Patents

Literature

46results about How to "The preparation method is simple and effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-bending multimode fiber and manufacturing method thereof

ActiveCN101634728AReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

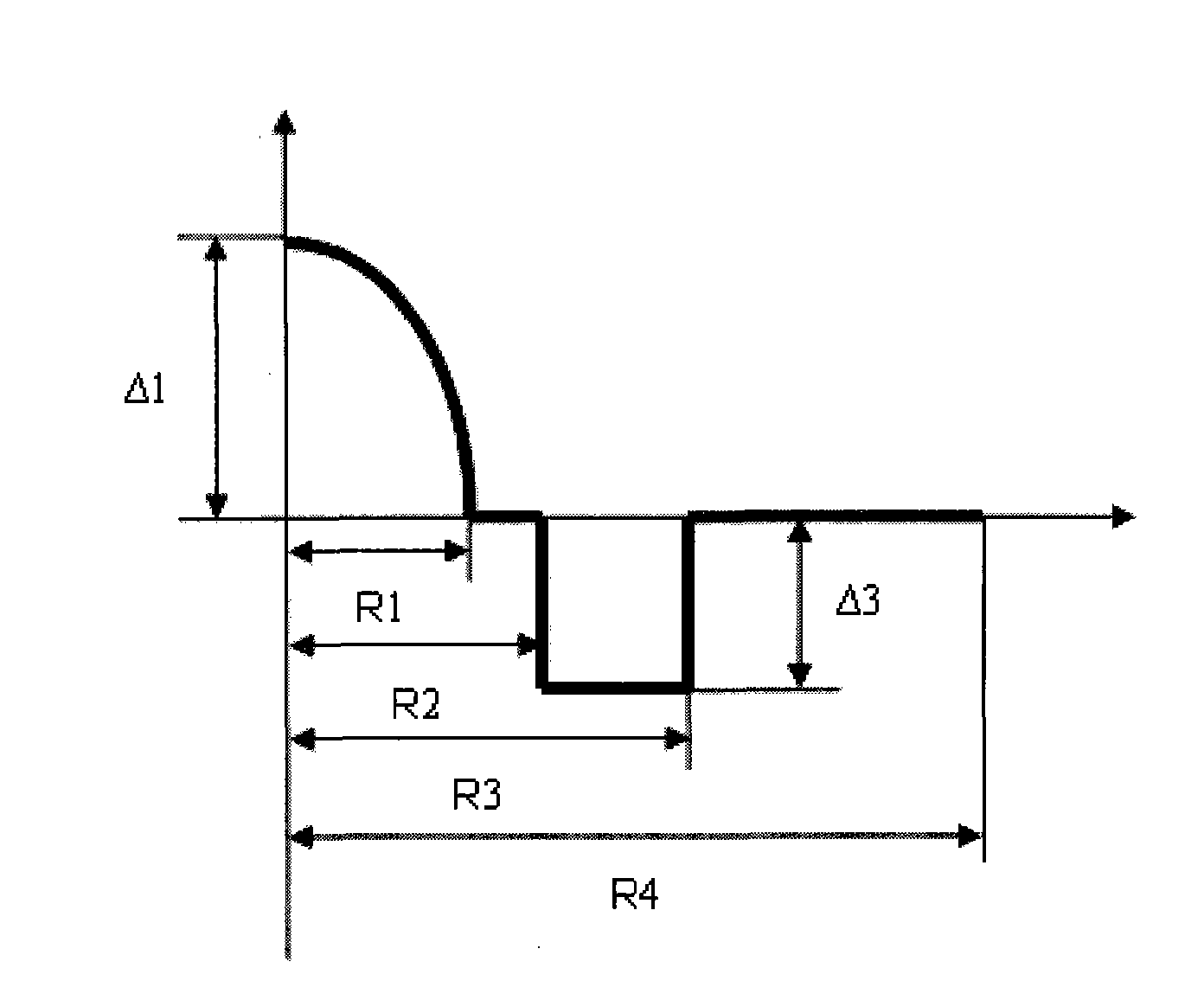

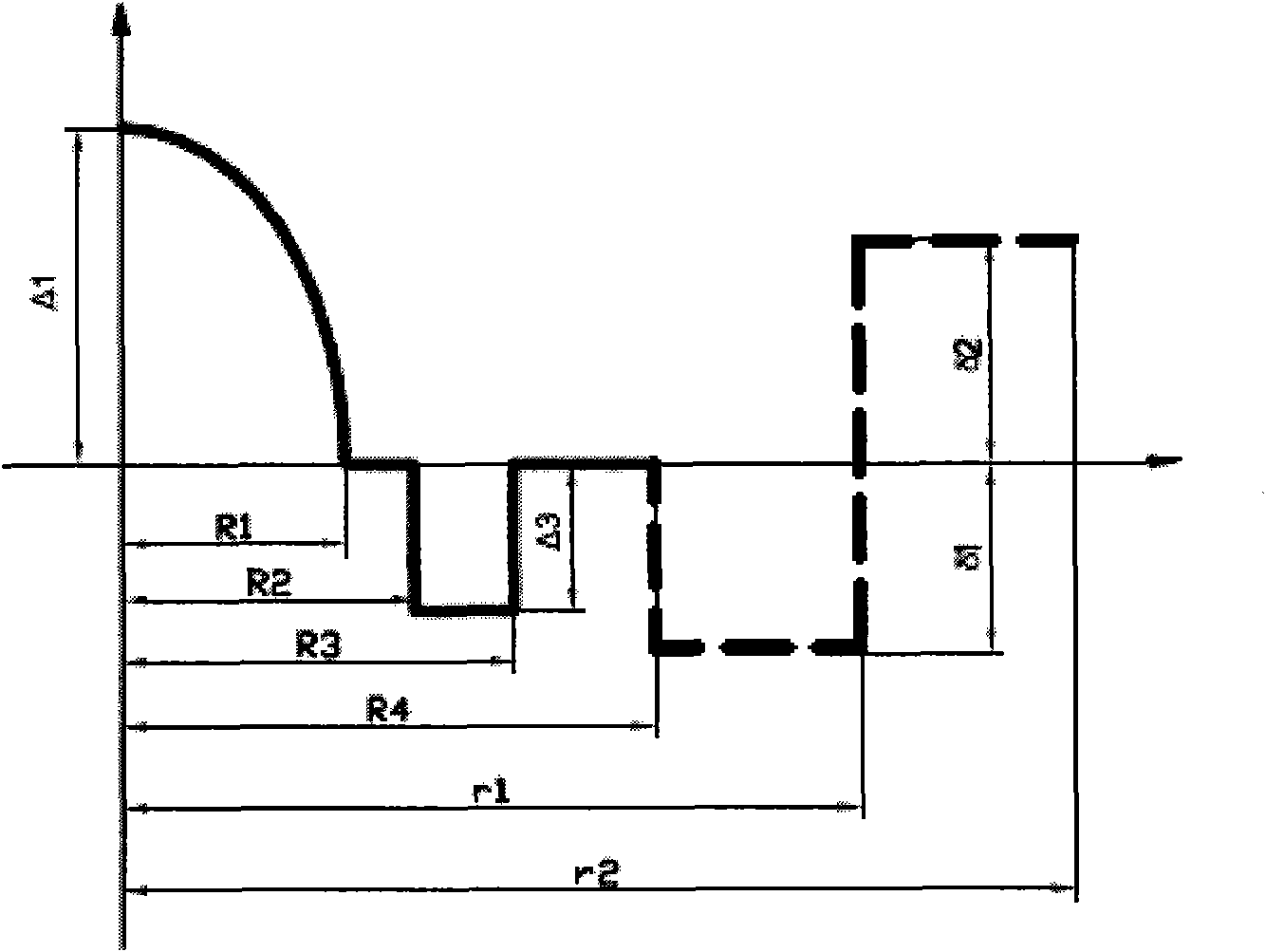

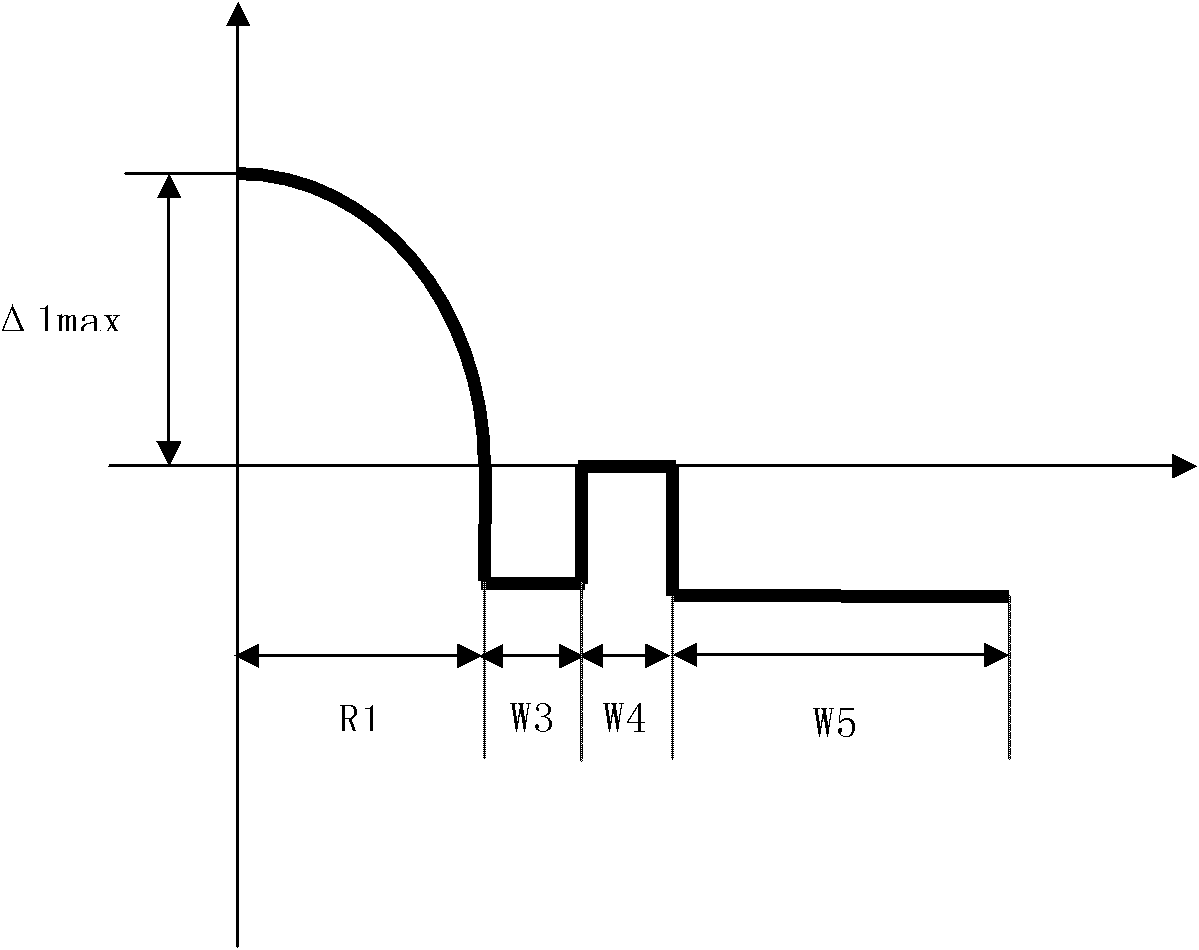

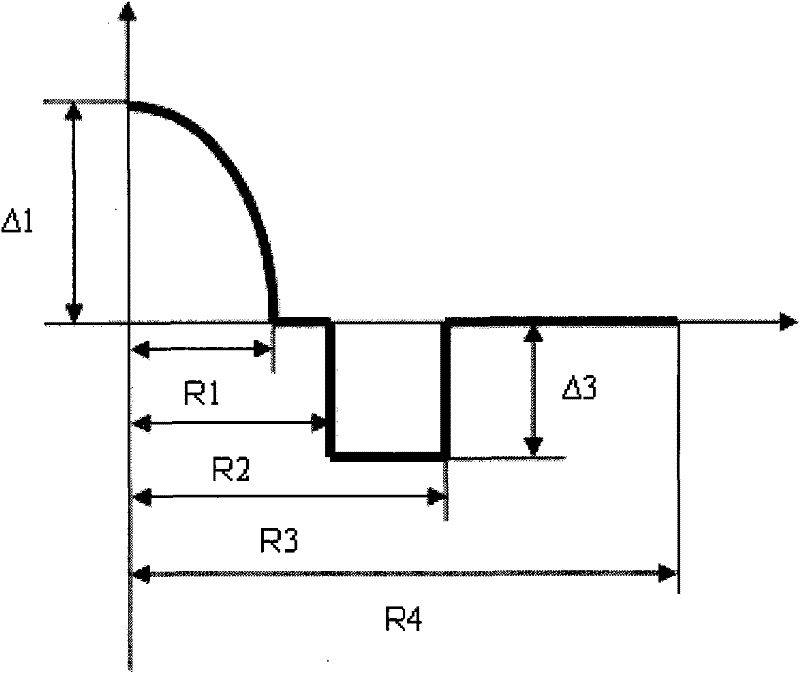

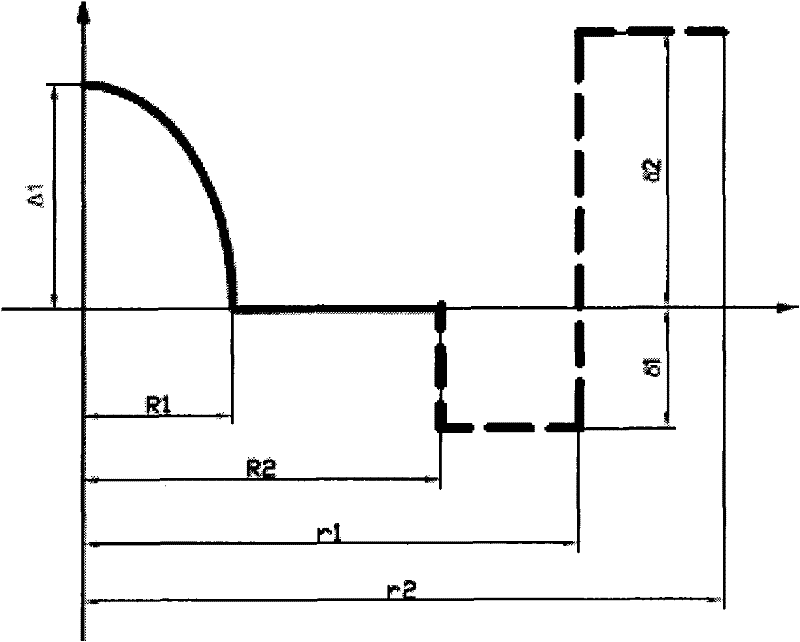

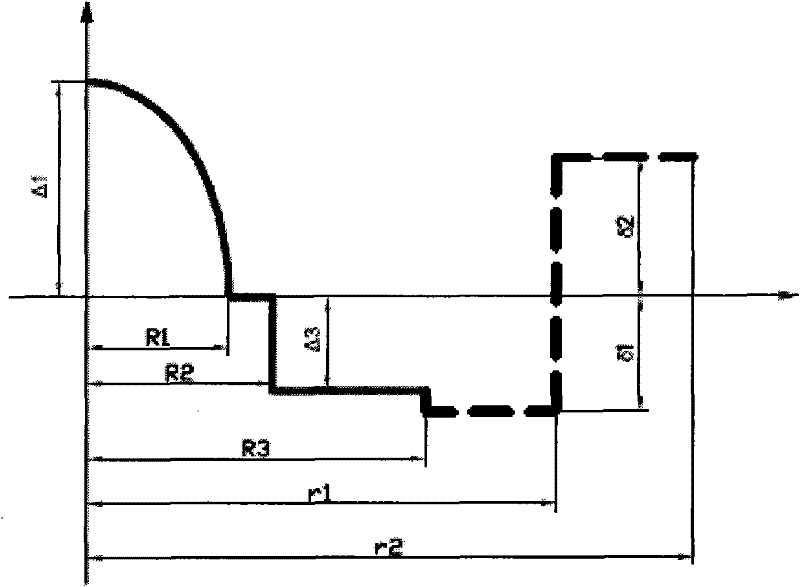

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

Bending-resistant multi-mode fiber

ActiveCN101840023AImprove mechanical propertiesFree from mechanical damageGlass optical fibreOptical fibre with multilayer core/claddingFiberRefractive index

