Patents

Literature

100results about How to "Avoid eccentric wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

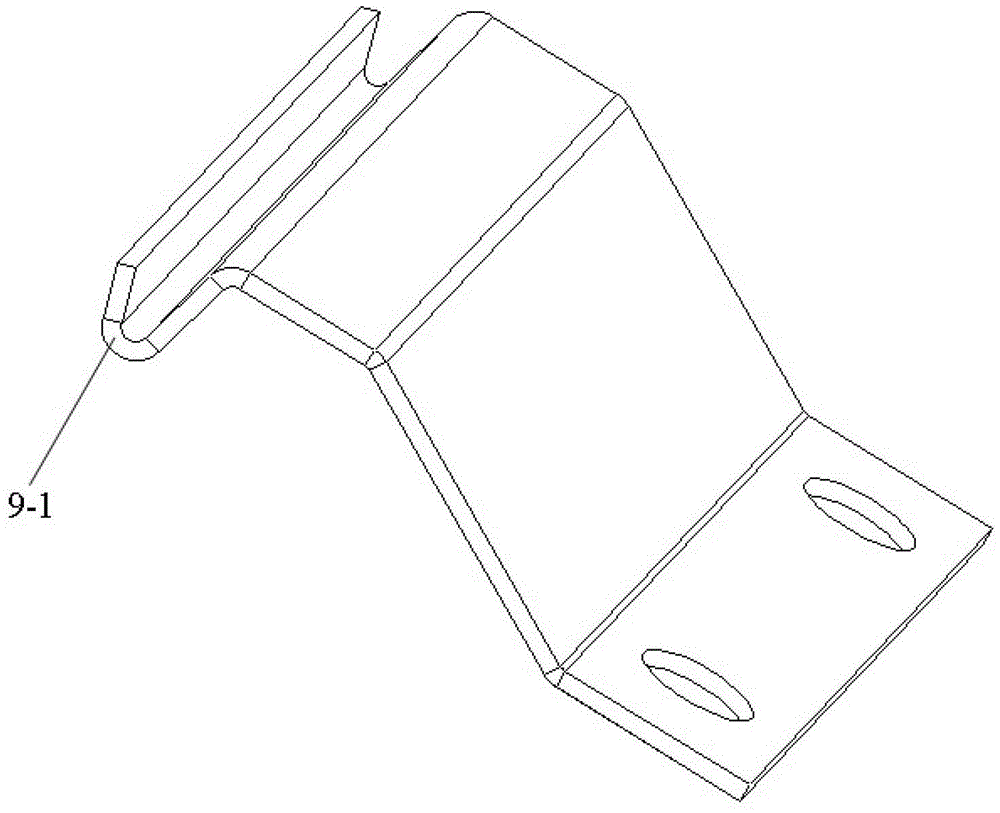

Inventor

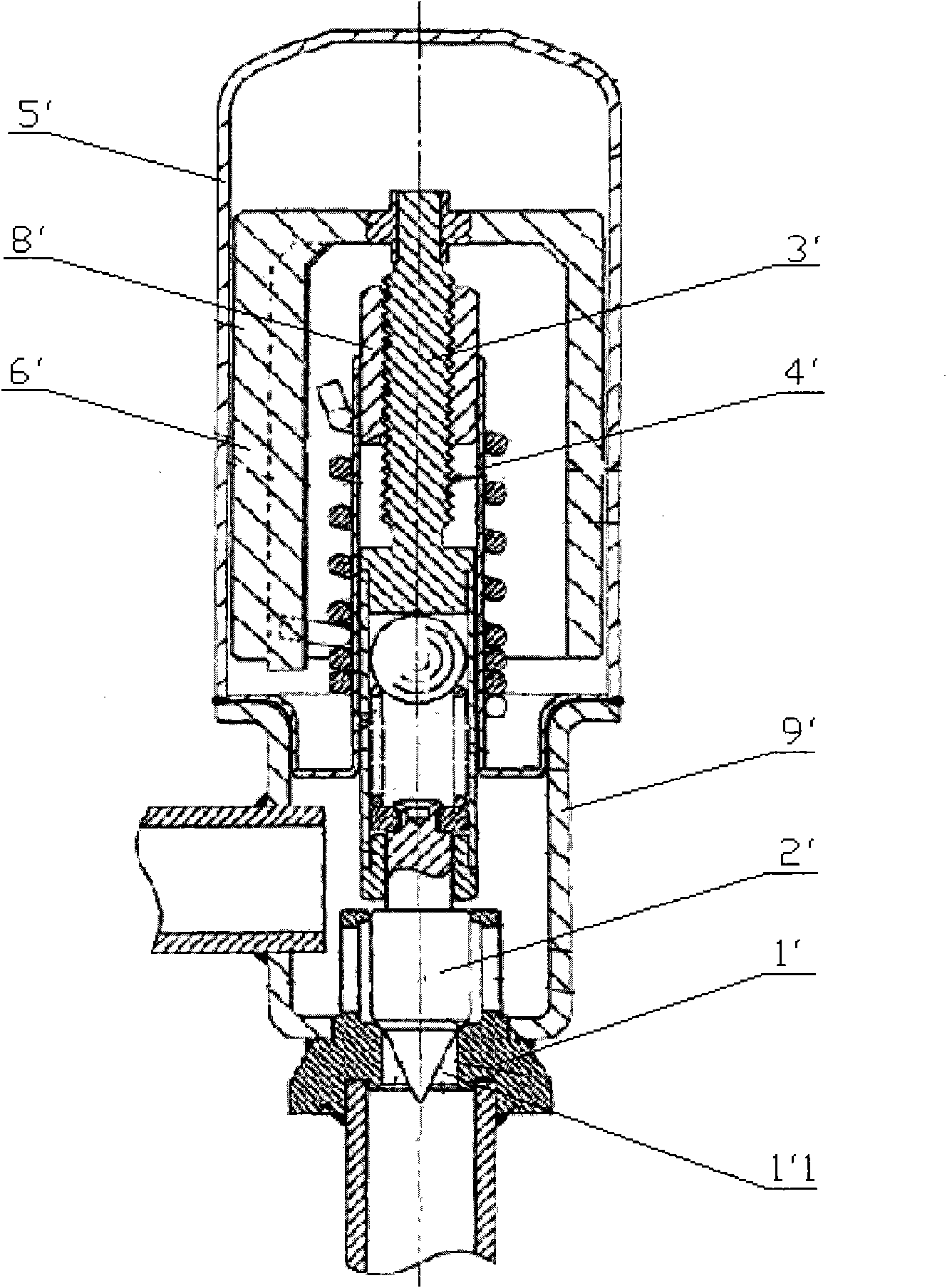

Electric valve

InactiveCN102454818AHigh operational reliabilityAvoid eccentric wearOperating means/releasing devices for valvesLift valveControl valvesFriction force

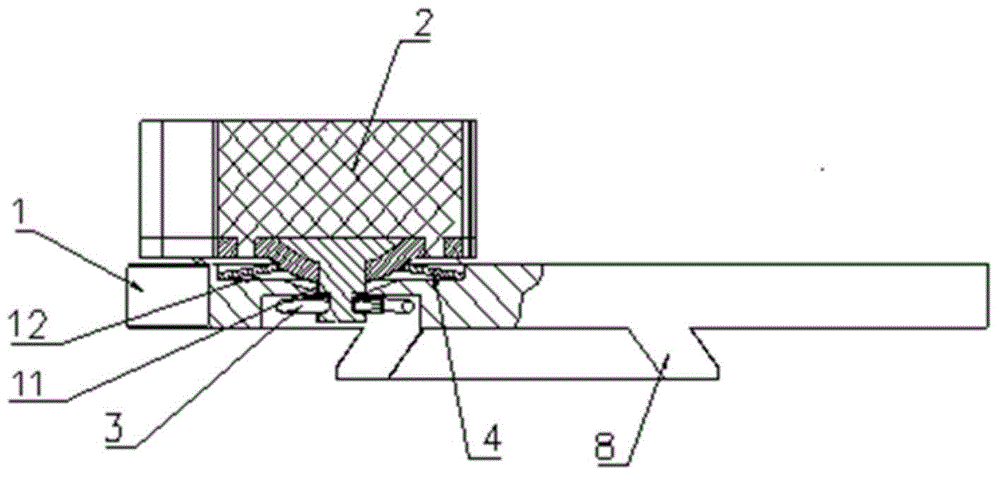

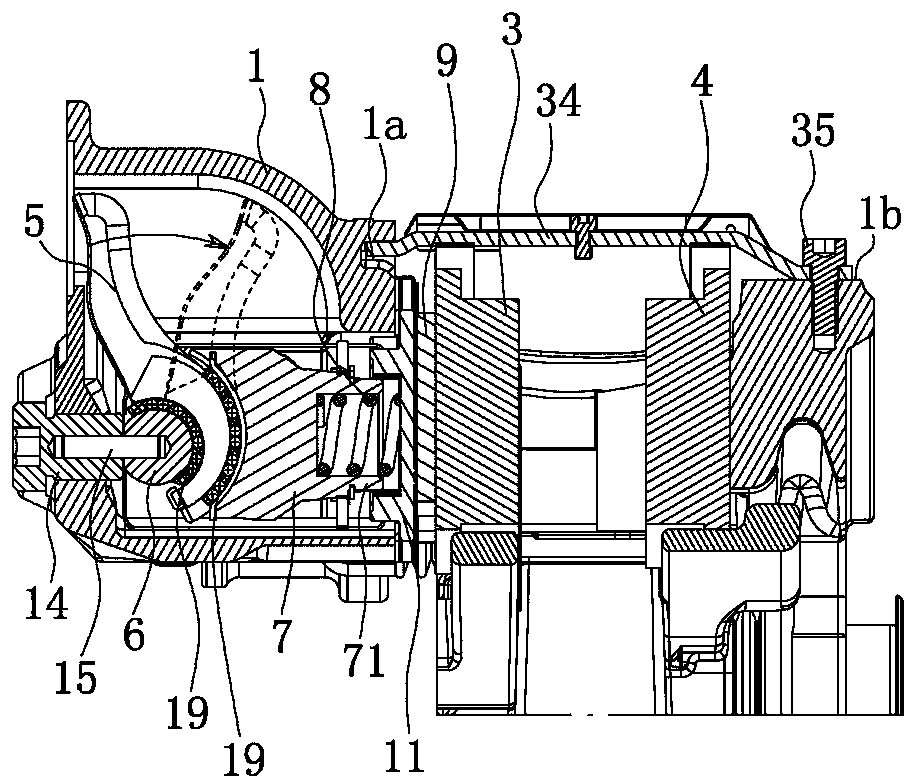

The invention relates to the technical field of control valves, in particular to an electric valve for regulating fluid flow. The electric valve comprises a valve seat component, a nut component and a valve needle lead screw component, wherein the valve seat component comprises a valve seat and a valve core seat; the nut component comprises a nut for mounting the valve needle lead screw component; and the lower end of the nut is sleeved with the upper end of the valve core seat. By the electric valve, the lower end of the nut which is used for mounting the valve needle lead screw component is connected with the upper end of the valve core seat in a sleeved mode, so that the coaxiality of the nut and a valve port of the valve core seat is extremely easy to guarantee, the coaxiality of a valve needle and the valve core seat is higher, and the problem that the valve port is loosely sealed or is subjected to eccentric wear can be solved. Meanwhile, because the coaxiality of the valve needle and the valve port is improved, the friction force can be obviously reduced when a rotor of a rotor component rotates, and the action reliability of the electric valve can be improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

