Patents

Literature

197results about How to "Solve agglomeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

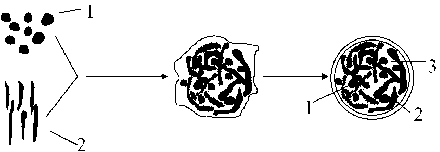

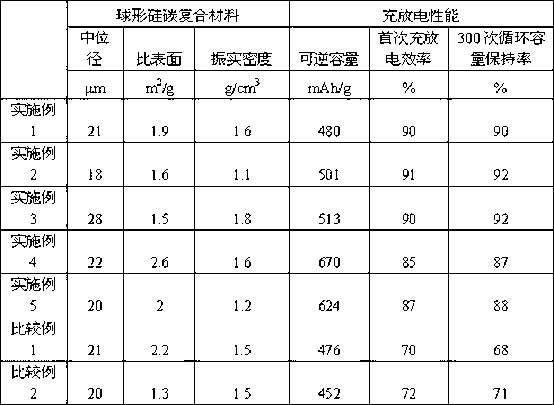

Spherical silicon carbon composite anode material of lithium ion battery and preparation method for spherical silicon carbon composite anode material

InactiveCN102709566AHigh specific capacityGood sphericityCell electrodesCarbon compositesElectrical battery

The invention provides a spherical silicon carbon composite anode material of a lithium ion battery and a preparation method for the spherical silicon carbon composite anode material. The spherical silicon carbon composite anode material comprises 5 to 12 percent of silicon, 68 to 90 percent of graphite and the balance of carbon material. A spherical precursor is prepared from silicon powder, flake graphite and the carbon source material by a constant-temperature mixing technology; and the spherical silicon carbon composite anode material is prepared by balling high-temperature thermal treatment, wherein the core of spherical silicon carbon composite anode material is anisotropically distributed and the surface of the flake / carbon is wrapped by the carbon material. In the spherical silicon carbon composite anode material, the reversible capacity can reach more than 480 Ah / g; the sequential efficiency at the first time can reach over 85 percent; and the capacity retention rate after circulation is performed for 300 times is more than 87 percent.

Owner:力芯(青岛)新能源材料有限公司

Children coating and preparation method thereof

The invention provides a children coating and a preparation method of the children coating. The children coating provided by the invention comprises the following raw materials: wood fibers, a purified emulsion, kieselguhr, an anion additive, titanium dioxide, triple superphosphate powder, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a preservative, a mildew preventive and tap water and the like. The wood fibers are added into the environmentally-friendly children coating by the invention so as to change the structure and the texture of a surface of a paint film, thereby feeling soft and smooth; and in addition, the porosity of the paint film is improved by the wood fibers in the paint film, the breathable performance is good, the quantity of heat and the transmission capacity of voice are reduced, and a good humidifying function can be created by the gaps of the paint film.

Owner:ZHEJIANG ZHIQIANG PAINT

Camellia oil microcapsule powder and preparation method thereof

InactiveCN102048159AImprove liquidityImprove stabilityFood shapingFood preparationEmulsionFreeze-drying

The invention discloses camellia oil microcapsule powder and a preparation method thereof. The camellia oil microcapsule powder comprises a core material and a capsule material for coating the core material, wherein the core material includes 1 part of camellia oil by weight, and the capsule material includes 0.8-9 parts of modified polysaccharide-SSOS (starch sodium octenyl succinate) by weight.The preparation method is as follows: camellia oil is added into an aqueous solution of SSOS, the solution is stirred to be a uniform emulsion system, the emulsion is subjected to high-pressure homogenizing through a high-pressure homogenizing machine to form a camellia oil emulsion, then camellia oil emulsion is subjected to spray drying or freeze drying, and finally the while camellia oil microcapsule powder with the grain size less than 1000 nm can be obtained and has high stability and good flowability. The camellia oil microcapsule powder keeps the activity of camellia oil, improves the stability and the bioavailability of camellia oil, and can be applied to food and health care products.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

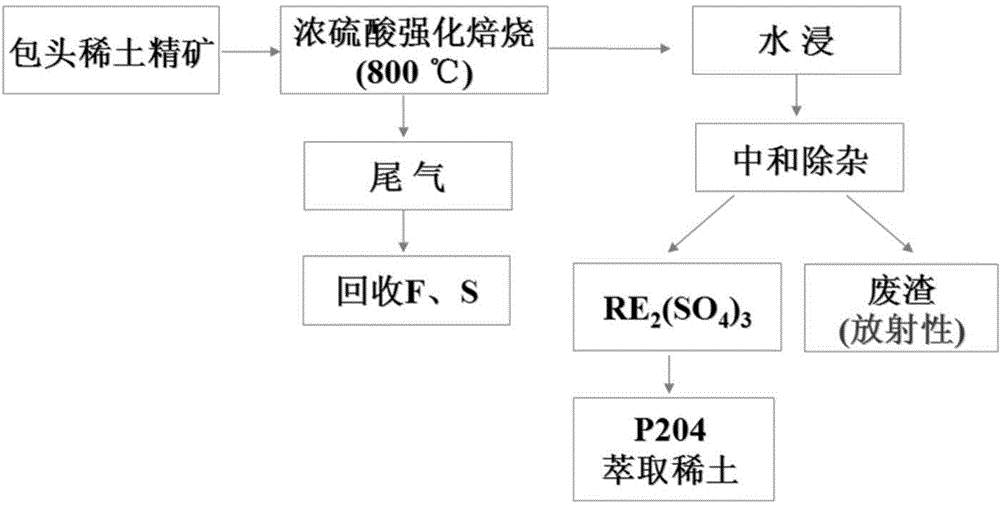

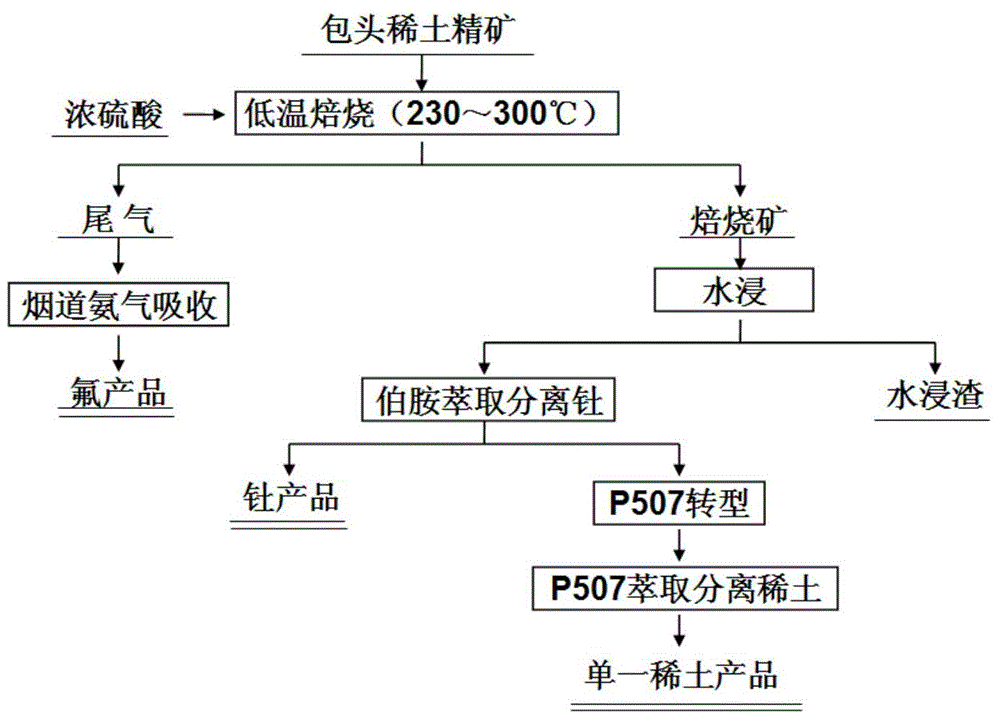

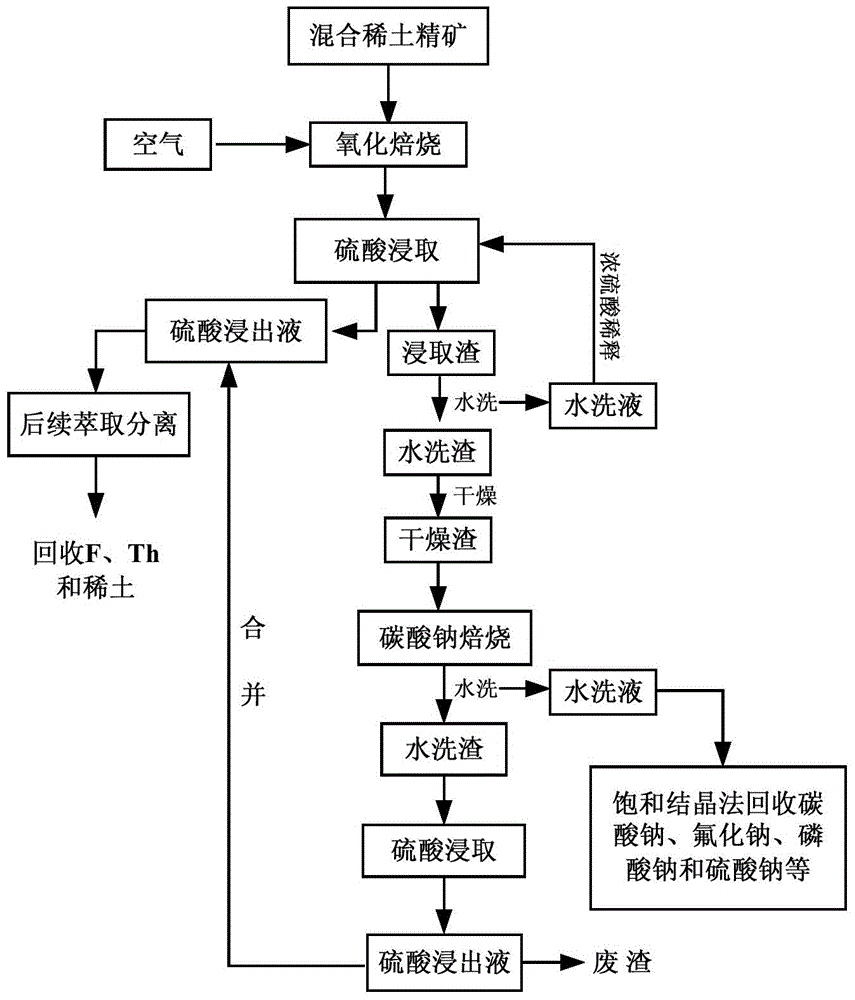

Cleaning smelting technology of bastnaesite and monazite mixed rare earth ore concentrate

InactiveCN104862502AEasy to recycleAchieve recyclingProcess efficiency improvementRare earthMaterials science

The invention relates to a cleaning smelting technology of bastnaesite and monazite mixed rare earth ore concentrate. In the cleaning smelting technology, first, bastnaesite and monazite mixed rare earth ore concentrate is roasted; the roasted products are subjected to acid leaching, and a sulfuric acid leachate containing F<->, Ce <4+>, Th<4+> and trivalent rare earth and leached residues are obtained; the leached residues are washed to be neutral, are dried, and are roasted together with sodium carbonate; the roasted product is subjected to water washing, and a washing liquid and washed residues are obtained; the washed residues are subjected to acid leaching, a sulfuric acid leachate containing a few of F<->, Ce <4+>, Th<4+> and trivalent rare earth is obtained, the sulfuric acid leachates are mixed, Ce and F are recoveried, Th is separated, then grouping separation of trivalent rare earth is achieved further. Through the above flows, integrated and efficient recovery of rare earth oxide and valuable elements fluorine, phosphor and thorium in mixed rare earth ore concentrate can be achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

