Patents

Literature

276results about "Mixing gases/vapours with solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

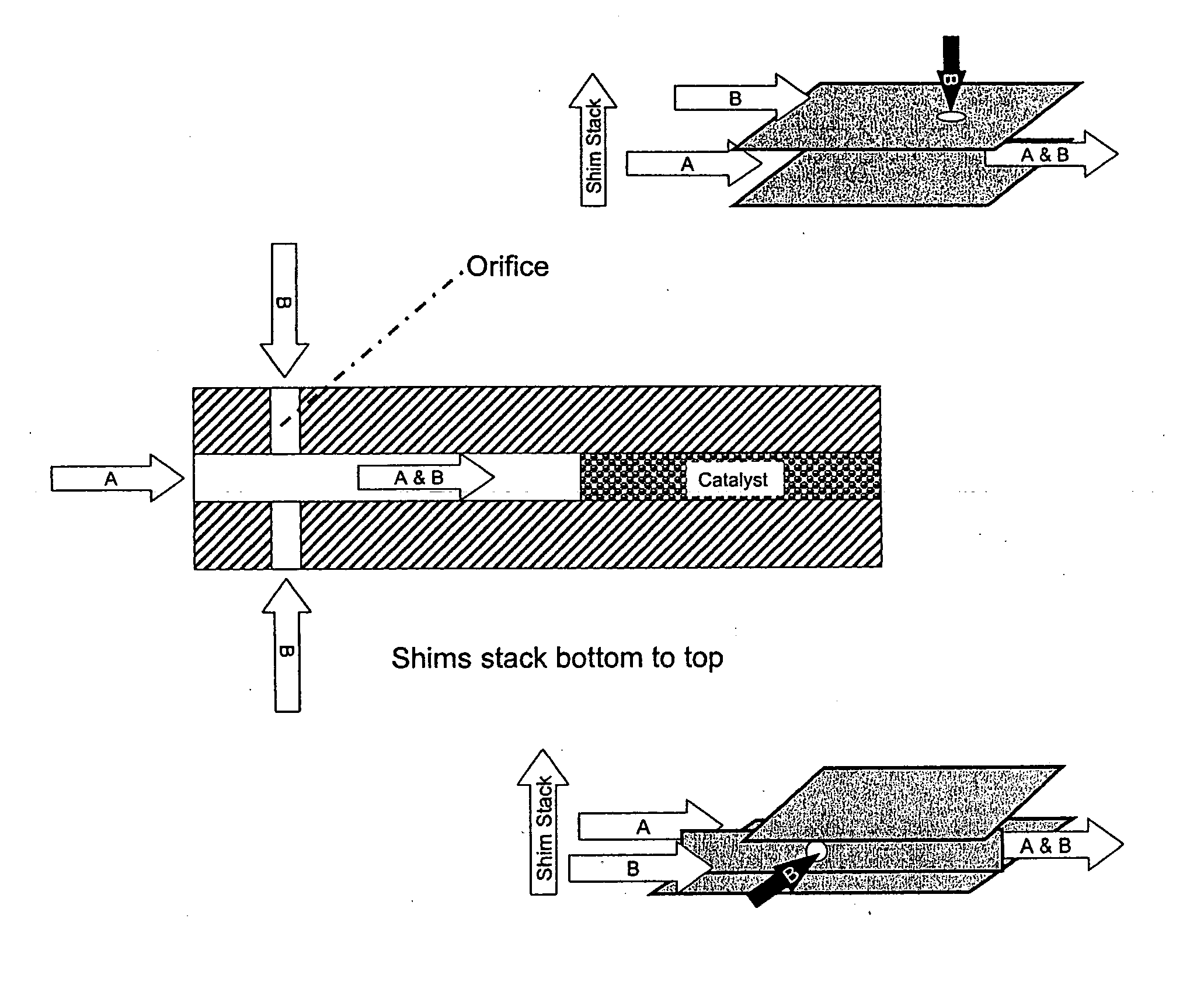

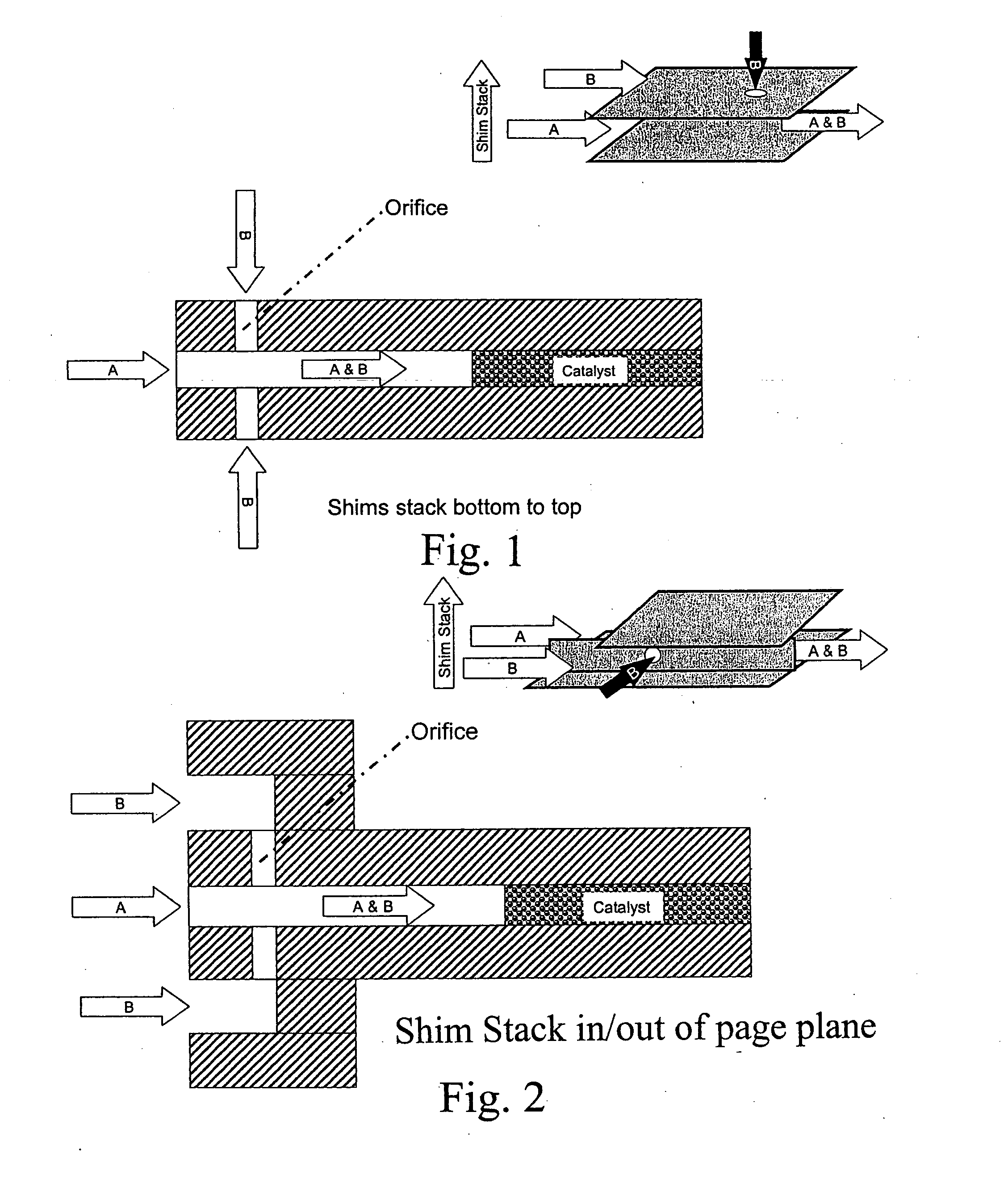

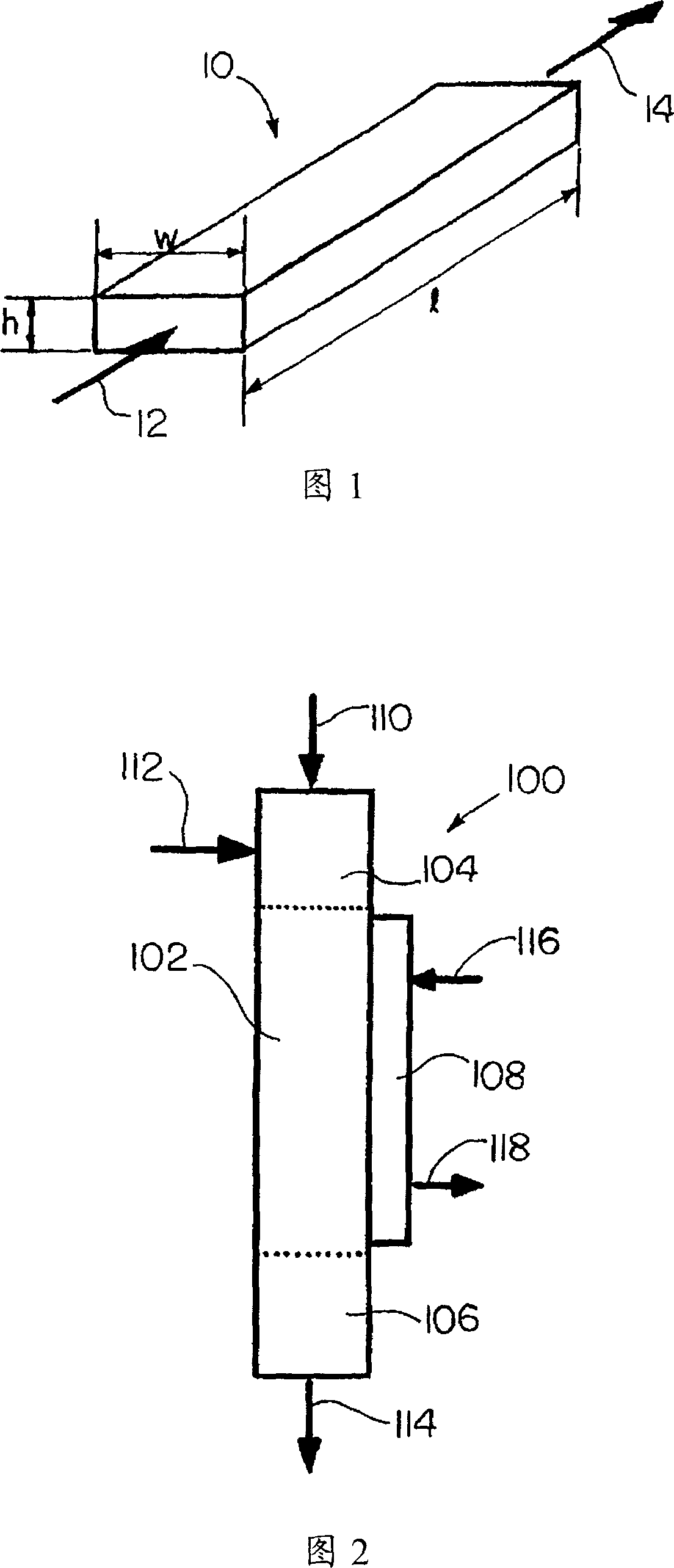

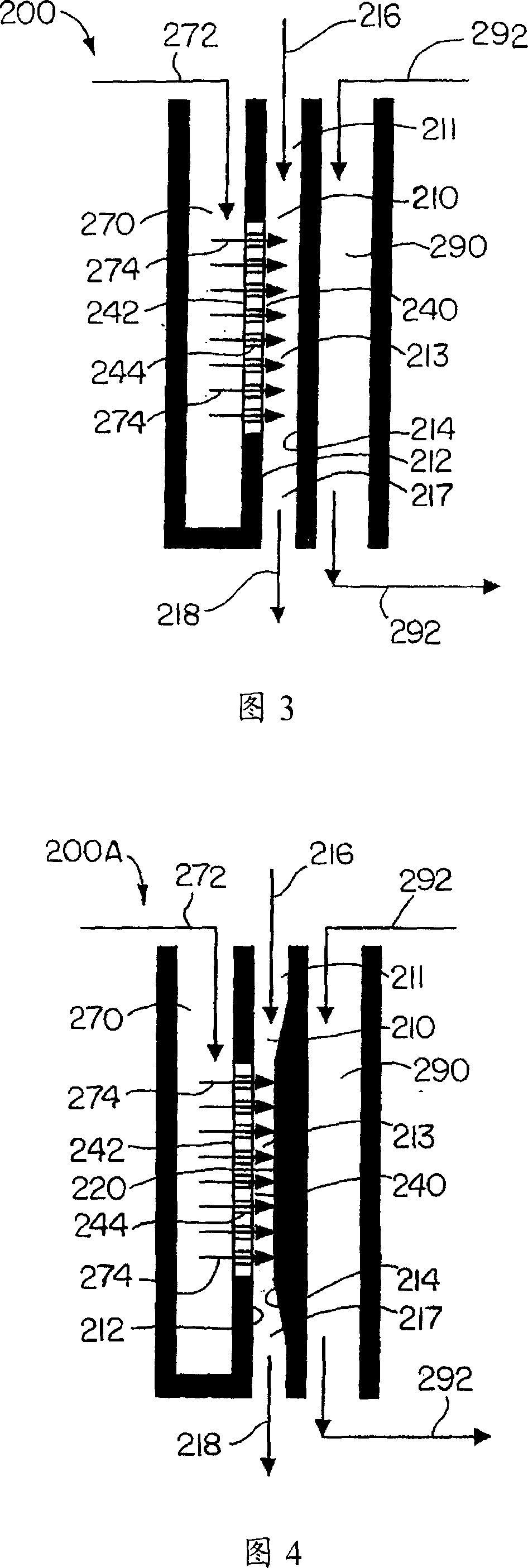

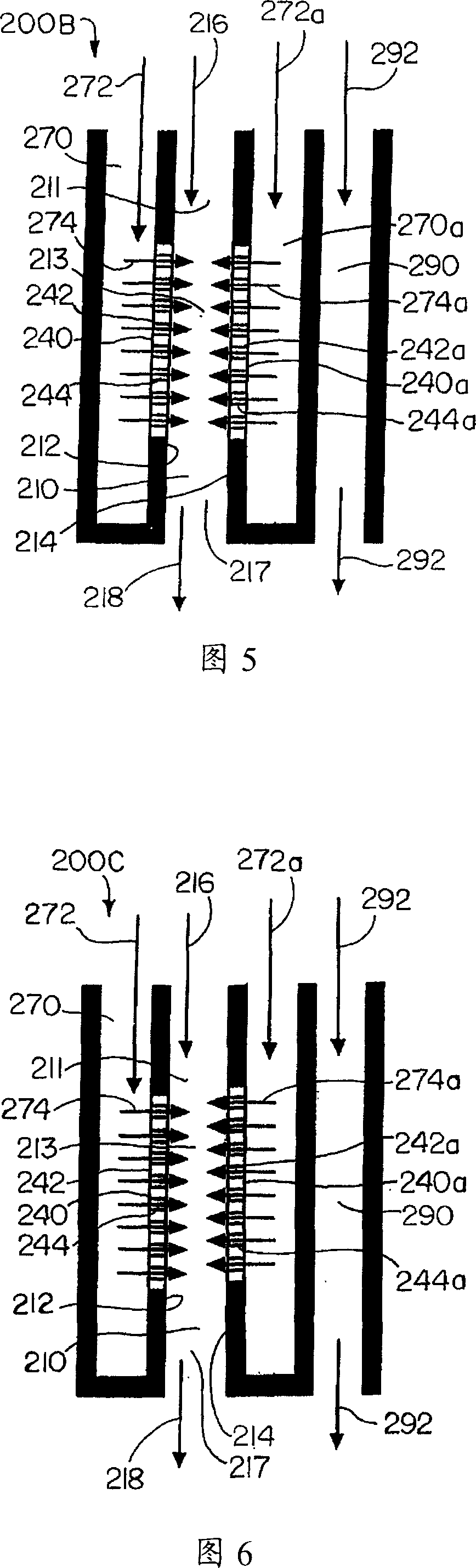

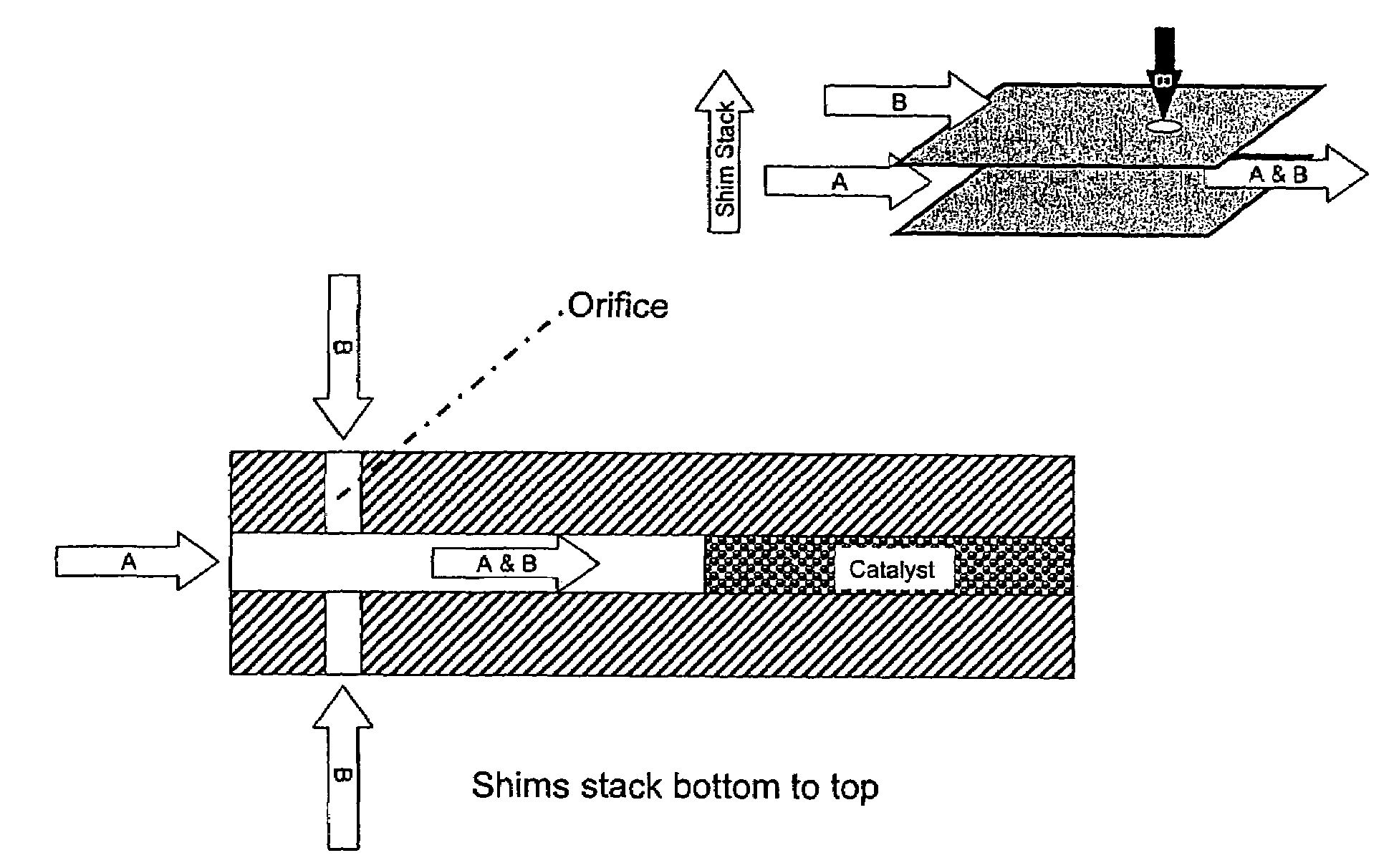

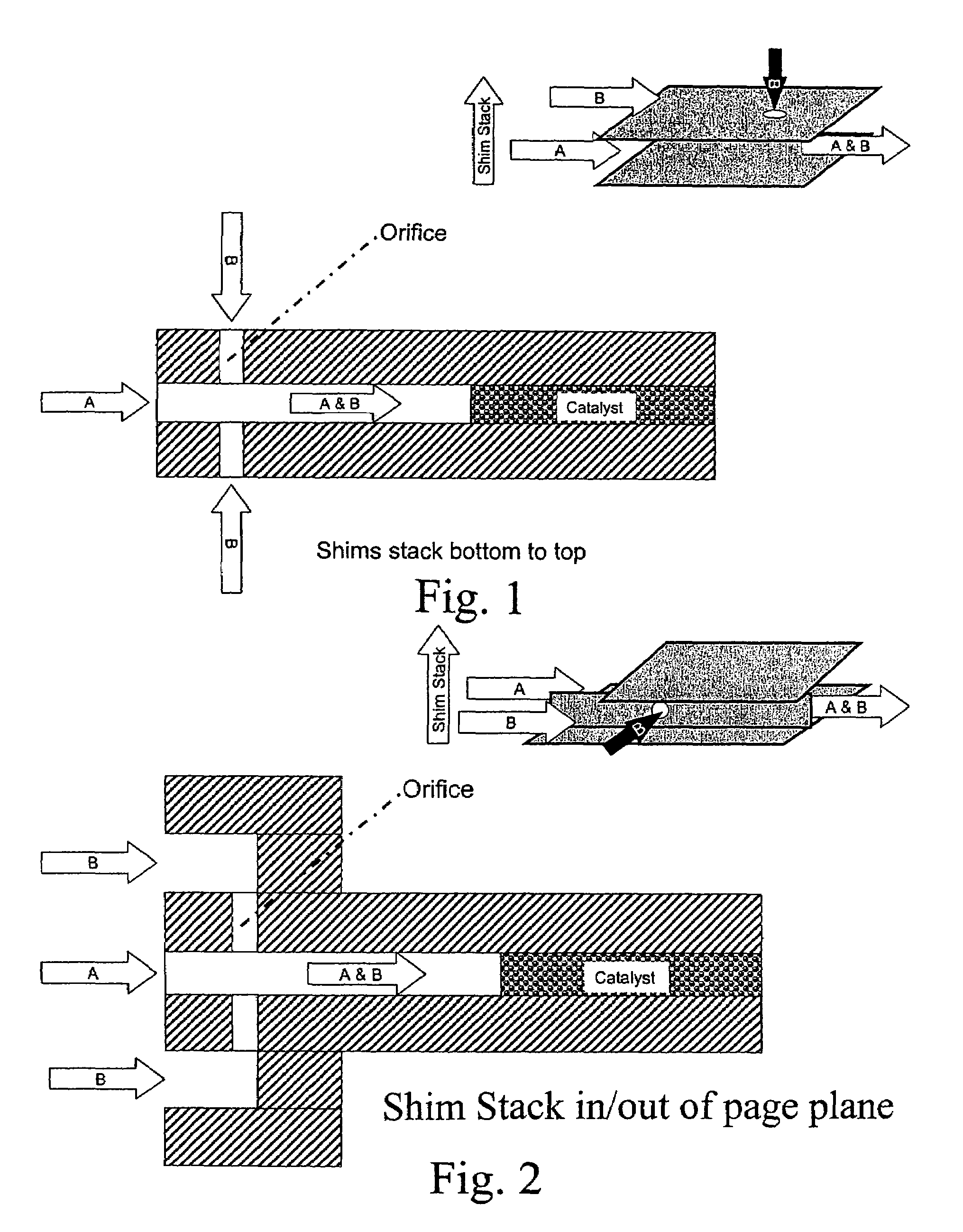

In situ mixing in microchannels

InactiveUS20050133457A1Reduce flammabilityImprove thermal conductivityPhysical/chemical process catalystsFlow mixersEngineering

