Method for mfg. metal silicide

A technology of metal silicide and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as spikes and lateral diffusion, interface leakage current, and nickel inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

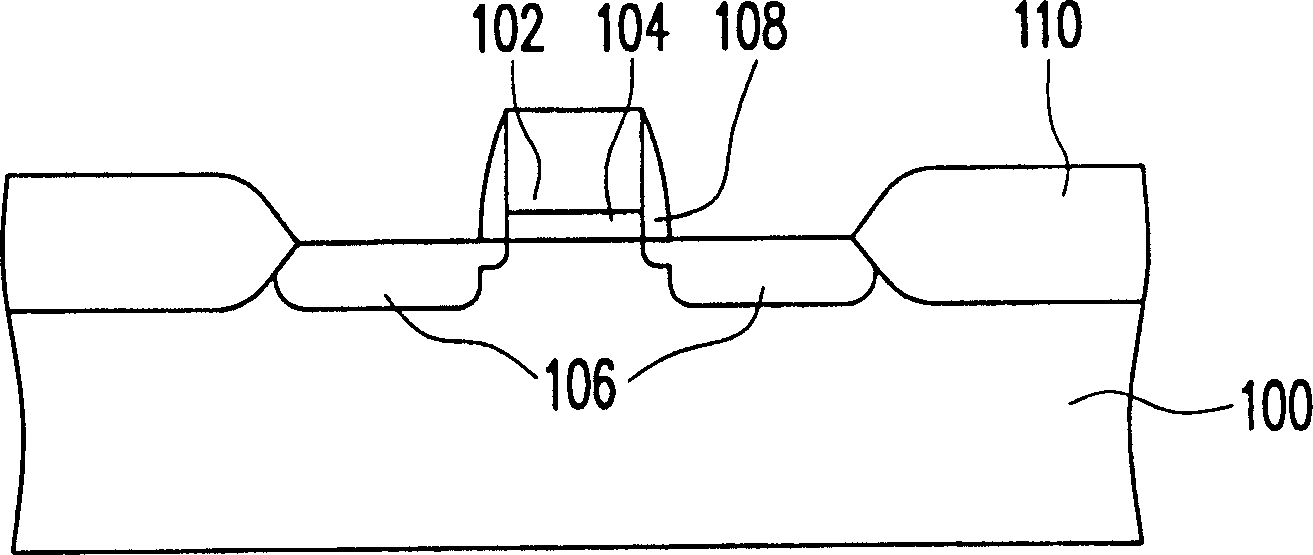

[0037] Figure 1A to Figure 1E It is a flow sectional view of a metal silicide manufacturing method according to a preferred embodiment of the present invention. First, please refer to Figure 1A , a silicon substrate 100 is provided, and an active area (active area) is defined on the substrate 100 by an isolation structure 110 . The isolation structure 110 is, for example, a field oxide layer formed by a local area thermal oxidation method or a shallow trench isolation structure formed by a shallow trench isolation method. A metal-oxide-semiconductor transistor is formed in the active region, and the metal-oxide-semiconductor transistor includes a drain / source 106, a gate 102, and a gate oxide layer 104 below the gate 102, and is formed on the sidewall of the gate 102. There is a spacer wall 108 .

