Patents

Literature

140results about How to "Avoid residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-bending multimode fiber and manufacturing method thereof

ActiveCN101634728AReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

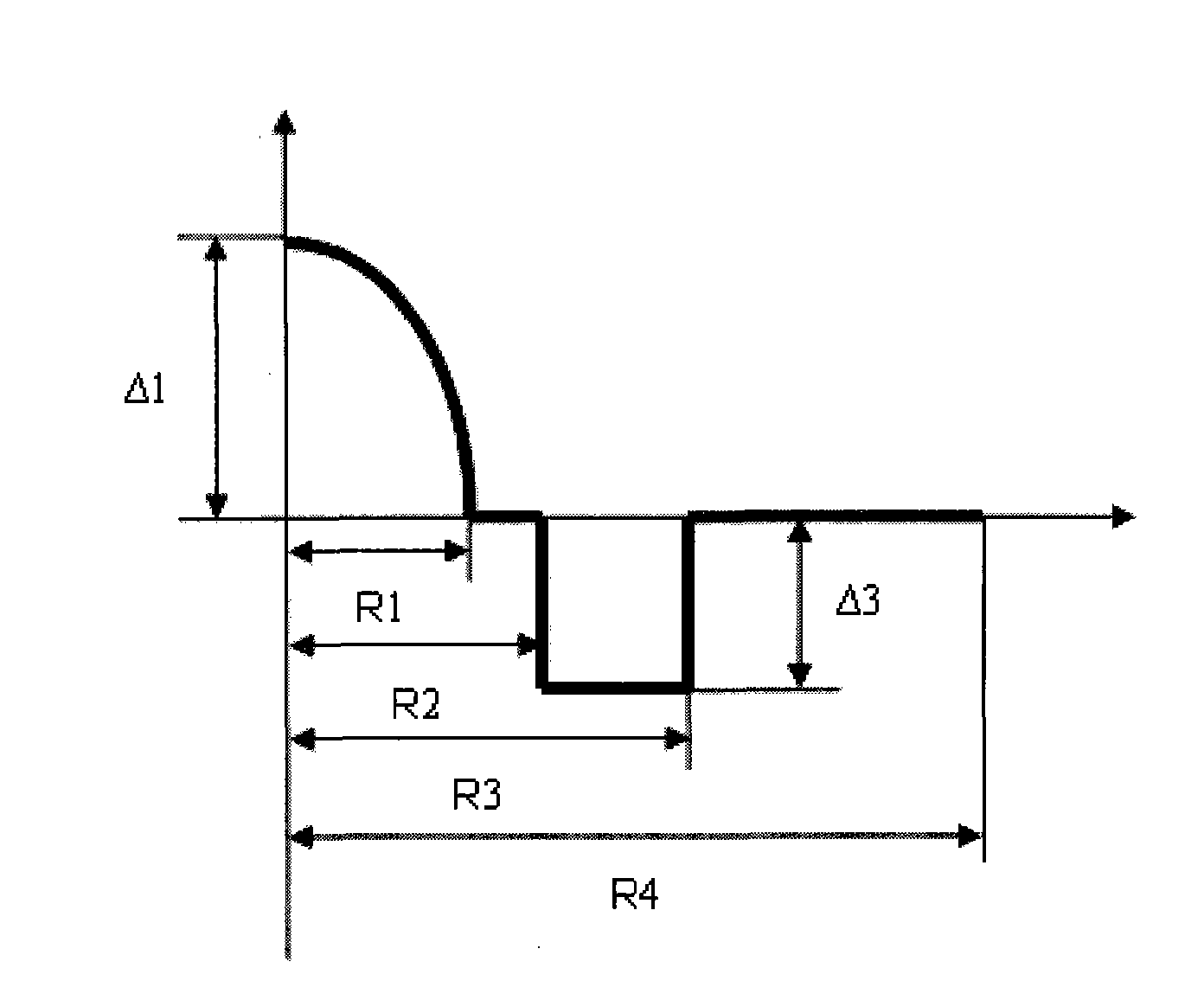

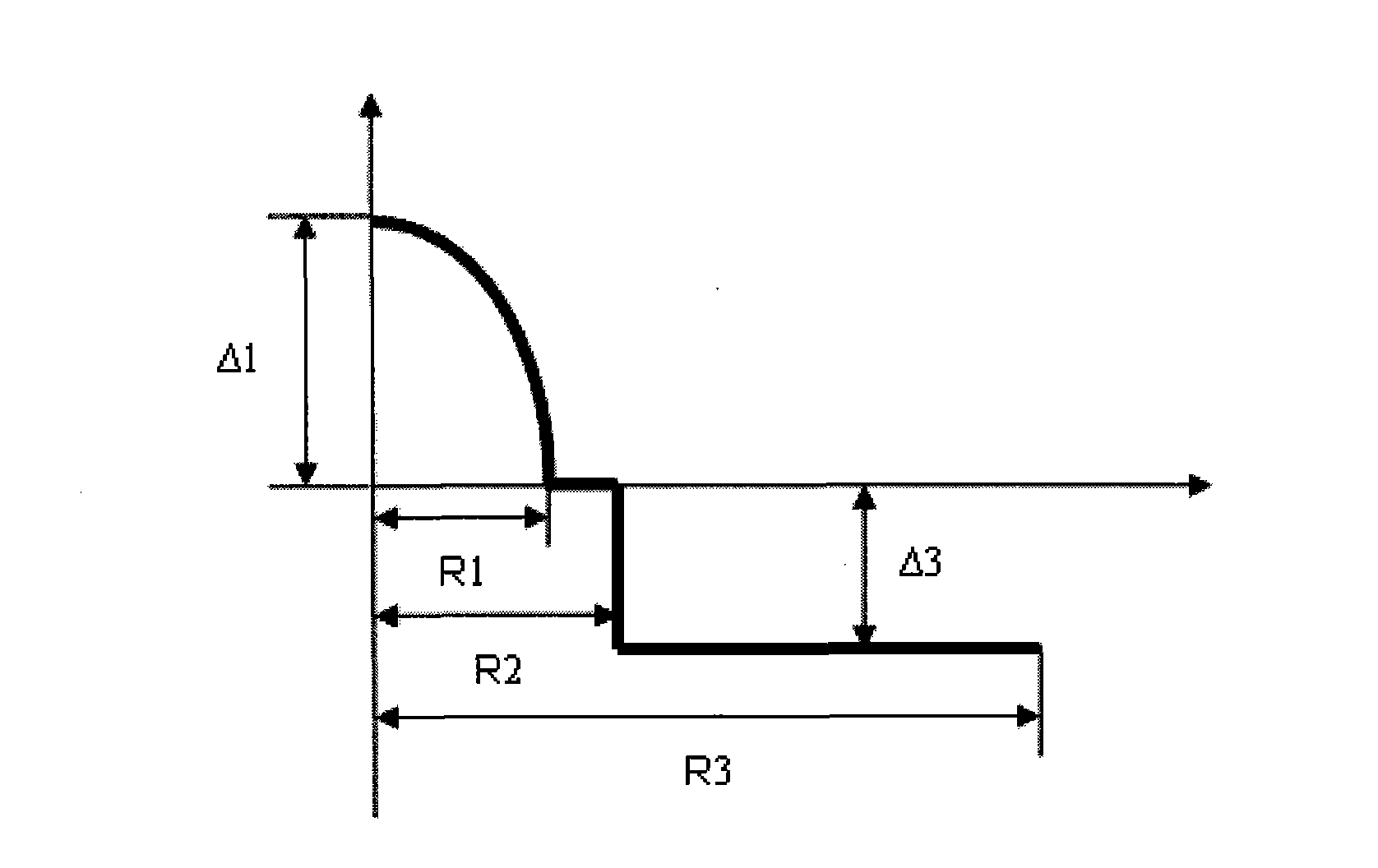

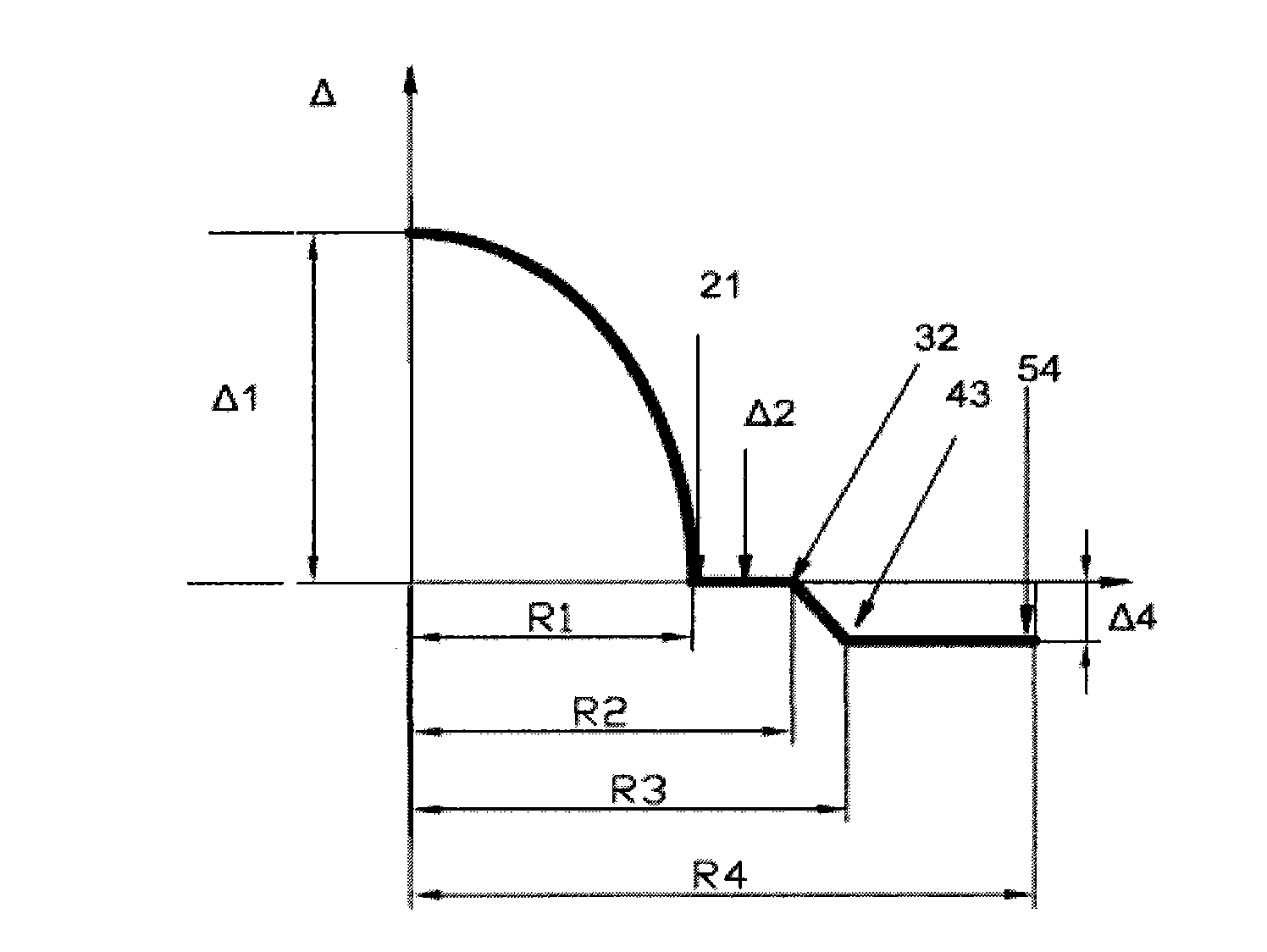

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

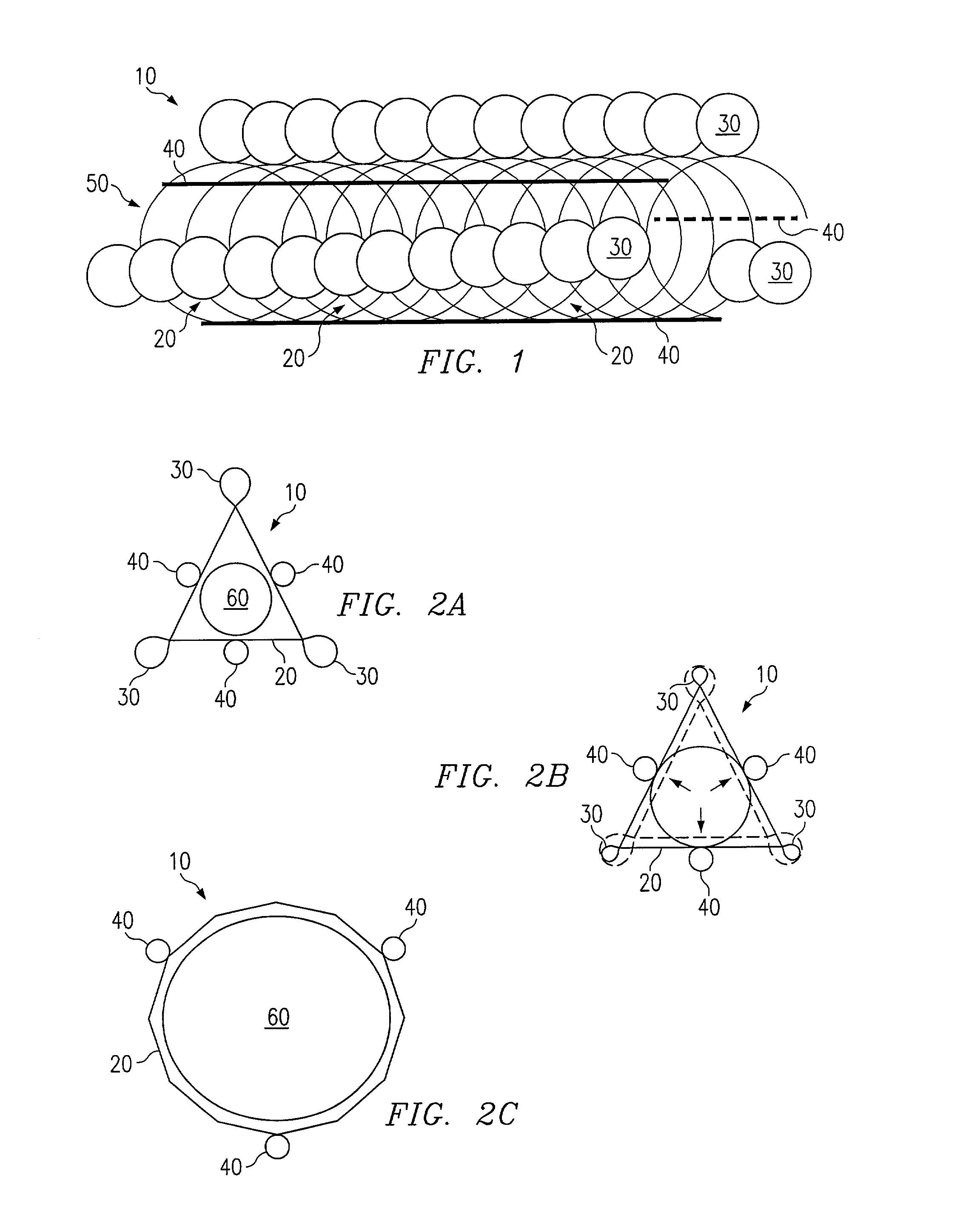

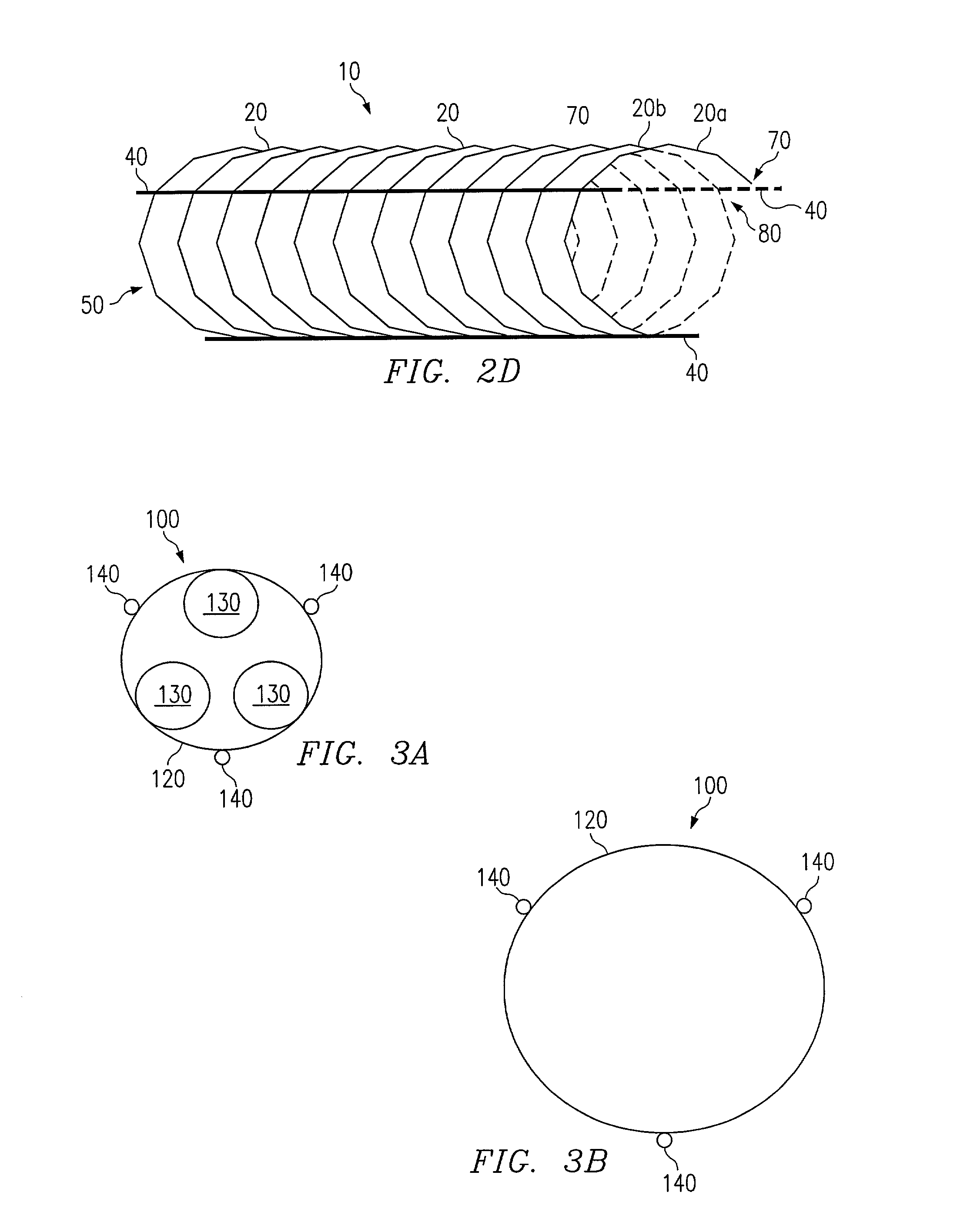

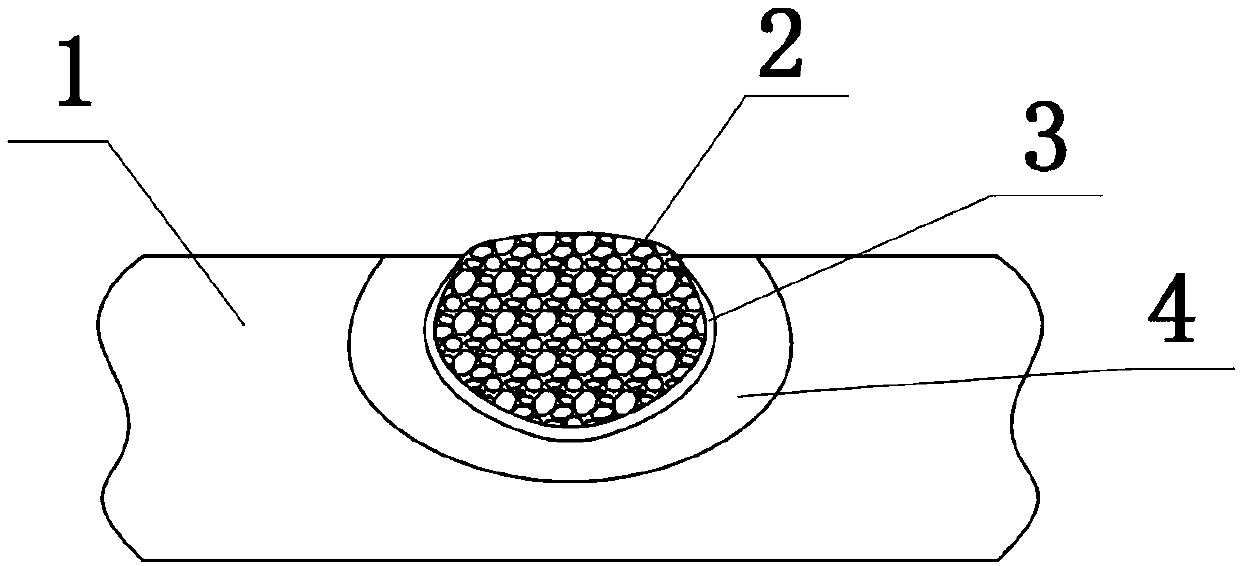

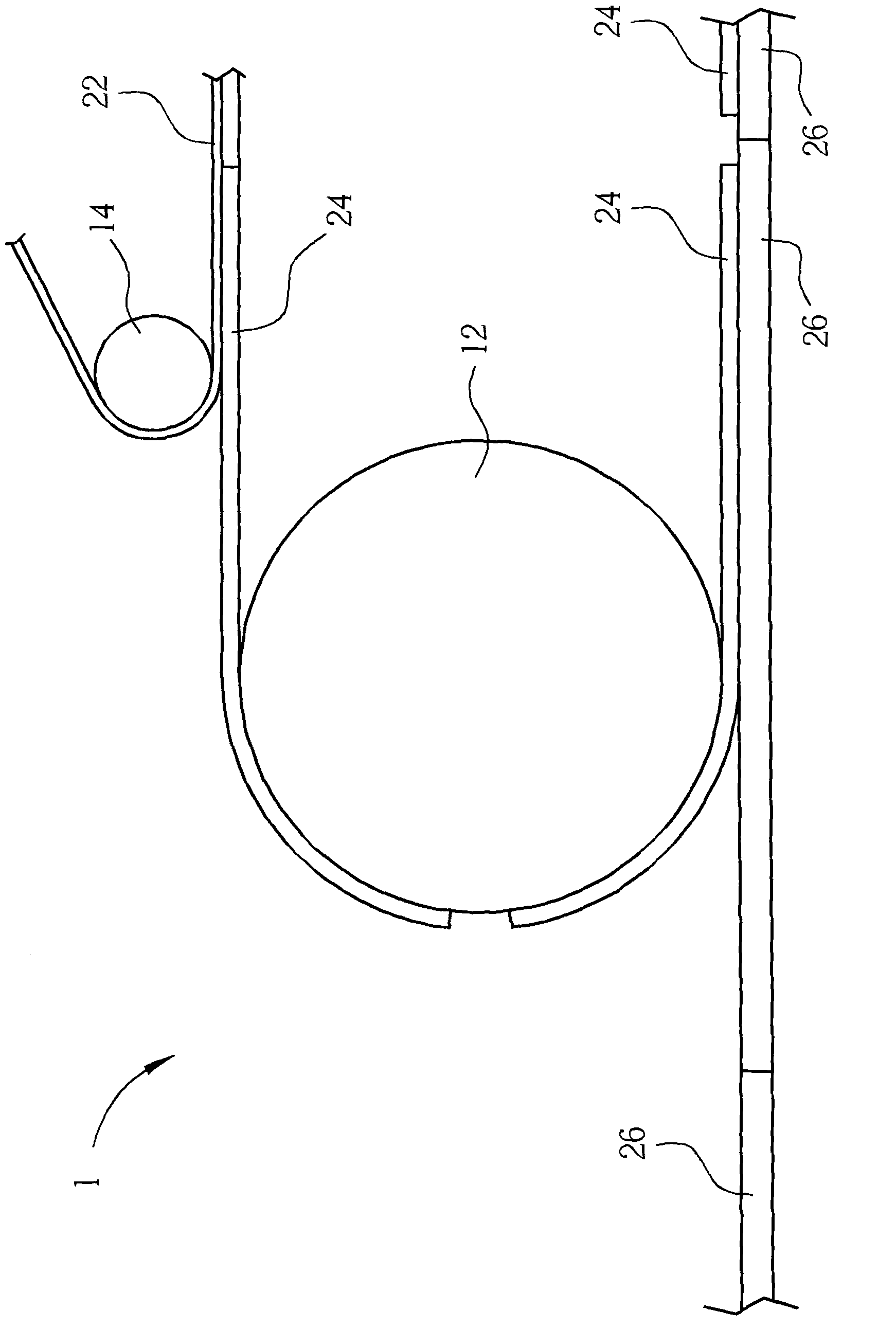

Expandable biodegradable polymeric stents for combined mechanical support and pharmacological or radiation therapy

InactiveUS7128755B2Avoid residual stressAbsorb in timeStentsBlood vesselsAngioplasty balloonRadiation therapy

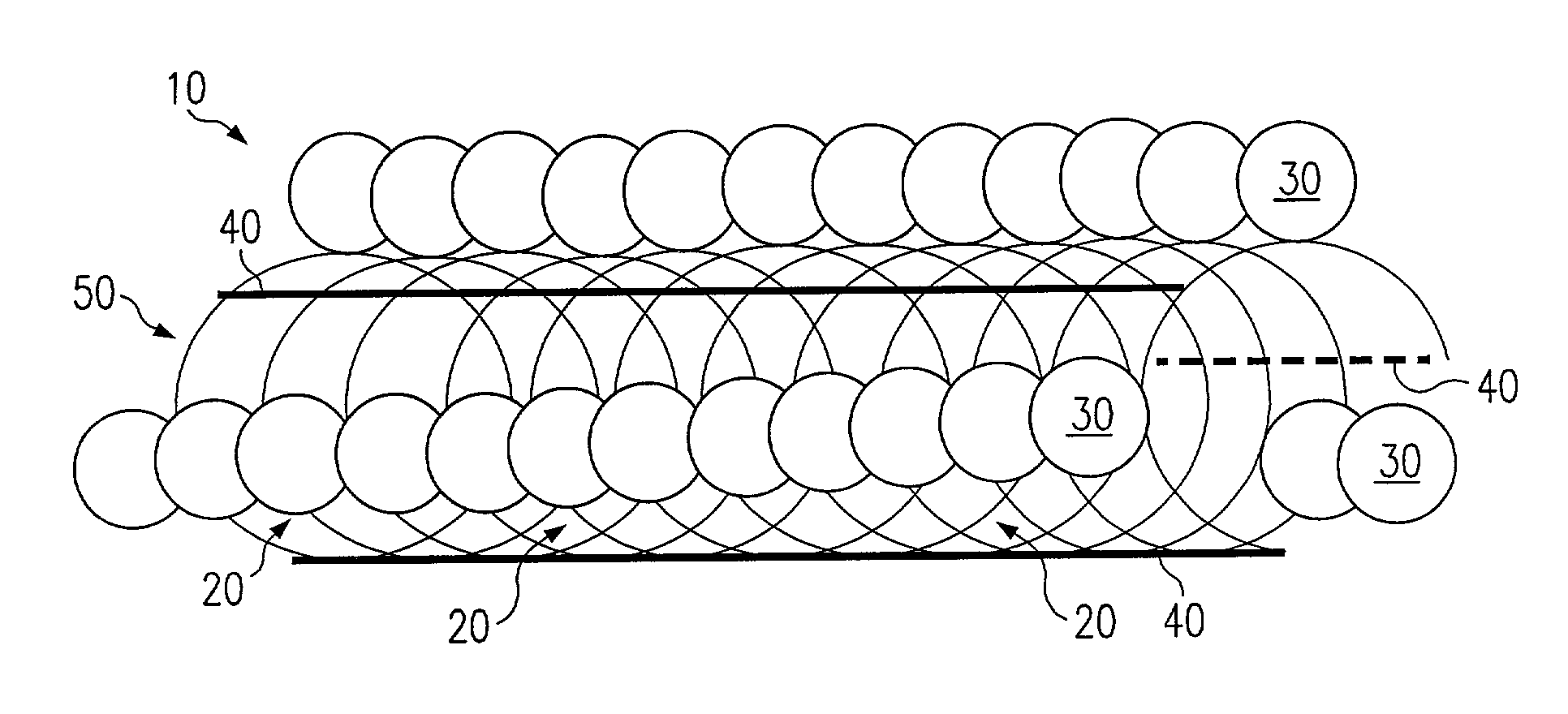

An expandable biodegradable polymeric stent is fabricated with biodegradable polymer fibers (Poly-L-lactic acid, PLLA) in a coil shape that is constructed with both central and external or internal peripheral lobes. It is delivered and expanded using a conventional angioplasty balloon system. The disclosed stent can serve as a temporary scaffold for coronary vessels after PTCA or for peripheral endovascular stenting, or it can provide mechanical palliation for strictures of ductile organs (trachea, esophagus, bile and pancreatic ducts, ureter etc.). The disclosed stent also serves as a unique device for specific local drug delivery. Therapeutic agents (chemical compounds, protein enzyme and DNA sequences) and cells can be loaded into the stent and gradually released to target tissues. Local radiation therapy can also be delivered by a specially adapted stent.

