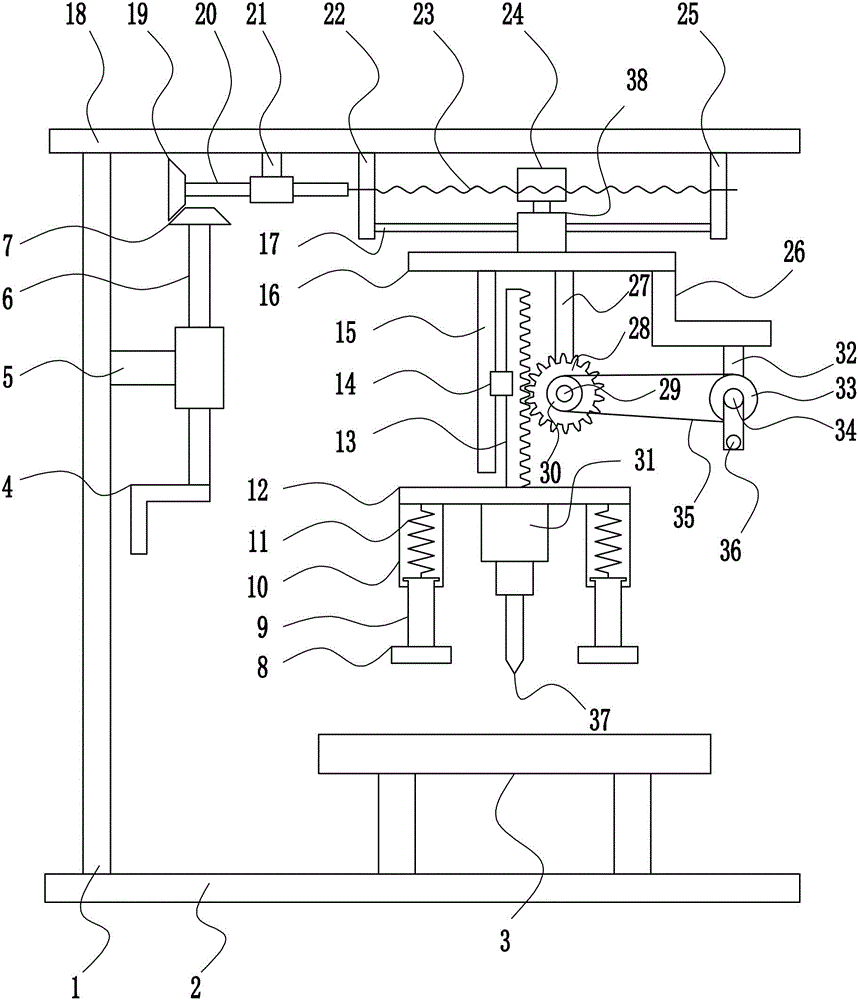

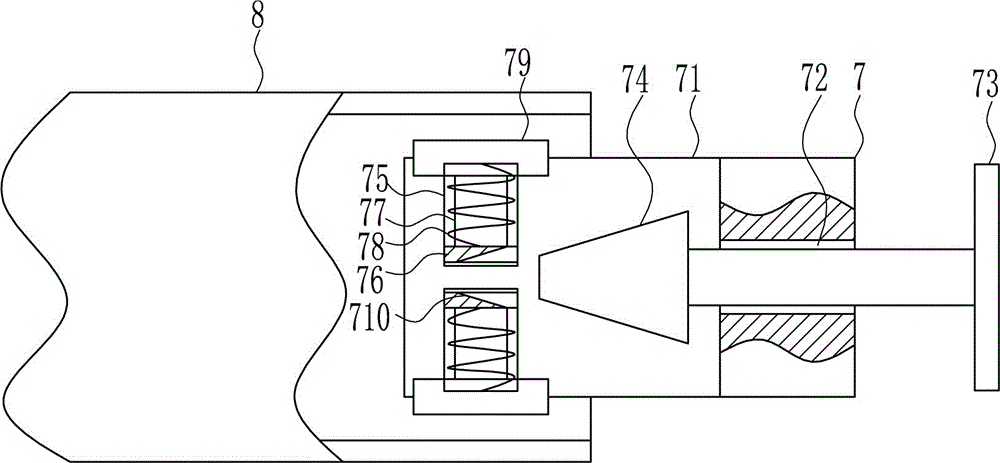

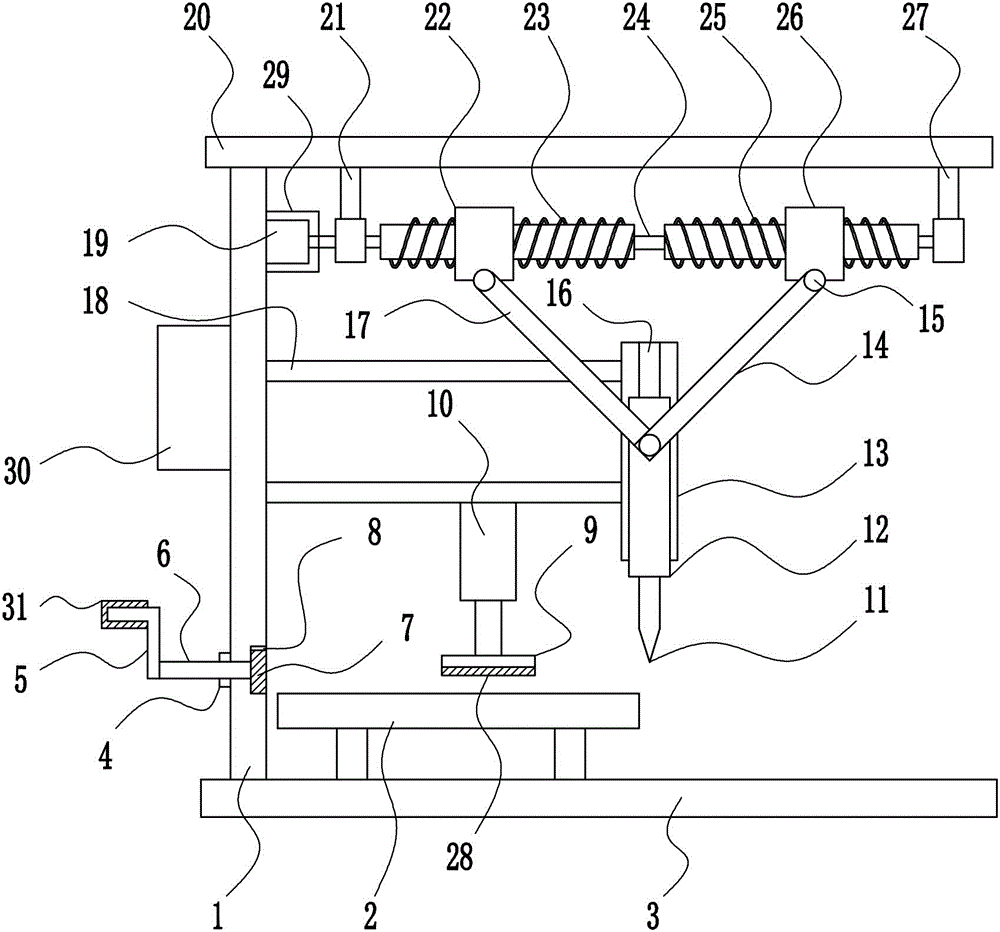

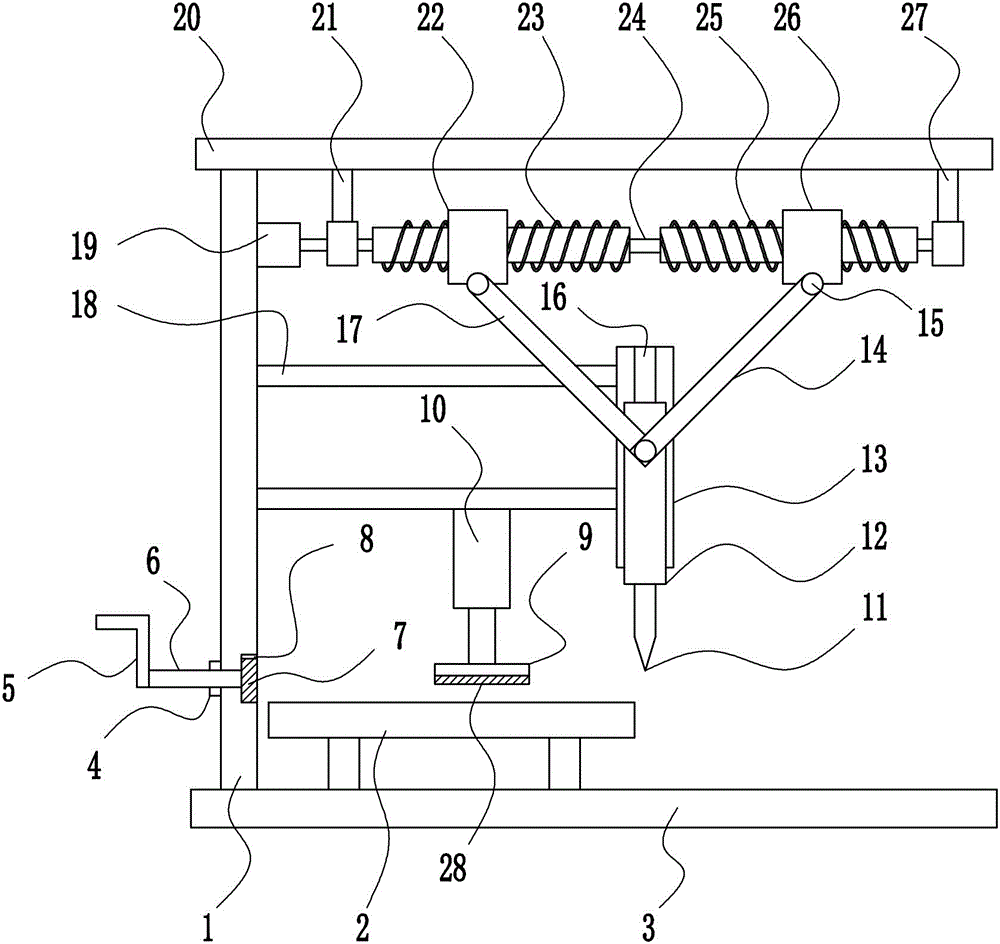

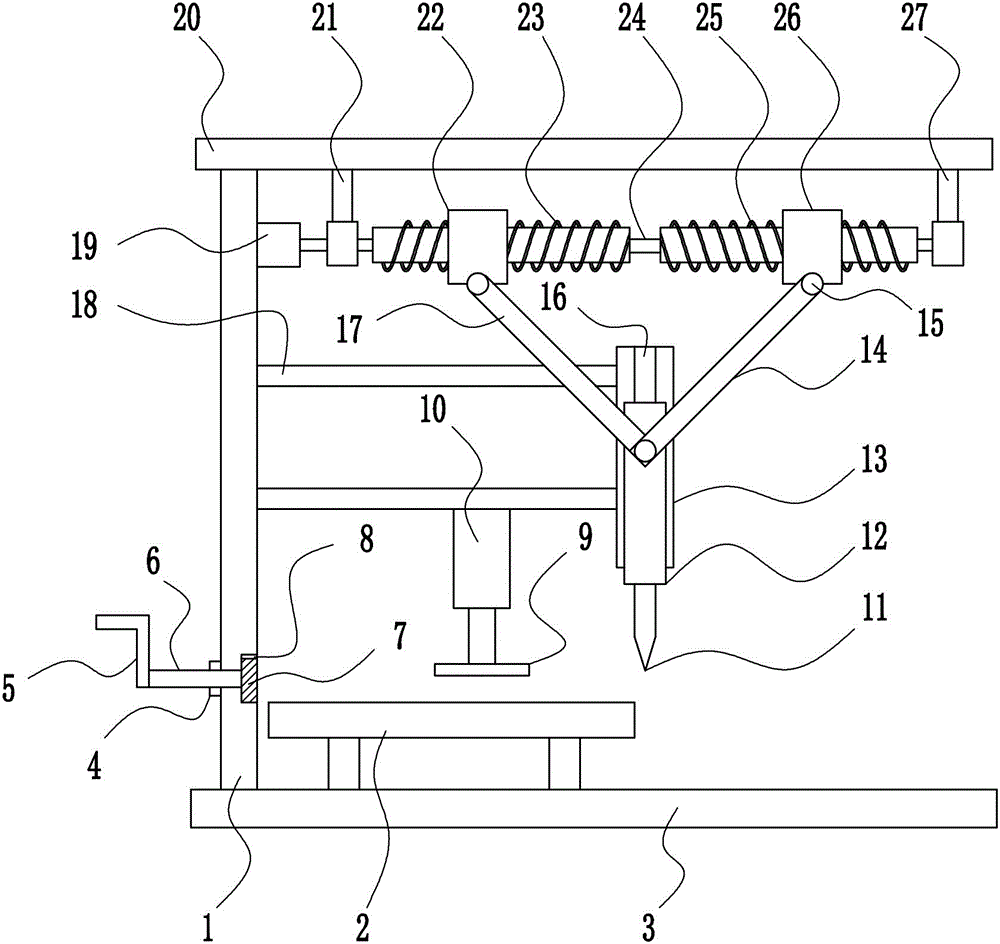

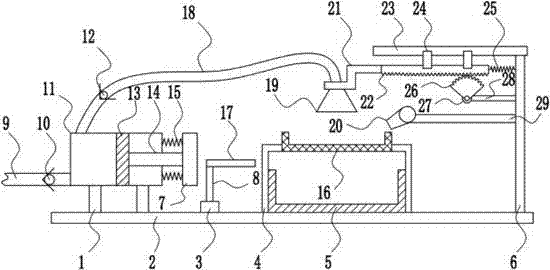

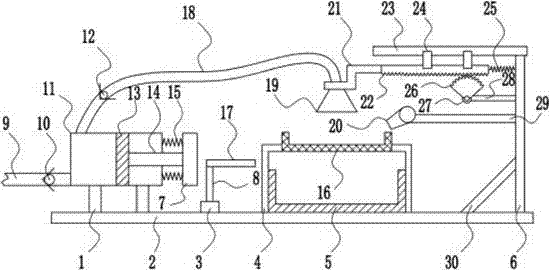

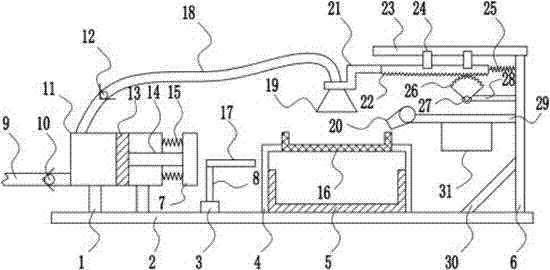

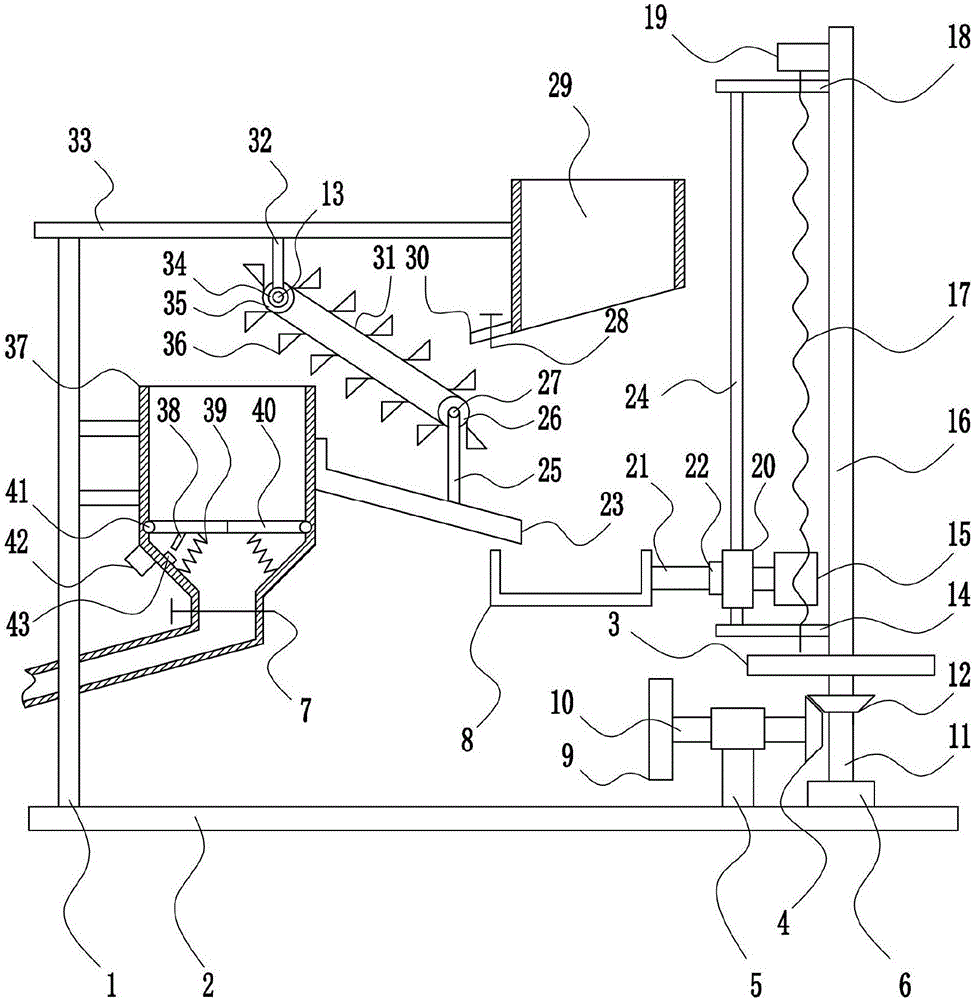

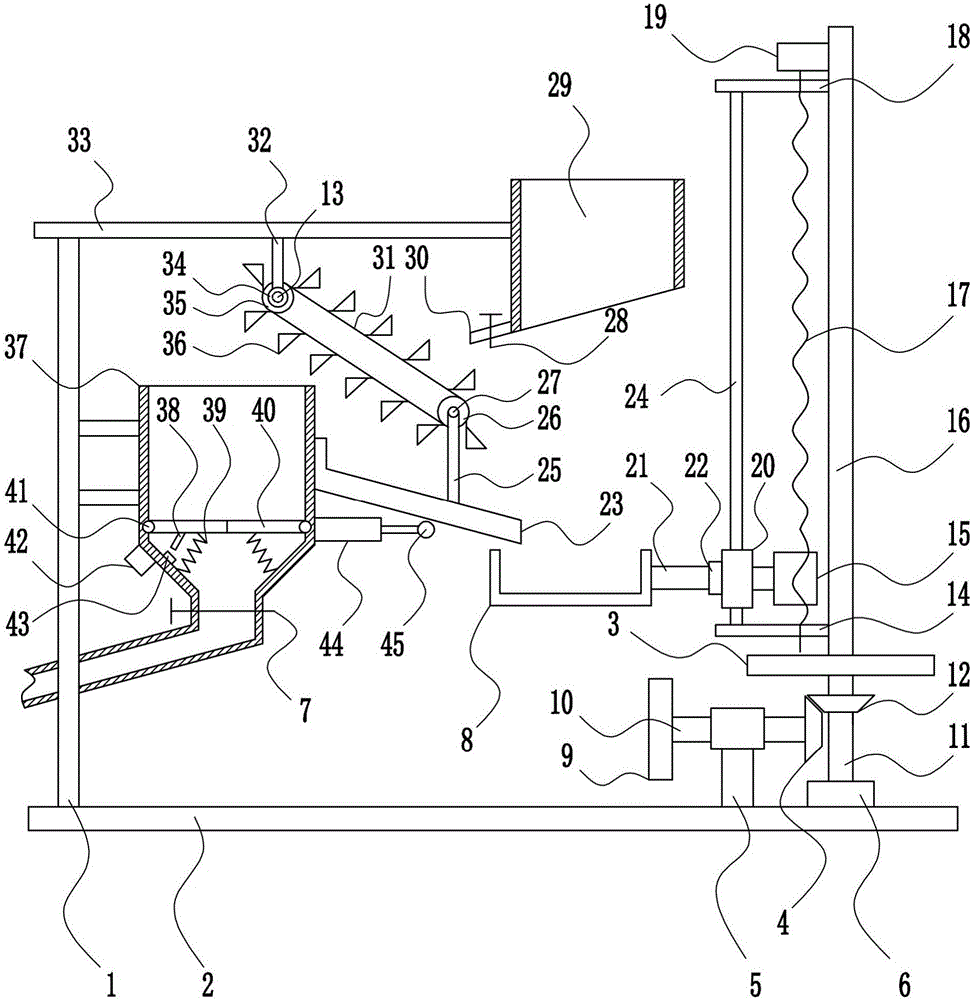

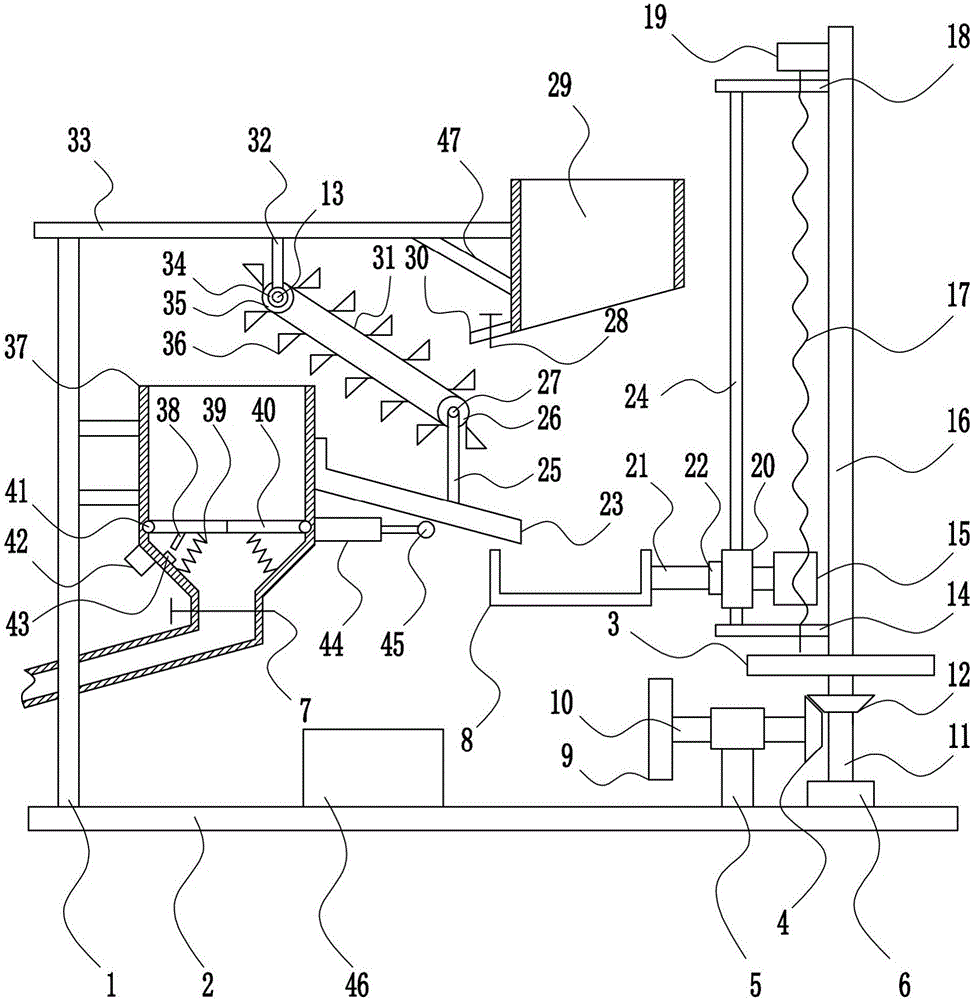

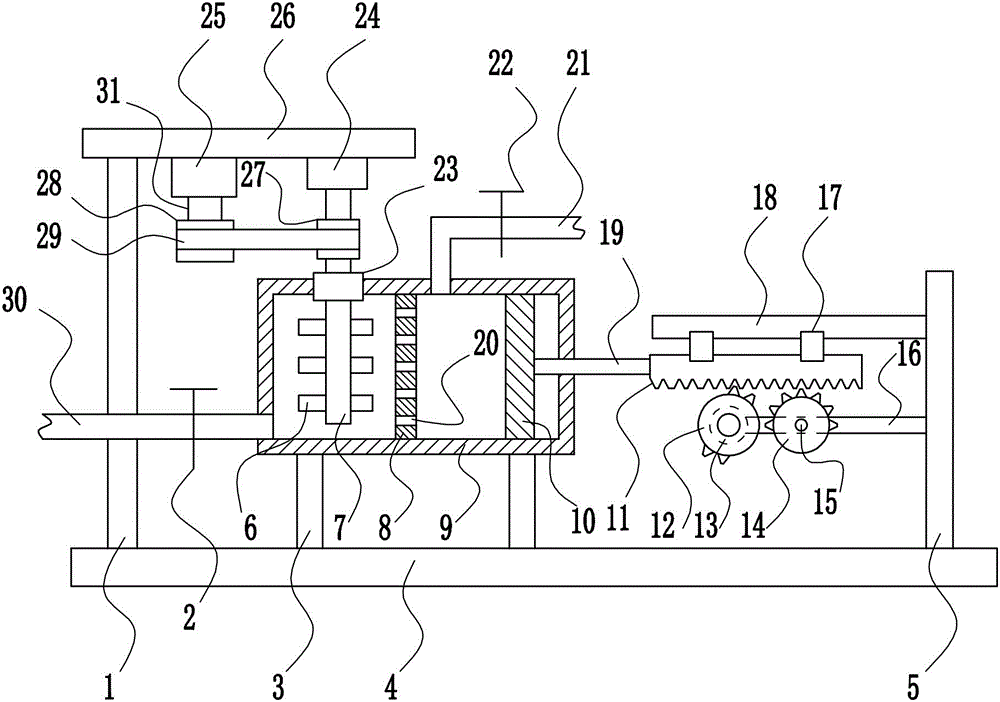

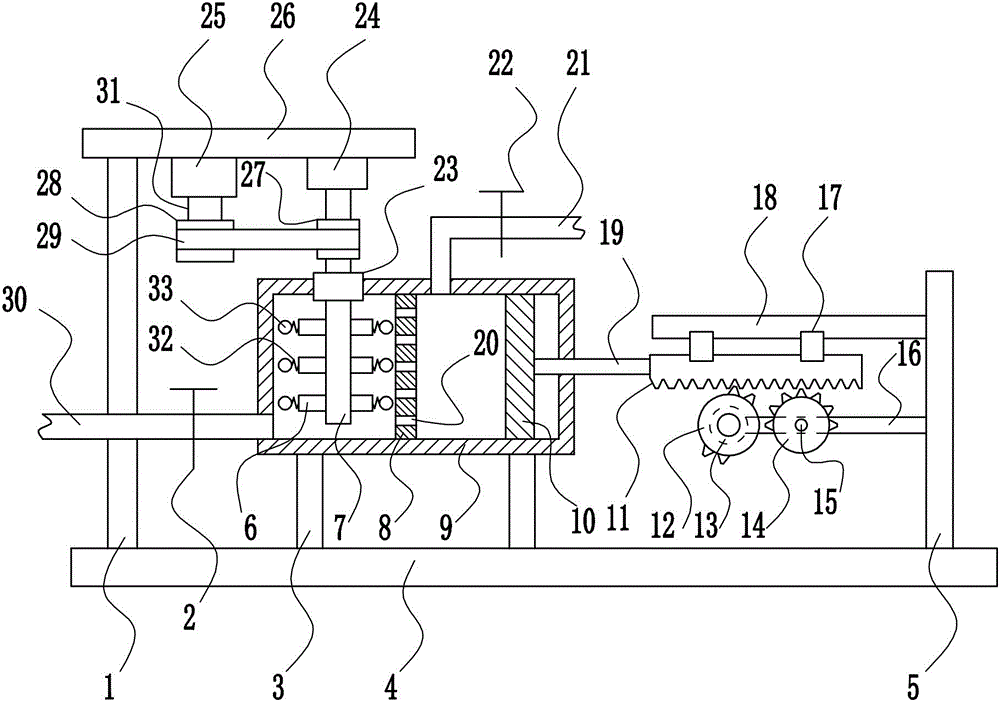

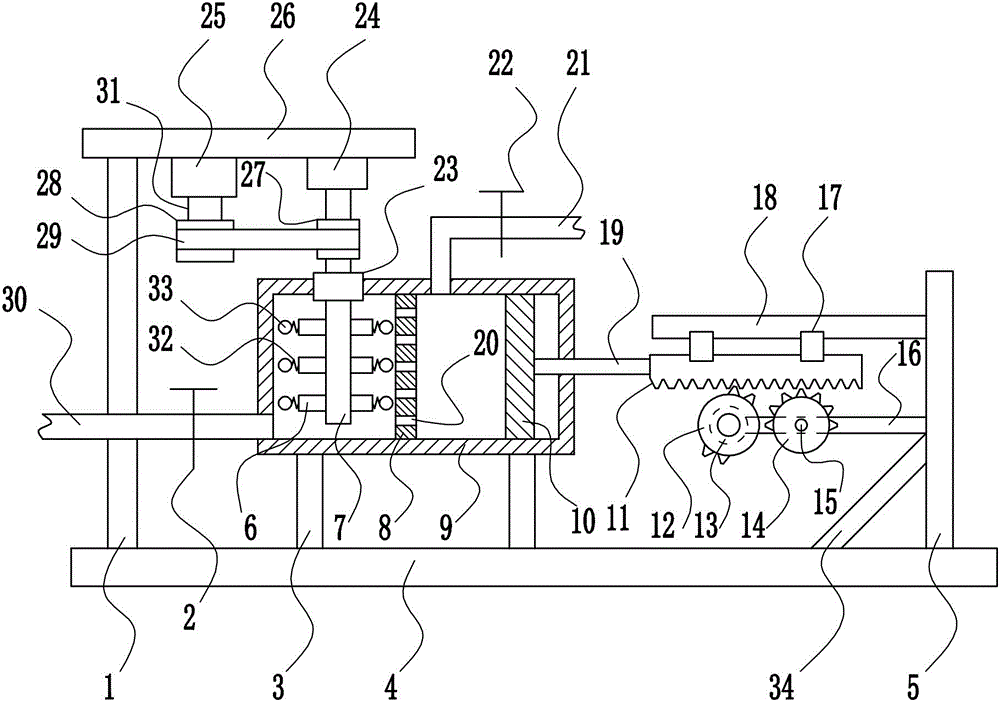

Novel drilling machine for carbon fiber composite plate

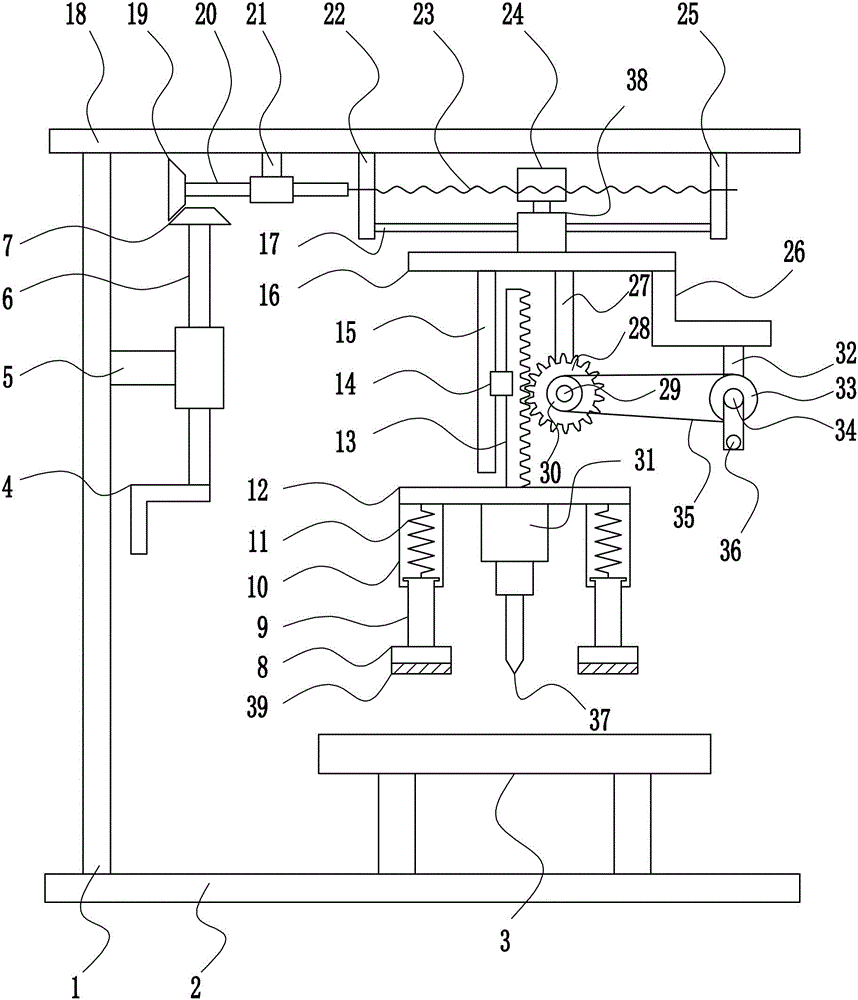

The invention relates to a drilling machine and particularly relates to a novel drilling machine for a carbon fiber composite plate. The technical problem to be solved by the invention is to provide the novel drilling machine for the carbon fiber composite plate, which is low in energy consumption, convenient to operate and high in drilling precision. In order to solve the technical problem, the invention provides such novel drilling machine for the carbon fiber composite plate, comprising a left frame, a bottom plate, a placing platform, a first rocking handle, a first bearing block, a first rotating shaft, a first bevel gear, a pressing block, a moving rod, a sleeve, an elastic element, a first fixed plate and the like; the left side of the top of the bottom plate is welded with the left frame; the middle of the top of the bottom plate is welded with the placing