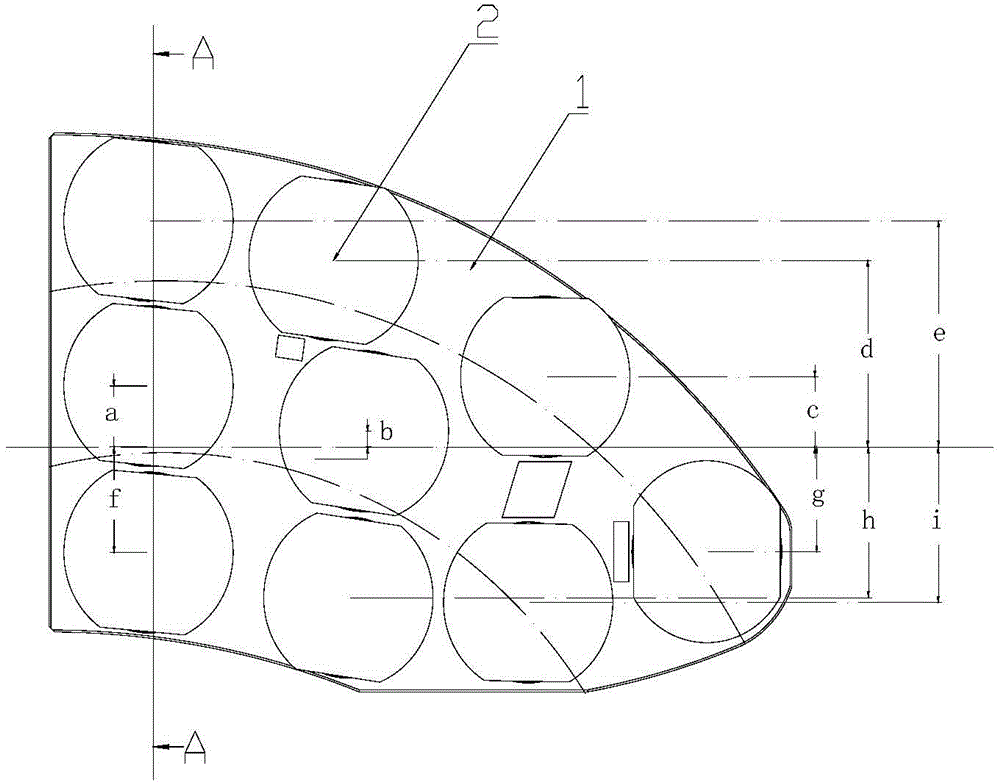

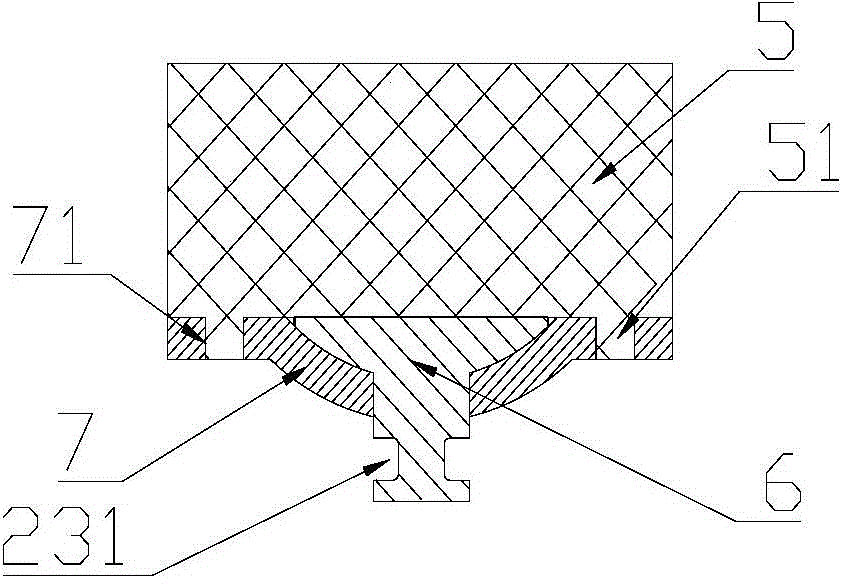

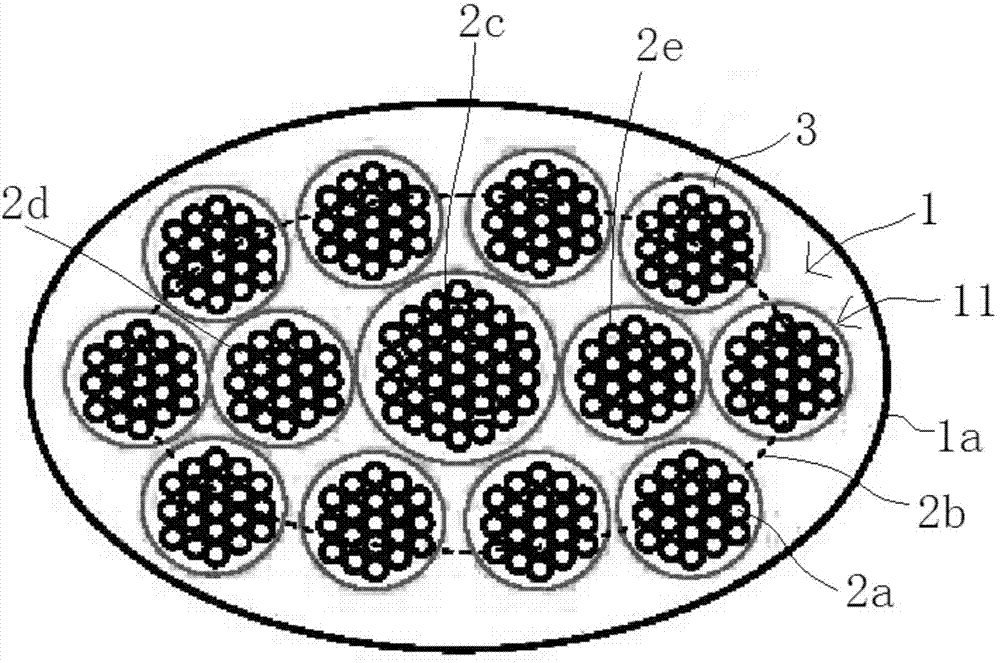

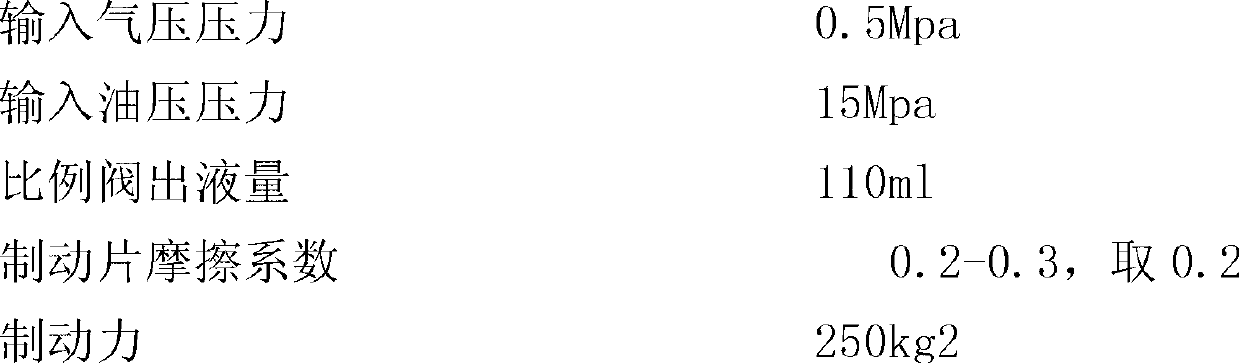

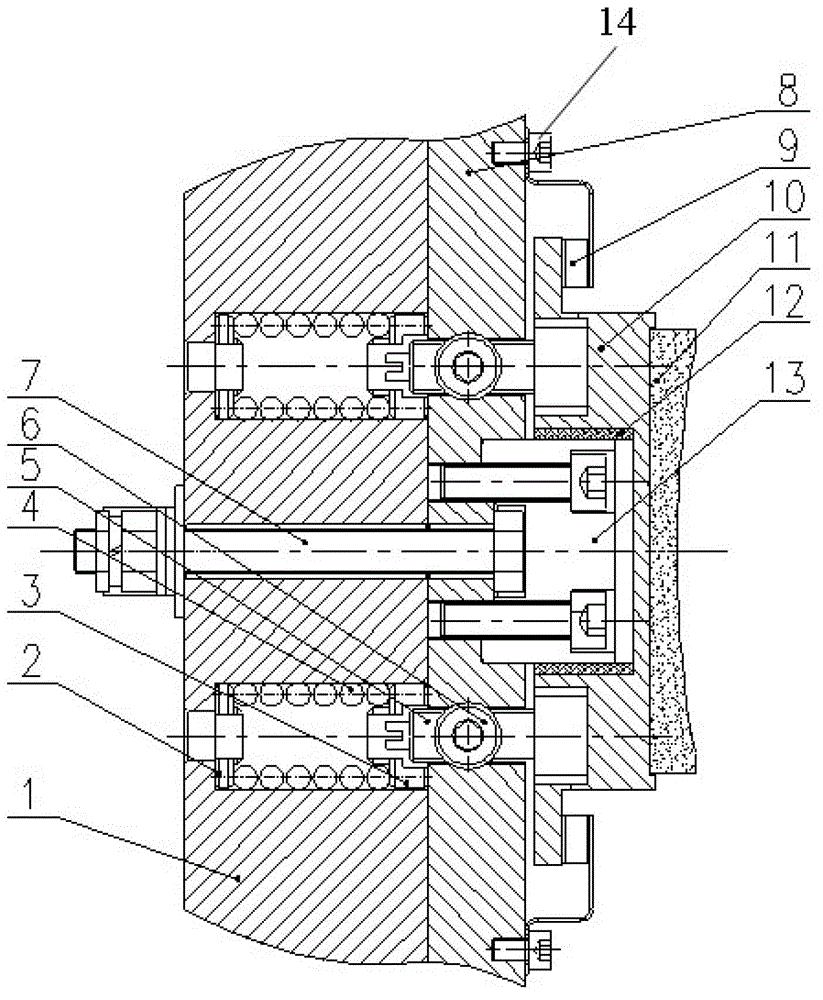

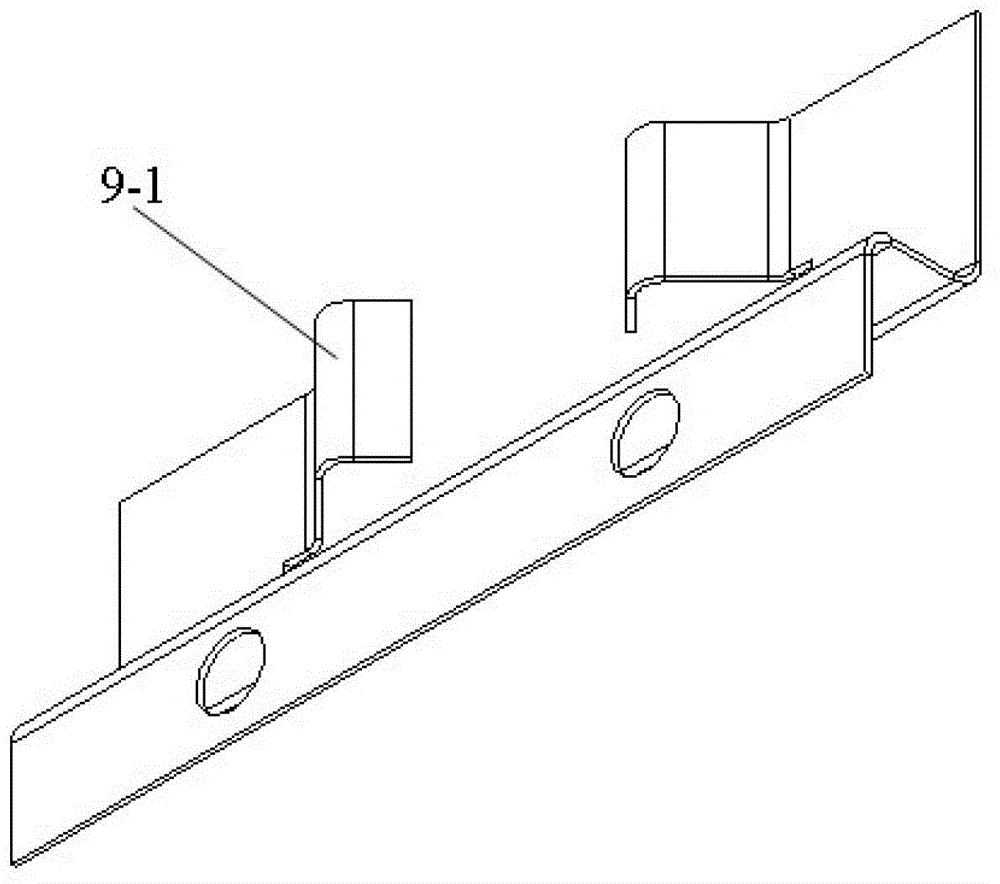

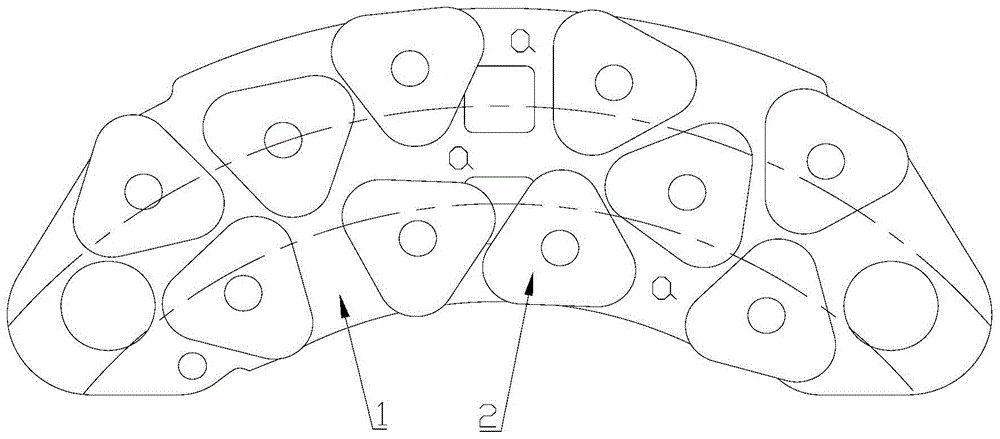

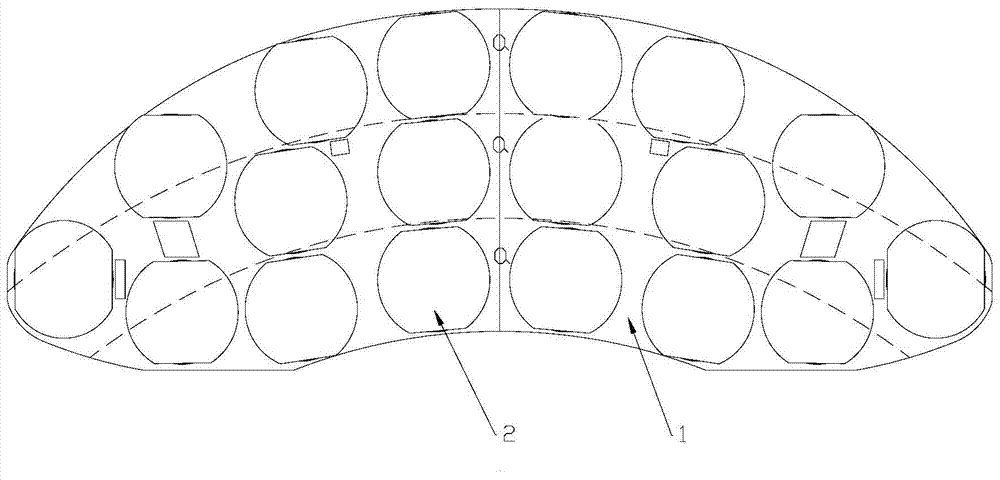

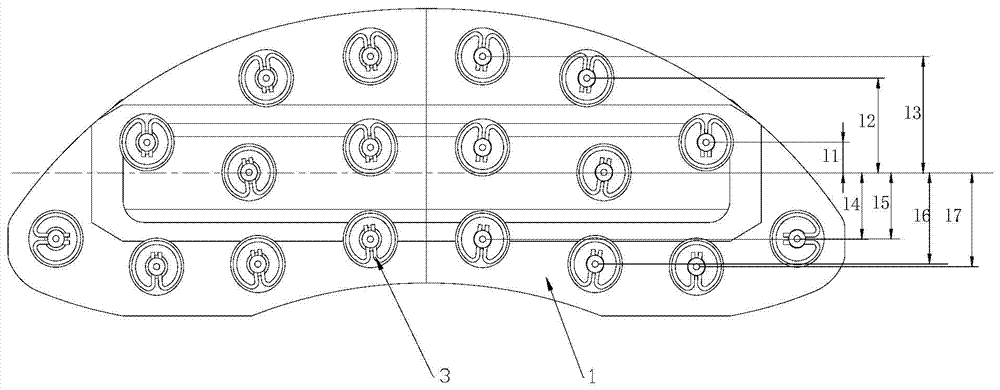

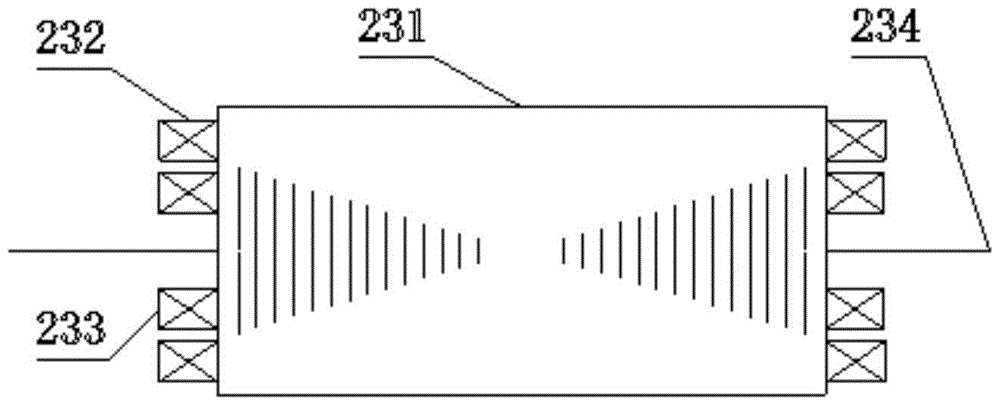

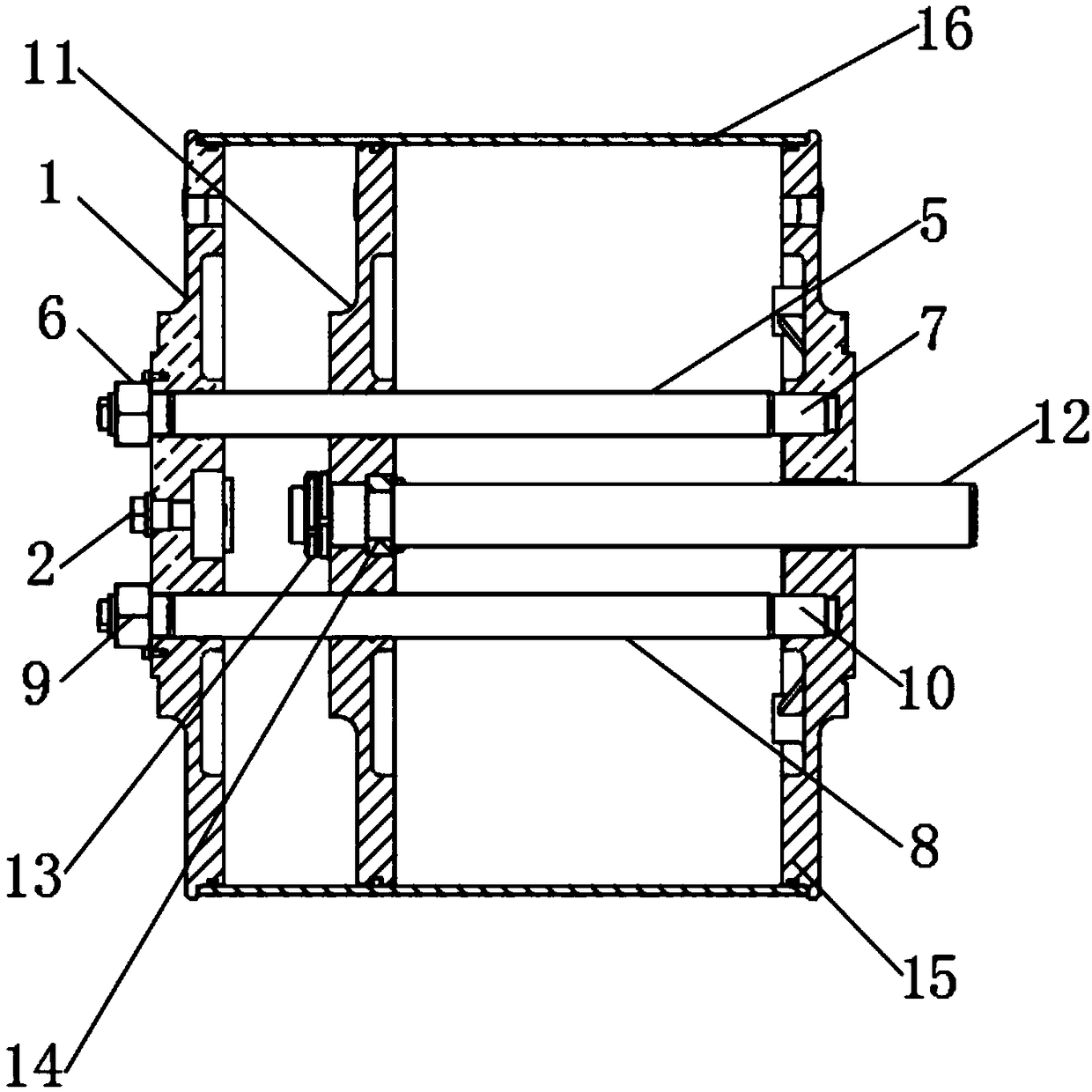

Floating type brake pad

InactiveCN104455105AConsistent heat fluxExtended service lifeBraking membersFriction liningStress concentrationEngineering

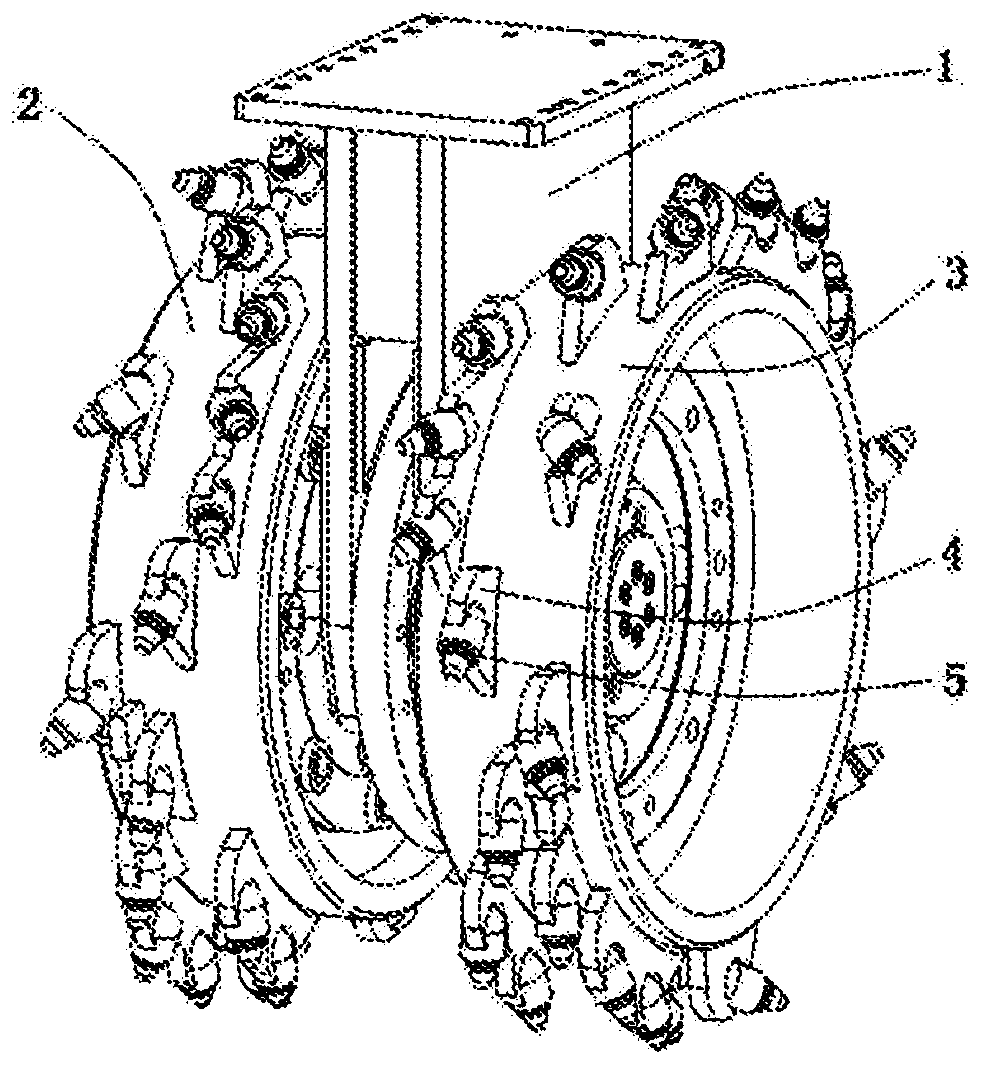

The invention discloses a floating type brake pad. The floating type brake pad comprises a back plate, a plurality of friction blocks, disc springs and clamping springs, wherein the friction blocks are arranged on the back plate, the disc springs are arranged between the friction blocks and the back plate, and the friction blocks are connected to the first back plate in a floating mode through the clamping springs. Positioning grooves are formed in the back plate, and the disc springs are arranged inside the positioning grooves. The back plate is divided into a plurality of concentric circular rings by using the circle center of a brake disc matched with the brake pad as the circle center. The circular rings are equal in radial length. The friction area of the friction block inside each circular ring is not larger than 15% of the standard average friction area compared with the standard average friction area. According to the floating type brake pad, the problem of fatigue cracks caused by instantaneous stress concentration during braking of existing disc springs is solved, meanwhile, gaps between the back plate and the friction blocks are reduced, oscillation of the friction blocks is small, meanwhile, the problem of eccentric abrasion of the friction blocks is avoided, and the brake stability is greatly improved.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

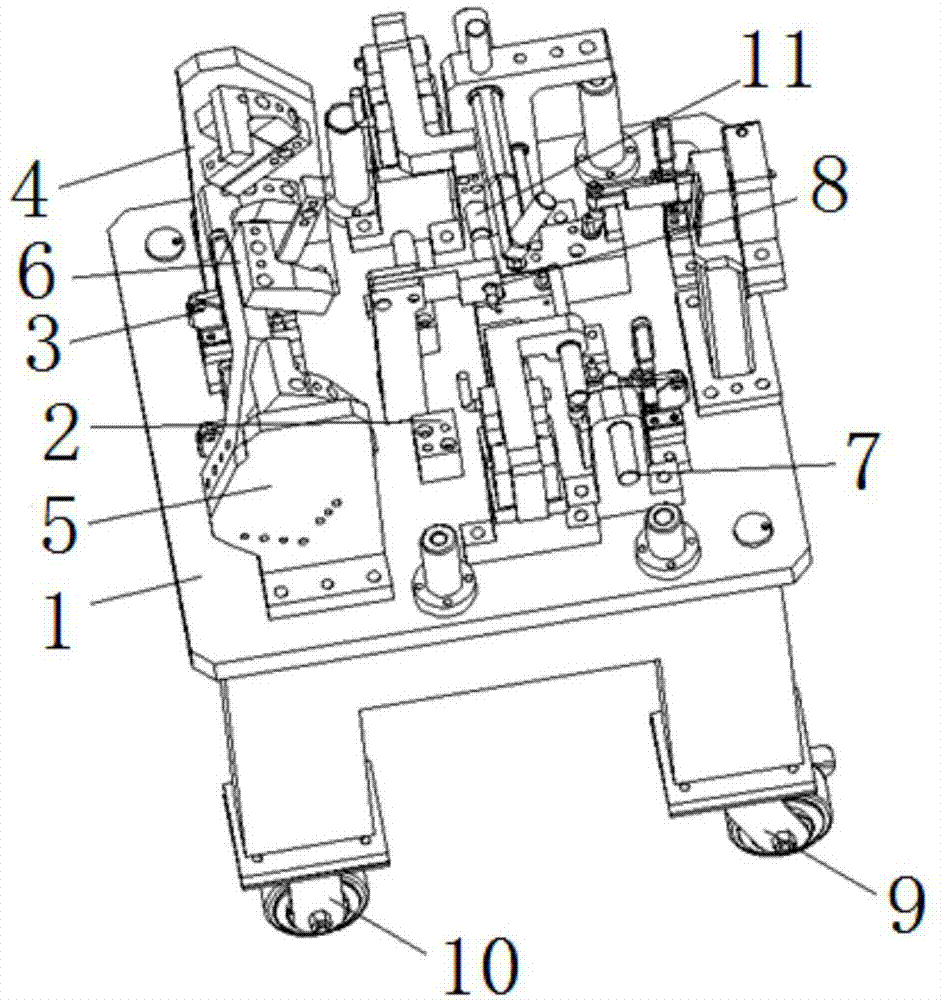

Automobile pedal assembly detecting tool

InactiveCN103575180AImprove assembly qualityAvoid eccentric wearMechanical measuring arrangementsMaster cylinderClutch

The invention discloses an automobile pedal assembly detecting tool. The automobile pedal assembly detecting tool comprises a base board, a positioning block and a clamp, wherein the positioning block and the clamp are arranged on the base board and are used for positioning a pedal assembly on the base board, and an accelerator cable hole detecting pin which is matched with an accelerator cable hole in the pedal assembly, a vacuum booster installation hole detecting pin which is matched with a vacuum booster installation hole in the pedal assembly and a main clutch cylinder hole detecting pin which is matched with a main clutch cylinder hole in the pedal assembly are arranged on the base board. The automobile pedal assembly detecting tool can detect all installation holes in the whole automobile pedal assembly, improve the assembling quality of the automobile pedal assembly, and prevent eccentric abrasion of a vacuum booster and a main clutch cylinder.

