Patents

Literature

431 results about "Complex materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex Materials. Complex Materials are a R&D part used in high level research and development plans, starting with level II ones. Obtained from. The items can be salvaged from high level gear and weapons at R&D Stations.

Anode active material, method of manufacturing the same, and lithium battery using the same

ActiveUS20070077490A1Large capacityGood capacity retentionNon-aqueous electrolyte accumulatorsElectrode thermal treatmentCarbon layerMetal alloy

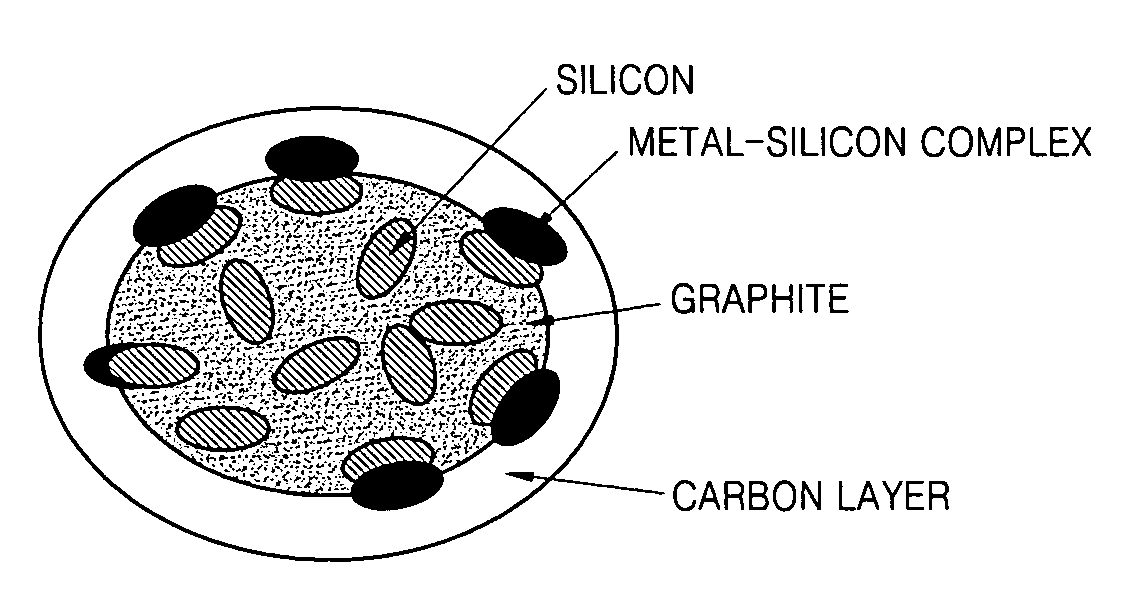

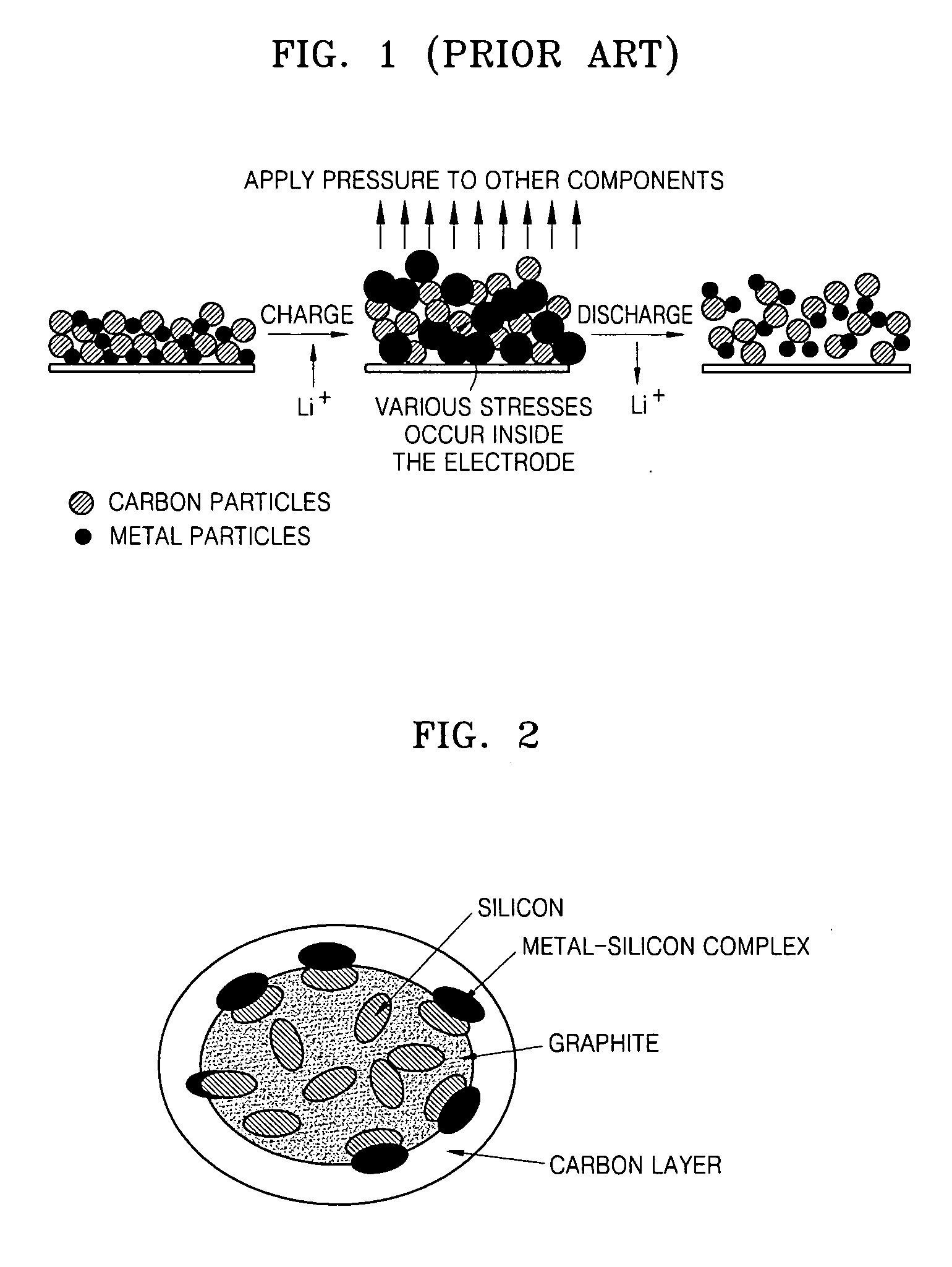

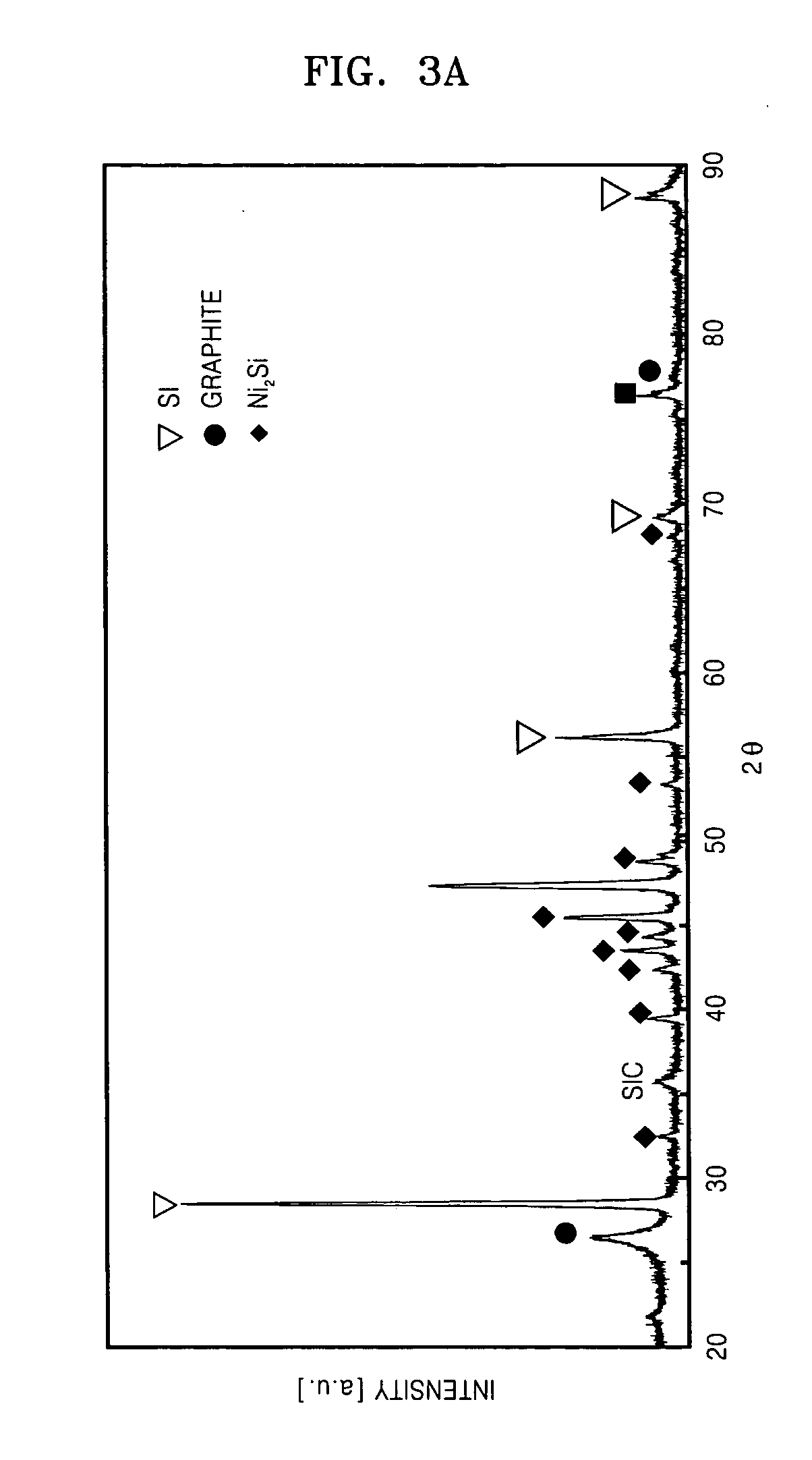

Anode active materials, methods of producing the same and lithium batteries using the same are provided. More particularly, an anode active material having high capacity and excellent capacity retention, a method of producing the same and a lithium battery having a long lifespan using the same are provided. The anode active material comprises complex material particles comprising silicon and graphite, a carbon layer covering the surface of the complex material particles, and a silicon-metal alloy formed between the complex material particles and the amorphous carbon layer.

Owner:SAMSUNG SDI CO LTD

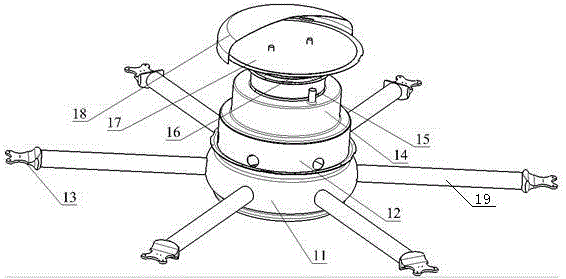

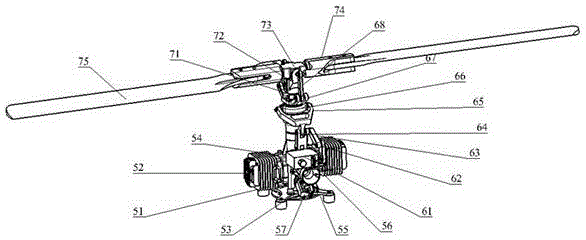

Direct-driven type oil-driving fixed-rotating-speed propeller pitch changing multi-rotor unmanned aerial vehicle and controlling method thereof

InactiveCN106697278ASimple structureReduce weightPropellersWeight reductionComplex materialsPropeller

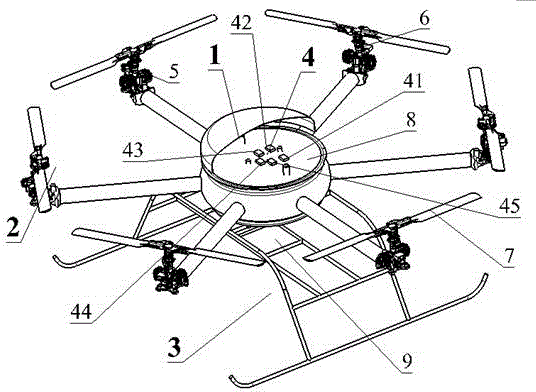

The adopted technical scheme of the invention is a direct-driven type oil-driving fixed-rotating-speed propeller pitch changing multi-rotor unmanned aerial vehicle and a controlling method thereof. The direct-driven type oil-driving fixed-rotating-speed propeller pitch changing multi-rotor unmanned aerial vehicle comprises a vehicle body, a power system, a landing gear and an avionic system. The vehicle body is a total complex material integrated vehicle body. The power system is composed of engine systems, propeller pitch changing systems, an oil supplying system and rotor systems. The landing gear is a skid landing gear. A flexible hoisting position is arranged on the landing gear to be fixedly connected with different task devices. A driving mechanism is not needed, the structure is simple, and the weight is reduced relatively by 10%-20%. Lifting force is adjusted through a propeller pitch changing angle, the abrasion of an engine is small, and the life is prolonged by 30% or above. The vehicle body adopts nested-type placement. The oil supplying system, a power supply system, a spraying system and the like are arranged inside the vehicle body, so that the space utilization rate is improved, and waste resistance is reduced.