platform; and the upper end of the right side of the left frame is connected with the first bearing block in a bolt connection way. According to the novel drilling machine for the carbon fiber composite plate, the horizontal movement of a drill bit and the drilling operation for any position on the carbon fiber composite plate can be realized through rotating the first rocking handle, and the vertical movement of the drill bit can be realized through rotating a second rocking handle.

Owner:江苏吉神环卫设备有限公司

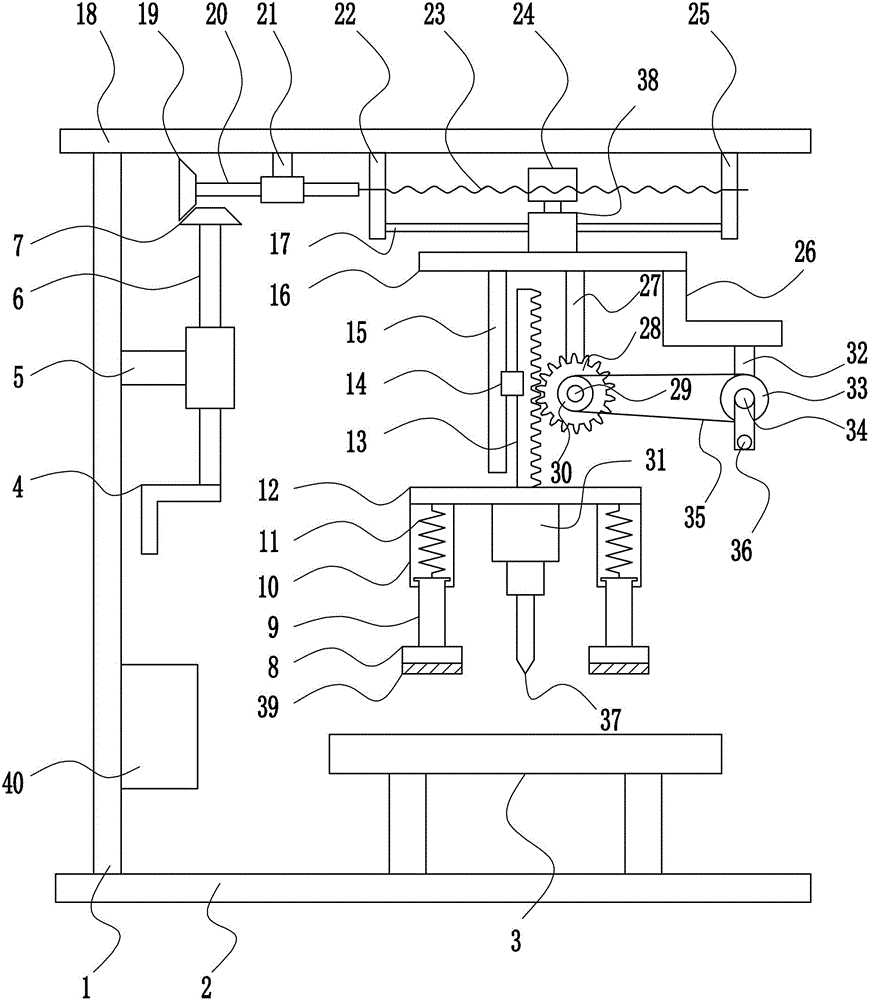

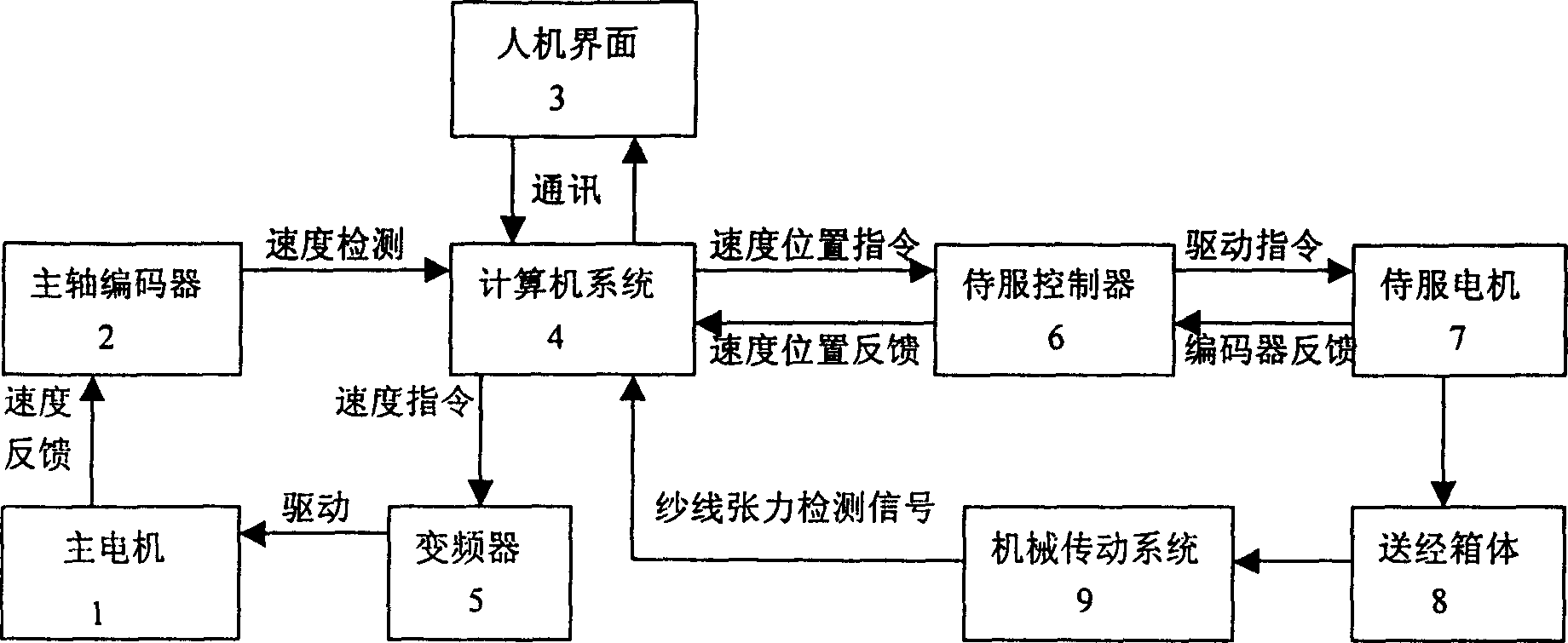

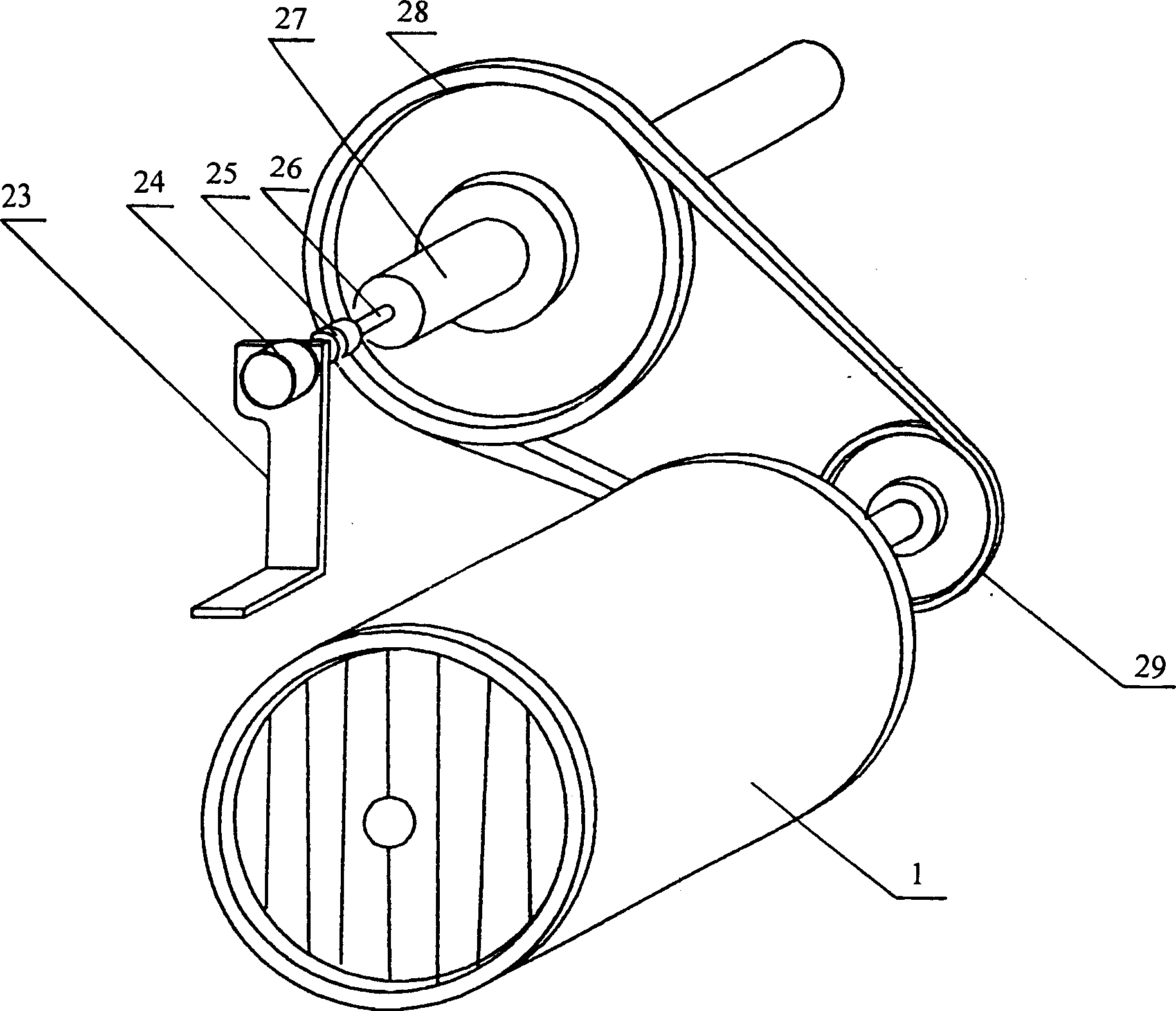

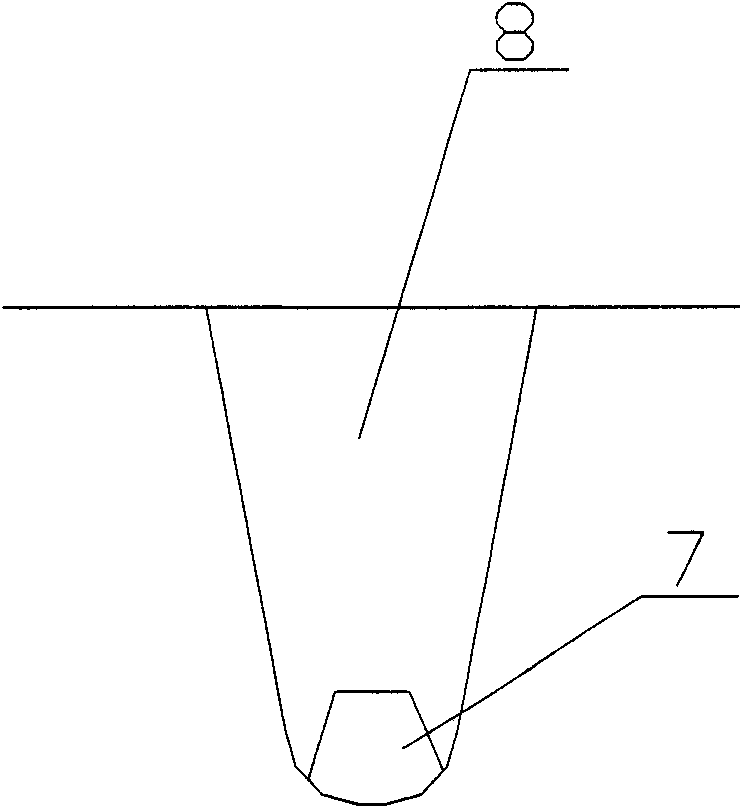

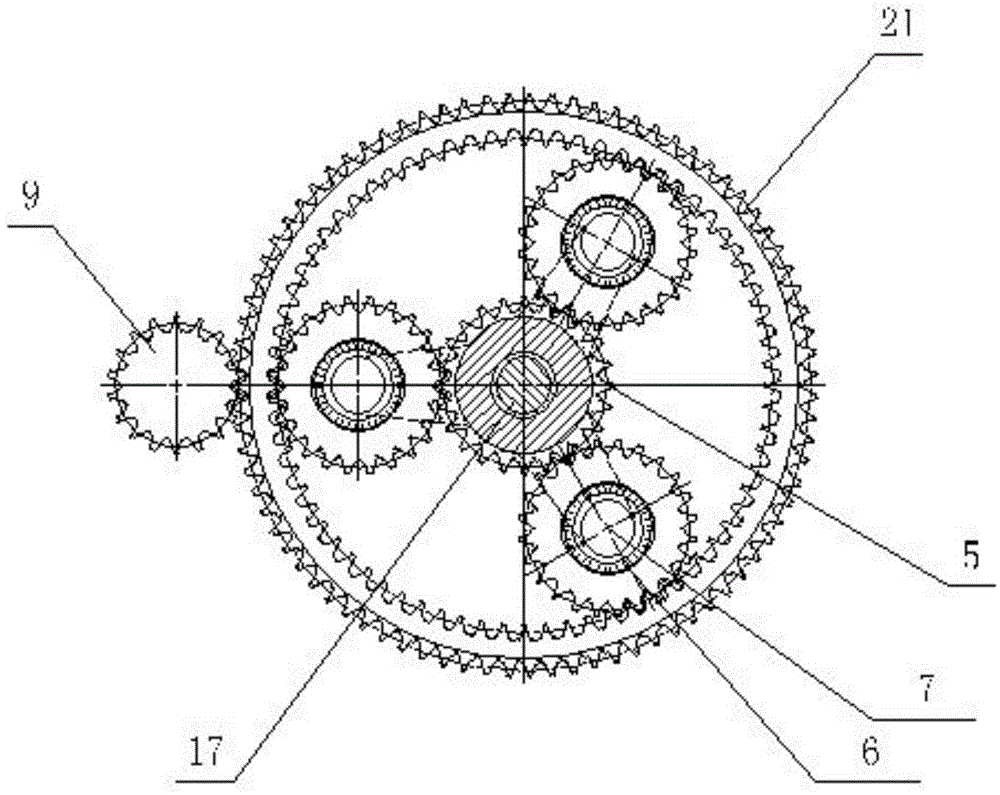

Electronic warp feeding system of warp knitting machine

InactiveCN1827886AGood high speed performanceStable and accurate let-offWarp knittingComputerized systemElectric machinery

The invention relates the warp knitting machine electronic let-off system, comprising main motor(1), chief axis encoder(2), computer system(4), converter(5), controller(6), motor(7), warp let-off box(8) and mechanical gearing system(9). The computer system (4) controls the main motor by converter (5). On the base of real-time rotary speed detection signal, the computer enters processing parameter and sends active instruction. The invention has the advantages of high-speed property, exact and steady warp run-in, easy adjustment, short operation processing time, and adopting multiple speed and position reaction to realize optimum dynamic adjustment.

