A kind of roasting decomposition method of mixed rare earth ore

A mixed rare earth and roasting technology, which is applied in the roasting and decomposition of sodium carbonate of mixed rare earth ore, the recovery process of thorium, fluorine and phosphorus, rare earth, roasting and decomposition of mixed rare earth ore, which can solve the problems of sodium carbonate agglomeration and reduce the consumption , Reduce production costs, no exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

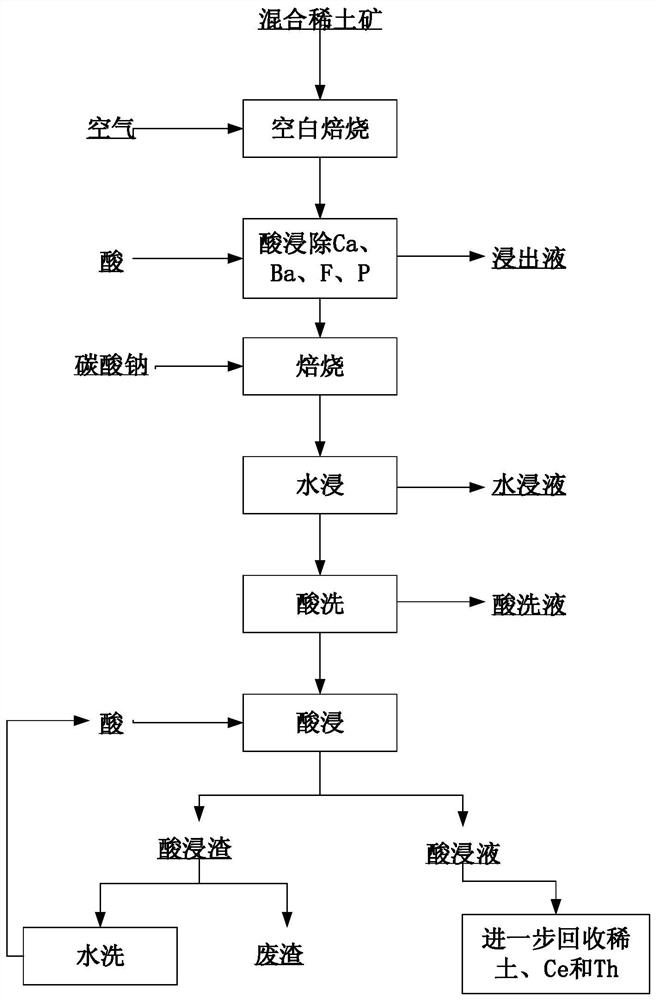

[0062] This embodiment provides a method for roasting and decomposing mixed rare earth ores, such as figure 1 As shown, the method includes the following steps:

[0063] (1) heating up the mixed rare earth ore to 550° C. in the air for blank roasting for 3 hours;

[0064] (2) According to the solid-to-liquid ratio of 2:1, the roasted product obtained in step (1) is mixed with hydrochloric acid with a concentration of 25 wt%, and then leached at 35° C., and the leachate and slag are obtained after filtering;

[0065] (3) Mix the slag and sodium carbonate obtained in step (2) according to a mass ratio of 3:1, heat up to 800°C and roast for 1.5h, and then use the obtained roasted product under water at 40°C according to a solid-to-liquid ratio of 1:1 Carry out leaching, obtain water immersion liquid and water leaching residue after filtering;

[0066] (4) According to the solid-to-liquid ratio of 2:1, use the hydrochloric acid that concentration is 10wt% to carry out pickling t...

Embodiment 2

[0070] Compared with Example 1, except that the temperature of sodium carbonate roasting in step (3) is adjusted to 650 ℃, other steps and conditions are exactly the same as Example 1.

Embodiment 3

[0072] This embodiment provides a method for roasting and decomposing mixed rare earth ores, said method comprising the following steps:

[0073] (1) heating up the mixed rare earth ore to 500° C. in the air and roasting in blank for 5 hours;

[0074] (2) According to the solid-to-liquid ratio of 2.5:1, the roasted product obtained in step (1) is mixed with hydrochloric acid with a concentration of 15 wt%, and then leached at 50°C, and the leachate and slag are obtained after filtering;

[0075] (3) Mix the slag and sodium carbonate obtained in step (2) according to a mass ratio of 4.5:1, heat up to 700° C. and roast for 1.5 h, and then use the obtained roasted product at 30° C. Carry out leaching, obtain water immersion liquid and water leaching residue after filtering;

[0076] (4) According to the solid-to-liquid ratio of 2:1, use hydrochloric acid with a concentration of 15wt% to pickle the water leaching residue obtained in step (3) at 25° C. to obtain pickling solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com