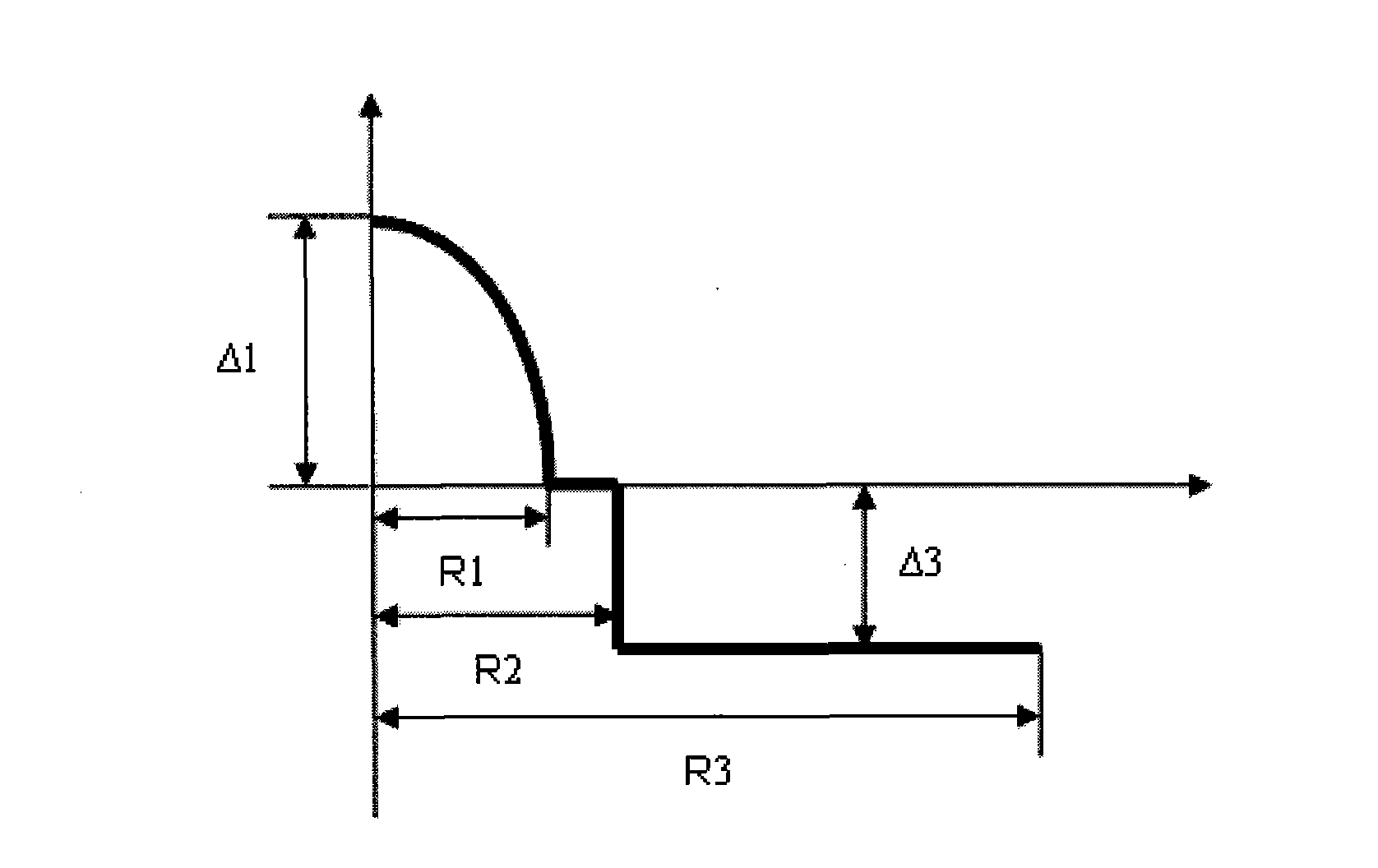

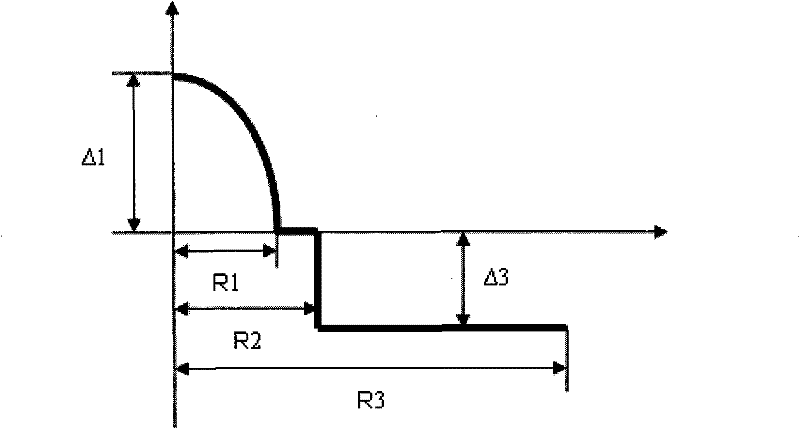

The invention relates to a bending-resistant multi-mode fiber used in an access network or a miniature optical device. The bending-resistant multi-mode fiber comprises an optical fiber and a coating coated on the outer surface of the optical fiber, wherein the fiber consists of a quartz glass core layer which has a section structure with a parabolic shape or step-type refraction index and a quartz glass cladding which surrounds the core layer. The optical fiber is characterized in that: the core layer has a diameter of between 20 and 200 mu m and consists of a germanium-and-fluorine-doped quartz glass material; and double solidified polymer coatings are coated out of the cladding, wherein an inner coating coated on the outer surface of the cladding is a low-refraction index flexible polymer coating while an outer coating is a high-Young's modulus polymer coating. Because of the design of the low-refraction index inner coating, an internal stress of the optical fiber is avoided, the mechanical performance of the optical fiber is greatly improved, and the use performance and the service life of the optical fiber working in a small-radius bending state are ensured. The bending-resistant multi-mode fiber has high bending-resistant performance; and at a wavelength of 850 nm, the additional attenuation of the bending caused by winding 1 circle with a bending radius of 10 mm is less than or equal to 0.15 dB. The bending-resistant multi-mode fiber has the characteristic of simple, convenient and effective manufacturing method, and is suitable for large-scale production.

Owner:EVERPRO TECH COMPANY

Negative Poisson ratio woven fabric and manufacturing method

InactiveCN106149150AReduce thicknessGood molding effectOrnamental textile articlesFibre typesWoven fabricHoneycomb

Owner:THE HONG KONG POLYTECHNIC UNIV

Bamboo fungus culturing base stock and preparation method thereof

InactiveCN103880547AThe preparation method is simple and effectiveMeet high-quality and high-yield productionFertilizer mixturesGypsumSlag

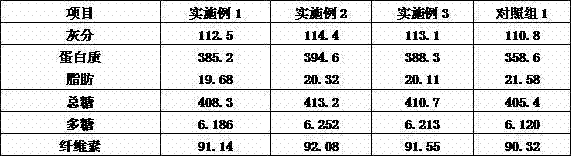

The invention provides a bamboo fungus culturing base stock and a preparation method thereof, and relates to the technical field of edible fungi cultivation. The culturing base stock is prepared from the following component: bamboo leaf, sawdust, astragalus smicus, cane slag, edible fungi slag, monopotassium phosphate, calcium superphosphate, gypsum powder, quicklime and a regulating agent, wherein the regulating agent comprises compound sodium nitrophenolate and forchlorfenuron. The preparation method of the culturing base stock comprises the following steps: (1) preparing materials; (2) mixing; (3) fermenting; (4) packaging. According to the bamboo fungus culturing base stock and the preparation method thereof, a plurality of waste materials are utilized as main materials, on the one hand, the materials are wide in sources, cost can be saved, and on the other hand, the culturing base stock is rich in nutrition, high-quality high-yield bamboo fungus production can be fulfilled, the protein content and mineral content of the produced bamboo fungus are superior to those of the bamboo fungus cultivated by the prior art, the preparation method of the culturing base stock is simple and effective, the period for culturing bamboo fungus can be shortened, and the benefit can be increased.

Owner:泗阳县农业科学研究所

Prepn process of aluminium chloride polymer as water purifier

InactiveCN1609012AGood effectReduce manufacturing costWater/sewage treatment by flocculation/precipitationChemistryCarbon black

The process of preparing aluminum chloride polymer as water purifier with kaolin mineral includes drying kaolin mineral, calcinations at 600-750 deg.c, adding water to compound slurry, ageing, centrifugally separating, reacting in a reactor at 85-95 deg.c for 3 hr, centrifugally treating reaction product, concentrating filtrate to obtain liquid purifier or spray drying to obtain solid purifier, and treating filter residue through secondary eliminating impurity, centrifugal treating and drying to obtain white carbon black as excellent stuffing. The preparation process has aluminum utilization up to 95 %, and the water purifier has average grain size smaller than 40 nm, high water treating effect, high sludge depositing speed and low production cost.