Owner:康盘方

Dual Interconnection in Stacked Memory and Controller Module

InactiveUS20110169171A1Less spaceLow costSemiconductor/solid-state device detailsSolid-state devicesComputer moduleInterconnection

Owner:WAFER LEVEL PACKAGING PORTFOLIO

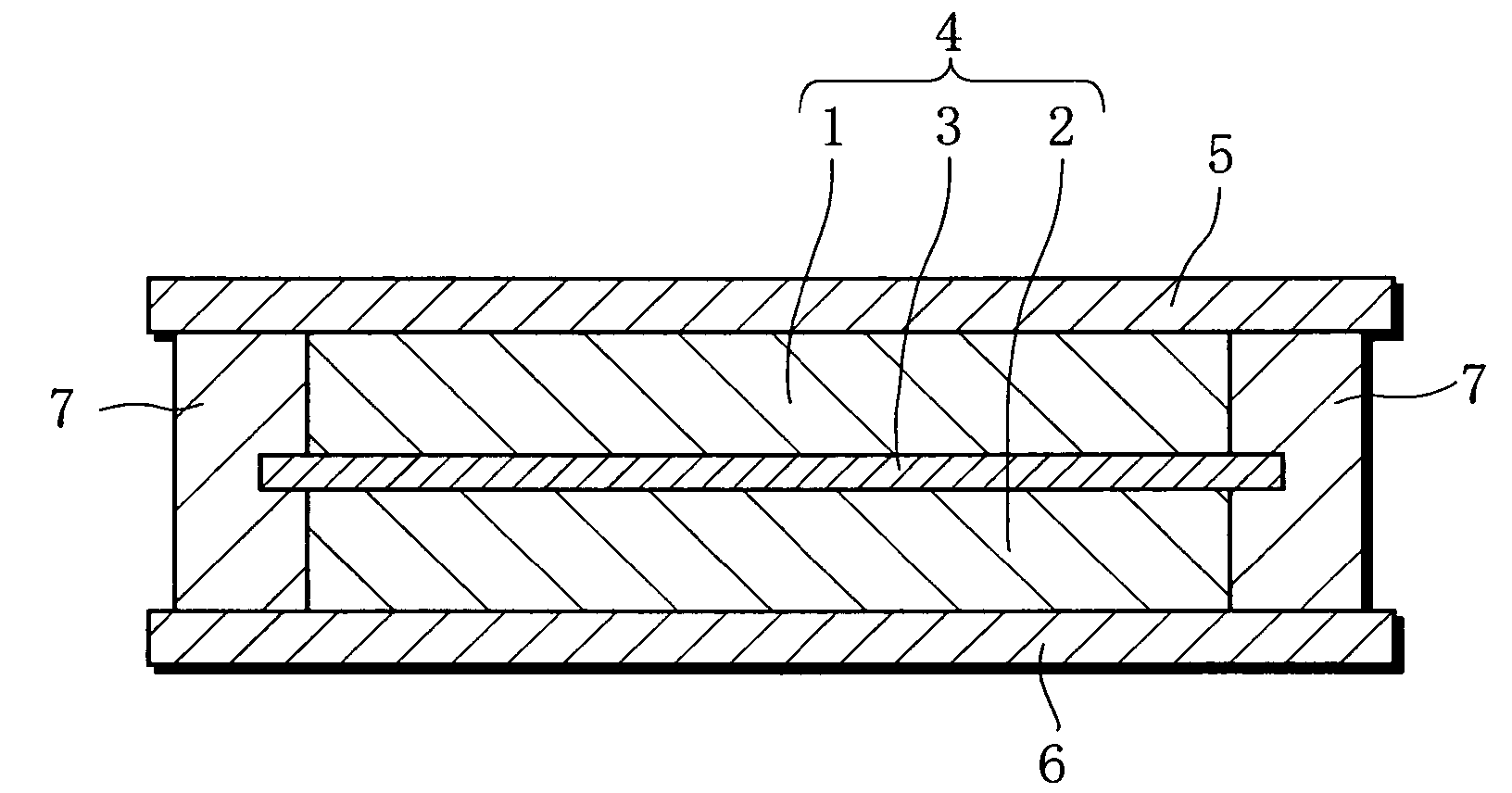

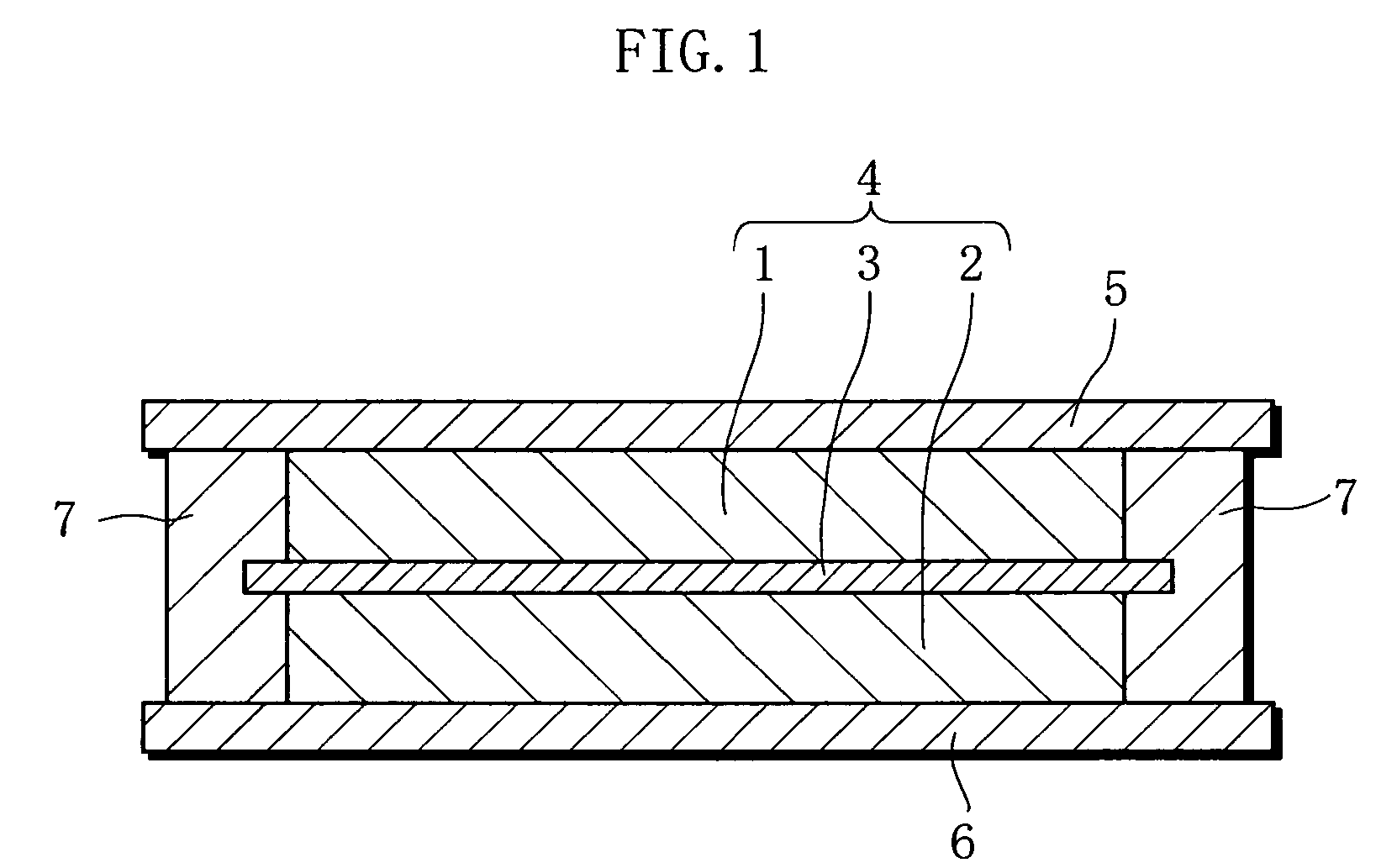

Electric double layer capacitor and method of manufacturing same

InactiveUS7382601B2Good high speed performanceIncrease capacityHybrid capacitor electrodesNanoinformaticsMicrowaveHigh rate

An electric double layer capacitor and a method of manufacturing are provided that are capable of improving high-rate performance and increasing capacity at lower costs. The electric double layer capacitor includes: an electrode unit having a pair of polarizable electrodes, each composed of a carbon material, and a separator interposed between the pair of polarizable electrodes; and an electrolyte solution impregnated in the pair of polarizable electrodes and the separator. The carbon material of at least one of the pair of polarizable electrodes contains fullerene activated by a microwave activation process and / or carbon nanotube activated by a microwave activation process.

Owner:SAGA SANYO IND +1

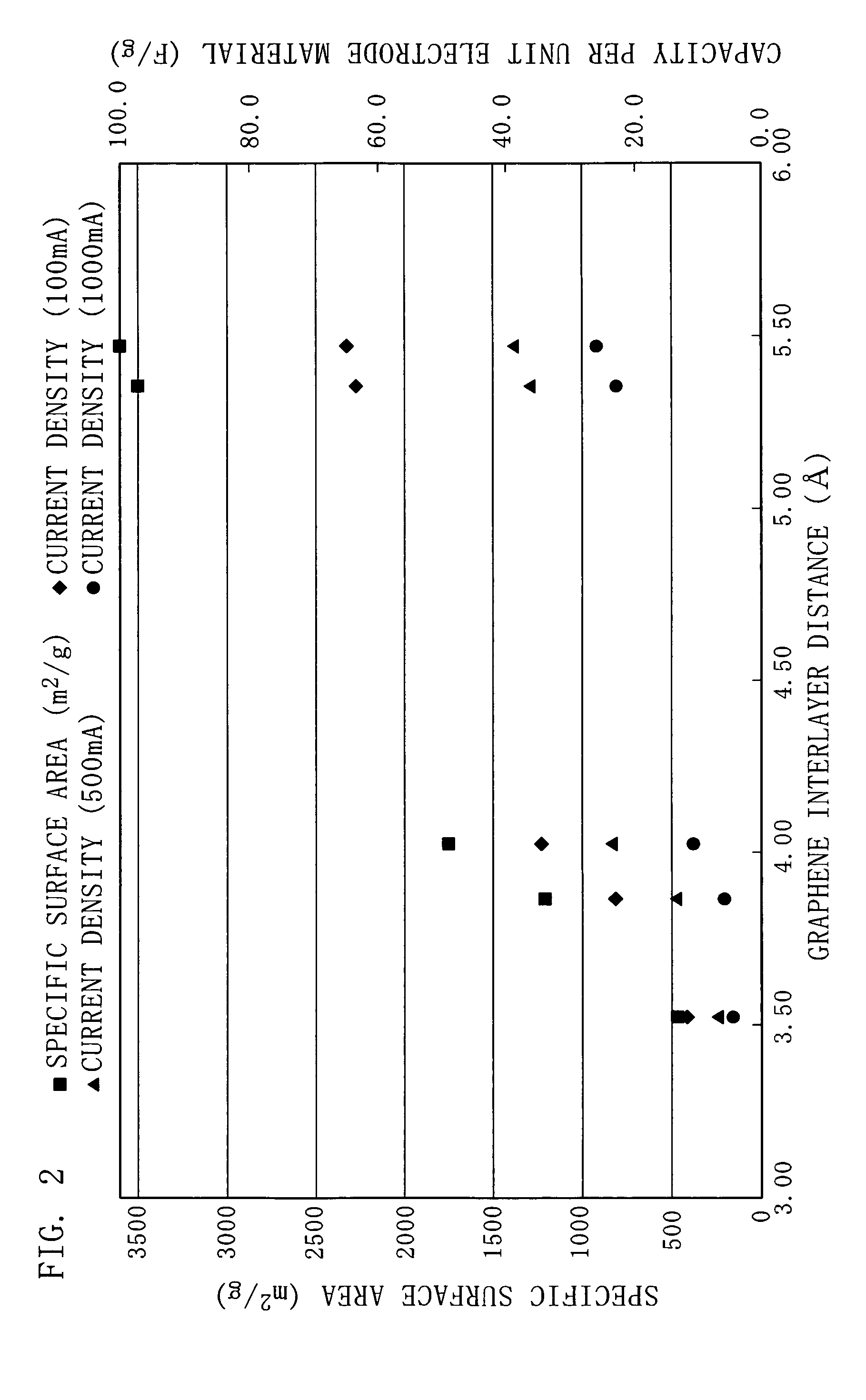

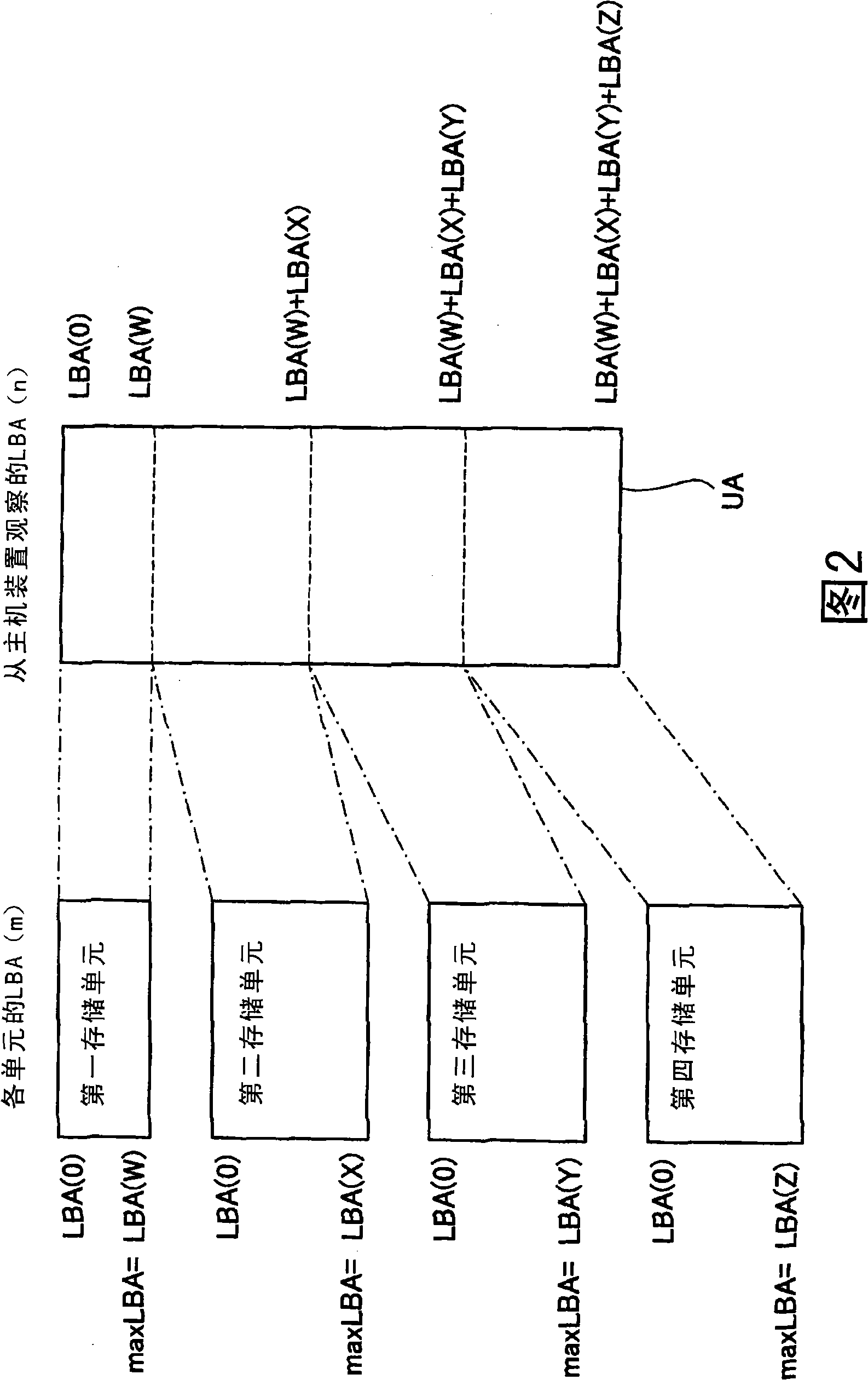

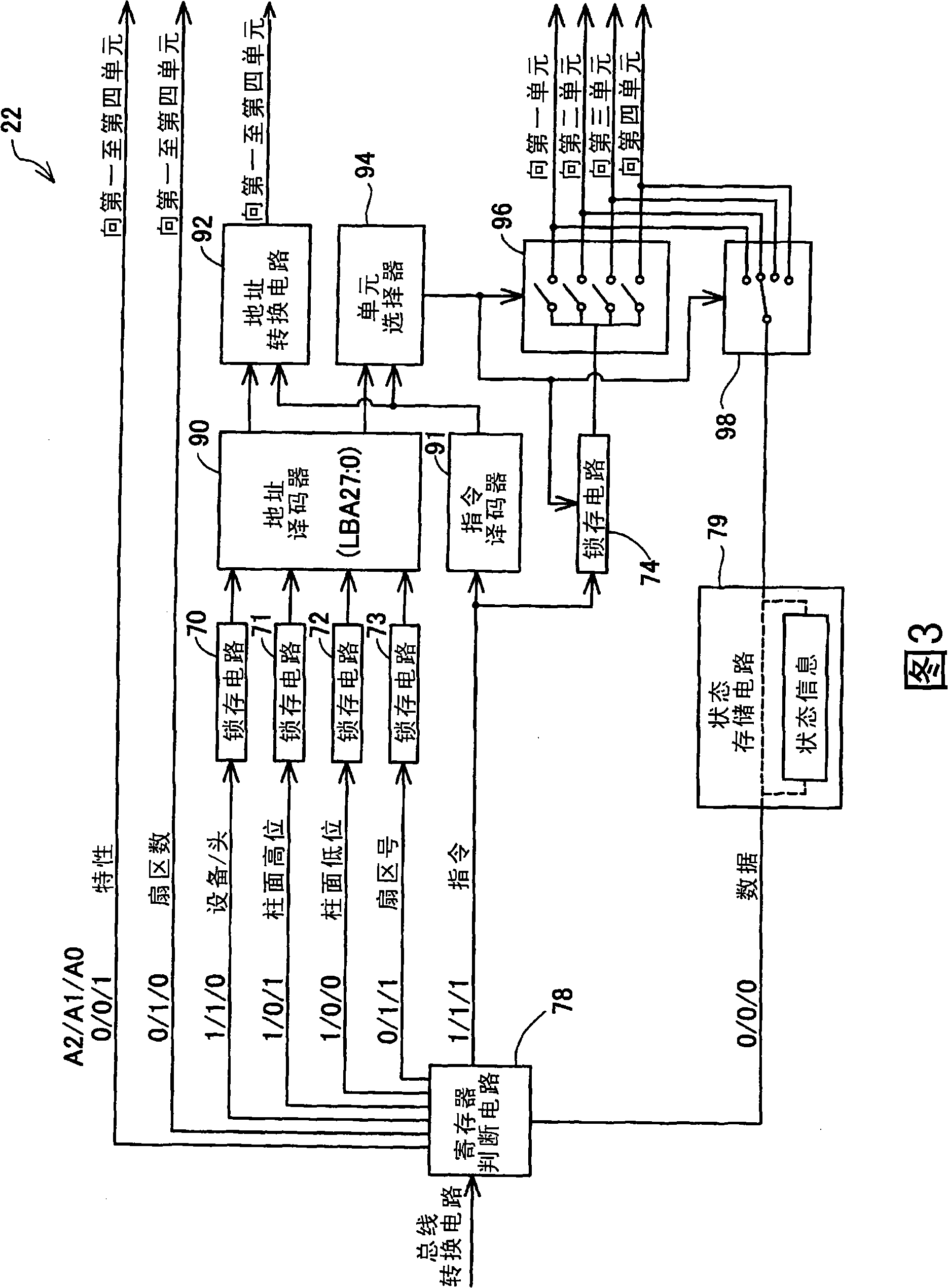

Storage device

ActiveCN101308698AGood high speed performanceImprove reliabilityMemory adressing/allocation/relocationDigital storageFile systemData management

The invention provides a storage device sufficiently acting the advantages of the SLC-type flash memory and the MLC-type flash memory. The storage device includes: a binary flash memory that has a first storage area and a capacity of storing two values per each cell; a multivalued flash memory that has a second storage area and a capacity of storing at least three values per each cell; and a controller configured to arrange the first storage area ahead of the second storage area, logically combine the first storage area with the second storage area to form a single combined storage area, and perform data reading and data writing from and into the combined storage area. Data management information is stored in a head of the combined storage area according to a predetermined file system.

Owner:BUFFALO CORP LTD

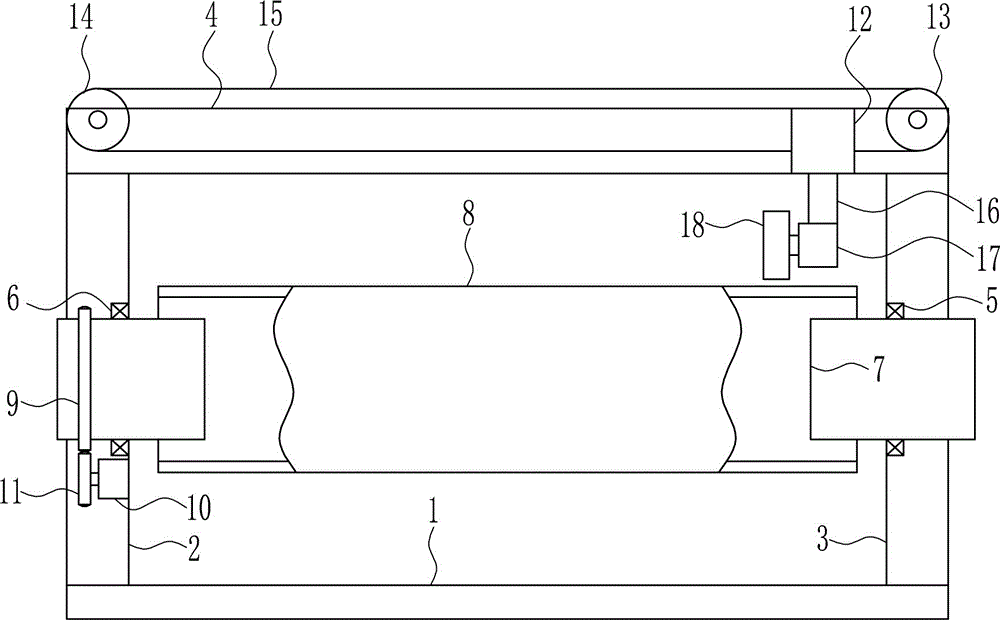

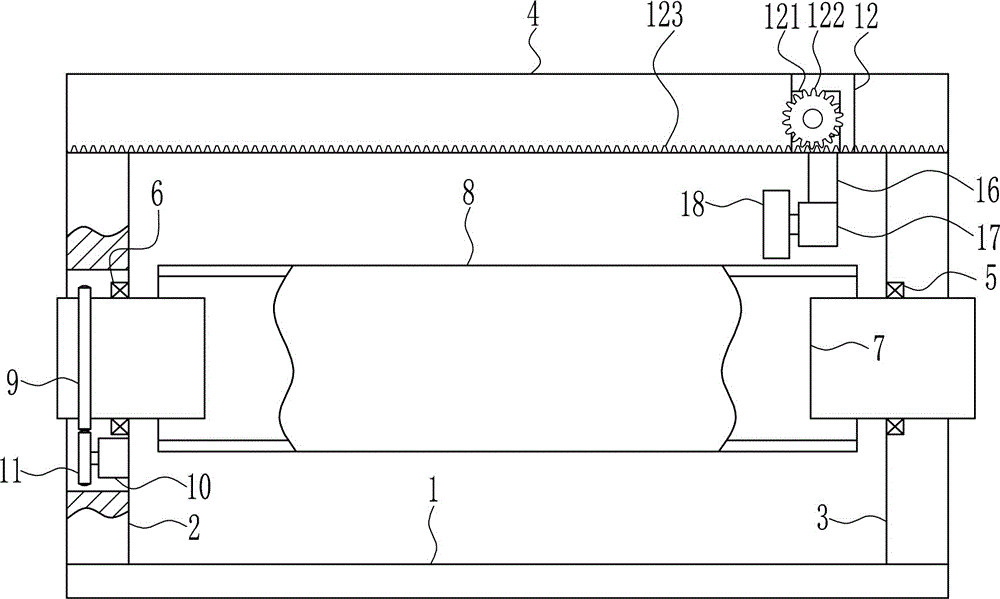

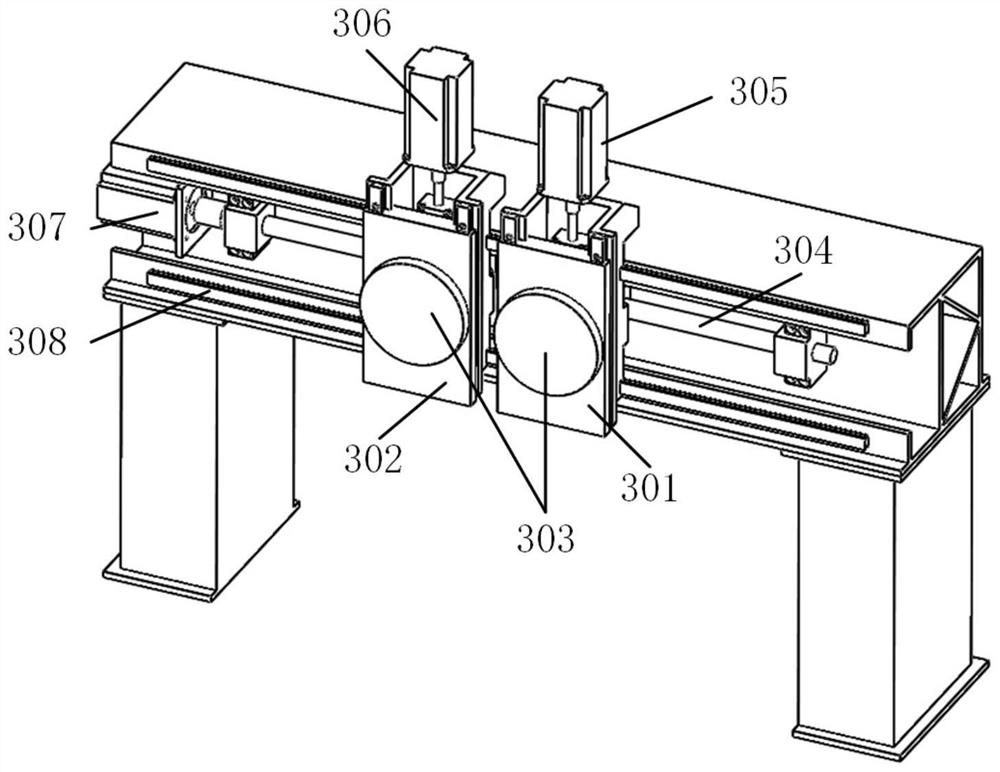

Polishing equipment for industrial steel pipe

InactiveCN106425818AHighly corrosiveStrong acid resistancePolishing machinesGrinding drivesIndustrial engineering

The invention relates to apolishingequipment, in particular to a polishing equipment for industrial steel pipes, and provides a polishing equipment for industrial steel pipes polishing uniformly, having less harm to people and saving both time and effort. In order to solve the technical problems, the invention provides the polishing equipment for industrial steel pipe. The polishing equipment for industrial steel pipes comprises a base plate, a first support plate, a second support plate, a first sliding rail, a first bearing pedestal, a second bearing pedestal, a positioning device, a steel pipe, a first gear and a first motor. The first support plate is welded at the left side of the base plate. The second support plate is welded at the right side of the base plate. The second support plate is arranged at the right of the first support plate. The polishing equipment for industrial steel pipes achieves the effect of uniform polishing, less harm to people and saving both time and labor during polishing through rotating steel pipes and moving polishing wheels.

Owner:南昌安润科技有限公司

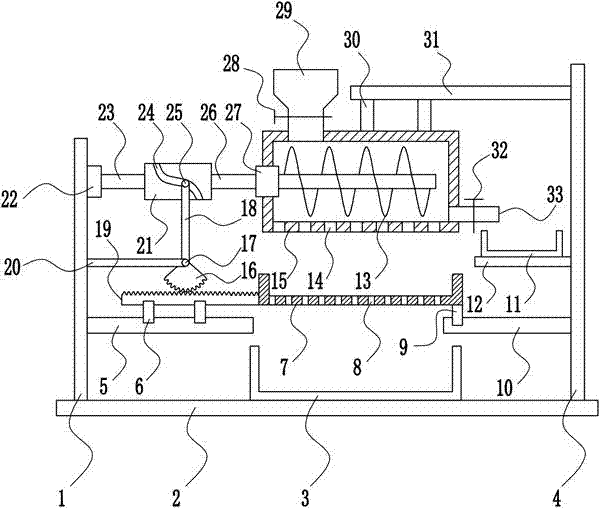

Agricultural mechanical equipment for efficient screening of soybean seeds

InactiveCN106903049ASave materialEasy to carryGas current separationAgricultural engineeringMechanical equipment

The invention relates to agricultural mechanical equipment for efficient screening of soybean seeds. The agricultural mechanical equipment comprises a left frame, a bottom plate, a first collecting frame, a right frame, a first sliding rail, a first sliding block, a screening plate, a second sliding block, a second sliding rail, a second collecting box, a fixing plate and the like. The left frame is welded to the left side of the top of the bottom plate, the right frame is welded to the right side of the top of the bottom plate, and the first collecting frame is placed in the middle of the top of the bottom plate. The agricultural mechanical equipment has the beneficial effects that the structure is novel, the screening speed is high, and the soybean seeds are not damaged; and a worker can achieve efficient screening work on the soybean seeds through the equipment, operation is simple, and in addition, time and labor are saved.