Owner:海南艾锐奥科技有限公司

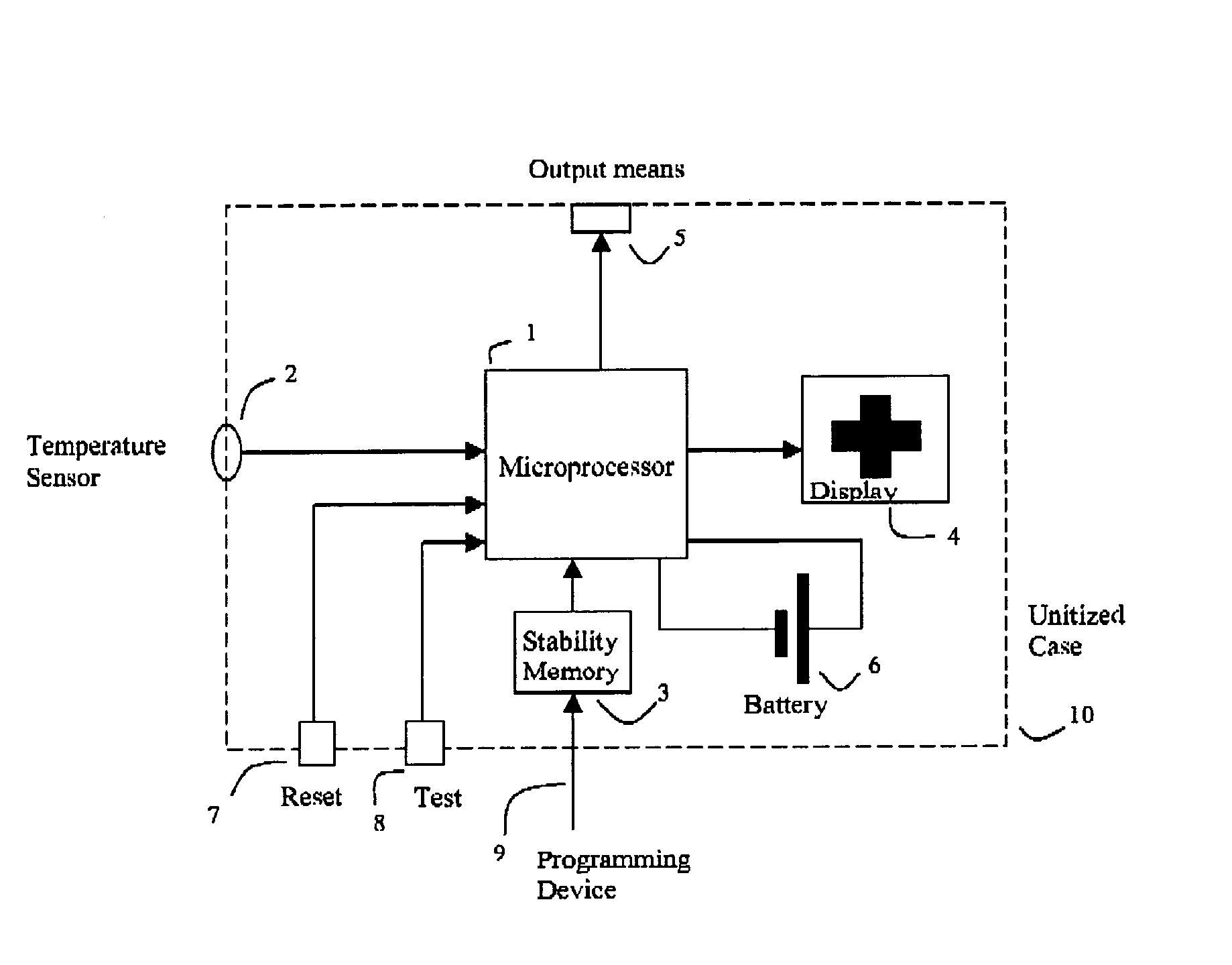

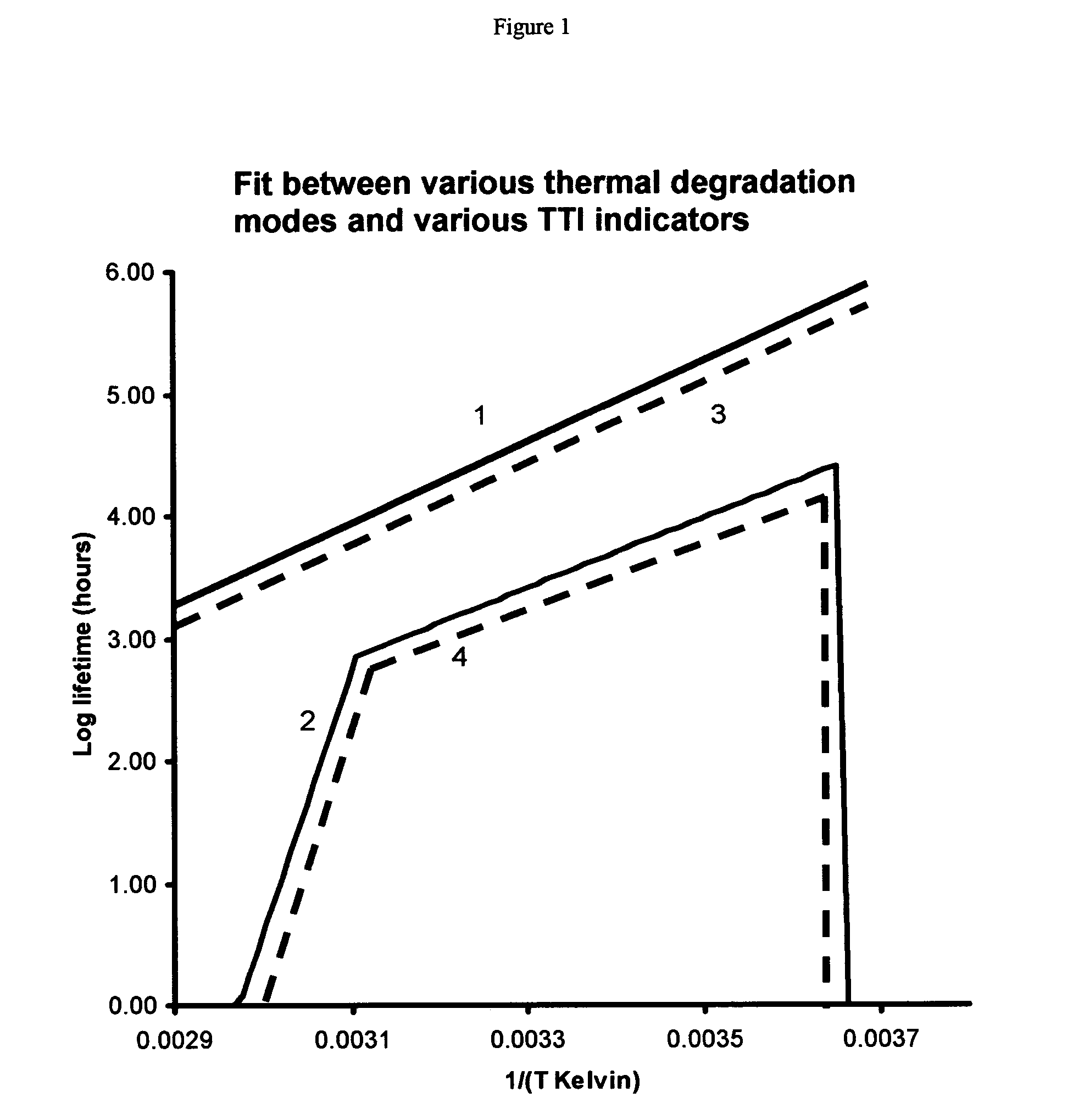

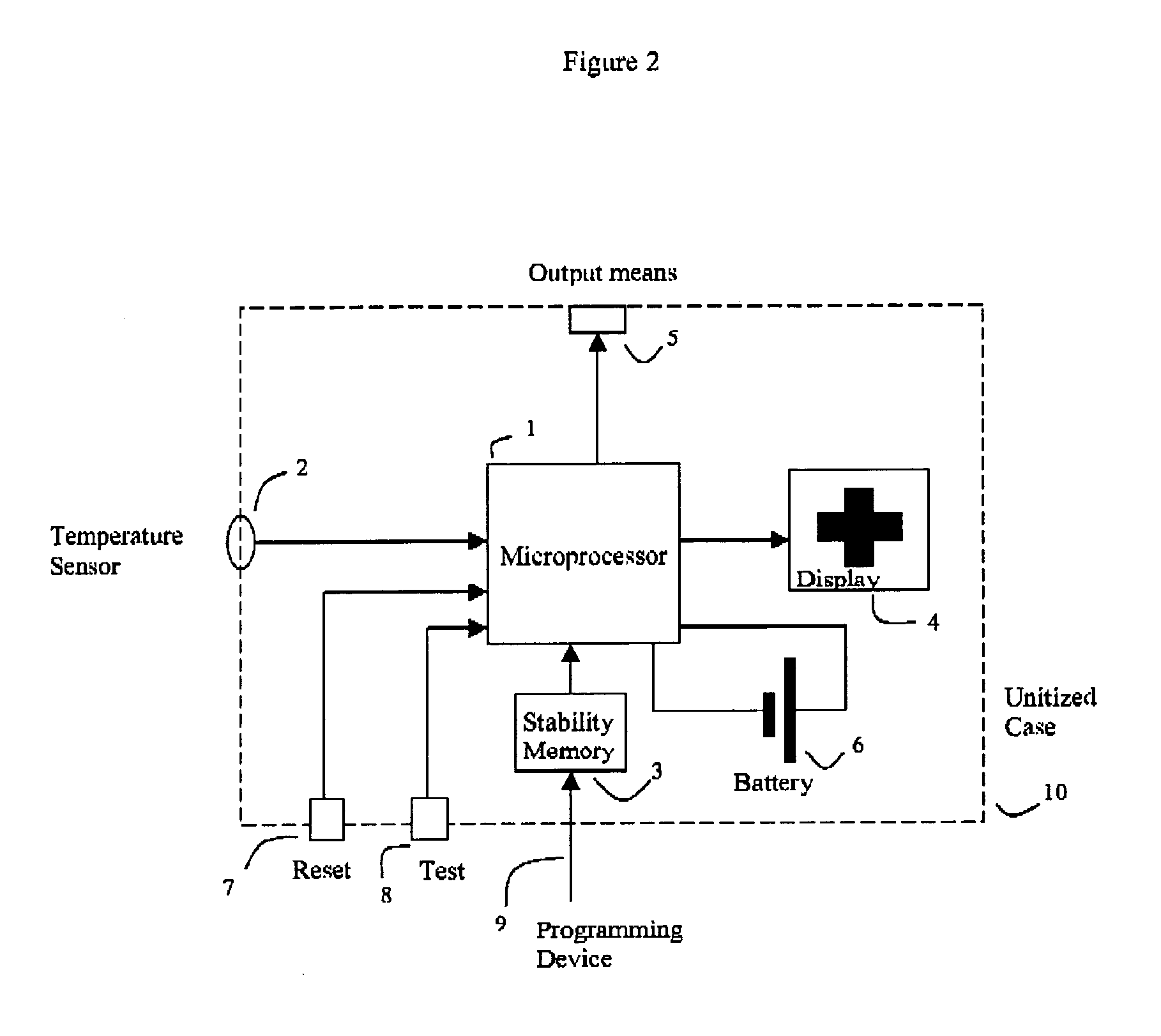

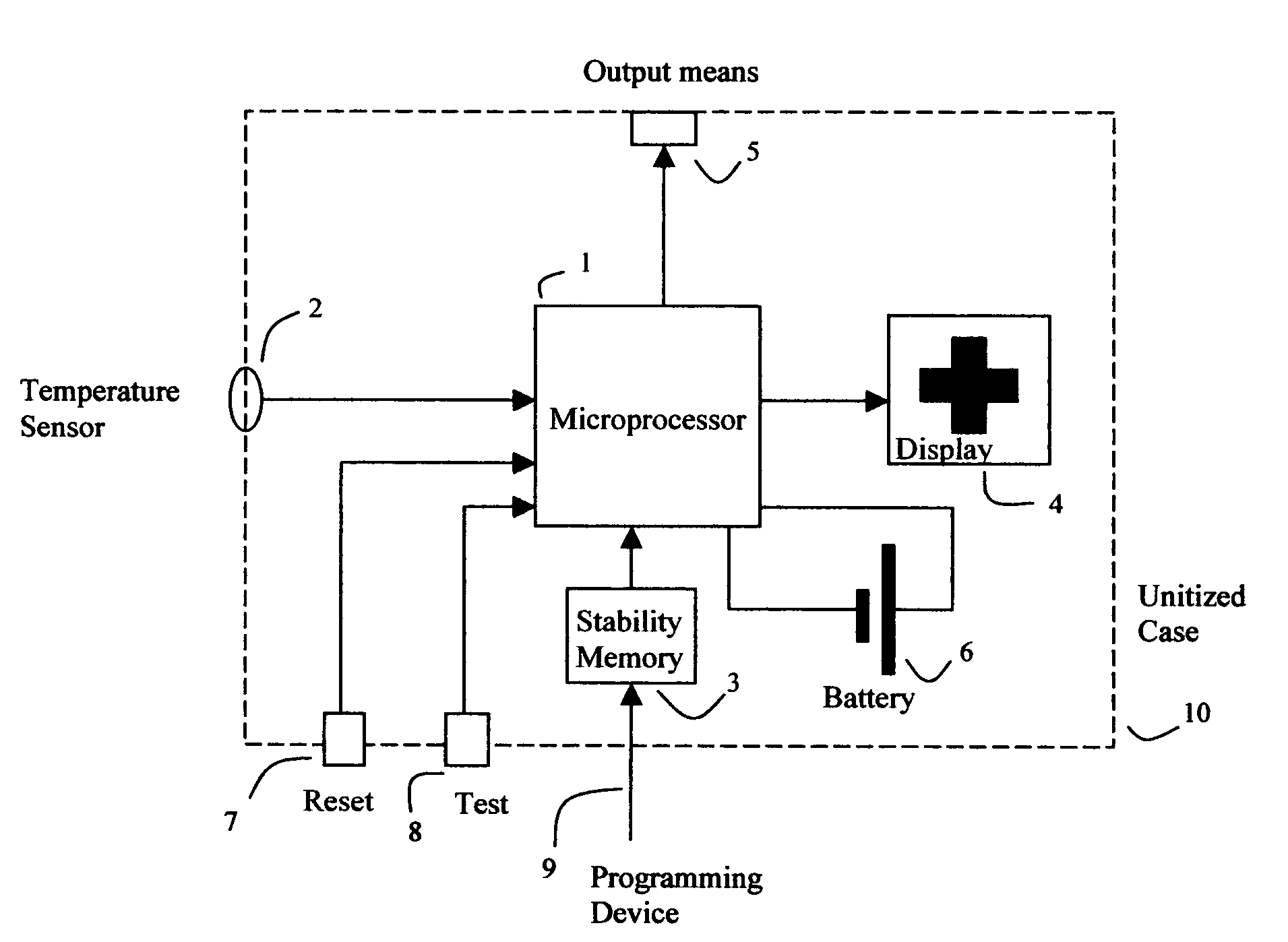

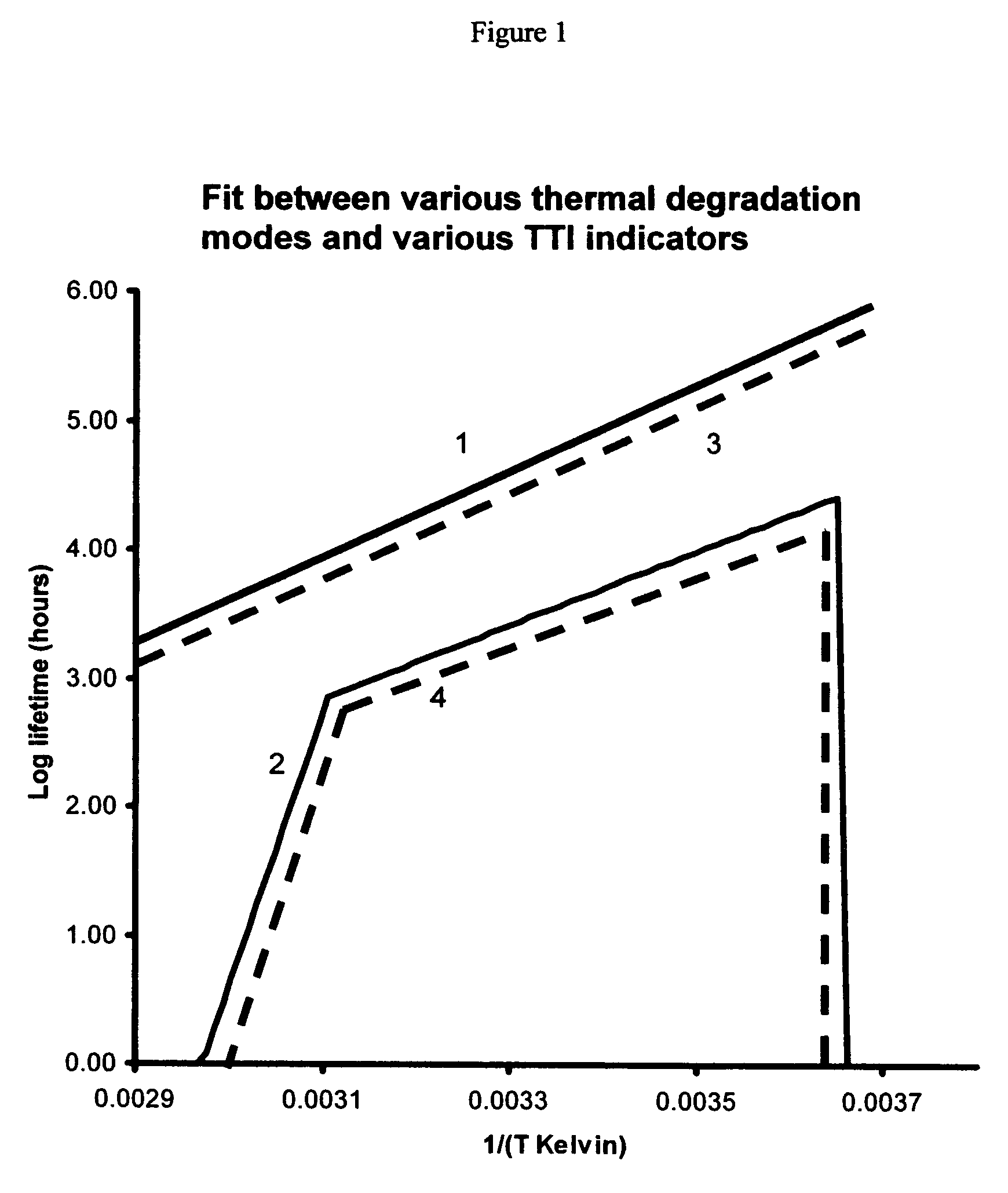

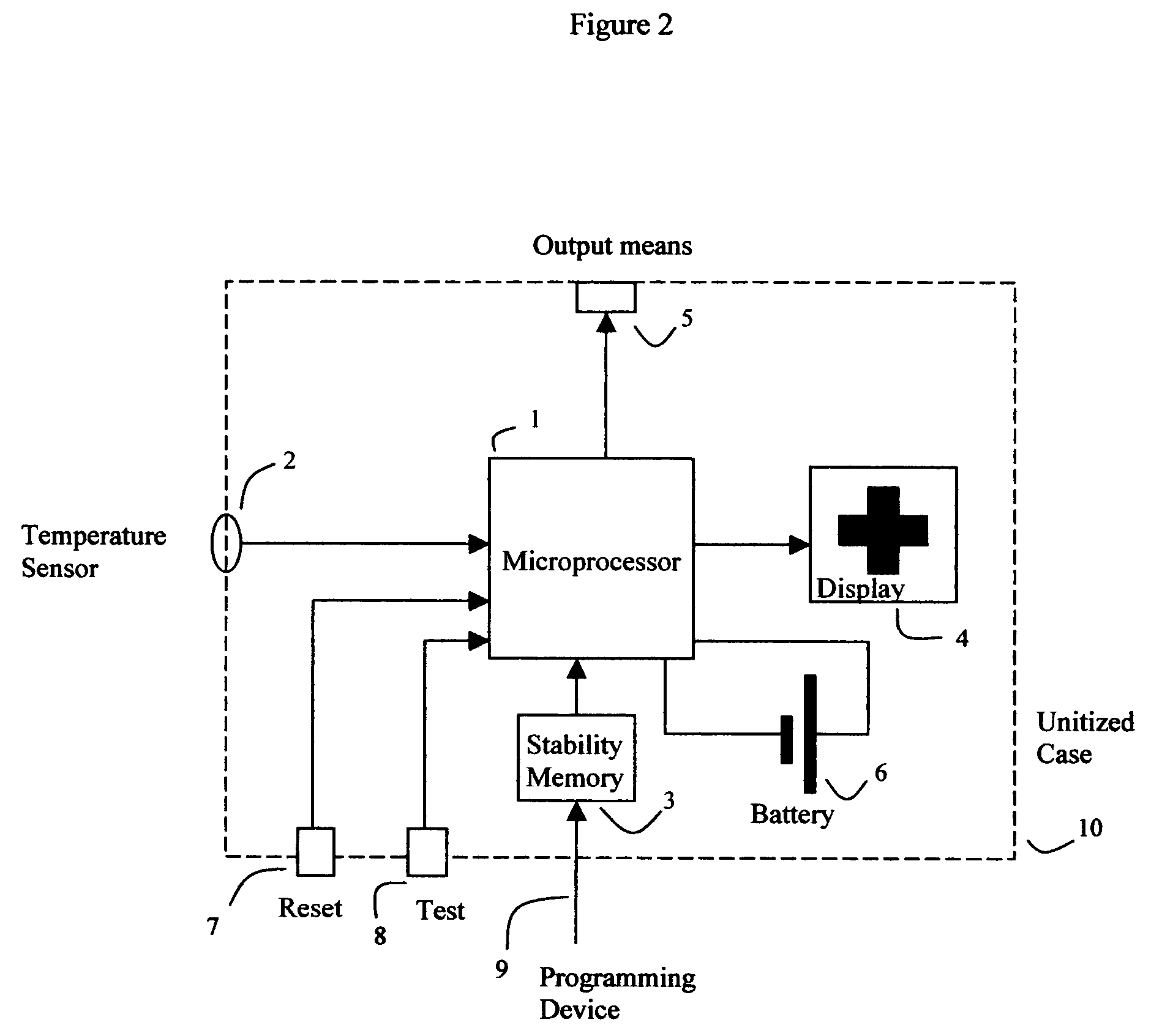

Electronic time-temperature indicator and logger

InactiveUS7102526B2Improve protectionEasily and precisely customizedThermometer detailsThermometers using mean/integrated valuesData transmissionComputer science

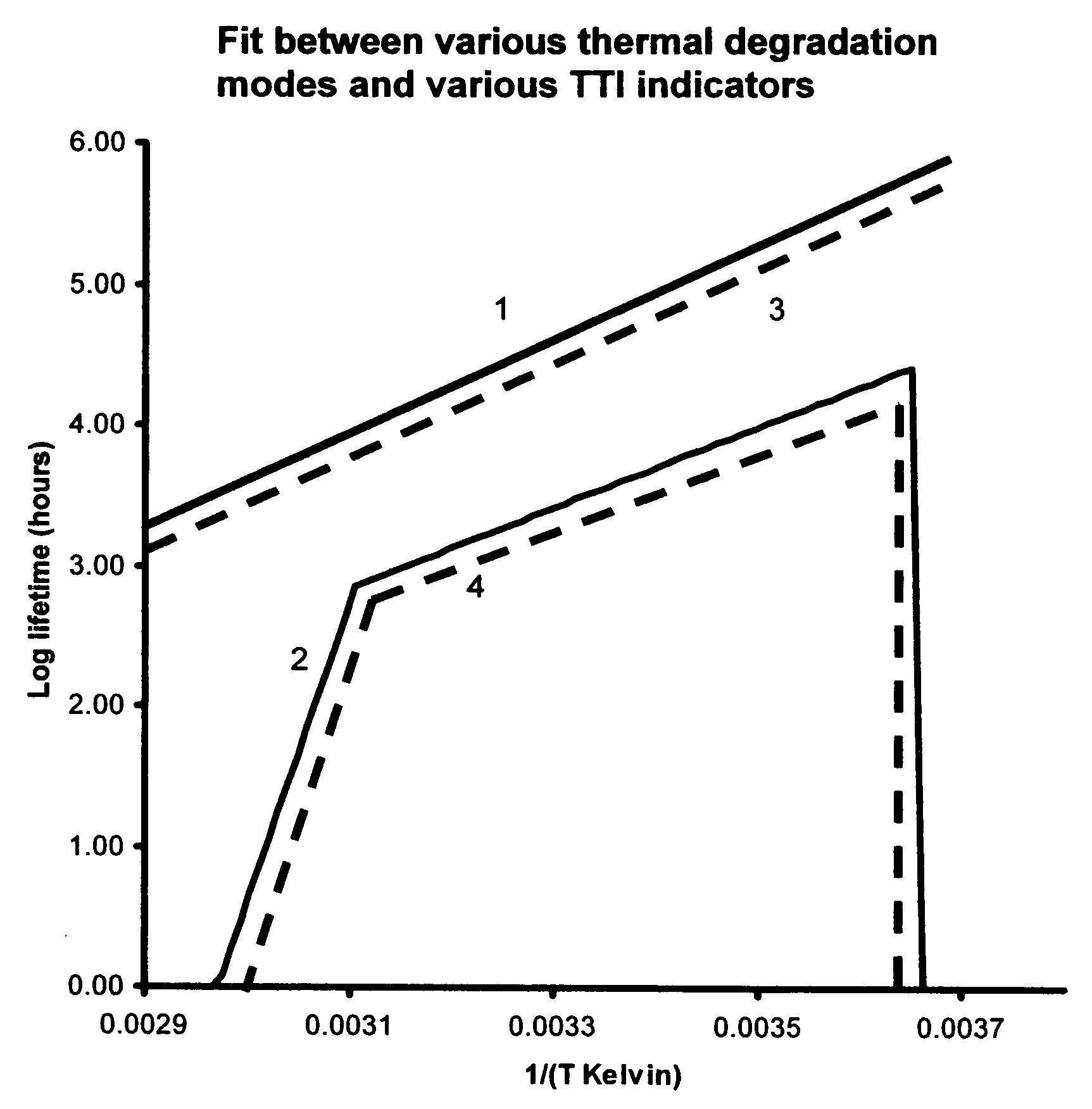

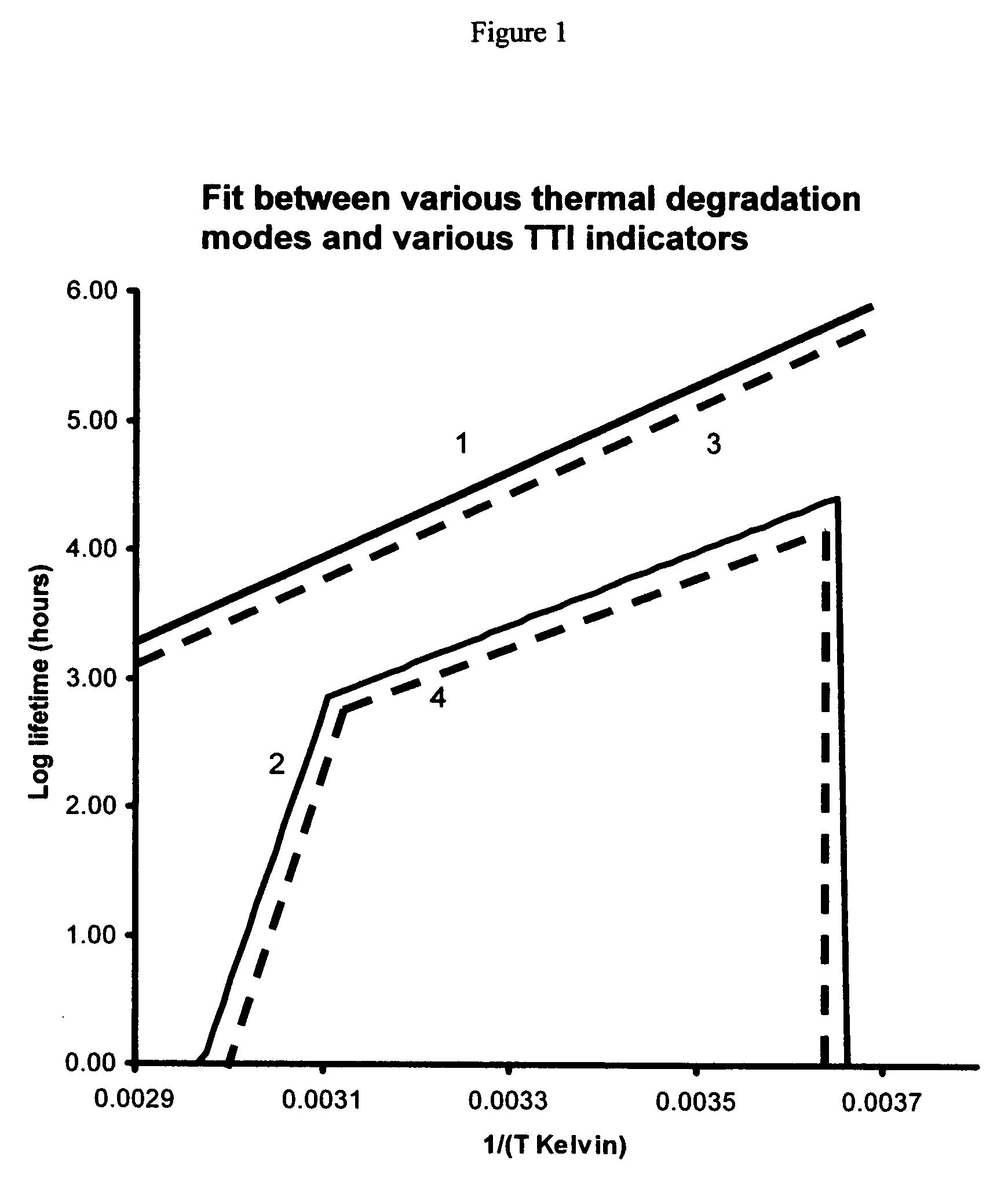

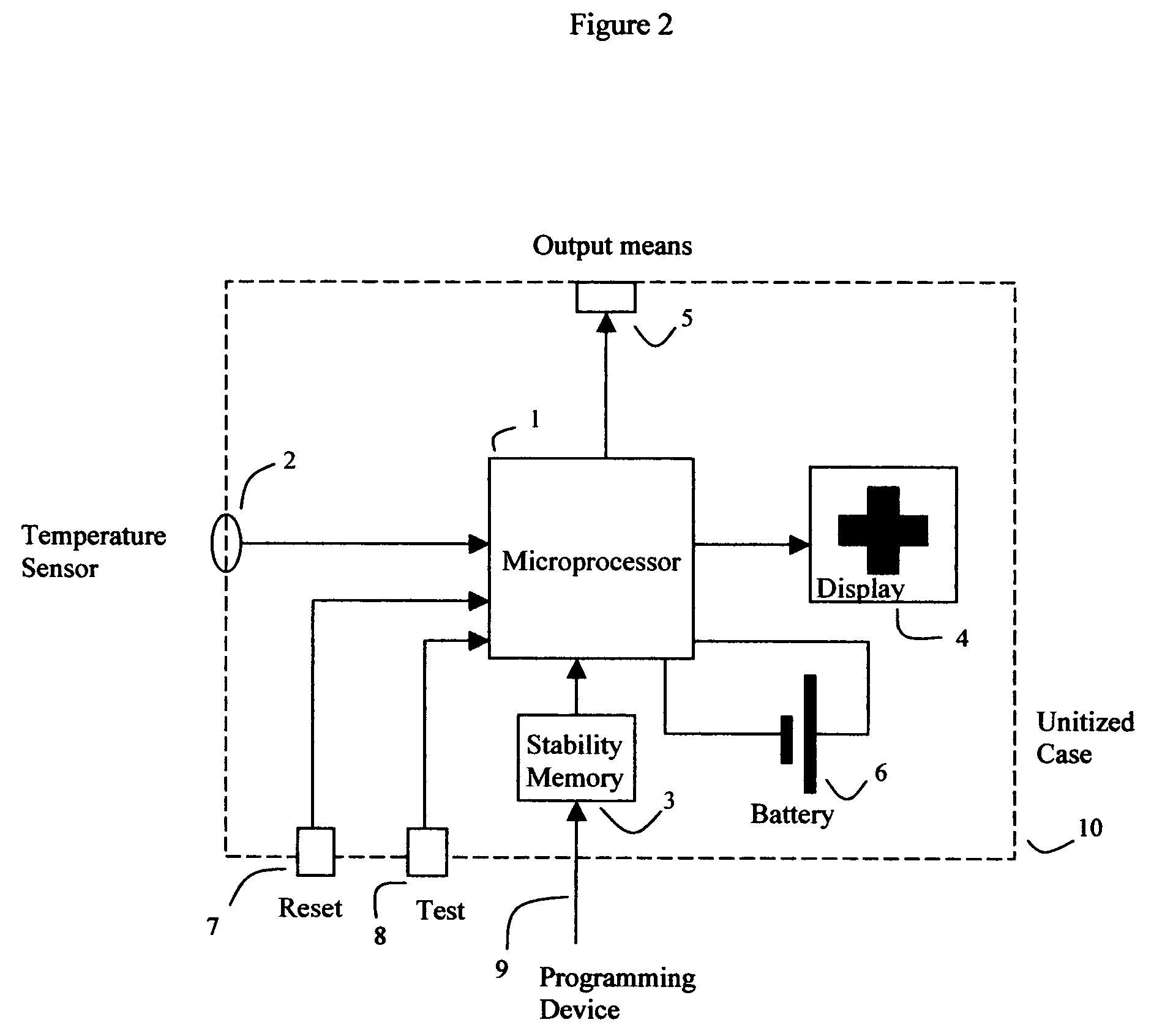

This invention covers improved electronic time-temperature indicators with a visual output, and other devices and methods by which the thermal history of a complex material, which may not obey a simple exponential Arrhenius law degradation equation, may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest.

Owner:ZWEIG STEPHEN ELIOT

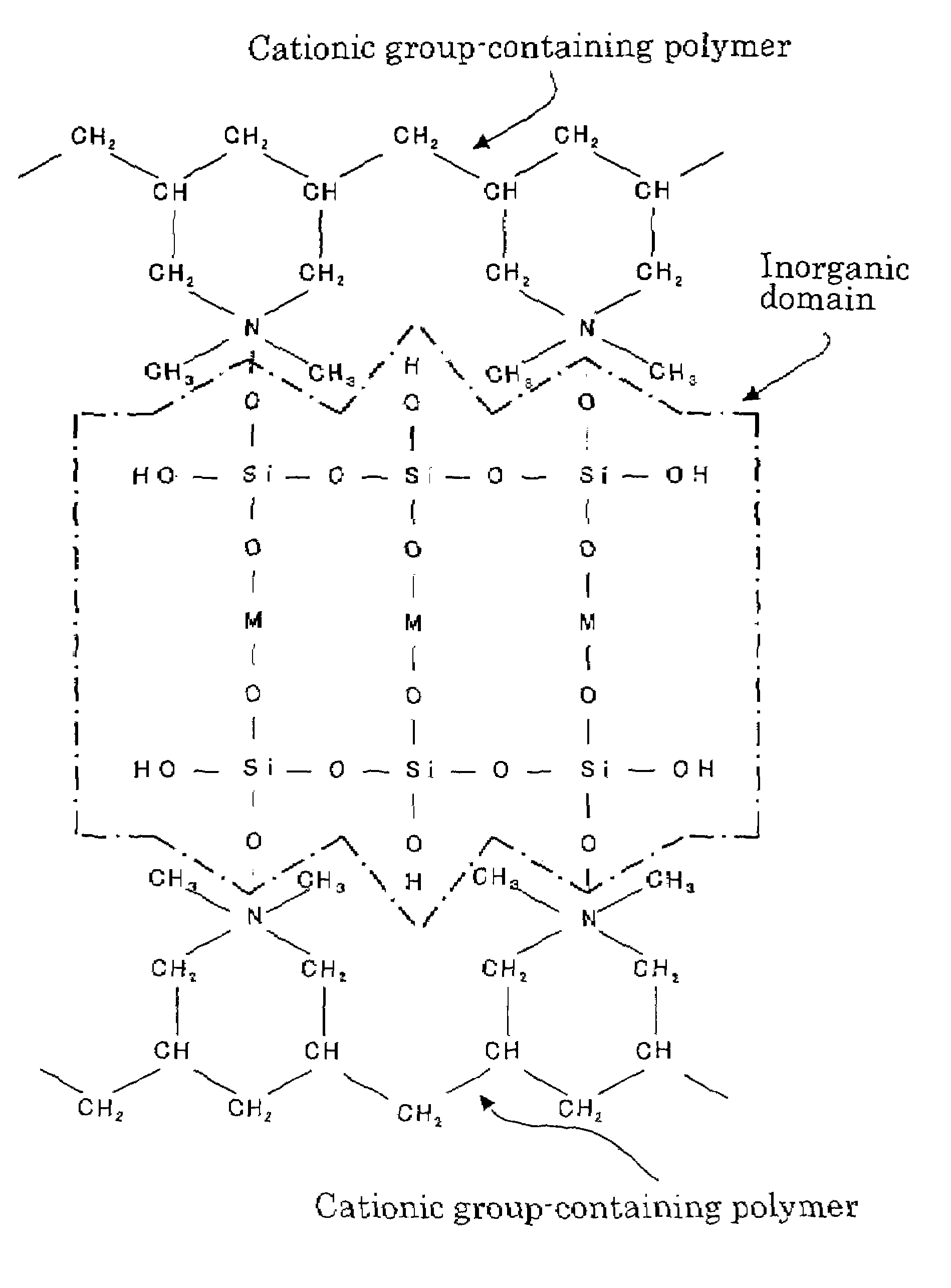

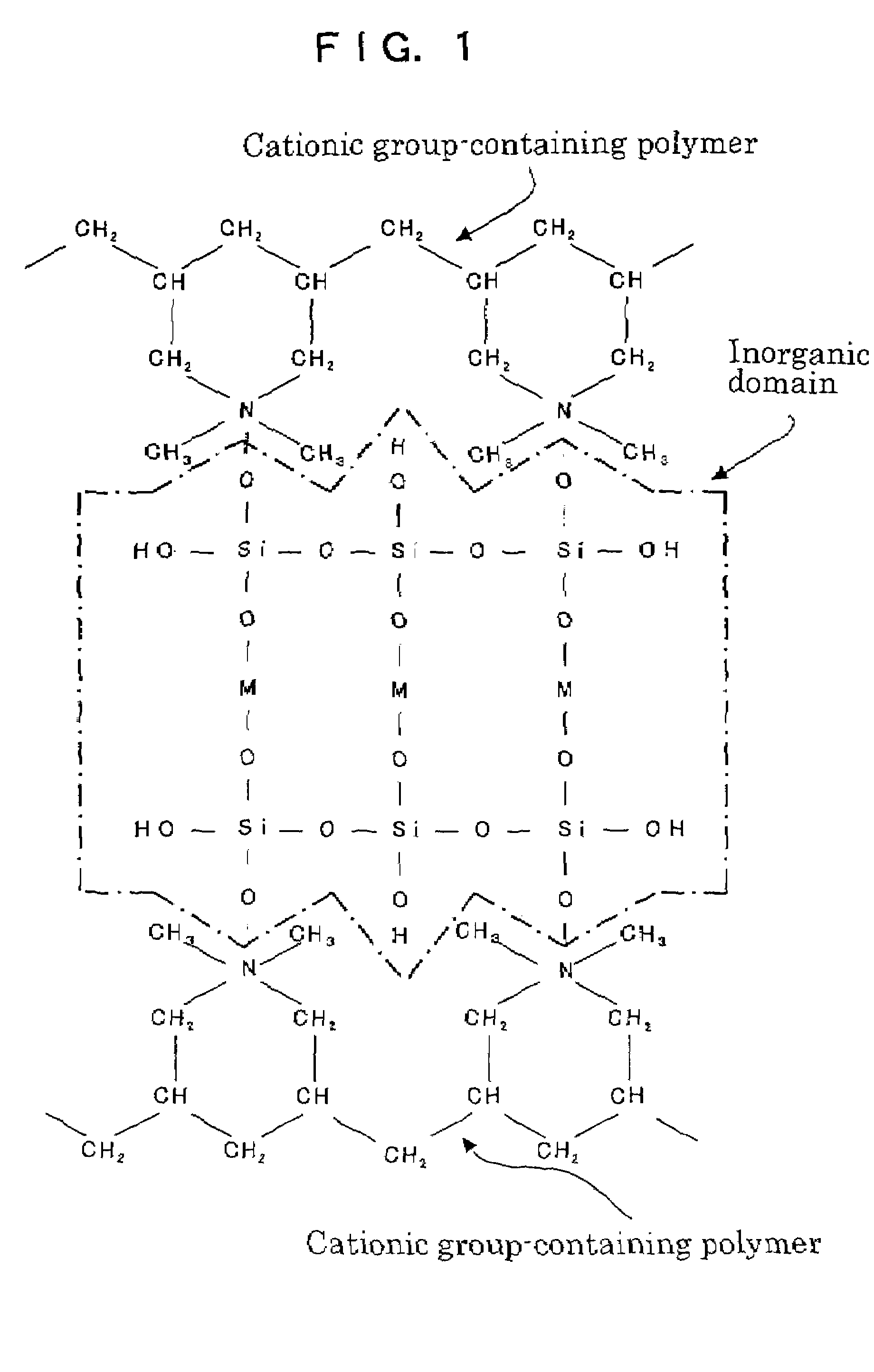

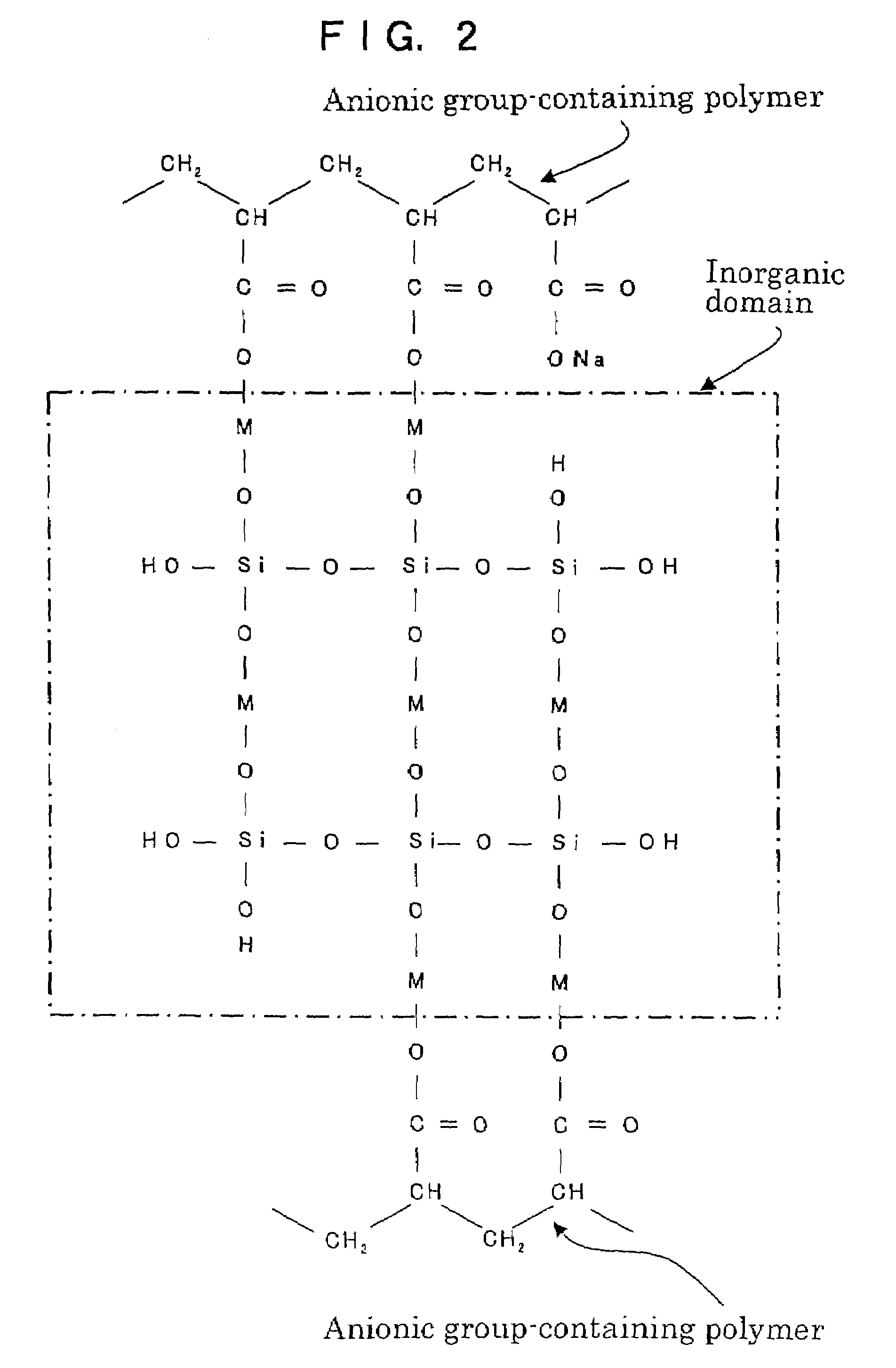

Organic domain/inorganic domain complex materials and use thereof

InactiveUS7244797B2Easy to produceImprove surface propertiesBiocideOrganic active ingredientsDivalent metalHybrid material

