Manufacturing method of actuating shaft for washing machine

A manufacturing method and drive shaft technology, applied in the field of washing machines, can solve the problems of multiple processing steps and high strength, and achieve the effects of simple manufacturing process, increased strength, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Refer to the attached Figure 5 Embodiments of the present invention are described in more detail:

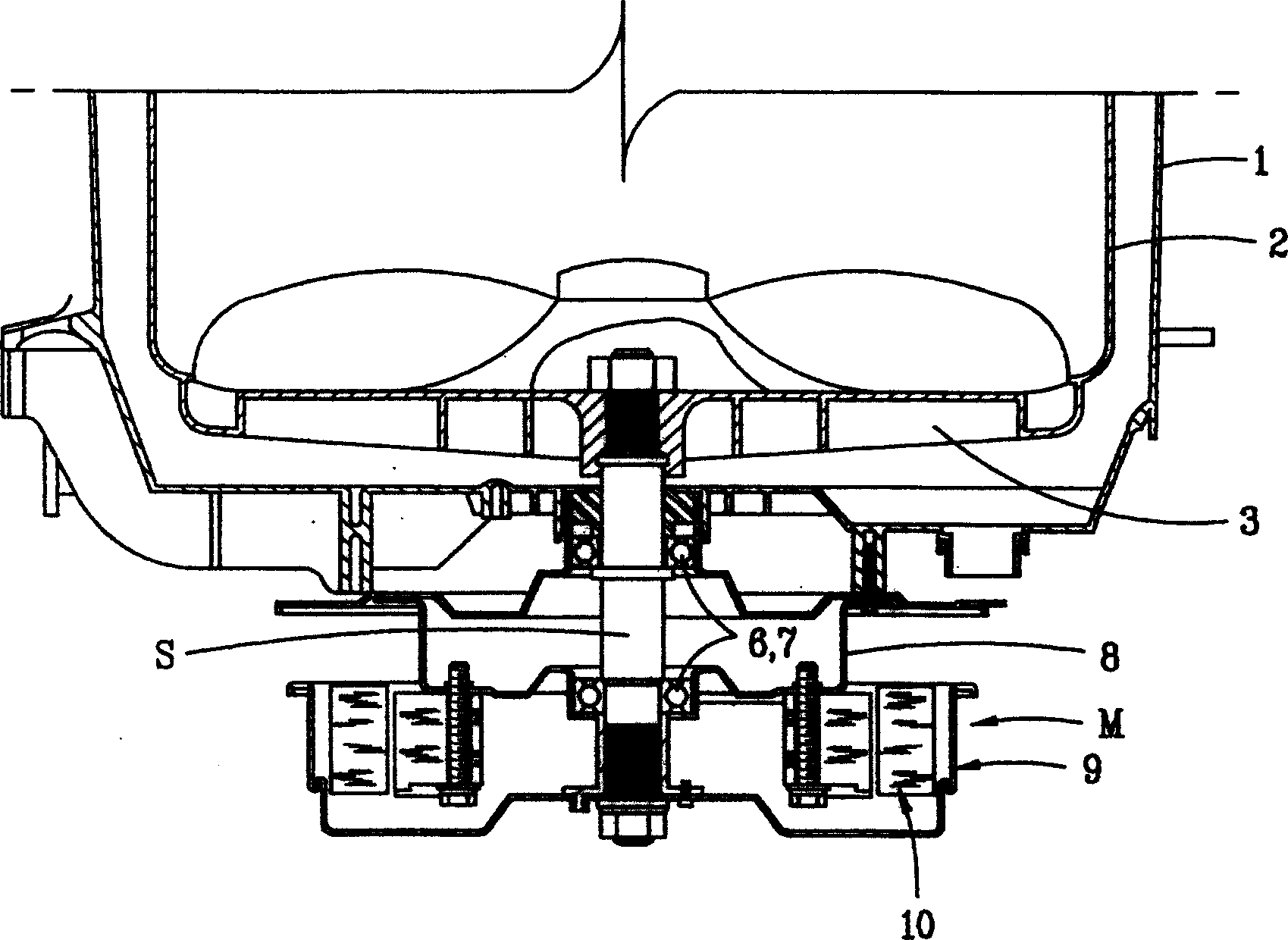