Owner:六安市富民农用器材制造有限公司

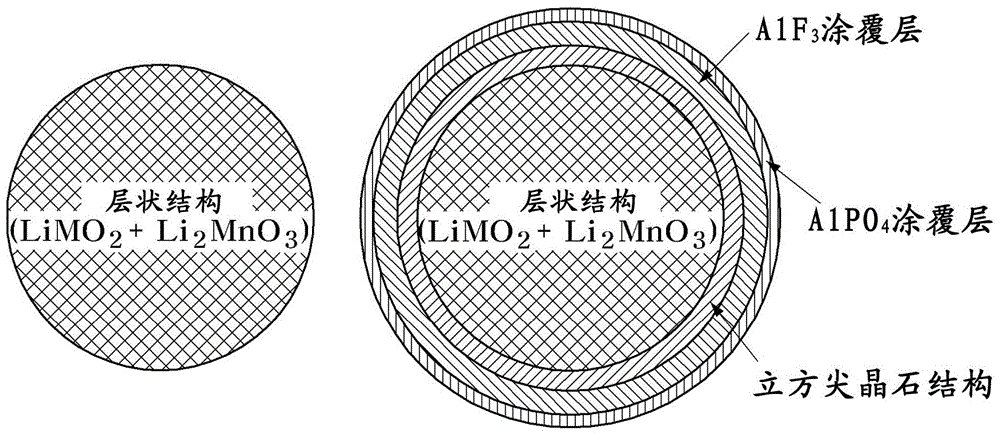

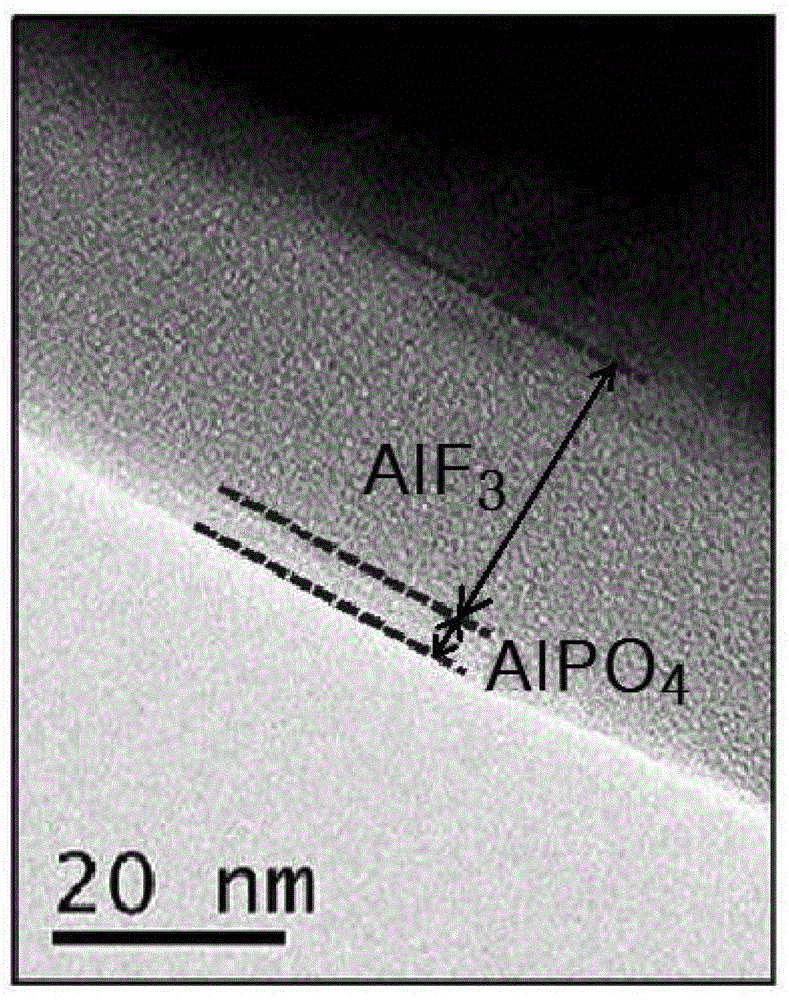

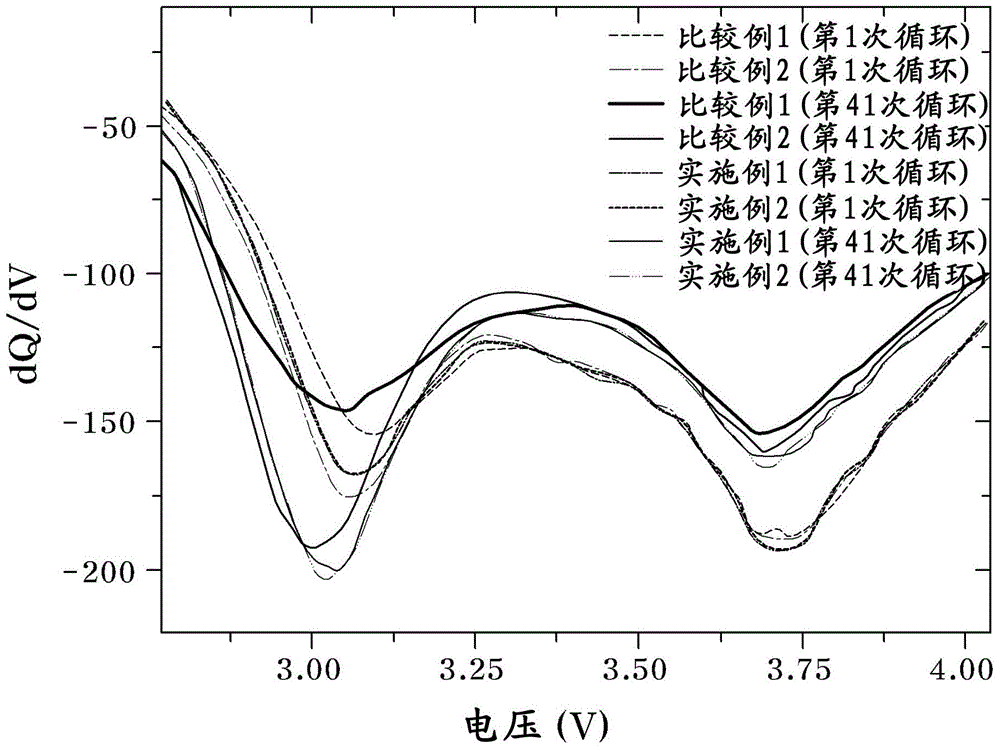

Cathode active material, method for preparing the same, and lithium secondary batteries including the same

ActiveCN103855380AImprove thermal stabilityPrevent nominal voltage dropPositive electrodesLi-accumulatorsElectrical batteryBattery cell

Owner:SAMSUNG SDI CO LTD

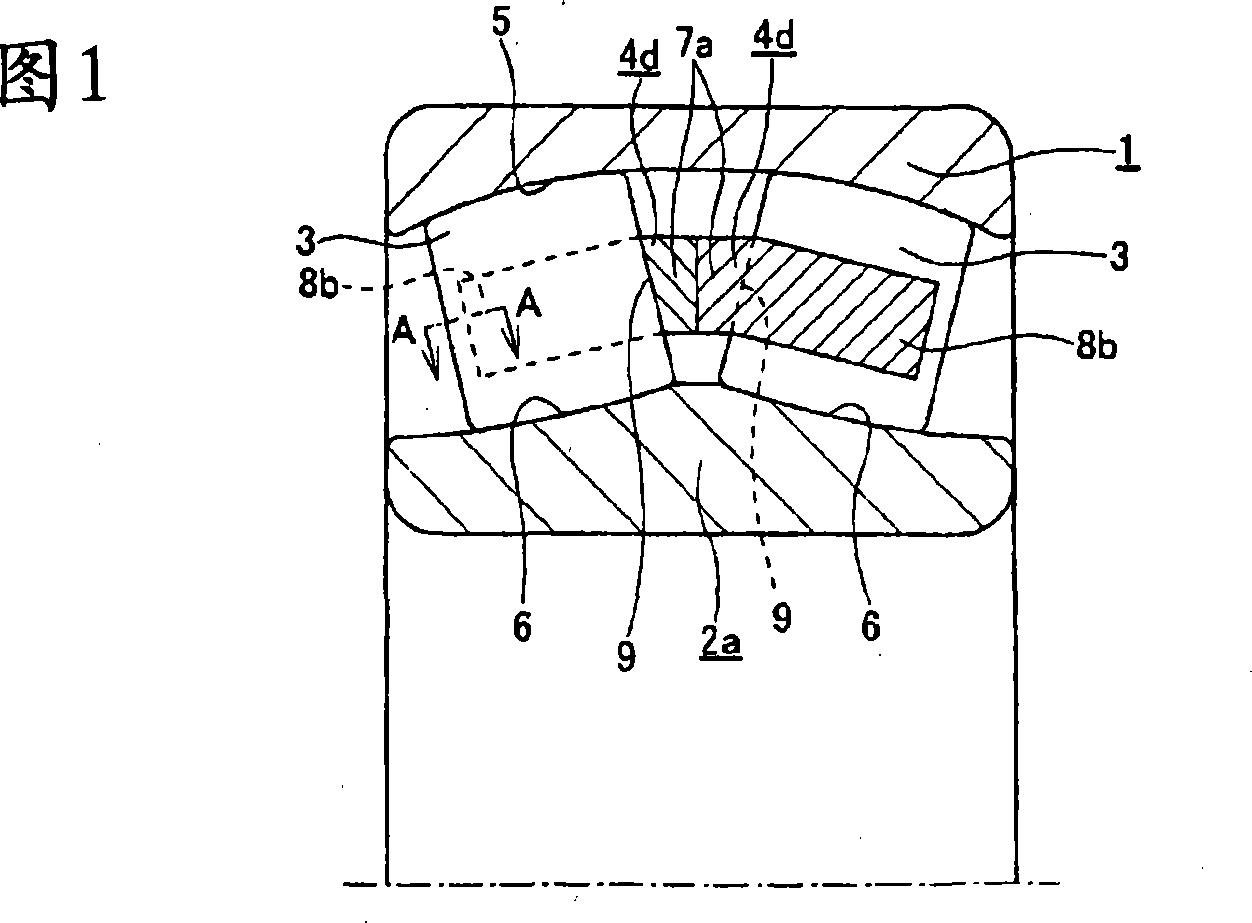

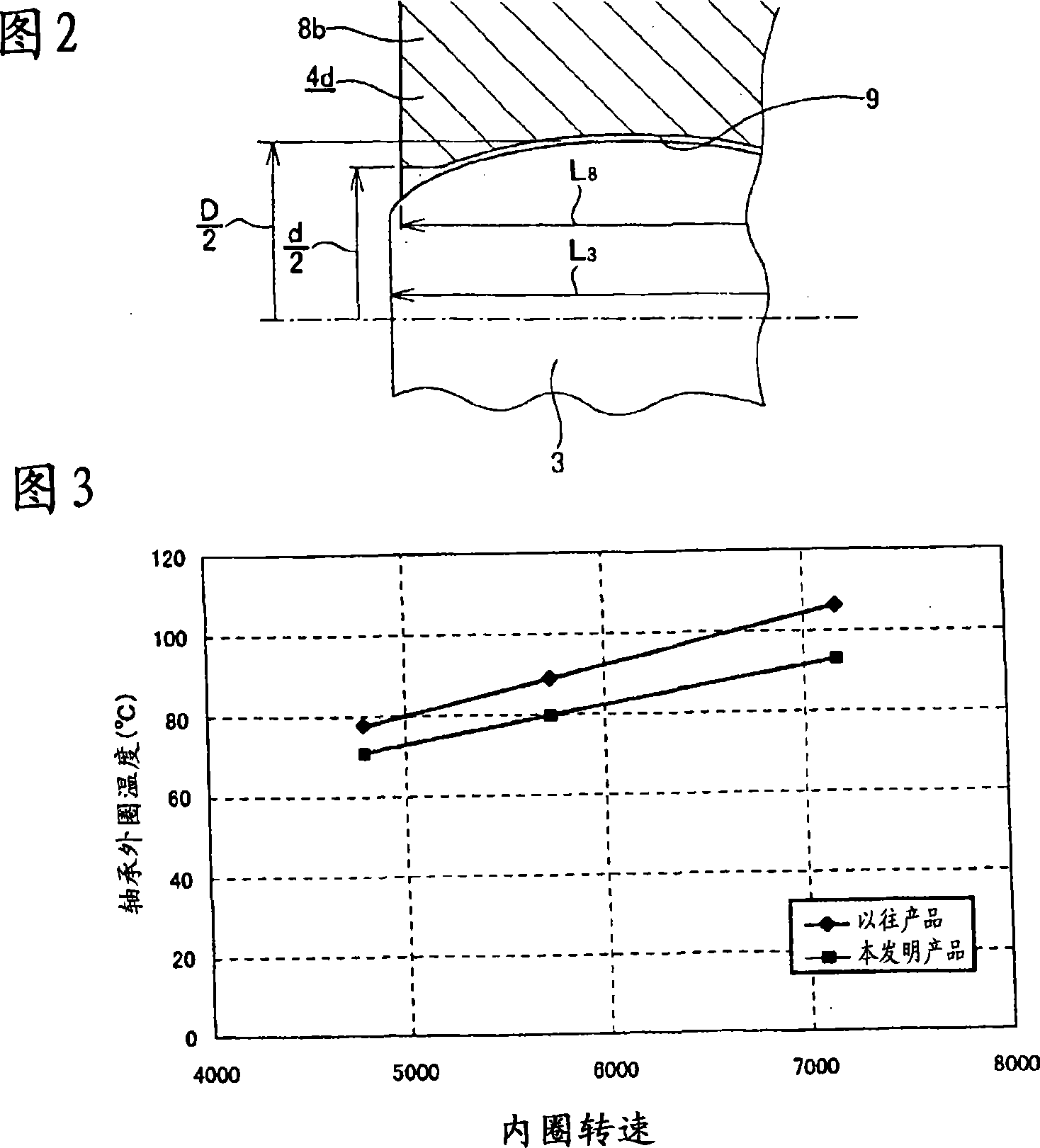

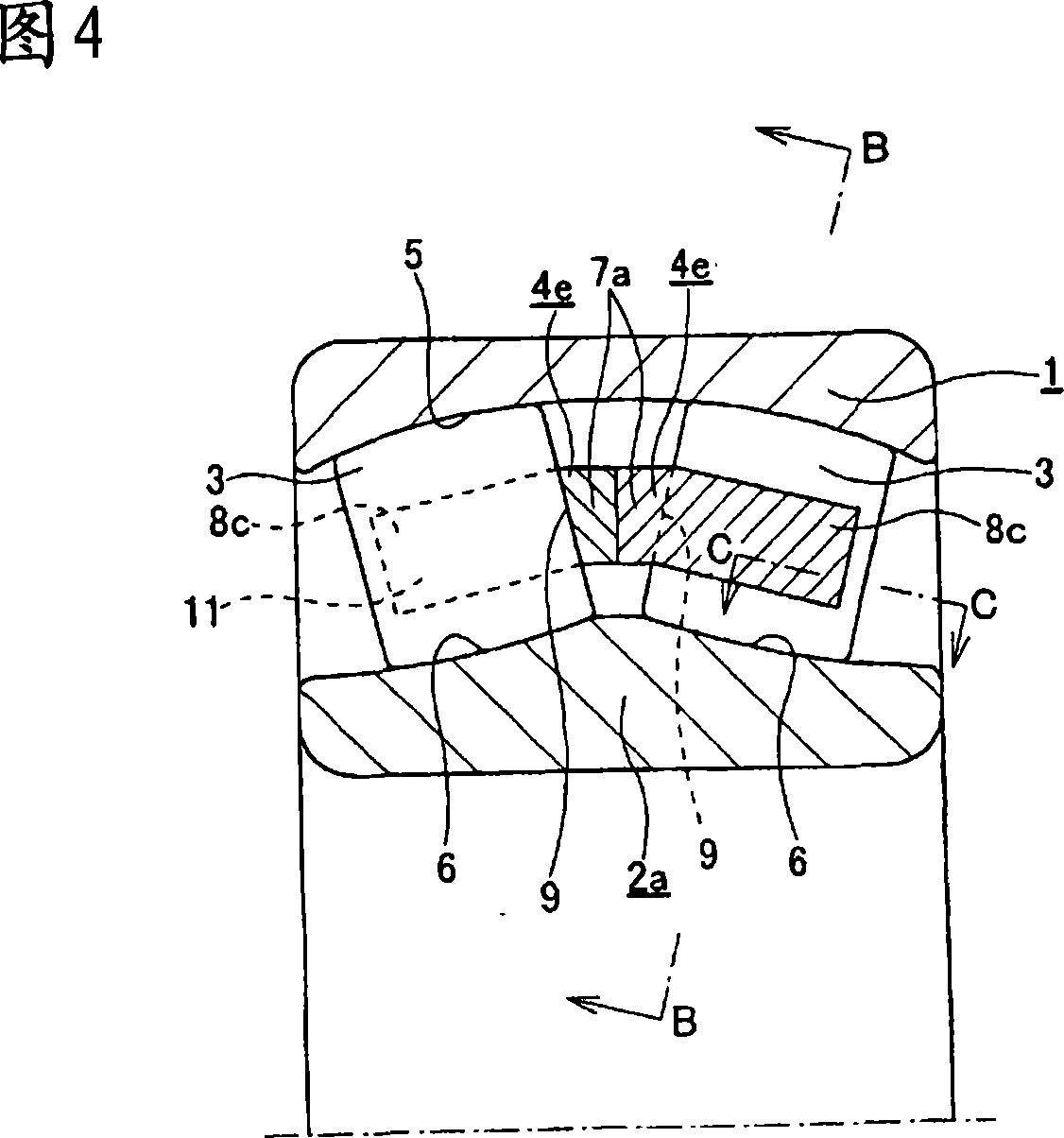

Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

ActiveCN101035995AEasy to processLow costRoller bearingsBearing componentsBarrel ShapedSpherical roller bearing

There is realized a self-aligning roller bearing with retainer that stabilizes the orientation of spherical rollers and prevents these spherical rollers from skewing, and which can be rotated at high speed, and furthermore which enables efficient lubricant feed into pockets 9. By rotating a turning tool 14 as it revolves, the surfaces on both sides in the circumferential direction of respective column sections are processed into concave curved surfaces that oppose a rolling surface of the respective spherical rollers across a pocket clearance into which lubricant oil can be fed. The length of the column sections 8c is less than the length in the axial direction of the spherical rollers, and greater than a half of the length, and an end portion of the side surface in the circumferential direction of the respective column sections 8c projects further in the circumferential direction than an intermediate portion thereof, and the spherical rollers are embraced in the pockets 9.A self-aligning roller bearing with a retainer enabling high speed operation by stabilizing the attitude of barrel shaped rollers to prevent the barrel shaped rollers from being skewed and the efficient feeding of a lubricant into pockets (9) and a method of manufacturing the retainer for the self-aligning roller bearing. In the self-aligning roller bearing, the both side faces of each column part (8c) in the circumferential direction are machined to recessed curved faces facing the rolling surface of each barrel shaped roller through pocket clearances allowing the lubricant to feed thereto with a cutting tool (14) revolving while rotating on its axis. Also, the length of each column part (8c) is set equal to or less than the axial length of each barrel shaped roller and more than the half of the axial length thereof, the side face tip portion of each column part (8c) in the circumferential direction are projected from the intermediate portion thereof in the circumferential direction.