Owner:CENT SOUTH UNIV

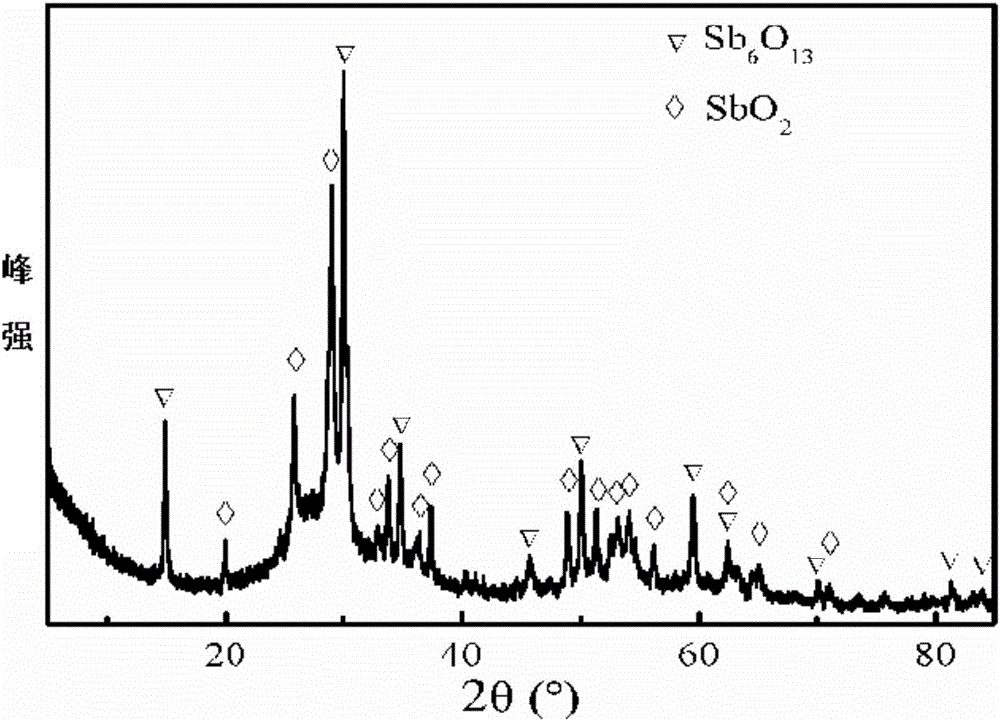

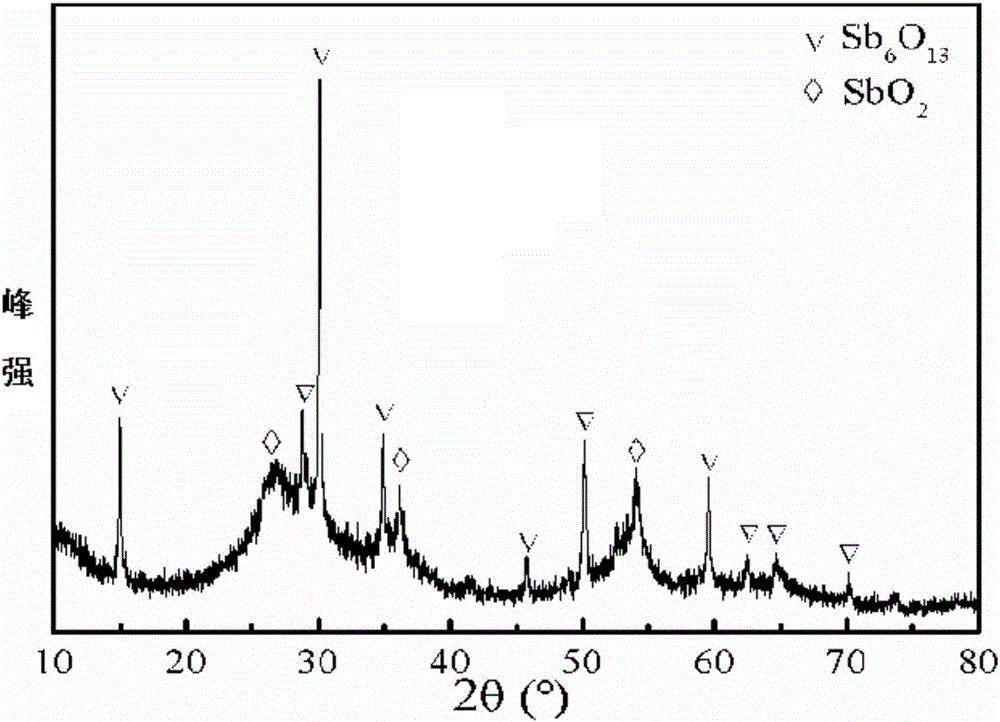

Method of using solution atomization method to prepare superfine Sb oxide

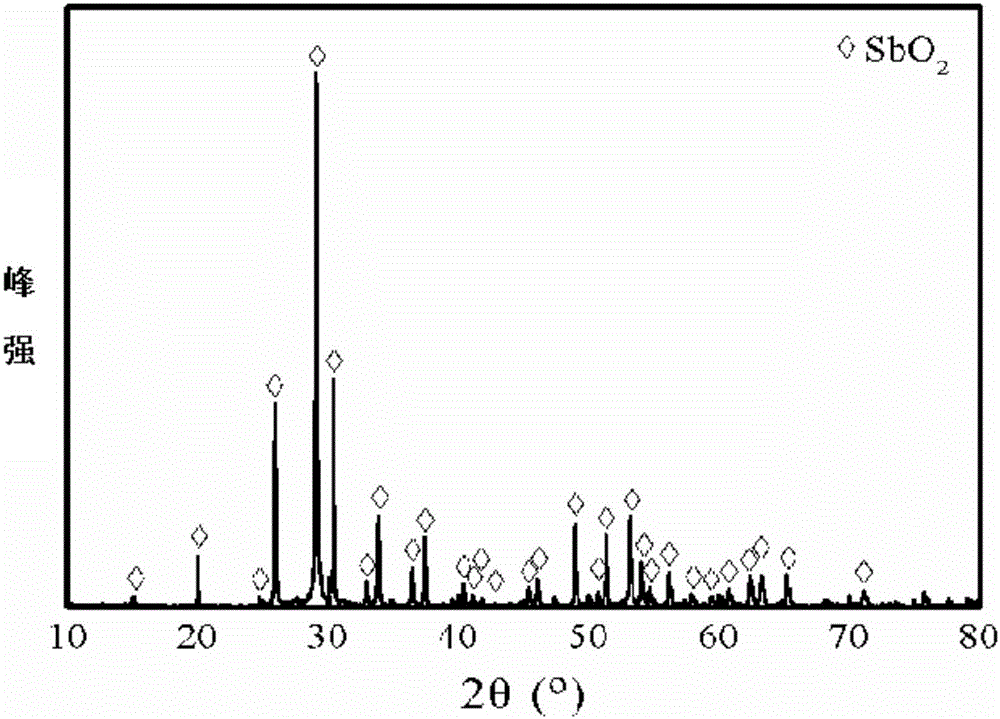

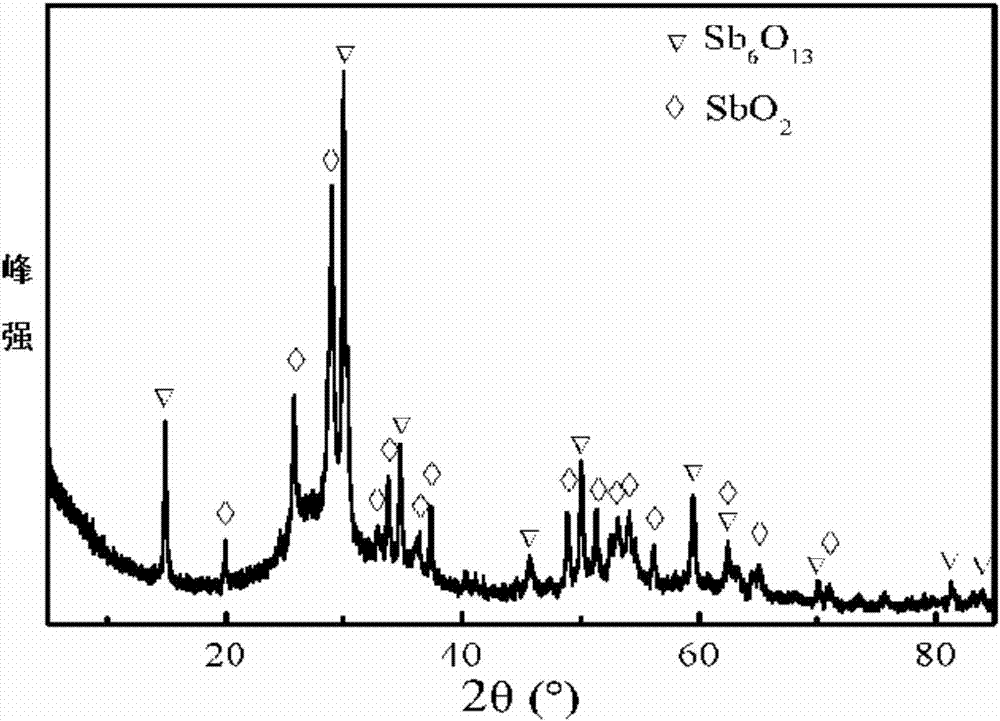

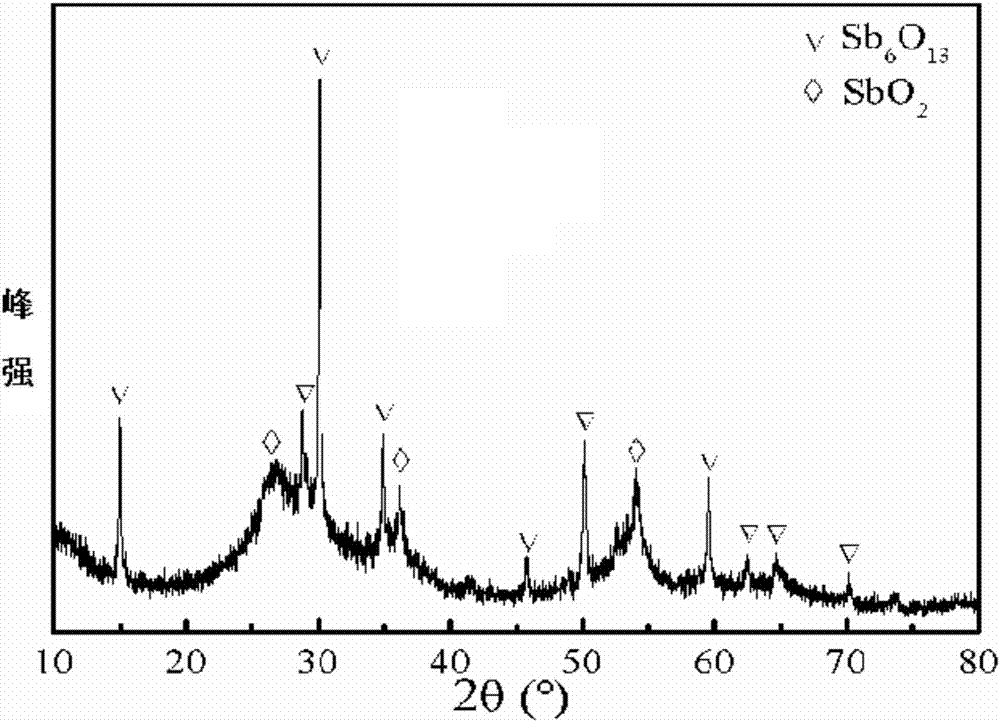

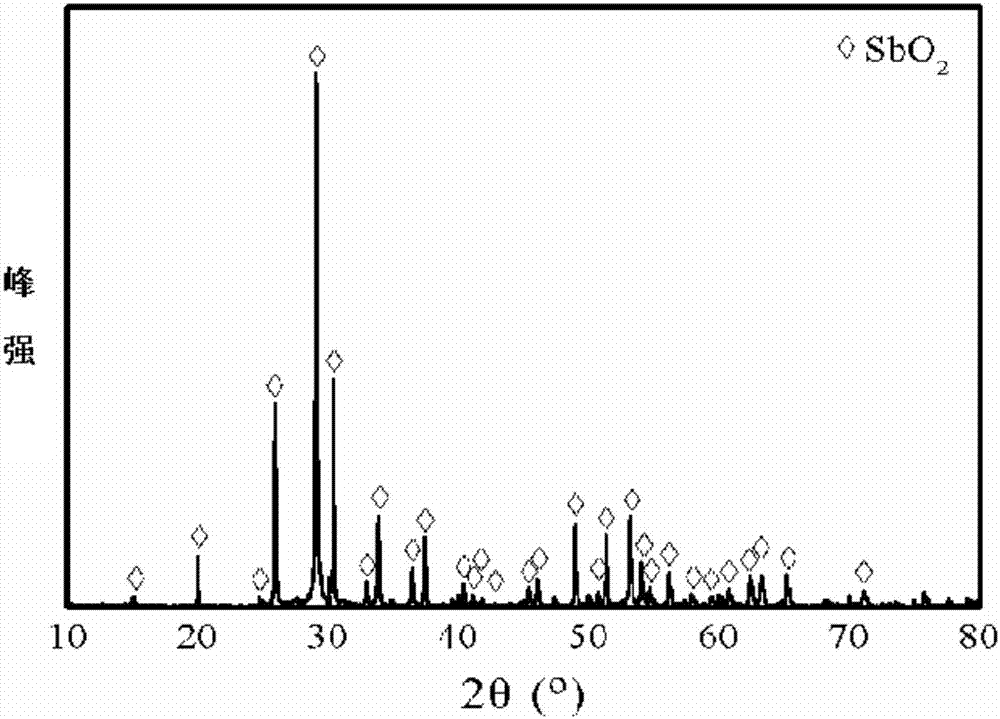

ActiveCN105858724ASimple processShort manufacturing processAntimony oxides/hydroxides/oxyacidsMaterials preparationSpray pyrolysis

The invention discloses a method of using a solution atomization method to prepare superfine Sb oxide. The method comprises the following steps: (1) trivalent Sb is added into a hydrochlric solution to prepare a Sb solution with the molar concentration of 0.05-0.8 mol / L; (2) clean oxidant is used to oxidize the solution obtained in step (1), and a pentavalent Sb solution is obtained; (3) Sb oxide powder is obtained after spray pyrolysis of the pentavalent Sb solution is obtained in step (2). According to the invention, trivalent Sb solution is used as a raw material, superfine Sb oxide powder materials are directly prepared through oxidization and spray pyrolysis, and the technological process is simple. Alternatively, lixivium from the conventional process of using an acid method in antimony smelting is directly used as the raw material. Therefore, the process of preparing the superfine Sb oxide powder materials is shortened; the conventional metallurgical process and the material preparation process are effectively combined; added value of products from conventional non-ferrous metal metallurgy is significantly increased; recycling of hydrochloric acid from lixivium is realized.

Owner:CENT SOUTH UNIV

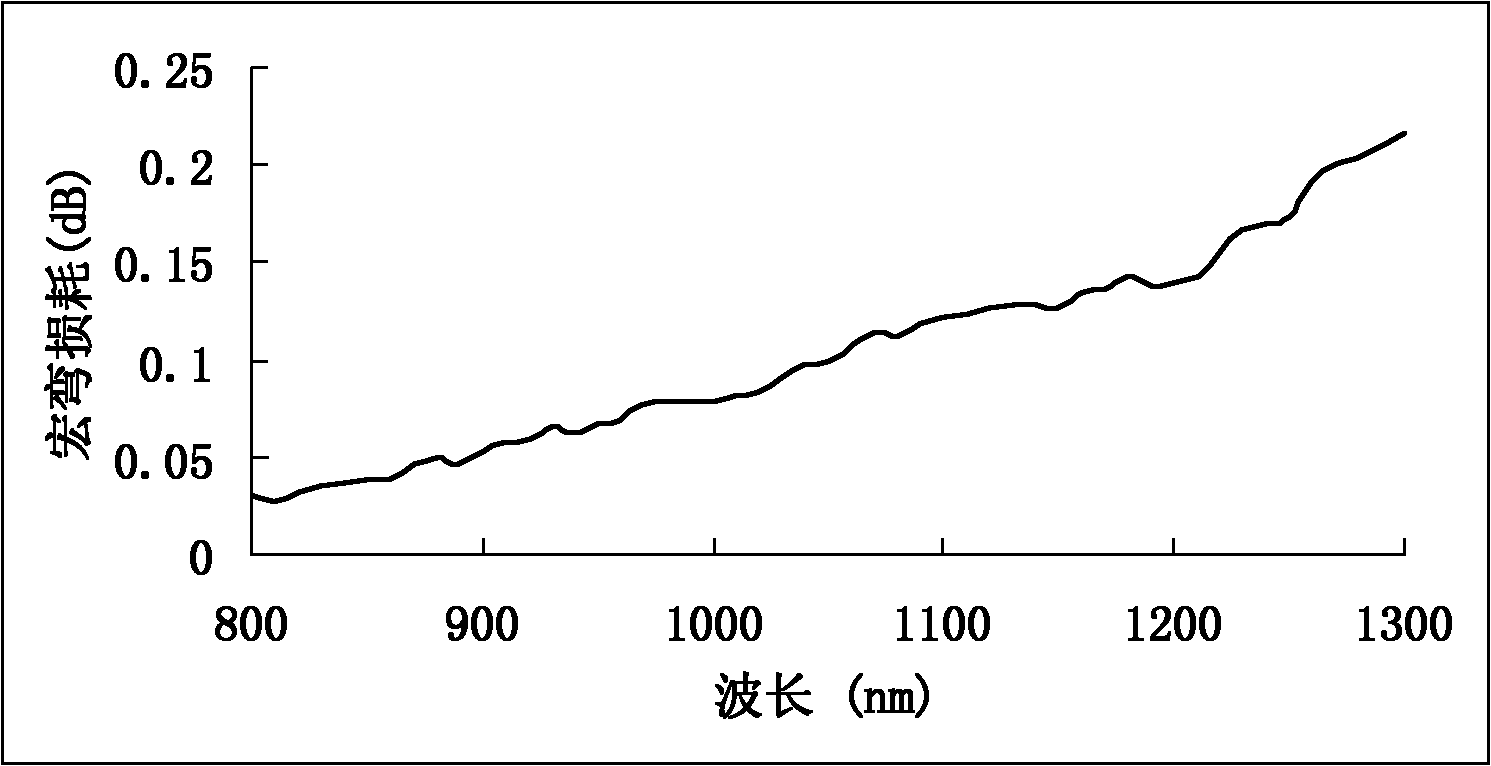

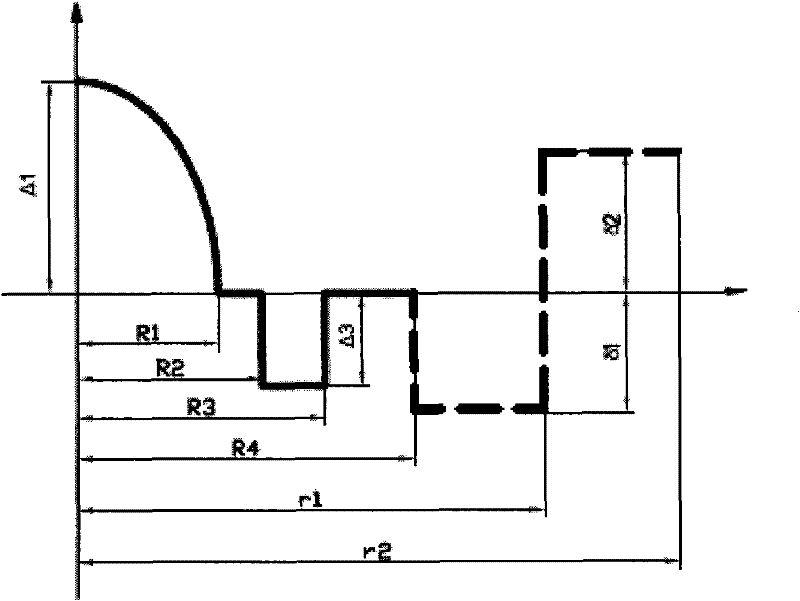

Bend-resistance multimode optical fiber

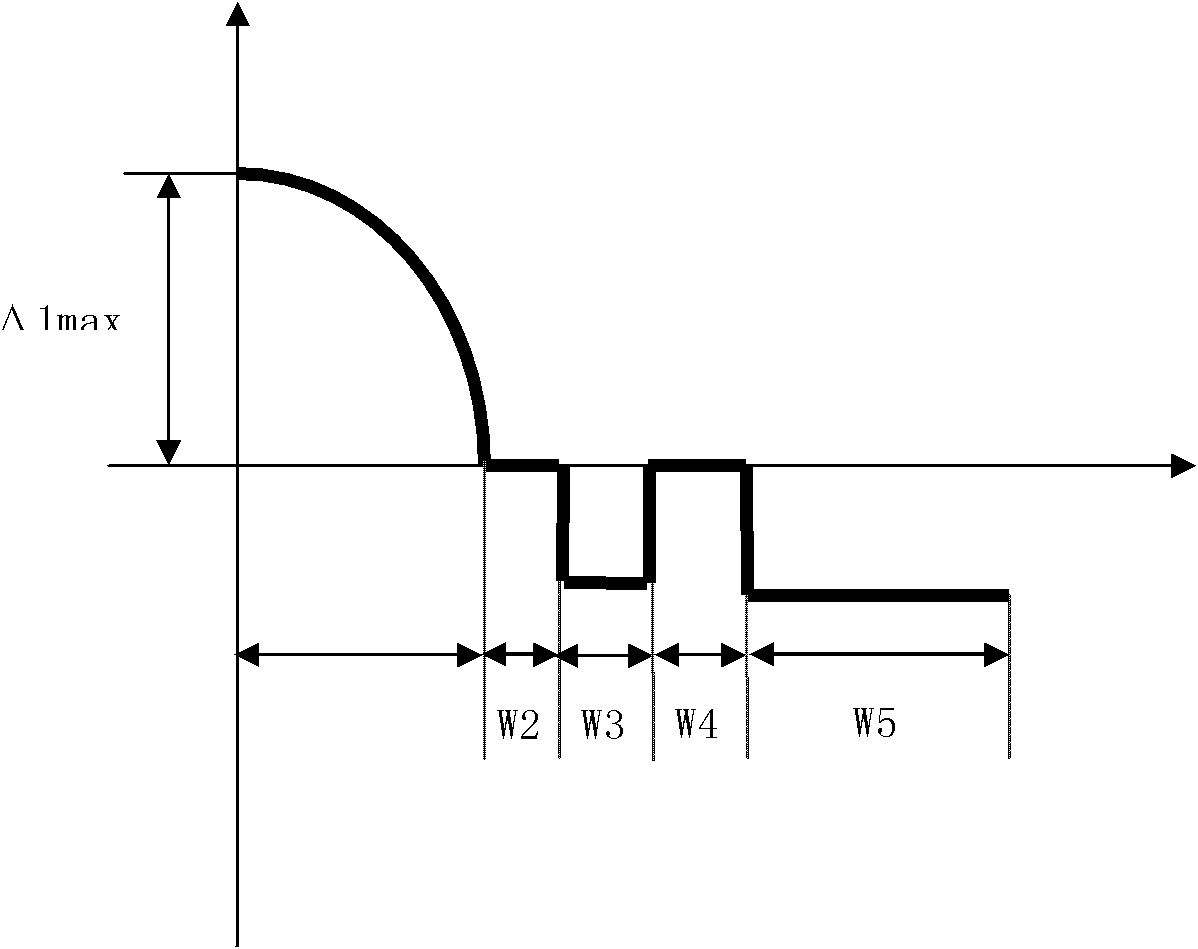

InactiveCN102043197AMacrobending Additional AttenuationLow Macrobending Additional AttenuationOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

