Method for manufacturing metal/carbon nanotube nano-composite using electroplating

a technology of carbon nanotubes and nano-composites, applied in the direction of nanotechnology, material nanotechnology, coatings, etc., can solve the problem of replacing existing metal thin film materials with big problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

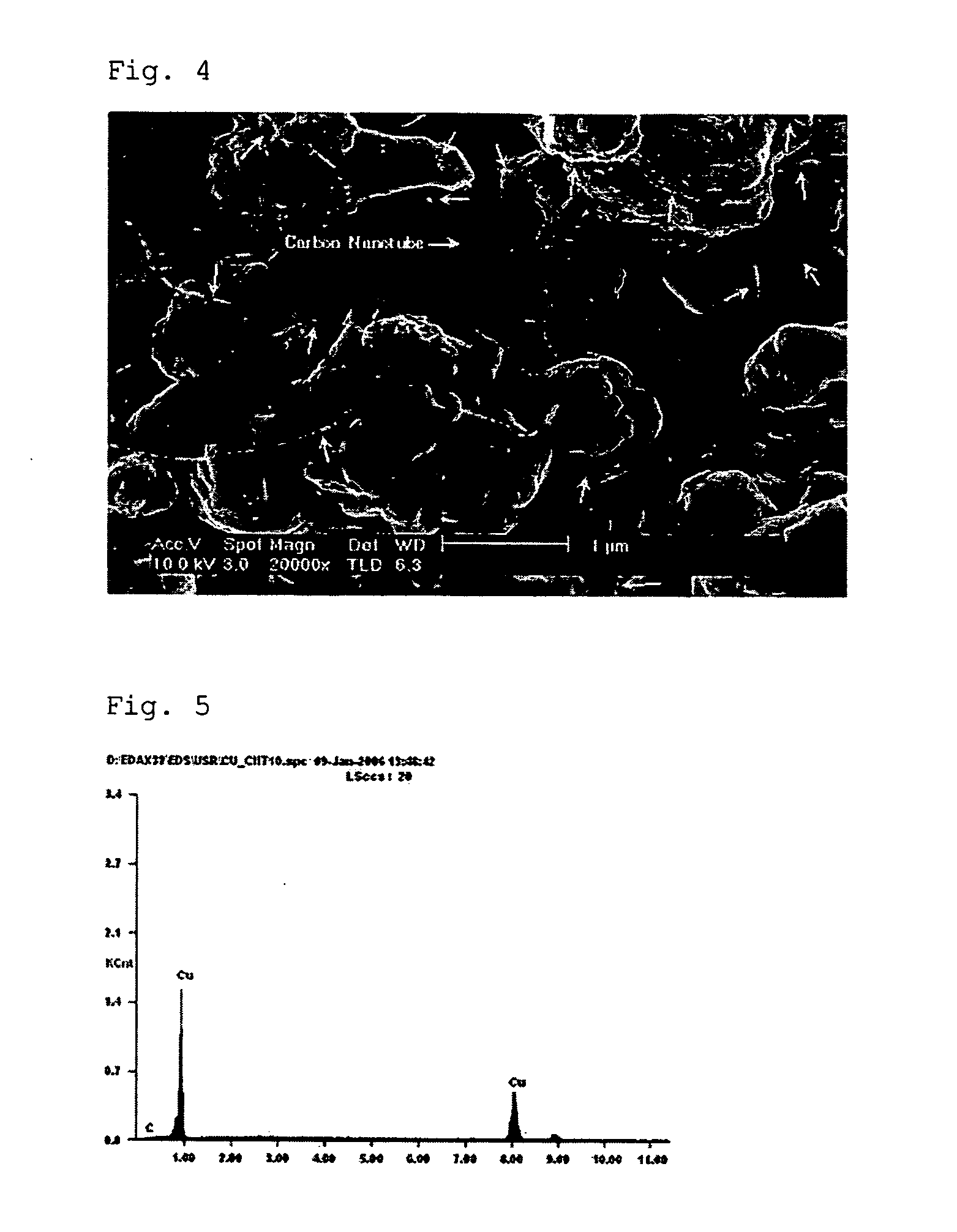

[0017]Hereinafter, the present invention now will be described in detail with reference to the accompanying drawings by steps.

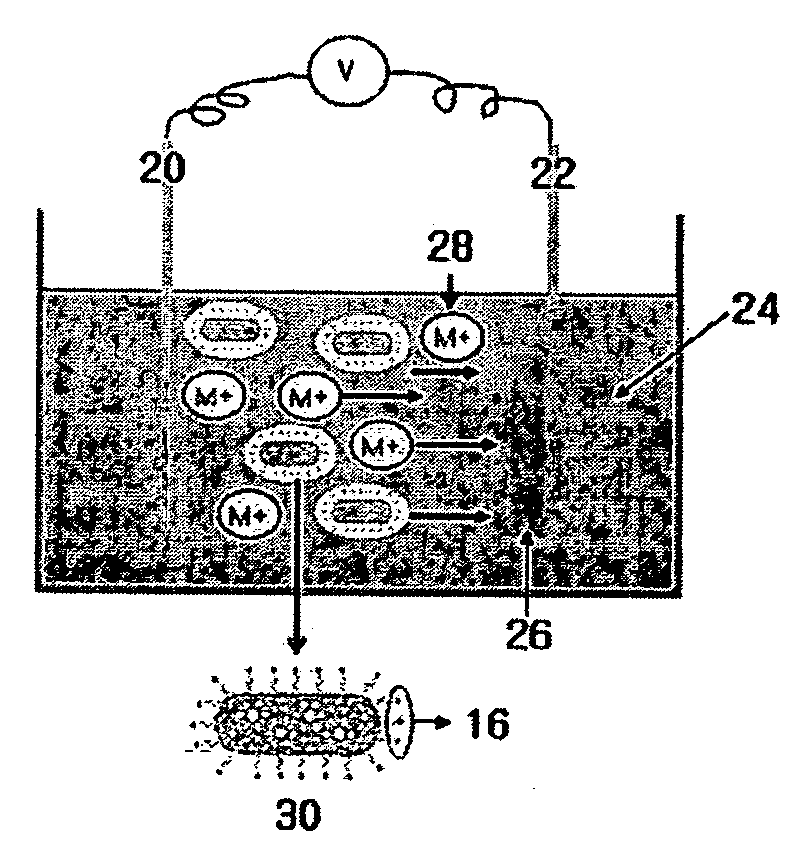

[0018]FIG. 1 is a schematic view showing a step for purifying and cutting carbon nanotubes in acid solution.

[0019]Acid treatment of carbon nanotubes is carried out in acid solution in order to remove residues such as catalyst metals of carbon nanotubes and to cutting(sever) the carbon nanotube into the level of molecules via an oxidation.

[0020]The acid solution may use at least one of sulfuric acid, nitric acid and hydrochloric acid. The embodiment described later uses acid solution with a component of sulfuric acid to nitric acid of 3:1 in volume ratio.

[0021]After carbon nanotubes are immersed into the acid solution, the predetermined treatments may be further carried out in order to improve purifying and cutting the carbon nanotubes. As an instance of these treatments, at least one of sonication, laser treatment and a stirring by an agitato r in acid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com