Owner:NSK LTD

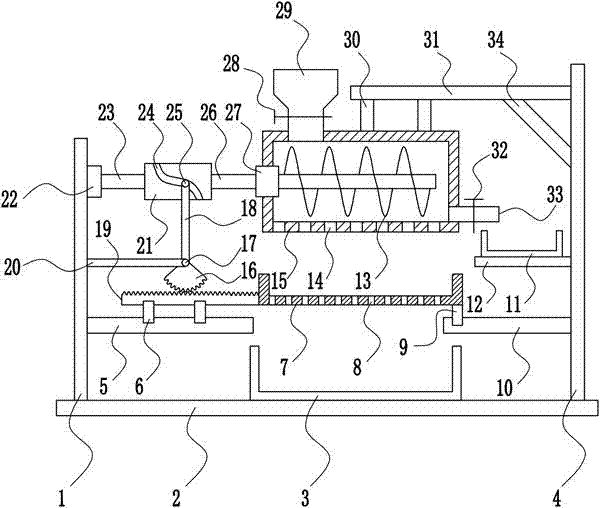

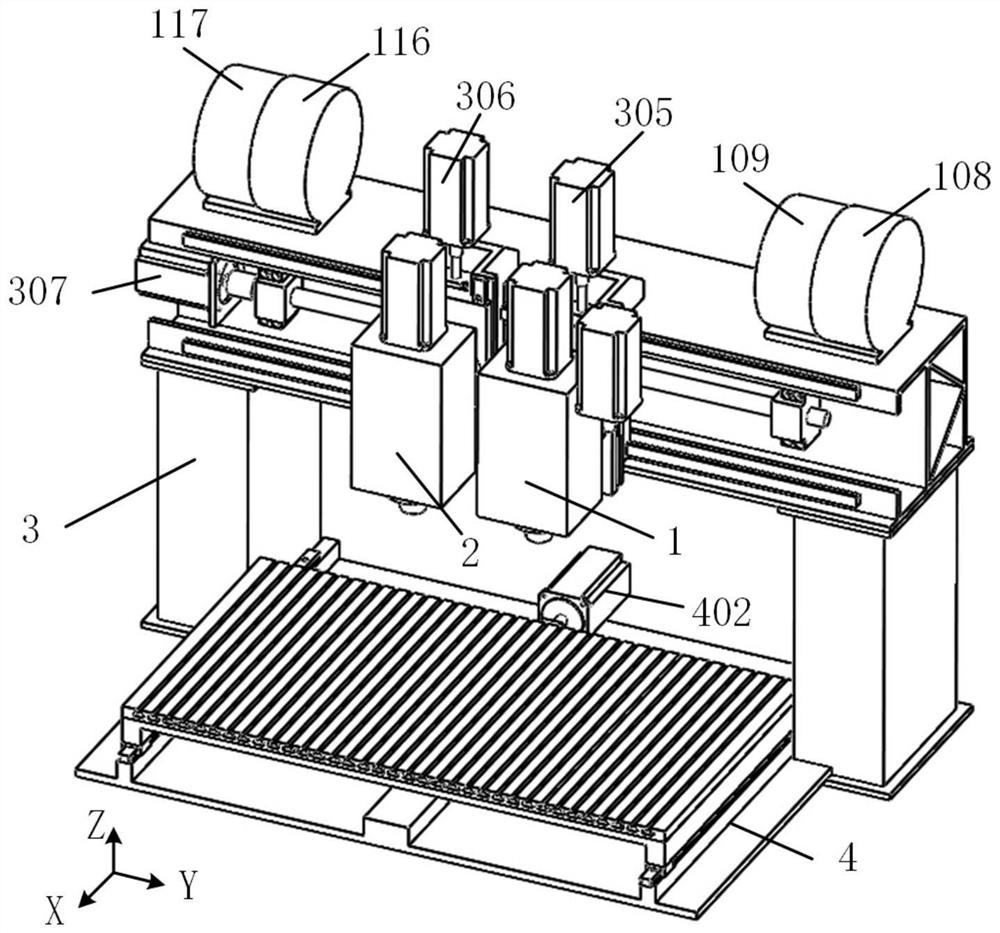

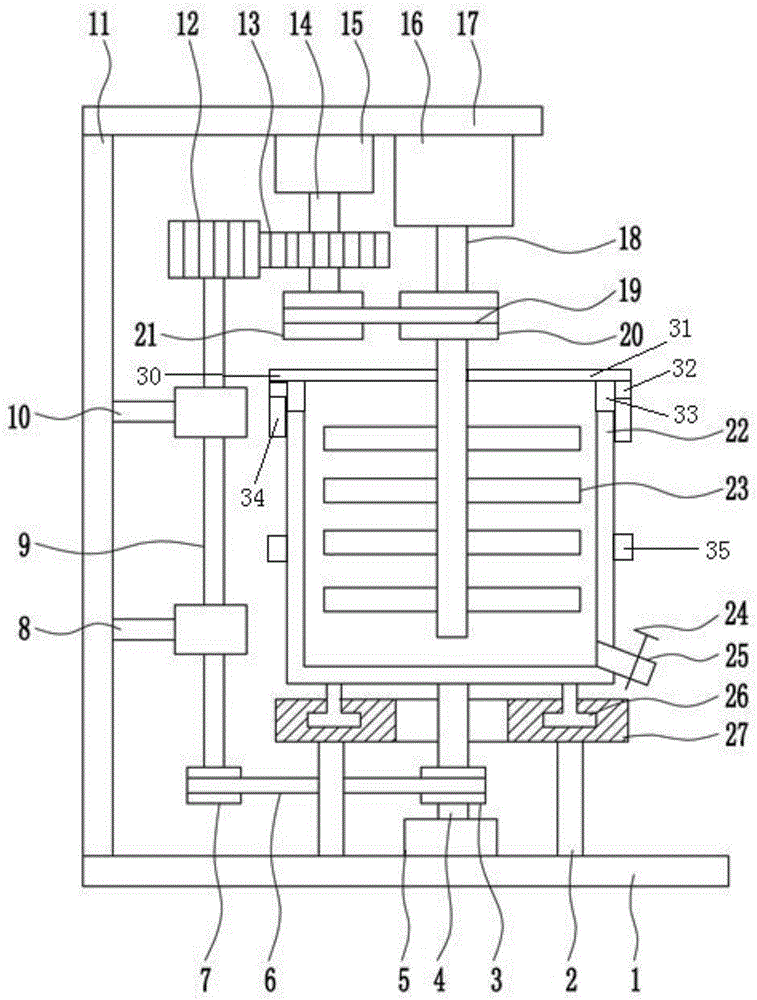

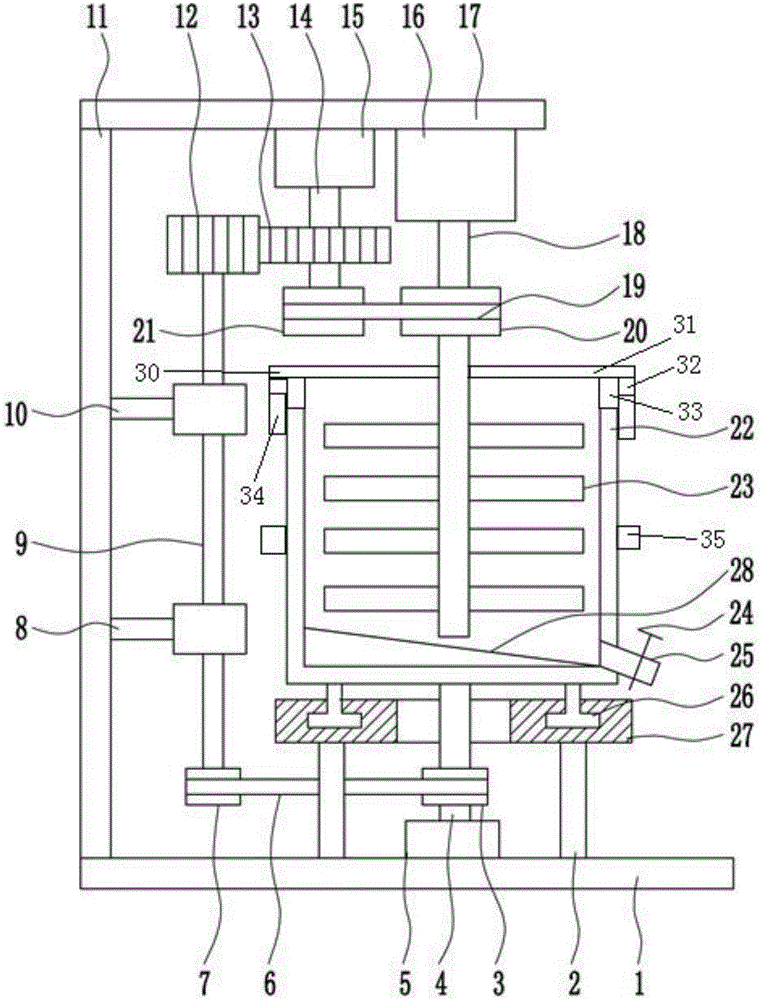

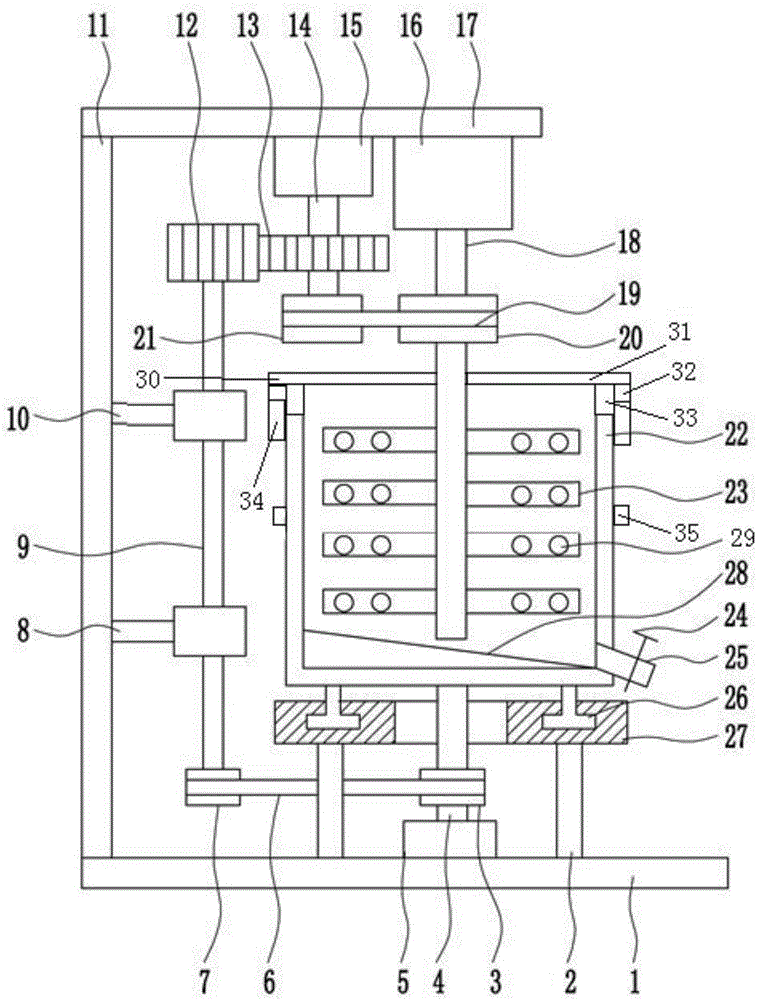

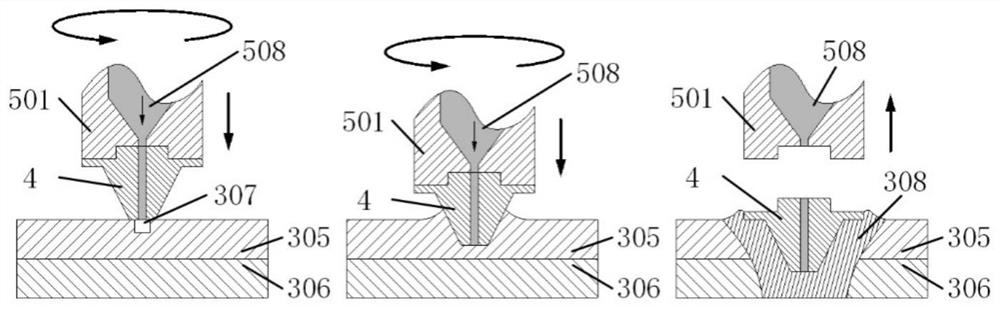

Stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials

ActiveCN111804910AImprove performanceEfficient Quality Additive ManufacturingAdditive manufacturing apparatusTransportation and packagingMaterial supplyIsothermal forging

The invention relates to a stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials. The device comprises four parts including a stirring friction additional material main shaft, an isothermal forging mechanism, a gantry type rack and a workbench; the stirring friction additional material main shaft is used for realizing mixing, preheating and supplying of powder or granular materials, conducting friction squeezing of materials output from a material supplying hole, and using friction heat and pressure to realize layer-by-layer additional material forming manufacturing; the isothermal forging mechanism is used for realizing isothermal forging and micro reshaping of an additional material layer; the gantry type rack is used for fixing the stirring friction main shaft and the isothermal forging mechanism and for realizing advancing as well as swaying angle adjustment of the stirring friction main shaft and the isothermal forging mechanism along the Y axis and the Z axis; and the workbench is used for fixing a substrate and realizing advancing of the substrate along the X axis. The method and the device can realize high-efficiency and high-quality additional material manufacturing of light alloy powder or granular materials, and have the advantages of higher efficiency, simple and convenient operation and lower energy consumption.

Owner:XI AN JIAOTONG UNIV

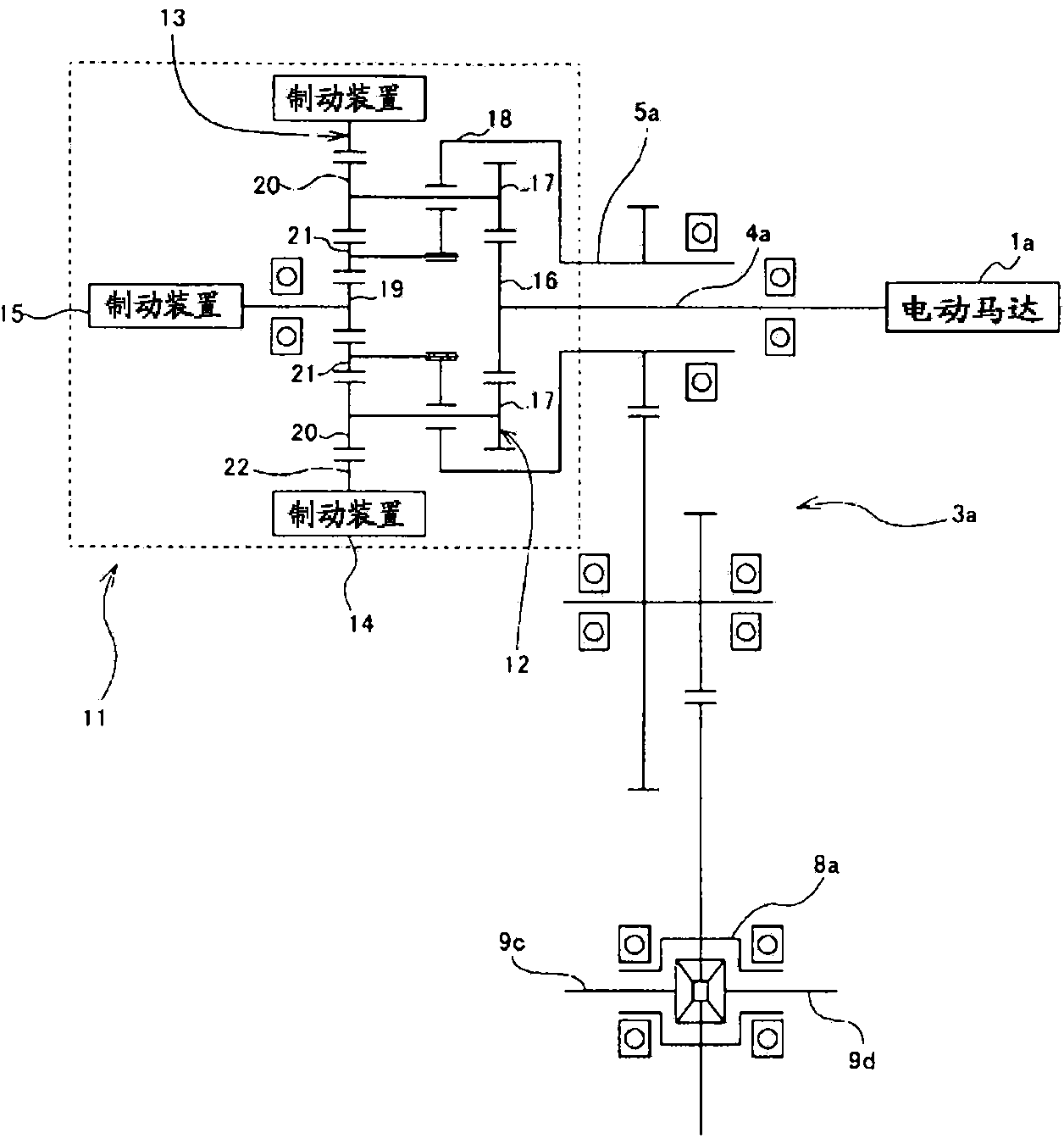

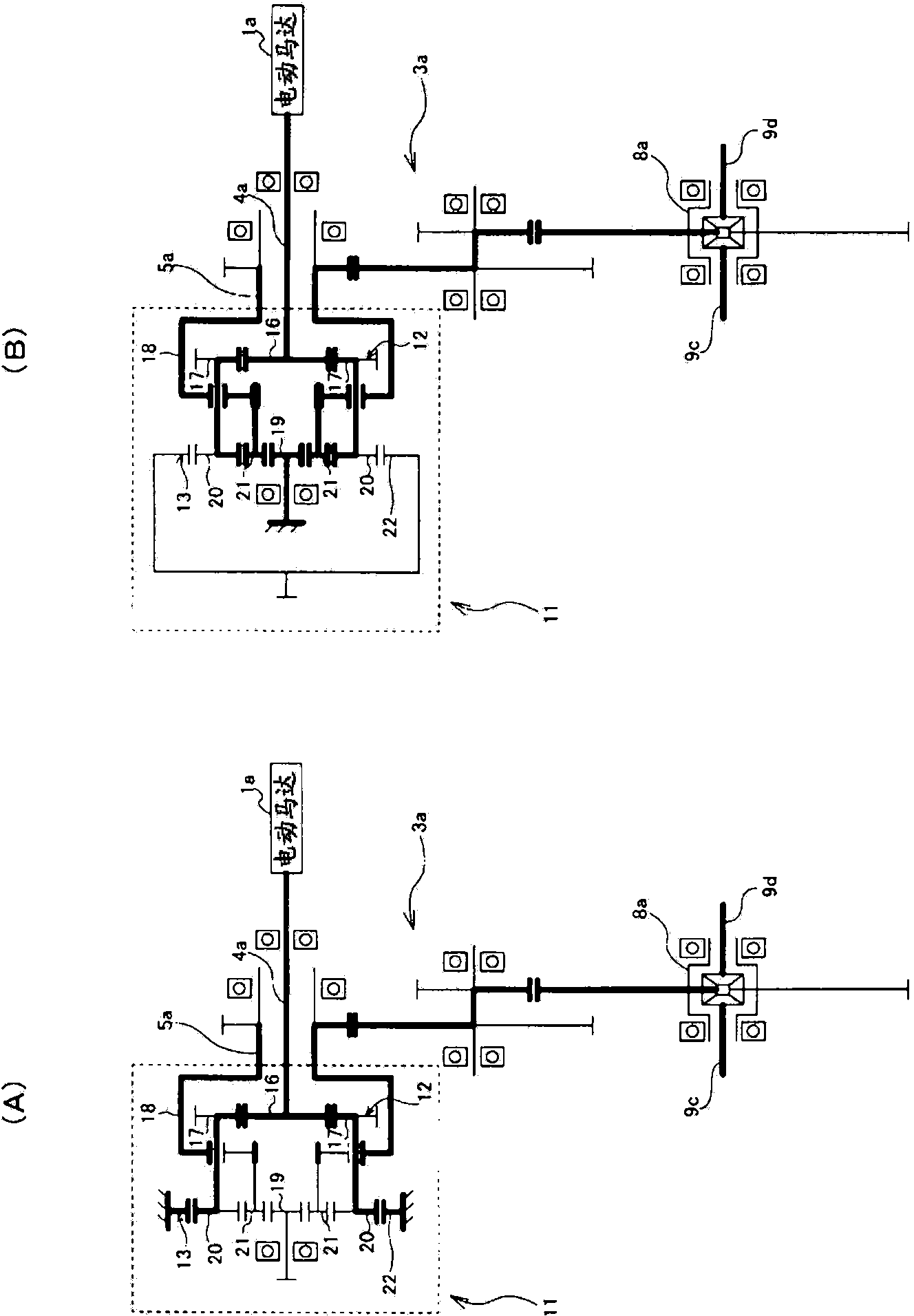

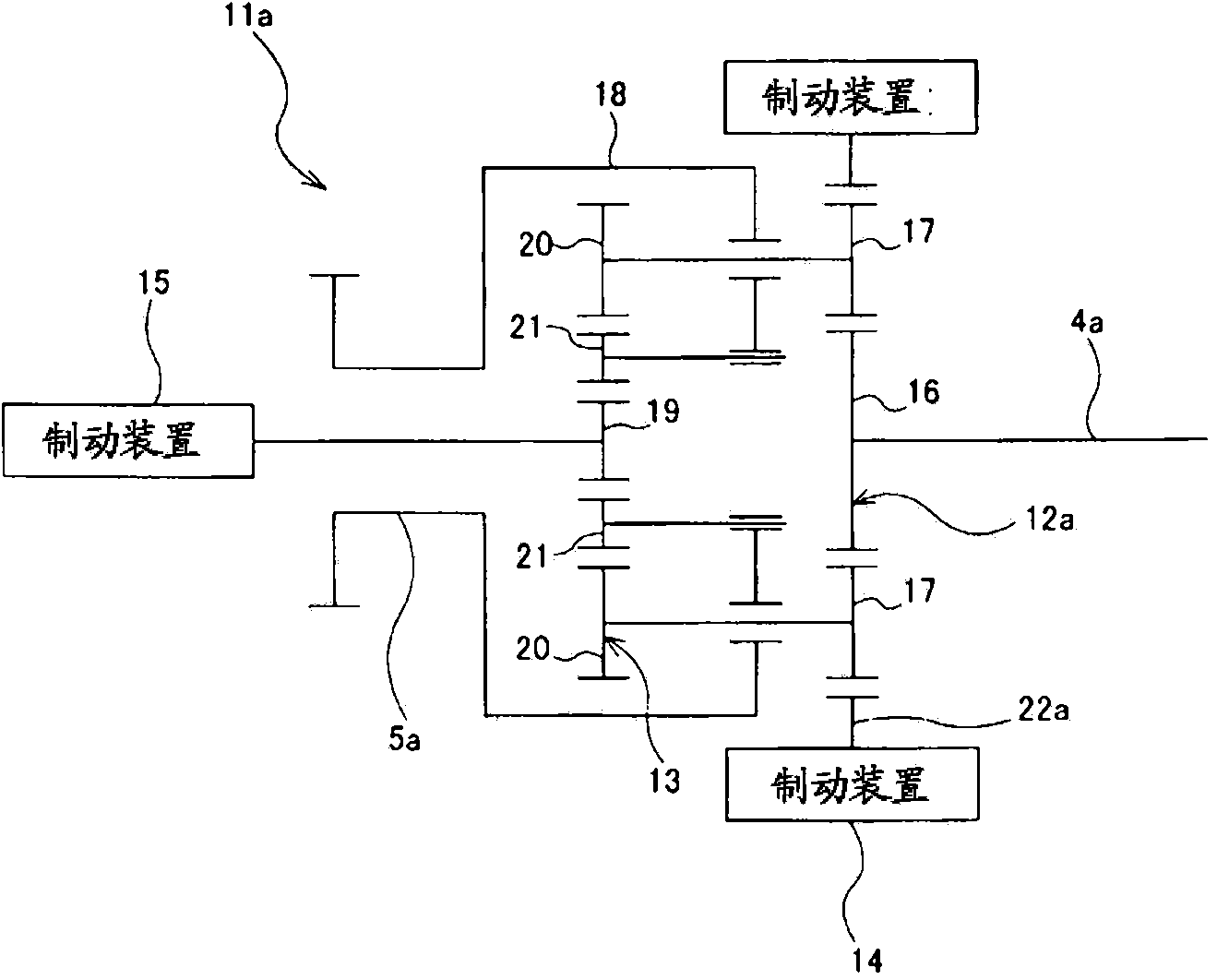

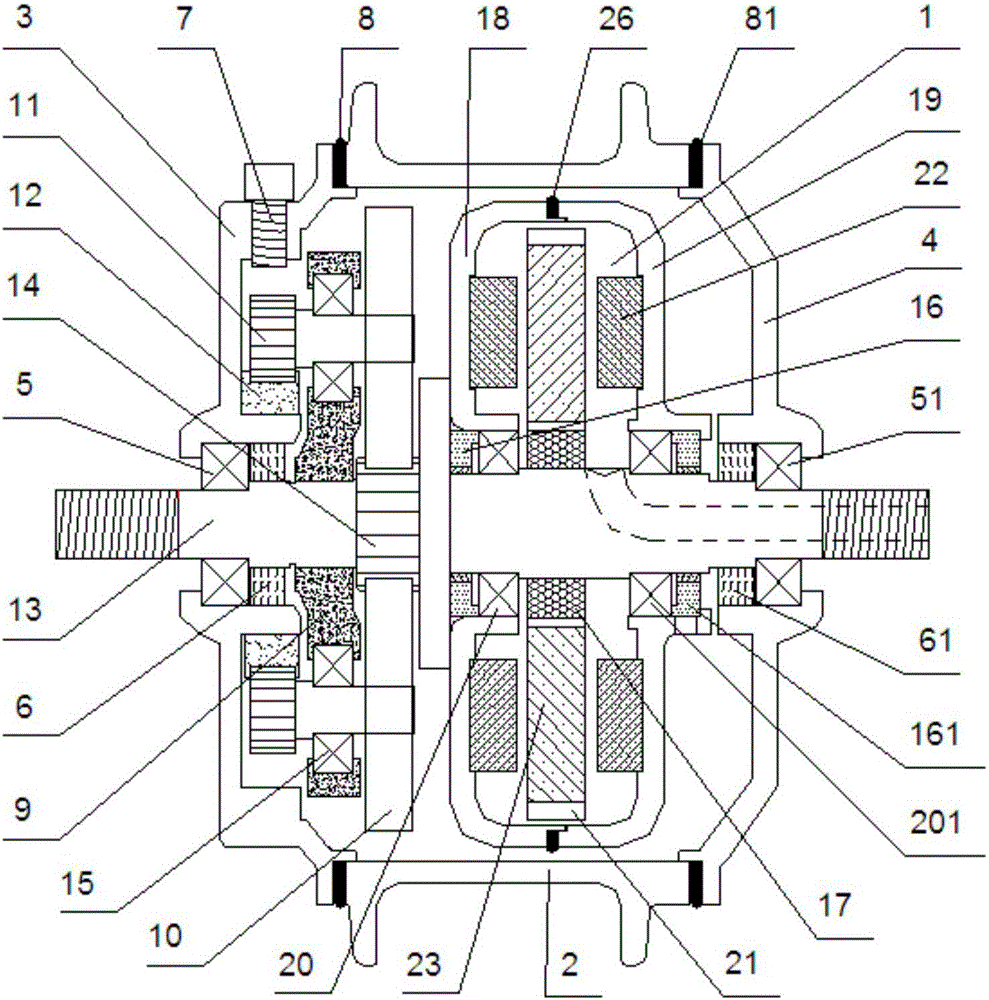

Electric vehicle driving device

InactiveCN103917803ASmall and simple configurationReduce intensitySpeed controllerElectric propulsion mountingEngineeringPinion

The purpose of the invention is to reduce in size and simplify an electric vehicle driving device embedding a planetary gear type transmission (11) to increase a running distance per charge and obtain the structure thereof capable of improving the convenience of an electric vehicle. The planetary gear type transmission (11) is constituted by a first planetary gear mechanism (12) of a single pinion type and a second planetary gear mechanism (13) of a double pinion type and transmits the power of an electric motor (1a) to a driven-side rotating shaft (5a) after reducing the speed according to a desired transmission gear ratio. A first braking device (14) and a second braking device (15) switch a ring gear (22) and a second sun gear (19) to the states of allowing and preventing rotation with respect to a fixed portion, respectively.

