Patents

Literature

142 results about "Back-fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A back-fire or backfire is combustion or an explosion produced by a running internal combustion engine that occurs in the air intake system rather than inside the combustion chamber. Unburnt fuel that is ignited in the exhaust system can produce loud sounds even if flames are not present at the tailpipe. This is called an afterburn or after-fire since a backfire occurs through the intake system. A visible flame may momentarily shoot out of the exhaust pipe under some conditions. Either condition may cause a loud popping noise and usually indicates an improperly tuned engine.

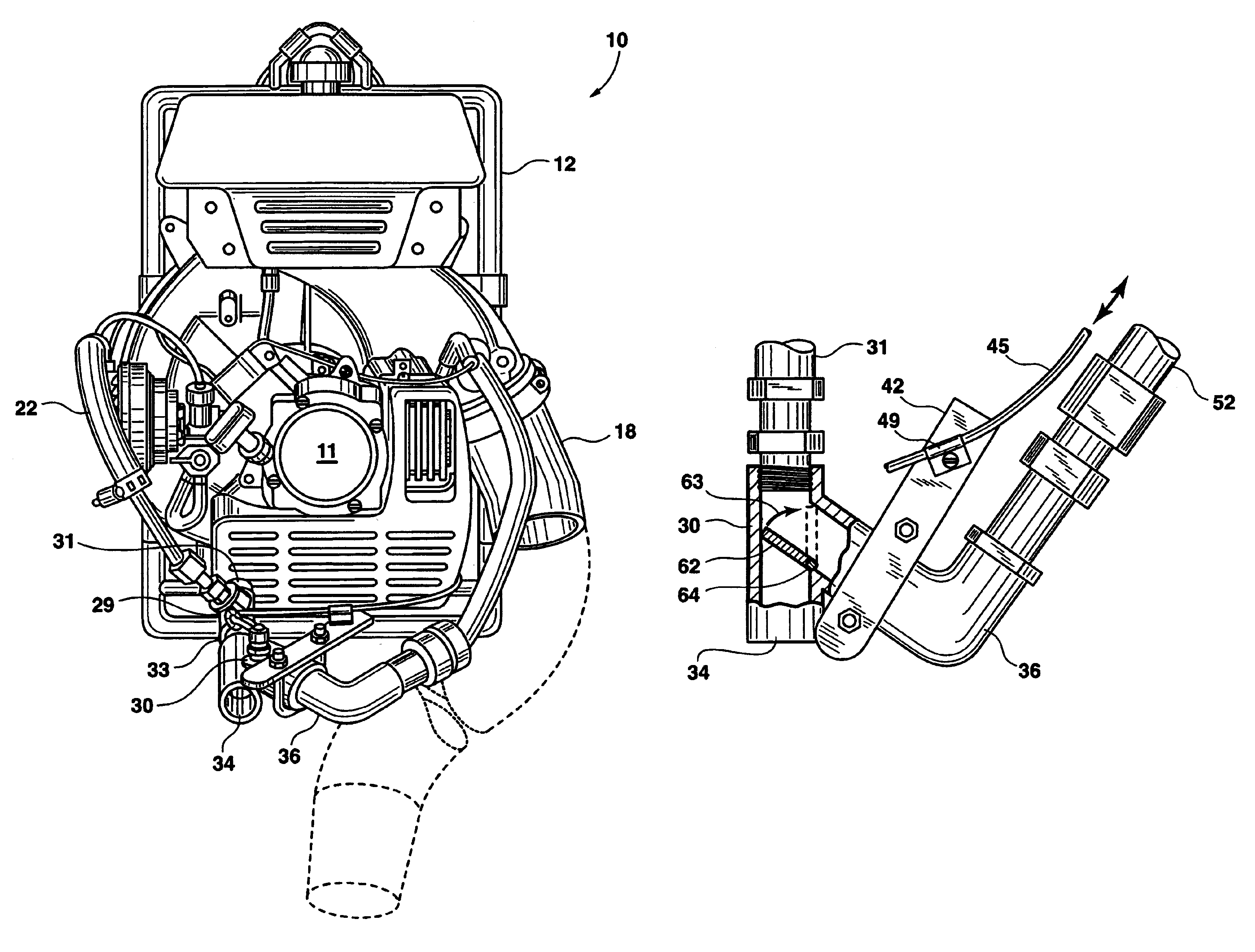

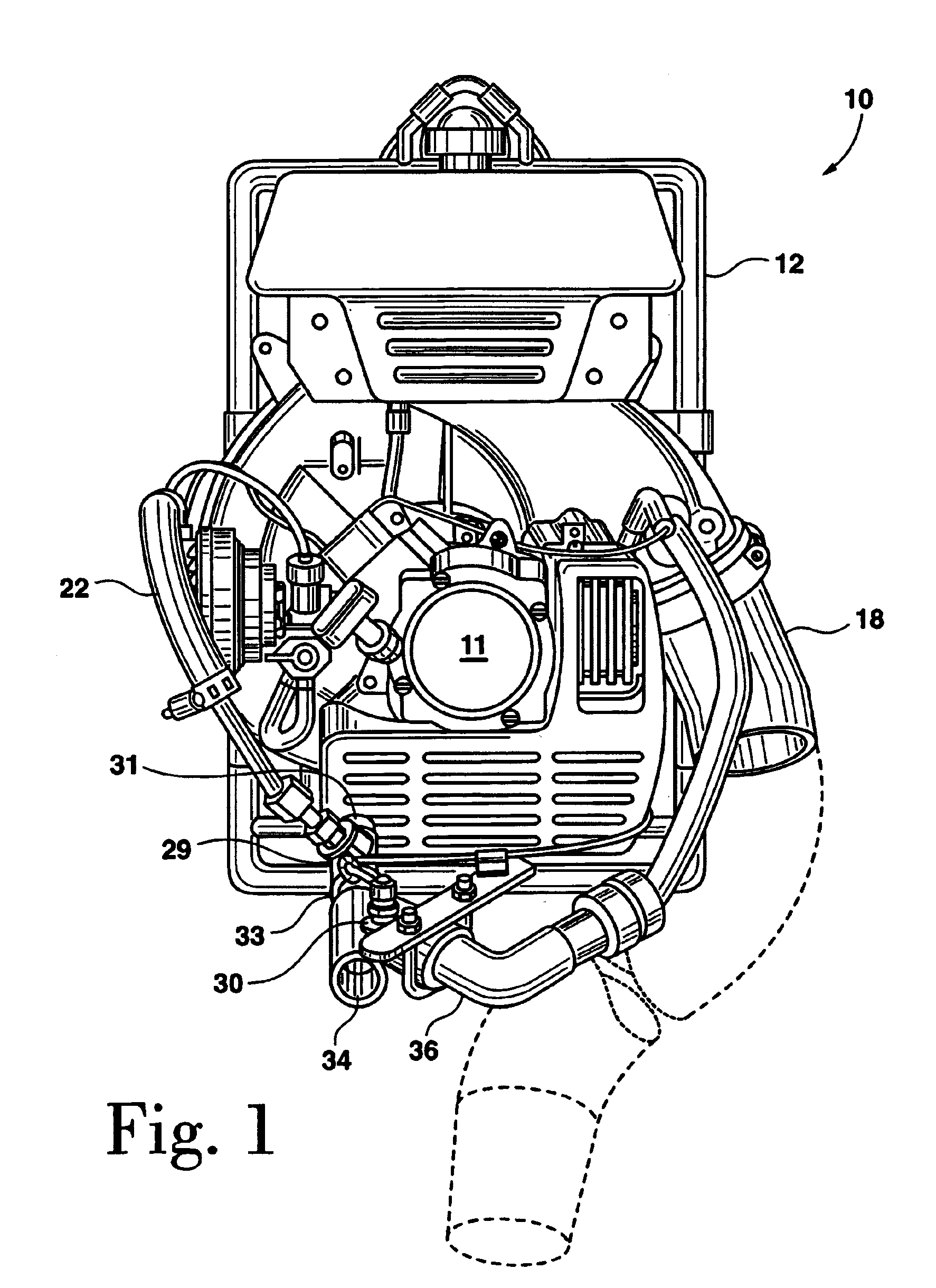

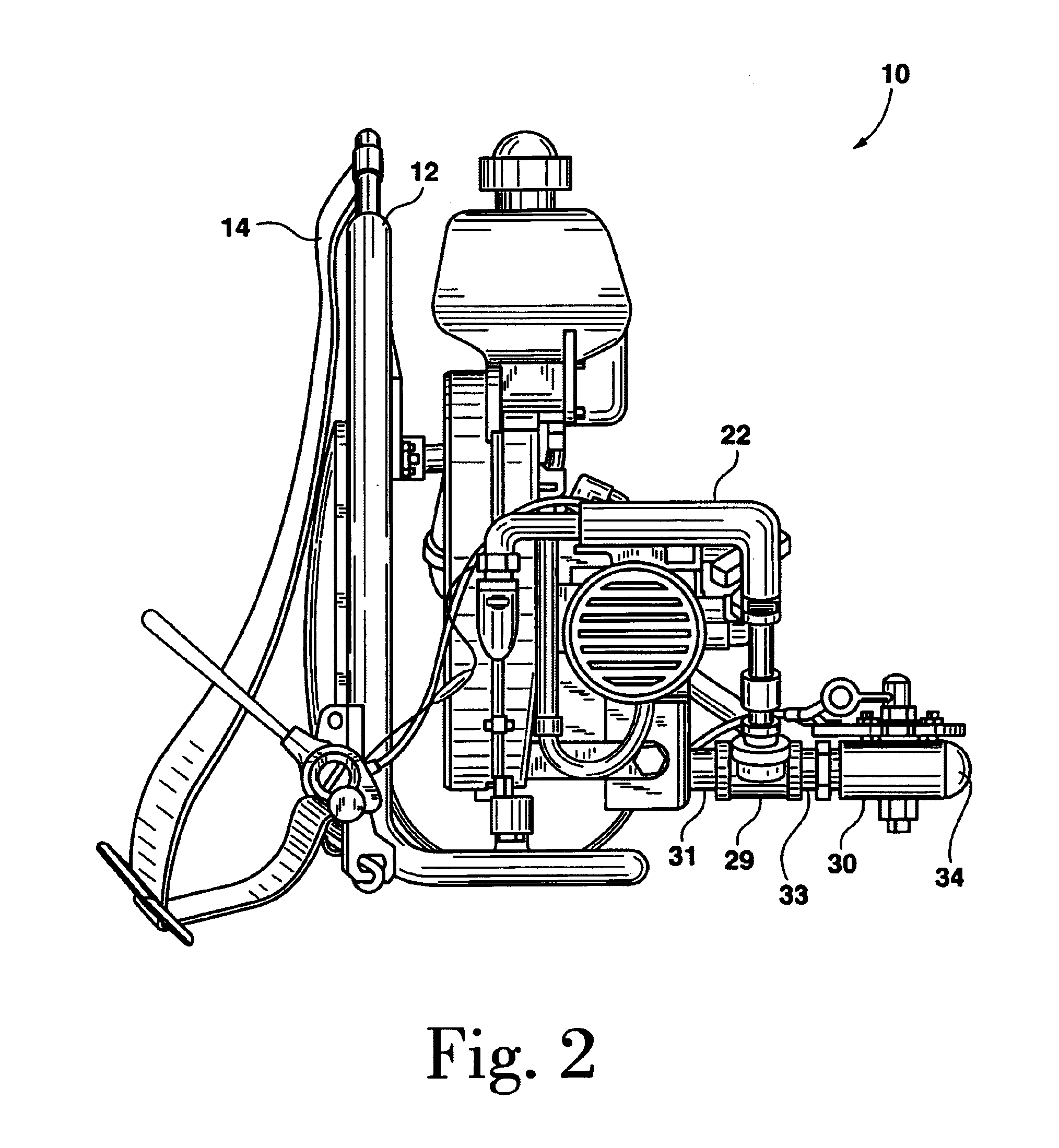

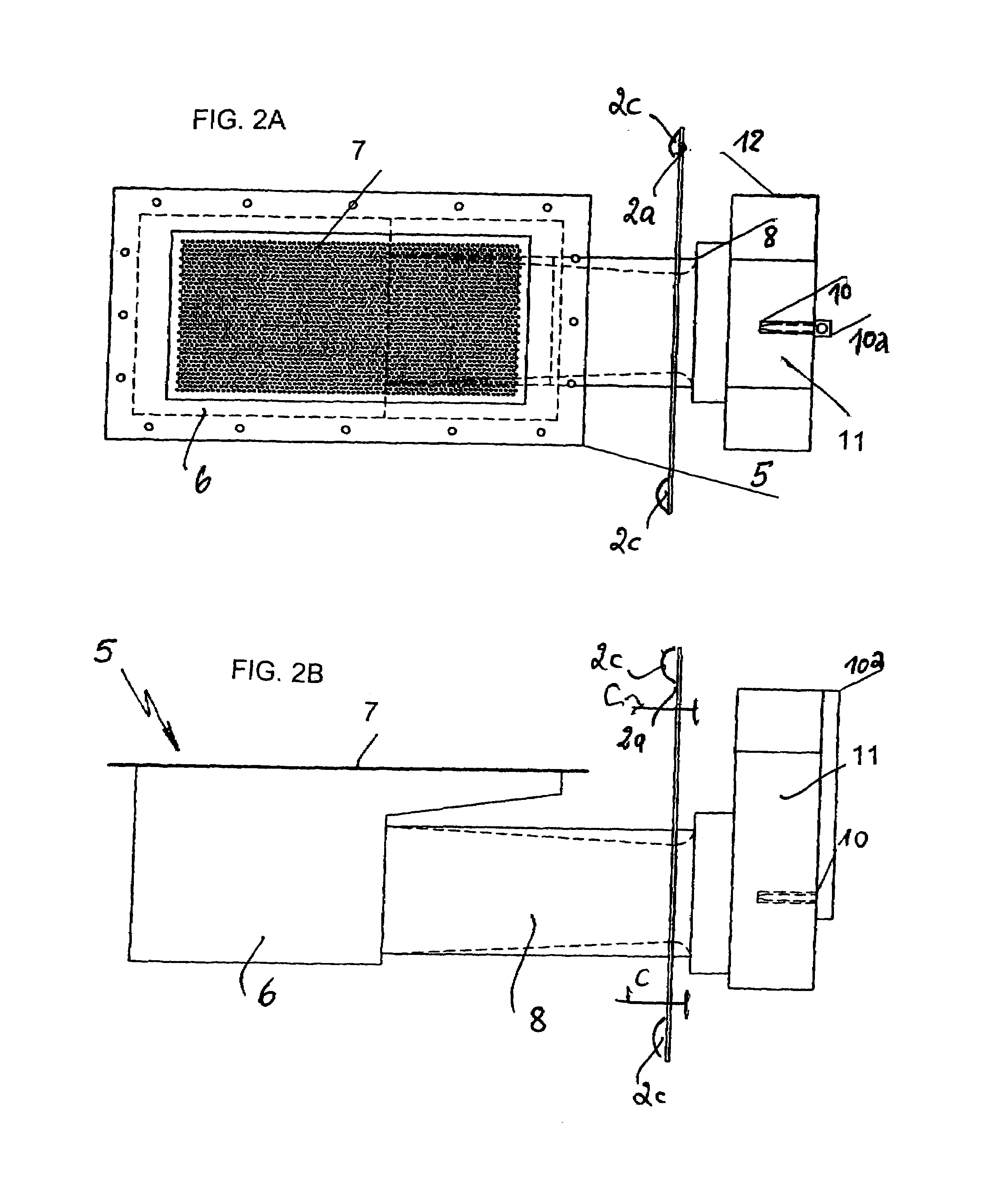

Air blower for extinguishing fires and method for extinguishing fires

The invention employs a blower of the type used by commercial landscapers. The device has an engine mounted on a frame. Shoulder straps attached to the frame allow the user to wear the device on his back leaving the hands of the operator free to operate other tools such as a chain saw or perform other tasks. Also, wearing the device on the back makes it easier to transport the device over long distances to the source of the fire or backfire to be started.The device's blower generates a stream of air at high speeds. This stream of air can be used to feed a fire when the air is directed at a fire. When used to extinguish a fire, air from the blower is tapped from a point 180 degrees removed from the blower output and mixed with exhaust from the engine. This mixture is diverted through a Y-shaped valve into the airstream coming out of the blower. When the device is used to start backfires a fire is started. The airstream, without the mixture of air and engine exhaust can be used to both encourage the propagation of the fire and direct the fire towards the main wild fire. The ability to quickly spread the backfire in the proper direction is imperative because a sudden change in wind direction or other weather conditions could cause the backfire to become as big a problem as the original fire.

Owner:EBNER EDWIN D

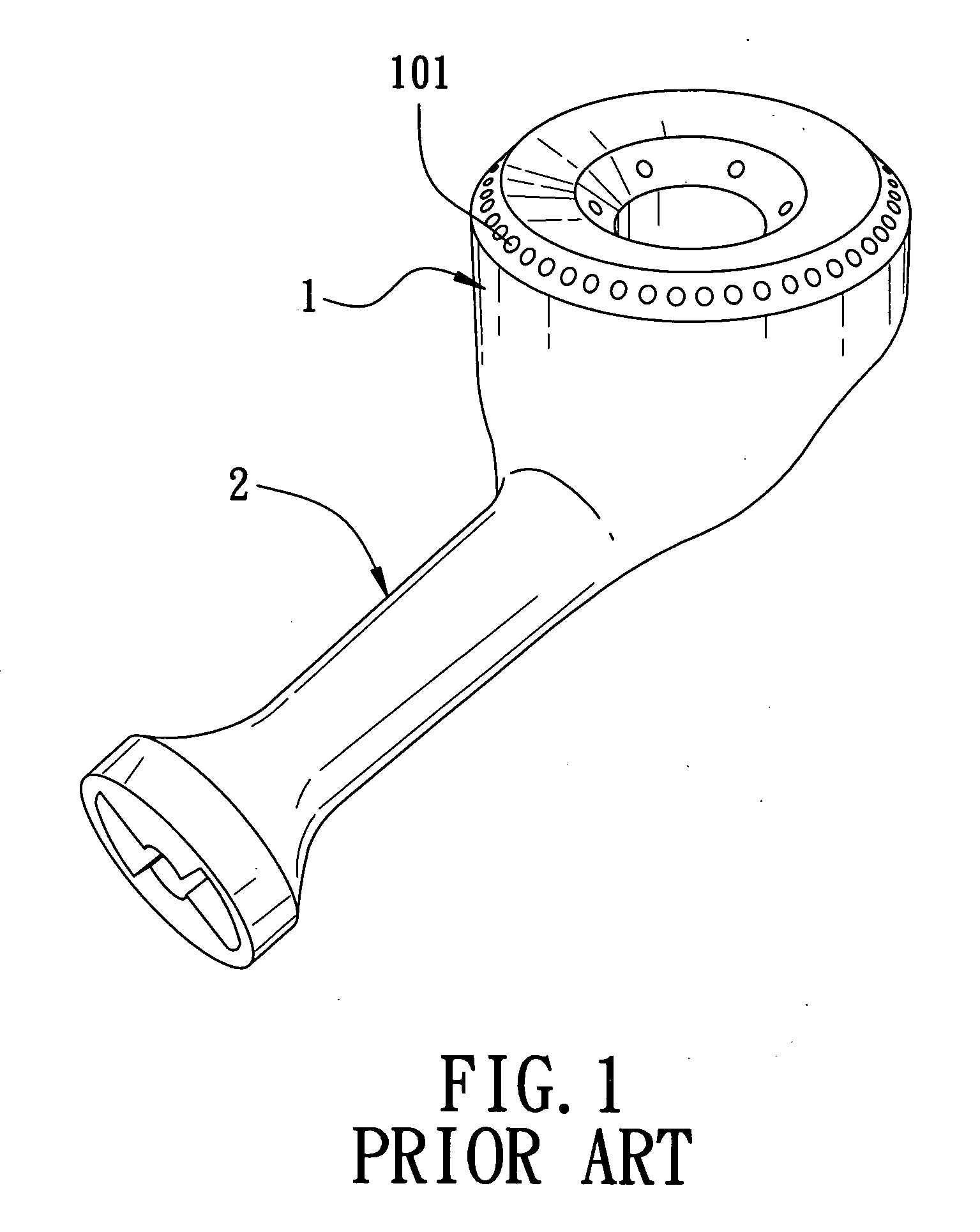

Gas burner

InactiveUS20070059657A1Low costAvoid it happening againBurner manufactureGaseous fuel burnerBack-fireEngineering

A gas burner includes a looped head seat formed by punching a metal plate, and defining therein a surrounding duct therein which is fluidly communicated with a gas conduit for supplying fuel gas to the surrounding duct, and a looped burner cap engaged with the head seat to define a partition space therebetween. One of inner and outer surrounding regions of an upper wall of the head seat has a plurality of intercommunicating ports, whereas one of corresponding inner and outer surrounding regions of an upper cap wall of the burner cap has a plurality of discharging orifices such that the fuel gas in the surrounding duct is guided to flow through the intercommunicating ports into the partition space and is discharged through the discharging orifices. By means of the arrangement of the ports and the orifices, occurrence of backfires in the surrounding duct can be prevented.