Owner:DUNING

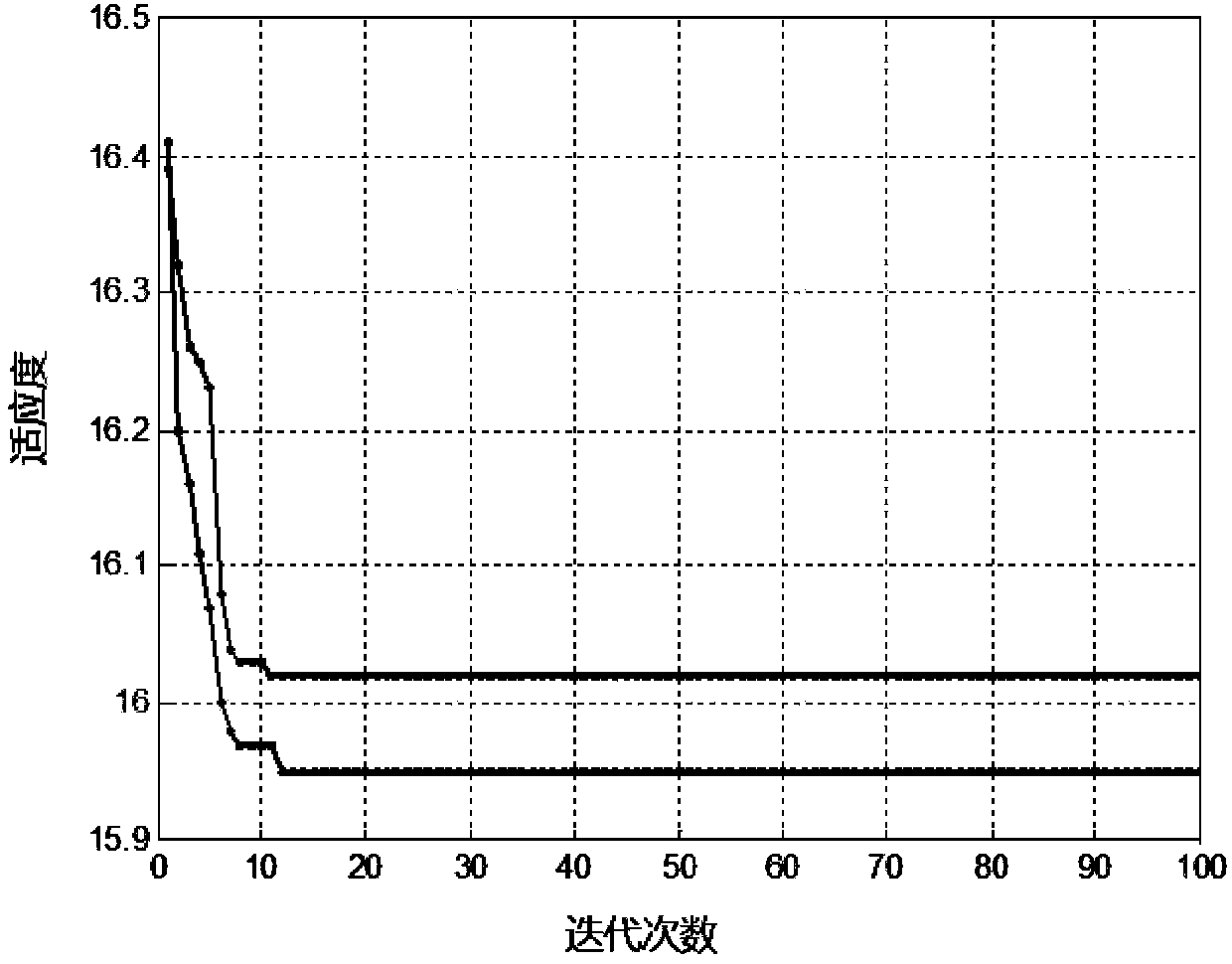

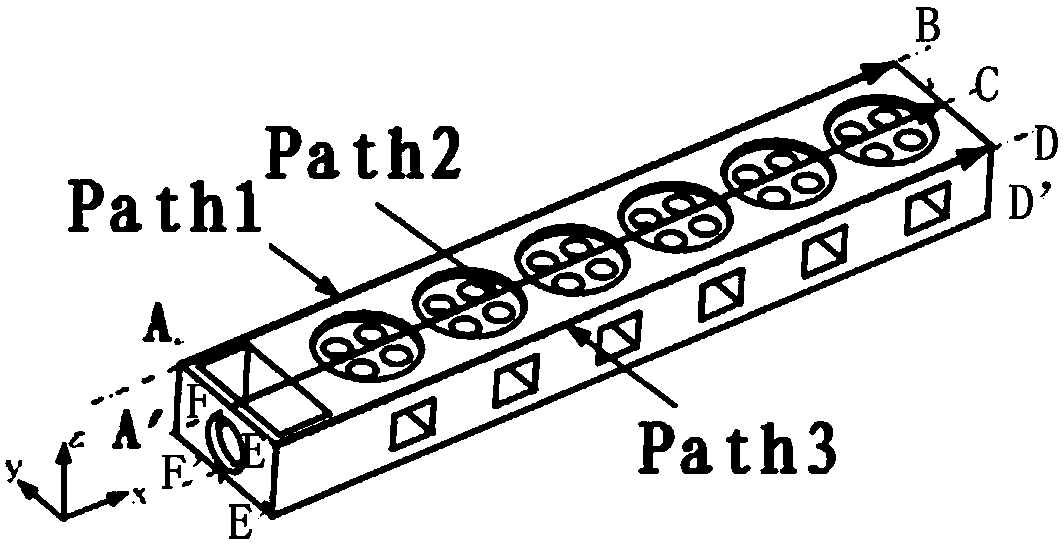

Method for predicting and simulating errors of end-milled surface

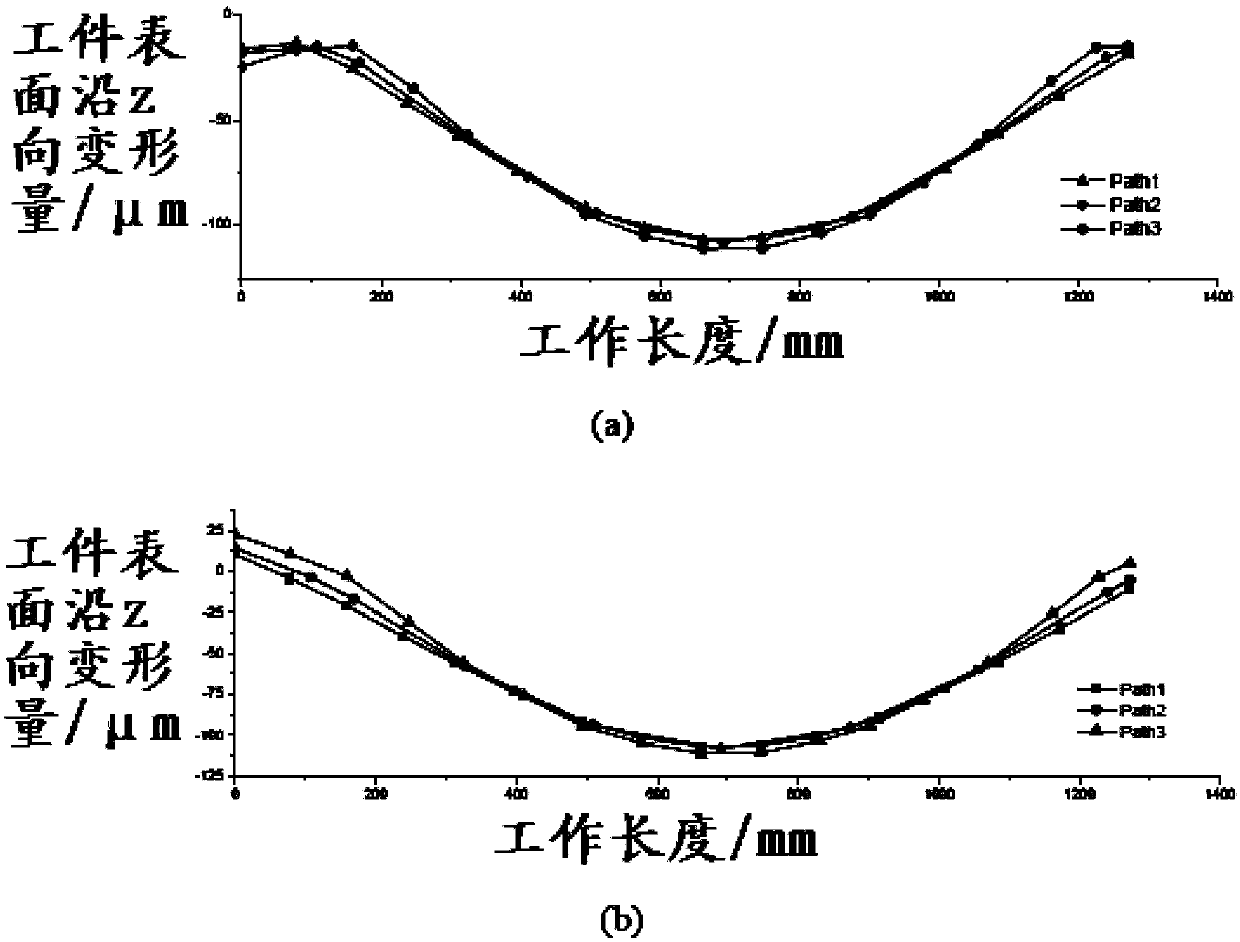

ActiveCN104298818ASimple methodEasy to operateSpecial data processing applicationsRelational modelMachined surface

The invention discloses a method for predicting and simulating errors of an end-milled surface. The method includes the steps that various influence factors causing the machining deformation errors in the end-milling cutting process are analyzed, and a machined-surface single-factor and multi-factor error vector model and an error accumulation vector relation model are built in cooperation with end-milling characteristics; by virtue of a calculation and simulated analysis method, based on a solving method for the machined-surface flatness errors, according to a least regional method, the flatness errors are calculated with a self-adaptation genetic algorithm based on real number encoding, verification is carried out through living example calculation, and contrastive analysis is carried out on the errors and errors of a traditional genetic algorithm. The method is simple and convenient to operate, and the problems that heat stress is caused by cutting heat, residual stress is caused by unloading and loading loads, strict quantitative or logical relationships do not exist between the heat stress and the residual stress, and great difficulty is brought to analysis of the machined surface errors are well solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

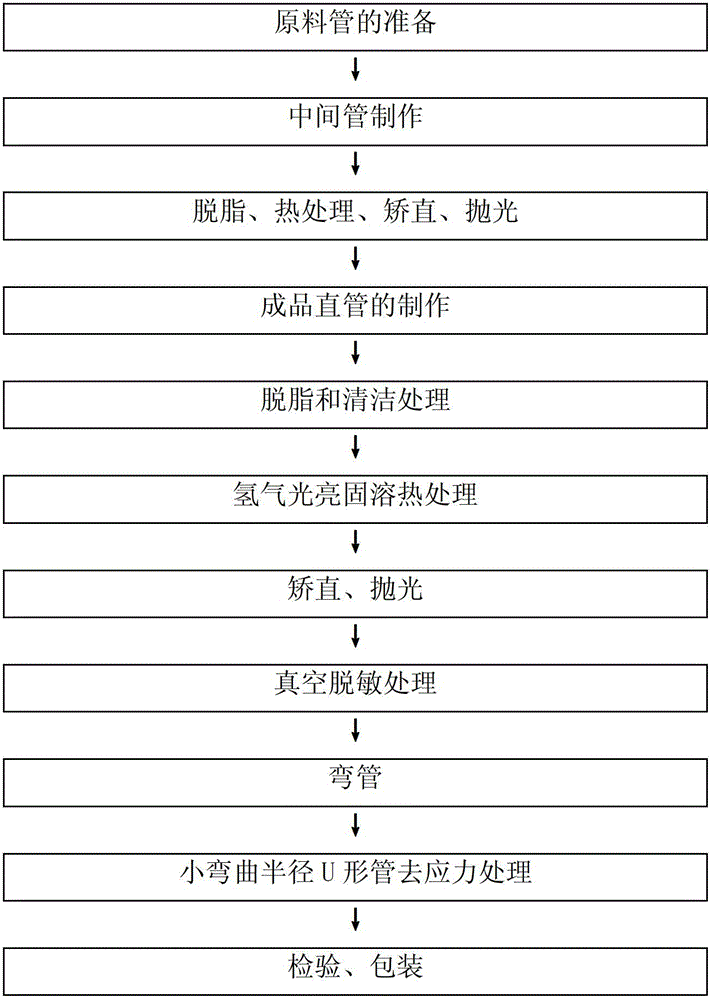

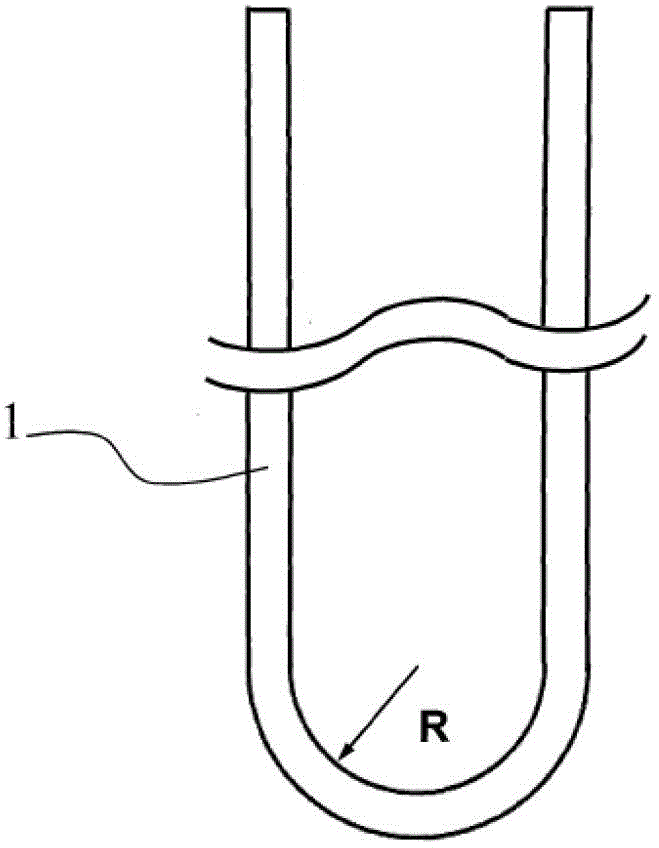

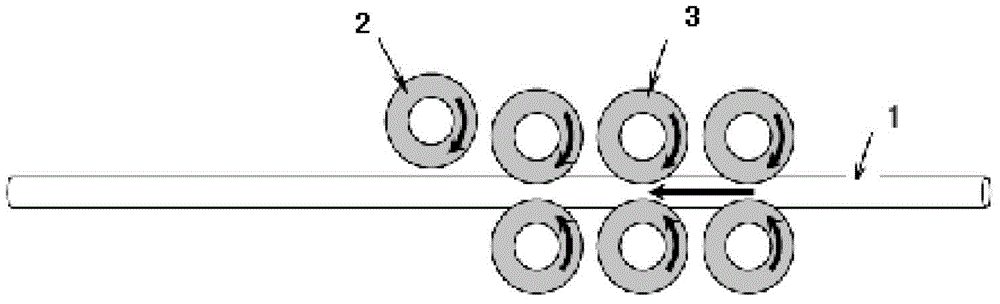

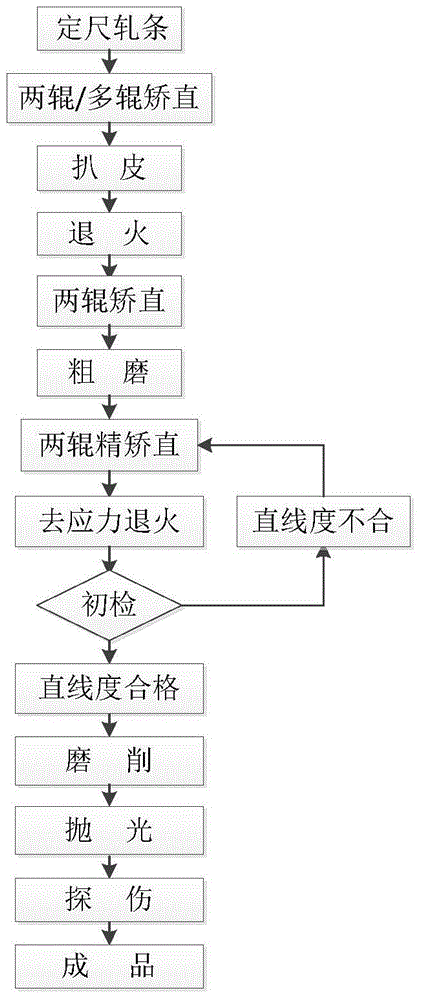

U-shaped seamless nickel-chromium iron alloy heat transfer tube for nuclear steam generator

The invention discloses a U-shaped seamless nickel-chromium iron alloy heat transfer tube for a nuclear steam generator. The U-shaped seamless nickel-chromium iron alloy heat transfer tube comprises the chemical ingredients of no less than 58% of Ni, 28-31% of Cr, 8-11% of Fe, 0.01-0.03% of C, no more than 0.5% of Si, no more than 0.5% of Mn, no more than 0.01% of S, no more than 0.015% of P, no more than 0.05% of Cu, no more than 0.016% of Co, no more than 0.5% of Ti, no more than 0.5% of Al, no more than 0.1% of Nb, no more than 0.003% of B, and no more than 0.005% of N. The surface quality and the dimensional accuracy of a straight pipe are ensured by hot-extruded nickel-chromium-iron alloy tube blank via a plurality of cold-rolling deformation, online degreasing, pure-hydrogen protecting continuous bright heat treatment and vacuum heat treatment; and meanwhile, the U-shaped seamless tube for a steam generator, which is overlong, thin in wall, and is in semicircle transition at the elbow part, is manufactured by bending and forming by the principle of forming a circle by three points.

Owner:BAOYIN SPECIAL STEEL TUBE CO LTD

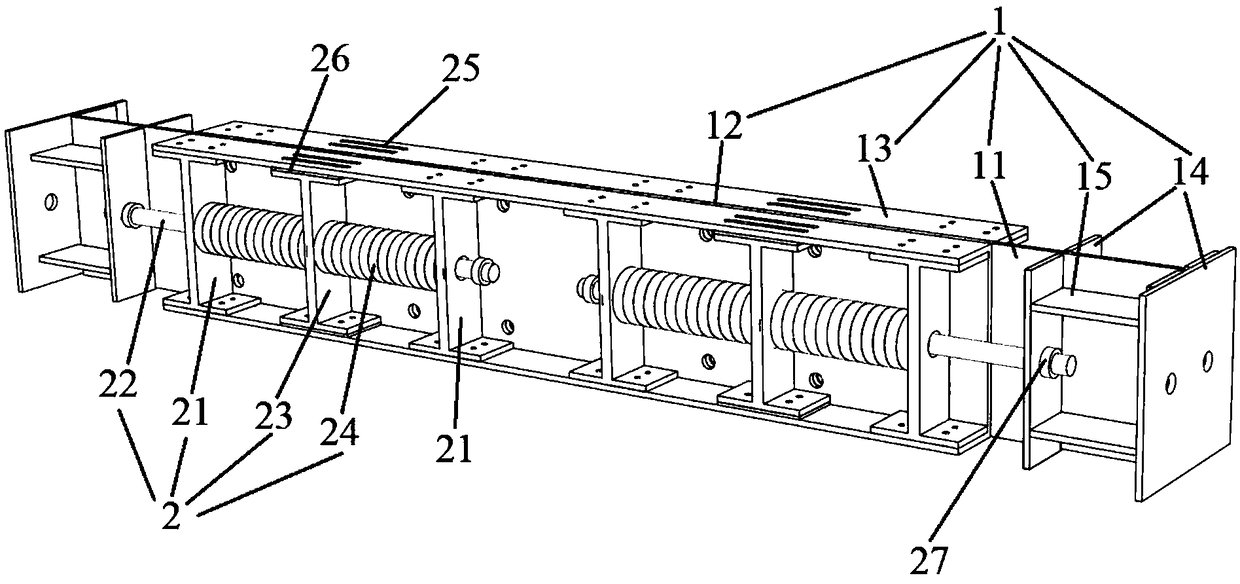

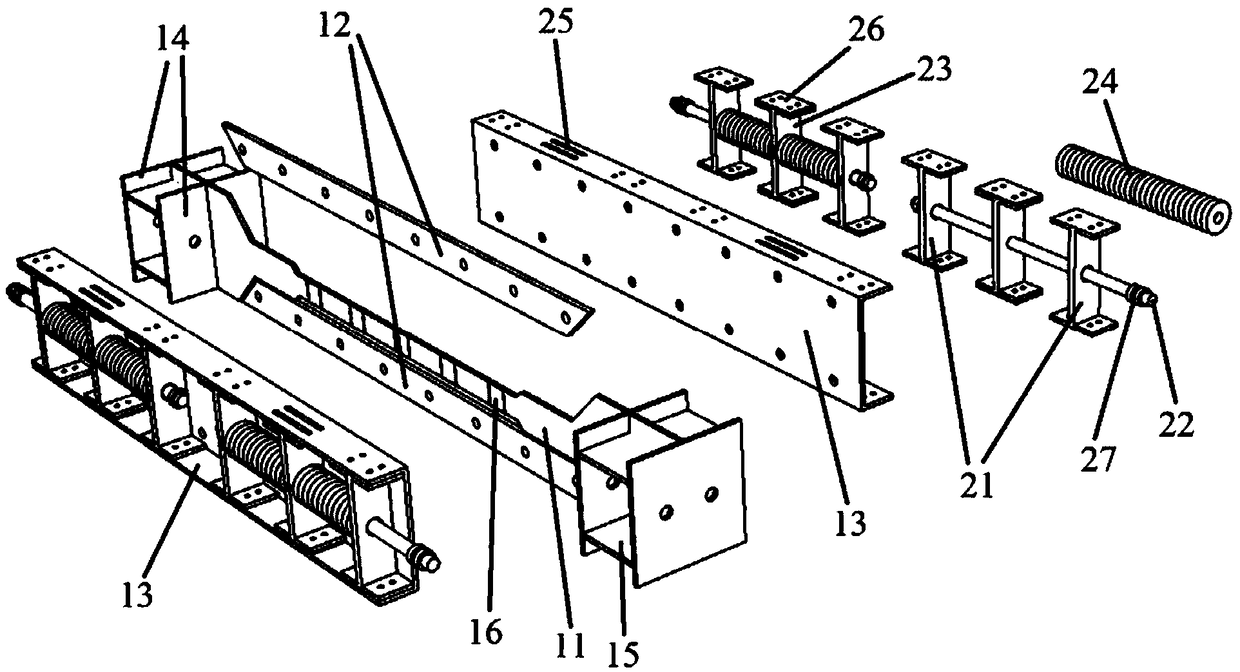

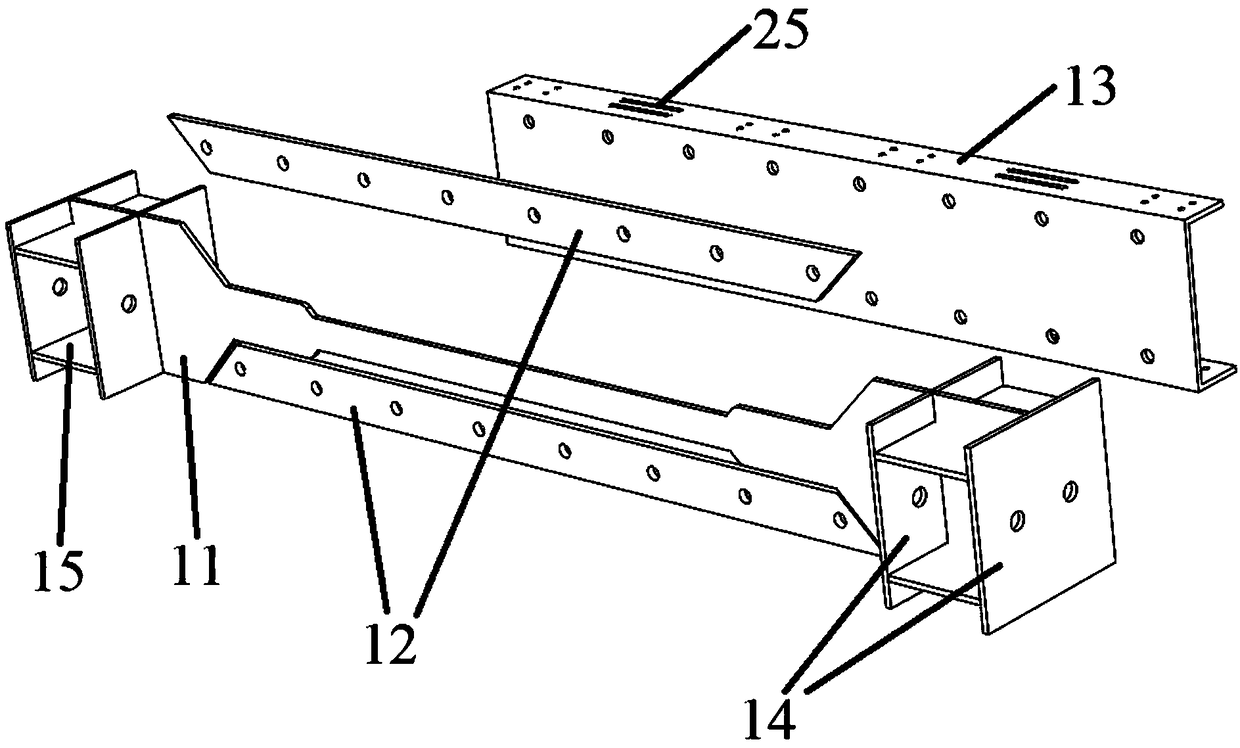

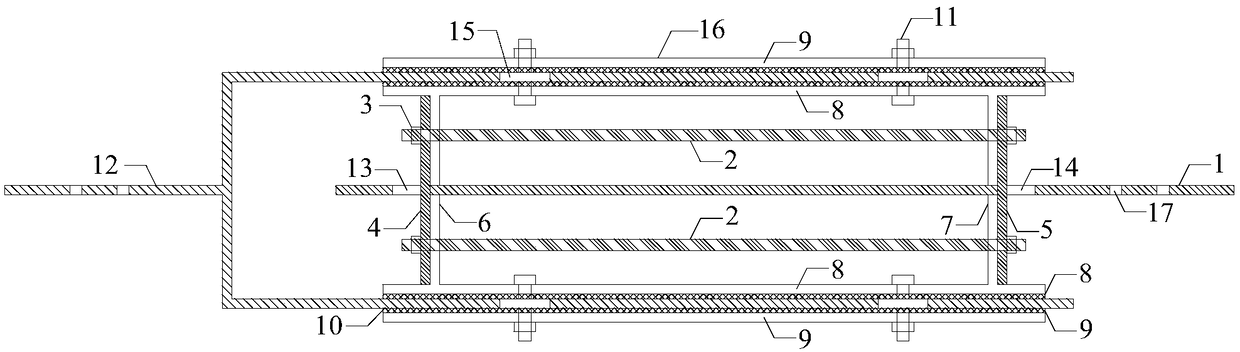

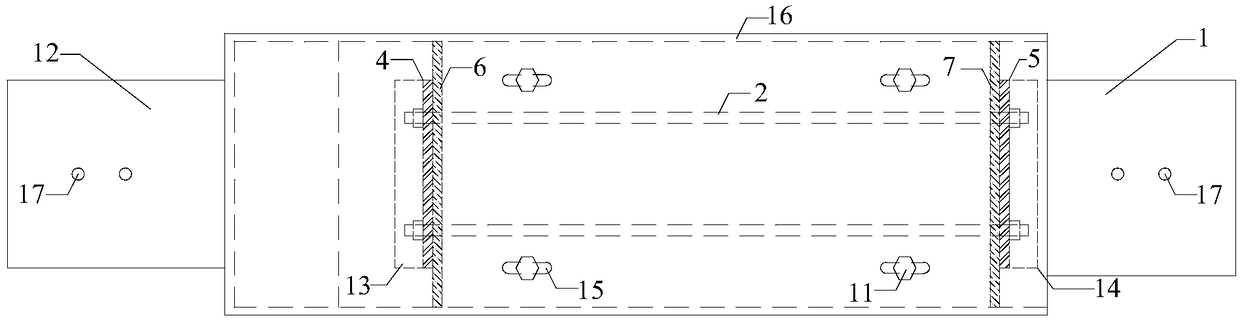

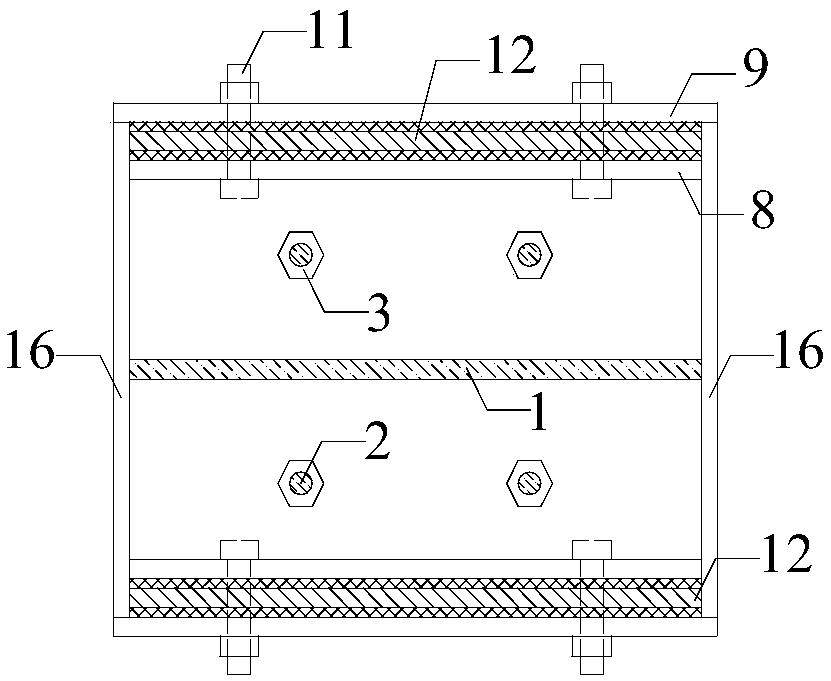

Double-restraint self-reset buckling-proof energy-dissipation support

PendingCN109457828AIncrease cumulative energy consumption capacityImprove energy performanceProtective buildings/sheltersShock proofingDuctilityHysteresis

The invention provides a double-restraint self-reset buckling-proof energy-dissipation support. The support consists of a novel disc spring self-reset assembly and a buckling-proof support assembly, wherein the self-reset assembly has a friction energy dissipation function, great self-reset performance under the action of medium and small earthquakes and an excellent energy dissipation capacity; the buckling-proof support assembly consists of a core plate, a limiting plate, constraint channel steel and a bolt, wherein the core plate adopts a linear section-variable form, and carbon fiber clothis stuck to the core plate locally to form a local reinforcing section in order to achieve the effect of a preset necking section. By fully utilizing the energy dissipation performance of the core plate in a necking stage of the steel, the accumulated energy dissipation capacity and hysteresis performance of the core plate are improved, and the performance of the core plate shows that a multi-wave buckling phenomenon of the support core plate is obviously inhibited and the accumulated ductility of the core plate is obviously improved. The double-restraint self-reset buckling-proof energy-dissipation support has good self-reset performance and great energy-dissipation performance and is simple in structure, convenient to install and easy to popularize.