Owner:VELOCYS CORPORATION

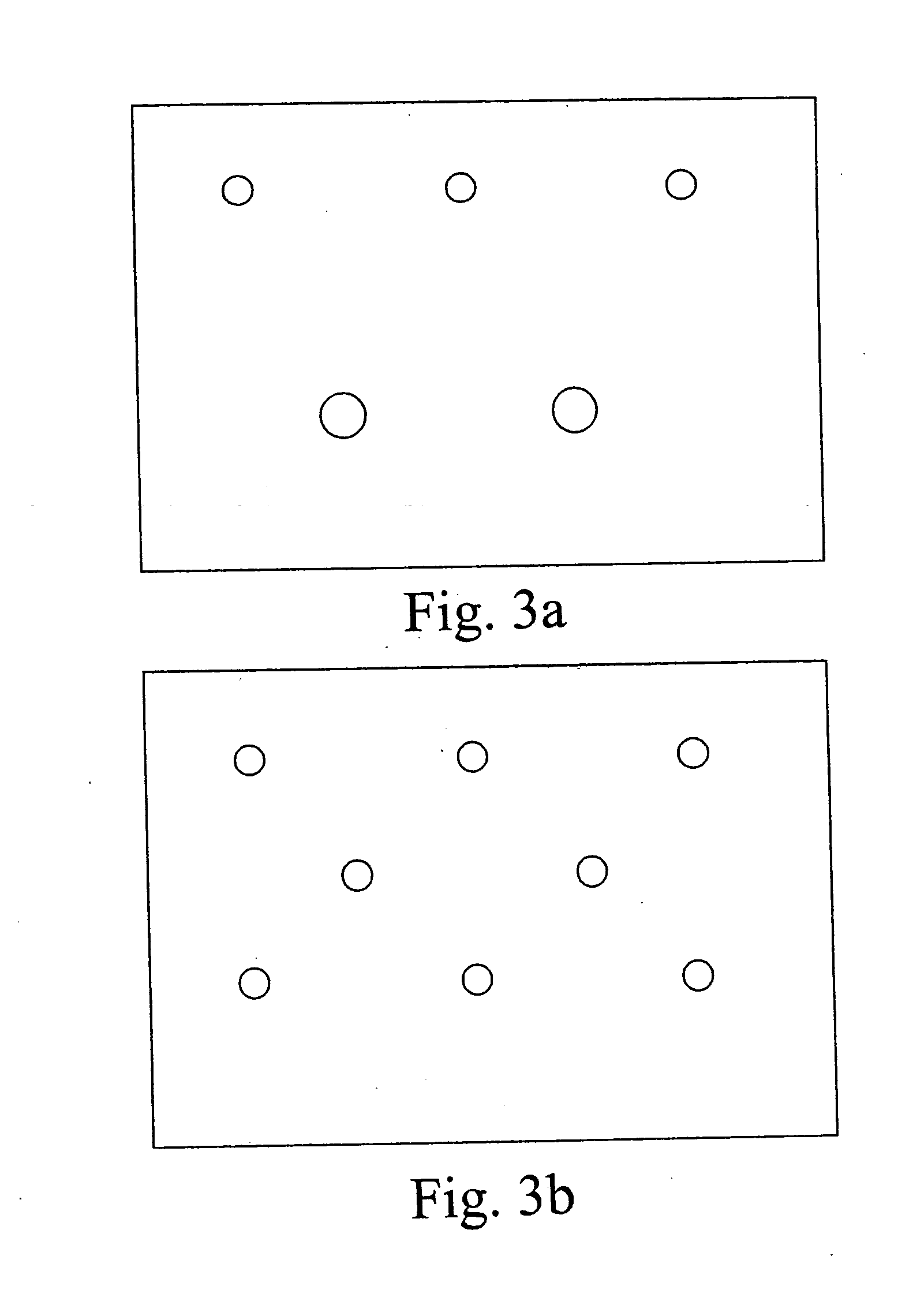

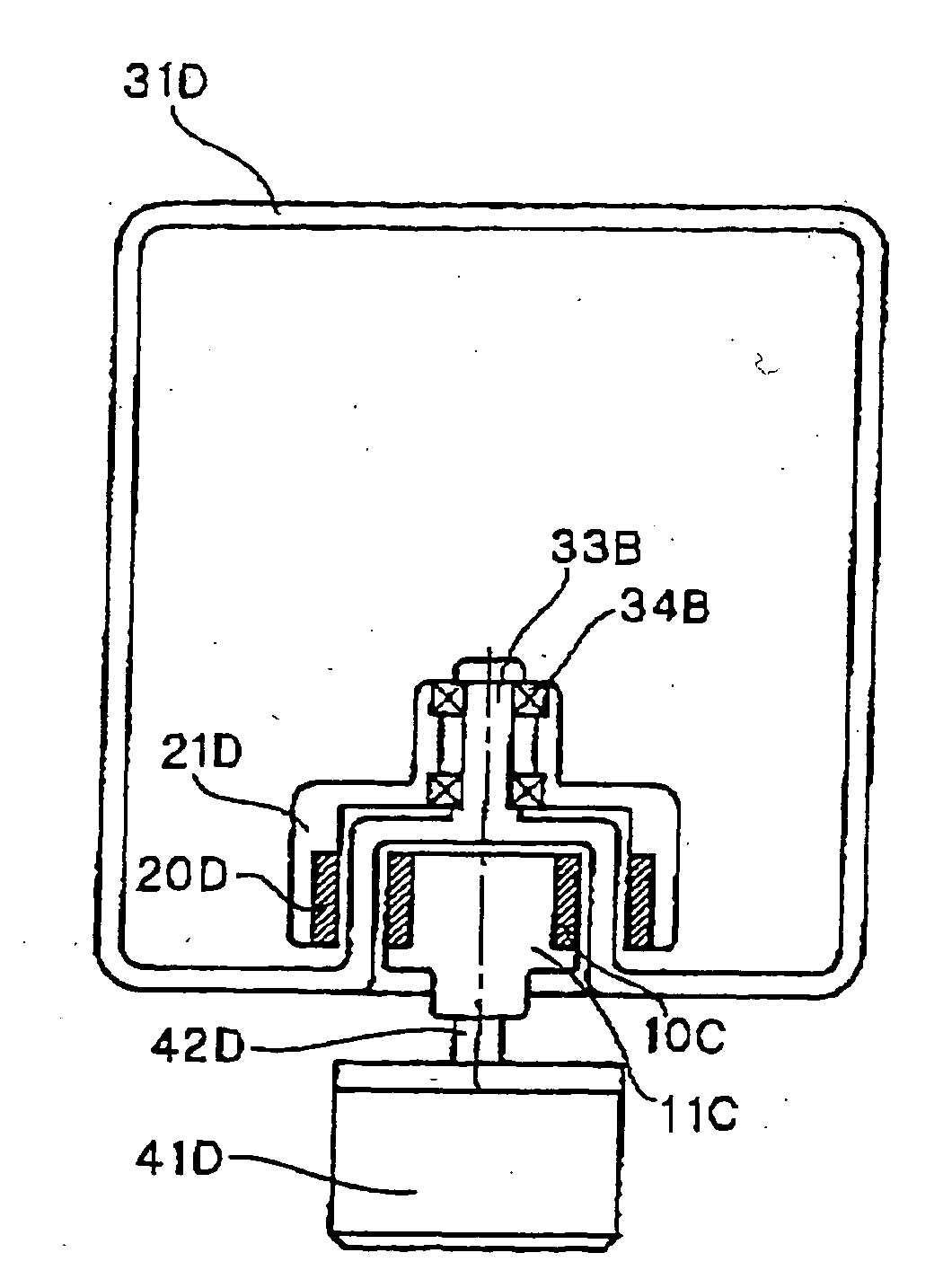

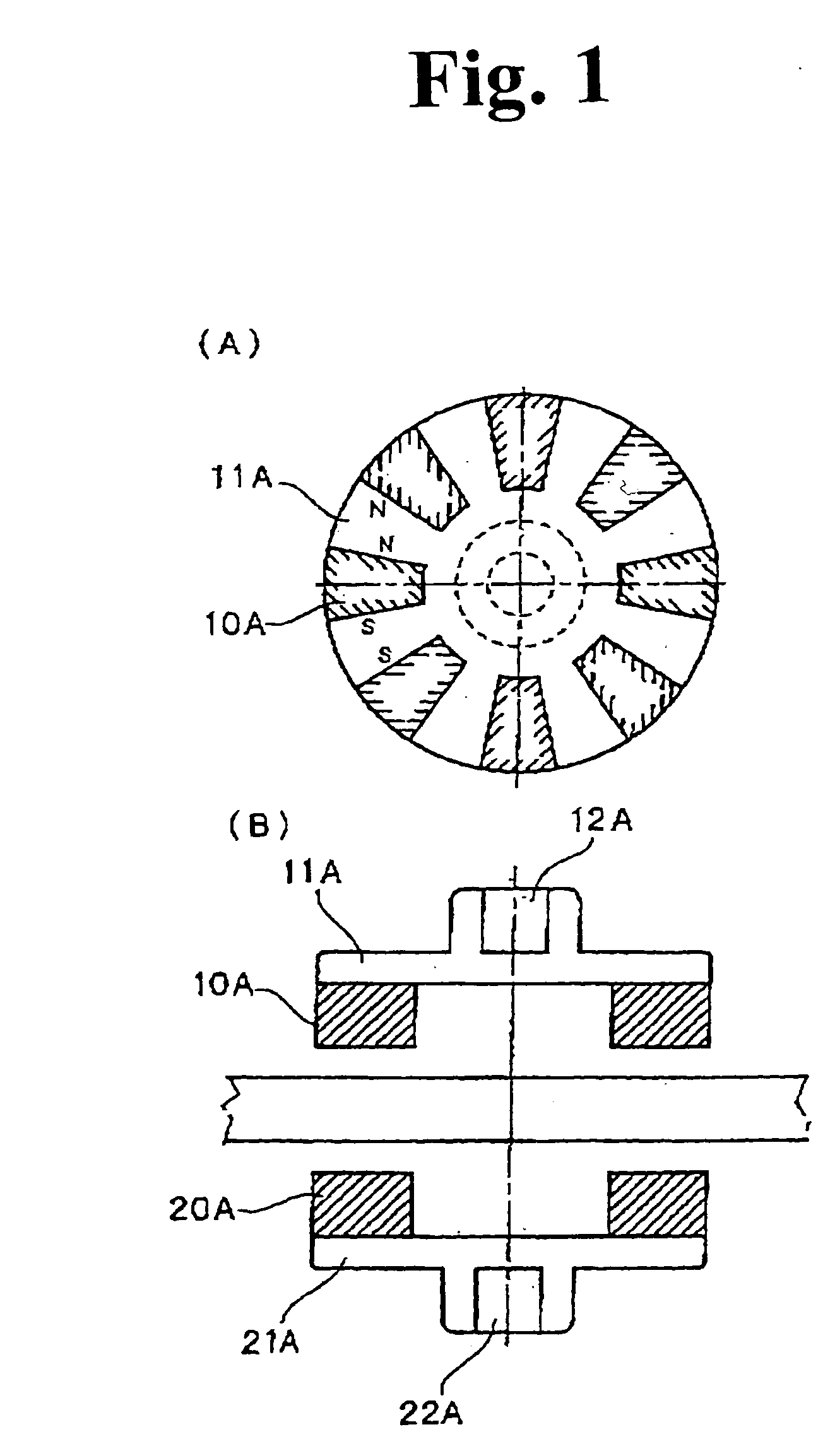

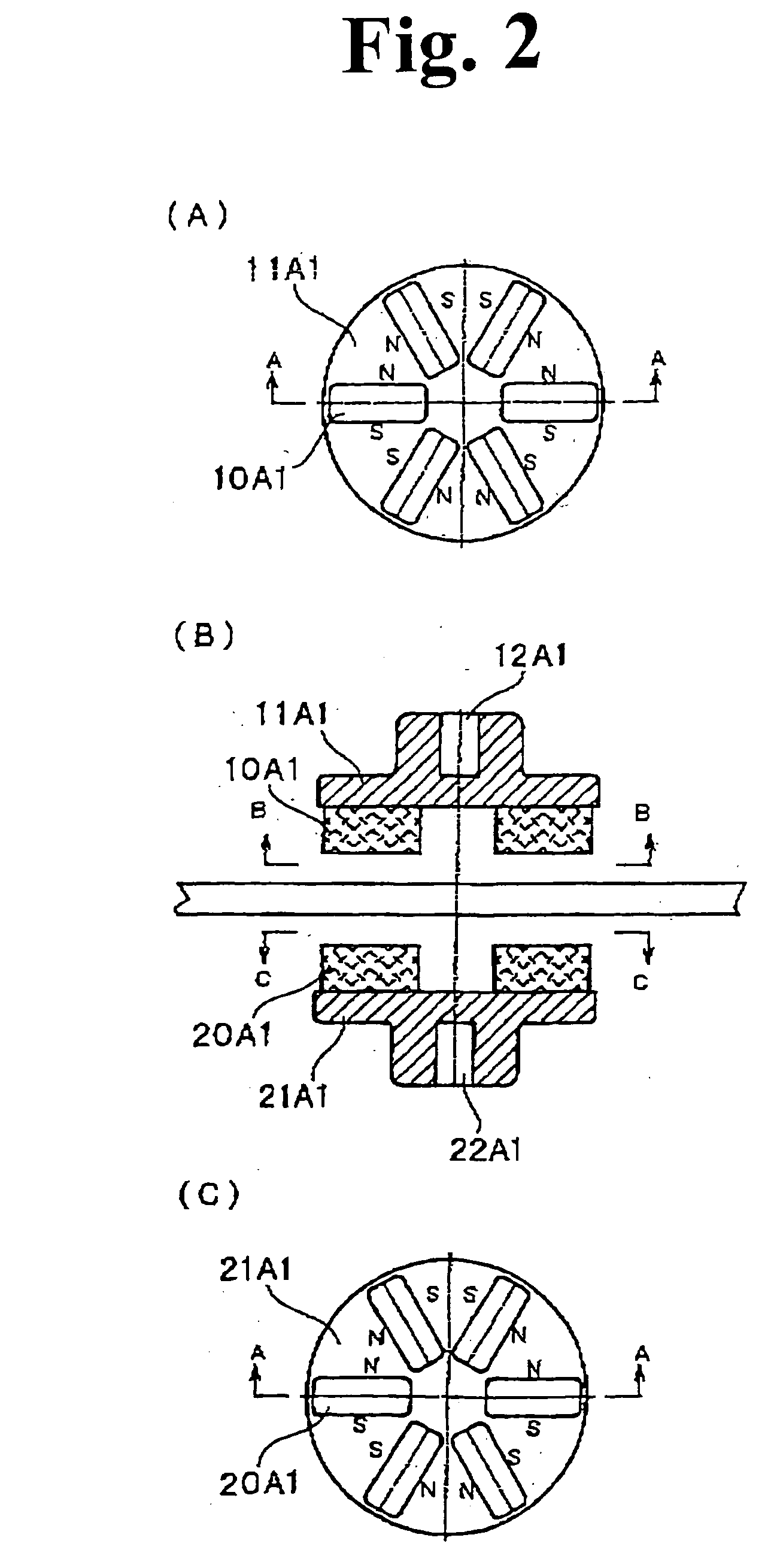

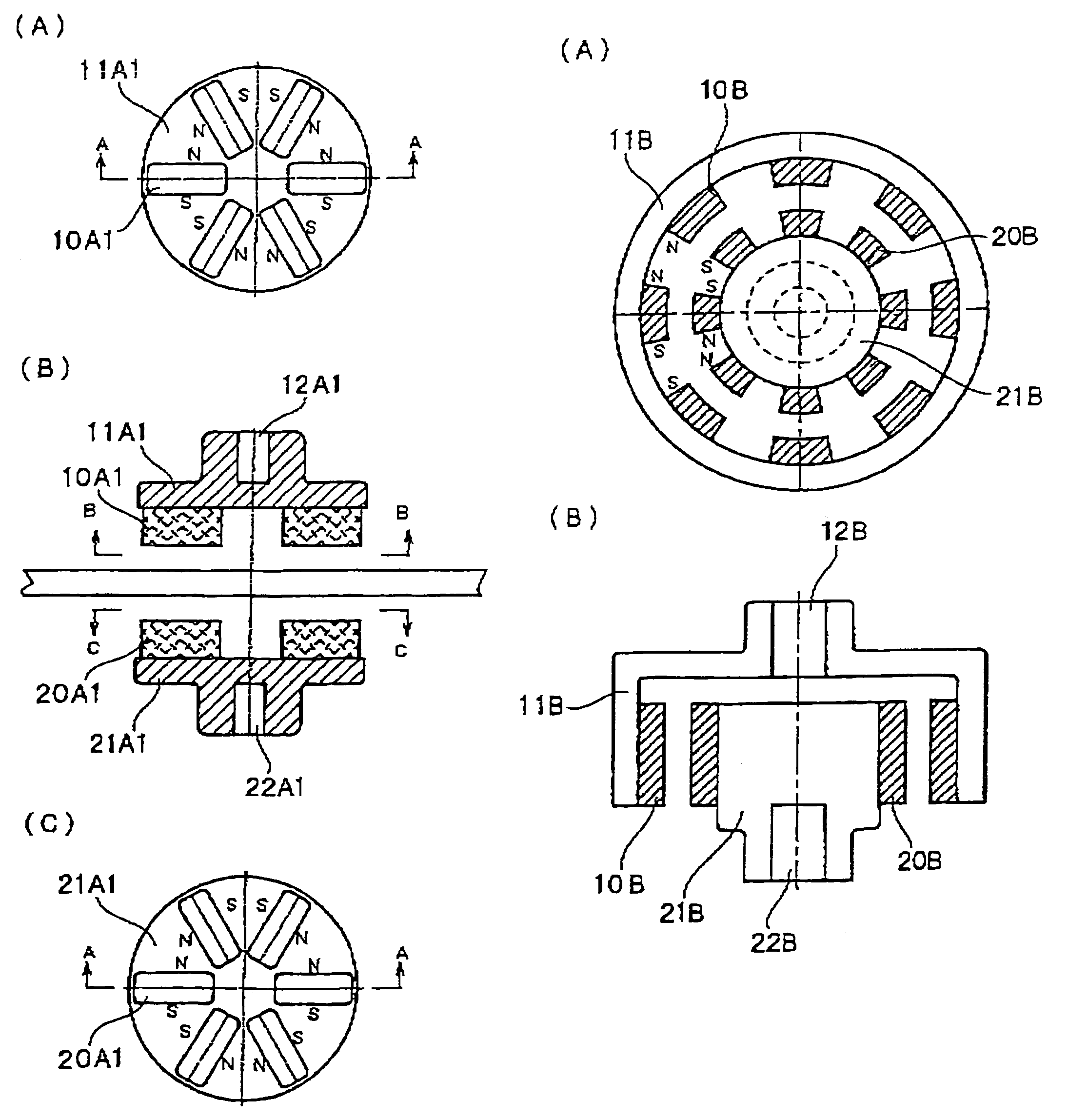

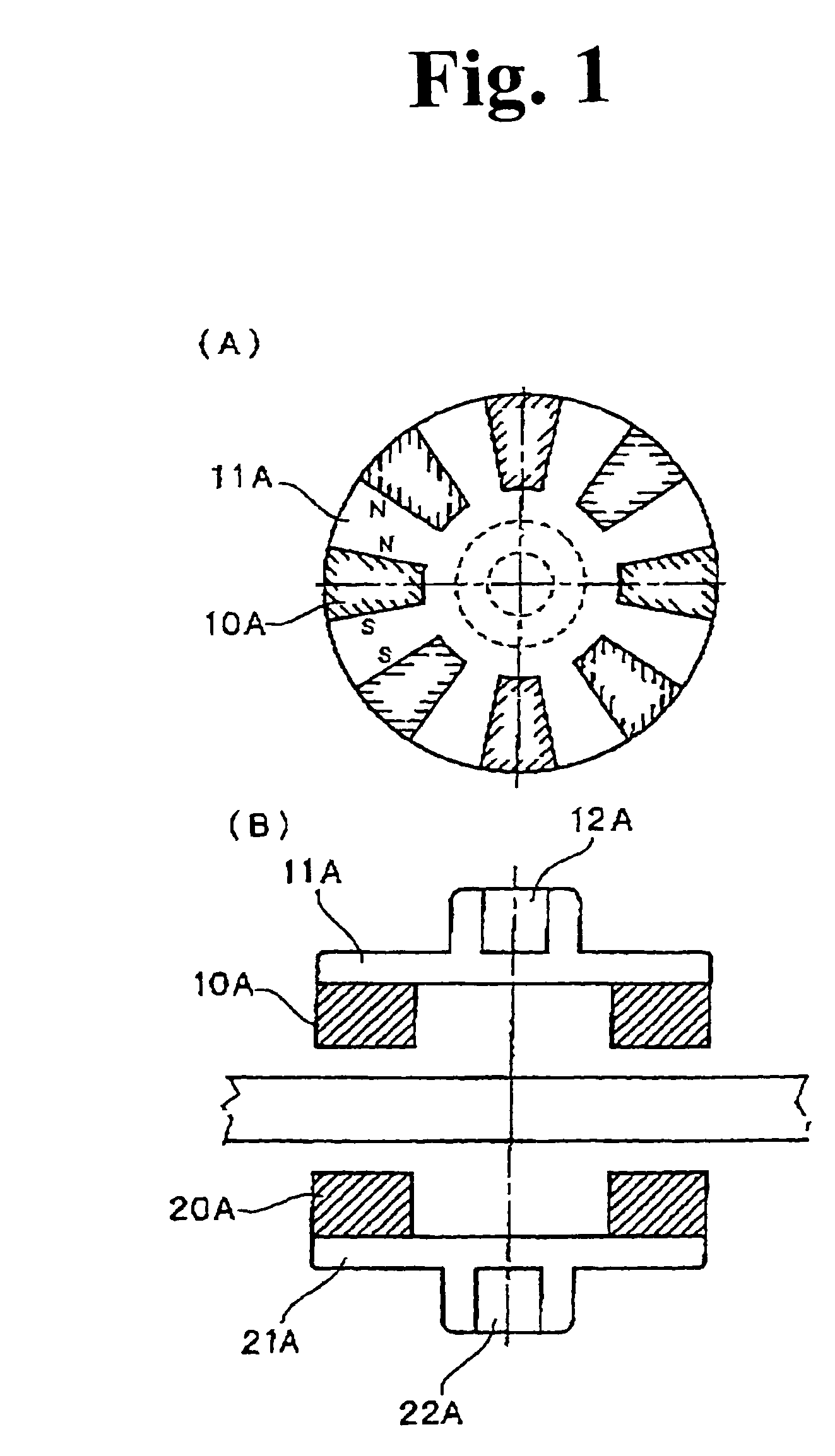

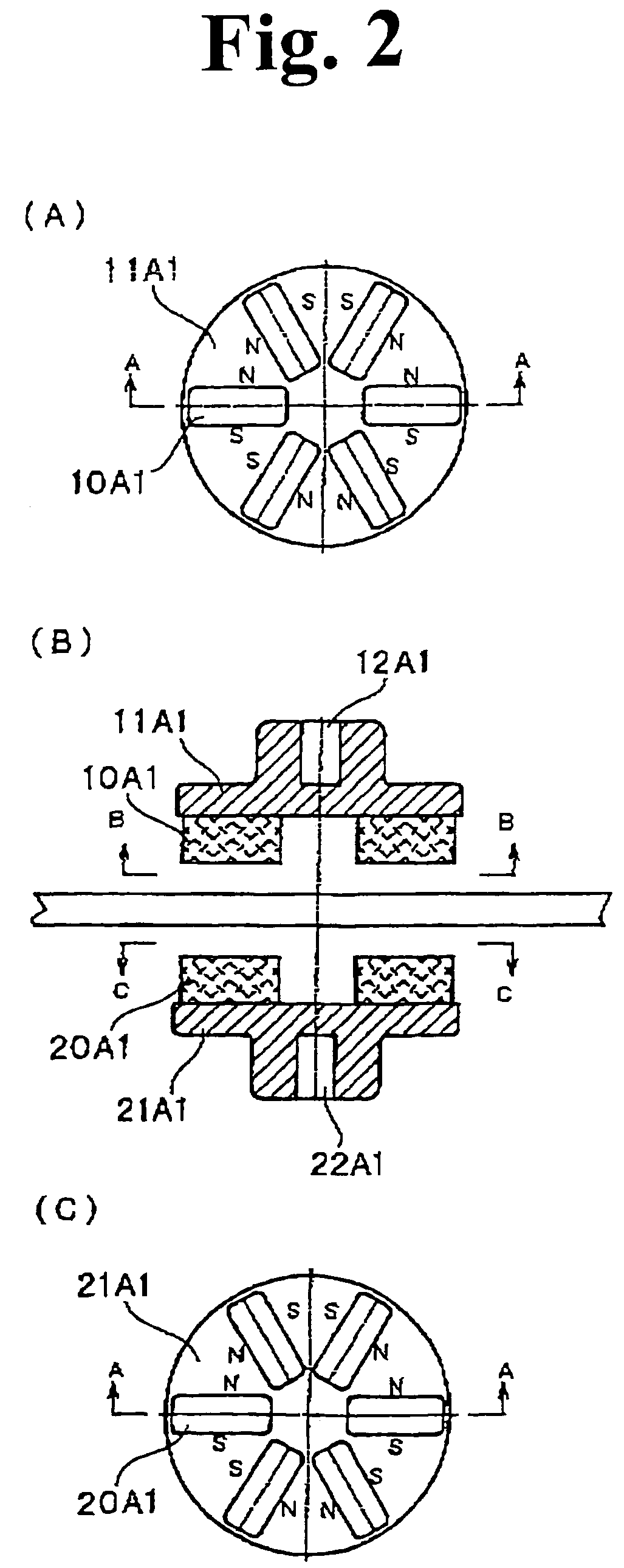

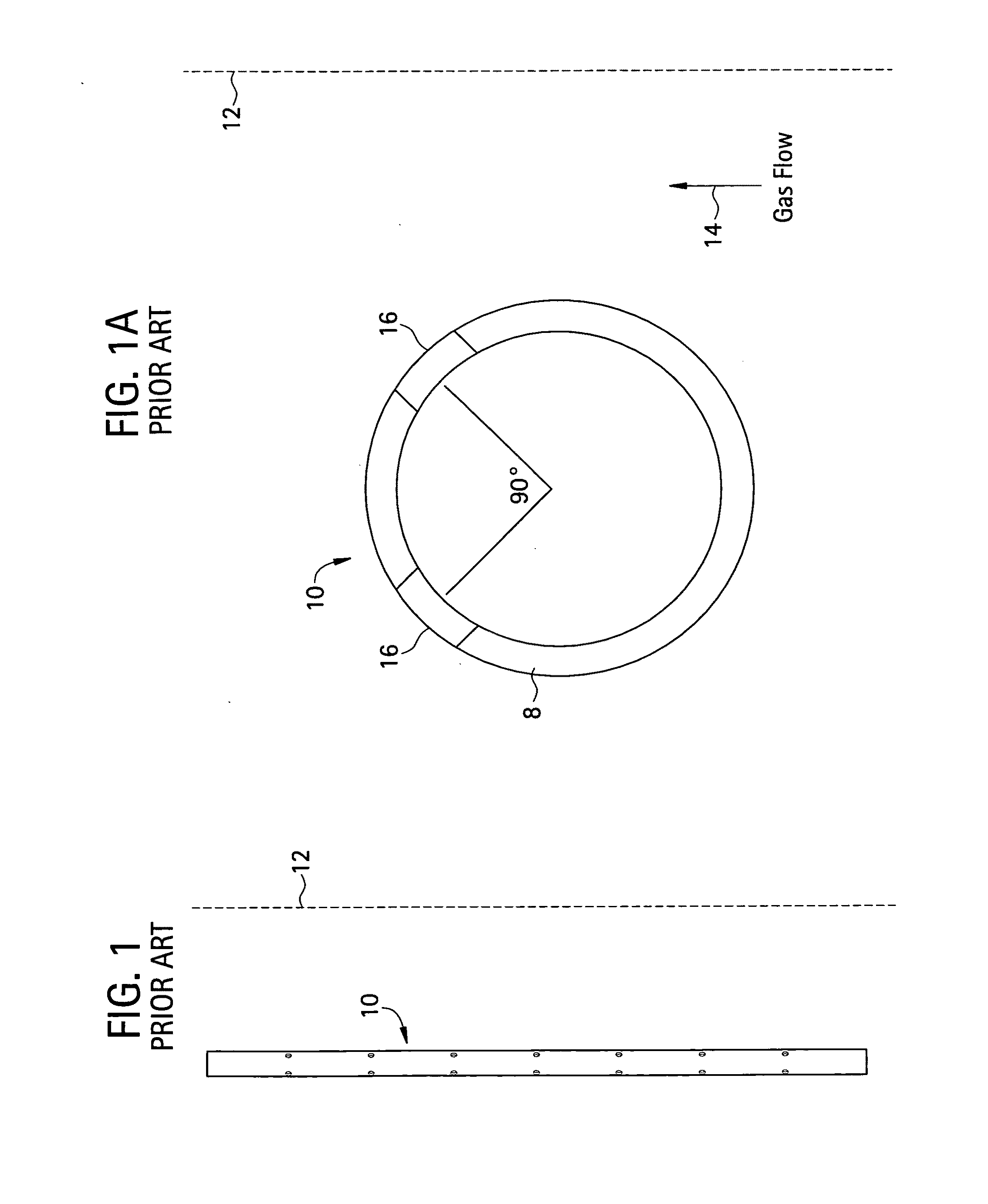

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS20050206260A1Dynamo-electric brakes/clutchesRotary stirring mixersElectric arc furnaceMagnetic rotation

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

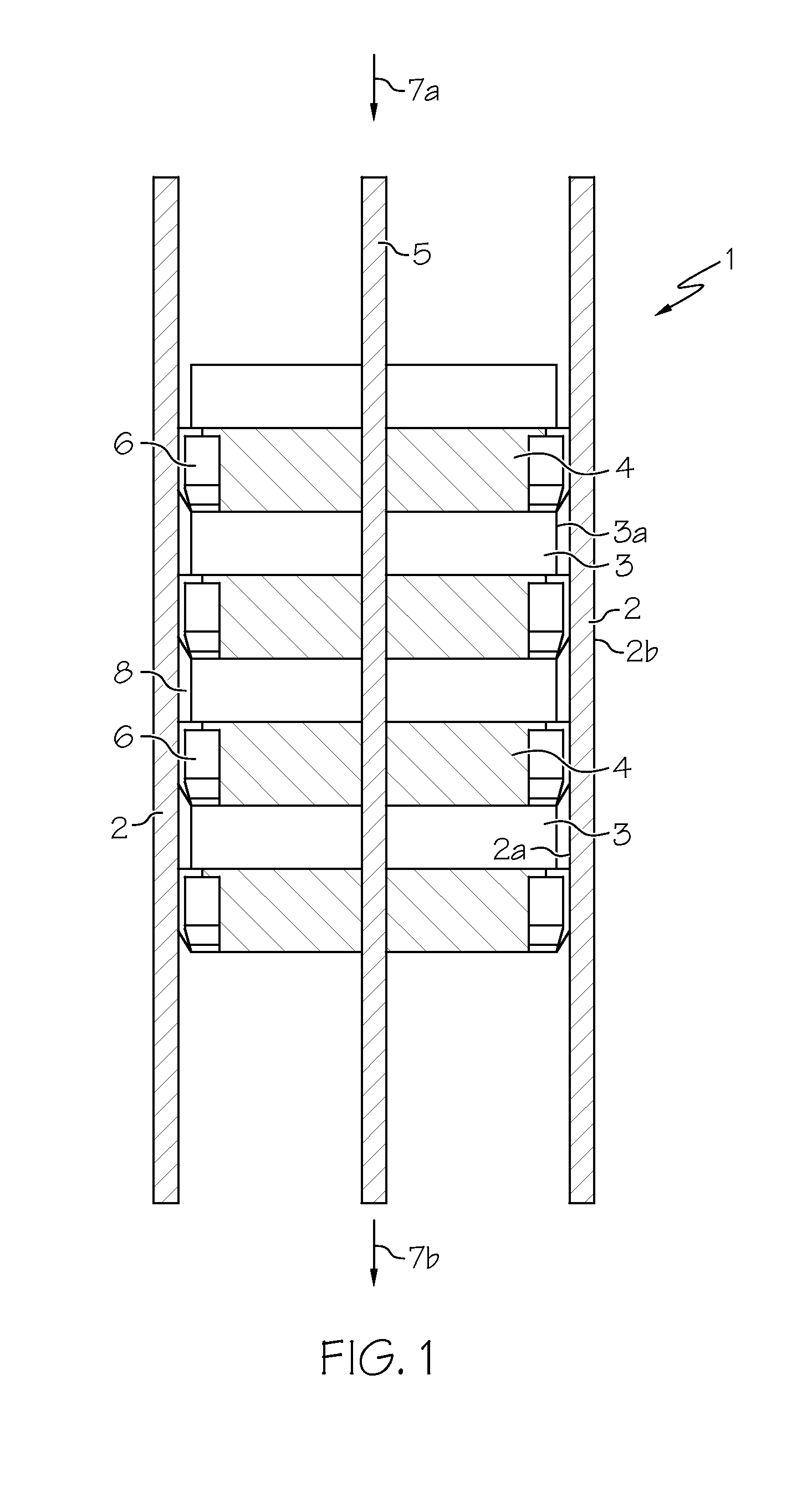

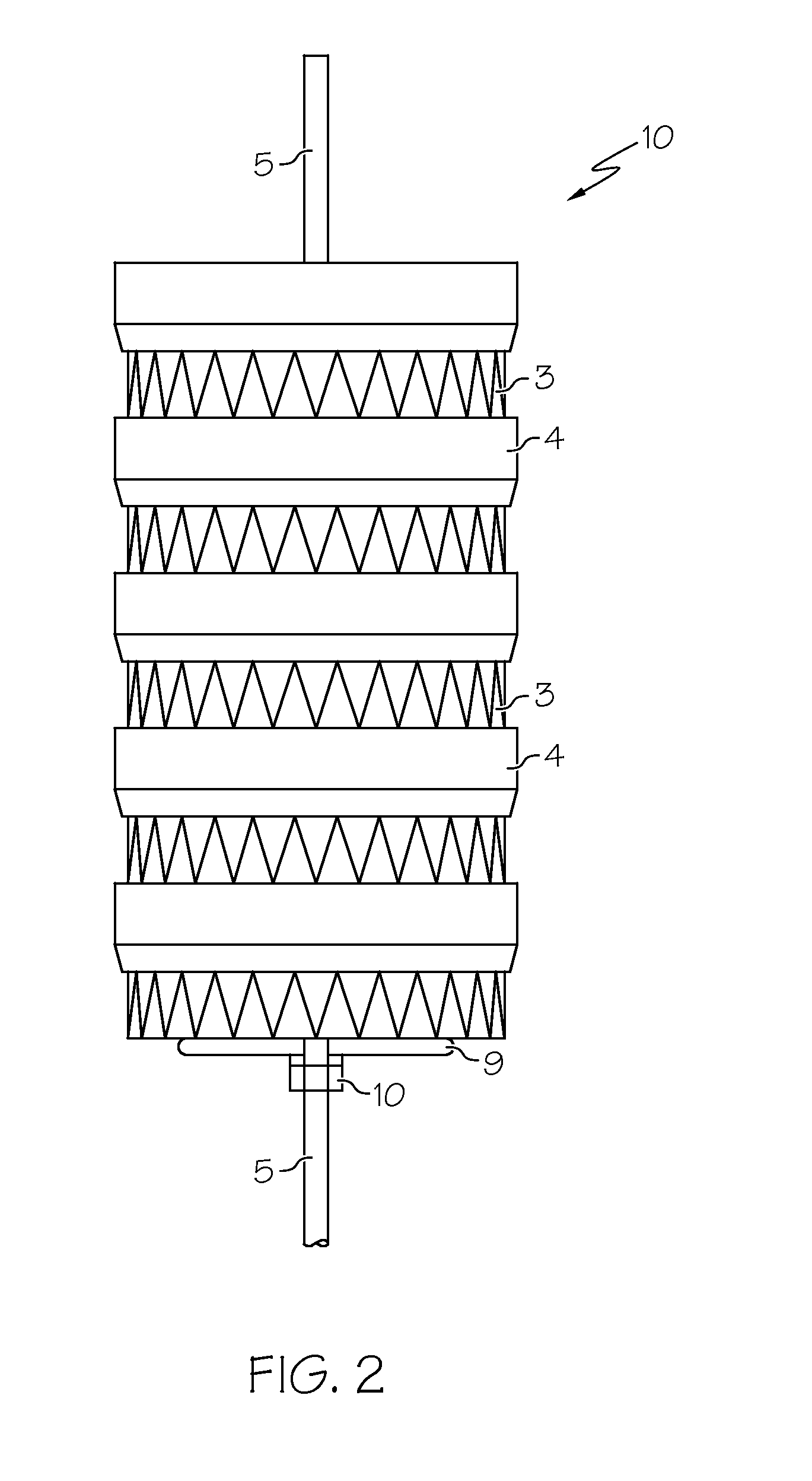

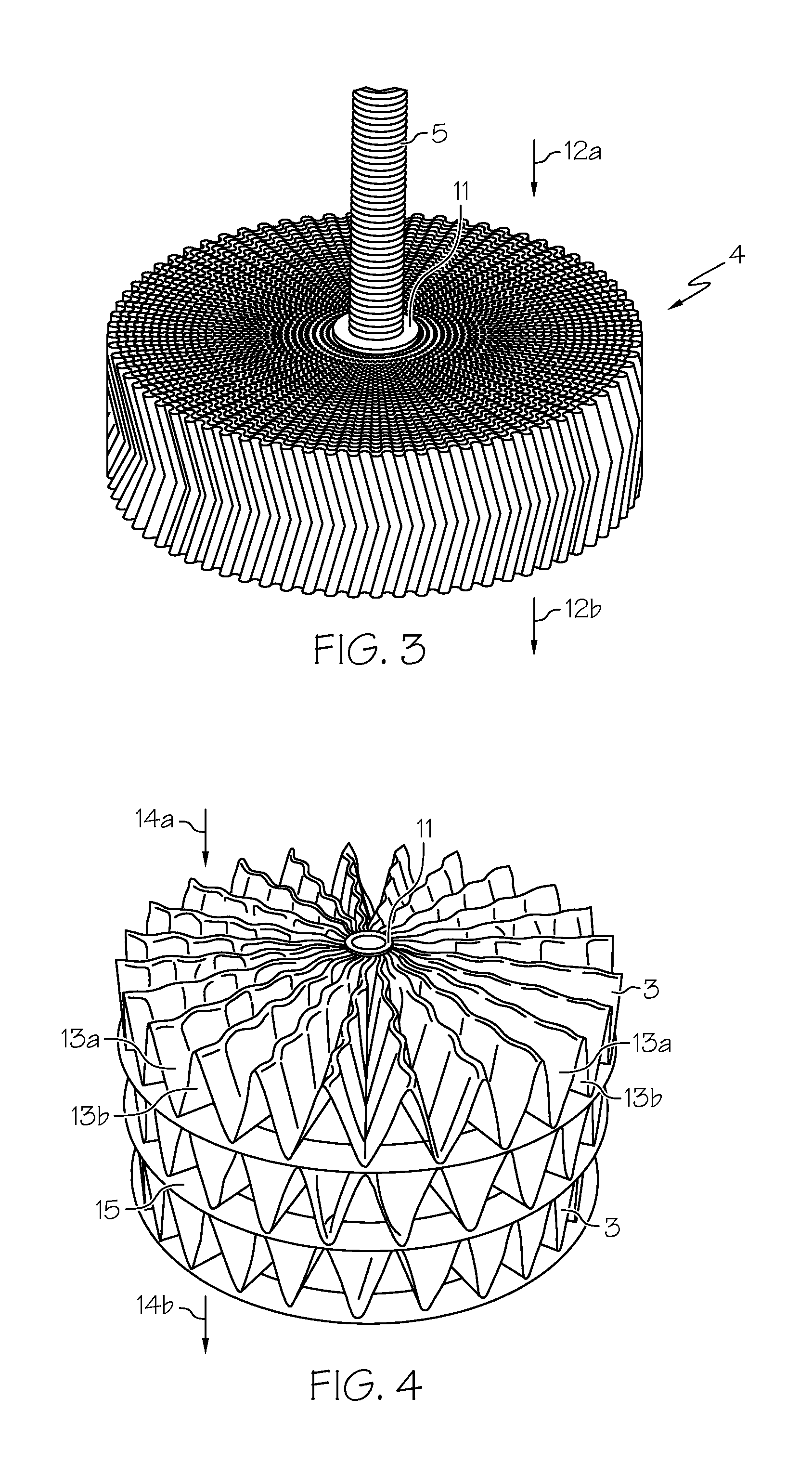

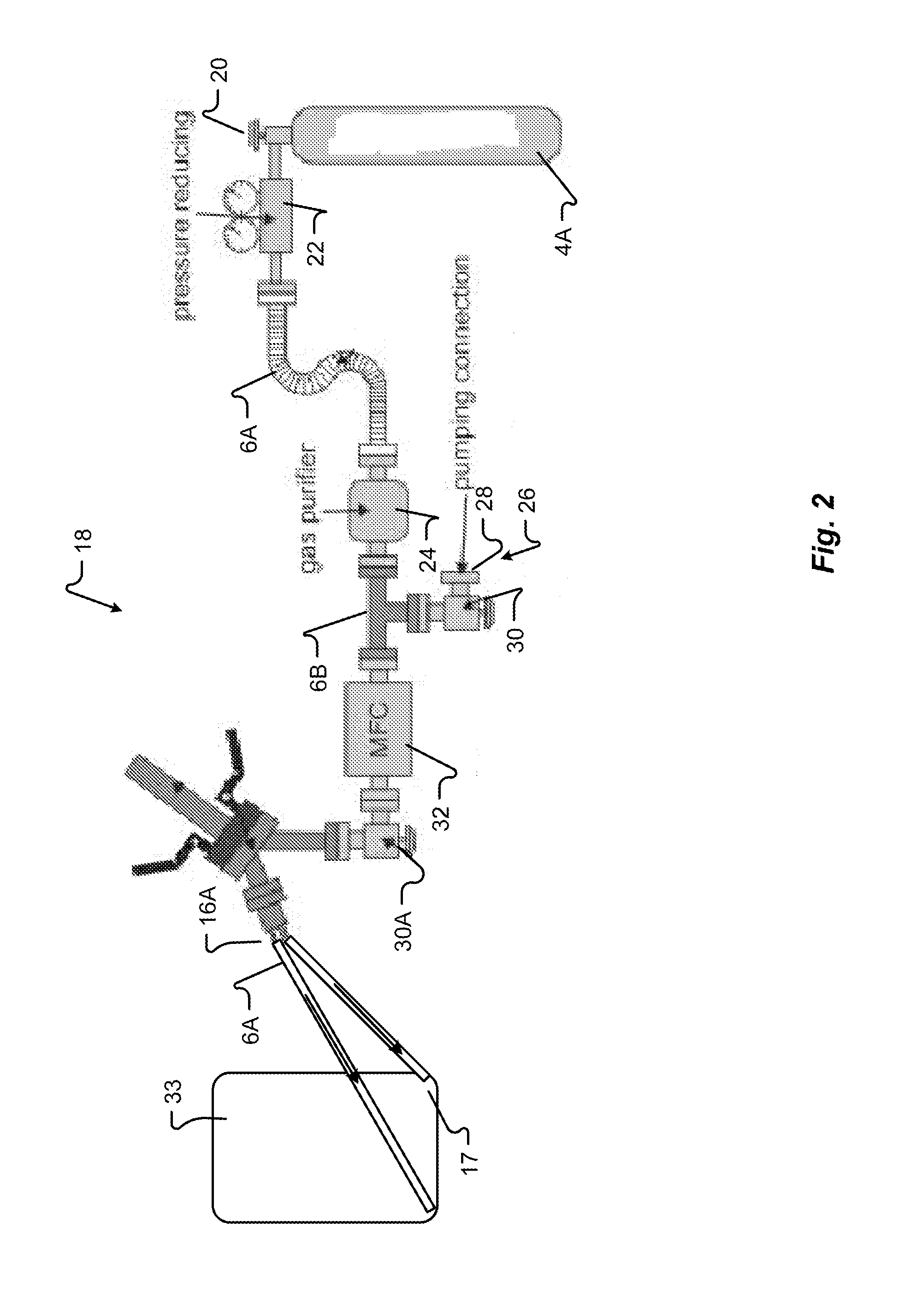

Stackable structural reactors

ActiveUS20120195801A1Improve heat transfer performanceHydrogenGaseous chemical processesNuclear engineeringHeat transfer

A reactor for carrying out catalytic reactions. The reactor includes a reactor component optionally arranged on a central rod in a reactor tube. The reactor component can have fluid ducts for directing fluid flow through the reactor. The fluid ducts are effective for increasing heat transfer in the reactor. The reactor component can further have a washer attached to a top or bottom surface for directing fluid flow.