Owner:YEN CHIA HSI

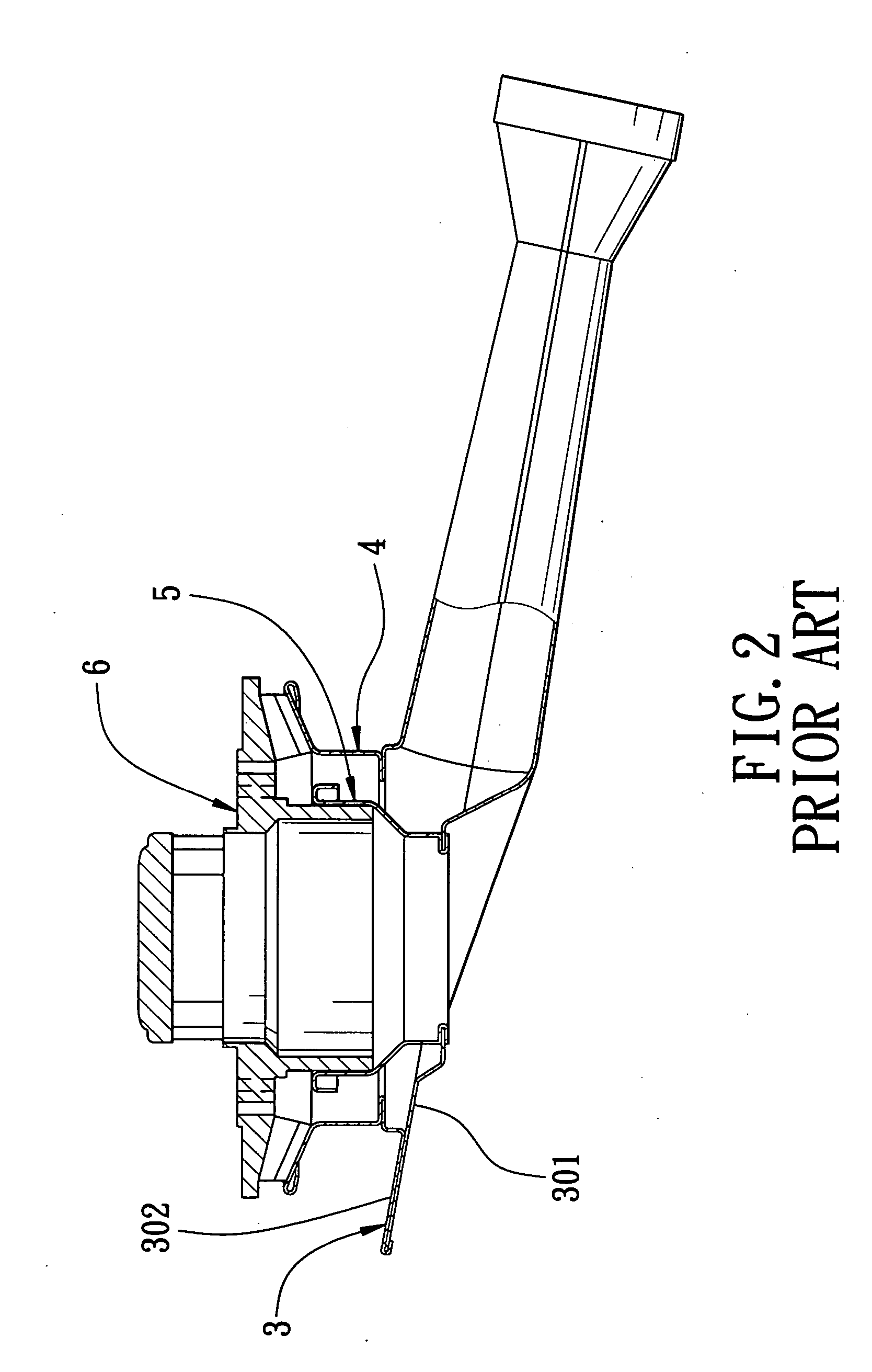

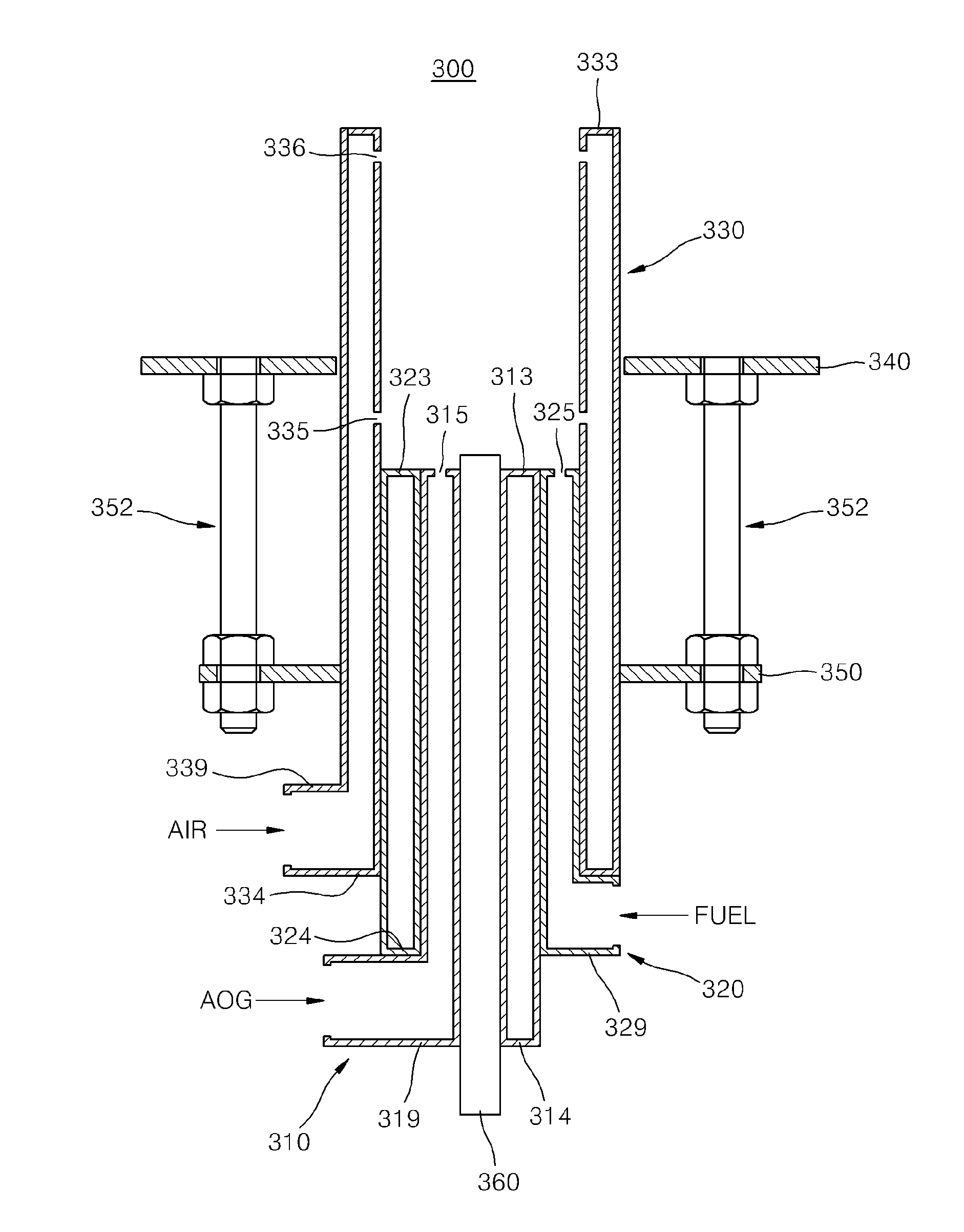

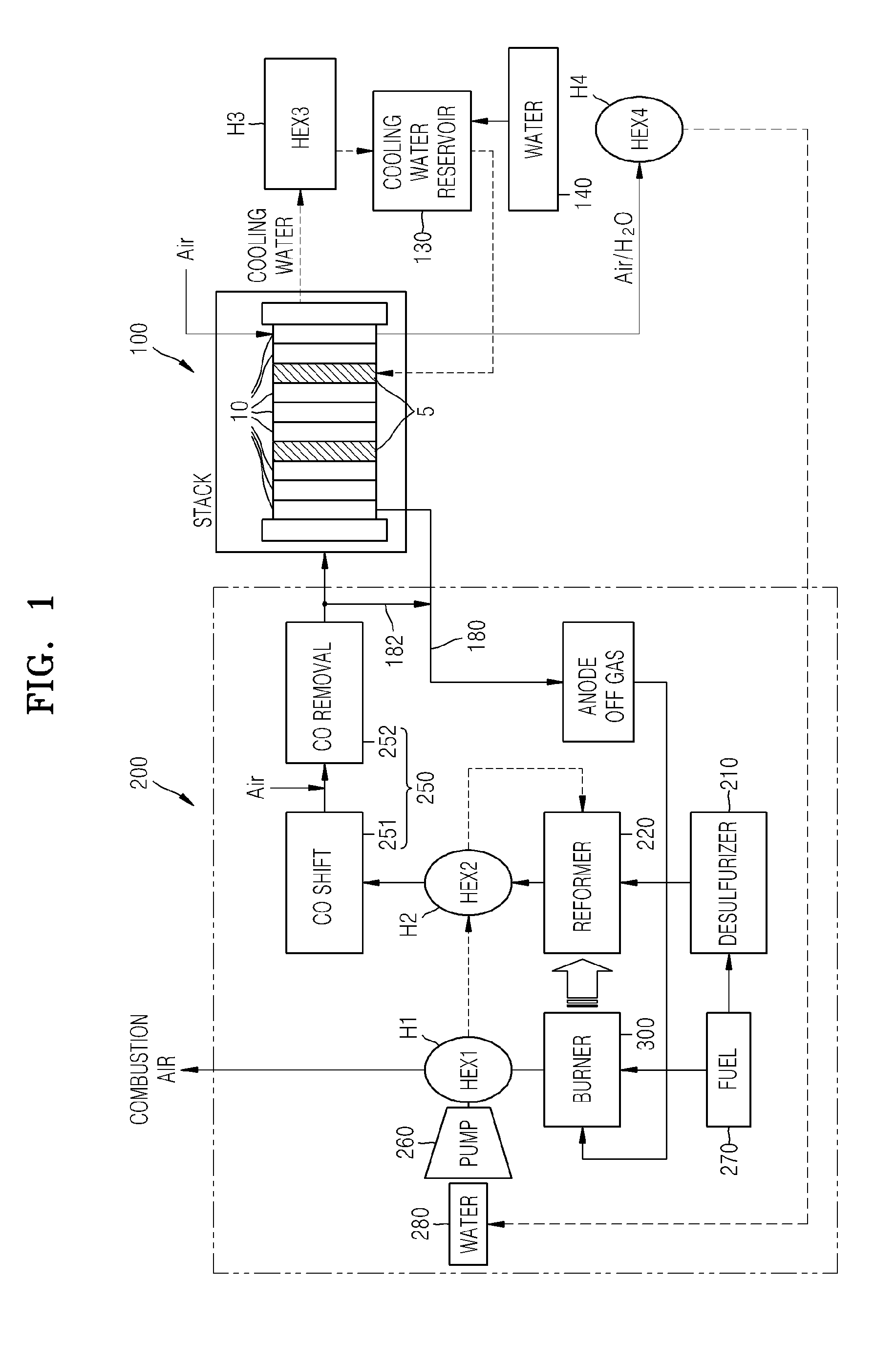

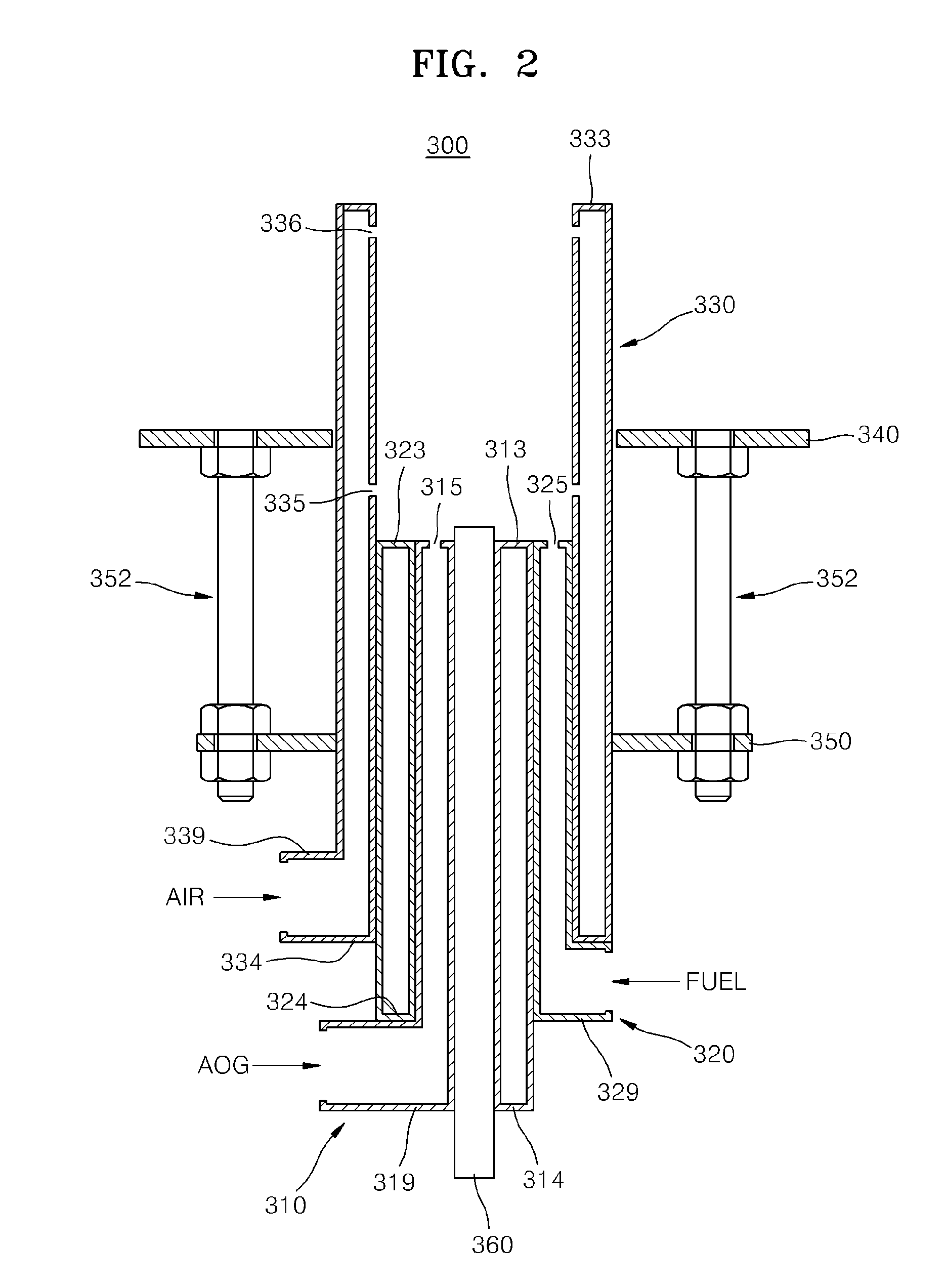

Fuel reformer burner of fuel cell system

A fuel reformer burner in which fuel gas and anode-off-gas (AOG) may be burned and backfire may be prevented during combustion of AOG includes a fuel supply portion, an anode-off-gas (AOG) supply portion; and a combustion air supply portion. The fuel supply portion and the AOG supply portion are arranged inside the combustion air supply portion, which is formed to extend beyond the discharge sides of the fuel supply portion and the AOG supply portion.

Owner:SAMSUNG ELECTRONICS CO LTD

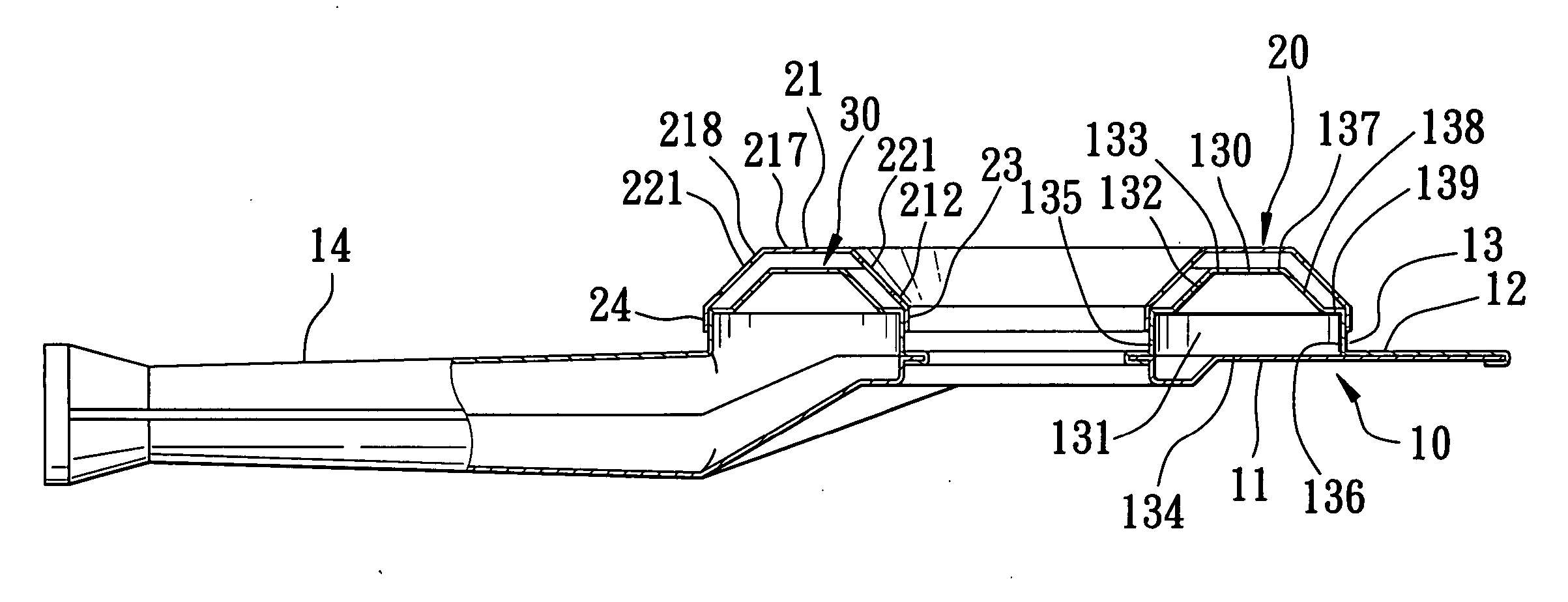

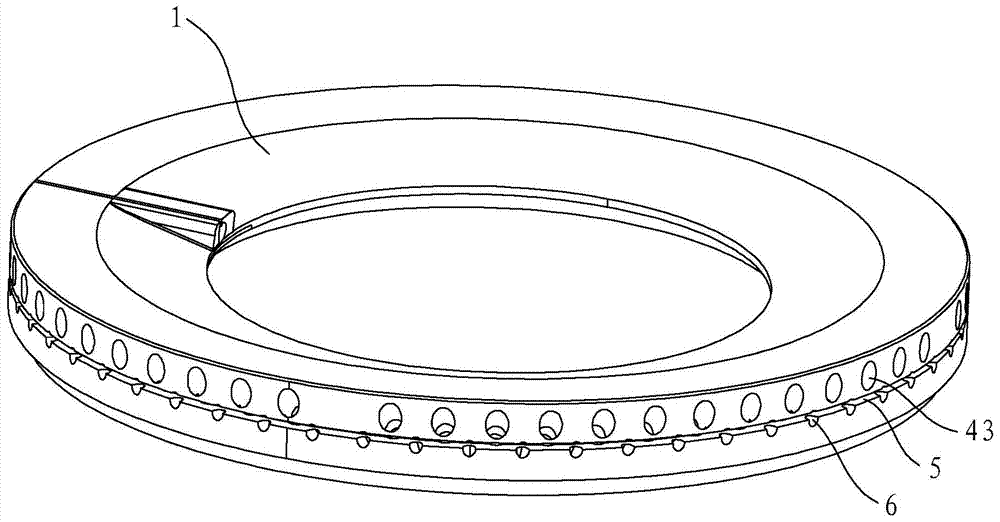

Burner fire cover used for gas cooking appliance and burner with fire cover

The invention discloses a burner fire cover used for a gas cooking appliance and a burner with the fire cover. The burner fire cover comprises a fire cover body. The fire cover body comprises annular side walls with fire holes. The burner fire cover is characterized in that at least two annular side walls are arranged, the corresponding fire holes are formed in each layer of annular side wall, and a gap is reserved between every two adjacent annular side walls to form a buffering layer. Compared with the prior art, the burner fire cover has the advantages that the buffer layers are formed between the adjacent side walls, after gas is buffered through the buffering layers in the process of flowing out of the fire holes in the outer layer annular side wall from the fire holes in the inner layer annular side wall, the blow-off limitation can be extremely increased, the back-fire limitation can be extremely reduced, and in other words, the adaptability of the gas can be improved on the premise of not increasing the depth of the fire holes; accordingly, according to the burner with the burner fire cover, gas in a gas mixing chamber of the burner can sequentially pass the gas mixing cavity and the fire holes in the inner layer annular side wall and then enters the buffering layer on the innermost side, and the adaptability of gas is improved after buffering is sequentially conducted through the multiple buffering layers.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Back-fire relief bag

InactiveCN1565673ASimple production processImprove fire resistanceFire rescueBoring toolsGlass fiberBack-fire

A fire retardant bag belonging to the fireproof sealing material field is disclosed. It relates to a bag shape fireproof material for solving problem of the complicated manufacturing technique, large investment, heavy weight and inconvenient uses of the fire retardant bag anti flaming fire proof materials. The fire retardant bag is made through enwrapping the antiflaming fireproof materials in the antiflaming bag. The antiflaming fireproof material is made by mixing the components in weight ratio as follows: chlorethene chlorovinylidene10-20, ammonium polyphosphate fire retardant 15-25, expandable graphite6-16, hollow microsphere 5-10, hydroxyethyl cellulose 1-4, calcium carbonate 20-30, water 8-15. The material of the antiflaming package is of close meshed hypo alkaline / non alkaline glass fiber cloth, the inner packaging bag of the antiflaming package bag is of thick type plastic bag. It is suitable for the fire partition or fireproof barrier of cable tunnel and cable shaft in electric power plants, electric substations, factory buildings and tall buildings.

Owner:应急管理部四川消防研究所

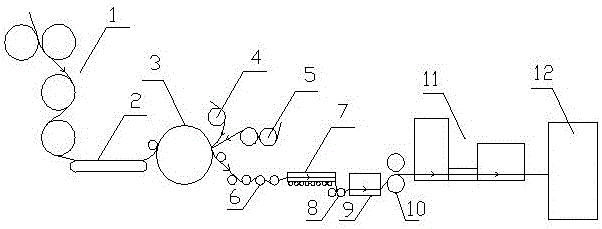

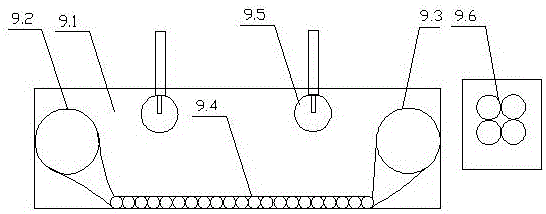

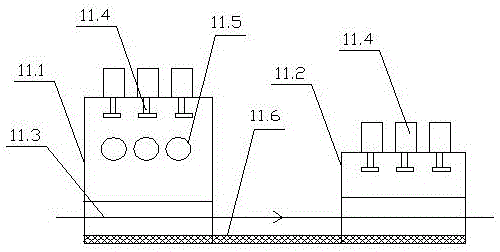

Production equipment for PVC composite coated floor

ActiveCN106218184AImprove stabilityImprove compactnessLamination ancillary operationsLaminationBack-fireEngineering

The invention relates to production equipment for a PVC composite coated floor. The production equipment comprises a cooling roller set used for cooling a PVC base layer obtained after rolling, an outlet of the cooling roller set is connected with the front end of a composite roller through a conveying belt, a printing layer lead-in roller and abrasion layer lead-in rollers are arranged at the rear end of the composite roller, an outlet of the composite roller is connected with a heating device through a conveying roller set, corresponding lines are formed on the surface of a PVC film heated through the heating device through an embossing roller, a cooling and shaping device for cooling and shaping the PVC film is arranged at an outlet of the embossing roller, the PVC film out of the cooling and shaping device is subjected to surface treatment with a UV device, a back-fire device is arranged on a rear channel of the UV device, and the PVC film out of the back-fire device enters a cutting machine to be cut. The investment of the equipment can be reduced, and the production process can be simplified; meanwhile, the stability, smoothness and abrasive resistance of the composite floor can be ensured, and the service life can be prolonged.

Owner:江阴市富华包装材料有限公司

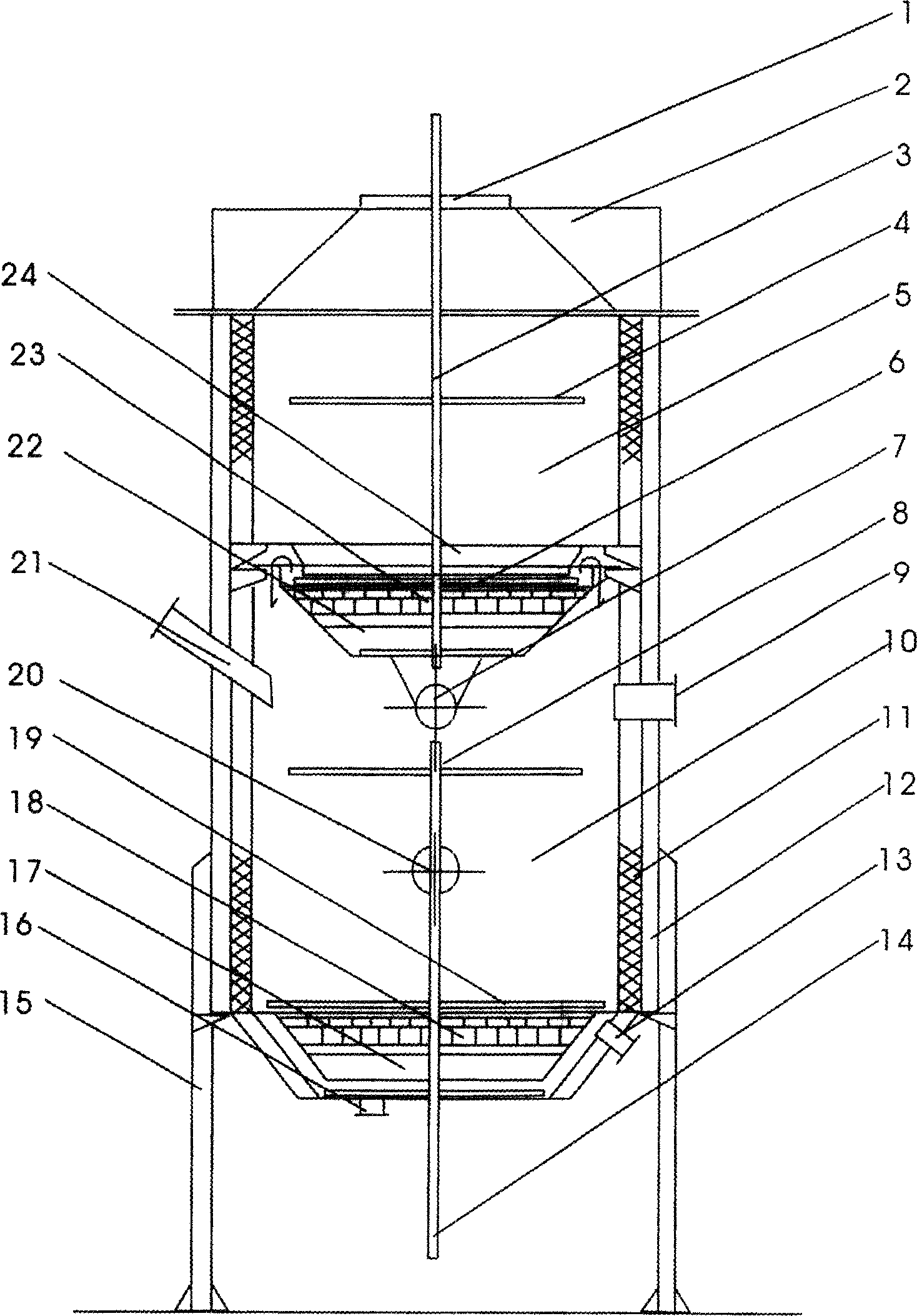

Method for producing biomass carbonized gas and back fire-biomass carbonated gas generating stove

InactiveCN1710022AIncrease incomeImprove protectionBiofuelsSpecial form destructive distillationBack-fireCarbonization

Its craft steps are: respectively cut material into pieces, comminute, and filtrate, add material unsuitable to produce carbonization into the upper layer converse fire gasifying stove cavity as its gasifying fuel; add gasifying material suitable for producing biomass charcoal into the carbonizing stove cavity equipped on the nether layer; produce biomass fuel gas and get biomass carbonized products. Its main structure is: there equips upper layer converse fire gasifying stove cavity and nether layer carbonizing stove cavity in the stove body. Its advantages are: its biomass carbonized fuel gas value can get to 5000 - 6000 KJ / h, add the produced biomass charcoal into water-soluble macromolecule cementing agent after comminuted to process into machine-made charcoal by mechanism extrusion; it can replace the carbonized produces of previous wood charcoal; its structure is simple and reasonable, and is convenient to operate; besides its processing material quantity is large, carbonization speed in stove is high and its efficiency is high.

Owner:韩连恩 +1

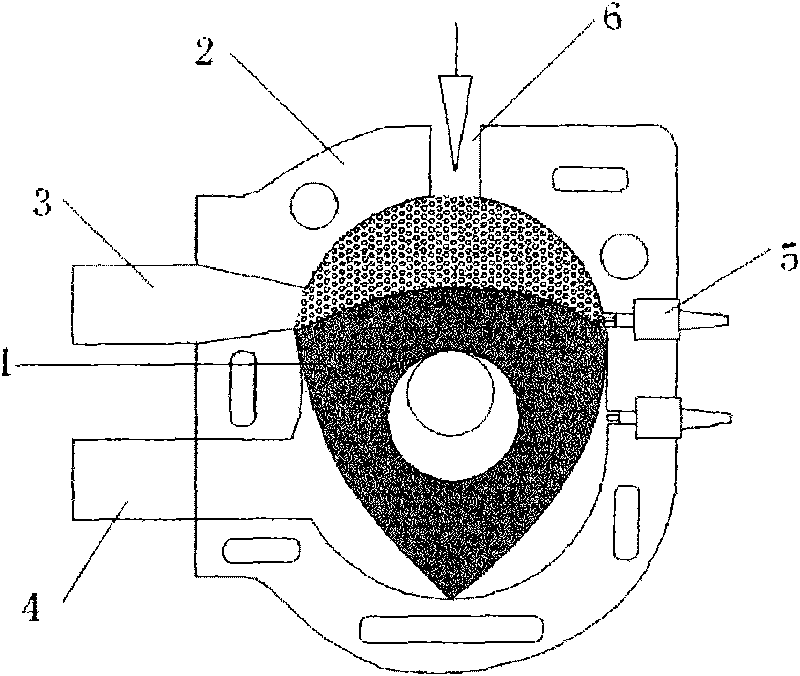

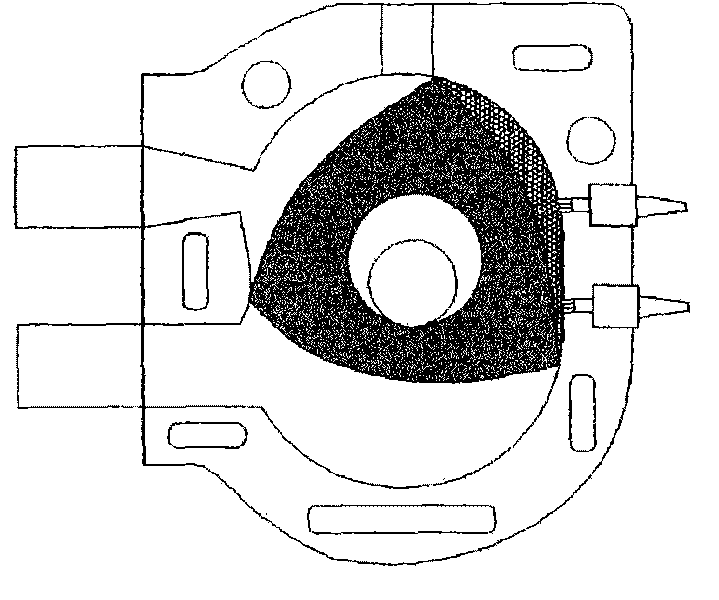

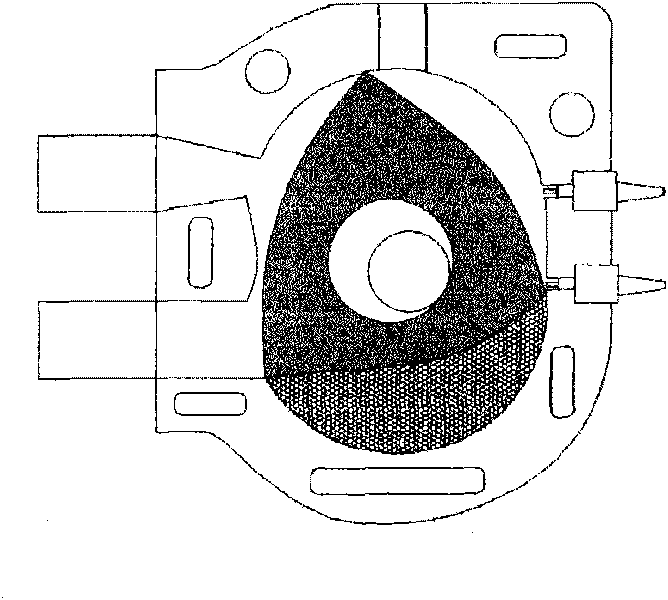

Application of hydrogen fuel and rotary engine thereof

InactiveCN101718221AUse technology to improveSolve backfire problemsInternal combustion piston enginesGaseous engine fuelsBack-fireRotary engine

The invention relates to application of hydrogen fuel and a rotary engine thereof; the hydrogen fuel can be effectively utilized and the problems of back fire, preignition and insufficient power of the hydrogen fuel engine; the technical proposal is that: the hydrogen fuel is used for the rotary engine, and the hydrogen fuel rotary engine is provided with a rotor and a shell, and an air inlet and an air outlet are arranged on the shell; the rotary engine is characterized in that: a hydrogen inlet is arranged on the shell.