Owner:CHANGAN UNIV

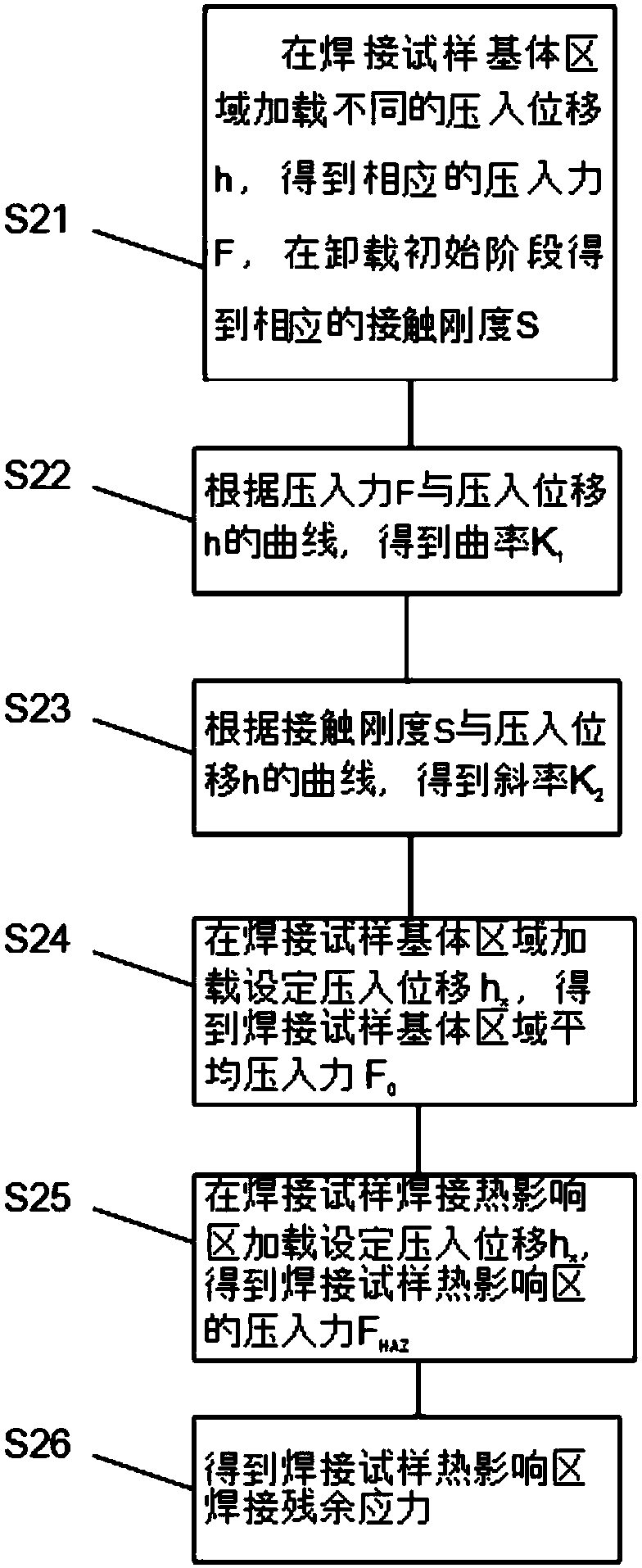

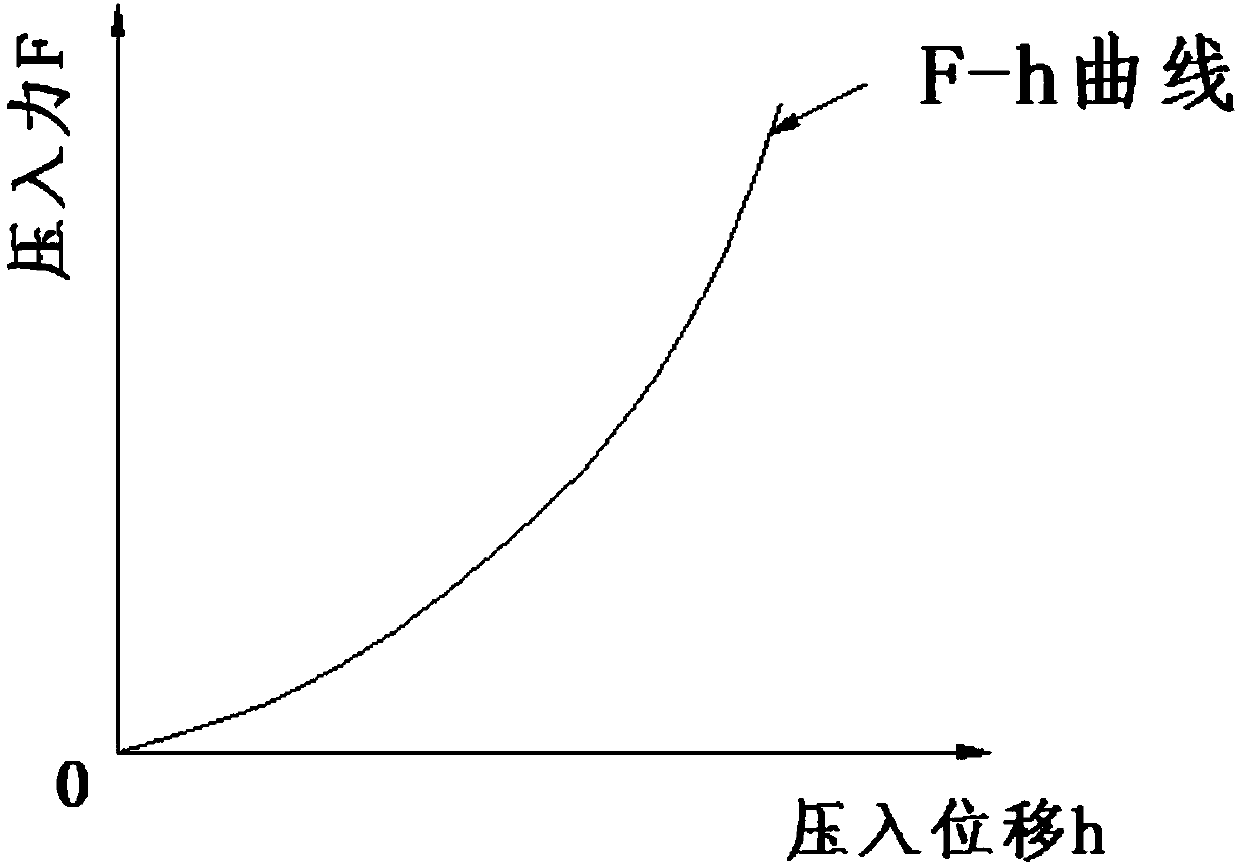

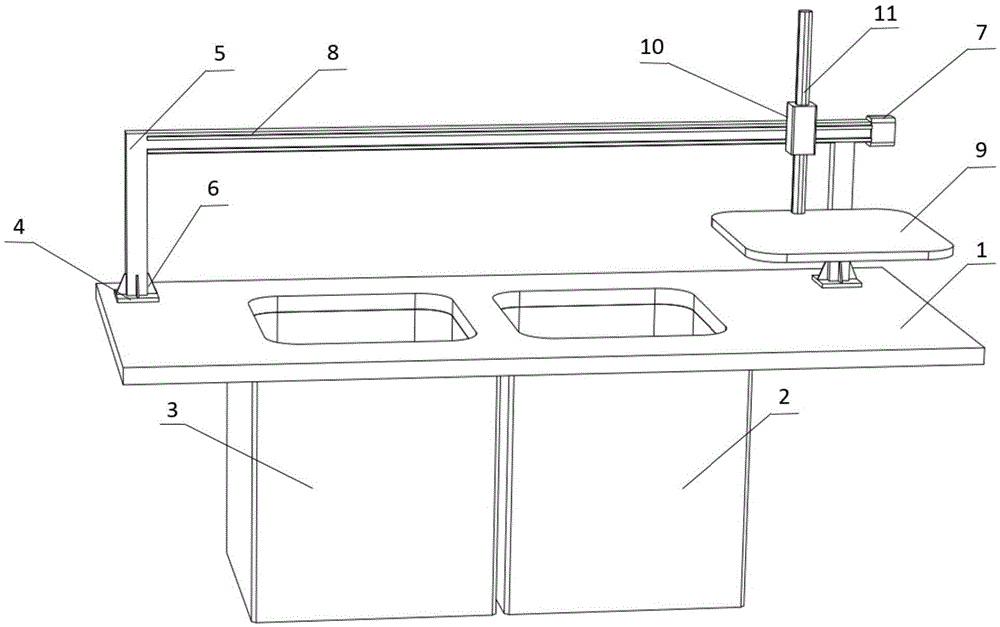

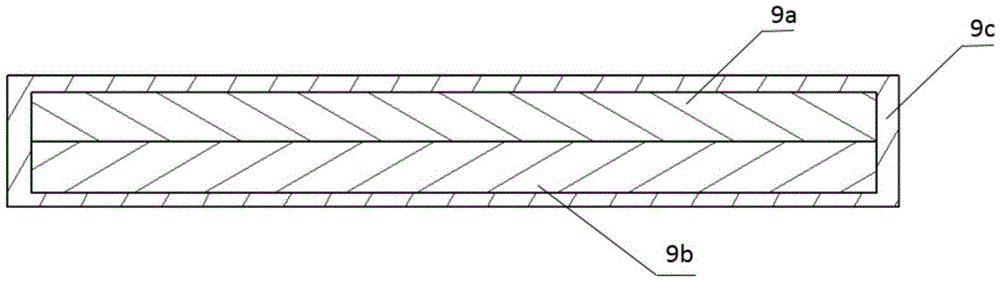

Method used for testing residual stress in welding heat affected zone

ActiveCN107643141AAvoid destructionAvoid the problem of inaccurate calculation of contact areaApparatus for force/torque/work measurementHeat-affected zoneWelding residual stress

The invention relates to the field of material mechanical property characterization, and in particular relates to a method used for testing residual stress in a welding heat affected zone. The methodcomprises the steps that different press-in displacements h are loaded in a welding sample base zone to acquire corresponding press-in force F, and corresponding contact stiffness S is acquired at theinitial phase of unloading; according to the curve of the press-in force F and the press-in displacements h, curvature K1 is acquired; curvature K2 is acquired according to the curve of the contact stiffness S and the press-in displacements h; the set press-in displacement hx is loaded in the welding sample base zone to acquire the average press-in force F0 of the welding sample base zone; the set press-in displacement hx is loaded in the welding sample welding heat affected zone to acquire the press-in force FHAZ of the welding sample heat affected zone; and the welding residual stress of the welding sample heat affected zone is acquired. According to the method, a welding seam is prevented from being damaged; the test application range is expanded; the problem of inaccurate contact area calculation caused by the wear of an indenter is avoided; the problem of inaccurate contact area caused by the stacking effect is avoided; and the testing accuracy is ensured.

Owner:BEIJING JIAOTONG UNIV

Electrostatic surface laying layer system manufactured through powder bed additive

InactiveCN105642900AImprove part densityAvoid residual stressAdditive manufacturing apparatusIncreasing energy efficiencyElectrostatic attractionResistance wire

The invention provides an electrostatic surface laying layer system manufactured through a powder bed additive. The electrostatic surface laying layer system comprises a formed working table top, a powder supply cylinder and a forming cylinder are arranged below the working table top, a truss mechanism is connected above the working table top through connection plates, the truss mechanism is configured with a sliding rail, the sliding rail is matched with a sliding block, a guide rod is connected to the sliding block, the bottom of the guide rod is connected with an electrode powder pressing plate, the sliding block is controlled by a stepping motor connected to the end of the sliding rail, a ceramic plate and a resistance wire are embedded into an electrode powder pressing plate body of the electrode powder pressing plate, and the ceramic plate is located above the resistance wire. According to the electrostatic surface laying layer system, a mode of electrostatic attraction force is adopted, and charged powder is densely adsorbed to the electrode powder pressing plate, so that the powder is compressed to the surface of a formed piece, and the effect of improving density of parts is achieved; after powder pressing is achieved, the electrode powder pressing plate preheats each layer of powder and the formed piece below the powder, and the phenomena of buckling deformation and the like are avoided; the mobile electrostatic surface laying layer system is high in speed, the powder laying amount is precisely controlled, and production efficiency is improved.

Owner:XI AN JIAOTONG UNIV +1

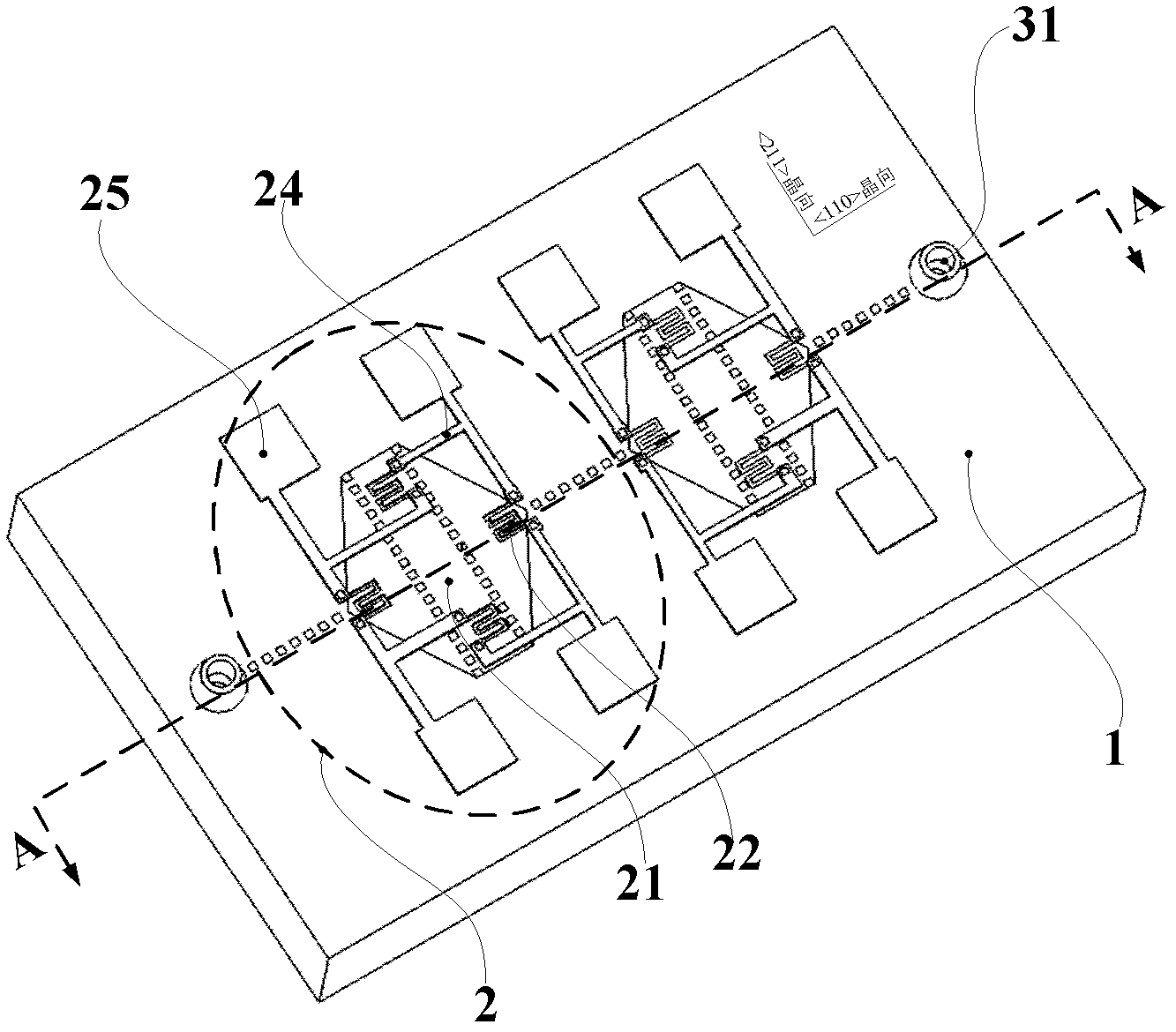

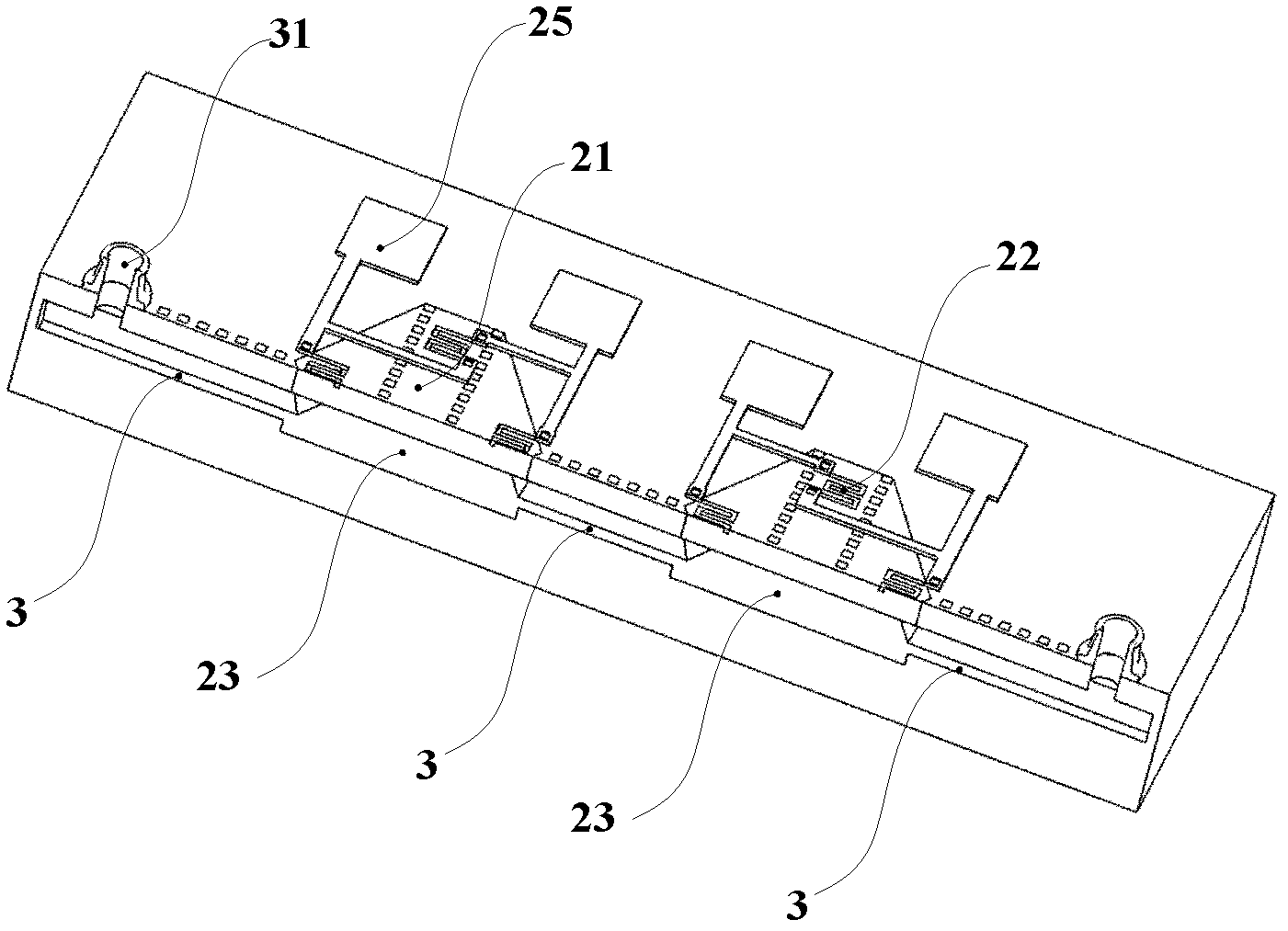

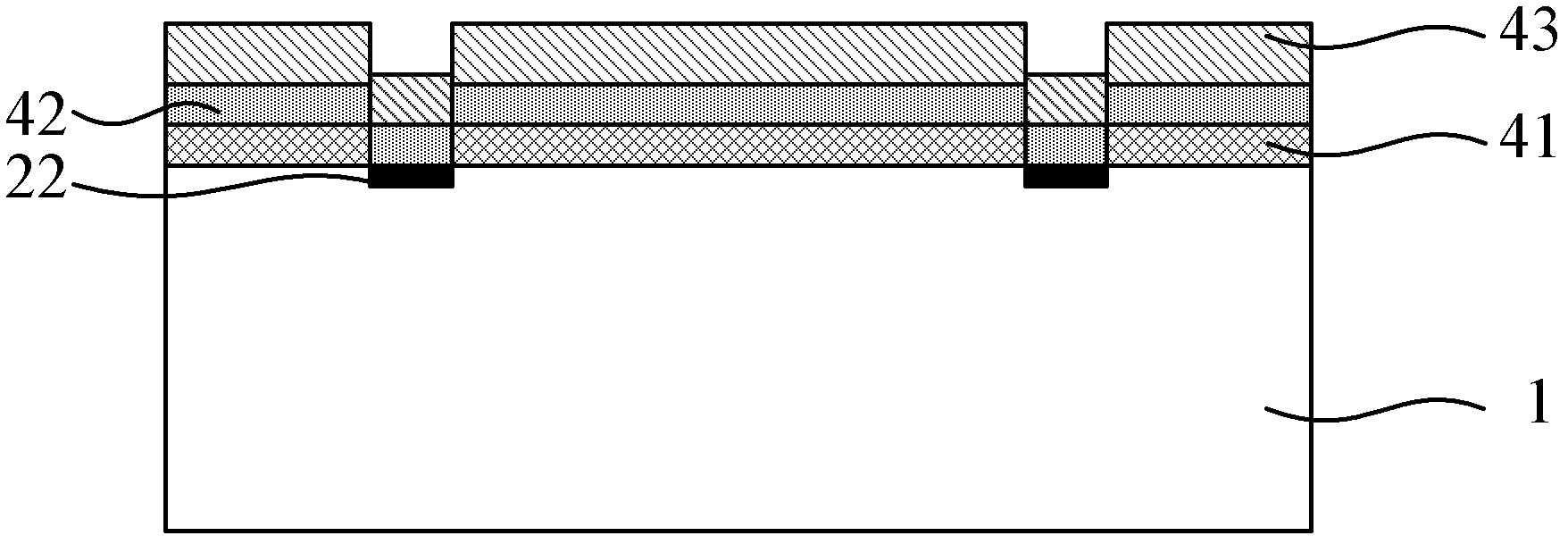

Single-silicon chip microflow sensor suitable to be packaged in surface mounting way and manufacturing method for single-silicon chip microflow sensor

ActiveCN103185613ASimple structureAvoid residual stressFluid pressure measurement using ohmic-resistance variationVolume/mass flow by differential pressureSilicon chipPressure sensitive

The invention provides a single-silicon chip microflow sensor suitable to be packaged in a surface mounting way and a manufacturing method for the single-silicon chip microflow sensor. The single-silicon chip microflow sensor comprises a monocrystalline silicon substrate, two pressure sensors and a microfluidic channel with an inlet / outlet. A single-silicon chip single-sided bulk silicon micromachining method is adopted, so that the microfluidic channel and reference pressure cavities of the pressure sensors are formed in the monocrystalline silicon substrate, and the two pressure sensors and the inlet / outlet of the microfluidic channel are ingeniously integrated on the same surface of the same monocrystalline silicon substrate, so that the single-silicon chip microflow sensor is simple in structure. The problems of residual stress caused by heat mismatch between different bonding materials and the thickness non-uniformity of pressure sensitive thin films of the pressure sensors are avoided, a surface mounting packaging technology is suitable for the integration of a bare chip of the single-silicon chip microflow sensor and a microfluidic system, the single-silicon chip microflow sensor and the manufacturing method have the characteristics of low production cost, convenience in packaging, high sensitivity, high stability and the like, and the single-silicon chip microflow sensor is suitable for mass production.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

First wall part coated with thick wolfram coat or copper alloy heat sink and mfg. method thereof

InactiveCN1787115AInhibit growthReduce residual stressNuclear energy generationVacuum evaporation coatingTemperature controlNuclear fusion

The invention discloses a first wall part or copper alloy heat sink sprayed with thick W coating and the making method thereof, composed by in turn adopting vacuum plasma to spray adaptive layer and W coating on the surface of the copper alloy, where the copper alloy acts as a heat sink material, the adaptive layer is of NiCrAl material, the W coating acts as a plasma facing material, the thickness of the adaptive layer is controlled within 0.5 mm, the central temperature of the spraying plasma arc is 12000K-15000K and the speed of the plasma arc is 400 m / s -500 m / s, the average grain size of the W powder is 2 mm-5 mm, the coating thickness is about 2 mm, the coating density is 85%-95% of the body material, the oxygen content is controlled at 0.06%-0.15%, and in the whole spraying course, the substrate temperature needs controlling at below 500 deg.C by active water cooling. The invention solves the key difficult problem of large-area connection between the two materials and can stably bear the long-time action of thermal load of 5 MW / m2 -10 MW / m2 on the active cooling condition, able to be widely applied to high-thermal load parts of a nuclear fusion tester, such as polarizing filter target plate and limiter.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

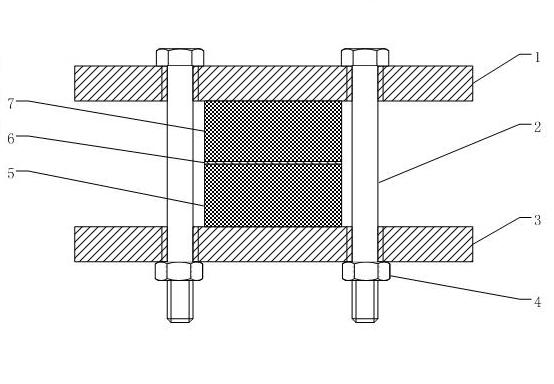

Method for welding foamed aluminum material by transient liquid phase diffusion

ActiveCN101954540ALittle impact on performanceSmall heat affected zoneNon-electric welding apparatusHeat-affected zoneImpurity

The invention relates to a method for welding a foamed aluminum material. The method comprises the following steps of: performing rust removing and deoiling on the foamed aluminum material, then polishing a weld interface of the foamed aluminum and an AL4004 foil to expose a fresh metal, removing impurities by using an ultrasonic apparatus, and then drying; placing the AL4004 foil between the connected interfaces of the two foamed aluminum materials, and then clamping the two foamed aluminum materials and the AL4004 foil by using a fixing clamp, wherein the clamping pressure is 10MPa; putting a connecting piece in a structure of the upper foamed aluminum, the middle AL4004 foil and the lower foamed aluminum into a heating furnace without vacuum environment and gas protective atmosphere for heating, preserving the heat at the temperature of between 580 and 700 DEG C for 20 to 90 minutes; and then performing furnace cooling on the connecting piece for 20 to 180 minutes, reducing the temperature to 220 to 560 DEG C, taking the connecting piece out for air cooling, and then removing the clamp to obtain the foamed aluminum structural component with high connection performance. The foamed aluminum material has the advantages of uniform tissue of the weld interface, sharing strength of 8 to 10MPa, high heat resistance, small heat affected zone of the weld interface, no residual stress and the like; and the method has the advantage of simple process and low cost.