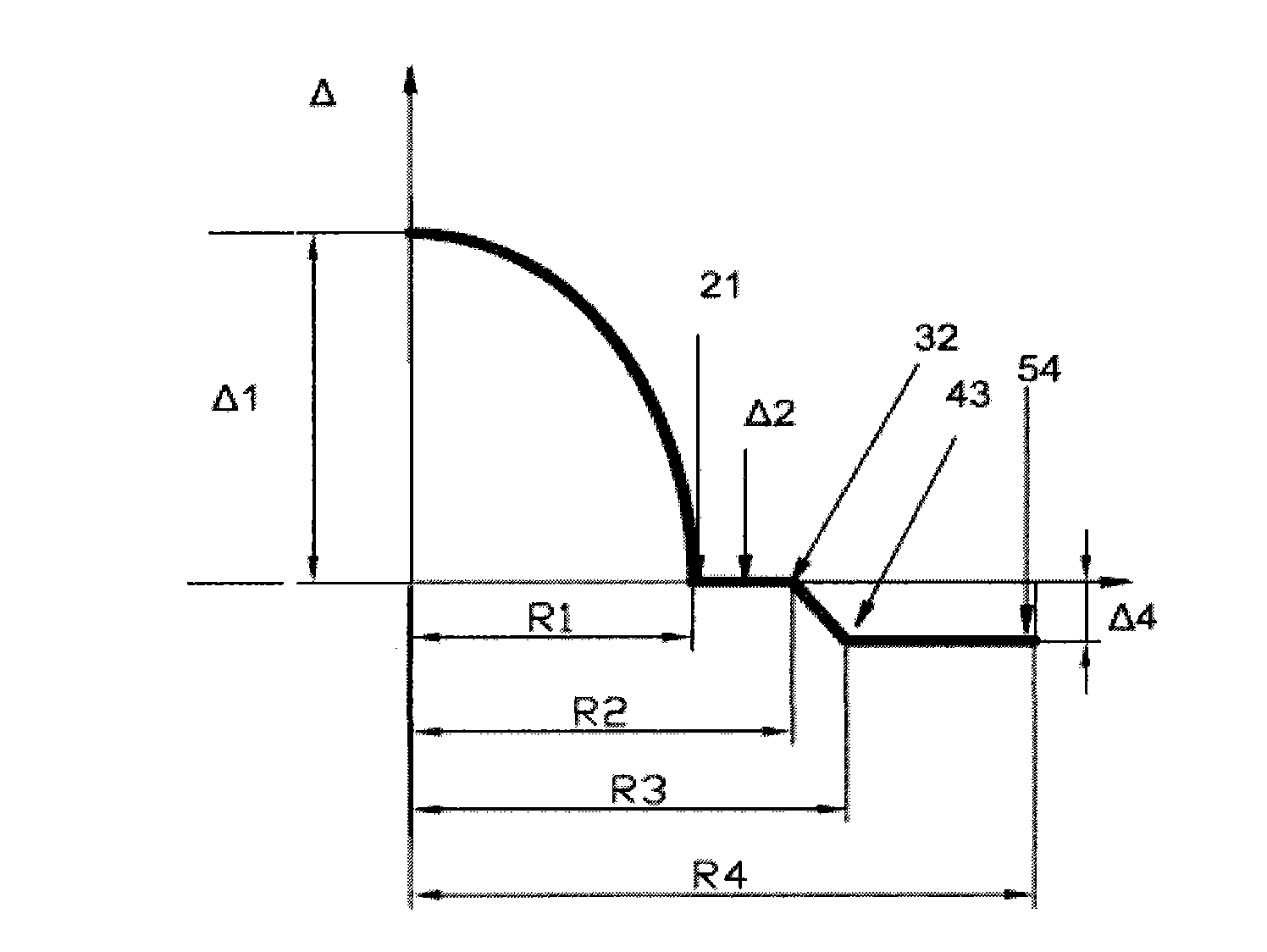

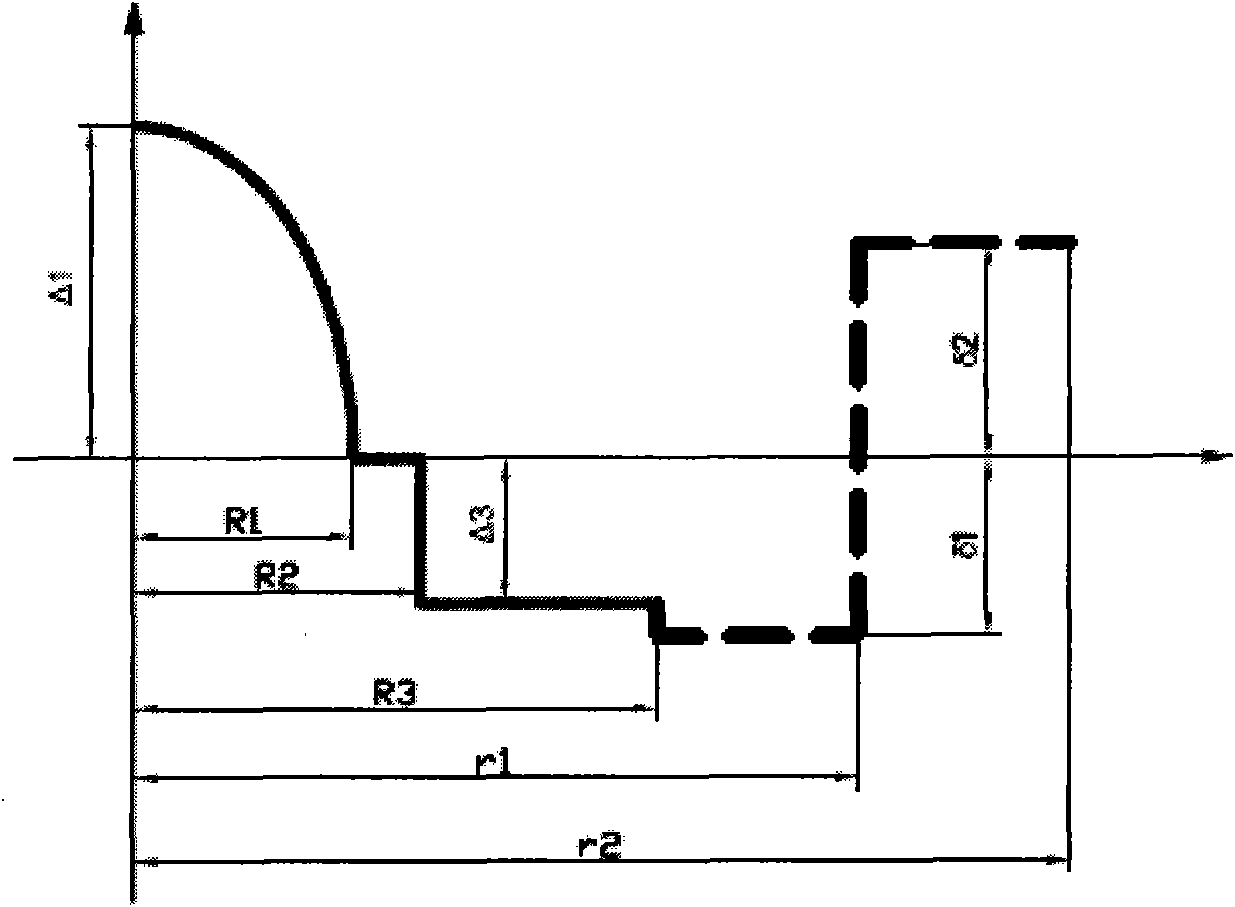

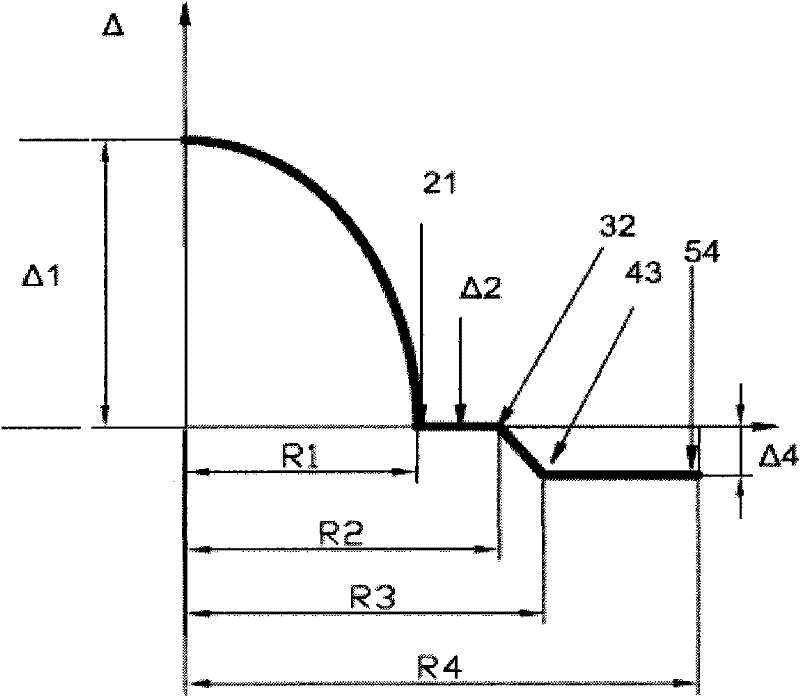

The invention relates to a bend-resistance multimode optical fiber, comprising a core layer and cladding layers. The bend-resistance multimode optical fiber is characterized in that the radius R1 of the core layer is 23-27 microns, the refractive index section of the core layer is a parabola, and the cladding layers outside the core layer successively comprise an inner cladding layer, a sunken ring, a rising ring and a sunken outer cladding layer; the thickness W2 of the single edge of the inner cladding layer is 0-2.5 microns, and the relative refractivity delta 2 of the inner cladding layer is -0.1% to 0.1%; the thickness W3 of the single edge of the sunken ring is 0.5-6 microns, and the minimum relative refractivity delta 3 min of the sunken ring is from -0.1% to -0.3%; the thickness W4 of the single edge of the rising ring is 0.5-10 microns, and the rising ring is a pure silica layer; the thickness W5 of the signal edge of the sunken outer cladding layer is 17-39 microns, and the minimum relative refractivity delta 5 min of the sunken outer cladding layer is from -0.15% to -0.6%; and delta 3 min is larger than delta 5 min. The bend-resistance multimode optical fiber has the characteristics of extremely low macro-bending additional attenuation, has the identical macro-bending property at dual-communication windows (850nm and 1300nm) and macro-bending flat feature; and the refractive index of the sunken ring is higher than that of the sunken outer cladding layer in the optical fibre cladding layer, and the band width of the bending-insensitive multimode optical fiber can be effectively improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