Owner:CHERY AUTOMOBILE CO LTD

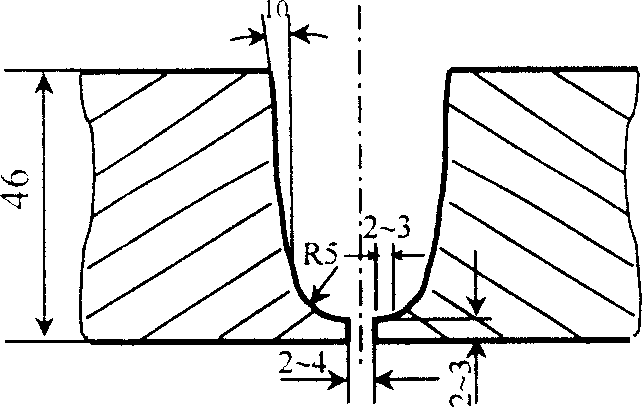

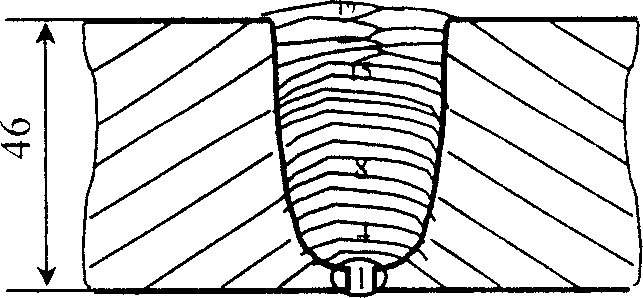

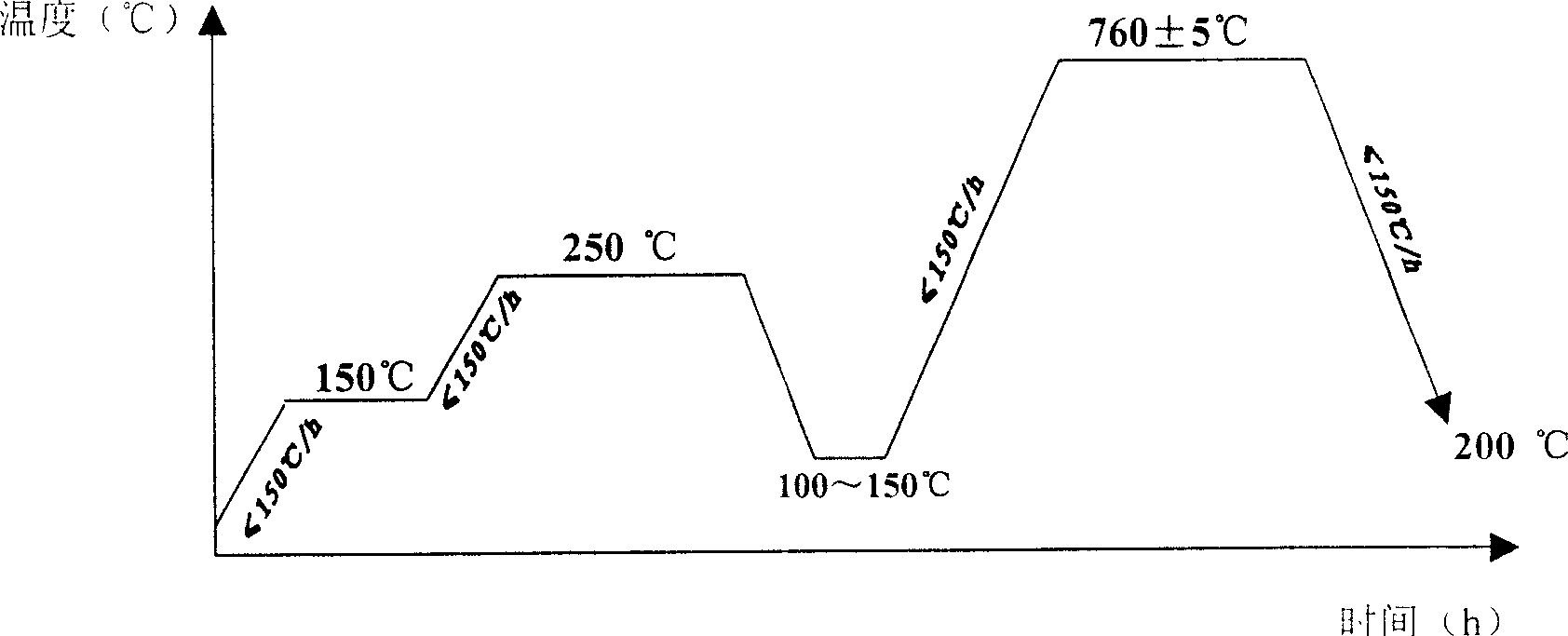

P91 steel welding method

InactiveCN1721118AIncreasing the thicknessReduce thicknessArc welding apparatusBack-fireThermal insulation

This invention provides welding method for P91 steel with basic steps of preheating, back welding with TGS-9CbªŽ2.4 solder wire, filler welding with C9MVªŽ2.5, C9MVªŽ3.2 welding rod and parameters of current 75-140A, welding time for every layer 6-21min, welding preheating temperature 150Deg and welding layer-to-layer temperature 200-300Deg, thermal insulation and thermal treatment. The technique progress can be found from: 1. increase welding current and speed about one times compared with generated method; 2. change layer bead arrangement, decrease welding bead and welding layer thickness convenient to operate, avoid dead angle, prevent welding bug; use layer-to-layer back fire effect to improve metal structure and performance of welding line; 3. come to welding operation standardization and process programming benefit for training and management to workers.

Owner:石家庄电力工业学校焊接培训中心

Anti-flashback nozzle and combustion device with the same

ActiveCN101315187AIncrease the turndown ratioPrevent backfireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionBack-fire

The invention relates to an anti-backfire nozzle for a gas burner and a burning device by adopting the nozzle. The nozzle particularly comprises a shell. A fuel passage, a combustion supporting gas passage, a mixing chamber positioned at the downstream of the fuel passage and the combustion supporting gas passage and a spout are arranged in the shell; the mixing chamber has N-stage mutually-communicating cavities. On the radial section of the nozzle, the cross-sectional area of the cavity positioned at the upstream is smaller than that of the adjacent cavity at the downstream. When little circulating gas enters the cavity at the downstream, the mixed gas is burned in the cavity at the downstream and the adjacent cavity at the upstream. With the sharp increase of pressure of combustion products, the combustion products are instantly jet out of the nozzle, thereby preventing the flame from being blown off by the circulating gas flow. Since the nozzle is specially provided with the anti-backfire structure, the burning device with the nozzle is adaptable to reversal convection blowing, provides good working hot gas flow and ensures good stability and high regulation rate of the nozzle flame.

Owner:ECLIPSE COMBUSTION EQUIP SUZHOU CO LTD

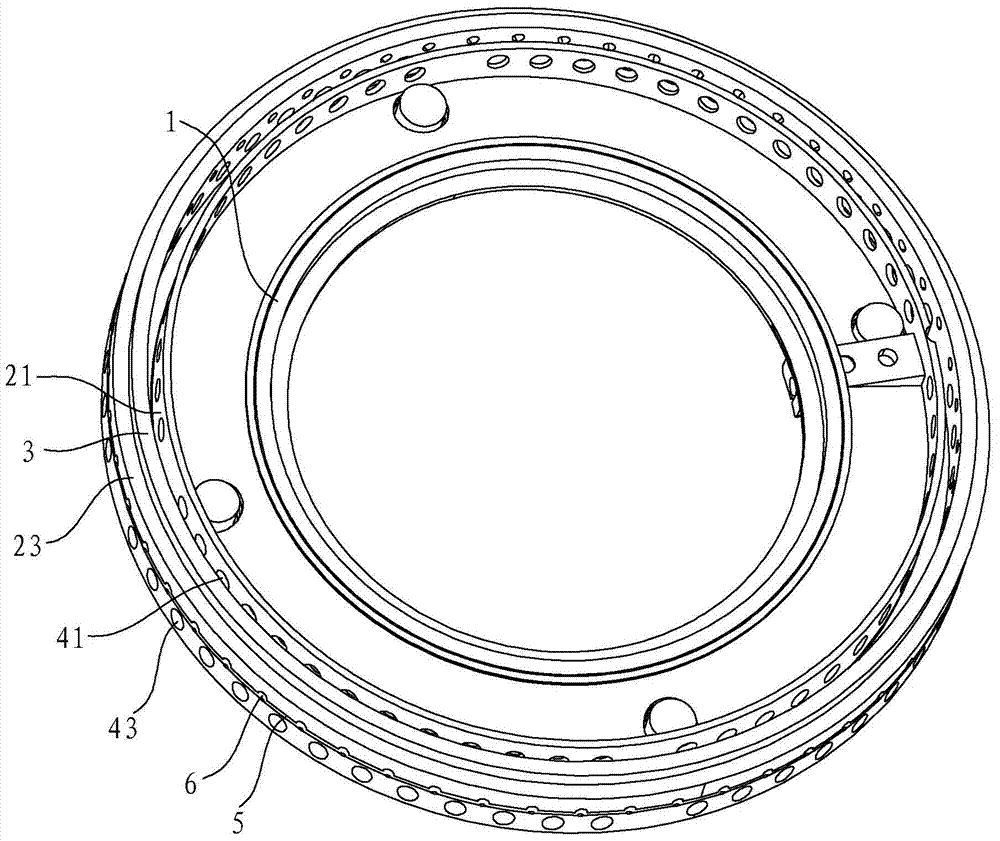

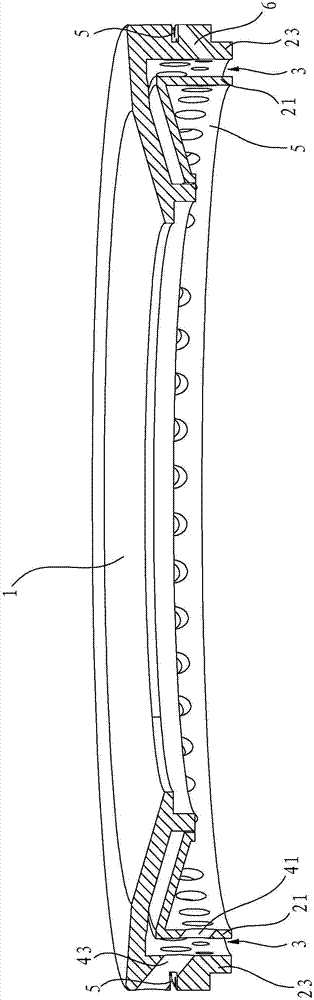

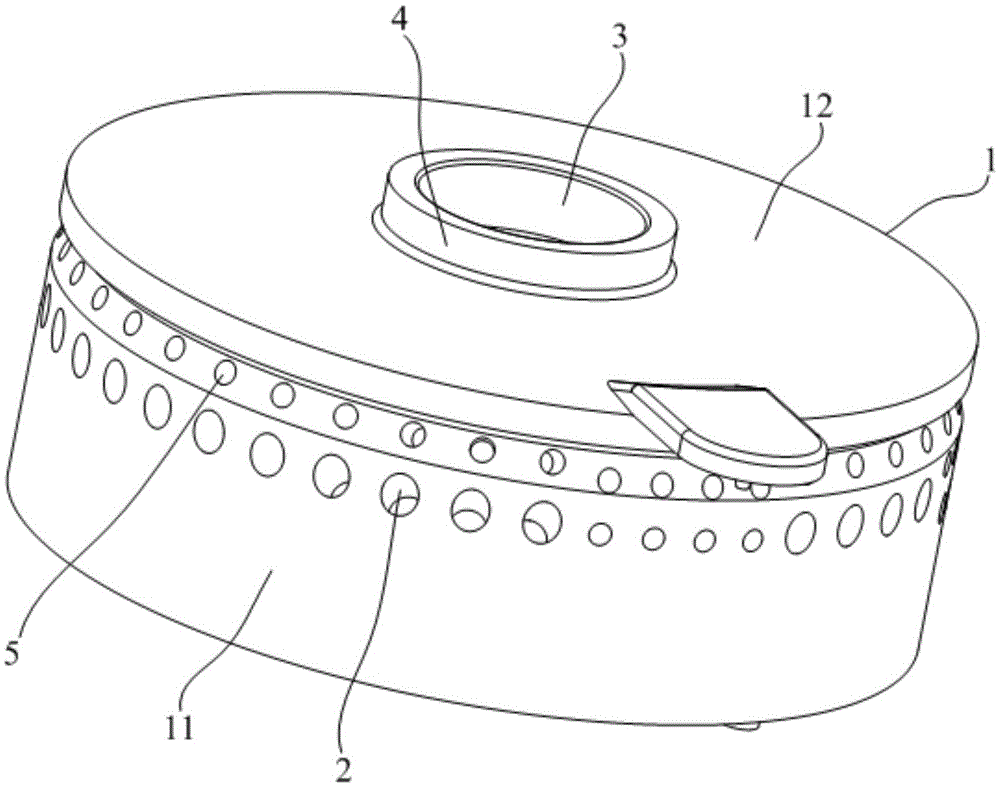

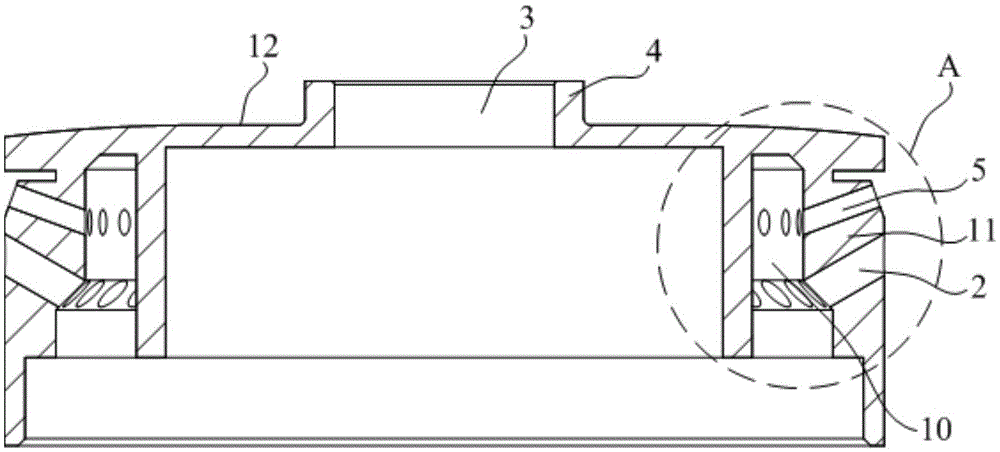

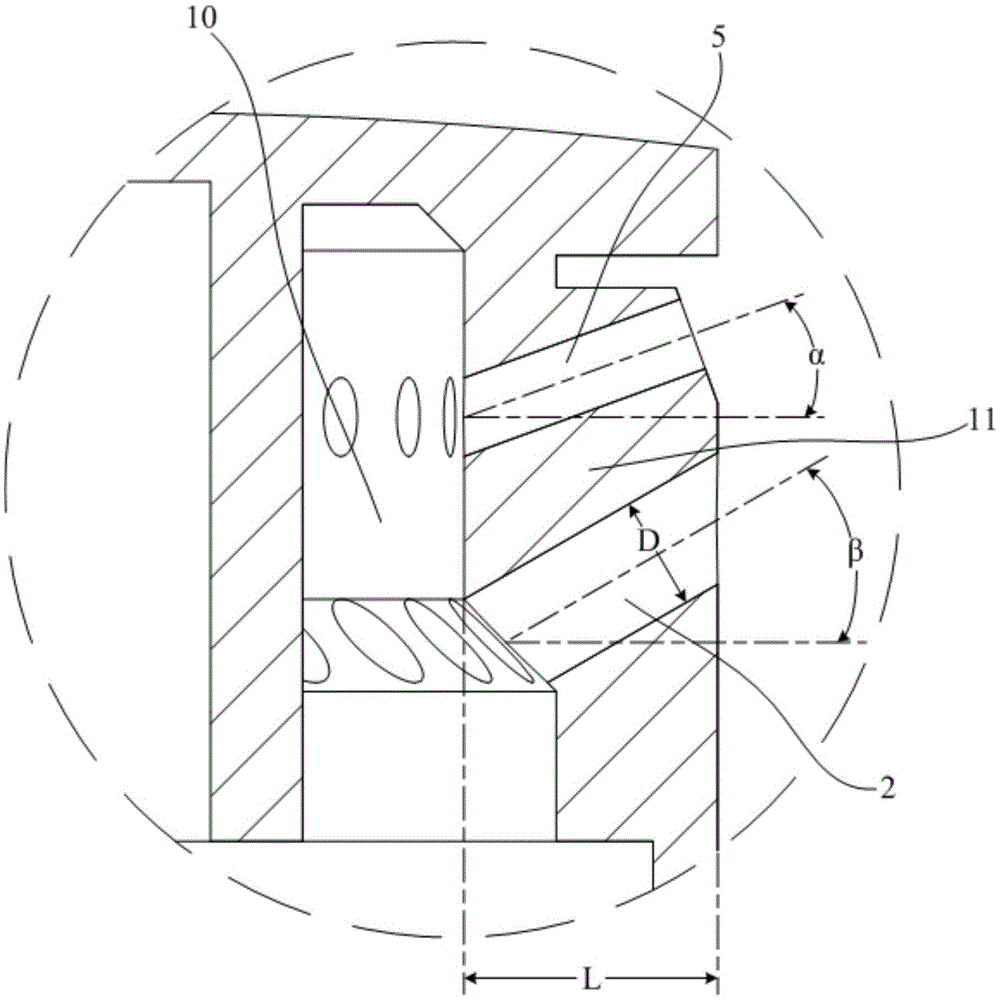

Fire cover, burner and gas stove

ActiveCN105605576ANot easy to temperImprove the safety of useDomestic stoves or rangesGaseous fuel burnerBack-fireEngineering

The invention discloses a fire cover, a burner and a gas stove. The fire cover is used for the burner and comprises a fire cover body which is provided with main fire holes, and the ratio of the thickness wall of the position, provided with the main fire holes, of the fire cover body and the hole diameter of the main fire holes is larger than or equal to 2.85. According to the technical scheme, by means of the fire cover, the burner and the gas stove, the back-fire phenomenon of the main fire holes of the fire cover can be avoided, and therefore the use safety of the burner with the fire cover is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

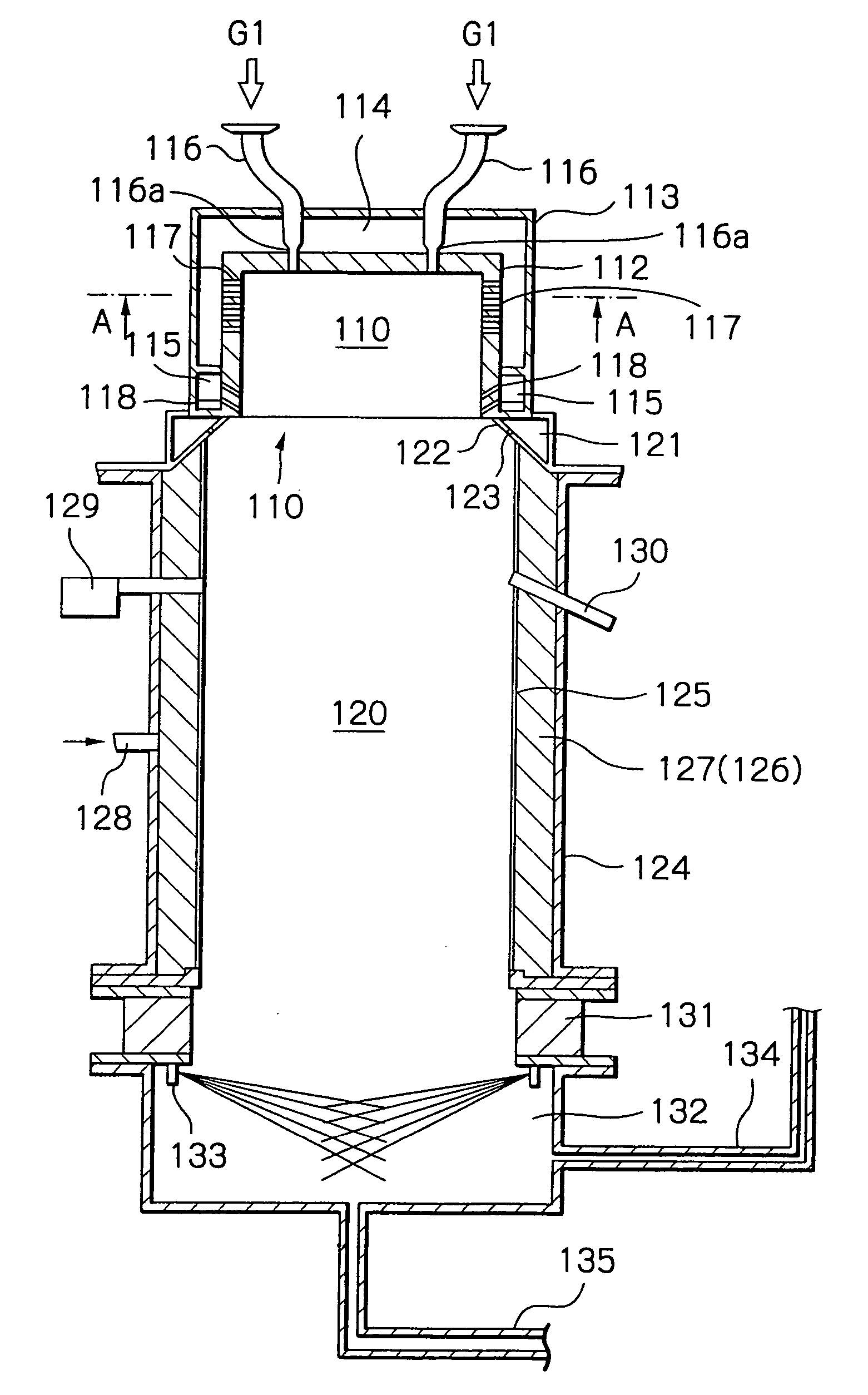

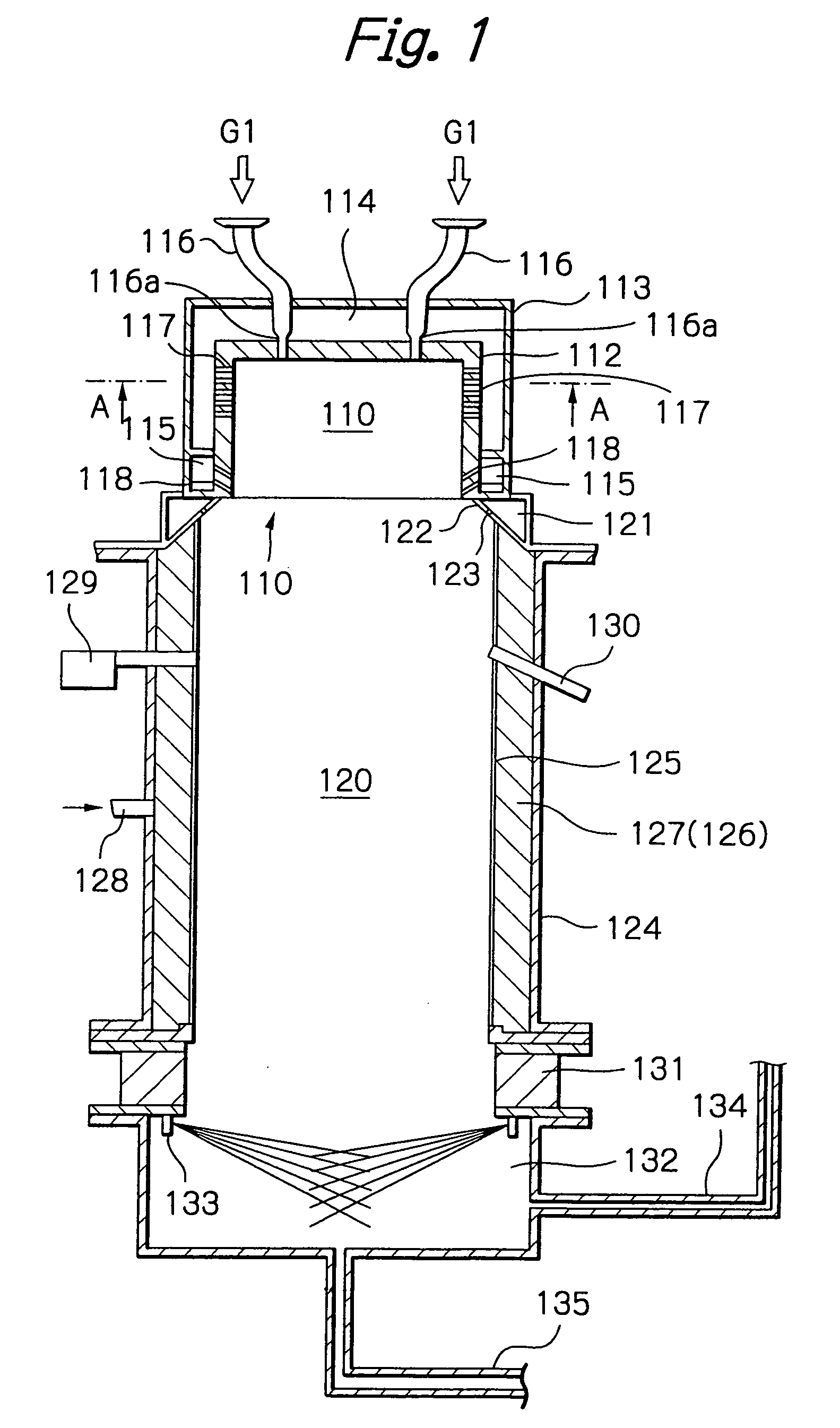

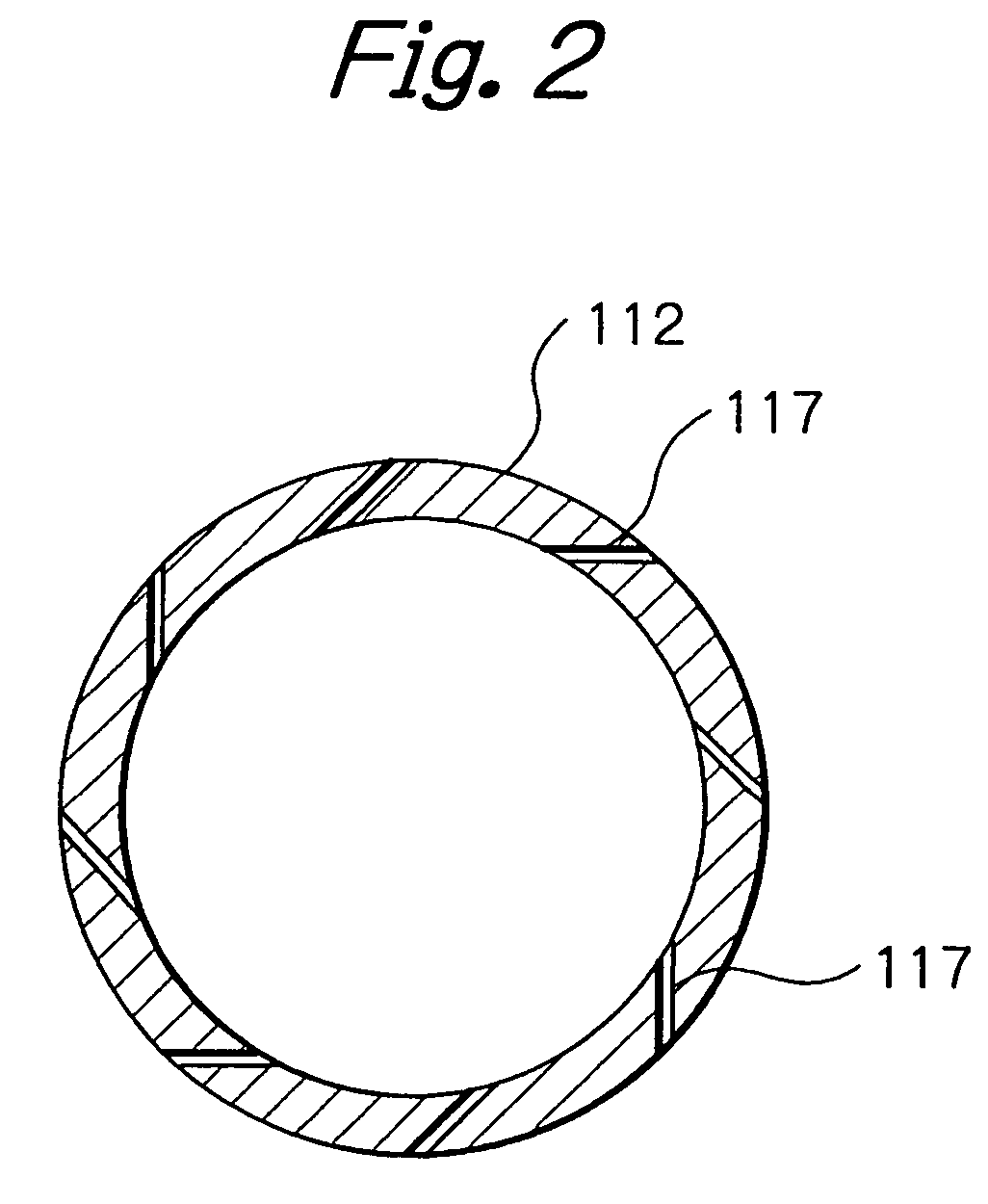

Combustion type waste gas treatment system

InactiveUS20050271988A1Improve the heating effectEliminate variationFire rescuePulverulent fuel combustion burnersCombustorBack-fire

A combustion type waste gas treatment system capable of oxidatively decomposing a hazardous combustible waste gas while heating efficiently with a structure which allows the waste gas to mix with an auxiliary burning gas efficiently without the occurrence of backfire in a waste gas inlet pipe. The combustion type waste gas treatment system has a burner part and a combustion chamber. Combustion flames are formed to extend from the burner part toward the combustion chamber, and a combustible waste gas is introduced into the combustion flames from waste gas inlet pipes thereby oxidatively decomposing the waste gas. A flow velocity accelerating device makes the flow velocity of the combustible waste gas flowing through the waste gas inlet pipe higher than the burning velocity of the combustible waste gas.