Owner:NORTHEASTERN UNIV

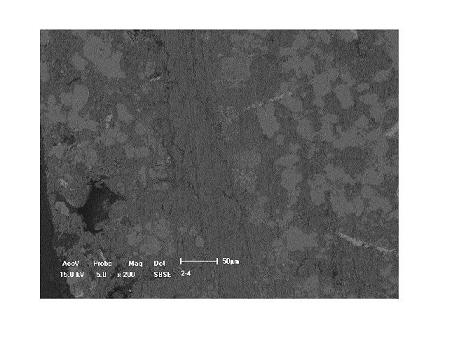

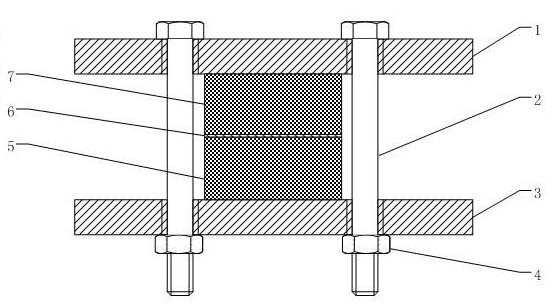

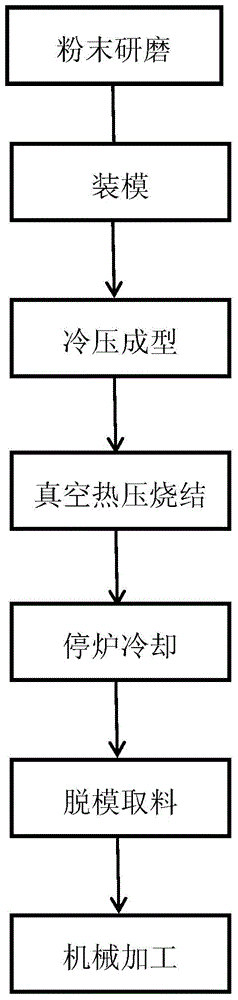

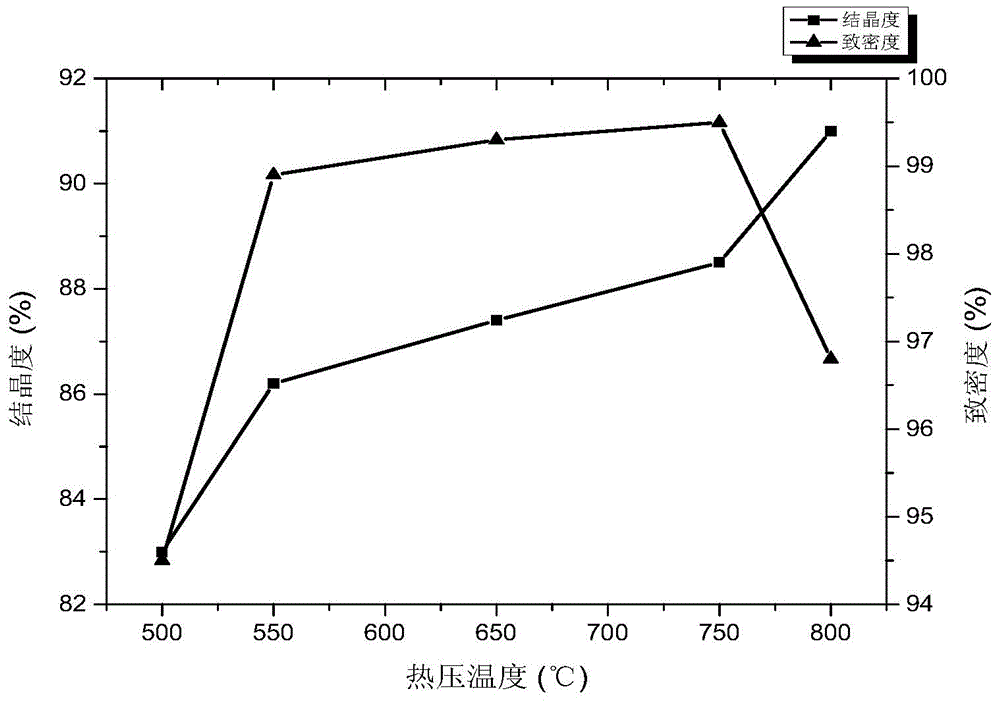

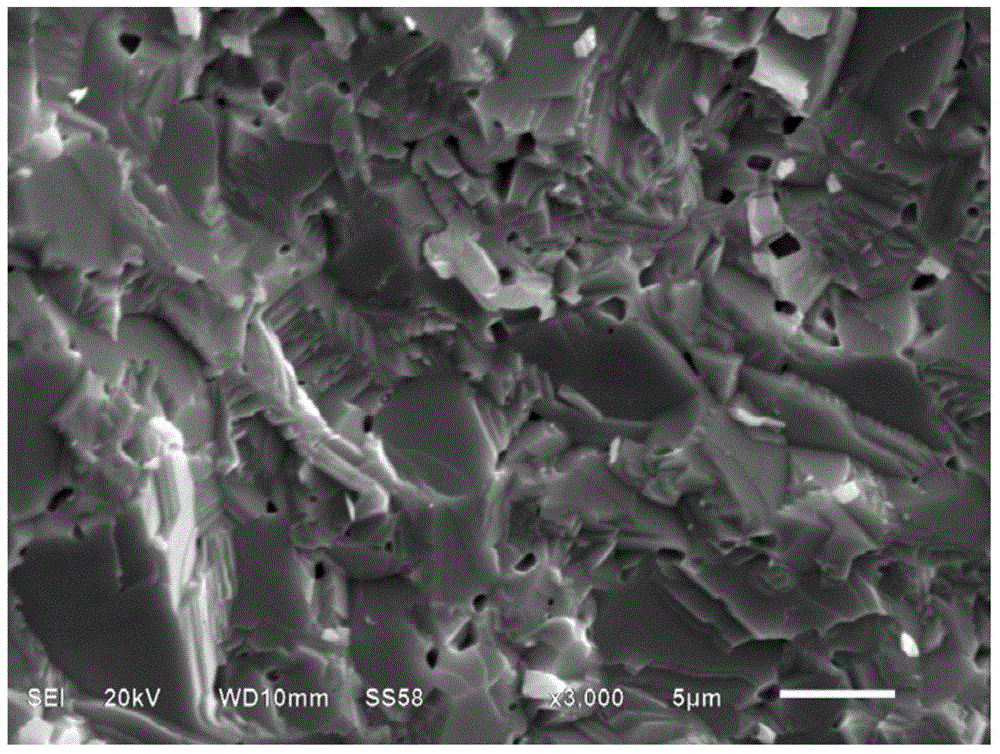

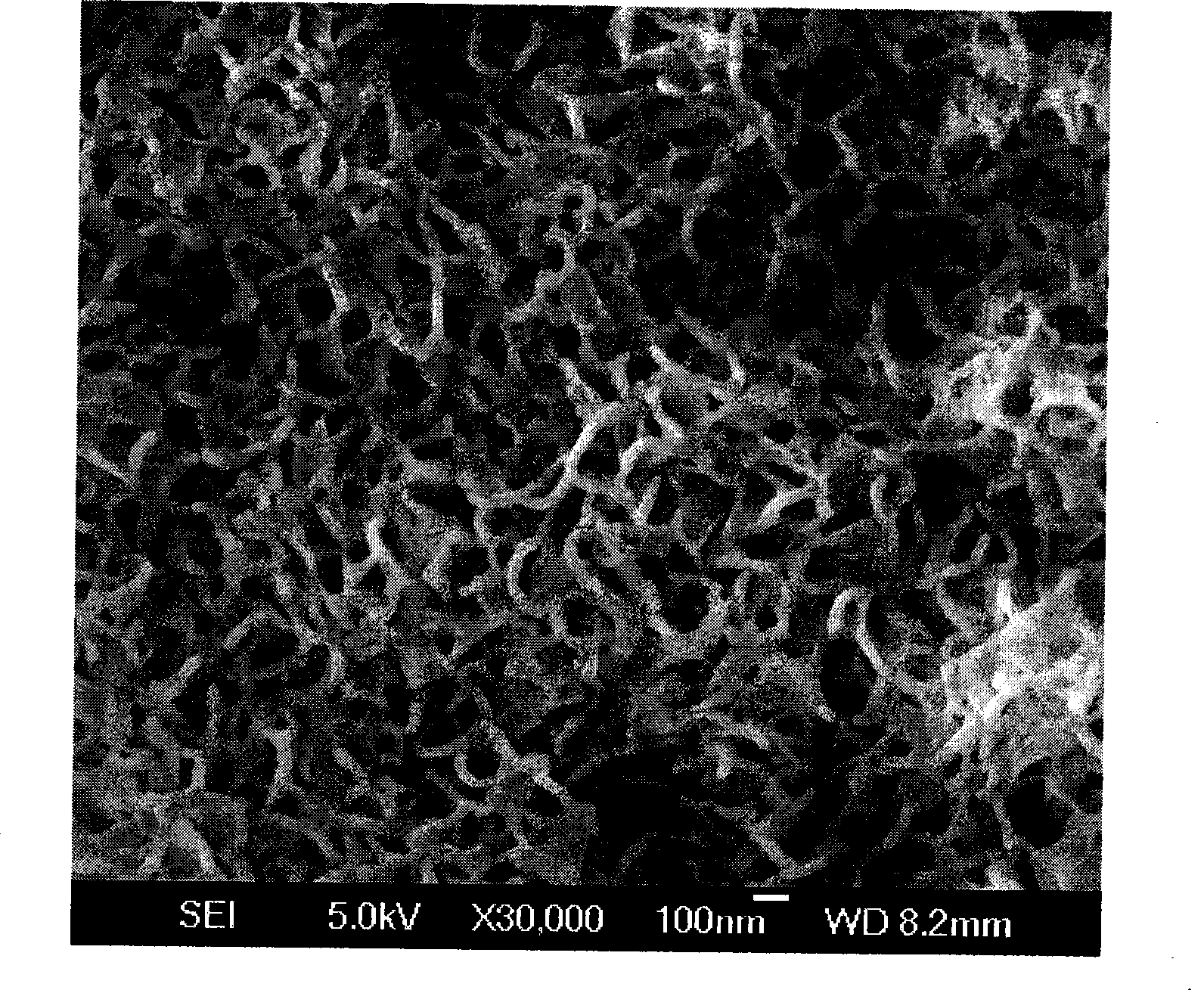

Preparation method of CdTe sputtering target material

ActiveCN104694889AImprove uniformityAvoid stratificationVacuum evaporation coatingSputtering coatingCrystallinitySolar cell

The invention relates to a preparation method of a CdTe sputtering target material, and belongs to the field of solar cell materials. The preparation method comprises the following steps: (1) crushing and grinding a CdTe block prepared through vacuum melting into powder, and loading the obtained CdTe powder into a mould for cold press moulding; (2) after the cold press moulding is finished, placing into a hot pressed furnace for vacuum hot pressed sintering, wherein the hot pressing temperature is 500-800 DEG C, the pressure is 20-200 MPa, and the temperature pressure keeping time is 30-120 minutes; and (3) after the vacuum hot pressed sintering is finished, stopping the hot pressed furnace for cooling, demoulding for taking a material, and machining. The CdTe sputtering target material obtained through the preparation method disclosed by the invention can achieve the density more than 98%, the average grain size less than 45 nanometers and the target material crystallinity more than 80%.

Owner:有研资源环境技术研究院(北京)有限公司

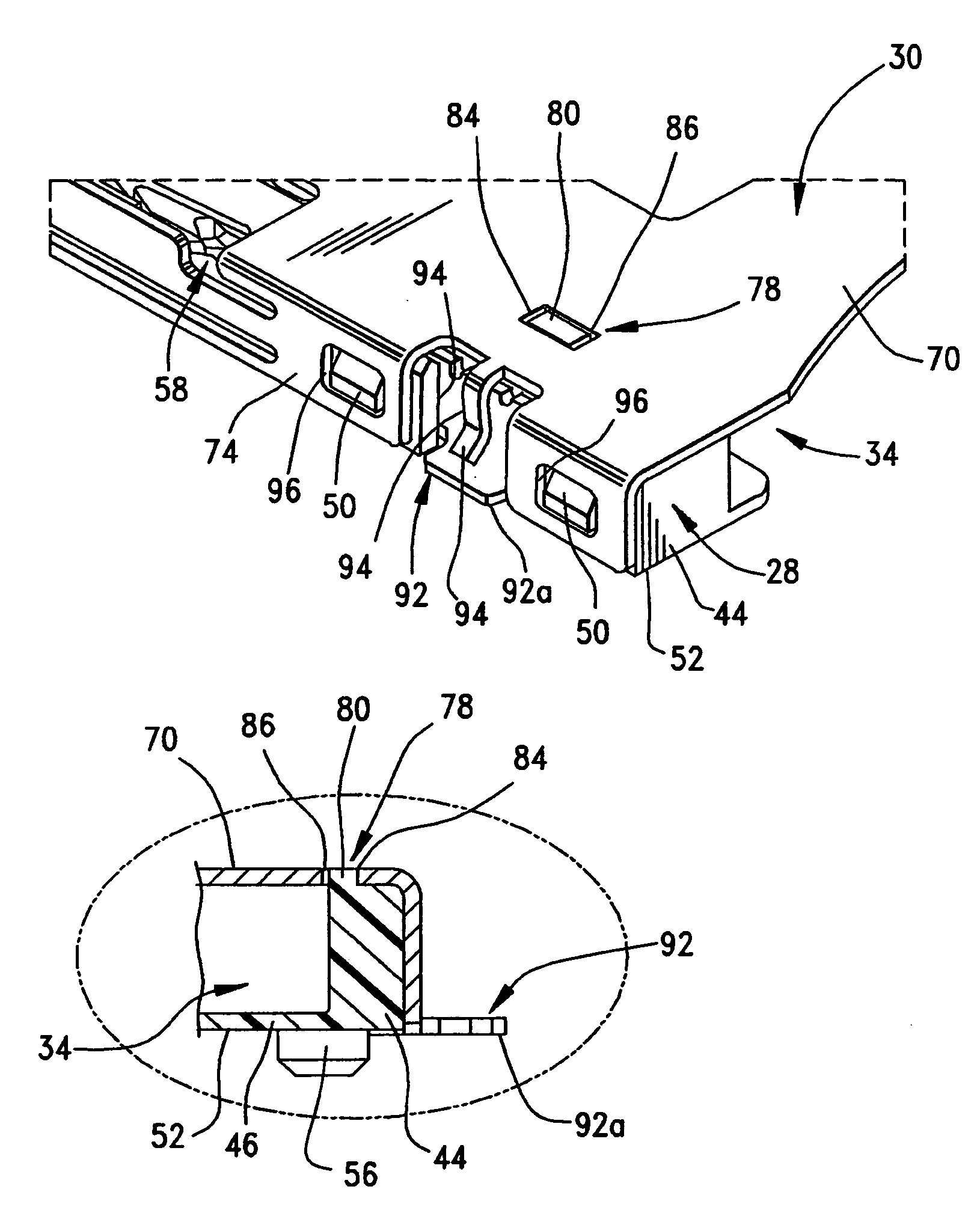

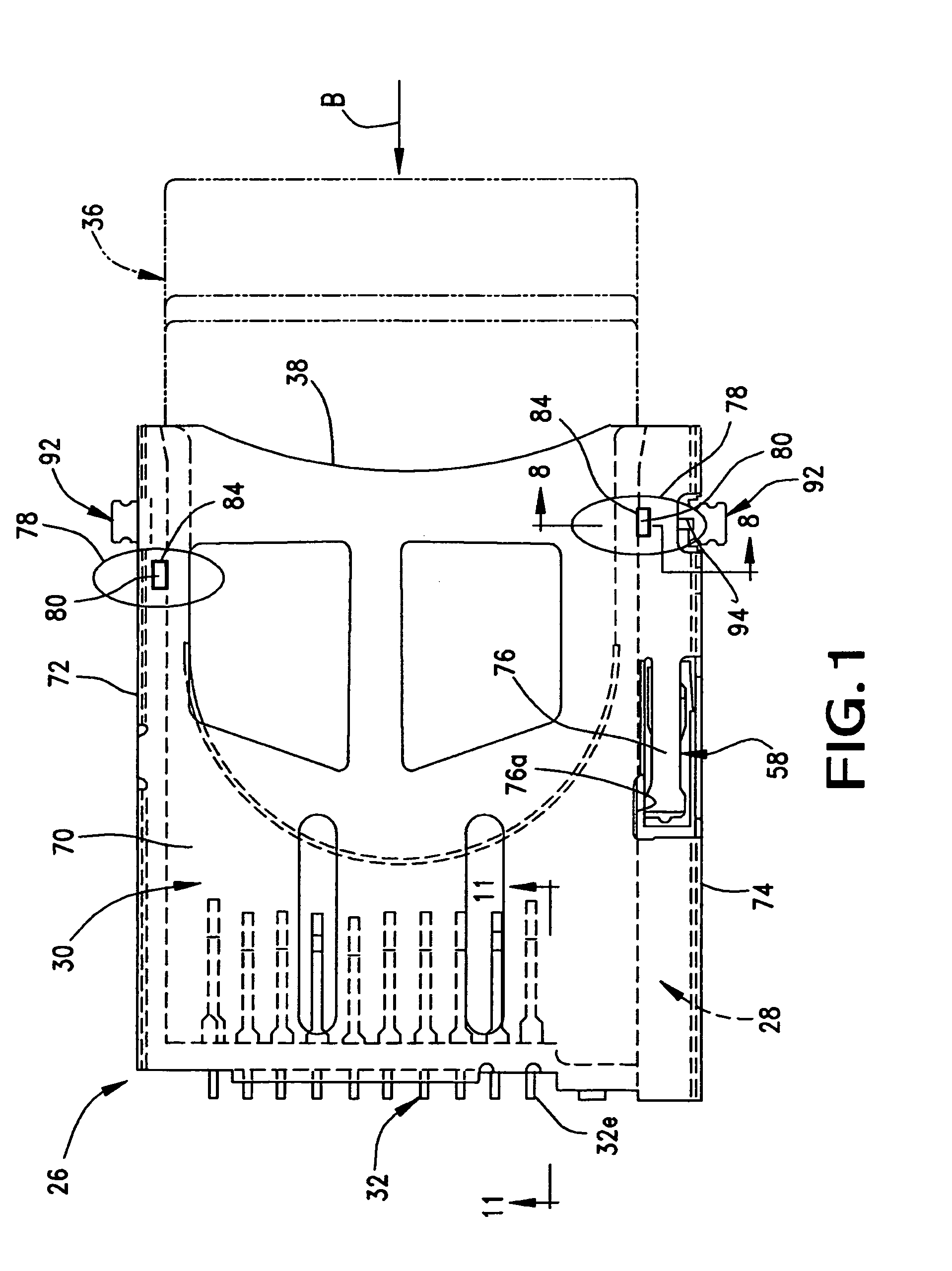

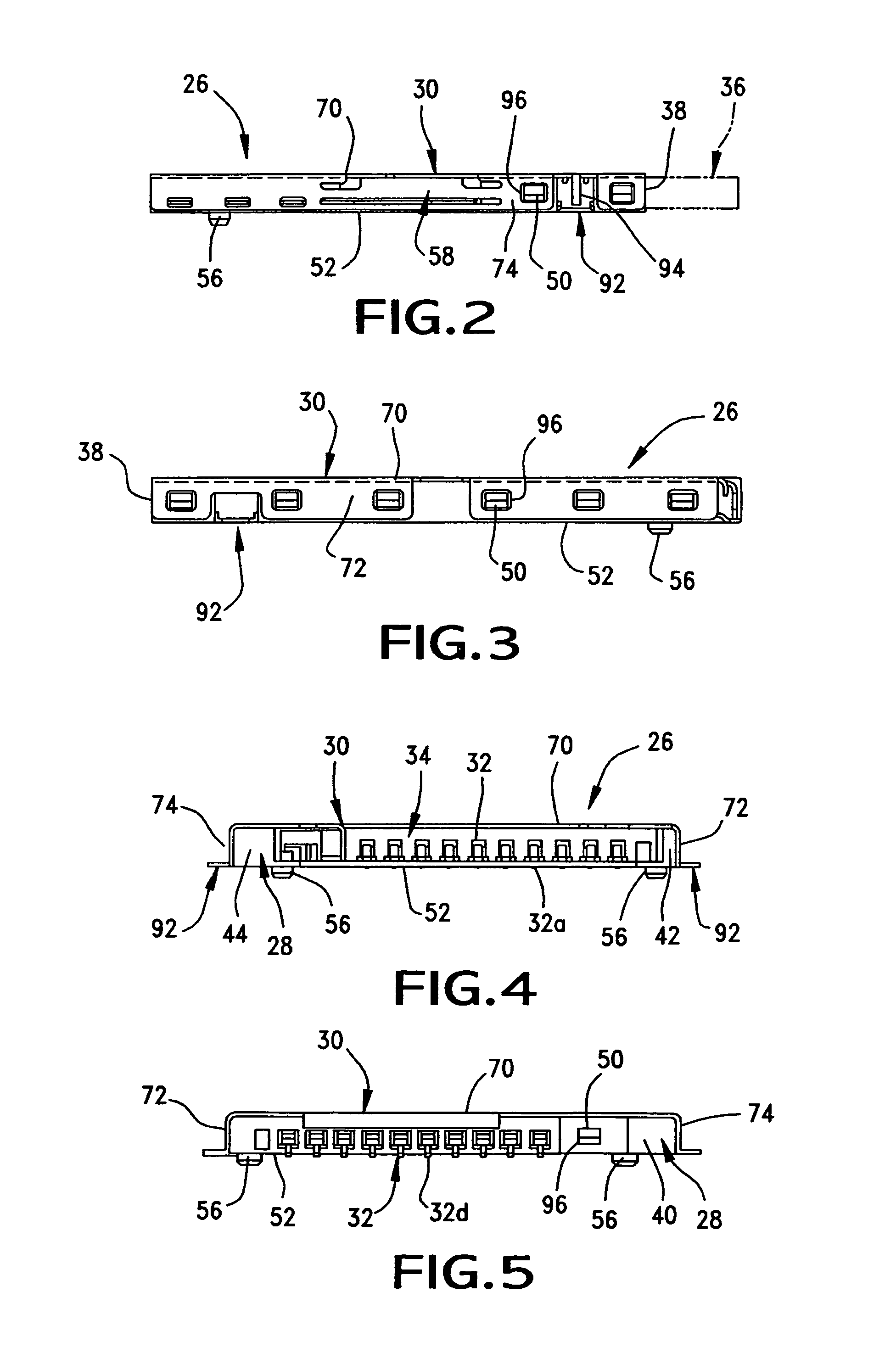

Memory card connector

InactiveUS7335064B2Avoid residual stressLine/current collector detailsTwo-part coupling devicesEngineeringMechanical engineering

A memory card connector includes an interior cavity for receiving a memory card. An insulating housing has a rear terminal-mounting section and at least one longitudinal side wall section extending forwardly from one end of the rear section. A metal shell covers at least a portion of the insulating housing and includes a cover plate overlying at least a portion of the longitudinal side wall section of the housing An engaging structure includes an engaging projection on one of the cover plate of the metal shell or the top surface of the side wall section of the housing extending into an engaging opening in the other of the cover plate or top surface to prevent relative movement therebetween in a plane generally parallel to the cover plate and top surface. A slight clearance is provided between the engaging projection and the engaging opening to avoid creating residual stresses in the housing.

Owner:MOLEX INC

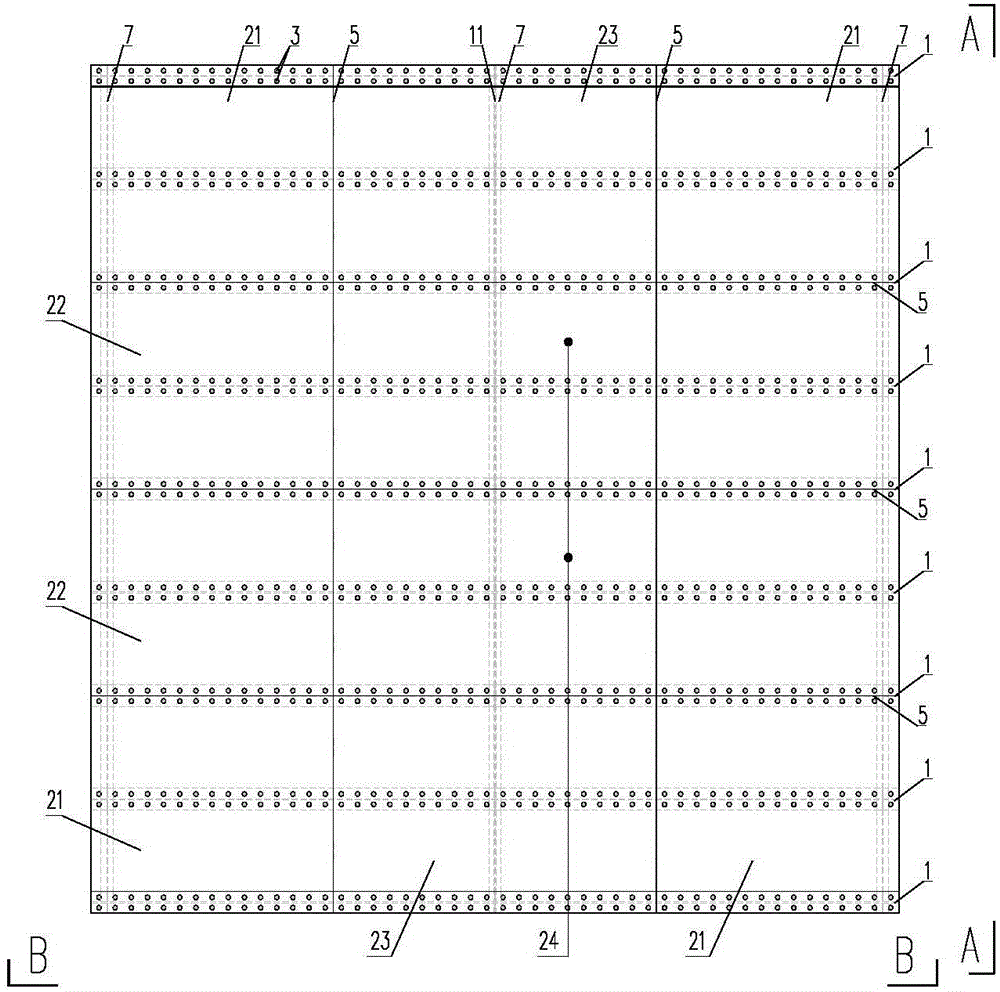

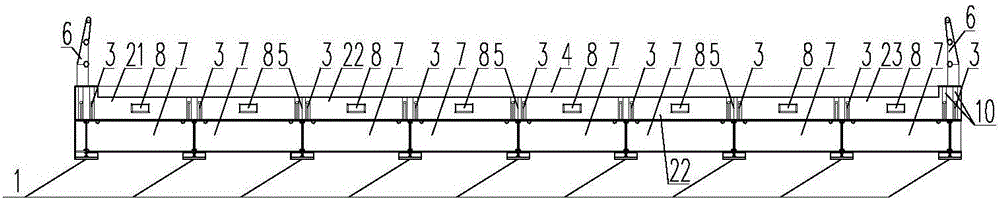

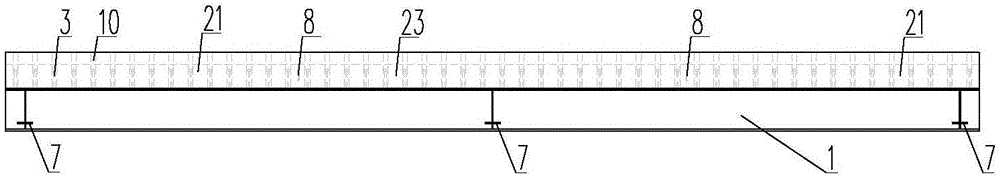

Novel prefabricated type steel-concrete composite beam bridge upper structure and manufacturing technology thereof

InactiveCN106120532AReduce quality problemsReduce fatigueBridge structural detailsBridge materialsManufacturing technologyConcrete beams

The invention provides a novel prefabricated type steel-concrete composite beam bridge upper structure comprising main steel beams, transverse connecting steel beams, metal connecting pieces and prefabricated reinforced concrete bridge deck slabs. The main steel beams are arranged according the shape of a bridge. The webs of the adjacent main steel beams are connected through the transverse connecting steel beams. The upper flanges of the main steel beams are provided with the metal connecting pieces. The prefabricated reinforced concrete bridge deck slabs are laid on the upper flanges of the main steel beams and provided with preformed holes used for grouting of grouting materials after the bridge deck slabs are well installed. The metal connecting pieces are located in the preformed holes. The invention further provides a manufacturing technology of the novel prefabricated type steel-concrete composite beam bridge upper structure. By the adoption of the novel prefabricated type steel-concrete composite beam bridge upper structure and the manufacturing technology of the novel prefabricated type steel-concrete composite beam bridge upper structure, damaged medium and small span concrete beam bridges can be rapidly replaced, the structure safety is good, the construction period is short, the cost is low, and the durability is good.