Disclosed are an organic domain / inorganic domain hybrid material comprising an organic domain comprising at least one water-soluble organic polymer having anionic and / or cationic functional groups, and an inorganic domain, the organic and inorganic domains being chemically bonded to each other through the functional groups, the inorganic domain comprising inorganic bridges, each independently comprising at least one Si atom, at least two O atoms and at least one divalent metal atom, wherein the Si atom and the O atoms together form at least one siloxane linkage arranged longitudinally of the inorganic bridge, wherein each divalent metal atom is ionically bonded to the O atoms of the siloxane linkages positioned adjacent to the divalent metal atoms, wherein, when at least a part of the organic domain is comprised of at least one organic polymer having an anionic functional group and optionally a cationic functional group, the organic domain / inorganic domain weight ratio is less than 1.0; and the use thereof as a hydrophilicity reagent and an antibacterial / antifungal reagent.

Owner:ASAHI KASEI KK

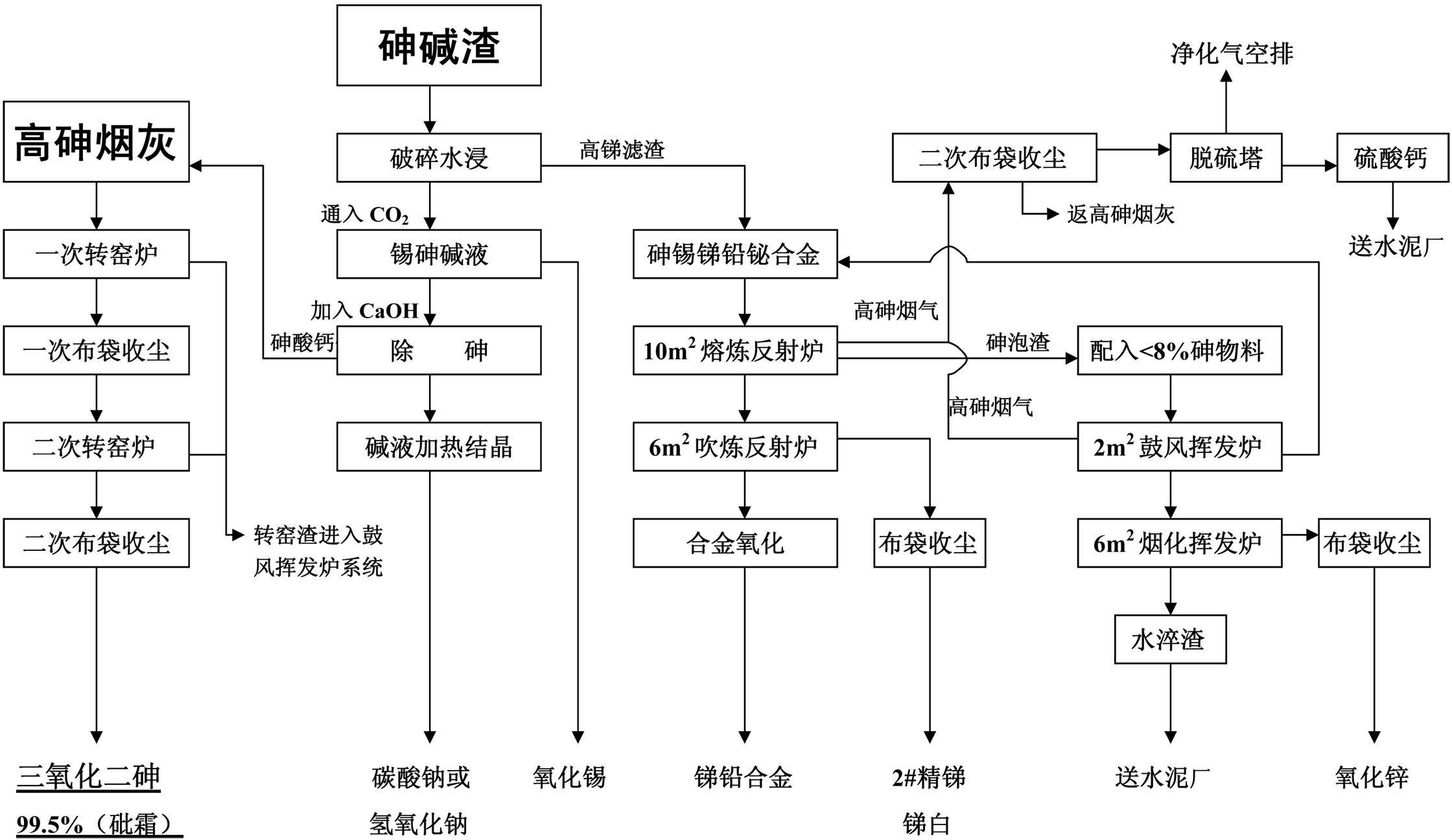

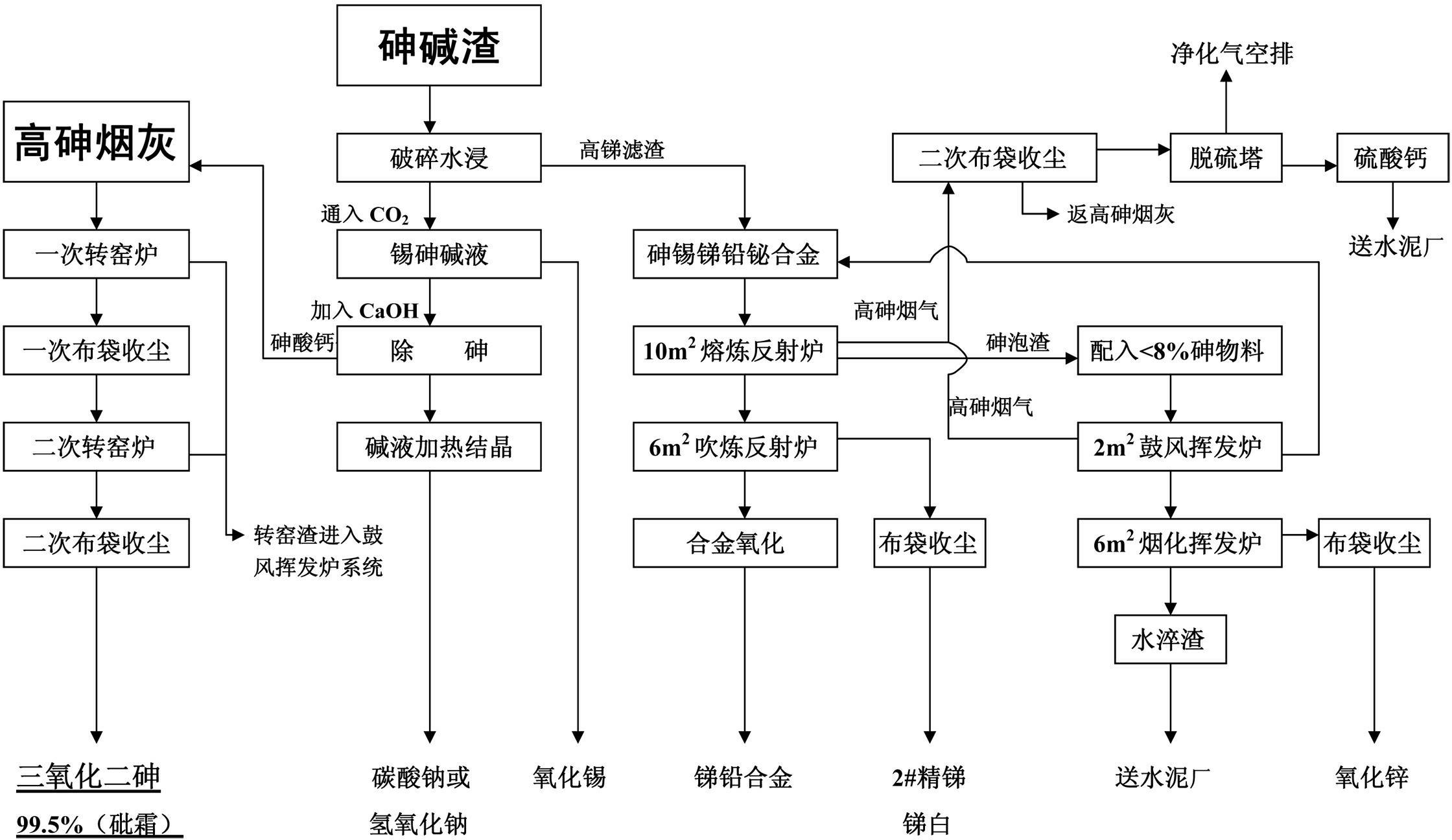

A comprehensive recovery method for complex arsenic-containing and valuable metal slag dust materials

ActiveCN102286665ANo pollutionCement productionProcess efficiency improvementRecovery methodTin dioxide

Disclosed is a comprehensive recovery method for a complex material containing arsenic and valuable metal slags, comprising passing the materials containing arsenic through a primary rotating kiln to volatilize the arsenic, and through a secondary rotating kiln to purify the arsenic, so that an arsenic product containing 99.5% As 2 O 3 is produced; reduction smelting slags from the primary and secondary rotating kilns in a blowing volatilization furnace, with the resultant highly arsenious dust being returned to the primary rotating kiln for treatment, and the slags being used as a raw material in a cement manufactory and a raw material for zinc after undergoing strongly reductive dearsenization and volatilization of zinc in a fuming furnace; the resultant alloy containing arsenic being subjected to basic oxidizing refinement, and the oxidized / refined alloy after dearsenizations containing Pb > 72%, Sb > 12%, As 2 O 3 <0.02%, being sold as a lead-antimony alloy; the basic slags from the refinement, containing As 2 O 3 10%-20%, being subjected to crushing, dissolution in base, and filtration, with the slags thereof being returned to a blowing volatilization furnace for treatment; precipitating tin from the basic solution containing tin and arsenic by blowing in CO 2 , with the filtered tin oxide being sold as a raw material for tin; adding Ca(OH) 2 into the basic filtrate containing arsenic to precipitate arsenic, returning the filtered slags of calcium arsenate to the primary rotating kiln for treatment, and evaporating the remaining basic solution to concentrate and recover the base.

Owner:LEIYANG YANXIN NON FERROUS METALS

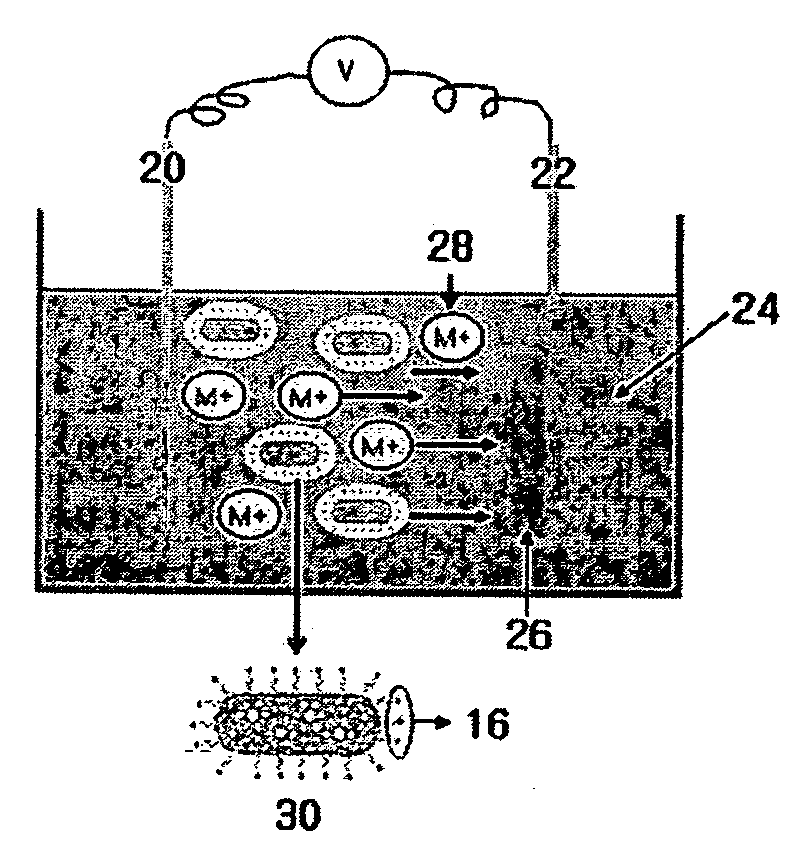

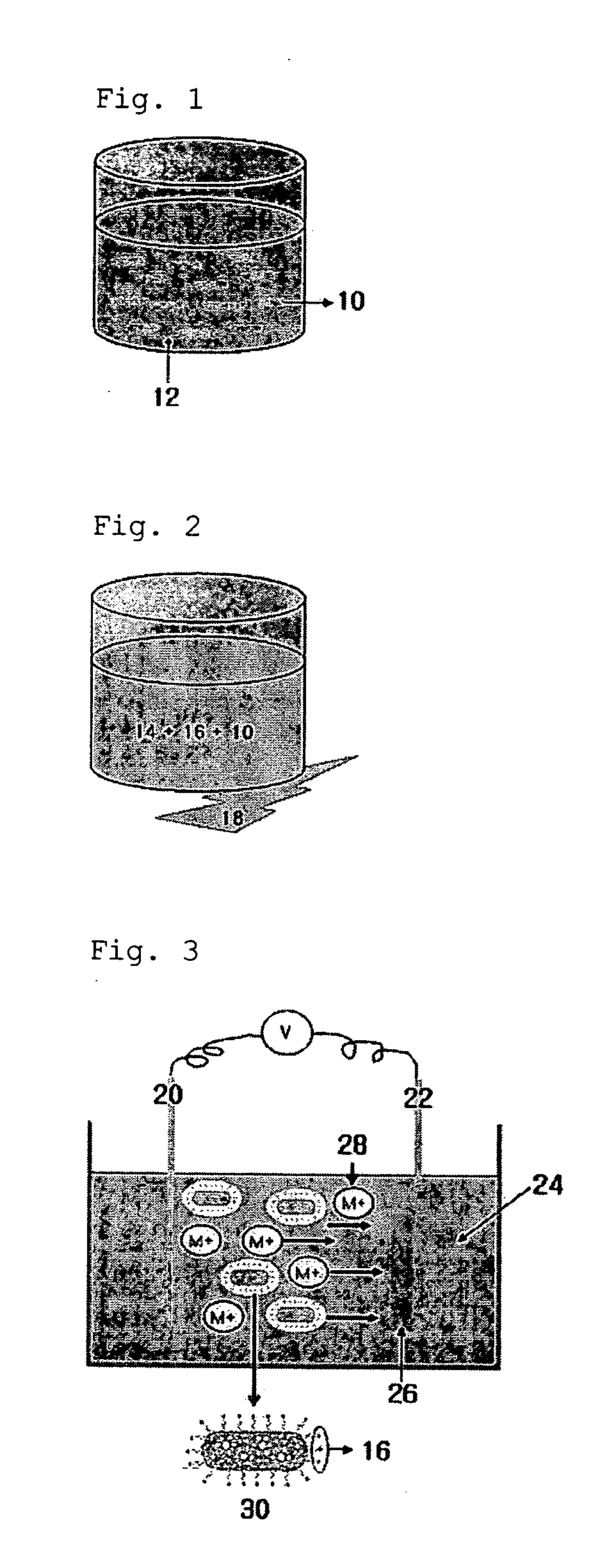

Method for manufacturing metal/carbon nanotube nano-composite using electroplating

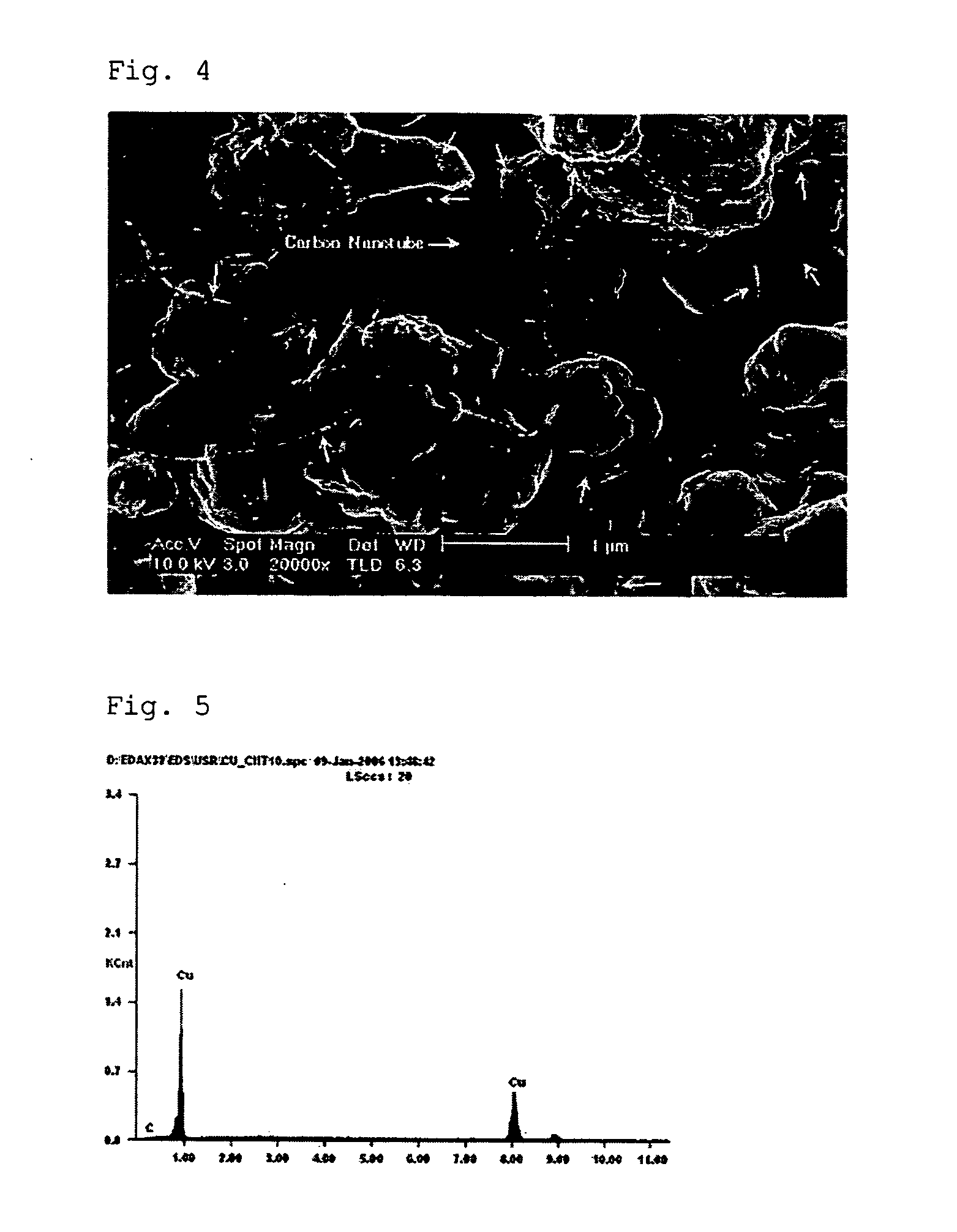

Disclosed herein is a method for manufacturing metal / carbon nanotube nano-composite using electroplating, more particularly, to a method for manufacturing metal / carbon nanotube nano-composite comprising: adding carbon nanotubes and cationic surfactants in metal plating solution including metal or metal salt and performing electroplating in the cathode.According to the present invention, the method for manufacturing metal / carbon nanotube nano-composite using electroplating comprises: immersing carbon nanotubes in acid solution and filtering the solution and carrying out heat treatment; adding the heat treated carbon nanotubes and cationic surfactants in metal plating solution including metal or metal salt and dispersing the carbon nanotubes; and providing a cathode and an anode in the metal plating solution including the carbon nanotubes and the cationic surfactant, to which current is applied and carrying out electroplating in order to obtain metal / carbon nanotube nano-composite(complex material).

Owner:KOREA ADVANCED INST OF SCI & TECH

Material lifetime data abstraction device and method

InactiveUS20070001862A1Improve protectionQuick configurationThermometer detailsThermometers using mean/integrated valuesData compressionData abstraction

This invention covers improved electronic time-temperature indicators with an RFID output, and other devices and methods by which the thermal history of a complex material, which may not obey a simple exponential Arrhenius law degradation equation, may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature RFID tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest. By utilizing data compression to compress a material's extensive thermal history into the small user data field transmitted by modern RFID tags, a considerable amount of information relating to product status and cause of failure may be rapidly transmitted within the small memory confines of standard RFID tag protocols.

Owner:ZWEIG STEPHEN ELIOT

Material lifetime data abstraction device and method

InactiveUS7564364B2Easily and precisely customizedHigh outputThermometer detailsThermometers using mean/integrated valuesData compressionData abstraction

This invention covers improved electronic time-temperature indicators with an RFID output, and other devices and methods by which the thermal history of a complex material, which may not obey a simple exponential Arrhenius law degradation equation, may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature RFID tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest. By utilizing data compression to compress a material's extensive thermal history into the small user data field transmitted by modern RFID tags, a considerable amount of information relating to product status and cause of failure may be rapidly transmitted within the small memory confines of standard RFID tag protocols.