Owner:KOMAI TETABUO +10

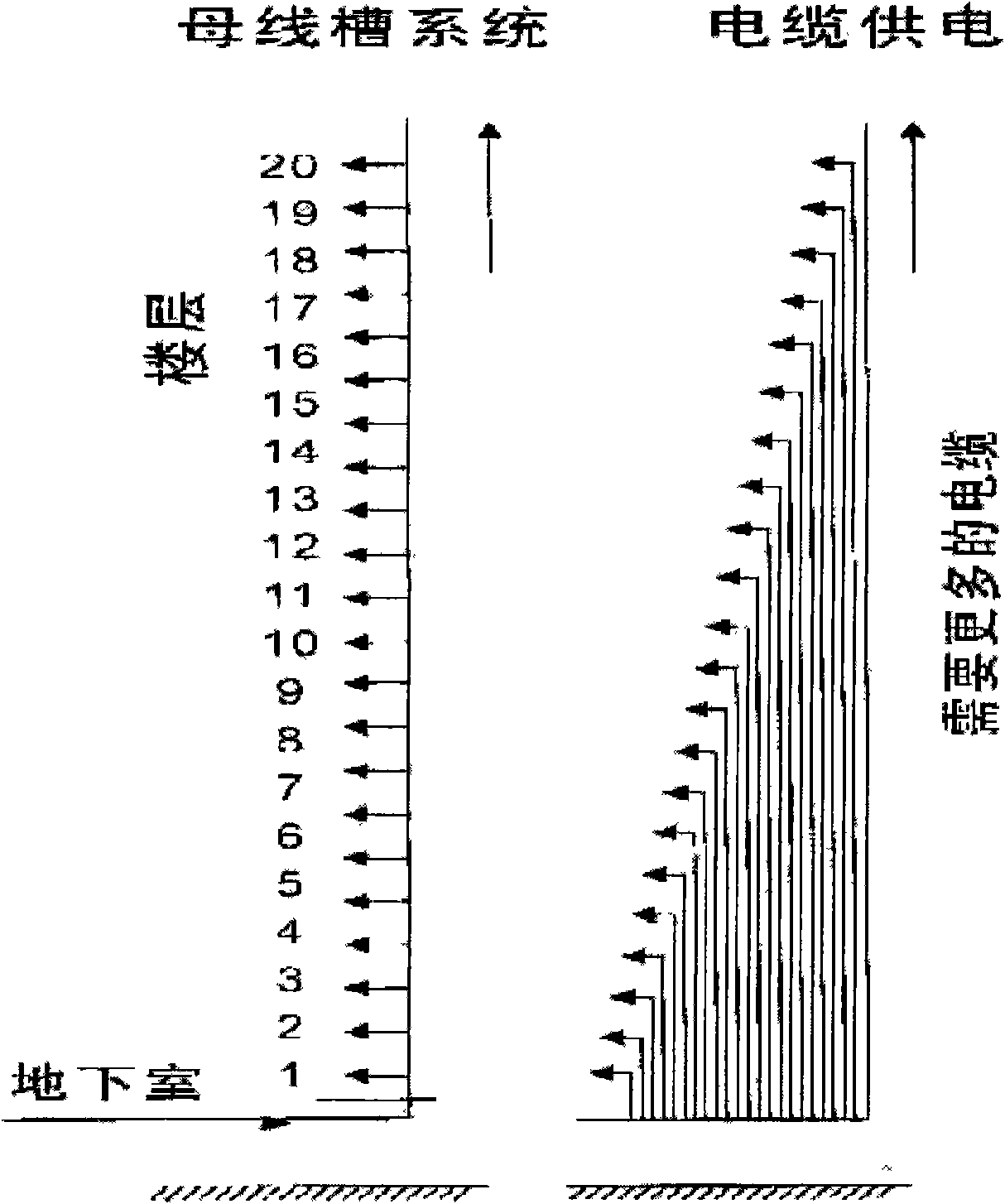

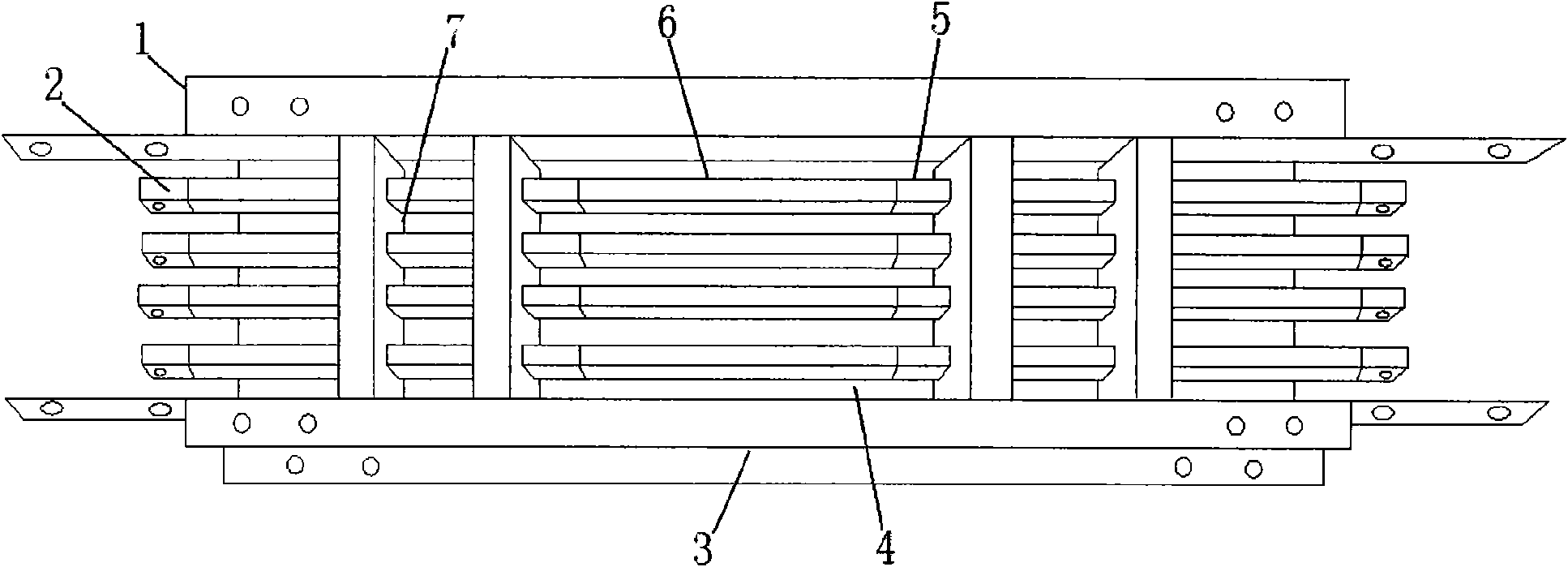

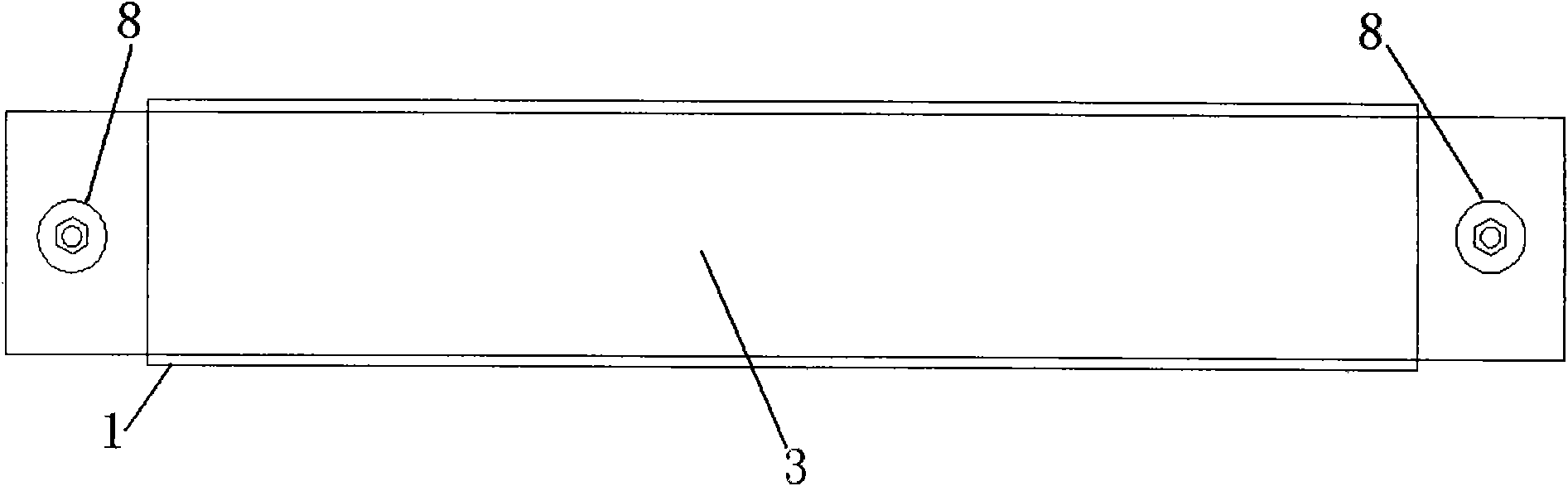

Insulated fireproof bus duct

InactiveCN101567536AHigh mechanical strengthLower backfire temperatureTotally enclosed bus-bar installationsElectrical conductorEngineering

The invention discloses an insulated fireproof bus duct, which comprises a shell and a conductor, wherein the shell consists of a side plate and a cover plate which are connected with each other through a fastener to clamp the conductor; the inner wall of the shell is sprayed and coated with fireproof materials; the conductor is coated by a high temperature resistant reinforced mica tape and externally coated by an insulator heat shrinkage sleeve; an interphase and a terminal are provided with spacer blocks made of inorganic glass fiber reinforcing materials; and the side plate and the conductor are riveted and fixed on a joint through a butterfly spring. The insulated fireproof bus duct can be fireproof for a long time, and the conductor is coated by the high temperature resistance reinforced mica tape and externally coated by the insulator heat shrinkage sleeve; the spacer blocks are made by pressing the inorganic glass fiber reinforcing materials, so that the spacer blocks are noncombustible and inexplosive and have good mechanical property; the inner wall of the shell is sprayed and coated with the fireproof materials, so that the back-fire temperature is reduced or the fireproof time is prolonged; and the butterfly spring has the function of automatic regulation to make the pressure uniformly applied to the contact surface, so that the contact resistance and the temperature rise are reduced. Moreover, the insulated fireproof bus duct has large capacity, low line loss, high short-circuit strength and good heat dispersion.

Owner:KUNSHAN POWER SUPPLY CO LTD OF JIANGSU ELECTRICPOWER +1

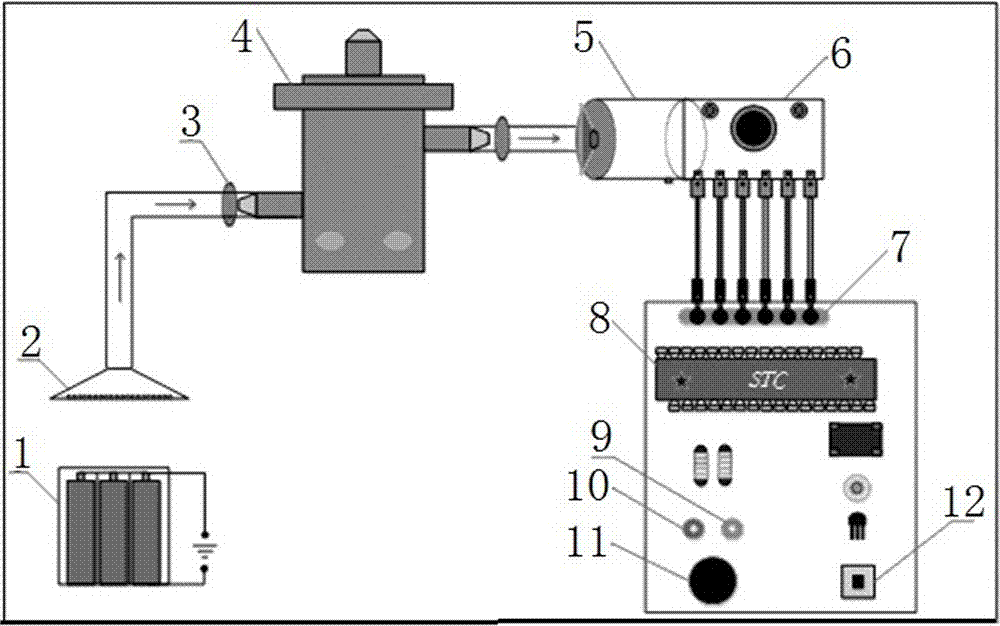

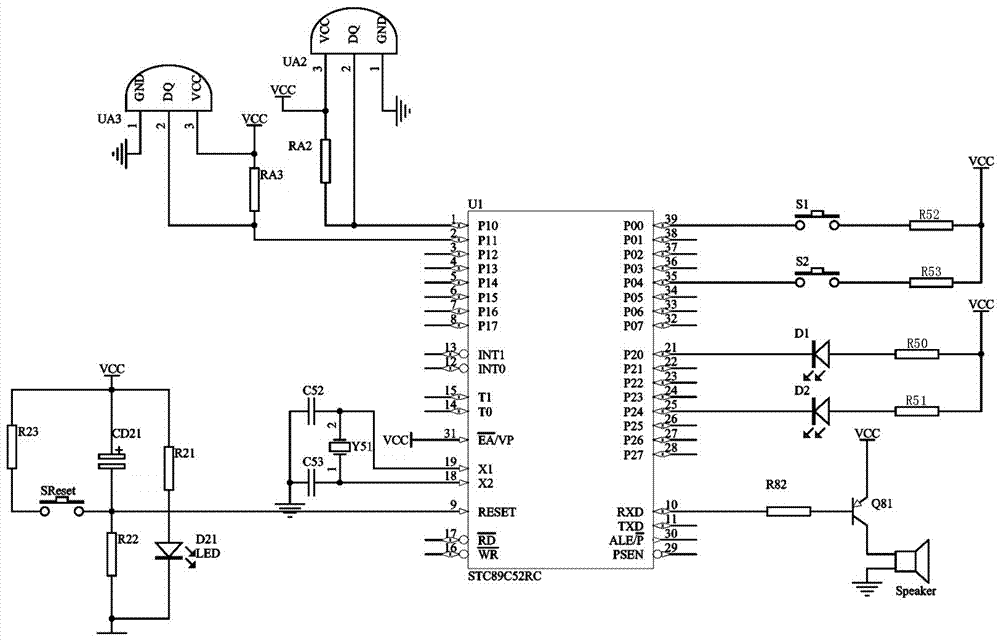

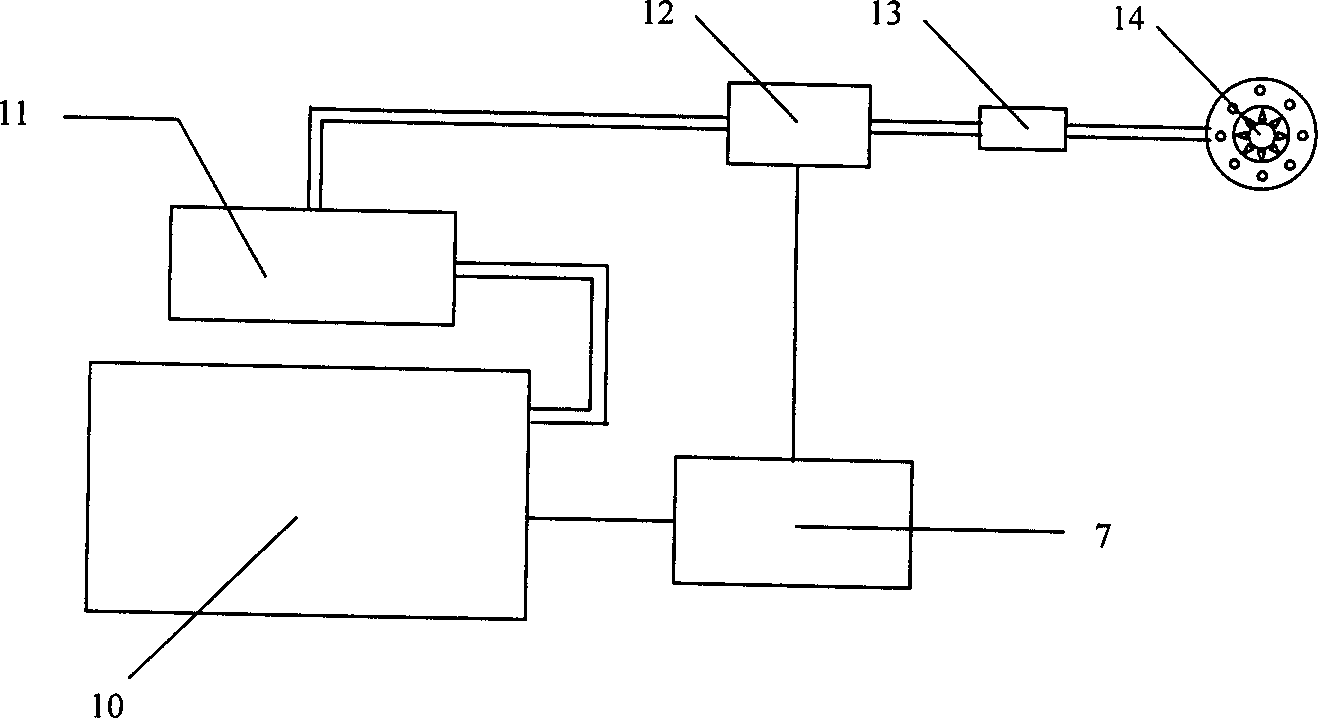

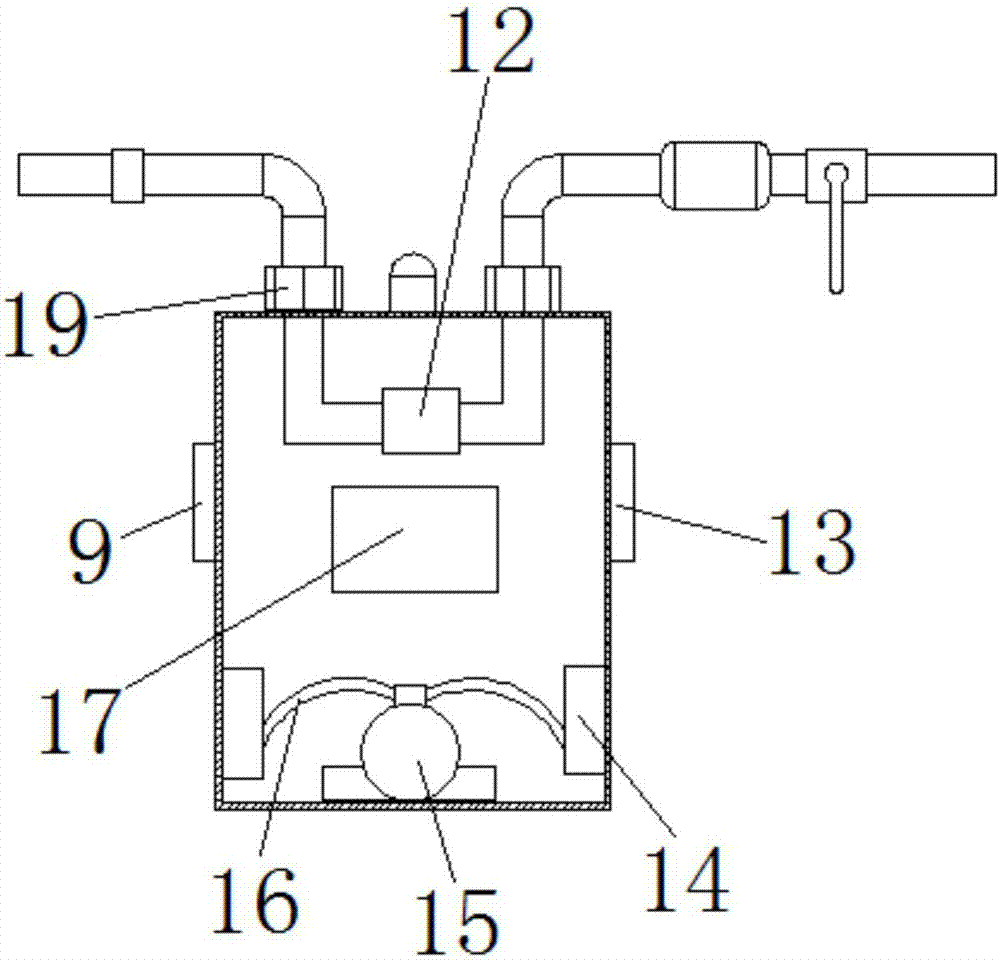

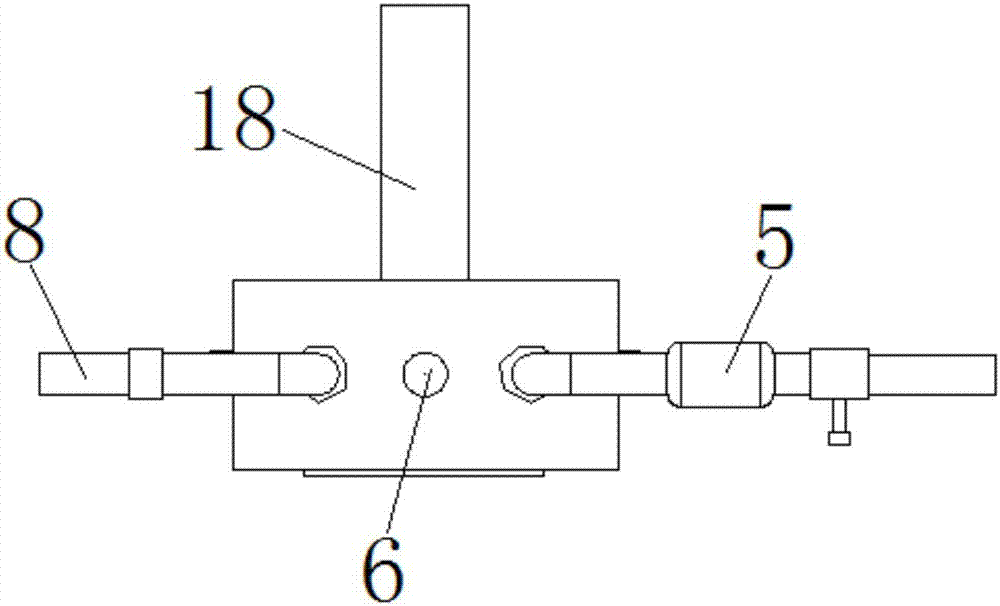

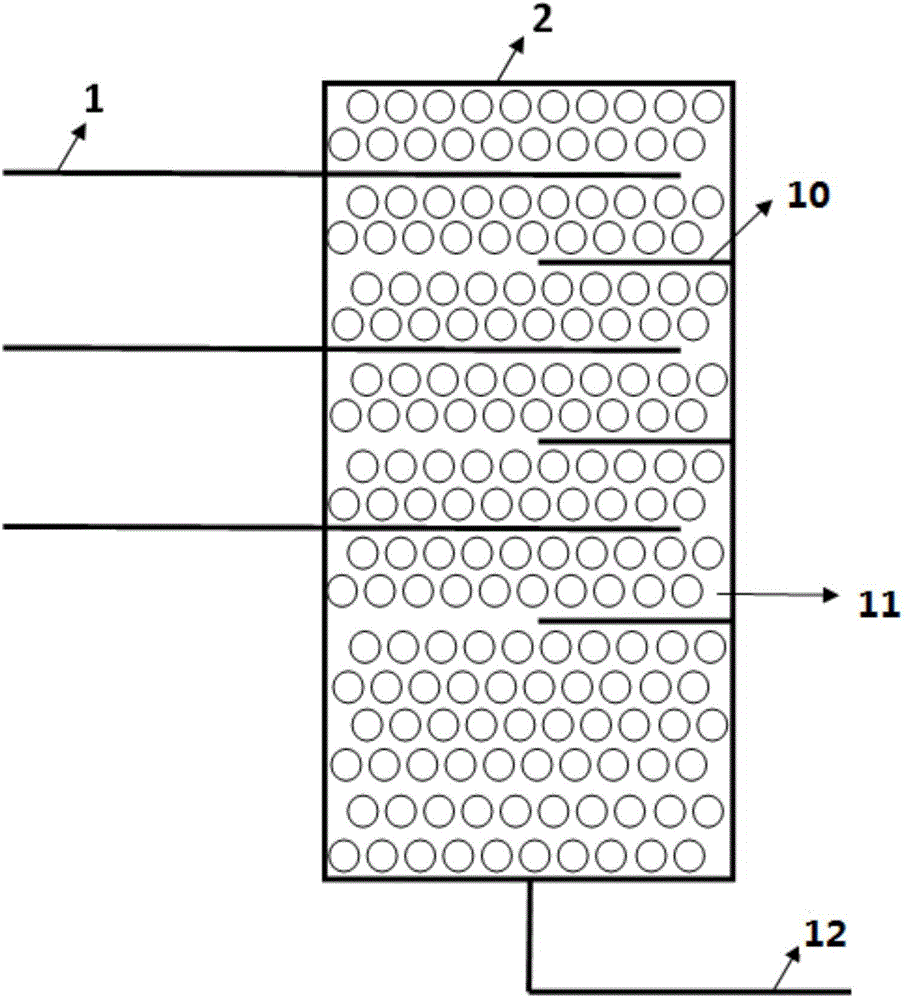

Lithium-ion battery pack thermal runway automatic alarming apparatus based on gas monitoring and monitoring method

PendingCN108008083AImprove securityAvoid casualtiesElectrical testingGas analyser construction detailsElectrical batteryAir pump

The invention discloses a lithium-ion battery pack thermal runway automatic alarming apparatus based on gas monitoring and a monitoring method, and relates to a thermal runway alarming device for letting out flammable and combustible gas for real-time monitoring and timely alarming during battery thermal runway aiming at the warehousing and charging process of a lithium-ion battery pack. The lithium-ion battery pack thermal runway automatic alarming apparatus is composed of a collecting device, a gas monitoring device, a controlling device and an alarming device, wherein the collecting deviceis composed of a collecting hood, a back-fire relief valve and a gas pump; the collecting hood is installed above a positive electrode of the lithium-ion battery pack, and is connected with a gas inlet of the gas pump through a gas pipeline, and the gas pipeline is internally provided with the back-fire relief valve; the gas monitoring device is composed of a gas collector, a gas sensor and a Dupont line. A gas outlet of the gas pump is connected with the gas collecting box, and the gas collecting box is internally provided with the gas sensor; the controlling device is composed of a control box, a single-chip microcomputer, a gas sensor, a gas sensor interface and a control electric circuit; the alarming device is composed of a blue LED alarming lamp, a red LED alarming lamp and a buzzer.