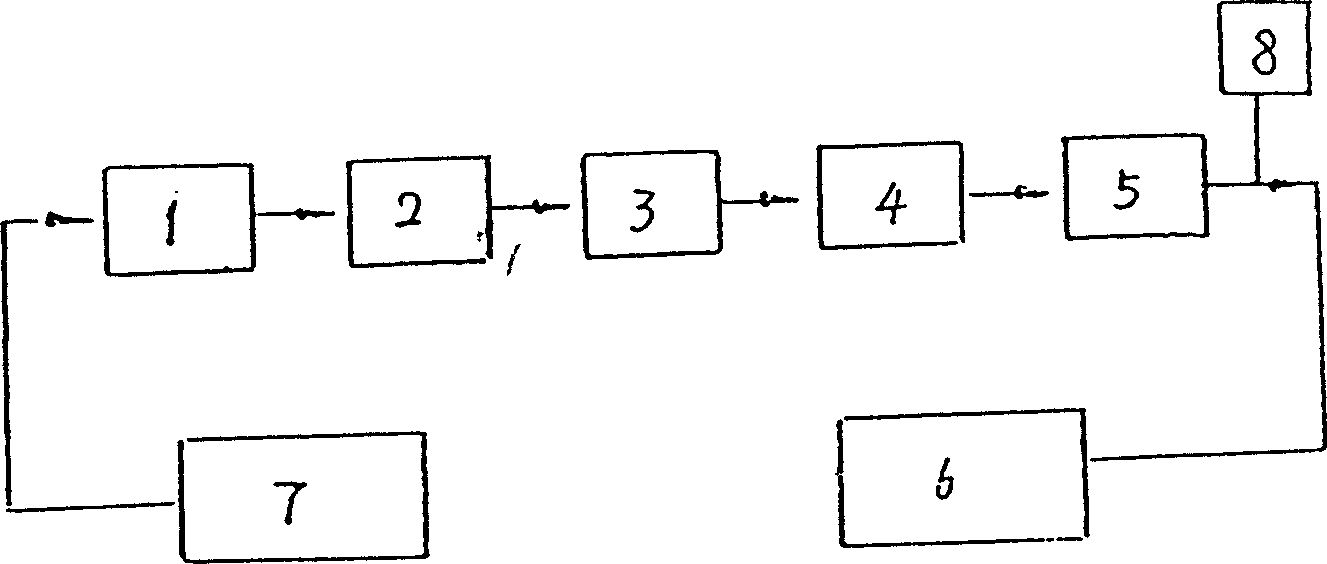

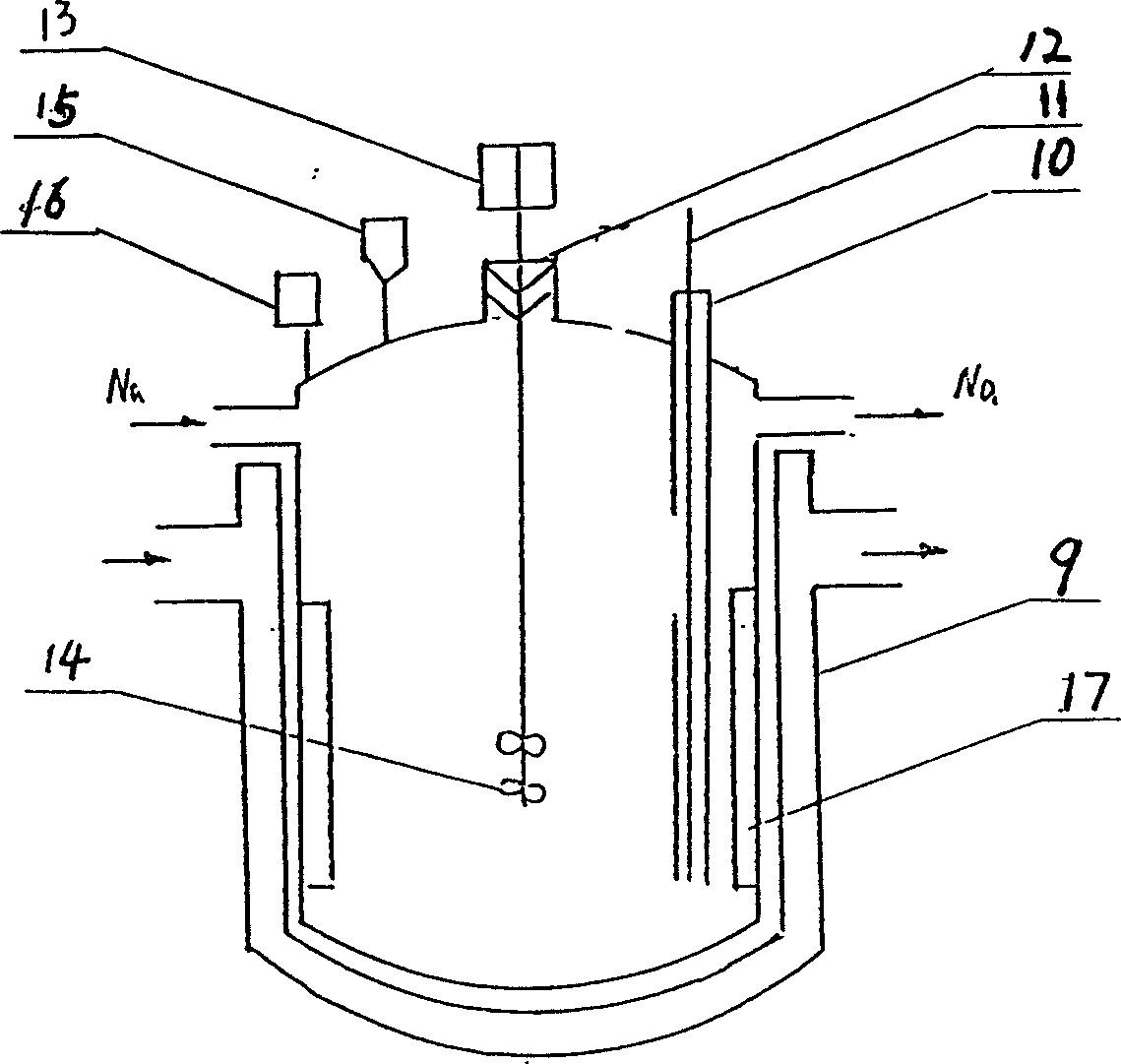

Sodium purifying process and purification system thereof

The invention belongs to alkali metals refinement field, more specificly it relates to the nucleus-grade sodium refinement process and its refinement system for reactor. The process comprises calcium reaction, two stage precipitation and two stage filtering. The refinement system mainly comprises sodium receiving tank, calcium removing reactor, first stage precipitator, first stage filter, second stage precipitator, second stage filter, sodium storage tank and spare cold trap purging loop. The refinement process can make calcium content reduce to below 0.001% from 0.045% of industrial sodium, oxygen content reduce to below 0.003% from 0.025%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for producing five-cereal coarse cereal recombinant food

The invention discloses a method for producing a five-cereal coarse cereal recombinant food. The method comprises the following steps of: cleaning raw materials, drying, crushing and sieving with an 80-mesh sieve; and weighing the raw materials in a specific ratio, mixing uniformly, tempering, extruding by using a single-screw extrusion machine, cutting, and drying to obtain the five-cereal coarse cereal recombinant food. According to the method, five-cereal coarse cereals are developed deeply, so that sensory indexes of smells, colors, tastes and the like of products are similar to those of rice, so that the aims of 'refining of coarse grain' and 'the matching of staple grain and the coarse grain' are fulfilled, and the value of agricultural products of the five-cereal coarse cereals and the like is improved.