Owner:ZWEIG STEPHEN ELIOT

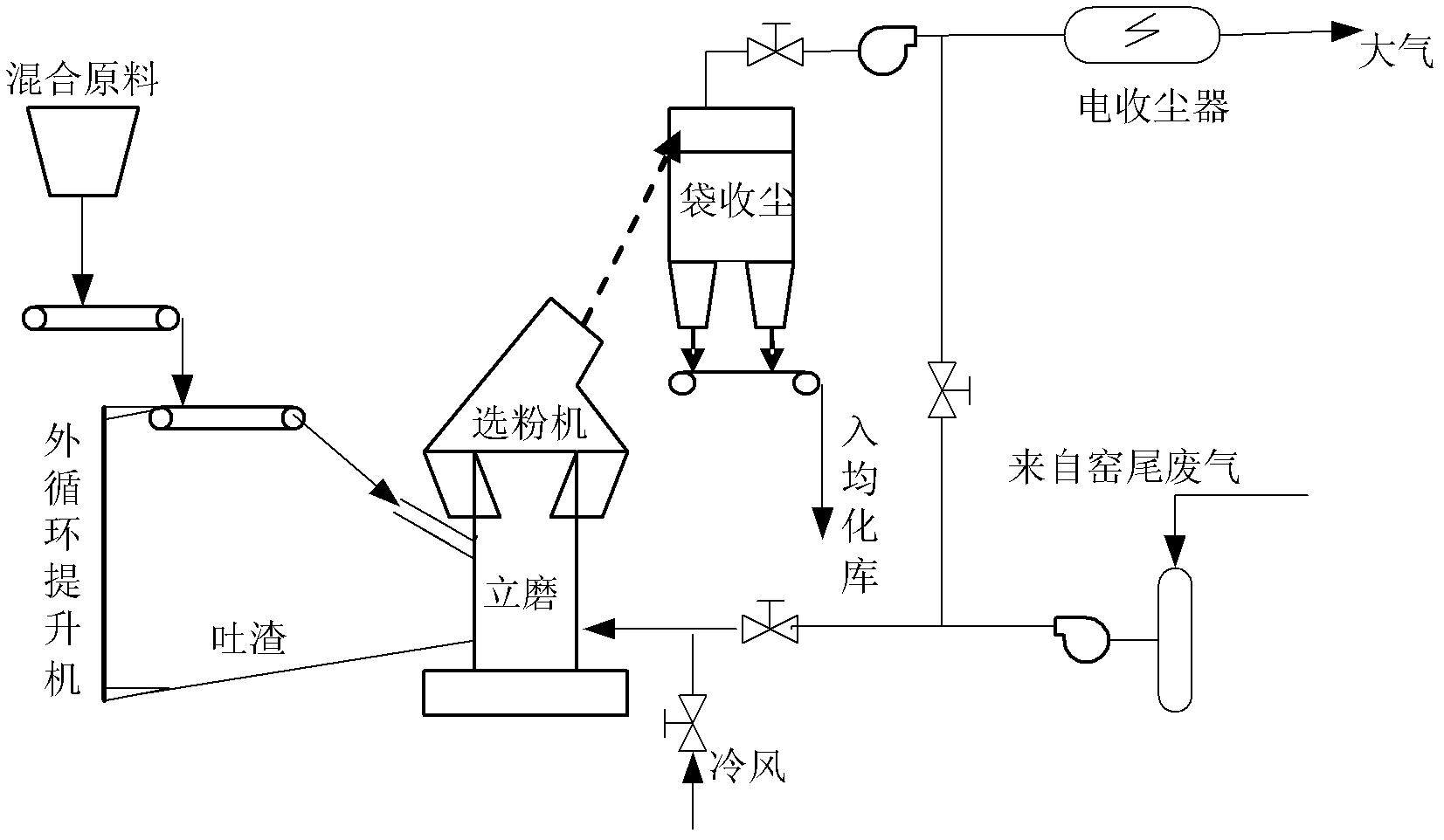

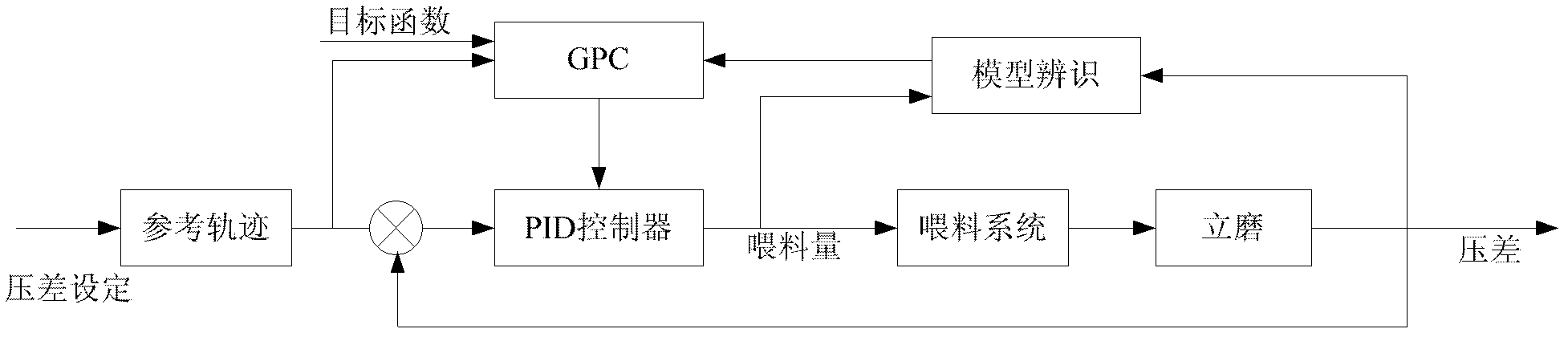

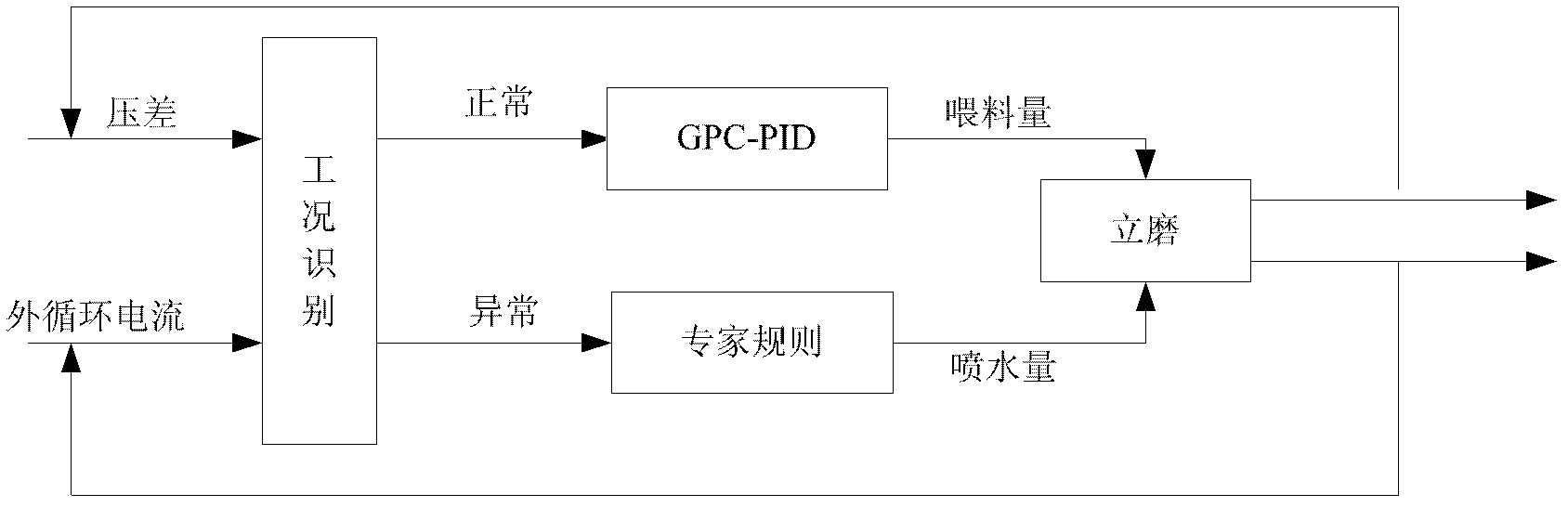

Method for intelligently controlling pressure difference of cement raw meal vertical mill

ActiveCN102319612AReduce labor intensityImprove robustnessGrain treatmentsMathematical modelEngineering

The invention discloses a method for intelligently controlling the pressure difference of a cement raw meal vertical mill. In the method, internal pressure difference of the mill is taken as a major controlled variable, external circulating current is taken as an auxiliary controlled variable, a feeding amount is taken as a major control variable, and a water spray amount is taken as an auxiliarycontrol variable. The method comprises the following steps of: judging a current production condition according to the internal pressure difference of the mill and external circulating current information with a production rule method; and under the normal working condition, controlling the internal pressure difference of the mill by adopting GPC-PID (Generalized Predictive Control-Proportion Integration Differentiation). In the method, a mathematic model for describing the change of the pressure difference along with the feeding amount can be established only by using input and output data of a process without analyzing the complex material milling process of the raw meal vertical mill, the identifying process is simple, and online identification is available; the method has certain adaptability to the change of the production condition; and the advantages of multistep prediction, rolling optimization and feedback correction of a GPC algorithm as well as the advantages of easiness and high robustness of a PID algorithm are fully utilized, so that the labor intensity of field operating personnel is lowered greatly.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

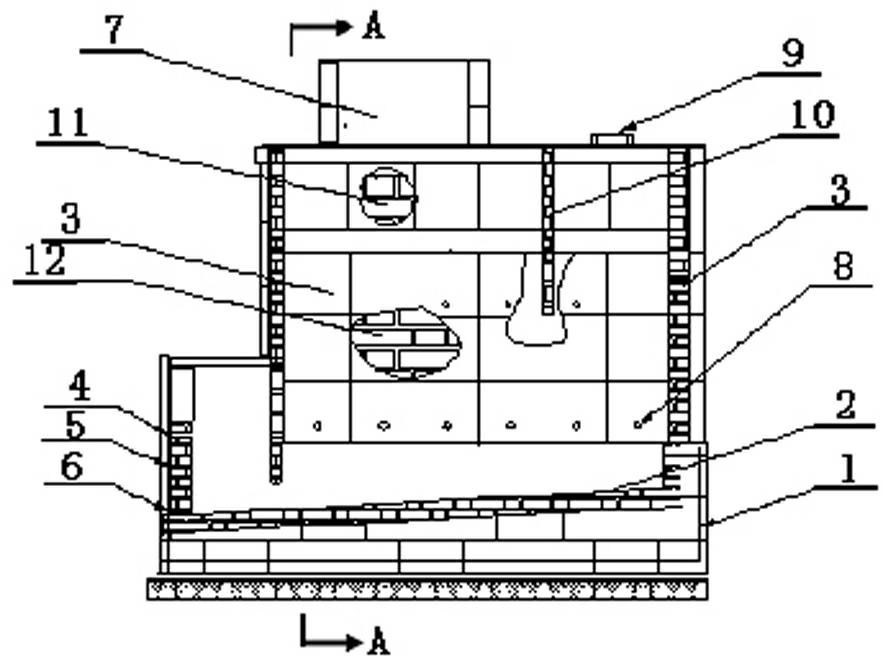

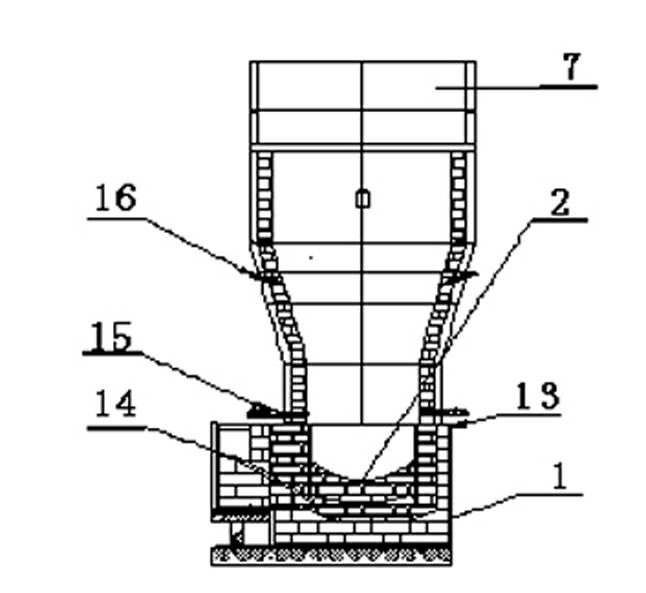

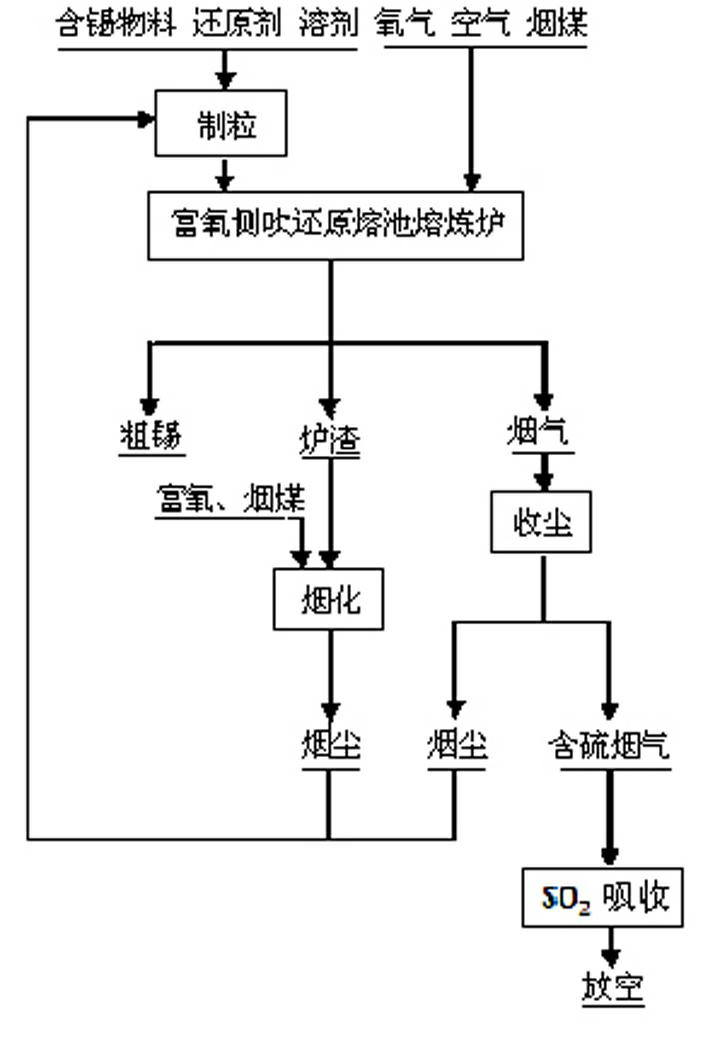

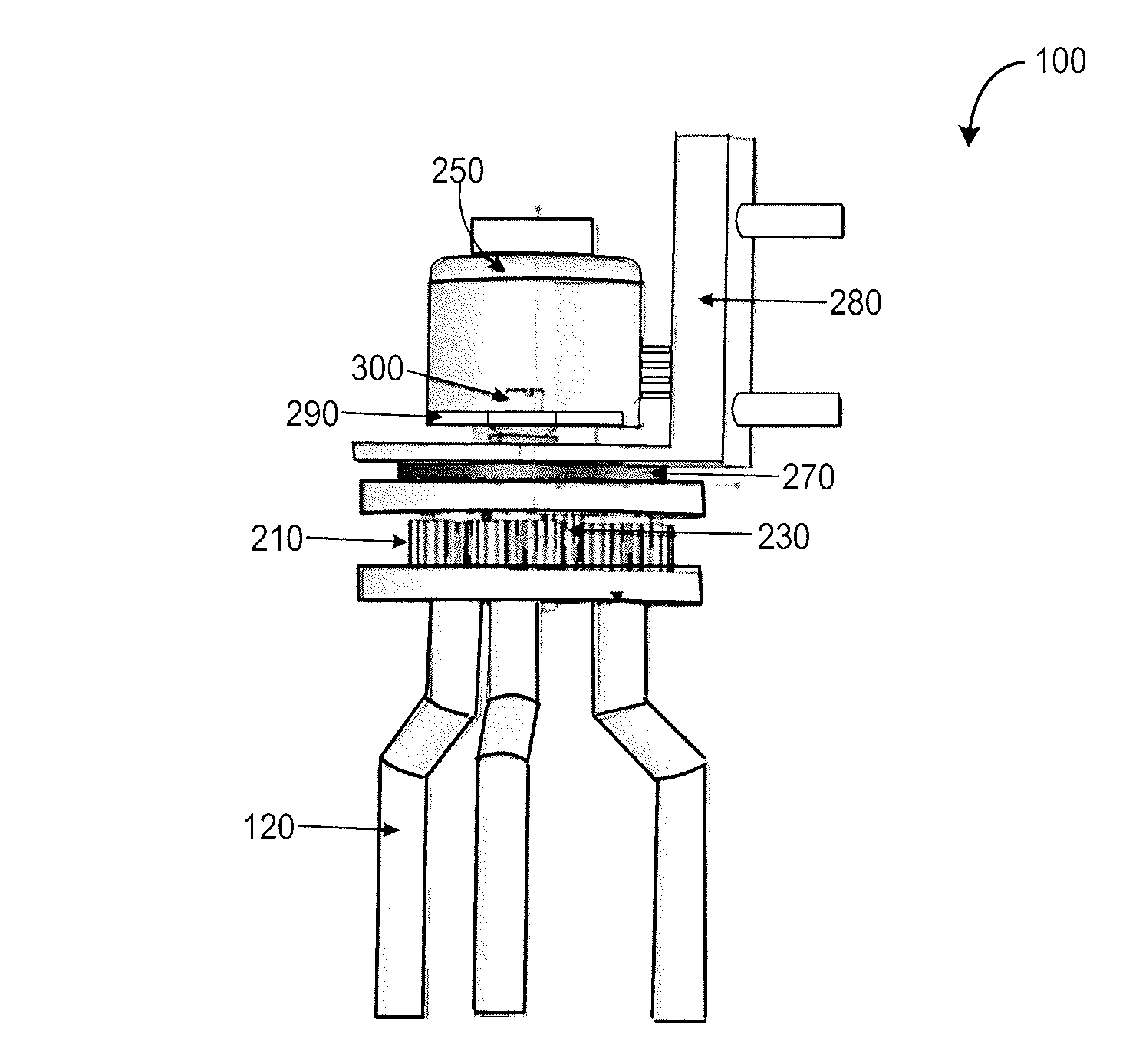

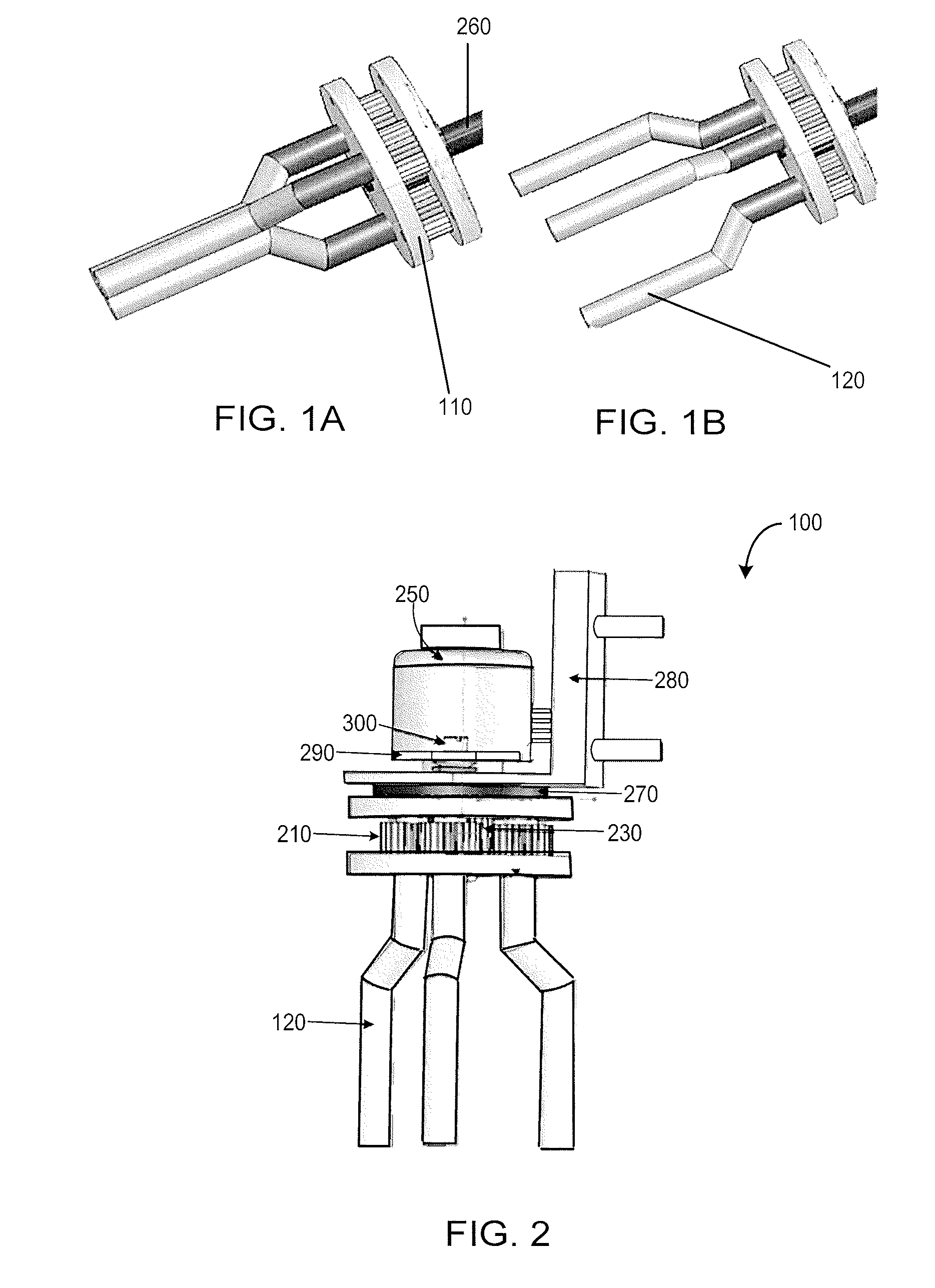

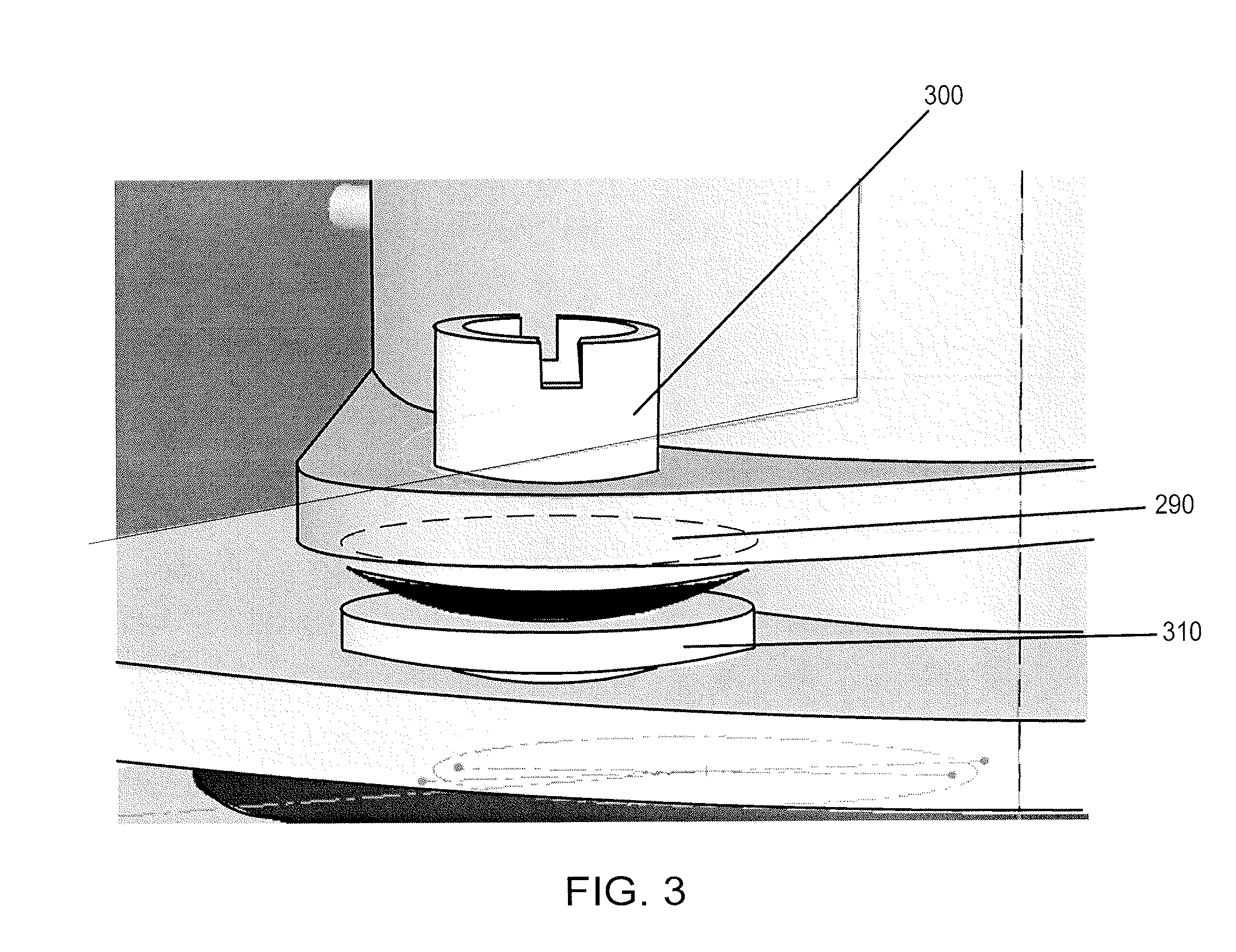

Oxygen-enriched side-blown reduction molten pool smelting furnace and method for smelting tin by using tin-enriched complex material in smelting furnace

The invention discloses an oxygen-enriched side-blown reduction molten pool smelting furnace and a method for smelting tin by using a tin-enriched complex material in the smelting furnace. The smelting furnace comprises a furnace body, a furnace cylinder, a molten pool, a furnace liner and a water jacket; a slope-shaped furnace bottom is arranged in the furnace cylinder; and the chromium magnesium brick furnace liner is arranged on the furnace liner in the middle of the furnace body. The method comprises the procedures of mixing, granulating, oxygen-enriched reduction smelting, slag fuming treatment and recycling of tin-containing smoke. By adopting an oxygen-enriched side-blowing technology in the oxygen-enriched side-blown tin reduction molten pool smelting furnace, the melt in the furnace is kept in a high-temperature molten state; by intensively bubbling and stirring the melt, liquid, solid and gas phases are quickly reacted; and when the tin metal is coagulated and grown into liquid drops of 0.5 to 5 millimeters, the tin metal quickly sinks and is demixed with the slag, so that the capacity of the furnace bed is improved to 100T / m<2>.d. When 10,000 tons of crude tin is produced, only one oxygen-enriched side-blown smelting furnace of 800kVA.2m<2> is needed; and by using lignite as a fuel, the smelting furnace is energy-saving and environment-friendly, and the work efficiency of the smelting furnace is improved by 5 to 10 times compared with the prior art. The recovery rate of tin is more than 95 percent, the smoke rate of the oxygen-enriched tin reduction furnace is controlled to be 10 to 15 percent, and the tin content of the slag of the oxygen-enriched tin fuming furnace is less than 0.1 percent.

Owner:个旧市富祥工贸有限责任公司

System for rapid analysis of glycated proteinaceous species in biological samples

InactiveUS20080085507A1Component separationMicrobiological testing/measurementAnalyteChemical composition

A device is described which provides an automated or manual means to perform chromatographic affinity-based A1c analyses of whole blood or hemolysates in less than 1 minute. Further, such applications are useful for the quantitation of glycated plasma proteins used in analysis of gestational diabetes. The device includes several modules integrated to accomplish processing and analysis of the blood sample. One such module includes a disposable liquid chromatographic column which may be rapidly packed and is easily assembled from readily available materials. Such columns and assemblies may be used in fluid chromatography applications requiring separations of complex materials for purposes of purification and / or quantitation of particular analytes. The columns may be used as stand-alone units or may be integrated into commercially available chromatography systems. The columns have a chemical composition and particle size that allow for low operational pressures.