Owner:NSK LTD

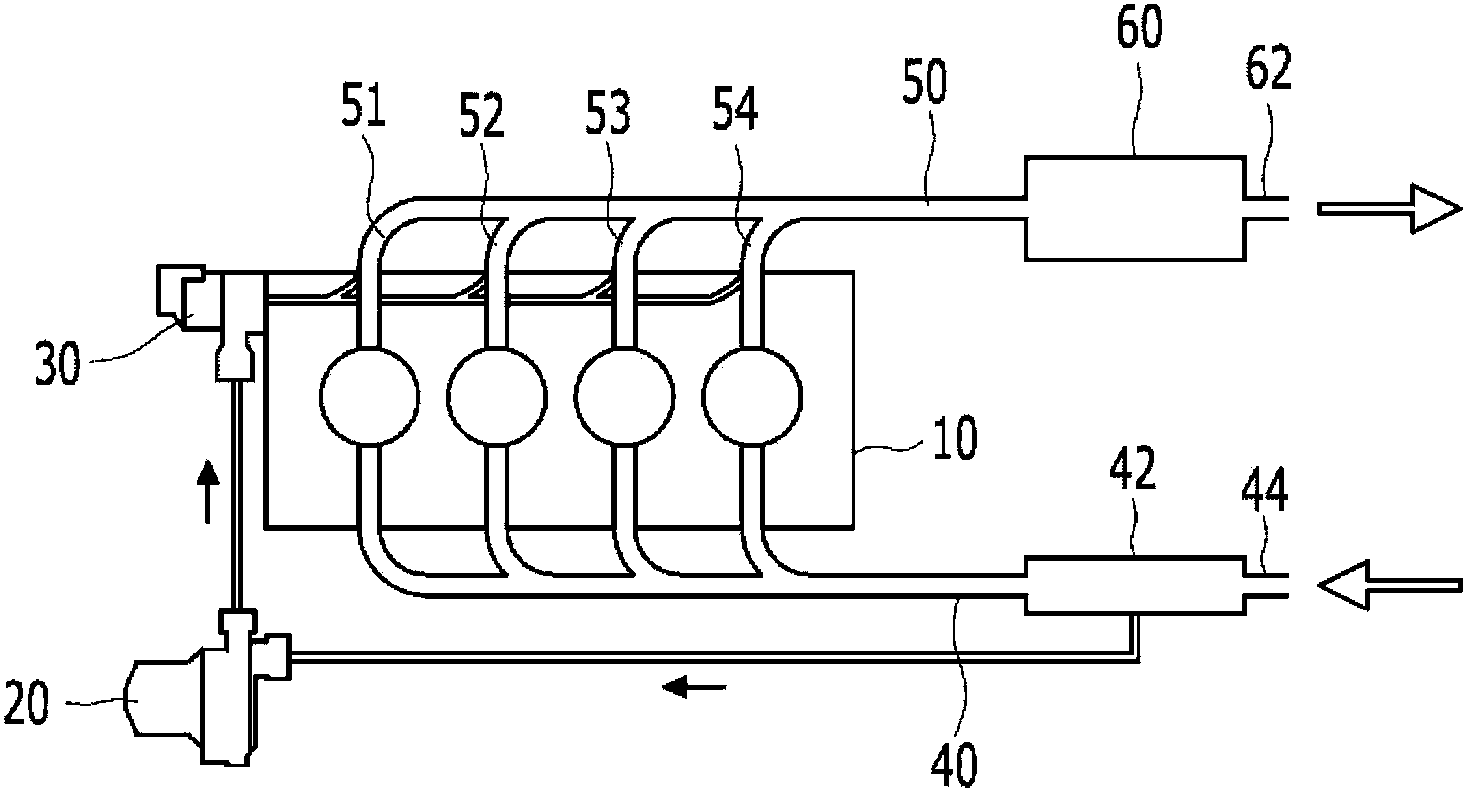

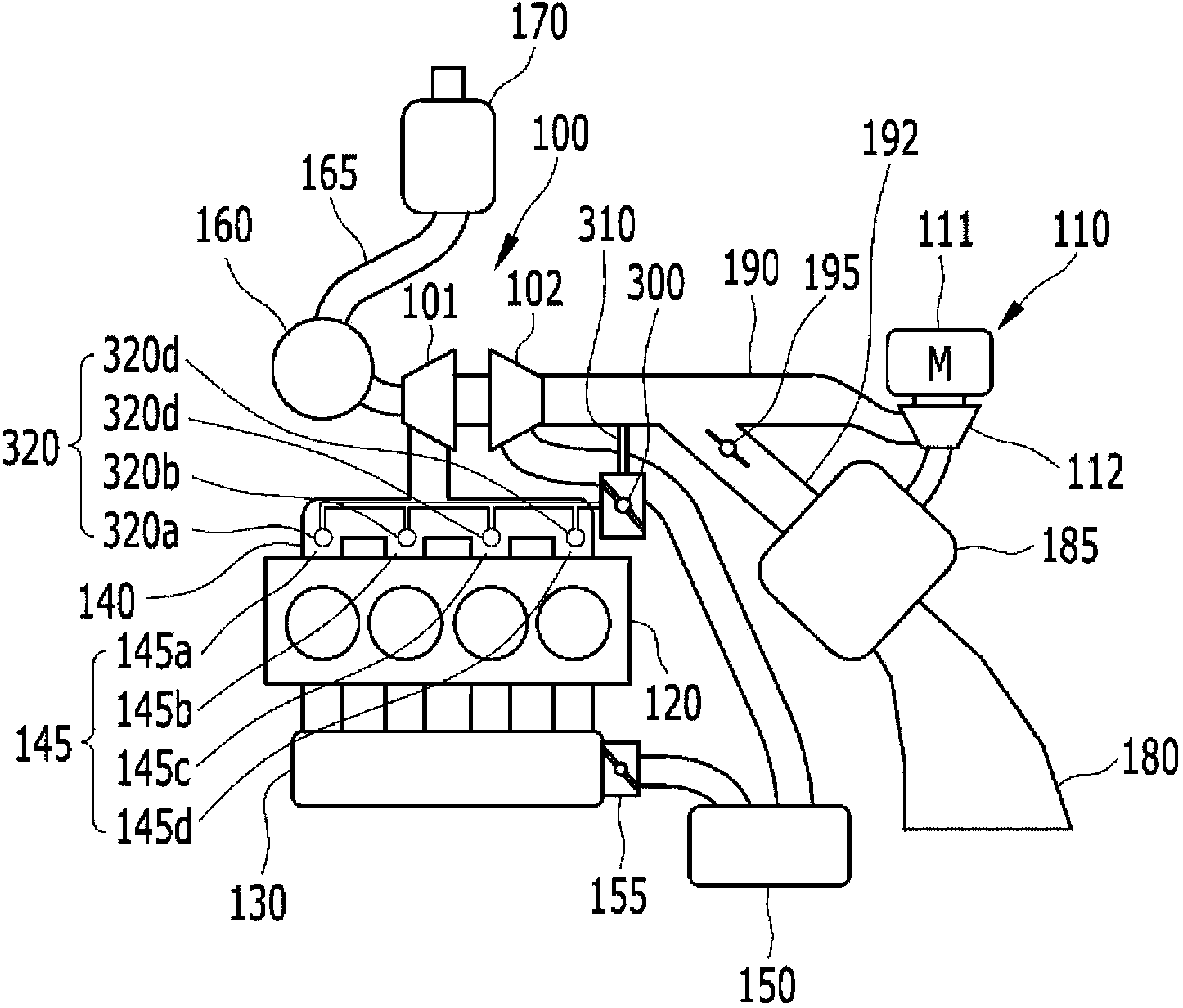

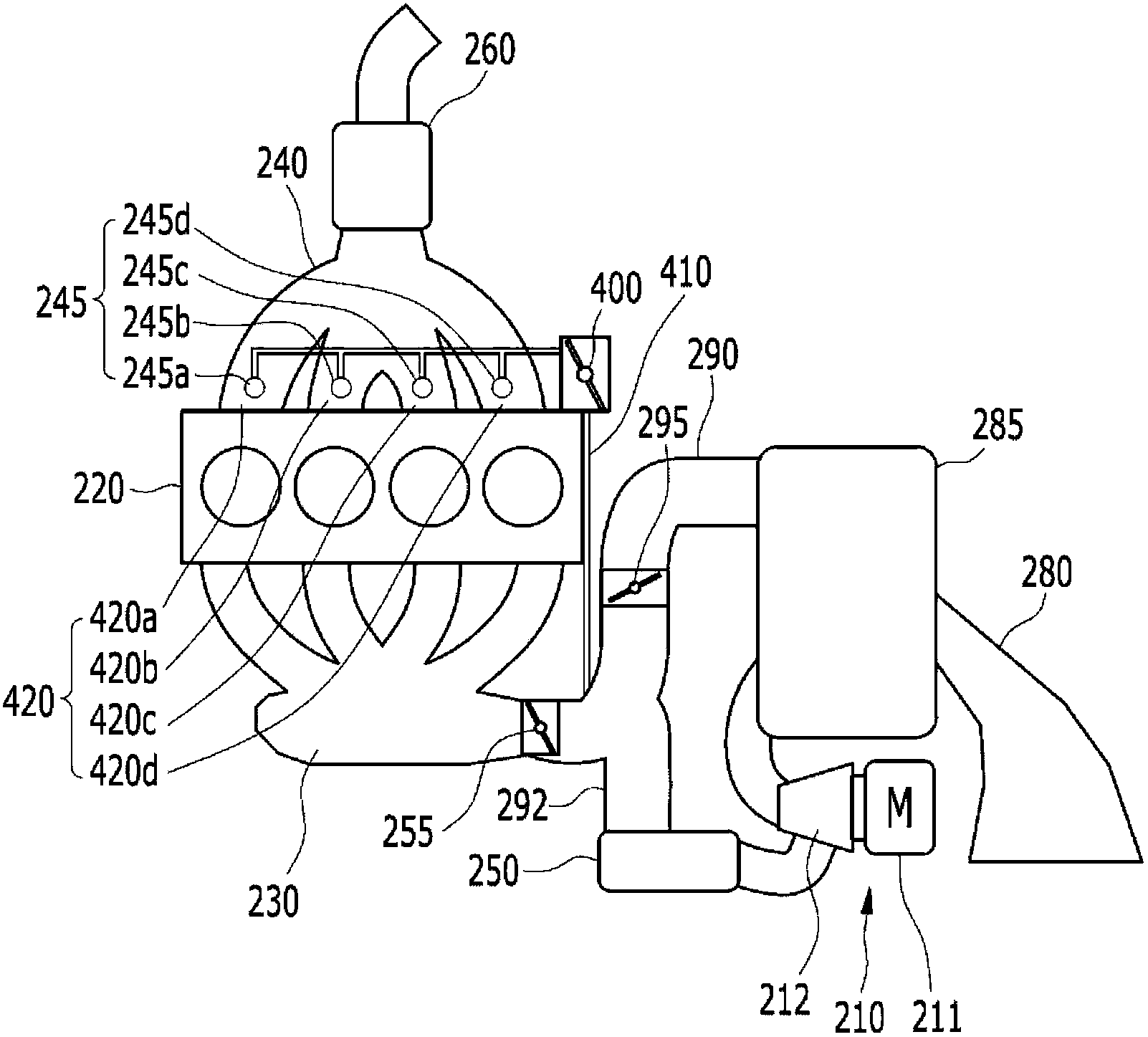

Secondary air injection system

InactiveCN103511064AReduce harmless ingredientsReduce the amount of precious metalsInternal combustion piston enginesExhaust apparatusInjection airGuide tube

The invention discloses a secondary air injection system. The secondary air injection system supplying some of air introduced into an intake manifold to an exhaust manifold may include: an electric supercharger compressing air introduced through an air duct; throttle valves installed at an upstream of the intake manifold and controlling the amount of air introduced into the intake manifold by controlling the amount of air passing through the electric supercharger; secondary air valves installed on branching paths branched from intake, lines that link the electric supercharger and the throttle vales and controlling the amount of air for secondary air injection; and an injector that post-combusts exhaust gas discharged from an engine by injecting secondary air passing through the secondary air valve to a runner of the manifold.

Owner:HYUNDAI MOTOR CO LTD

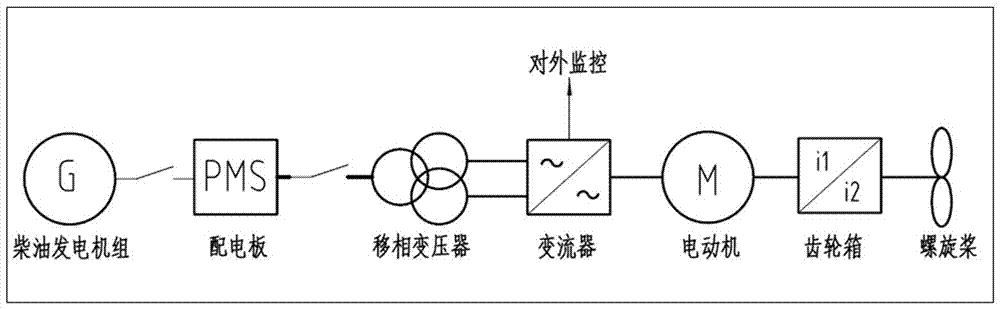

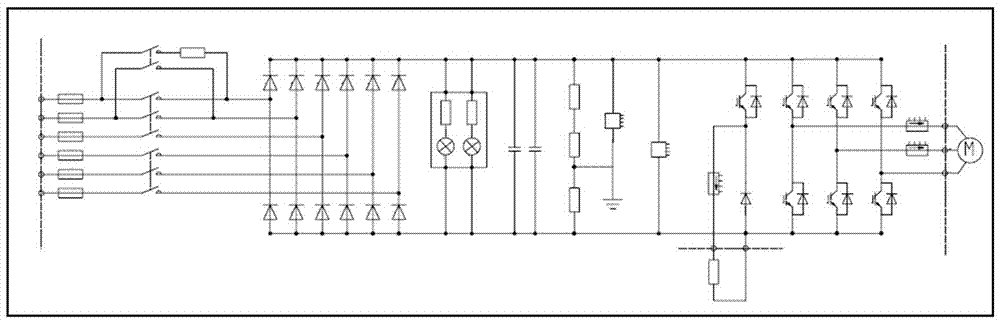

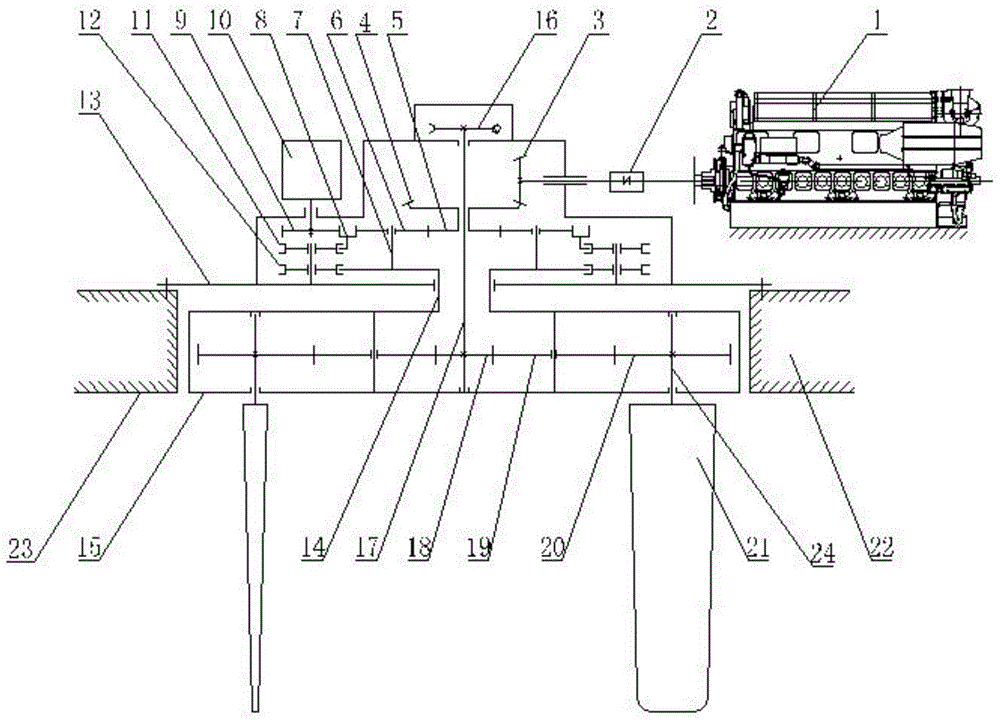

Electric propulsion converter for ocean fishing boat

InactiveCN107395027AReduce fuel consumptionReduce operating costsPropulsion power plantsPropulsive elementsLow speedLow voltage

The invention relates to an electric propulsion converter device for an ocean fishing boat, and in particular relates to an electric propulsion converter for an ocean fishing boat. The electric propulsion converter comprises a cabinet; a power unit, a control unit, a cooling unit and wiring harnesses are arranged in the cabinet; the power unit comprises a rectifier module, an inverter chopper module and a direct-current support capacitor; the rectifier module comprises a rectifier input copper bar, a rectifier power module and a main contactor; the inverter chopper module comprises a three-phase inverter output copper bar and an inverter chopper power module; the control unit comprises a traction control unit, a sensor, a filter and a power supply; the cooling unit comprises a heat exchanger, a water pump, a water replenishing box, a pipeline, a temperature sensor, a pressure sensor, a valve and a cooling pipeline; and the wiring harnesses include low-voltage wiring harness and high-voltage wiring harness. Electric transmission based on the converter gradually replaces the traditional transmission mode by the advantages, such as low speed, large toque, uniform low-speed operation, flexible configuration and high reliability; the electric transmission is the mainstream development direction of ship propulsion; and thus, the electric propulsion converter has wide application prospect.

Owner:CRRC YONGJI ELECTRIC CO LTD

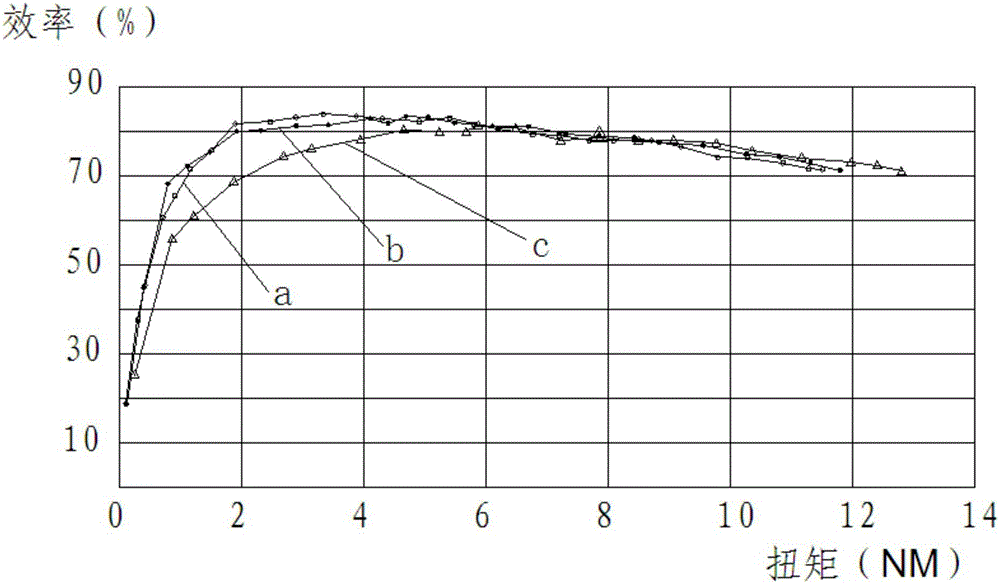

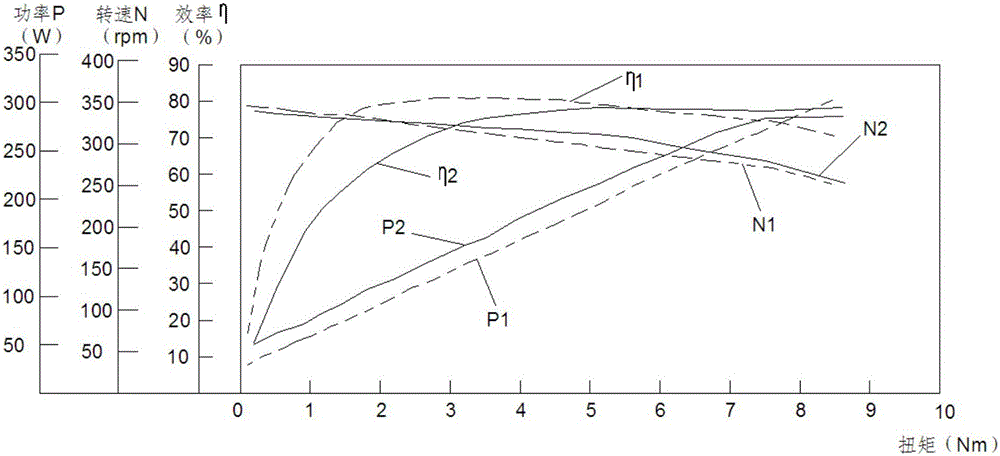

Gear hub motor lubricated by liquid lubricating oil

ActiveCN106208588ASmall air gap flux densityIncrease speedDC commutatorMechanical energy handlingFully developedReducer

The invention discloses a gear hub motor lubricated by liquid lubricating oil. The gear hub motor comprises a left end cover, a right end cover, a main shaft an a hub, wherein the left end cover sleeves the main shaft through a first bearing and a first oil seal; an oil filling opening is formed in the left end cover, the right end cover or the hub; the right end cover sleeves the main shaft through a second bearing and a second oil seal; the left end cover is connected with the right end cover through a seal ring and the hub; the left end cover is connected with a solar gear ring through a reducing mechanism; the solar gear ring is fixed on the motor; and the solar gear ring is driven to rotate through the motor, so that the left end cover is driven to rotate through the reducing mechanism to drive the hub to rotate. A two-stage reduction planetary gear reducer mechanism is adopted under the premise of keeping a through shaft structure, so that the reliability of the hub motor structure is ensured; the high-speed performance of a disc-type coreless DC motor can be fully developed; the reducing mechanism is lubricated by the liquid lubricating oil; and the transmission efficiency of the motor is high.

Owner:眭华兴

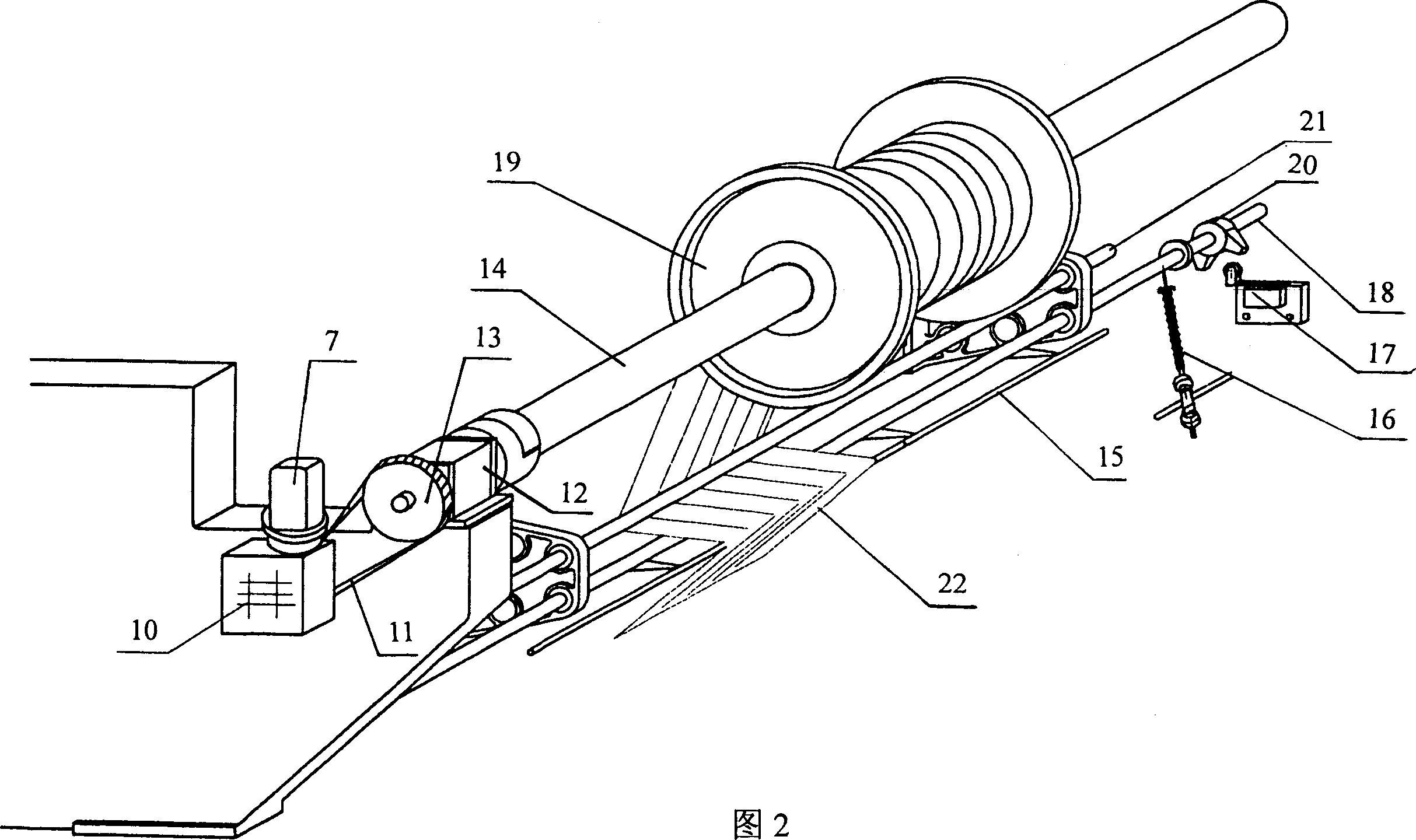

Precision hardware punching device

The invention relates to a punching device, in particular to a precision hardware punching device and aims at achieving the technical purpose of providing the precision hardware punching device convenient to operate and capable of punching flat sections and reducing burrs. To achieve the above technical purpose, the precision hardware punching device is provided and comprises a left frame, a containing table, a bottom plate, a first nut, a rocking handle, a screw, a push block, a pressing block, an electric push rod, a cutter, a sliding block, a fixing plate, a first connecting rod and the like. The left frame is welded to the left side of the top of the bottom plate. The containing table is welded to the left side of the top of the bottom plate and located on the right side of the left frame. A groove is formed in the lower portion of the right side of the left frame. The first nut is welded to the lower portion of the left side of the left frame. A rotation motor is used for driving a first rotation shaft to rotate, the first rotation shaft drives a first bolt and a second bolt to rotate, and the first bolt and the second bolt drive a second nut and a third nut to move towards the middle from the two sides correspondingly.