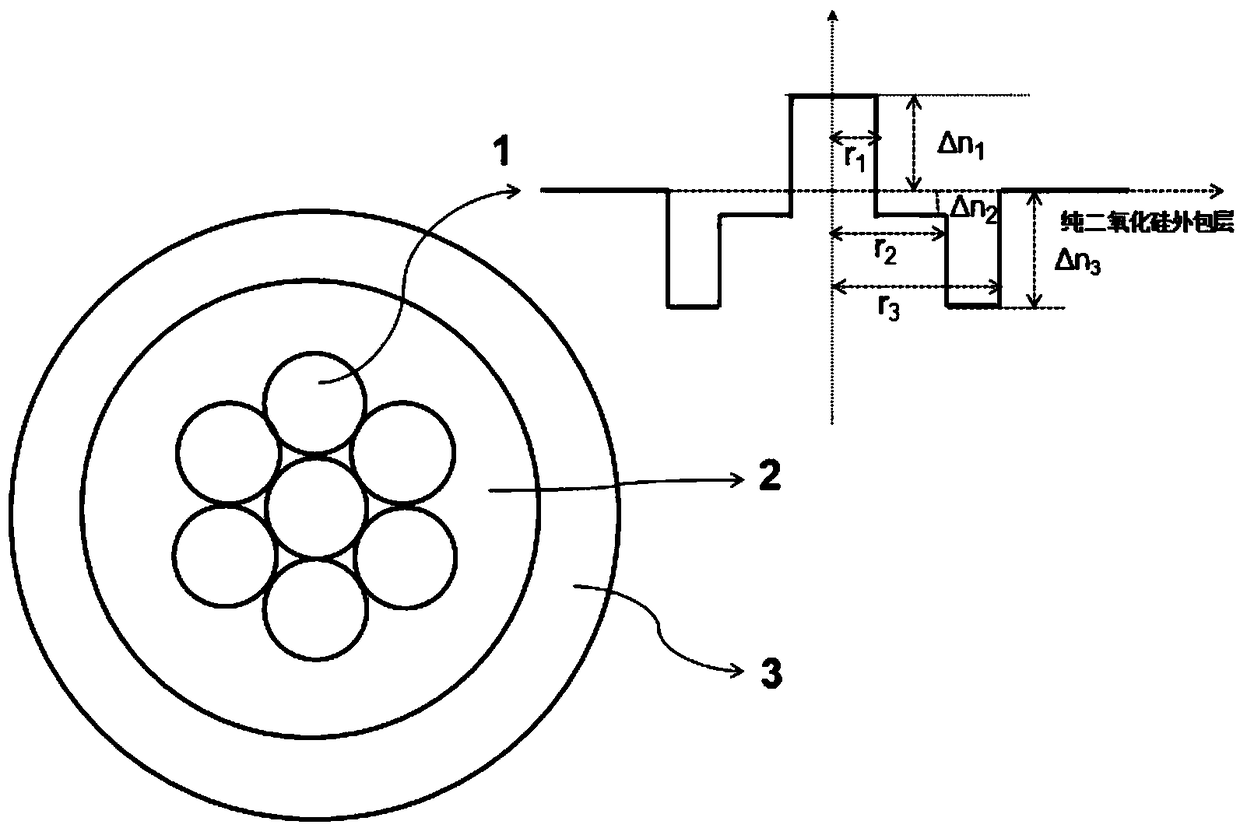

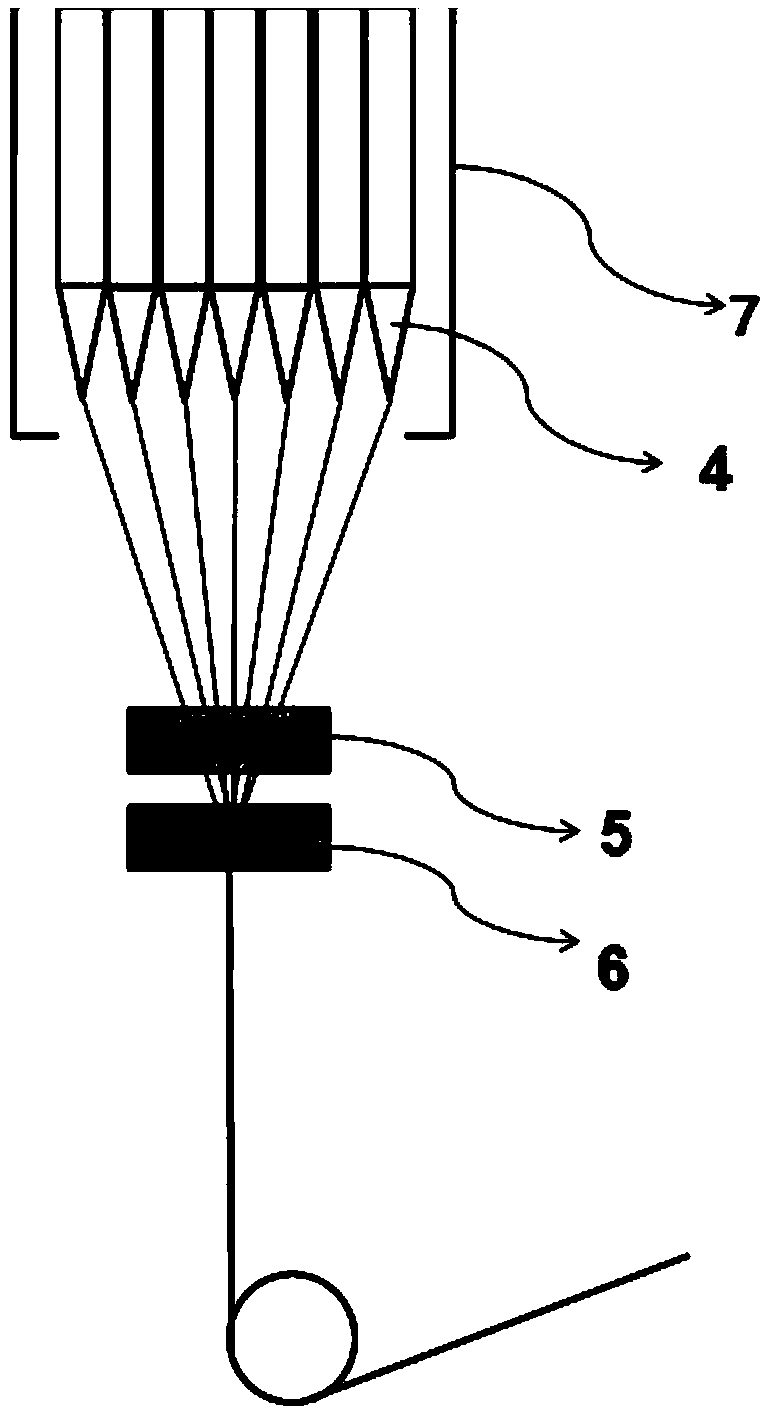

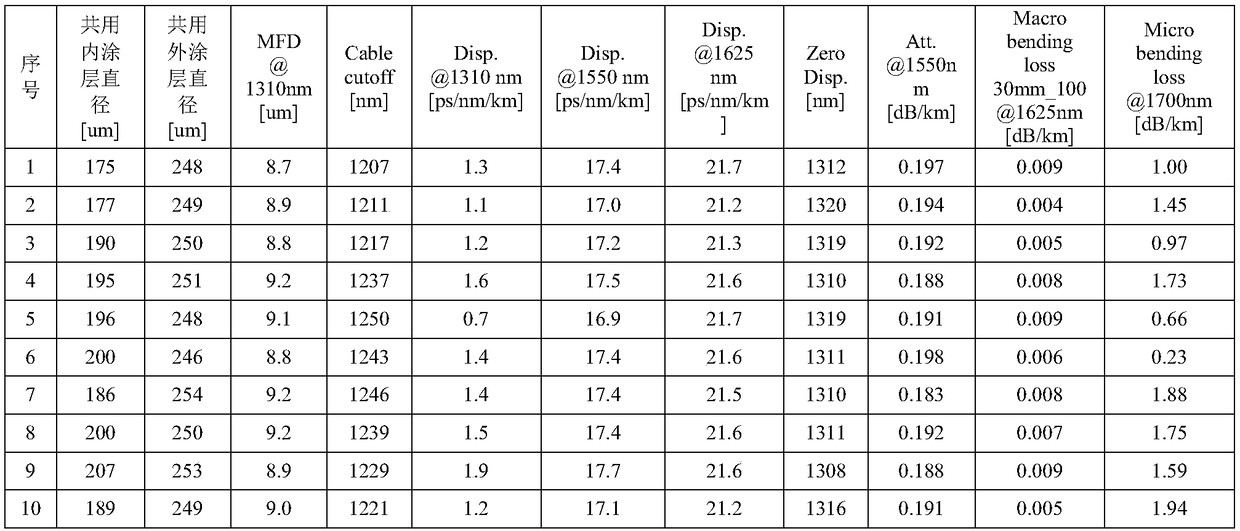

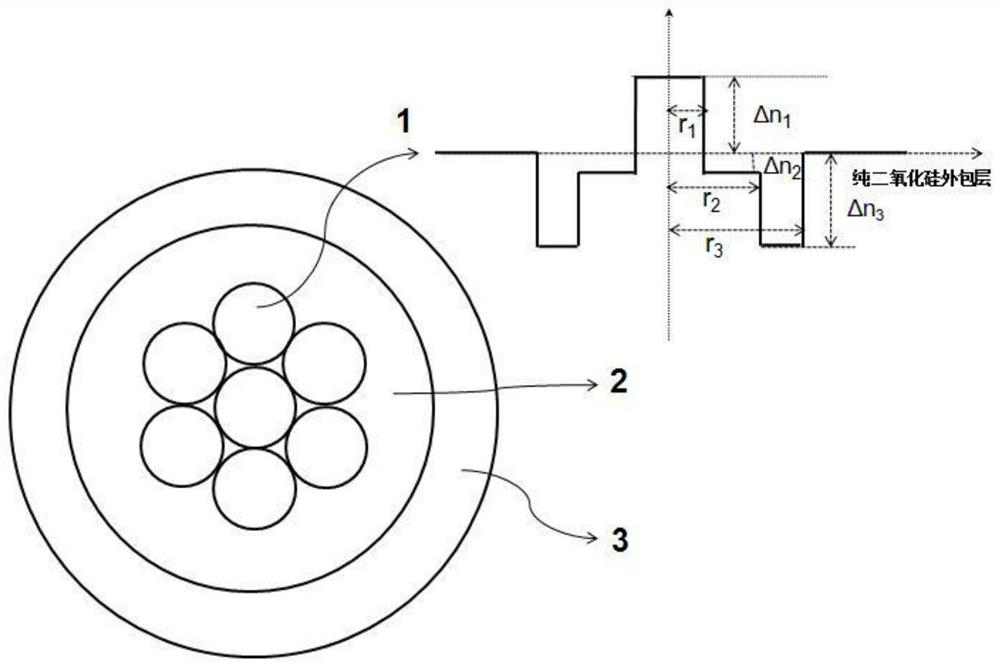

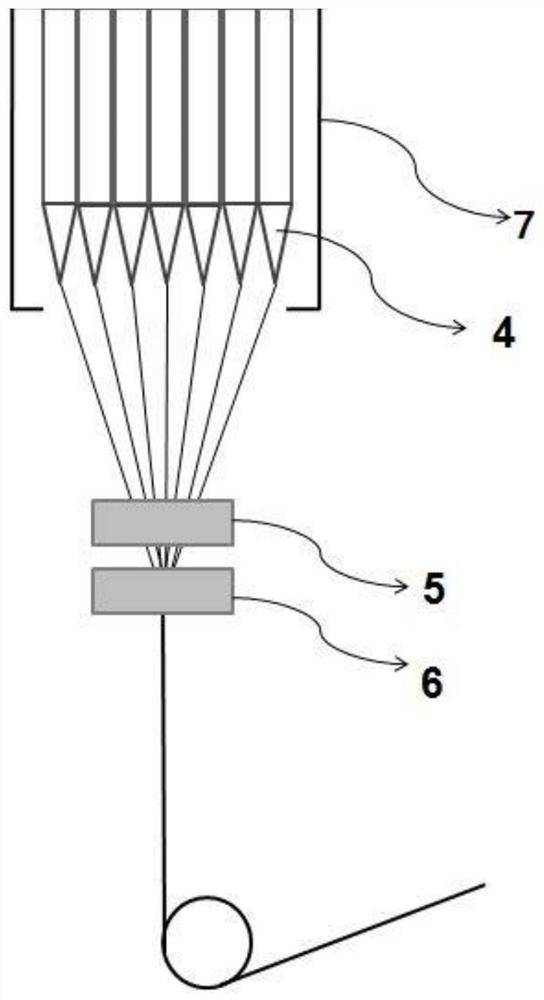

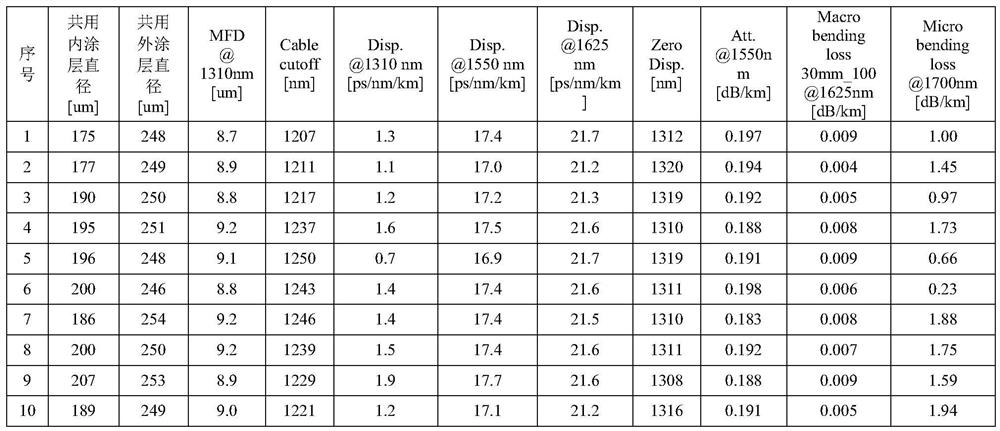

Seven-core small-diameter single mode fiber and manufacturing method thereof

ActiveCN109061793AImprove waveguide transmission conditionsReduce additional lossOptical fibre with multilayer core/claddingGlass fibre drawing apparatusUltrasound attenuationLength wave

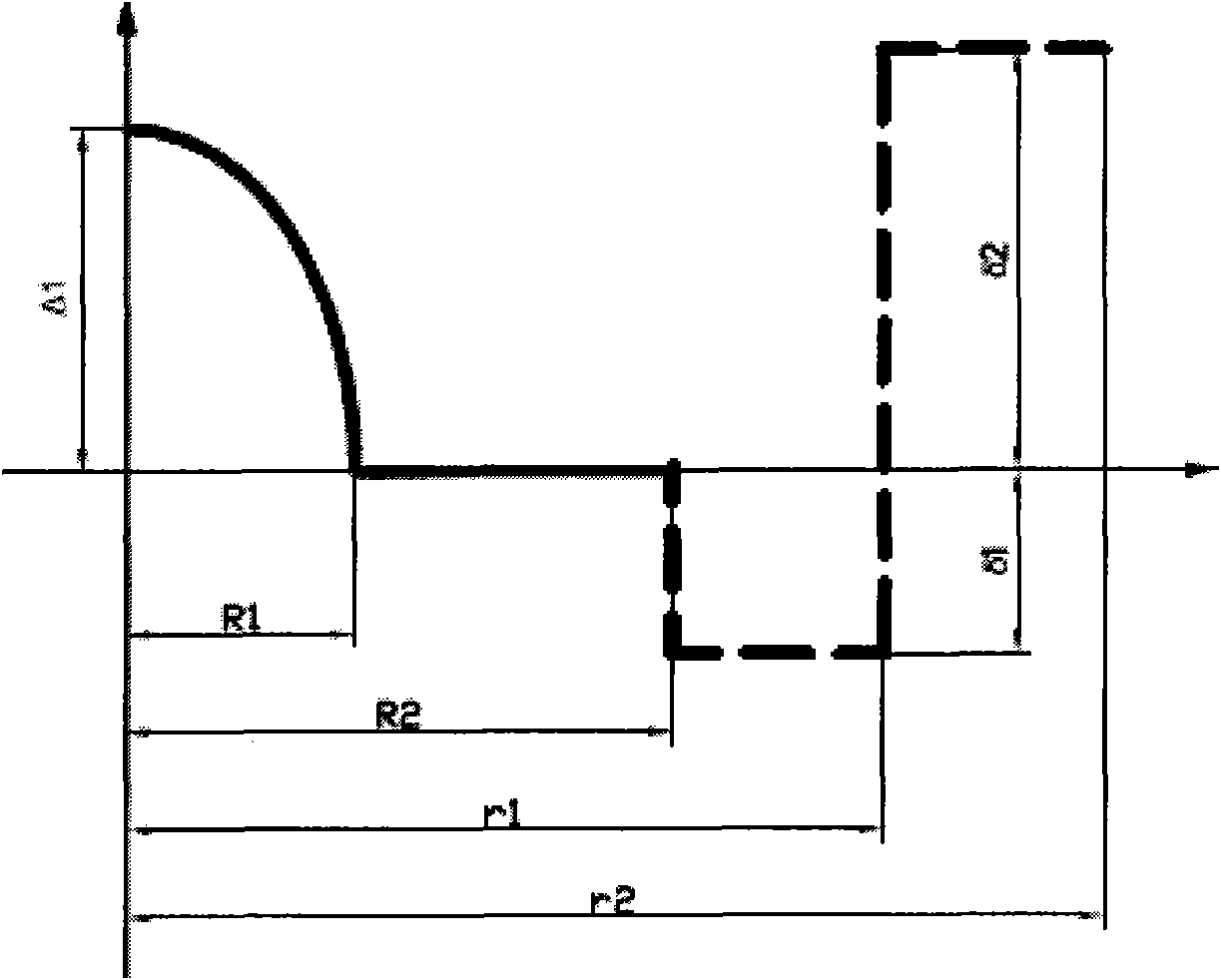

The invention relates to a seven-core small-diameter single mode fiber. The seven-core small-diameter single mode fiber comprises seven single-mode fibers having the same core cladding structure, wherein the seven fibers combined together closely, one fiber located at the center of the fibers, and the other six fibers surround the periphery of the center fiber; the single-mode fiber comprises a core layer and a cladding layer, the cladding layer comprises an inner cladding layer, a sunken cladding layer and an external cladding layer from the inside to the outside, radius r4 of the external cladding layer is 20-25 microns, ratio r4 / r1 of the radius of the external cladding layer to the radius of the core layer is 5.1-5.5, ratio r4 / r2 of the radius of the external cladding layer to the radius of the inner cladding layer is 2.4-2.8, and ratio r4 / r3 of the radius of the external cladding layer to the radius of the sunken cladding layer is 1.6-2.0. With the fiber provided by the invention,external diameter of the multi-core fiber is reduced greatly, and communication capacity density of unit cross section of the fiber is improved remarkably; consequently, space resource for paving pipelines is reduced; meanwhile, signal crosstalk influence among different fiber units is eliminated. The fiber provided by the invention has excellent comprehensive performance parameters, such as wavelength, mode field, attenuation and chromatic dispersion, in application wavebands, has microbending loss which is small enough. The fiber provided by the invention can be produced through a simple and convenient manufacturing method and needs low manufacturing cost.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD

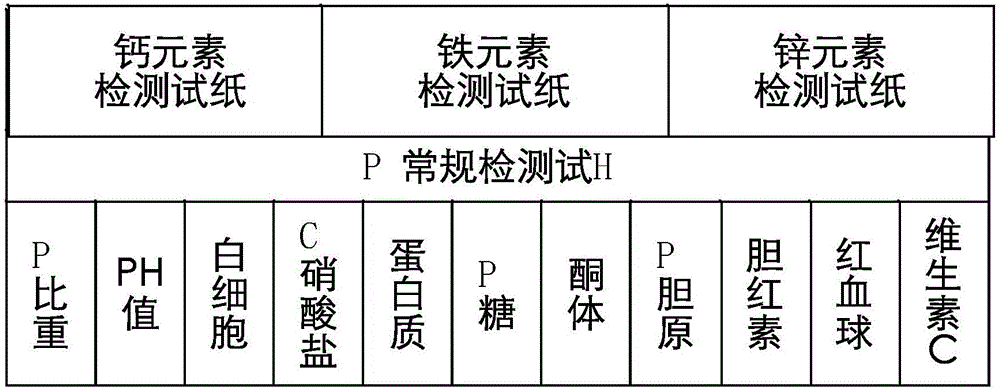

Test paper for detecting trace elements and production method thereof

InactiveCN106198523AThe preparation method is simple and effectiveEasy to useLiquid surface applicatorsMaterial analysis by observing effect on chemical indicatorTrace elementEngineering

The invention disclose test paper for detecting trace elements. The test paper is spliced by routine urine test paper, test paper for detecting calcium elements, test paper for detecting iron elements and test paper for detecting zinc elements, and each color identification block corresponds to the detection result of each test paper. By the test paper for detecting the trace elements, whether the routine urine test items and content of trace elements such as the calcium elements, the iron elements and the zinc elements in the urine of a child are normal or not can be detected conveniently. A production method of the test paper for detecting the trace elements is simple and effective, and the disposable test paper is low in use cost, convenient to use and fast and accurate in detection result.

Owner:BABY CARE DEV TECH CORP

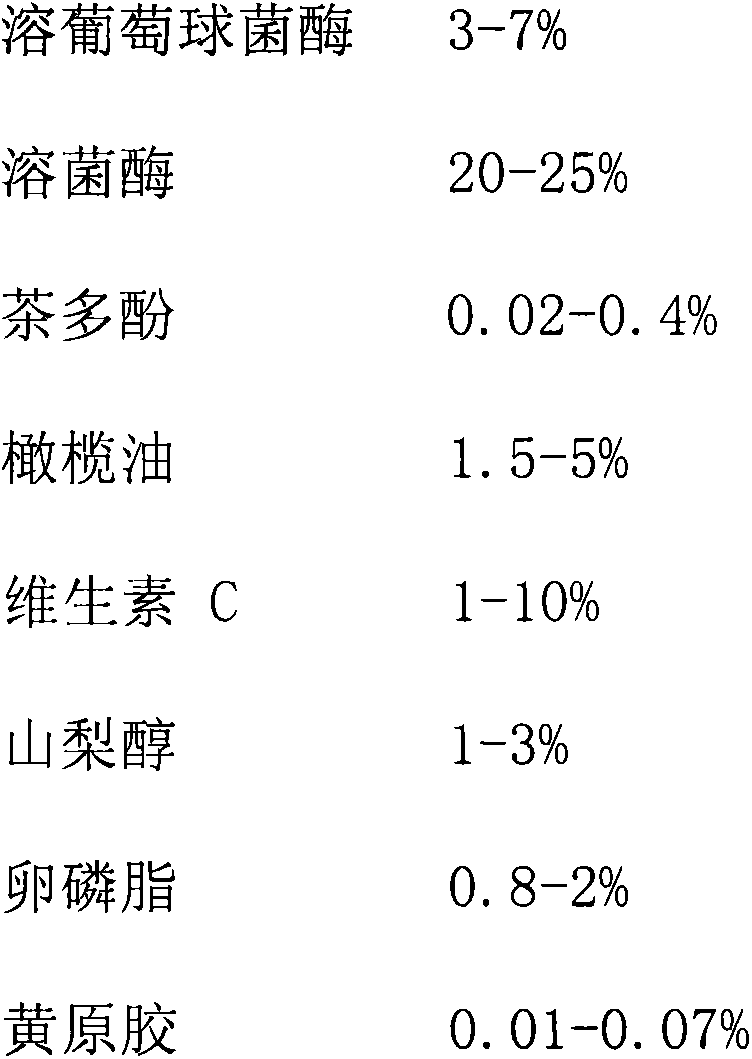

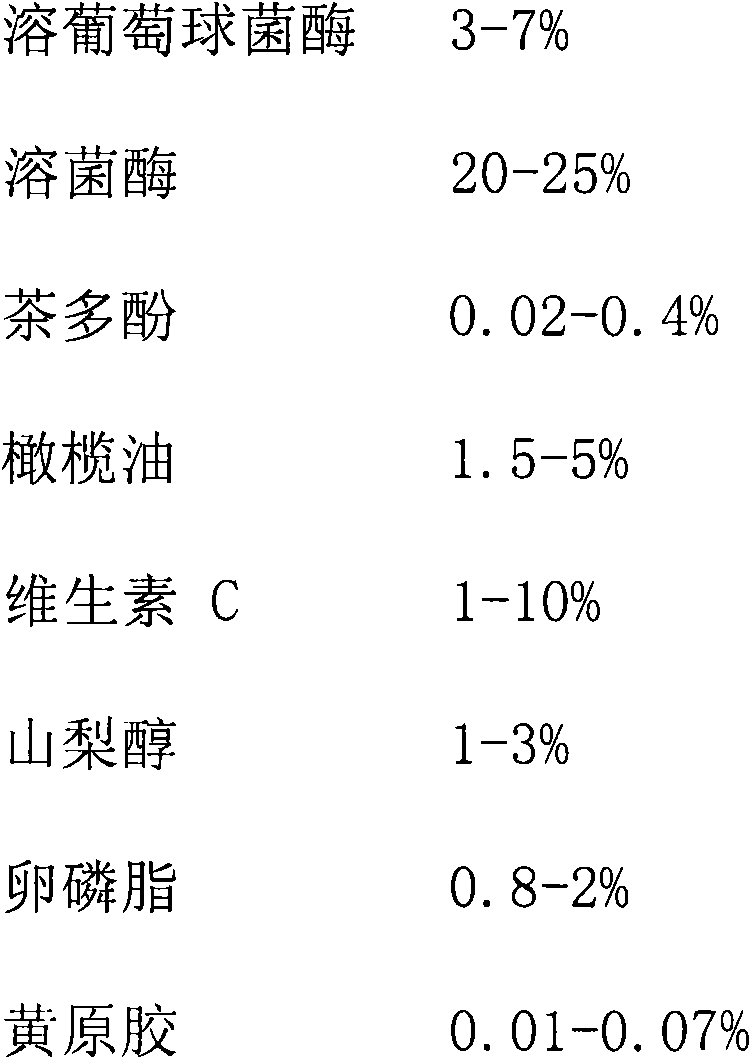

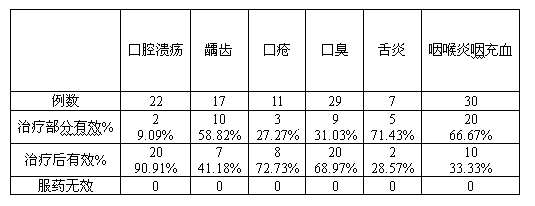

Composite lysozyme oral spray and preparation method thereof

InactiveCN103736084ALess resistantInhibit oral streptococcus mutansOrganic active ingredientsPeptide/protein ingredientsTear lysozymeTreatment effect

The invention relates to a composite lysozyme oral spray and a preparation method thereof. The composite lysozyme oral spray is remarkable in effect and convenient to use, and does not contain alcohol; all components are extracted from natural products, enable fresh breath after used and do not have toxic or side effect under combined action of lysozyme, tea polyphenol and vitamin C; the oral spray has good prevention and treatment effects to dental ulcer, decsyed teeth, aphtha, ozostomia, glossitis, sphagitis and other dental diseases; the preparation method is concise and effect, and low in cost; the prepared composite lysozyme oral spray is good in stability.

