Double-cylinder multi-fluidization circulating type aerosol generator

An aerosol generation and circulation type technology, applied in the directions of dissolution, fluid mixer, chemical instruments and methods, etc., can solve the problems of poor fluidity, spontaneous coagulation, powder agglomeration, etc., and achieves unique design, simple operation, increased The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

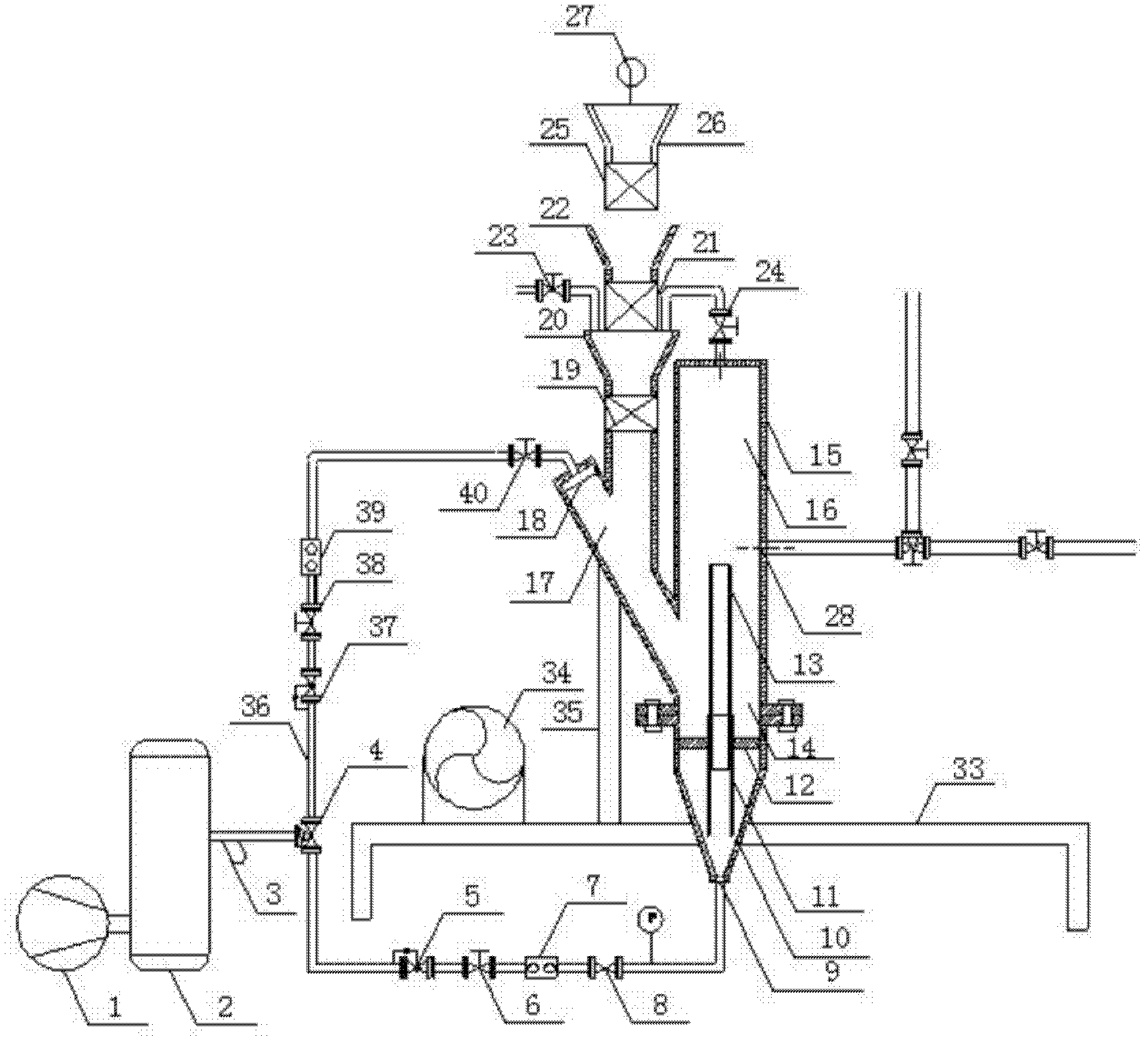

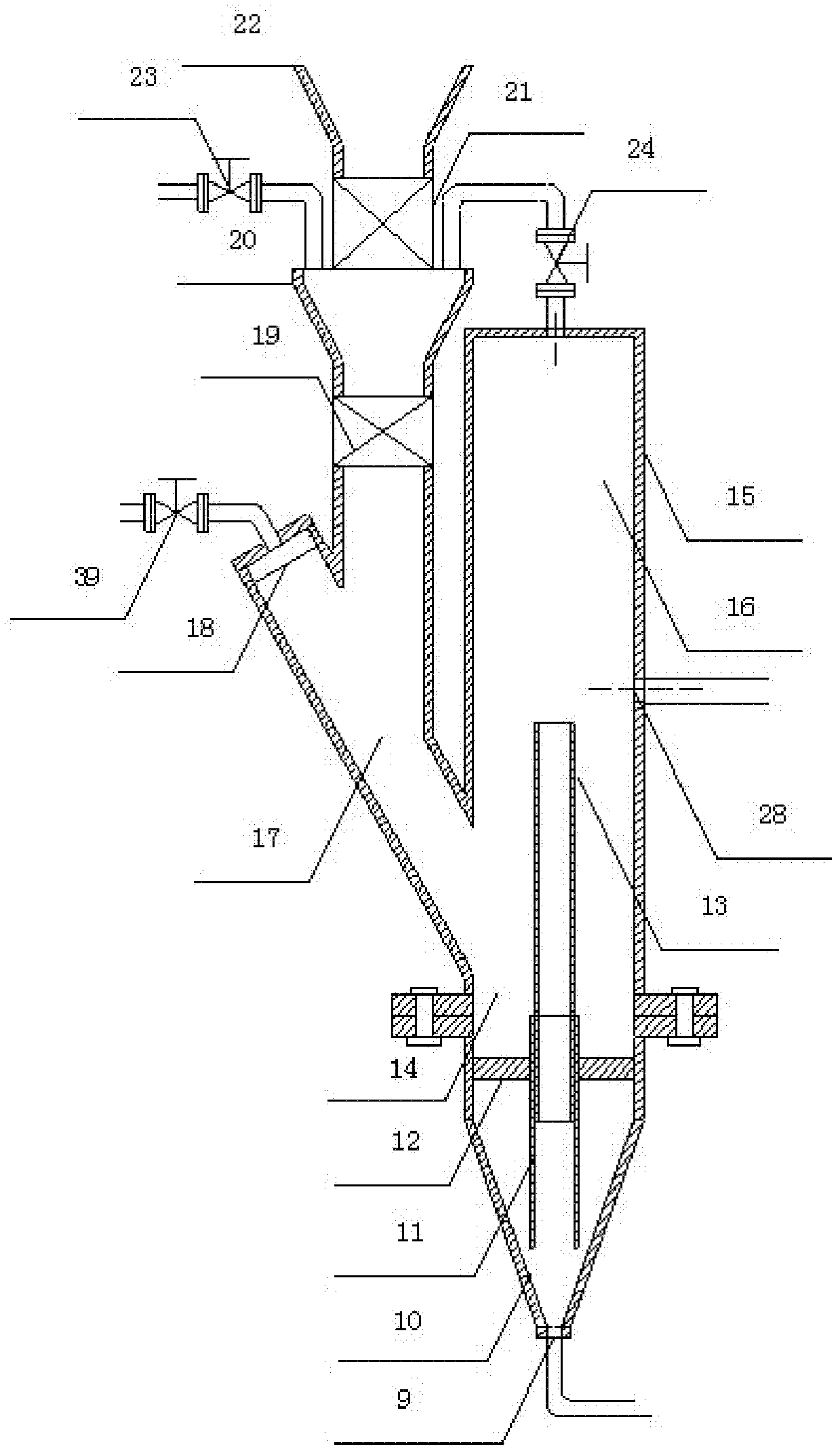