Owner:JOHNSON MATTHEY PLC

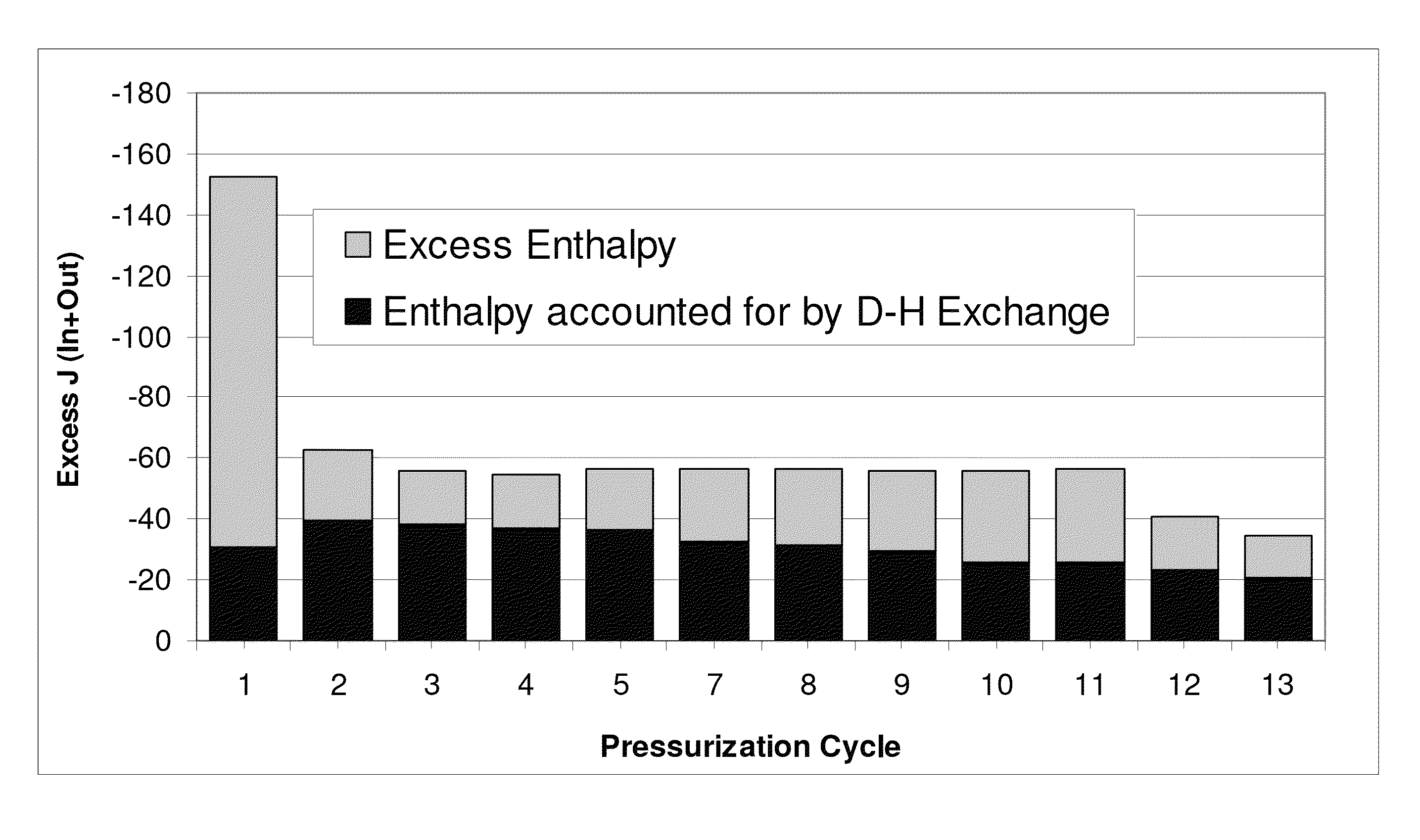

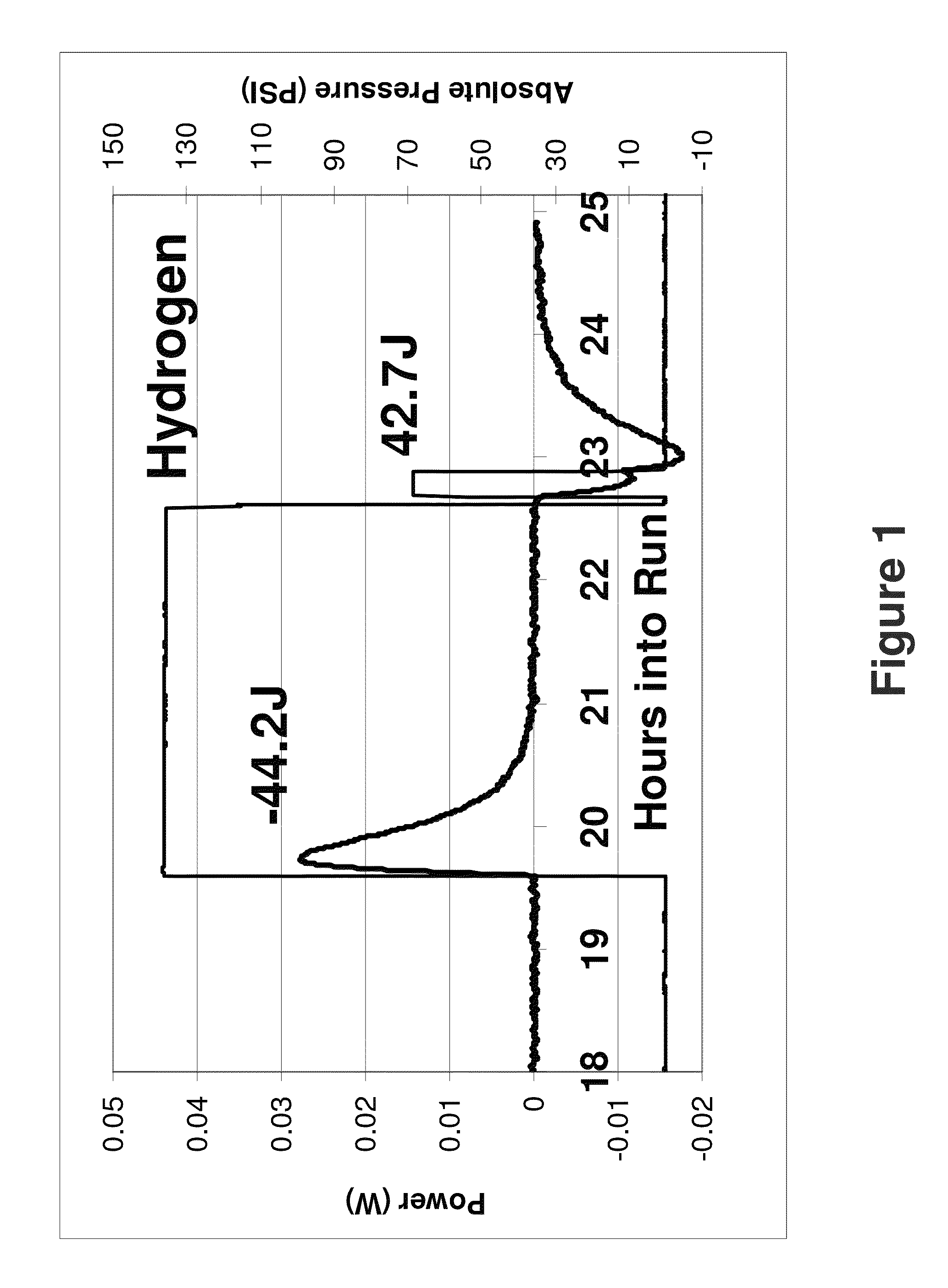

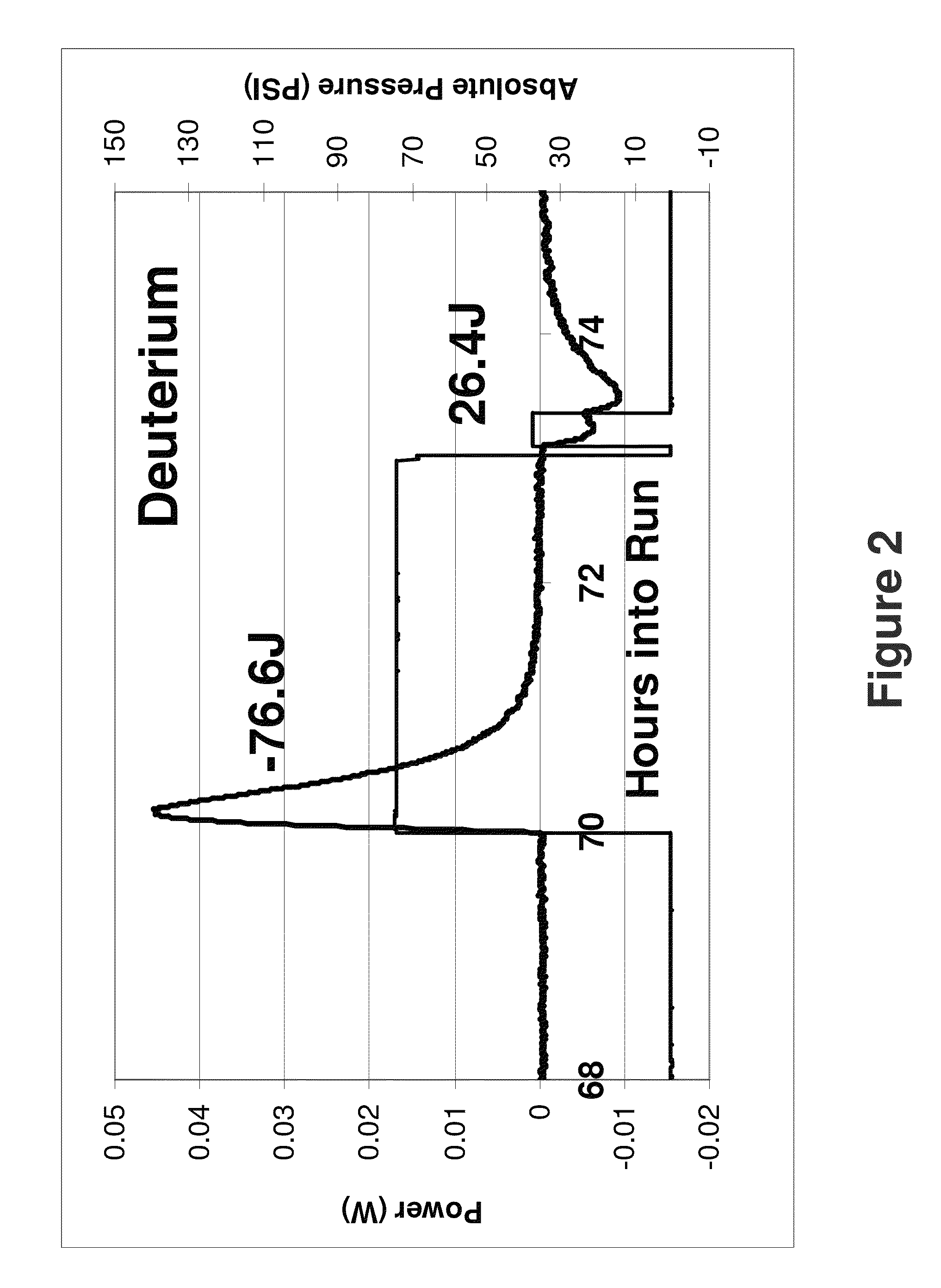

Excess enthalpy upon pressurization of nanosized metals with deuterium

A method for producing excess enthalpy by impregnating metallic precursors on an oxide support that reduces sintering and particle growth; drying the impregnated support at a temperature where the particle growth is minimal; reducing the metallic precursors at a second temperature where the particle growth results in supported metallic particles 2 nm or less in size; and pressurizing the supported metallic particles in the presence of deuterium. The metal particles may comprise palladium, platinum, mixtures thereof, or mixtures of palladium and / or platinum with other elements. Also disclosed is a method for measuring excess enthalpy by placing a test material in a pressure vessel; heating the pressure vessel; evacuating the pressure vessel; introducing deuterium, hydrogen, or both into the pressure vessel; measuring the enthalpy generated during pressurization; again evacuating the pressure vessel; and measuring the enthalpy used during depressurization.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

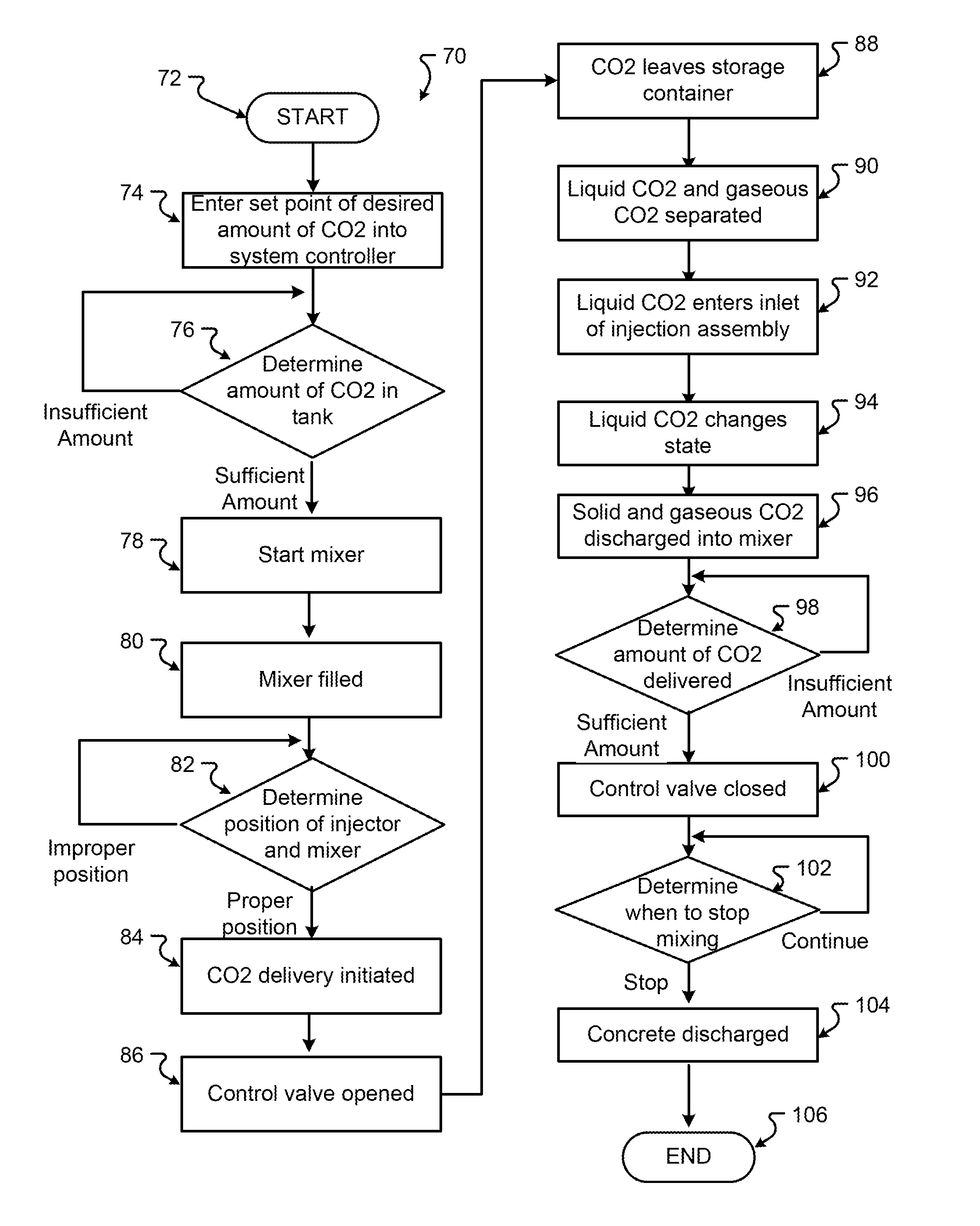

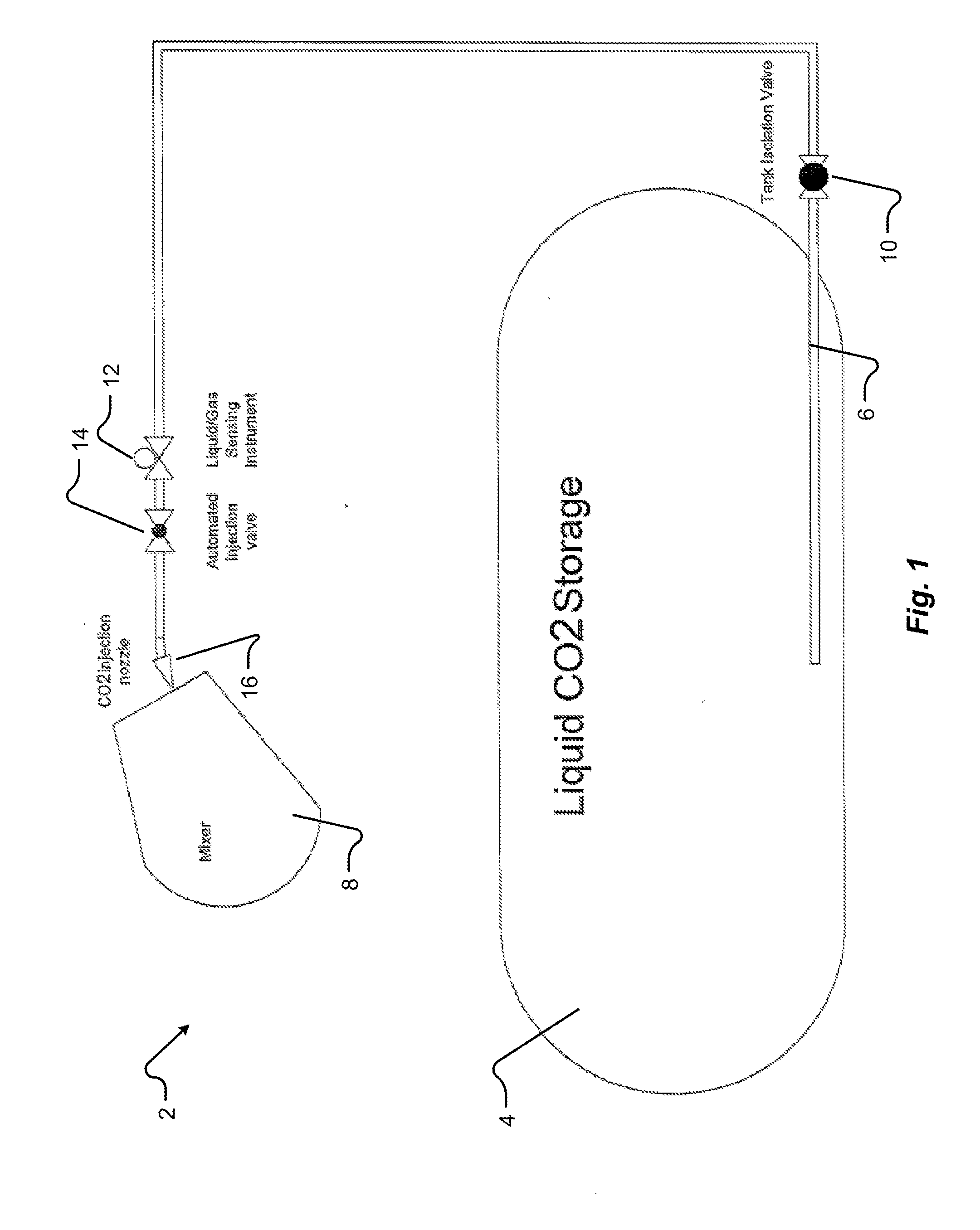

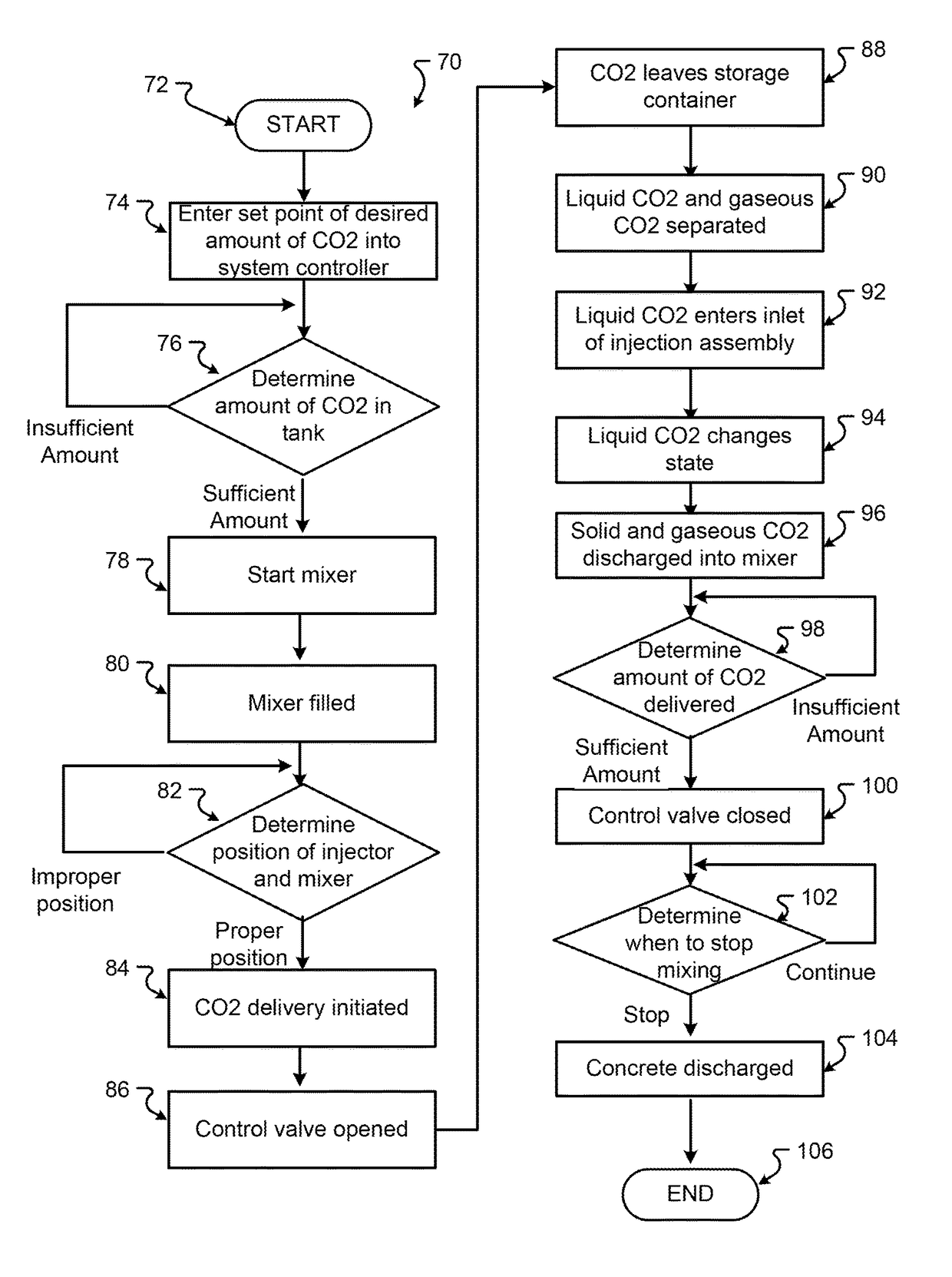

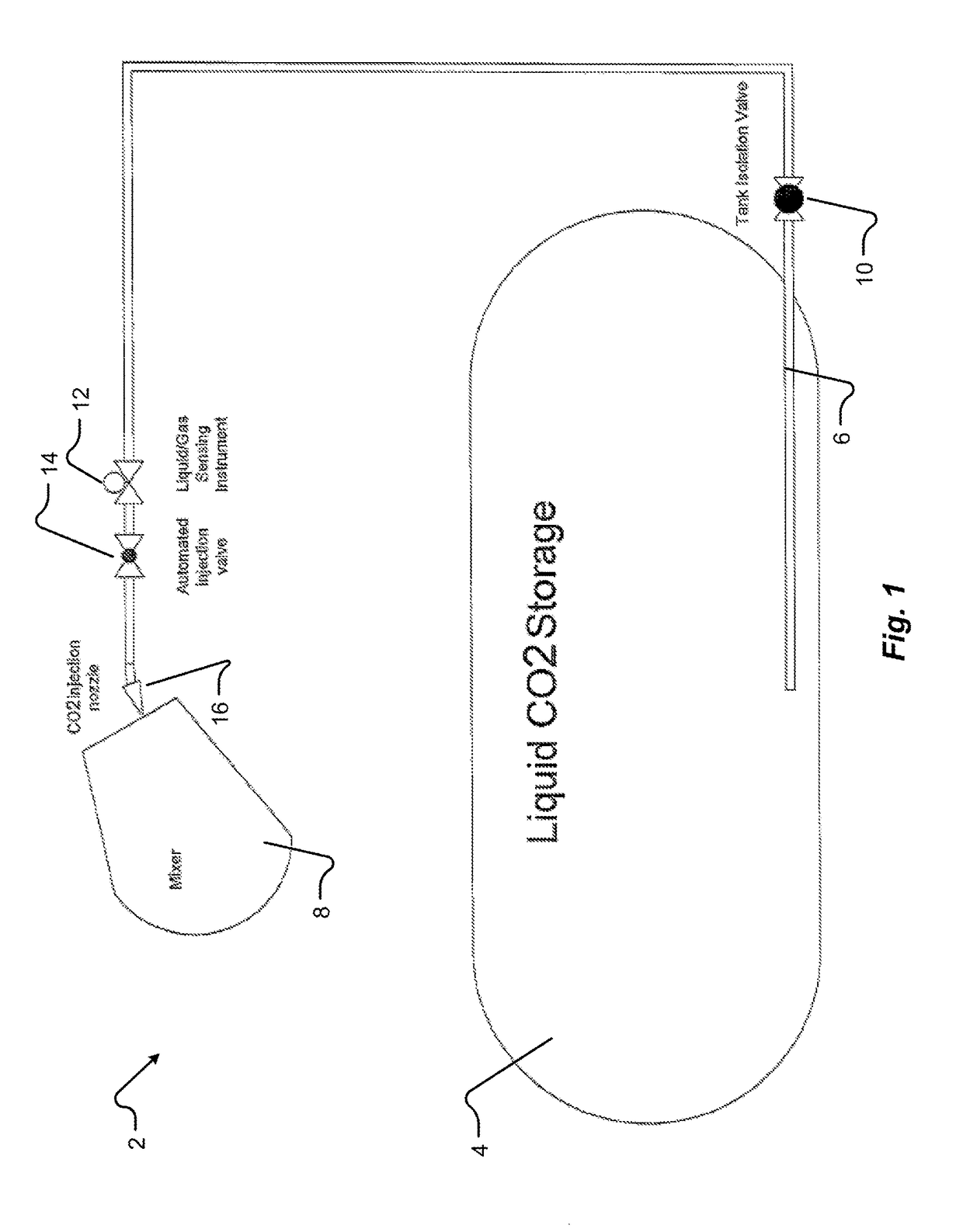

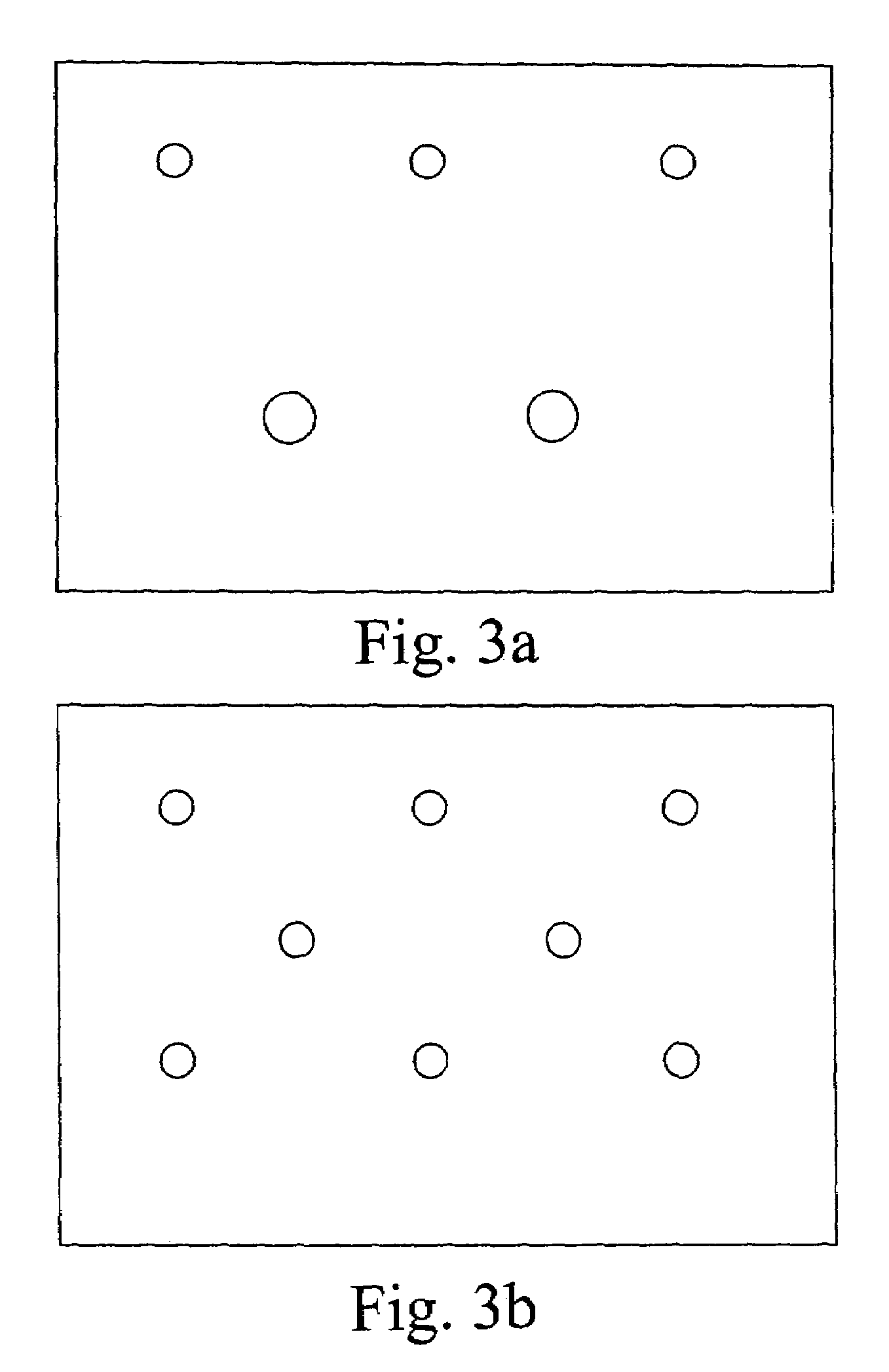

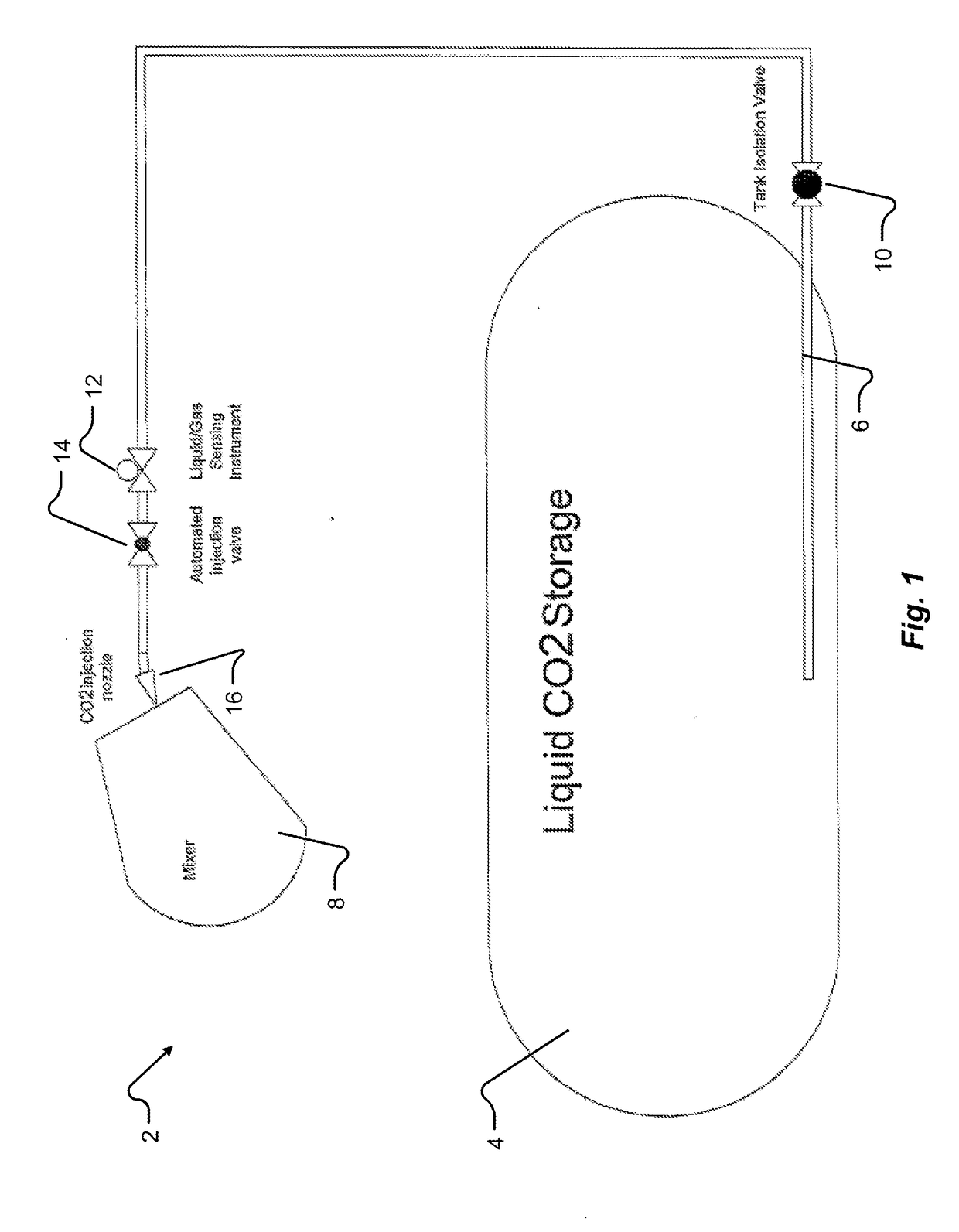

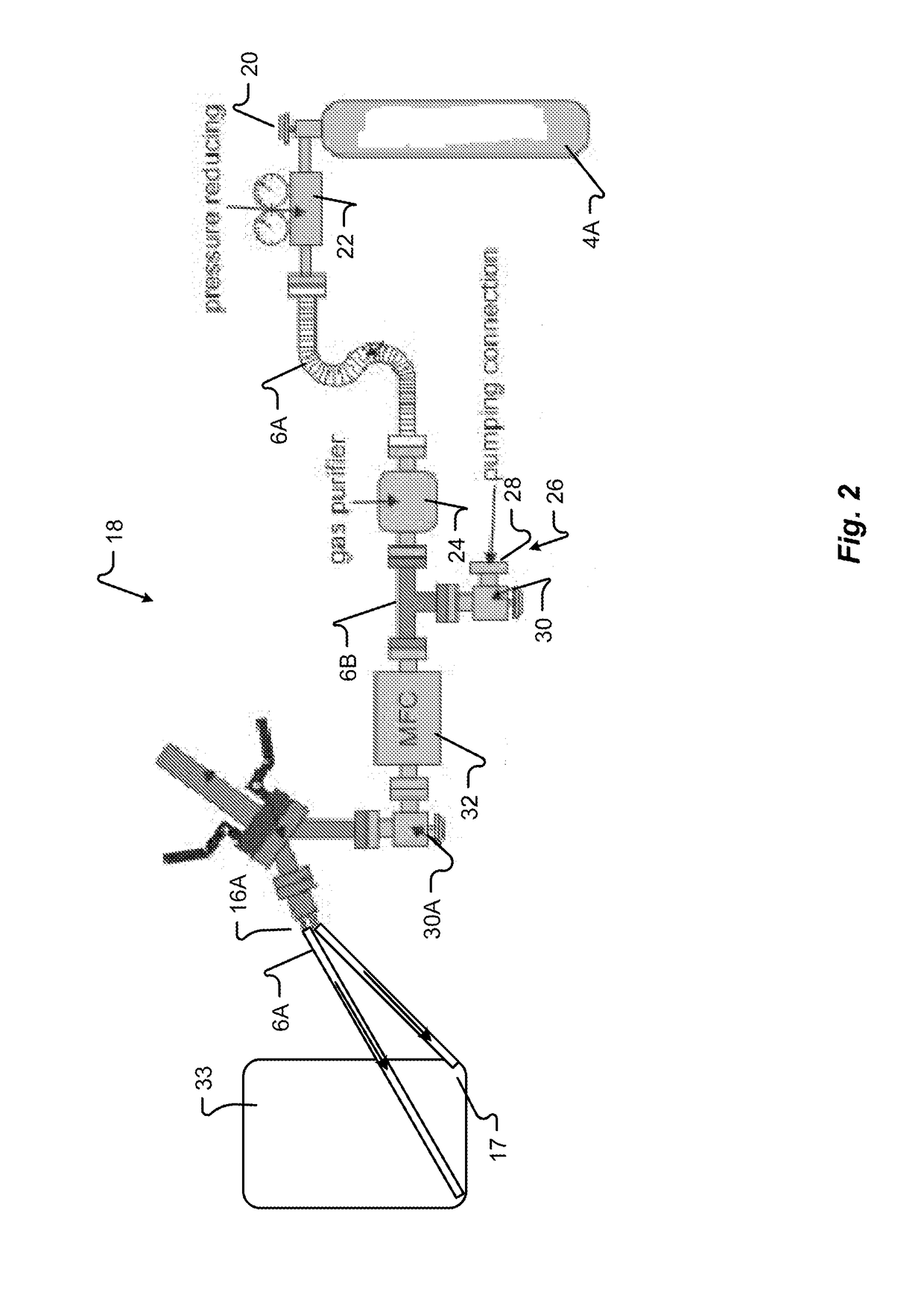

System and method of applying carbon dioxide during the production of concrete

InactiveUS20140216303A1Low costReduce energy consumptionFlow mixersTransportation and packagingMulti materialProcess engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