Owner:ANHUI YANZHIFANG FOOD

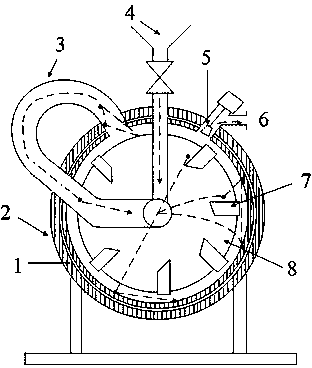

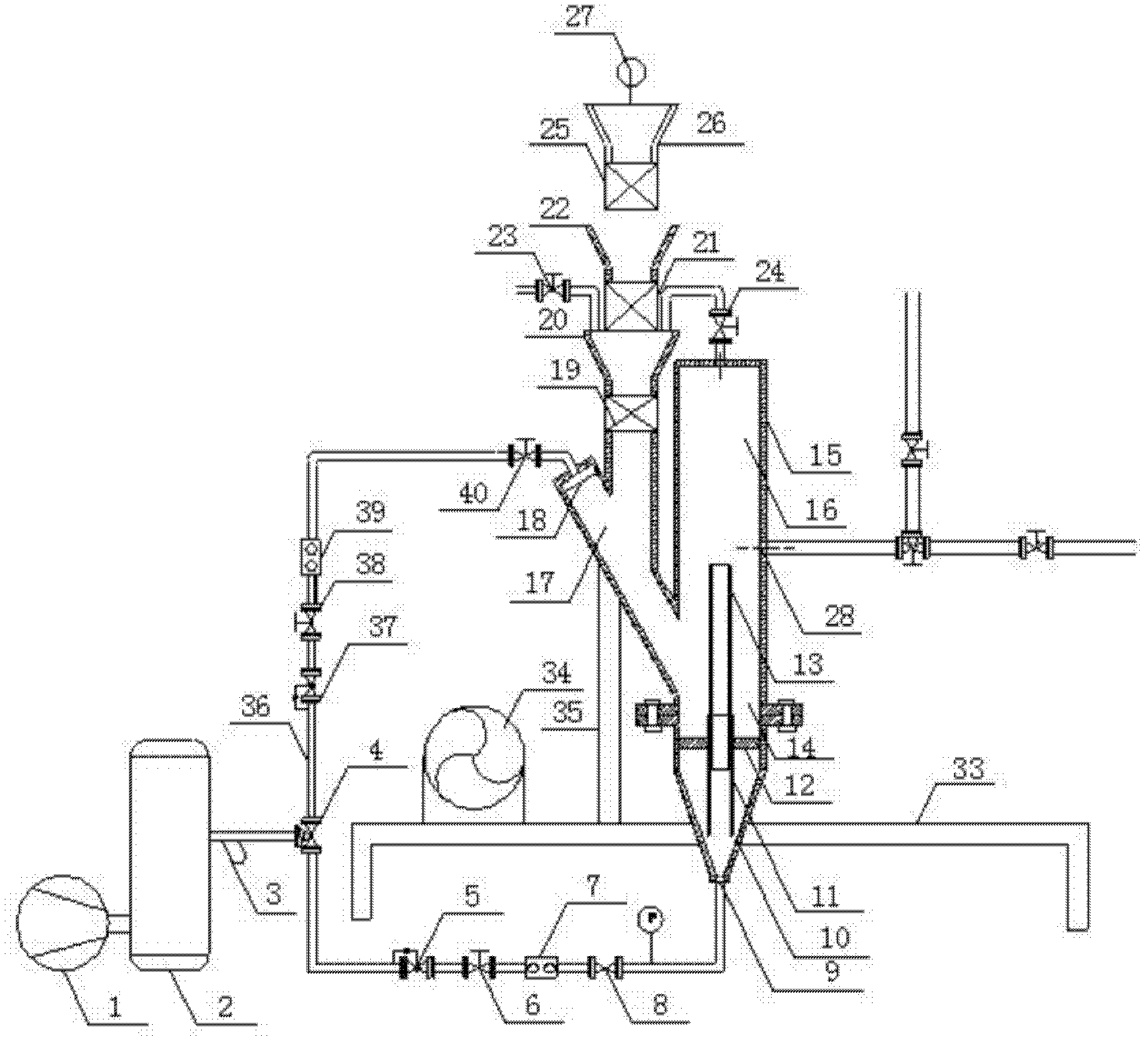

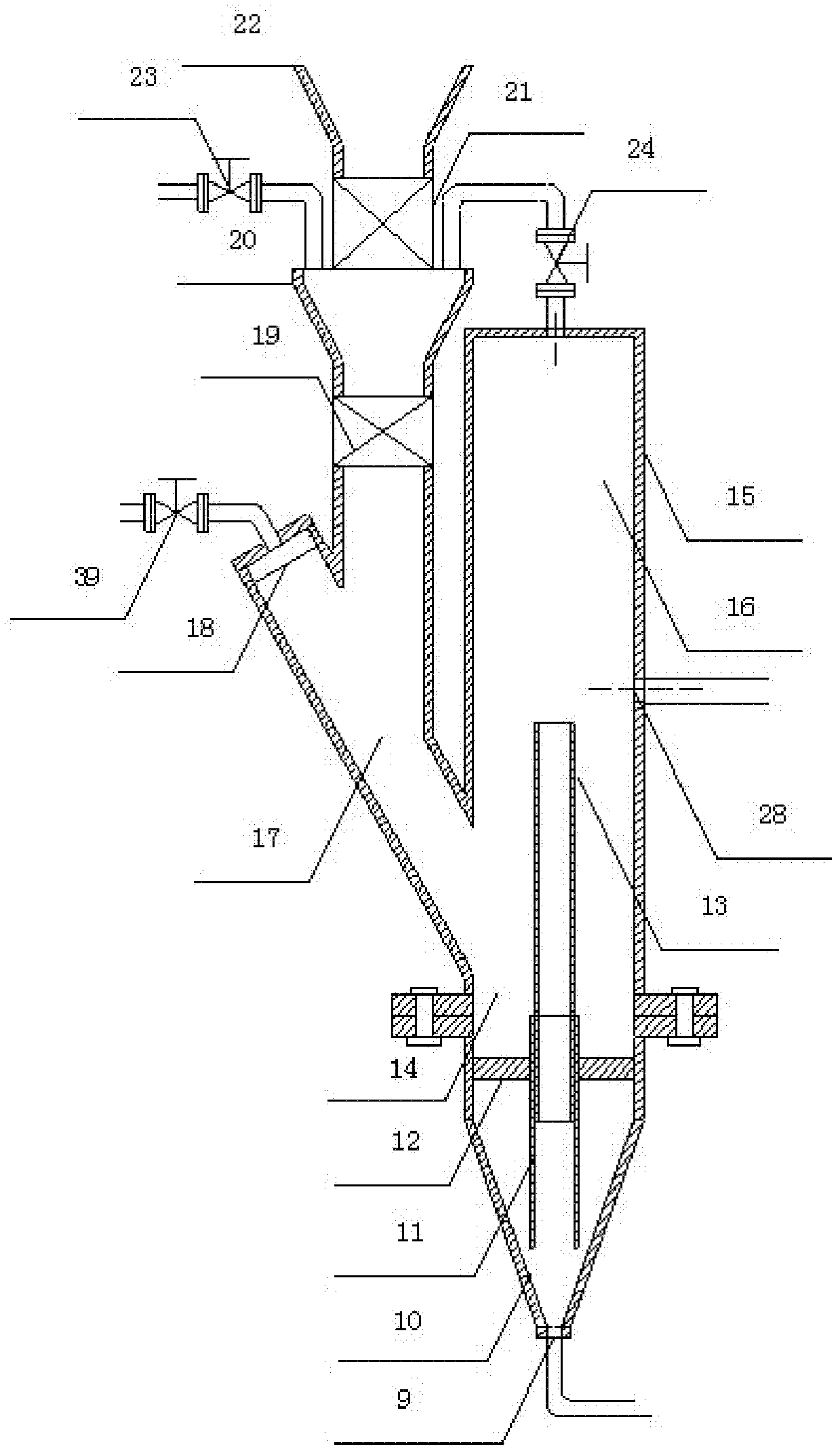

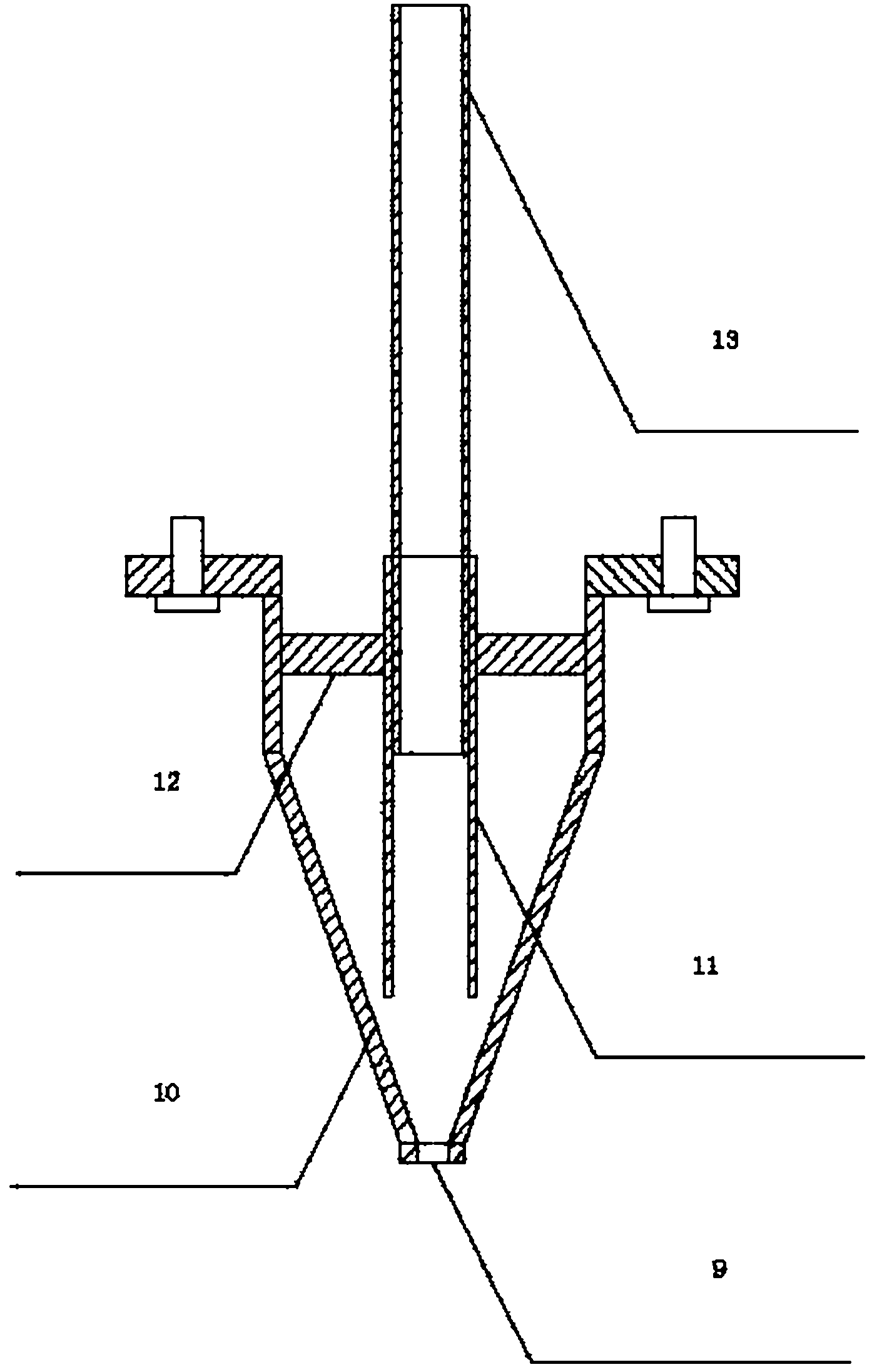

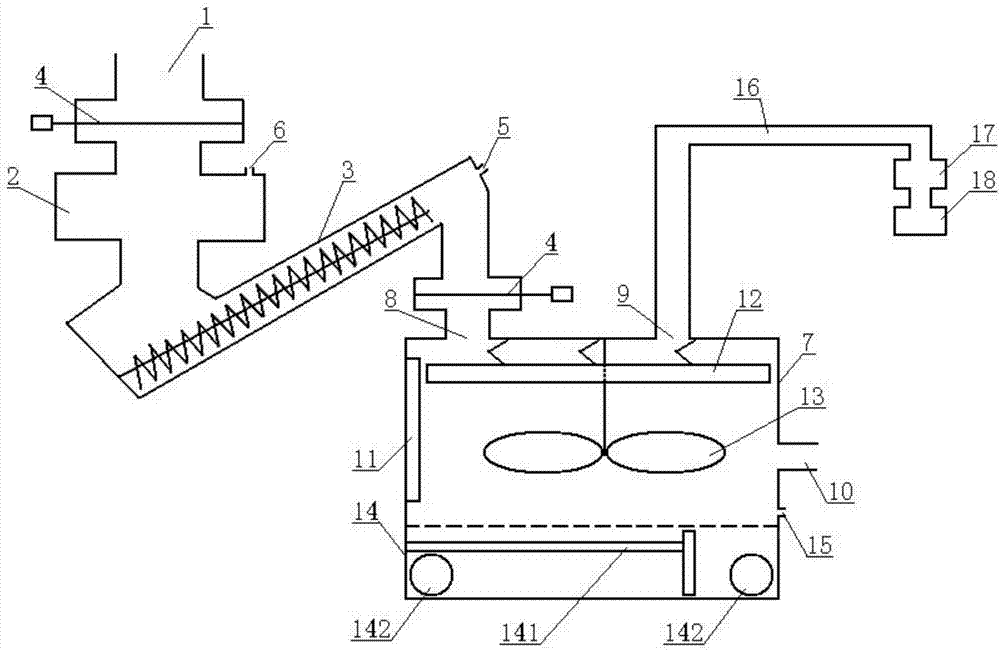

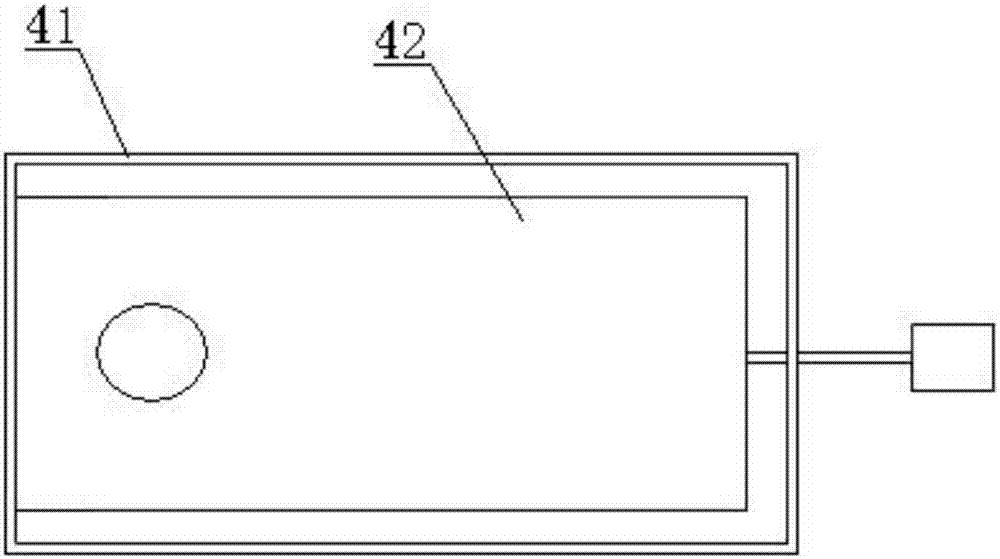

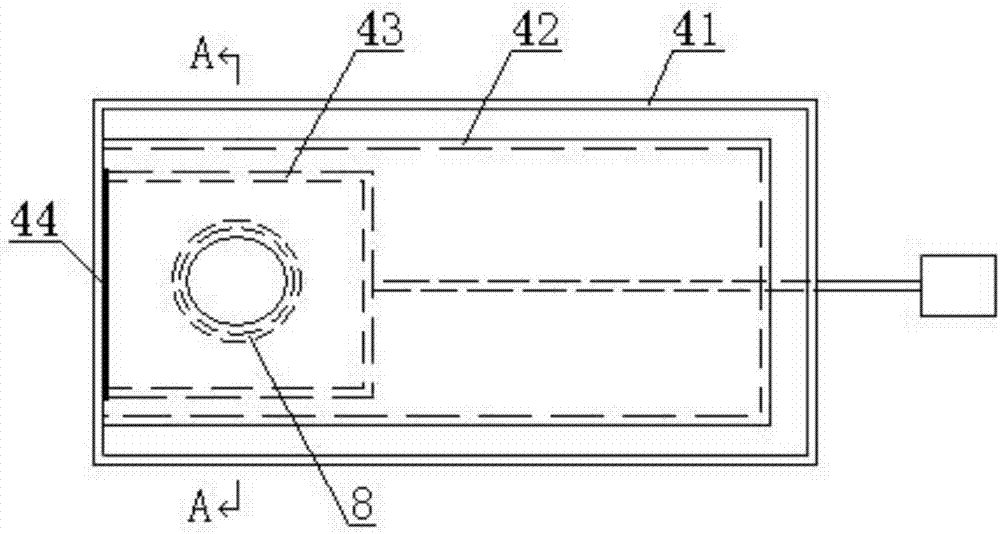

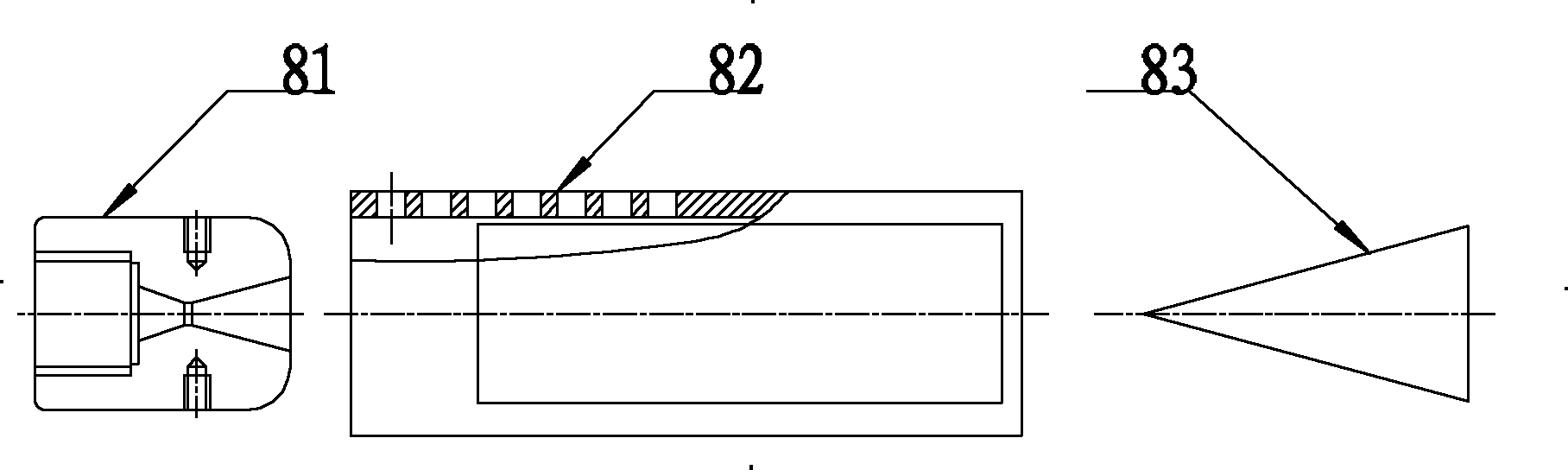

Double-cylinder multi-fluidization circulating type aerosol generator

ActiveCN102658039ASolve agglomerationSolve problems that cannot be used for high-pressure system distributionFlow mixersMixing gases/vapours with solidsEngineeringHigh pressure

The invention aims to provide a double-cylinder multi-fluidization circulating type aerosol generator which comprises an online continuous power supply portion, a powder fluidization and circulation portion, an air circuit control portion, a vibrating motor and a base frame. The online continuous power supply portion, the powder fluidization and circulation portion and the air circuit control portion are connected with one another. The vibrating motor, the online continuous power supply portion and the powder fluidization and circulation portion are all mounted on the base frame. The online continuous power supply portion is further connected with the base frame through support members. The double-cylinder multi-fluidization circulating type aerosol generator is simple to operate, unique in design, widely applicable to various viscous or non-viscous powder samples, and applicable to distribution of high-pressure systems.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Coating for water-based magnesia casting and preparation method thereof

InactiveCN102941312AEasy to prepareReduce dosageFoundry mouldsFoundry coresWater basedSurface finish

The invention discloses a coating for water-based magnesia casting and a preparation method thereof. The coating comprises effective components of, by mass, 60%-75% of fire-resistant powder materials, 1%-8% of binders, 1%-6% of suspending agents, 20%-30% of carrier liquid and 0.05%-0.2% of surfactants, and ccccccccccccsthe total content of the components is 100%. The method includes feeding weighed fire-resistant powder materials and the binders into an edge runner mill for grinding, then feeding the suspending agents, the carrier liquid and the surfactants into the edge runner mill sequentially for grinding, and finally taking out the coating from the edge runner mill after passing through a colloid mill so as to obtain the coating for the water-based magnesia casting. According to the coating and the method, magnesia and the like are taken as the fire-resistant materials, alcohol is taken as a solvent, and the coating is prepared into a powder or paste shape. The coating is high in suspensibility, good in painting, high in surface finishment, not easy to precipitate or caking and good in liquidity and stability.

Owner:XI'AN POLYTECHNIC UNIVERSITY

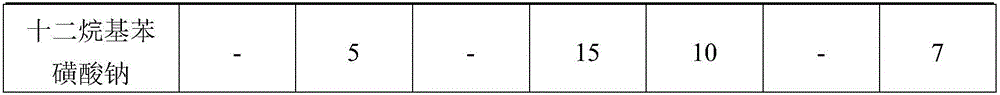

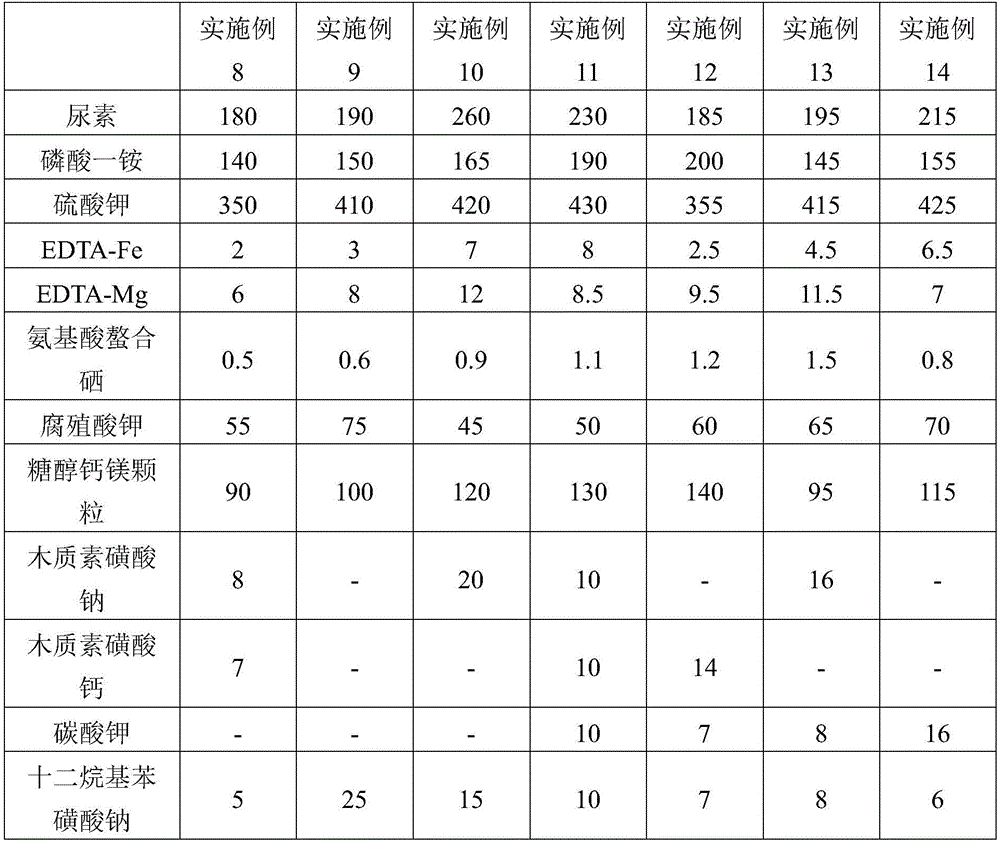

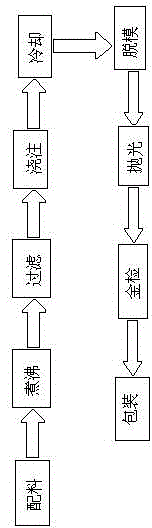

Humic-acid-containing water-soluble fertilizer capable of increasing selenium content of grapes, and preparation method and application thereof

InactiveCN106631517ANo caking phenomenonAnti-acidAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateAlcohol sugars

The invention discloses humic-acid-containing water-soluble fertilizer capable of increasing selenium content of grapes, and belongs to the technical field of fertilizer. The humic-acid-containing water-soluble fertilizer comprises, by weight, 180-260 parts of urea, 140-200 parts of monoammonium phosphate, 350-430 parts of potassium sulphate, 2-8 parts of EDTA (ethylene diamine tetraacetic acid) chelated iron, 6-12 parts of EDTA chelated magnesium, 0.5-1.5 parts of amino acid chelated selenium, 45-75 parts of potassium humate, 90-140 parts of sugar alcohol calcium magnesium particles and 20-40 parts of lignosulfonate and / or potassium carbonate and / or sodium dodecyl benzene sulfonate. The invention further provides a preparation method and application of the humic-acid-containing water-soluble fertilizer. The humic-acid-containing water-soluble fertilizer is particularly applied to selenium element absorption in growth period of the grapes, and sugar degree and yield are increased.

Owner:河北中仁化肥集团有限公司 +1

Sea-buckthorn fruit juice jelly and preparation method thereof

The invention relates to the technical field of foods, and particularly relates to a sea-buckthorn fruit juice jelly prepared from plateau sea-buckthorn as a raw material and a preparation method of the sea-buckthorn fruit juice jelly. The sea-buckthorn fruit juice jelly comprises the following raw materials in percentage by weight: 34 percent of glucose syrup, 32 percent of white granulated sugar, 13 percent of purified water, 3 to 8 percent of sea-buckthorn fruit juice, 7 percent of modified starch, 1.9 to 6.9 percent of gelatin, 1.5 percent of dextrose, 1.2 percent of sorbitol. 0.9 percent of citric acid, 0.12 percent of essence and 0.05 percent of a pigment in the first step, and 0.23 percent of palm wax and 0.1 percent of sea-buckthorn oil in the second step. The invention has the benefits as follows: the sea-buckthorn fruit juice jelly uses plateau sea-buckthorn as the raw material, and contains fragrant sea-buckthorn flavor; the preparation method adopts low-temperature forming equipment, nutritional ingredients of sea-buckthorn fruit juice are not damaged, and simultaneously, by the addition of the sea-buckthorn fruit juice in the jelly, the taste of the jelly is improved to a certain extent.

Owner:QINGHAI TSINGHUA BIOTRY BIO TECH

Powder organic-inorganic water-soluble fertilizer and preparing method thereof

InactiveCN107188656AReduce packaging costsHigh nutrient contentCalcareous fertilisersMagnesium fertilisersPotassiumNutrient

The invention belongs to the field of soil fertilizer, and discloses a powder organic-inorganic water-soluble fertilizer and a preparing method thereof. The powder organic-inorganic water-soluble fertilizer comprises water-soluble organic matter, microelement water-soluble fertilizer, medium element water-soluble fertilizer, and a water-soluble anti-blocking agent. The content of nitrogen, phosphorous and potassium is larger than or equal to 30%, the content of calcium and magnesium is larger than 1%, and the content of organic matter is larger than 10%. According to the powder organic-inorganic water-soluble fertilizer and the preparing method thereof, the preparing technology is simple, the condition is mild, heating and fermenting are not needed, particles do not need to be prepared into, the four materials are directly uniformly mixed to prepare the powder organic-inorganic water-soluble fertilizer, the powder organic-inorganic water-soluble fertilizer can promote the absorption and utilization of crop to nitrogen, potassium, calcium and magnesium, soil beneficial microorganism reproduction is promoted, soil acidization and salinization are relieved, the crop root system growth is promoted, the utilization efficiency of crops to the water and nutrients is improved, the capability of the crops in resisting adversity is improved, and finally the purposes of increasing the yield and improving the product quality are achieved. Long term application of the powder organic-inorganic water-soluble fertilizer can also improve the soil structure and raise land fertility.