Owner:童渝

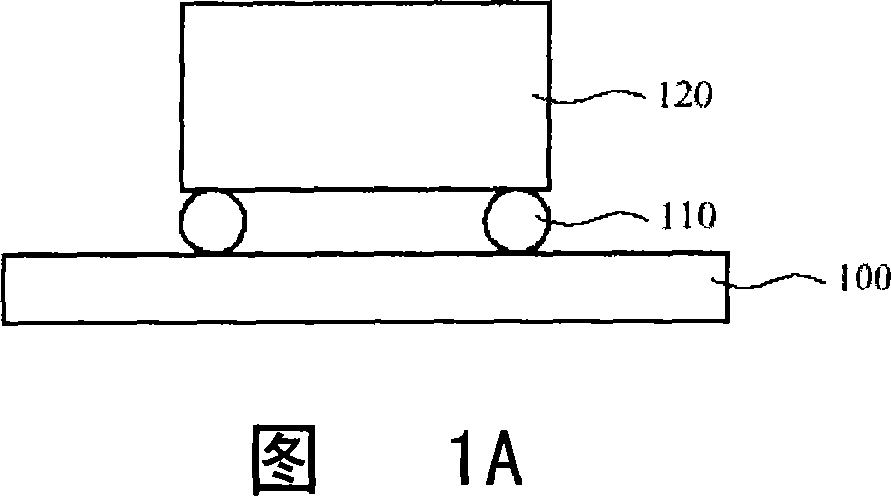

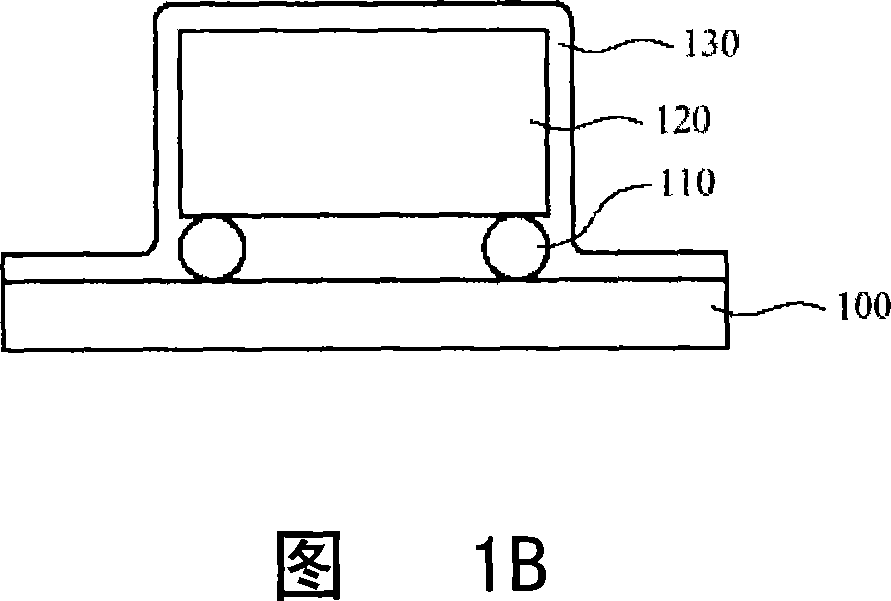

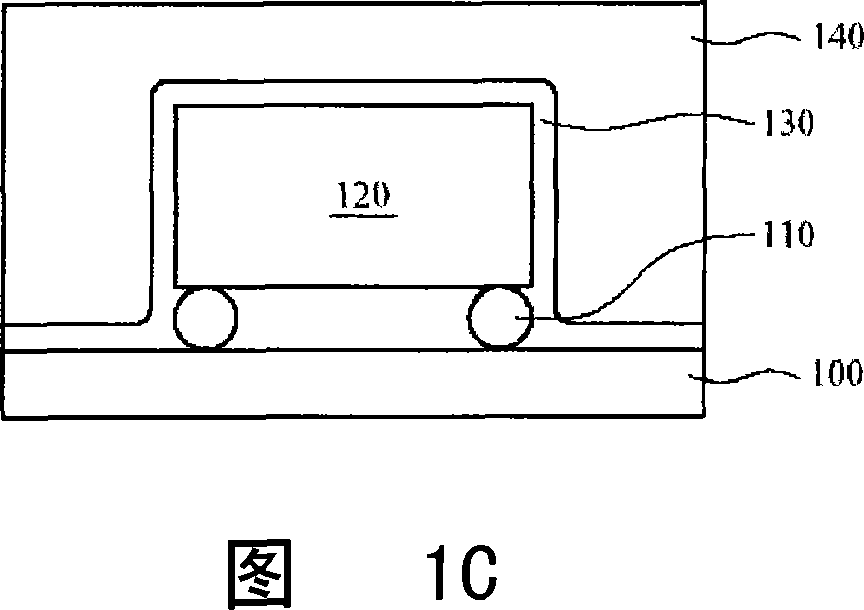

LED package structure and method for manufacturing the same

InactiveCN101047221AImprove light extraction efficiencyReduce reflection lossSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexChemical vapor deposition

A LED package structure is disclosed. The LED package structure includes a substrate, a light emitting diode, a plasma chemical vapor deposition layer and a transparent material layer, wherein the substrate has a plurality of contacts. The light emitting diode is disposed on the substrate and electrically contacted to the contacts. The plasma chemical vapor deposition layer is disposed on the light emitting diode and the refractive index of the plasma chemical vapor deposition layer is smaller than that of the light emitting diode. The transparent material layer is disposed on the plasma chemical vapor deposition layer and the refractive index of the transparent material layer is smaller than that of the plasma chemical vapor deposition layer.

Owner:CHI LIN OPTOELECTRONICS CO LTD

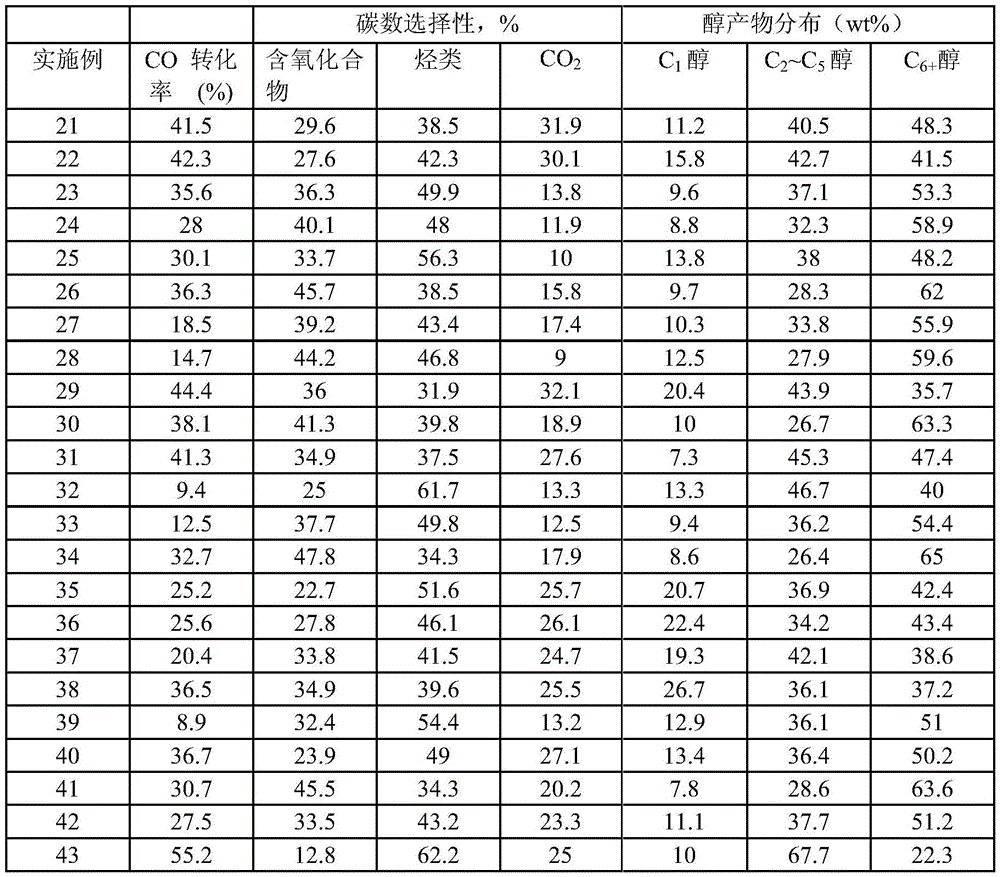

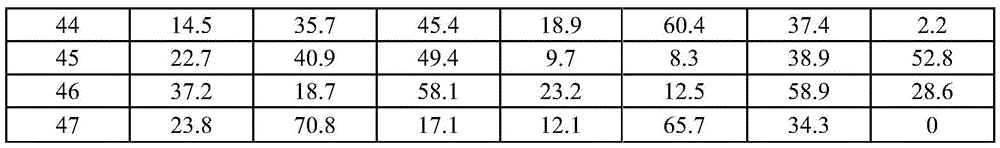

Mixed oxide catalyst for preparing highalcohol with synthesis gas

ActiveCN105664964AImprove conversion rateImprove use valueOrganic compound preparationHydroxy compound preparationSyngasMixed oxide

The invention discloses a mixed oxide catalyst for preparing highalcohol with synthesis gas. The catalyst comprises, by weight, 1-99% of a Co-based catalyst A and 99-1% of a Cu-based catalyst B. The catalyst is high in activity, total alcohol selectivity and C<2+> and C<6+> alcohol selectivity, good in stability and long in service life, the operation temperature can be maintained at 180-350 DEG C, and reaction pressure is 0.1-10 MPa. Due to the fact that catalyst preparation method of the catalyst is simple and easy to repeat, the catalyst has potential industrial application prospect.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Composite lysozyme oral spray and preparation method thereof

ActiveCN103705912AUnique bactericidal mechanismLower resistanceOrganic active ingredientsPeptide/protein ingredientsOral diseaseDisease

The invention relates to a composite lysozyme oral spray. The oral spray is characterized by comprising the following components in percentage by weight: 3-7 percent of lysostaphin, 20-25 percent of lysozyme, 0.02-0.4 percent of tea polyphenol, 1.5-5 percent of olive oil, 1-10 percent of vitamin C, 1-3 percent of sorbitol, 0.8-2 percent of lecithin, 0.01-0.07 percent of xanthan gum, and the balance of purified water. The oral spray is remarkable in effects and convenient to use, and does not contain alcohol; all components are extracted from natural products, and enable fresh breath and no toxic or side effect in the action of compatibility of composite lysozyme, tea polyphenol and vitamin C. The composite lysozyme oral spray has good preventing and treating effects on dental ulcer, decayed teeth, aphtha, halitosis, glossitis, sphagitis and other oral diseases; the preparation method is concise and effective and low in cost, and the prepared composite lysozyme oral spray is good in stability.

Owner:JIANGSU XUE BAO DAILY CHEM CO

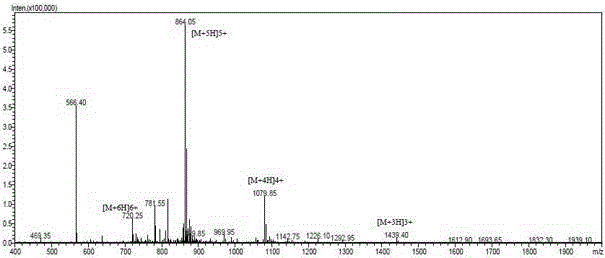

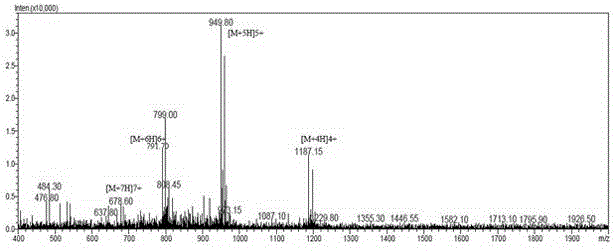

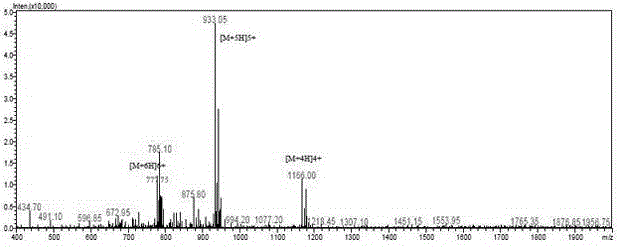

Structure-modified GLP-1 analogs and preparation method thereof

ActiveCN104945499AExtended half-lifeImprove in vivo stabilityPeptide/protein ingredientsMetabolism disorderDiseasePerylene derivatives

The invention relates to structure-modified GLP-1 analogs and a preparation method thereof, particularly exenatide derivatives and a preparation method thereof, and a pharmaceutical composition containing the analogs and application thereof in treating diseases, such as Type II diabetes. The exenatide derivatives are obtained by carrying out structure modification on the C terminal of exenatide. The prepared compounds can obviously provide intracellular cAMP (cyclic adenosine monophosphate) content. The animal experiment indicates that the exenatide derivatives have equivalent and even higher bioactivity than the exenatide. Meanwhile, compared with the exenatide, the compounds provided by the invention have the advantages of high stability and obviously longer in-vivo half life.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