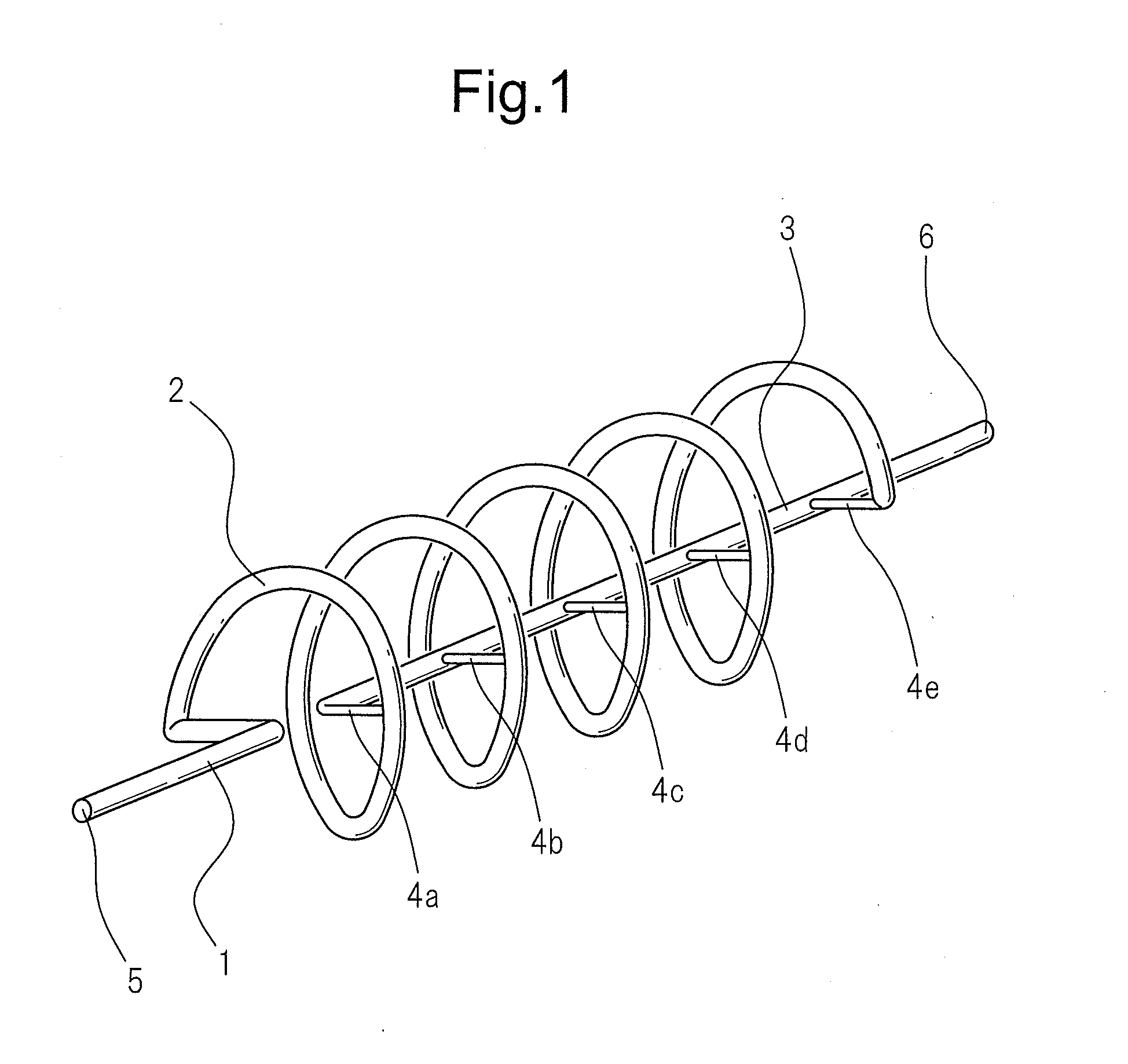

Fluid mixer and apparatus using fluid mixer

ActiveUS20110128814A1Avoid defectsEvenly distributedFlow mixersTransportation and packagingEngineeringSpiral flow

A fluid mixer which can mix fluid while making the distribution of concentration or distribution of temperature of the fluid in the direction of flow uniform without any unevenness and which is both compact and easy to install piping for is provided. This fluid mixer has a fluid inlet, a first flow path connected to the fluid inlet, a spiral flow path connected to the first flow path, a plurality of branch flow paths branched from the spiral flow path, a second flow path to which the plurality of branch flow paths are connected, and a fluid outlet connected to the second flow path, the plurality of branch flow paths branching from different positions of the spiral flow path and being connected with the second flow path at different positions of the second flow path.