Owner:WUHU POWER TECH

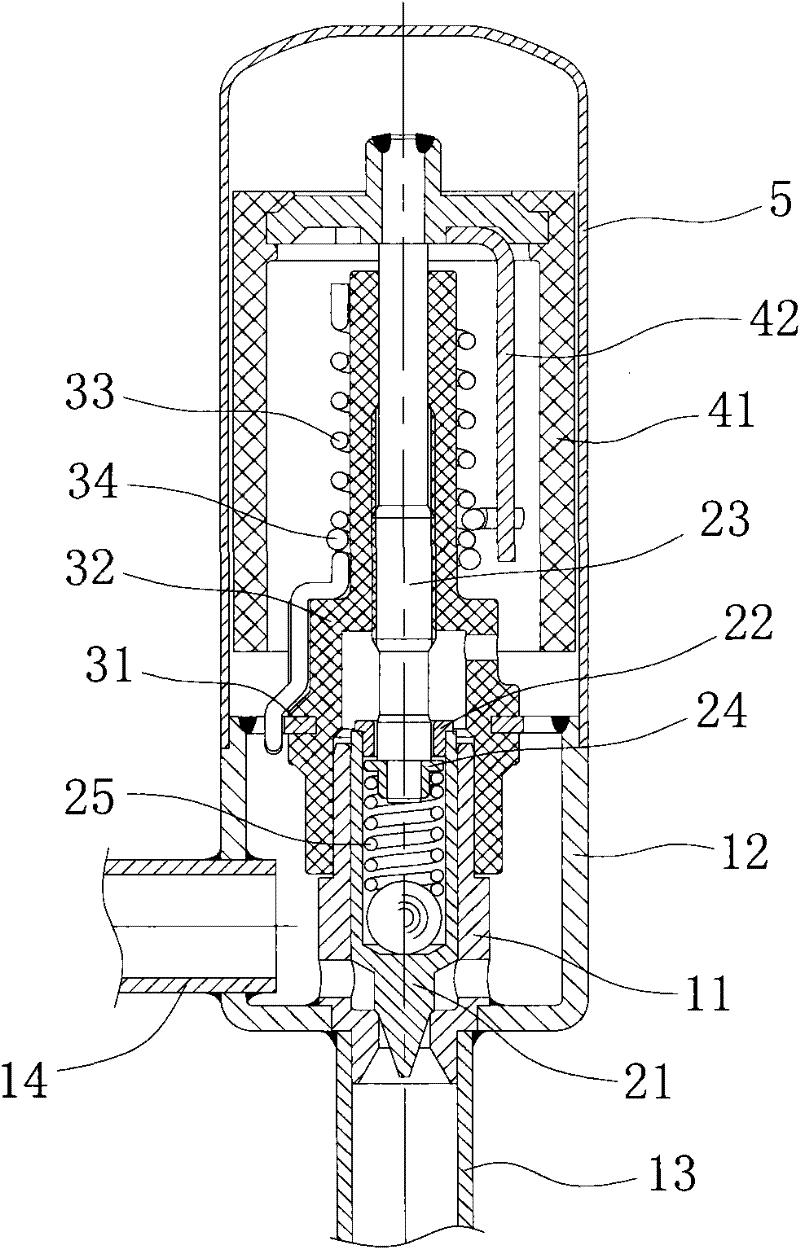

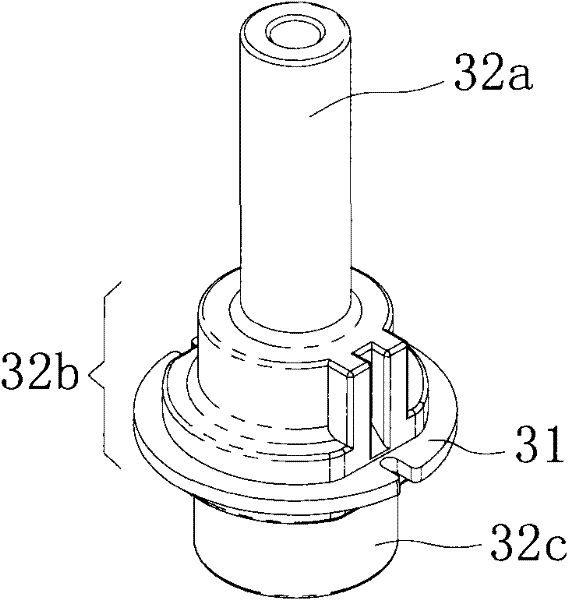

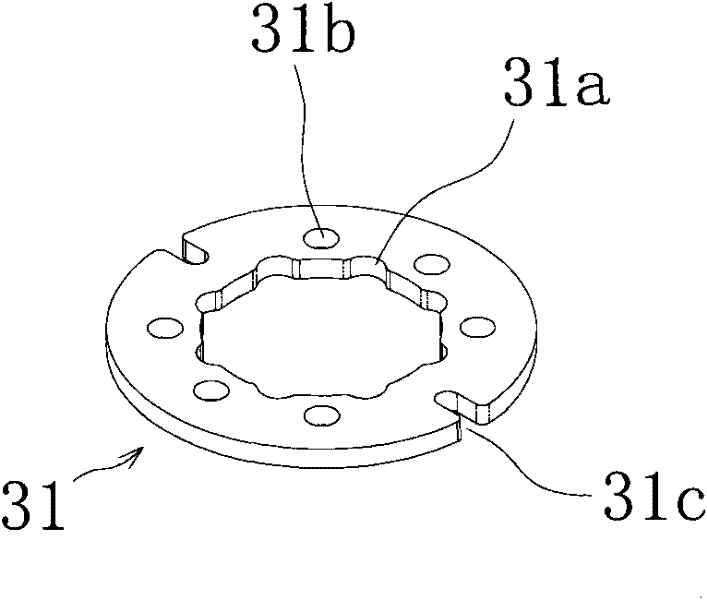

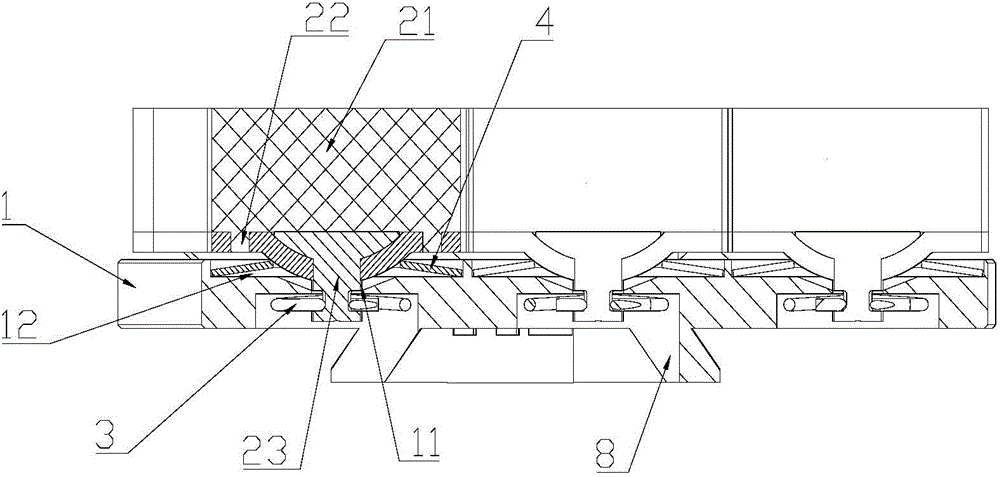

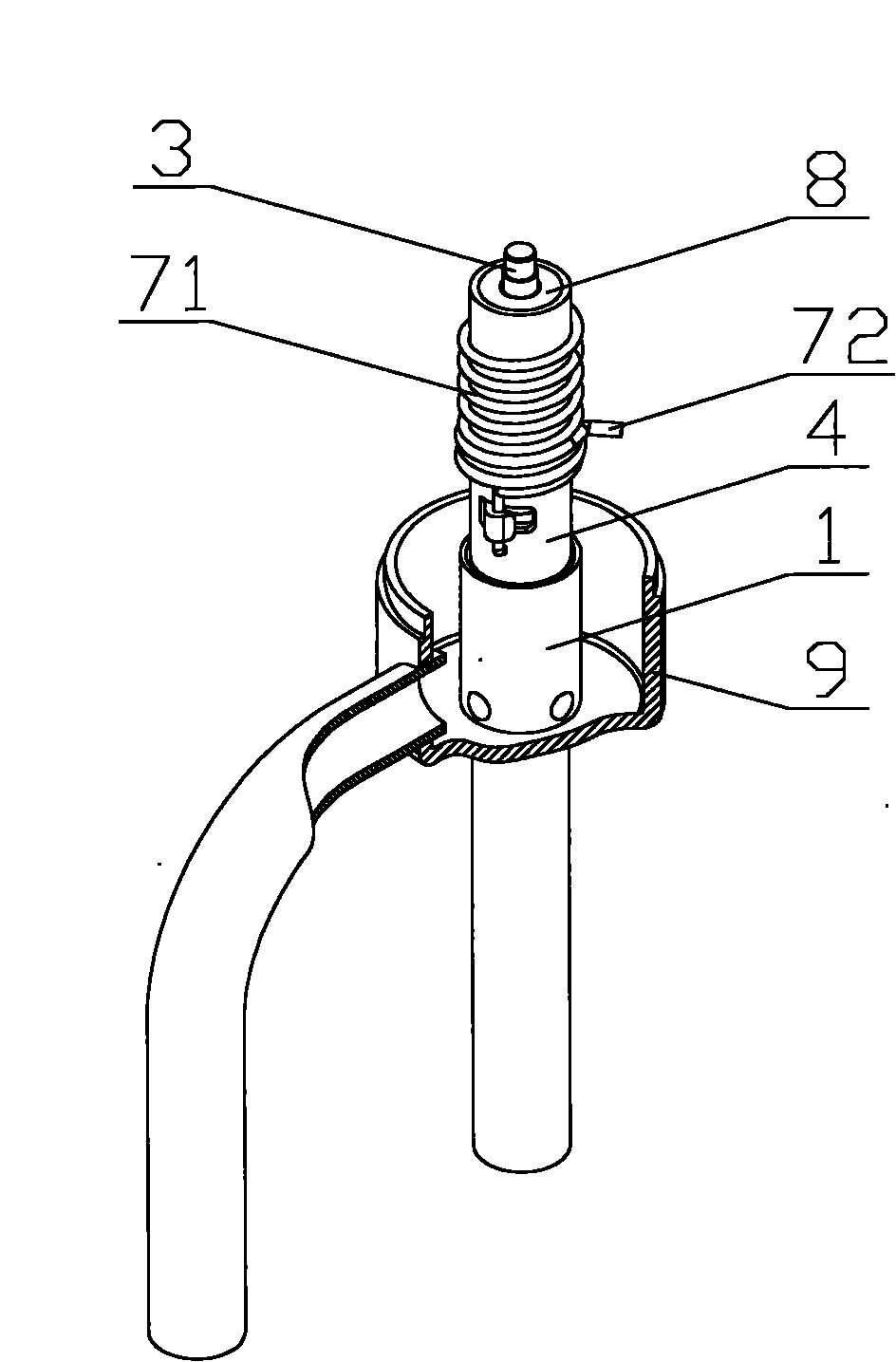

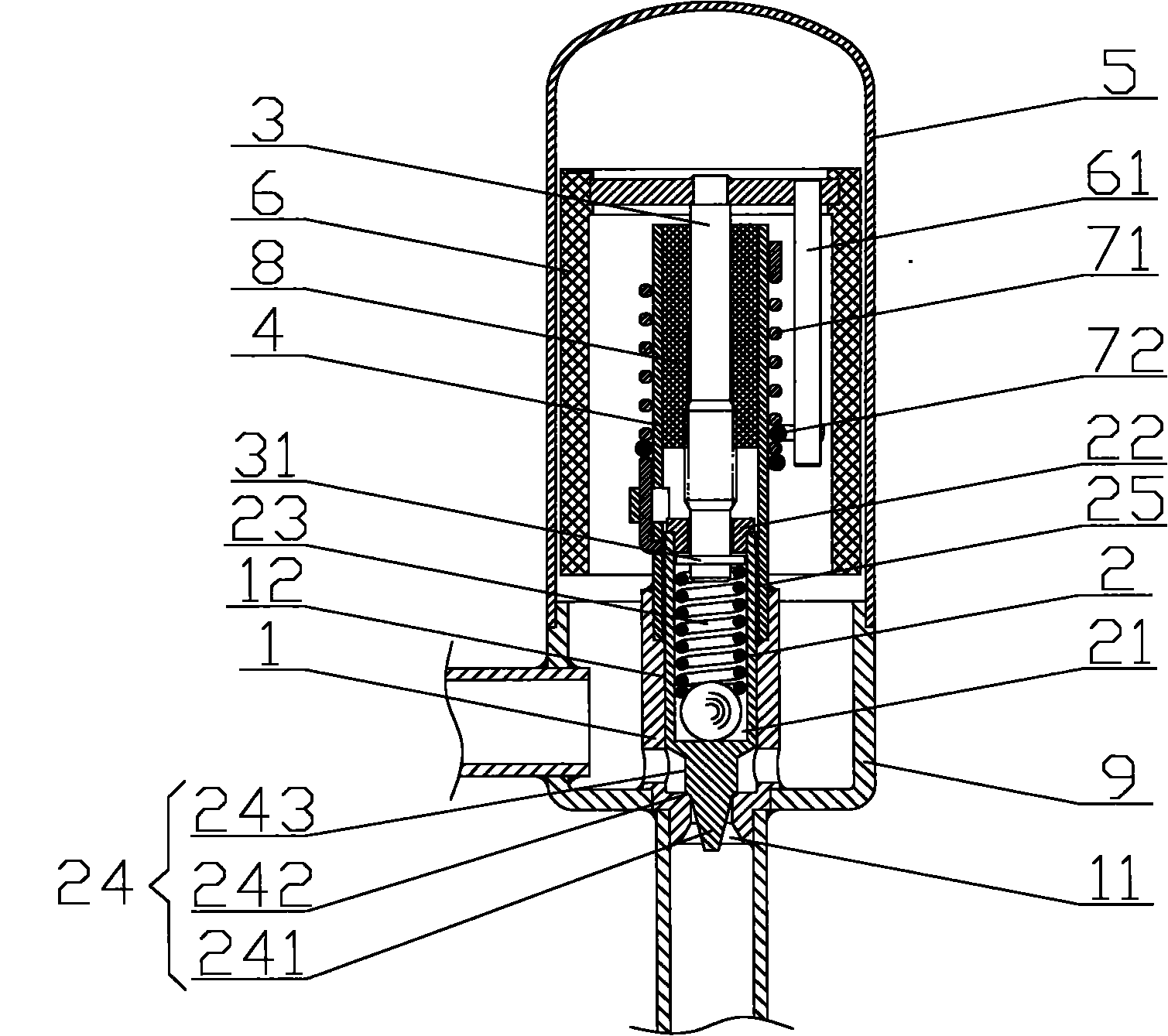

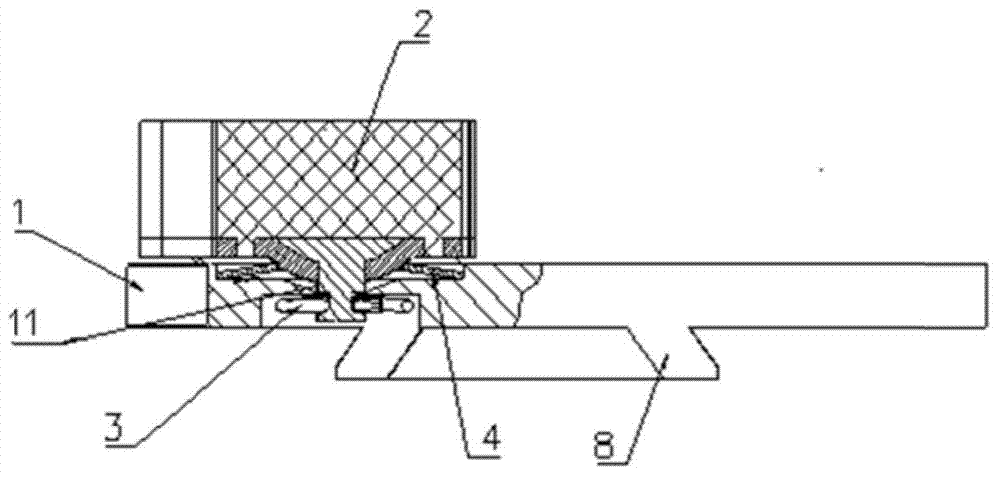

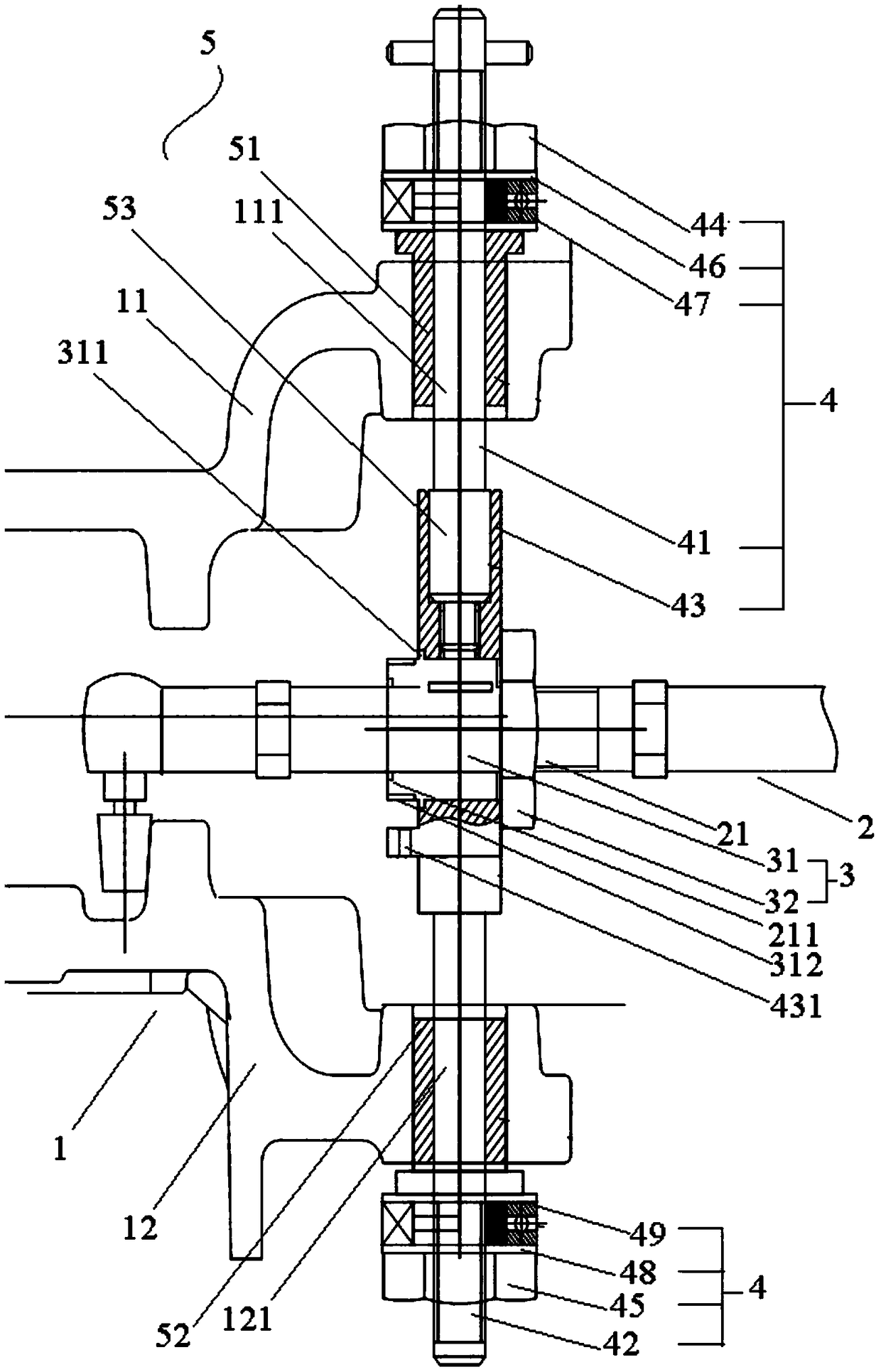

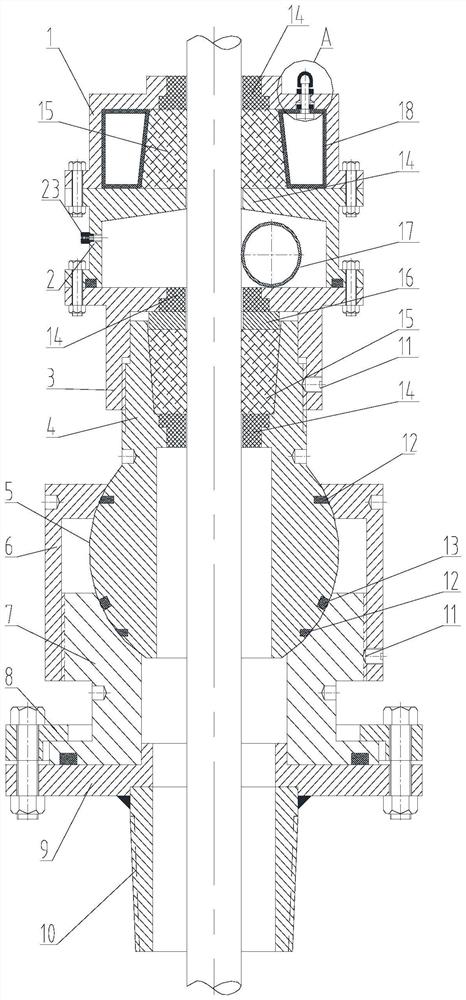

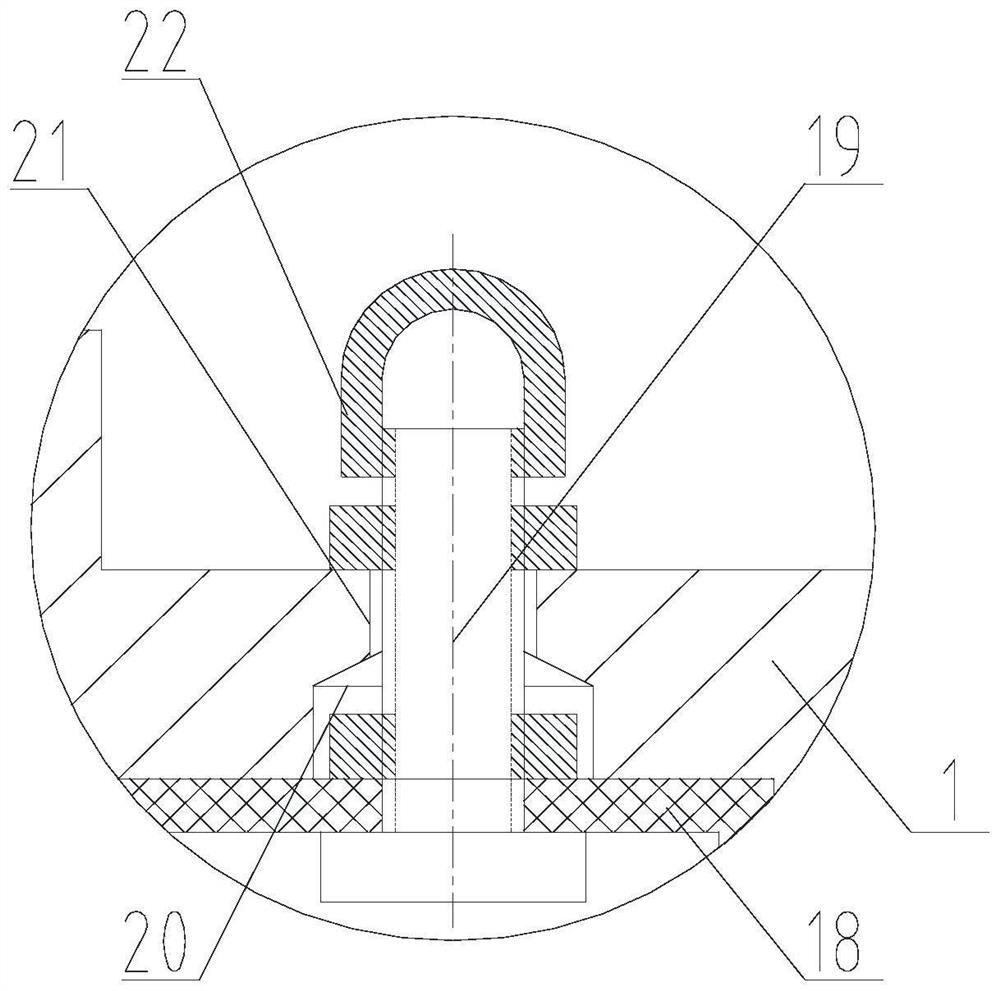

Electrically operated valve and heat exchange device comprising same

InactiveCN102252119AImprove reliabilityGuaranteed coaxialityOperating means/releasing devices for valvesValve housingsEngineeringMetallic Lead

The invention discloses an electrically operated valve. The electrically operated valve comprises a valve plug base (1) which is provided with a valve plug cavity and a valve port (11) communicated with the valve plug cavity, and a valve needle (2) which is extended into the valve plug cavity and is matched with the valve port (11); a lead screw (3) is connected with the upper part of the valve needle (2); and a pilot sleeve (4) is arranged outside the lead screw (3) and is fixedly connected with the valve plug base (1). By the electrically operated valve, the concentricity between the pilot sleeve (4) and the valve port (11) can be improved so that the sealing performance between the valve needle (2) and the valve port (11) can be improved and the frictional resistance during rotation of a rotator (6) can be reduced. Moreover, the invention also discloses a heat exchange device comprising the electrically operated valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

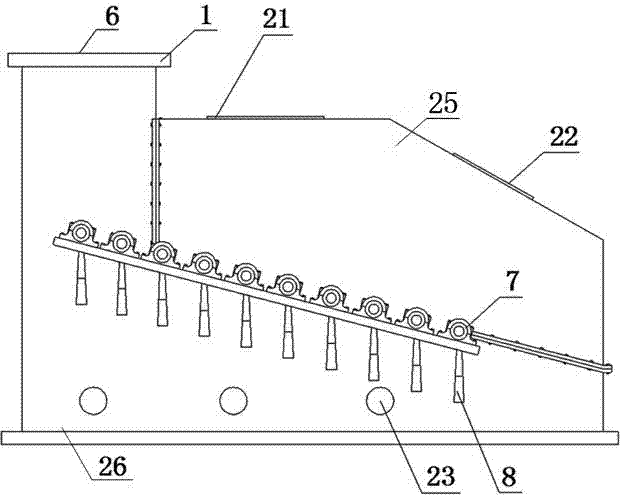

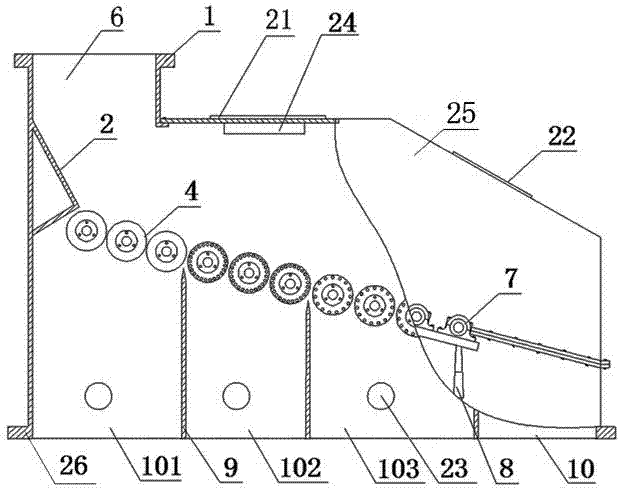

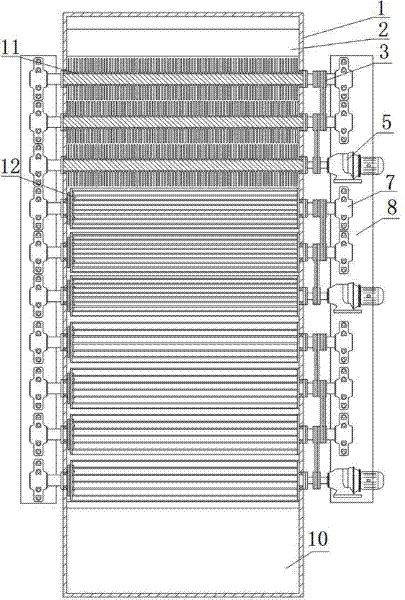

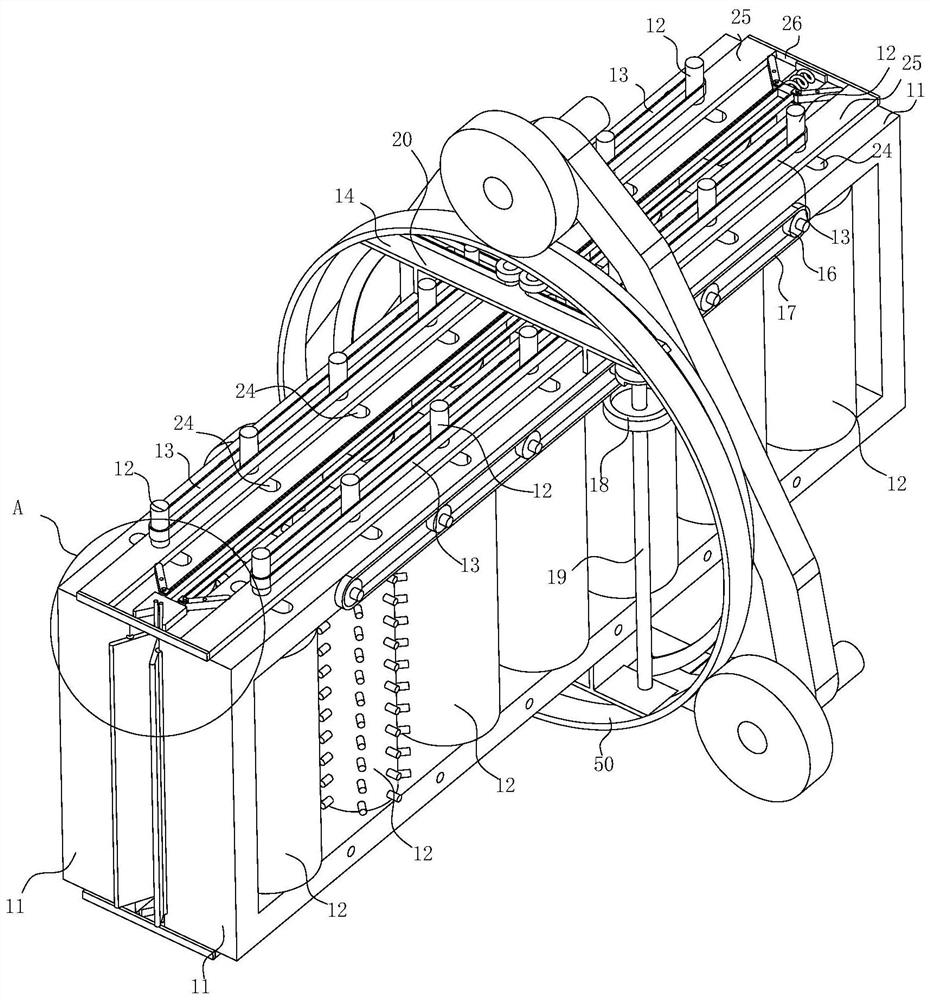

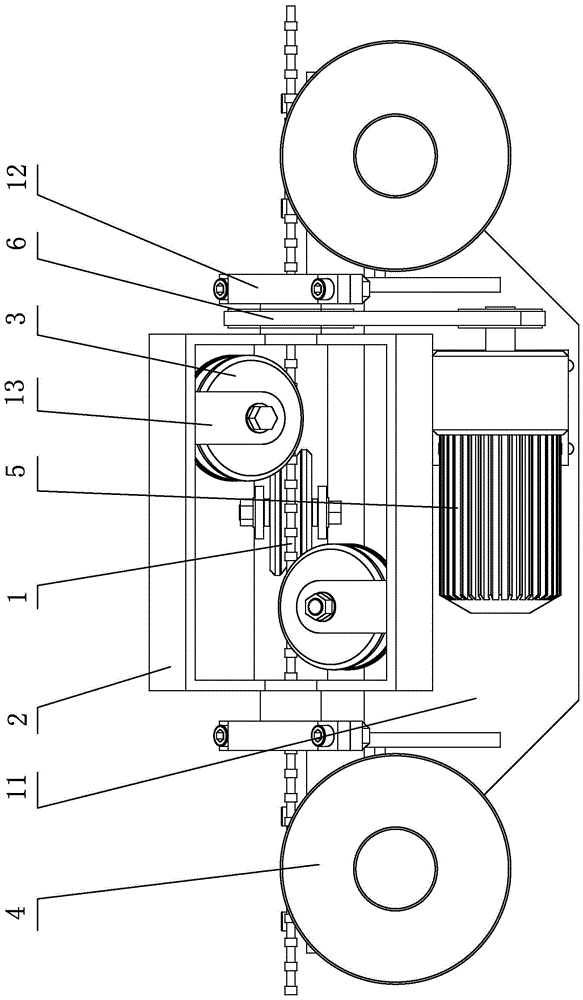

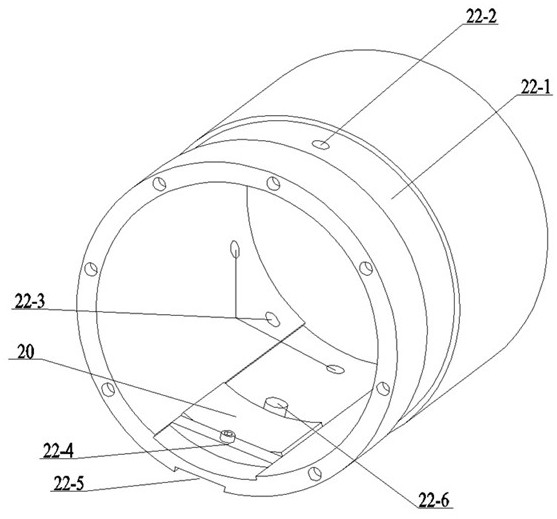

Material distributing screening machine

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Retractable rope used for elevator

ActiveCN103663057AImprove carrying capacityHigh resistance to torsional deformationElevatorsTextile cablesDiameter ratioEngineering

The invention discloses a retractable rope used for an elevator. The retractable rope is characterized by being composed of at least one bearing body capable of bearing independently and a wrapping layer, wherein the cross section of the retractable rope is oval, and the short axis of the oval is vertical to the retracting direction of the retractable rope. Compared with a plastic coated wire rope with a circular section, the retractable rope mainly has two advantages that (1) on the condition that the bearing force is the same, the contact area of the retractable rope and a running wheel is increased, the retractable rope is evenly stressed, and service life of a coated layer is prolonged; (2) a plurality of independent bearing bodies in the retractable rope are distributed in parallel, the diameter of each bearing body is 2 mm, according to the requirement in GB7588 that the rope diameter ratio can not be smaller than 40, and the diameter of the running wheel can be reduced to 100m. When the retractable rope is used, a traction pulley needs to have a groove type which is complementary with the appearance of the retractable rope so that the traction pulley can be well meshed with the rope when the elevator operates, the guide performance of the rope is improved and eccentric wear is restrained.