Owner:江西先益农生物科技有限公司

Barley seedling clear juice powder processing method

InactiveCN104738430AEfficient removalQuality assuranceFood preparationMegasonic cleaningMaterial selection

The invention relates to a barley seedling clear juice powder processing method, and belongs to the technical field of foodstuff preparation. The barley seedling clear juice powder processing method comprises the steps of material selection, cleaning, soaking, ultrasonic cleaning and the like, and barley seedling clear juice powder which is balanced in nutrition and high in product purity can be produced. The barley seedling clear juice powder meets the nutritional requirements of different people.

Owner:JIANGSU ZHENYA FOOD CO LTD

Aqueous high weather-proof matt exterior wall emulsion paint and preparation method thereof

InactiveCN103409023ALess detection finenessSmall smellEmulsion paintsPolymer scienceDefoaming Agents

The invention discloses an aqueous high weather-proof matt exterior wall emulsion paint and a preparation method thereof. The emulsion paint comprises the following components by weight: 30-40 parts of emulsion, 0.2-0.5 part of an organosilicone hydrophobic agent, 2-8 parts of diatomite, 4-7 parts of sericite powder, 20-25 parts of titanium dioxide, 6-14 parts of a calcium carbonate powder, 0.4-0.7 part of a dispersant, 0.1-0.3 part of a wetting agent, 0.3-0.6 part of a defoaming agent, 0.1-0.3 part of an antifreeze, 1.5-2 parts of a coalescing agent, 0.4-0.9 part of a thickening agent, 0.2-0.5 part of a leveling agent, 0.1-0.3 part of a preservative, 0.1-0.3 part of a mildew preventive and 20-30 parts of water. The preparation method provided by the present invention comprises steps of: pre-blending, grinding disperse, and addition of emulsion and auxiliary agent, etc. The aqueous high weather-proof matt exterior wall emulsion paint provided by the invention has advantages of soft texture, flattening and fine paint film surface, and soft matt effect.

Owner:ZHEJIANG ZHIQIANG PAINT

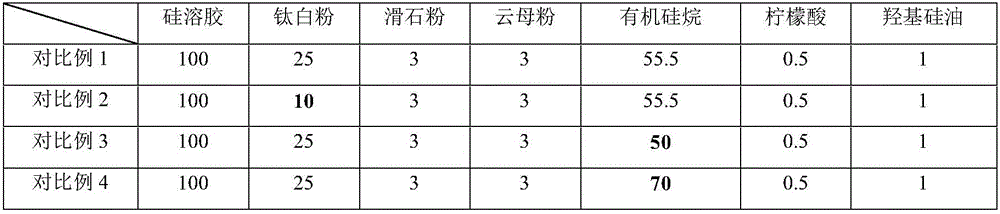

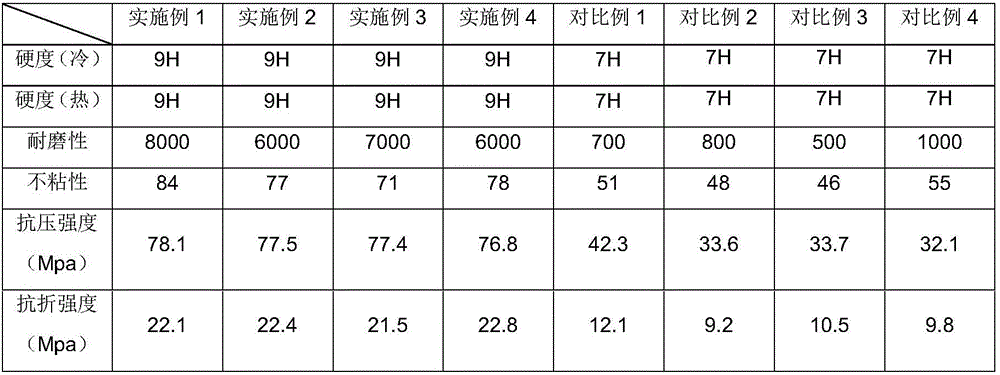

Ceramic coating with high hardness in hot environment

The invention provides a ceramic coating with high hardness in a hot environment. The ceramic coating consists of silica sol, organosilane, a catalyst, titanium dioxide, hydroxyl silicone oil, a filler and a toner, wherein the weight ratio of the silica sol, the organosilane, the catalyst, the titanium dioxide, the hydroxyl silicone oil, the filler and the toner is 100:(55.5-60.5):(21-25):(1-5):(2-30):(0-30), the content of Si2O in the silica sol is 25 to 30 percent, silica sol emulsion particles are 500 to 600 nm, the particle size of the titanium dioxide is 40 to 50 nm, and the hydroxyl content of the hydroxyl silicone oil is 4.2 to 4.5 percent. The prepared ceramic coating can be directly used without curing, and has high cold and heat stability, wear resistance and non-adhesion.

Owner:FOSHAN POLIMA ADVANCED TECH & SUPPLIES CO LTD

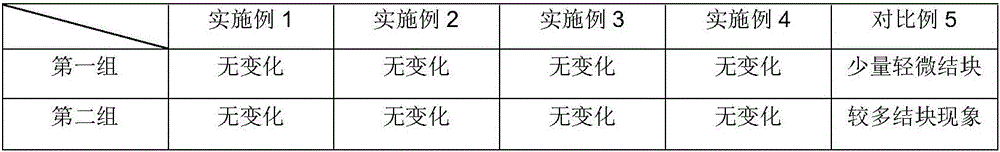

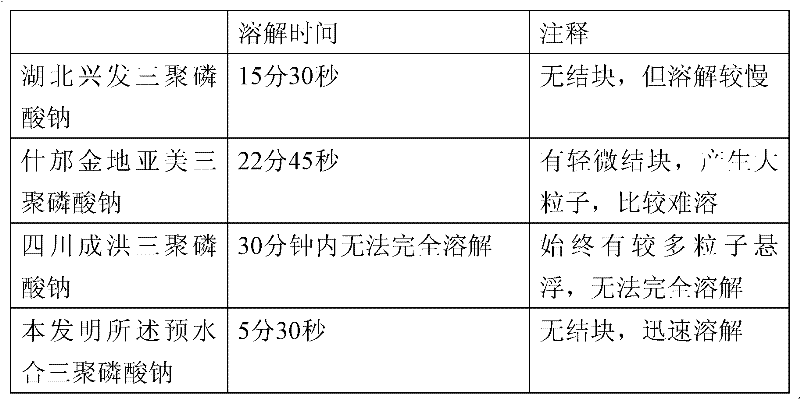

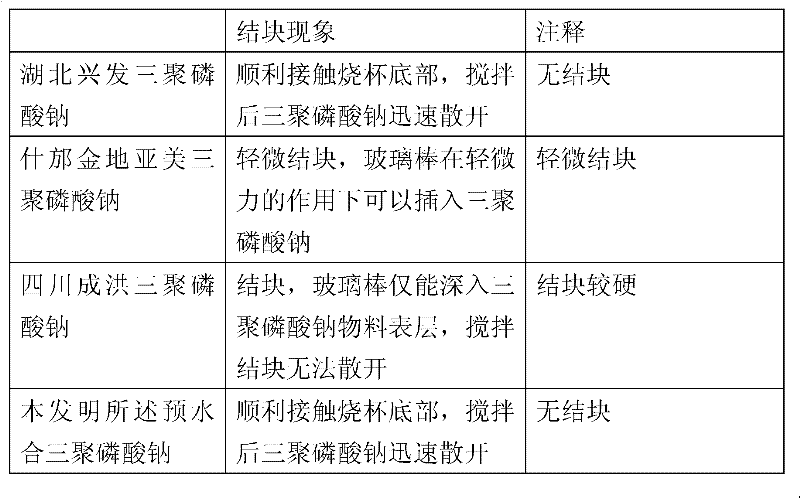

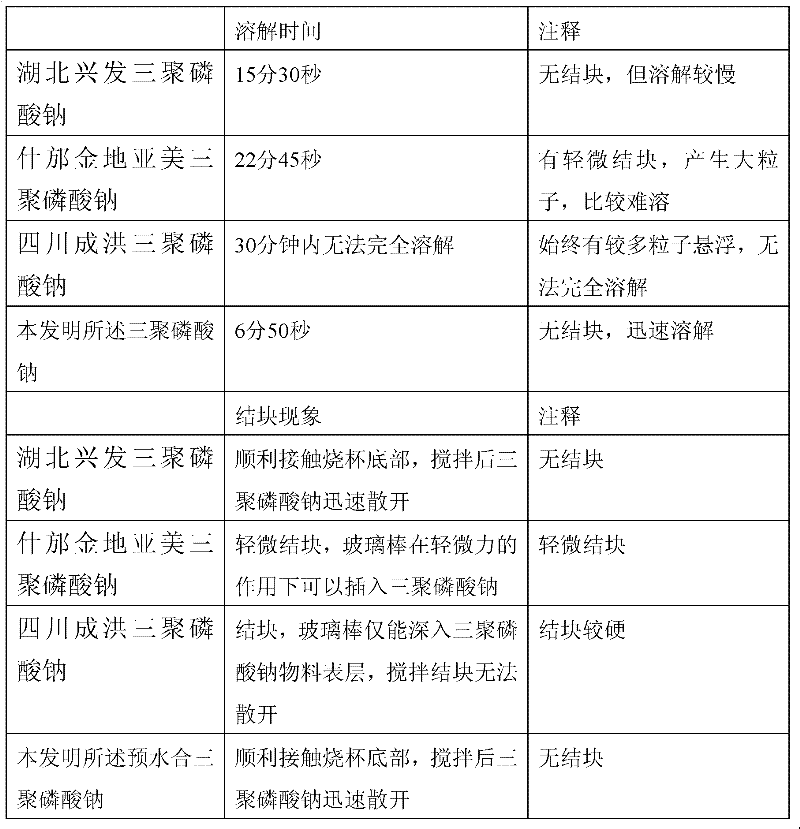

Anti-caking prehydration sodium tripolyphosphate capable of dissolving in saline water quickly and preparation method thereof

ActiveCN102502559AEasy for food industry applicationsSimple production processPhosphorus compoundsSaline waterSodium triphosphate

Owner:苏州闻达食品配料有限公司

Organic waste disposal system

ActiveCN107011930AGuaranteed to proceed normallyReduce the chance of security incidentsProductsReagentsExhaust gasContinuous operation

The invention provides an organic waste disposal system which comprises a feeding device, a reaction device and a tail gas emission device, wherein a water seal device is arranged between the feeding device and the reaction device; the water seal device comprises a water tank, a gland and a movable cover; a feeding port of the reaction device penetrates through the bottom part of the water tank and is fixedly connected with the water tank; the gland is reversely buckled in the water tank; a through hole corresponding to the position of the feeding port is formed in the top part of the gland; the movable cover is arranged between the water tank and the gland; a side wall arranged on the bottom surface of the movable cover in the direction near the feeding port is opened; the movable cover does reciprocating motion at the upper part of the feeding port, so that the feeding port and the through hole are communicated and isolated; a seal strip is further arranged on the position where the opening position of the side wall of the movable cover and the inner wall of the water tank are in contact, therefore, the feeding port is completely sealed when the movable cover plays a role of isolating. According to the organic waste disposal system, continuous operations of feeding and processing the waste are realized, the pollution to the outside environment, caused by the gas, is alleviated, and the occurrence of an explosion accident is also avoided.

Owner:湖南野百和科技有限公司

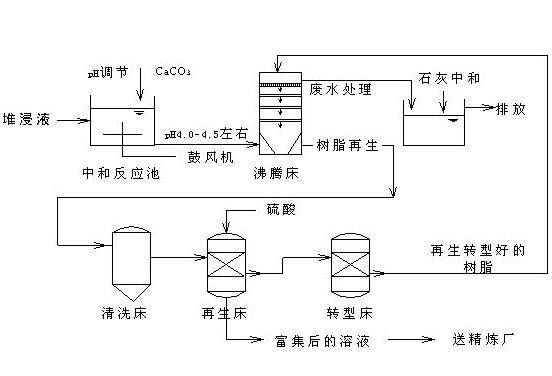

Method for treating nickel sulfide ore biological heap leaching solution

InactiveCN102010996AReduce processing costsReduce energy consumptionProcess efficiency improvementIon exchangeIon

The invention discloses a method for treating nickel sulfide ore biological heap leaching solution, which relates to nickel sulfide ore, in particular to a method for recovering valuable metals from high-magnesium high-iron nickel sulfide ore biological heap leaching solution. The method is characterized by comprising the following steps of: adding lime into the biological heap leaching solution for pulpifying, introducing air for oxidization reaction, oxidizing Fe<2+> in the biological heap leaching solution into Fe<3+>, hydrolyzing to generate Fe(OH)3, and performing the adsorption recovery of the valuable metals such as nickel, cobalt and copper in an ion exchange column. Normal temperature iron deposition is realized with low energy consumption; valuable metal ions in the treated heap leaching solution can be lowered to below 3ppm; and the recovery rates of the valuable metal ions are high, and both the recovery rates of the nickel and cobalt metal ions are over 99 percent. The method has low treatment cost and high economic benefit, and industrialized production is easy to realize.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

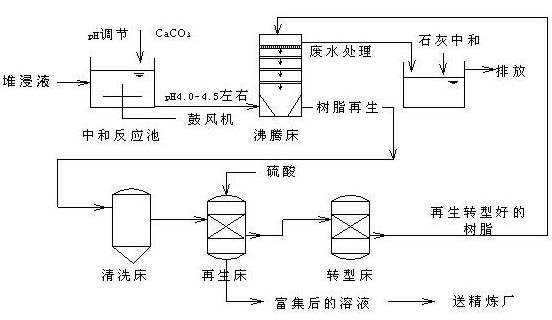

Miniaturized brown beverage production process

The invention discloses a miniaturized brown beverage production process and belongs to the technical field of beverage production. The miniaturized brown beverage production process includes the steps of chemical material hydration, browning, sterilization, fermentation, cooling, material mixing, homogenizing, filling and the like. The miniaturized brown beverage production process has the advantages that the production cost is lowered, product impurities are reduced, and the process is suitable for miniaturized production.

Owner:QINGDAO NEWHOPE QINPAI DAIRY

Ultrasonic-crushing planetary ball mill

The invention provides an ultrasonic-crushing planetary ball mill which comprises a planetary gear transmission mechanism. The input end of the planetary gear transmission mechanism is connected with a motor. At least two ball mill tanks are arranged on a rotary disc of the planetary gear transmission mechanism. An ultrasonic generator is arranged in each ball mill tank. When planetary ball milling is carried out on materials by the ultrasonic-crushing planetary ball mill, ultrasonic wave intensity energy fields are exerted, and therefore while even material mixing is achieved, material powder can be crushed into the nanometer order from the micro order; and the ultrasonic-crushing planetary ball mill has the advantages of being simple in structure, high in ball milling efficiency and capable of crushing powder.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of transparent bactericidal medical ultrasonic coupling agent

ActiveCN103007305BMedium transparentSolve agglomerationEchographic/ultrasound-imaging preparationsUltrasonographyWater based

The invention discloses a preparation method of a transparent bactericidal medical ultrasonic coupling agent, solving the technical problems of product agglomeration and turbidness by adding a certain proportion of solubilizer, adjusting the material mixing sequence and strictly controlling the temperatures and stirring speeds of the materials. The preparation method has the beneficial effects that the water-based polymer gel type medical bactericidal ultrasonic coupling agent has a transparent, exquisite and smooth medium, has good biocompatibility and does not cause cytotoxicity, sensitization or irritation to skins; and the material components are more reasonably proportioned and blended, the product is safer and more reliable and the ultrasonic images are clearer and more stable.