Owner:ASAHI YUKIZAI KOGYO CO LTD

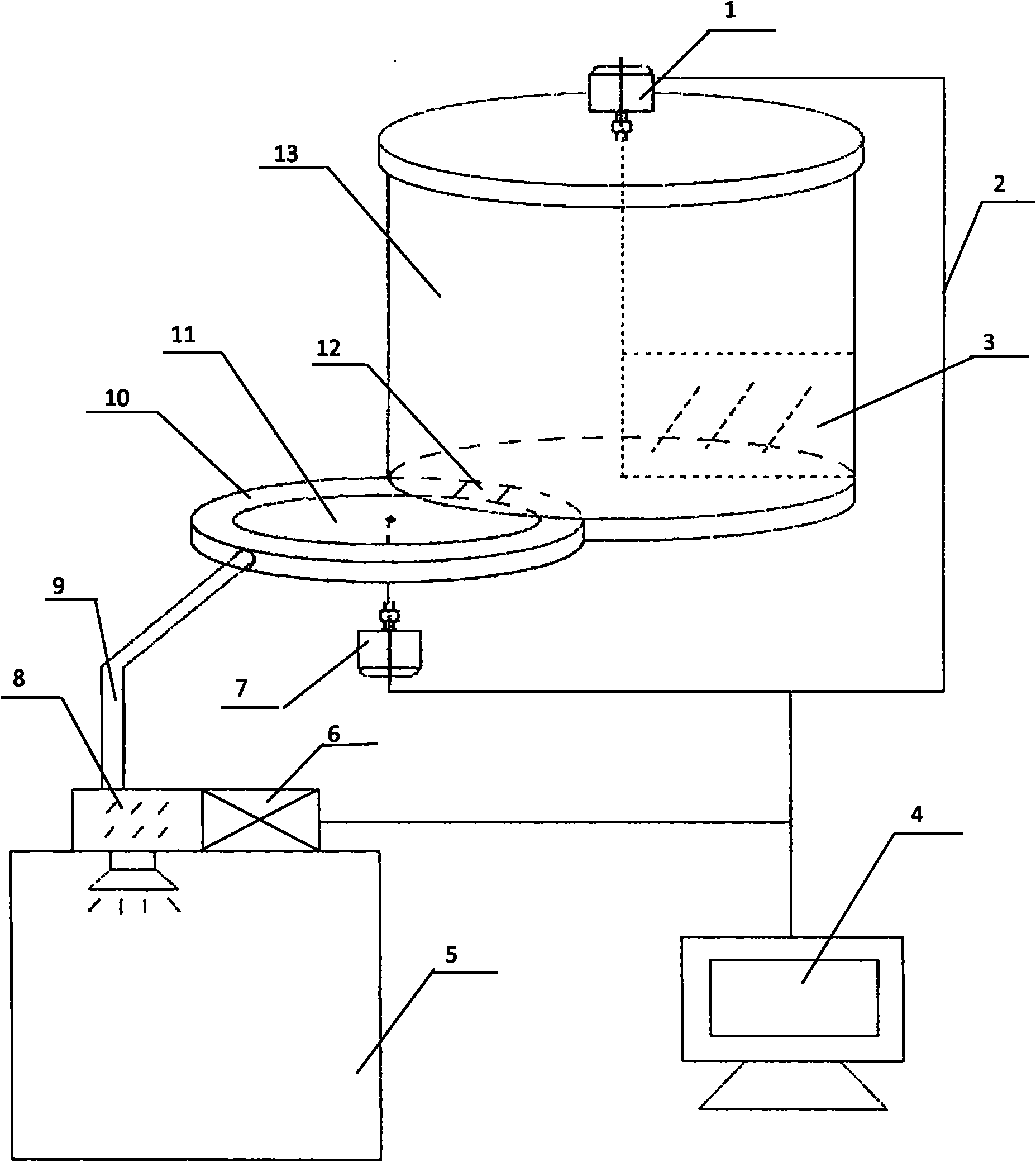

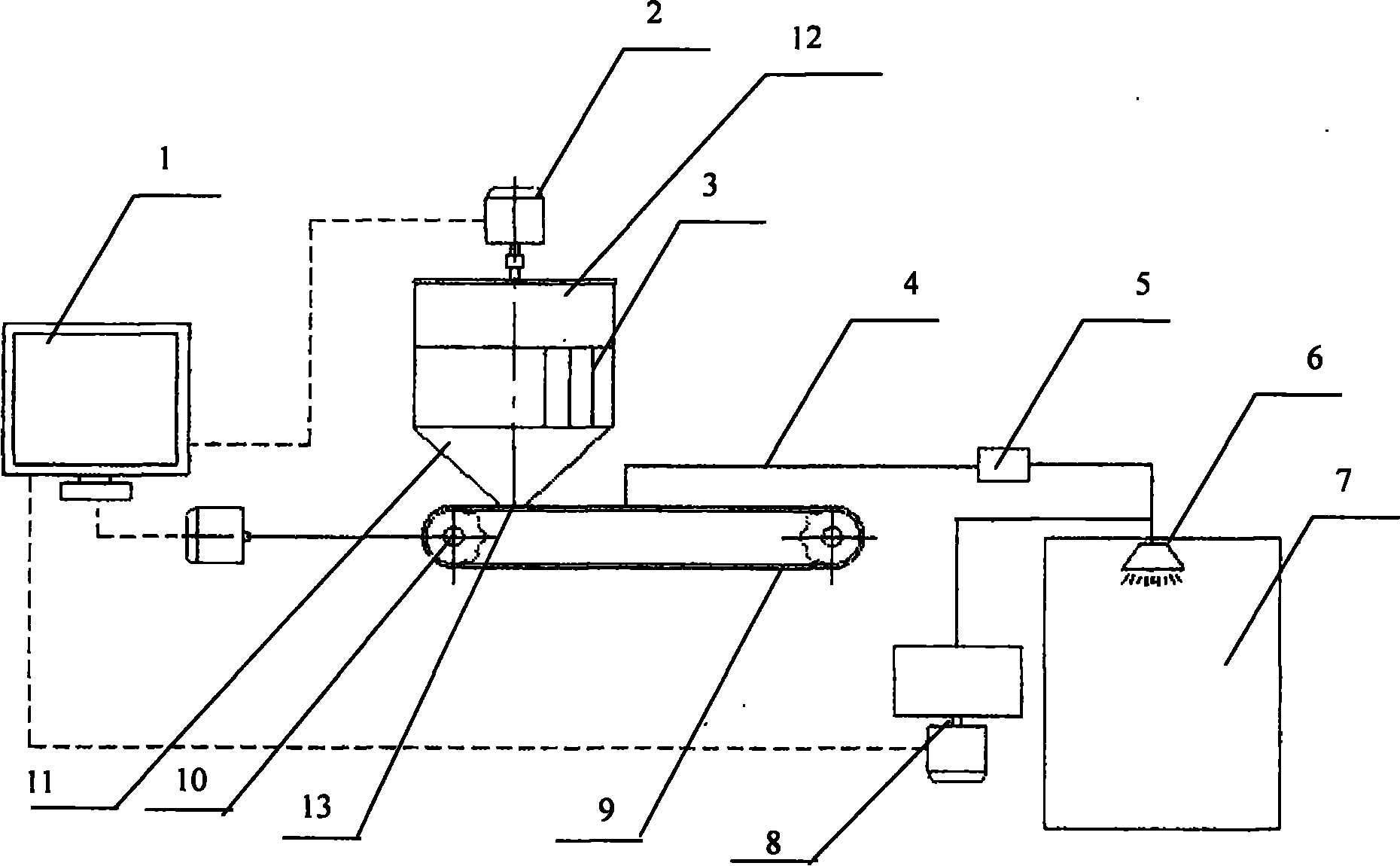

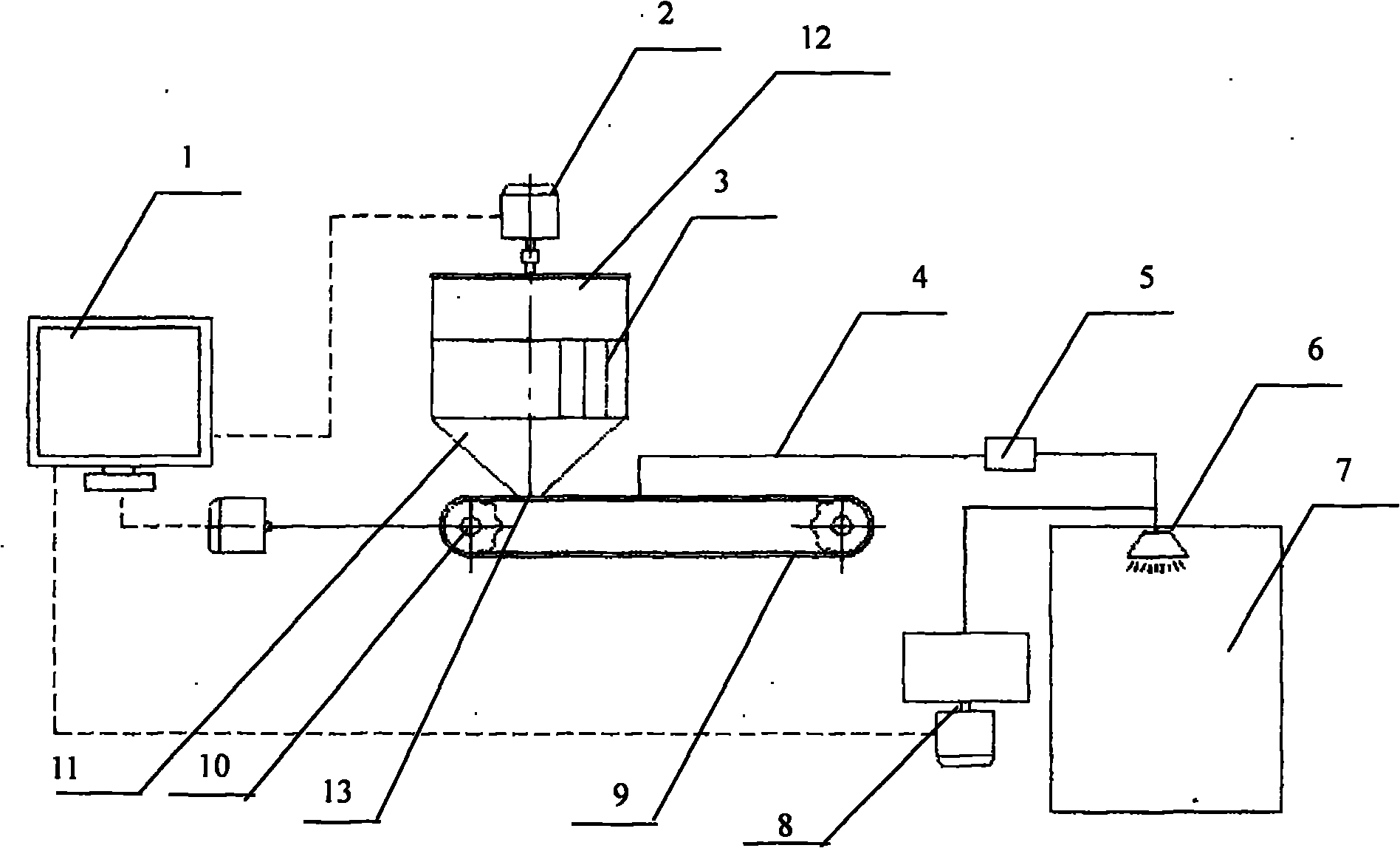

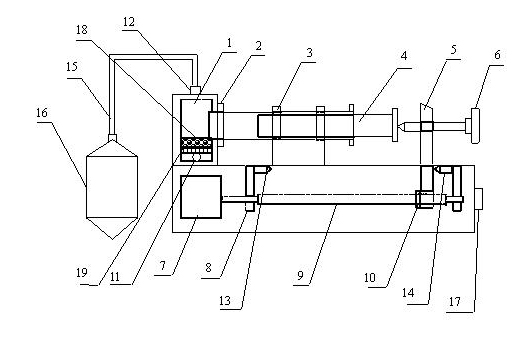

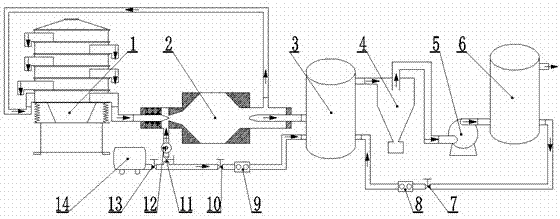

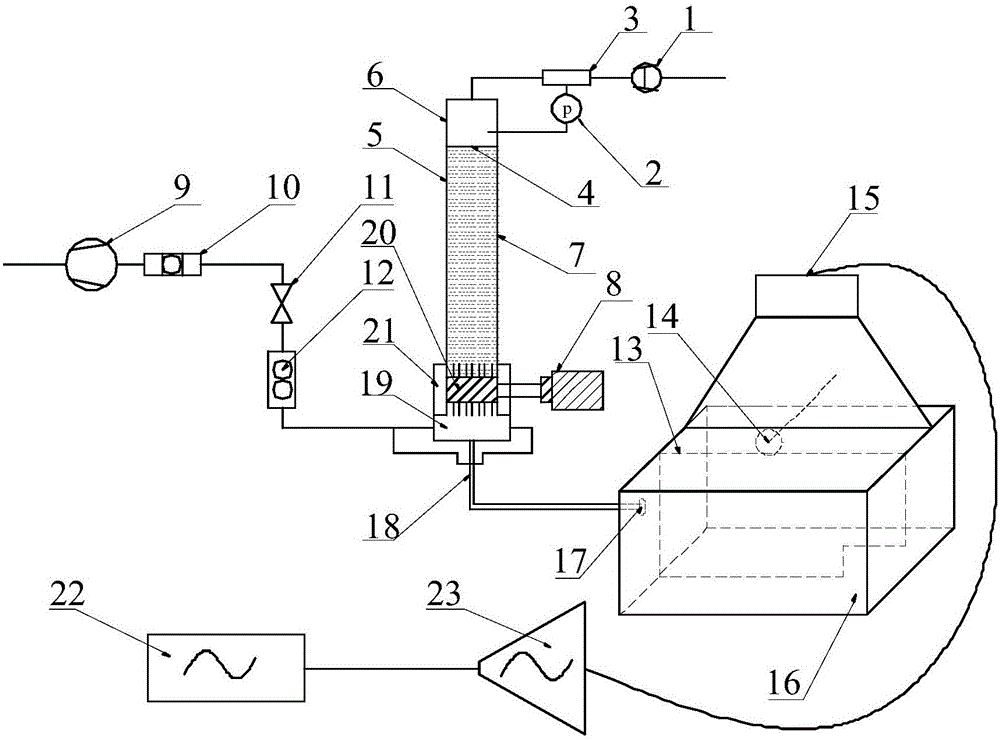

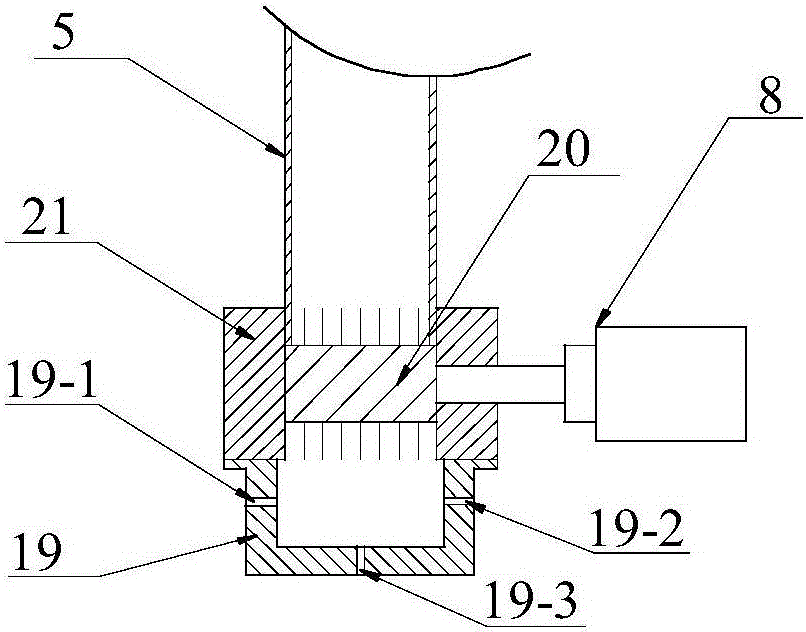

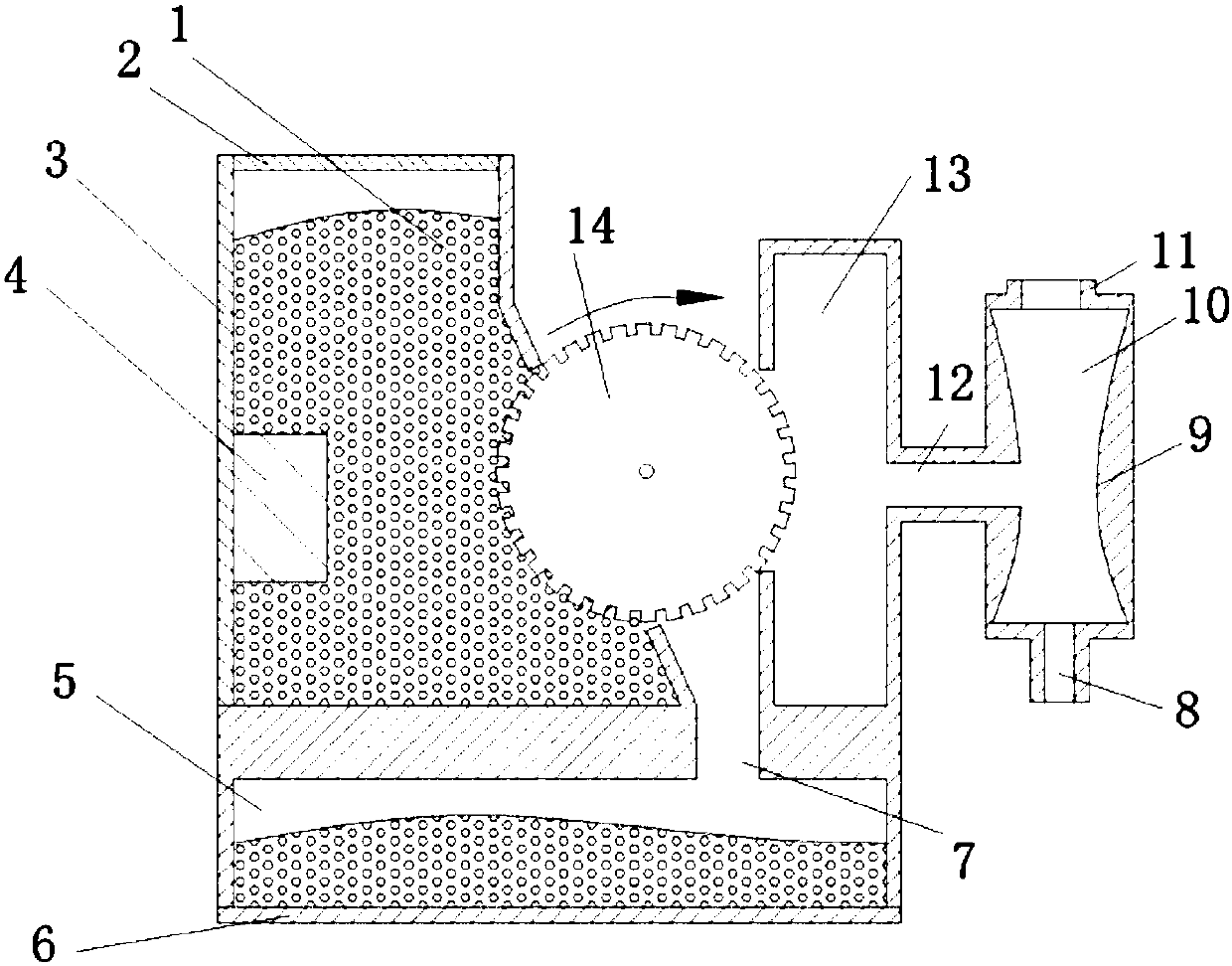

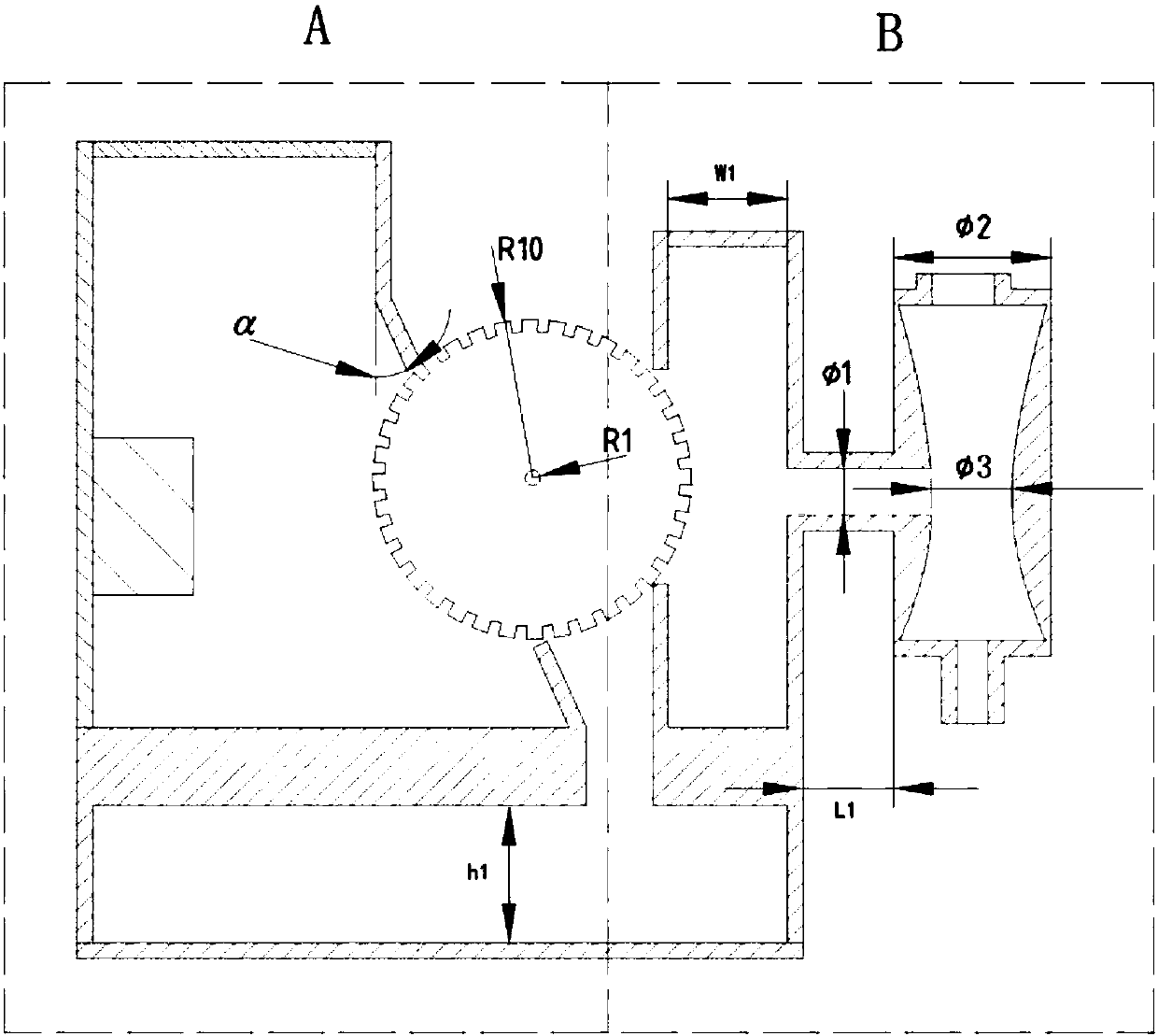

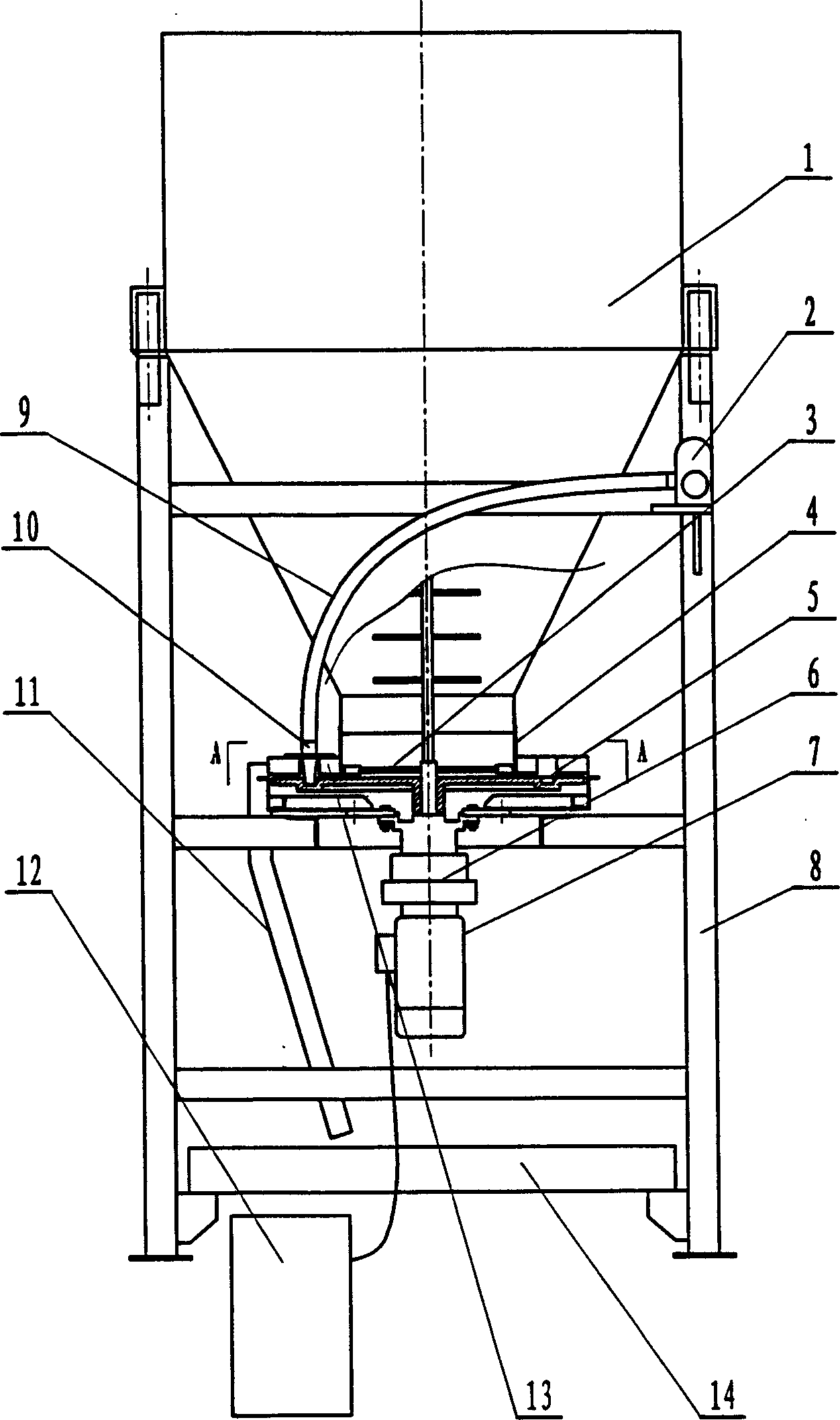

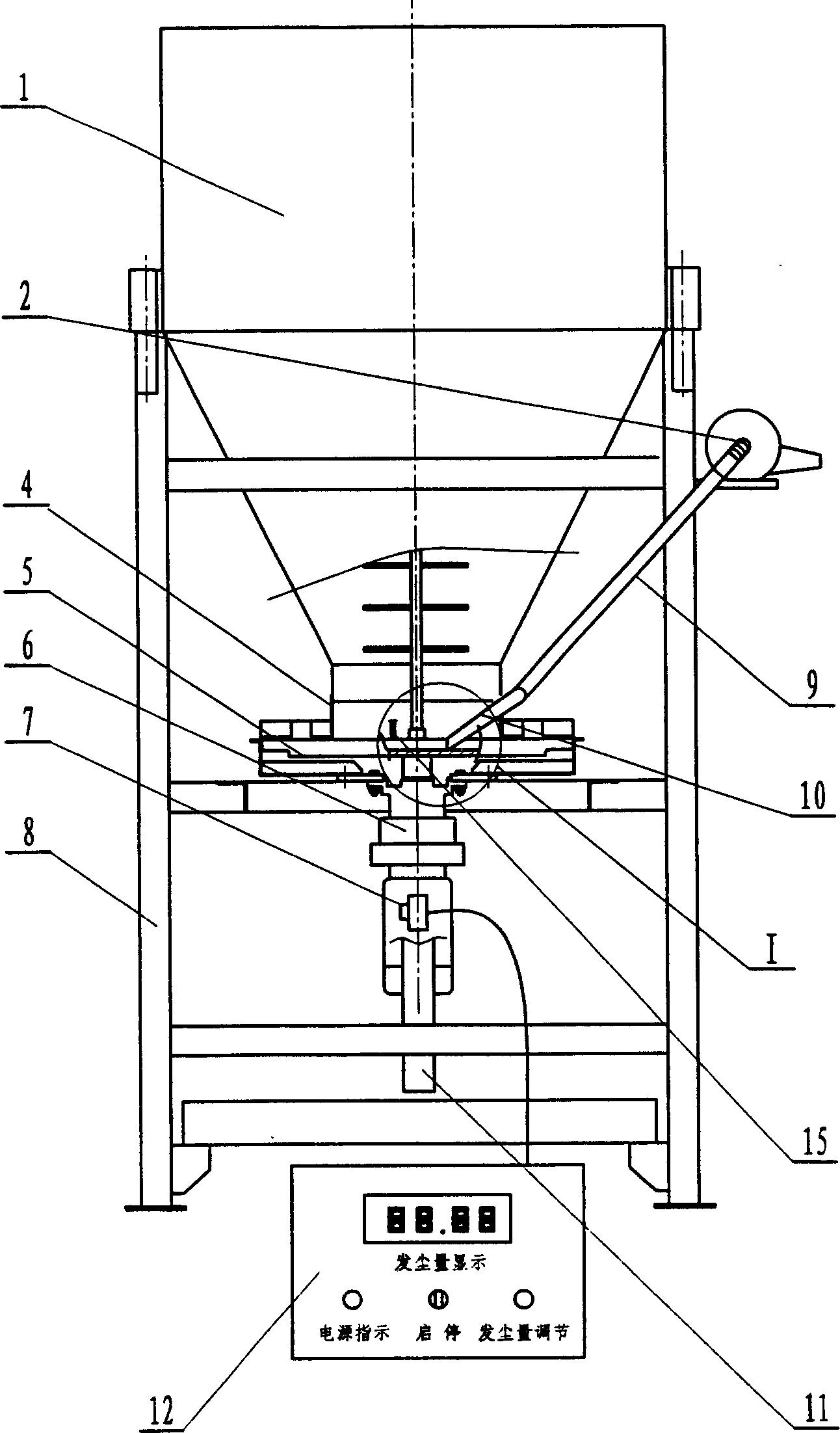

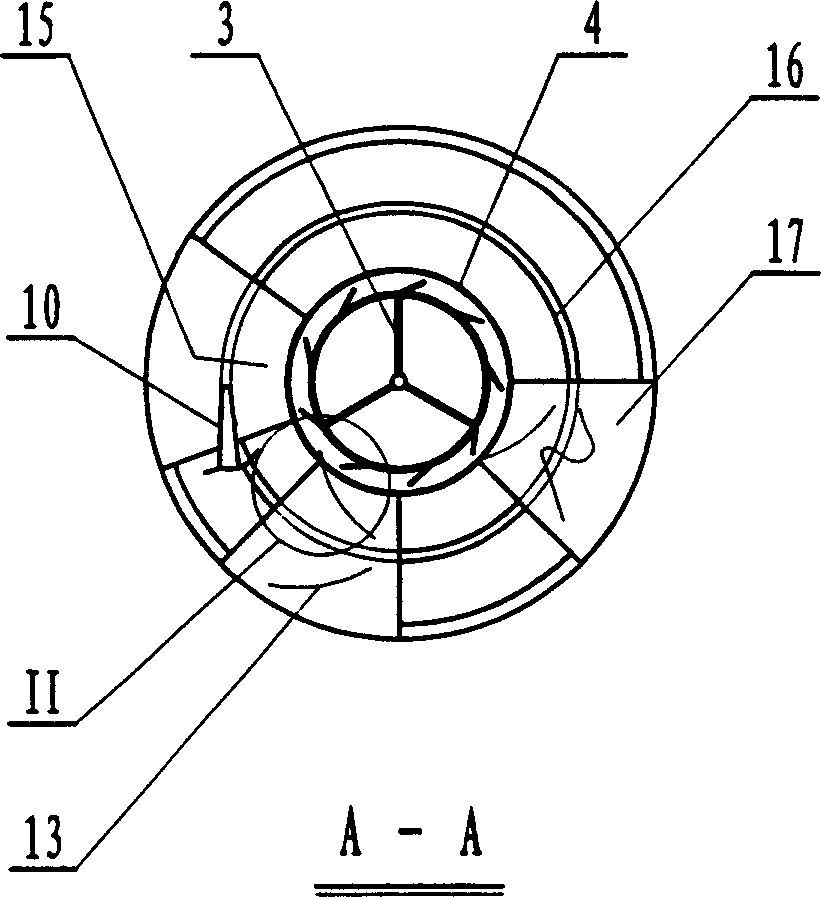

Rotating disc type dust aerosol generating device

ActiveCN102008911AAddressing the Persistent Distribution SituationContinuous generationMixersMixing gases/vapours with solidsMotor controlEngineering

The invention provides a rotating disc type dust aerosol generating device characterized in that an agitating motor is controlled by a computer to drive an agitating blade in a flowing chamber to rotate, and dust in the flowing chamber is uniformly agitated and conveyed to a pit which is arranged on a rotating disc below a drain hole on the bottom of the flowing chamber and specially used for carrying dust; and dust stored in the pit on the rotating disc is absorbed into a dust spray dissolution cavity by a negative pressure generator which is controlled by the computer through a negative pressure dust suction pipe, and dust aerosol is formed and then conveyed into an aerosol detection laboratory chamber to be detected and experimented. When the agitating motor controlled by the computer rotates at different rotating speeds and uses rotating discs of different pit widths, the quantity of dust conveyed to the negative pressure dust suction pipe is different, and the concentration of dust aerosol formed by dust flowing in the dust spray dissolution cavity is also different. Therefore, dust aerosol of stable concentration can be continuously, accurately and quantitatively generated by selecting a rotating disc of proper pit width and proper rotating disc rotating speed and remaining unchanged.

Owner:范维林

Multiphase mixing process using microchannel process technology

The disclosed invention relates to a process for making a multiphase mixture, comprising: flowing a first fluid stream through a process microchannel, the first fluid stream comprising at least one liquid and / or at least one gas, the process microchannel having an apertured section; flowing a second fluid stream through the apertured section into the process microchannel in contact with the first fluid stream to form the multiphase mixture, the second fluid stream comprising at least one gas and / or at least one microbody-forming material, the first fluid stream forming a continuous phase in the multiphase mixture, the second fluid stream forming a discontinuous phase dispersed in the continuous phase.

Owner:VELOCYS CORPORATION

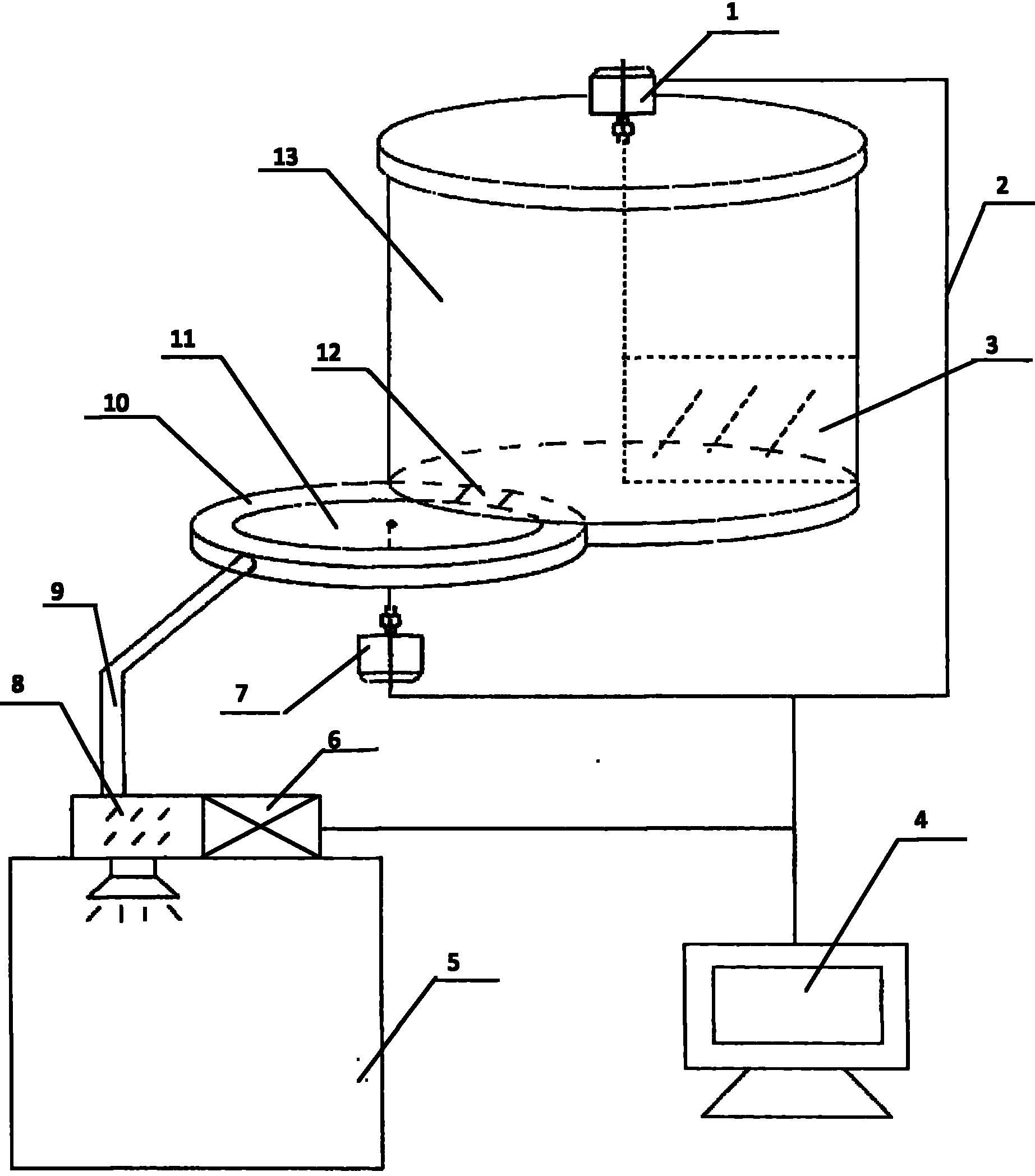

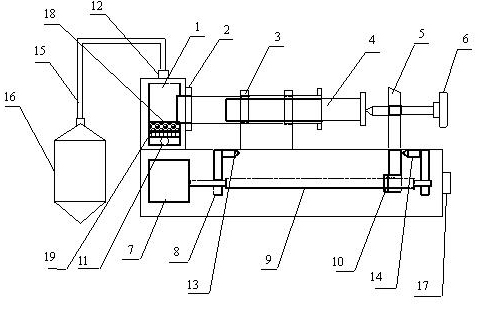

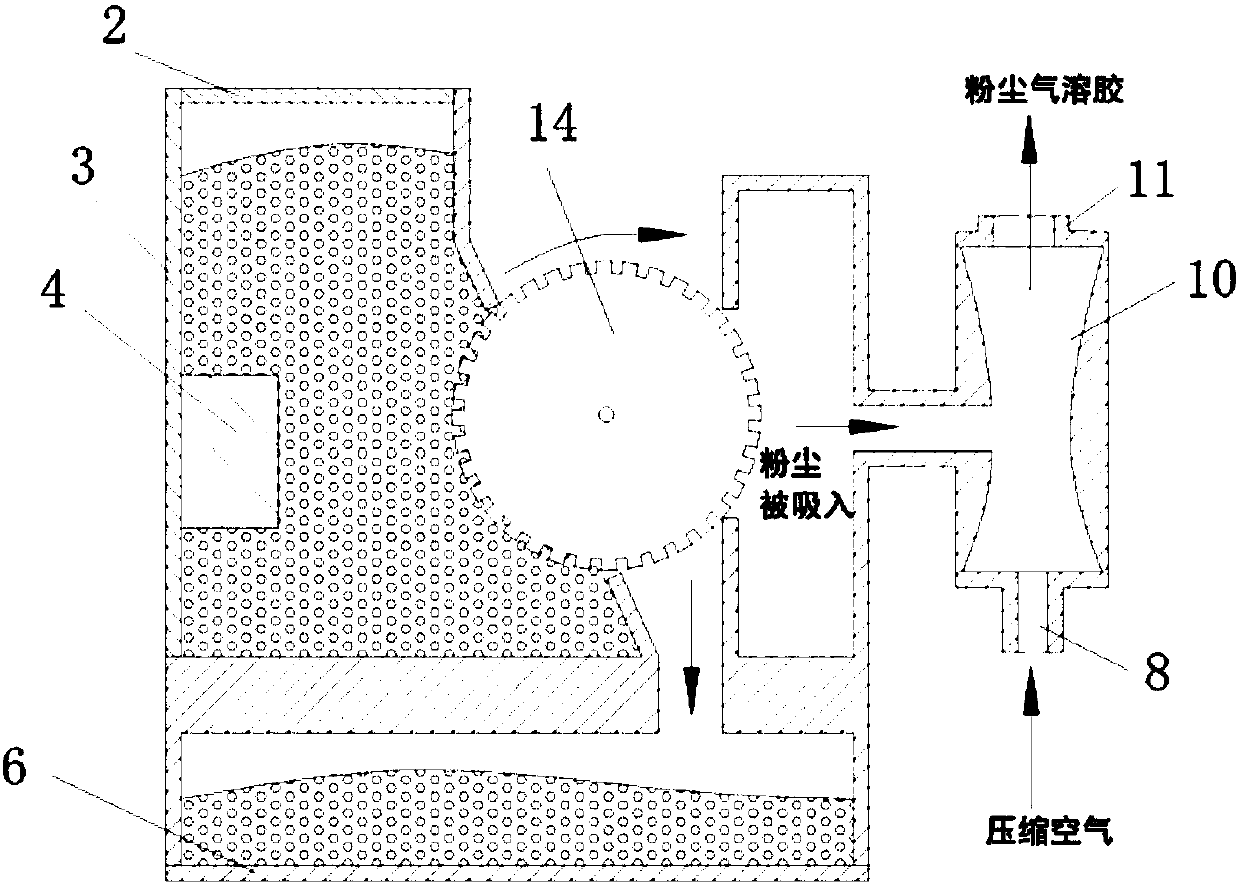

Generating device of dust aerosol

ActiveCN102008910ASolve technical problemsFlow mixersTransportation and packagingDrive wheelMotor control

The invention provides a generating device of a dust aerosol, which is characterized in that a stirring motor controlled by a computer drives a comb type brush in a flowing barn to uniformly rotate, dust materials in the barn are delivered into a dust collecting groove and are delivered onto a conveyer belt through a leaking hole at a bottom part, and the computer controls a driving wheel to drive the conveyer belt for working so as to control the generated concentration of dust. A negative pressure generator controlled by the computer makes a negative pressure dust entering pipe attract the dust on the conveyer belt to flow into a special dusting dissolving and separating cavity to form the dust aerosol which is delivered into an aerosol detecting experiment cabin. The generating device of the dust aerosol has the function for continually and quantificationally generating the dust aerosol.

Owner:范维林

Emulsions for lignocellulosic products, methods of their manufacture, improved lignocellulosic products and methods for their manufacuture

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic products. In one embodiment, the emulsions contain a nonsaponifiable wax, a saponified wax, an alkyl phenol component, a dispersant / surfactant such as a salt of polynaphthalenesulfonic acid, and a carboxymethylcellulose. Such emulsions may be added to hot, even boiling, water without the emulsion separating or curdling. Various embodiments are stable for extended periods of time when stored at room temperature, do not require the addition of a preservative biocide to avoid contributing to biodegradation in a lignocellulosic product. The emulsions are pourable liquids at room temperature. Optionally, the emulsions may be added to lignocellulosic products with a preservative to inhibit the preservative from leaching out.

Owner:HEXION INC

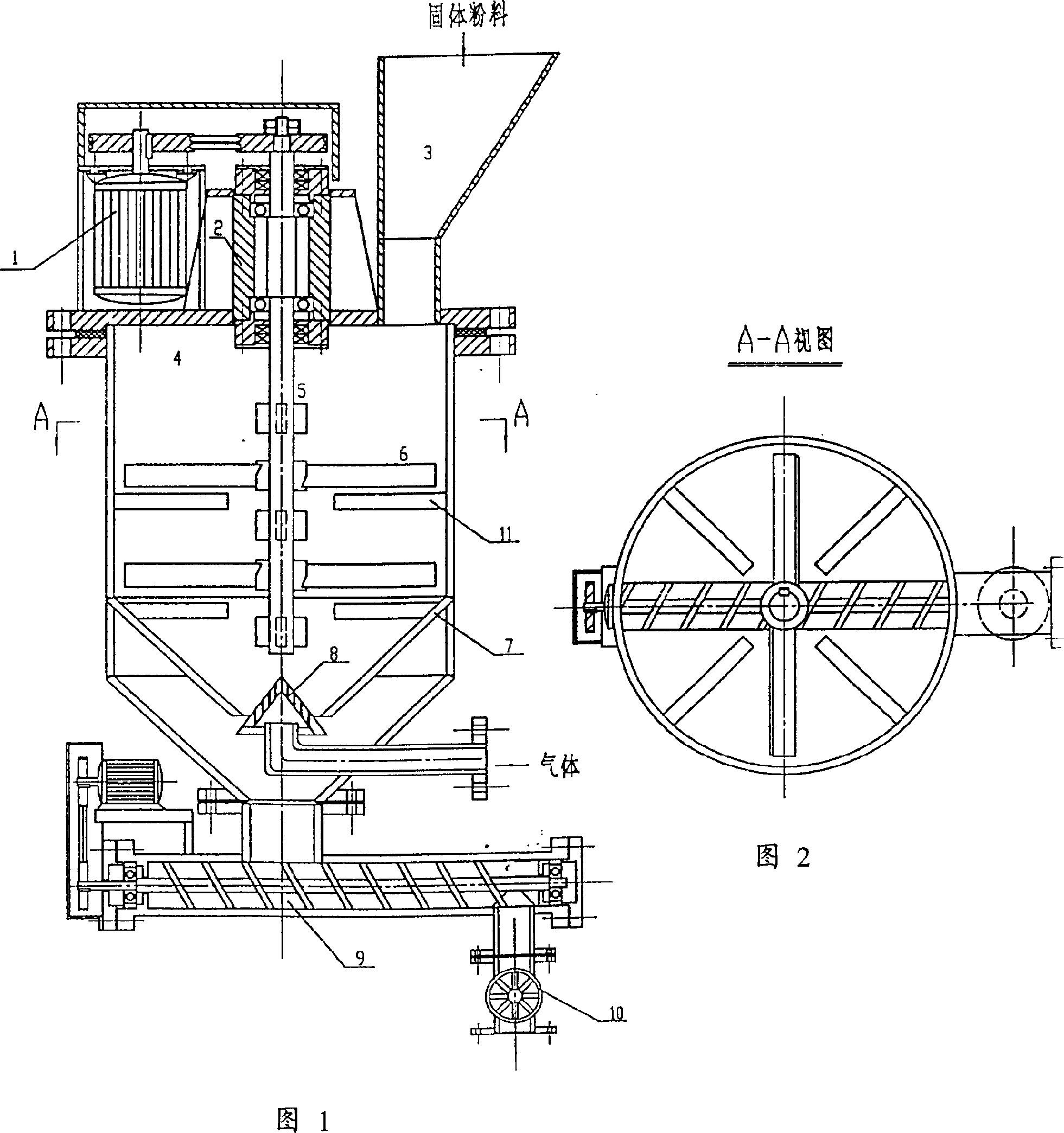

Powder feeding and mixing device for preparing magnetic grinding material through atomization and rapid solidification and powder feeding and mixing method

ActiveCN102328091AImprove performanceEasy to controlOther chemical processesFlow mixersGas solidJet flow

The invention provides a powder feeding and mixing device for preparing a magnetic grinding material through atomization and rapid solidification and a powder feeding and mixing method. The powder feeding and mixing device comprises a powder feeding device and a powder mixing device. The powder feeding and mixing control method comprises the following steps in the specification, wherein the steps1 and 2 are combined to achieve the purposes of (1) regulating a material control valve to a maximum opening degree, and (2) regulating the opening degree of a balancing valve and simultaneously observing a pressure displayed by a balance barometer, wherein the pressure of the balance barometer is regulated to be 0.05-0.5MPa; the steps 1, 2 and 3 are combined to realize regulation of blowing pressure; the steps 1 and 6 are combined to realize regulation of controlling and debugging pressure of jet flows of a flow mixing pipe; the steps 1, 2, 3, 6 and 7 are combined to realize the flow regulation of hard grinding materials; and the steps 6, 7 and 8 are combined to realize the regulation of control pressure for the jet flows of the flow mixing pipe. Under the action of the powder feeding and mixing pipe, the hard grinding materials in the flow mixing pipe are fully mixed with high-pressure gas so as to form a gas-solid two phase flow. According to the invention, an important condition is provided for a novel method for preparing the magnetic grinding material.

Owner:SHANDONG UNIV OF TECH

Propelled dust aerosol generating equipment

InactiveCN102166488AQuantitative control is accurateEasy to cleanTransportation and packagingMixer accessoriesMotor driveBall screw

The invention provides propelled dust aerosol generating equipment. The equipment comprises a front opened syringe and a stepping motor, wherein the front opened syringe loads powder; the rotation speed of the stepping motor can be adjusted; the stepping motor drives a ball screw to rotate so that a ball nut drives an advancing block to move; a manual adjusting wheel is arranged on the advancing block and can slightly adjust the front opened syringe; a front limit switch and a rear limit switch control the maximal stroke of the advancing block; the powder is pushed into a dust dissolving and separating cavity and bumps with microspheres driven by air flow entering from an air inlet to generate atomized aerosol; and the atomized aerosol is sent to a sealed diffusing cabin through an air outlet and a pipeline. The invention provides the dust aerosol generating equipment, which is precisely and quantificationally controlled, is not easy to block and uniformly dissolves and separates dust; a large amount of dust aerosol can be convenient to prepare reliably; the equipment is applied to researches in the aspects of environmental science, atmosphere physics and chemistry, weather science, industrial manufacturing, medicament and health, and the like, and required dust aerosol related tests and production; a new method is developed; and the precision and the efficiency are improved.

Owner:TIANJIN HOPE IND & TRADE

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS7112904B2Dynamo-electric brakes/clutchesRotary stirring mixersMagnetic rotationElectric arc furnace

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

System and method of applying carbon dioxide during the production of concrete

ActiveUS9790131B2Reduce energy consumptionLow costFlow mixersTransportation and packagingMulti materialArchitectural engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

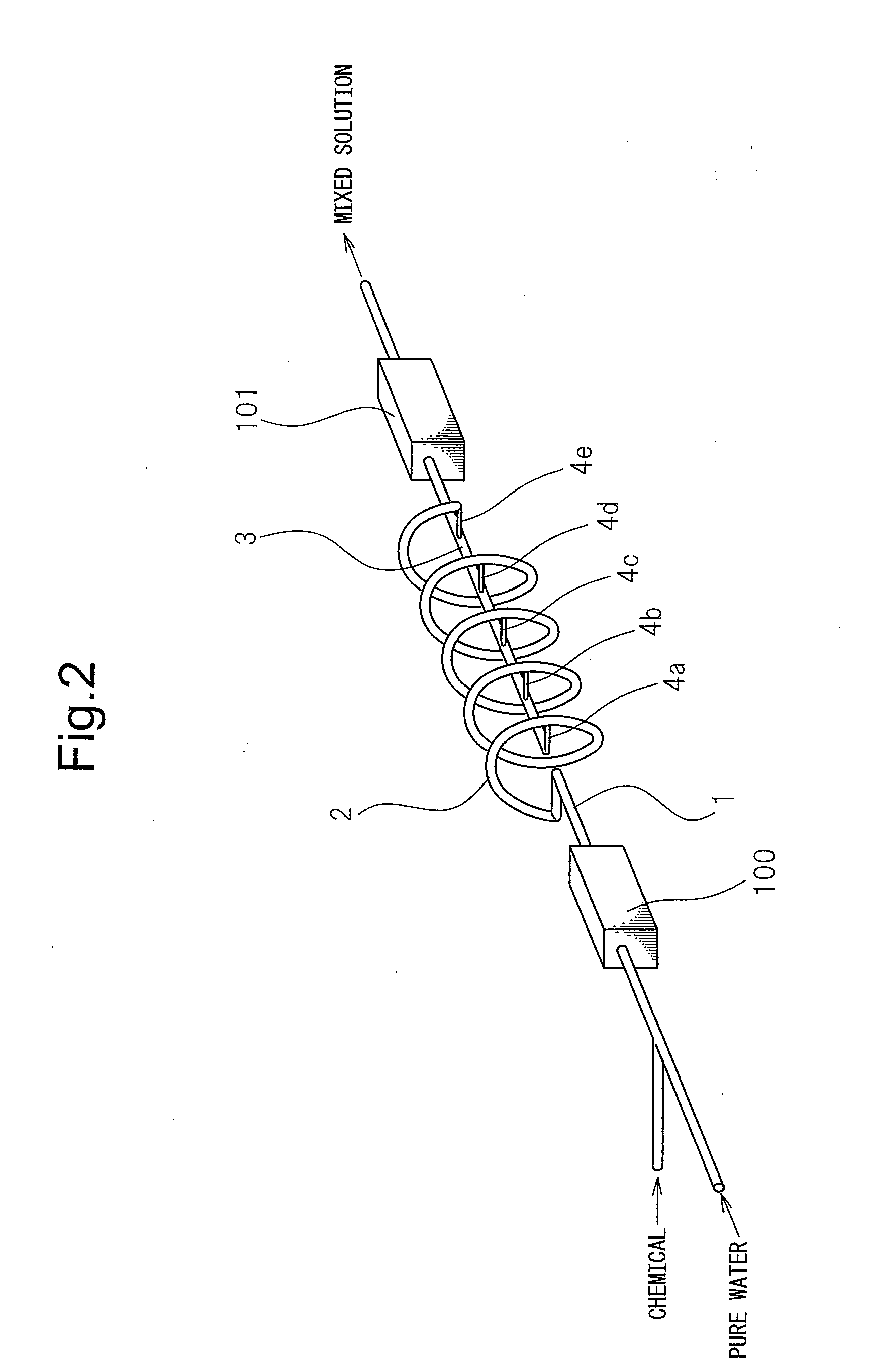

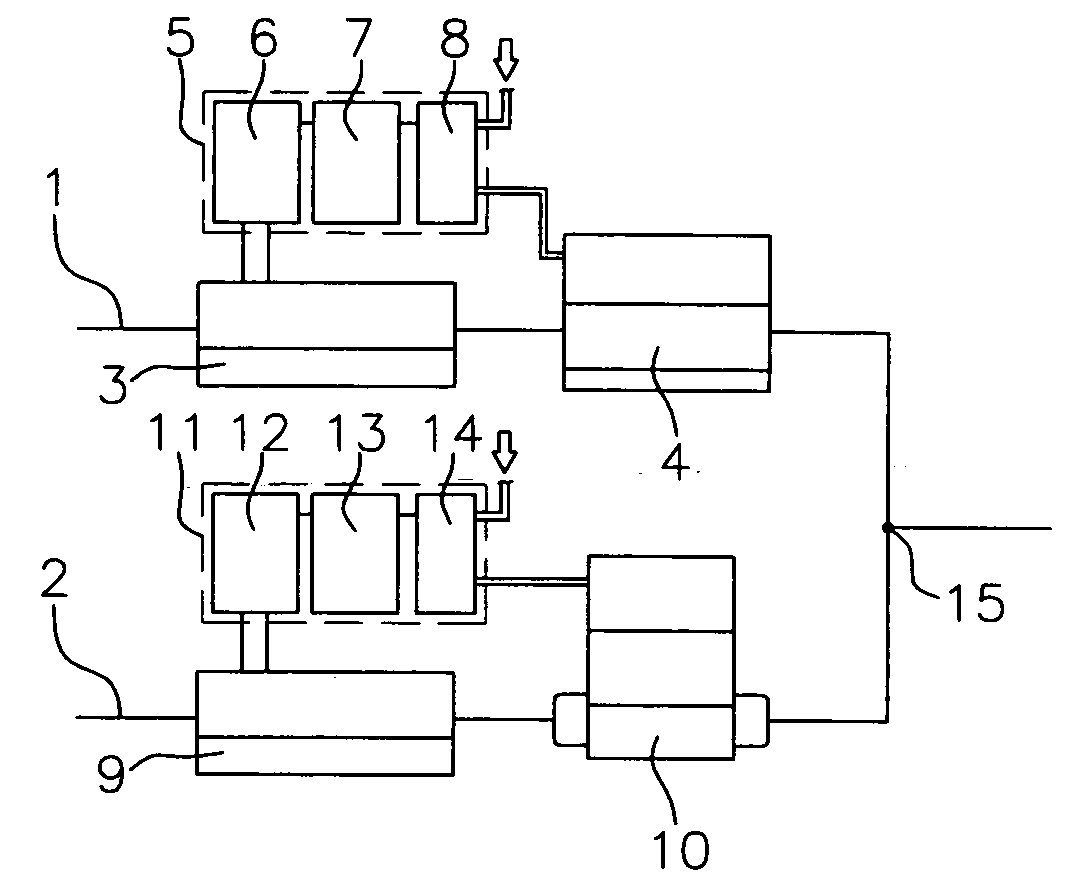

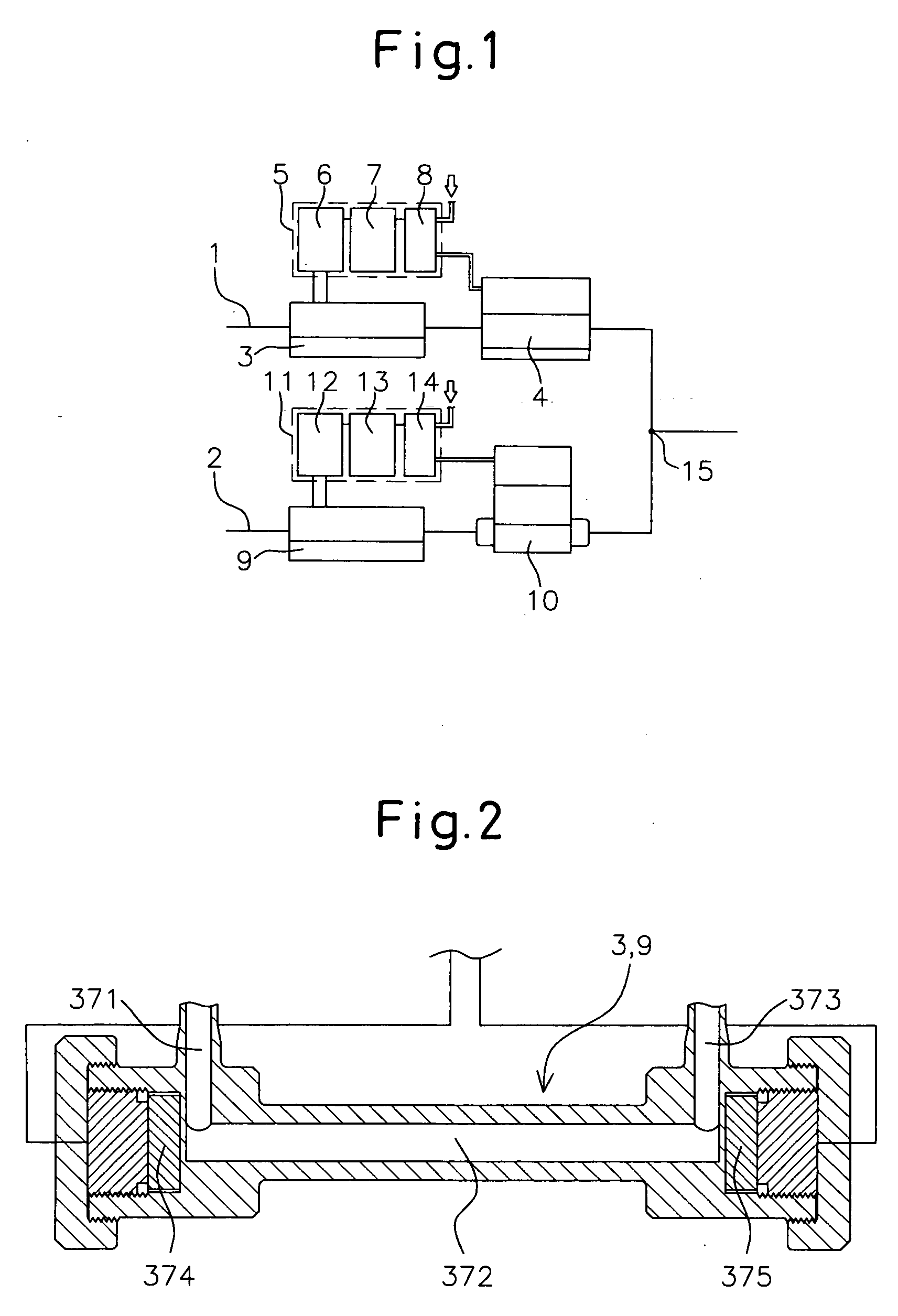

Fluid mixing system

InactiveUS20070204914A1Avoid corrosionImprove responseOperating means/releasing devices for valvesFlow mixersHydrofluoric acidFluid control

An object of the present invention is to provide a fluid mixing system able to mix the fluids of different lines by any ratio and control the flow rates of even pulsating fluids, able to control the flow rate of even a pulsating fluid, compact in configuration and able to be installed in a narrow space, and enabling easy pipe laying and pipe connection at the time of installation.In the system of the present invention, its two feed lines are provided with first and second fluid control valves, flow rate measuring devices measuring the actual flow rates of the lines and outputting signals, and control units outputting command signals for controlling the fluid control valves and mixing the fluids flowing through the two feed lines by any ratio. The first fluid control valve controls the pressure of the fluid by the pressure operation of the control fluid, while the second fluid control valve changes the opening area of the channel to control the flow rate of the fluid. In the system of the present invention, for example, to obtain a washing solution for semiconductor production, hydrofluoric acid or hydrochloric acid is mixed with pure water by a ratio of 1 part to 10 to 200 parts.

