Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

A technology of mixing solution, tungsten and molybdenum, applied in the field of tungsten and molybdenum metallurgy, to achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Organic phase composition (volume percentage): 80% TBP+10% P350+10% sulfonated kerosene.

[0038] Raw material liquid: A company uses sulfur-phosphorus mixed acid to obtain the leaching liquid of high-molybdenum scheelite, containing WO 3 120.5g / L, Mo 12.05g / L, phosphoric acid concentration 1.3mol / L, sulfuric acid concentration 1.1mol / L.

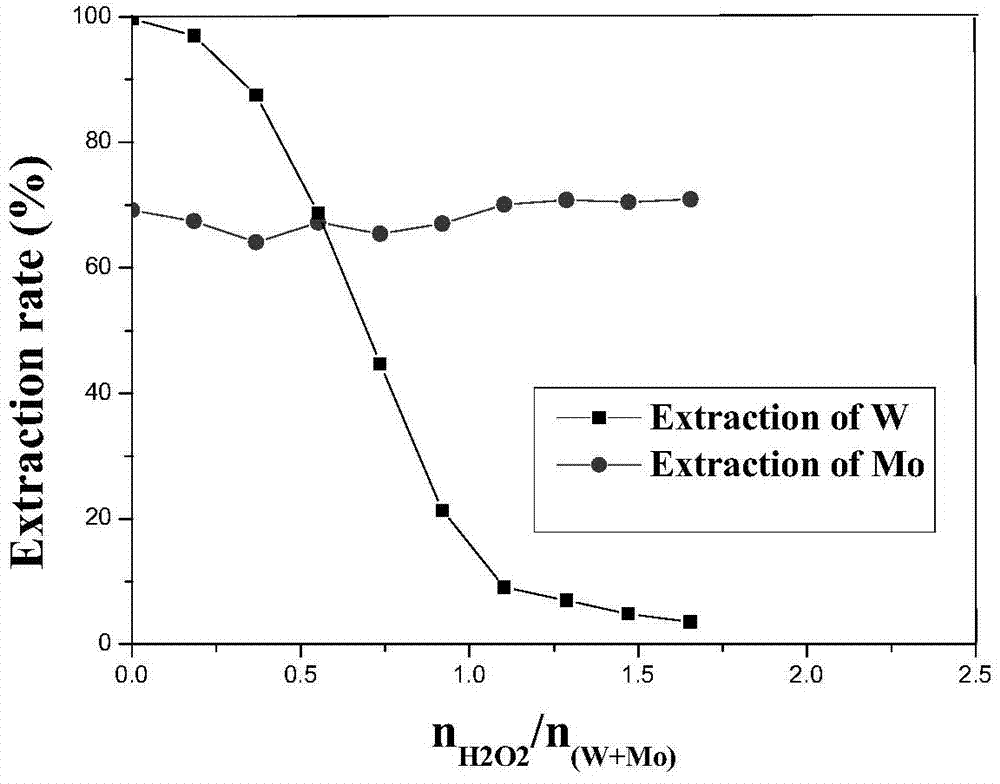

[0039] Feed liquid adjustment: add H at a concentration of 30% to it 2 o 2 solution, H 2 o 2 The added amount is 1.4 times of the total amount of moles of tungsten and molybdenum. get containing WO 3 114.1g / L, Mo 11.41g / L, WO 3 / Mo=10 / 1, a hydrogen peroxide-containing feed solution with a phosphoric acid concentration of 1.2 mol / L and a sulfuric acid concentration of 1 mol / L.

[0040] Extraction and separation: the above-mentioned organic phase and aqueous phase feed liquid are subjected to 6-stage countercurrent extraction under the condition of a ratio of 1 / 1 to obtain a loaded organic phase and a raffinate. Wherein, the loa...

Embodiment 2

[0043] Organic phase composition (volume percentage): 70% TBP+15% P350+15% sulfonated kerosene.

[0044] Raw material liquid: a company uses phosphate to decompose high-molybdenum scheelite under alkaline conditions. The leaching liquid contains WO 3 105.3g / L, Mo 5.27g / L, phosphorus concentration 0.82mol / L, sodium hydroxide concentration 0.4mol / L.