Owner:宁波金蛟龙重工钢构有限公司

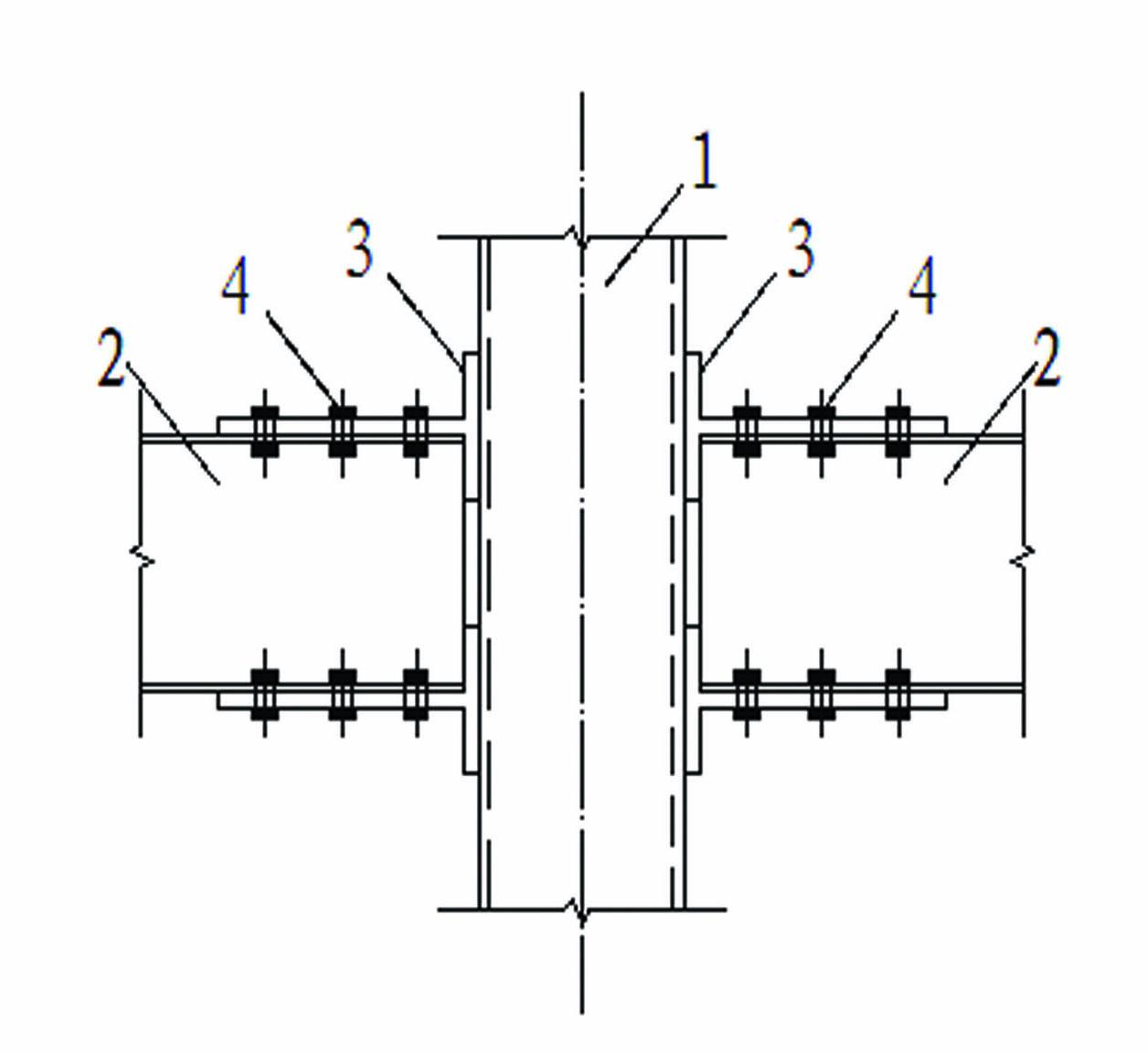

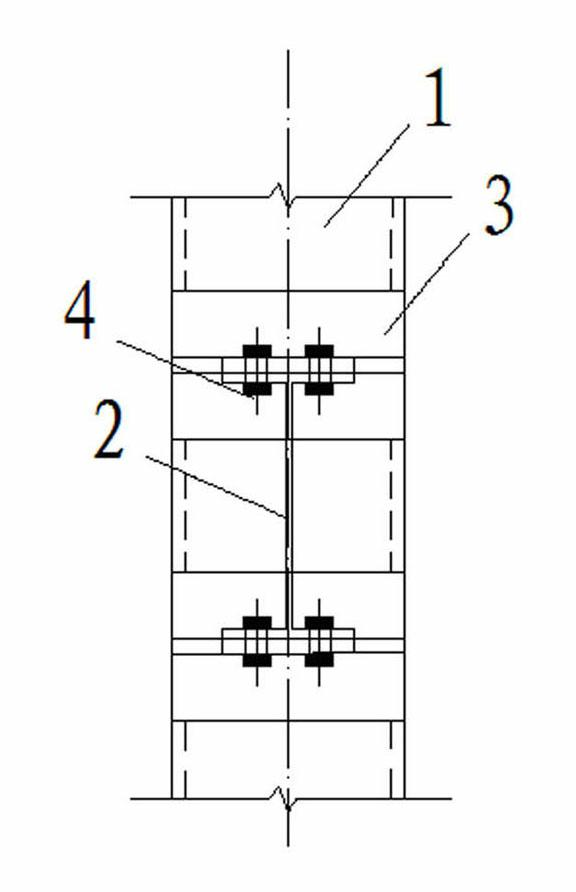

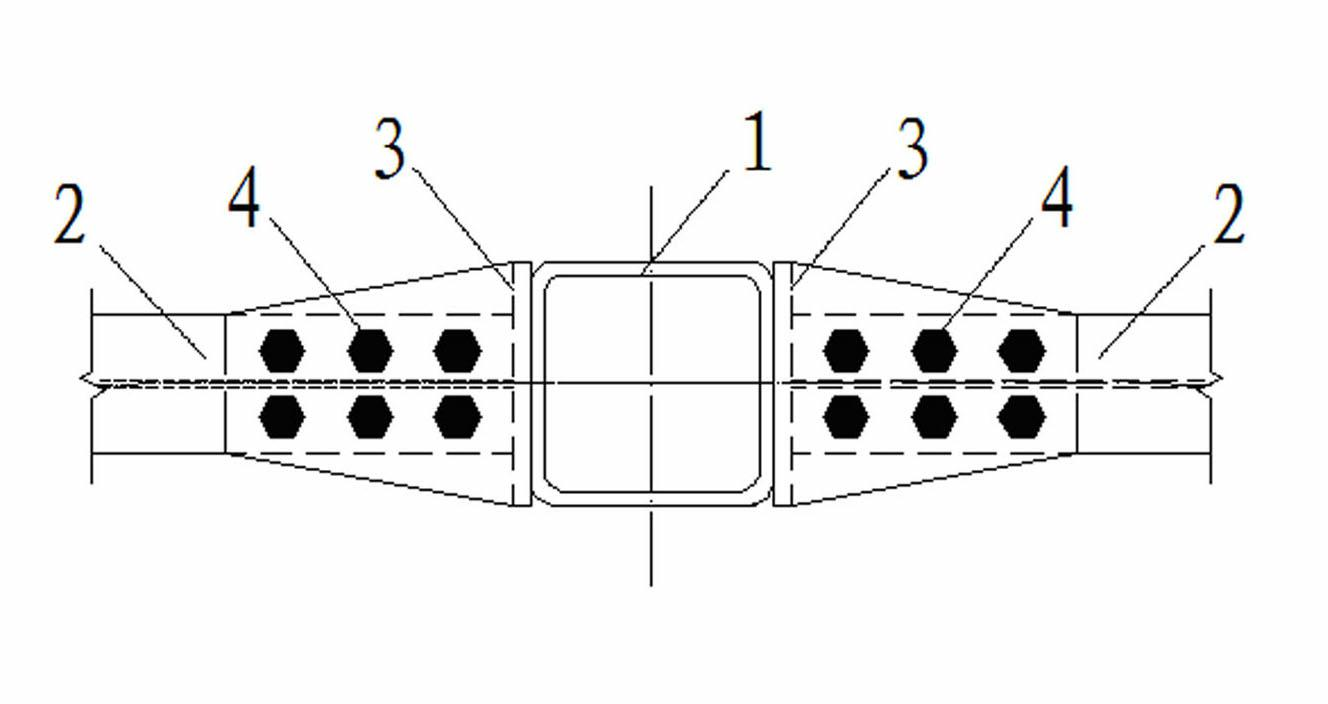

Connecting node of square steel pipe column and H-shaped steel beams

InactiveCN102635166APrevent local bucklingImprove the shortcomings of insufficient stiffnessBuilding constructionsFloor slabShock resistance

The invention relates to a connecting node of a beam and a column of building steel structures, in particular to a connecting node of a square steel pipe column and H-shaped steel beams for multi-layer and high-rise steel structures. The connecting node comprises a square steel pipe column, H-shaped steel beams and T-shaped steels; the T-shaped steels are arranged on the lateral wall of the square steel pipe column and the upper and lower wing edges of the H-shaped steels; webs of the T-shaped steels are connected with the wing edges of the H-shaped steel beams; and the wing edges of the T-shaped steels are fixedly connected with the lateral walls of the square steel pipe column. According to the connecting node of the square steel pipe column and the H-shaped steel beams, the connecting node is simple in structure, and the problem of construction difficulty in installing an internal separating plate is solved; a plastic hinge shifts outwards and better shock-absorbing property is achieved; the construction of an upper floor and the casting of concrete in the square steel pipe are not influenced; and the steel consumption is low. Therefore, the connecting node has high economic and social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

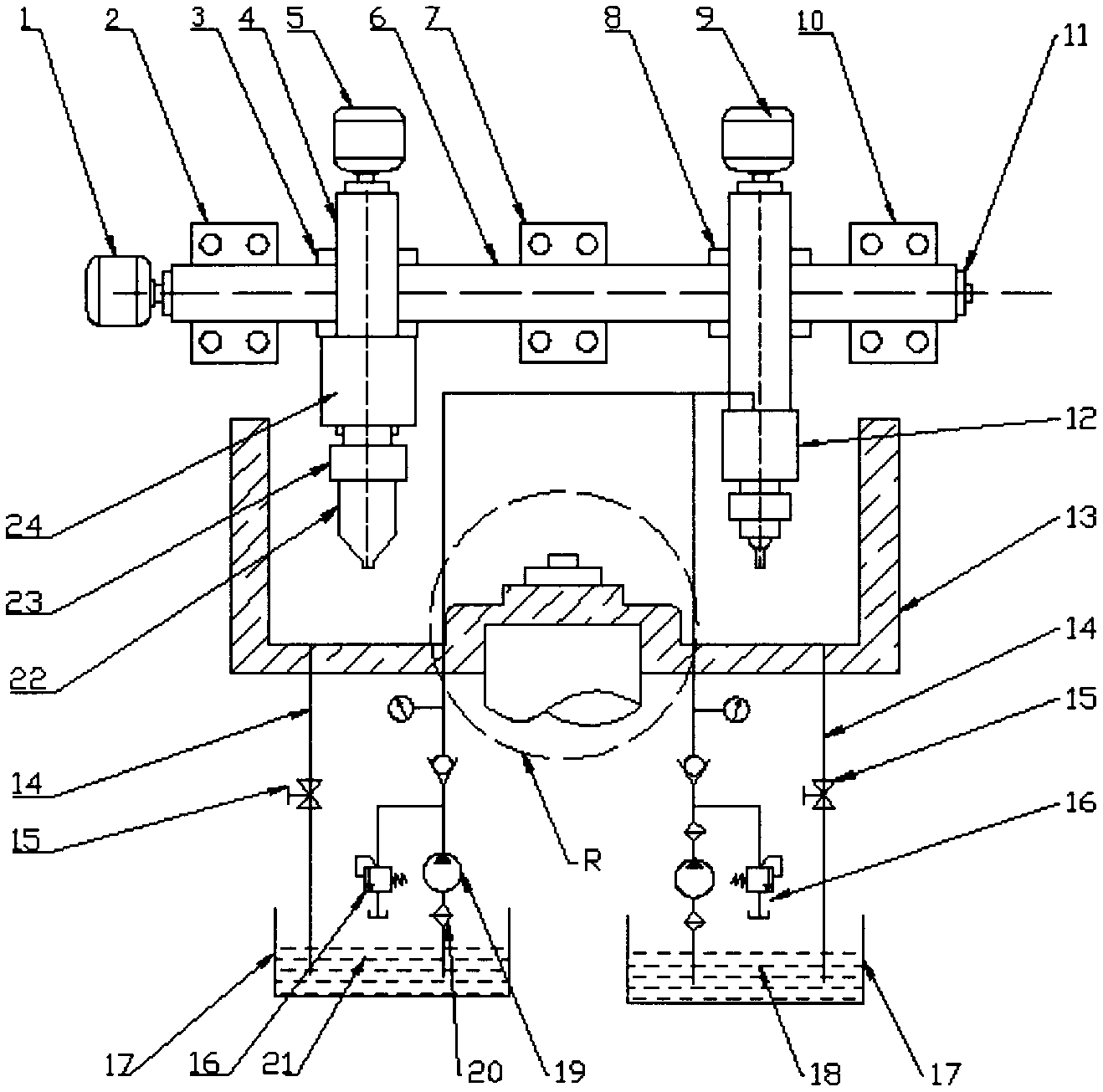

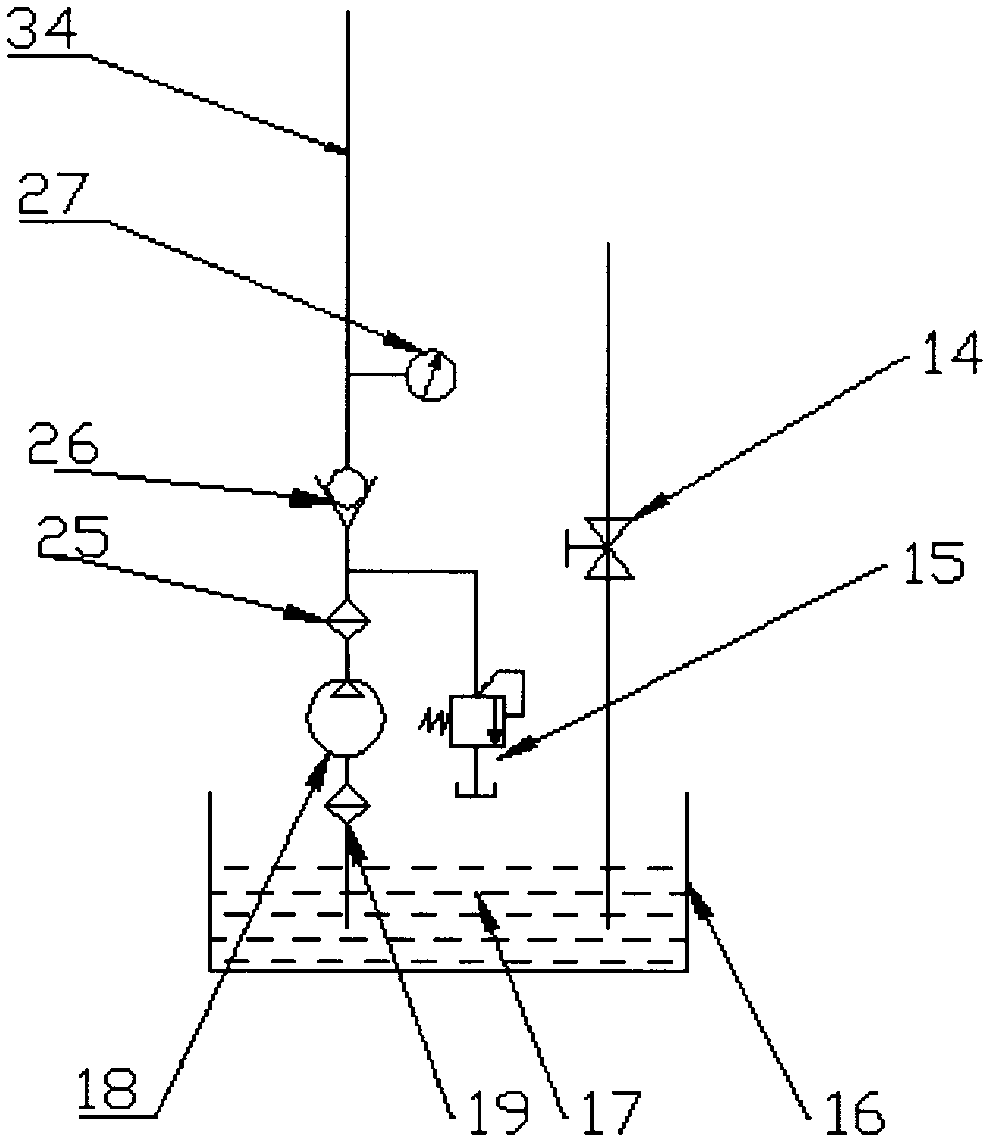

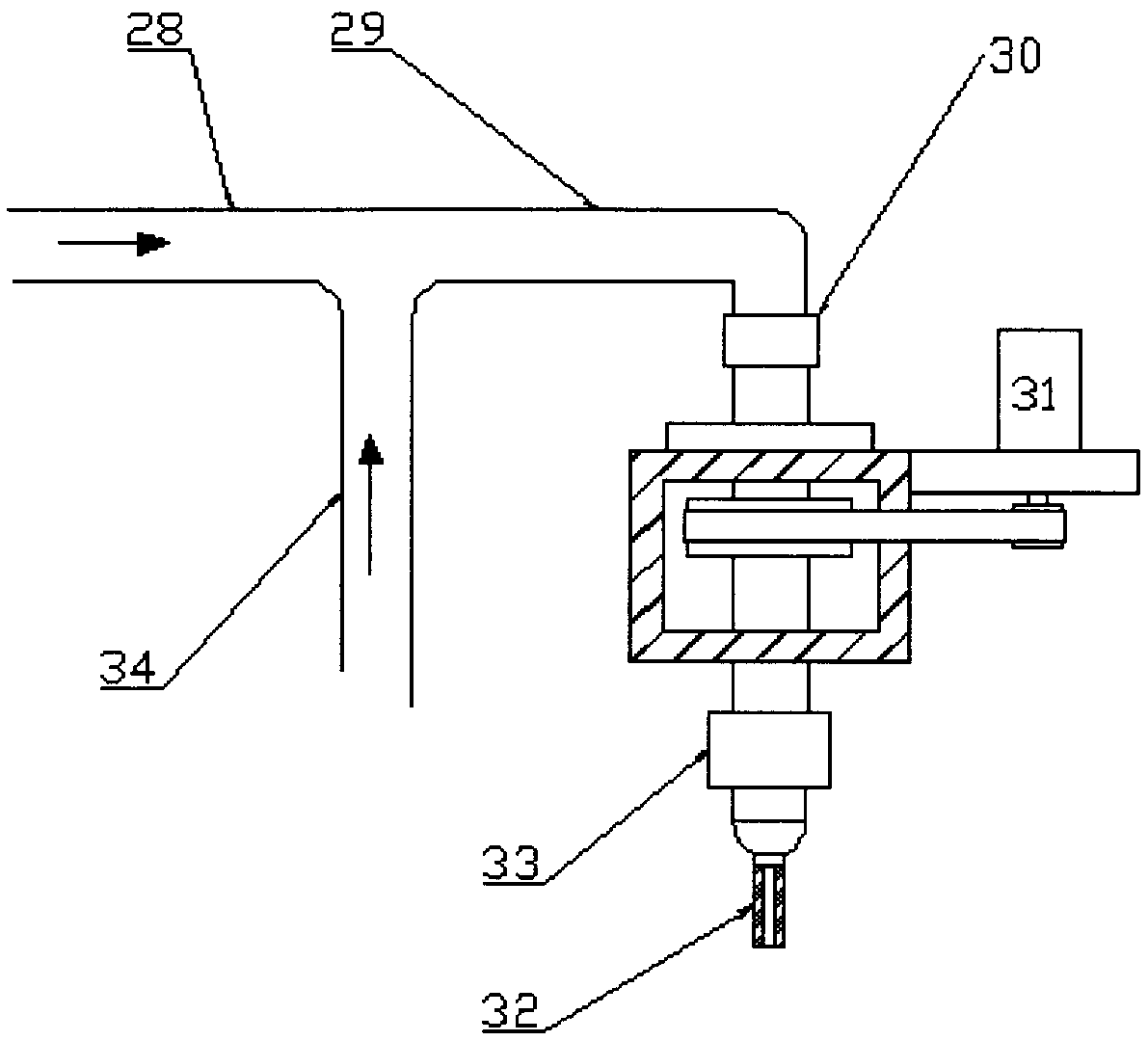

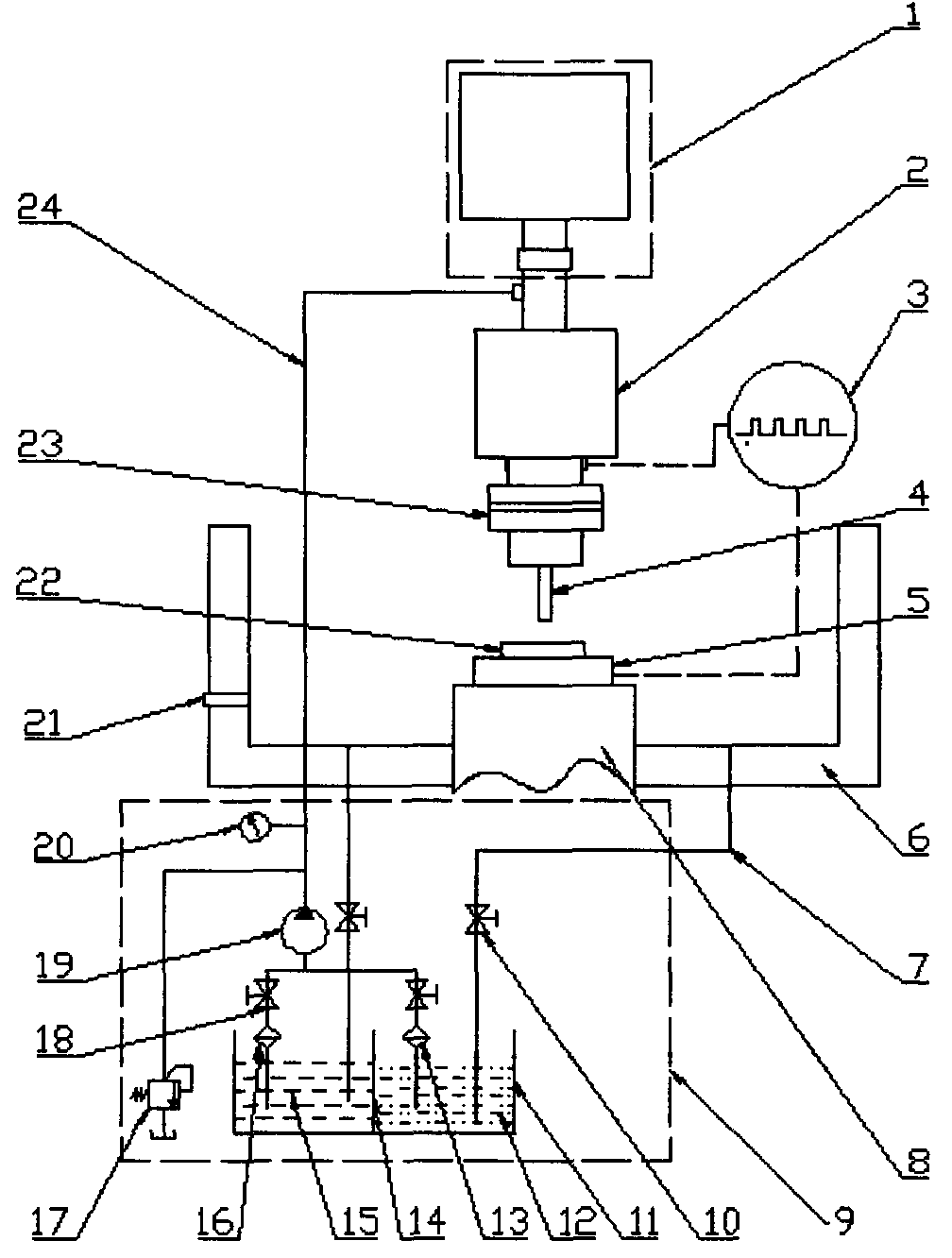

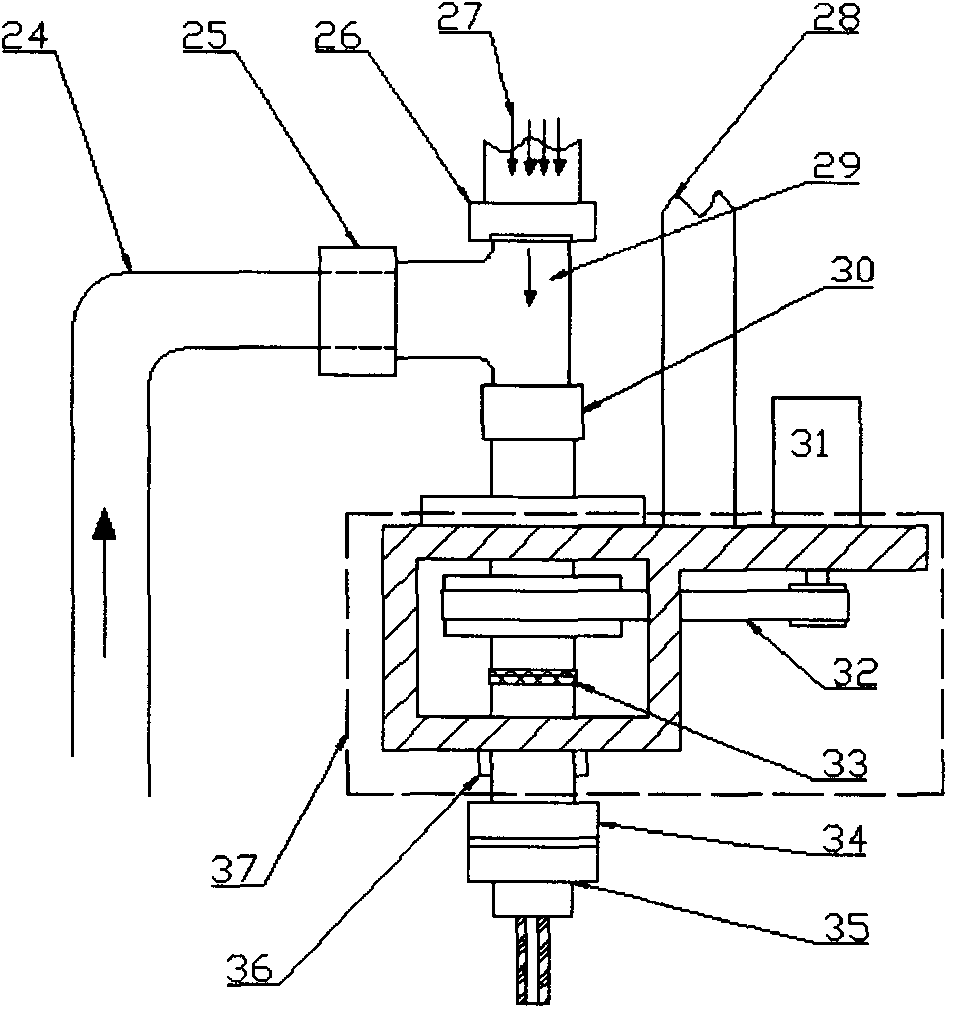

Combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads

The invention relates to a combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads. The method comprises the steps: carrying out through hole pre-machining on the micro holes with the countersunk heads on a workpiece through a laser beam, carrying out electric spark machining on the countersunk heads of the micro holes through a tubular copper electrode to achieve needed precision of the shape of the countersunk heads basically, and carrying out electrolytic machining electrolysis machining on the whole micro holes with the countersunk heads through a high-speed jet electrolyte beam coaxial with the electric spark machining electrode to remove recast layers remaining after the former two machining steps. The device comprises a laser generation device, a combined electric spark machining and electrolysis machining device, a machining mode conversion device, a working solution circulation system, a power supply and a control system. According to the method, laser machining and electric spark machining are the main machining modes and supplemented by electrolysis machining, and the high speed, high precision and high quality can be achieved at the same time. By means of the method and device, rapid machining of the micro holes with the various special-shaped countersunk heads can be achieved, and various shortcomings caused by the adoption of a single specific machining mode in the prior art can be overcome.