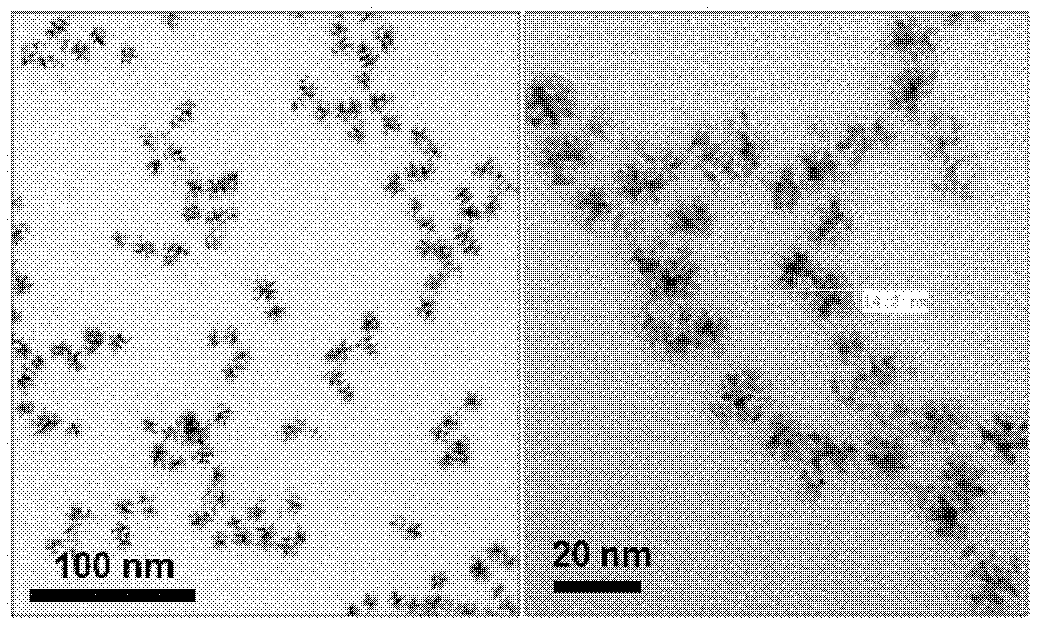

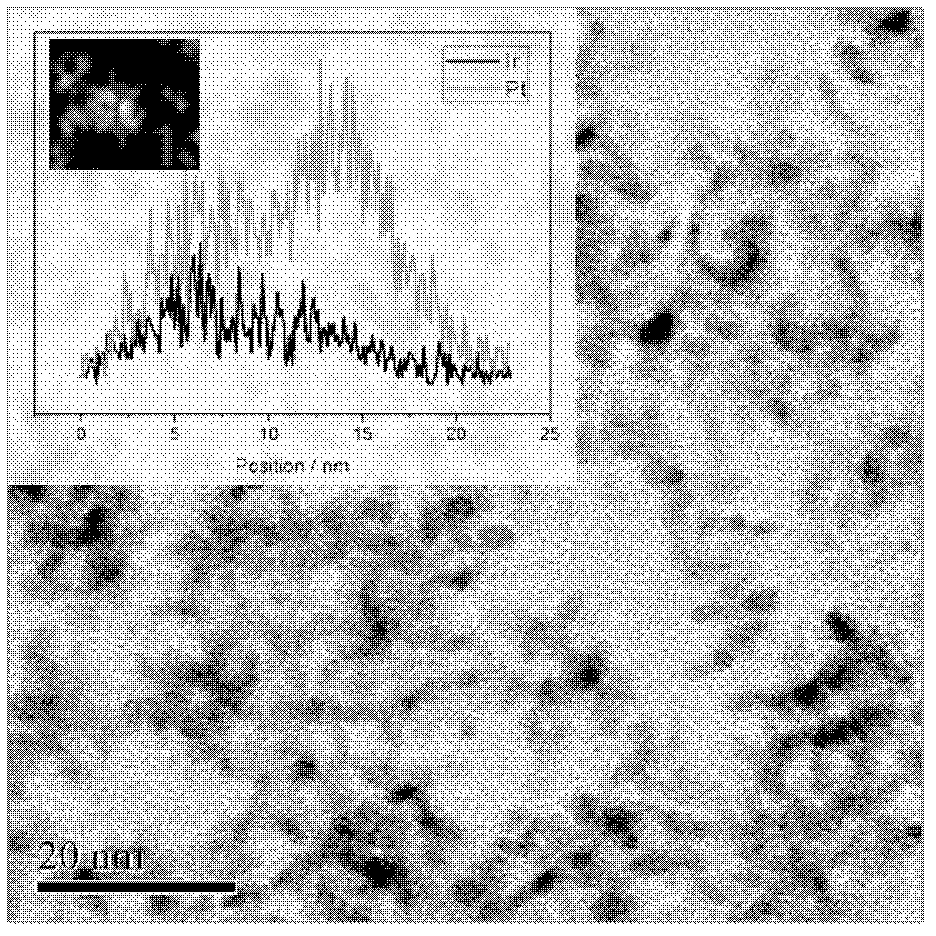

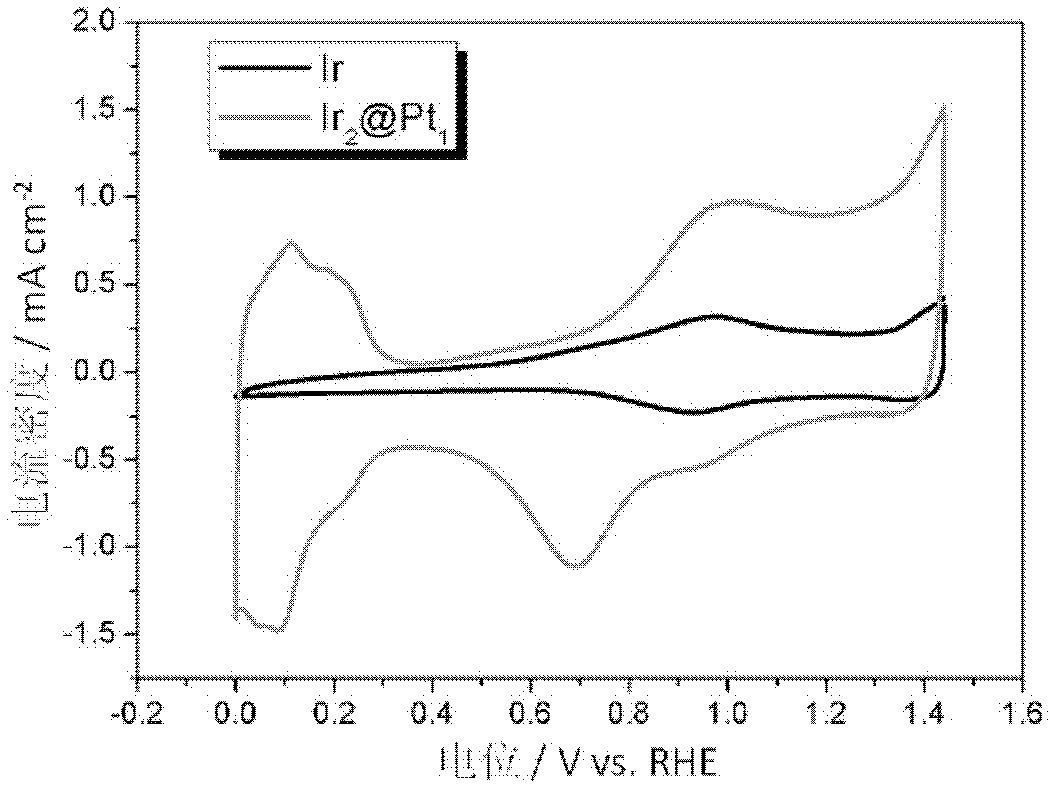

Preparation method of double-effect oxygen electrode catalyst with core-shell structure for fuel cells

ActiveCN103170329ASpecial nano-dendrite morphologyHigh activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsOxygenOxygen evolution

The invention provides a preparation method of double-effect oxygen electrode catalyst with a core-shell structure for unitized regenerative fuel cells. The preparation method includes the following steps: firstly preparing nano dendritic crystal Ir by utilizing strong reducing agents, and then, depositing platinum on the surface of Ir by utilizing a weak reducing agent to obtain Ir@Pt nano particles with core-shell structure. The preparation method is simple and effective, and the particle size distribution of the obtained Ir@Pt catalysts with the core-shell structure is from 10nm to 20nm, and the Ir@Pt catalyst has nano dendritic crystal morphology. The preparation method is simple and effective, and moderate in reaction condition, and the obtained catalyst has good oxygen reduction and oxygen evolution activities, and can be perfectly applied to the unitized regenerative fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

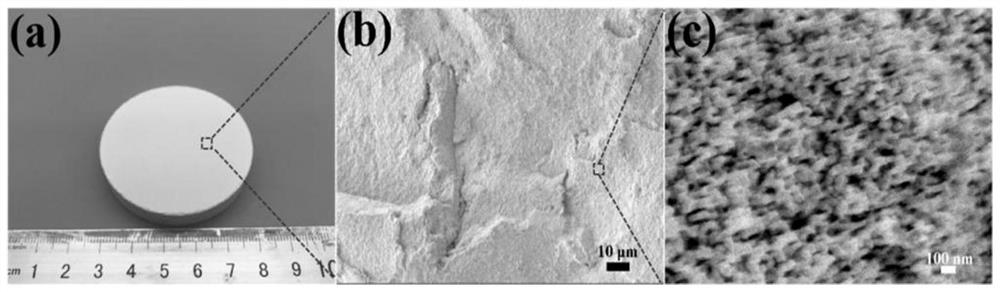

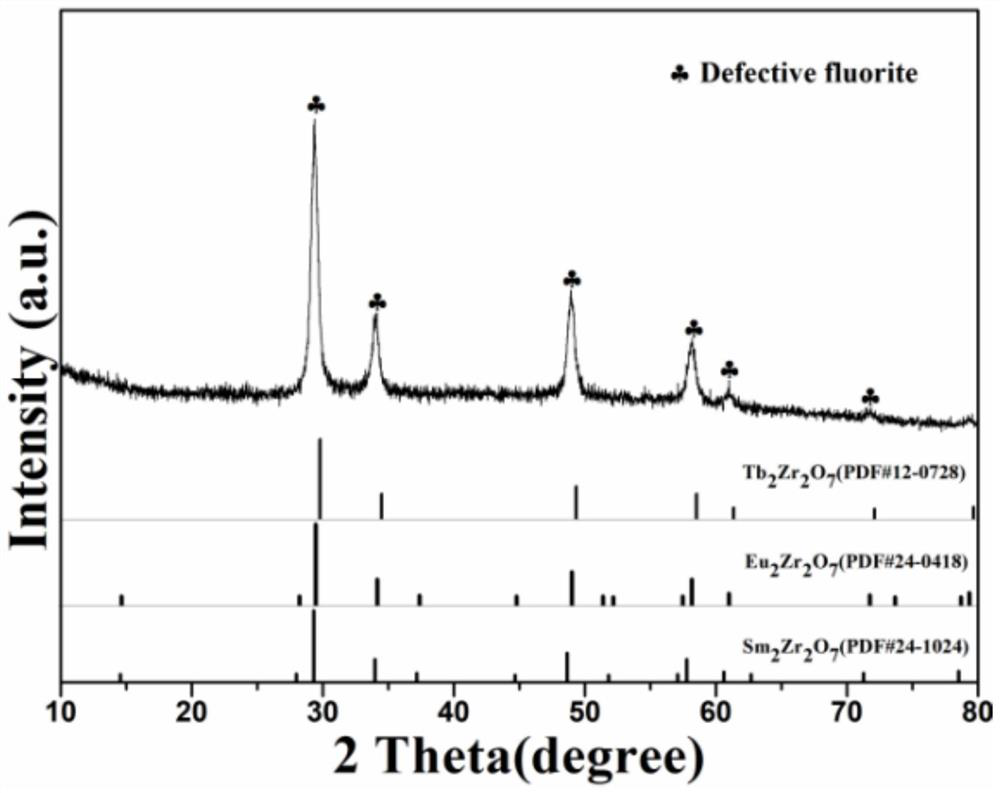

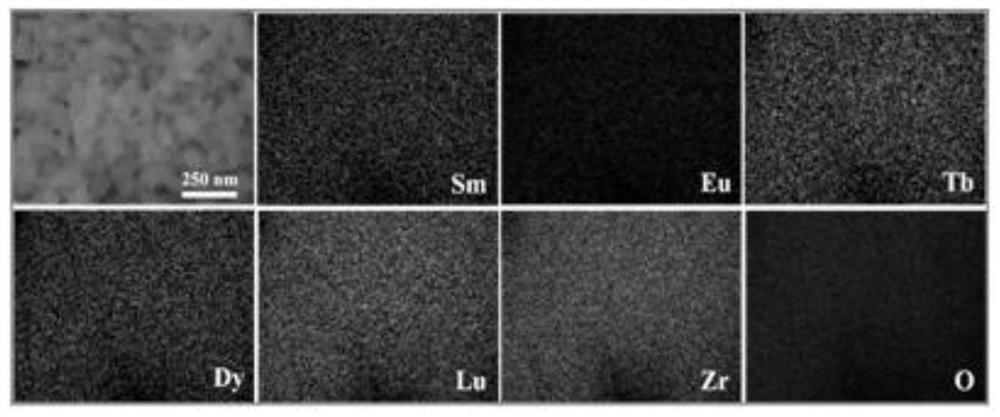

High-entropy rare earth zirconate nano aerogel as well as preparation method and application thereof

ActiveCN113501543AHigh synthesis efficiencyThe method is simple and feasibleZirconium compoundsNanotechnologySupercritical dryingThermal insulation

The invention discloses high-entropy rare earth zirconate nano aerogel as well as a preparation method and application thereof, and belongs to the technical field of ultrahigh-temperature ceramic materials. Phenolic resin, organic silicon resin or polyimide is used as a template, the high-entropy rare earth zirconate nano aerogel is obtained through a sol-gel method in combination with a supercritical drying technology and a high-temperature calcination means, the nanopore of the high-entropy rare earth zirconate nano aerogel is 40-60 nm, and compared with similar high-entropy rare earth zirconate powder particles, the high-entropy rare earth zirconate nano aerogel has high specific surface area and high-temperature stability, and can be widely applied to the fields of high-temperature thermal insulation materials, catalytic materials, ion conductor materials, electrolyte materials, thermal barrier coatings, radioactive nuclear waste treatment and the like. In addition, the preparation method of the material is simple, convenient and effective, the use cost is low, the synthesis efficiency is high, and large-scale production of the high-entropy rare earth zirconate nano aerogel is facilitated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