Owner:YUNGTAY ELEVATOR EQUIP CHINA

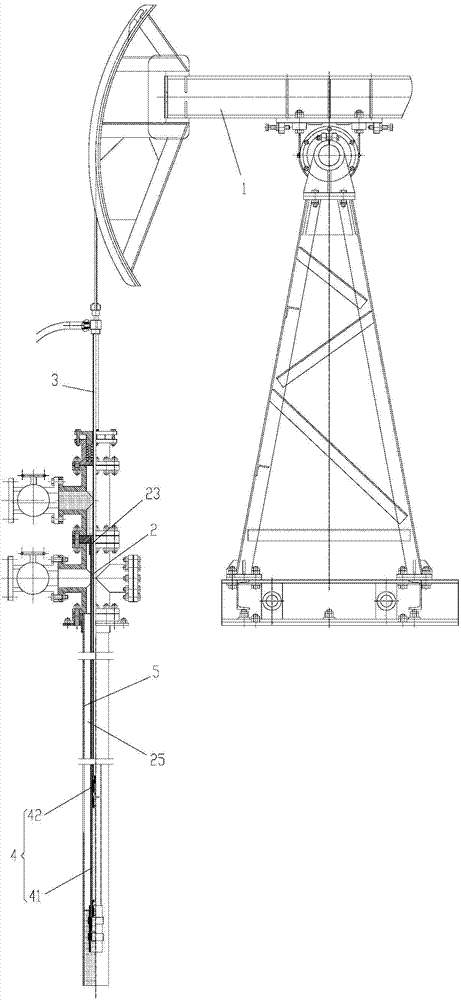

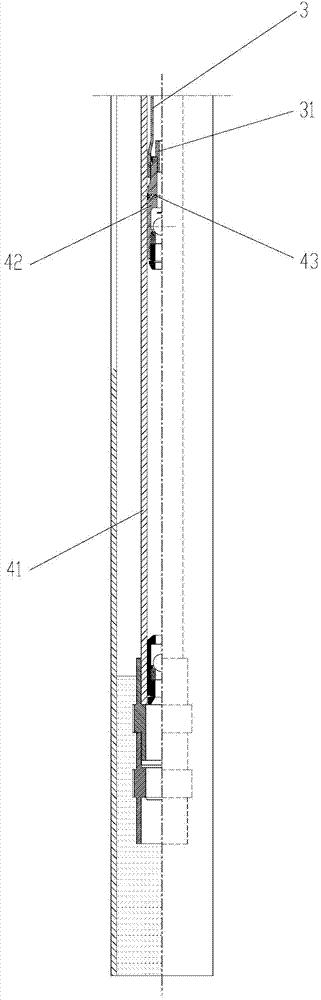

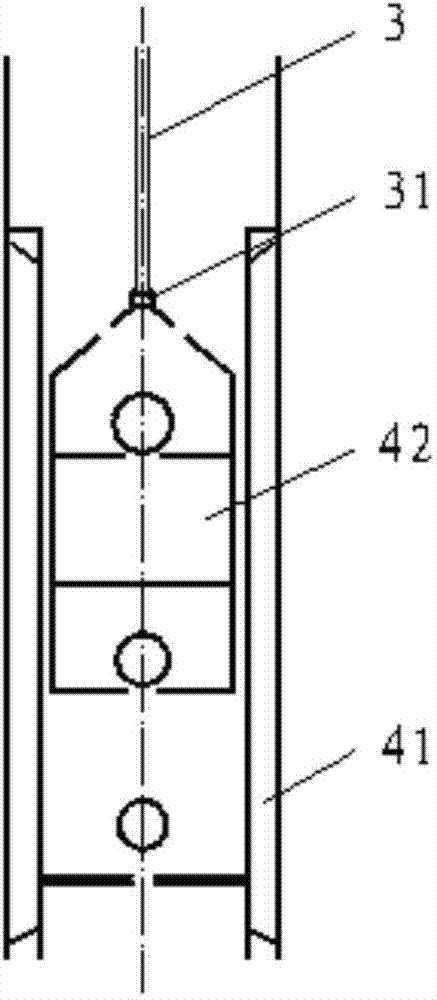

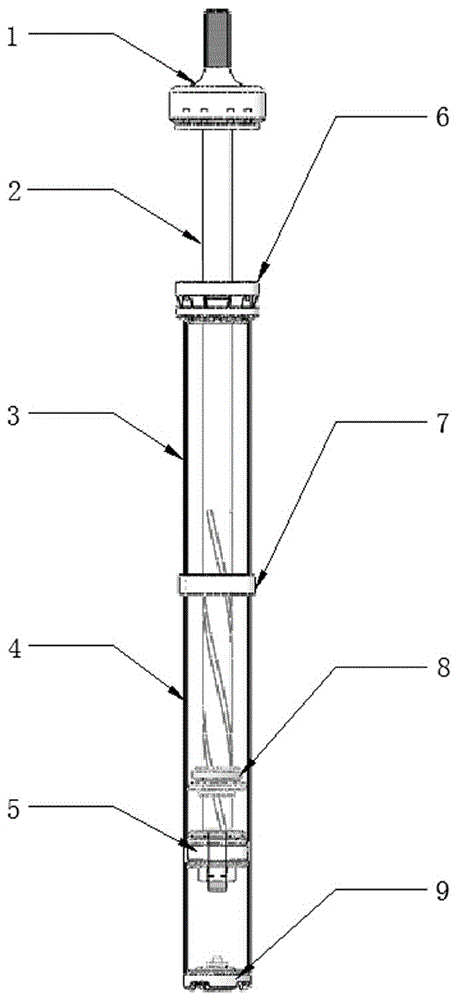

Sucker-rod pump device for coal seam gas exploitation

ActiveCN104763621AAvoid eccentric wearNo additional operating costsDrilling rodsFlexible member pumpsCoalEngineering

The invention discloses a sucker-rod pump device for coal seam gas exploitation. The sucker-rod device for the coal seam gas exploitation comprises an oil pumping unit, an oil pipe, a pumping rod, and a sucker-rod pump. The oil pipe is installed inside a casing pipe downhole. The sucker-rod pump comprises a pump cylinder and a plunger matched with each other. The pump cylinder is located at the lower end of the oil pipe and is communicated with the oil pipe. The bottom of the pump cylinder and the bottom of the plunger are both provided with traveling valves. An upper housing of the plunger is provided with a communicating hole. The oil pumping unit is located on the ground and is able to drive the plunger to reciprocate through the pumping rod. The pumping rod is a hollow structure. The joint between the pumping rod and the plunger is provided with an openable sealing structure for closing a casing pipe annular space and a rod tube annular space. The extraction is performed through the interior of the pumping rod upon opening the sealing structure. The sucker-rod pump device is able to use two extraction manners; the appropriate extraction manner can be selected based on the variation of the water yield. The two extraction manners can be continuously switched for continuously and stably reducing the pressure and draining the water in the shaft without well repair operations, accordingly ensuring the continuous and stable production of the coal seam gas well.

Owner:CHINA UNITED COALBED METHANE +1

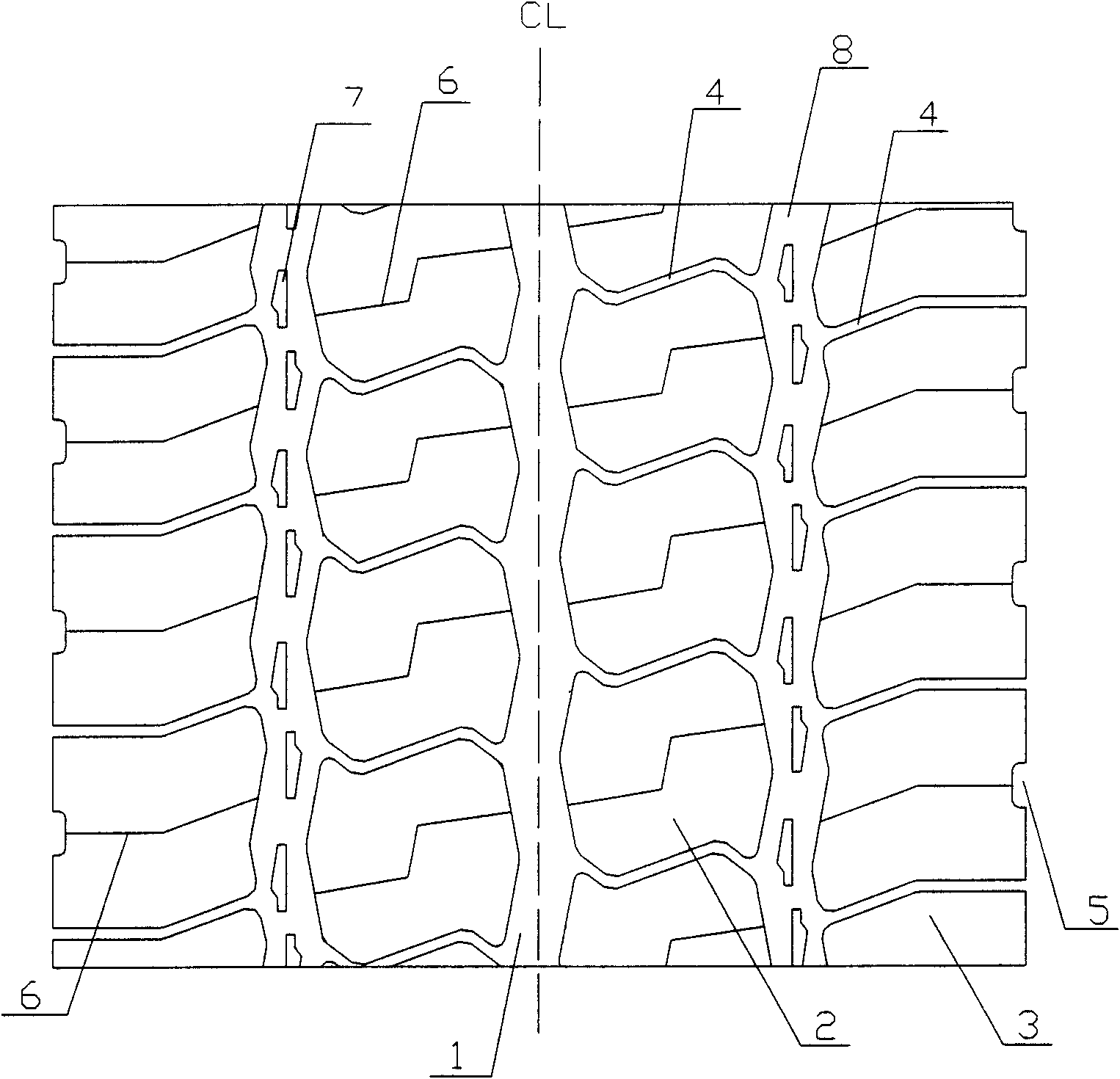

Truck tyre tread

ActiveCN101618664AAvoid eccentric wearImprove maneuverabilityTyre tread bands/patternsEngineeringTruck

The invention relates to an auto tyre structure, in particular to a tread pattern structure for a tyre of a truck. The truck tyre tread comprises a central vertical circumferential pattern groove arranged on the center position of the tyre tread, namely the center line of the tyre tread, wherein the central vertical circumferential pattern groove equally divides the tyre tread into two eudipleural parts, the left side and the right side of the central vertical circumferential pattern groove are provided with lateral pattern blocks and shoulder pattern blocks in turn regularly from inside to the outside, the lateral pattern blocks and the shoulder pattern blocks are spaced by the vertical circumferential pattern groove, and the groove bottom of the vertical circumferential pattern groove is provided with a bulge which is connected with the two side walls of the circumferential pattern groove; and two adjacent lateral pattern blocks and two adjacent shoulder pattern blocks are spaced by a transverse pattern groove respectively. The tyre tread of the truck tyre adopts mixed patterns and has sufficient braking force, good maneuverability, and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

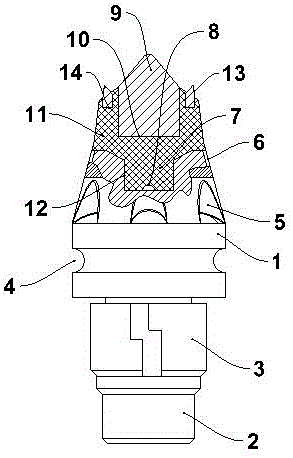

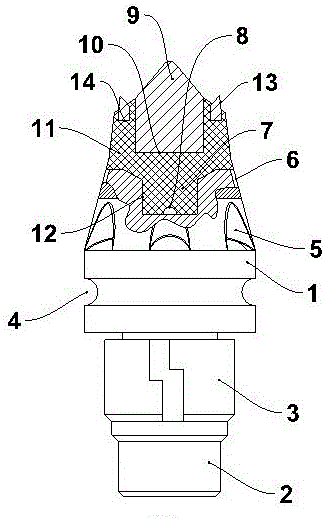

Abrasion-resistant tool bit

InactiveCN106522940AExtended service lifeGuaranteed service lifeSlitting machinesCutting machinesTool bitMetallic materials

The invention provides an abrasion-resistant tool bit. The abrasion-resistant tool bit comprises a tooth body, a main tooth head, a tool bit base and a tooth handle. The upper portion of the main tooth head and the upper portions of auxiliary tooth heads are conical, and the lower portion of the main tooth head and the lower portions of the auxiliary tooth heads are cylindrical. The tool bit base is made of a cemented carbide material. A main cutting tooth groove is formed in the top surface of the tool bit base, and the lower portion of the main tooth head is embedded into the main cutting tooth groove. A plurality of auxiliary cutting tooth grooves are formed in the top surface of the tool bit base and located in the outer circle of the main cutting tooth groove. The lower portions of auxiliary tooth heads are embedded in the auxiliary cutting tooth grooves. A protruding rod is arranged in the center of the bottom surface of the tool bit base. A concave groove is formed in the top surface of the tooth body, and the protruding rod is embedded in the concave groove. The bottom surface of the tool bit base makes contact with the top surface of the tooth body and is fixedly connected with the top surface of the tooth body. A hole used for stress relief is formed in the bottom of the protruding rod. The tooth body is made of metal. The surface of the upper portion of the tooth body is covered with a hard-face alloy layer. The abrasion-resistant tool bit is reasonable in structural design, the abrasion resistance and impact resistance are improved, the tooth body is effectively protected, and the service life of the tool bit is prolonged.

Owner:新昌县东韩机械有限公司

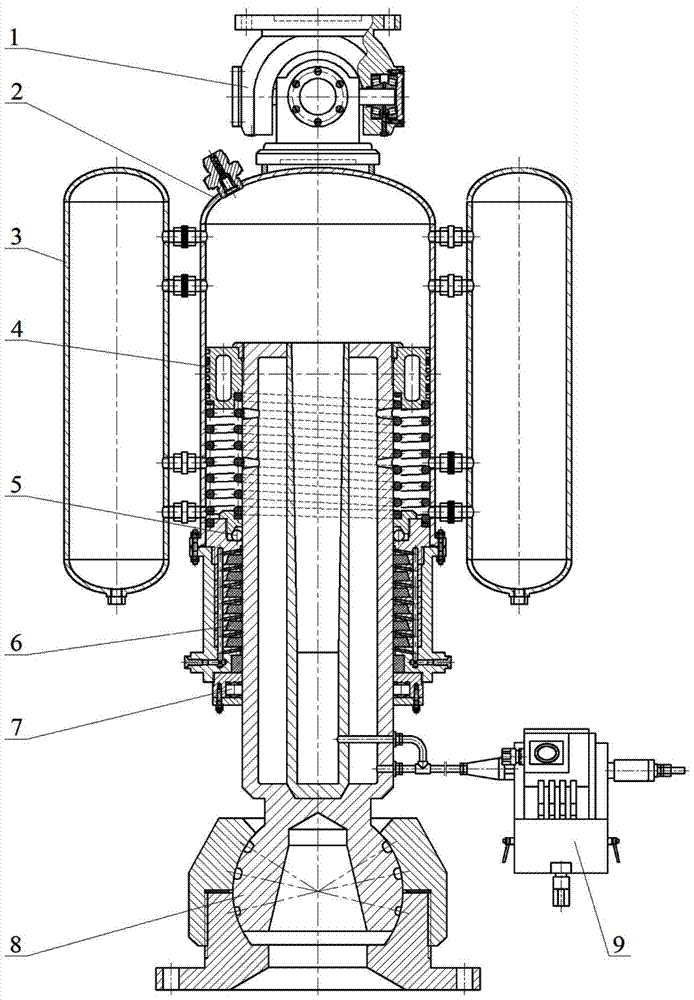

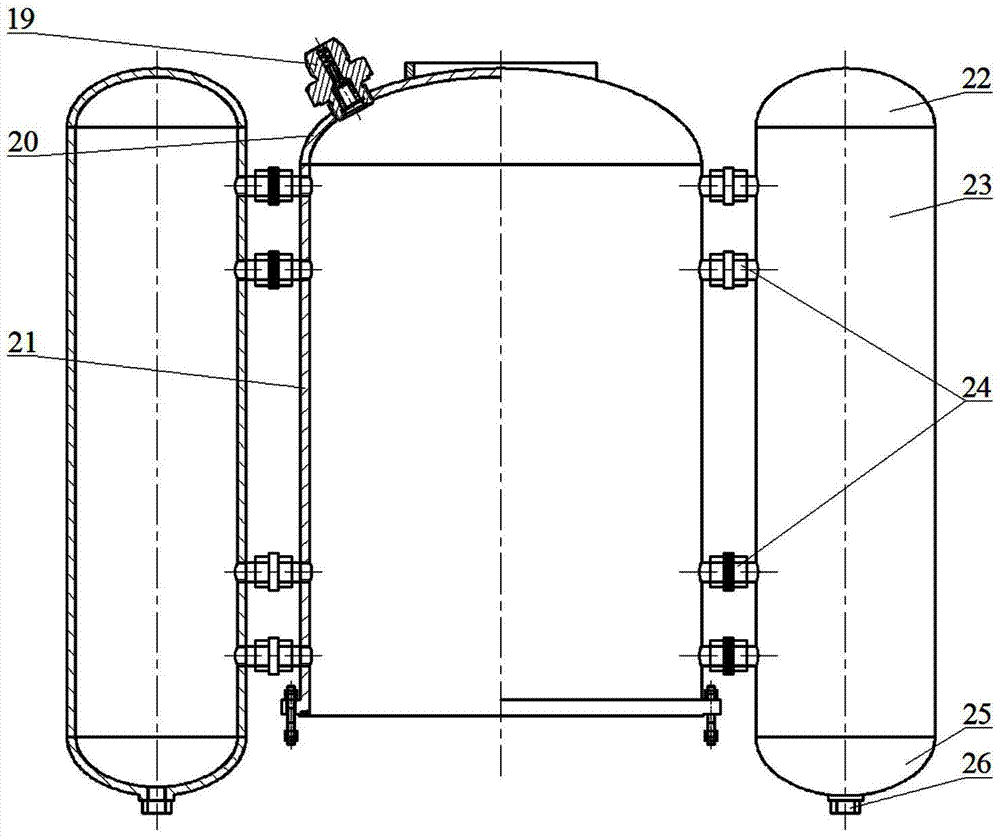

Offshore drilling supporting platform servo alignment pneumatic flexible connector

ActiveCN104265227AAvoid eccentric wearCompact structureSealing/packingEngineeringAtmospheric pressure

The invention provides a servo alignment pneumatic flexible connector which is applied to the connection of an offshore drilling supporting platform and other platforms. A gas storage tank of the flexible connector and a cylinder and a piston cylinder are arranged in a trinity mode and the structure is compact; the difference of the required gas is timely complemented through the gas stored in the gas storage tank, the platform vibration loads are balanced by the piston cylinder through the compression or expansion of the gas of an upper chamber and a lower chamber of the cylinder and the applied force of retraction and extension of an inner spring and an outer spring together, and the radial displacement is automatically adjusted; the servo alignment is implemented through an alignment device and accordingly the same axis of the cylinder and the piston cylinder is maintained and the angle deviation adjustment is achieved through a deviation adjustment device and accordingly the upper end surface of the deviation adjustment device is maintained to be level; an upper guider is combined with a lower guider to implement the radial guide effect to enable the axis of the cylinder and the axis of the piston cylinder to be overlapped and meanwhile the cylinder and the piston cylinder are sealed through a combined packing sealing structure of a sealing body; the automatic gas filling or closing is ensured through an automatic gas filler, the emergency release of the air pressure is implemented through a pressure safety valve, and the integral device is easy to detach and install and operate and maintain.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

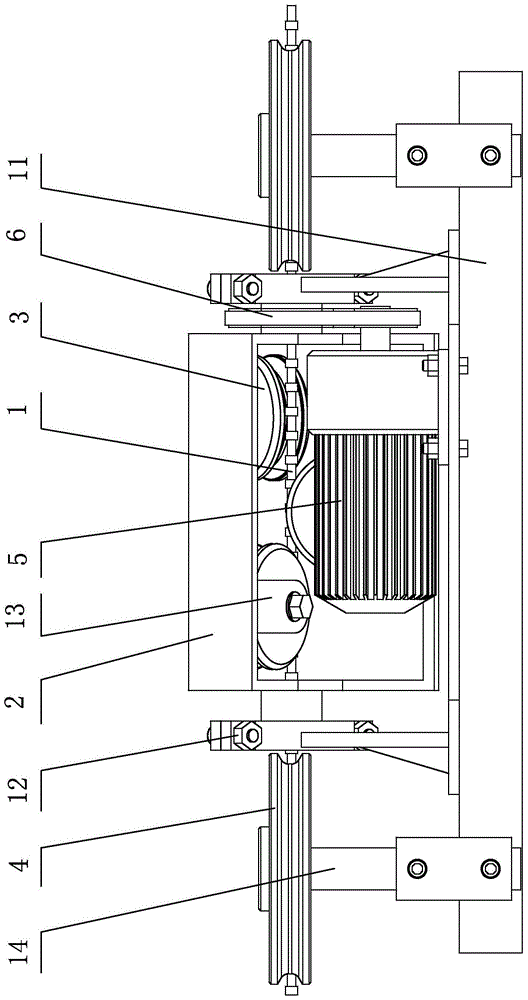

Electromagnetic brake

ActiveCN103058091AAvoid eccentric wearHeight adjustableHoisting equipmentsElastic componentEngineering

The invention discloses an electromagnetic brake which comprises an electromagnet (1), an armature (8), a brake plate (10) and a brake pad (11). The brake plate (10) is fixedly connected with the brake pad (11). The outer side of the brake pad (11) is of a recessed arc shape. The electromagnet (1) is connected with the armature (8) through a central bolt (7) and attached to a first side of the armature (8). The armature (8) is provided with an elastic recovery mechanism. The elastic recovery mechanism presses the brake plate (10) towards a second side of the armature (8). The armature (8) is fixedly connected with a guide shaft (13). The brake plate (10) is partially sleeved outside the guide shaft (13). The armature (8) is connected with an adjustable bolt (5) in a threaded manner. An end cap of the adjustable bolt (5) penetrates into an adjusting hole of the brake plate (10) and is in clearance fit with the same. The other end of the adjustable bolt (5) rightly faces and can penetrate into a through hole of the electromagnet (1). An elastic component (4) which generates outward acting force on the armature (8) is mounted in the through hole of the electromagnet (1). The brake pad component and the armature are separated and can rotate at a certain angle, and accordingly contact between a brake wheel and the brake pad can be adjusted automatically.