Owner:JIANGNAN UNIV

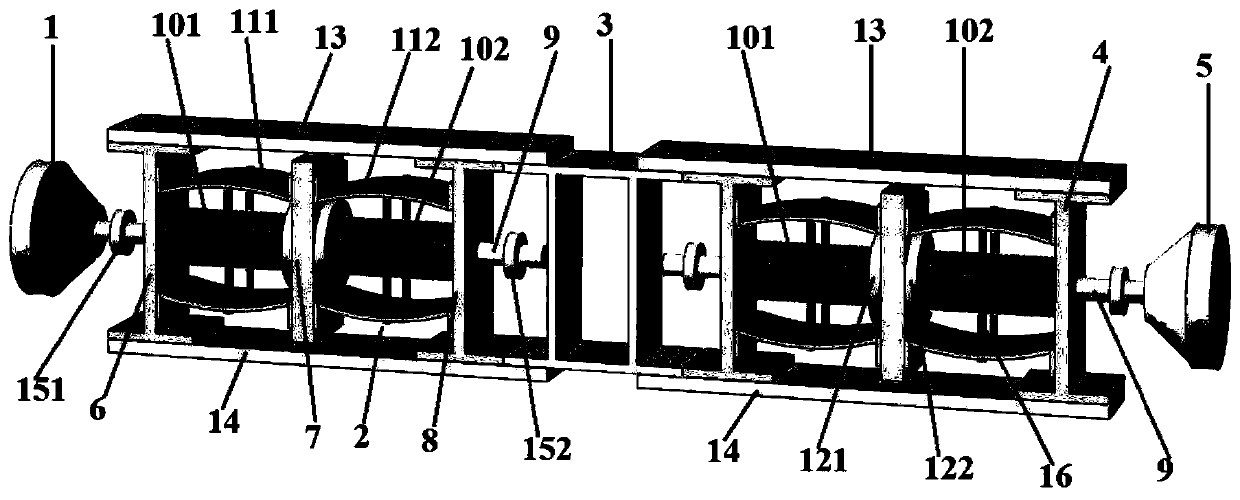

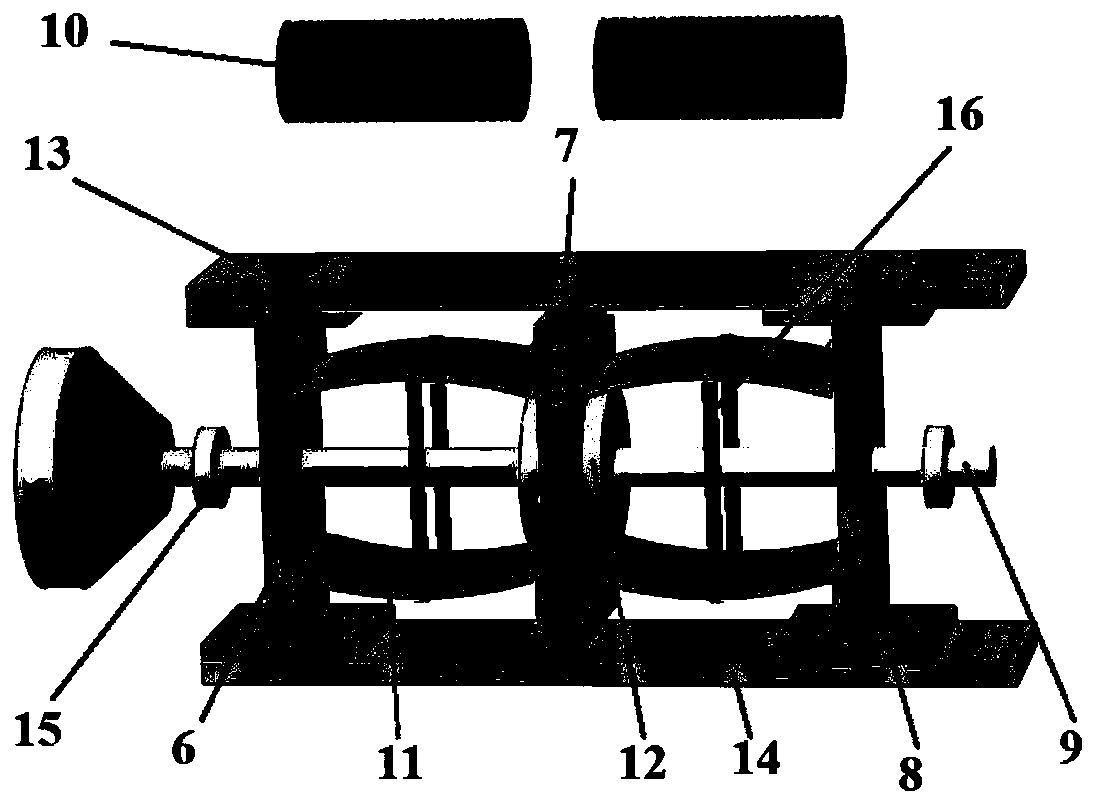

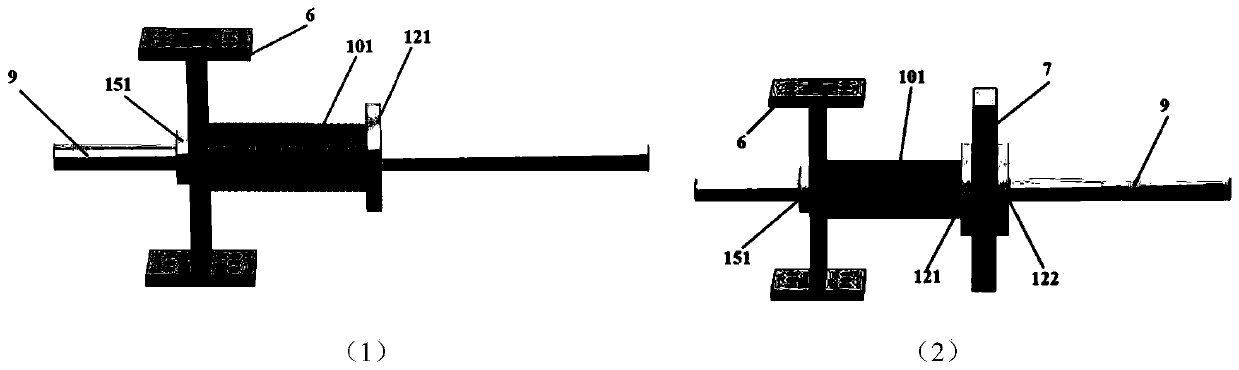

Jet-flow-guided laser-spark-electrolysis combined machining device

The invention relates to a jet-flow-guided laser-spark-electrolysis combined machining device, and belongs to the field of non-traditional machining. The jet-flow-guided laser-spark-electrolysis combined machining device adopts the structure integrating three non-traditional machining methods, and is composed of a laser generator, a machining module, a working solution circulation system and a power supply module, wherein the laser generator is placed above the machining module, and laser beam machining and spark machining are ensured to be coaxial; an electrode in the machining module for sparking machining can be stationary or rotary; the working solutions for jet-flow-guided laser machining and spark machining employ deionized water, and form a set of working solution circulation system with the working solution for electrolytic machining. When the device is used for machining, the jet-flow-guided laser machining and spark machining are employed as the main means for removing material, being accompanied by electrolytic machining; speed, accuracy and surface quality of part manufacturing are all taken into consideration; thereby, rapid machining of various micro holes with abnormal countersunk heads, and various defects caused by using single non-traditional machining method are overcome.

Owner:JIANGNAN UNIV

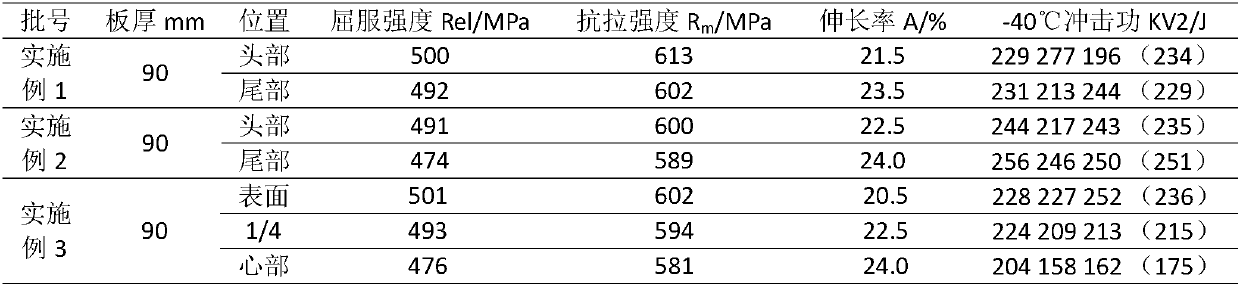

Corrosion-resistant steel plate for ocean platform and production method of steel plate

The invention belongs to the technical field of ferrous metallurgy, and discloses a corrosion-resistant steel plate for an ocean platform and a production method of the steel plate. The corrosion-resistant steel plate is prepared firstly from the combination of proper components in percentage by weight and then by carrying out KR molten iron pretreatment, converter smelting, argon-blowing station fed with aluminum wire, LF furnace refining, VD vacuum refining, continuous casting, heating, controlled rolling and controlled cooling, heap cooling, quenching, tempering and the like. According to the corrosion-resistant steel plate for the ocean platform and the production method of the steel plate, compared with the prior art, the produced steel plate has the advantages of excellent corrosion resistance, good low-temperature impact toughness and excellent comprehensive performance, and is especially suitable for being used under cold weather and seawater corrosion conditions.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

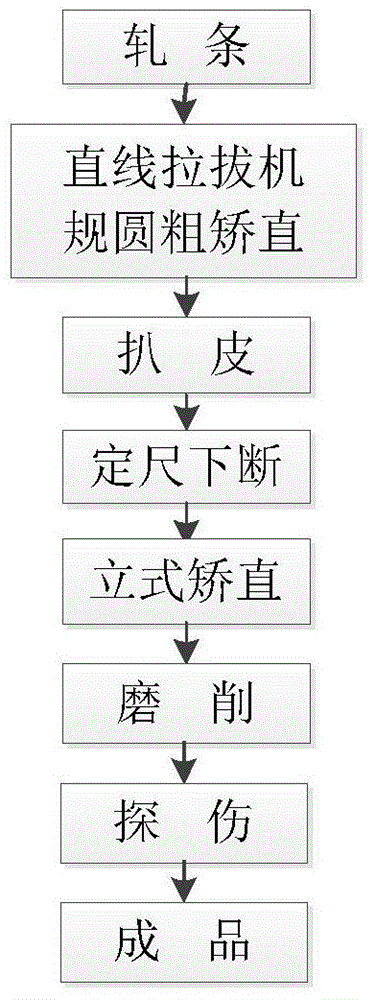

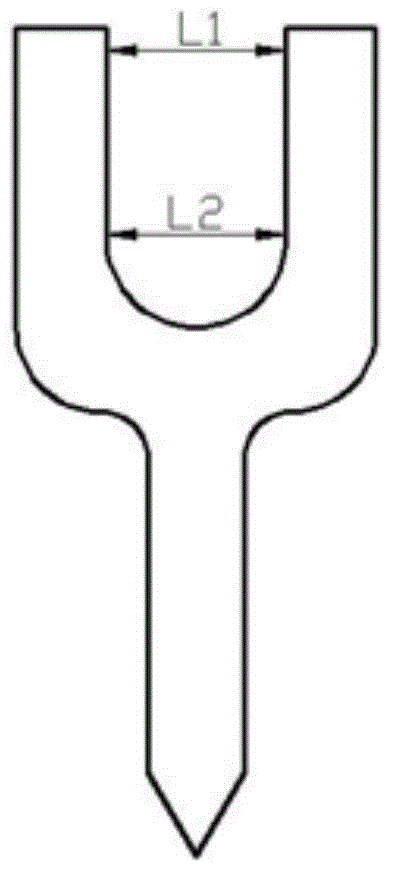

Preparation method of titanium alloy bar for pedicle screw

ActiveCN104056872AEasy to prepareSuitable for mass production and processingCenterless grindingElectric heating

The invention discloses a preparation method of a titanium alloy bar for a pedicle screw. The preparation method comprises the following steps: firstly, performing rounding coarse straightening treatment on original rolled bar blanks by adopting a straight drawbench, then removing surface defects by using a flaying machine, simultaneously performing sizing determining operation at a discharge hole, straightening in a vertical electrothermal straightening mode, and finally, performing centerless grinding treatment to obtain a finished bar. According to the preparation method of the titanium alloy bar for the pedicle screw, the rounding coarse straightening treatment is performed on the rolled bar blanks by adopting the straight drawbench, and a traditional two-roll or multi-roll straightening rounding mode is replaced, so as to prevent residual stress due to coarse straightening; the residual stress generated by traditional two-roll or multi-roll fine straightening is removed by utilizing the vertical straightening mode, and the problem of necking caused by unbalanced stress of a U-shaped groove of the pedicle screw due to excessive inner stress of the titanium alloy bar prepared in the prior art is solved; the preparation method has the advantage of simplicity and is suitable for mass production and machining.

Owner:西安赛特思迈钛业有限公司

Soft thin film transferring device and soft thin film transferring method

InactiveCN101958281AContribute to qualityResolve curlLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses a soft thin film transferring device and a soft thin film transferring method. The soft thin film transferring device comprises a first roller wheel, a connecting component and a second roller wheel, wherein the connecting component is pivoted to the second roller wheel and is connected to the first roller wheel telescopically so that the second roller wheel can protrude out from a first peripheral surface; and the peripheral surfaces of the first roller wheel and the second roller wheel are respectively provided with a controllable adsorption device. When in use, the soft thin film transferring method comprises the following steps of: peeling the edge part of a soft thin film which is adhered to a first support plate from the first support plate by using the second roller wheel; peeling the main part of the soft thin film from the first support plate by using the first roller wheel; adhering the edge part to a second support plate by using the second roller wheel; and adhering the main part to the second support plate by using the first roller wheel. Therefore, the device and method solve the problem of warpage when the soft thin film is transferred in the prior art.

Owner:AU OPTRONICS CORP

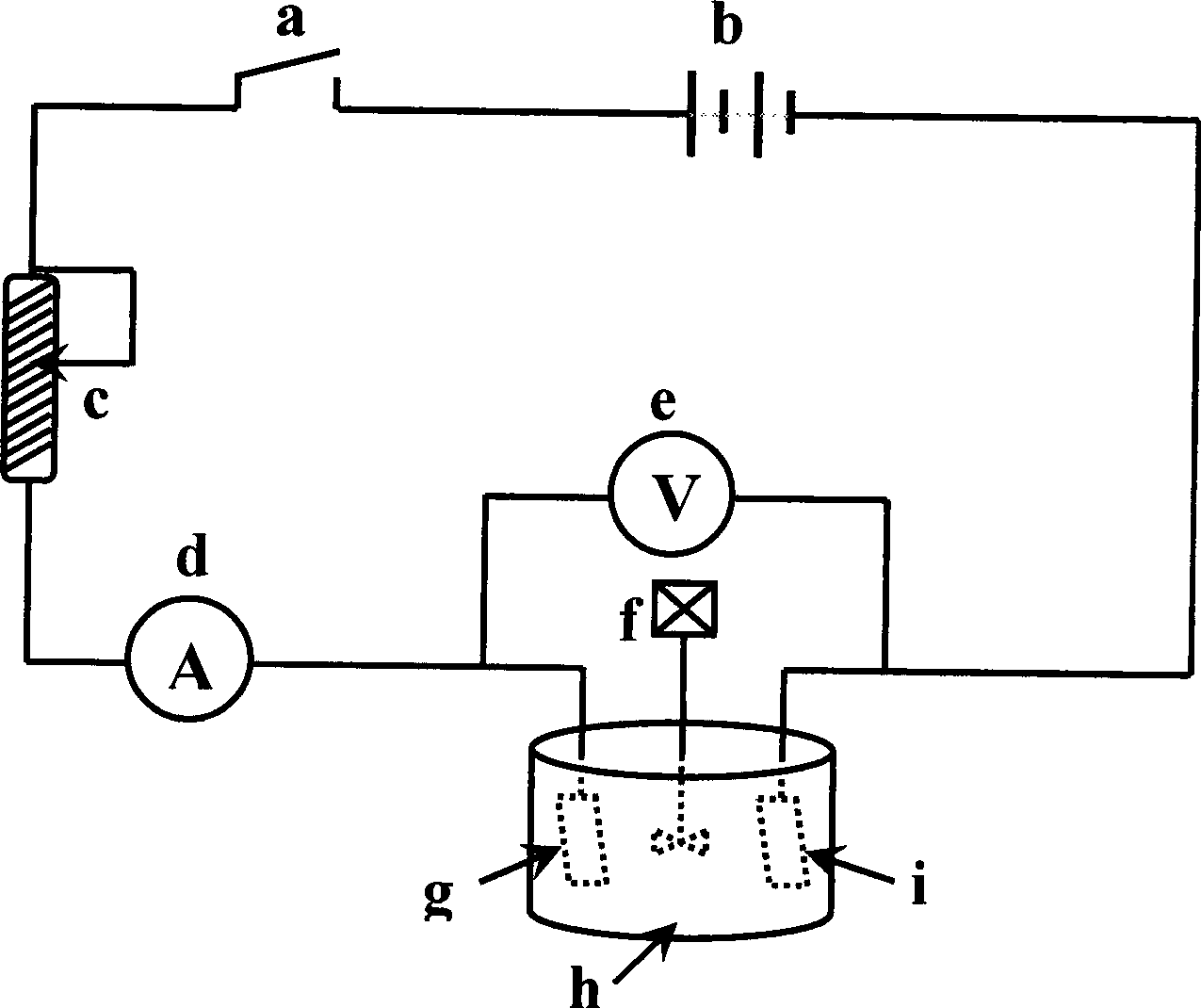

Electrochemical modification method for silicon face biology performance

InactiveCN101498053AGood biocompatibilityTightly boundAnodisationAfter-treatment detailsElectrolysisAcid electrolyte

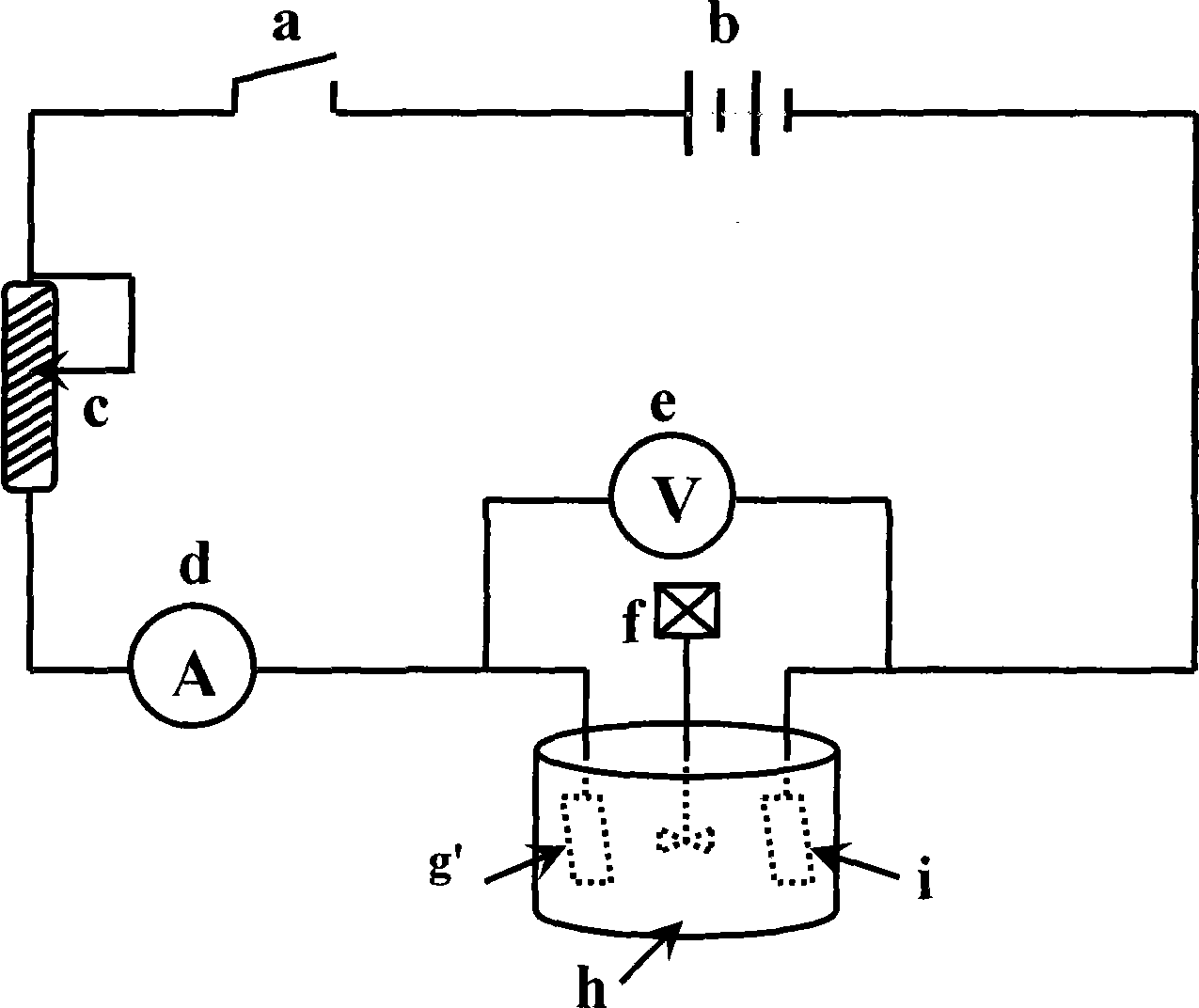

The invention discloses a method of electrochemistrically modifying the biological performance of a silicon surface. The method comprises the following steps: firstly, dissolving an alkaline reagent or a weakly acidic reagent into water to obtain an alkaline or weakly acidic electrolytic solution; then using crystal silicon as an anode (g) and conductive inert material as a cathode (i) to form a double-electrode electrolytic system, using the prepared alkaline or weakly acidic electrolytic solution as an electrolyte (h) and adopting a direct current (b) to oxidize the anode (g) of the crystal silicon; afterwards, preparing a bionic solution with a certain ingredients, soaking the crystal silicon after anode oxidization treatment at a temperature close to a physiological temperature, periodically refreshing the silicon-soaked bionic solution and drying the bionic solution to obtain an osteolith coating of a silicon-based type. The invention can be directly applied to biomedical crystal silicon material to improve the biological compatibility and the binding performance of the silicon material surface, has low cost, mild modification conditions and is convenient and controllable.

Owner:HUNAN UNIV

Self-resetting double-bow opposite-pull double energy dissipation supporting device

ActiveCN109853770AStable energy performanceEasy to controlProtective buildings/sheltersShock proofingSteel platesEngineering

The invention discloses a self-resetting double-bow opposite-pull double energy dissipation supporting device. A belleville spring is adopted as a reset system, an arc-shaped steel plate is used as ametal energy dissipation element, in the case of the metal energy dissipation element, the arc-shaped steel plate belongs to a bending yield energy dissipation type, compared with other traditional metal energy dissipation modes, the energy dissipation performance of the arc-shaped steel plate is stable, damaged positions of the element are easy to control, in addition, the arc-shaped steel plateenergy dissipation element is easy to replace after an earthquake, recycling of integral support is realized, the economical and practical requirements are confirmed, and wide popularization is easy;in the case of a reset device, the price of the belleville spring is low, restoring force can be stably provided, and the influence on the temperature, humidity and other external factors is smaller;and no damage and low damage during the earthquake and self-resetting after the earthquake of the supporting device are realized, the structural construction is simple and clear, and the manufacturingand mounting process is simple and convenient.

Owner:CHANGAN UNIV

Molding system having a micro heating element for molding a micro pattern structure

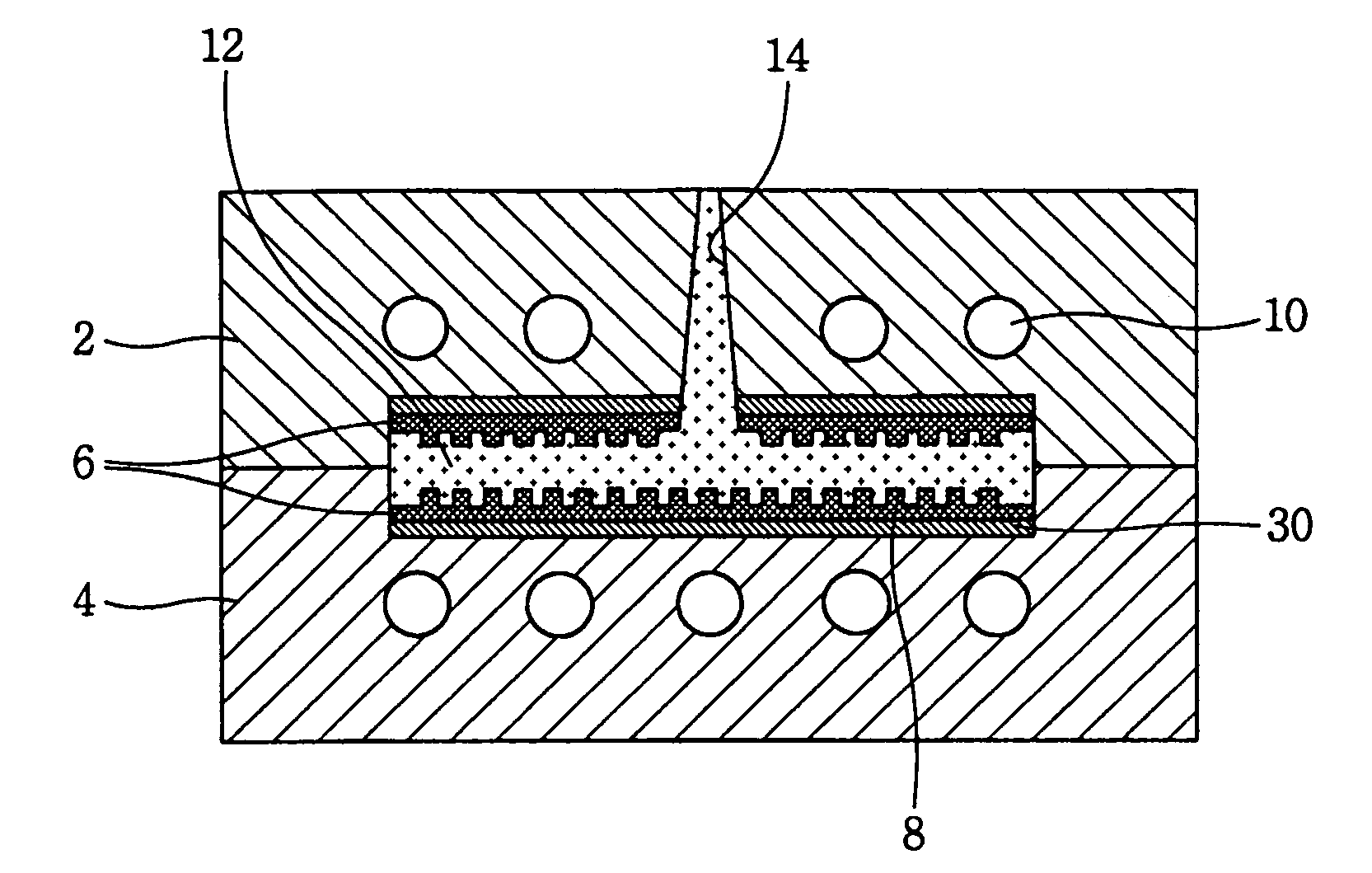

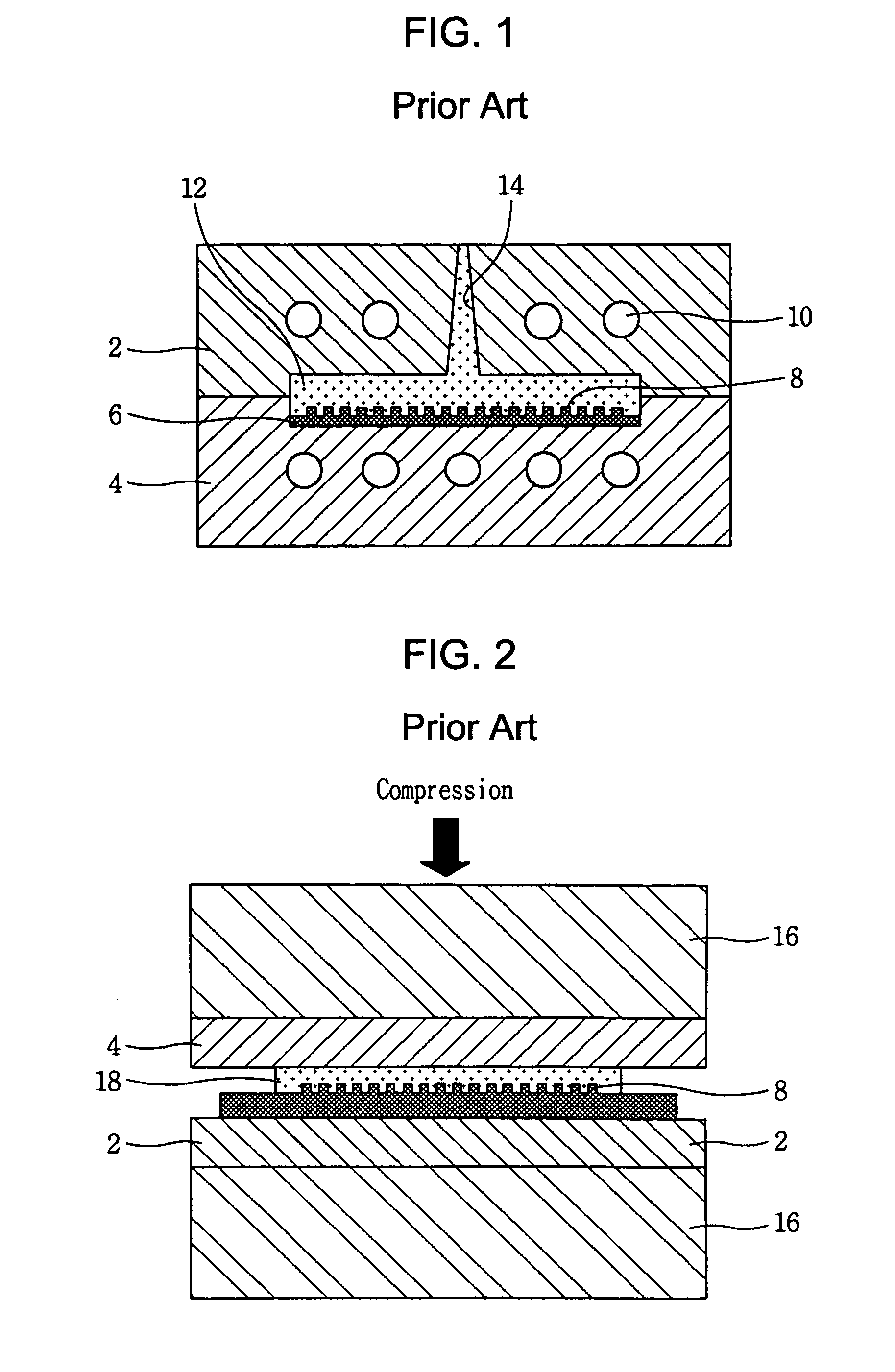

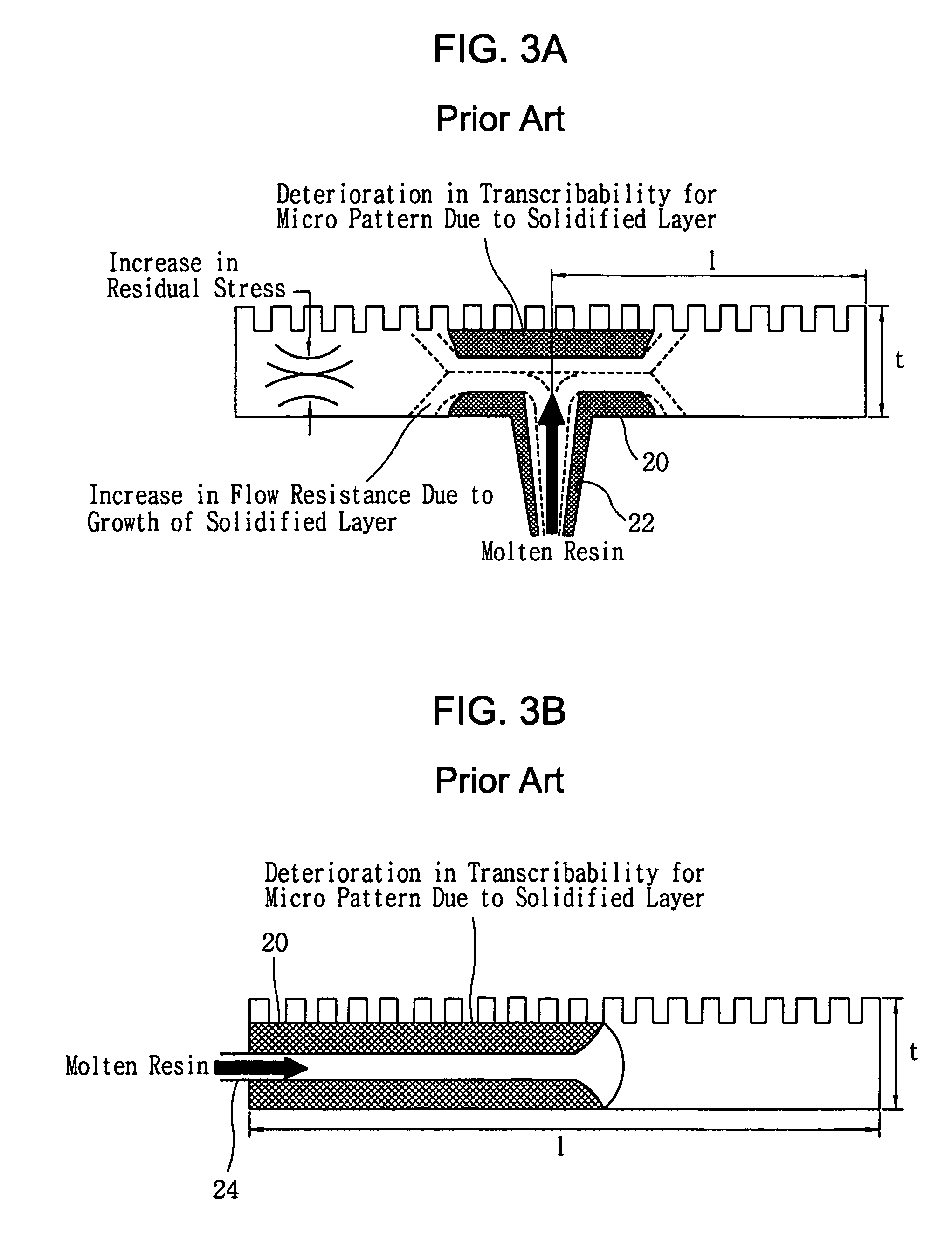

InactiveUS7291004B2Quickly heat and coolAvoid layeringRecord carriersNanoinformaticsElectricityLithography process