Owner:ASAHI YUKIZAI KOGYO CO LTD

In situ mixing in microchannels

Owner:VELOCYS INC

System and method of applying carbon dioxide during the production of concrete

ActiveUS20170158569A1Reduce energy consumptionLow costFlow mixersTransportation and packagingMulti materialArchitectural engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

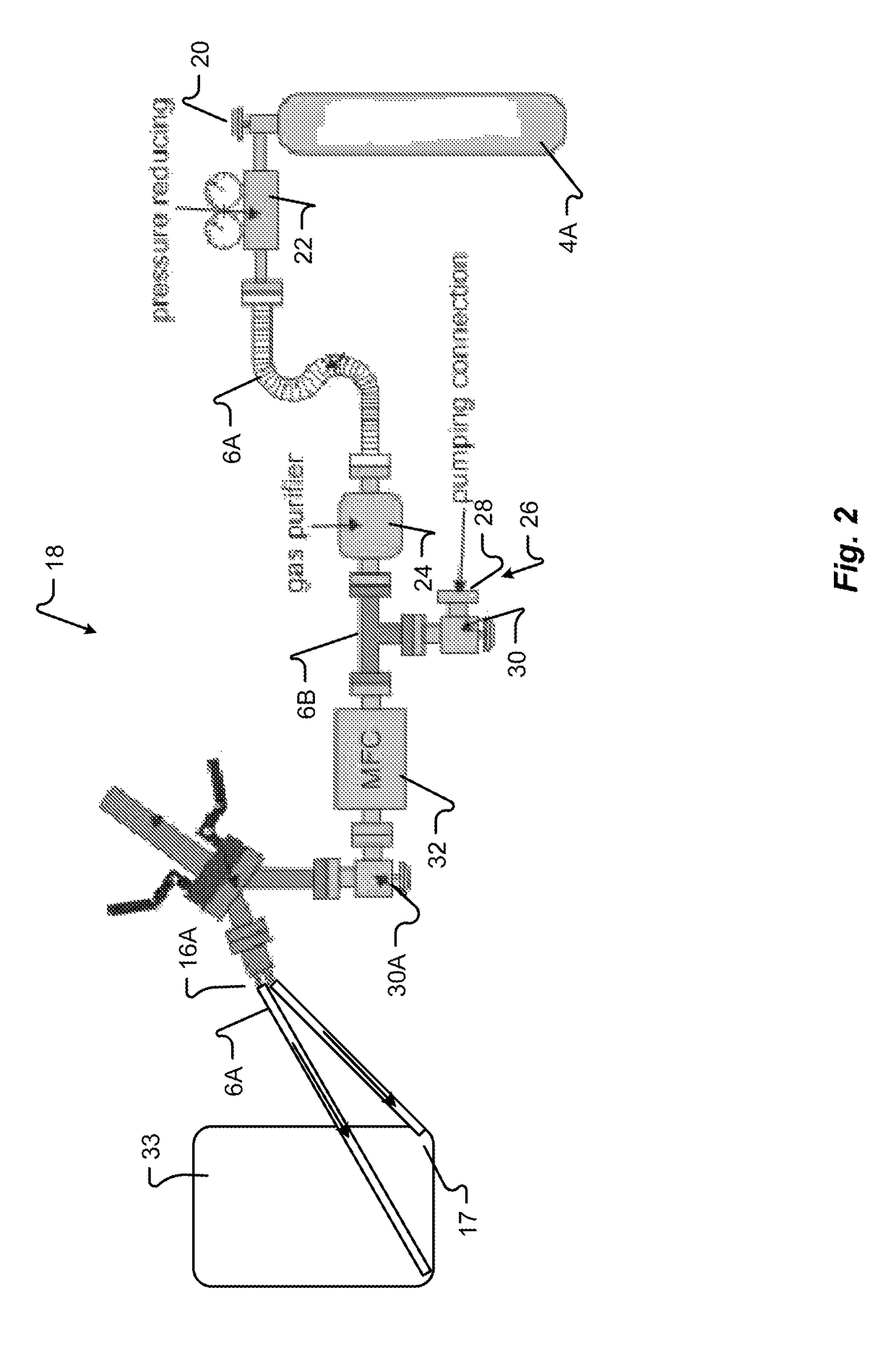

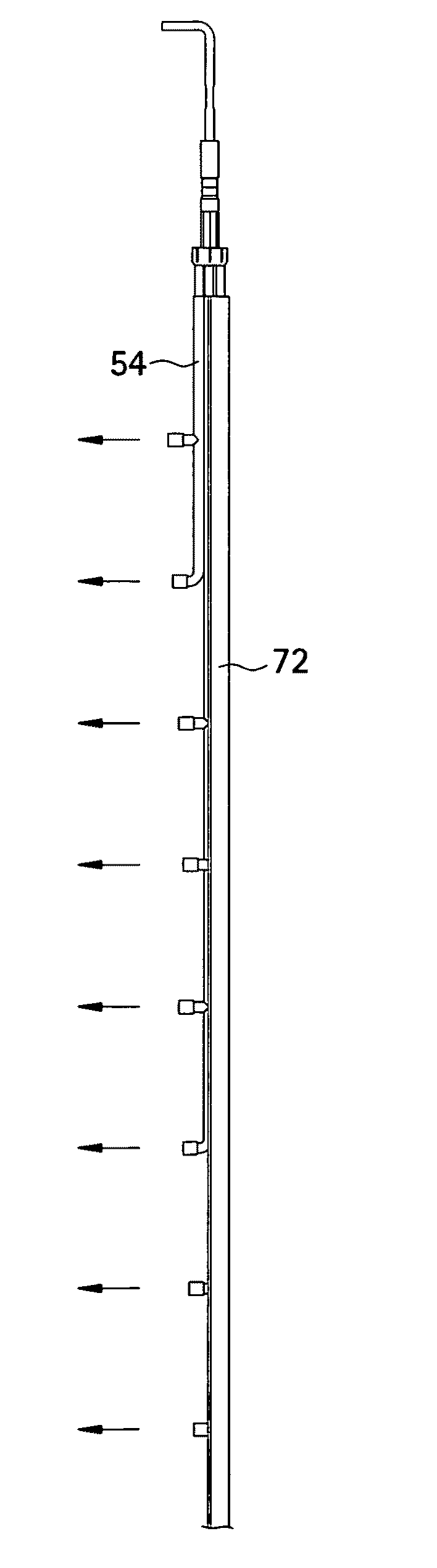

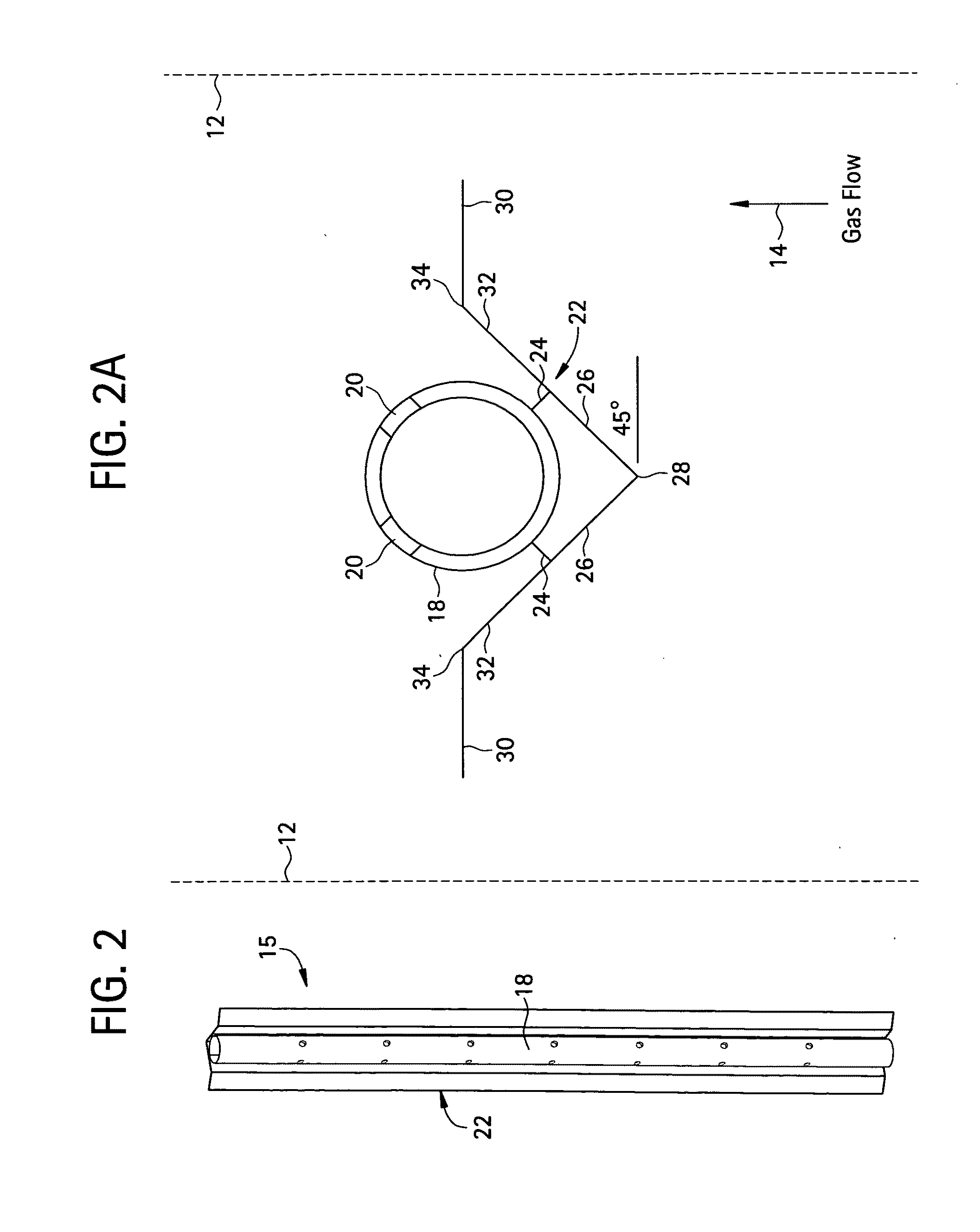

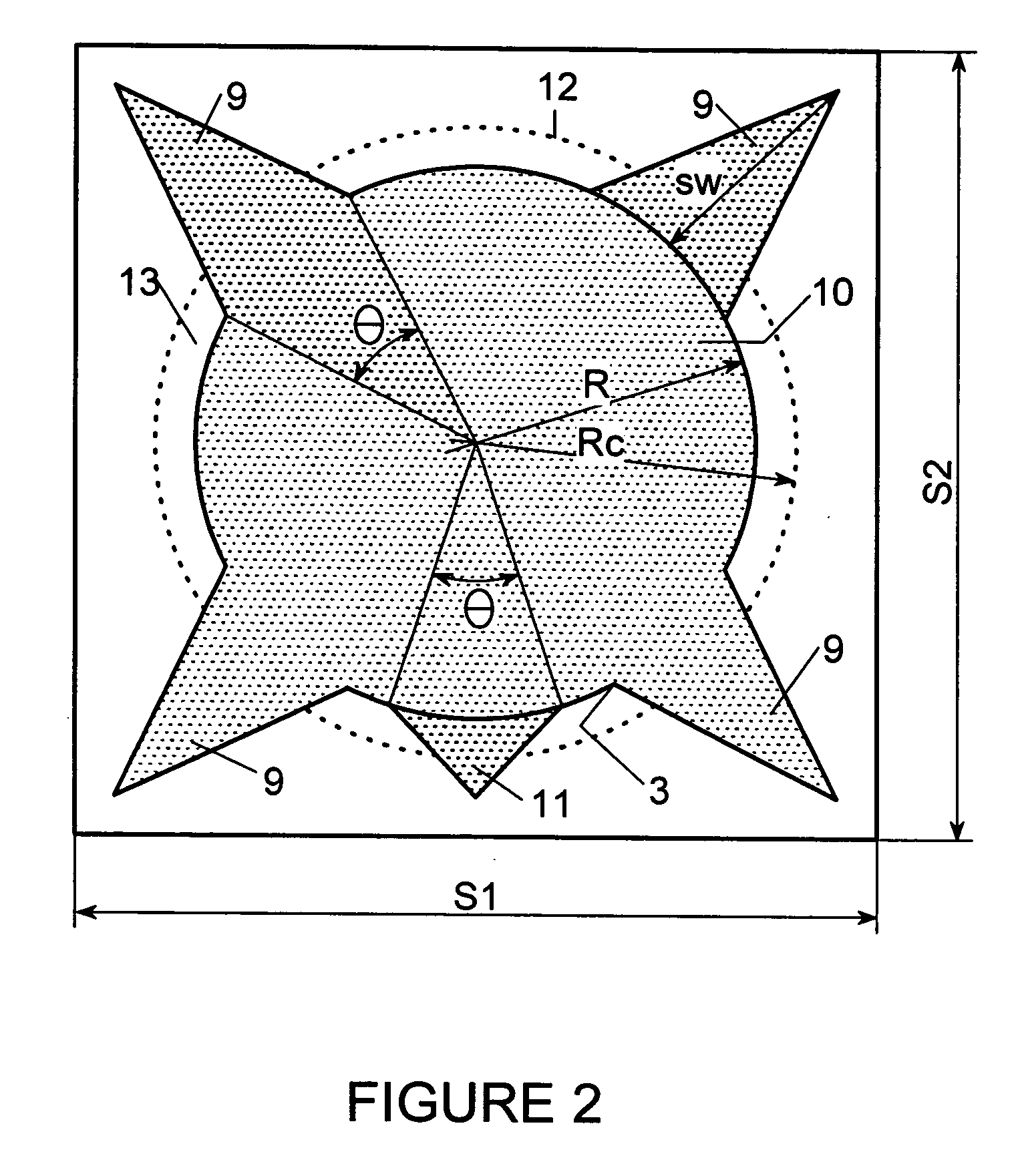

Dispersion lance and shield for dispersing a treating agent into a fluid stream

ActiveUS20090293721A1Increase surface areaImprove overall utilizationFlow mixersOther chemical processesSorbentStream flow

A dispersion apparatus for dispersing a treating agent into a fluid treatment system that includes a flow duct in which a fluid stream flowing through the duct is mixed with the treating agent. The apparatus is based on a multi-pipe lance positioned in the stream flow, where each pipe supplies a minimum of feed discharge nozzles (typically one to four), and the individual pipes branch off from the same location. Use of the multi-pipe lance, in combination with a suitable baffle, results in better overall dispersion / distribution of the injected medium by surface area. By improving the surface area distribution, better utilization of the injected sorbent can be achieved. The baffle acts to generate a low pressure zone on its downstream side and creates a high-intensity turbulence plume in the fluid. The orifices of the pipe are located to inject the treating agent into the turbulence plume to better distribute and intermix the injected treating agent into the surrounding fluid.