Owner:NANJING UNIV OF TECH

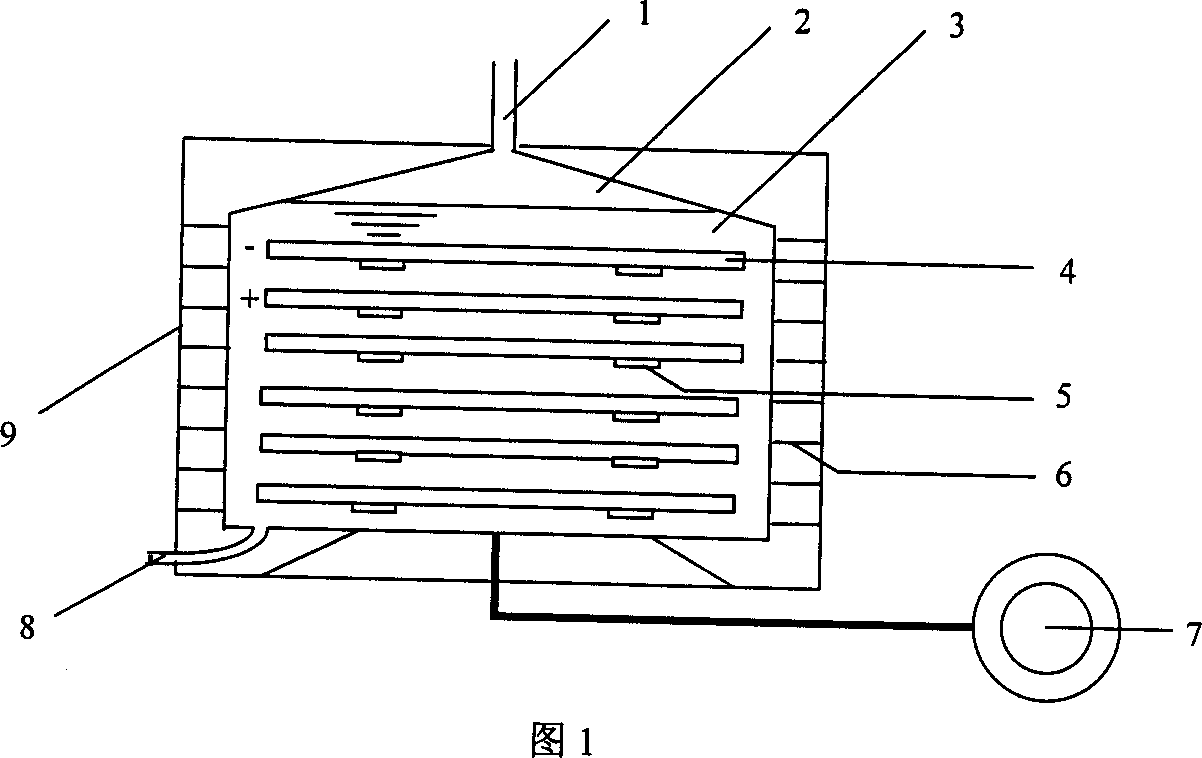

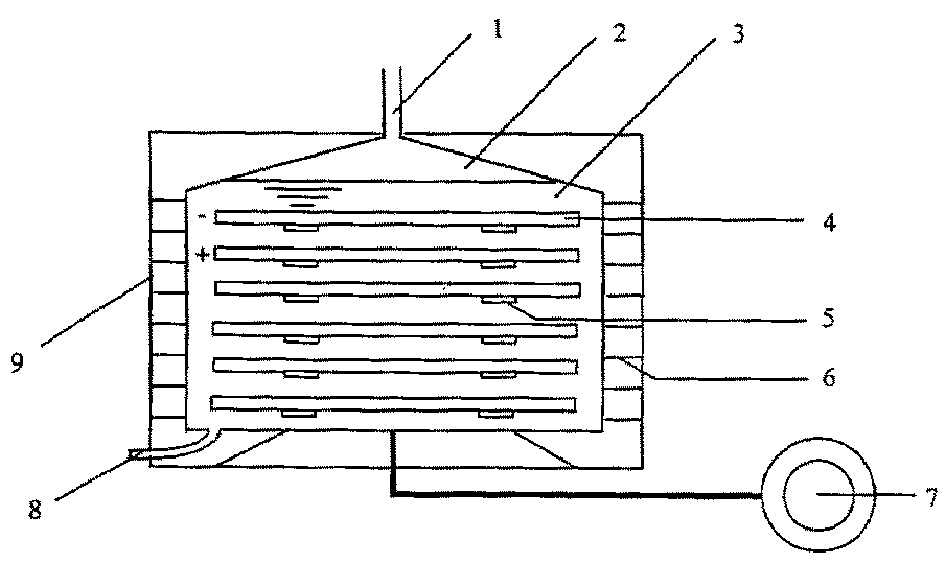

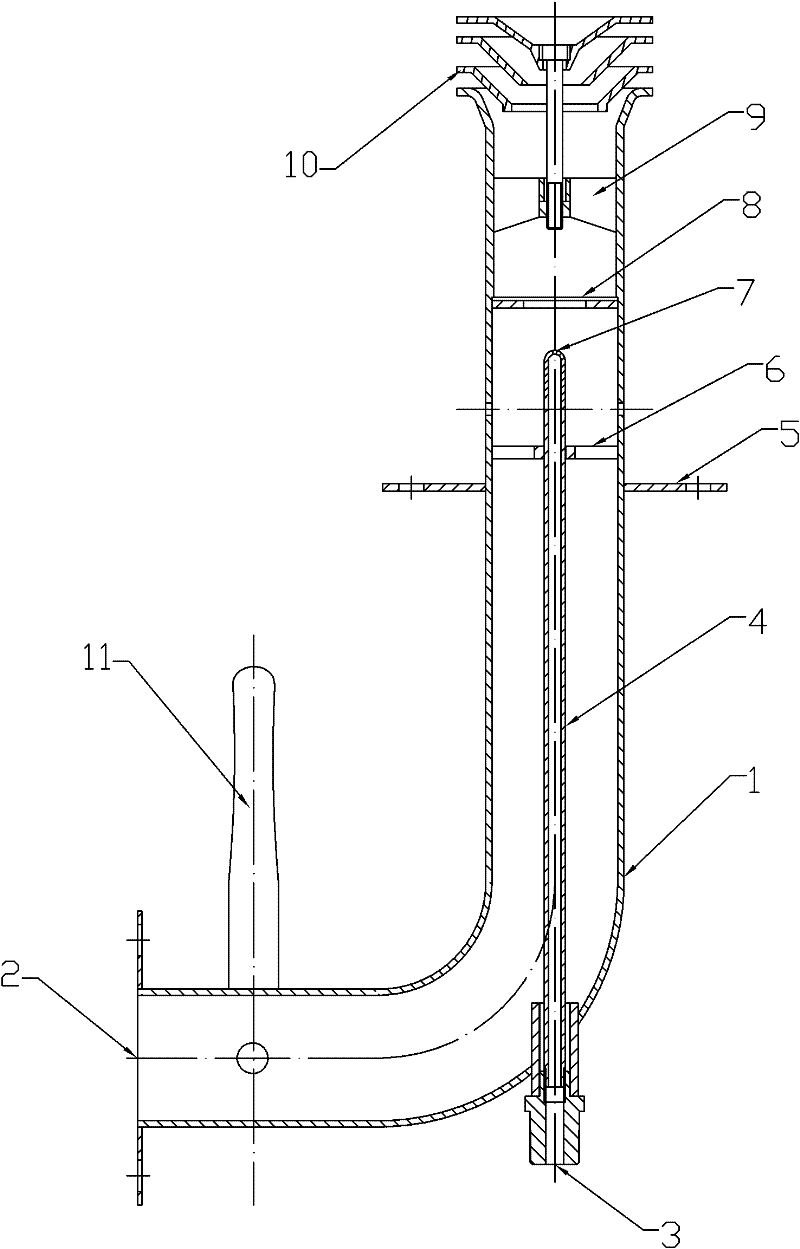

Efficient electrolyzer and its water-burning unit

InactiveCN1363726AImprove energy conversion efficiencyEasy to moveGaseous fuel burnerElectrodesProcess engineeringBack-fire

An efficient electrolyzer is composed of electrolyzing cavity with liquid inlet and outlet and gas outlet, composite electrodes parallelly arranged in said electrolyzing cavity, piezoelectric oscillating plates attached to said electrodes, casing, and heat radiator. An efficient water-buring appliance consists of said electrolyzer, gas tank, pressure limit and back-fire stopping valve. Its advantages include only generating water vapour after combustion, immediate generation of gas, small size, light weight and high efficiency of energy conversion.

Owner:TSINGHUA UNIV +1

Natural gas pipeline switch safety protection device

The invention discloses a safety protection device for a switch of a natural gas pipeline, which comprises a rectangular casing, and gas inlet pipes and gas outlet pipes are respectively arranged on the left and right sides of the upper part of the rectangular casing. The safety protection device for a natural gas pipeline switch has a simple structure and is easy to install , it occupies a small space when used, and can play a good role in safety protection for natural gas users. The use of the display enables the present invention to display the concentration of natural gas in the surrounding environment and the amount of natural gas used in real time, which is convenient for users. When a fire occurs, the flame arrester can effectively prevent the combustion of natural gas in the outlet pipe, the natural gas concentration detector can monitor the content of natural gas in the surrounding gas in real time, and the temperature sensor can monitor the temperature of the surrounding gas. The gas machine can discharge the surrounding air together with the natural gas to the outside, which can effectively prevent the occurrence of fire.

Owner:潘庞博

Fuel cell hydrogen supplying system for backup power

InactiveCN102569850ANon-stop operationWith purge functionFuel cell auxillariesFuel cell detailsFlame arresterDifferential pressure

The invention relates to a fuel cell hydrogen supplying system for a backup power. The fuel cell hydrogen supplying system for the backup power comprises a main hydrogen supplying bottle component and a spare hydrogen bottle component, wherein the main hydrogen supplying bottle component and the spare hydrogen bottle component pass by ball valves, are connected with a differential pressure valve through high-pressure pressure relief valves respectively, and are connected with drain pipes through drain valves respectively; a P1 pressure sensor and a P2 pressure sensor are arranged on the high-pressure pressure relief valves in the main hydrogen supplying bottle component and the spare hydrogen bottle component respectively; the P1 pressure sensor and a P2 pressure sensor are connected with a controller respectively and are used for monitoring pressures of the two hydrogen bottles in real time and converting the pressures into hydrogen margins in real time through the controller; flame arresters for preventing back fire are arranged at the tail ends of the drain pipes; and safety ground interfaces for guiding static electricity generated in the draining process are formed on the drain pipes. The fuel cell hydrogen supplying system for the backup power can not only realize on-line switching to replace the hydrogen bottles, low-voltage safe hydrogen relief and air purge but also estimate the residual pressures of the hydrogen bottles more accurately.

Owner:KUSN FUERSAI ENERGY

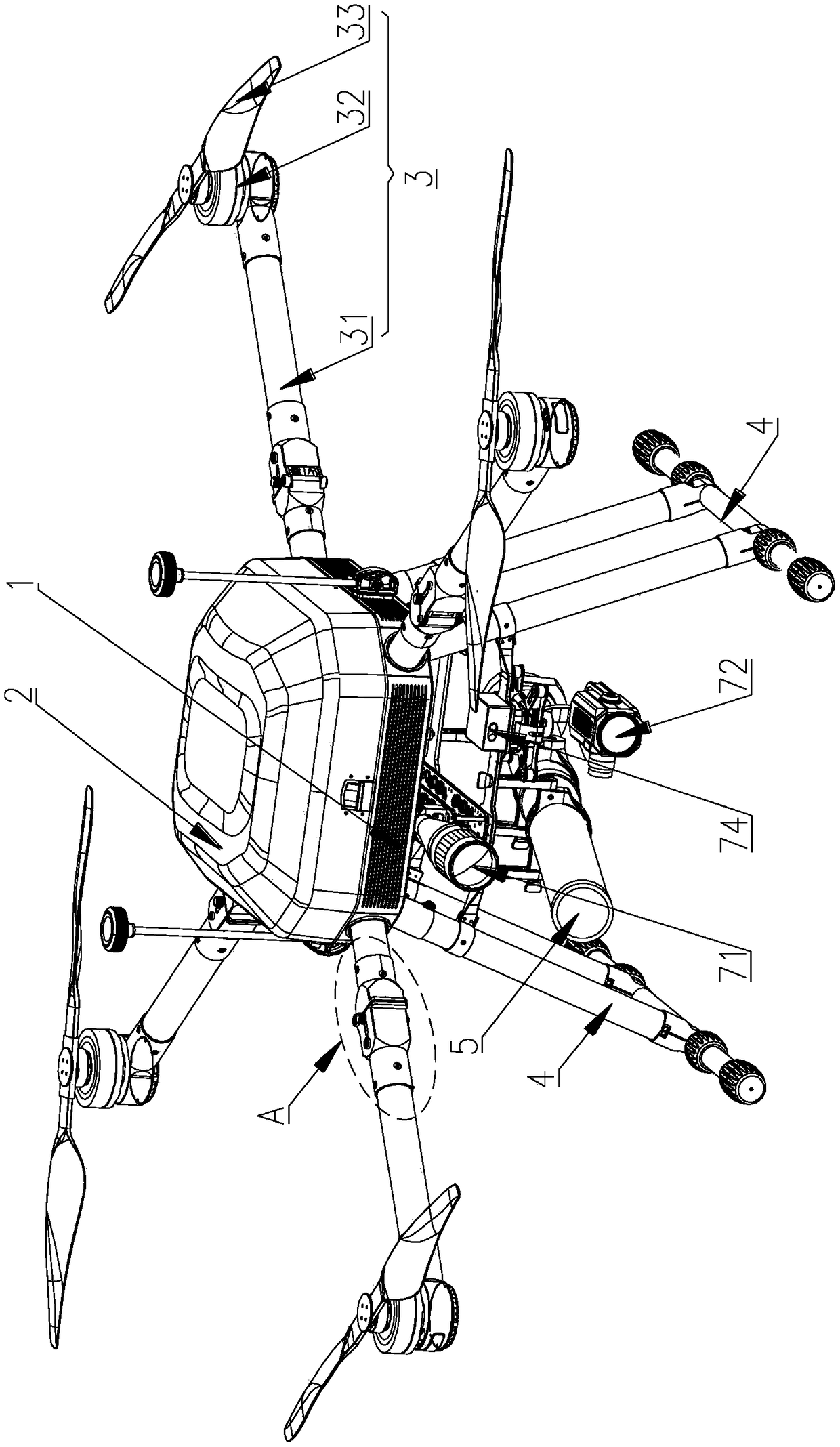

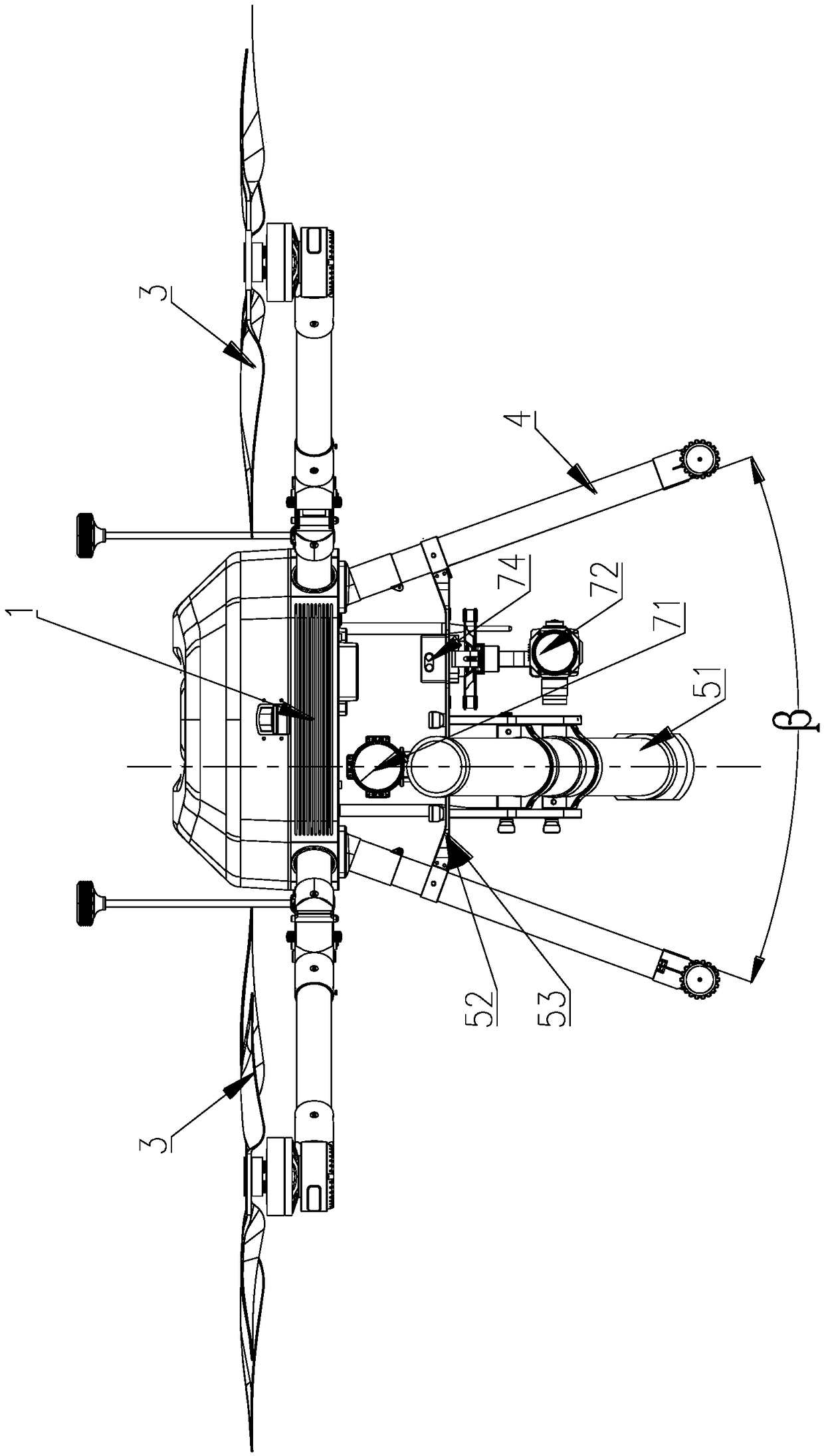

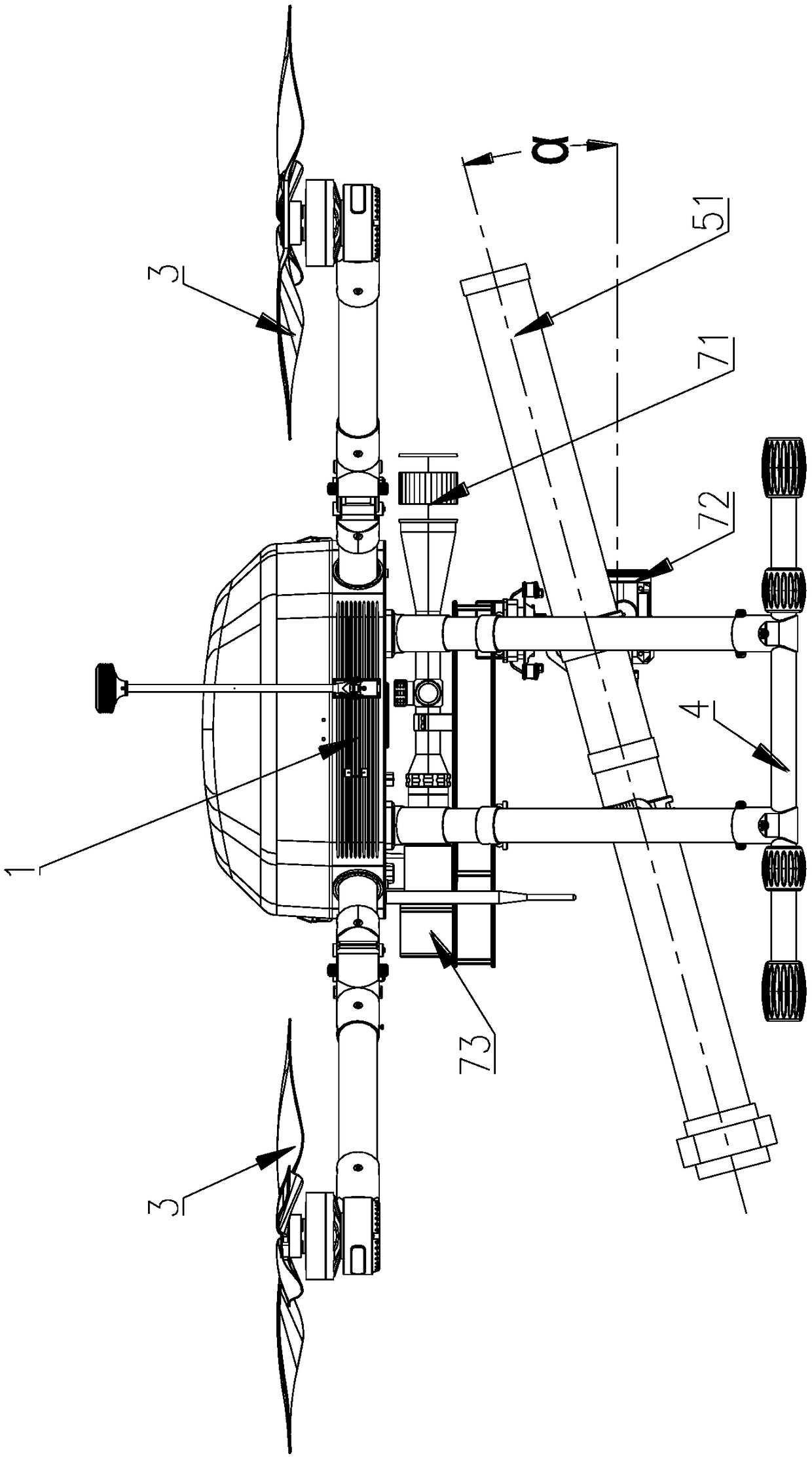

Triggering method for firefighting drone to shoot firefighting cartridge

ActiveCN109383806AReduce the chance of misjudgmentHigh precisionFire rescueFuselagesDisaster areaBack-fire

The invention relates to the field of drones, in particular to a triggering method for a firefighting drone to shoot a firefighting cartridge. The method comprises the steps of controlling the firefighting drone to fly to a fire disaster area; utilizing the firefighting drone for hovering near the fire disaster area; sending back fire disaster area images through a holder camera on the firefighting drone; determining the shooting distance L between a shooting port of a firefighting barrel and the center of a fire disaster; sending back sighting pictures of the drone through a sighting telescope; according to the sighting pictures, adjusting the angle of the shooting port of the firefighting barrel, and sighting the firefighting barrel towards the fire disaster area; sending motion signalsto the firefighting barrel through a remote-control end, so that a triggering switch is turned off and the firefighting cartridge is shot. According to the method, the firefighting cartridge is sighted before being being triggered, the precision and effectiveness of fire extinguishing are improved, one-button circuit signals are adopted for triggering of shooting of the firefighting cartridge, thereaction is quick, and the operation is convenient.