Owner:AFFINEX

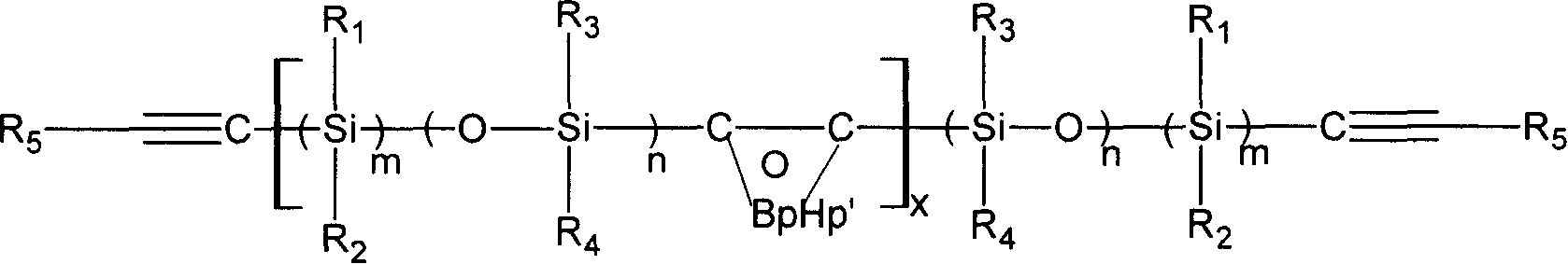

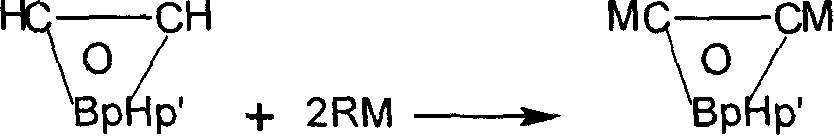

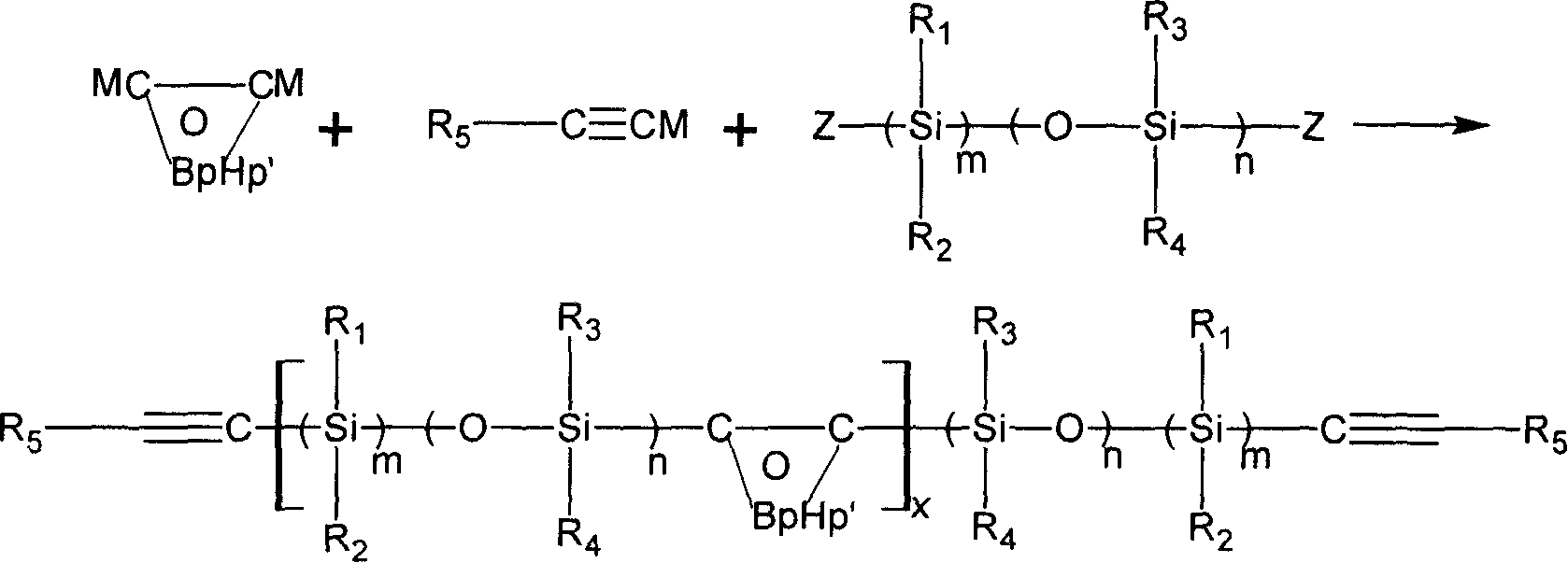

Novel carborane- (siloxane or silane)- ethinyl high temperature resistant polymer and its preparation method

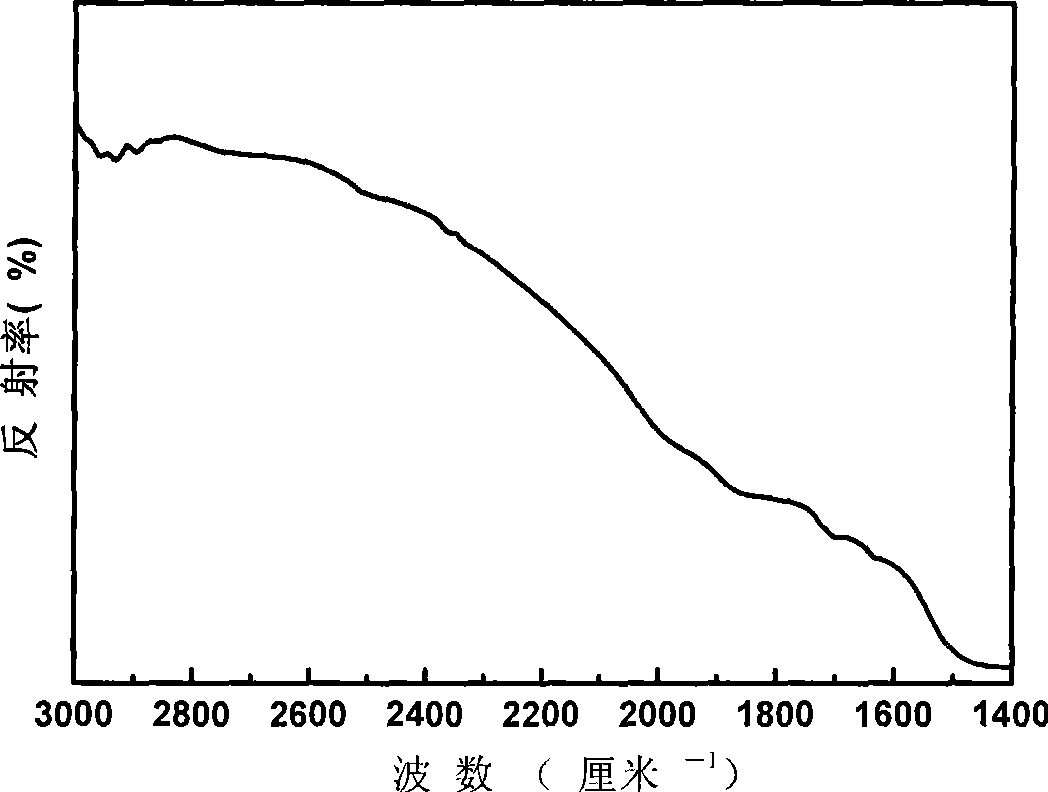

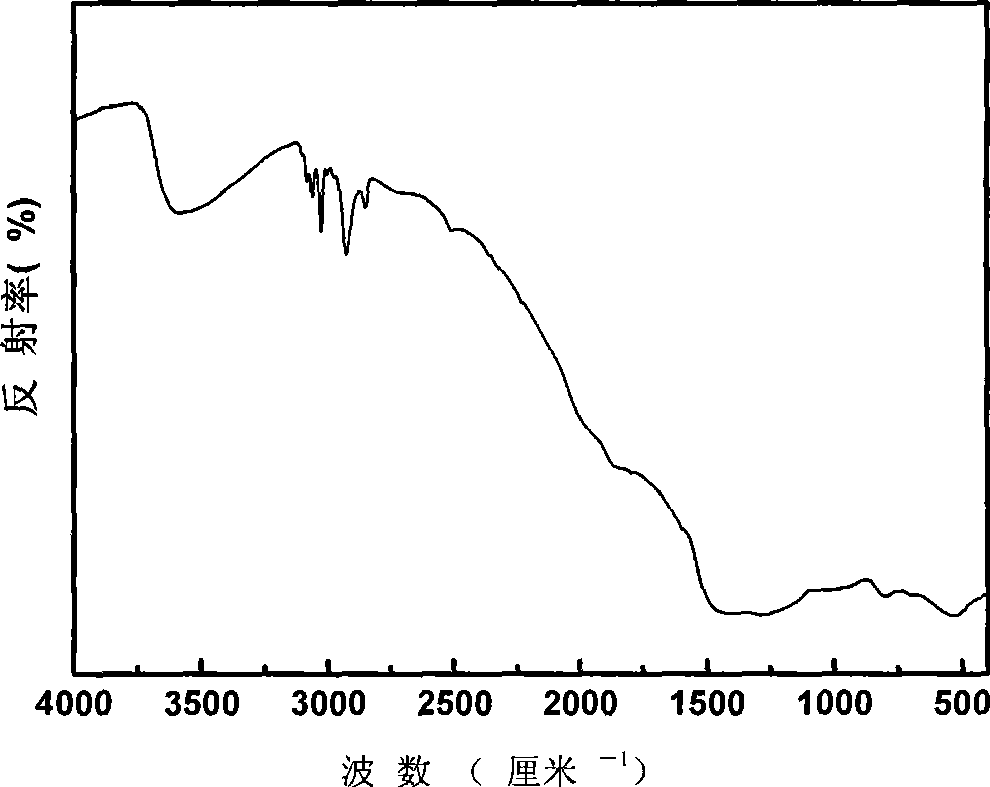

InactiveCN1884343AThe synthesis process is simpleRaw materials are easy to getFireproof paintsSilanesFunction group

The invention discloses a new kind of carborane- silane- phenylacetylene polymer and the method for preparing the same. Said polymer employs methylchlorosilane, phenylacetylene, carborane and organic lithium agent as raw material, anhydrous tetrahydrofuran (THF) as dissolvent and preparing with protection of nitrogen. The invention moderates molar ratio between simple function group ethynyl compound and carborane to easily control molecular weight of polymer, crosslinking density and carborane content, and realizes purpose of adjustable polymer property. The invention is characterized by simple process and easy operation. The prepared polymer forms thermostable thermosetting material with excellent thermal oxidation performance by heat, light and chemical initiation. Said thermosetting material can be produced to ceramic structure by heating on air or inactive gas. The polymer can be used as base resin and thermo-stable coating for advanced complex material and for preparing ceramic pioneer body.

Owner:EAST CHINA UNIV OF SCI & TECH

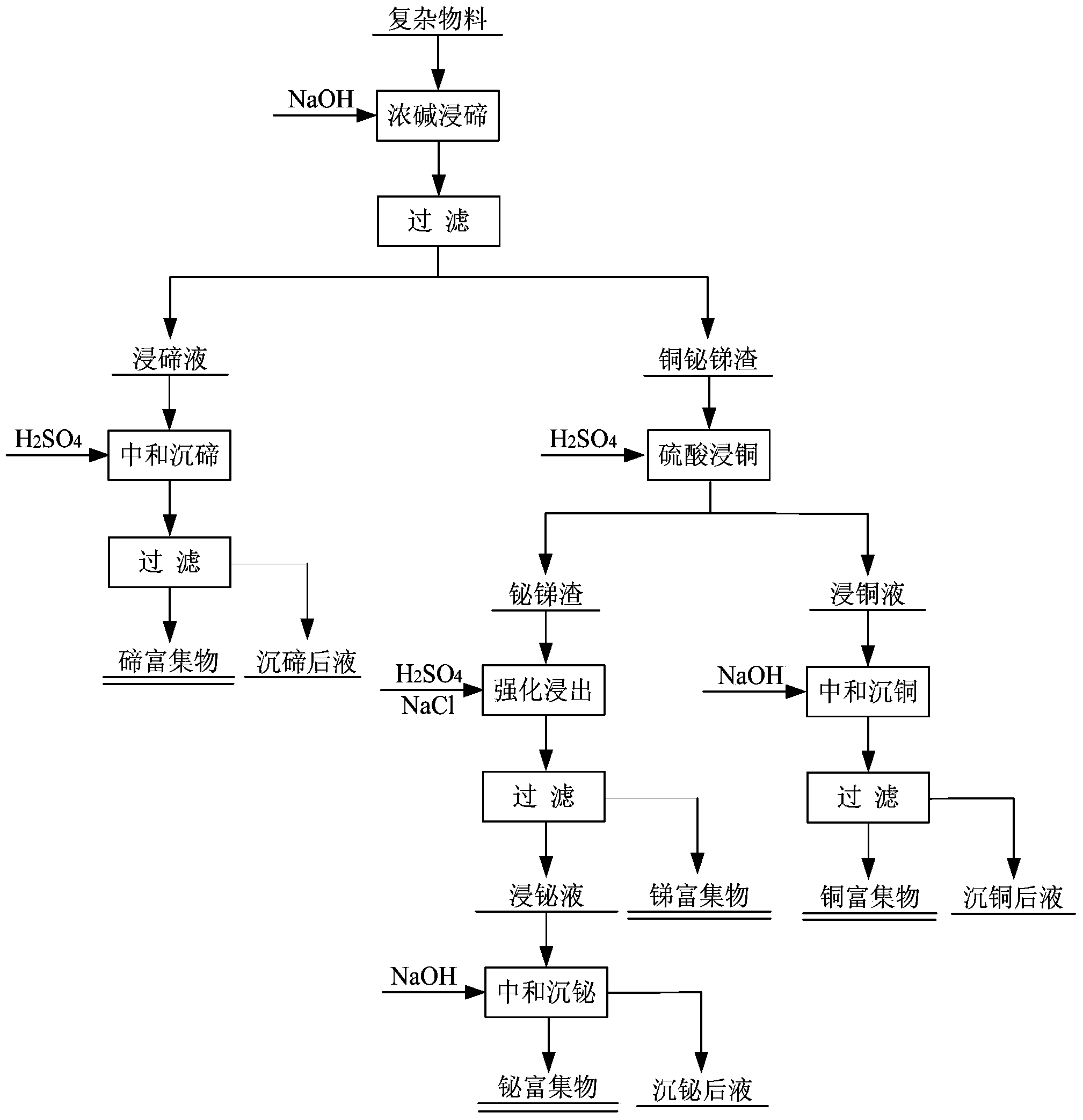

Method for recovering tellurium, bismuth, antimony, and copper from complex material

The invention aims at providing a method for recovering tellurium, bismuth, antimony, and copper from a complex material. The method comprises the steps that: the complex material is added into a sodium hydroxide solution according to a solid-liquid ratio; a temperature and a stirring time are controlled; when a reaction is finished, bismuth, antimony and copper slag and tellurium leaching liquid are obtained; the pH of the tellurium leaching liquid is regulated by adding dilute sulfuric acid; the mixture is settled and is subjected to solid-liquid separation, such that tellurium enrichment is obtained; the bismuth, antimony and copper slag is added into a dilute sulfuric acid solution according to a solid-liquid ratio; a reaction is sufficiently carried out, such that bismuth and antimony slag and copper leaching liquid are obtained; the solution temperature of the copper leaching liquid is controlled, and NaOH is added for precipitating copper; according to a solid-liquid ratio, the bismuth and antimony slag is added into a mixed solution of sulfuric acid and sodium chloride; the mixture is violently stirred, such that bismuth-antimony separation is realized; NaOH is used for regulating solution pH value and for precipitating bismuth; when the reaction is completed, bismuth enrichment and bismuth-precipitated liquid are obtained. With the technical scheme provided by the invention, tellurium, bismuth, antimony, and copper valuable metals can be comprehensively recovered from the complex material, such that waste is turned into valuable matters.

Owner:JIANGXI COPPER

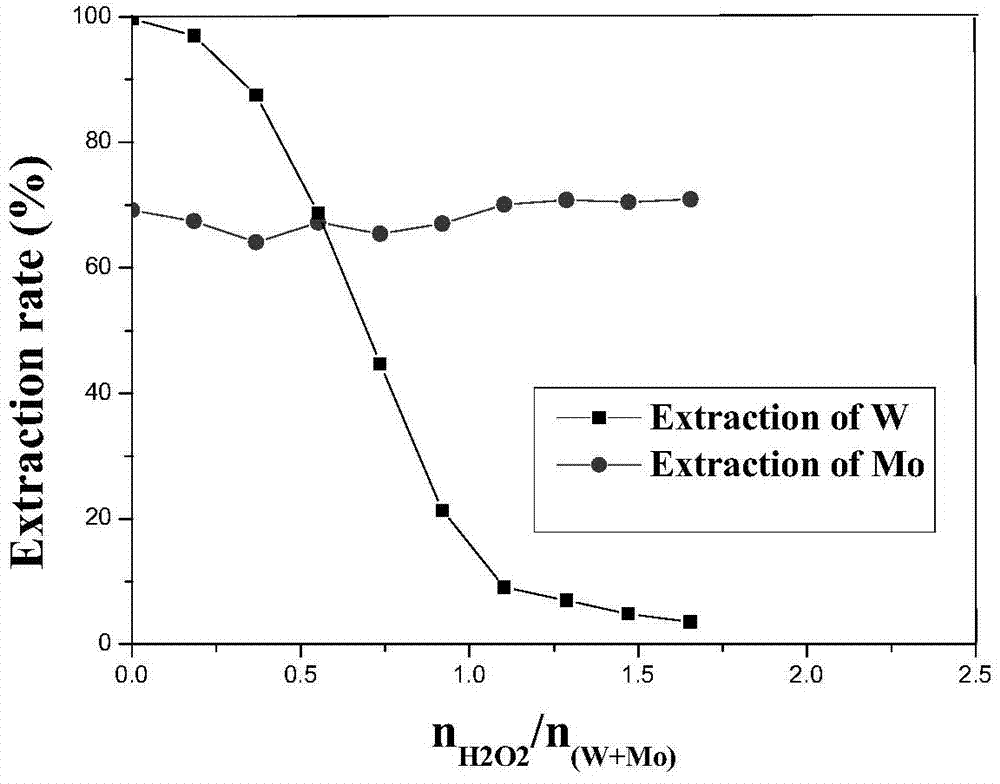

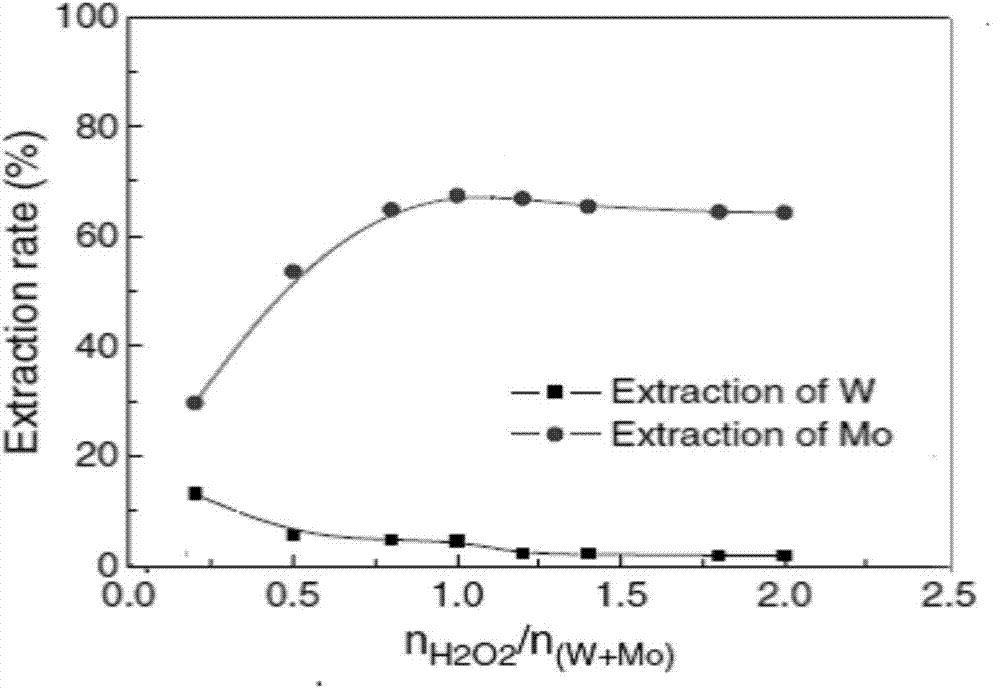

Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

ActiveCN104711422ARealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

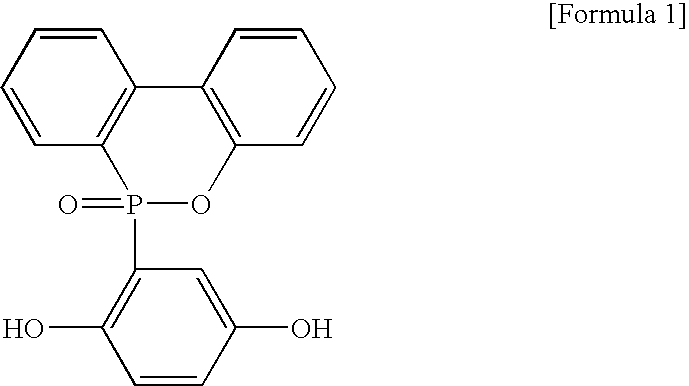

Non-Halogen Flame Retardant and Highly Heat Resistant Phosphorous-Modified Epoxy Resin Compositions

InactiveUS20080097014A1Improve heat resistanceImprove flame retardant performanceWater contaminantsPrinted circuit aspectsCompound aEpoxy

Disclosed is a non-halogen type highly heat resistant flame retardant epoxy resin composition that is made by compounding a phosphorous-modified epoxy resin with a phosphazene compound as a flame retardant additive, wherein the phosphorous-modified epoxy resin is obtained by reacting a phosphorous-containing compound with an epoxy resin. The non-halogen flame retardant and highly heat resistant phosphorous-modified epoxy resins according to the present invention have the excellent flame retardancy property and the good thermal property without halogen and thus can be advantageously utilized in manufacturing a printed circuit board (PCB) and for complex materials.

Owner:KUKDO CHEM CO LTD

Polymer graft modification composite hollow micro-bead and preparation thereof

InactiveCN101434683AHigh compressive strengthSuppression of defective structuresPigment treatment with macromolecular organic compoundsPolymer scienceMicrosphere

The invention relates to a complex hollow microsphere of polymer grafting modification and a preparation method thereof, and pertains to the technical field of surface modification of hollow microsphere. The method provides the complex hollow microsphere of polymer grafting modification and the preparation method thereof aiming at the disadvantages that the surface properties and the compressive strength of the hollow microsphere up to now are hard to be improved simultaneouly. The complex hollow microsphere causes the compressive strength and the compatibility with matrix to be greatly improved by graft polymer on a surface, and can also inhibit defect structure in the surface of the complex hollow microsphere. The method is simple, easy to be operated, and low in cost. The complex hollow microsphere of polymer grafting modification is applied to complex material as light intensified filling.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Heat sensitive resistor for high Curie temperature BaTiO3 base positive temperature coefficient and its making method

InactiveCN101188156AAchieve lead-freeReduce synthesisPositive temperature coefficient thermistorsElectrical resistance and conductanceMixed materials

The invention relates to a BaTiO3 group positive temperature coefficient thermistance and a preparation method thereof, wherein, the BaTiO3 group positive temperature coefficient thermistance has high Curie temperature. The invention belongs to the electronic ceramics technique. The recombination positive temperature coefficient thermistance is composed of main materials and assistant materials. The mol ratio of TiO2 and (BaCO3+SrCO3+Bi2O3+Na2CO3) of the main materials is 1:1. The mol components of the assistant materials are that Nb2O5 is 0.0011; TiO2 is 0.01; Sb2O3 is 0.0006; MnO2 is 0.0004; SiO2is 0.005; Al2O3 is 0.0017. The preparation process comprises that materials are weighed and mixed according to the mol prescription; the mixed materials are processed with ball milling after being added with water, and preparative complex materials are made through drying and heat preservation. The preparative complex materials are again added with raw materials, and then the preparative complex materials are processed with ball milling after being added with the water, thus the positive temperature coefficient thermistance is made through drying, granulation, foliation and baking. The invention has the advantages that the process of the composite (Na0.5Bi0.5)TiO3 is simple; the made positive temperature coefficient thermistance is unleaded and environment-friendly.