Owner:山西康灵医疗器械有限公司

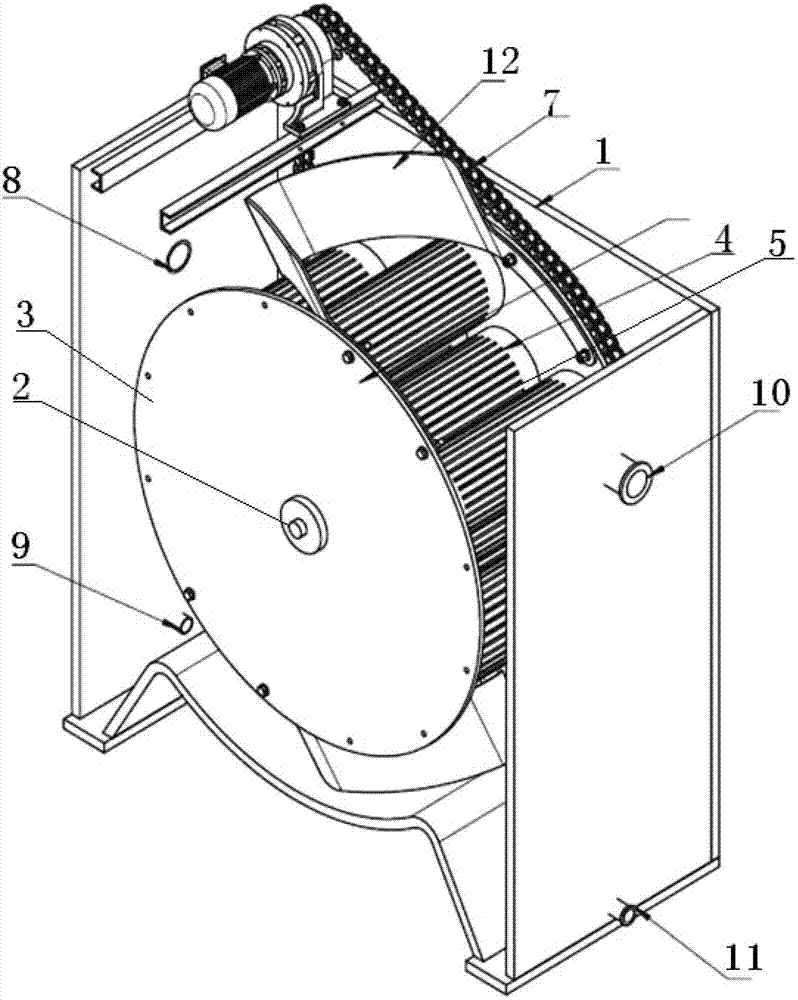

Rotary-type wastewater treating device

ActiveCN103172145AAchieve aerationAddress Surface UpdatesTreatment using aerobic processesTreatment with anaerobic digestion processesWastewaterCaking

The invention relates to a rotary-type wastewater treating device, comprising a container, wherein a rotating shaft is arranged in the container; a toothed rotating disc with the rotating shaft as the axis is arranged at one end of the rotating shaft; two groups of cylinders with the rotating shaft as the center are arranged on the rotating disc; a slit is formed on the cylinder; a driving device is arranged on the container and connected with the rotating disc through a chain; a water outlet pipe and a dredge pipe are arranged on the sidewall of the container on which the driving device is mounted; and a water inlet pipe and a blow-down pipe are arranged on the other corresponding sidewall of the container. The rotary-type wastewater treating device is capable of thoroughly stirring the wastewater, and simultaneously capable of charging oxygen; and a micro-electrolytic material can be filled in the cylinders so that electrochemical and physical treatment processes are realized and caking and blockage can be prevented.

Owner:JIANGSU LONG LEAPING ENG DESIGN

Brown sugar agglomeration crushing device

InactiveCN106824418ASolve agglomerationSolve efficiency problemsGrain treatmentsMechanical crushingDrive shaft

The invention discloses a device for crushing brown sugar agglomerates, which comprises a bracket, on which a cylindrical barrel is arranged, and the cylindrical barrel includes a crushing bin and a storage bin arranged from top to bottom, and a screen is arranged between the crushing bin and the storage bin A crushing blade is arranged in the crushing bin, and a scraping blade is arranged in the storage bin, and both the crushing blade and the scraping blade are connected to a transmission shaft, and the transmission shaft is connected to a driving mechanism; a discharge mechanism is also arranged under the storage bin. A brown sugar block crushing device of the present invention solves the problems of low yield and low efficiency in the brown sugar production process, replaces manual crushing with mechanical crushing, and at the same time, the product quality meets the national requirements; the labor efficiency is improved several times, avoiding It prevents personnel from contacting materials and creates efficient and environmentally friendly production equipment.

Owner:南京甘汁园股份有限公司

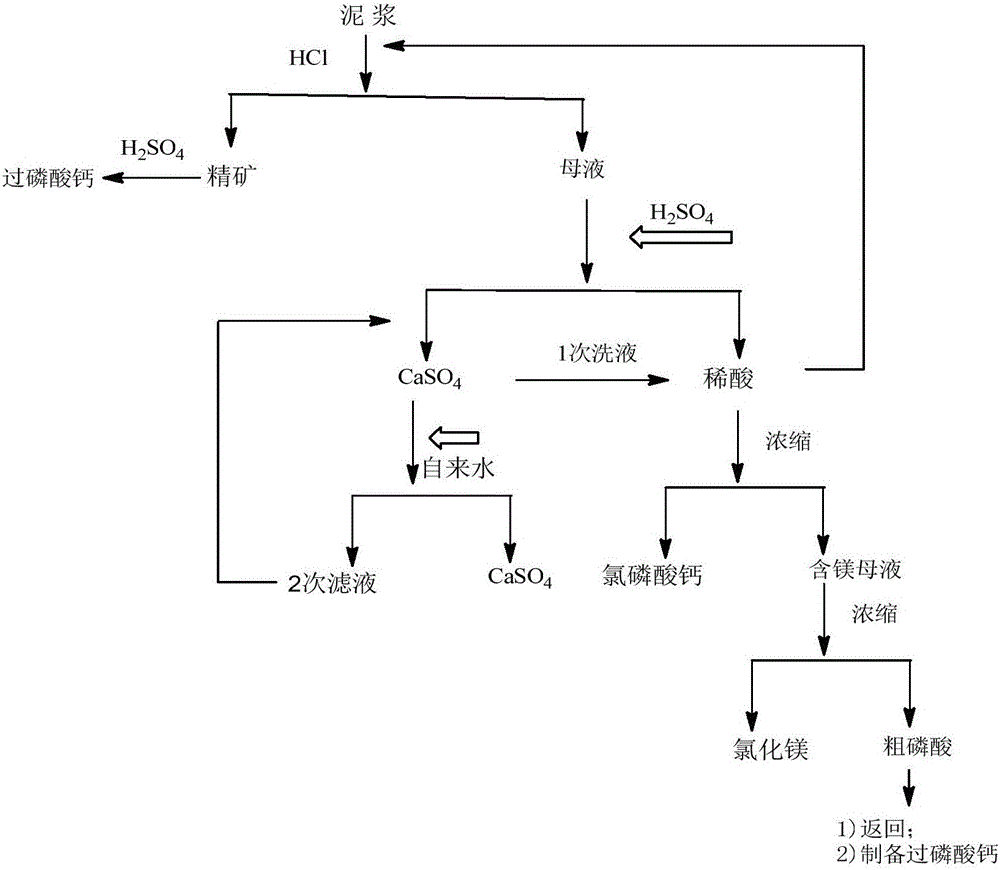

Method for green-producing high-quality calcium superphosphate co-generated magnesium chloride by low-level collophanite

InactiveCN106517124AReduce contentSolve problems such as poor qualitySuperphosphatesMagnesium chloridesDecompositionCarbonate

The invention relates to a method for green-producing high-quality calcium superphosphate co-generated magnesium chloride by low-level collophanite, comprising steps of a, performing acid splitting on carbonate in the phosphorite by hydrochloric acid and preparing phosphorus concentrate; b, preparing high-purity calcium sulfate; c, preparing magnesium chloride; after concentrating the filter fluid to a certain volume, preparing magnesium chloride. The invention has the advantages that the method is applicable to prepare high-efficient phosphatic fertilizer by directly producing high-quality low-magnesium phosphorite in hydrochloric acid decomposition, carbonate of low-level phosphorite and in particular to high-magnesium phosphorite; no waste discharges during the whole technical flow; by applying the invention, the phosphorus pentoxide content of phosphorite is promoted through one acidolysis while content of magnesium oxide in the phosphorite is also reduced; thus the problem of agglomeration and poor phosphatic fertilizer quality caused by high magnesium content during the ordinary calcium production can be solved; the phosphorite therefrom is directly reacted with sulfuric acid, thus high-quality phosphatic fertilizer of which available phosphorus is improved to 16-18% P2O5 can be obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

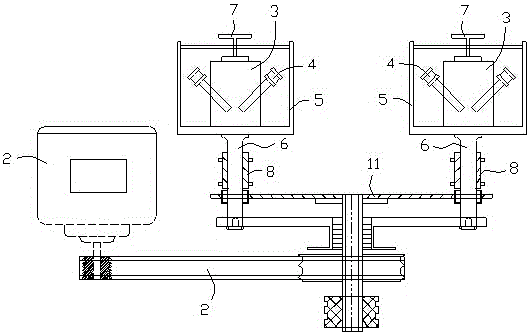

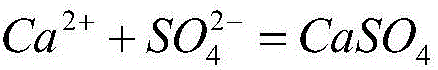

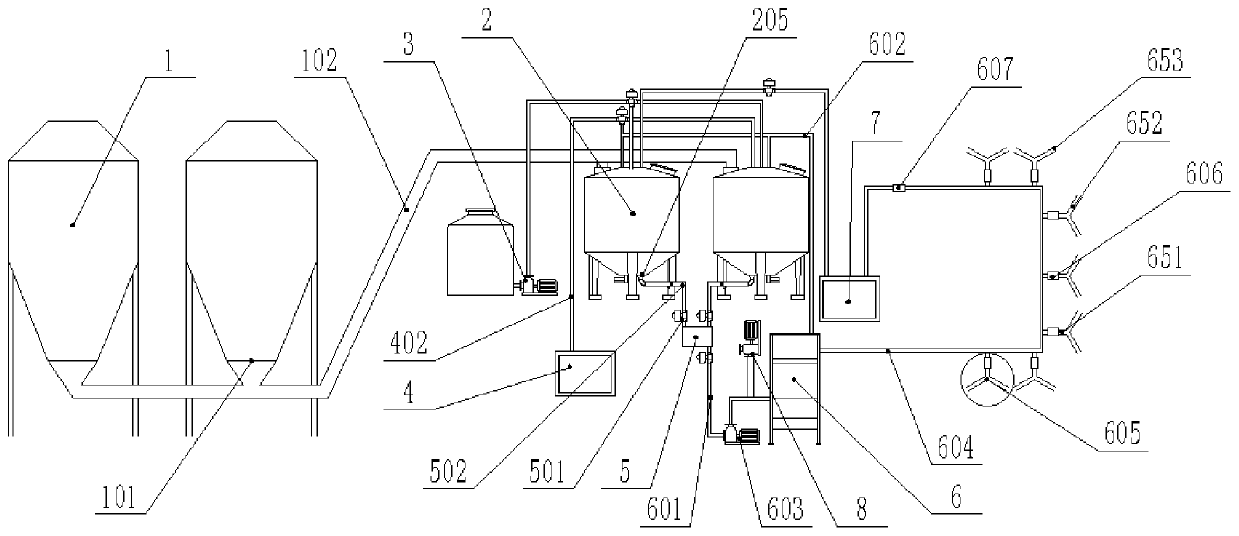

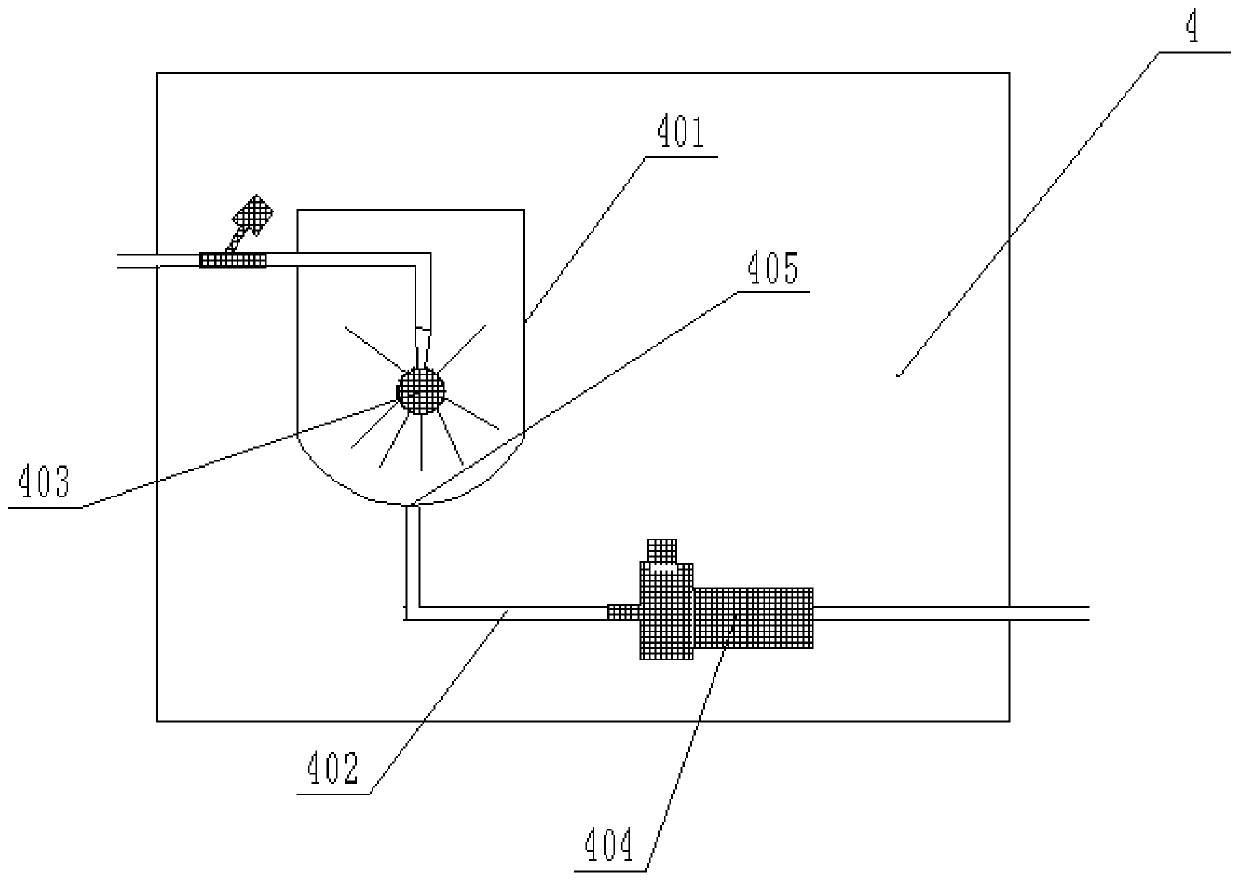

Liquid feeding system

PendingCN110521623ASolve agglomerationSolve for uniformityFeeding-stuffTransportation and packagingMechanical engineeringBooster pump

The invention discloses a liquid feeding system. The liquid feeding system comprises multiple material bins, multiple stirring tanks, a first water injection device, a convergence box and a supplementary material adding device, wherein each material bin is communicated with a feeding port of the corresponding stirring tank through a material conveying pipe system, the material conveying pipe system comprises first valves used for controlling connection or disconnection of each material bin and the corresponding stirring tank, and a tank cavity of each stirring tank is provided with a stirringdevice and a material through port; the first water injection device is communicated with each stirring tank; a first opening of the convergence box is communicated with the material through port of each stirring tank through a material through pipeline, a second opening of the convergence box is communicated with the feeding port of each stirring tank through a return pipeline in a branch returnpipeline system, the material through pipelines are provided with second valves, the branch return pipeline system is also provided with a first booster pump, third valves used for controlling the second opening and a discharging pipeline enabling materials to flow out; the supplementary material adding device is provided with a mixing cavity, a second water injection device and a mixing piece, the mixing cavity is communicated with each stirring tank through a supplementary material pipeline, and the supplementary material pipelines are provided with fourth valves.