A molding system for molding a micro pattern structure includes a mold; a mold insert 6 having a micro pattern, the mold insert 6 being fixed to the mold; and a micro heating element 30 having a micro heater 32 between the mold and the mold insert 6, the micro heater 32 being formed in an integrated manner by using a MEMS process; wherein the amount of Joule's heat produced by the micro heater 32 is controlled by controlling the amount of electricity applied to the micro heater 32 so as to control a temperature of the mold insert 6. A method for fabricating the mold insert 6 for molding the micro pattern structure, the mold insert 6 being heated by a micro heater 32, includes the steps of: coating a photoresist on a back side of either the mold insert 6 or a plate 40 fixed onto the mold insert 6; patterning the photoresist by removing a part of the photoresist corresponding to the micro heater 32 using a lithography process; coating a material for forming the micro heater 32; and removing the residual photoresist.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

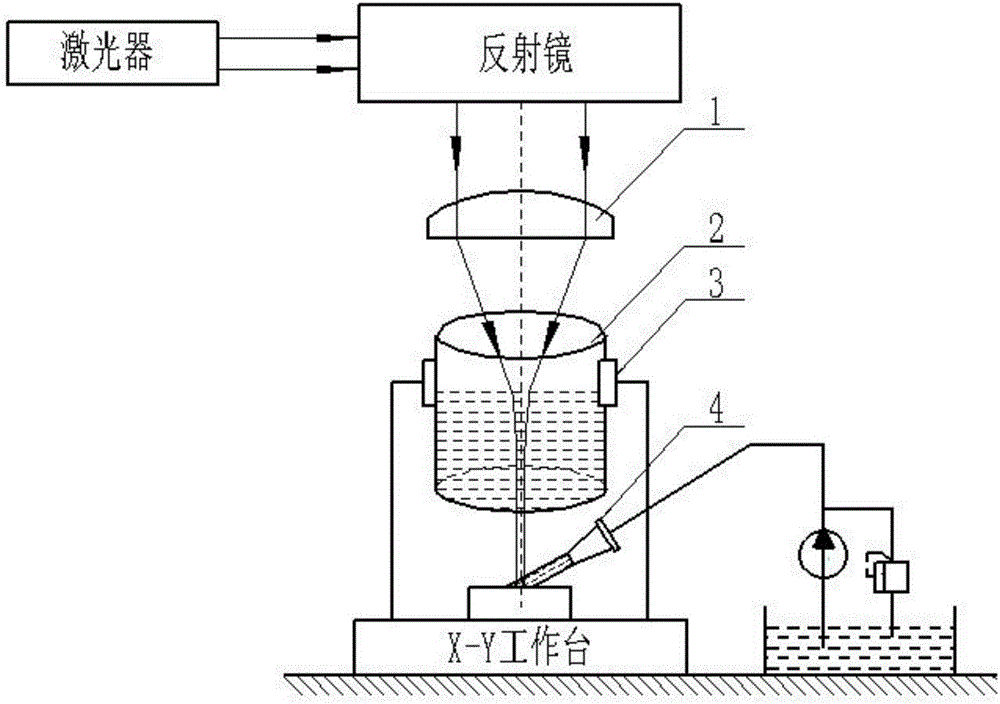

Self-focusing laser processing device

ActiveCN106312302ASmall diameterIncrease energy densityLaser beam welding apparatusEtchingLaser processing

The invention relates to a self-focusing laser processing device. A container for containing a non-linear medium is fixed between a lens and a workbench by the aid of a clamping mechanism. A laser beam is focused on the surface of the non-linear medium, the laser beam focused by the lens enters the non-linear medium to be transferred to produce self-focusing, and through two times of focusing by the lens and the non-linear medium, the laser beam leaving the container has the extremely small diameter and is linearly spread to the surface of a workpiece. The depth of the non-linear medium in the container, that is, the self-focusing distance L is related to energy of the laser beam and the refractive index of the adopted non-linear medium. A water jet auxiliary device is also provided, and the laser focus point on the surface of the workpiece coincides with the jet injection point center. Impact of water jet on the surface of the workpiece carries away residues and heat removed by laser. Lens focusing and self-focusing are combined, almost half of the diameter of the laser beam is reduced, and the energy density of the laser beam is increased. Laser alignment transfer is realized after self-focusing, the divergence angle is small, longitudinal etching is facilitated, the processing depth is increased, and the etching accuracy and efficiency are guaranteed.

Owner:GUILIN UNIV OF ELECTRONIC TECH

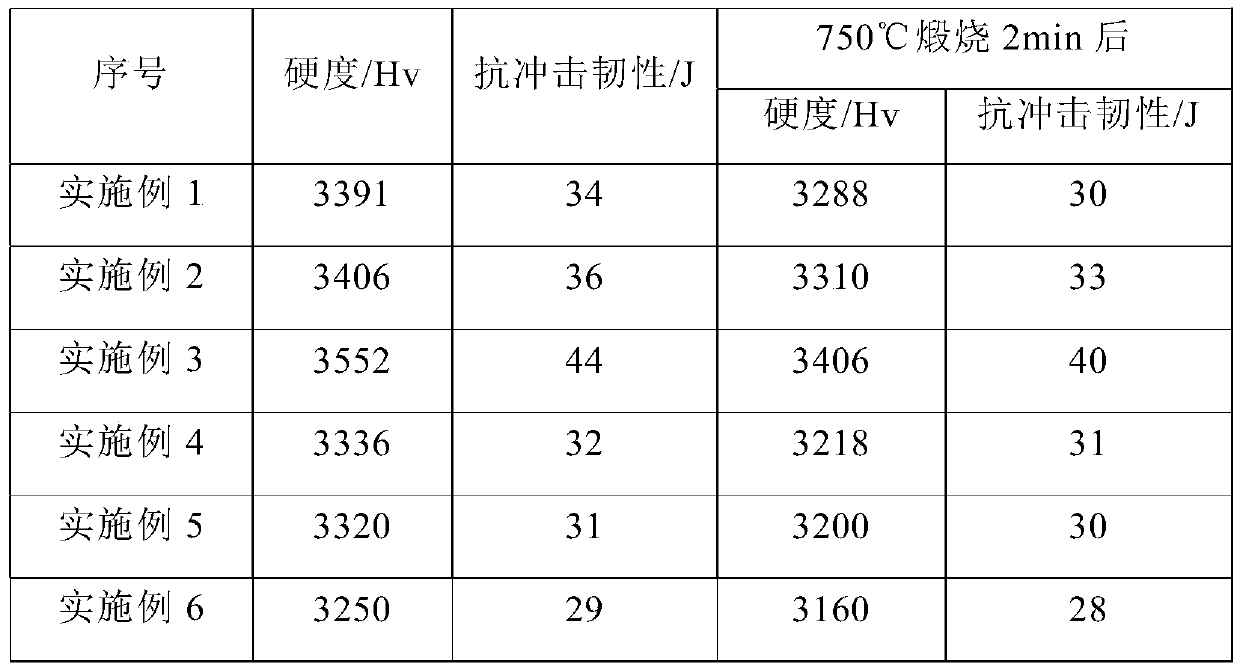

Polycrystalline diamond cubic boron nitride composite sheet and preparation method thereof

ActiveCN111057925AHigh bonding densityIncrease bond densityTransportation and packagingMetal-working apparatusPolycrystalline diamondAlloy substrate

The invention provides a polycrystalline diamond cubic boron nitride composite sheet. The polycrystalline diamond cubic boron nitride composite sheet comprises a hard alloy substrate, a polycrystalline diamond composite layer, a polycrystalline cubic boron nitride composite layer and a hard alloy protective layer which are sequentially arranged from bottom to top, wherein the polycrystalline diamond composite layer is composed of diamond micro powder and a nano metal binding agent, and the polycrystalline cubic boron nitride composite layer is composed of cubic boron nitride micro powder and ametal ceramic bonding agent. The invention further provides a method for preparing the polycrystalline diamond cubic boron nitride composite sheet. The method comprises the following steps that the diamond micro powder and the nano metal bonding agent are used for preparing a diamond bonding agent mixture; the cubic boron nitride micro powder and the metal ceramic bonding agent are used for preparing a cubic boron nitride bonding agent mixture; the hard alloy substrate is put into a tantalum cup, and the diamond bonding agent mixture and the cubic boron nitride binding agent mixture are sequentially poured into the tantalum cup; and the hard alloy protective layer is put into the tantalum cup, then vacuum heat treatment is carried out, and then high-temperature high-pressure sintering treatment is carried out. The composite sheet has high impact toughness and high strength.

Owner:FUNIK ULTRAHARD MATERIAL

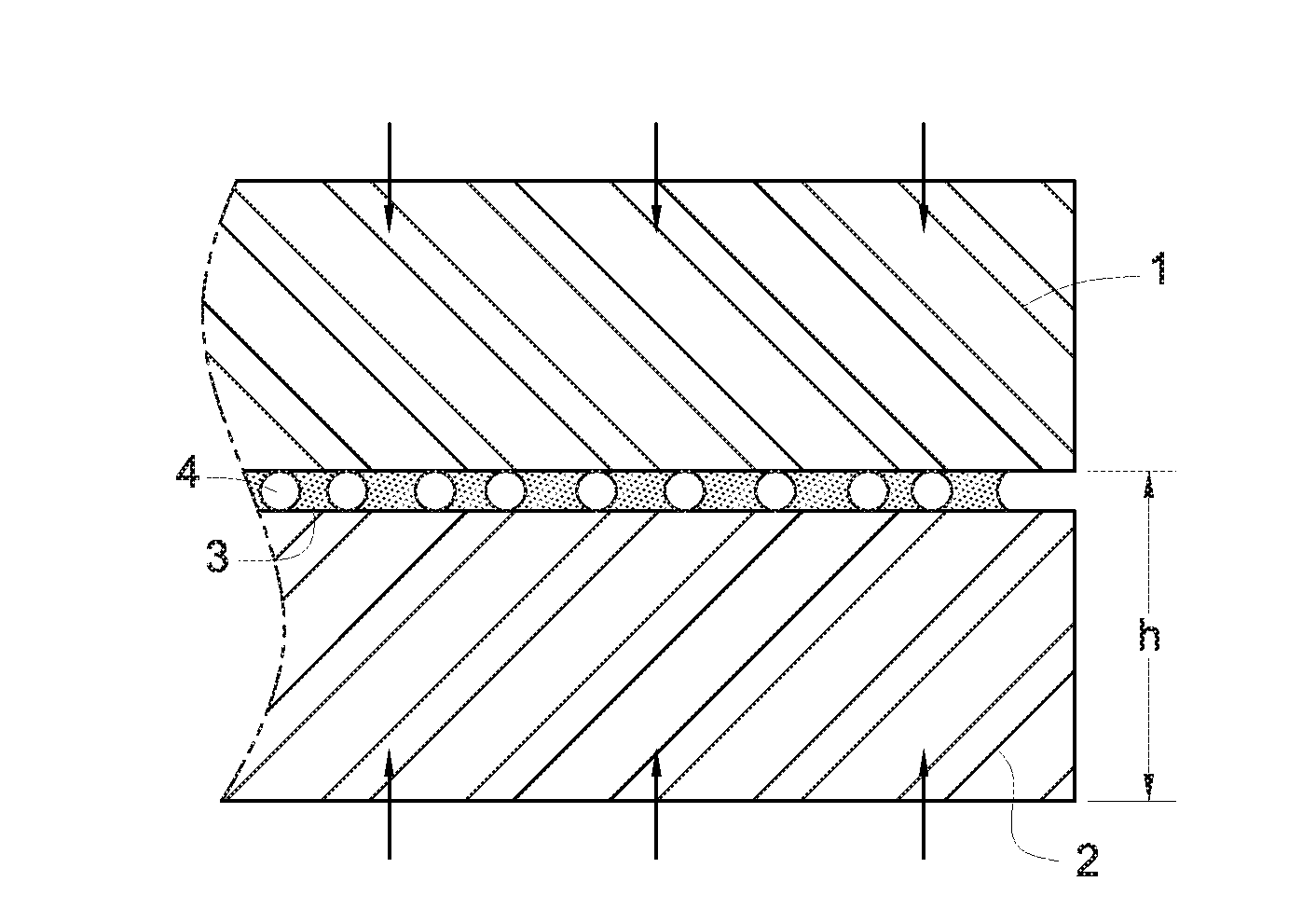

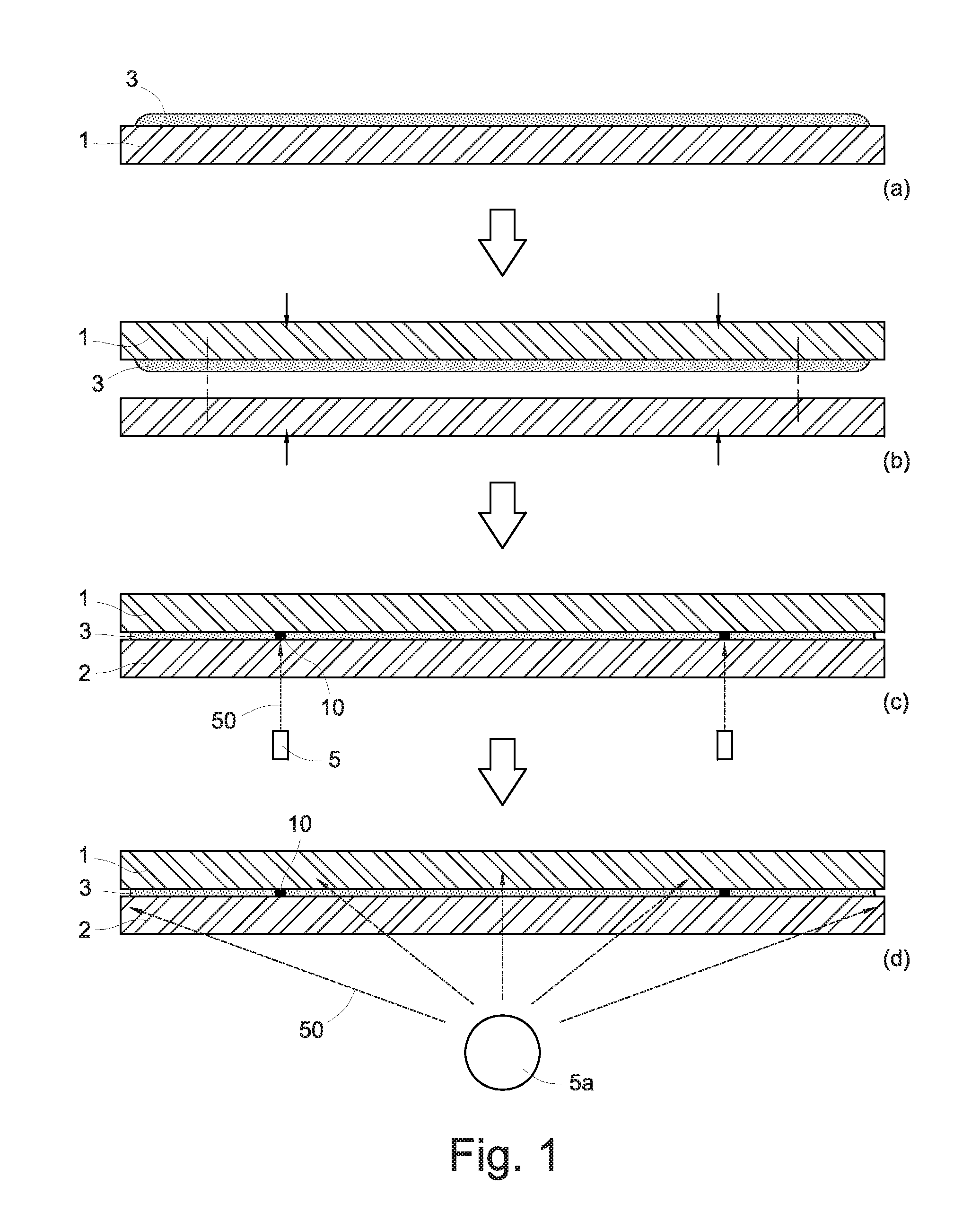

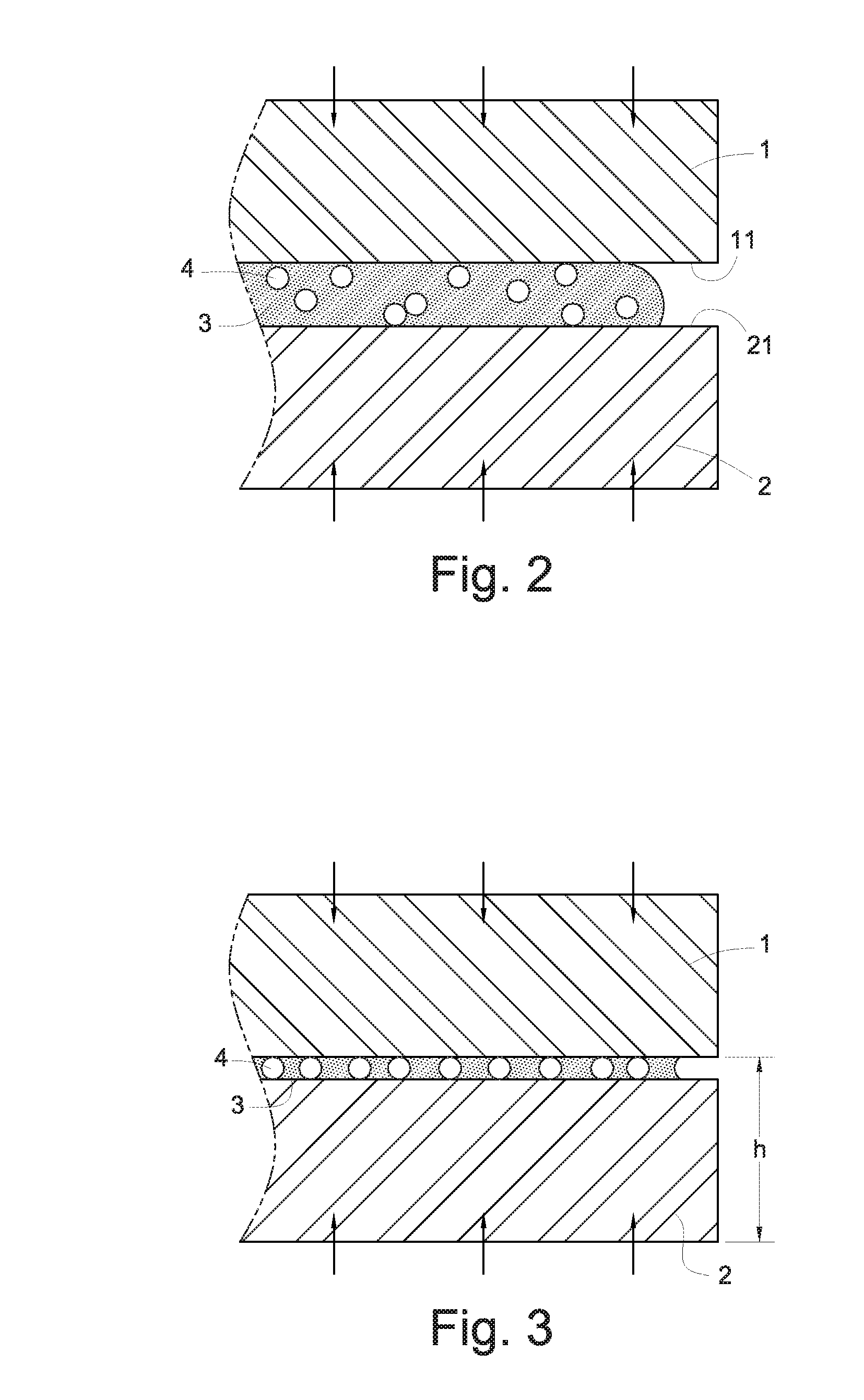

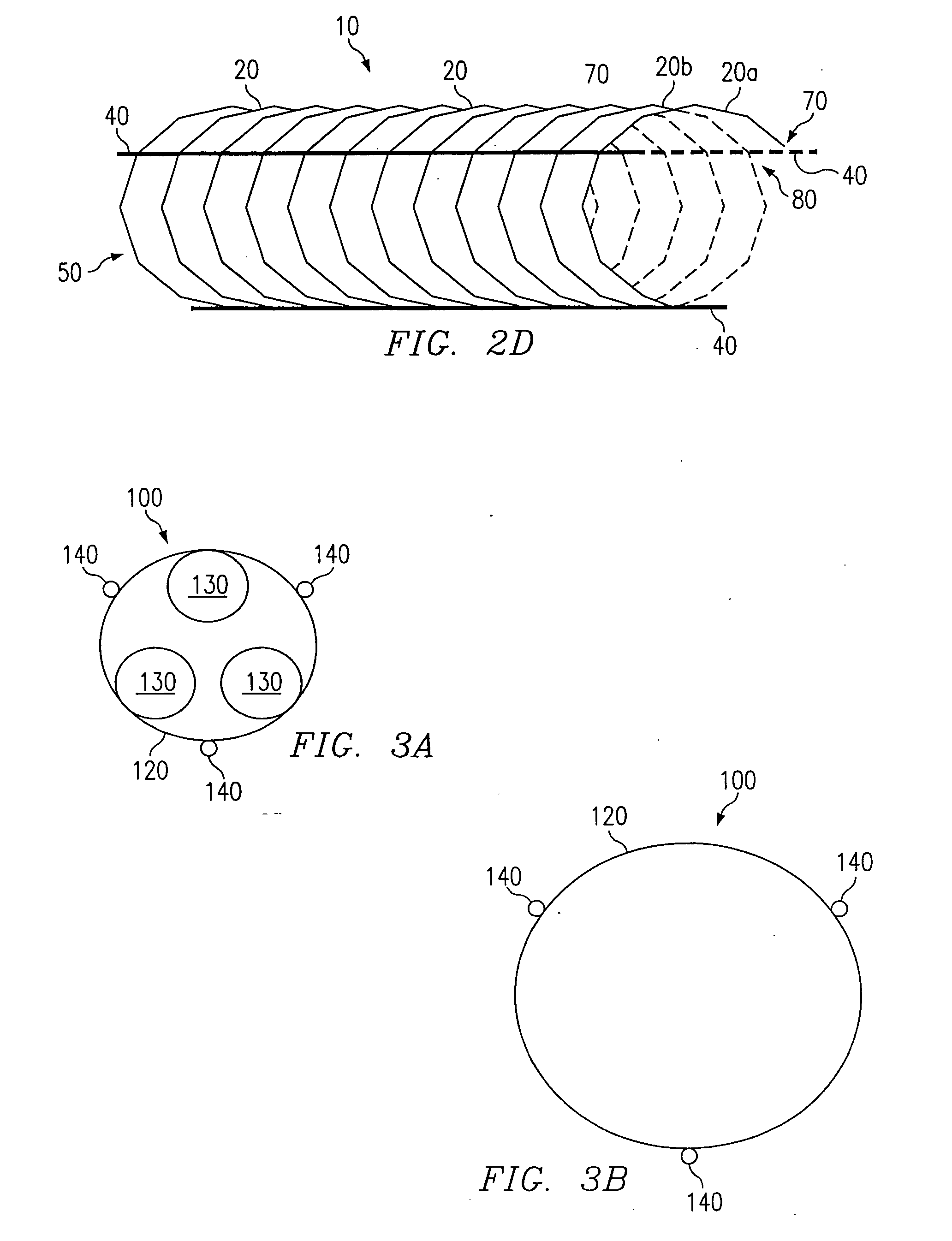

Optical curable resin composite for laminating optical substrates and method thereof

InactiveUS20130101827A1Avoid residual stressAvoid defectsAdhesive processesLamination ancillary operationsElastomerBead shape

In an optical curable resin (OCR) composite for laminating optical substrates and a method of using the OCR composite to laminating two optical substrates, the OCR composite is formed by projecting an ultraviolet light to cure a liquid adhesive containing a plurality of bead-shaped elastic particles, and the method includes the steps of coating the liquid adhesive onto a first optical substrate, stacking the first optical substrate to a second optical substrate, such that each particle is separated between the first and second optical substrates, and projecting the ultraviolet light onto the first and second optical substrate again to cure the liquid adhesive, so that the particles are separated to form a gap with equal heights between the first and second optical substrates to enhance the lamination efficiency and quality of the optical substrates.