Owner:渡边精密金属(珠海)有限公司

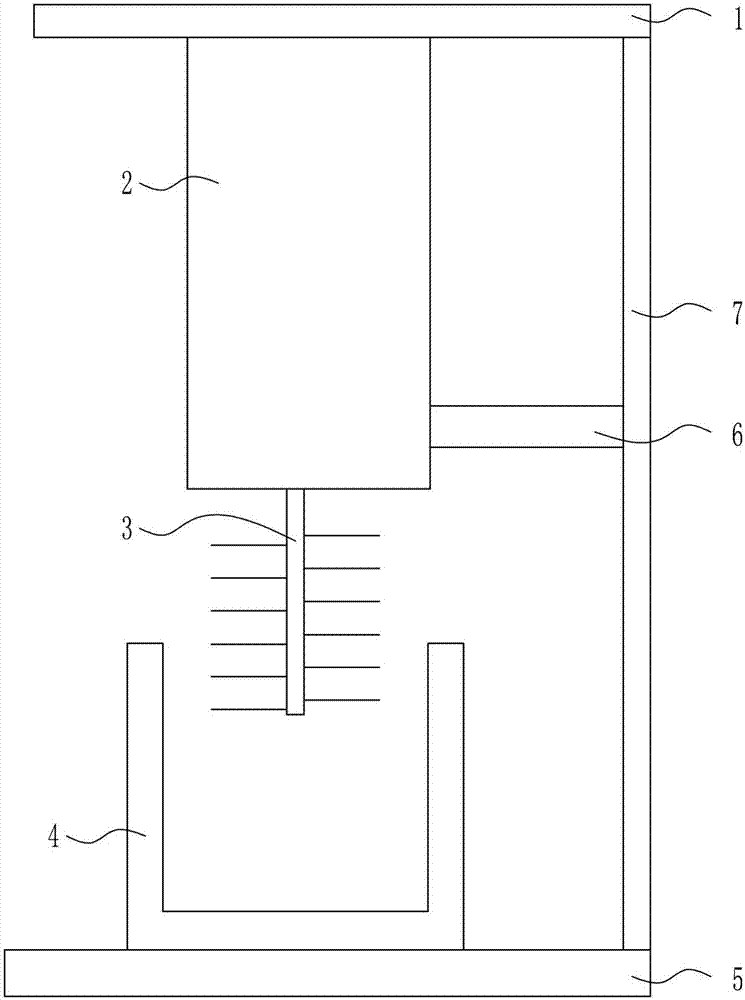

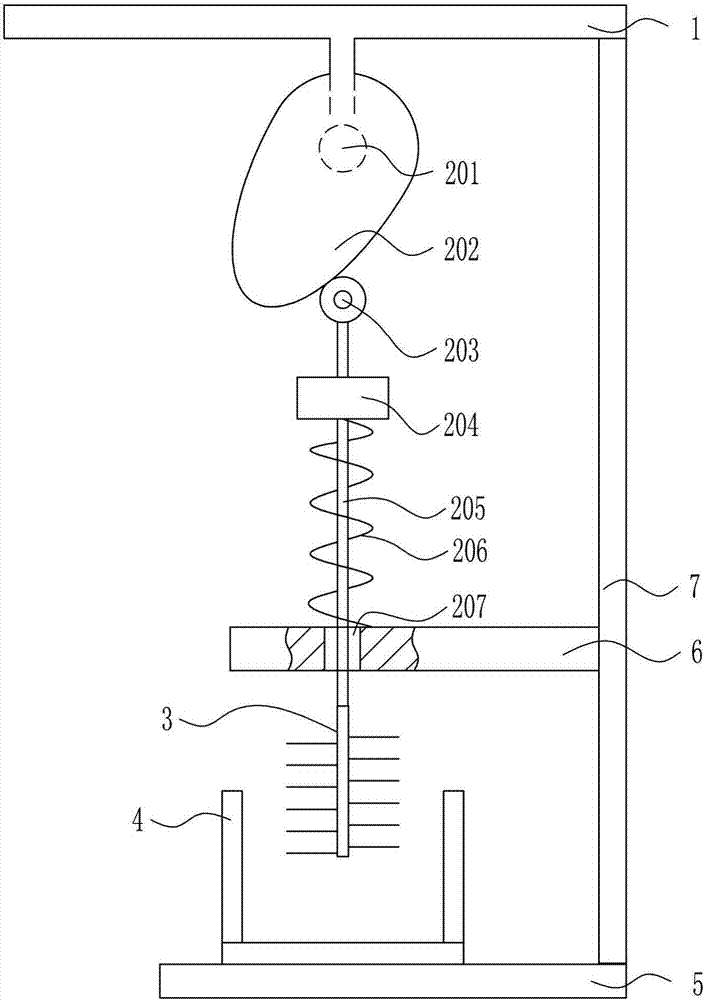

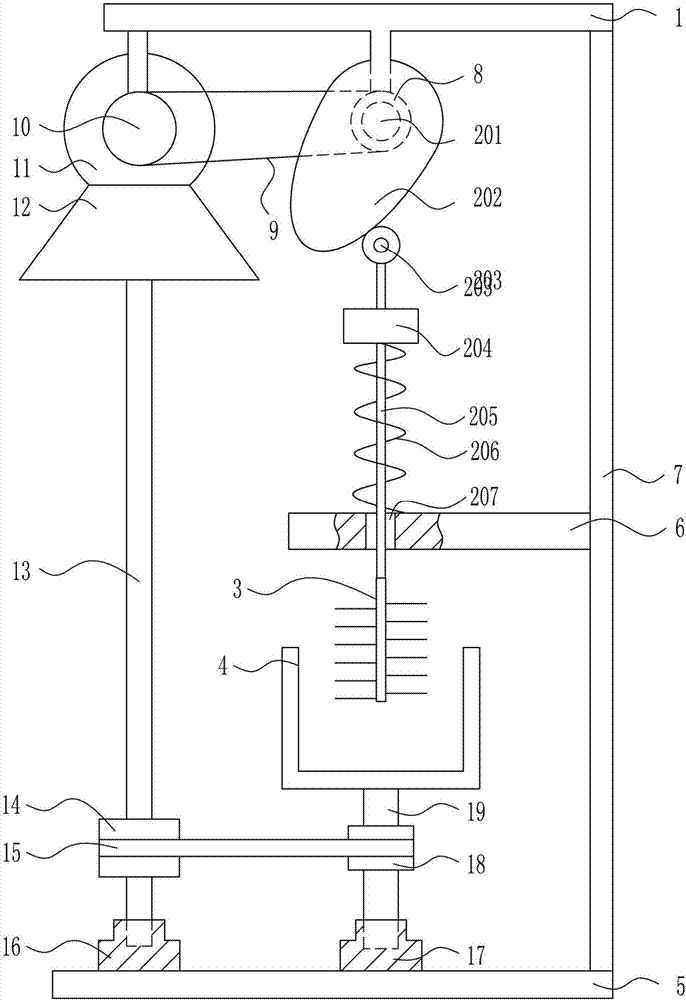

Quick stirring device for water purifier assembling

The invention relates to a stirring device, in particular to a quick stirring device for water purifier assembling. According to the stirring device for water purifying equipment assembling, time and labor are saved, uniform smearing is easy, and smearing is convenient. The quick stirring device for water purifier assembling comprises a top plate and the like. A lifting mechanism and a bracket are arranged at the bottom of the top plate; the lifting mechanism is located on the left portion of the bracket; a stirring rod is arranged at the bottom of the lifting mechanism; a supporting rod is arranged on the left side of the bracket and connected with the lifting mechanism; a bottom plate is arranged under the bottom of the top plate; a stirring box is arranged on the top of the bottom plate; and the right side of the top of the bottom plate is connected with the bracket. According to the quick stirring device, a sealing ring and Vaseline are more conveniently stirred, so that the Vaseline is smeared on the sealing ring more evenly, and the sealing ring and the Vaseline can be stirred more quickly.

Owner:施亮

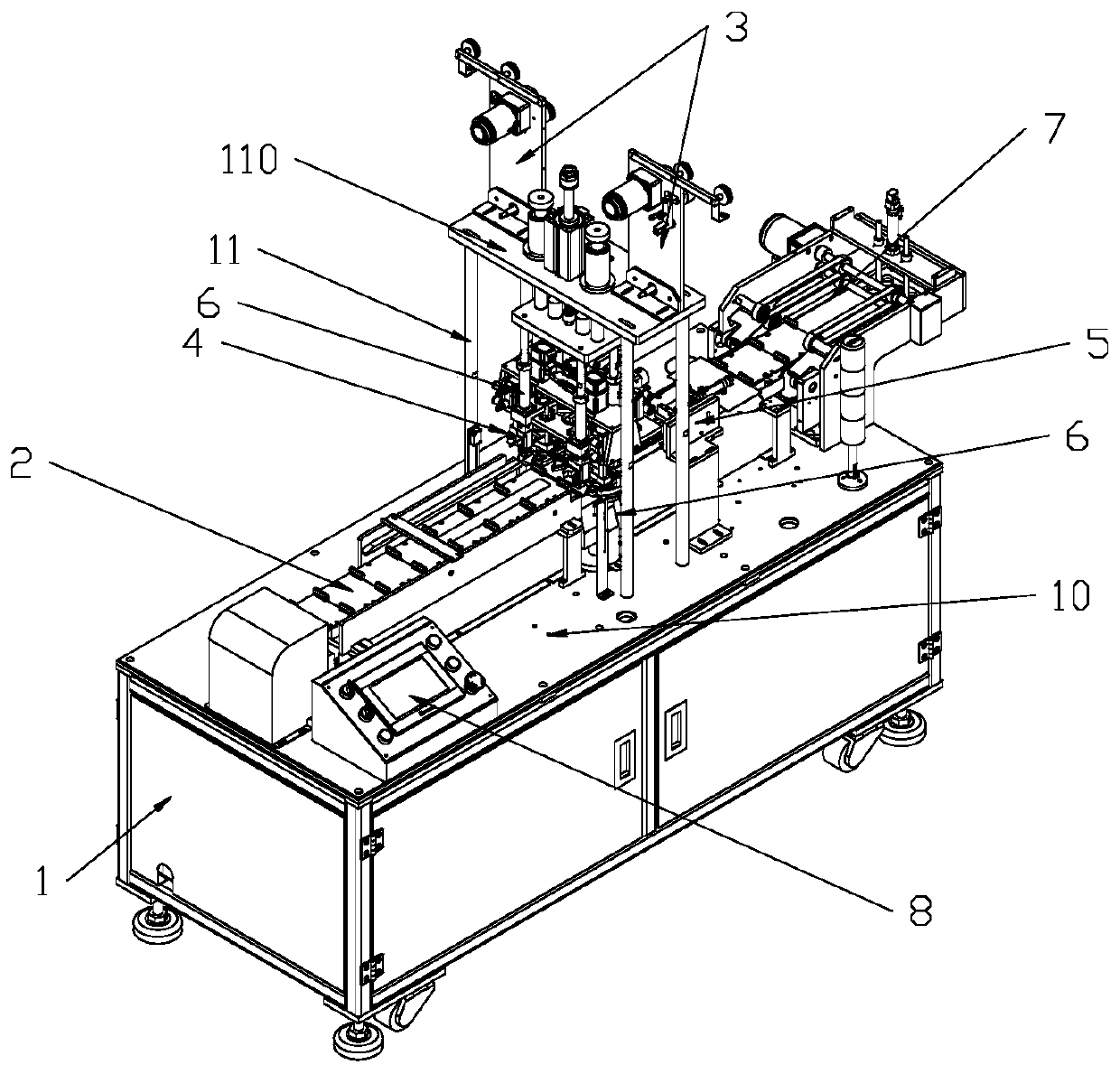

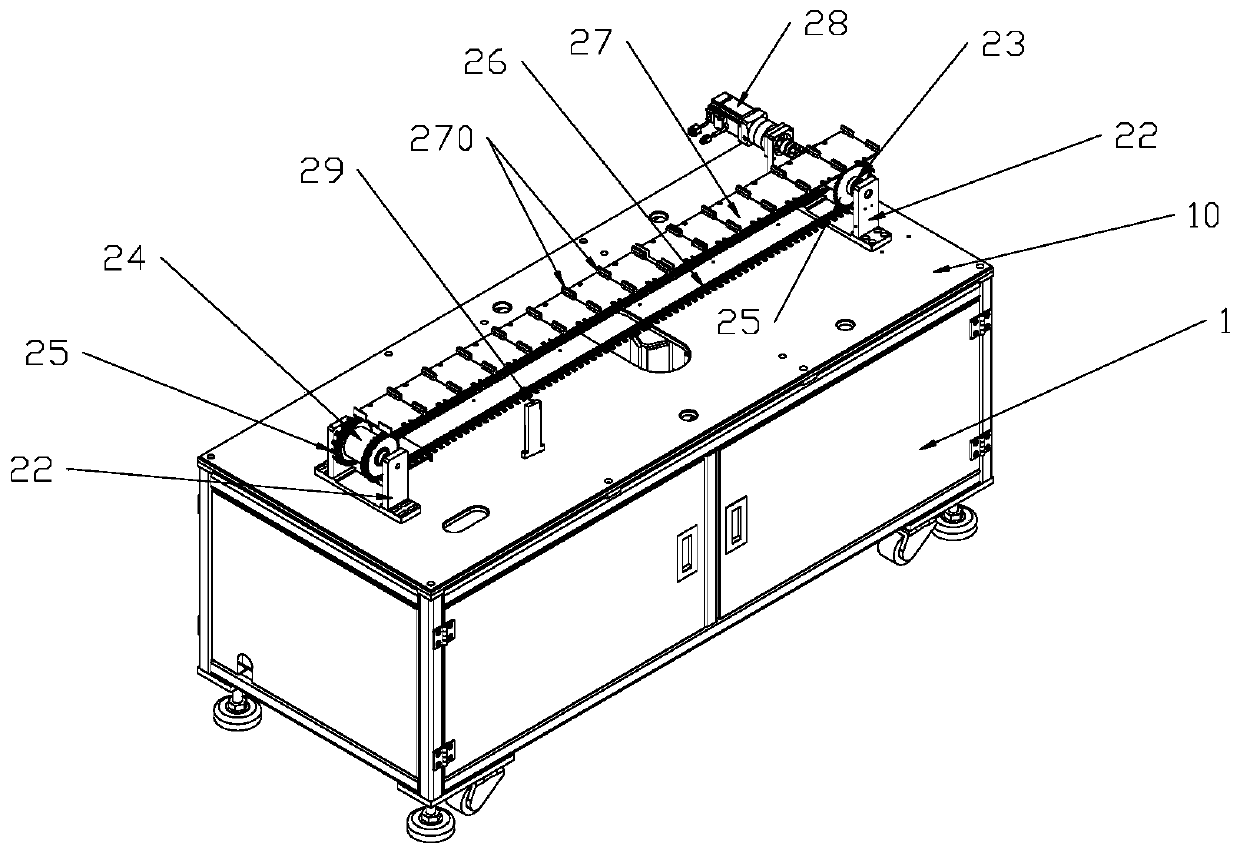

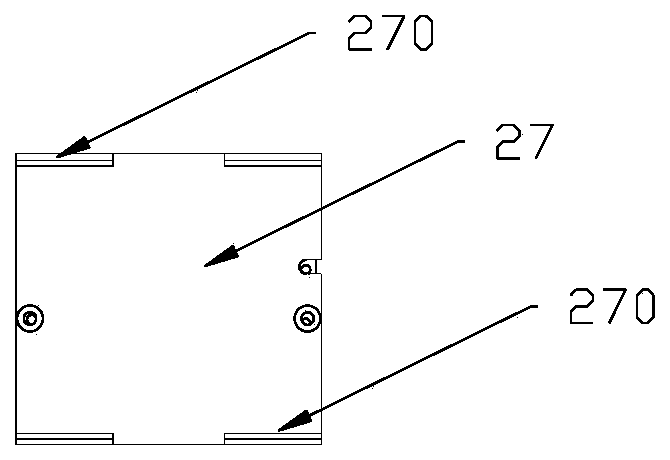

Automatic welding machine for ear straps of face mask

PendingCN111590904AImprove efficiencyImprove pass rateDomestic articlesProtective garmentWinding machinePalletizer

The invention discloses an automatic welding machine for ear straps of a face mask. The automatic welding machine for the ear straps of the face mask comprises a rack. An equipment platform is arranged on the rack, a mask conveying mechanism, a thread feeding mechanism, a thread winding mechanism, a thread shearing mechanism, a welding mechanism, a stacking mechanism and a controller are arrangedon the equipment platform, and the thread feeding mechanism, the thread winding mechanism, the thread shearing mechanism and the welding mechanism are arranged above the mask conveying mechanism. Thestacking mechanism is arranged at the output end of the mask conveying mechanism, the mask conveying mechanism comprises two chain wheel supports, a driving double-chain wheel and a driven double-chain wheel, two parallel and tensioned chains are arranged between the driving double-chain wheel and the driven double-chain wheel, and the two chains are both located on the surface of the equipment platform. A plurality of flat plate type mask carriers are transversely and evenly laid on the two chains. The automatic welding machine for the ear straps of the face mask has the beneficial effects that the conveying positioning precision is high, the average transmission ratio is accurate, the transmission is stable, the efficiency is high, the transmission power is high, the overload capacity ishigh, the high-speed performance is excellent, and maintenance and debugging are convenient.

Owner:HUIZHOU HAPPY VAPING TECH LTD

Raw material sealing and mixing device for dry battery production technology

InactiveCN106582394AReduce wasteProtect your healthRotating receptacle mixersTransportation and packagingMixing effectBolt connection

The invention belongs to the technical field of dry battery production, particularly relates to a raw material sealing and mixing device for the dry battery production technology and aims at providing the raw material sealing and mixing device for the dry battery production technology, wherein the raw material sealing and mixing device for the dry battery production technology is easy to operate, small in workload and uniform in mixing. The device comprises a bottom plate, supports, a first large belt wheel, a first rotating shaft, a rotation motor, a first flat belt, a first small belt, a first bearing block, a second rotating shaft, a second bearing block, a sliding block, a sliding rail, a first cover, a second cover, a lower protrusion, a closed ring and the like. A left frame is welded to the left end of the top of the bottom plate, and the supports are symmetrically welded to the right side of the top of the bottom plate. The top ends of the two supports are connected with the sliding rail in a bolt connecting manner. According to the raw material sealing and mixing device, the effects of simple operation, the small workload and uniform mixing are achieved; and the raw material sealing and mixing device has important functions that a good mixing effect is achieved, in addition, the work efficiency is improved, and safety is high.

Owner:陈红

Leather shoe shell fabric tailoring equipment for leather shoe processing

The invention relates to tailoring equipment and in particular relates to leather shoe shell fabric tailoring equipment for leather shoe processing. The invention aims to provide the leather shoe shell fabric tailoring equipment for leather shoe processing, wherein the position of the leather shoe is easily fixed when the leather shoe is formed and the equipment is conveniently used by shoe-making personnel. In order to solve the technical problem, the invention provides the leather shoe shell fabric tailoring equipment for leather shoe processing. The leather shoe shell fabric tailoring equipment for leather shoe processing comprises a top plate, a tailoring device, a bottom plate, a placing table, a clamping device and the like, wherein the placing table is arranged on the top of the bottom plate, the top plate is arranged right above the bottom plate, the tailoring device is arranged on the bottom of the top plate, and the locking device is mounted on the bottom of the tailoring device. The equipment provided by the invention is simple to operate and convenient for the shoe-making personnel to use, and a new tailoring blade is conveniently replaced by the shoe-making personnel and the tailoring blade can be fixed well.

Owner:林安益

Quick cleaning equipment for medicinal material processing

InactiveCN107262425APlay a buffer roleReduce impact forceCleaning using liquidsWastewaterEngineering

The invention relates to a cleaning device, which includes a support rod, a bottom plate, a first motor, a bracket, a waste water frame, a right frame, a push plate, a rotating shaft, a first water pipe, a first one-way valve, a cylinder body, and a second one-way valve etc.; the left end of the bottom plate top is welded with a strut, the upper end of the strut is welded with a cylinder body, and the right wall of the cylinder body is symmetrically connected with the first elastic member up and down through the connection mode of the hook. The invention achieves the effects of novel structure, convenient operation, and no damage to medicinal materials. Workers can realize quick cleaning work during medicinal material processing through the device, which is not only simple in operation, but also saves time and effort.

Owner:六安市富民农用器材制造有限公司

Method for manufacturing novel super-high speed precision ball bearing

InactiveCN104674177AImprove performanceImprove temperature rise performanceVacuum evaporation coatingSputtering coatingBall bearingSteel ball

The invention discloses a method for manufacturing a novel super-high speed precision ball bearing. The method comprises the following steps: (a) preparing a Cr-N-C gradient compound coating; (b) washing a steel ball sample and drying with cold air; (c) highly vacuumizing by putting the steel ball in a cavity; (d) introducing Ar2, exerting a negative bias after rising of the air pressure, opening a Cr target to promote the current, washing the matrix, and opening a rotary workpiece clamp to rotate the steel ball in a constant speed; (e) reducing the negative bias and the chromium target current; (f) depositing the Cr-N-C gradient compound coating by exerting a negative bias on the matrix, wherein the Cr-N-C gradient compound coating is composed of a Cr bottom layer, a Cr-N transition layer and a Cr-N-C work layer; and (9) closing the Cr target, the C target and the nitrogen, and continuously introducing an argon. By adopting the technical solution provided by the invention, the temperature rise of the precision ball bearing can be greatly reduced, the vibration of the bearing can be reduced and the vibration stationarity can be increased, and then the high speed performance of the precision ball bearing and the reliability of the performance life can be increased and simultaneously the loading ability can be increased.

Owner:LUOYANG INST OF SCI & TECH

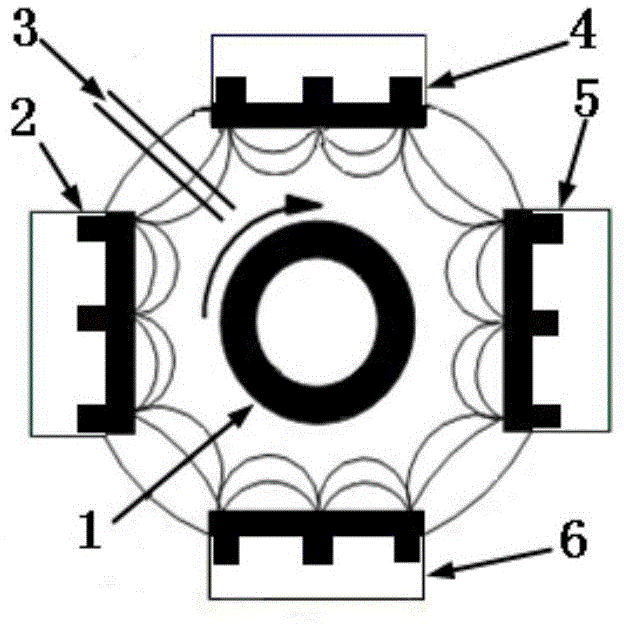

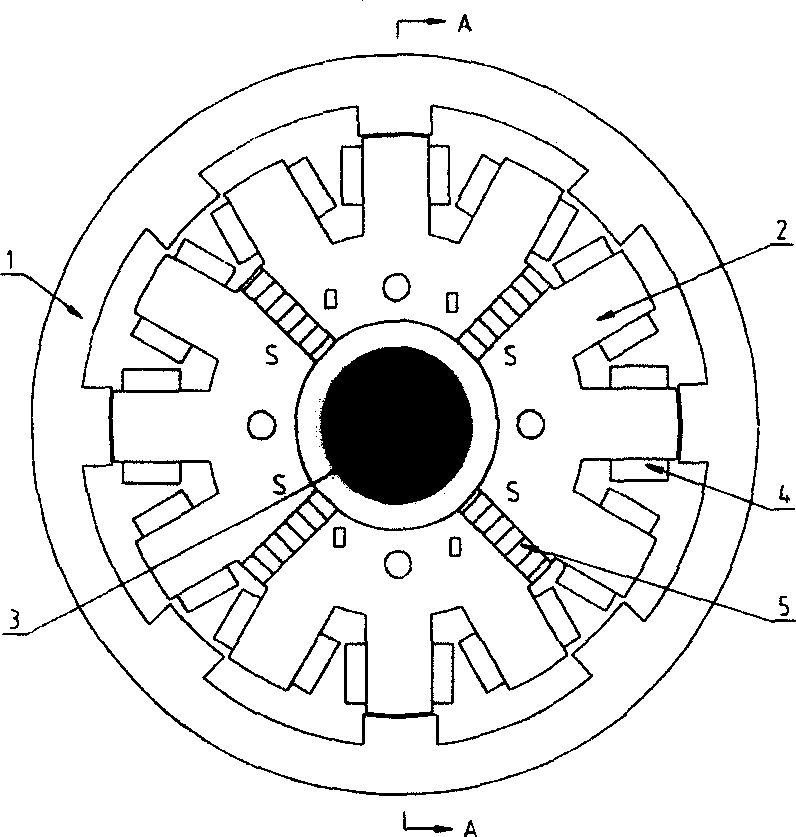

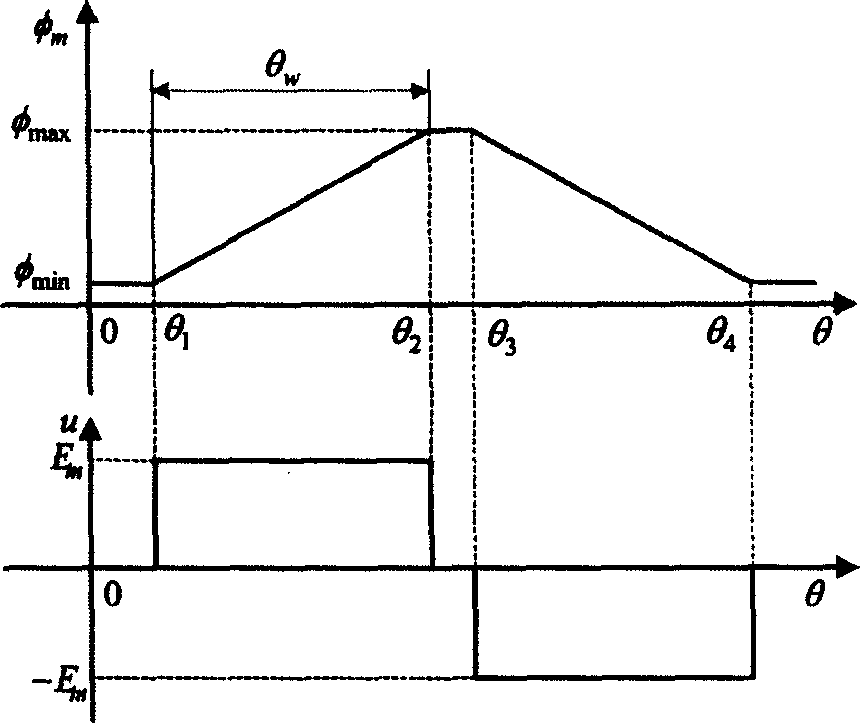

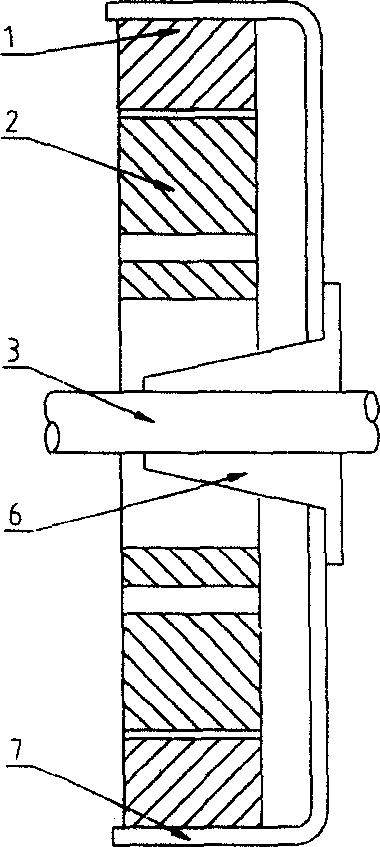

Three phase external rotor double salient pole permanent magnet brushless electric generator

InactiveCN1753287AImprove reliabilityGood high speed performanceSynchronous machinesElectrical polarityThree-phase

A three-phase double convex pole permanent magnet brushless generator is in the structure of a stator inside and a rotor outside, the magnet and an armature winding are set on the stator fixed on the base by four installing holes, the rotor is connected with the shaft by the shell and a shaft sleeve base, four magnets are distributed uniformly along the circum at the yoke of the stator, the poles of which are distributed in N,S,S,N,N,S,S,N, 12 convex poles are uniformly distributed on the outer circum of the stator, 8 convex poles are uniformly distributed on the inner circum of the rotor and placed on the two face to face poles of the stator and two face to face vertical poles connected with them and the centralized windings of the four poles are serial to one three-phase armature winding in 120deg. difference.