Owner:浙江西子富沃德电机有限公司

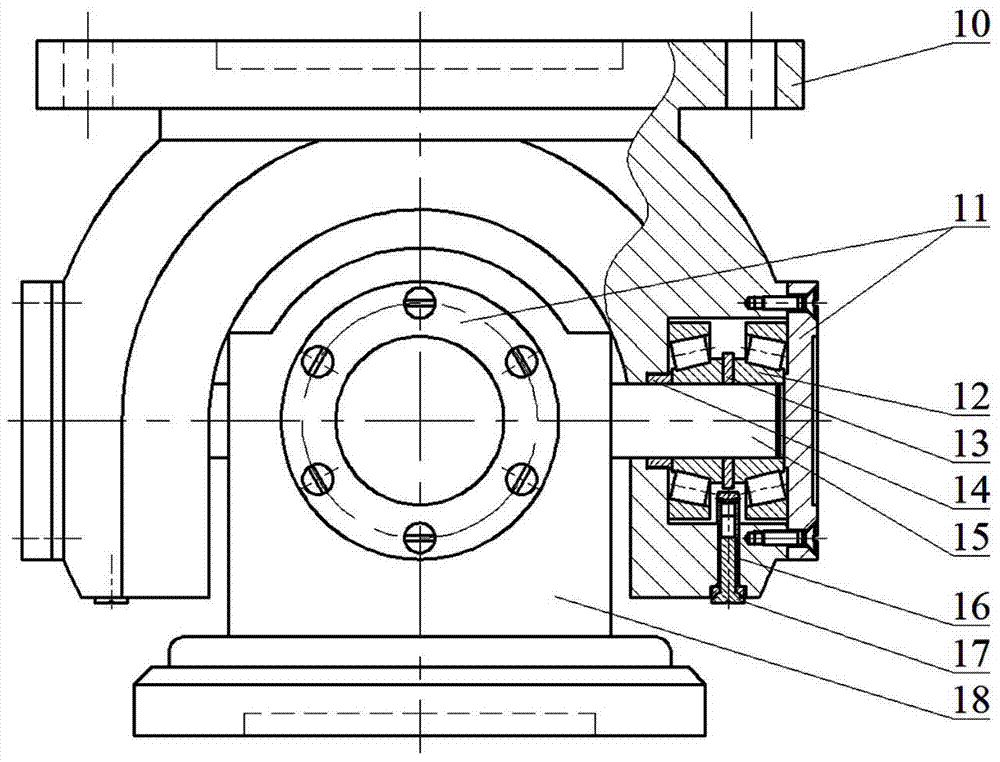

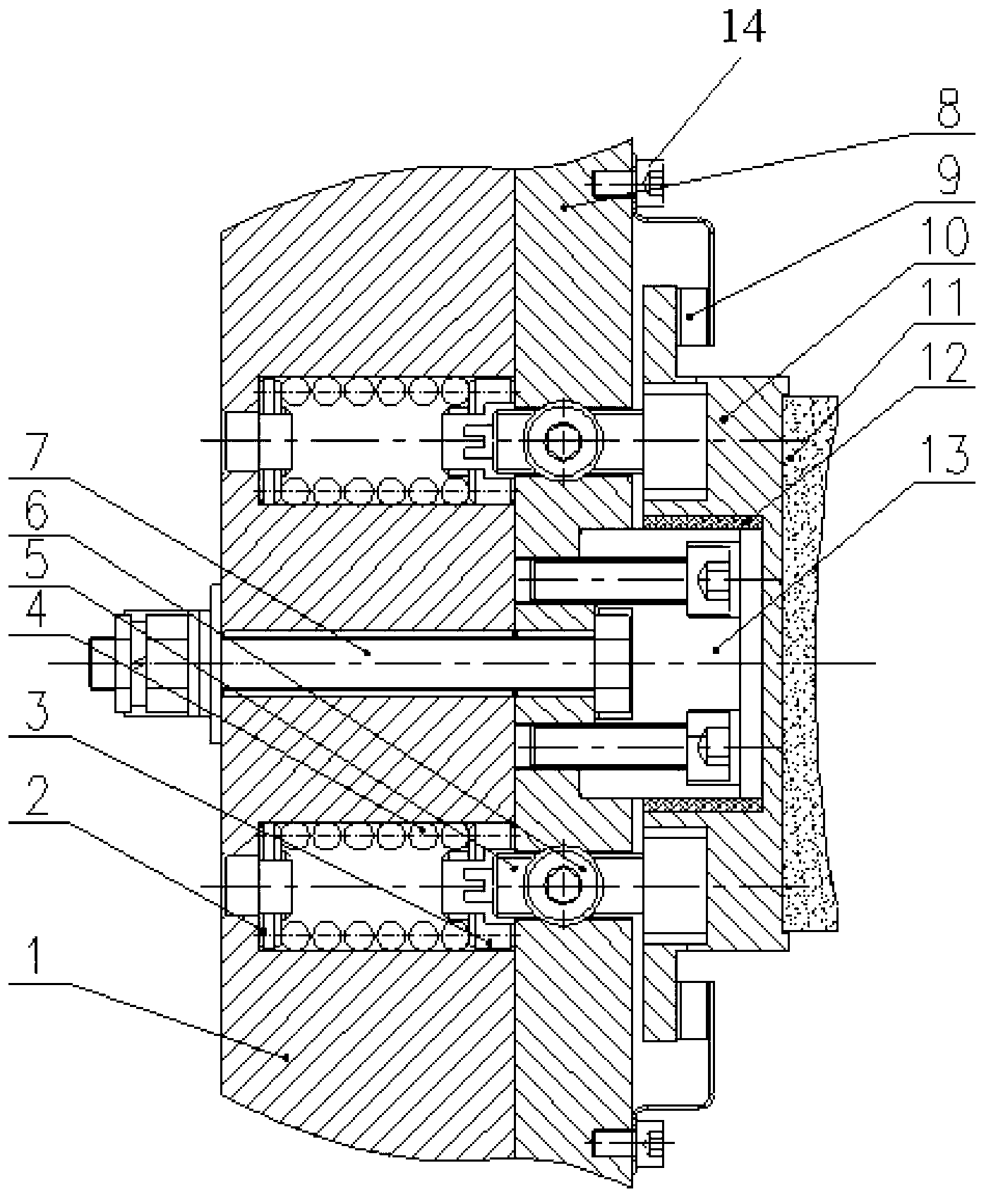

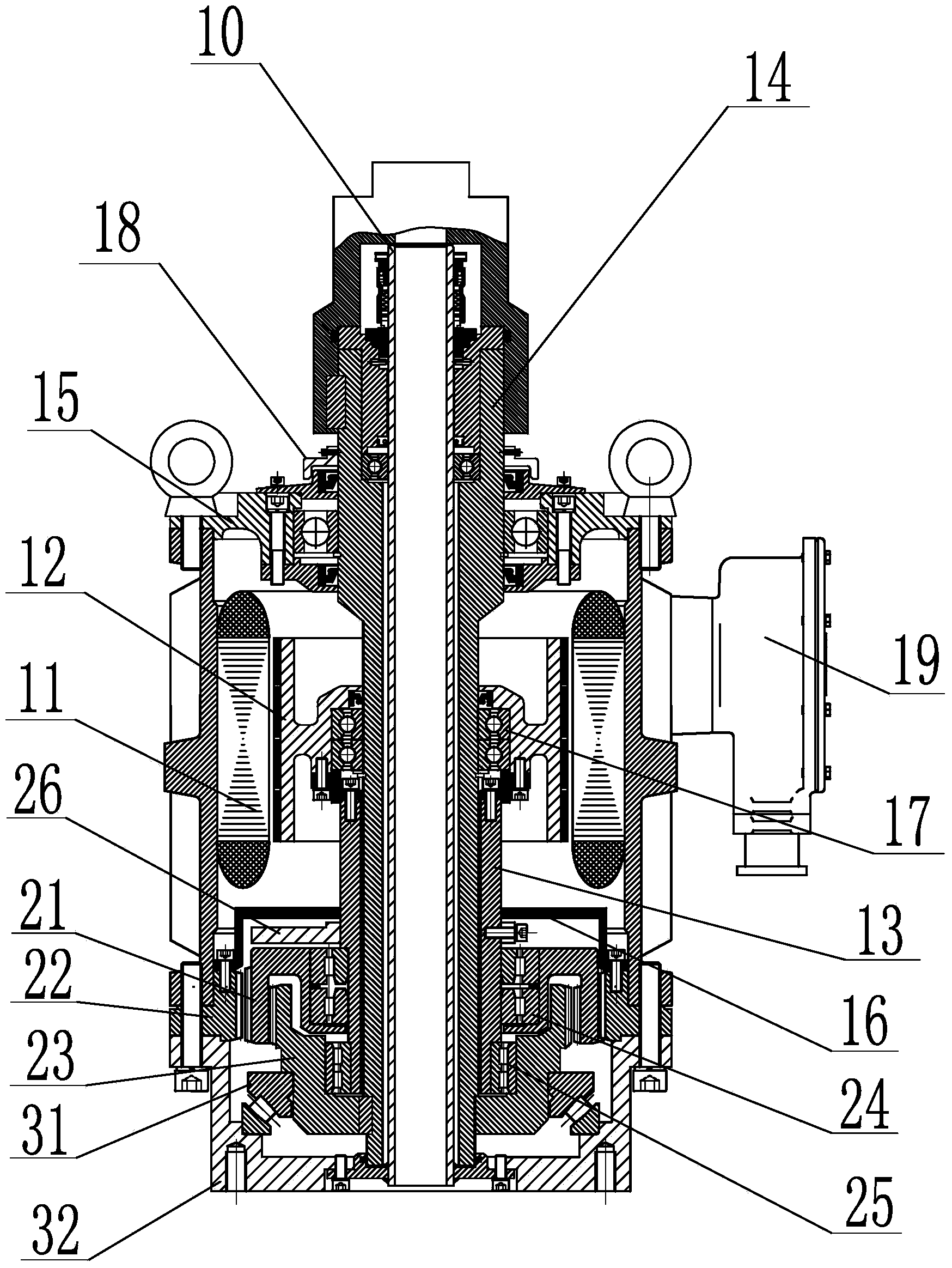

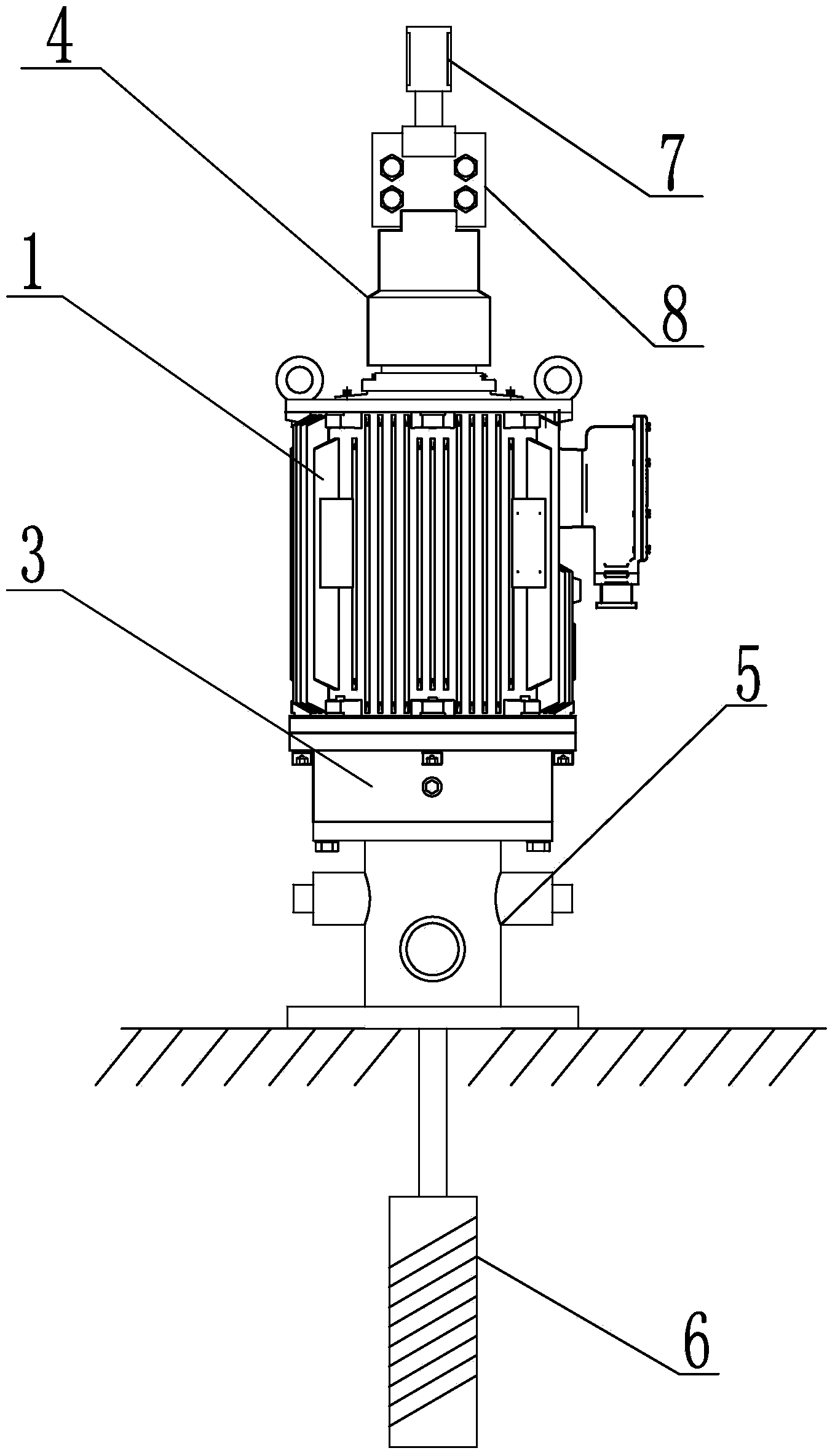

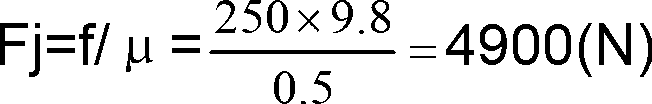

Ground driving motor of teetch-difference deceleration screw pump

InactiveCN104037979AAvoid eccentric wearReduce loadToothed gearingsMechanical energy handlingMotor driveEngineering

The invention relates to a ground driving motor of a teeth-difference deceleration screw pump. The ground driving motor comprises a motor driving portion and a bearing support component, wherein the motor driving portion comprises a stator, a rotor, a spindle, an eccentric shaft and a rotor bearing, the bearing support component comprises a load bearing bearing and a support seat, the motor driving portion and the bearing support component are connected via a gear reduction mechanism, teeth-difference gear groups are adopted by a gear reducer which comprises a fixed gear ring, a planet gear ring and an output gear ring, the fixed gear ring is fixed between a shell and the support seat via bolts, an outer-wall gear of the planet gear ring is meshed with an inner-wall gear of the fixed gear ring, a first gear ring bearing is arranged between the planet gear ring and the eccentric shaft, an outer-wall gear of the output gear ring is meshed with an inner-wall gear of the planet gear ring, a second gear ring bearing is arranged between the output gear ring and the eccentric shaft, and the output gear ring is fixedly connected with the spindle. The ground driving motor of the teeth-difference deceleration screw pump is capable of avoiding eccentric wearing of an oil pumping polish rod caused by eccentricity, decreasing a sealing invalidation happening rate and improving operation safety.

Owner:ZHEJIANG DEQING XICHUAN ELECTRICAL SCI & TECH

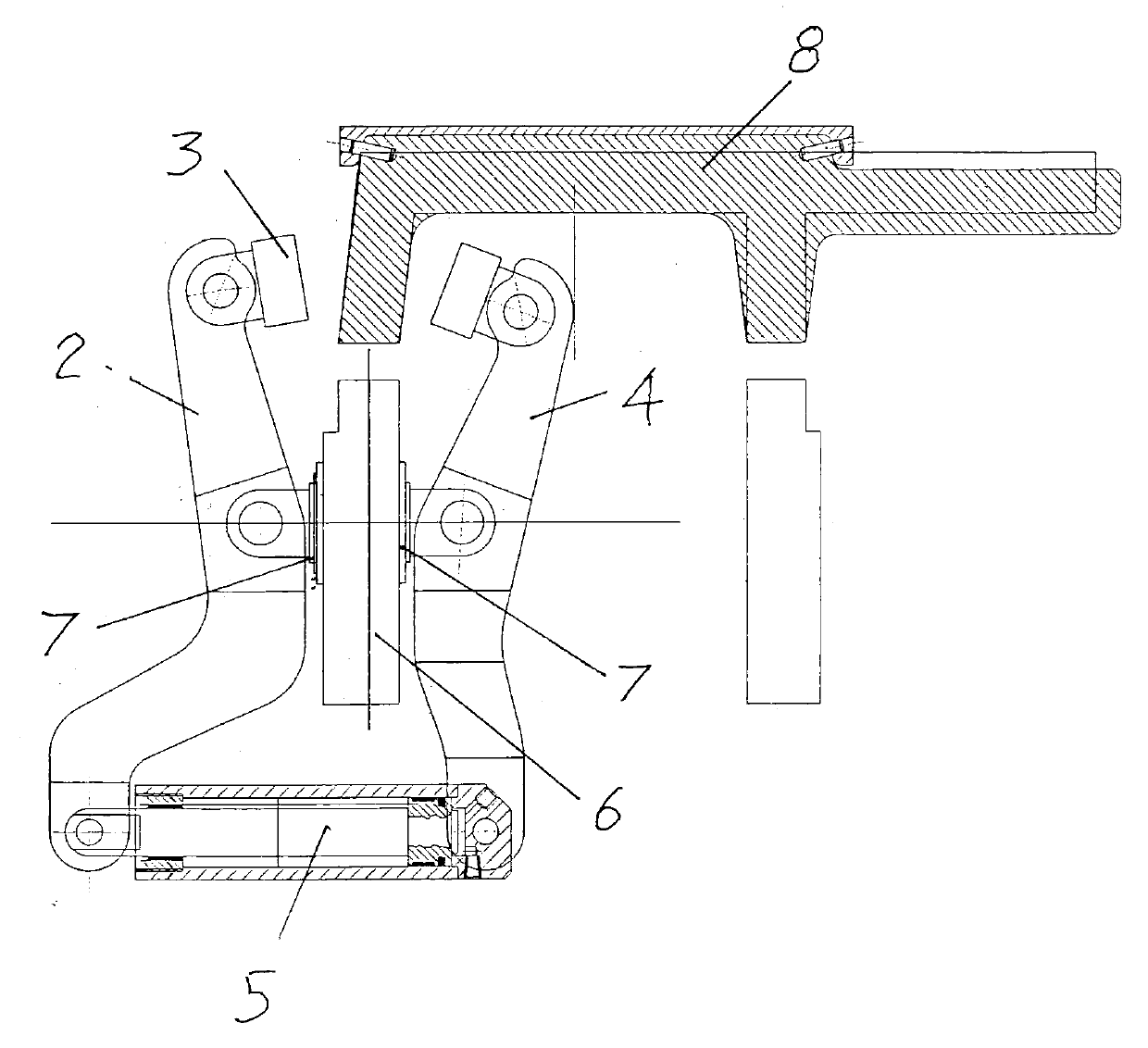

Lever type magnetic suspension brake

InactiveCN102996685AEasy to installEasy to replaceAxially engaging brakesHydraulic cylinderEngineering

The invention discloses a lever type magnetic suspension brake. The middle parts of an outside lever device and an inside lever device are respectively connected at two sides of a pole plate through respective middle shaft and respective shaft bracket; a rubber spring is arranged between each of the two shaft brackets and the pole plate; the opposite inner side surfaces of the upper ends of the outside lever device and the inside lever device are respectively connected with a brake pad through a pin shaft; and the lower ends of the outside lever device and the inside lever device are respectively connected at two sides of a hydraulic cylinder through a connecting shaft. A plier-type brake structure is adopted by the lever type magnetic suspension brake, and the hydraulic cylinder is used as a brake force generating unit and controlled by a brake control loop such as brake valves, wherein a brake arm at the inner side of the brake is of a small bending radius structure and therefore the installation of the brake arm at the inner side is facilitated. The ultimate displacement of the brake arm is plus or minus 10mm; and the inclined angle of a track can be protected against eccentric wear through the slight up and down swinging of the brake pad, thus good tightness is obtained and maintenance and installation are facilitated; and friction plates can be conveniently dismantled to replace and the operation cost is saved.

Owner:TIANJIN JL RAILWAY TRANSPORT EQUIP +1

Electromagnetic brake

ActiveCN103058091BAvoid eccentric wearHeight adjustableHoisting equipmentsElastic componentEngineering

The invention discloses an electromagnetic brake which comprises an electromagnet (1), an armature (8), a brake plate (10) and a brake pad (11). The brake plate (10) is fixedly connected with the brake pad (11). The outer side of the brake pad (11) is of a recessed arc shape. The electromagnet (1) is connected with the armature (8) through a central bolt (7) and attached to a first side of the armature (8). The armature (8) is provided with an elastic recovery mechanism. The elastic recovery mechanism presses the brake plate (10) towards a second side of the armature (8). The armature (8) is fixedly connected with a guide shaft (13). The brake plate (10) is partially sleeved outside the guide shaft (13). The armature (8) is connected with an adjustable bolt (5) in a threaded manner. An end cap of the adjustable bolt (5) penetrates into an adjusting hole of the brake plate (10) and is in clearance fit with the same. The other end of the adjustable bolt (5) rightly faces and can penetrate into a through hole of the electromagnet (1). An elastic component (4) which generates outward acting force on the armature (8) is mounted in the through hole of the electromagnet (1). The brake pad component and the armature are separated and can rotate at a certain angle, and accordingly contact between a brake wheel and the brake pad can be adjusted automatically.

Owner:浙江西子富沃德电机有限公司

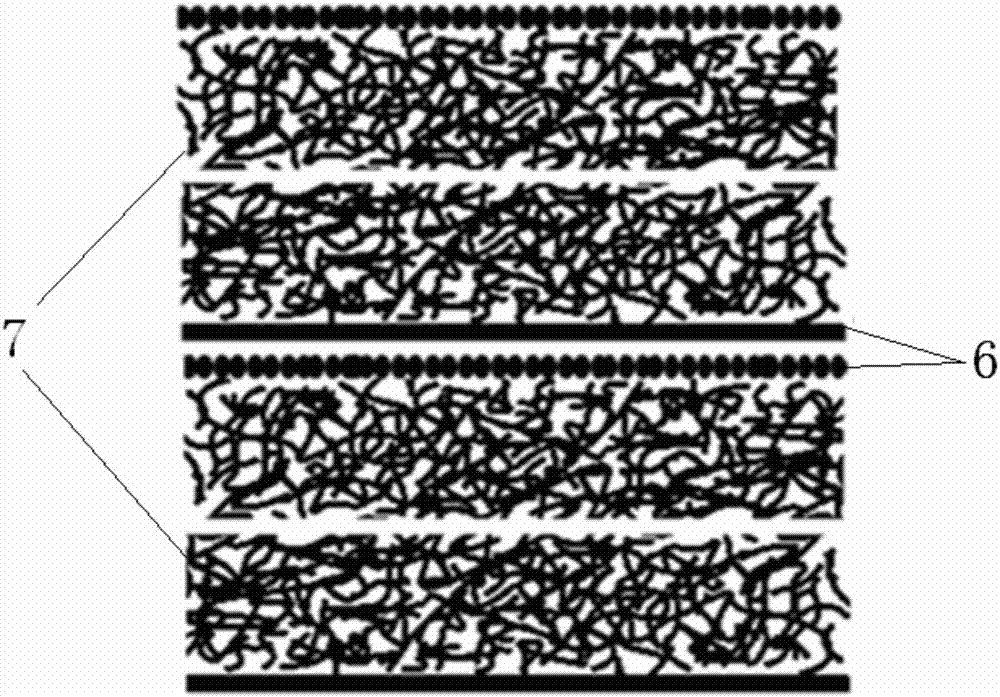

Preparing method of double-sided knitted carbon brake disc prefabricated body

InactiveCN107974764AIncrease deposition rateHigh porosityLaminationLamination apparatusBack structureMechanical engineering

A preparing method of a double-sided knitted carbon brake disc prefabricated body relates to a double-sided composite knitting technology, and the double-sided composite knitted prefabricated body isformed by overlapping and laying mesh tire / weft-free cloth. The mode of laying one mesh tire or weft-free cloth on each side of the two sides for double-sided knitting is adopted. The feeding speed, knitting frequency, knitting pressure and knitting speed of a composite needle machine reach the optimum compatibility, and the mode of laying the mesh tire to the mesh tire and laying the weft-free cloth to the weft-free cloth in a back-to-back structure is adopted. The deposition rate is increased by 20%, and the eccentric wear phenomenon can be well prevented.

Owner:XIAN AVIATION BRAKE TECH

Glass toughening treatment equipment and process

ActiveCN113635192AImprove applicabilityAvoid eccentric wearEdge grinding machinesGrinding drivesElectric machineryStructural engineering

The invention discloses glass toughening treatment equipment in the technical field of glass toughening. The glass toughening treatment equipment comprises a motor and two groups of symmetrically fixed rectangular frames, the motor is fixedly mounted in the centers of the lower ends of the two groups of rectangular frames through a bracket, and a plurality of polishing rollers are vertically arranged on the inner walls of the two rectangular frames at equal intervals. The problems that when an existing grinding device grinds the periphery of glass, the glass is usually horizontally placed on a conveying roller, the glass needing to be ground passes through a rotating grinding wheel, then edges of the moving glass are ground, certain pressure is usually needed to be applied to opposite edges of the ground glass in the grinding mode, the ground edge can be better attached to the grinding wheel, and due to the fact that the sizes of glass are different, the applied pressure is too large or too small, the phenomenon that the grinding amount is too large or too small is caused, and the quality of tempered glass products is uneven is caused are solved.