Owner:CHEN CHIN YU

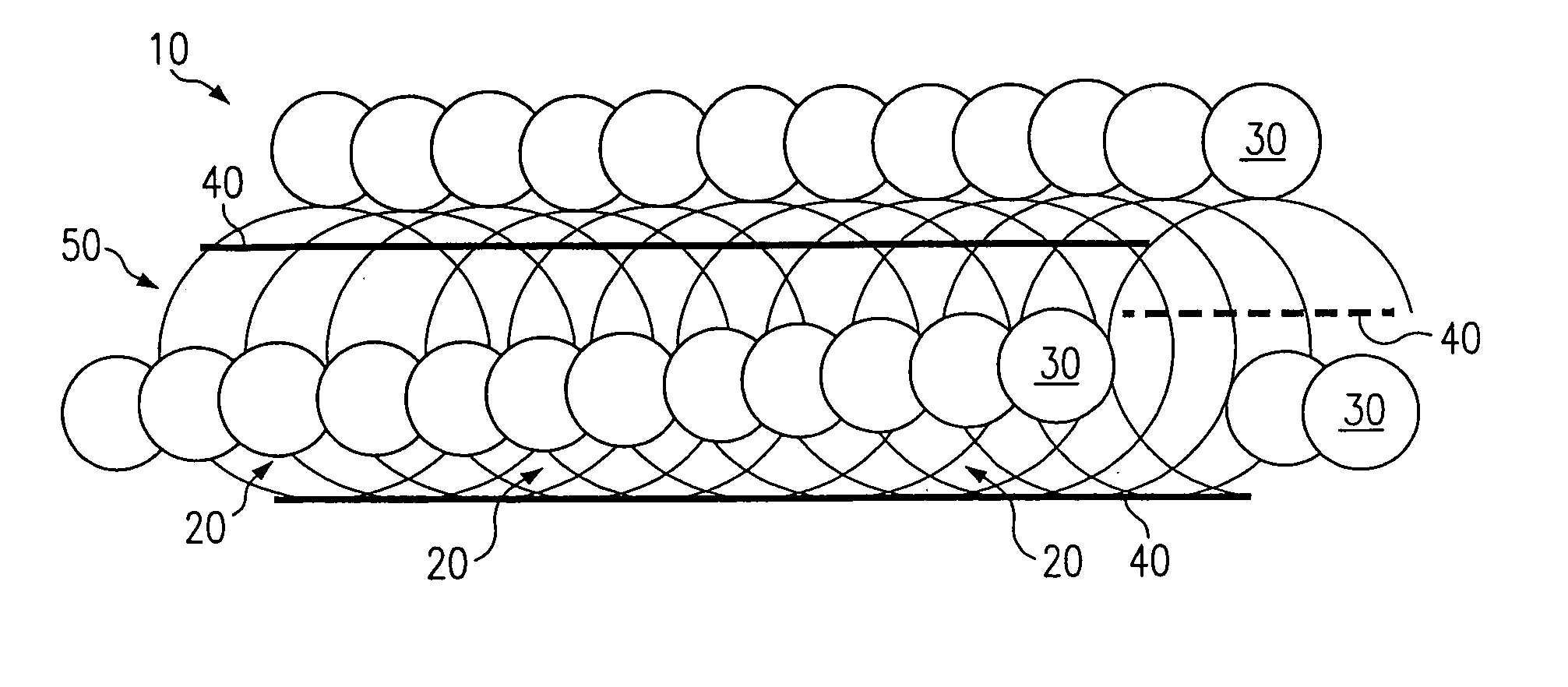

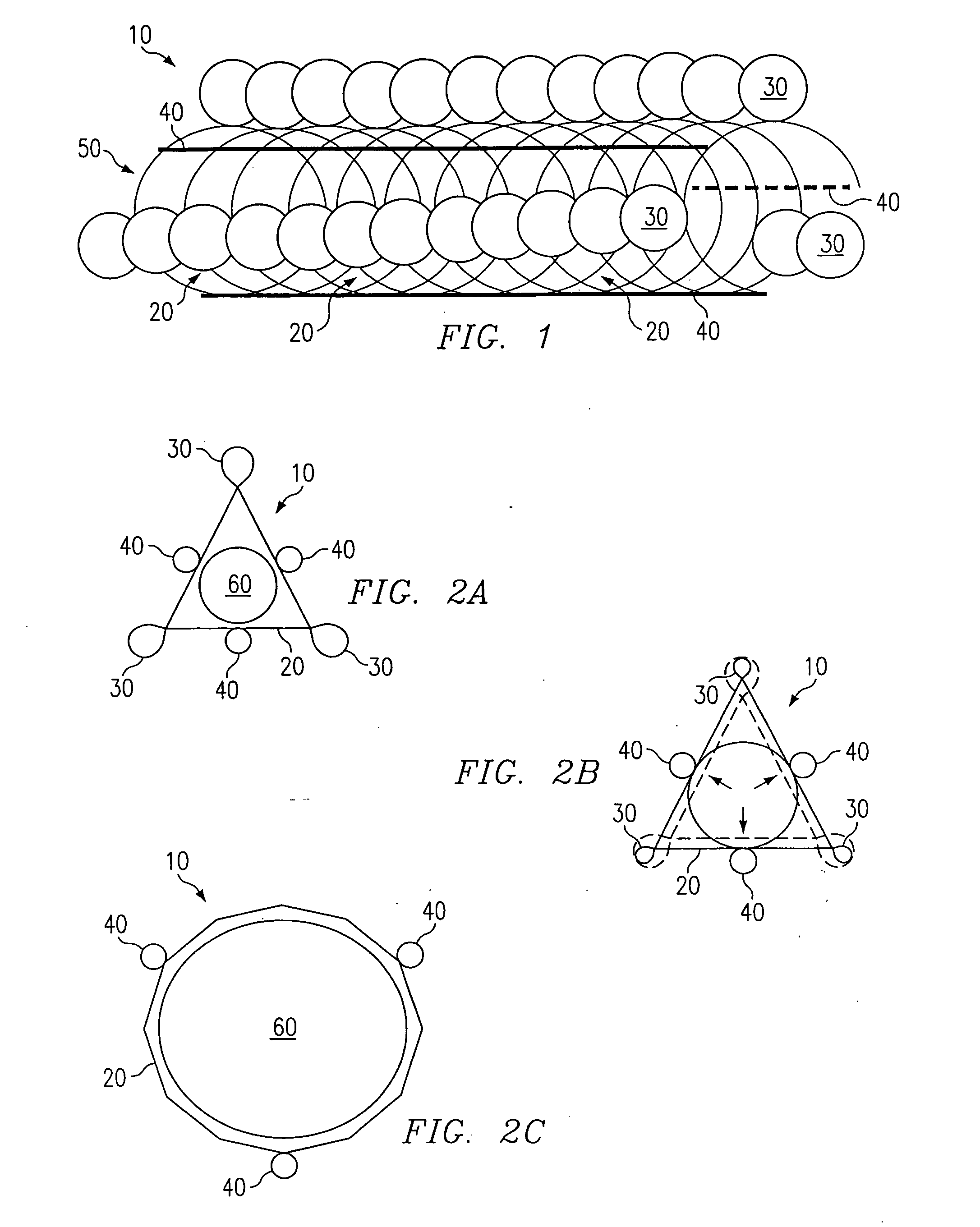

Expandable biodegradable polymeric stents for combined mechanical support and pharmacological or radiation therapy

InactiveUS20070129793A1Avoid residual stressAbsorb in timeStentsBlood vesselsAngioplasty balloonRadiation therapy

An expandable biodegradable polymeric stent is fabricated with biodegradable polymer fibers (Poly-L-lactic acid, PLLA) in a coil shape that is constructed with both central and external or internal peripheral lobes. It is delivered and expanded using a conventional angioplasty balloon system. The disclosed stent can serve as a temporary scaffold for coronary vessels after PTCA or for peripheral endovascular stenting, or it can provide mechanical palliation for strictures of ductile organs (trachea, esophagus, bile and pancreatic ducts, ureter etc.). The disclosed stent also serves as a unique device for specific local drug delivery. Therapeutic agents (chemical compounds, protein enzyme and DNA sequences) and cells can be loaded into the stent and gradually released to target tissues. Local radiation therapy can also be delivered by a specially adapted stent.

Owner:TEXAS STENT TECH

Memory alloy self-restoring heat dissipation damper

ActiveCN109024961AProtection of building structuresEliminate residual deformationProtective buildings/sheltersShock proofingCushionEngineering

The invention discloses a memory alloy self-restoring heat dissipation damper. A first inner pulling and pressing board and an outer pulling and pressing board capable of sliding relatively are arranged. A self-restoring structure is formed by a vertical blocking board and a limiting blocking board set so as to convert relative motion of the inner pulling and pressing board and the outer pulling and pressing board to a pulled state of memory alloy rods. Damping cushion is realized by utilizing material performance of the memory alloy rods. When the stress is too large, friction layers betweenthe inner pulling and pressing board and the outer pulling and pressing board act in common so as to dissipate energy input of the structure, and dissipation of great energy is realized through friction deformation, and absorption of dissipated energy by stressed parts in a building structure in an earthquake is reduced, so that an effect of protecting the building structure is realized. The memory alloy rods in the damper can enable the damper after an earthquake to restore to an initial state, so that residual deformation of a building is reduced and even eliminated after the earthquake. Theinvention can provide comparatively large damping force and utilizes the memory alloy rods and the friction layers to dissipate energy in a graded manner. The cost of the damper is reduced and structural energy dissipation requirements of different phases are met.

Owner:CHANGAN UNIV

Method for manufacturing diamond compact

The invention provides a method for manufacturing a polycrystalline diamond compact and belongs to the fields of oil drilling and engineering machinery. The diamond compact comprises a matrix and composite layers, wherein the composite layers are manufactured by stirring and sintering tungsten carbide micropowder, a metal bond, a grain growth inhibitor and diamond micropowder, and comprise the composite layer I, the composite layer II and the composite layer III which sequentially cover and coat the upper end of the matrix; the composite layer I and the composite layer II are bonded by the metal bond; and the composite layer II and the composite layer III are also bonded by the metal bond. The diamond compact manufactured by the method avoids residual stress between a hard alloy matrix baseplate and the polycrystalline diamond composite layers, therefore, is high in strength, and excellent in tenacity, and has the characteristics of high impact toughness and bending resistance, and the like. Accordingly, the polycrystalline diamond compact is improved in usability and prolonged in service life.

Owner:李涛

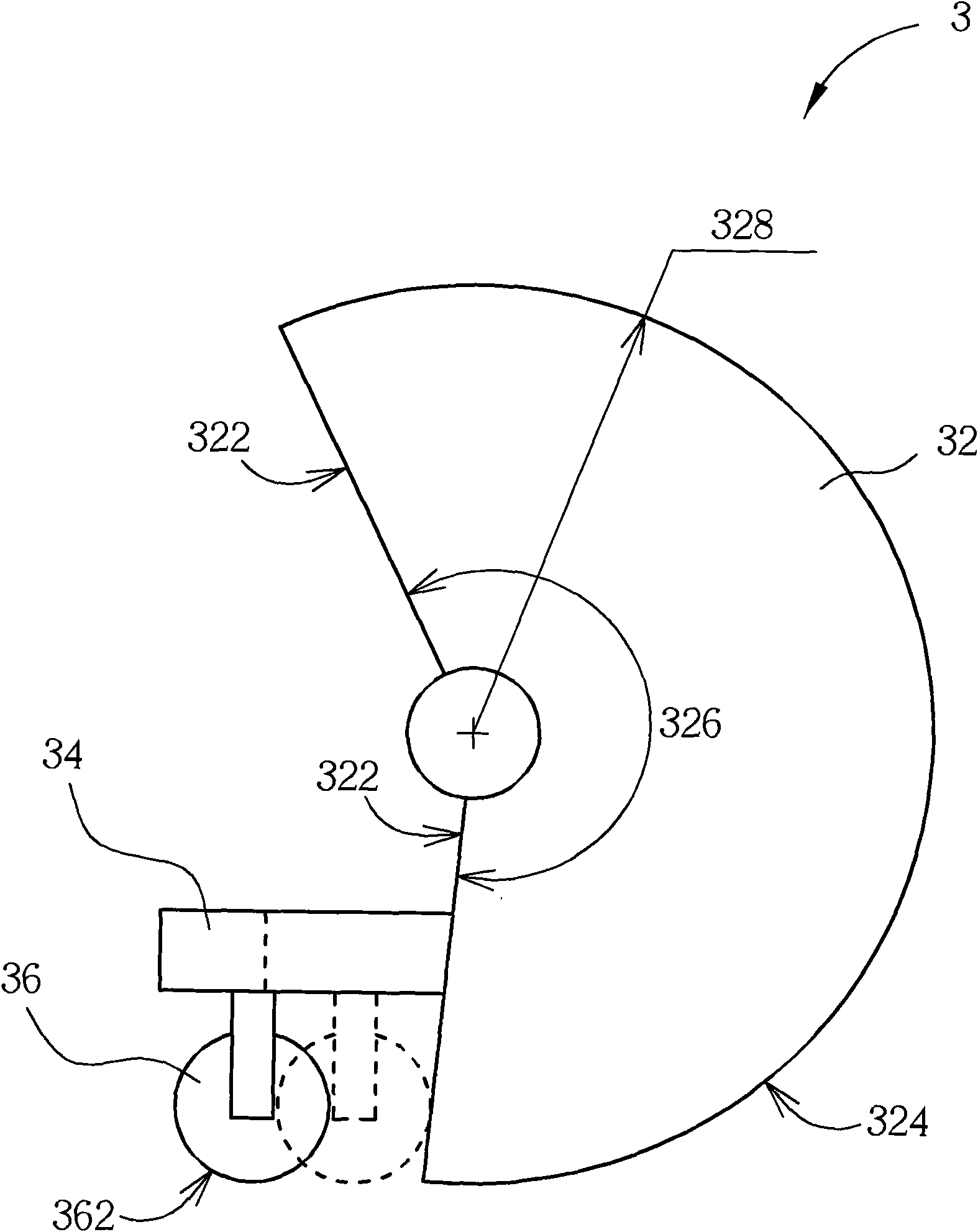

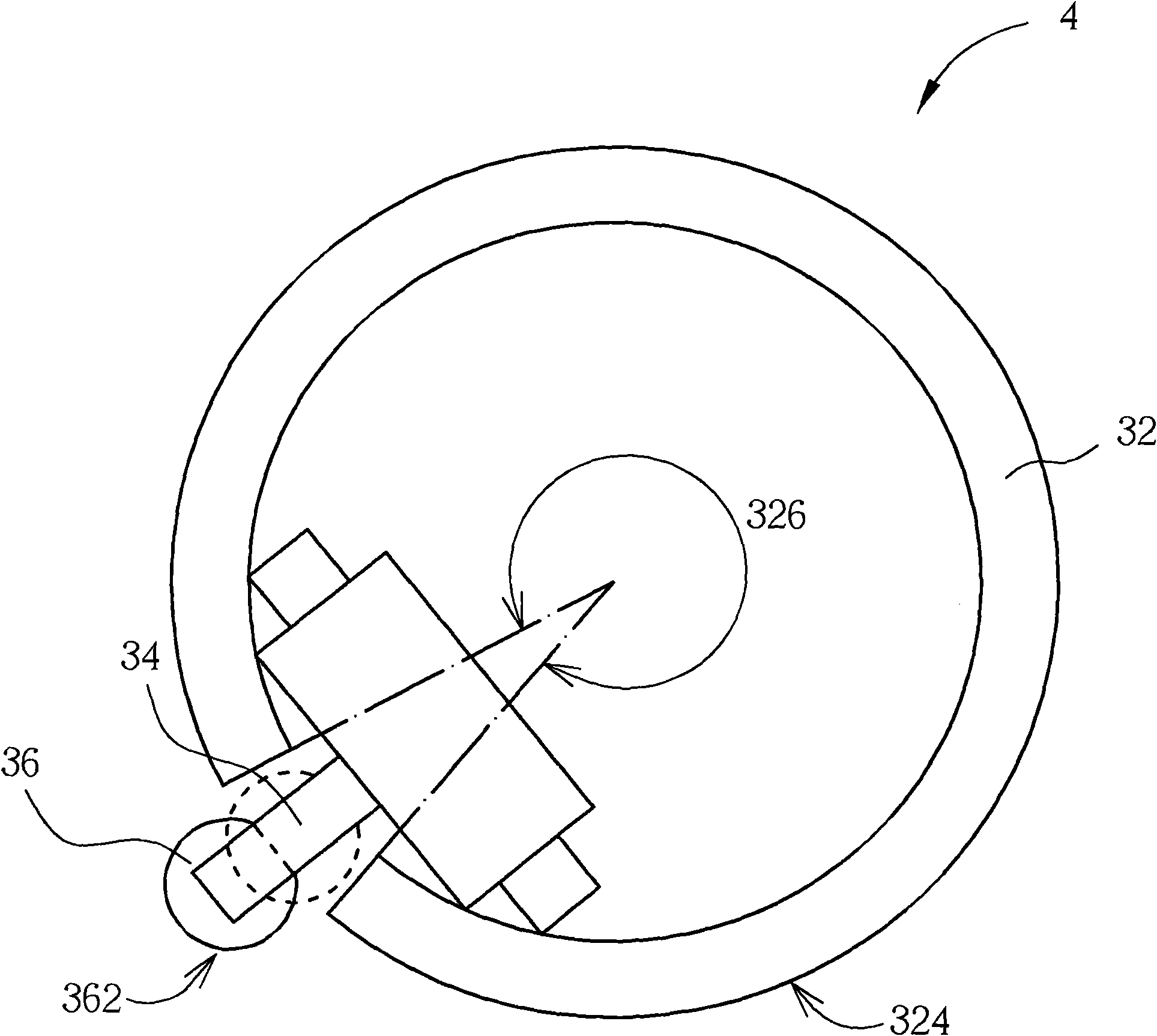

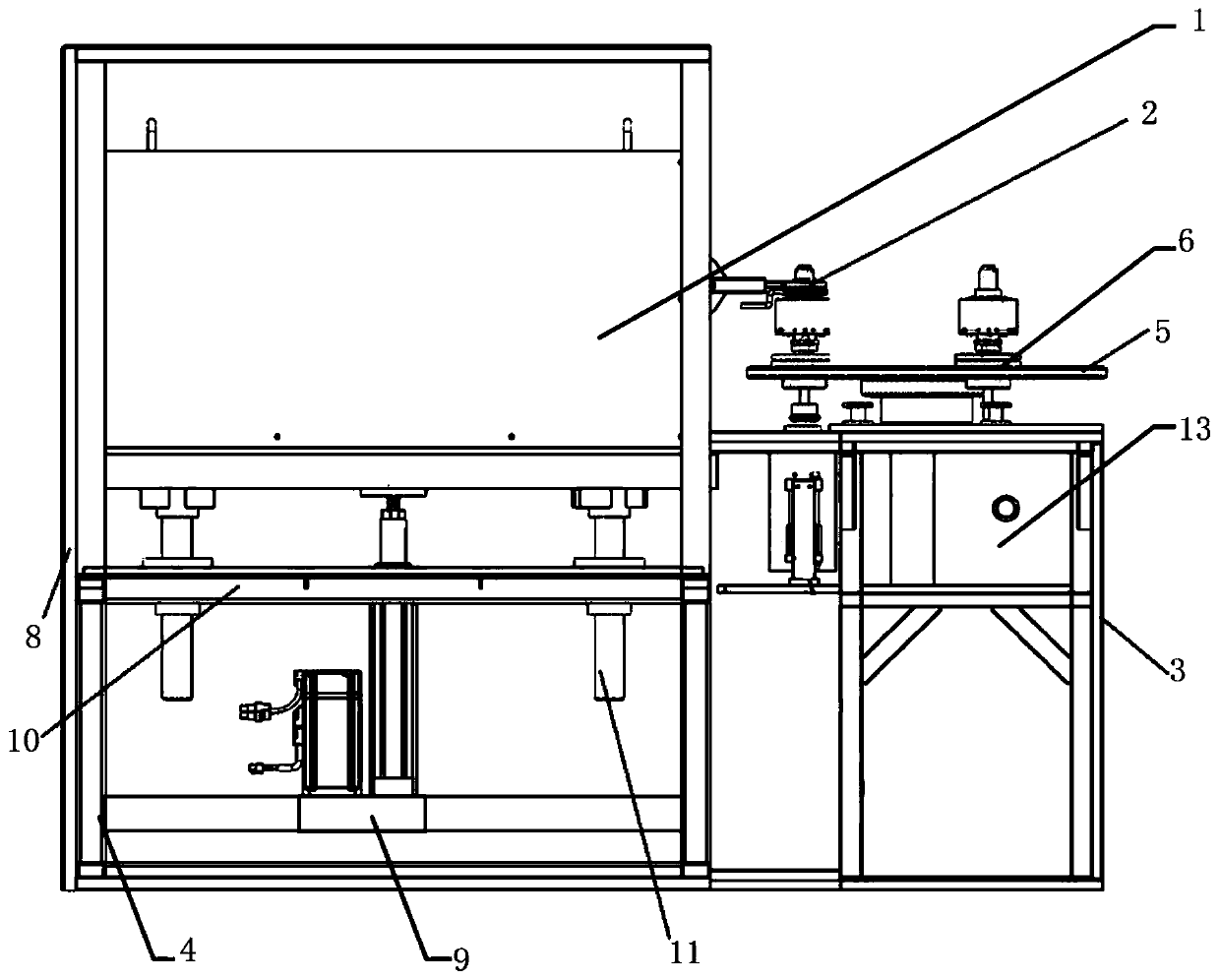

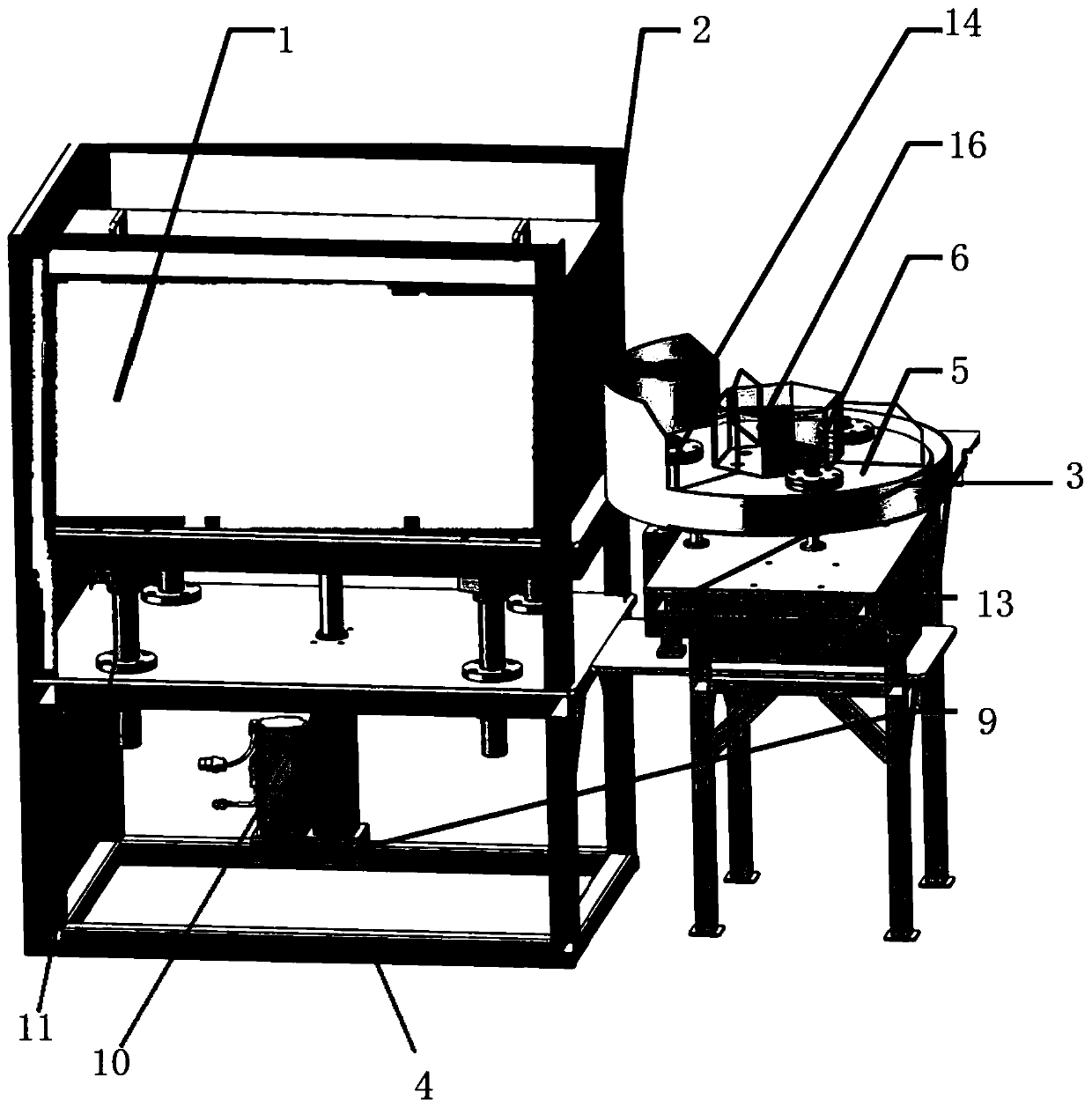

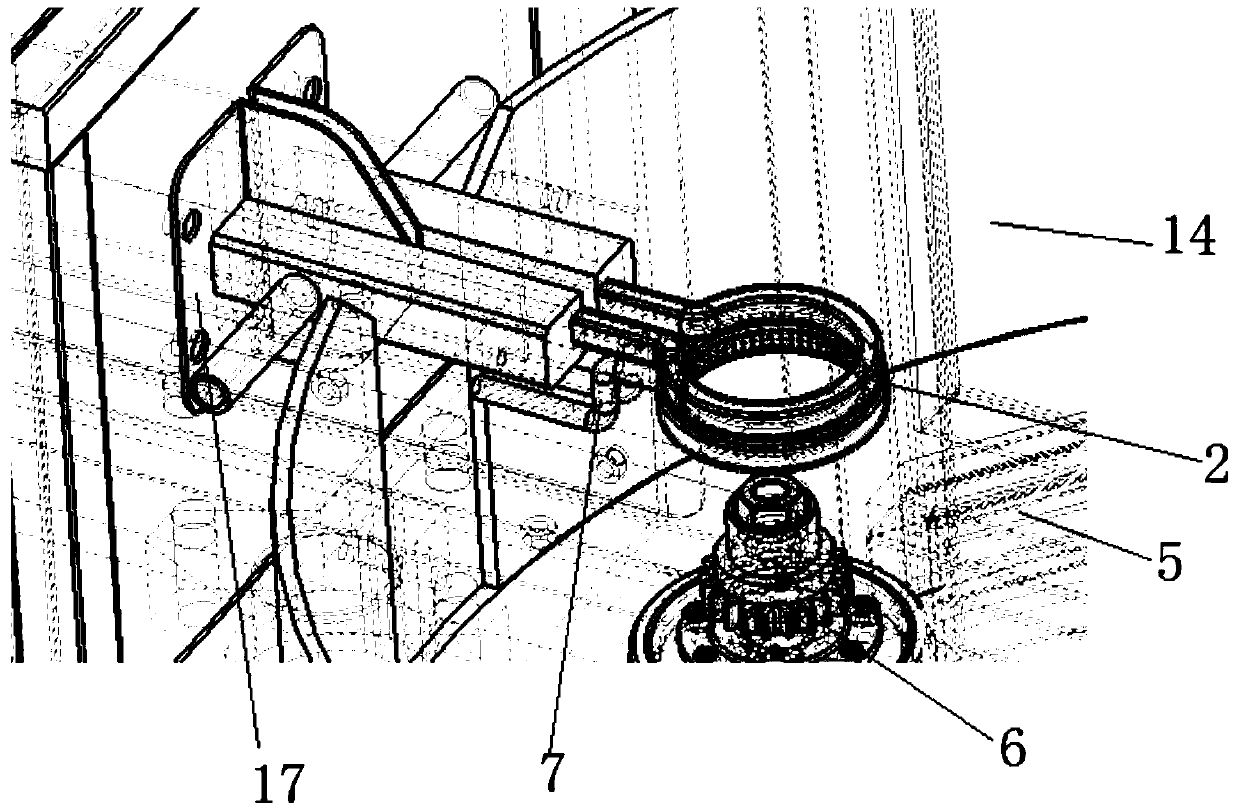

Gear synchronous quenching device

PendingCN110144437AImprove quenching efficiencyTimely heatingFurnace typesIncreasing energy efficiencyEngineeringQuenching

The invention discloses a gear synchronous quenching device. The device comprises a quenching power supply extension machine, an annular sensor and a clamping tooling used for clamping to-be-quenchedgears. The annular sensor is fixed to the quenching power supply extension machine and connected with a quenching power supply extension machine output power supply. A lifting mechanism is arranged atthe lower end of the quenching power supply extension machine. An annular water pouring ring is arranged at the lower end of the annular sensor and fixed to the outer wall of the quenching power supply extension machine. A plurality of water pouring nozzles are formed in the inner wall of the annular water pouring ring. The clamping tooling comprises a rotating turntable and self-rotating toolingbodies uniformly arranged on the rotating turntable along a rotating turntable rotary shaft. The to-be-measured gears are mounted on the self-rotating tooling bodies correspondingly and driven by theself-rotating tooling bodies to rotate. The to-be-measured gears are heated uniformly through heating of the annular sensor, residual stress produced due to non-uniform heating of the to-be-measuredgears is prevented, meanwhile, the to-be-measured gears are quenched by means of the annular water pouring ring, quenching can be performed in time, deformation produced because of the long time duration between part heating and quenching, and the gear synchronous quenching device is simple in structure and can be used for greatly improving the gear quenching efficiency.

Owner:西安北辰亿科电子科技有限公司

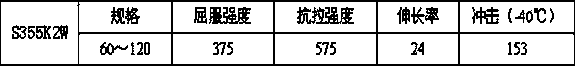

Weather-proof structural steel S355K2W thick plate and production method

InactiveCN103695787ASimple production processCancel the heat treatment processProcess efficiency improvementSlow coolingMaterials science

The invention discloses a 60-120mm improved weather-proof structural steel S355K2W thick plate and a production method thereof. The weather-proof structural steel S355K2W thick plate comprises the following chemical components by mass percent: 0.08-0.15% of C, 0.20-0.45% of Si, 1.20-1.45% of Mn, less than or equal to 0.018% of P, less than or equal to 0.007% of S, 0.015-0.050% of Als, less than or equal to 0.15% of Nb+V+Ti, 0.45-0.70% of Cr, 0.30-0.50% of Cu, and the balance of Fe and residual elements. A technological process of the weather-proof structural steel S355K2W thick plate comprises the steps of high-quality molten iron and KR molten iron pretreatment, a 100 / 120t top-bottom combined blowing converter, LF (ladle furnace) refining, vacuum degassing treatment, casting blank pile cooling for 24-60h, a pusher type heating furnace, a 3800m rolling mill, ACC (accelerated) laminar cooling, an 11-roll thermal straightener, pile cooling, finishing, external inspection, fault detection and warehousing. The weather-proof structural steel S355K2W thick plate and the production method have the benefits that the performance of the steel plate can reach a requirement of a national standard in a TMCP (thermal mechanical control processing) rolling and steel plate piling slow cooling mode under the condition of constant traditional S355K2W carbon equivalent; a production technology is simplified; a heat treatment process is cancelled; the production energy consumption is reduced; and the production cost is lowered greatly.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com