Rotating disc type dust aerosol generating device

An aerosol generation, turntable technology, applied in the directions of dissolution, gas/vapor and solid mixing, mixers, etc., can solve the problem of inability to generate continuous high-concentration fine particle dust aerosols, unable to simulate the continuous distribution of nanomaterials and dust aerosols situation, inability to carry out scientific testing and calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

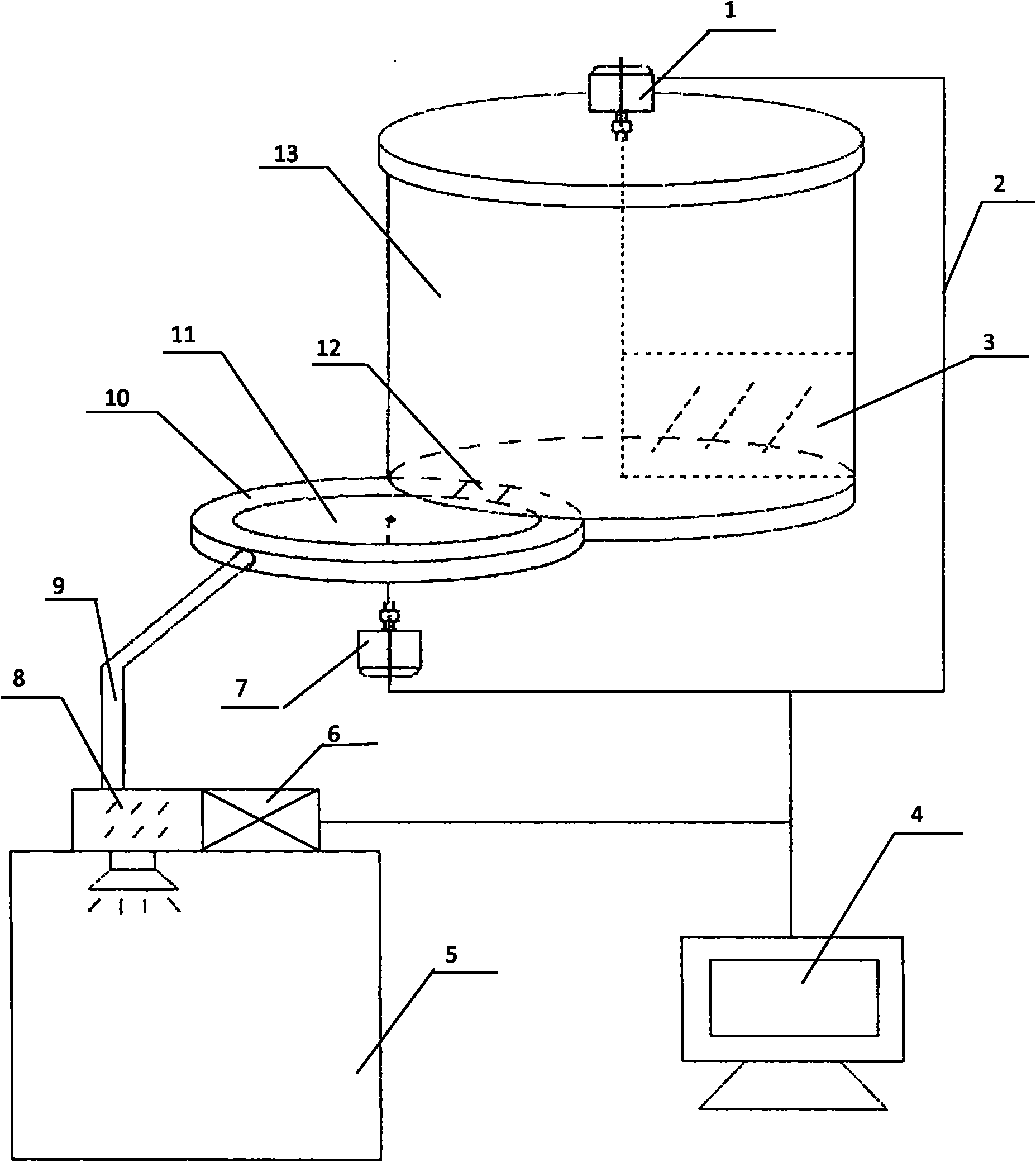

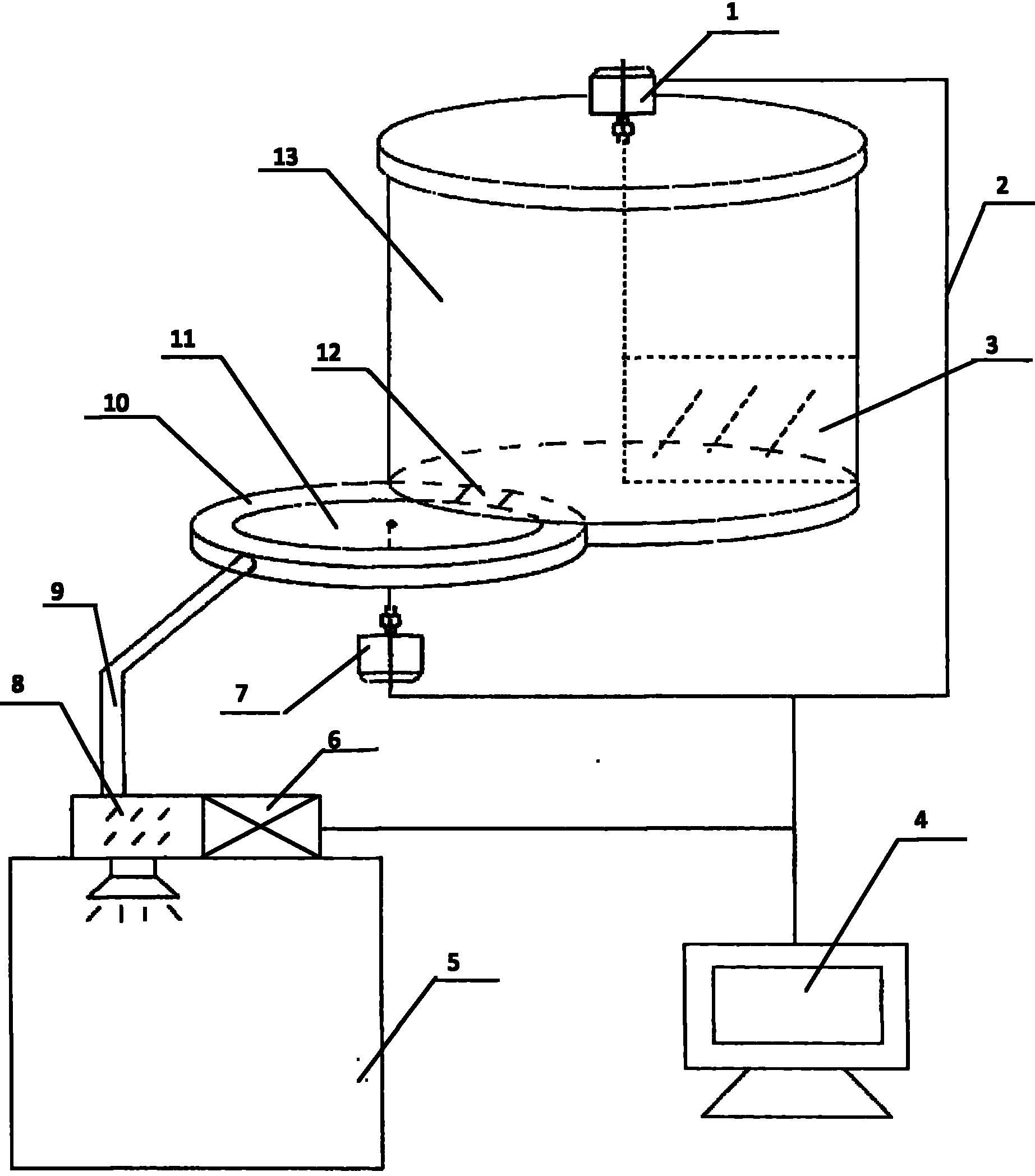

[0022] The present invention is described with reference to the drawings and embodiments.

[0023] As shown in the drawings, the device includes a stirring motor (1) controlled by a computer (4) to drive the stirring plate (3) in the flow bin (13) to rotate, to stir the internal dust evenly and transport it to the flow bin (13). In the pit (10) specially carrying dust on the rotating disk (11) below the bottom leakage hole (12). The amount of dust to be transported can be precisely controlled by selecting a rotating disc (11) with a suitable width of the pit (10). The rotating disk (11) rotates to transport the dust to the negative pressure powder suction pipe (9), and the amount of dust to be conveyed can be further accurately controlled by selecting different rotational speeds of the rotating disk (11) through computer control. The negative pressure generator (6) controlled by the computer (4) sucks the dust carried in the pit (10) on the rotating disk (7) into the powder s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com