Low-frequency axial vibration drilling knife handle

A technology of axial vibration and drilling, applied in the direction of vibrating fluid, turning equipment, toolholder accessories, etc., can solve the problem of high cost, achieve the effect of compact structure, strong versatility, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

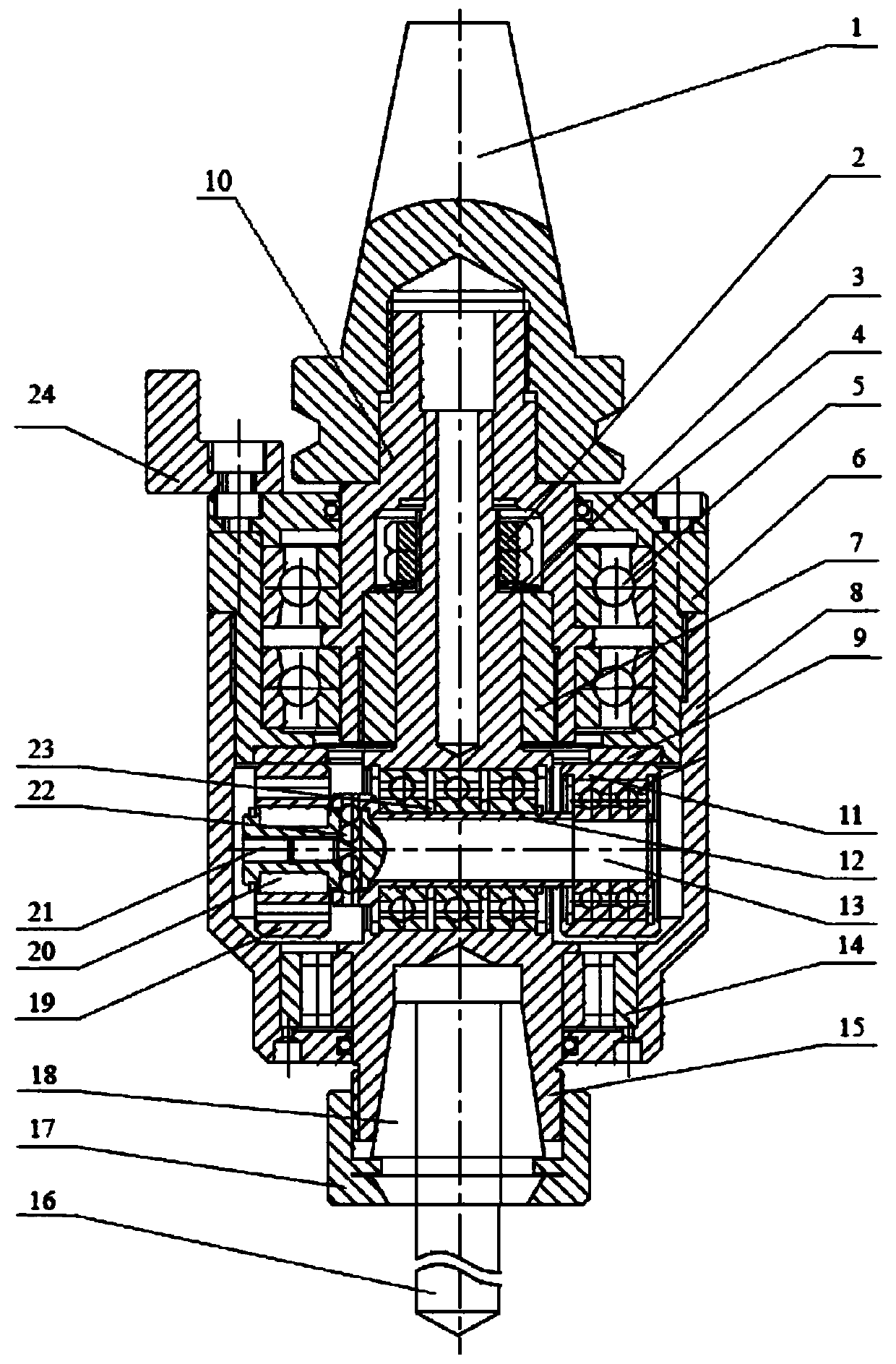

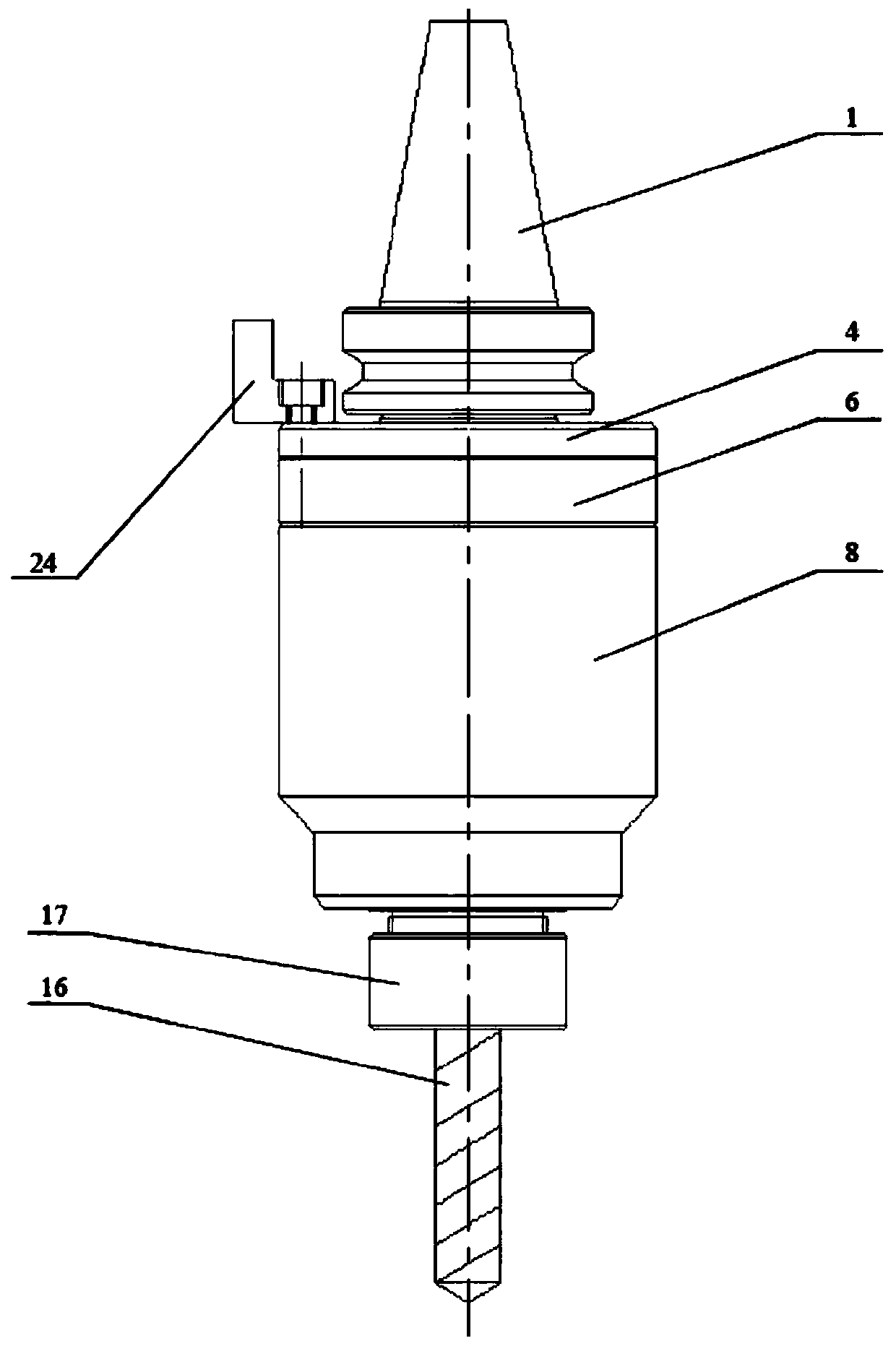

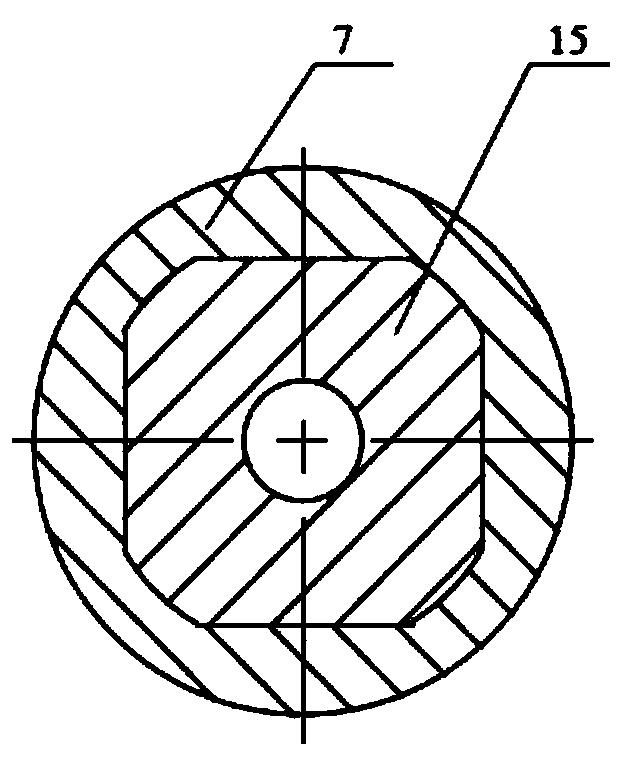

[0036] The low-frequency axial vibration drilling tool holder of the present invention, such as figure 1 , 2As shown, including the taper shank 1, one end of the straight shank 10 is installed in the taper shank 1 away from the taper tip, and the outside of the straight shank 10 near the end of the taper shank 1 is provided with two angular contact ball bearings 5, and the two angular contact ball bearings The bearing 5 is located on both sides of the boss of the straight handle 10, and the vibration main shaft 15 is installed in the straight handle 10, and the outer side of the special-shaped shaft of the vibration main shaft 15 is covered with a wear-resistant transmission sleeve 7, and the wear-resistant transmission sleeve 7 is connected with the inner side of the straight handle 10 , the body of the vibration main shaft 15 near the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com