Owner:GUANGZHOU WALKERA TECH CO LTD

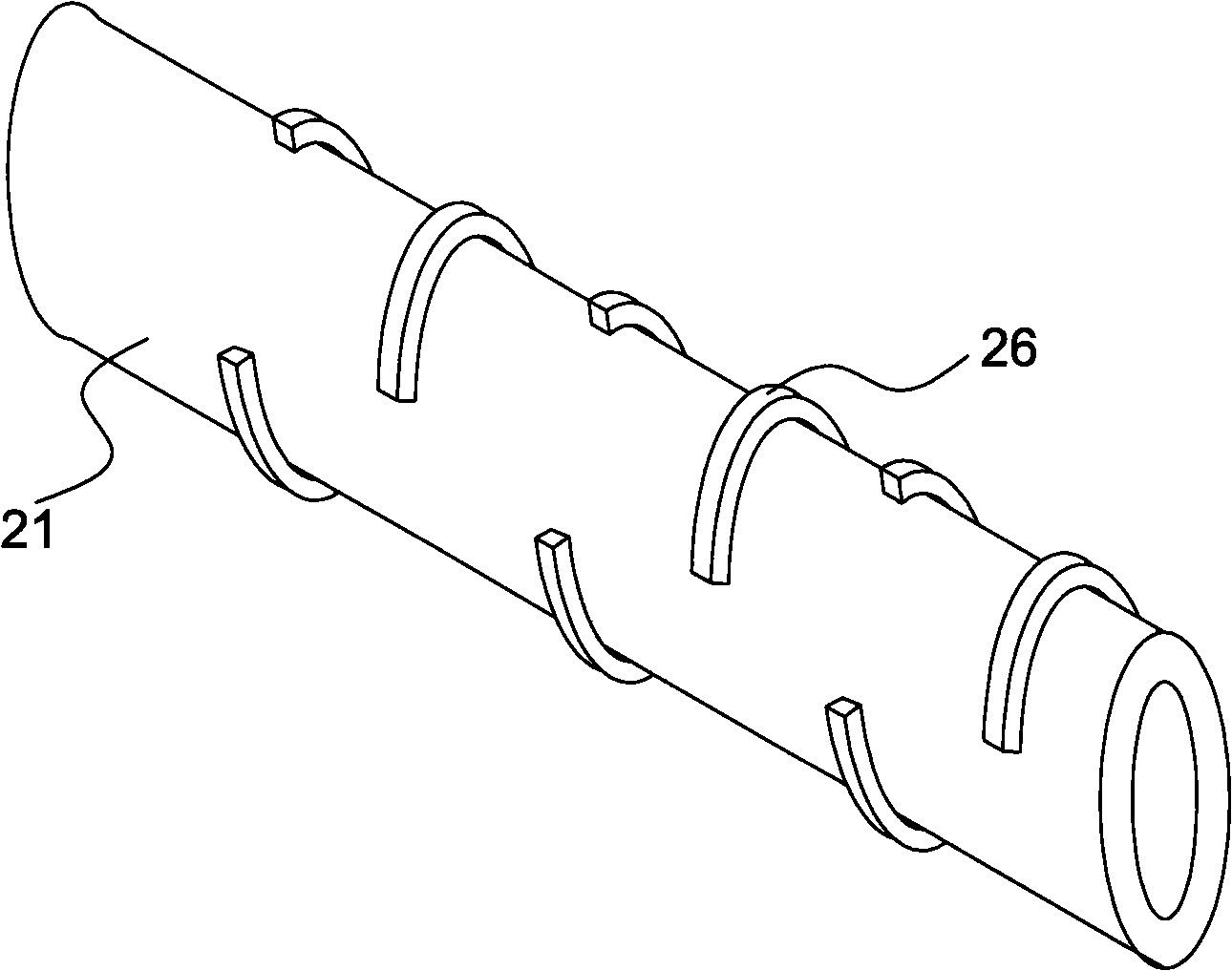

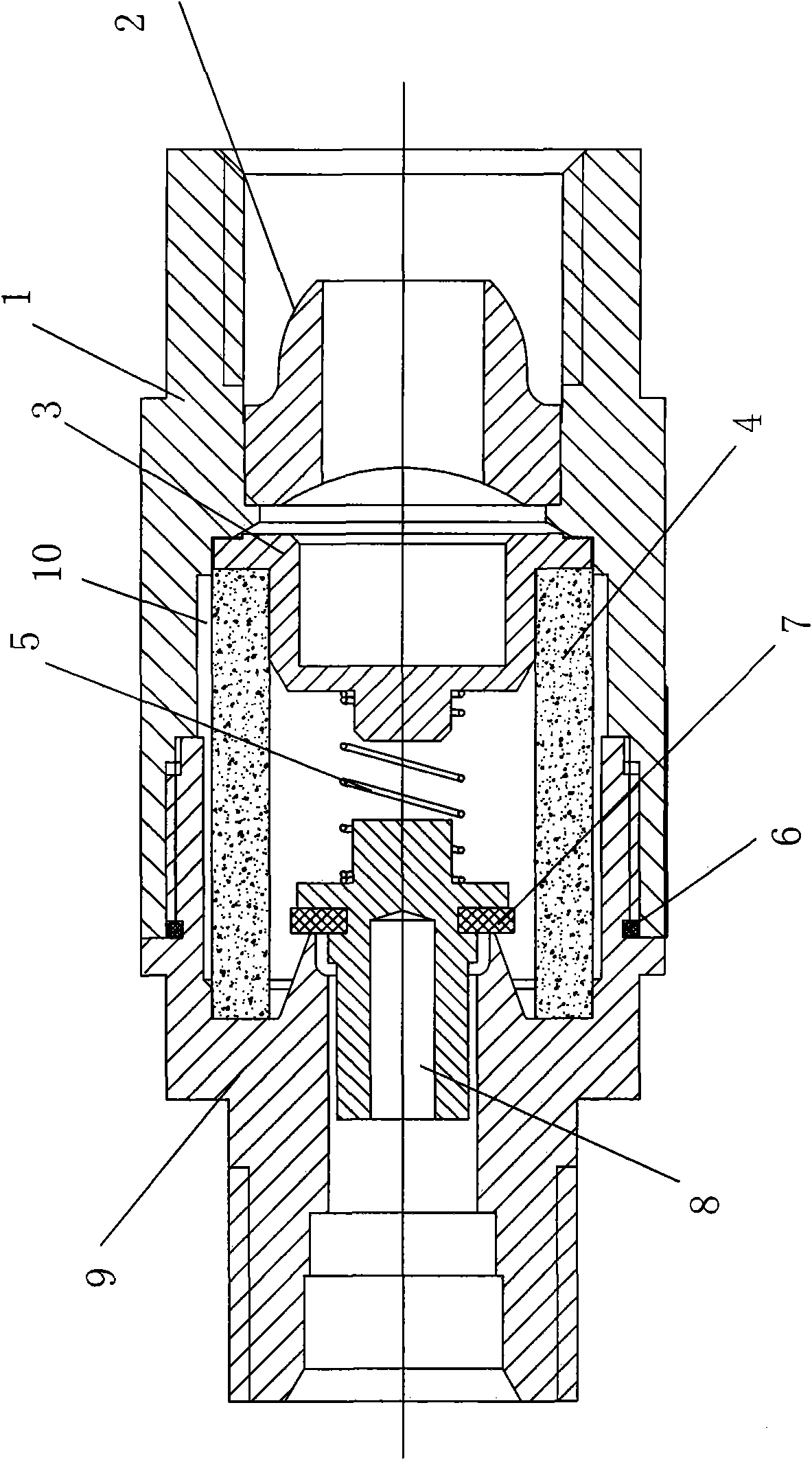

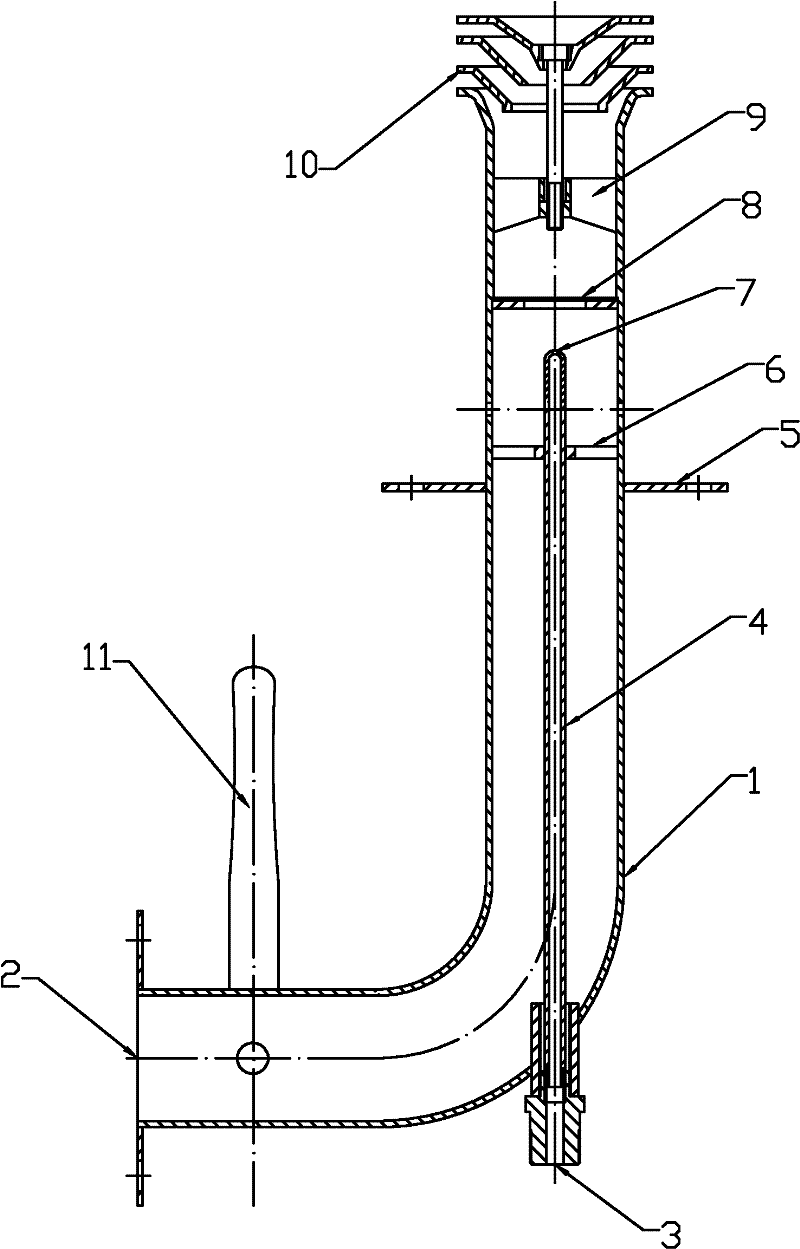

Back-fire arrestor

The invention discloses a back-fire arrestor which comprises a main body, an input joint, a one-way valve and an output joint, wherein the input joint is connected with the main body; the one-way valve is installed in the cavity of the main body; a spring seat is arranged in the cavity of the main body; the output joint is connected with the end part of the spring seat; one end of a valve spring is sleeved on the head part of the spring seat, and the other end of the valve spring abuts against a valve core; and a potted component and a fire-stopping pipe which is arranged above the spring seat are lined between the valve core and the input joint. The back-fire arrestor is characterized in that the potted component is a valve pad made of a fluororubber material; the fire-stopping pipe is prepared by sintering 80-100 mesh stainless steel particles; in a gas through return passage, gas enters from the middle passage, and the gas is discharged from the edge passages; when a gas negative pressure generated by backfire flame is higher than a forward normal pressure, the one-way valve of the back-fire arrestor is quickly closed, thereby effectively cutting a gas source off; because the one-way control valve takes fluororubber as a sealing material, so that the closing property and service life of the one-way valve are greatly improved; and the backfire ratio is effectively improved, simultaneously, the safe property is also improved, and the service life of the arrestor is prolonged.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Gap filler with waterproof and flame retardant functions and preparation method thereof

InactiveCN1702140APrevent penetrationWaterproofOther chemical processesBuilding insulationsBack-fireColloid

The invention relates to a building material, especially building gap-filling glue having a function of both water resistance and back-fire relief and the method for preparation. The gap-filling glue is prepared by mixing bulging water-proof colloid with bulging fire retardant and stirring, the weight ratio of said bulging water-proof colloid being 50-75%, and said bulging fire retardant being 25-50%. The prepared gap-filling glue having a function of both water-proof and back-fire relief expands the function of present only water-proof building gap-filling glue, having a function of back-fire relief.

Owner:JINGTAN ALBERT BEIJING TECH

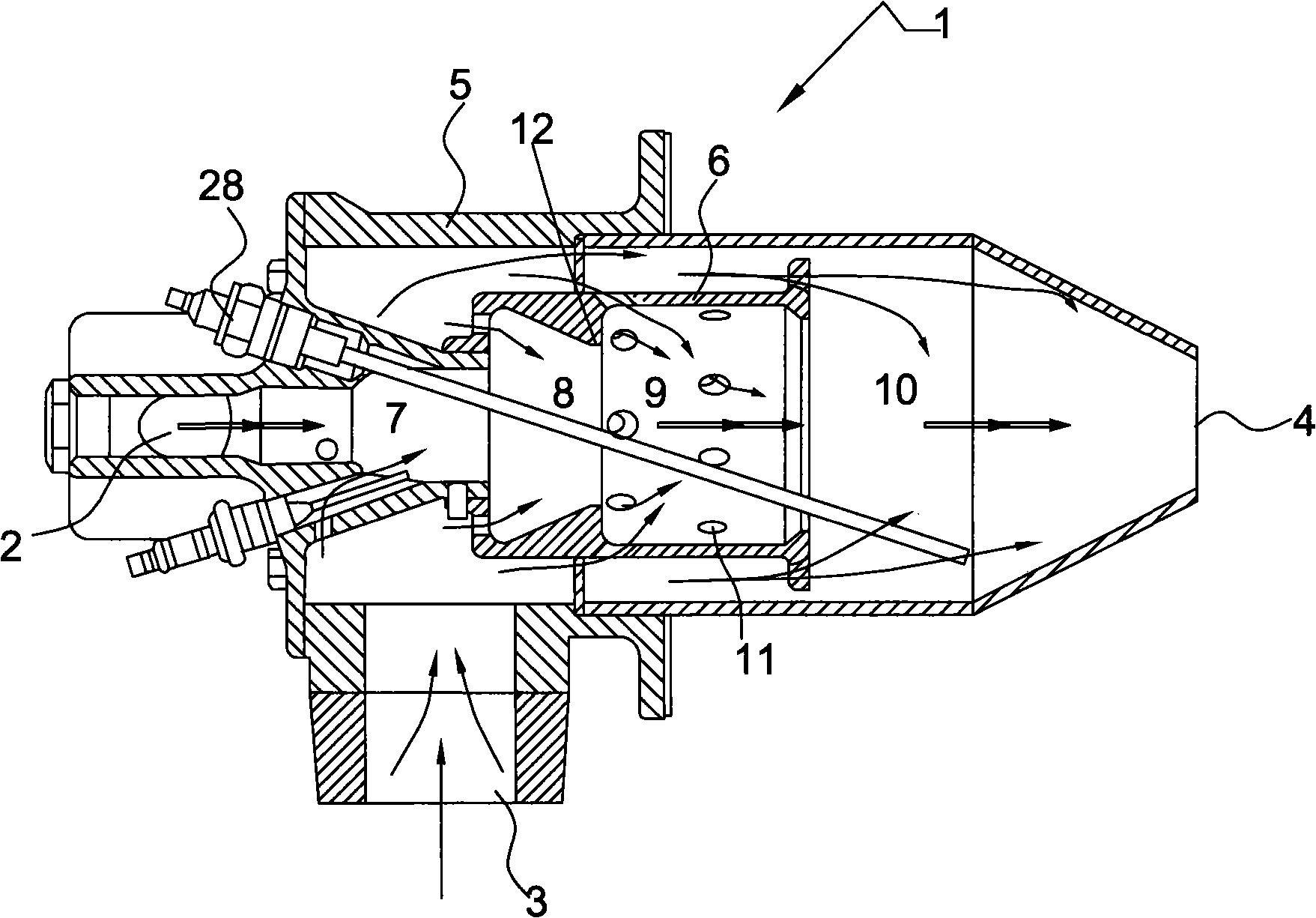

Gas-fired water heater

InactiveUS6945196B1Rapidly and easily assembled and disassembled and exchangedLower overall pressure dropCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberMixed gas

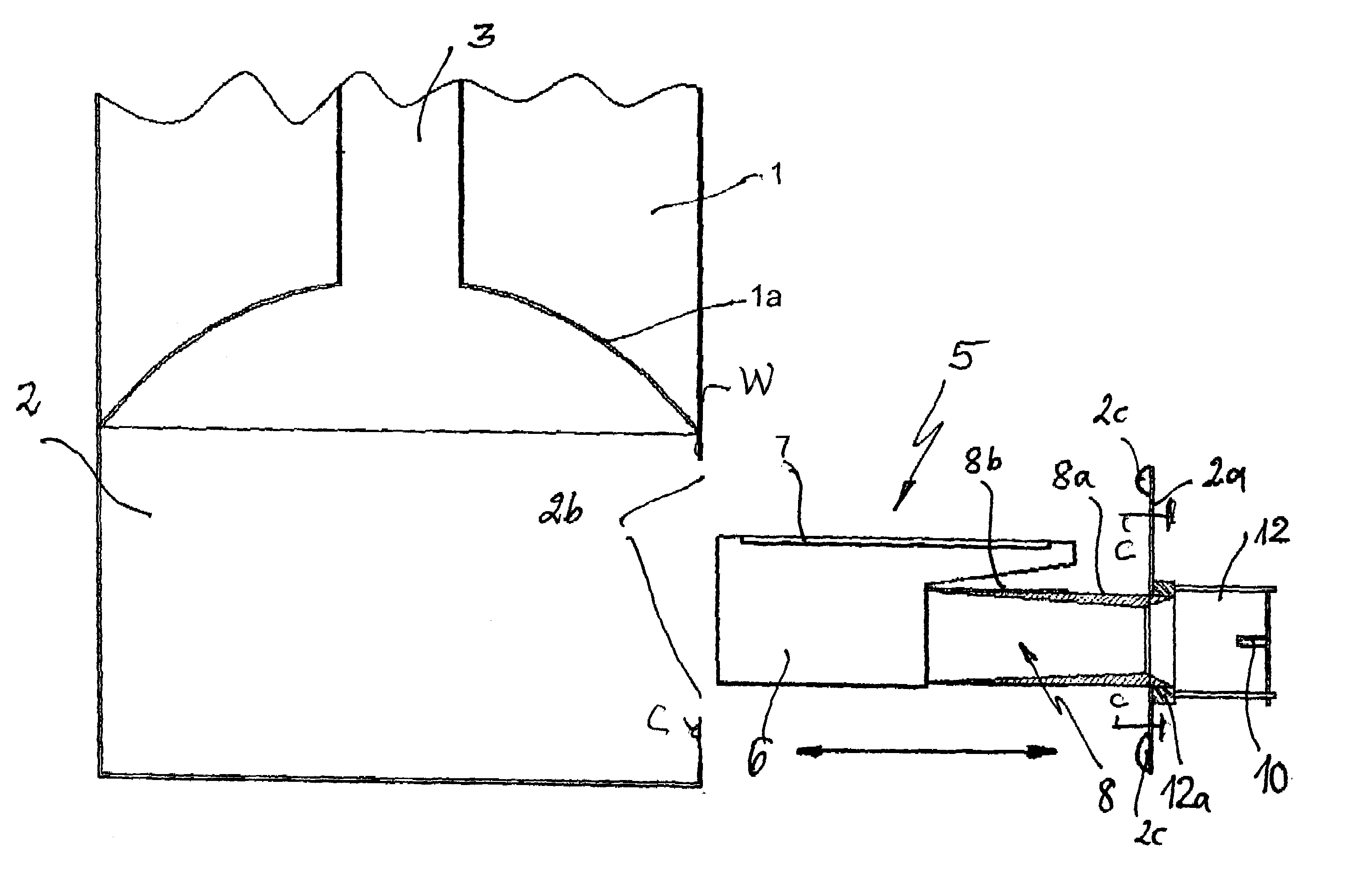

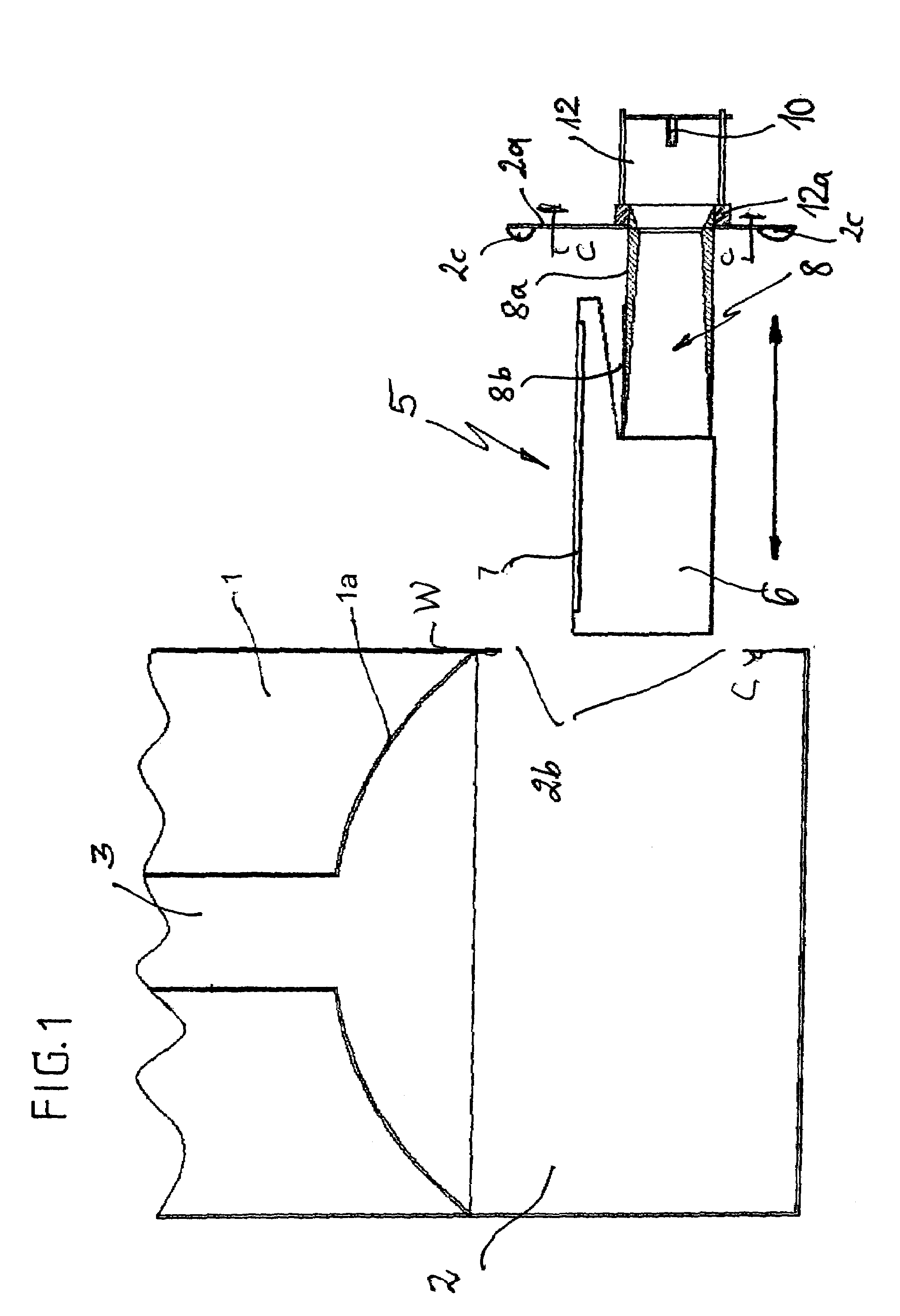

The water heater has an upright water tank (1), an exhaust flue (3) extending through the water tank, a combustion chamber (2) arranged under the water tank, an atmospheric gas burner (5) in the combustion chamber and a complete pre-mixing gas / air supply system with outside gas and air intakes. The gas burner has a burner mat (7) with a pressure drop less than 5 to up to 45 Pa. The combustion chamber (2) is provided with an opening (2b), which is not sealed, but enclosed in a flame-blocking manner. The gas burner (5) is attached to a wall section (2a), which is mounted releasably on the: combustion chamber wall (W) over opening (2b) so that a gap of predetermined width is formed between the wall section and wall (W), which prevents backfire of flames into the surroundings but admits secondary air.

Owner:ORKLI SCOOP

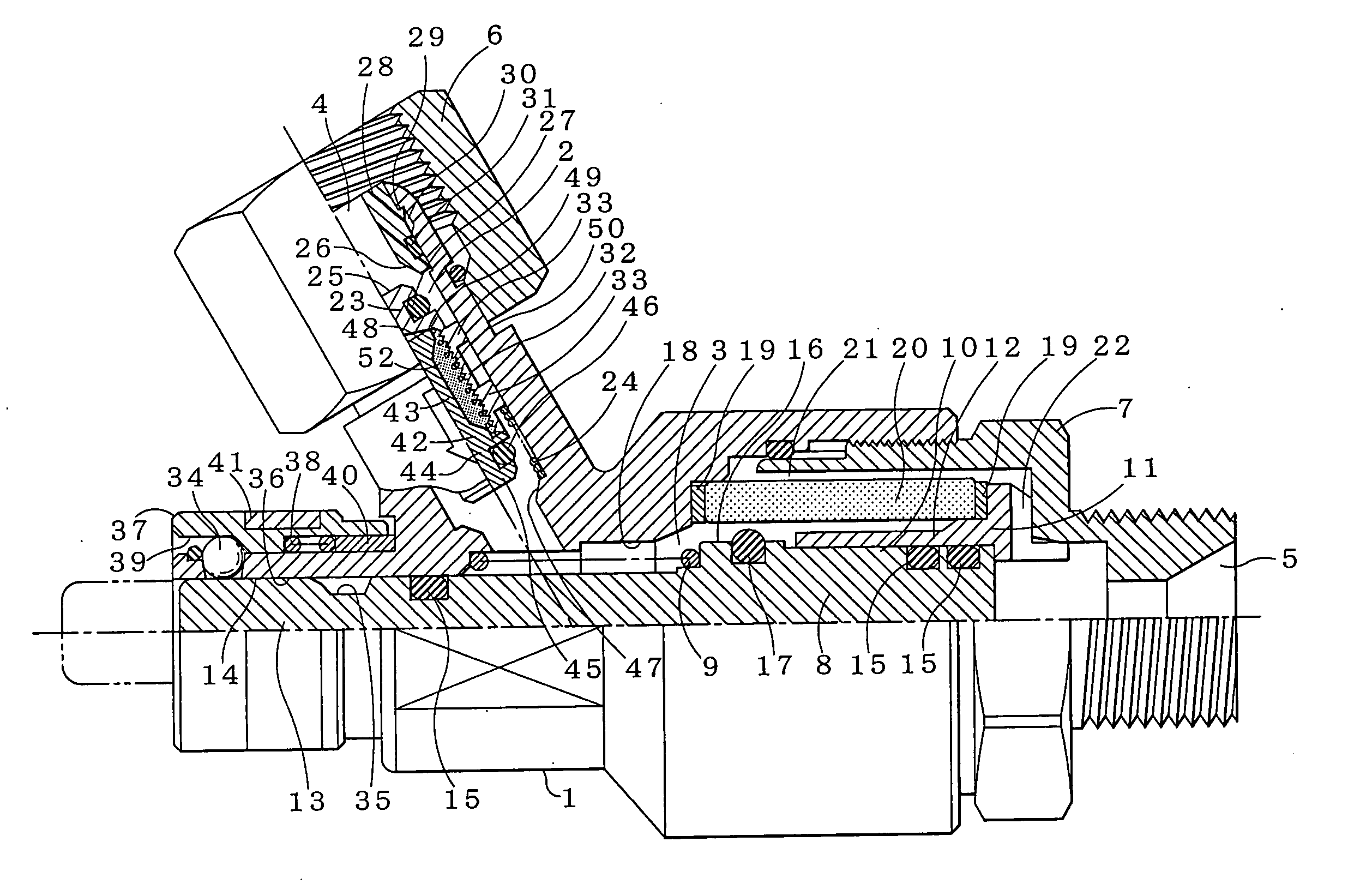

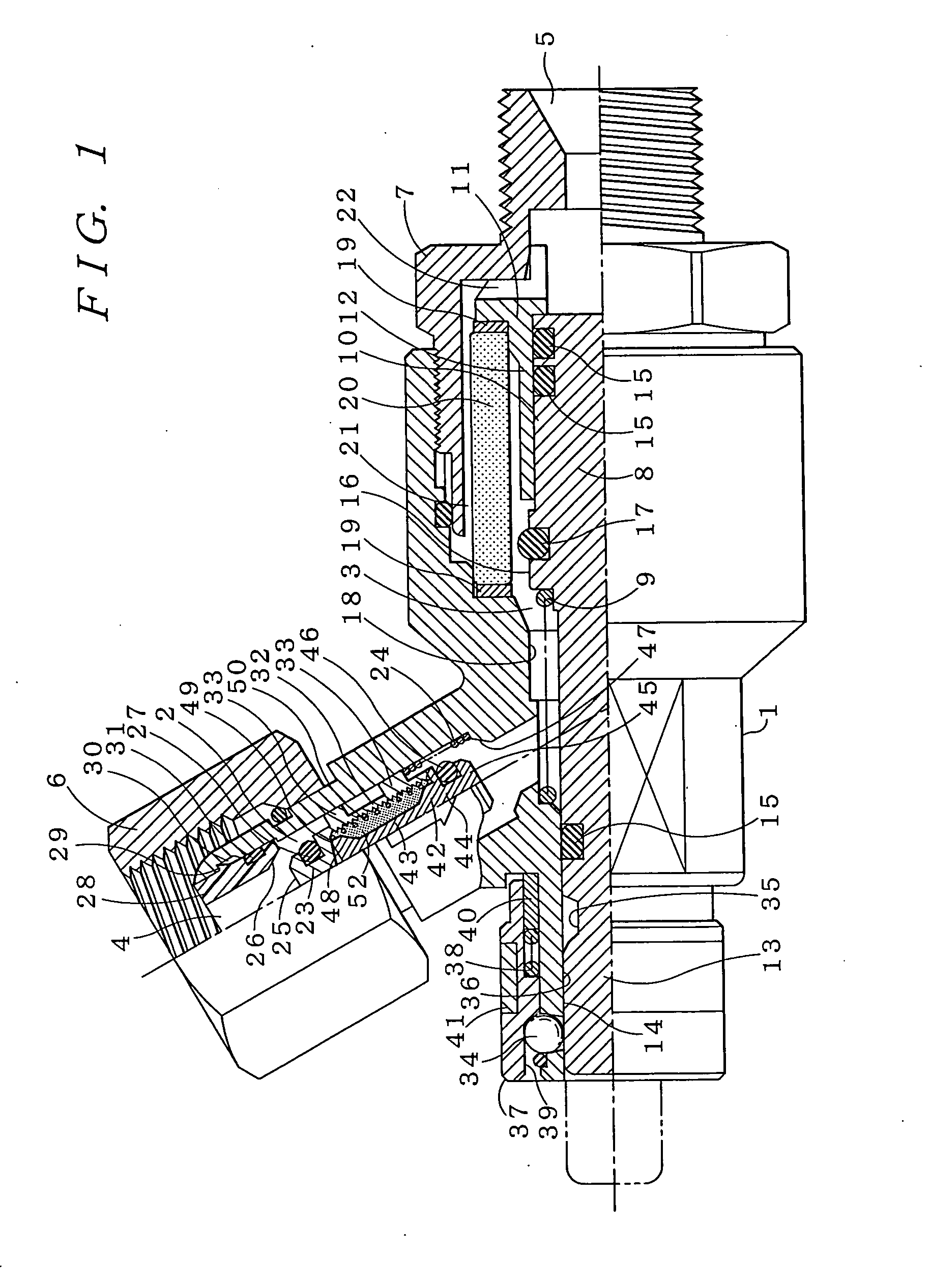

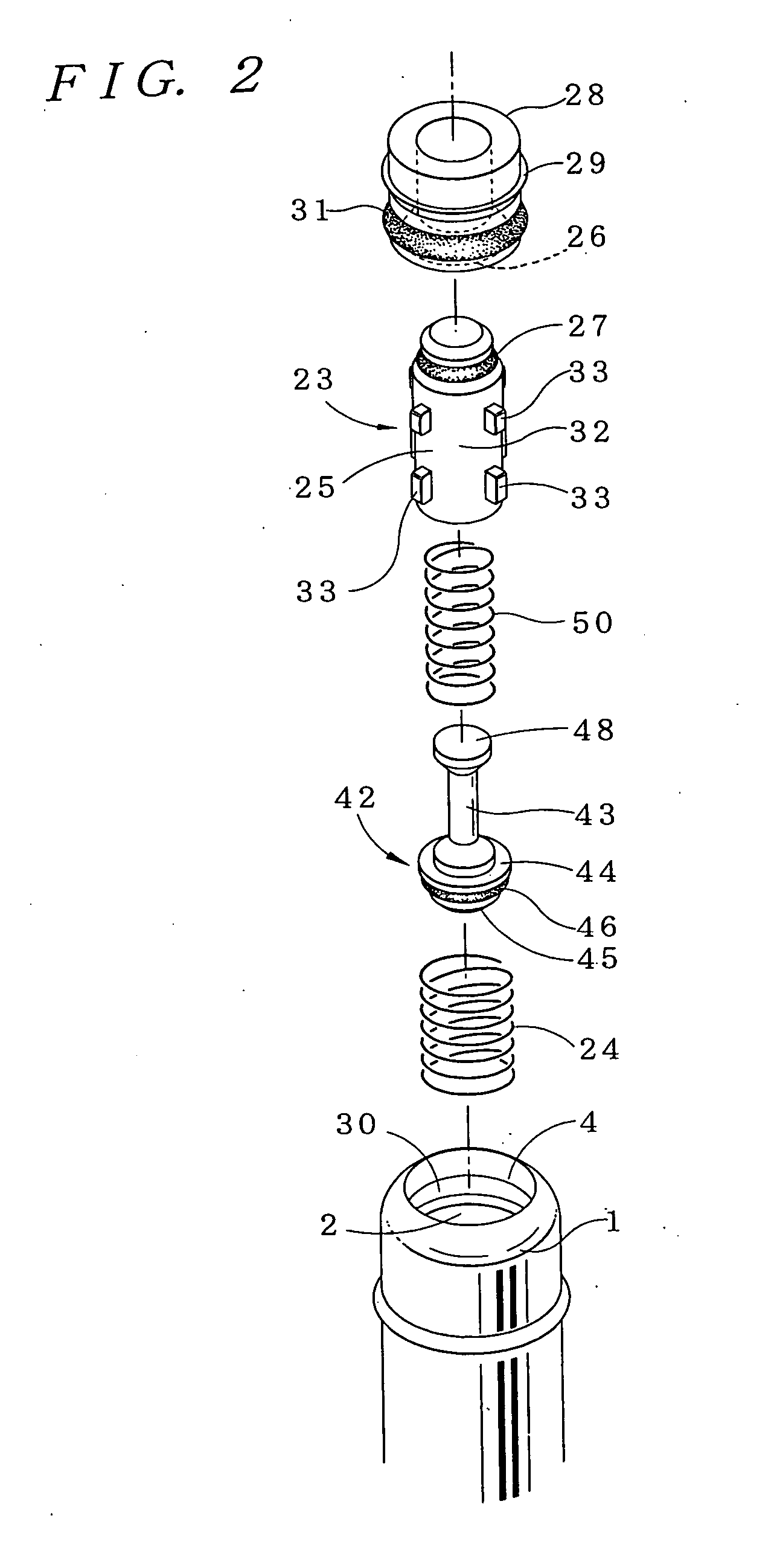

Dry safety device for an inflammable gas

ActiveUS20050045226A1Operational securityRugged in constructionCheck valvesFuel feedersOpen portCounter flow

A dry safety device for an inflammable gas comprises a case main body having a gas passage which terminates at one end in a primary side open port connectable to a source of inflammable gas and terminates at the other end in a secondary side open port connectable to a gas-fired appliance. A spindle undergoes sliding movement in the case main body between an open position for opening the gas passage and a closed position for closing the gas passage, and a spindle spring normally urges the spindle to the open position and permits the spindle to move to the closed position in response to a counter-flow pressure exerted on the spindle by a counter flow of inflammable gas directed from the secondary side open port to the primary side open port. A flame-extinguishing filter disposed in the gas passage extinguishes a back fire that may occur during a counter flow of inflammable gas, and a normally open shutoff valve disposed in the gas passage upstream from the filter closes the gas passage when an ambient temperature exceeds a given value.