Owner:TIANJIN UNIV

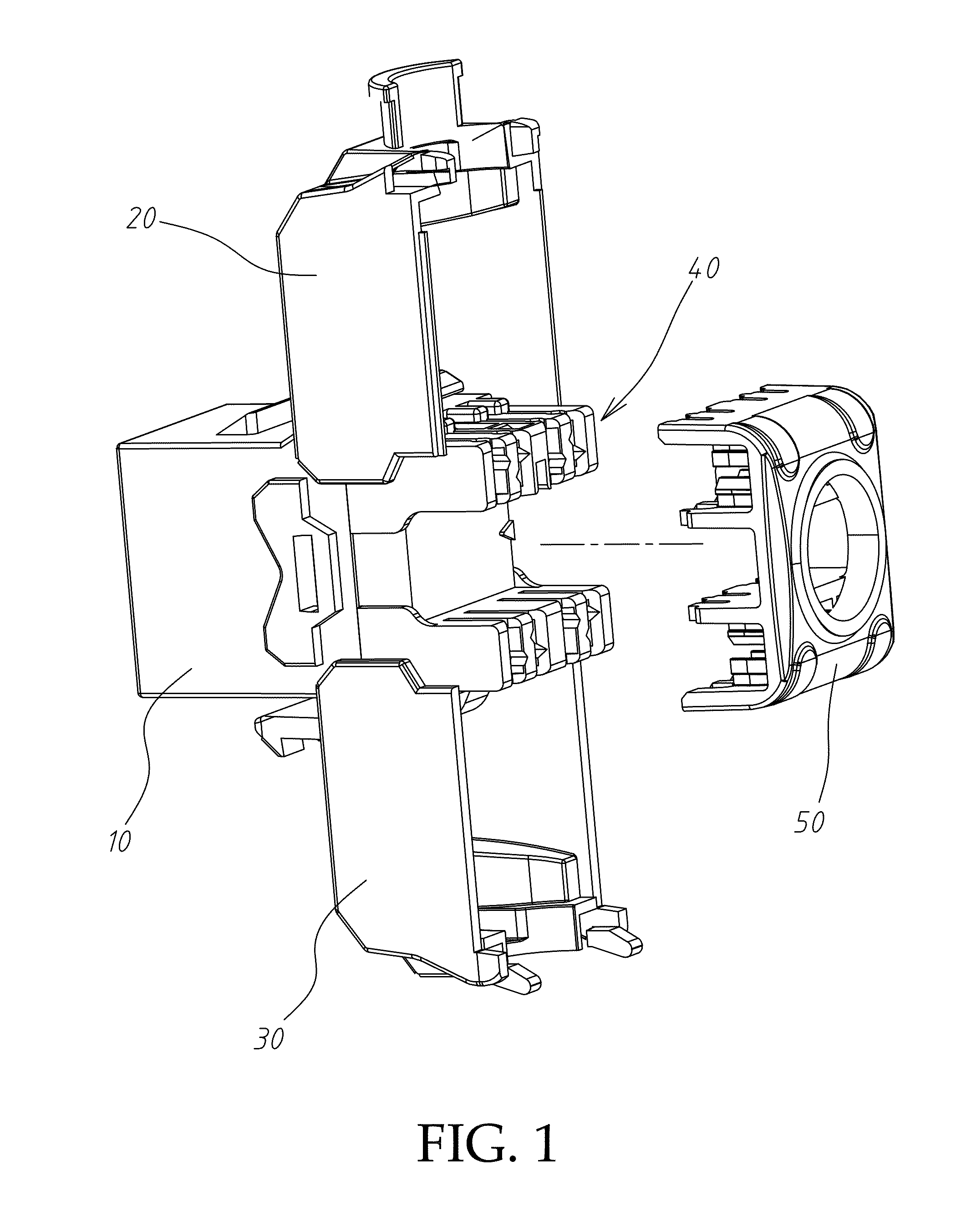

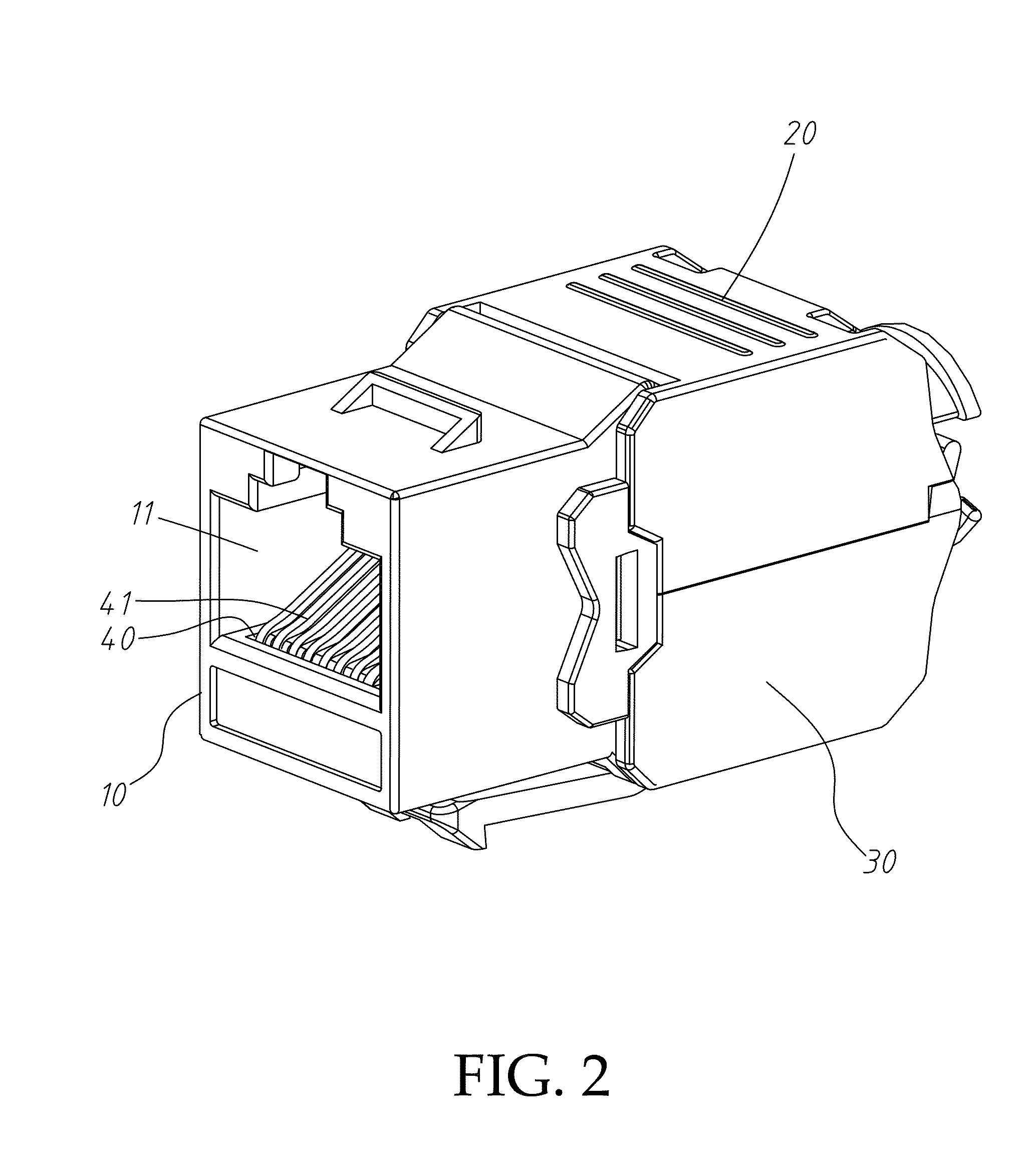

Alien crosstalk preventive electrical socket, electrical plug and network cable

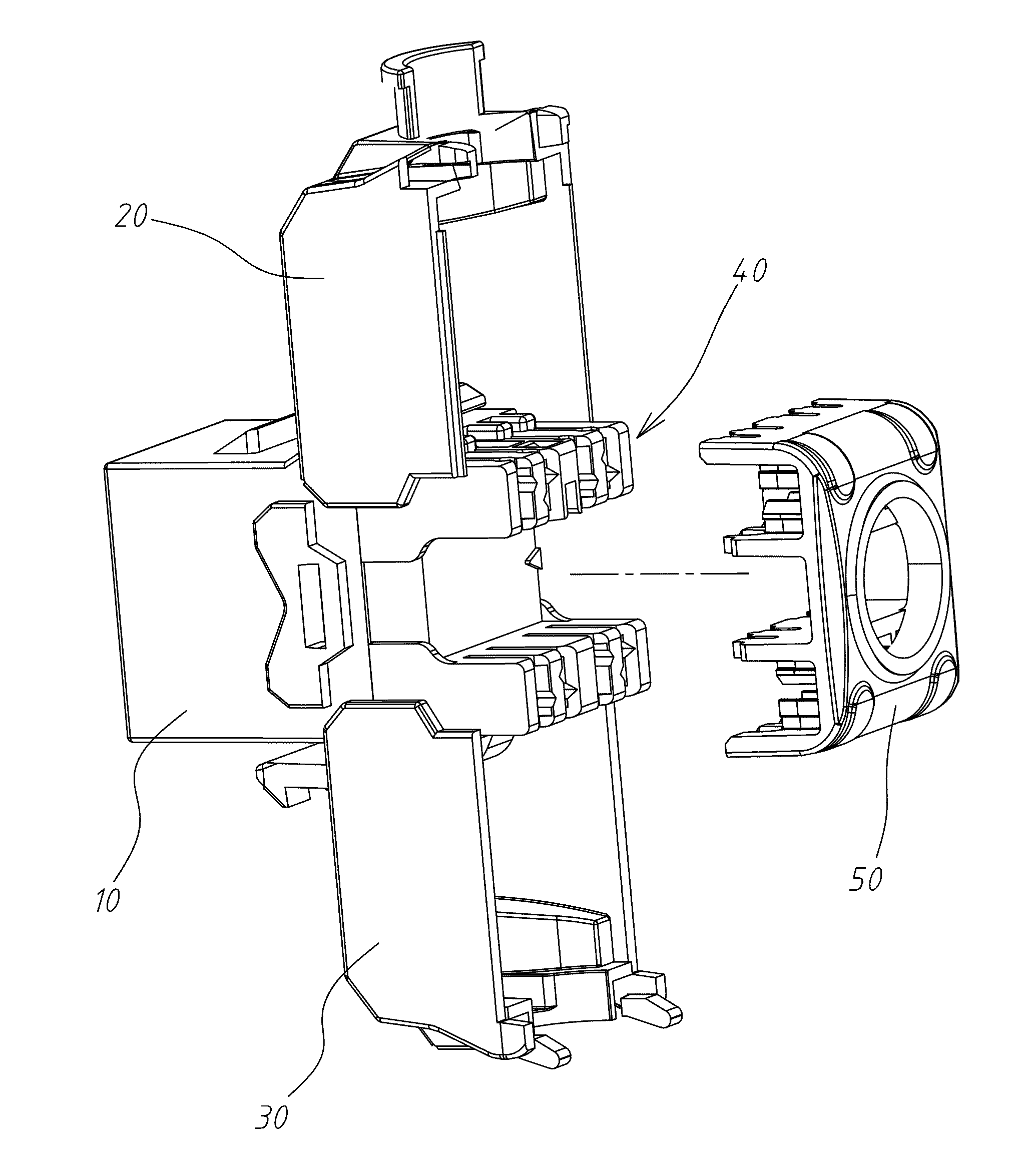

ActiveUS7972150B1Reduce alien crosstalkAvoid radiationTwo-part coupling devicesCoupling protective earth/shielding arrangementsDielectricElectricity

An alien crosstalk preventive electrical socket, electrical plug and network cable, in which the body, upper back cover, lower back cover and IDC housing of the electrical socket, the insulative jacket, rack and plug body of the electrical plug and the cylindrical outer insulation of the network cable are made of an electrically conductive plastic complex material prepared from a compound of a plastic material and an electrically conductive material, said electrically conductive plastic complex material having high dielectric index and low electrical resistivity characteristics to avoid signal in and signal out and to reducing alien crosstalk, thereby effectively preventing EMI (electromagnetic interference) radiation.

Owner:JYH ENG TECH

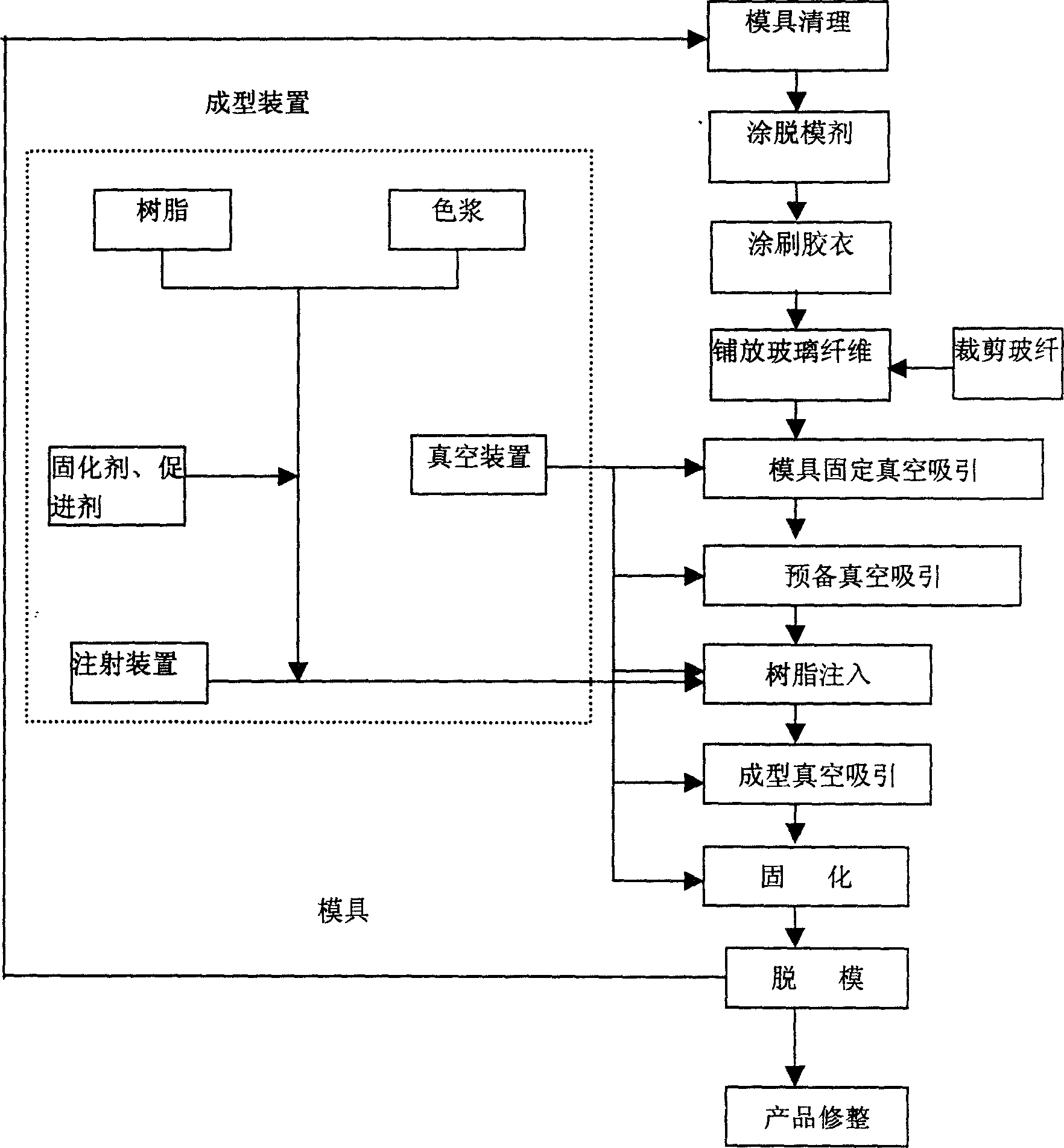

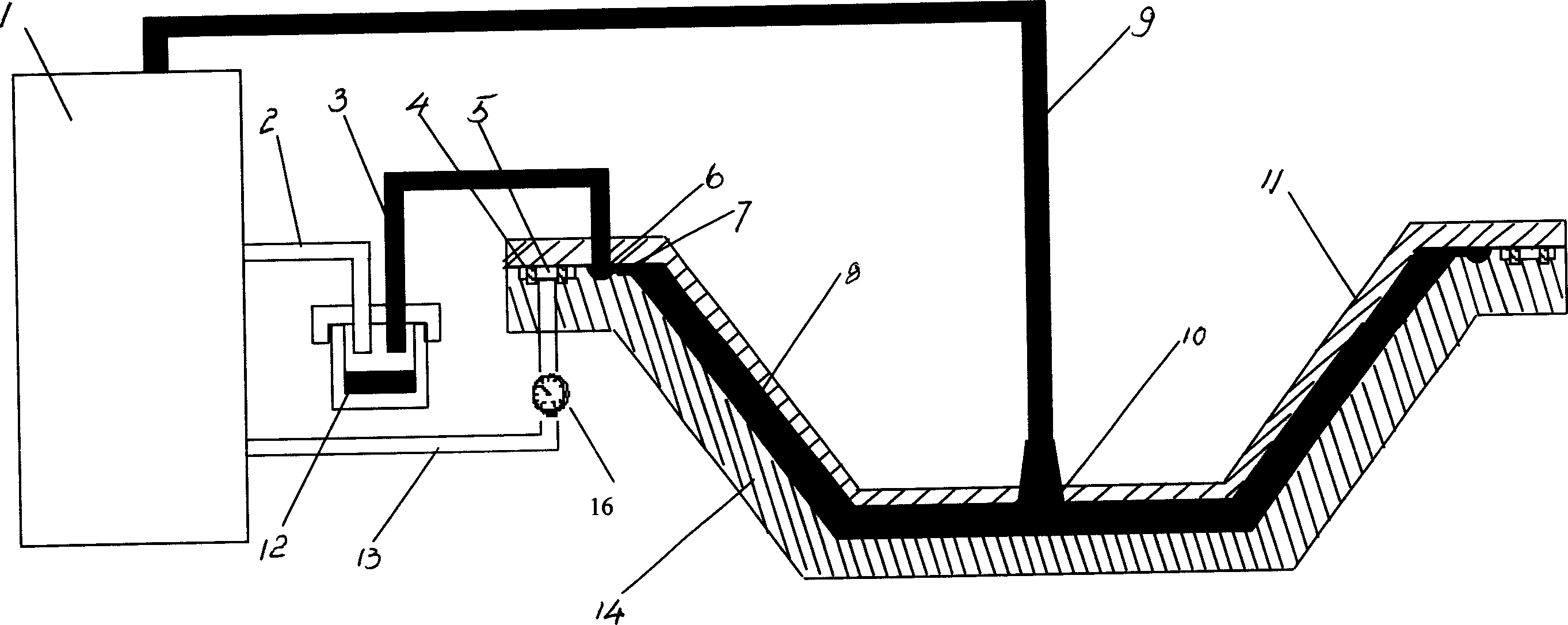

Vacuum auxiliary resin penetration process for composite material and mould therefor

The invention belongs to complex material shaping technics and the moulds. The technics includes that inject the resin through the injecting system into the soft mould to expand, close the injecting port after the determined resin is all injected and evacuate the mould cavity to let the resin fills the unfilled sections at the edge so to fill the whole cavity with resin. The mould includes upper mould which is ferroglass soft mould, lower mould which is ferroglass hard mould. Injecting and shaping evacuating ports are on the upper mould while equal flow canals and shaping vacuum circuit and fixing vacuum circuit are on the lower mould. Its advantages are that it is environmental, of low cost, and is able to shaping with products of large area and thin walls.

Owner:北京玻钢院复合材料有限公司

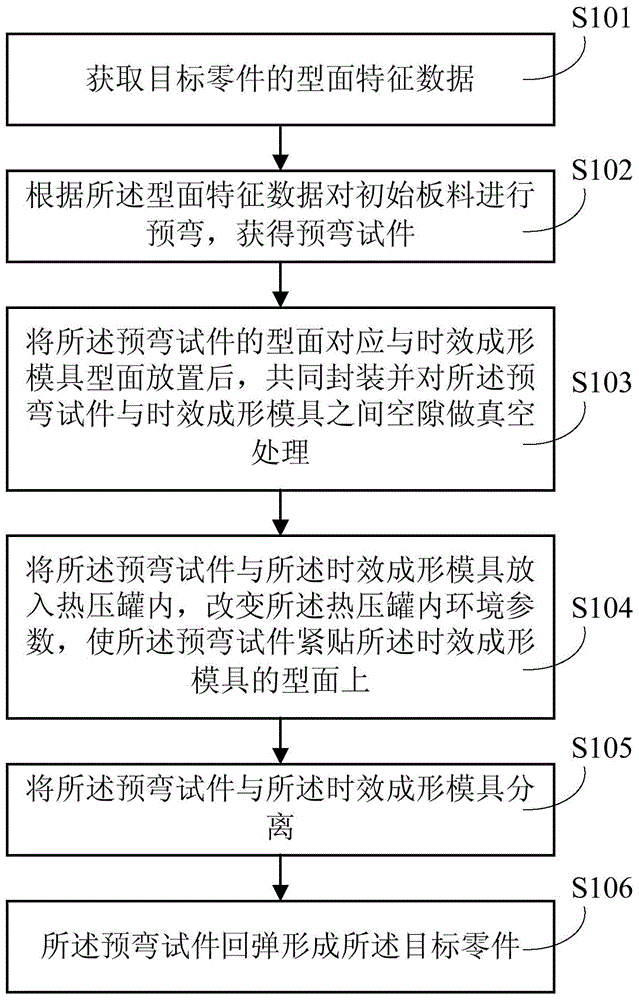

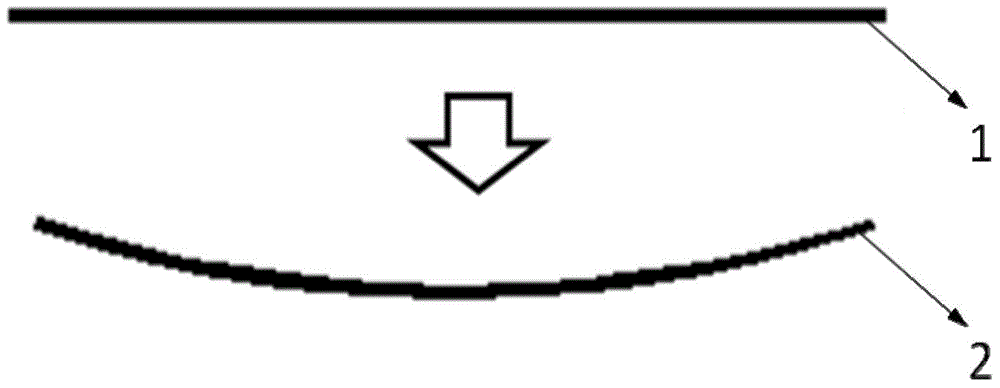

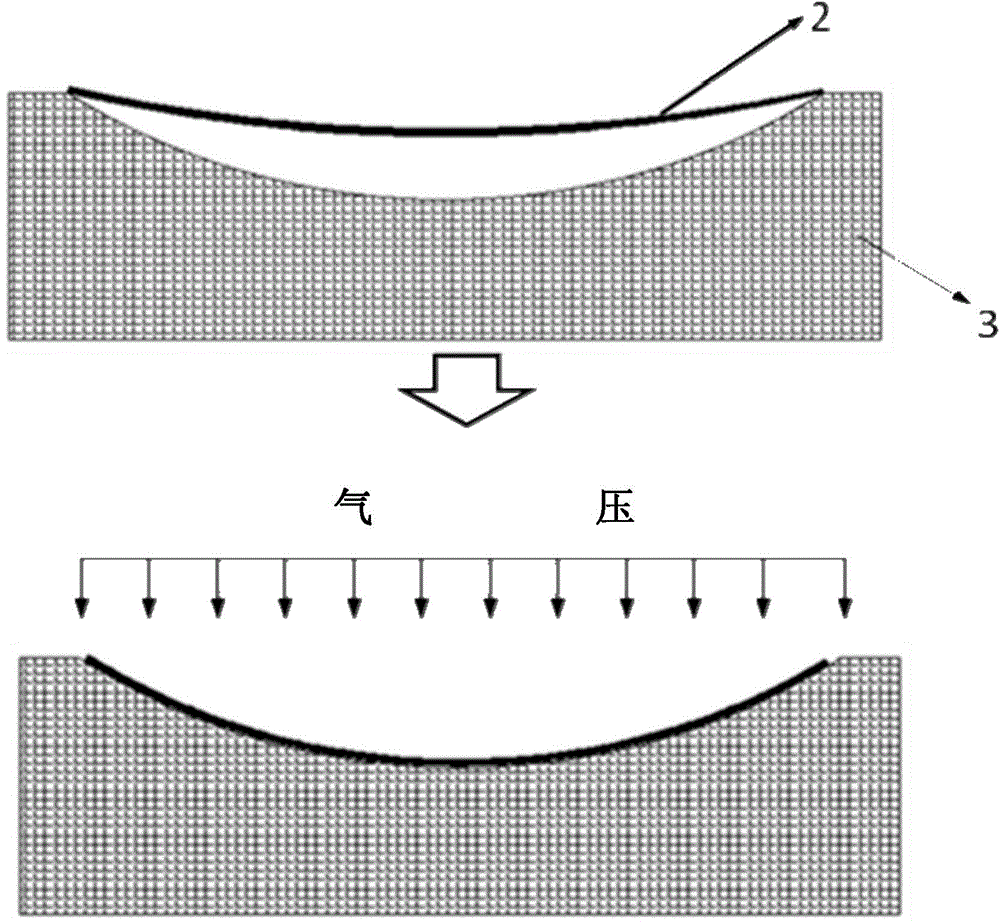

Creep age forming technological method

The invention provides a creep age forming technological method. The technological method comprises the following steps: obtaining molded surface characteristic data of a target part; prebending an initial sheet material according to the molded surface characteristic data, so as to obtain a prebent test piece; placing the prebent test piece to enable the molded surface of the prebent test piece to correspond to that of an age forming die, then jointly packaging the prebent test piece and the age forming die, and performing vacuum treatment on a gap between the prebent test piece and the age forming die; putting the prebent test piece and the age forming die into an autoclave, and changing environment parameters in the autoclave, so as to ensure that the prebent test piece is closely adhered to the molded surface of the age forming die; separating the prebent test piece from the age forming die; enabling the prebent test piece to rebound, so as to form the target part. Accordingly, parts with complex molded surfaces and good material comprehensive properties are formed, the application field of the creep age forming technology is broadened, the flexibility of the forming technology of wallboard components with complex molded surfaces is improved, and the part forming precision is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A kind of production method of high-tower organic-inorganic compound fertilizer

InactiveCN102285830ASmooth and round appearanceGood sustained release effectAgriculture gas emission reductionFertilizer mixturesSolubilityLow nitrogen

A kind of production method of high-tower organic-inorganic compound fertilizer, comprising slurry mixing, granulation, drying, cooling, screening, active humic acid is added in urine, after fully mixing, the obtained mixed slurry is sent into high Tower granulator granulation. The present invention uses active humic acid as the filling material produced by high-tower compound fertilizer, which can not only solve the problem of low nitrogen utilization rate, but also improve the solubility of the product, and combine the synergistic function of humic acid with fertilizer production, It is possible to develop a multifunctional, synergistic and value-added fertilizer. Using the two-stage mixing granulation technology, the problem of the imbalance of the solid-liquid ratio caused by the large solid ratio in the production of organic and inorganic fertilizer products in the high-tower production line is solved; during the production process, urine and humic acid are mixed in the first-stage mixing tank to cause chelation Combination reaction, change their internal valence bond structure, form a large number of stable complex substances, and also help to improve the sustained release of urea.

Owner:河南财鑫实业化工有限责任公司

Bamboo and wood composite veneer for structure and decoration, and method for manufacturing the same

The invention is a structure mainly made of wood and bamboo and relates to decorative wood and bamboo complex gluing sheet and its production technique. Its feature is that the core layers are constructed with normal multi-layer wood, bamboo complex material or multi-layer wood sheets. Outer layer has one or more than one bamboo screen. The outside two bamboo layers is laid equidirectionally to perform when the outer layer has more than on bamboo screen. The face layer is a single wood sheet with perpendicular veins to that of bamboo screens. The coat layer is soaking decorative paper. The product is obtained through processes of gluing, performing, pressing and then once or twice of heat press.

Owner:贵州新锦竹木制品有限公司

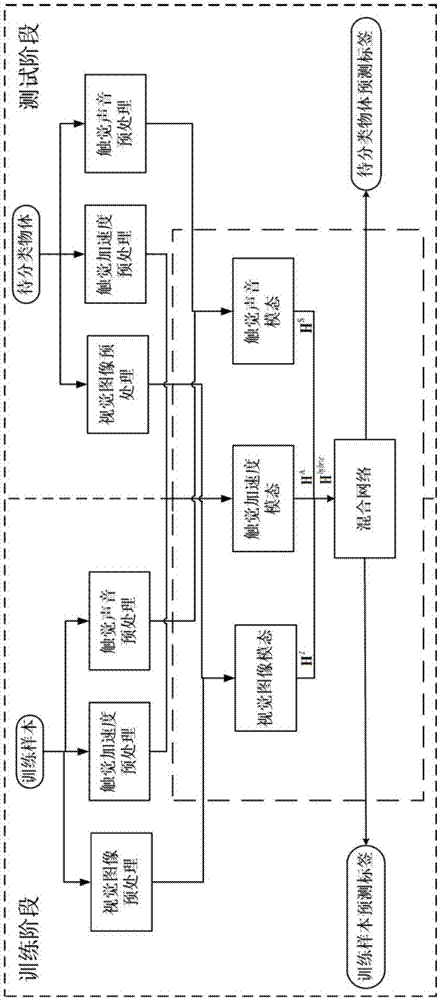

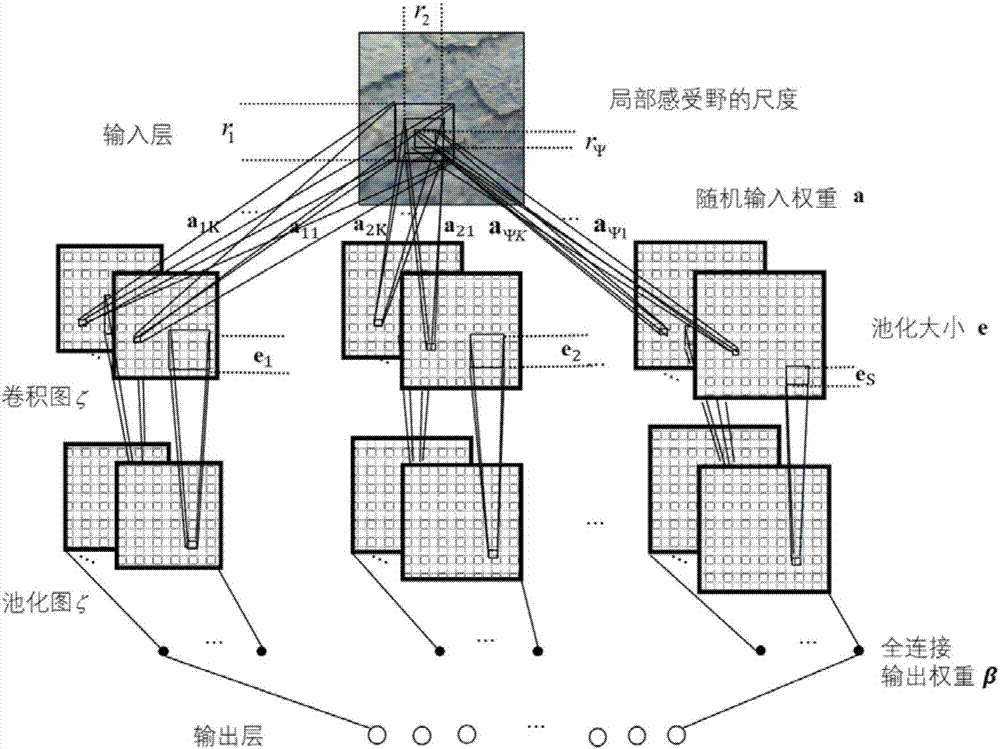

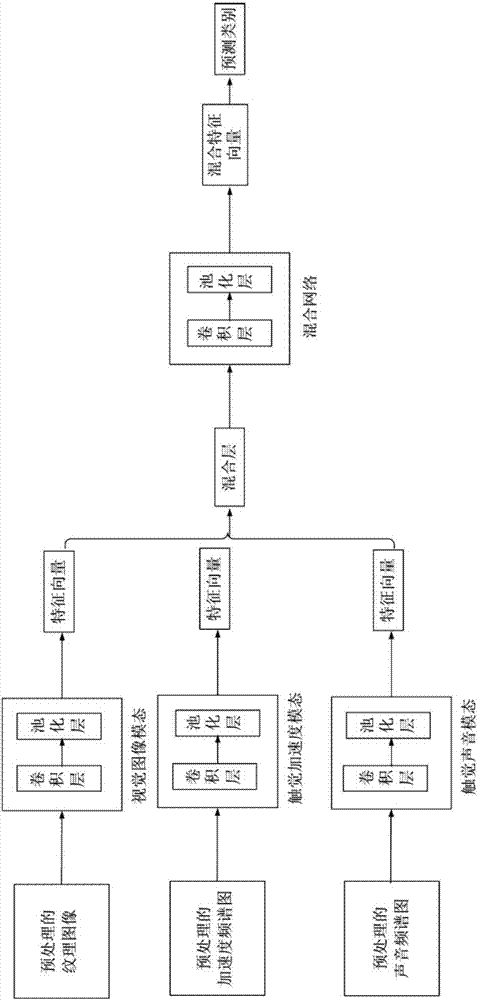

An object material classification method based on multimodal fusion deep learning

ActiveCN107463952AImplement classificationEfficient integrationCharacter and pattern recognitionMachine learningLearning machineMaterial classification

The invention relates to an object material classification method based on multimodal fusion deep learning and belongs to the technical field of computer vision, artificial intelligence and material classification. The object material classification method based on multimodal fusion deep learning is a multimodal fusion method of an extreme learning machine based on multi-scale local reception fields. The method achieves accurate classification of object materials through fusion of perceptual information (including visual images, tactile acceleration signals and tactile sound signals) of different modes of object materials. The method not only can perform high-representativeness feature extraction on complex materials by using multi-scale local reception fields but also can fuse information of all modes effectively to achieve information complementation between modes. The method can improve the robustness and accuracy of complex material classification, thereby having greater applicability and universality.