Owner:河南瑞昂畜牧科技有限公司

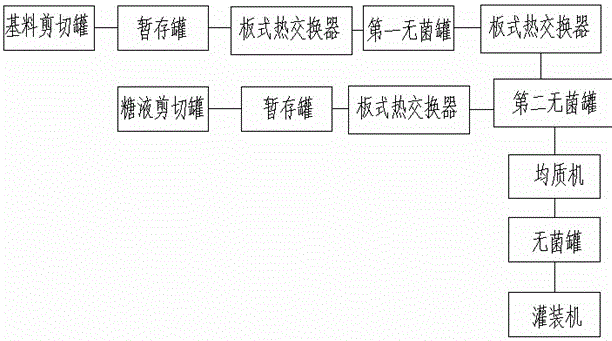

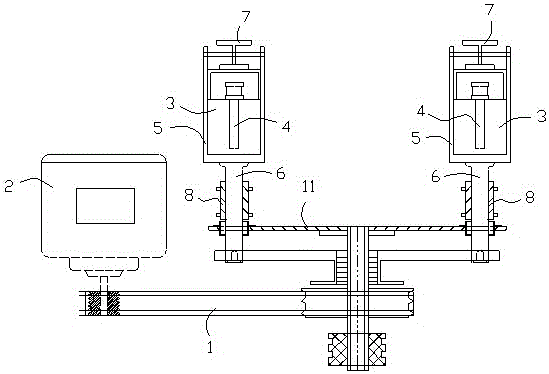

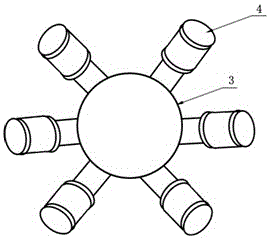

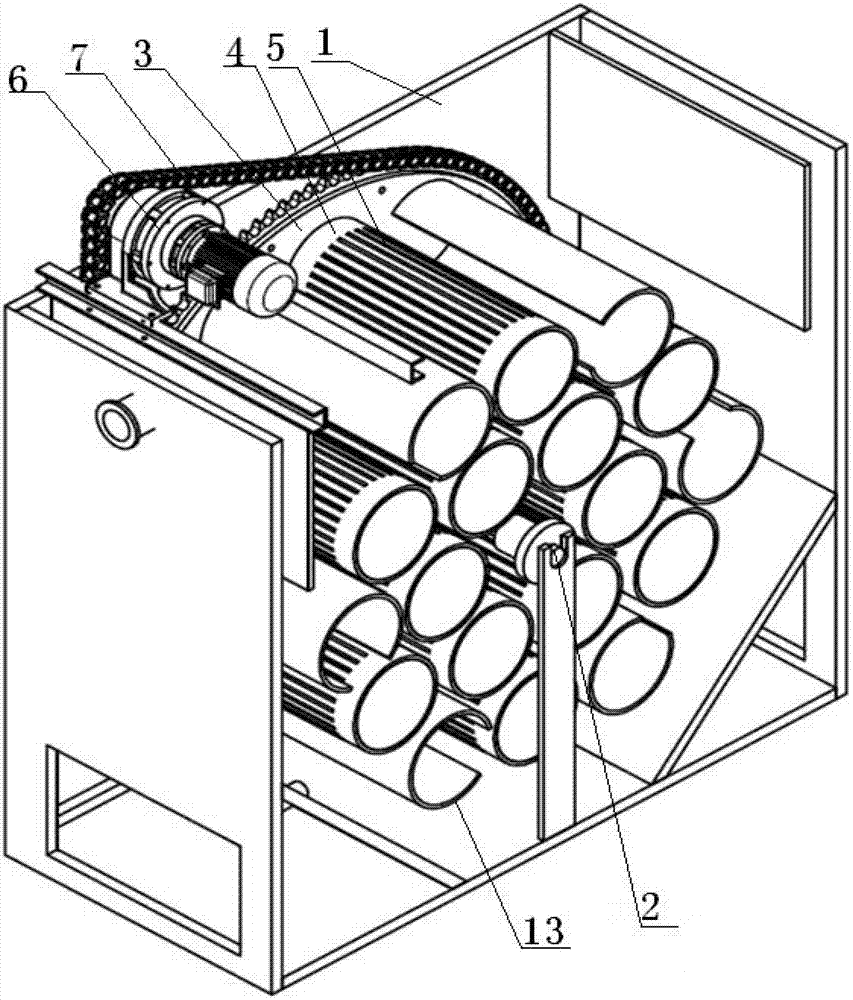

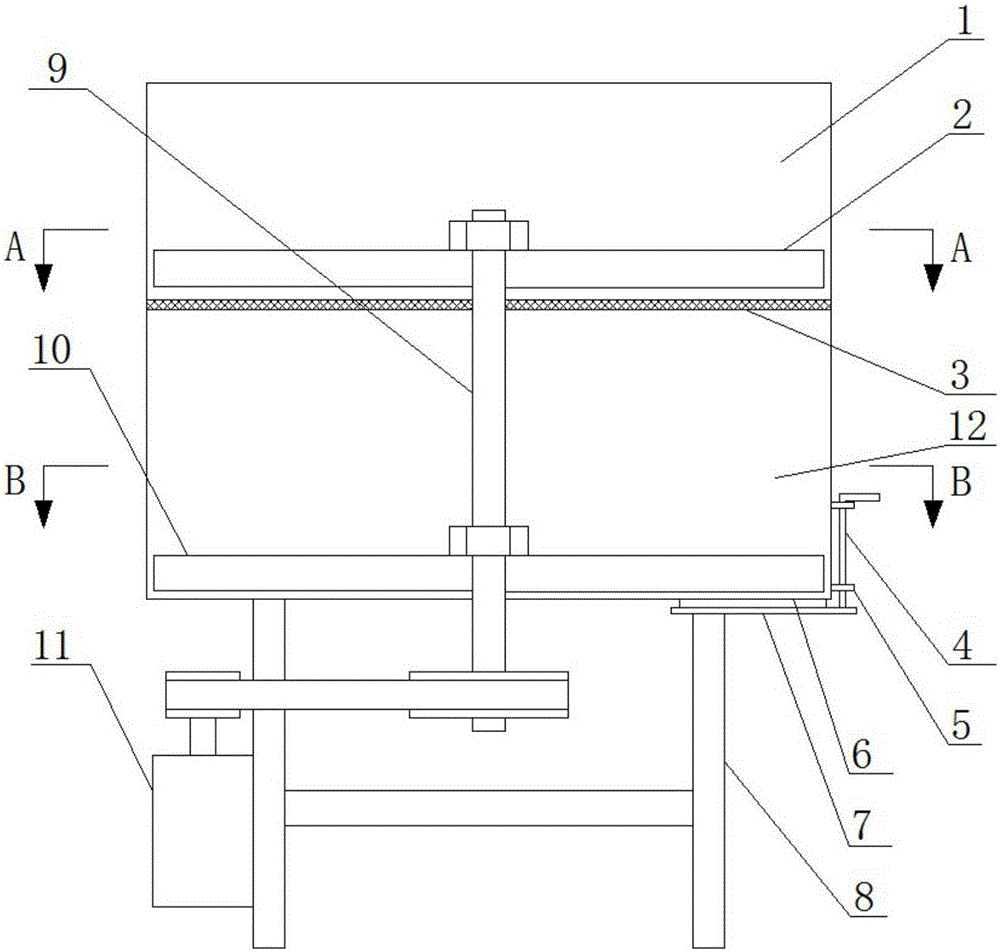

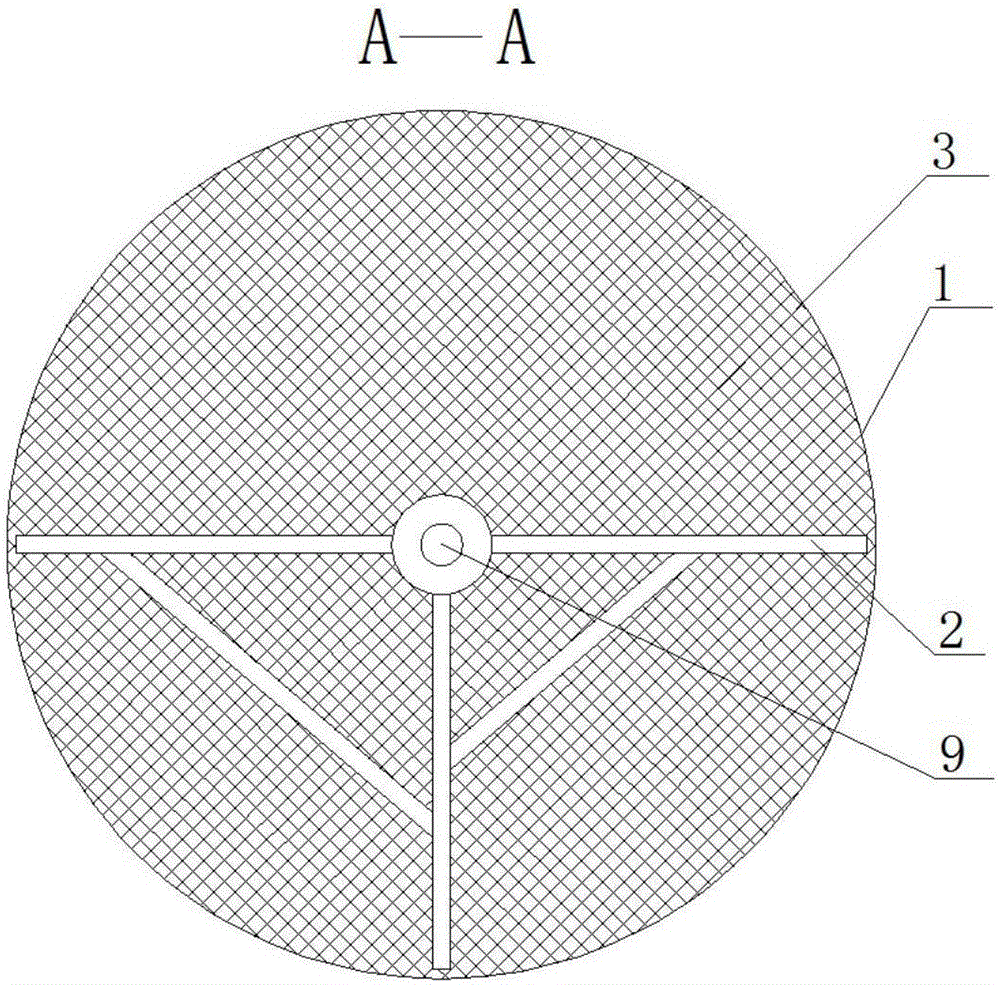

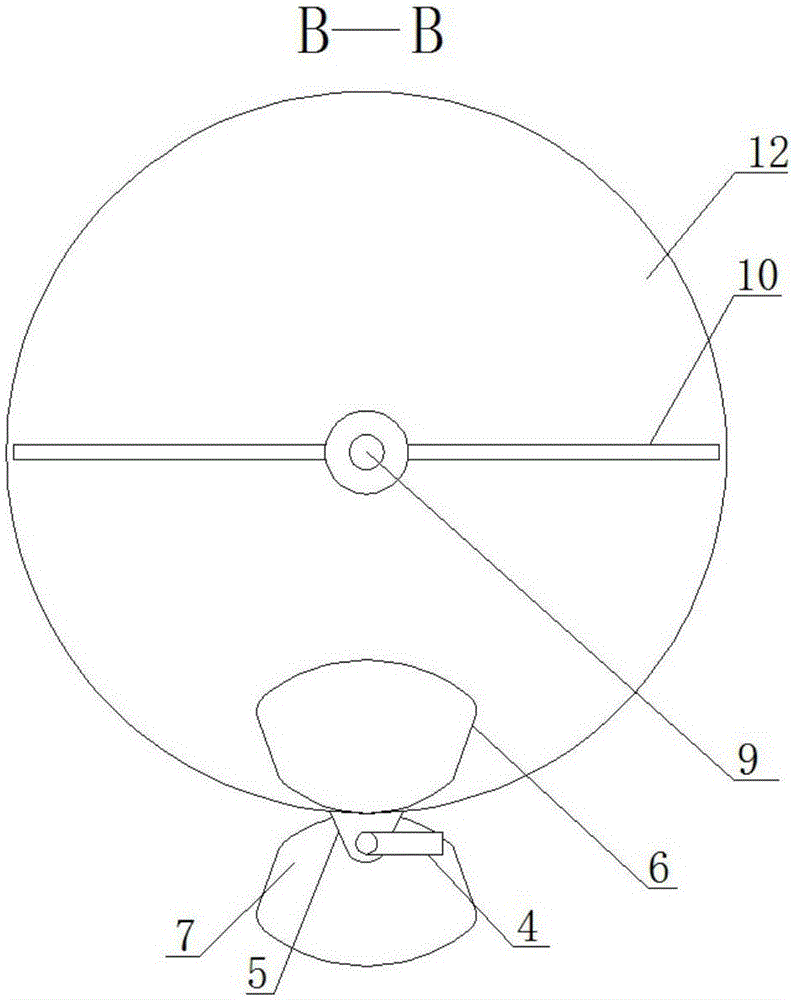

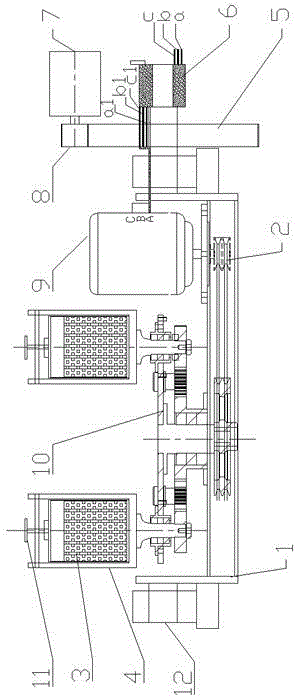

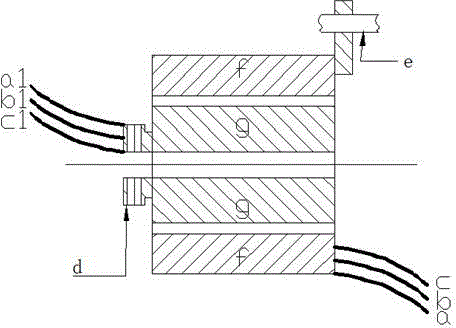

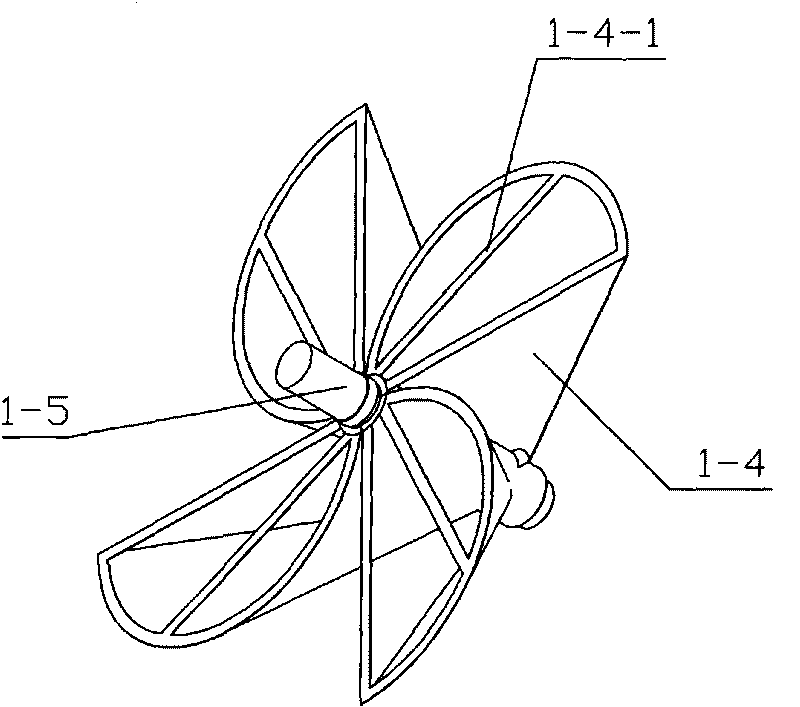

All-directional planetary ball mill

The invention relates to an all-directional planetary ball mill. According to the technical scheme, the all-directional planetary ball mill comprises a rotating frame (1), a transmission motor (9), a planetary transmission mechanism (10), grinding tanks (3) and grinding tank bases (4); the transmission motor (9) drives the planetary transmission mechanism (10) through a belt wheel (2), and the planetary transmission mechanism (10) drives the grinding tanks (3) to rotate through the grinding tank bases (4); the rotating frame (1) is fixed to the planetary transmission mechanism (10), a large gear (5) is installed on a shaft of the rotating frame (1), and a gear motor gear (8) and the large gear (5) are driven through a gear motor (7) to achieve transmission. The all-directional planetary ball mill is characterized by further comprising a via hole slip ring (6), wherein the via hole slip ring comprises a stator (f) and a rotor (g), and a terminal wire of the transmission motor (9) is connected with a stator wire and a rotor wire of the via hole slip ring to achieve electric conduction. The all-directional planetary ball mill can achieve all-directional 360-degree turnover movement and meanwhile has the advantages of being free from maintenance, convenient to assemble, capable of achieving sealing and insulation and high in safety.