Owner:SANKI CO LTD

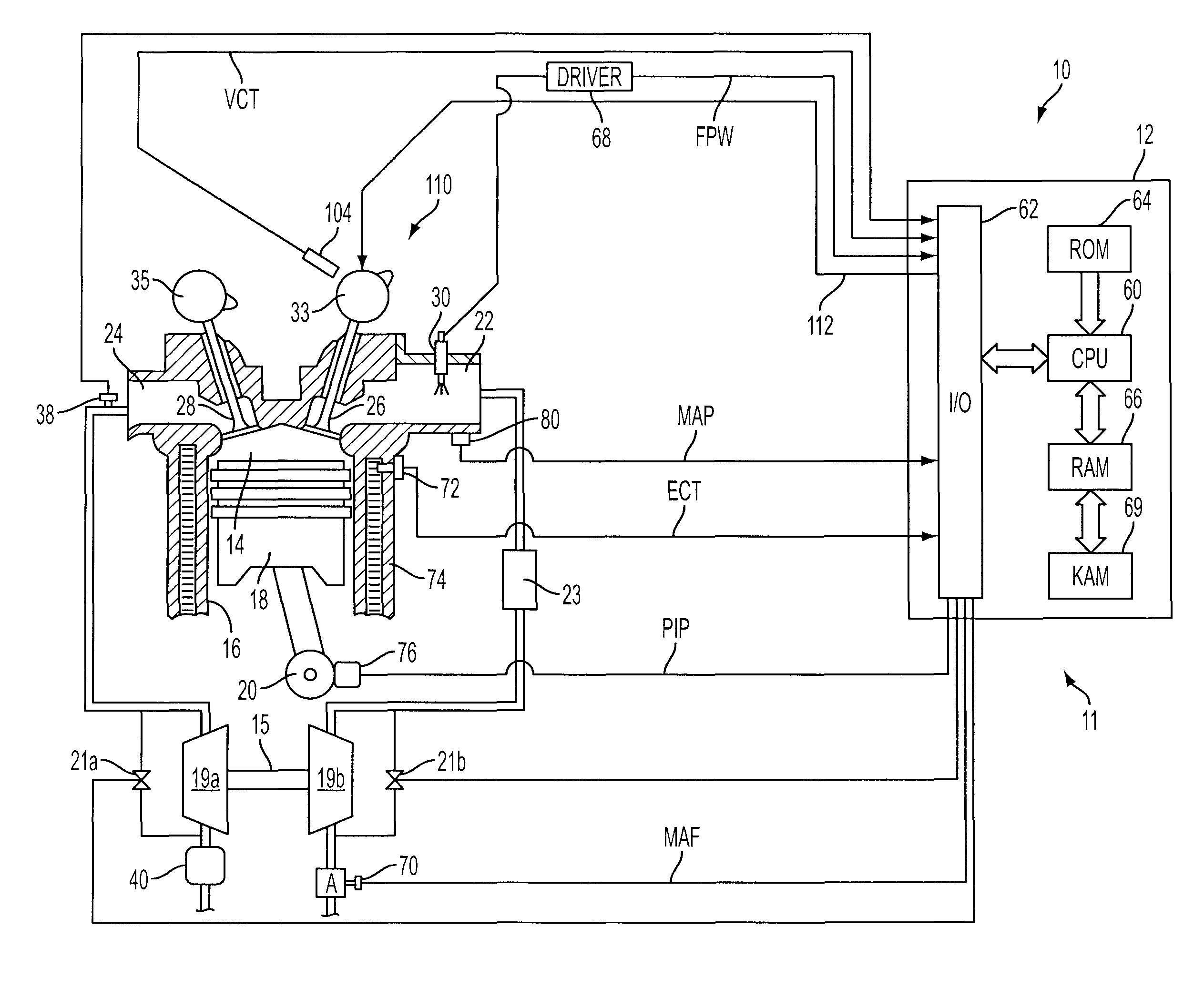

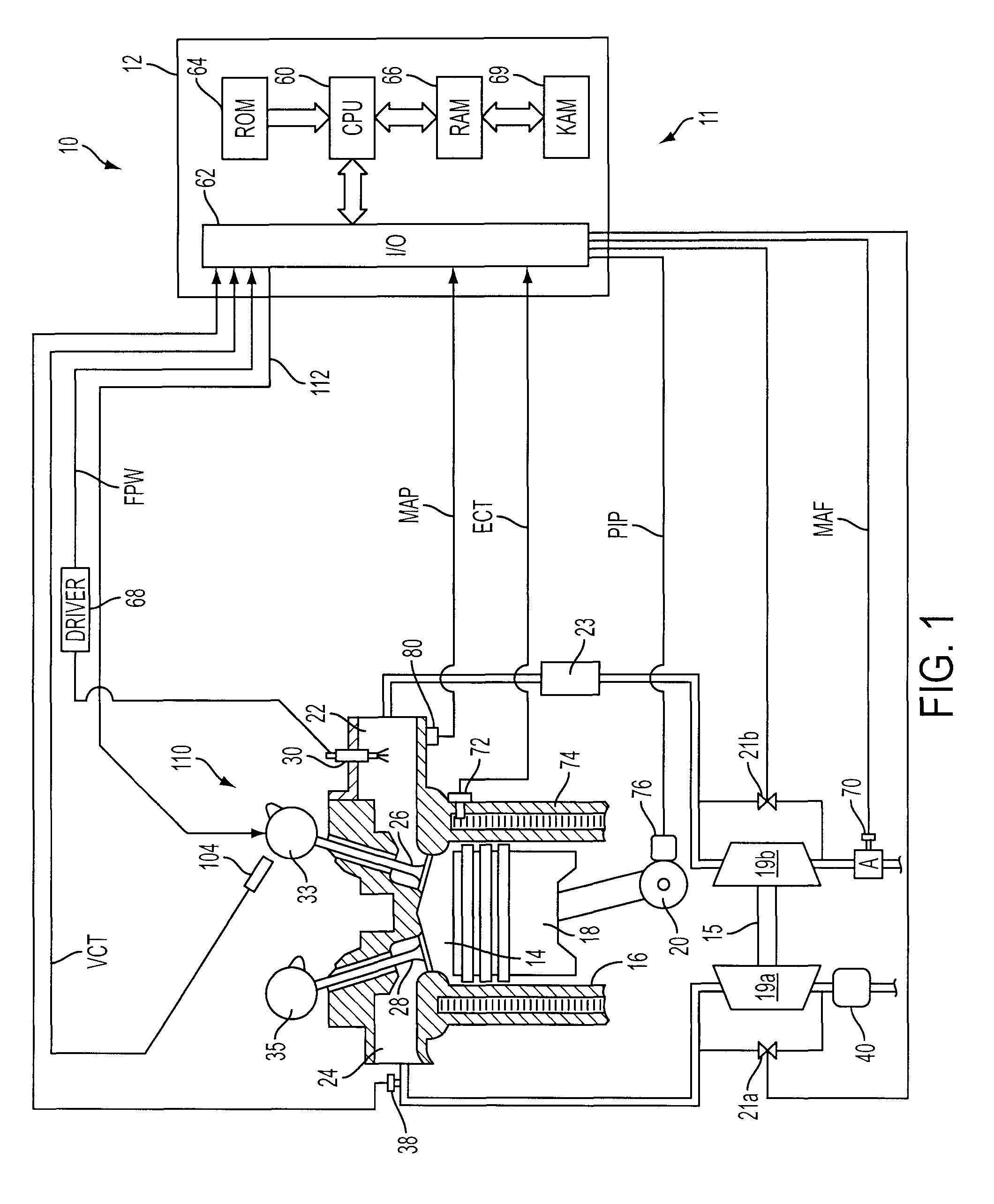

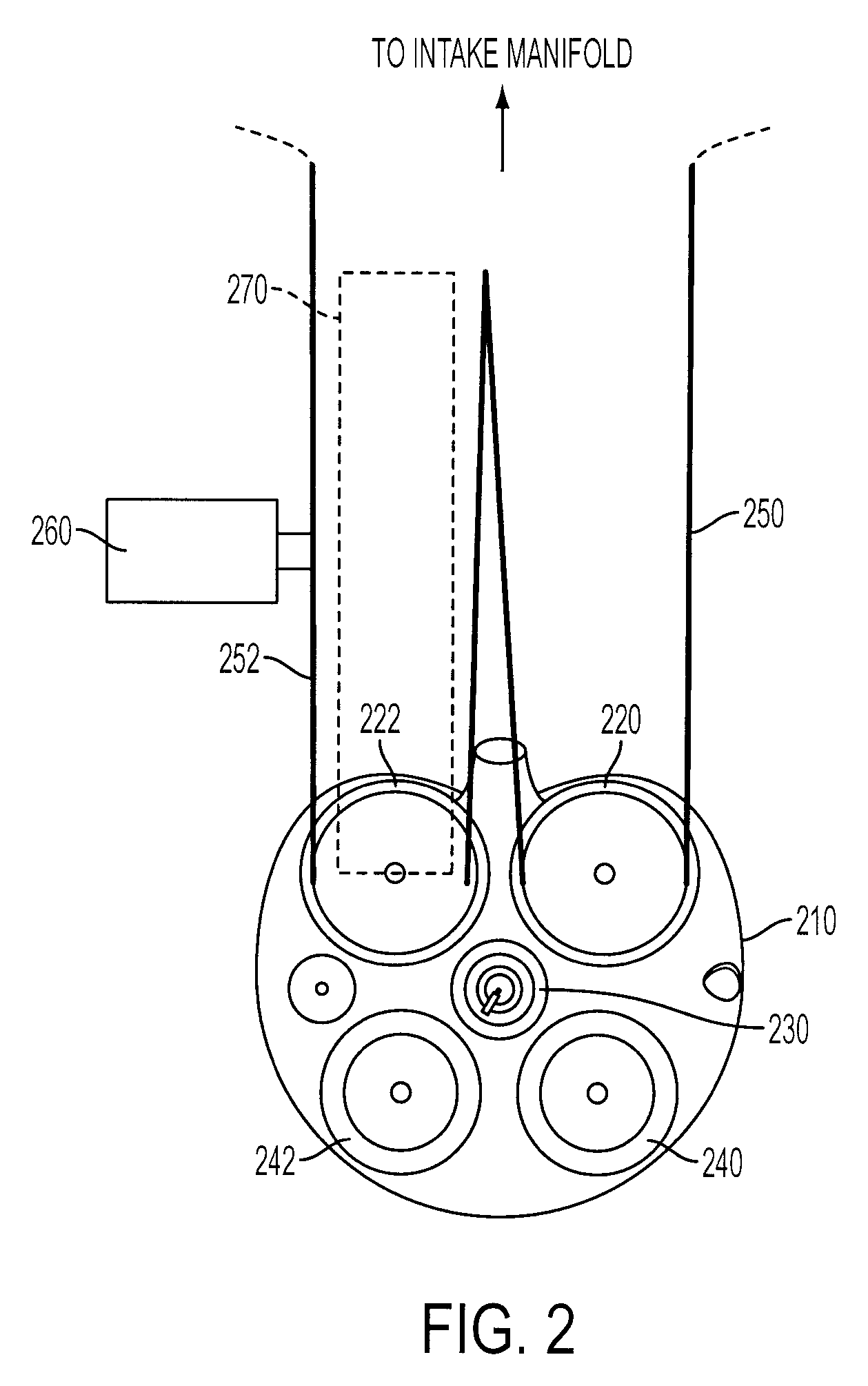

Staggered intake valve opening with bifurcated port to eliminate hydrogen intake backfire

InactiveUS7980220B2Lower potentialImprove economyValve arrangementsElectrical controlBack-fireInlet valve

Owner:FORD GLOBAL TECH LLC

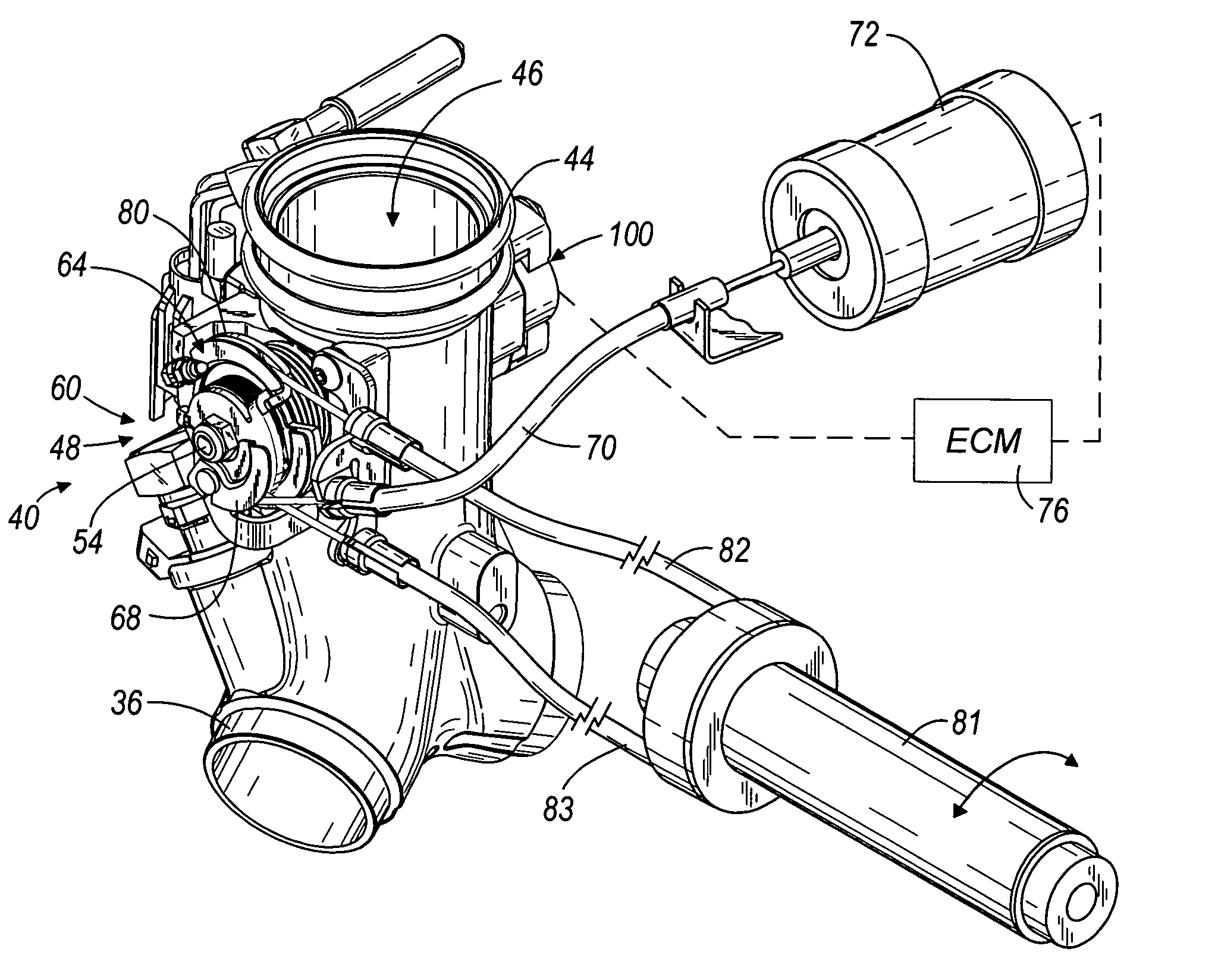

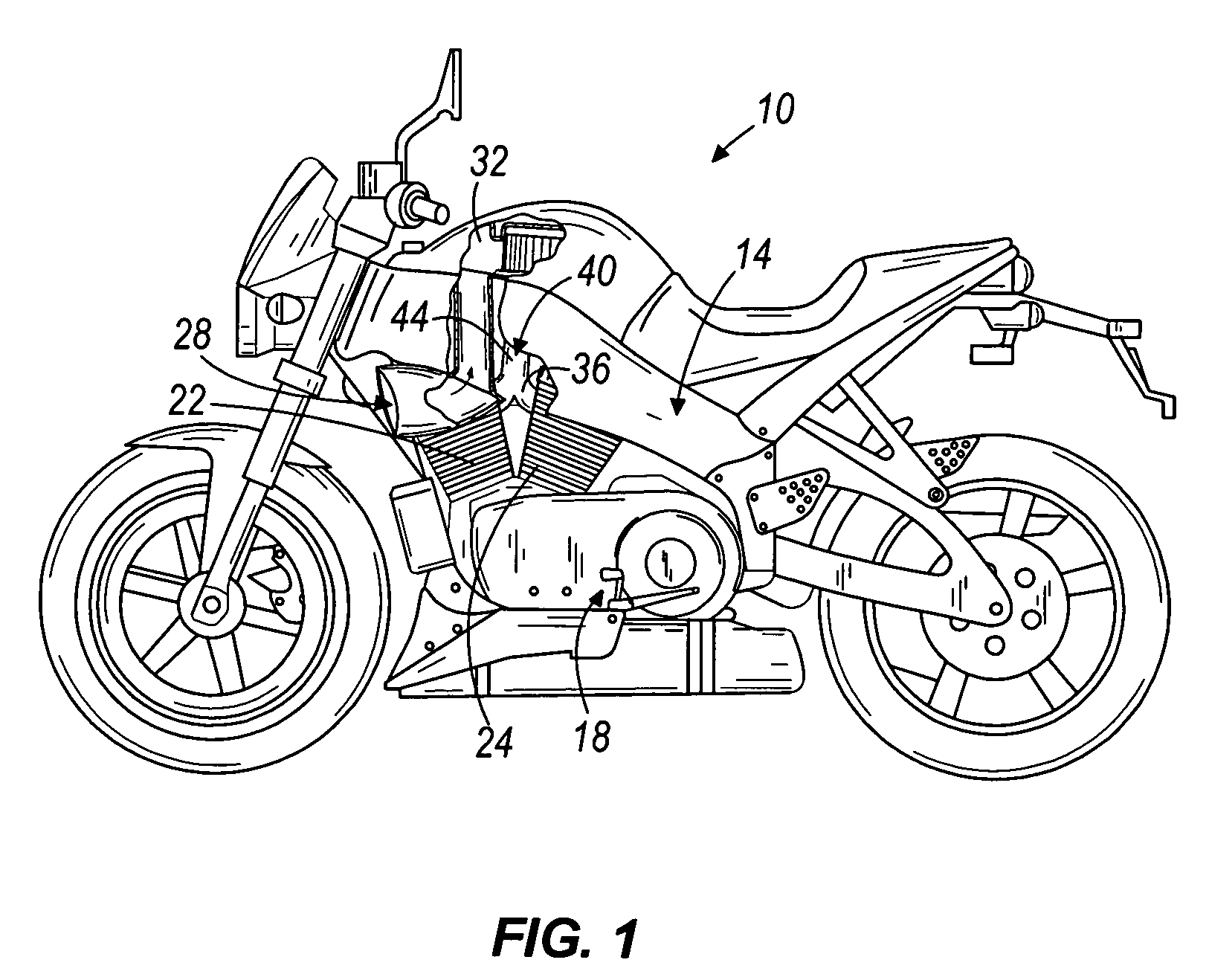

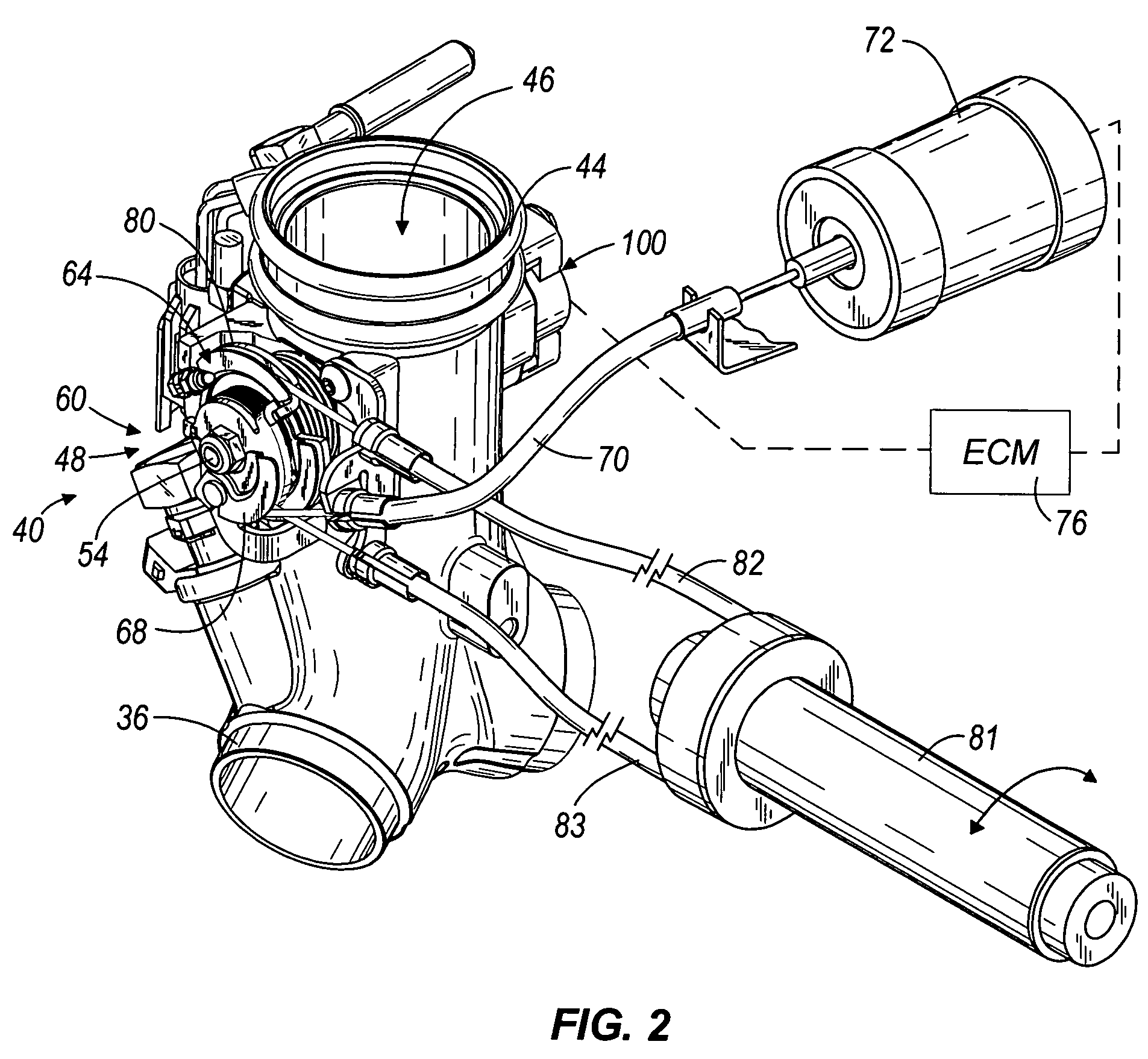

Power control device and method for a motorcycle

A power control device and method for a motorcycle. The power control device controls the power of the motorcycle engine in predetermined situations. The power control device controls the power output of the engine while maintaining an optimal air-to-fuel ratio to prevent backfires and misfires during combustion. In one embodiment, the power control device reduces the airflow to the engine by rotating a throttle valve. The amount of fuel delivered to the engine is also reduced corresponding to the position of the throttle valve. By reducing the amount of fuel delivered to the engine based upon the amount of airflow to the engine, the air-to-fuel ratio within the engine remains optimal for combustion. The throttle valve can be rotated by the operator and by the power control device. The position of the throttle plate and corresponding power output of the engine is controlled by the operator until overridden by the power control device.

