Manufacturing method for semiconductor chips

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、电固体器件等方向,能够解决不能避免碎屑等问题,达到改善横向破裂强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

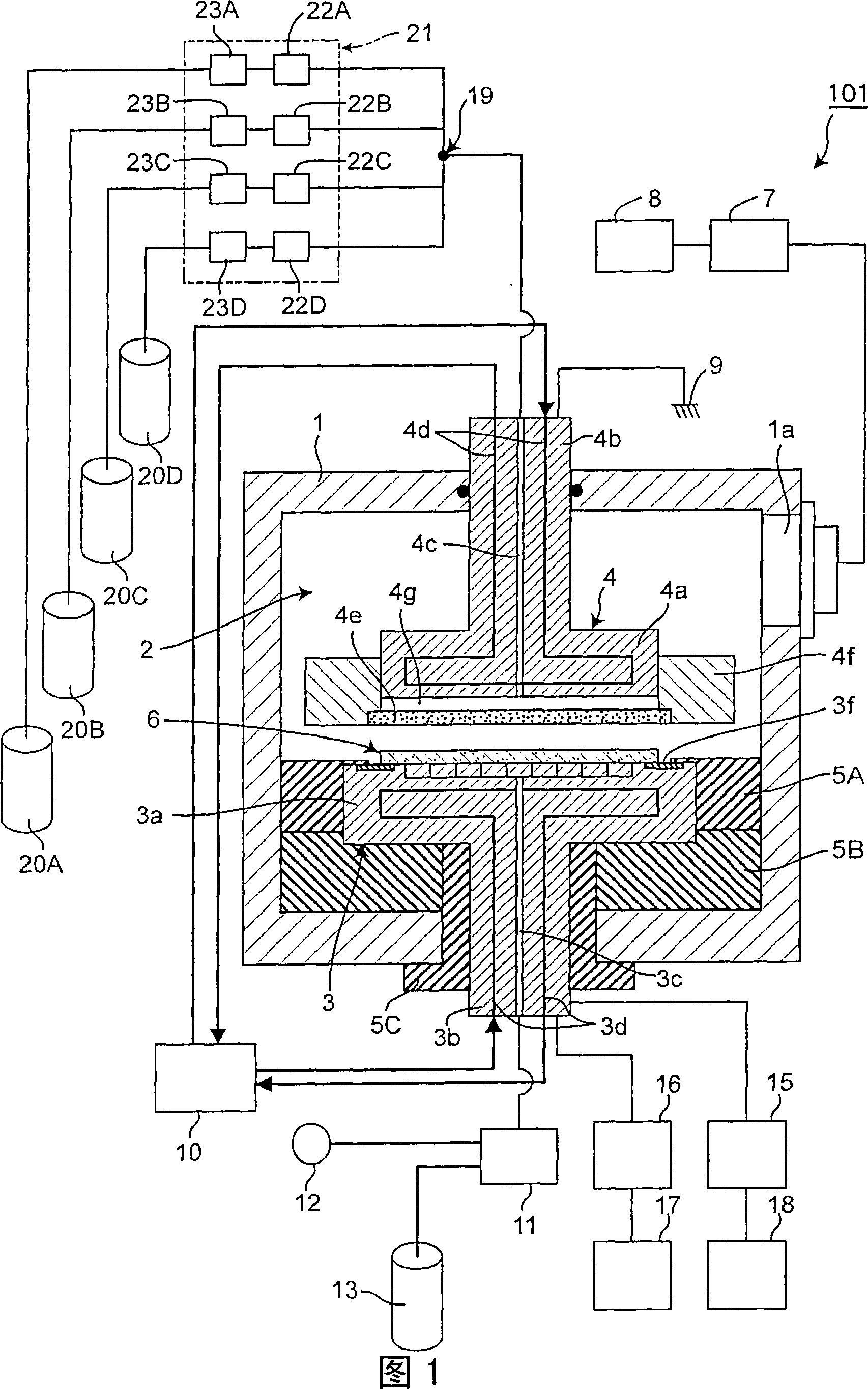

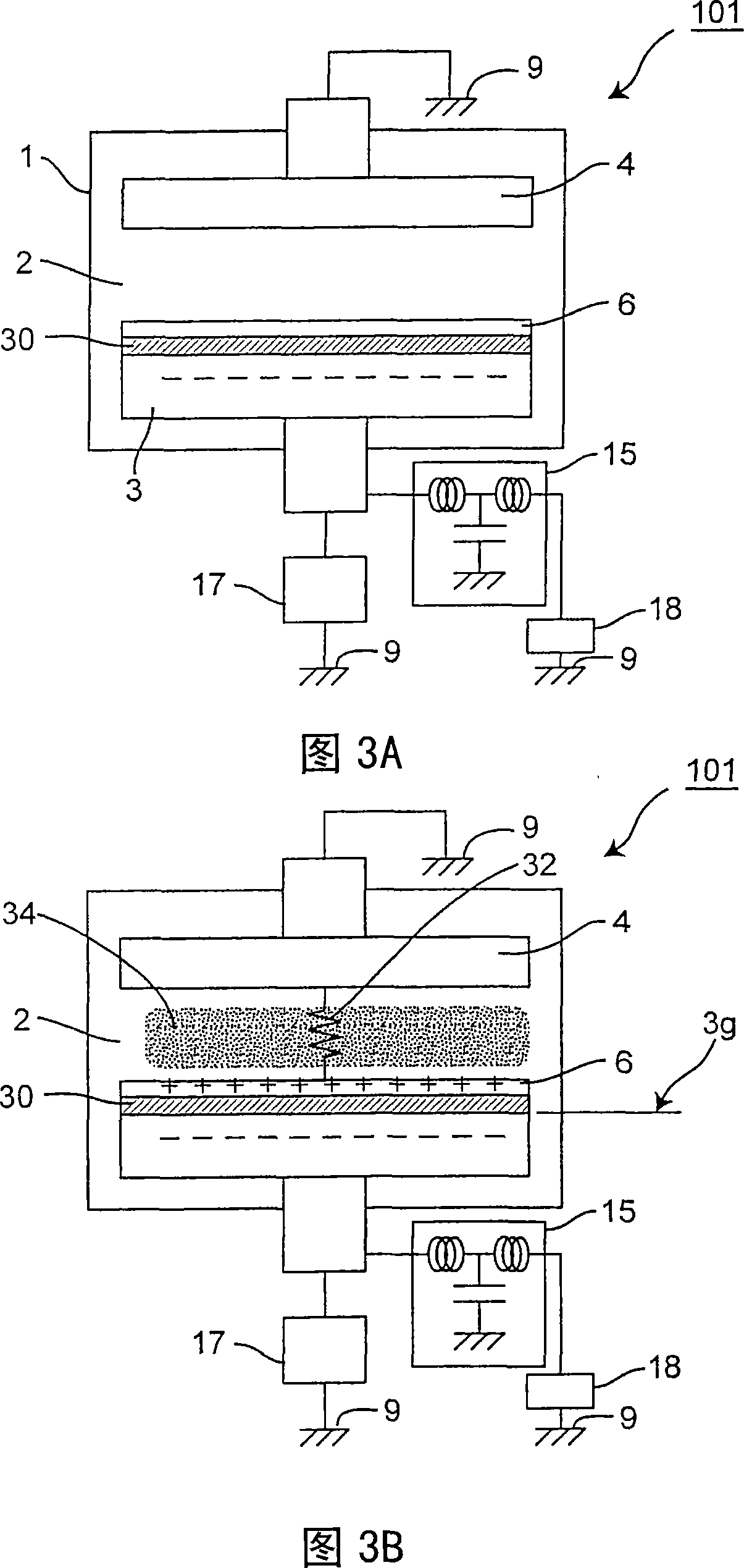

[0142] Structure of plasma processing equipment

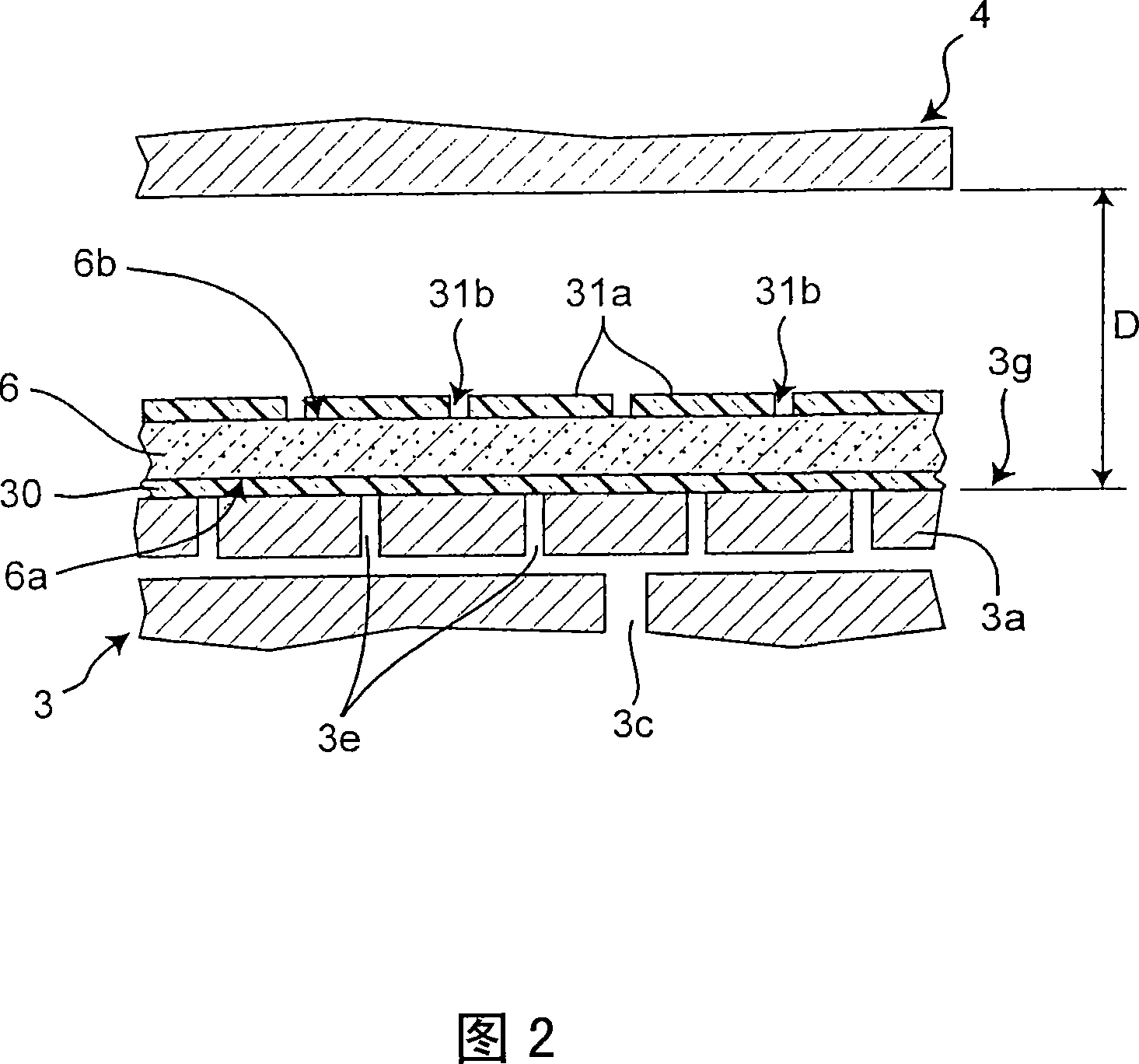

[0143] FIG. 1 shows a schematic structural view schematically showing the structure of a plasma processing apparatus for dividing a semiconductor wafer by a method of manufacturing a semiconductor chip according to a first embodiment of the present invention. It should be noted that FIG. 1 is a longitudinal sectional view showing a plasma processing apparatus 101 . The plasma processing apparatus 101 is an apparatus that manufactures semiconductor chips by dividing a semiconductor wafer into individual pieces of semiconductor chips including semiconductor devices on a circuit formation surface (first surface) on which a plurality of semiconductors are formed.