Owner:长沙天创粉末技术有限公司

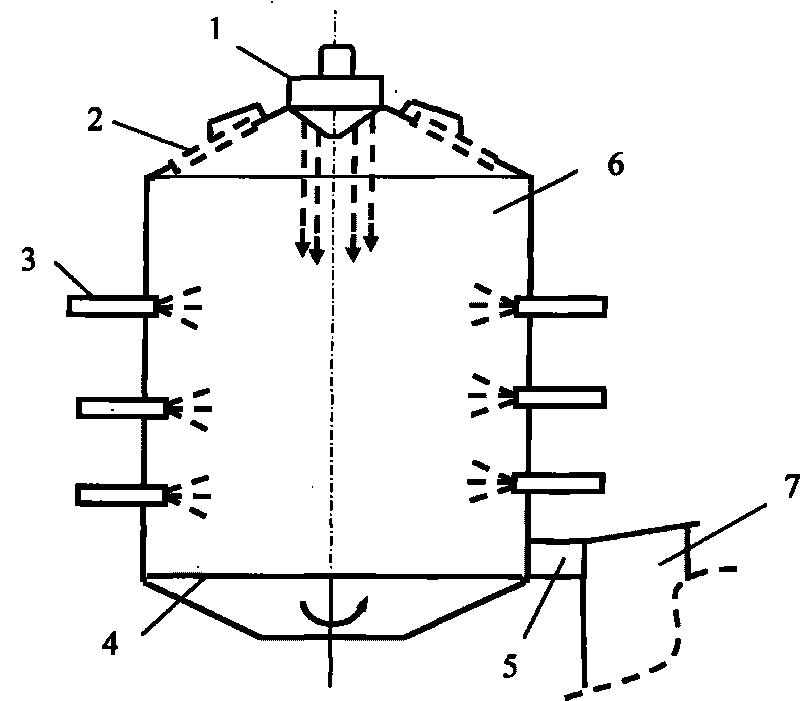

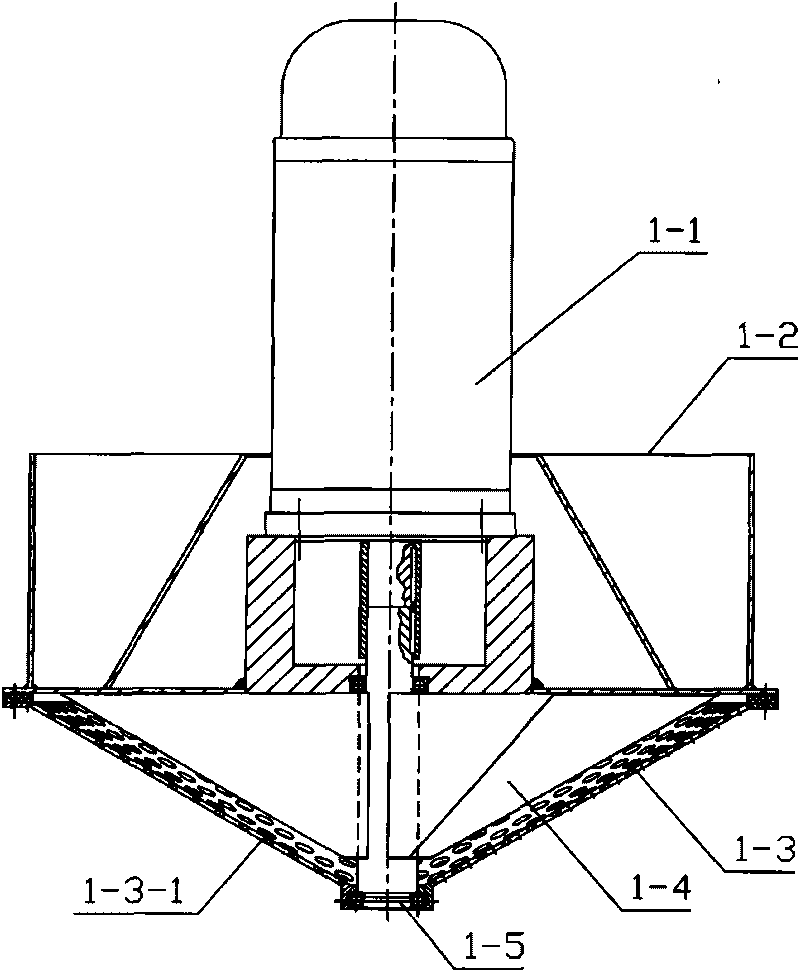

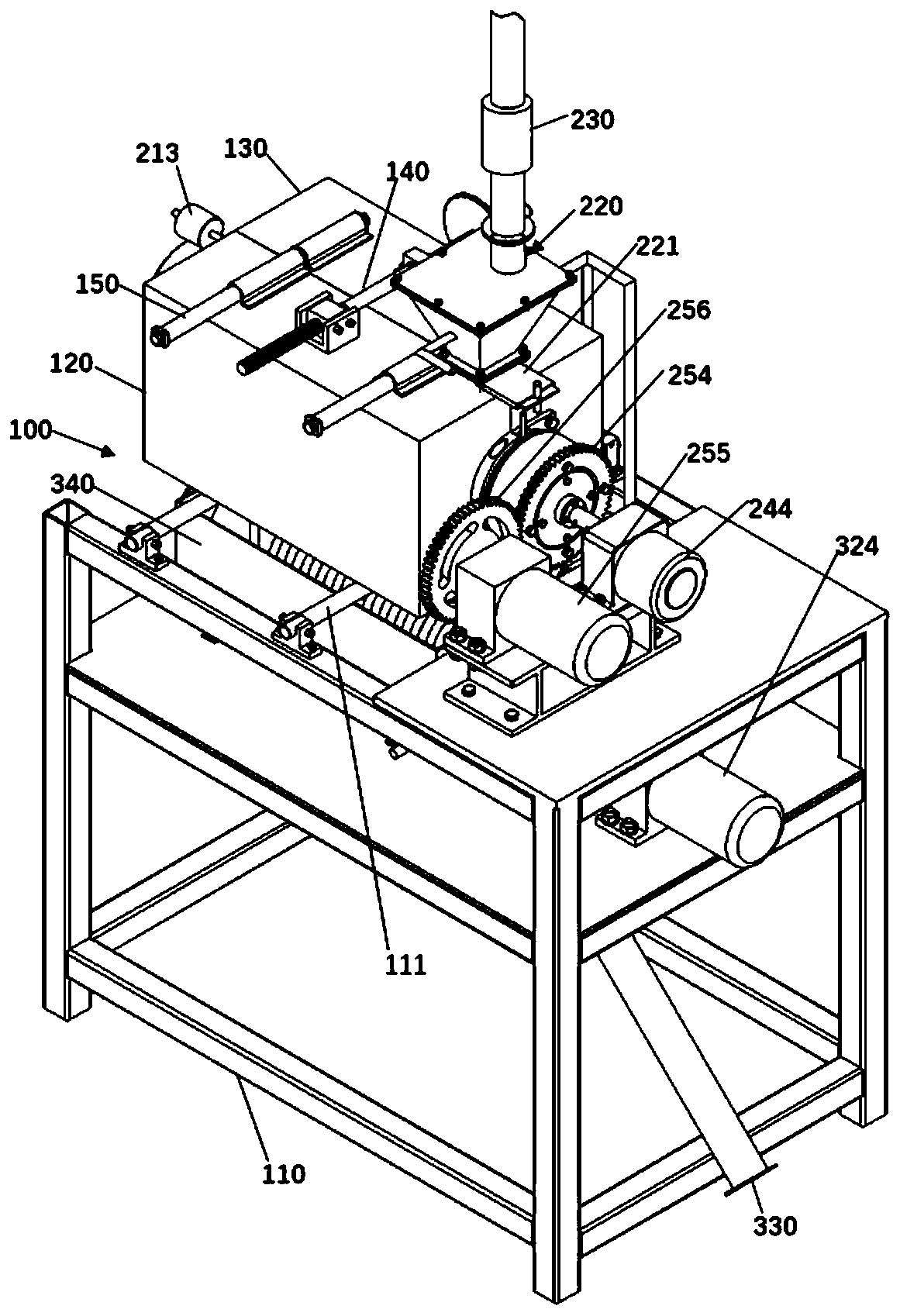

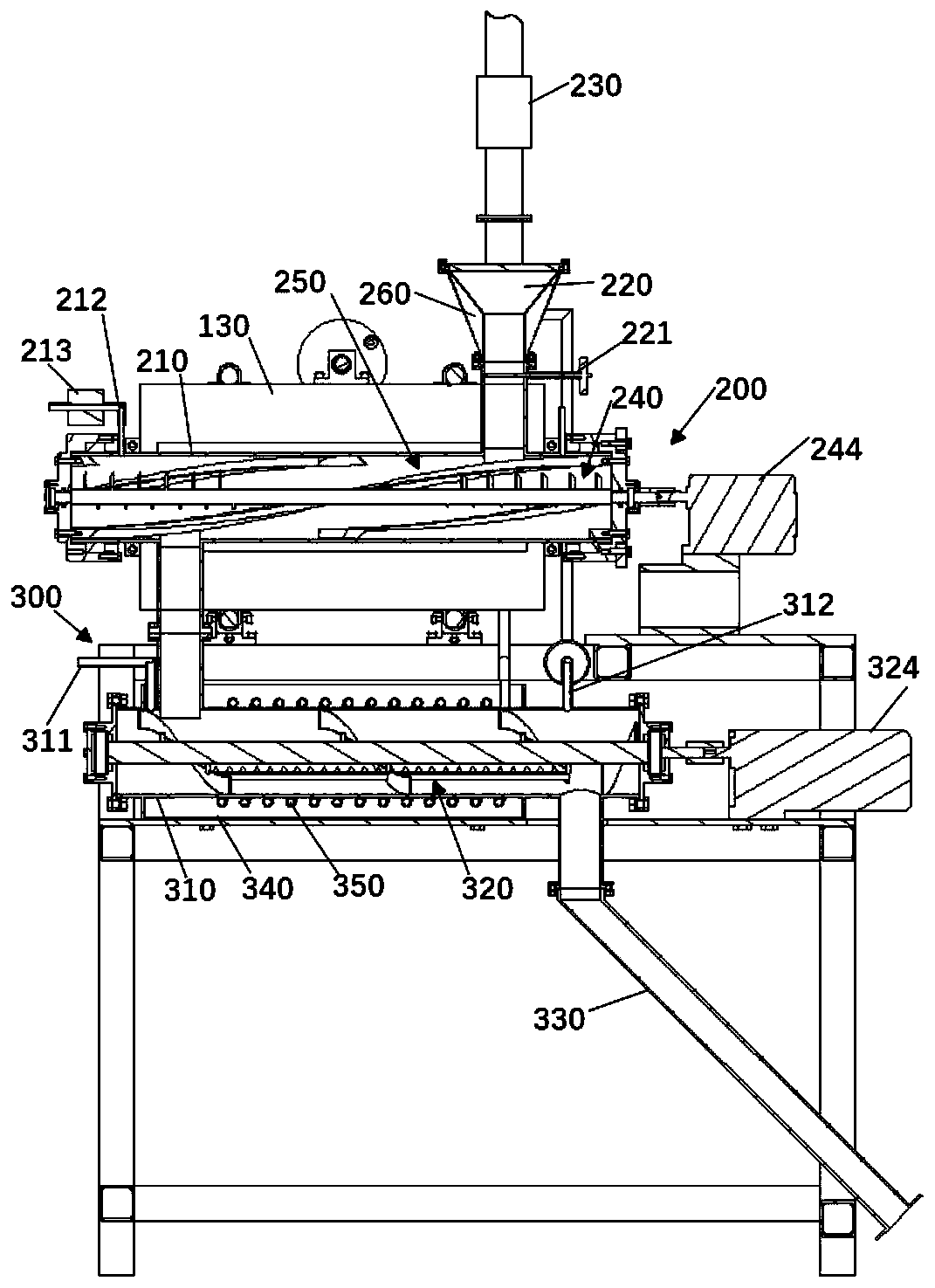

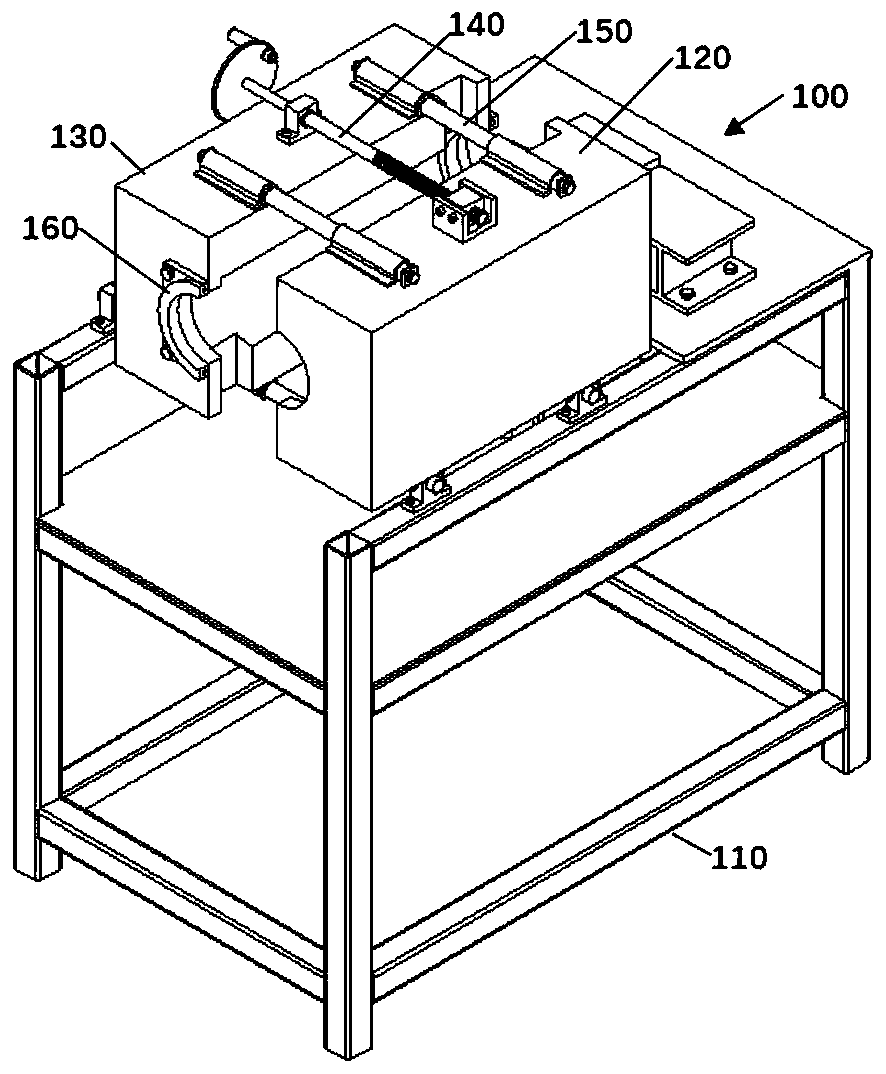

Method and equipment for granulating wet sludge soft particles

InactiveCN101703907AFine grainReduce drying costsSludge treatment by de-watering/drying/thickeningGranulation in rotating dishes/pansCombustionSludge