Owner:TSINGHUA UNIV

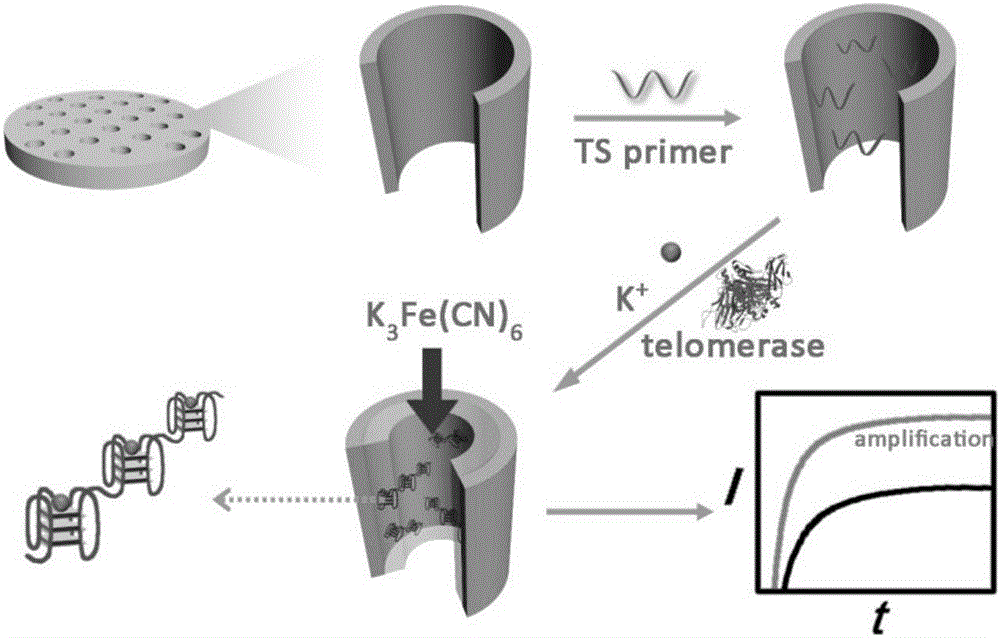

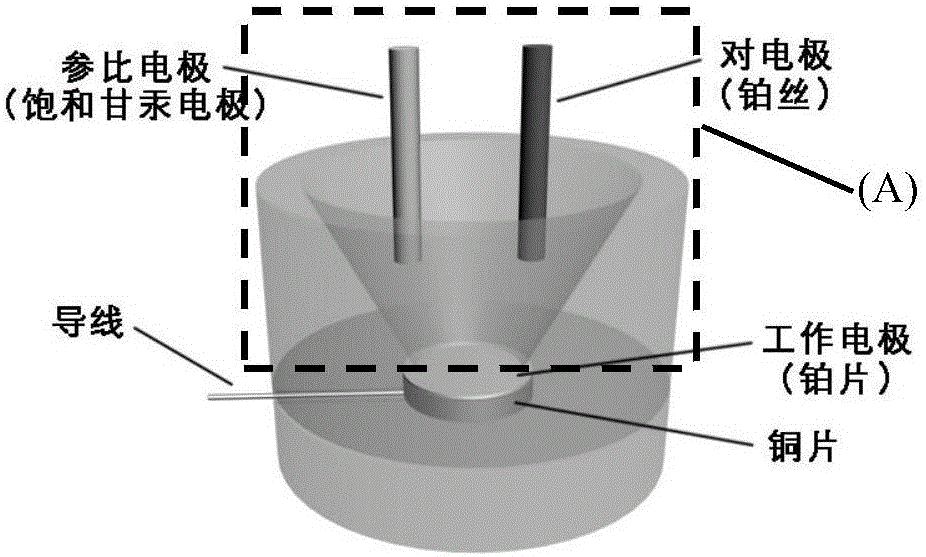

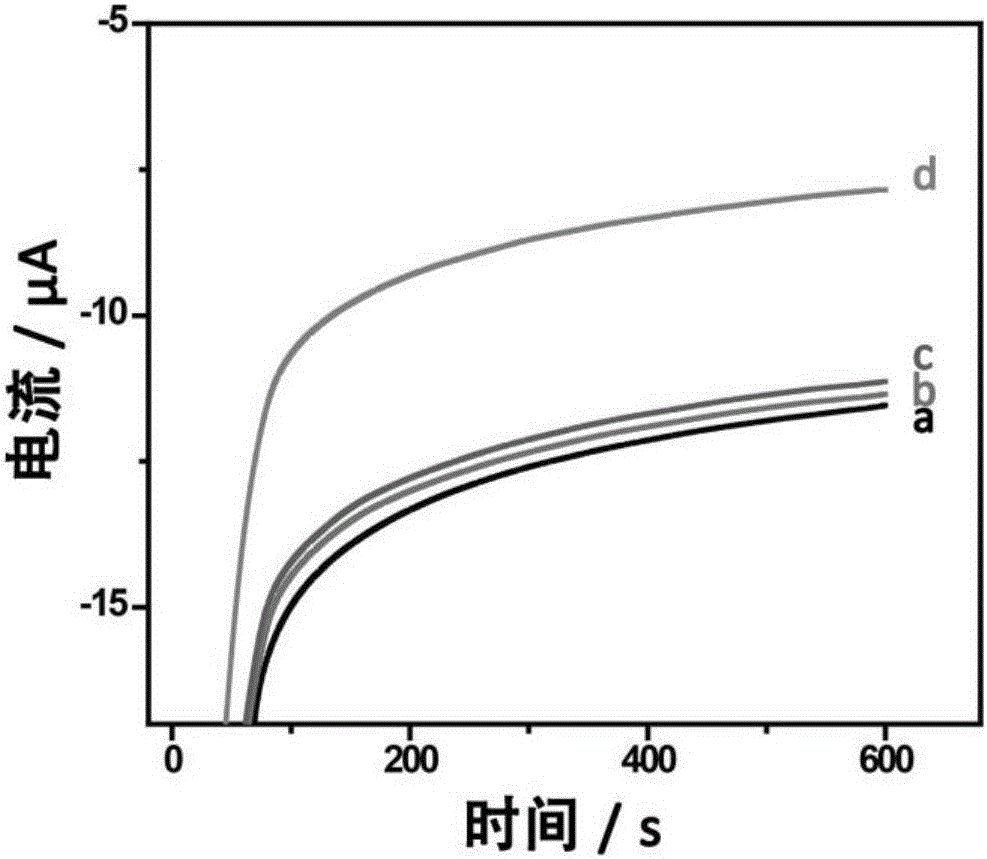

Method for quantitatively detecting telomerase activity based on nano pore channel and electrochemical sensing

ActiveCN105806912AAperture adjustableStable structureMaterial analysis by electric/magnetic meansTelomerasePower flow

The invention discloses a method for quantitatively detecting telomerase activity based on a nano pore channel and electrochemical sensing.The method comprises the following steps that firstly, a telomerase recognition sequence is connected to the inner wall of a porous anodic alumina template or a polyethylene terephthalate film to serve as a primer; secondly, telomerase amplifies the primer to form a G-rich sequence; a G-quadruplex is formed in the presence of potassium ions; electrochemical detection is conducted on the current produced through indicating molecules of the nano pore channel by utilizing an electrochemical workstation.The method does not need complex material preparation and DNA probe marking, and can avoid the defects of high detection cost, complicated operation and poor reproducibility caused by the complex material preparation and DNA probe marking and has the advantages of being low in cost, quick, simple, convenient, high in sensitivity and good in accuracy.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

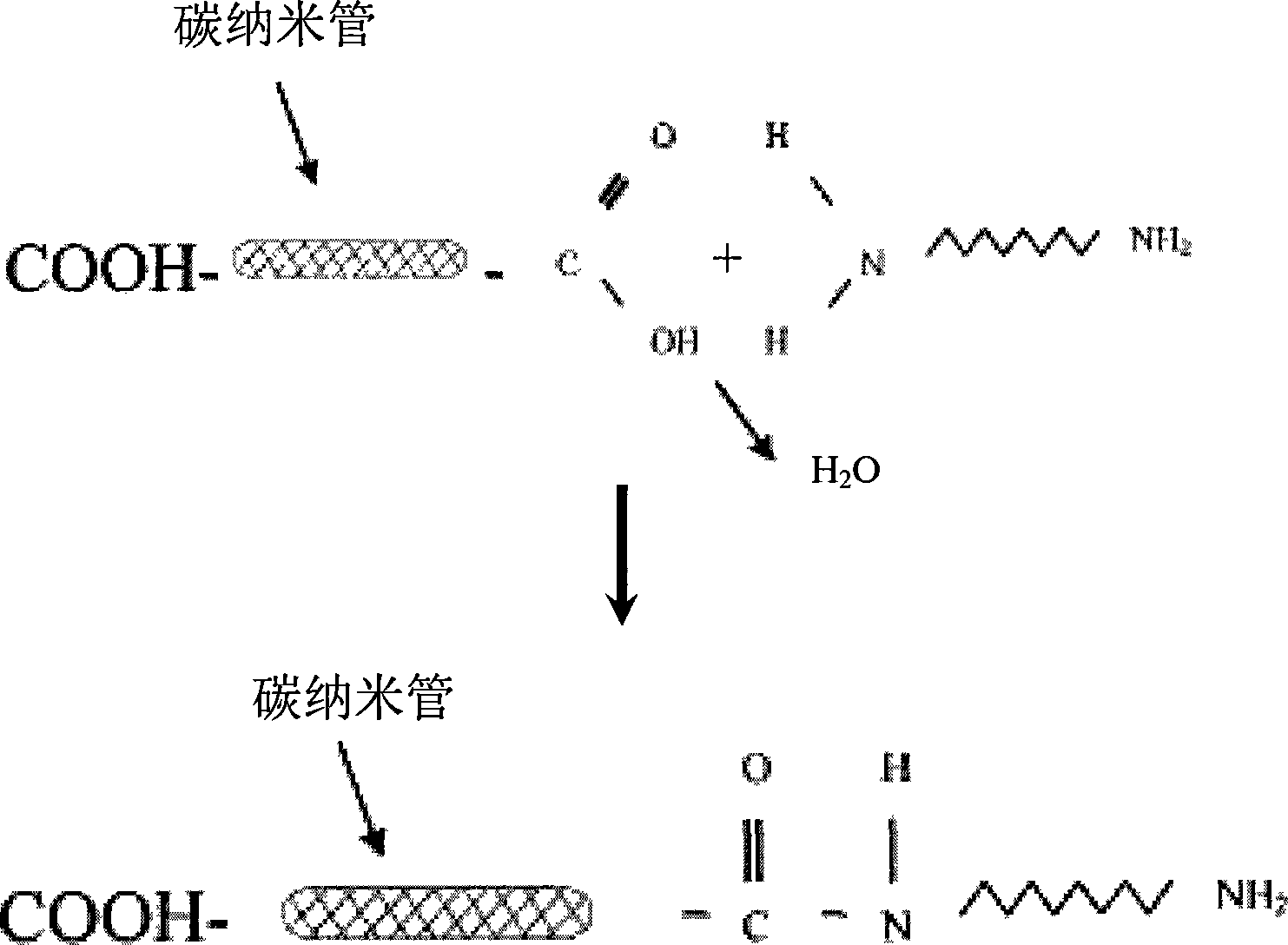

Conducing composite material and preparation method thereof

InactiveCN101085863AImprove conductivityImprove performanceNon-conductive material with dispersed conductive materialCarbon nanotubePolyamide

The invention relates to a conductive complex material, comprising functional carbon nanopipe and polyamide. The weight of said carbon nanopipe is 0.1- 10% of that of polyamide, and said carbon nanopipe is carboxylate carbon nanopipe. The carboxyl in carboxylate carbon nanopipe is reacted with polyamide or amidol in polyamide monomer to generate amido bond. The invention is characterized in that the antistatic property of polyamide is improved, and the conductivity is avaliable, and the application range is enlarged, such as used as nylon rope, nylon bale, pad and nylon braid.

Owner:上海扬泽纳米新材料有限公司

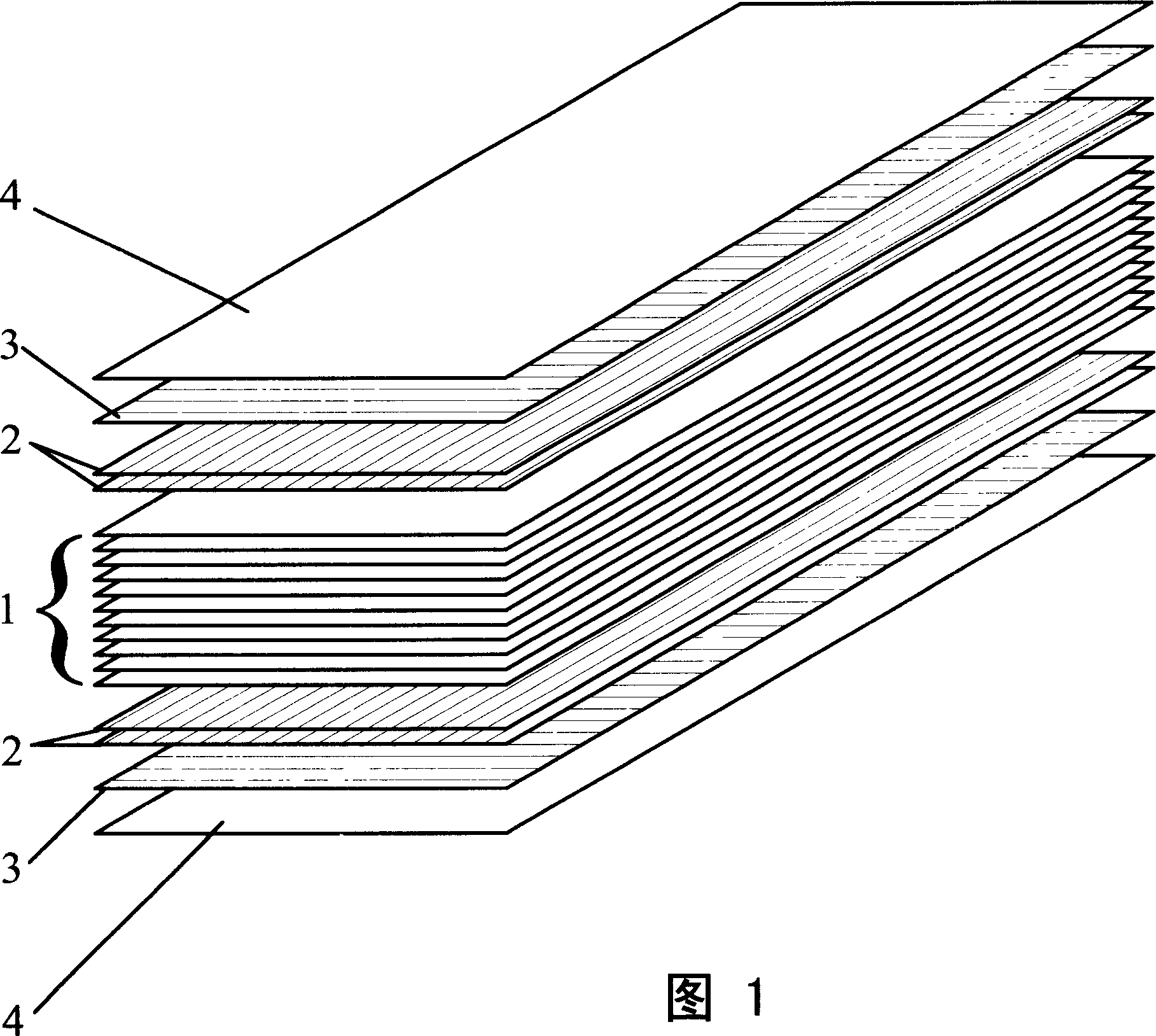

Method for preparing polyimide multilayer complex films containing inorganic nanometer powder

InactiveCN101812183AImprove mechanical propertiesSolve the shortcomings of insufficient mechanical propertiesDiaminodiphenyl etherPolyamic acid

The invention relates to a method for preparing polyimide multilayer complex films containing inorganic nanometer powder. Polyimide multilayer complex materials containing inorganic nanometer powder often reduce the mechanical property of films, and obviously reduce the property of the films especially when the nanometer powder is unevenly distributed. The method comprises the following steps of: (1) pre-processing the inorganic nanometer powder; (2) dissolving 4, 4'- diaminodiphenyl ether and pyromellitic dianhydride as raw material monomers into a solvent, and polymerizing to generate polyamic acid solution; (3) dispersing the pre-processed inorganic nanometer powder to the solvent through an ultrasound, and adding the solvent to the polyamic acid solution to prepare the polyamic acid solution containing the inorganic nanometer powder; (4) sequentially paving films on the polyamic acid solution containing the inorganic nanometer powder and the pure polyamic acid solution; and (5) putting the films in an oven for hot-imidization treatment at the temperature of 50 to 400 DEG C to obtain the polyimide hybrid multilayer complex films containing the inorganic nanometer powder. The invention is used for preparing the polyimide multilayer complex films containing the inorganic nanometer powder.

Owner:HARBIN UNIV OF SCI & TECH +1

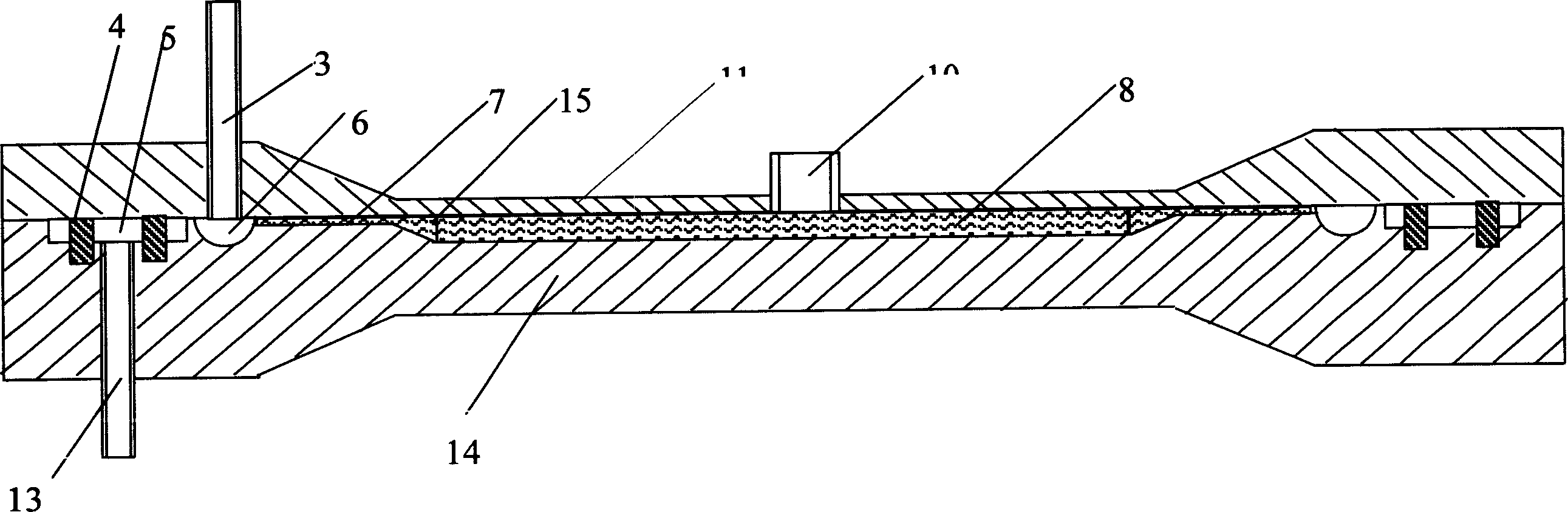

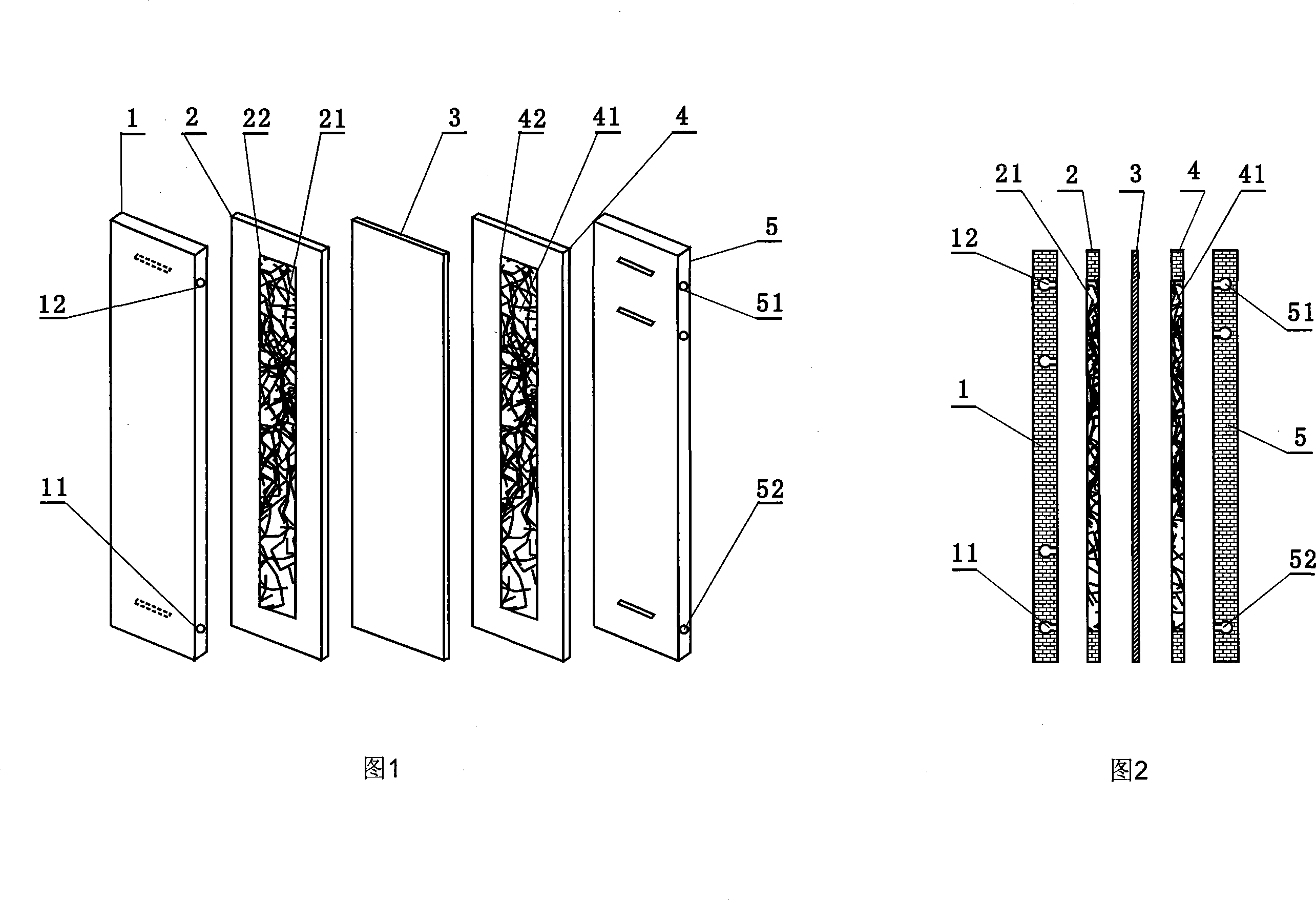

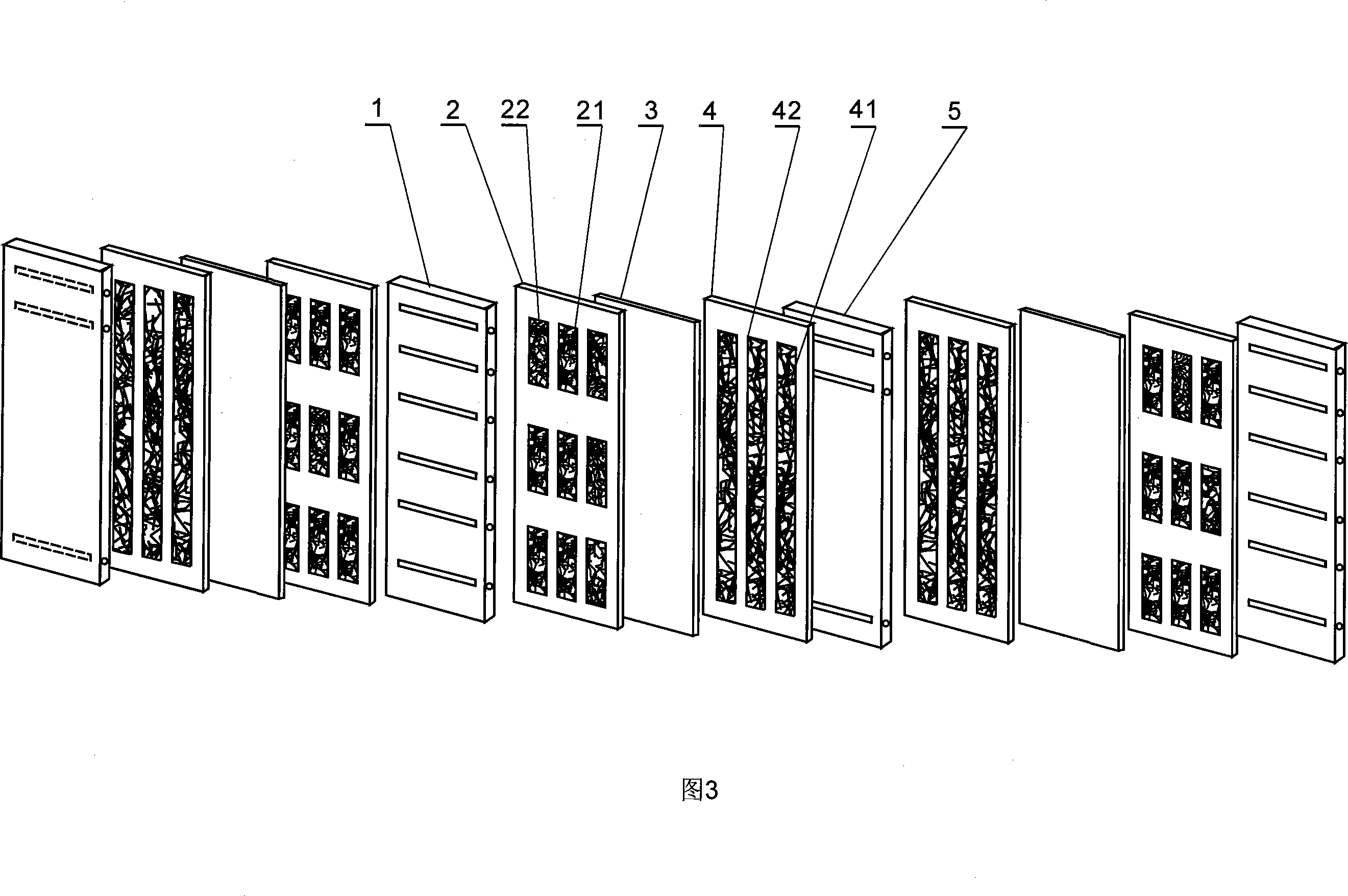

Composite heat exchange filling type micro-reactor

InactiveCN101234323AFacilitates micron-scale segmentationSmall pressure dropChemical/physical/physico-chemical processesComplex materialsHeat transfer fluid

The invention discloses a complex heat transfer filling micro-reactor, consisting of a heat transfer fluid inlet / outlet seal plate, a heat transfer channel plate, a middle heat transfer disc, a reaction channel plate and a reactant inlet / outlet seal plate; wherein, a heat transfer channel and a reaction channel internally filled with complex materials are arranged on the heat transfer channel plate and the reaction channel plate respectively; the heat transfer fluid inlet / outlet seal plate is provided with at least a heat transfer fluid inlet and a heat transfer fluid outlet; the reactant inlet / outlet seal plate is provided with at least a reactant inlet and a reactant outlet; the middle heat transfer disc is arranged in a middle part with two sides which are respectively provided with the heat transfer channel plate and the reaction channel plate; the heat transfer fluid inlet / outlet seal plate is arranged on the other side of the heat transfer channel plate and the reactant inlet / outlet seal plate is arranged on the other side of the reaction channel plate. The micro-reactor of the invention is simple in structure, easy in processing, easy in amplification and lower in manufacturing cost.