Owner:SOUTHEAST UNIV

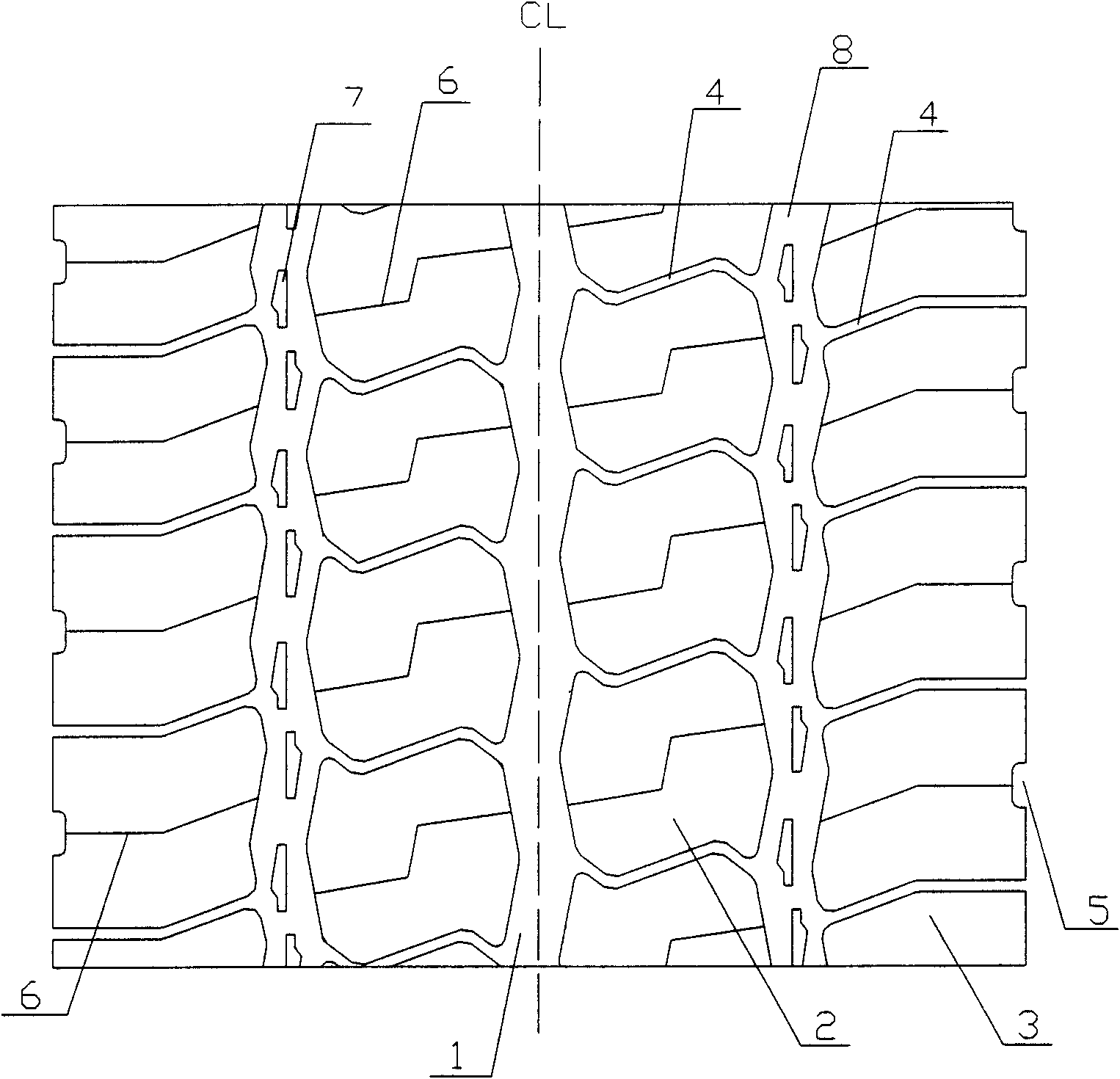

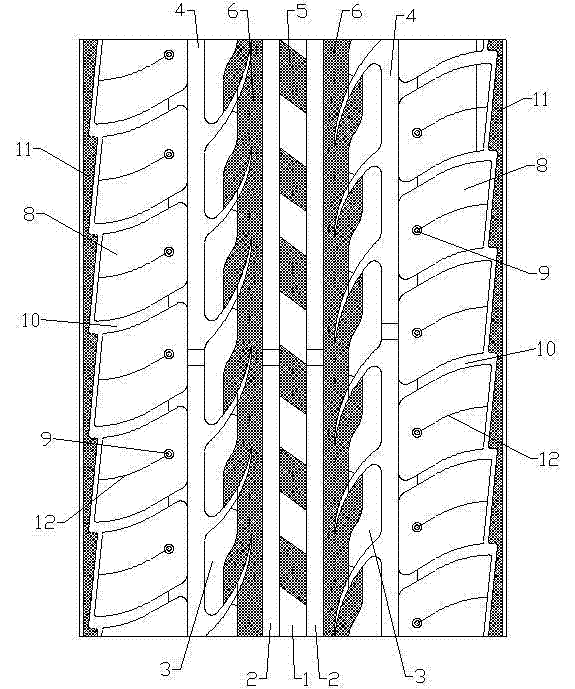

Truck tyre tread

ActiveCN101618664AAvoid eccentric wearImprove maneuverabilityTyre tread bands/patternsEngineeringTruck

The invention relates to an auto tyre structure, in particular to a tread pattern structure for a tyre of a truck. The truck tyre tread comprises a central vertical circumferential pattern groove arranged on the center position of the tyre tread, namely the center line of the tyre tread, wherein the central vertical circumferential pattern groove equally divides the tyre tread into two eudipleural parts, the left side and the right side of the central vertical circumferential pattern groove are provided with lateral pattern blocks and shoulder pattern blocks in turn regularly from inside to the outside, the lateral pattern blocks and the shoulder pattern blocks are spaced by the vertical circumferential pattern groove, and the groove bottom of the vertical circumferential pattern groove is provided with a bulge which is connected with the two side walls of the circumferential pattern groove; and two adjacent lateral pattern blocks and two adjacent shoulder pattern blocks are spaced by a transverse pattern groove respectively. The tyre tread of the truck tyre adopts mixed patterns and has sufficient braking force, good maneuverability, and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

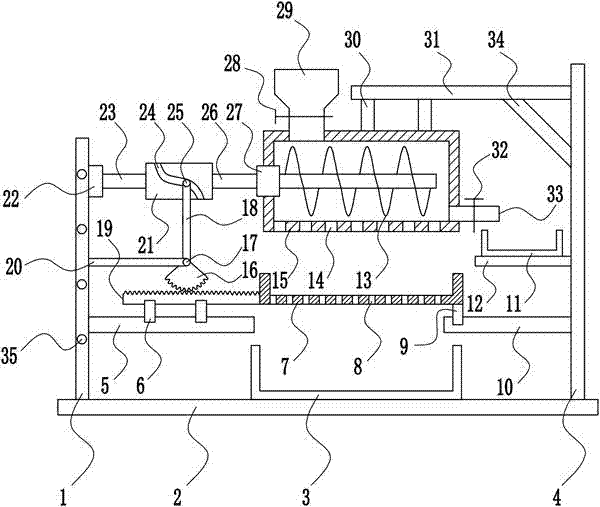

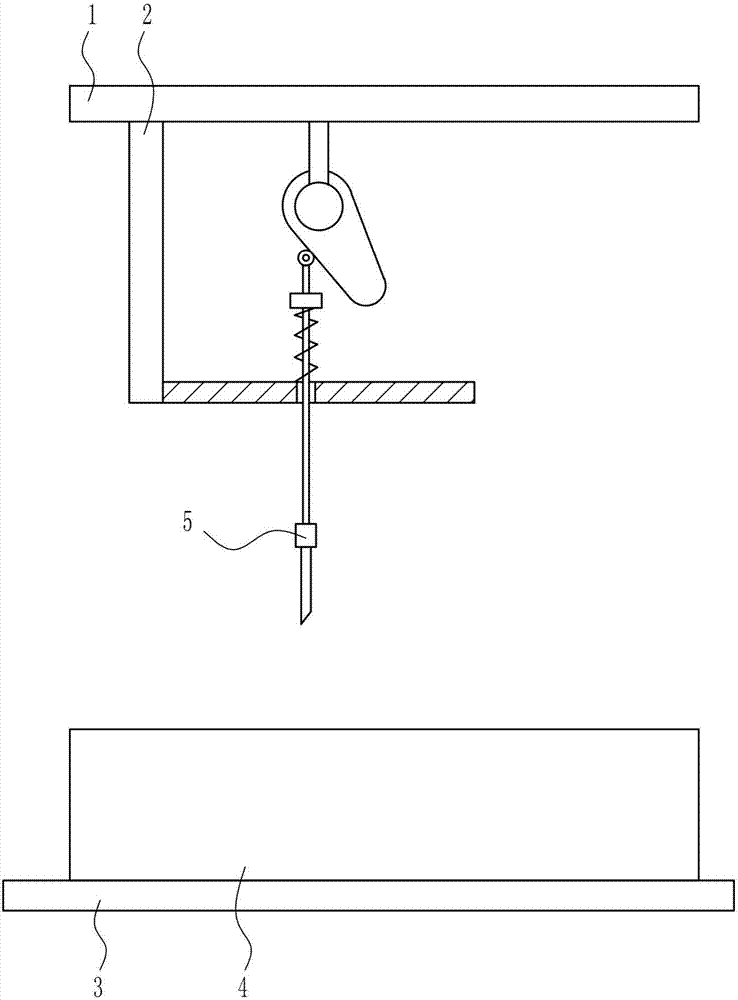

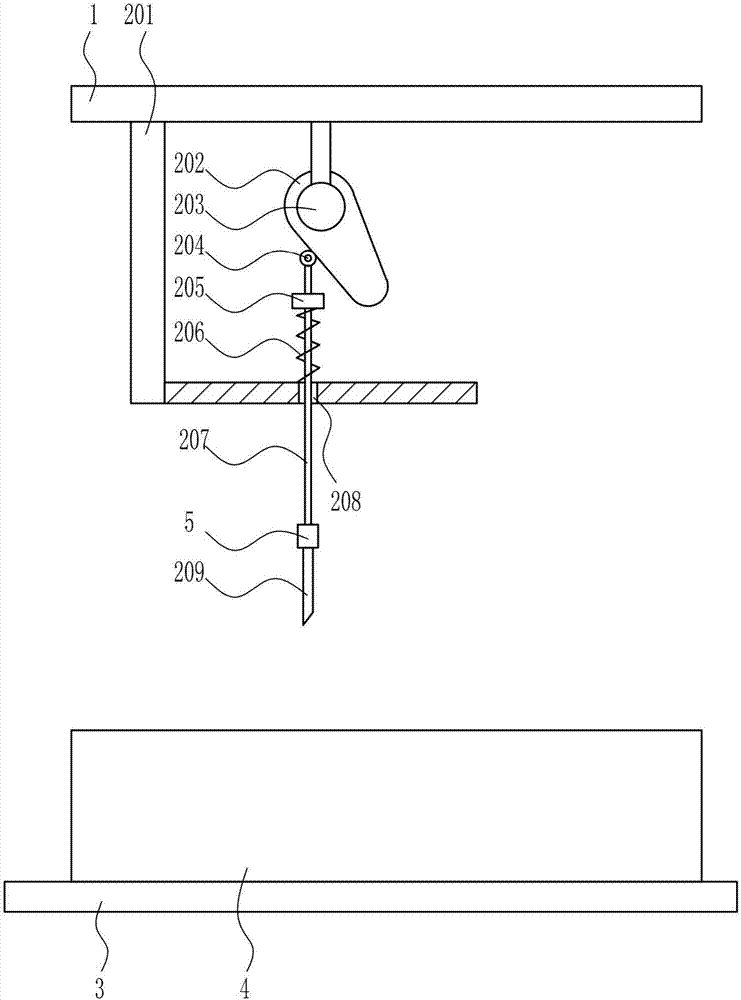

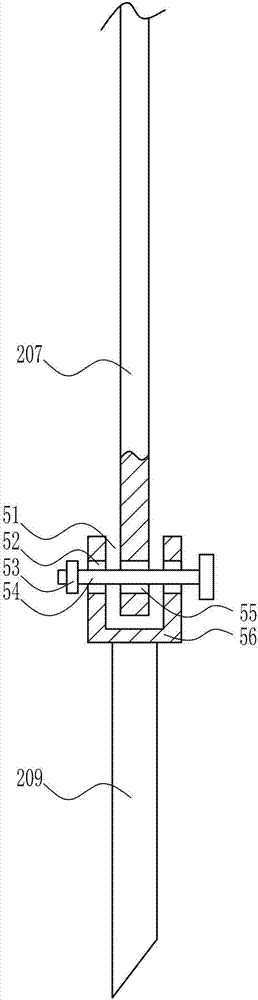

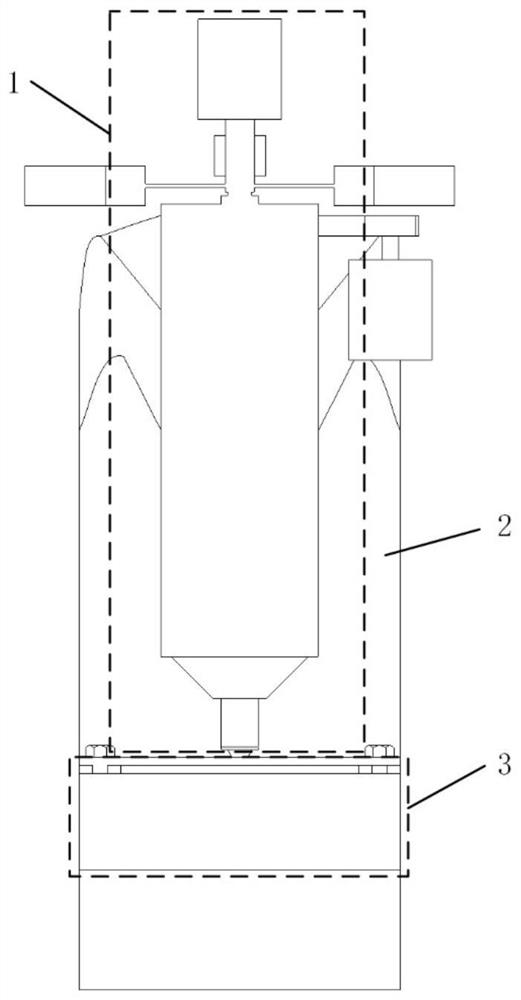

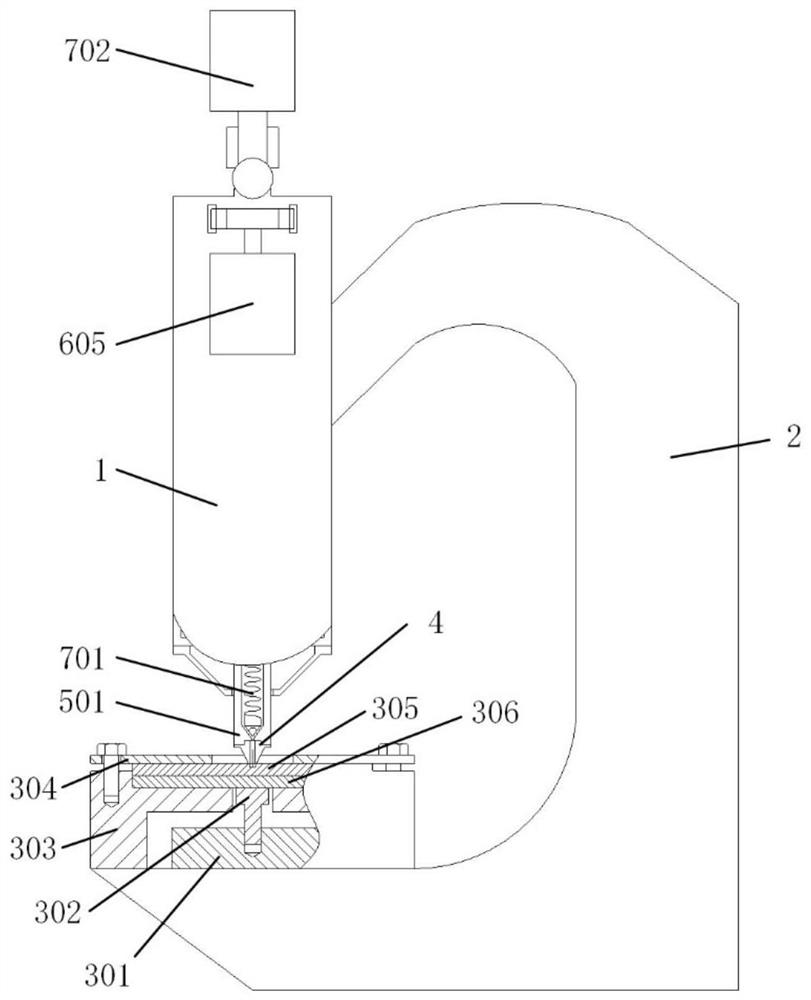

Powder reinforced stirring friction riveting method and device

ActiveCN111805073AImprove air tightnessReduce airtightnessNon-electric welding apparatusEngineeringForce sensor

The invention relates to a powder reinforced stirring friction riveting device. The powder reinforced stirring friction riveting device comprises a stirring friction riveting main shaft, a C-shaped rack and a workbench, wherein the stirring friction riveting main shaft comprises a rotary mechanism, a feeding mechanism, a vibrating / rotating mixing mechanism and a powder feeding mechanism; the stirring friction riveting main shaft is used for realizing the rotary motion and feed motion of a rivet and feeding and mixing powder; the C-shaped rack is used for fixing the stirring friction riveting main shaft and the workbench; and the workbench is mainly composed of a force cell, a sensor head, a tool die and a tool pressing plate and is used for clamping a to-be-riveted workpiece and testing the riveting acting force of the main shaft in real time. According to the powder reinforced stirring friction riveting device, the powder reinforced stirring friction riveting between same or differentlight plates at room temperature can be realized, a riveted stirring friction riveting joint without key hole defects and with good joint forming quality and high connecting strength can be obtained,the required riveting forming force is less than that of traditional riveting, and the powder reinforced stirring friction riveting device has the advantages of high efficiency, simplicity and convenience in operation and low energy consumption.

Owner:XI AN JIAOTONG UNIV

Automatic charging intelligent control device

ActiveCN106743719ASpeed up the fallImprove work efficiencyConveyorsLoading/unloadingEngineeringControl valves

The invention relates to a charging device, in particular to an automatic charging intelligent control device. The automatic charging intelligent control device aims at achieving the technical purposes of being novel in structure, easy to operate and high in automation degree. To achieve the technical purposes, the automatic charging intelligent control device comprises a left rack, a bottom plate, a first fixing plate, a first bevel gear, a first bearing pedestal, a second bearing pedestal, a first electronic control valve, a collecting frame, a rotating disc, a first rotating shaft and the like, wherein the left rack is welded to the left side of the top of the bottom plate, the first bearing pedestal and the second bearing pedestal are connected to the right side of the top of the bottom plate in a bolted connection mode, and the first bearing pedestal is located on the left side of the second bearing pedestal. The automatic charging intelligent control device has the advantages of being novel in structure, easy to operate and high in automation degree; intelligent automatic raw material filling can be achieved through the device for working staff, operation is easy and convenient, and time and labor are saved.

Owner:NANJING MAKE BEST SCI & TECH

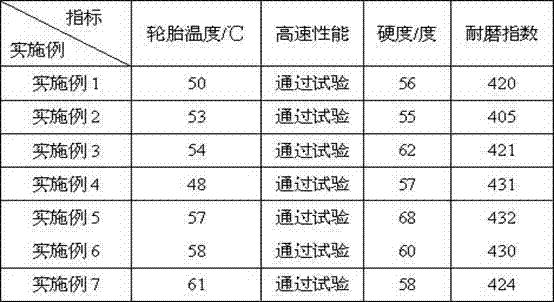

Tread rubber for high thermal diffusivity semisteel car tire and tire

ActiveCN103756024ALow heat generationImprove cooling effectSpecial tyresMicrocrystalline waxEngineering

The invention relates to tread rubber for a high thermal diffusivity semisteel car tire, the tread rubber comprises the following effective raw materials: by weight, 50 parts of natural rubber, 20-30 parts of high vinyl polybutadiene rubber, 20-30 parts of solution polymerized styrene-butadiene rubber, 30-40 parts of polydimethylsiloxane, 1-5 parts of dithiophosphate, 4-7 parts of zinc oxide, 2-4 parts of stearic acid, 0.1-0.3 part of antiscorching agent CTP, 2-6 parts of microcrystalline wax, 5-8 parts of aromatic hydrocarbon, 1-2 parts of cobalt naphthenate and 2-5 parts of clay, by the interaction of each effective raw material, the themogenesis is low, and by adding of the polydimethylsiloxane as a reinforcing agent, the tread rubber strength is effectively increased, and the tread rubber is low in cost, low in carbon and environmentally friendly; in addition the tread rubber is also added with the cobalt naphthenate, so that tread and steel wire combination is more tightly, the strength of a tire made of the tread rubber is further enhanced, and the tire made of the tread rubber is good in thermal diffusivity, strong in ground catching performance and high in high speed performance.

Owner:SHANDONG LONGYUE RUBBER

Solidification-prevention gel supplying device for LED lamp production

PendingCN106362909AImprove the mixing effectAvoid lossLiquid surface applicatorsCoatingsEngineeringElectric control

The invention relates to a gel supplying device, in particular to a solidification-prevention gel supplying device for LED lamp production. The solidification-prevention gel supplying device for LED lamp production aims at achieving the technical aims of being low in gel supplying speed, and capable of improving the gel performance and improving the work efficiency. In order to achieve the technical aims, the solidification-prevention gel supplying device for LED lamp production comprises a left frame, a first electric control valve, supporting rods, a bottom plate, a right frame, a stirring rod, a first rotating shaft, a baffle, a gel storage tank, a piston, a rack, a first gap gear and the like; the left frame is welded to the left side of the top of the bottom plate, the supporting rods are welded to the middle of the top of the bottom plate in a bilateral symmetry manner, the right frame is welded to the right side of the top of the bottom plate, and the gel storage tank is welded to the upper ends of the supporting rods. The effects of being low in gel supplying speed, and capable of improving the gel performance and improving the work efficiency are achieved.

Owner:安陆鲸鱼嘴电子科技有限公司

Constant speed variable pitch straight wing all direction propeller

ActiveCN104149961ARealize the speed change functionLarge thrustPropulsive elements of rotary typeTransmission with mechanical gearingPropellerRudder

The invention discloses a constant speed variable pitch straight wing all direction propeller which comprises a main engine, an engine base, a main shaft, a rotating disc, a steering engine, a rudder shaft, a central gear, an intermediate gear, a blade gear, blades and blade shafts. The main engine drives a sun gear to rotate, the sun gear is meshed with a planet gear, the planet gear is meshed with a gear ring, the gear ring is meshed with a speed control gear, and the speed control gear is controlled through auxiliary power to rotate; the planet gear is in running fit with a fixing shaft on a planet carrier, the planet carrier is linked with the rotating disc through the main shaft, and the main shaft is in running fit with the engine base; the rudder shaft sequentially penetrates through the sun gear, the main shaft and the rotating disc, one end of the rudder shaft is linked with the steering engine, and the other end of the rudder shaft penetrates through the rotating disc and then is connected with the central gear in the rotating disc; the blade shafts are in running fit with the interior of the rotating disc, the blade shafts are parallel to the main shaft, the blade shafts are evenly distributed in the circumferential direction with the central gear as a center, the blade shafts penetrate through the blade gear and are fixedly connected to the blade gear, and the blade gear is meshed with the central gear through the intermediate gear; one end of each blade shaft is connected with the corresponding blade.

Owner:ZHEJIANG FENGSHEN MARINE ENG TECH

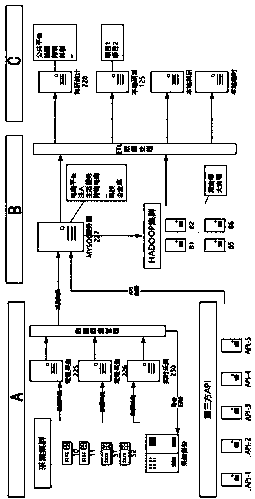

Big data-oriented data management system

InactiveCN107656995AReduce the impactTightly boundDatabase distribution/replicationSpecial data processing applicationsData centerSql server

The invention discloses an efficient data management system. The system comprises an acquisition center, a data center and a user-oriented user center; a HADOOP cluster subsystem of the data center comprises a data integration module, a data cleaning module, a classification module and a data storage module; the data integration module is used for integrating multi-source heterogeneous data transmitted by the acquisition center through an SQL server so as to form structured data records; and the classification module is used for classifying the cleaned data. The system is capable of rapidly, efficiently and reliably carrying out data acquisition and data processing, and capable of providing application data for user subsystems in multiple industries. The data center is capable of completing big data, so that the processing and analysis of mass data become possible; and preliminary analysis is carried out on the mass data, so that data preparation is provided for the subsequent furtherapplication and analysis of users.

Owner:温州市鹿城区中津先进科技研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com