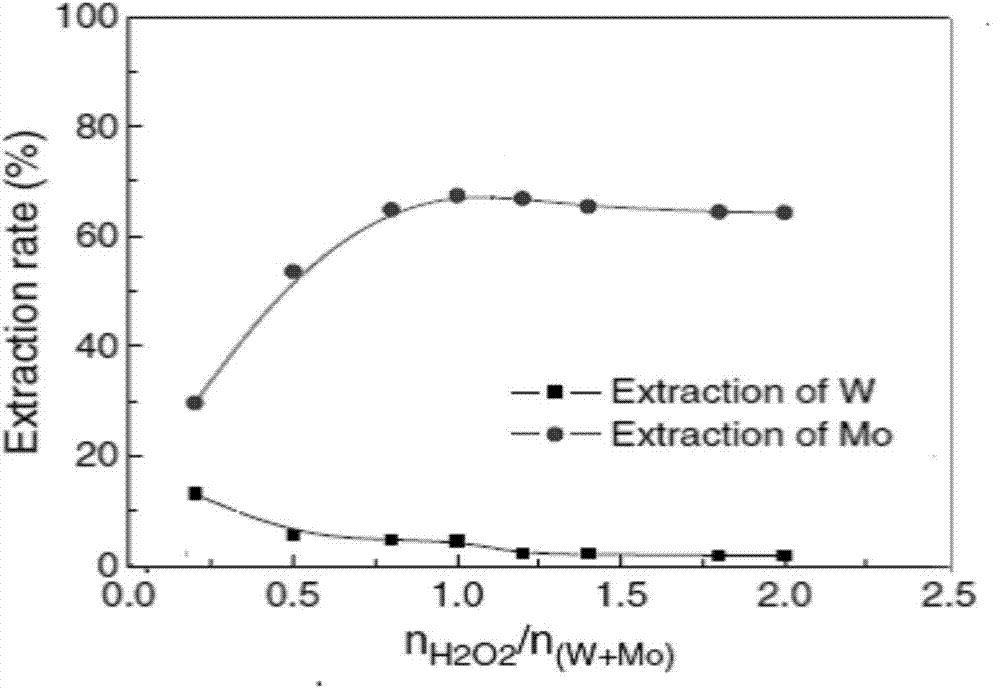

[0045] Feed liquid adjustment: add sulfuric acid thereinto, the final feed liquid containing sulfuric acid concentration is 1.4mol / L; And add concentration is 30% H 2 o 2 solution, H 2 o 2 The added amount is 0.8 times of the total amount of moles of tungsten and molybdenum. The final result contains WO 3 90.5g / L, Mo 4.53g / L, WO 3 / Mo=20 / 1, a hydrogen peroxide-containing feed solution with a phosphorus concentration of 0.7mol / L and a sulfuric acid concentration of 1.4mol / L.

[0046] Extraction and separation: the above-mentioned organic phase and aqueous phase feed liquid are subjected to 5-stage countercurrent extraction un...

Embodiment 3

[0049] Organic phase composition (volume percent): 80% TBP+20% benzene.

[0050] Raw feed liquid: feed liquid contains WO 3 8.21g / L, Mo 82.1g / L, phosphorus concentration 4.5mol / L, nitric acid concentration 2.6mol / L, hydrochloric acid concentration 1.9mol / L.

[0051] Feed liquid adjustment: add H to it 2 o 2 solution, H 2 o 2 The added amount is 1.2 times of the total amount of moles of tungsten and molybdenum. get containing WO 3 7.21g / L, Mo 72.1g / L, WO 3 / Mo=1 / 10, a hydrogen peroxide-containing feed solution with a phosphorus concentration of 4mol / L, a nitric acid concentration of 2.3mol / L, and a sulfuric acid concentration of 1.7mol / L.

[0052] Extraction and separation: the above-mentioned organic phase and aqueous phase feed liquid are subjected to 4-stage countercurrent extraction under the condition of a ratio of 2 / 1 to obtain a loaded organic phase and a raffinate. Wherein, the loaded organic phase is back-extracted with 1mol / L ammonium carbonate aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com