Owner:SANMING UNIV +2

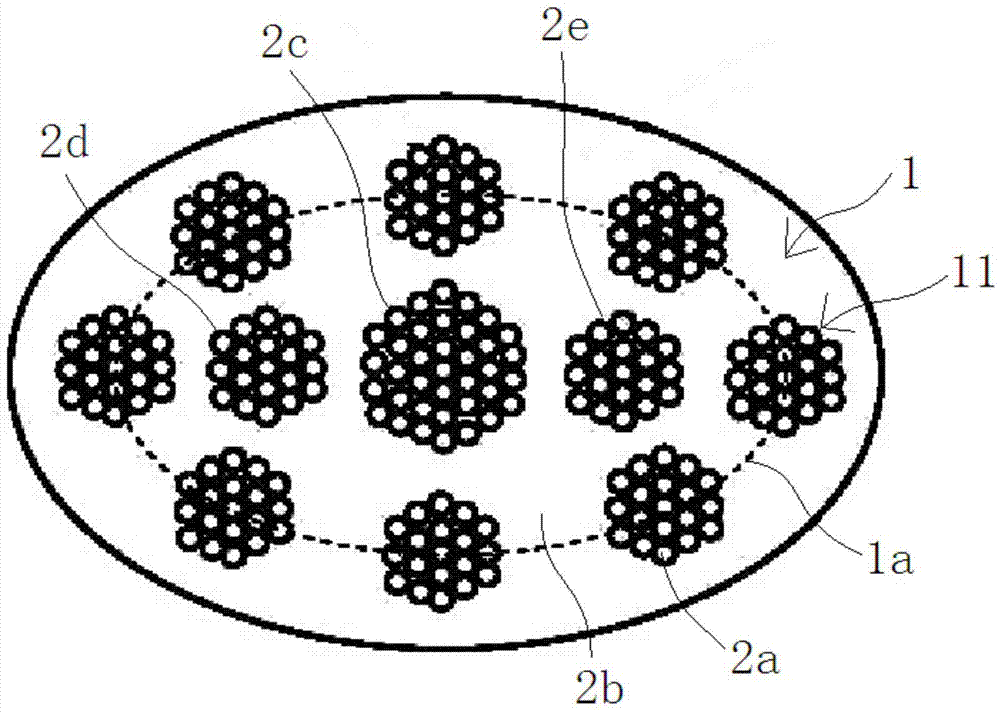

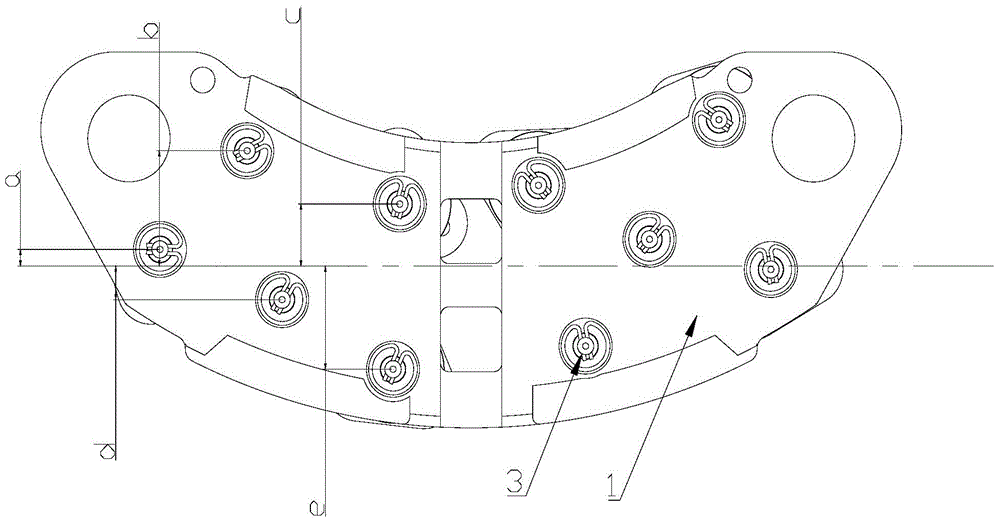

Floating type brake pad

InactiveCN104455104AConsistent heat fluxAvoid deformationBraking membersFriction liningEngineeringBrake pad

The invention discloses a floating type brake pad. The floating type brake pad comprises a back plate (1) and a plurality of friction blocks (2) installed on the back plate (1), the friction blocks (2) are connected to the back plate (1) through a plurality of snap springs (3) arranged on the other side of the back plate (1), and disc springs (4) are arranged between the friction blocks (2) and the back plate (1); the back plate (1) is separated into a plurality of circular rings (a) by taking the circle center of a brake disc matched with the floating type brake pad as a circle center, the radial lengths of the circular rings (a) are equal, and the difference between the friction area of the friction block (2) in each circular ring (a) and a reference average friction area does not exceed 15% of the reference average friction area. The floating type brake pad solves the problems that unstable thermoelasticity of an existing floating type brake pad causes poor braking stability and the service life of the existing floating type brake pad is short.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Milling wheel with cutting teeth and for double-wheel slot milling machine

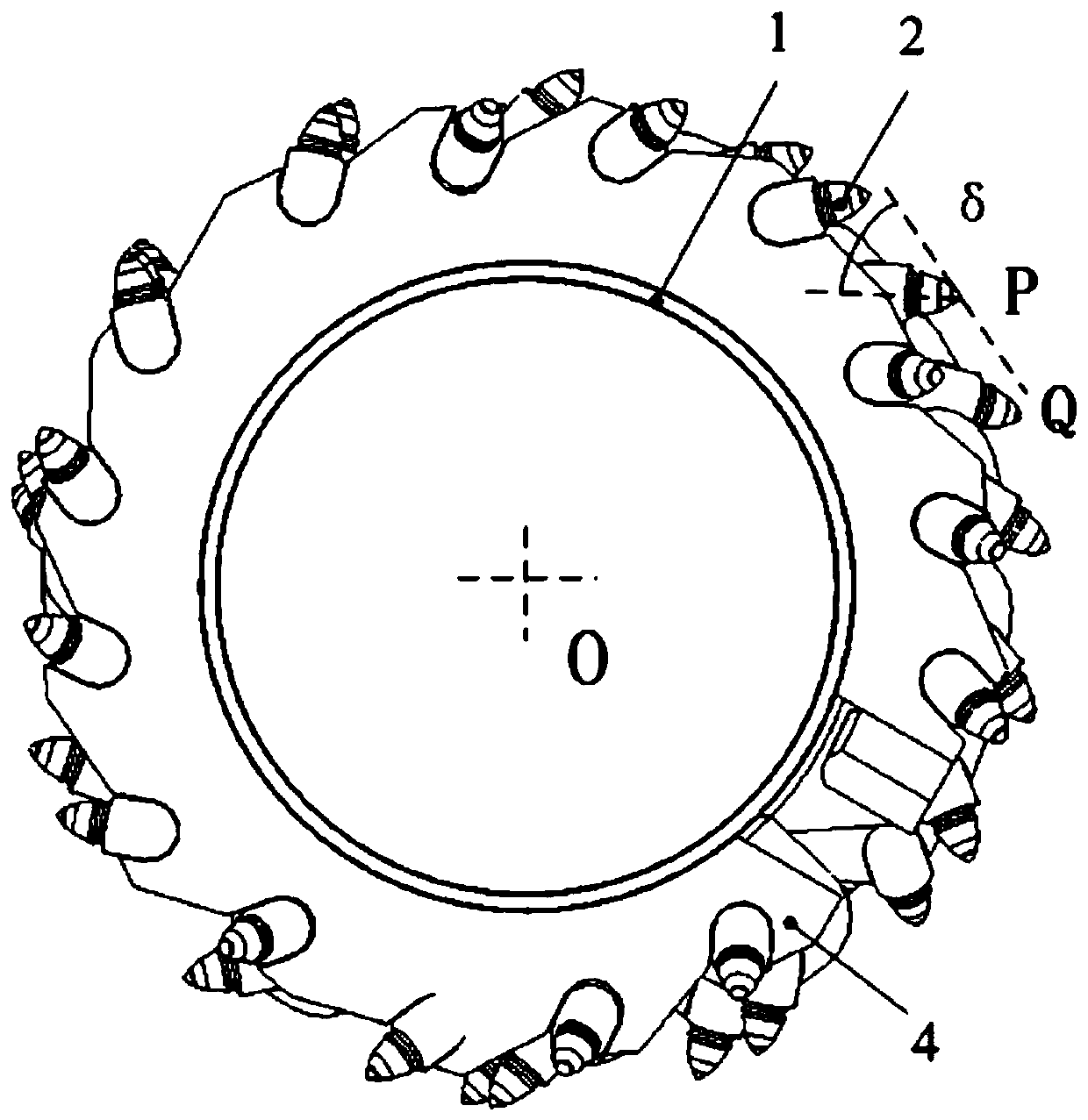

ActiveCN109811818AHigh blocking rateImprove efficiencySoil-shifting machines/dredgersEngineeringLine segment

The invention discloses a milling wheel with cutting teeth and for a double-wheel slot milling machine. The milling wheel comprises a wheel hub, the cutting teeth, tooth holders and a support plate, wherein the support plate is fixed on an outer ring of the wheel hub; the tooth holders are fixed in corresponding mounting holes in the support plate; and each tooth holder is rotationally provided with one cutting tooth therein. Sharp tooth points of the cutting teeth on different circumferences but on the same axis are connected to form an envelope line of the milling wheel; the middle part of the envelope line is a straight line segment, and the two ends of the envelope line are respectively an arc segment and a parabolic segment; and the three segments are connected sequentially and tangentially. The tooth clearances and milling radii of the cutting teeth arranged on the arc segment and on the parabolic segment are not greater than the tooth clearance and milling radius of the cuttingteeth arranged on the straight line segment. According to the scheme, the cutting teeth on the straight line segment have high rate of stone block and high efficiency when used for milling rocks; thecutting teeth on the two sides have a small milling clearance, are under a small stress and are used for simultaneously completing the milling of the bottom surfaces and side walls of rocks and soil;the service lives of the cutting teeth on the two sides are increased; and the design method of the segmented envelope line of the milling wheel is helpful to realize the parametric design of the milling wheel, thereby significantly improving the design efficiency of the milling wheel.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD +1

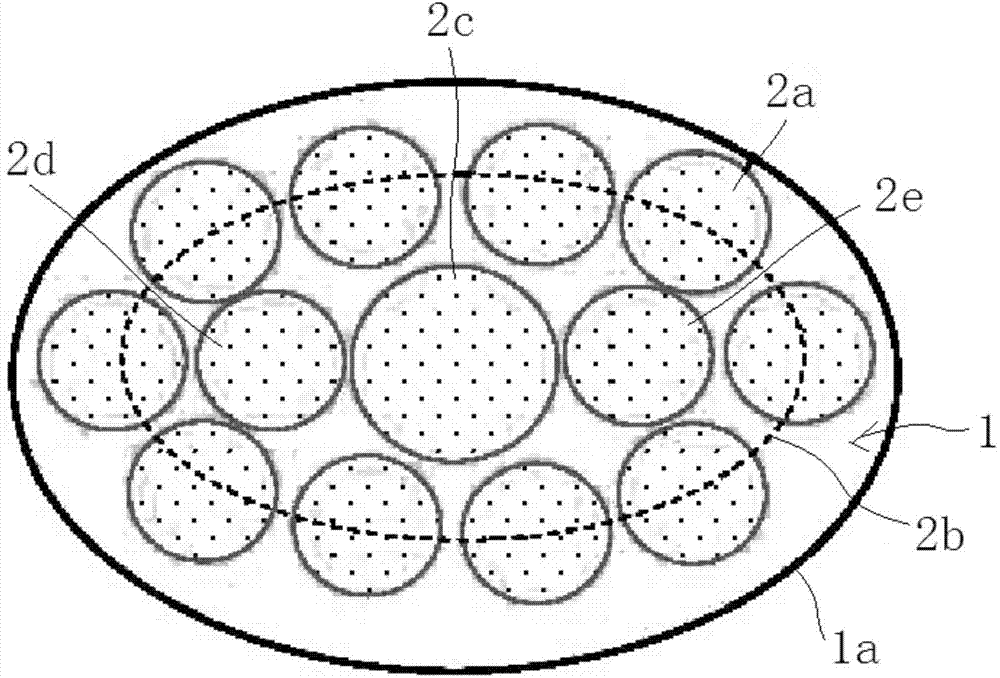

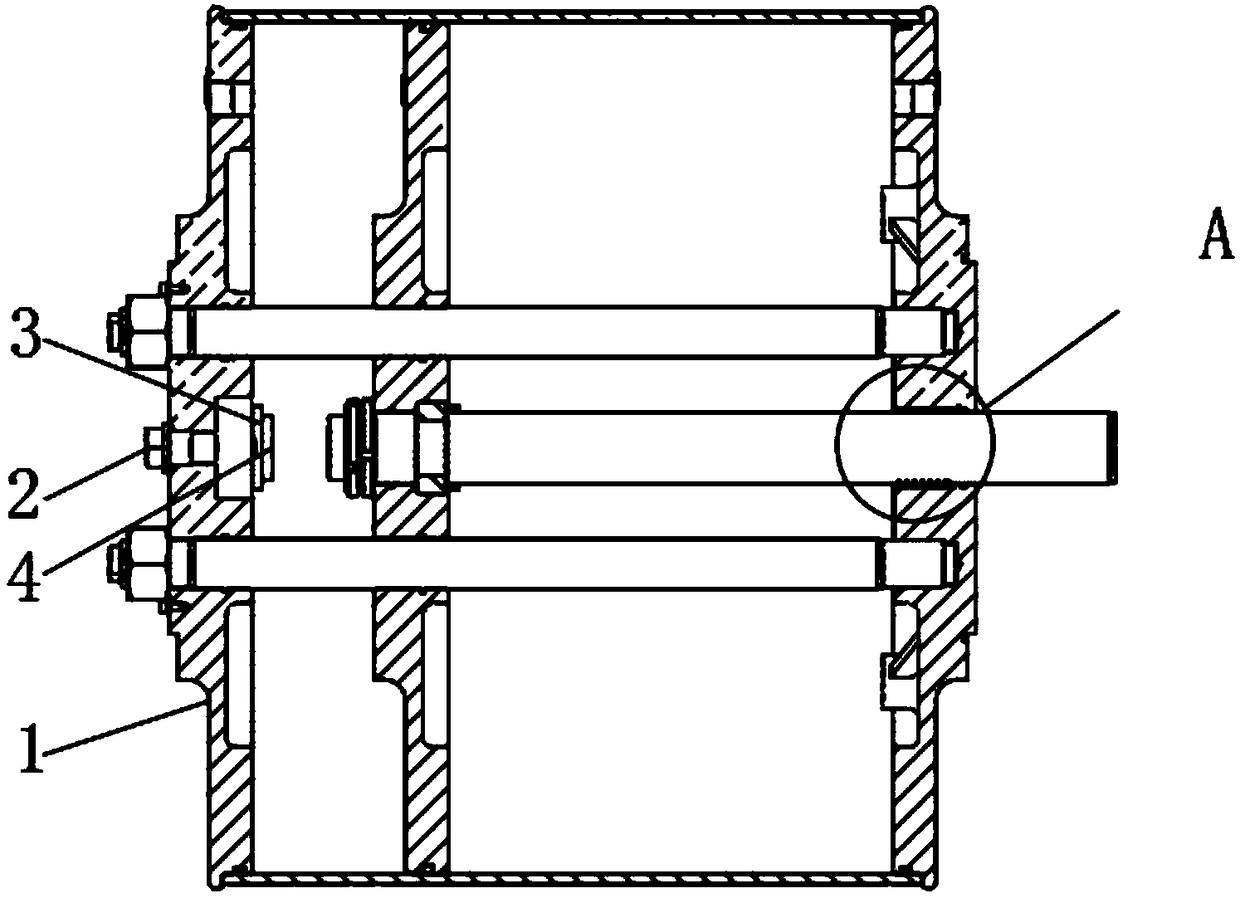

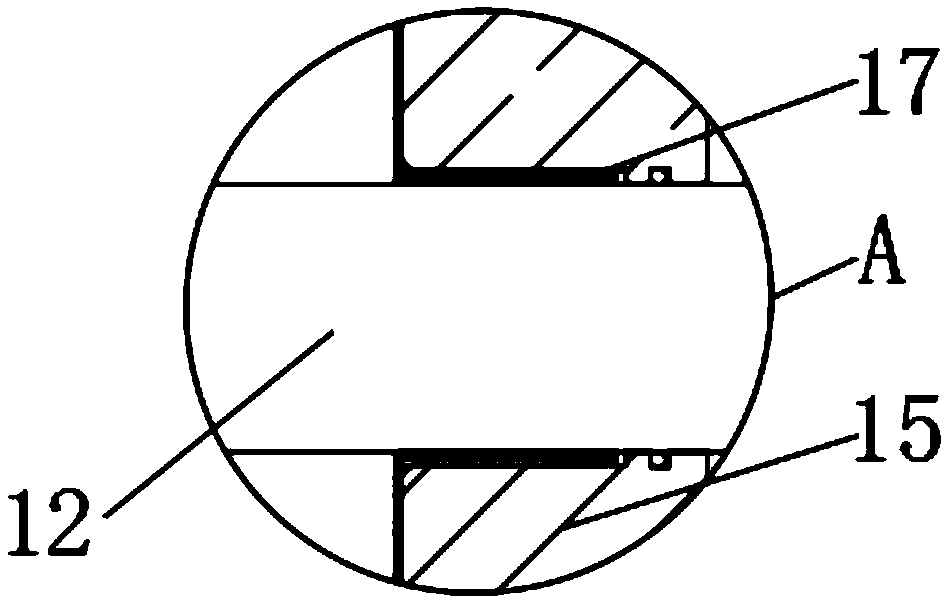

Brake pad

ActiveCN104500628AAvoid deformationAvoid crack phenomenonFriction liningBiomedical engineeringBrake pad

The invention discloses a brake pad. The brake pad comprises a back plate (1) and a plurality of friction blocks (2). A plurality of positioning holes (11) are formed in the back plate (1), and the friction blocks which are mounted on the back plate (1) are inserted into the positioning holes (11) and connected onto the back plate (1) through a plurality of snap springs (3) arranged on the other side of the back plate (1). The back plate (1) is partitioned into a plurality of circular rings (a) by centering on the center of a circle of a brake disc matched with the brake pad, the circular rings (a) are radially equal in length, and the friction area of the friction blocks (2) in each circular ring (a) is not more than and not less than 15% of a standard average friction area. The brake pad has the advantage that the problems of short service life and poor brake stability of an existing brake pad due to instable thermoelasticity are solved.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

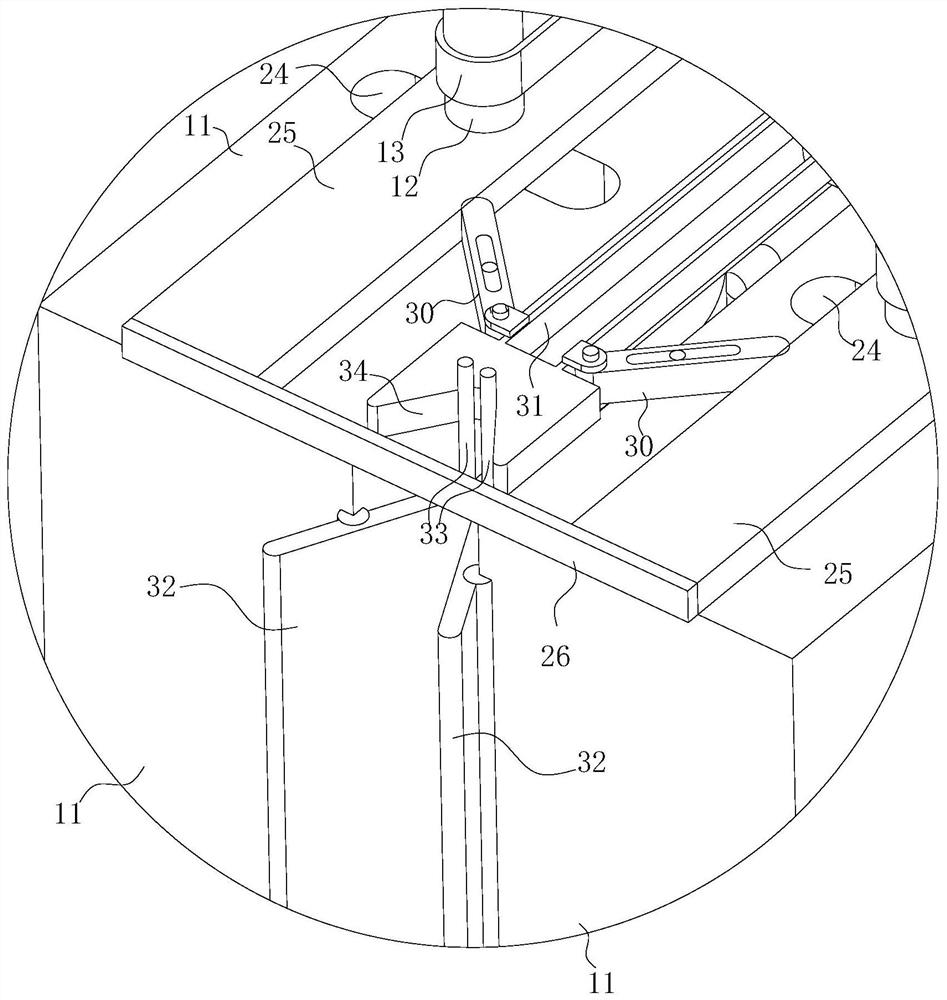

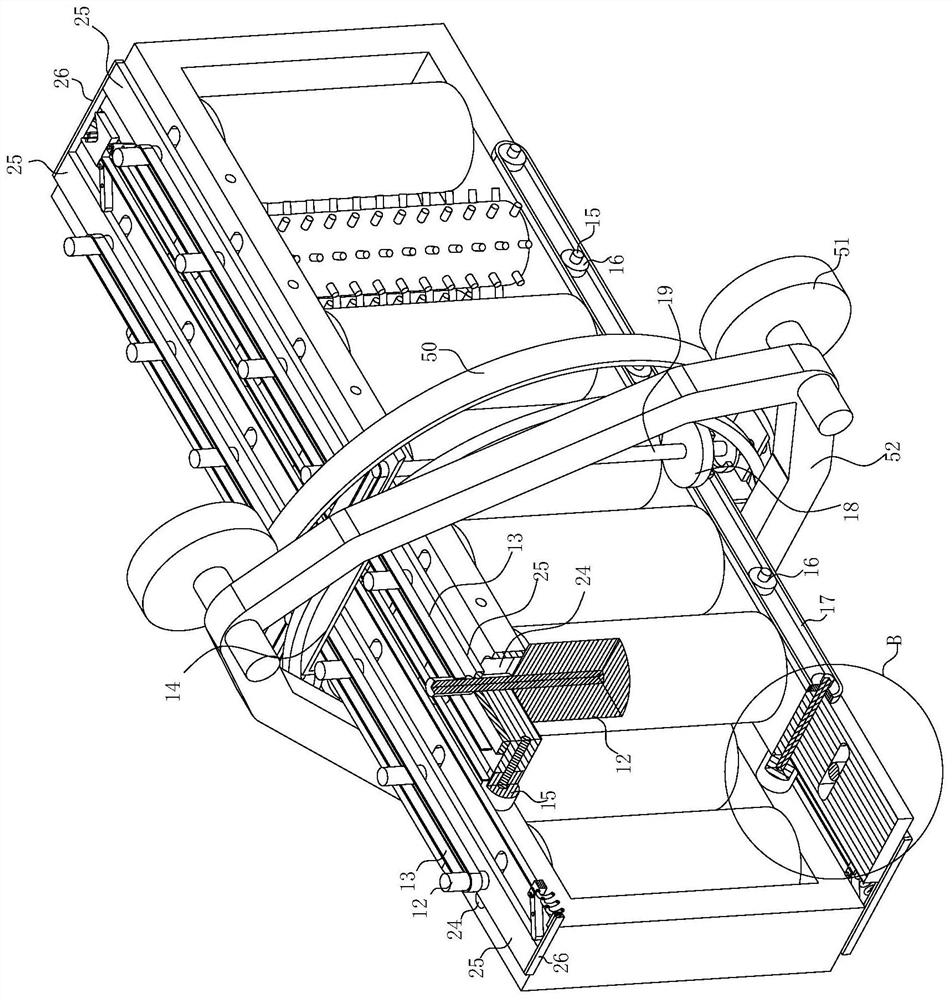

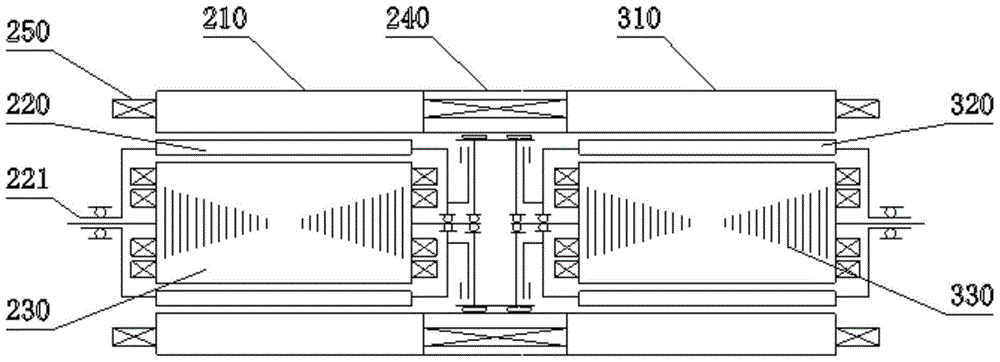

Grinding and machining device for traction table of coupler body

ActiveCN109366296AAvoid unbalanced loadAvoid eccentric wearGrinding machine componentsGrinding machinesMachiningTraction table

The invention relates to a grinding and machining device for traction tables of coupler bodies and comprises a grinding and machining device for grinding working surfaces of an upper traction table and / or a lower traction table through a cavity area between the upper traction table and / or the lower traction table of the coupler body; a radius adjusting device arranged on the grinding and machiningdevice and used for adjusting a grinding radius of the grinding and machining device; a height adjusting device which is arranged between the upper traction table and the lower traction table, installed on the radius adjusting device and used for adjusting the height of the grinding and machining device; and a circle center locating device connected to the height adjusting device and used for adjusting the height adjusting device to enable the height adjusting device to be concentric with an upper hook ear hole and a lower hook ear hole. According to the grinding and machining device for thetraction tables of the coupler bodies, the grinding and machining of the working surfaces of the upper and lower traction table is realized through positioning achieved by the upper and lower hook earholes, and the concentricity of the arc working surfaces of the upper and lower traction tables and the relative positions of the upper and lower hook ear holes is effectively improved.