Owner:URS

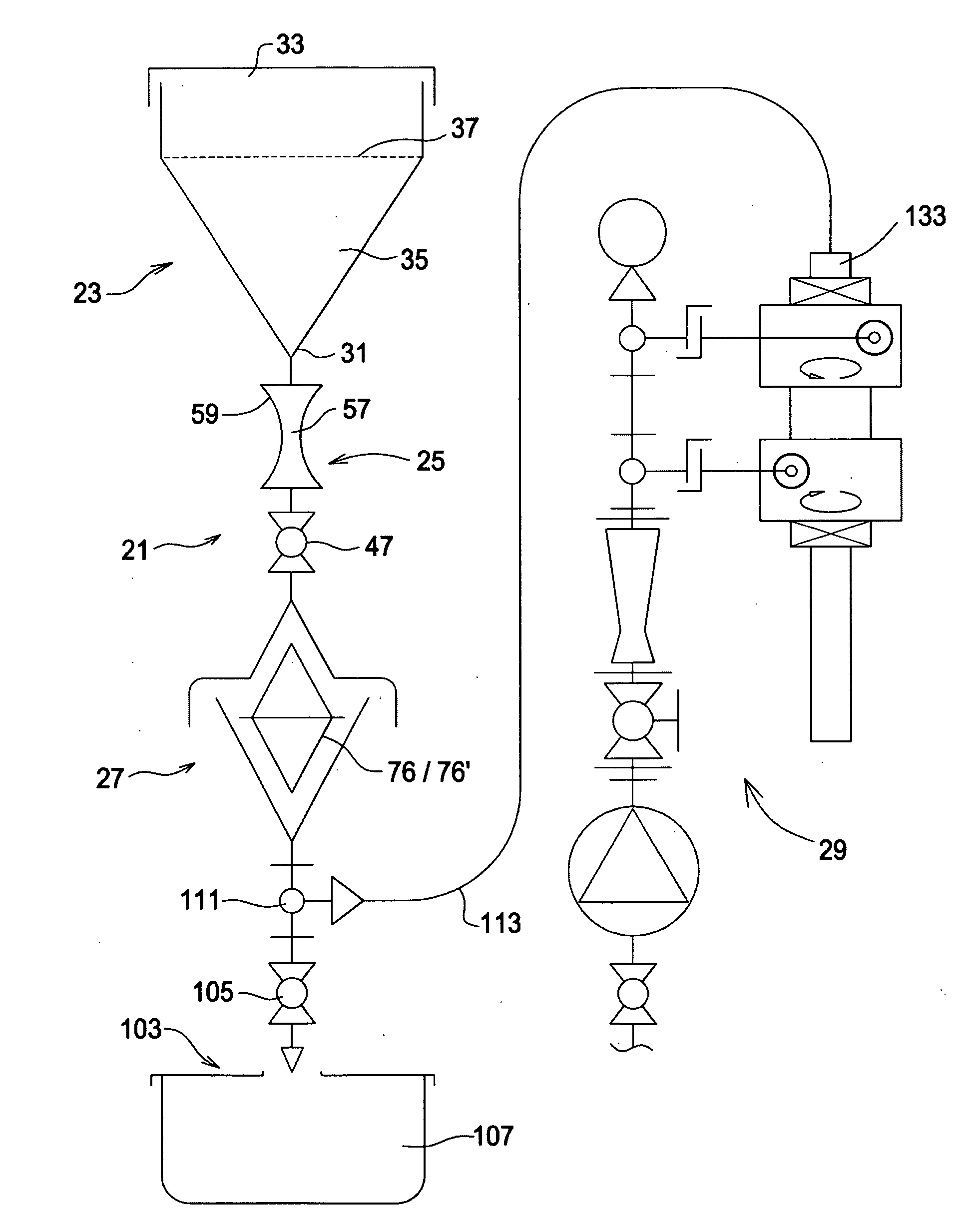

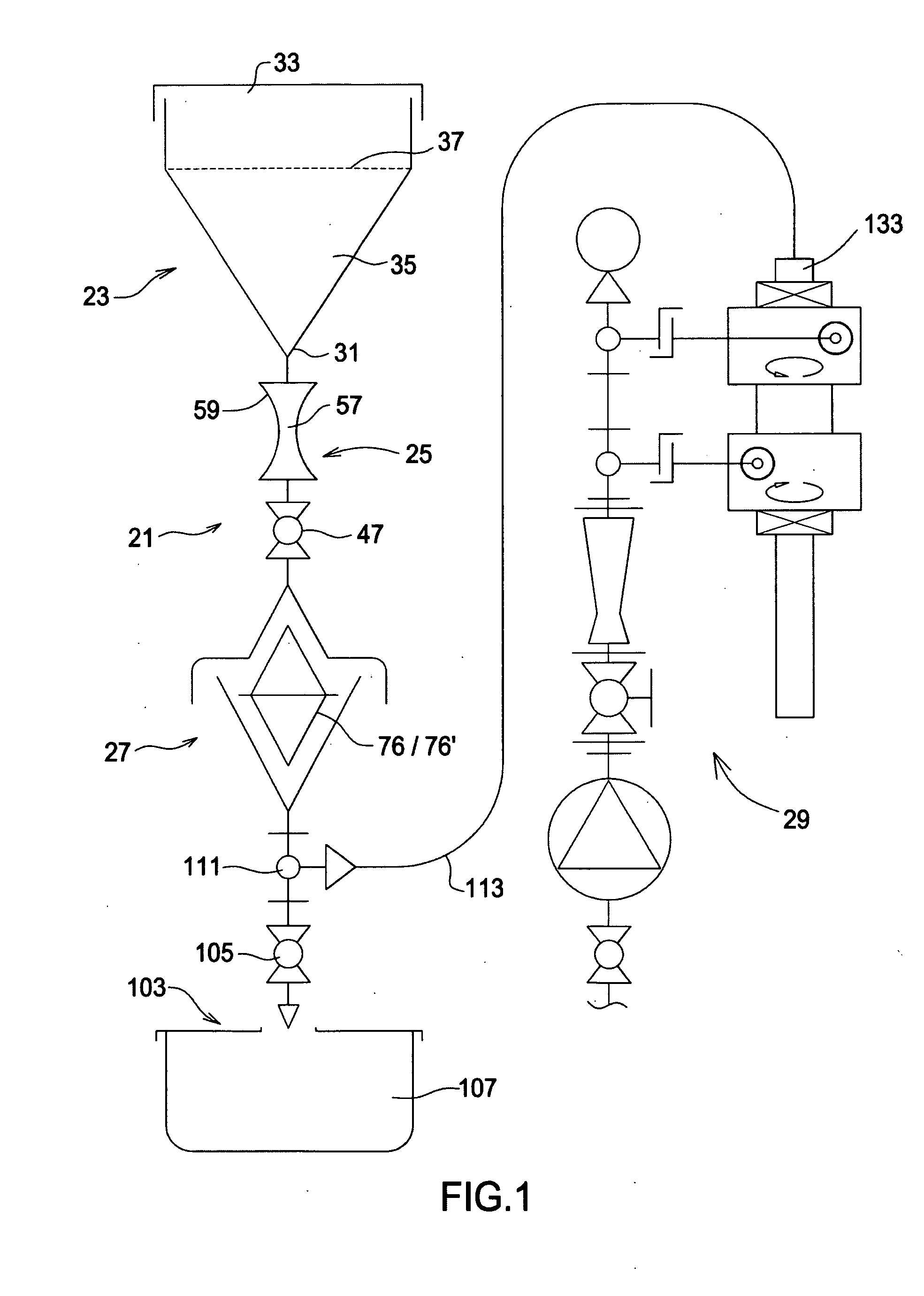

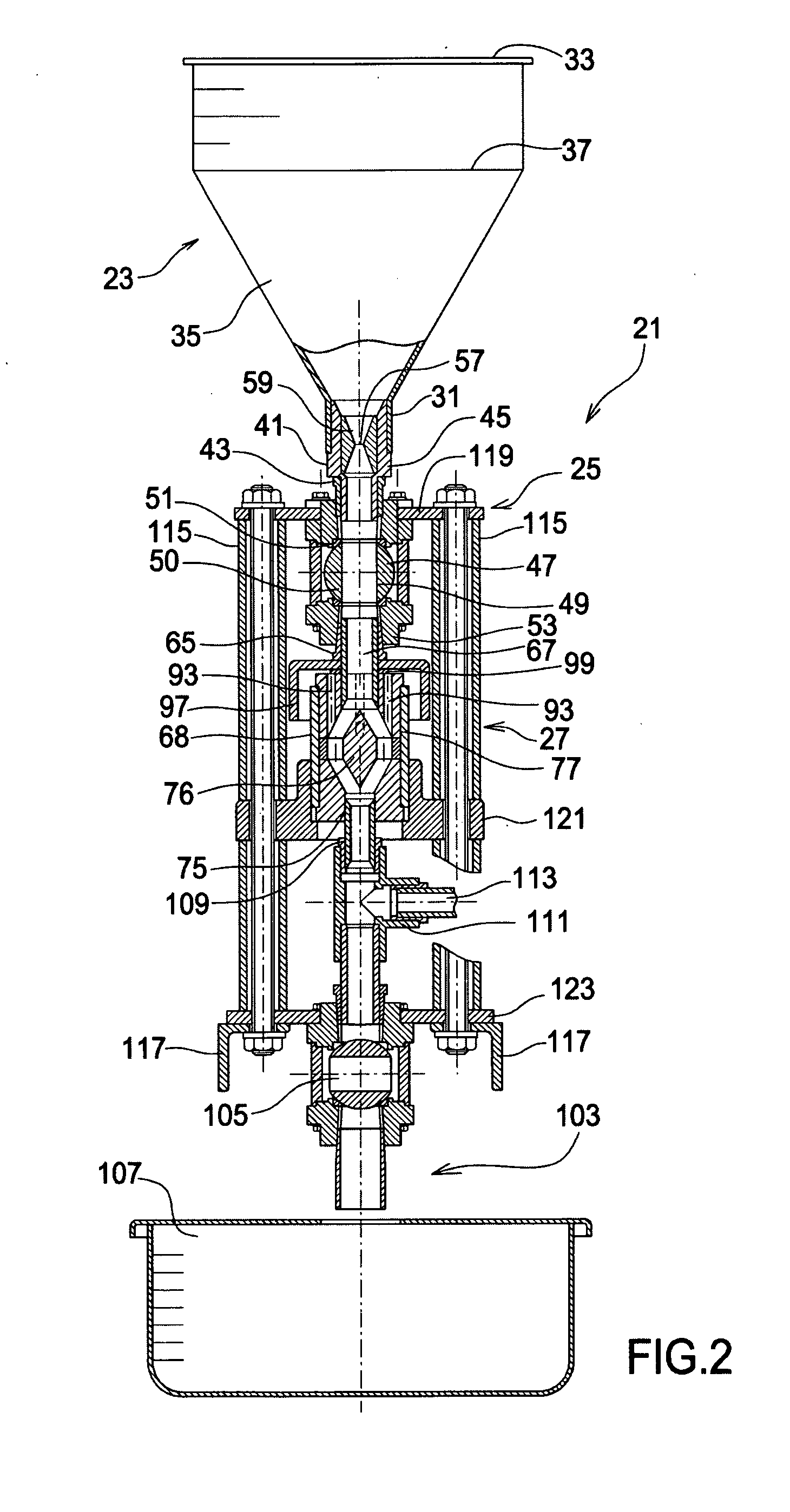

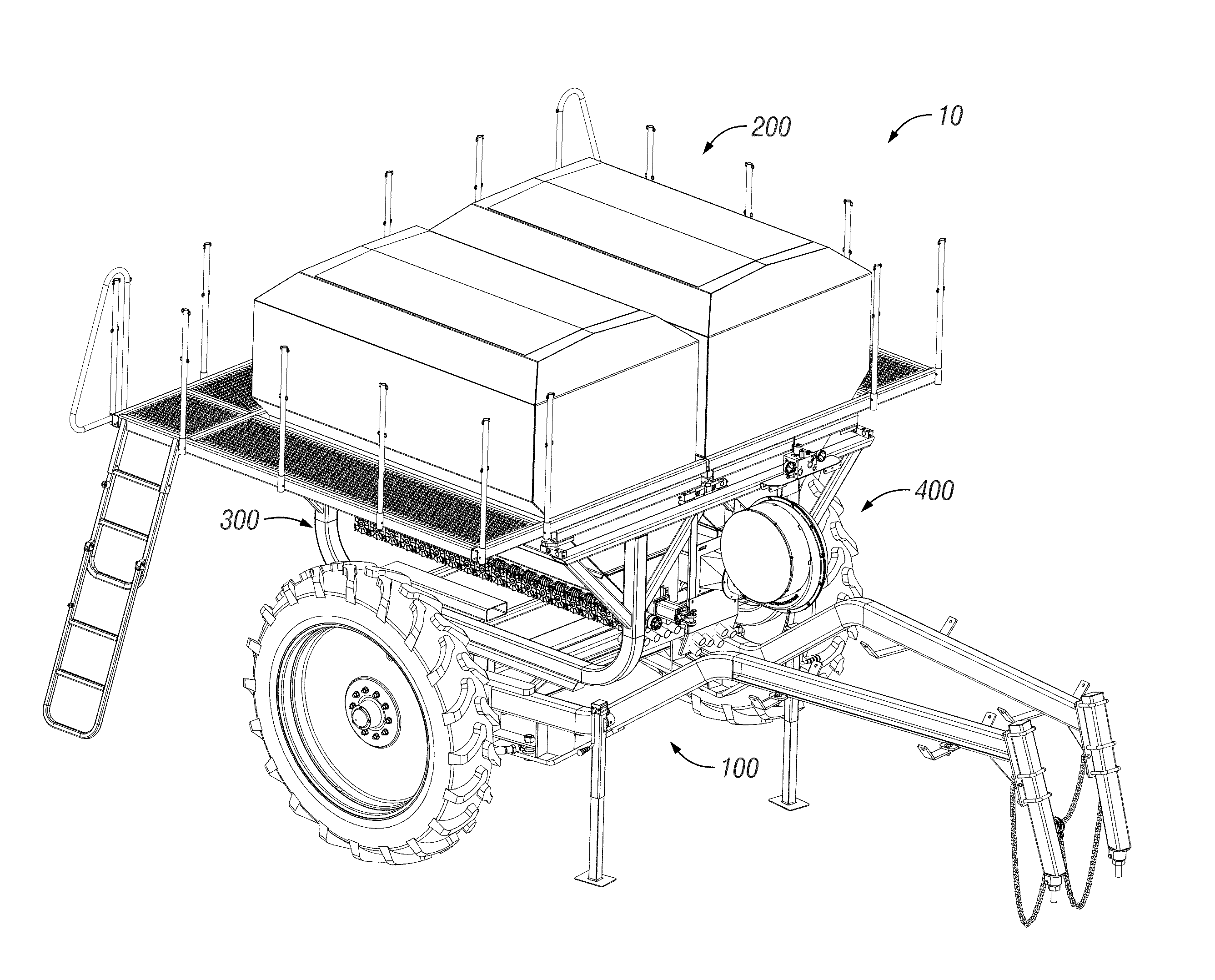

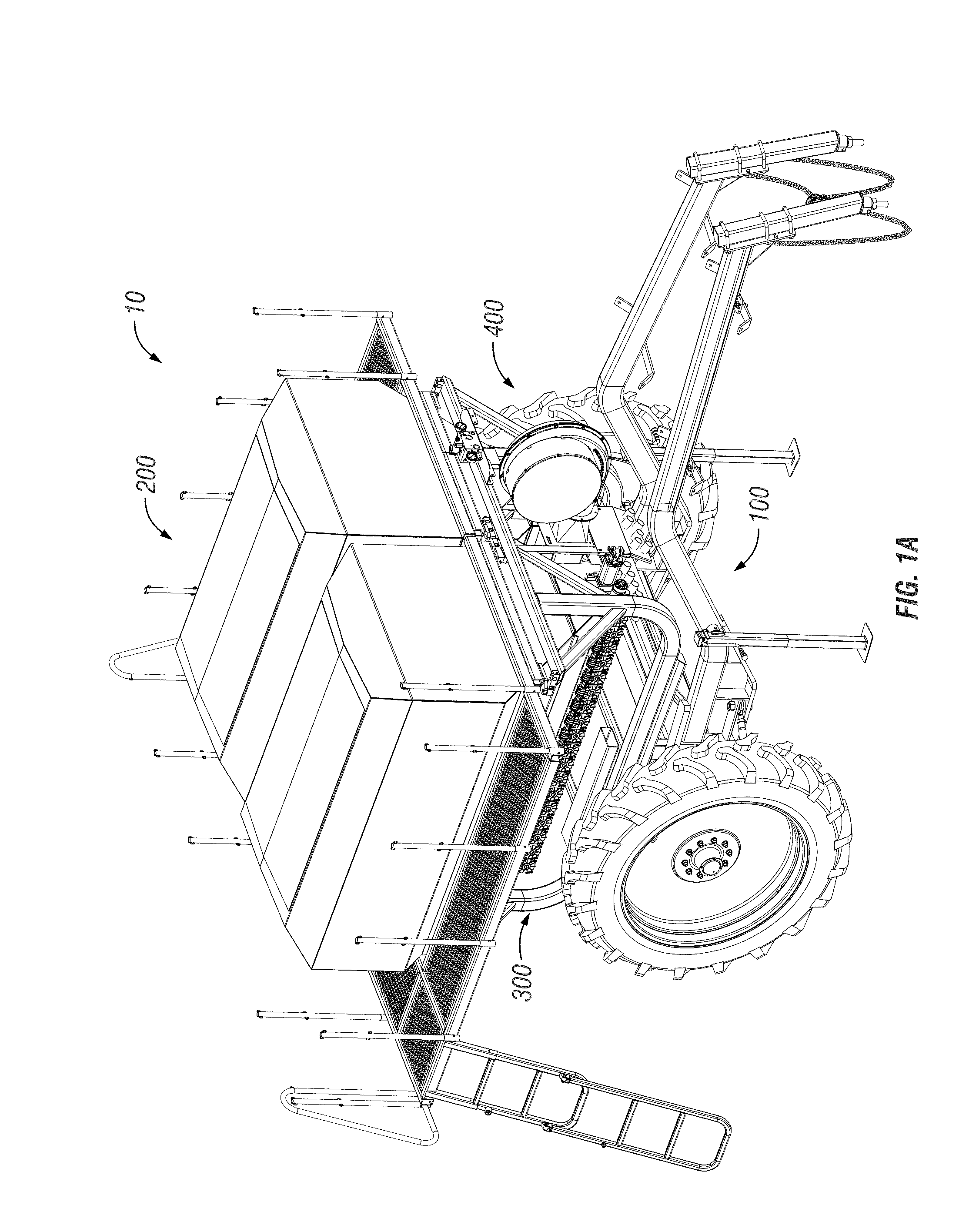

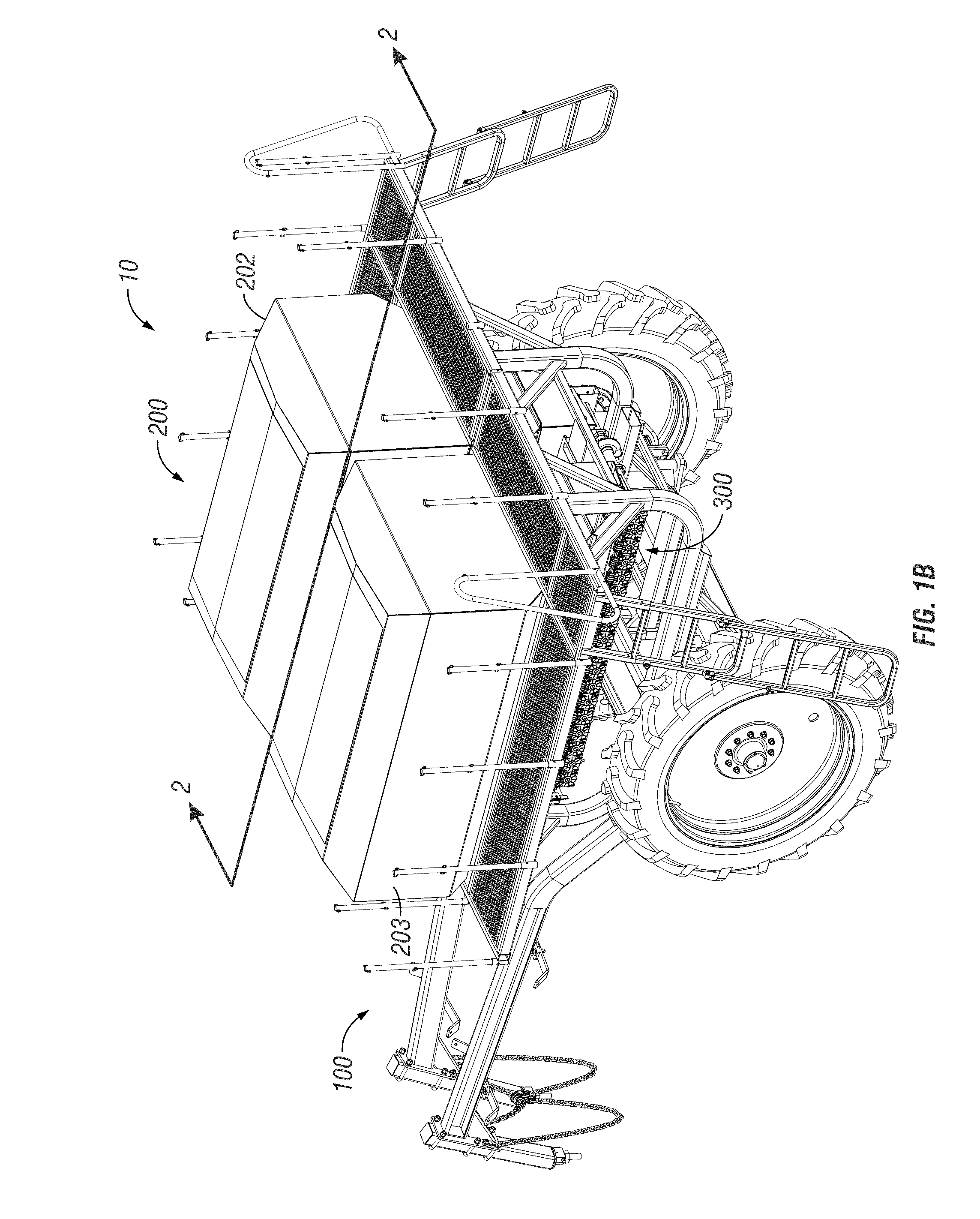

Apparatus and methods for entraining a substance in a fluid stream

InactiveUS20160167897A1Durable and simple to assembleDurable and simple to and useMixing gases/vapours with solidsBulk conveyorsParticulatesGravity feed

Apparatus and methods are disclosed for uptake and transport of particulate matter in a gas stream. The apparatus includes a receiver for the particulate matter connected with a gravity feed input channel assembly with a passive metering orifice therein. An in-line aeration and distribution chamber assembly is connected with an outlet from the input channel assembly and includes a chamber with plural discrete gas intake passageways opening thereinto. An outlet channel exits the chamber and is connectable with a vacuum suction source for directing a gas stream having the particulate matter entrained therein from the apparatus.

Owner:ROCKWATER RESOURCE

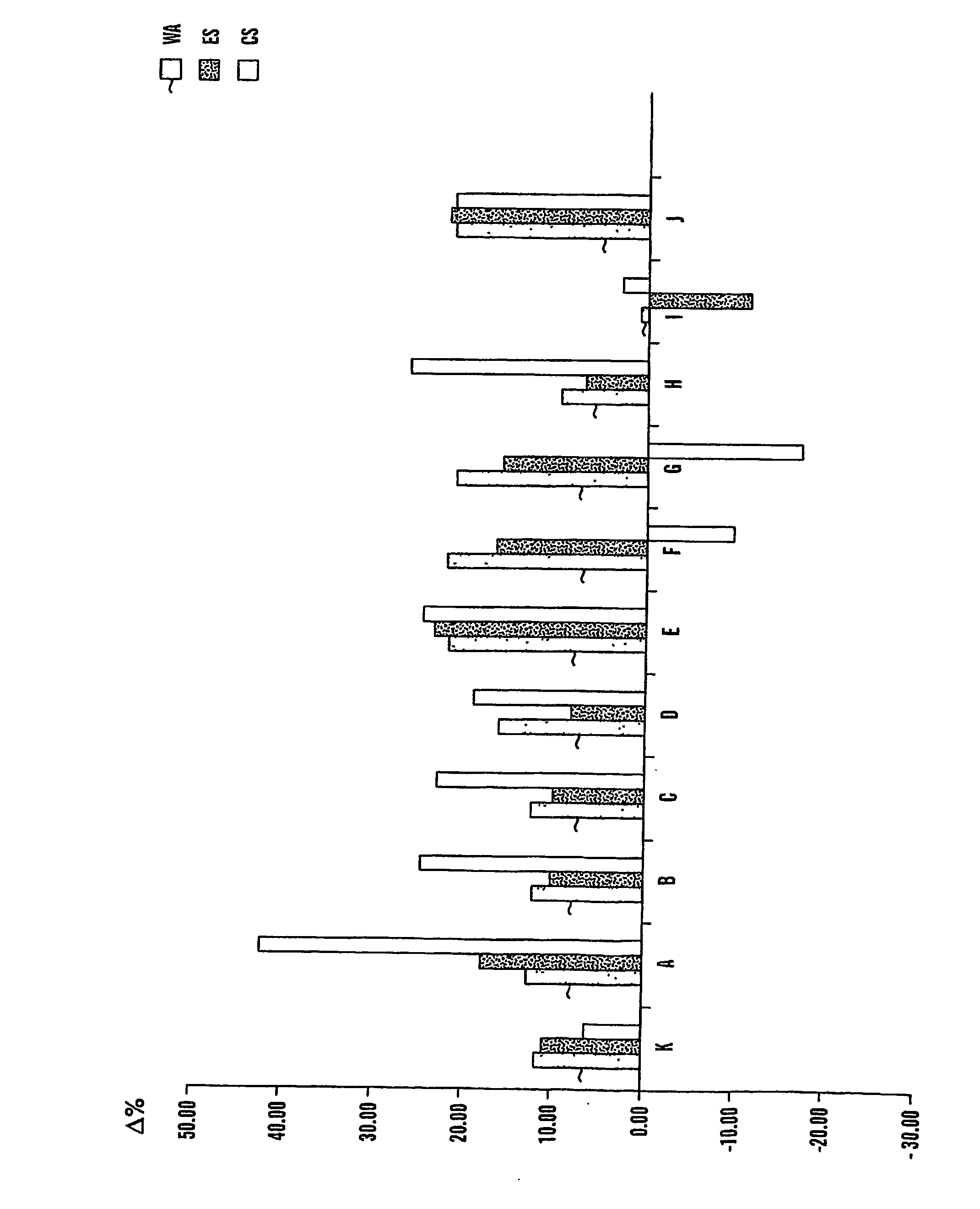

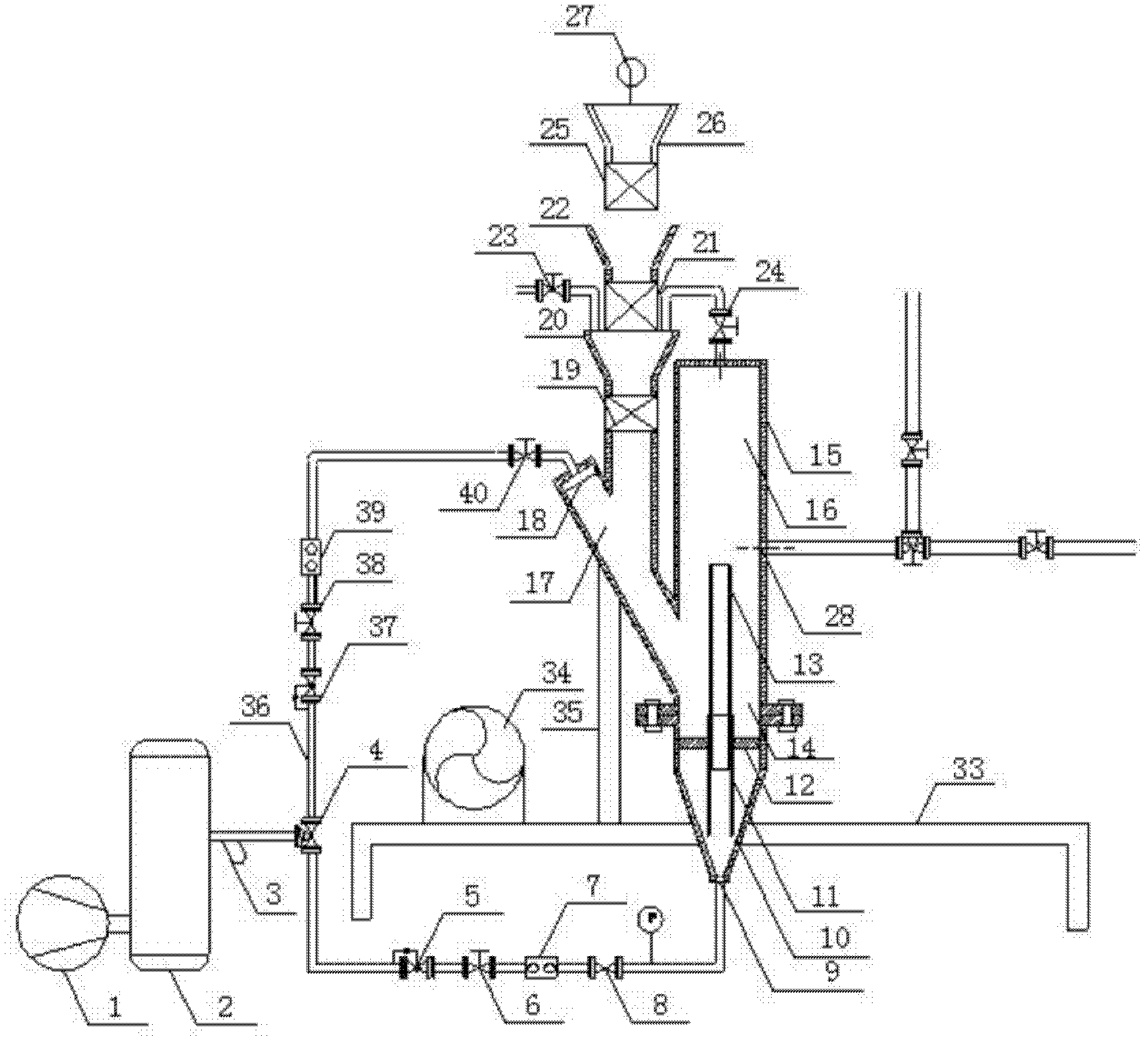

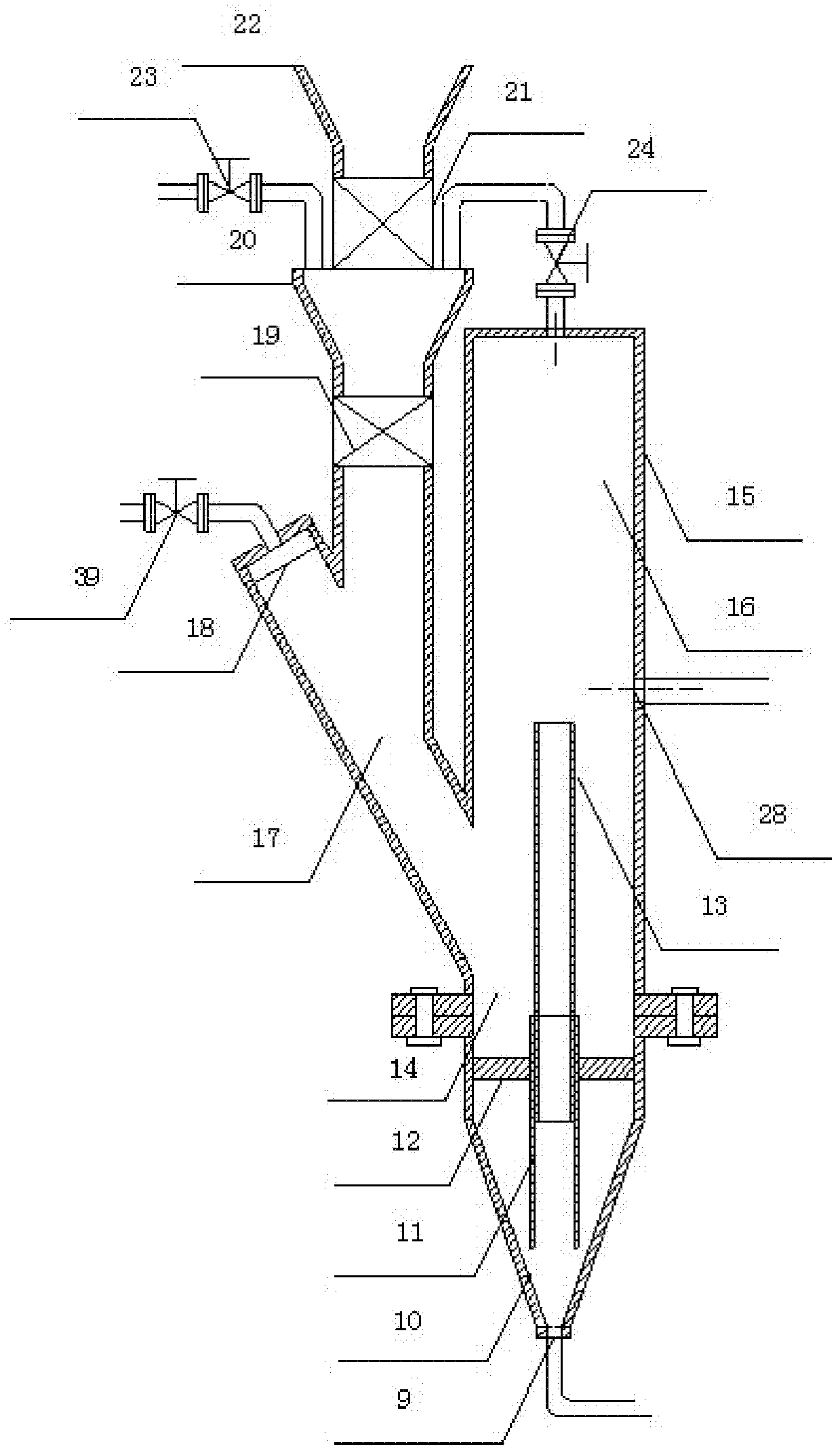

System and method for producing high-time diluted PM2.5 aerosol

ActiveCN103566840AAutomatic continuous and stable generationSmooth dischargeFlow mixersMixer accessoriesBuffer tankAir compressor

The invention discloses a system and a method for producing high-time diluted PM2.5 aerosol. The system is characterized in that a vibration sieve feeding machine, an aerosol dust raiser, a first-stage diluter, an aerosol buffer tank, a second-stage diluter, a PM2.5 separator, a draft fan and an aerosol buffer tank are sequentially connected together; the aerosol buffer tank, a return material airflow control valve, a return material airflow meter, the aerosol buffer tank and the second-stage diluter are sequentially connected together; the aerosol dust raiser, the first-stage diluter and the bottommost vibration sieve stage of the vibration sieve feeding machine are sequentially connected together; compressed air provided by an air compressor is divided into two paths, one path is connected with the aerosol buffer tank and the second-stage diluter after sequentially passing through a compressed air supplement control valve and a flow meter of the second-stage diluter, and the other path is connected with the aerosol dust raiser and the first-stage diluter after sequentially passing through a jet flow pressure control valve and a pressure gauge of the first-stage diluter. Due to adoption of the system, high-time diluted PM2.5 aerosol with low concentration can be automatically, continuously and stably produced, and the size of an aerosol grain when being cut is precise.

Owner:ZHEJIANG UNIV

Photocatalytic titanium oxide sol, and coating composition and member using the same

ActiveUS20080081758A1Little discolorationImprove antibacterial propertiesLayered productsGold compoundsCatalytic oxidationAmmonium hydroxide

A photocatalytic titanium oxide sol presents antibacterial properties in a dark place, and, in particular, relates to a photocatalytic titanium oxide sol which is stable and causes no discoloration by light even though containing silver, and relates to a coating composition and a member using the same. The photocatalytic titanium oxide sol includes silver, copper and a quaternary ammonium hydroxide, may be dispersed in a binder, and may be coated on the surface of a substrate.

Owner:TAKI CHEM CO LTD +1

Metering system for solid particulate

An improved particulate metering system is provided. The system includes a flow path having an inlet in communication with an intake and an outlet in communication with a discharge. The flow path receives a first input and a plurality of inputs, each of the plurality of inputs having a separate origin. A mixing area within the flow path comprises a confluence of the first input and one or more of the plurality of inputs. One or more metering controls are in operable communication with the first input and the plurality of inputs for controlling a blend of the plurality of inputs at the confluence.

Owner:MONTAG INVESTMENTS

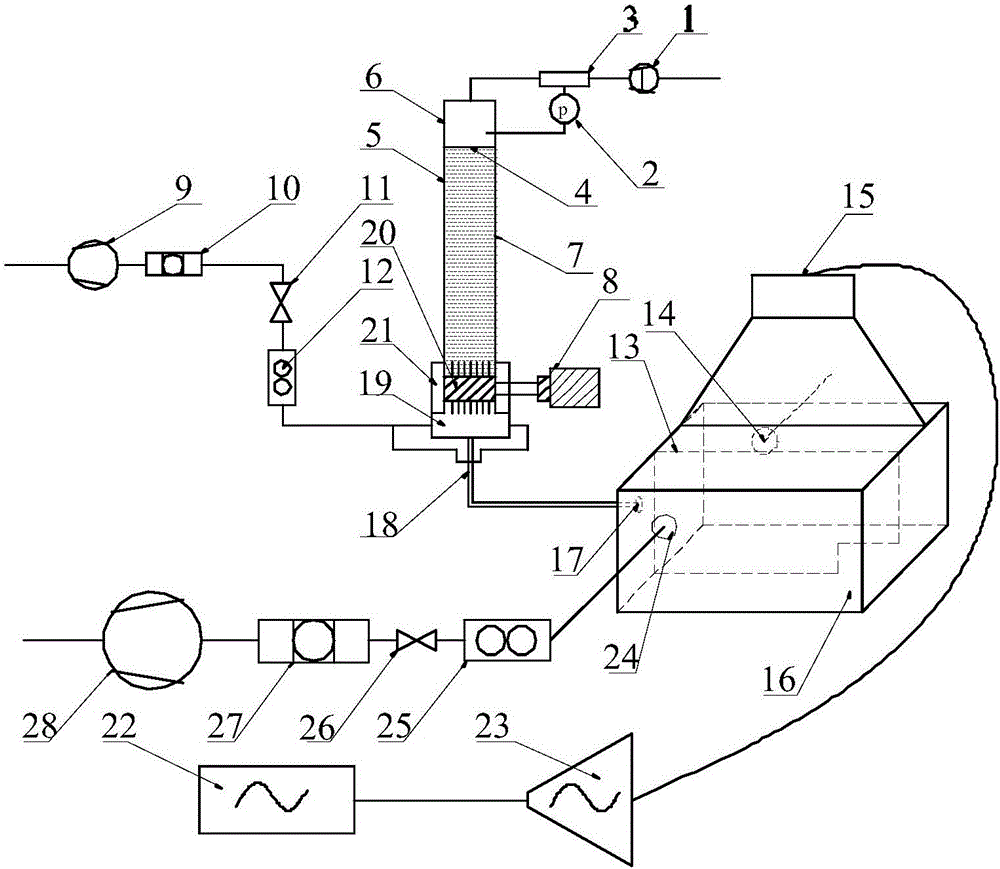

System capable of stably generating dust aerosol

ActiveCN105126712AThere will be no phenomenon of unstable feedingPropel at a constant speedMixer accessoriesMixing gases/vapours with solidsEngineeringLoudspeaker

A system capable of stably generating dust aerosol includes a material feeding apparatus, a dust diffusion apparatus, and a sound wave-type aerosol stabilizing apparatus. The material feeding apparatus includes a cylindrical body, a piston, a pressure sensor, a pushing gas source and a pressure controller. The dust diffusion apparatus includes a dust diffusion brush, a shell, a motor, a dust diffusion basin and a dust diffusion gas supply device. The sound wave-type aerosol stabilizing apparatus includes an aerosol stabilizing chamber, a signal generator, a signal amplifier and a loudspeaker. The system employs a gas-flow constant-pressure method for pushing a raw material powder, and then introduces the aerosol generated through primary diffusion into the aerosol stabilizing apparatus, in which the loudspeaker is installed, for outputting the aerosol, so that obtained aerosol particles are uniformly distributed and are stable in concentration.