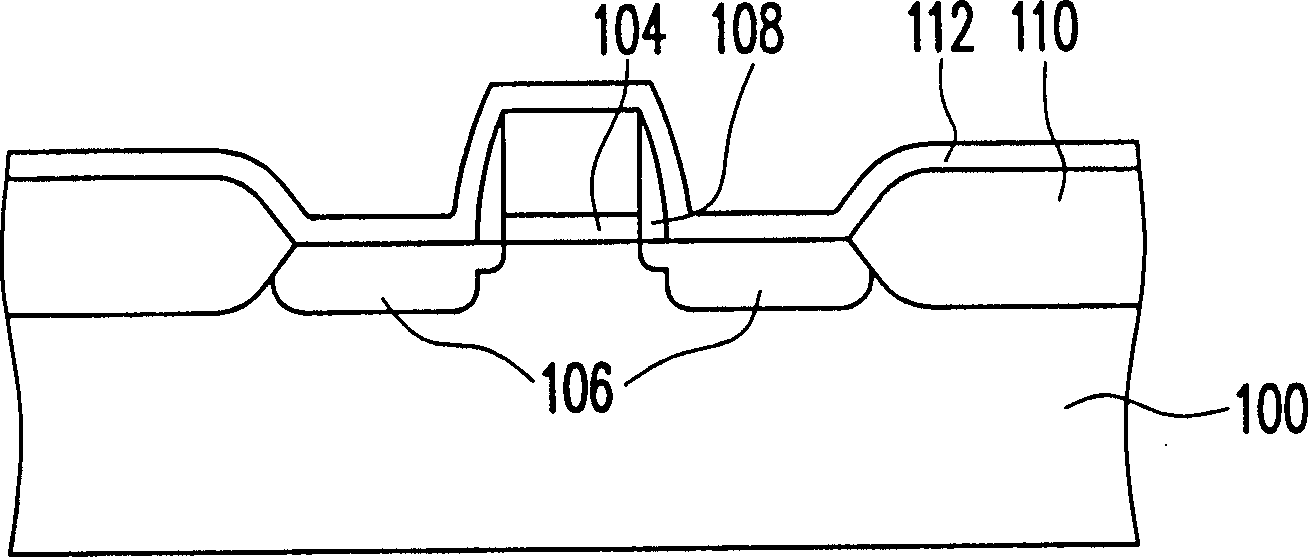

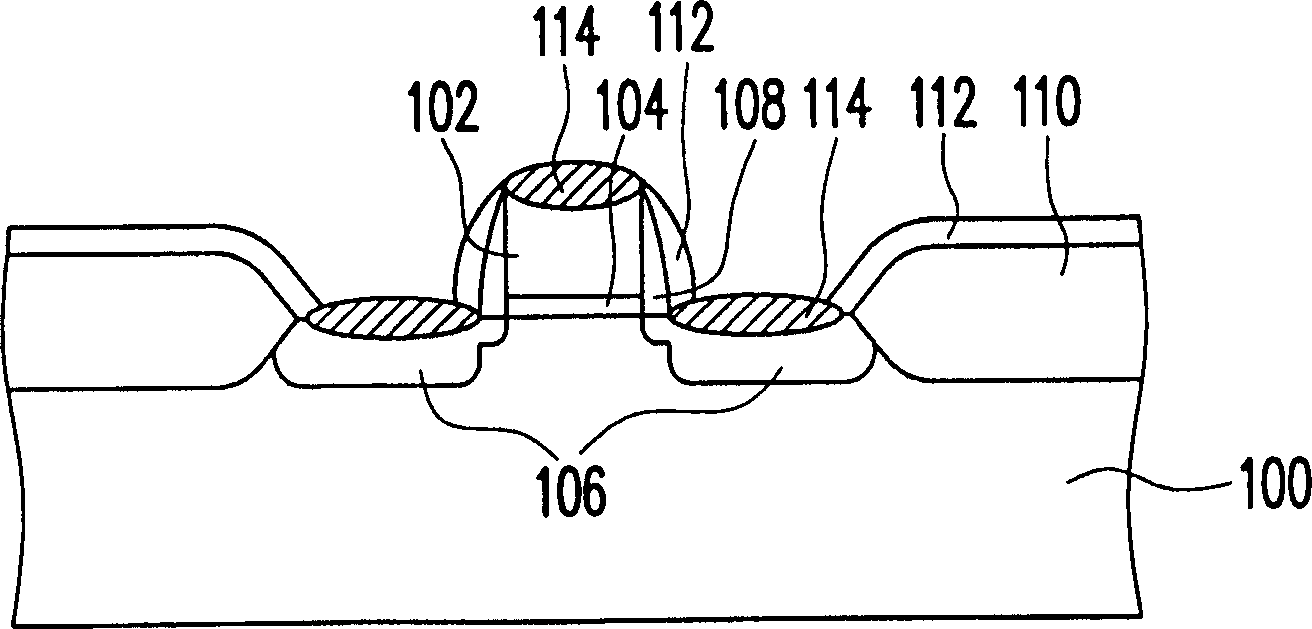

[0038] Next, please refer to Figure 1B On the substrate 100, a metal layer 112 is deposited, and the material of the metal layer 112 includes heat-resistant metals, such as ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com