Owner:CRRC YANGTZE CO LTD

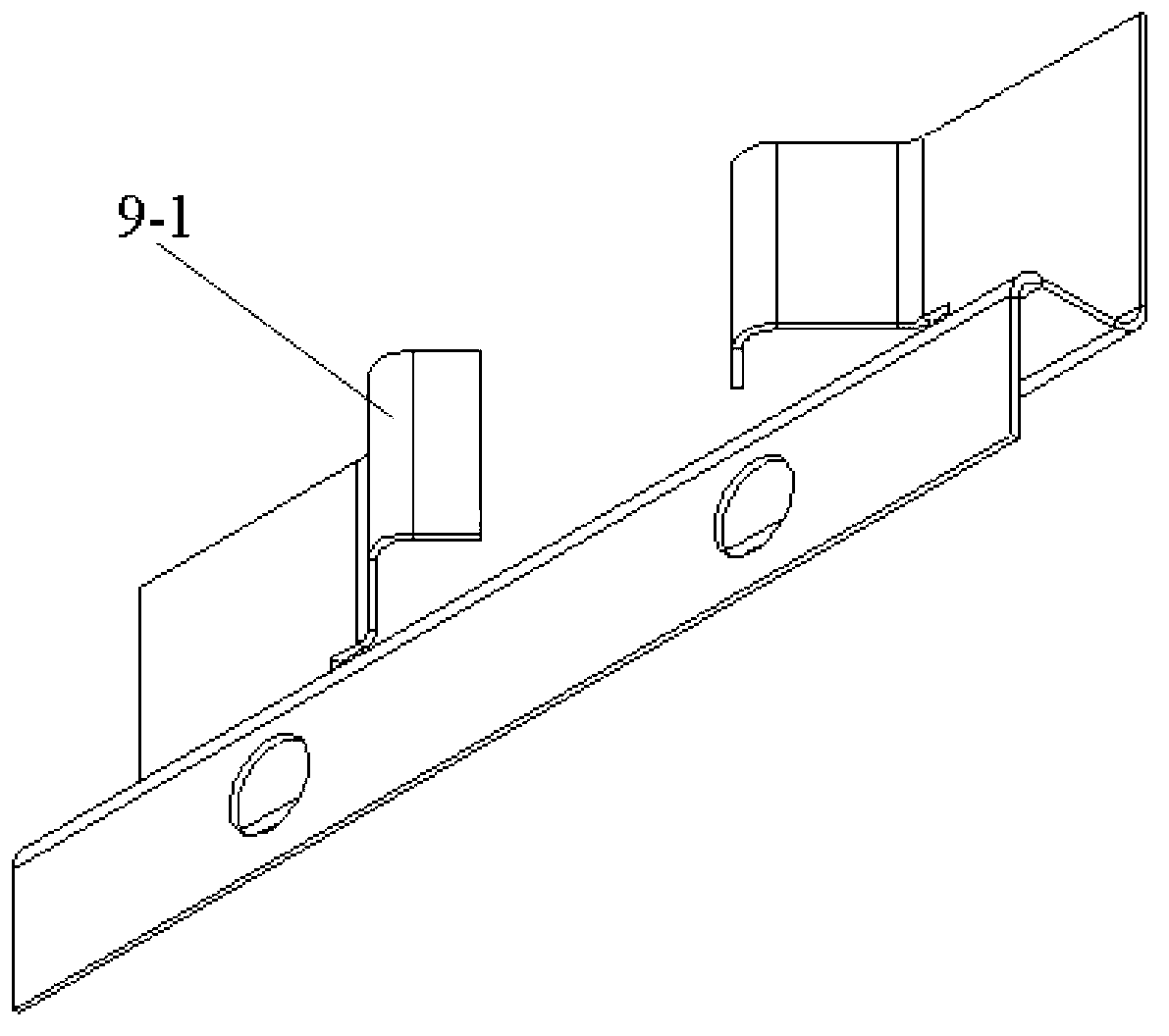

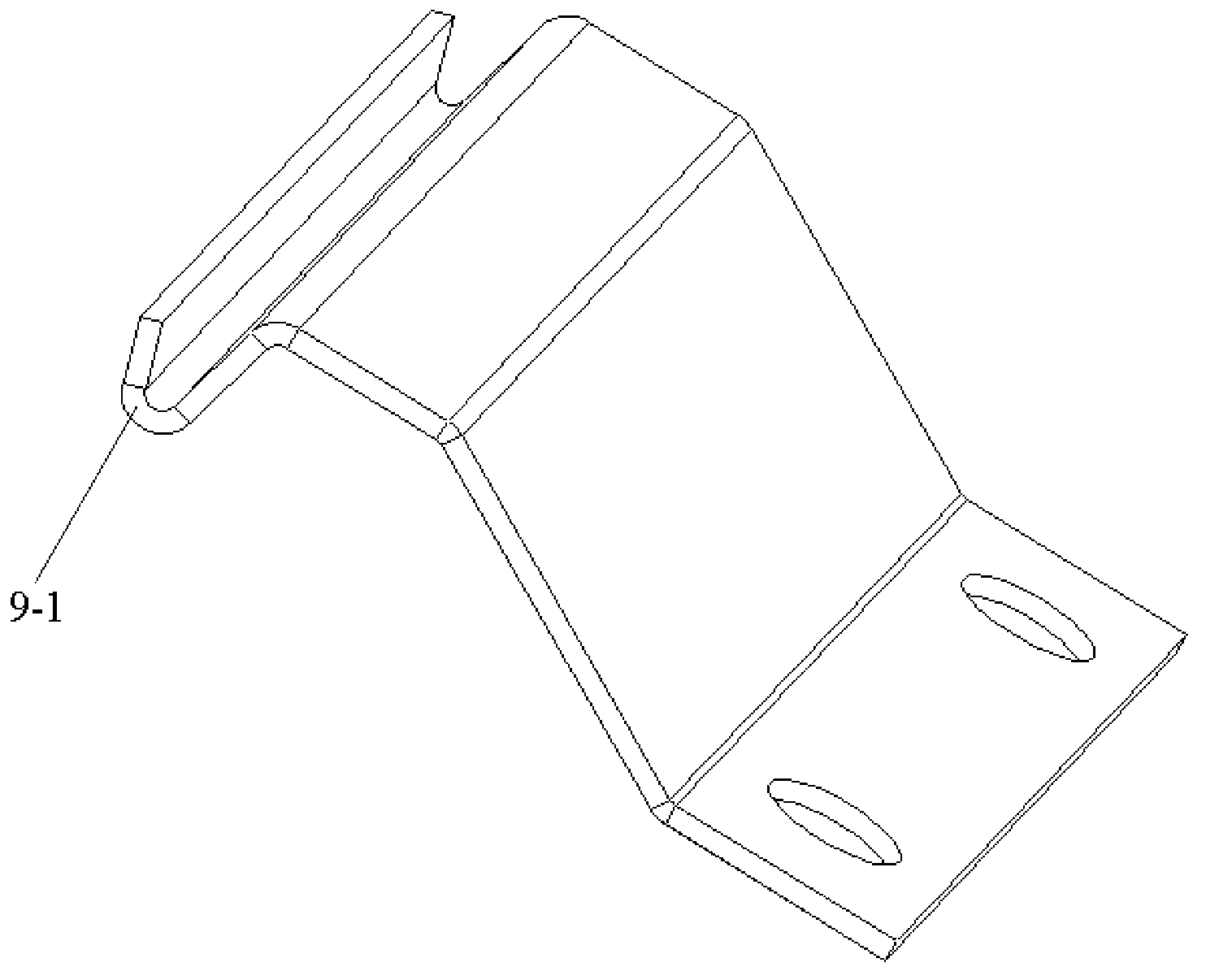

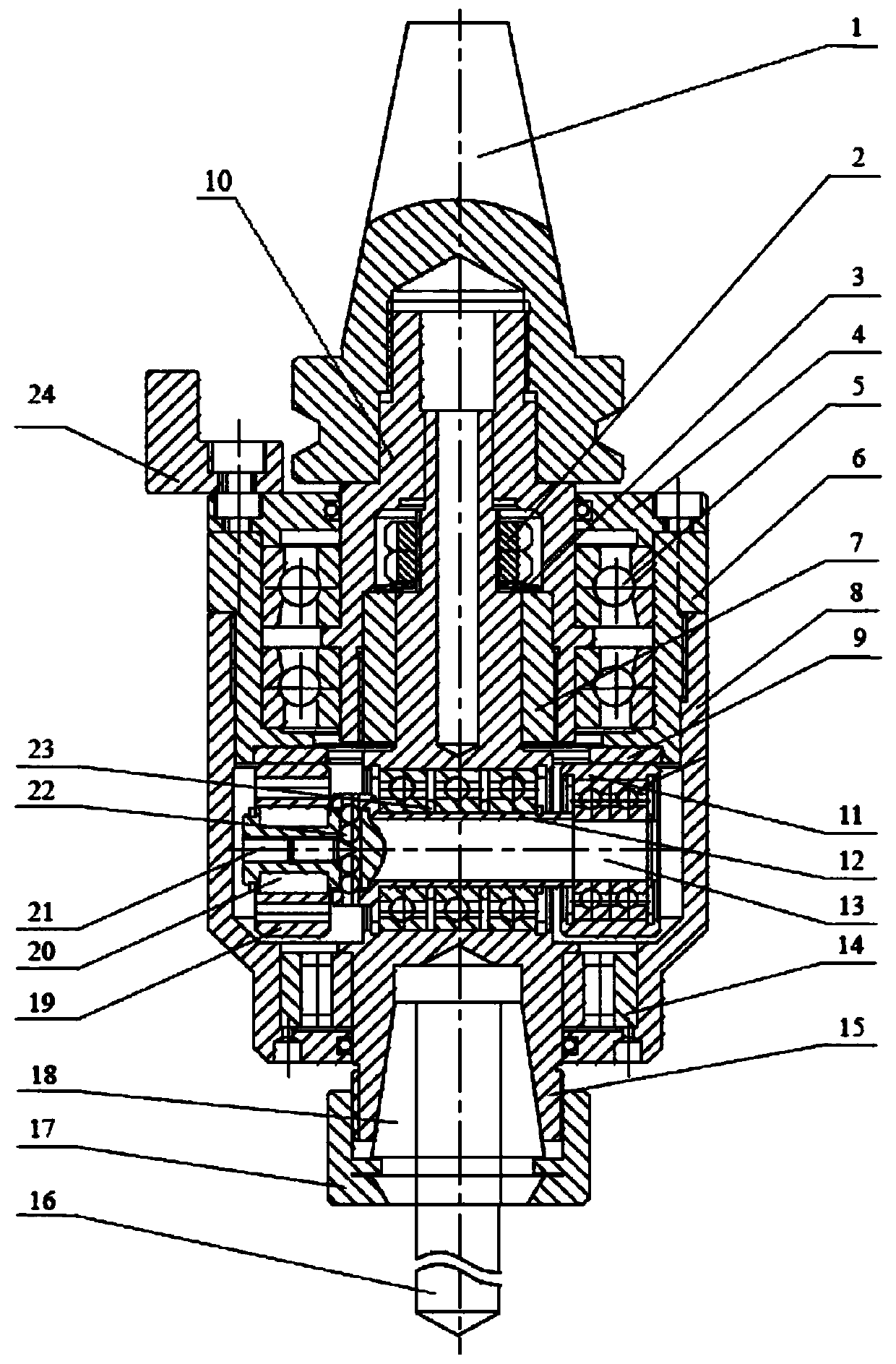

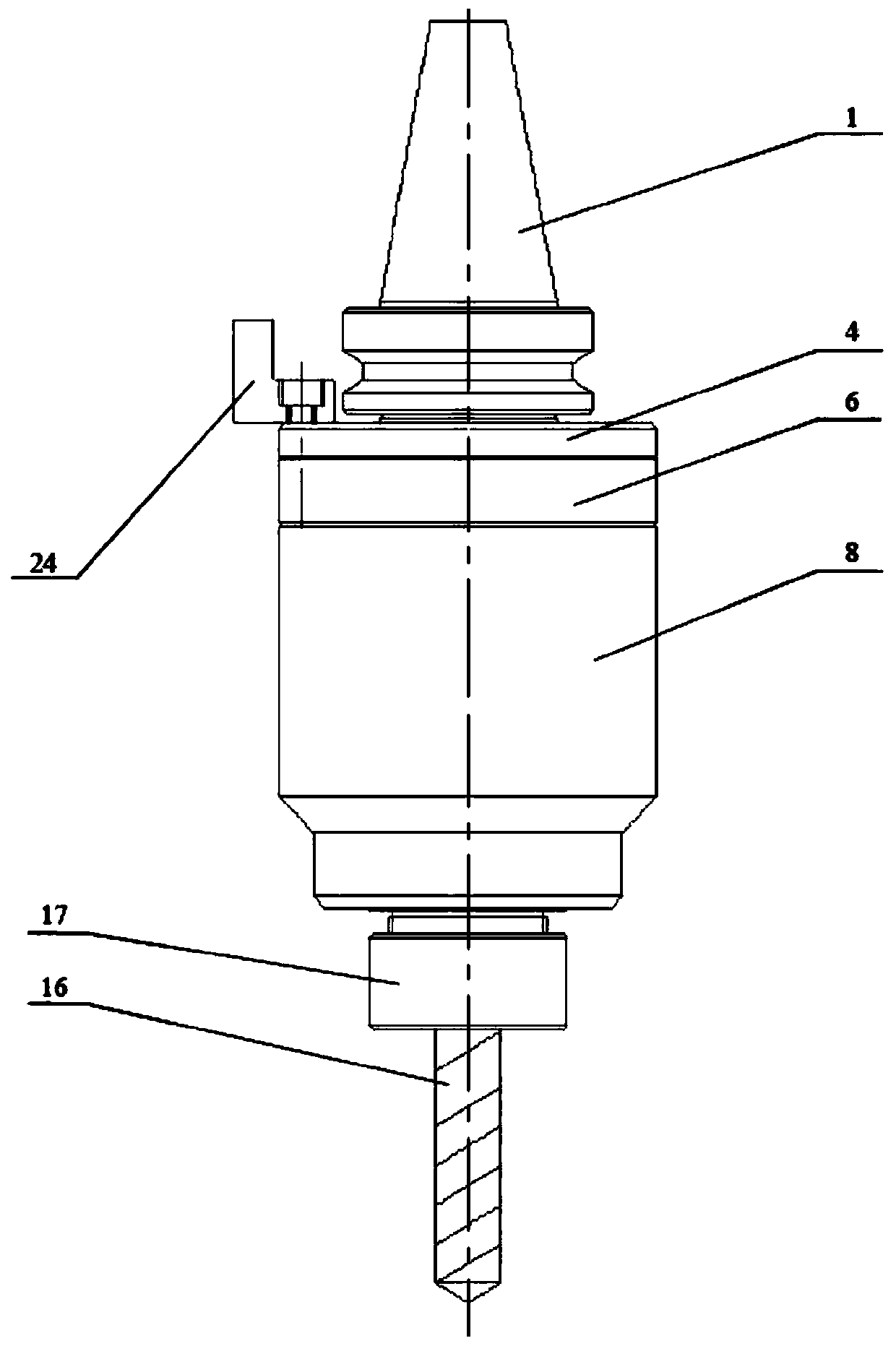

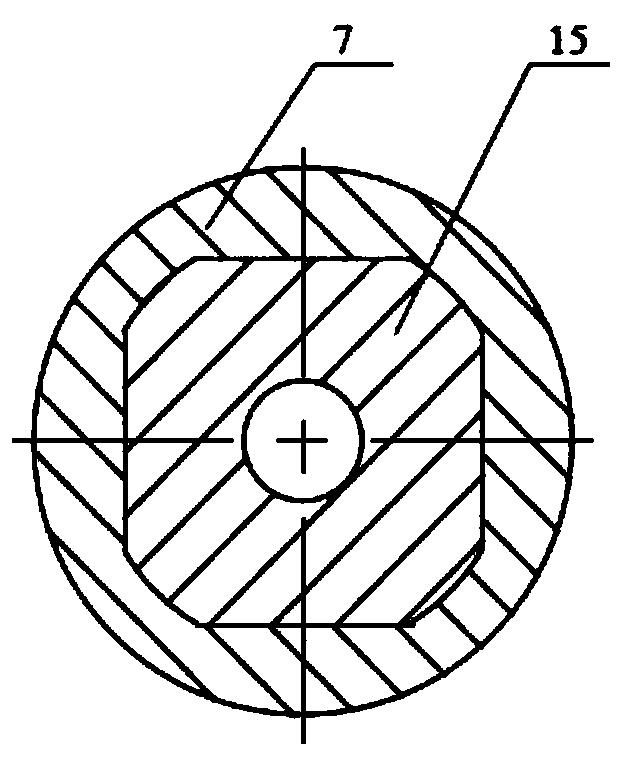

Low-frequency axial vibration drilling knife handle

InactiveCN110480068ASimple driveCompact structureTurning machine accessoriesMechanical vibrations separationBall bearingWear resistant

The invention discloses a low-frequency axial vibration drilling knife handle. The low-frequency axial vibration drilling knife handle comprises a taper handle, one end of a straight handle is installed inside the taper handle far away from a taper tip, the outer side, close to the end part of the taper handle, of the straight handle is provided with at least two angular contact ball bearings, theangular contact ball bearings are located on the two sides of a boss of the straight handle, a vibrating main shaft is installed in the straight handle, a wear-resistant transmission sleeve is arranged on the outer side of a special-shaped shaft of the vibrating main shaft in a sleeve mode, the wear-resistant transmission sleeve is connected with the inner side of the straight handle, a radial cylindrical hole is arranged in a vibration main shaft body close to the bottom of the special-shaped shaft, an eccentric shaft assembly is installed in the cylindrical hole, a taper hole is formed towards the vibration main shaft body along the other end of the vibration main shaft, an elastic chuck is arranged in the taper hole, a drill bit is clamped in the elastic chuck, a cylindrical roller bearing is installed on the outer side of the other end of the vibration main shaft, a locking nut is installed on the outer side of the end part of the vibration main shaft, and the end part of the elastic chuck is clamped in the locking nut. According to the low-frequency axial vibration drilling knife handle, the rotary motion of the machine tool main shaft is converted into rotary motion and low-frequency axial vibration of the vibration main shaft, and the universality is wide.

Owner:XIAN UNIV OF TECH

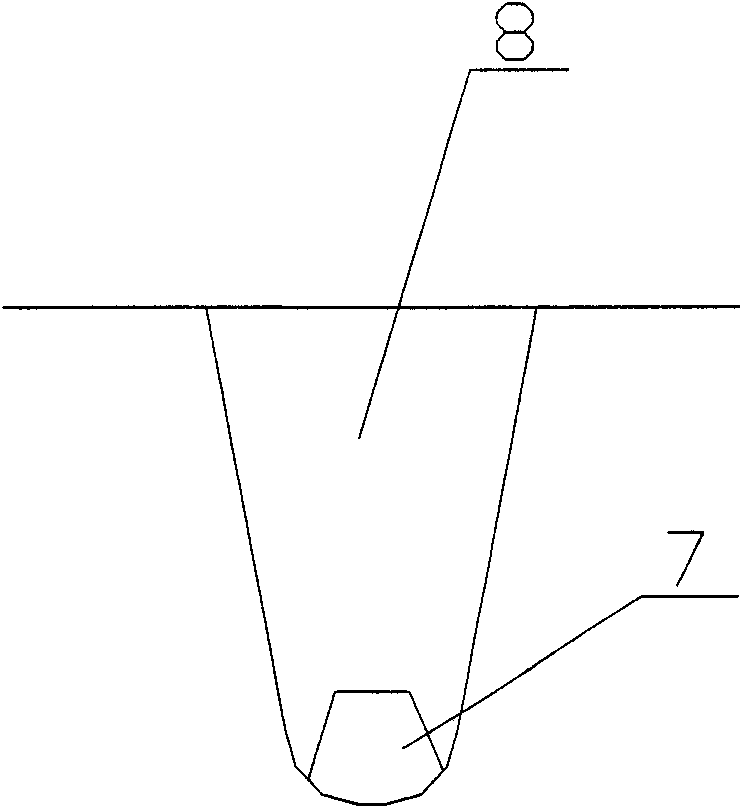

Novel absorber capable of effectively avoiding eccentric abrasion of connecting rod

ActiveCN106090106AAvoid partial wearAvoid eccentric wearSpringsResilient suspensionsEngineeringScrew thread

The invention provides a novel absorber capable of effectively avoiding eccentric abrasion of a connecting rod. The novel absorber solves the problem that when an existing absorber is used, the connecting rod is prone to eccentric abrasion. The novel absorber comprises the connecting rod, a guider and a recovery buffering block, wherein the connecting rod penetrates through an inner cylinder barrel of the absorber. At least two threads with semi-circular cross sections are machined on the surface of the connecting rod from the lower end to the upper portion. The inner cylinder barrel is composed of an upper inner cylinder barrel body and a lower cylinder barrel body which are connected through a circular nut. A thread of the circular nut is matched with the threads on the connecting rod. The two end faces of the circular nut are each provided with a groove, wherein the depth of each groove is 3 mm, the width of each groove is equal to the thickness of the inner cylinder barrel wall, and the grooves can be matched with the inner cylinder barrel and can keep sealing. According to the novel absorber, the eccentric abrasion of the connecting rod is effectively prevented, abrasion to the connecting rod is relieved, and therefore the service life of the absorber is prolonged.