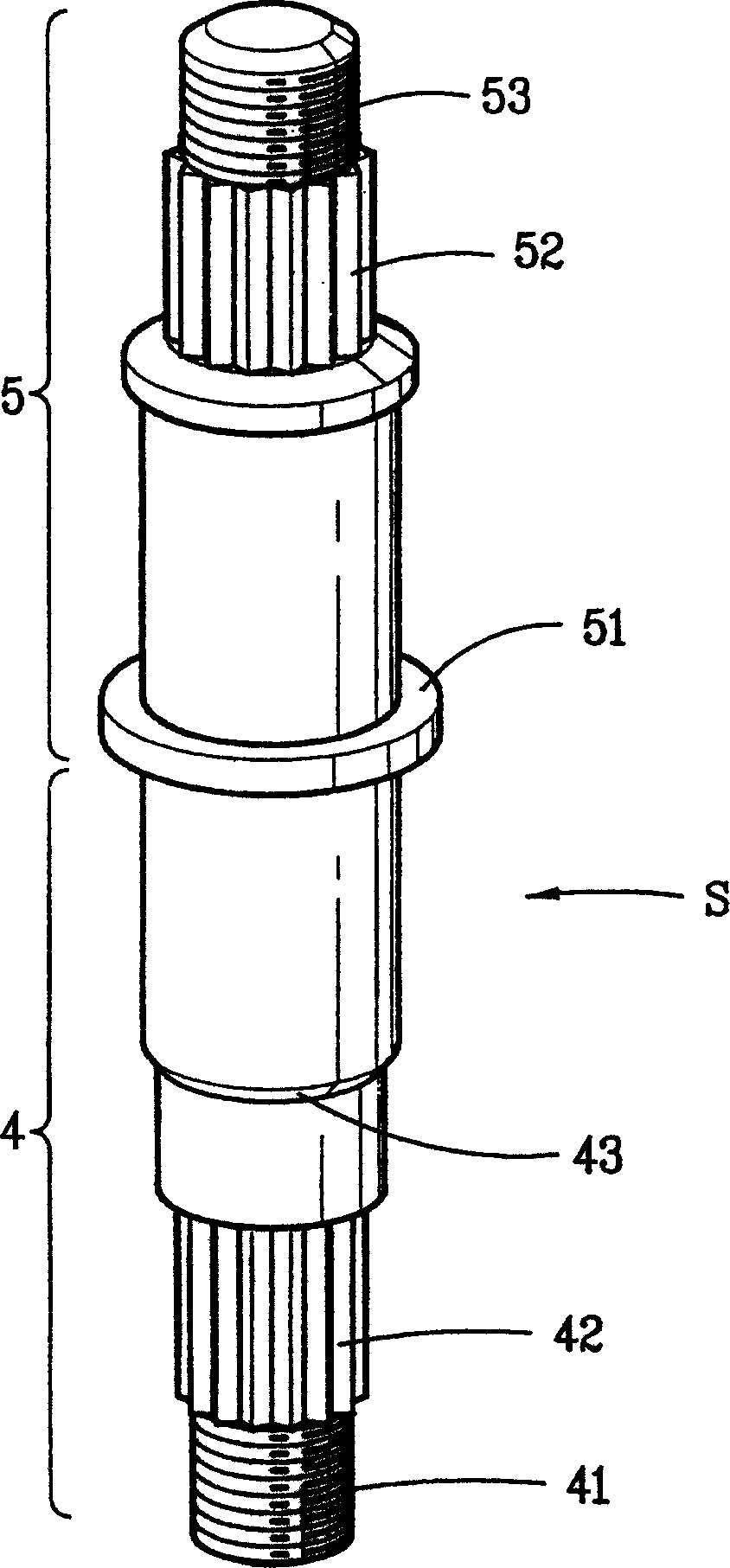

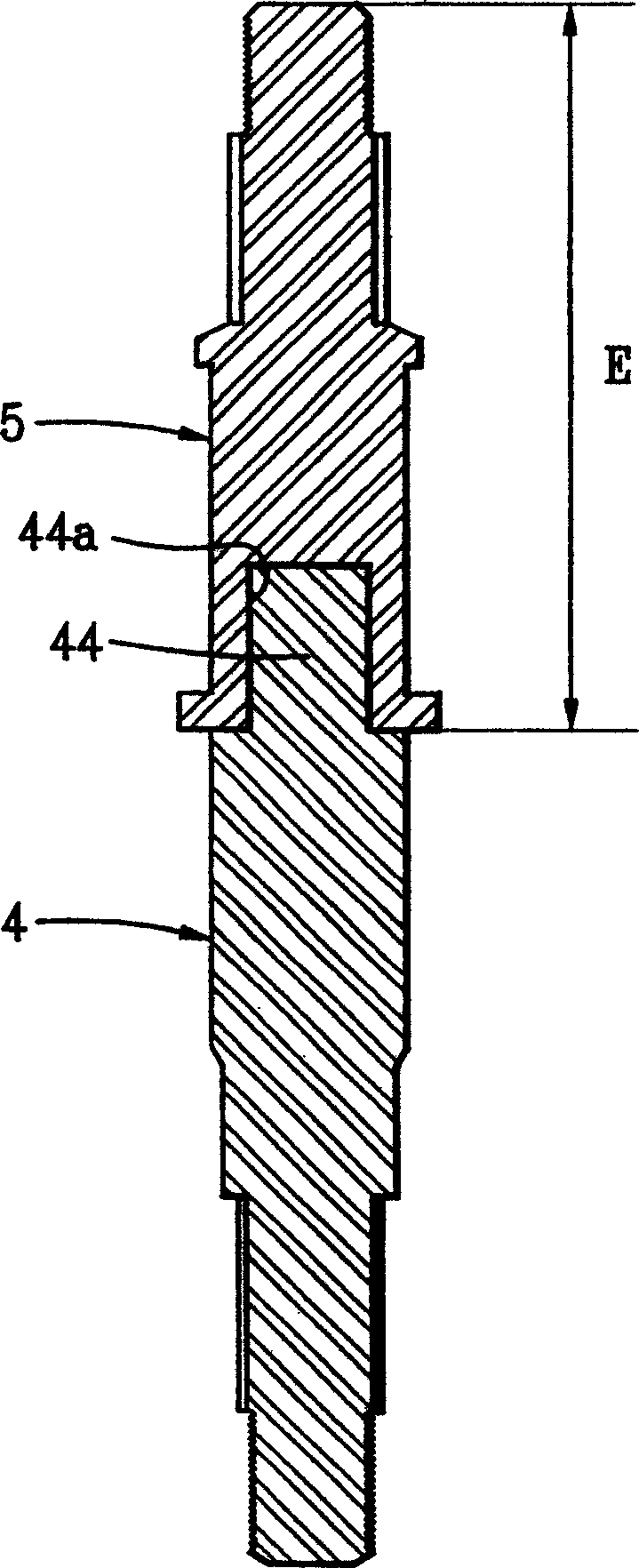

[0030] The present invention comprises: a cylinder-shaped water storage bucket 1 for containing washing water; a washing bucket 2 rotating in the water storage bucket 1; a motor M for driving the washing bucket 2; a drive for transmitting the driving force of the motor M to the washing bucket 2 Axis S. The manufacturing method of the drive shaft is carried out according to the following procedures: Cutting process: the drive shaft cuts the stainless steel plate according to the requirements of processing into a cylindrical shape; welding process: welds the joint part of the stainless steel plate after cutting, and welds it into a cylindrical tubular structure; Cutting process: cutting the outer surface of the cylindrical tube into a specified shape; hobbing process: after completing the above cutting process, hobbing is performed on the specified position to form a gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com