[0144] In the sequence of the semiconductor manufacturing process as described above, a protective sheet made of a material that is more difficult to etch than silicon, which is the basic material of the semiconductor wafer, is pasted on the circuit formation surface o...

no. 2 example

[0243] The present invention is not limited to the above embodiments, but allows implementation in various modes. For example, a method of manufacturing a semiconductor chip according to a second embodiment of the present invention is described below with reference to schematic exemplary views shown in FIGS. 16A to 16C , FIGS. 17A to 17C , FIGS.

[0244] The semiconductor chip manufacturing method of this second embodiment differs from the first embodiment in that a polyimide (PI) film is used as an insulating film instead of using the silicon oxide film 35 as in the semiconductor wafer 6 of the first embodiment. As an insulating film formed in a portion corresponding to the divided region R2. Only the differences are described below. The fact that the plasma processing apparatus used in the first embodiment is similarly used by the semiconductor chip manufacturing method of this second embodiment is the same, and therefore a description for the apparatus is not provided. In...

no. 3 example

[0261] Next, it will be described with reference to the flow chart of the program shown in FIG. 22 and the schematic exemplary diagrams shown in FIGS. 23A to 23C, FIGS. 24A to 24C, FIGS. 25A and 25B, and FIGS. A method of manufacturing a semiconductor chip according to a third embodiment of the present invention. With the method of manufacturing a semiconductor chip of this third embodiment, notch formation and the like are performed by using a protective sheet having an insulating property as an insulating film placed in a division different from that of the first and second embodiments. in zone R2. Only the differences are described below. Furthermore, the manufacturing method of the semiconductor chip of the third embodiment can be performed by the processing device 101 used in the first embodiment. Therefore, a description of the structure and the like of the plasma processing apparatus 101 will not be provided.

[0262]As shown in FIG. 23A , a semiconductor device 344 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com