Owner:成都民航六维航化有限责任公司

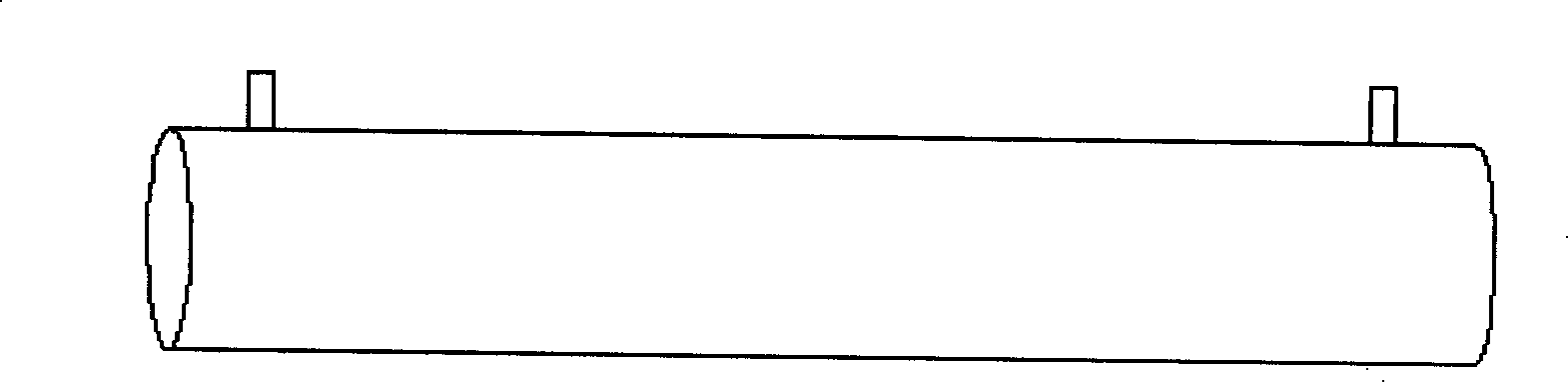

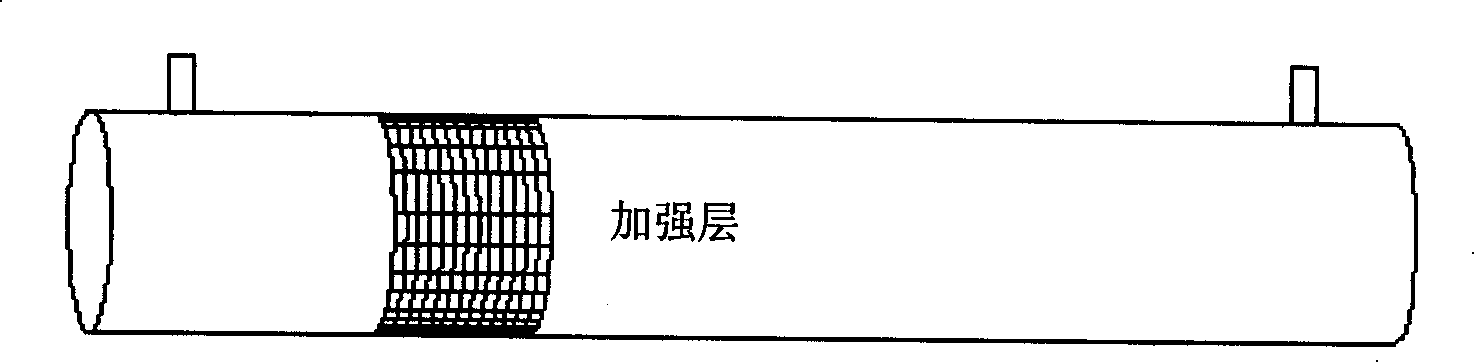

Method for renovation and reinforcement of pipe using basalt fibre complex material

The invention relate to a method applicable to pipeline, in particular to a method of repairing reinforcing or strengthening a metallic pipe. The main materials used in the invention are basalt fiber reinforcing material and resin basis material. According to the invention, as the strength and the modulus of reinforcing or strengthening materials are similar with those of the metallic pipe body material, the materials used in the invention can be integrated with the pipe body into a whole to bear pressure in the pipe together and finally form a bearing capacity of a composite repairing layer reaching or exceeding the bearing capacity of the original pipe; as the basalt fiber material is insulating, the compatibility between the pipe and cathodic protection and the electrochemical corrosion resistant capacity of the pipe are greatly improved. The method provided by the invention which has simple construction not only facilitates the close attaching between the reinforcing material and the pipe body and between reinforcing layers, but also enables repairing reinforcing and strengthening operations on pipelines in active service.

Owner:BEIJING SAFETECH PIPELINE

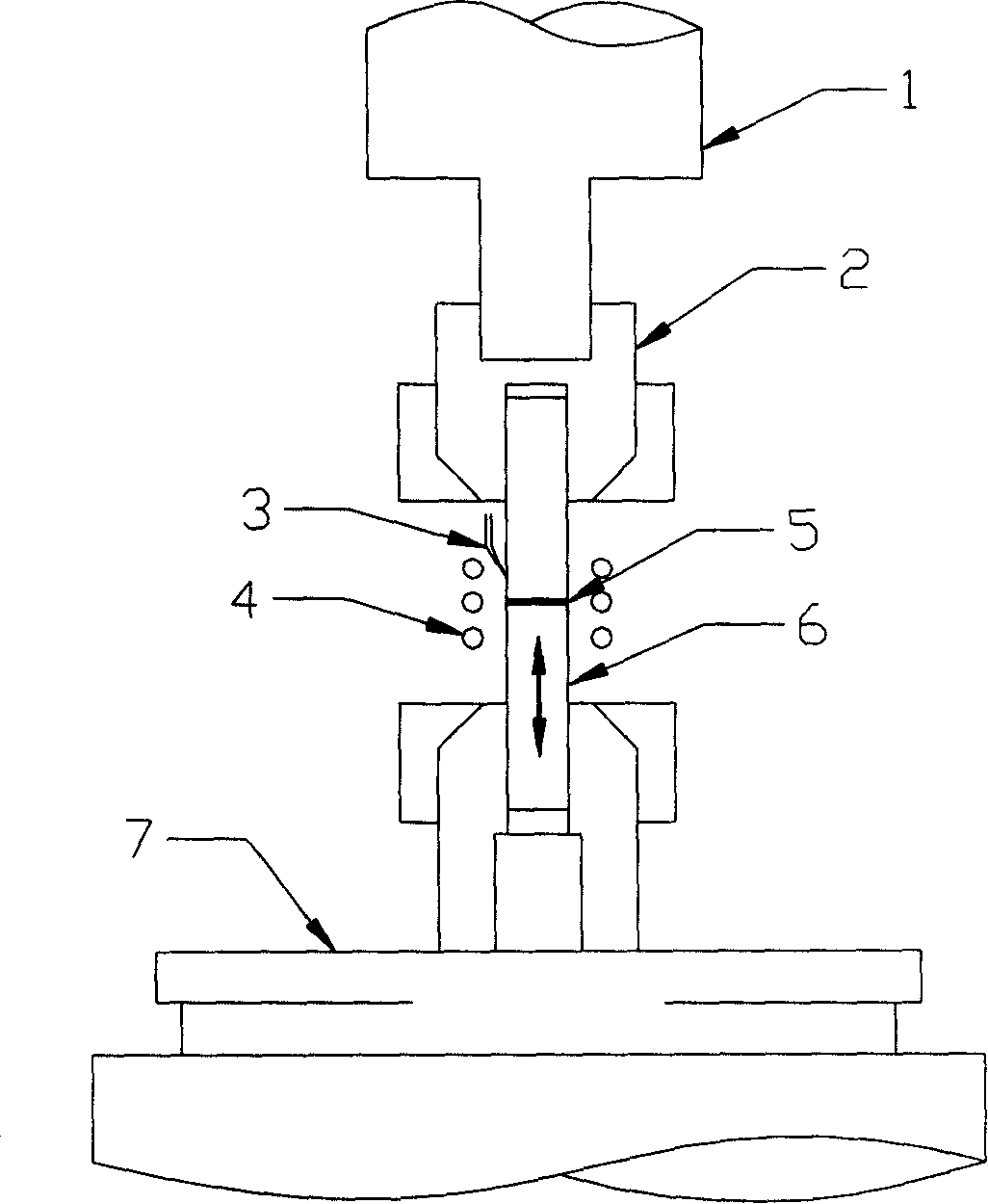

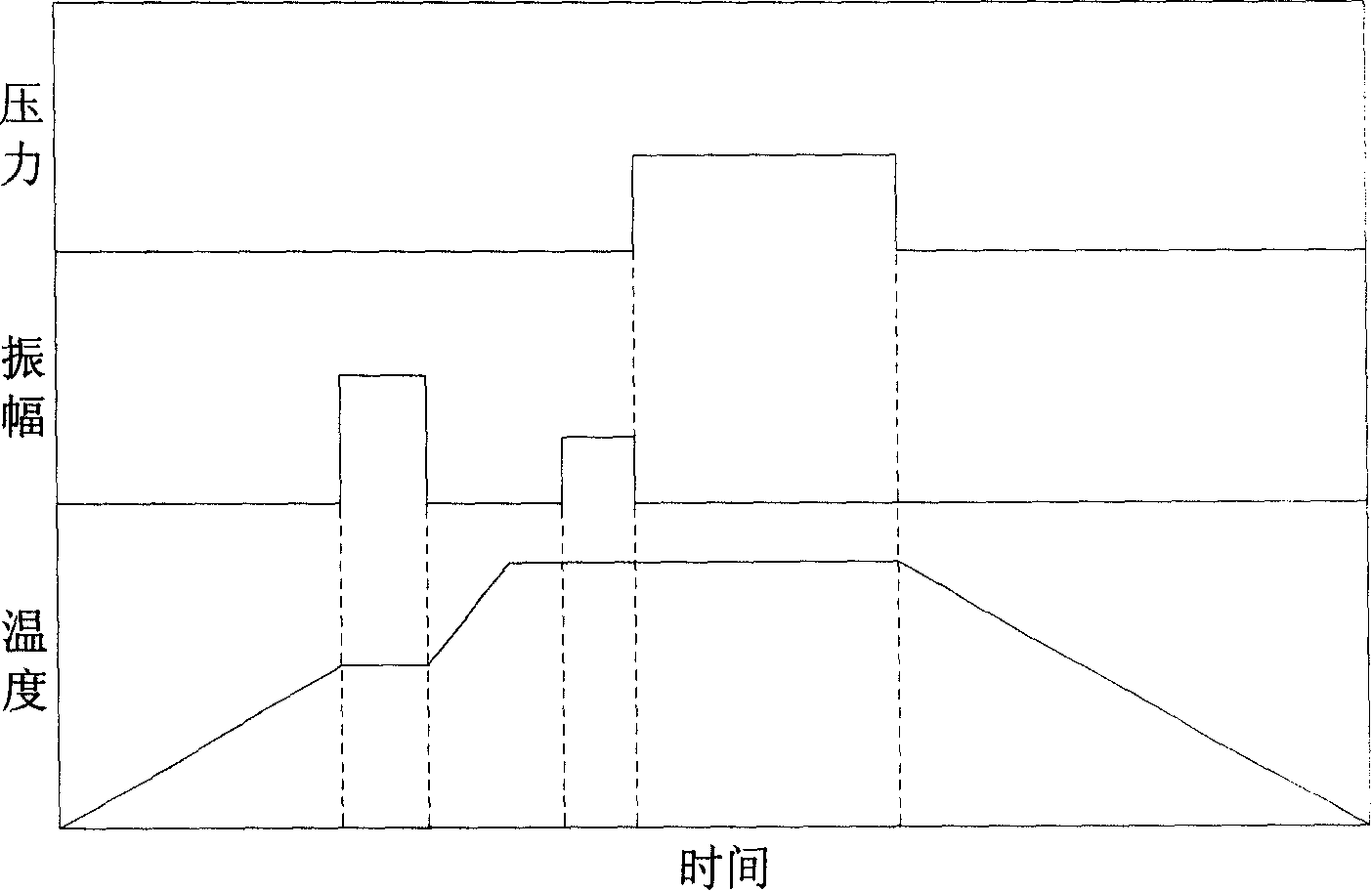

Aluminum alloy and its composite material non-vacuum semi-solid state vibration-rheological connection method

InactiveCN1876302AAchieve weldingShort welding cycleSoldering apparatusNon-electric welding apparatusForce constantSemi solid

The invention provides a method for anti-vacuum vibrating theological connecting aluminum alloy and its complex material. The invention is characterized in that: clamping aluminum alloy or complex material weldment on chucking appliance and placing medium temperature welding material on two pre-welding surface, heating weldment with temperature being 380-400 Deg. C, starting vibrating device after welding material fusion, the amplitude is 0.1-0.5 mm. The temperature during vibrating process is the same, and the vibrating time is 10-300 seconds. The temperature is increased to 450-520 Deg. C after vibration, and it is kept for 1-5 minutes. Then starting vibrating device again, the amplitude is 0.1-1 mm, stopping after 3-60 seconds, forcing constant pressure with pressure range being between 0.1-2 Mpa, keeping temperature for 5-30 minutes, and cooling. The invention is characterized by low cost, high efficiency and quality.

Owner:HARBIN INST OF TECH

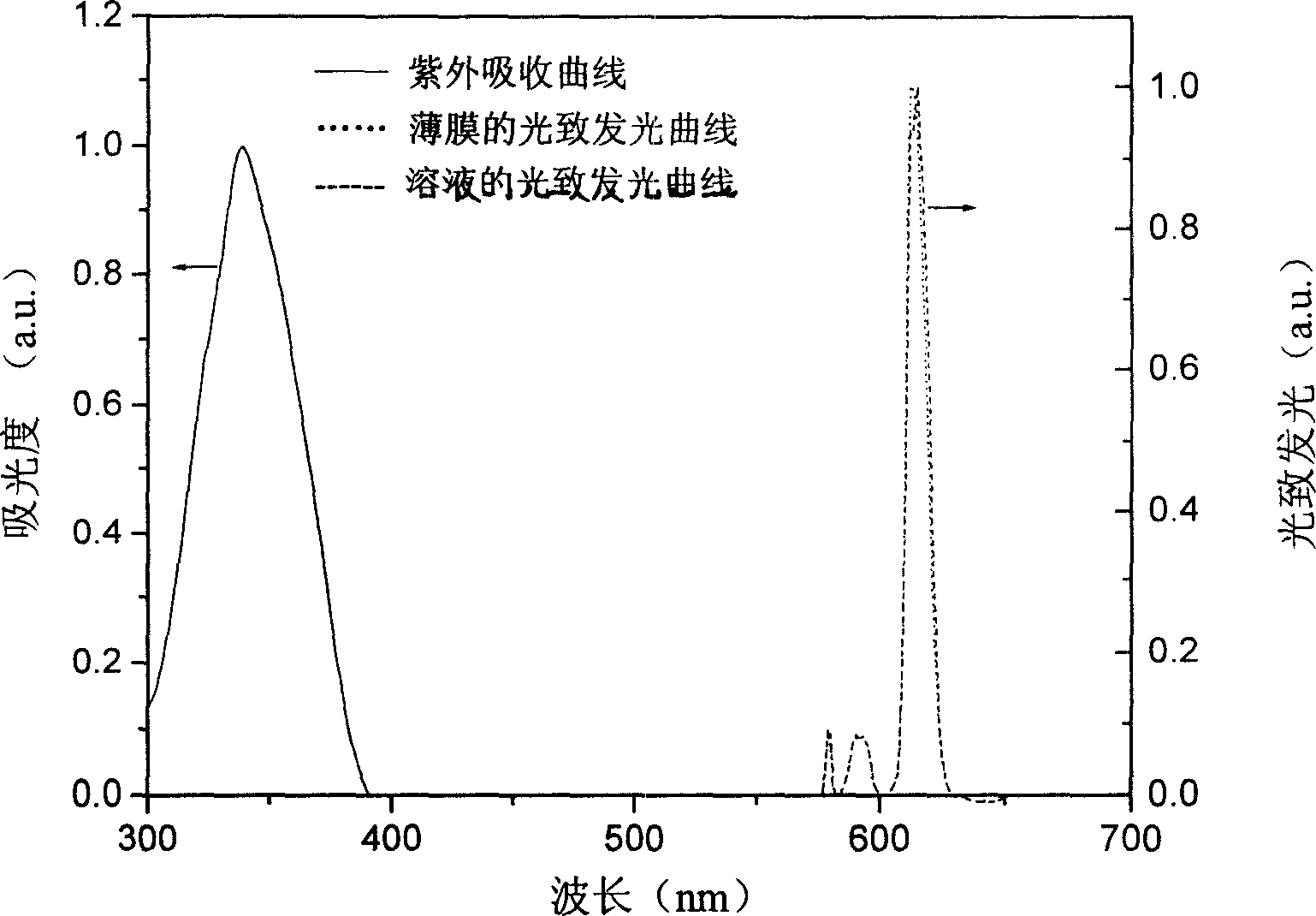

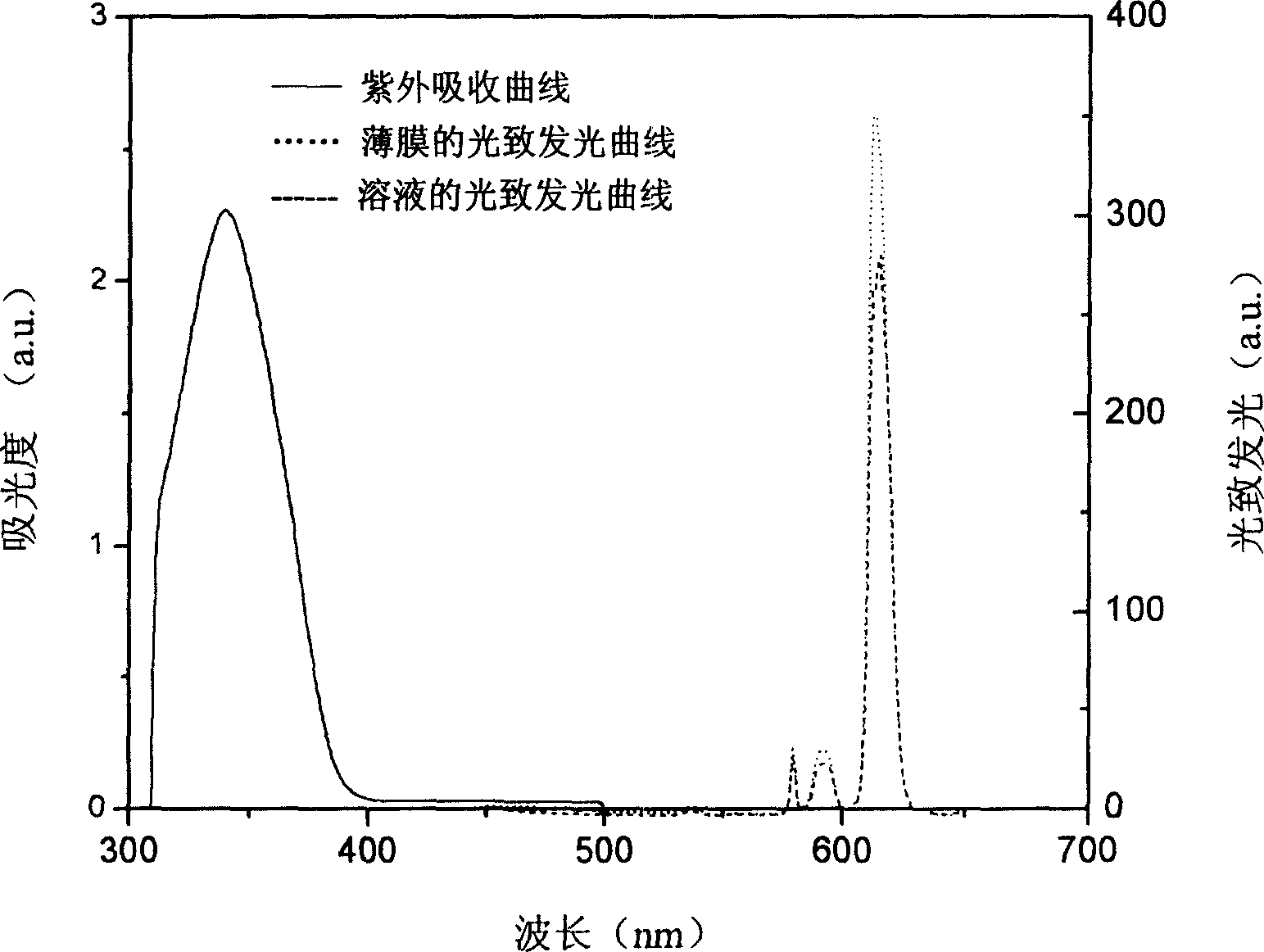

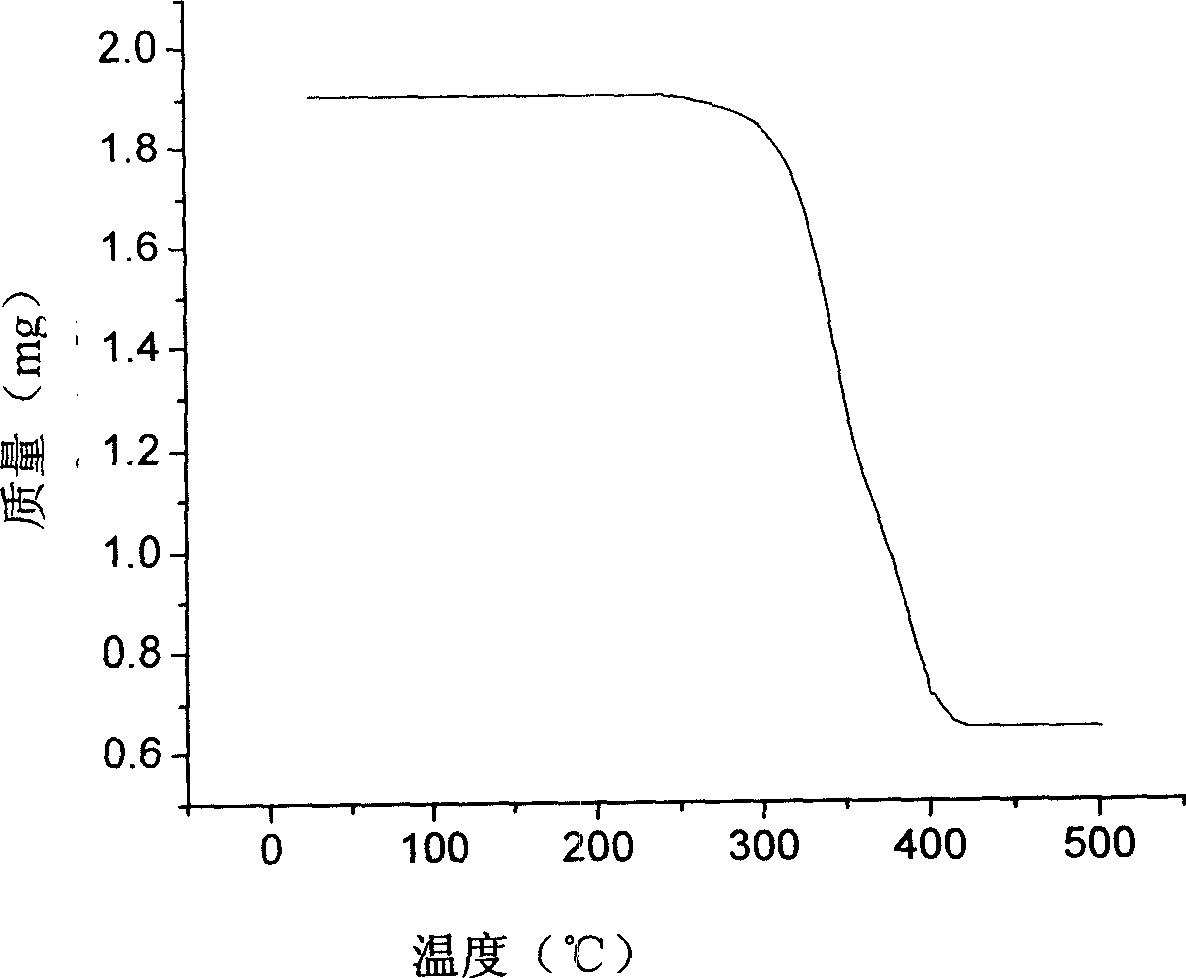

Rare earth complexes chelated by aromatic base substituted diphosphine dioxide and its synthesizing process

InactiveCN1687080AElectrical apparatusGroup 5/15 element organic compoundsHigh current densityRare earth

The present invention relates to a kind of high-performance photoelectric function rare earth complex material and its preparation method. Said invention uses substituted diphosphine dioxide containing aromatic group as ligand, and utilizes complexation reaction to synthesize a series of high-effective rare earth photoelectric function complexes, and prepares doped red electroluminescent device containing above-mentioned rare earth photoelectric function material, said electroluminescent device can obtan satisfactory result in the luminance, current density and efficiency under the high current density.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com