Owner:河南天一减振器科技有限公司

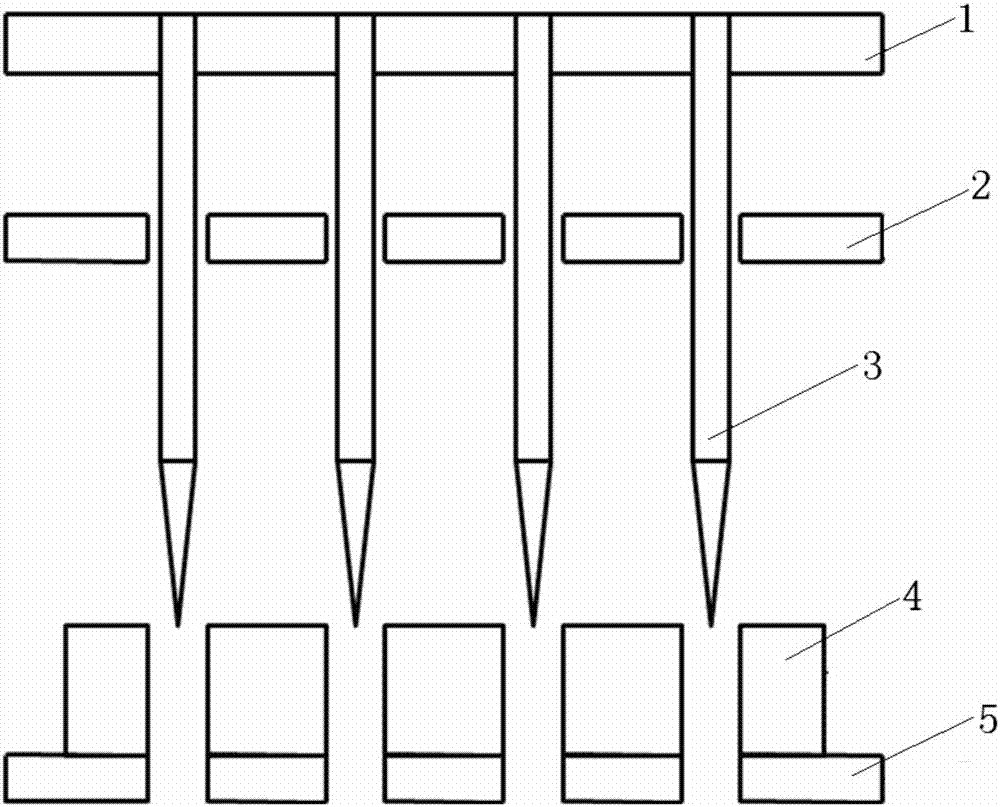

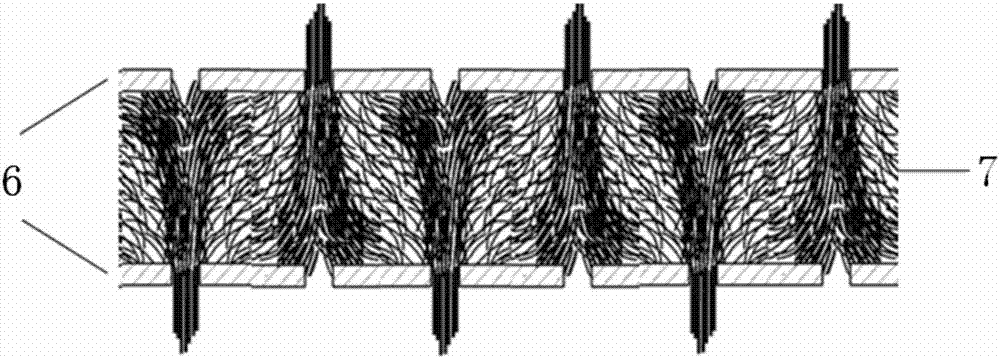

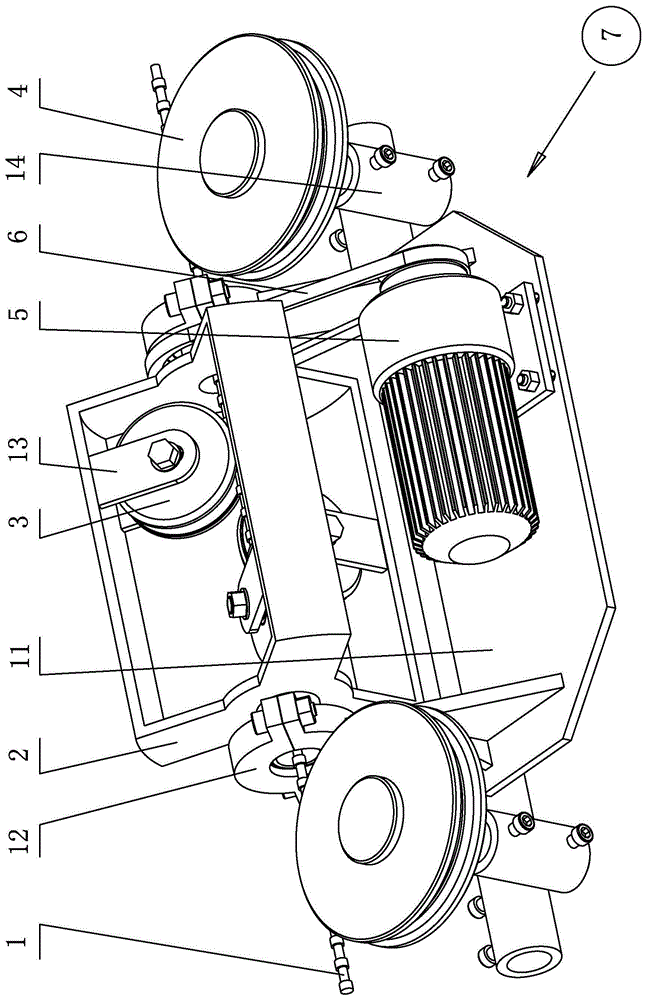

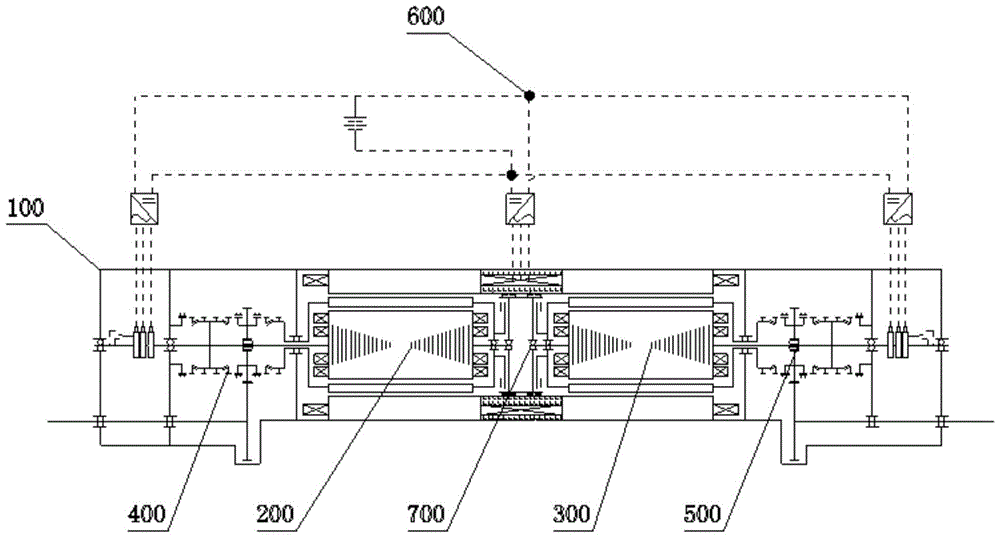

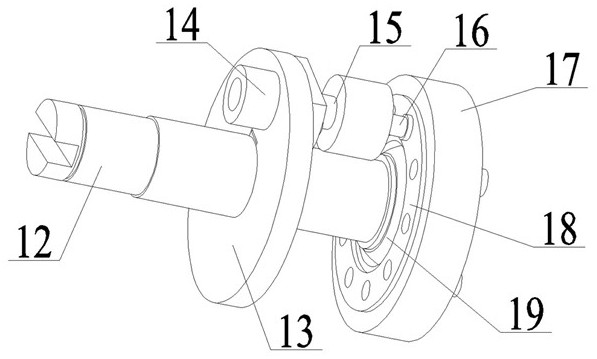

Wire saw twisting machine and method for preventing eccentric grinding of diamond wire saw by using the wire saw twisting machine

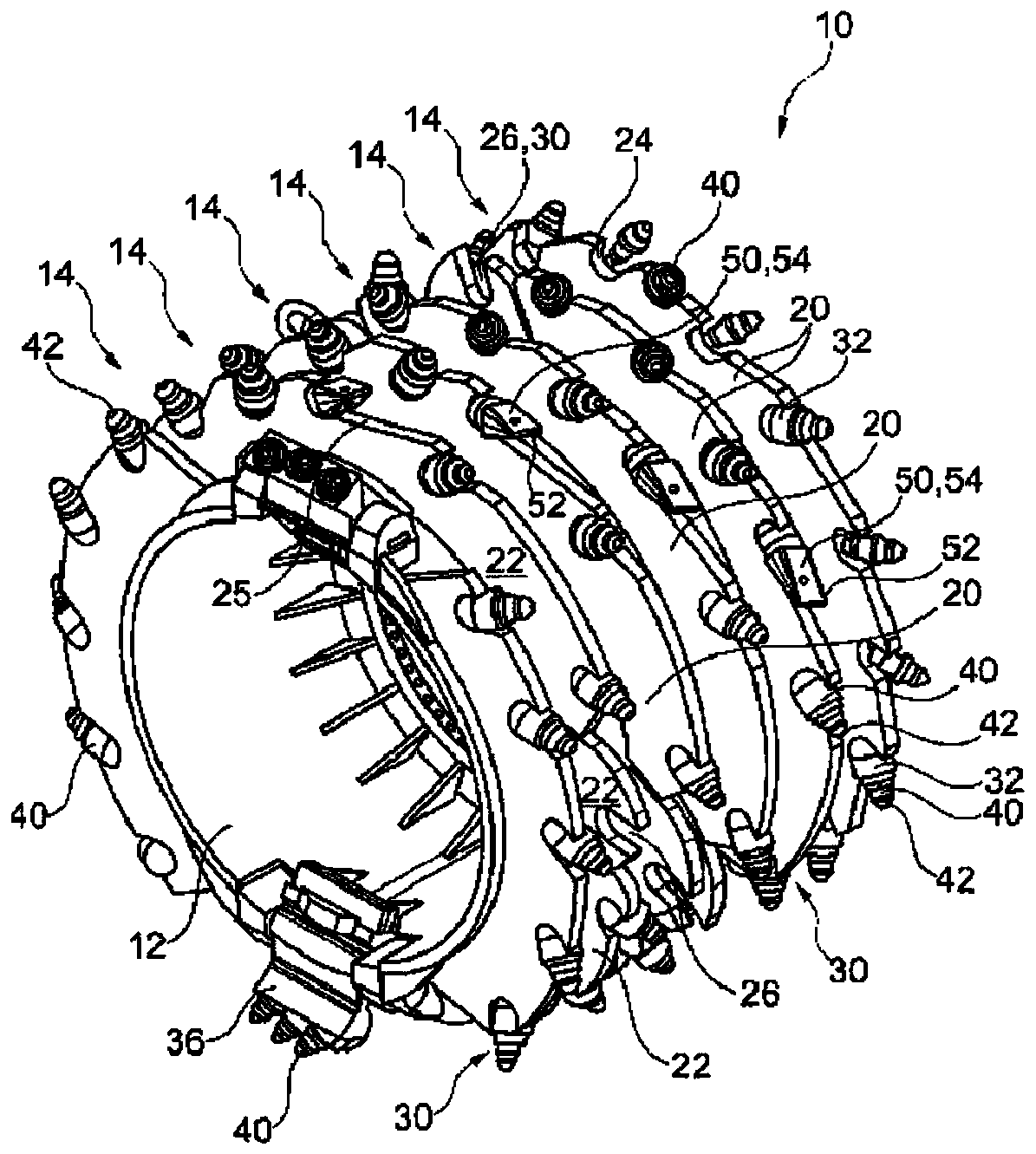

ActiveCN104786374BImprove rotation performanceAvoid eccentric wearStone-like material working toolsDiamond wire sawEngineering

The invention discloses a wire saw rotary machine. The wire saw rotary machine comprises a rotary rack which rotates coaxially with a diamond wire saw, wherein a wheel set which is formed by at least three rotary trolleys is arranged in the rotary rack; the rotary trolleys are axially arranged next to the diamond wire saw in front, middle and rear positions; the groove on the face of each of the rotary trolleys is rolled on the diamond wire saw; the included angles of the central faces of the trolley bodies between two rotary trolleys are 120 degrees; guide wheels which are located on the same side of the diamond wire saw are arranged on front and rear sides of the rotary rack; the groove of the face of each guide wheel is rolled on the diamond wire saw. A method for preventing eccentric wear of the diamond wire saw by adopting the wire saw rotary machine is implemented by arranging the wire saw rotary machine on a wire saw. The self-rotating ability of the diamond wire saw cutting is increased by virtue of the wire saw rotary machine so as to prevent eccentric wear of the diamond wire saw.

Owner:GUILIN TEBON SUPERHARD MATERIAL

A dual mechanical port drive device for electric vehicles

InactiveCN105515312BIncreased handling and stability control capabilitiesImprove controlElectric propulsion mountingElectric machinesEngineeringElectric vehicle

The invention discloses a dual mechanical port driving device for an electric automobile. The dual mechanical port driving device comprises a first driving mechanism, a second driving mechanism, a cage rotor, a first transmission mechanism and a second transmission mechanism, wherein the first driving mechanism and the second driving mechanism are coaxially arranged in parallel. The first driving mechanism and the second driving mechanism each comprise a stator and a wound rotor, wherein the stator is fixedly arranged and wound with a stator winding; and the wound rotor is rotatably arranged in the stator and can perform rotary motion to be output through a first shaft. The cage rotor is arranged between the stator and the wound rotor and performs rotary motion to be output through a second shaft. The first transmission mechanism and the second transmission mechanism are connected with the first driving mechanism and the second driving mechanism respectively, selectively output power of the first shaft or the second shaft, and can selectively fix the first shaft. According to the dual mechanical port driving device, multiple working modes can be achieved, the first driving mechanism and the second driving mechanism can be locked together, and the dual mechanical port driving device has the advantage of being high in reliability.

Owner:JILIN UNIV

Pneumatic isobaric multi-stage sealing device for wellhead of oil pumping unit

ActiveCN114673467ASave electricityLong sealing cycleDrilling rodsSealing/packingWellheadClose coupling

The invention discloses a pneumatic equal-pressure multi-stage sealing device for a wellhead of a pumping unit. Relates to the technical field of oil-gas well equipment. The lower end of the upper section is connected with the middle section through a flange and a bolt, the packing is clamped between the upper section and the middle section, and the air bag is installed in the space between the upper section and the middle section on the outer side of the packing. The device has the following beneficial effects that the air bag has an energy storage function, the packing is pressurized by continuous and uniform force, close coupling of the packing and a sucker rod is guaranteed, the hollow ball is arranged to be pushed to the center hole along the conical surface of the middle section by the pressure of the bottom of a wellhead after the rod is broken, blowout accidents are prevented, the deviation adjusting and follow-up function mechanism is automatically coaxial with the sucker rod, and the operation is convenient. The eccentric wear phenomenon is avoided, the service life of the packing and the sucker rod is prolonged, the sucker rod pushes the packing box through the centralizing sleeve, the deviation adjusting mechanism and the follow-up mechanism move flexibly along with the sucker rod, it is guaranteed that the follow-up mechanism and the sucker rod work coaxially all the time, eccentric wear is eradicated, and the service life of the sucker rod and the packing is prolonged.

Owner:DAQING DANNUO PETROLEUM TECH DEV

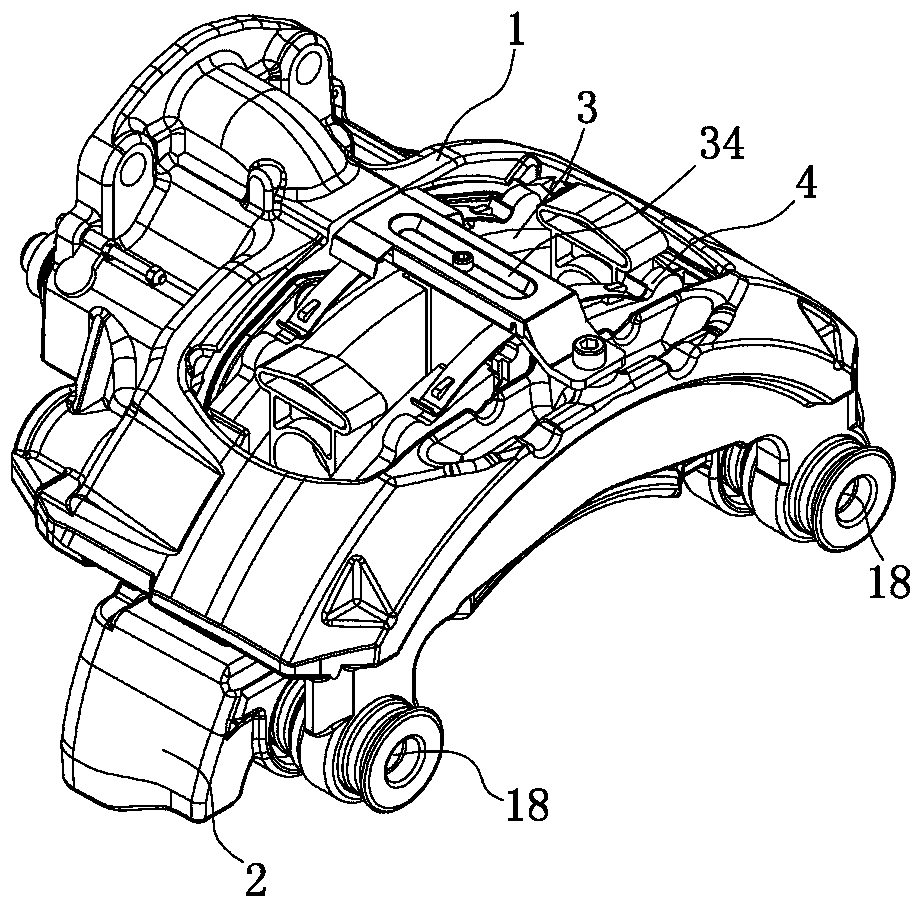

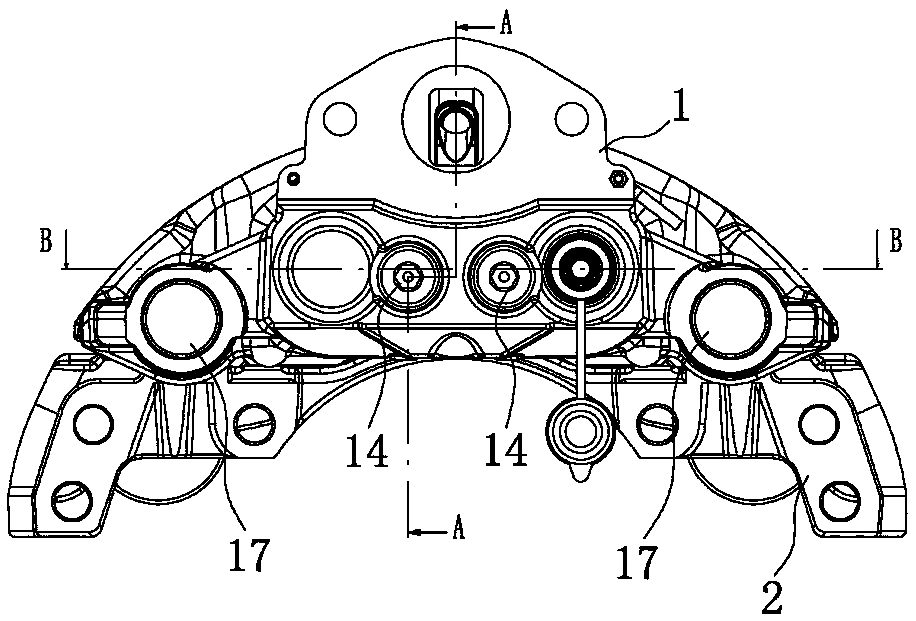

Pneumatic disc brake caliper assembly

PendingCN108626272AImprove rigidityHigh strengthAxially engaging brakesSlack adjustersEngineeringCalipers

The invention provides a pneumatic disc brake caliper assembly, and belongs to the technical field of vehicle accessories. By adoption of the pneumatic disc brake caliper assembly, the problems that an existing pneumatic disc brake caliper is poor in strength, inconvenient to machine and the like are solved. The pneumatic disc brake caliper assembly comprises a caliper body, a force-augmentation gap adjustment assembly and a support. The caliper body is of an integrated structure. A thrust support is provided with a cylindrical mounting base. A cover plate is provided with a guide groove, anda sliding bearing is arranged in the guide groove. A support reset spring is located in the mounting base and provides elastic force to make the thrust support tend to be away from the cover plate allthe time. The end, located outside a cavity, of the caliper body is provided with threaded holes which are bilaterally symmetrical. Supporting bases are connected into the two threaded holes. The inner ends of the two supporting bases protrude out of the inner wall of the cavity, and the inner end faces of the two supporting bases are located on the same plane. Positioning holes coaxial with thesupporting bases are formed in the inner ends of the supporting bases. A fixing rotary shaft is fixedly connected with positioning pins inserted into the corresponding positioning holes. The pneumaticdisc brake caliper assembly has the advantages of being good in strength, convenient to machine and position, and the like.

Owner:ZHEJIANG GUOCHANG MACHINERY CO LTD

Inner pull rod design

InactiveCN108757822AAvoid damageExtended service lifePlungersNon-rotating vibration suppressionCylinder headSteel ball

The invention discloses an inner pull rod design. The inner pull rod design comprises a first cylinder head and a second cylinder head. A fastening bolt is movably mounted at the position, near the middle, of the inner surface of one end of the first cylinder head, and a fixing seat is fixedly mounted on the outer surface of the other end of the fastening bolt. A buffer cushion block is arranged on the outer surface of one side of the fixing seat, and a first pull rod is arranged at the position, located above the fastening bolt, of the inner surface of one end of the first cylinder head. A first nut is movably mounted on the outer surface of the first pull rod, and a first connector is fixedly mounted on the outer surface of one end of the first pull rod. The inner pull rod design is provided with the buffer cushion block, the first pull rod, a second pull rod and rolling steel balls, vibration generated when the pull rods are in telescopic contact can be reduced, and the service lifeof an air cylinder can be prolonged and the unreliability of the air cylinder can be improved, the friction generated by the pull rods during moving can be further reduced, and the inner pull rod design is suitable for different working conditions and brings better use prospects.

Owner:联创企业顾问(连云港)有限公司

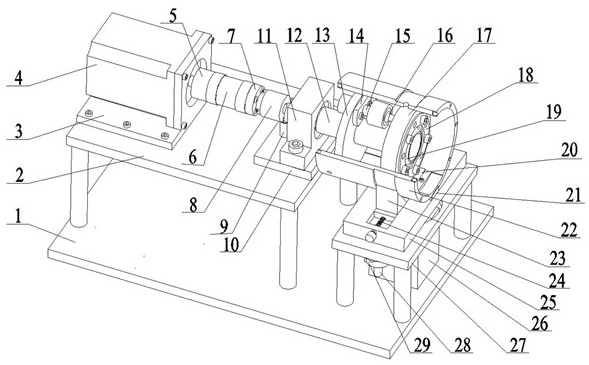

Bearing bush self-adaptive contact friction wear test device

ActiveCN112782024AAvoid eccentric wearStable full-time adaptive contactInvestigating abrasion/wear resistanceDrive shaftCoupling

The invention discloses a bearing bush self-adaptive contact friction wear test device, which relates to the field of bearing bush friction wear experiment test equipment, and mainly comprises a motor, a coupler, a torque sensor, a slip ring, a transmission shaft, a turntable, a linear bearing, a slide bar, a ball rod joint bearing, an expansion sleeve, a radial joint bearing, a bearing bush clamp, a triangular block, a force transmission plate, an air cylinder and the like. The ring sample and the bearing bush sample in the device are in sliding friction. By adding the self-adaptive contact device, the ring sample and the bearing bush sample are in full-time stable contact, the eccentric wear phenomenon is overcome, and the accuracy of a friction wear test result is improved; the loading and unloading stability of the device is improved by additionally arranging the spring at the triangular block for lifting the bearing bush clamp; oil outlets are formed in different height positions of the bearing bush clamp, so that the adaptability of a friction-wear test under various lubricating oil quantities is improved; and by simplifying the device and reducing the volume, the assembling easiness and green economy of the test device are improved.

Owner:JIANGSU UNIV OF SCI & TECH

Mining multi-tooth-head cutting tooth tool bit

InactiveCN106593440AExtended service lifeGuaranteed service lifeSlitting machinesTool bitMetallic materials

The invention provides a mining multi-tooth-head cutting tooth tool bit. The mining multi-tooth-head cutting tooth tool bit comprises a tooth body, a main tooth head, a tool bit pedestal and a tooth handle. The upper portions of the main tooth head and vice tooth heads are in conical shapes, and the lower portions of the main tooth head and the vice tooth heads are in cylindrical shapes. The tool bit pedestal is made of hard alloy materials, and a main cutting tooth groove is formed in the top face of the tool bit pedestal. The lower portion of the main tooth head is internally embedded into the main cutting tooth groove, a plurality of vice cutting tooth grooves are formed in the position, on the outer circle of the main cutting tooth groove, of the top face of the tool bit pedestal, and the lower portions of the vice tooth heads are internally embedded into the vice cutting tooth grooves. A protruding rod is arranged at the center of the bottom face of the tool bit pedestal, a sunken groove is formed in the top face of the tooth body, and the protruding rod is internally embedded in the sunken groove. The bottom face of the tool bit pedestal and the top face of the tooth body make contact with each other and are fixedly connected, and a hole used for releasing stress is formed in the bottom of the protruding rod. The tooth body is made of metal materials, and the surface of the upper portion of the tooth body is coated with a hard face alloy layer. According to the mining multi-tooth-head cutting tooth tool bit, the structure design is reasonable, abrasive resistance and impact resistance are reinforced, the tooth body is effectively protected, and the service life o the tool bit is improved.

Owner:XINCHANG HONGSHENG MACHINERY

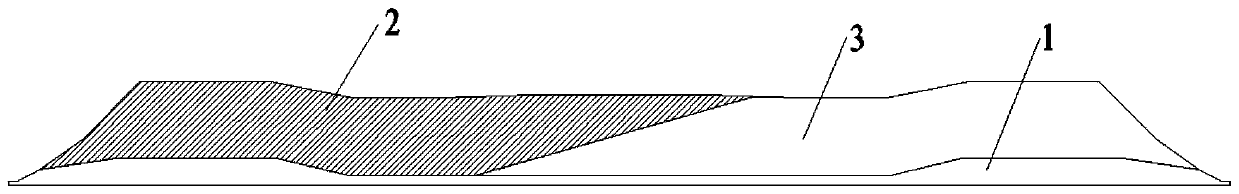

Eccentric wear prevention tread structure

InactiveCN110341383AGuaranteed uniformityImprove driving comfortTyre tread bands/patternsTire uniformityWear resistant

The invention relates to the tread structural design of pneumatic tires, and specifically relates to an eccentric wear prevention tread structure. The tread structure includes bottom base rubber and tread rubber; the tread rubber includes inner side tread rubber and outer side tread rubber; the outer side tread rubber is attached to the bottom base rubber; one side, close to a tire shoulder, of the inner side tread rubber is attached to the bottom base rubber, and the other side of the inner side tread rubber covers the outer side tread rubber; and the wear resistance of the inner side tread rubber is higher than that of the outer side tread rubber. The tread structure is suitable for automobile tires with inclination angles, the eccentric wear phenomenon on the inner sides of tires causedby the inclination angles can be effectively prevented; the inner and outer sides of the tread rubber are selected from rubber with different wear resistant degrees, so that the same weight of the left and right of the tires and the uniformity of the tires can be guaranteed, and driving comfortability of the tires during driving can be enhanced; and the wear resistance of the inner side tread rubber is designed to be higher than that of the outer side, so that the uniform abrasion of the left and right of the tires during using can be realized.

Owner:JIANGSU GENERAL SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com