Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

A self-aligning, roller bearing technology, applied in the direction of roller bearings, rolling contact bearings, bearing components, etc., to achieve the effects of suppressing deflection, increasing flow, and suppressing cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

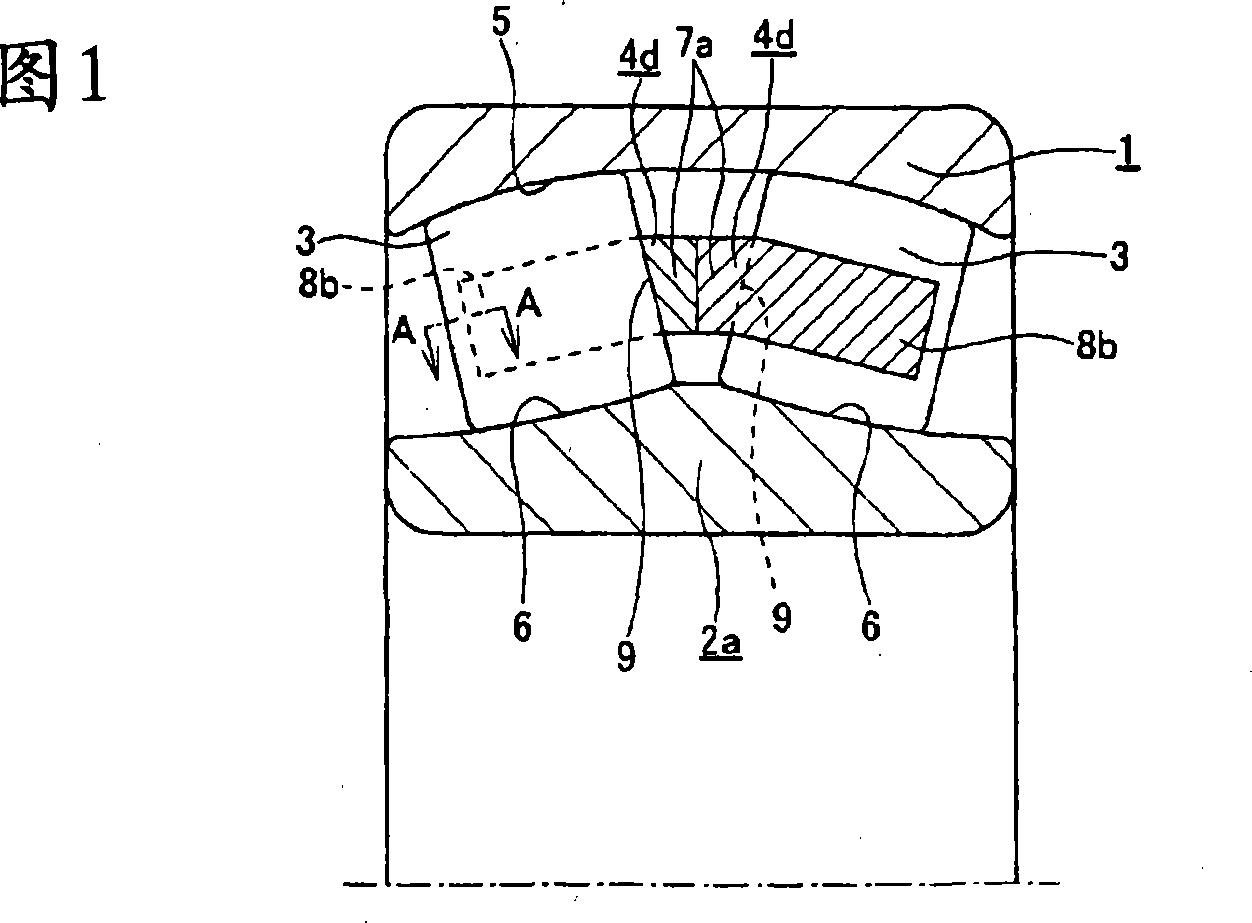

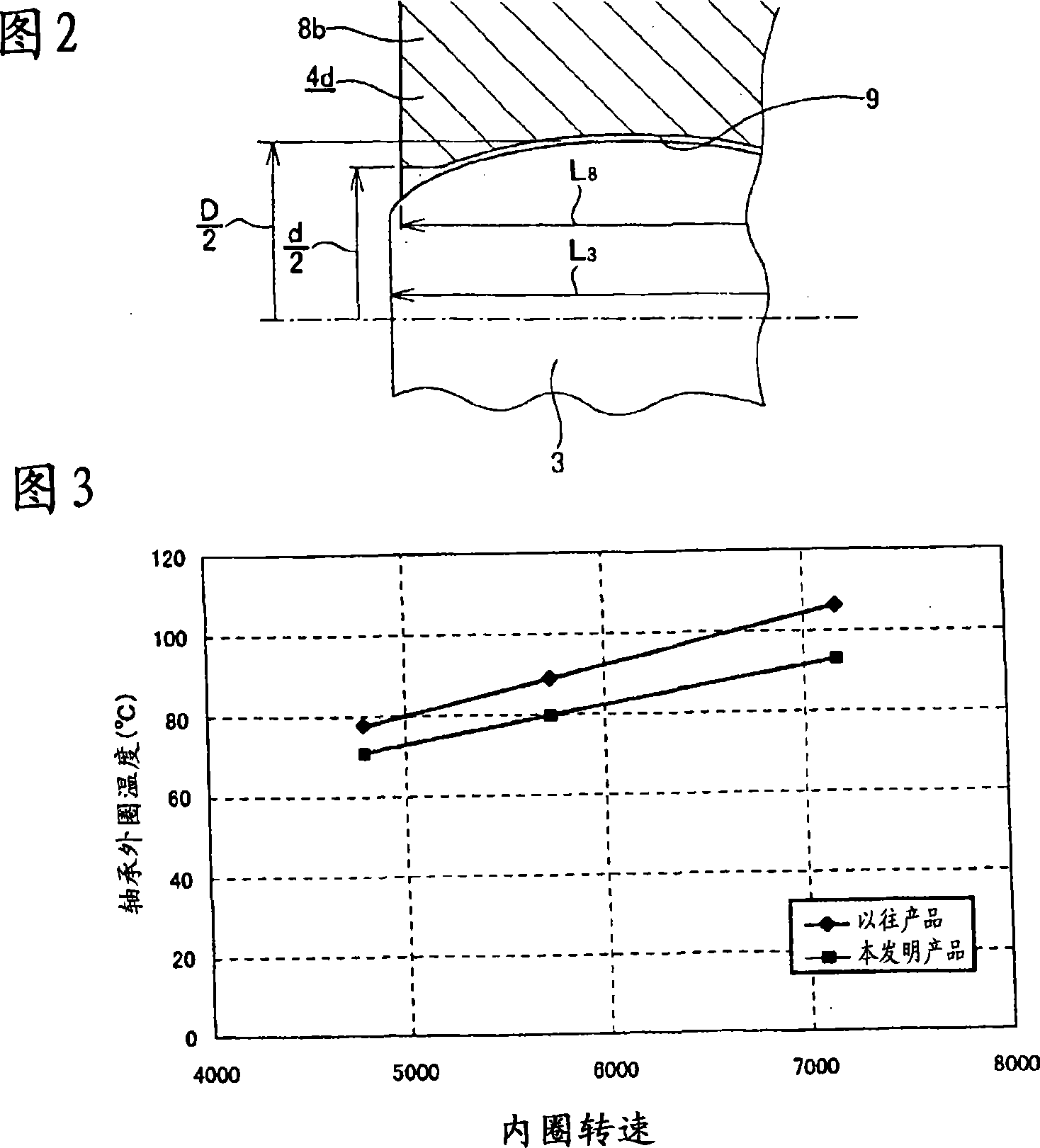

[0082] First example of embodiment

[0083] 1 and 2 show a first example of an embodiment of the present invention corresponding to the first aspect. The self-aligning roller bearing with cage in this example is the same as the second example of the existing structure shown in Fig. A pair of holders 4d that can be combined in a relatively rotatable manner.

[0084] Among them, the outer ring 1 has an outer ring rail 5 having a single central spherical concave surface formed on its inner peripheral surface.

[0085] In addition, the inner ring 2 a has a pair of inner ring rails 6 facing the outer ring rails 5 formed on its outer peripheral surface. This inner ring 2a is different from the case of the second example of the above-mentioned conventional structure in that the flange portions 10 are not provided on the outer peripheral surfaces of both ends (see FIG. 20 ). The inner ring 2a incorporated in this example has the same shape as that of the third example of the conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com