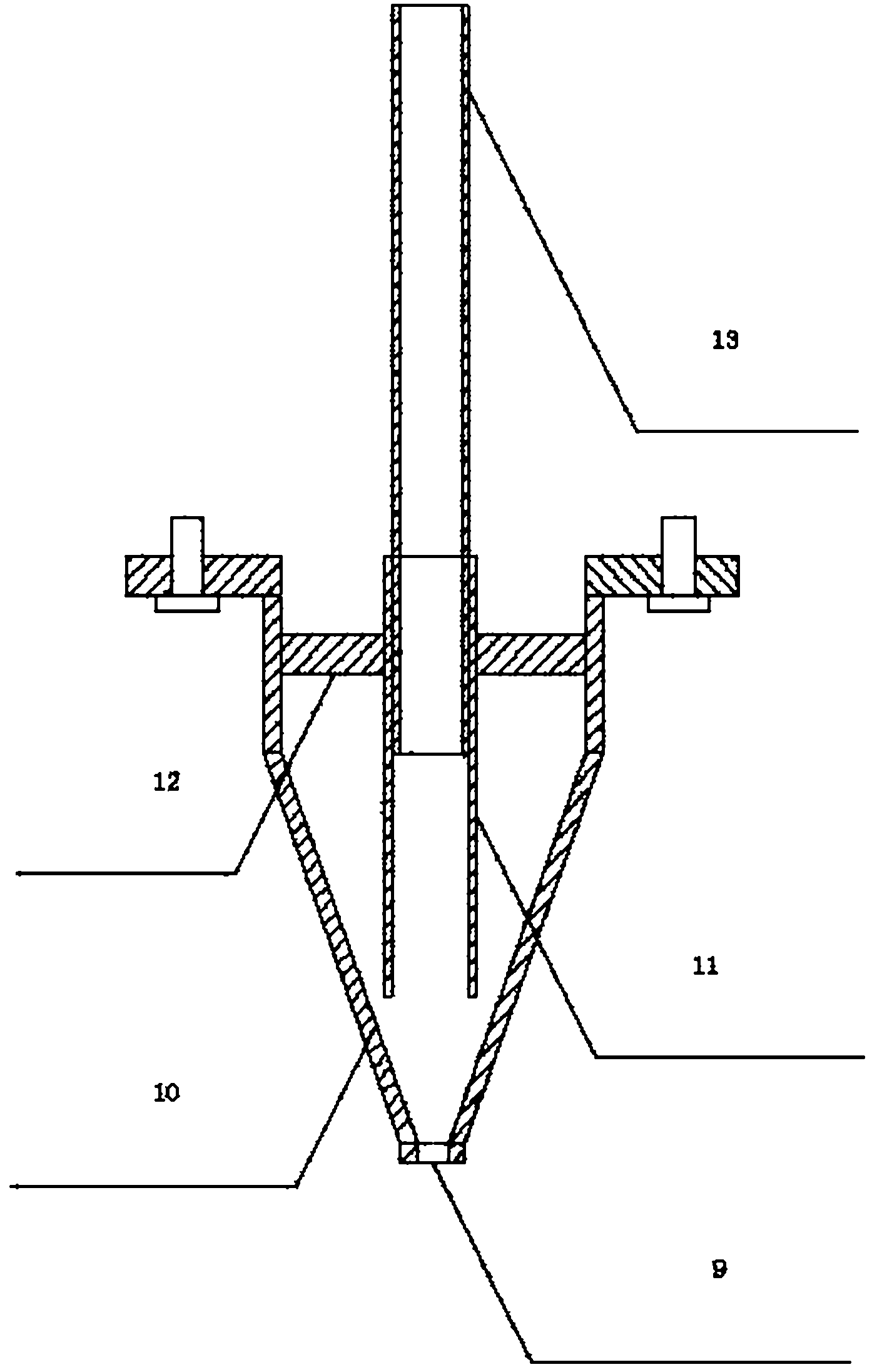

[0030] combine Figure 1~3, the present invention provides a double-tube multi-stage fluidized circulation type aerosol generating device, the aerosol generating device is composed of a powder online continuous powder supply part, a powder fluidization and circulation part, a gas path control part, and a vibrating motor part; The online continuous powder supply part is mainly composed of a load cell 27, a material storage container 26, a valve 25, a feed hopper 22, a feeder 20, a balance air pressure valve 24, an exhaust valve 23, two feeding valves 21, 19, a high The slope feeding transition section 17 and the porous air equalizing plate 18 are composed of the online continuous powder supply under high pressure and the first-stage fluidization function of the powder; the powder fluidization and circulation part is mainly composed of a cone 10 and a double-stage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com