Owner:SICHUAN UNIV

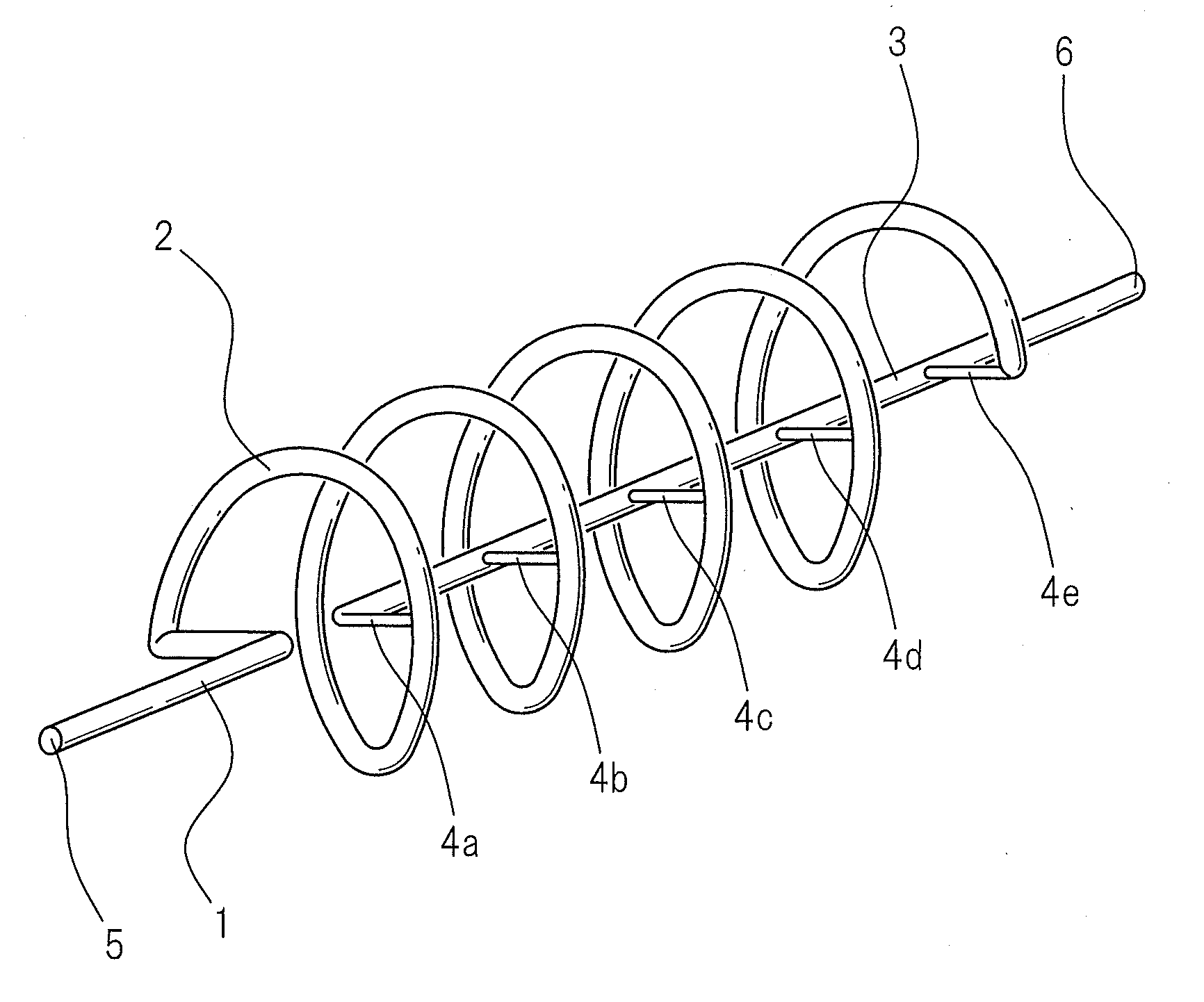

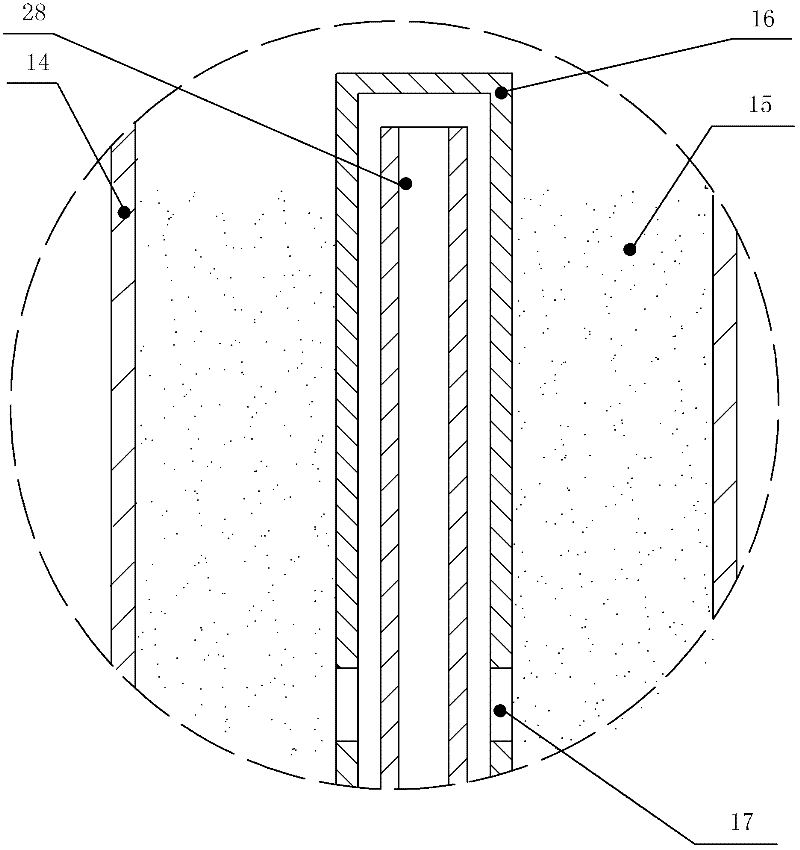

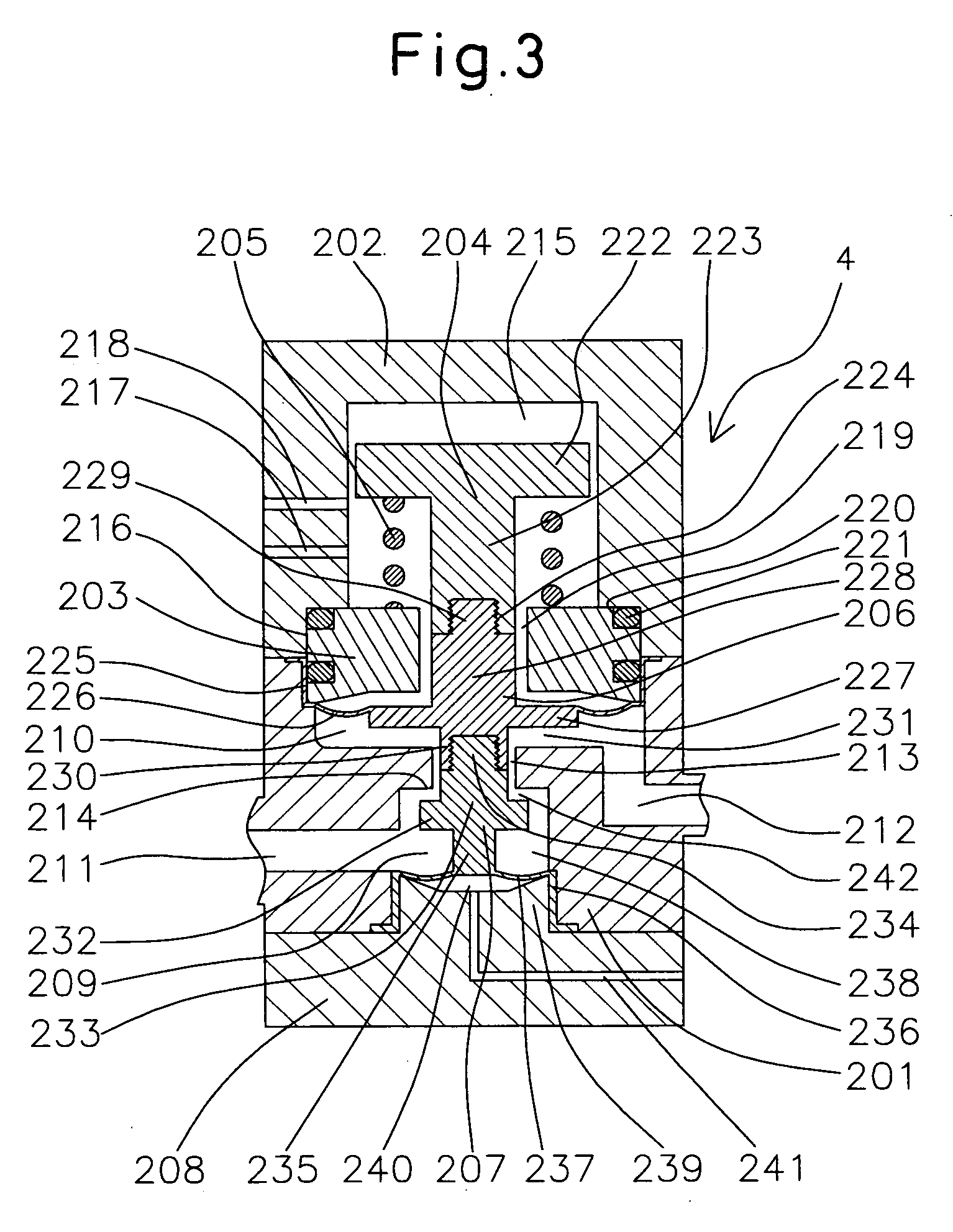

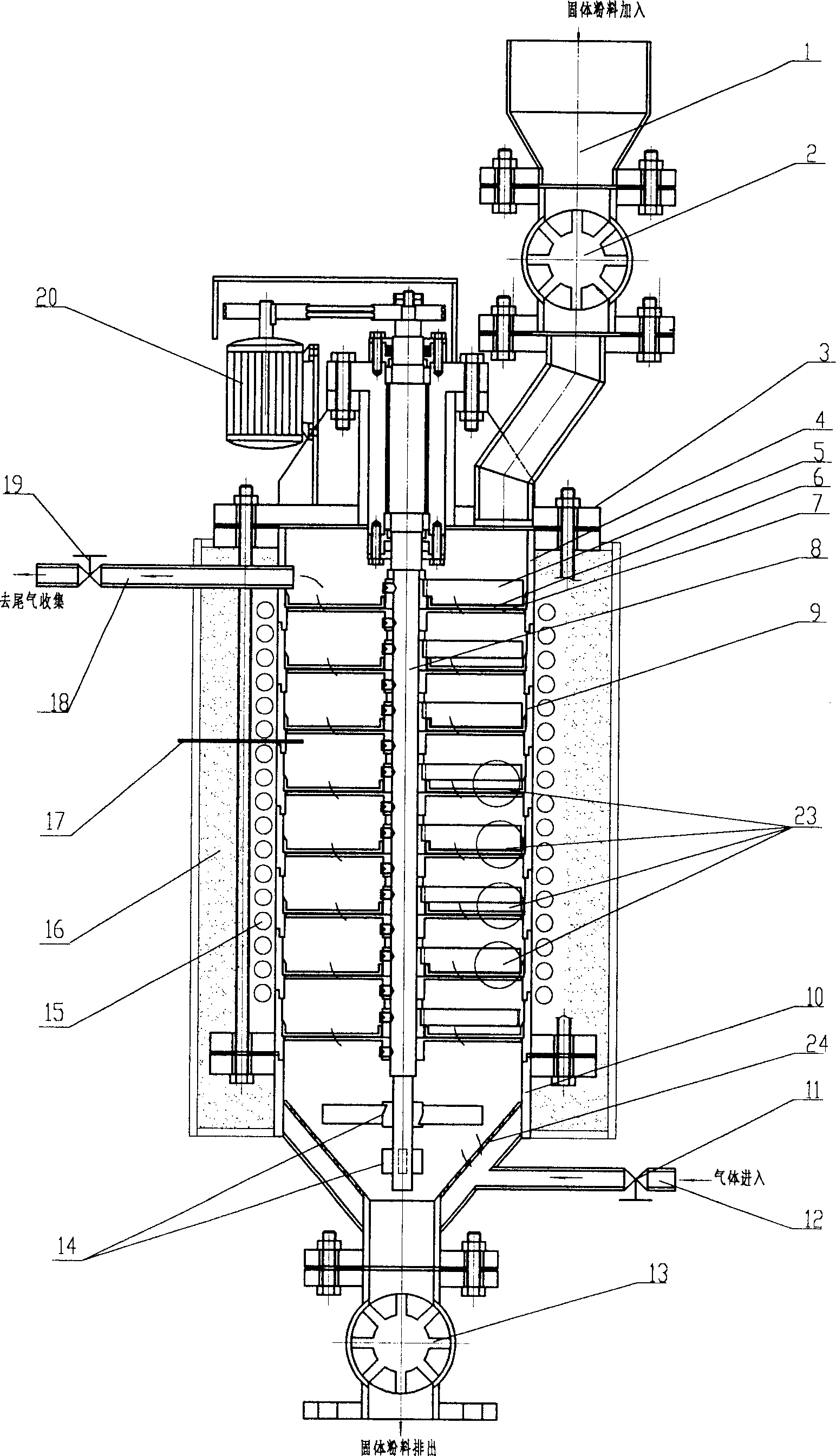

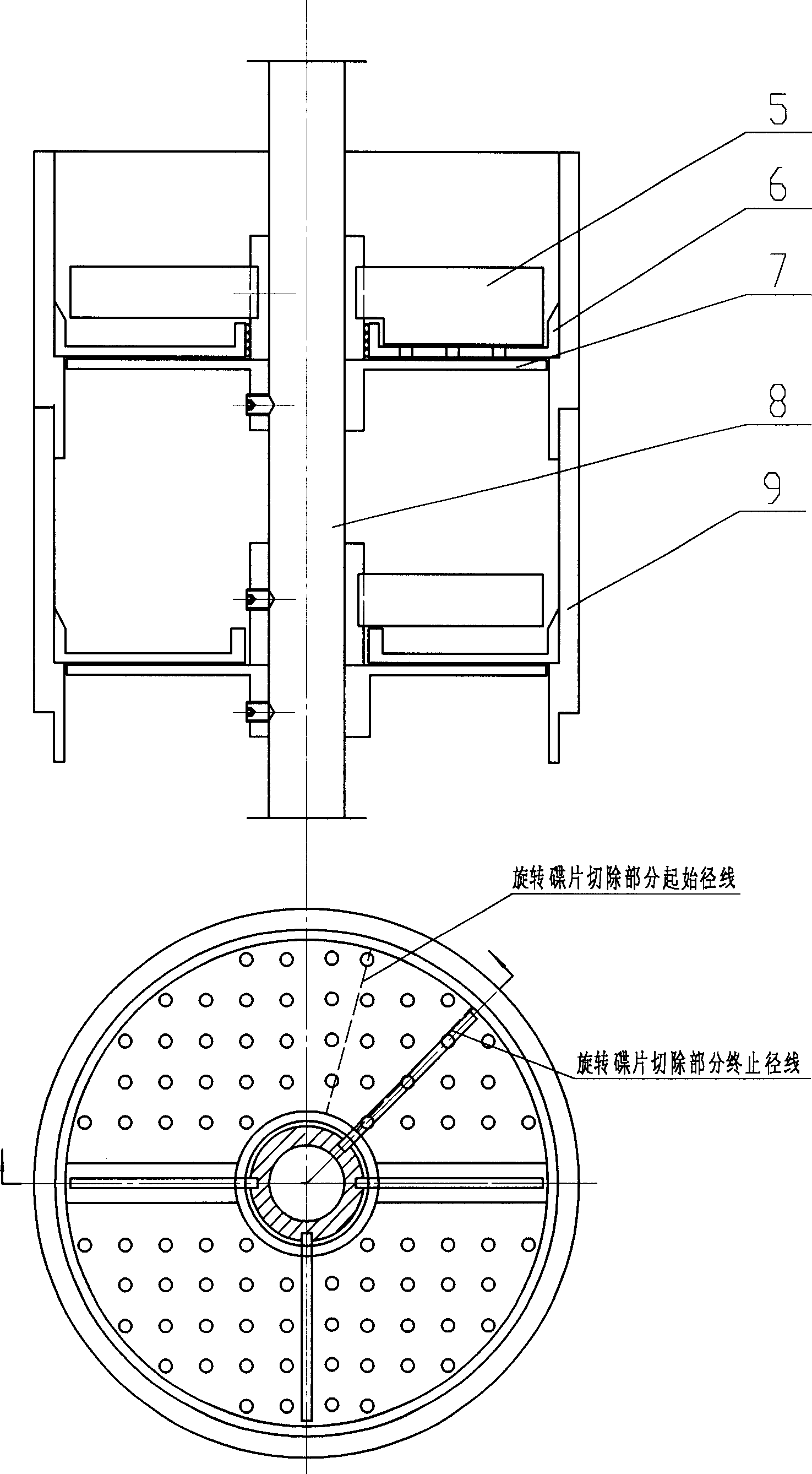

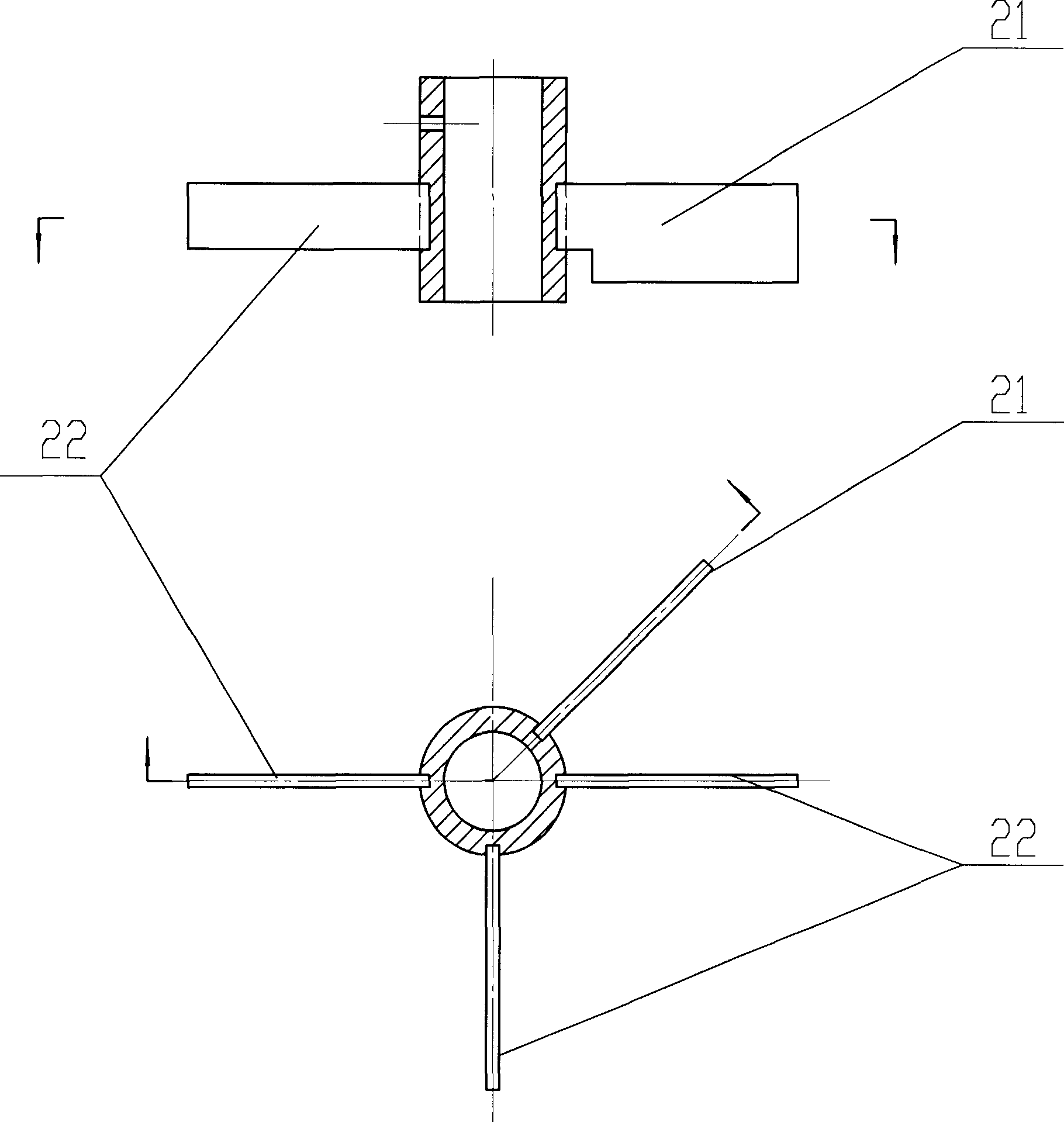

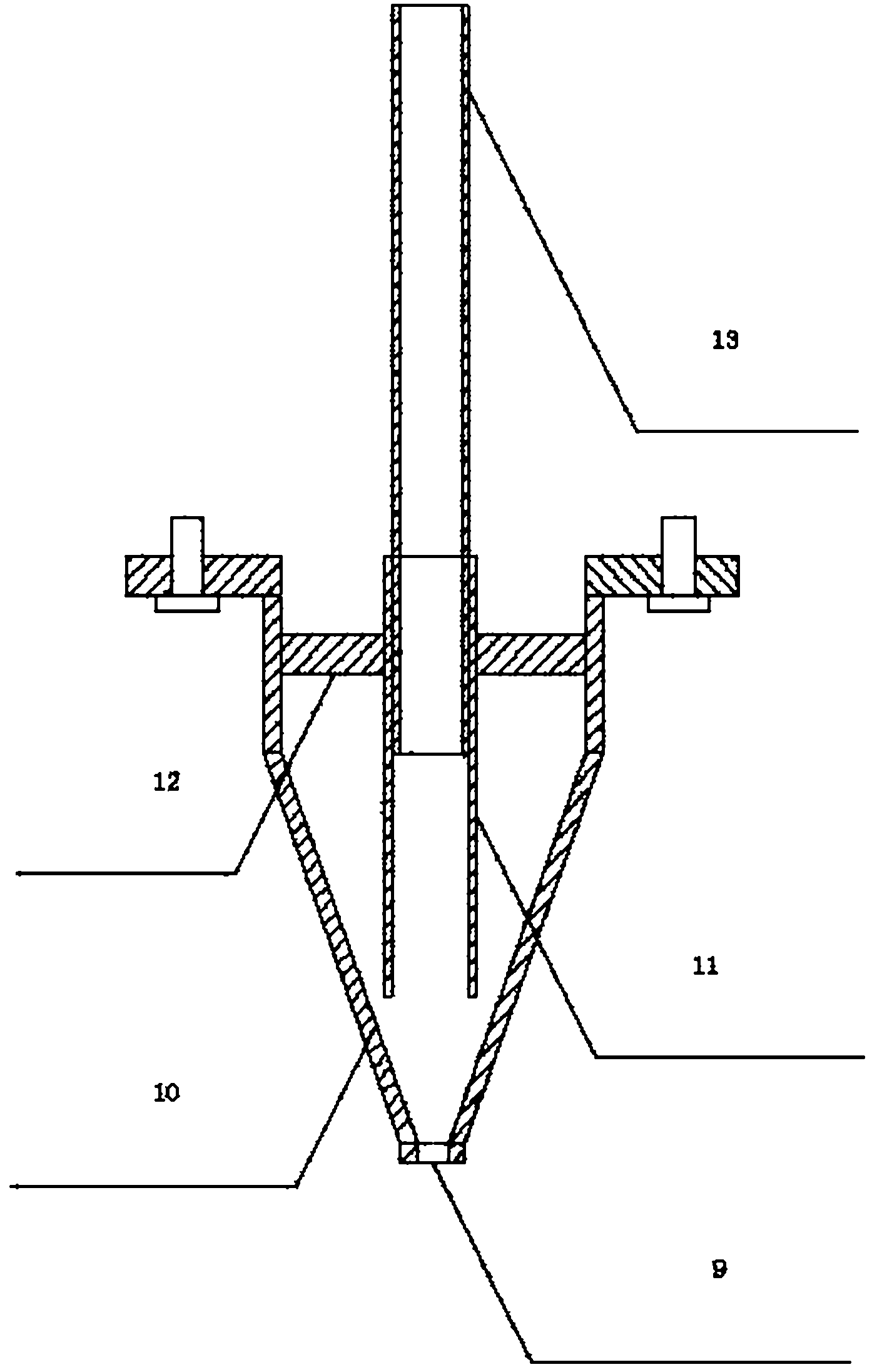

Continuous high temperature gas solid reactor

ActiveCN1765486APrecise control of dwell timeControl dwell timeMixing gases/vapours with solidsChemical/physical/physico-chemical stationary reactorsGas solidNuclear engineering

Disclosed a continuous high temperature gas-solid reactor mainly comprises: a solid material inlet (1), a charging valve (2), a cap cover of reactor (3), a main body of reactor (4), inner element units (23), a main shaft (8), a lower cover of reactor (10), a gas inlet (12), a material outlet (13), and a gas outlet pipe (18). Wherein, said solid material inlet (1) and the charging valve (2) are arranged on the top of reactor; the main body of reactor (4) is in the cylinder shape; the main shaft is arranged on the central axis of said reactor; two or more inner element units formed by mixing oar (5), fixed butterfly blade (6) and rotational butterfly blade (7) are parallel vertically mounted on the main shaft; the gas inlet (12) is arranged on bottom of said reactor while the gas outlet pipe (18) is mounted on the upper part of said reactor and above the inner element units. The invention can accurately control the reaction time, continuously charge and discharge material in the condition of high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemical method of making a suspension, emulsion or dispersion of pyrithione particles

A method for producing a suspension, emulsion or dispersion of de-agglomerated particles (advantageously submicron-sized particles) of pyrithione salts comprising contacting agglomerated pyrithione salt particles with a de-agglomerating agent to produce the desired de-agglomerated pyrithione salt particles. Also disclosed is a method for making de-agglomerated submicron-sized particles of pyrithione salts comprision a heating step. Also disclosed are the particles made by the above methods and compositions comprising the particles and a base medium.

Owner:ARCH CHEM INC

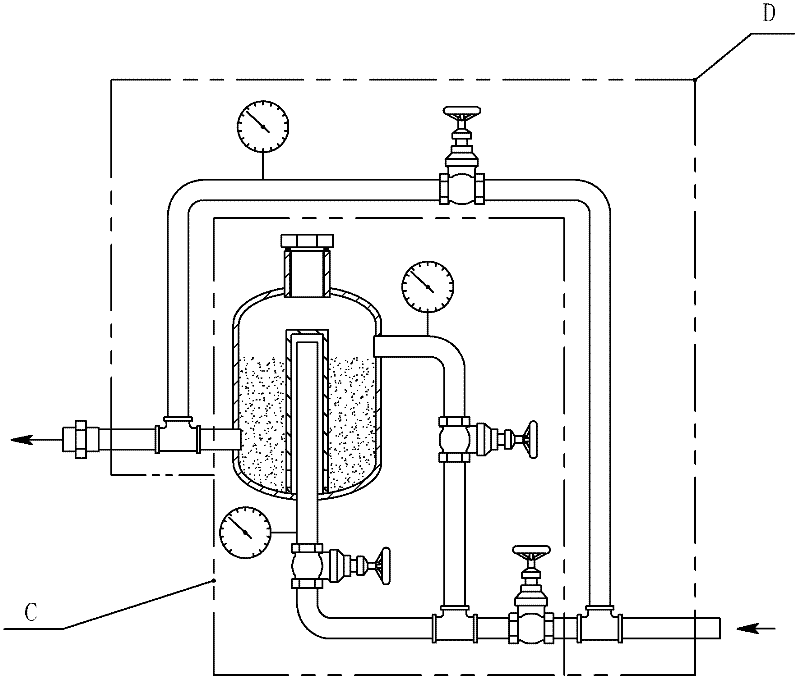

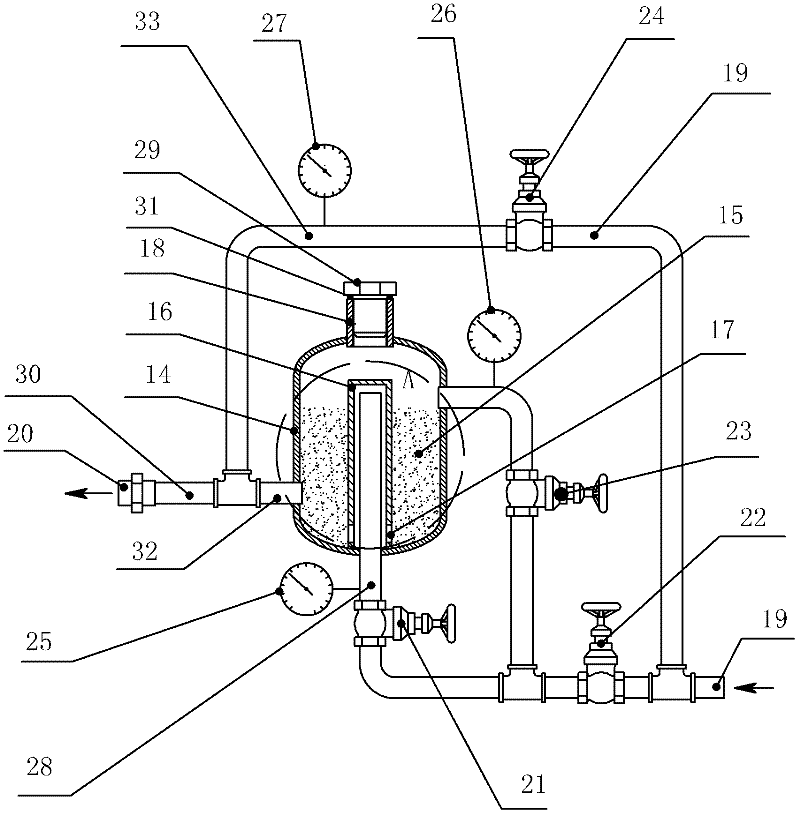

Double-cylinder multi-fluidization circulating type aerosol generator

ActiveCN102658039ASolve agglomerationSolve problems that cannot be used for high-pressure system distributionFlow mixersMixing gases/vapours with solidsEngineeringHigh pressure

The invention aims to provide a double-cylinder multi-fluidization circulating type aerosol generator which comprises an online continuous power supply portion, a powder fluidization and circulation portion, an air circuit control portion, a vibrating motor and a base frame. The online continuous power supply portion, the powder fluidization and circulation portion and the air circuit control portion are connected with one another. The vibrating motor, the online continuous power supply portion and the powder fluidization and circulation portion are all mounted on the base frame. The online continuous power supply portion is further connected with the base frame through support members. The double-cylinder multi-fluidization circulating type aerosol generator is simple to operate, unique in design, widely applicable to various viscous or non-viscous powder samples, and applicable to distribution of high-pressure systems.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Gas-solid reactor

InactiveCN1448211ATake advantage ofImprove mass transfer conditionsMixing gases/vapours with solidsGas solidSpool valve

The gas-solid reactor includes the main parts of main body, solid feeding port, tail gas exhausting port, stirring shaft, stirring blades, truncated cone solid discharger, turned conic gas distributor, screw conveyor, air sealed slide valve and baffle. The main body includes cylindrical upper part and conic lower part; the solid feeding port and the tail gas exhausting port are in the top of thereactor; the stirring shaft with fixed stirring blades is perpendicular to the central axis of the reactor; the inner wall of the reactor has one or several layers of baffles set; the solid discharger is in the lower part of the reactor; the gas distributor with homogeneously distributed holes is below the solid discharger; and the bottom of the reactor is connected to the screw conveyor; and theslide valve is set on the material discharging pipe of the screw conveyor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid dust aerosol generation device and method

InactiveCN107670518AReduce exposed areaNot easy to polluteTransportation and packagingMixersDust particlesMixing chamber

The invention provides a solid dust aerosol generation device and method. The aerosol generation device comprises an ash storage chamber, a mixing chamber, a Venturi tube and a rotating disk; the rotating disk is arranged between the ash storage chamber and the mixing chamber; a plurality of conveying pits are arranged on the side surface of the rotating disk, the conveying pits on the side surface of the rotating disk are filled with dust particles in the ash storage chamber and then enter the mixing chamber from the top of the rotating disk, the conveying pits return to the ash storage chamber from the bottom of the rotating disk, and negative pressure is generated in the mixing chamber by gasflow passing through the Venturi tube, so that the dust is absorbed from the mixing chamber andcan form stable aerosol after being sprayed out of the Venturi tube along with the gasflow. The solid dust aerosol generation device is more suitable for being used under the conveying conditions of fine dust and low-flow dust, is simple and compact in structure, low in cost and high in precision; the generated solid dust aerosol is distributed uniformly and has stable quality.

Owner:CHANGAN UNIV

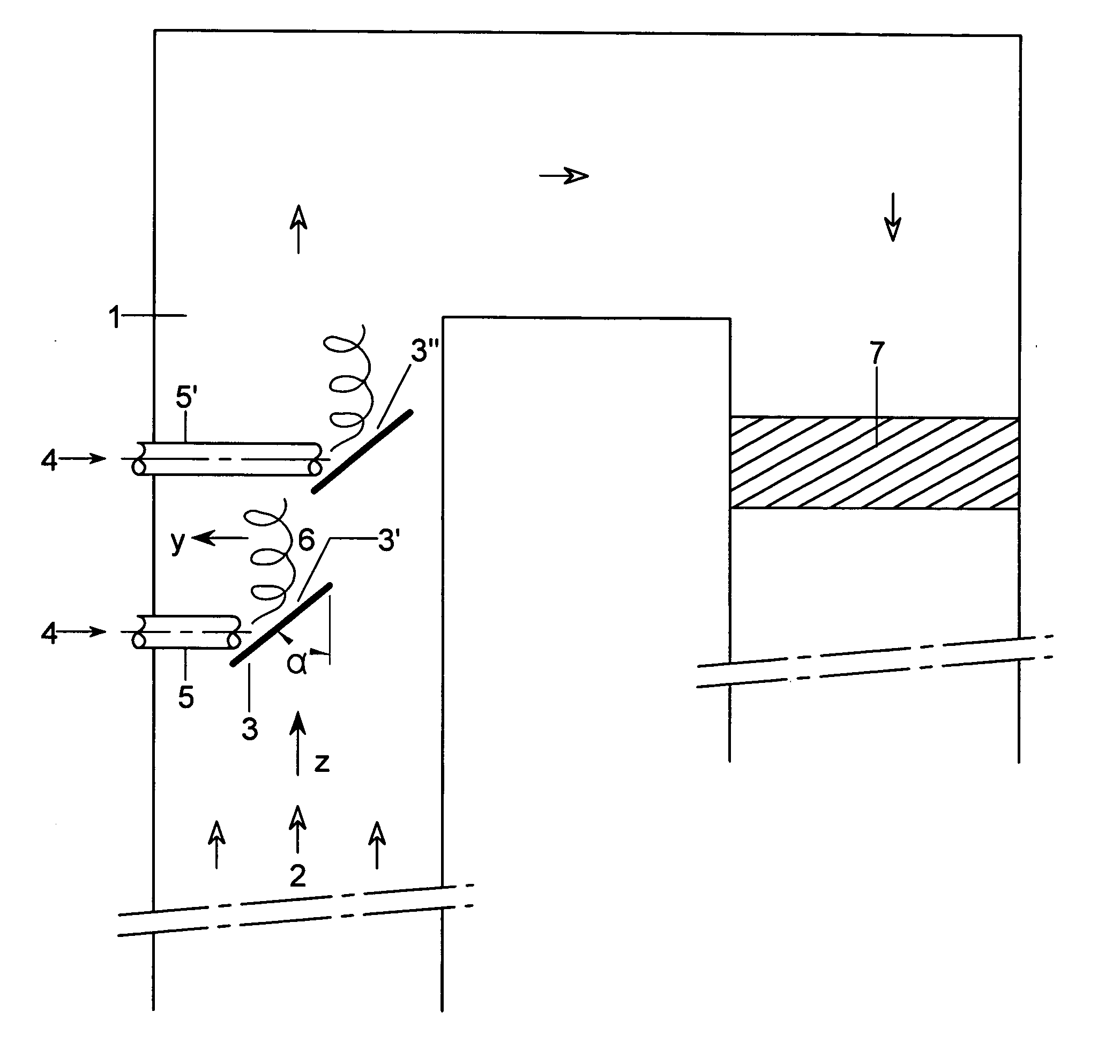

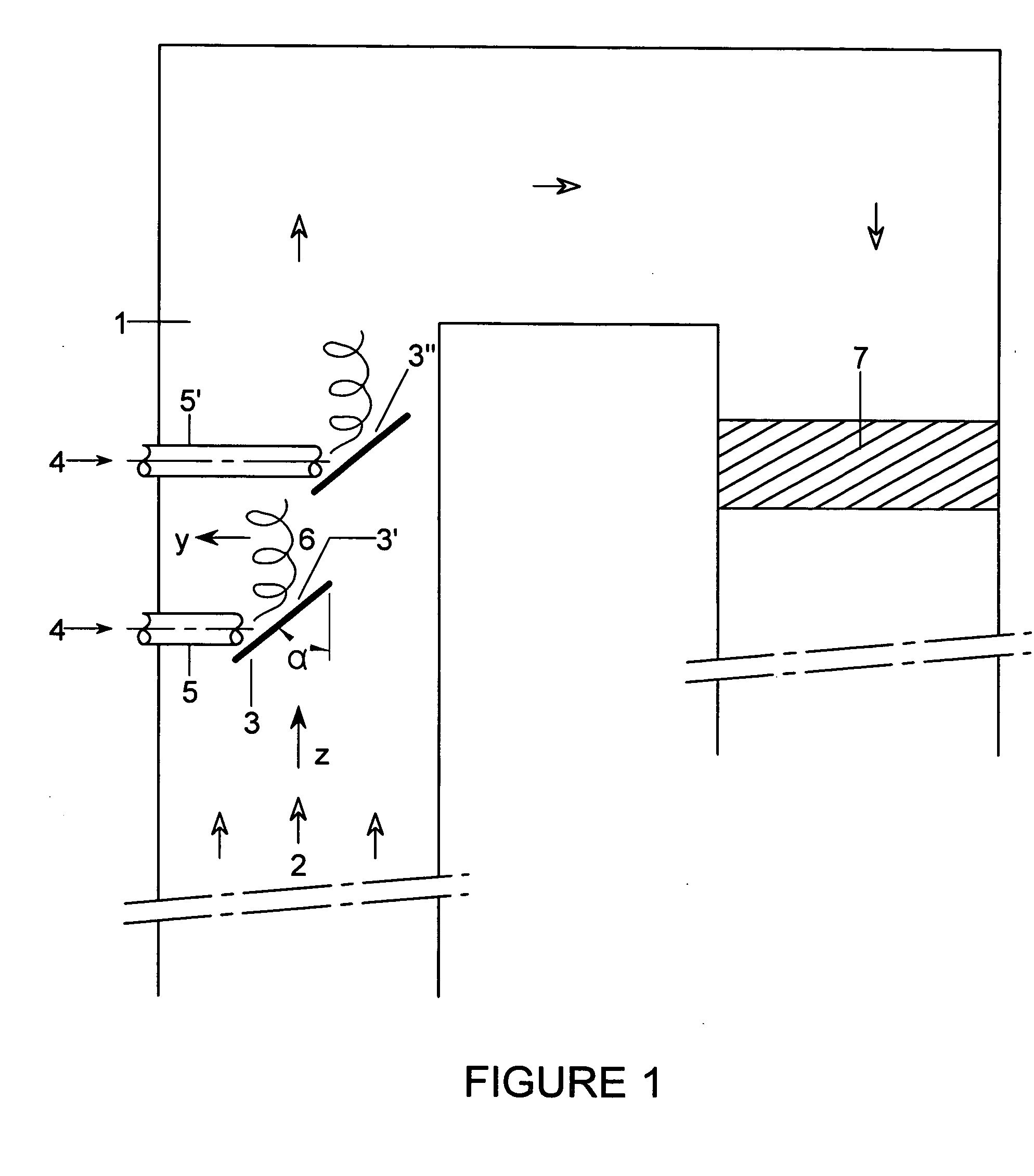

Arrangement for mixing of fluid streams

ActiveUS20050190643A1Prevent backflowReduce total pressure lossFlow mixersTransportation and packagingEngineeringMechanical engineering

An arrangement for mixing fluid streams in a duct, said arrangement comprising: at least one mixing device having front side and back side and positioned within said duct through which a first major stream travels, the at least one mixing device determining a total cross-sectional area which is significantly lower than that of the duct so as to allow for the passage of said first major stream, in which the at least one mixing device is a solid plate provided with one or more protrusions extending outward from the main solid plate body.

Owner:HALDOR TOPSOE AS

Disc type dust dispersedly generating apparatus using capacity quantitative dry method

InactiveCN1557534ANo choiceNon hygroscopicMixing gases/vapours with solidsCircular discFrequency changer

The constant-volume dry dust distributing apparatus consists of dust storing bin, material supplying disc, driving motor, powder sucking sprayer and other parts. It has motor driving the controlling box with frequency converter via cable, the material supplying disc with one circular groove in trapezoidal cross section, the dust storing bin with an inner stirring conveyer, the controller connected to the dust storing bin and the material supplying disc and with some small hole, the material guide unit set at the small hole and on the groove of the material supplying disc and crushing filler set also on the groove of the material supplying disc. The rotating shafts of the motor, the material supplying disc and the stirring conveyer are connected directly; and the powder sucking sprayer consists of material sucking nozzle, blowing pipe and sucking and blowing fan. The apparatus has features great dust distributing capacity, wide regulation range, etc.

Owner:中钢集团天澄环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com