Owner:BUELL MOTORCYCLE COMPANY +1

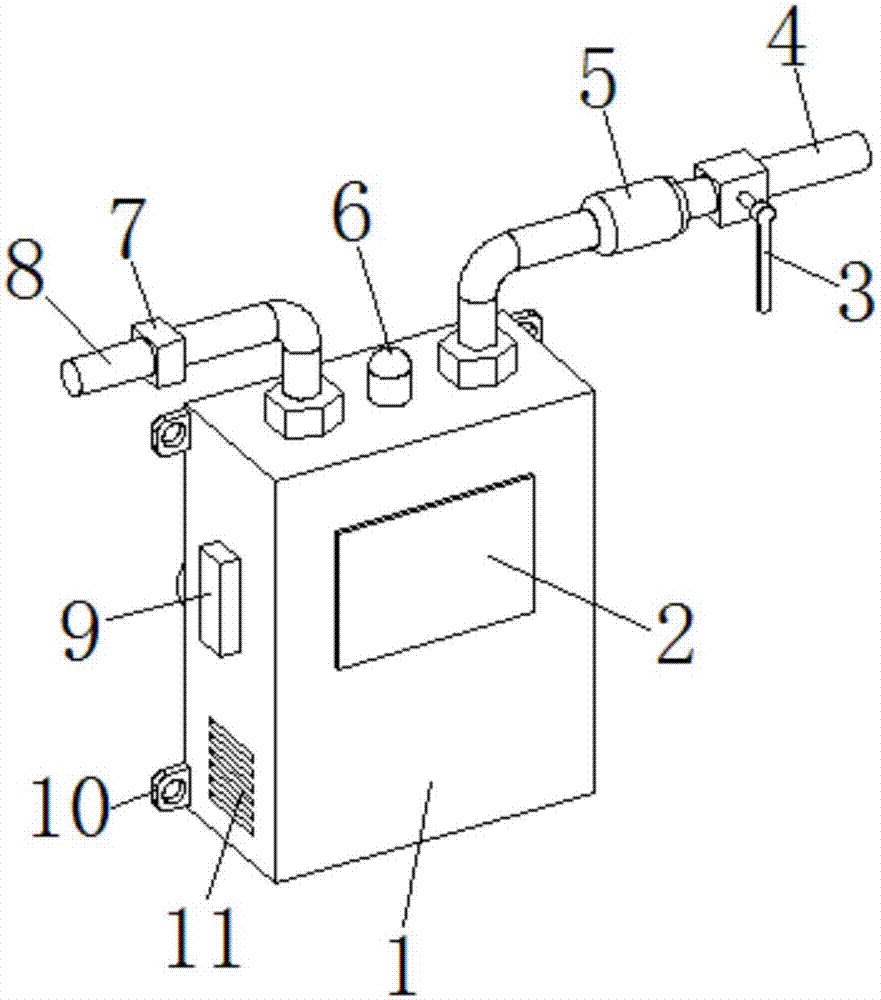

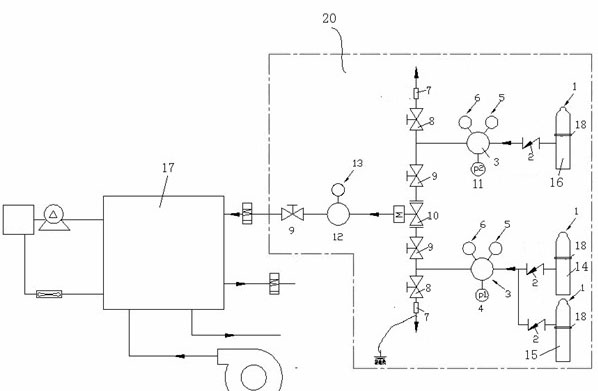

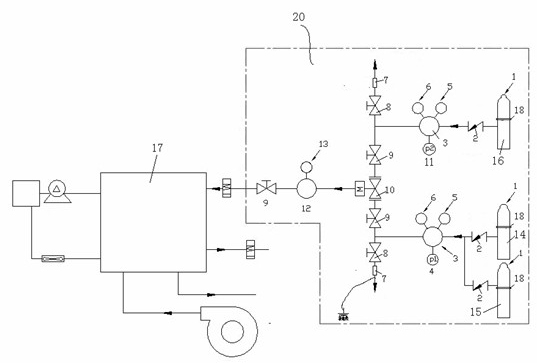

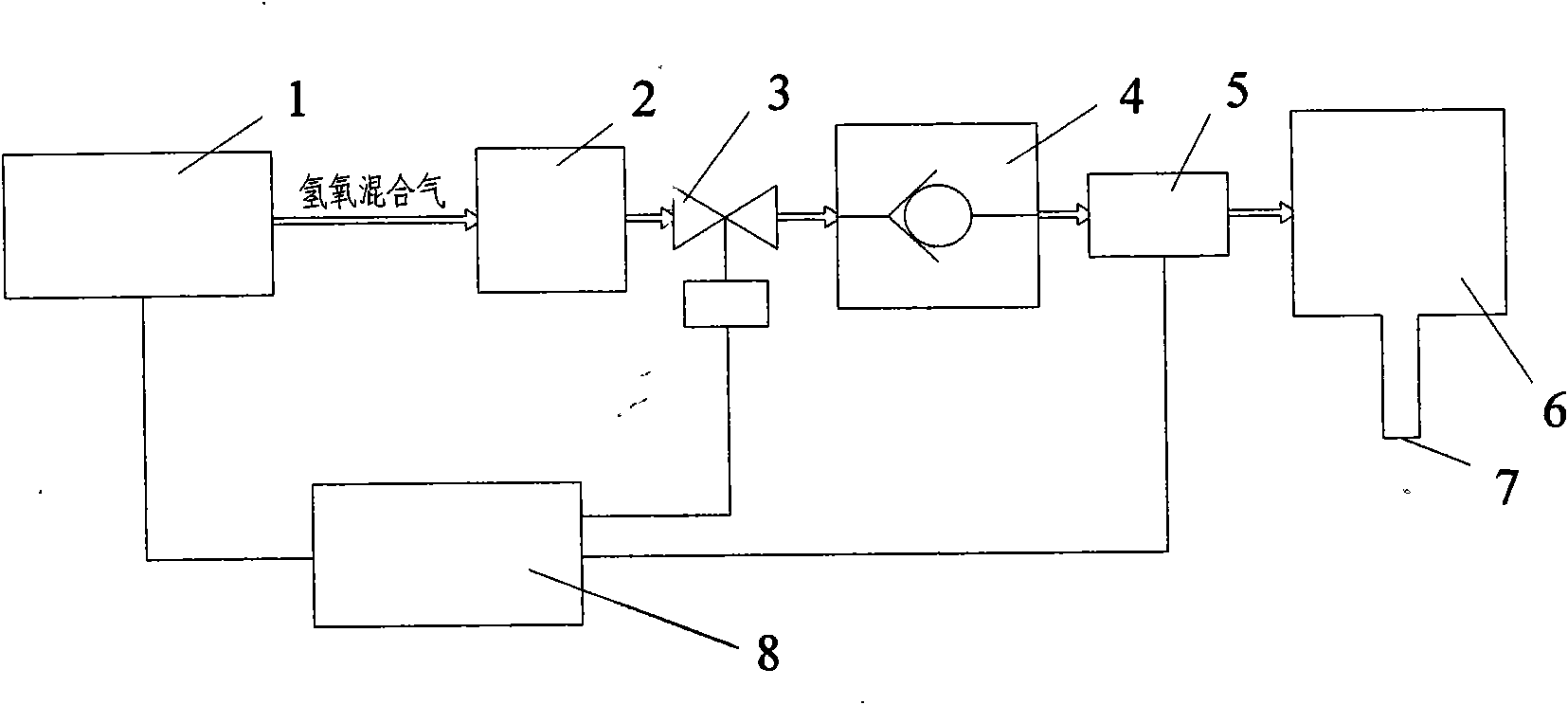

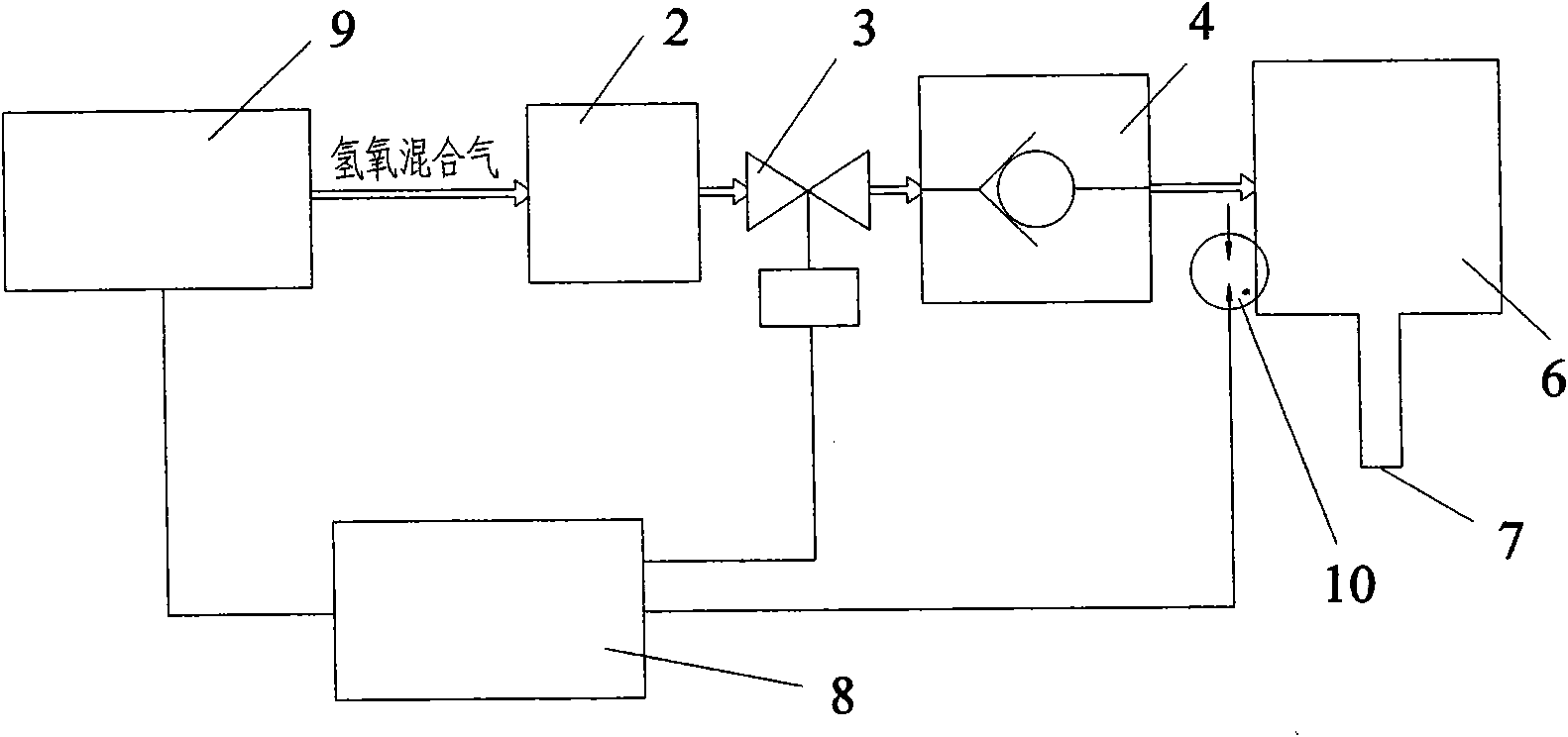

Application of oxygen hydrogen gas in shock tank blasting and soot blowing method

The invention discloses an application of oxygen hydrogen gas in a shock tank blasting and soot blowing method and relates to the technical field of blasting and soot blowing, which mainly prepares mixed gas of hydrogen and oxygen through a water splitting oxygen hydrogen device or a solar oxygen hydrogen generator. The mixed gas of hydrogen and oxygen of the method enters a back-fire relief valve, a solenoid pilot actuated valve, a one-way valve and a shock tank in sequence from a gas path pipeline; a controller is electrically connected with the solenoid pilot actuated valve to control the air supply time and simultaneously control an ignition device on the shock tank to ignite according to procedures; and then the shock tank generates blasting and instantly generates an explosive pulsewave, which is sprayed out and jetted through a nozzle at a high speed to realize soot blowing operation on the heated surface of a boiler. The invention discloses an application of mixed gas of oxygen and hydrogen in the shock tank blasting and soot blowing method, which can achieve the advantages of large wave intensity, good soot blowing effect, easy operation and control as well as safe and reliable application without needing to pre-mix gas sources of oxygen and hydrogen and simplifying the technique.

Owner:ZHEJIANG HELI HYDROGEN ENERGY TECH CO LTD

Process for manufacturing high-temperature resistant back-fire bag

InactiveCN101209571ALight weightImprove fire performanceSold ingredients supply apparatusMixing operation plantFiberMetallurgy

The invention relates to a preparation method of a high-temperature resistance firestopping pillow. According to the weight percentage, the compounding of the raw material is 40.0%-50.0% of aluminum silicate fiber cotton particle and 50.0%-60.0% of raw vermiculite. The manufacturing steps are that (1) weighing and dosing; (2) mixing and pouring; (3) sealing of firestopping pillow; (4) detection and storage. The invention provides the firestoppign pillow which is widely applied to the cable engineering in industries such as power, metallurgy, petrochemicals, buildings, etc. and can resist the high temperature which is more than 1000 DEG C. The invention has the advantages of light bulk density, good fireproof performance, long firestopping time, convenient disassembly and assembly, repeated application after disassembly, etc.

Owner:嵊州市电缆防火附件厂

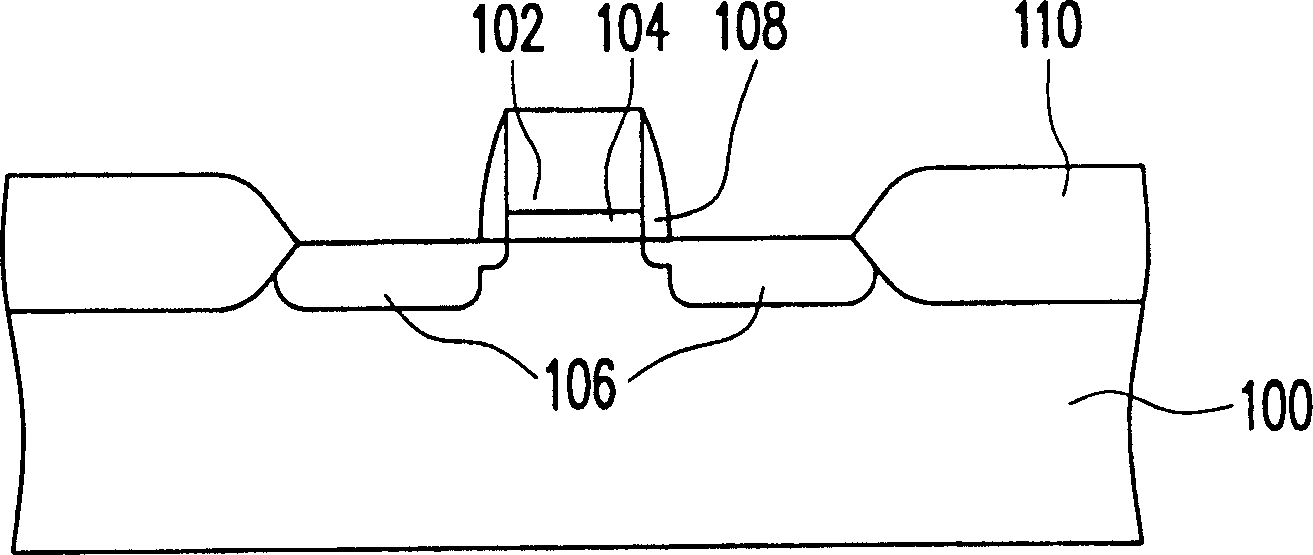

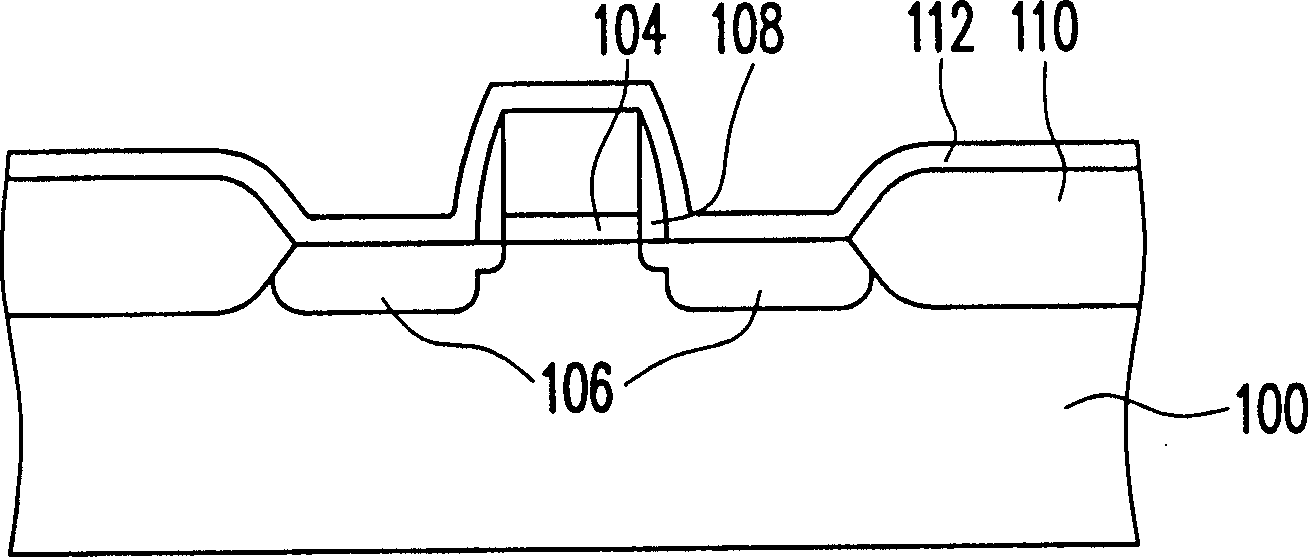

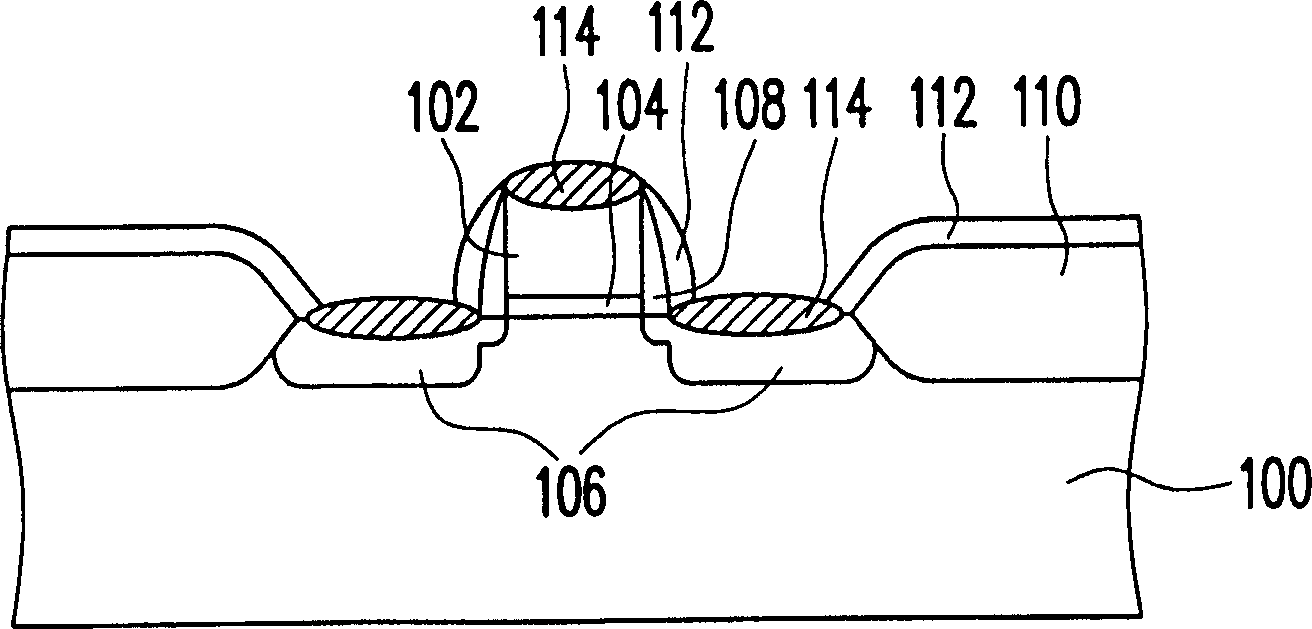

Method for mfg. metal silicide

InactiveCN1862779AManufacturing Method ImprovementsFast heating processSemiconductor/solid-state device manufacturingSalicideJunction leakage

This invention relates to one metal silicide manufacturing method. This invention is used to metal silicide technique. It is used to deposition anti heat metal layer and the layer is first back fired and the unreacted metal is eliminated. Species injection technique is done to inject the species into the metal silicide to destroy lattice structure in the metal silicide, that is done to avoid spiking and lateral diffusion brought by high temperature of the metal silicide when the second back fire, and the junction leakage problem generated is also avoided.

Owner:UNITED MICROELECTRONICS CORP

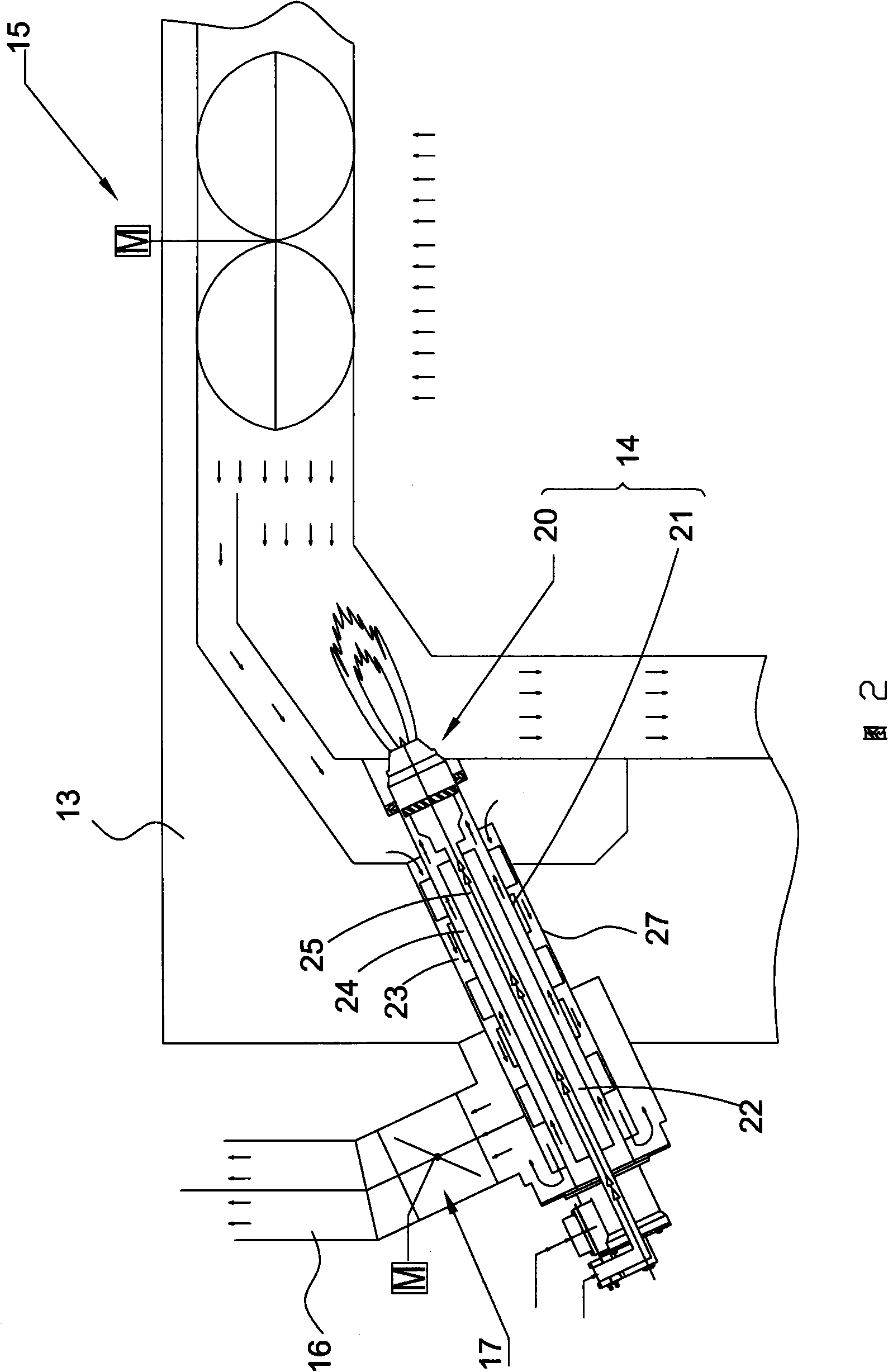

Forced-draft flameless combustor

The invention discloses a forced-draft flameless combustor, which mainly solves the problems of incomplete gas combustion and black smoke rising of the conventional combustor. The forced-draft flameless combustor comprises a combustor main body, wherein an air inlet is arranged at the bottom of the combustor main body, and a combustion seat is arranged at the top of the combustor main body; a gas inlet pipe is arranged in a vertical part of the combustor main body; a gas inlet is arranged at the bottom end of the gas inlet pipe, and an internal nozzle is arranged at the top end of the gas inlet pipe; the combustion seat is formed by movably overlapping a plurality of layers of funnel-shaped structures; and an adjustable clearance is reserved between every two layers of funnel-shaped structures. By unique design of the forced-draft flameless combustor, gas can be completely combusted, temperature is uniform during the arrangement of a plurality of combustors, a disk-shaped blue flame can be formed, a process is safe, carbon absorption is avoided, the problems of back fire and black smoke rising are solved, and the forced-draft flameless combustor is particularly applicable to a cracking furnace.

Owner:JINAN TORCH CREATION ENERGY SCI & TECH

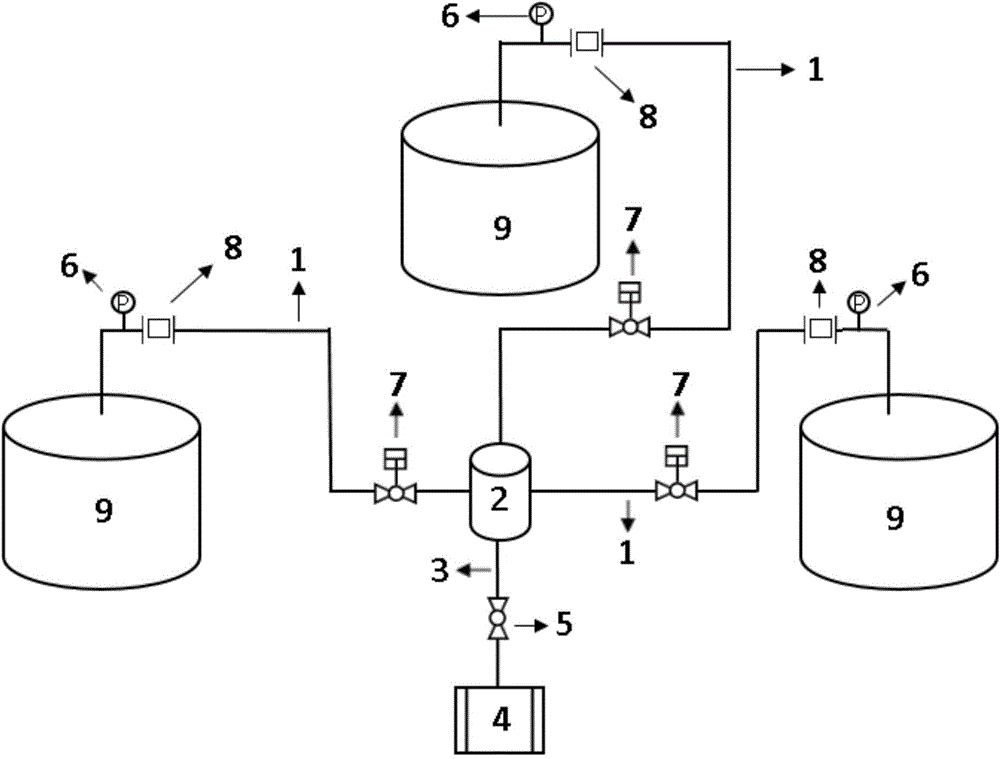

Storage tank gas phase communication device

ActiveCN104787513AAvoid direct connectionAvoid it happening againLarge containersLine tubingGas phase

The invention relates to a storage tank gas phase communication device. The storage tank gas phase communication device mainly solves the problem of breathing loss in the prior art, and meanwhile solves the problems of gas phase fire blasting risks and lower oil-gas recovery efficiency. The storage tank gas phase communication device comprises gas phase communication pipes (1), an oil-gas adsorption and desorption tank (2), an oil-gas recovery pipe (3), an oil-gas recovery device (4), a control valve (5), quick action emergency valves (7), back-fire relief valves (8) and at least one storage tank (9); the gas phase communication pipes (1) led out from gas phase space of each storage tank (9) are provided with the quick action emergency valves (7) and the back-fire relief valves (8), the oil-gas adsorption and desorption tank (2) is provided with the oil-gas recovery pipe (3), and the oil-gas recovery pipe (3) is connected with the oil-gas recovery device (4). According to the technical scheme, the above problems are better solved, and the storage tank gas phase communication device can be used for storage tank gas phase communication.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Process for preparing low-alloy wear-resistant steel without high temperature heat treatment

This invention is high temperature heat treatment low alloy antifriction cast steel preparation technique. It is a low energy consumption, high mechanical properties low alloy antifriction cast steel. Tiny or few elements added in the alloy batching can make heat treatment C curve shift right liquid steel qualified is added into casting mold to control solidification temperature of casting, casting is taken out from casting mold when the temperature is down to certain value and quenched in water. It is taken out from water when temperature is down below 1000C, and back fire at 00~3000C. High temperature heat treatment is removed in this invention, so a great deal of electric energy or fuel can be saved and high temperature heat treatment can be eliminated. Working condition can be improved, oxidation and burning loss of alloy material during heat treatment is avoided. Production cycle of casting is shortened, labor productivity is highly improved. metal material loss can be reduced, and environmental pollution by heat treatment is reduced.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com