The invention discloses a method for granulating wet sludge soft particles. Sludge after being pressed and filtered is extruded into sludge strings by a sludge string extrusion machine at the top of a mixing tank, combustible powder is sprayed to the sludge strings for serving as an isolator by adopting a powder spraying machine of a powder spraying gun which is fixedly connected on the side wall of the mixing tank in the process that the sludge strings fall from top to bottom, the sludge strings coated with the combustible powder fall on a turntable granulating machine of which the bottom is laid with the combustible powder, and soft body granulation is carried out under the rotation of the turntable granulating machine to form dispersive wet sludge soft particles. The invention also discloses equipment for realizing the method. The invention simplifies a subsequent sludge drying process; the sprayed combustible powder can be used as the isolator, which is beneficial to sludge granulation and solves the problems of sludge caking and wall sticking effectively; moreover, the sprayed combustible powder can also act as a combustion-supporting function when sludge is incinerated; and the invention has simple equipment, low energy consumption and high benefit, is safe and sanitary, is convenient for popularization and use and can promote the industrialization progress of the drying incineration of the sludge.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

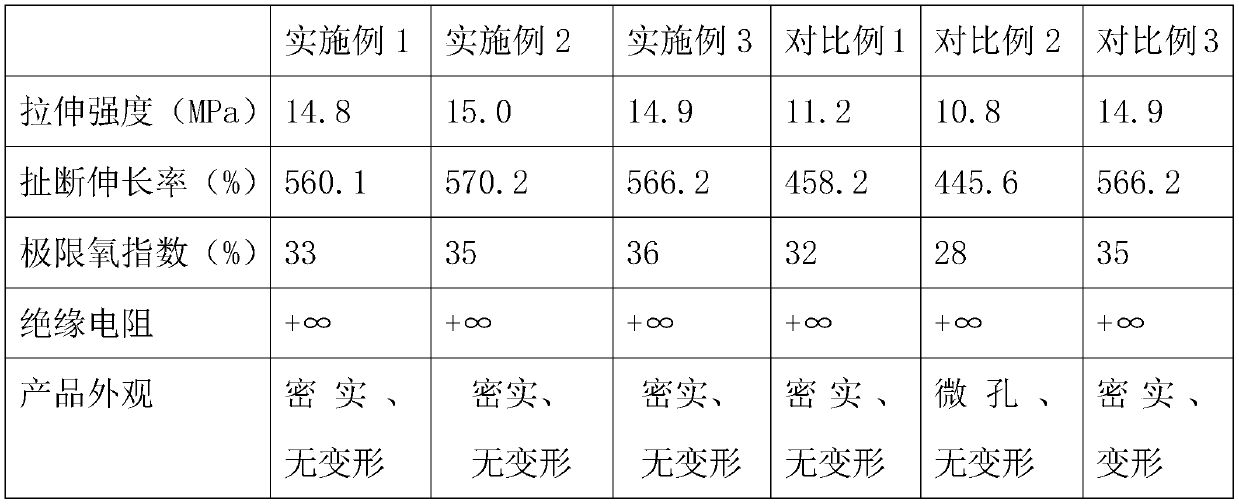

Insulating flame-retardant ethylene-propylene-diene monomer hose composition and preparation method thereof

ActiveCN110240760AMeet mechanical strength requirementsMeet performance requirementsRubber insulatorsAntimony trioxideStearic acid

The invention discloses an insulating flame-retardant ethylene-propylene-diene monomer hose composition which is characterized by comprising the following components in parts by weight: 100 parts of an EPDM (ethylene-propylene-diene monomer) 5890F, 2-6 parts of kaolin, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 2-5 parts of paraffin, 1-3 parts of an anti-aging agent MB, 50-70 parts of carbon black SP6400A, 130-190 parts of a flame retardant, 10-30 parts of paroline, 1-2 parts of sulfur, 10-15 parts of calcium oxide and 1.6-3 parts of an accelerant, wherein the accelerant comprises 0.2-0.5 part of an accelerant TT; and the flame retardant comprises 80-100 parts of aluminum hydroxide, 20-40 parts of zinc borate, 10-20 parts of antimonous oxide and 20-30 parts of decabromodiphenyl ethane. The invention has another purpose of providing a preparation method of the insulating flame-retardant ethylene-propylene-diene monomer hose composition, and on premise that electric insulation and insulation resistance of vulcanized rubber are met, mechanical strength requirements of rubber can be met.

Owner:青岛铁路橡胶厂

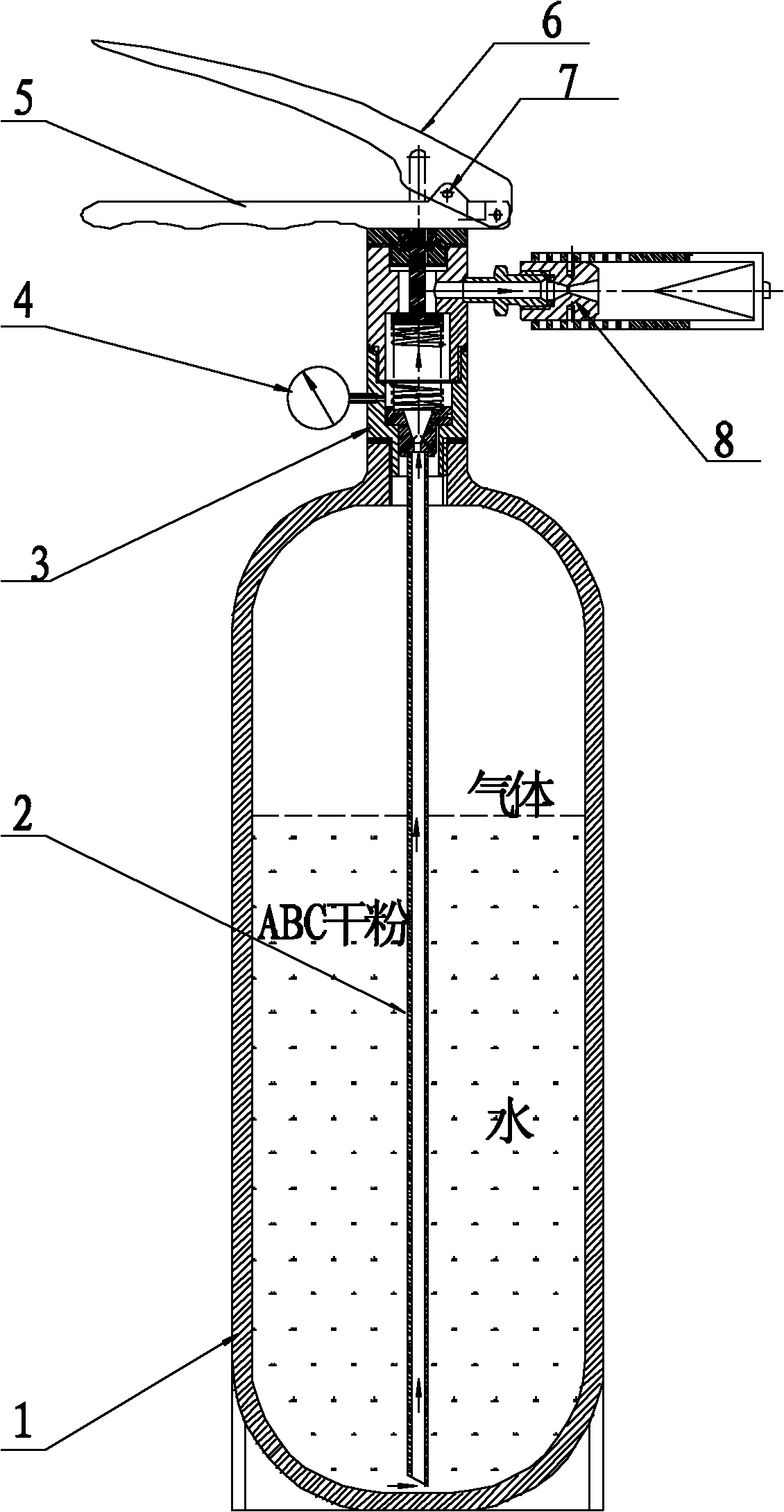

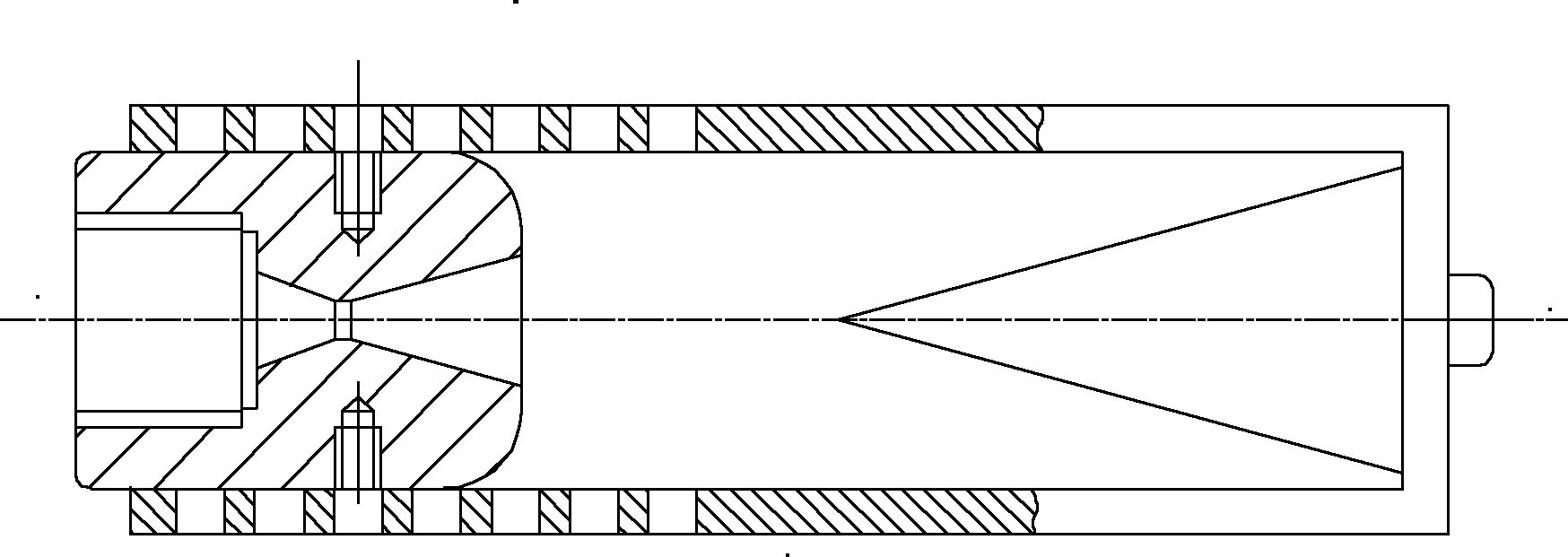

Three-phase jet extinguishing method

ActiveCN102078667AImprove fire extinguishing efficiencyGood fire extinguishing effectFire rescueFire extinguisherSingle phaseNitrogen gas

The invention relates to a portable three-phase jet extinguishing method. In the method, a portable two-phase flow water mist extinguishing device is used as a carrier; the surface of ABC dry powder is modified to be hydrophobic; the modified dry powder is shaken up with water and then injected into a gas-water mixed loading bottle of the extinguishing device; nitrogen or other inert gases are charged into the bottle; then the extinguishing device is placed for later use; and the dry powder is sprayed out from the portable two-phase flow water mist extinguishing device under the extrusion of high-pressure gas when the device is used for extinguishing. The method has a comprehensive gas-liquid-solid extinguishing effect; the temperature can be reduced, the oxygen concentration can be diluted, the surface of a fuel can be cooled, a combustion reaction chain can be quickly obstructed, and the like; a type-A fire disaster and a type-B fire disaster can be effectively extinguished; the extinguishing efficiency is high; the method is basically pollution-free to a protected place; and the extinguishing effect is obviously superior to those of a single-phase flow portable extinguishing device and a two-phase flow portable extinguishing device.

Owner:BEIHANG UNIV

Wall scraping type propelled steel rolling oil sludge pyrolysis carbonization treatment device and method

PendingCN111423086ASolve the sludge sticking wallSolve product agglomerationSludge treatment by pyrolysisByproduct vaporizationProcess engineeringWaste treatment

The invention belongs to the technical field of steel rolling oil sludge, sludge and other solid waste treatment equipment. The invention provides a wall scraping type propelled steel rolling oil sludge pyrolysis carbonization treatment device and method. The device comprises a heating furnace body unit, a pyrolysis carbonization unit and a residue crushing unit; the heating furnace body unit is used for providing heat required by pyrolysis for the pyrolysis carbonization unit and fixing the pyrolysis carbonization unit and the residue crushing unit; the pyrolysis carbonization unit comprisesa rack, a furnace cover, a furnace body and an opening and closing lead screw, the pyrolysis carbonization unit is used for pyrolyzing steel rolling oil sludge and comprises a reaction pipe, a storagebin, a booster pump, a propelling stirring paddle and a spiral wall scraping device, and the residue crushing unit is used for crushing and conveying out residues conveyed by the pyrolysis carbonization unit and comprises a crushing pipe and a crushing spiral conveying device. According to the wall scraping type propelled steel rolling oil sludge pyrolysis carbonization treatment device providedby the invention, the problems that the steel rolling oil sludge adheres to the wall and a product is caked are solved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Special fertilizer for China roses and preparation method thereof

The invention discloses special fertilizer for China roses and a preparation method thereof. The special fertilizer comprises the following raw materials in parts by weight: 65-75 parts of pond mud, 20-30 parts of chicken manure, 3-4 parts of ammonium carbamate, 35-45 parts of montmorillonite, 2-4 parts of organic matter, 3-5 parts of humic acid, 1-3 parts of sodium aluminate, 2-3 parts of sodium metasilicate, 0.3-0.5 parts of menthol, 1.5-1.8 parts of ferrous sulfate, 10-12 parts of soil nutritional agent, 5-7 parts of cypermethrin, 1-3 parts of ammonium phosphate and 10-15 parts of groundnut leaf. The fertilizer disclosed by the invention has the advantages that the loss of nutritional ingredients in the fertilizer and the accumulation of harmful products can be reduced; the soil caking problem can be solved; the fertilizer needed in the whole growth and development process of the China roses is guaranteed, a proper amount of fertilizer is applied in earlier, middle, and later stages of the China roses and the use ratio of the fertilizer is increased.

Owner:明光市业兴非金属材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com