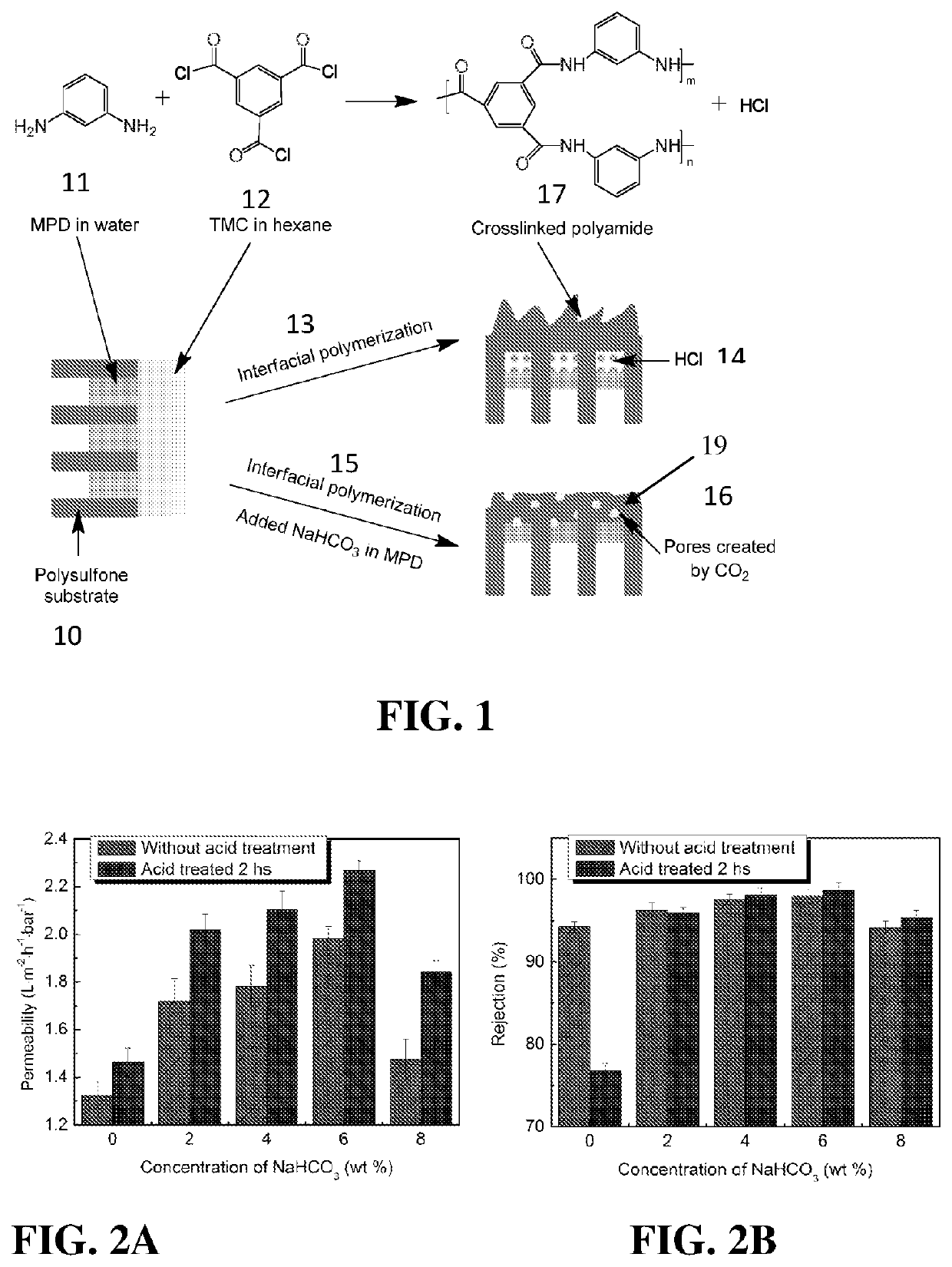

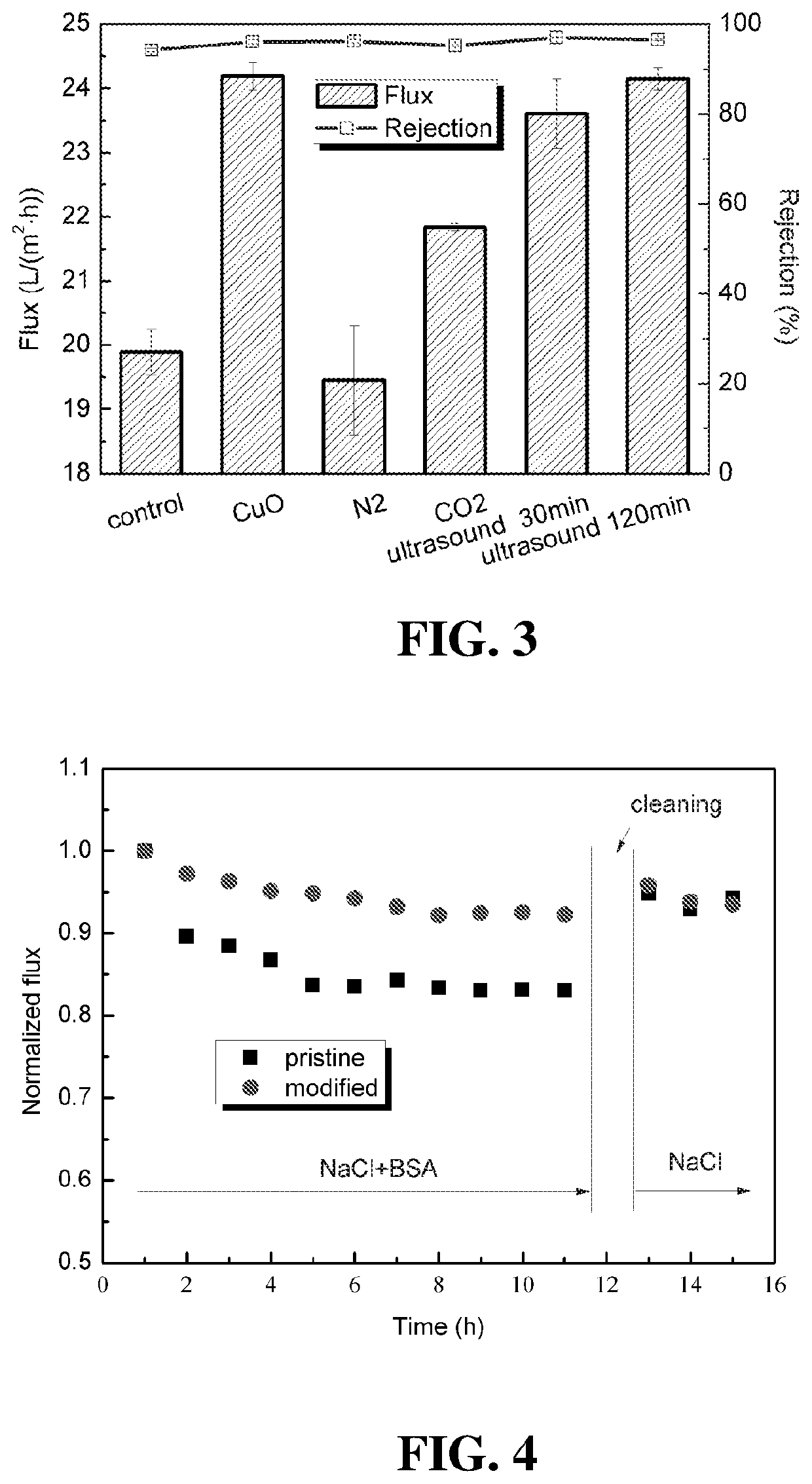

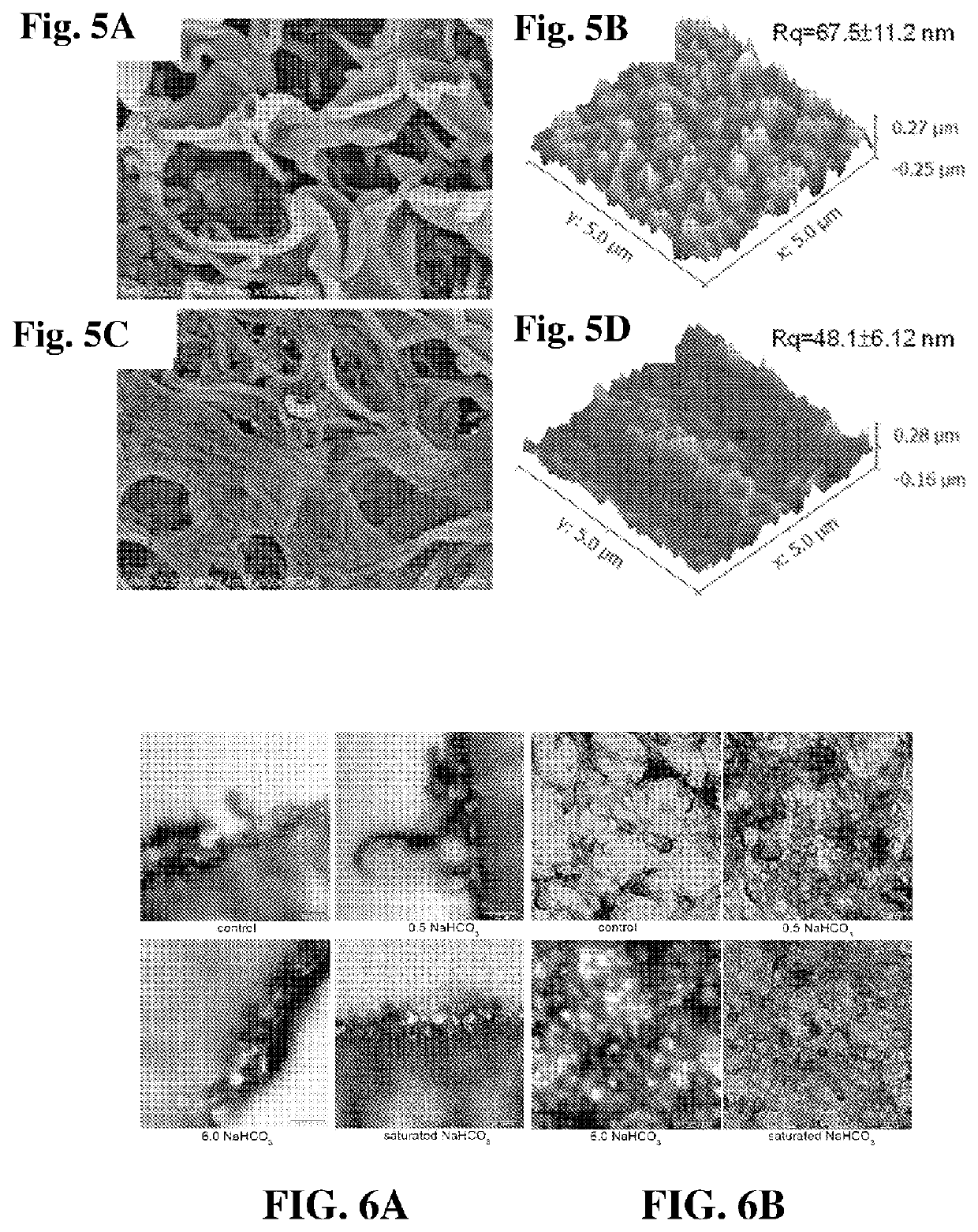

Thin Film Composite Membrane with Nano-sized Bubbles Having Enhanced Membrane Permeability, Preparation Methods and Uses Thereof

ActiveUS20200129931A1The preparation method is simple and effectiveReduce membrane resistanceSemi-permeable membranesMembranesMembrane permeabilizationCarboxylic acid halides

Thin film composite membrane with nano-sized bubbles having enhanced membrane permeability, preparation methods and uses thereof are provided. The method of preparation of a thin film composite membrane, comprising: a) an aqueous solution containing at least an amine, and b) an organic solution containing at least a polyfunctional acyl halide, an additive or soluble gas being present in a) and / or b), or a nano-bubble generator or ultrasound are used to generate nano-bubbles in a) and / or b). Interfacial polymerization of a) and b) occurs at or near the surface of a porous support membrane. The advantage of creating nano-sized bubbles in the separating layer of membrane is that it can reduce membrane resistance without sacrificing the mechanical strength and stability of the membrane so as to improve its water permeability, salt rejection and antifouling. In addition, the process is simple to adopt while performance improvement of the membrane is remarkable.

Owner:THE UNIVERSITY OF HONG KONG

Anti-bending multimode fiber and manufacturing method thereof

ActiveCN101634728BReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

Prepn process of aluminium chloride polymer as water purifier

InactiveCN1275874CEasy to handleSettling fastAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideSludge

The process of preparing aluminum chloride polymer as water purifier with kaolin mineral includes drying kaolin mineral, calcinations at 600-750 deg.c, adding water to compound slurry, ageing, centrifugally separating, reacting in a reactor at 85-95 deg.c for 3 hr, centrifugally treating reaction product, concentrating filtrate to obtain liquid purifier or spray drying to obtain solid purifier, and treating filter residue through secondary eliminating impurity, centrifugal treating and drying to obtain white carbon black as excellent stuffing. The preparation process has aluminum utilization up to 95 %, and the water purifier has average grain size smaller than 40 nm, high water treating effect, high sludge depositing speed and low production cost.

Owner:CENT SOUTH UNIV

Tobacco additive and preparation method thereof

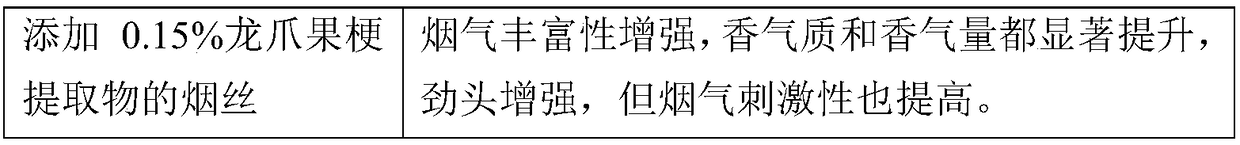

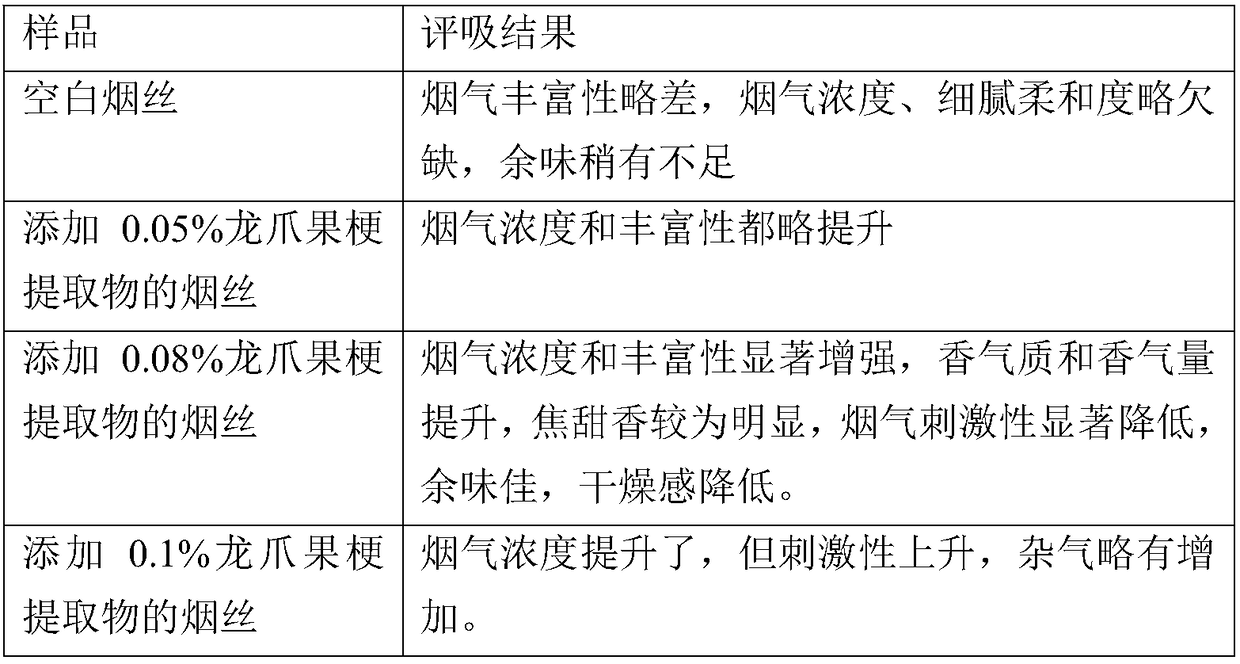

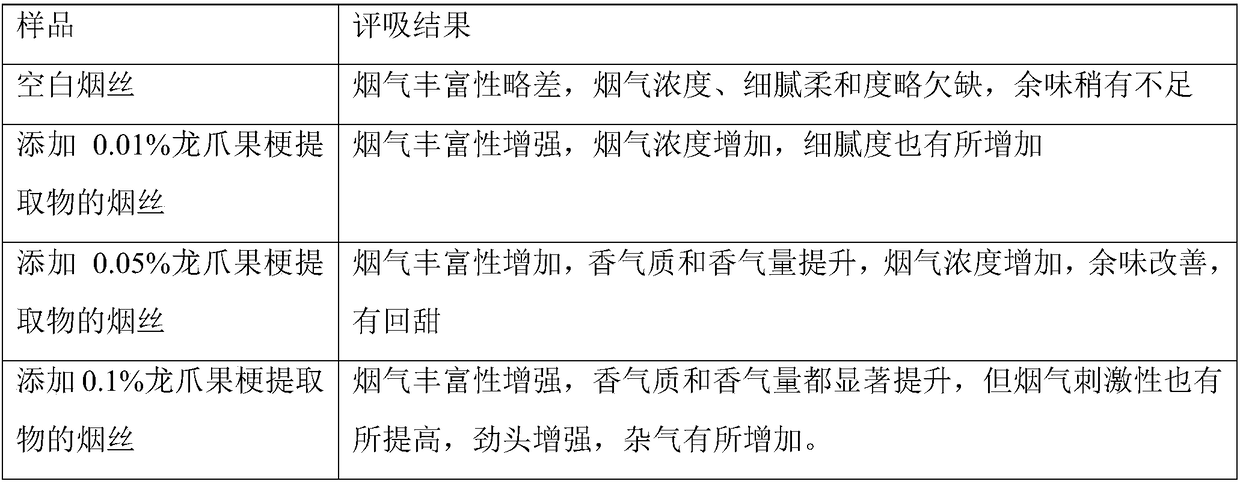

InactiveCN108433172AImprove suction qualityImprove water holding capacityTobacco treatmentSolventSemen

The invention provides a tobacco additive and a preparation method thereof, and particularly relates to a preparation method of a semen hoveniae stem extract. The method comprises the following stepsof 1) crushing semen hoveniae stems, and sieving with a 40-mesh sieve to obtain semen hoveniae stem powder; mixing the semen hoveniae stem powder with water to form a mixed solution; 3) heating and sterilizing the mixed solution at 70-90 DEG C; 4) adding enzymatic for hydrolysis to form a hydrolyzate; 5) heating the hydrolyzate at 80-100 DEG C to obtain a reaction solution; 6) centrifuging the reaction solution to obtain a supernatant; 7) concentrating the supernatant to obtain the semen hoveniae stem extract. The invention discloses the tobacco additive and the preparation method thereof. Thepreparation method is simple and effective, is suitable for large-scale industrialization and safe production, and is simple and easy to operate, the solvent used is cheap and easy to obtain, and method does not cause environment pollution, and does not introduce offensive odor.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

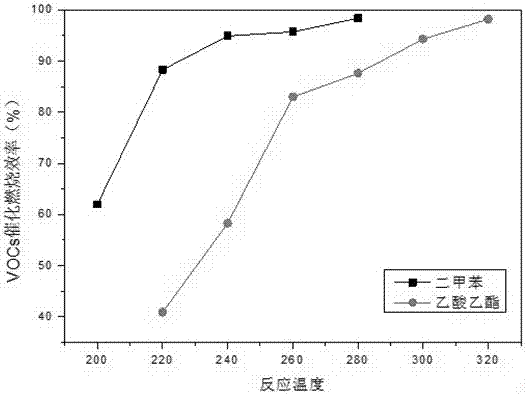

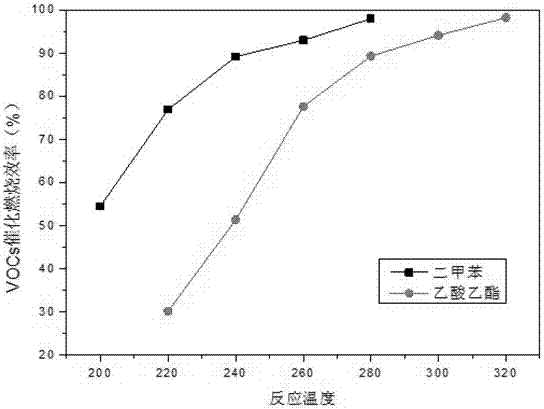

Preparation method of granular catalyst suitable for catalytic combustion of VOCs

InactiveCN107970924AGood dispersionLarge specific surface areaIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsReduction treatmentPre treatment

The invention belongs to the technical field of VOCs purification treatment, and particularly relates to a preparation method of a granular catalyst suitable for catalytic combustion of VOCs. The preparation method successively comprises the following steps: carrier pretreatment, carrier impregnation, reduction treatment and post-treatment. The preparation method of the granular catalyst suitablefor the catalytic combustion of the VOCs achieves an objective of effective preparation of the granular catalyst through the four-step preparation method of carrier pretreatment, carrier impregnation,reduction treatment and post-treatment. The preparation method has the advantages of simple and effective preparation method, easy availability of raw materials, good dispersibility of the prepared granular catalyst, large specific surface area, multiple active sites and high catalytic activity.

Owner:HANGZHOU KAIMING CATALYSTS

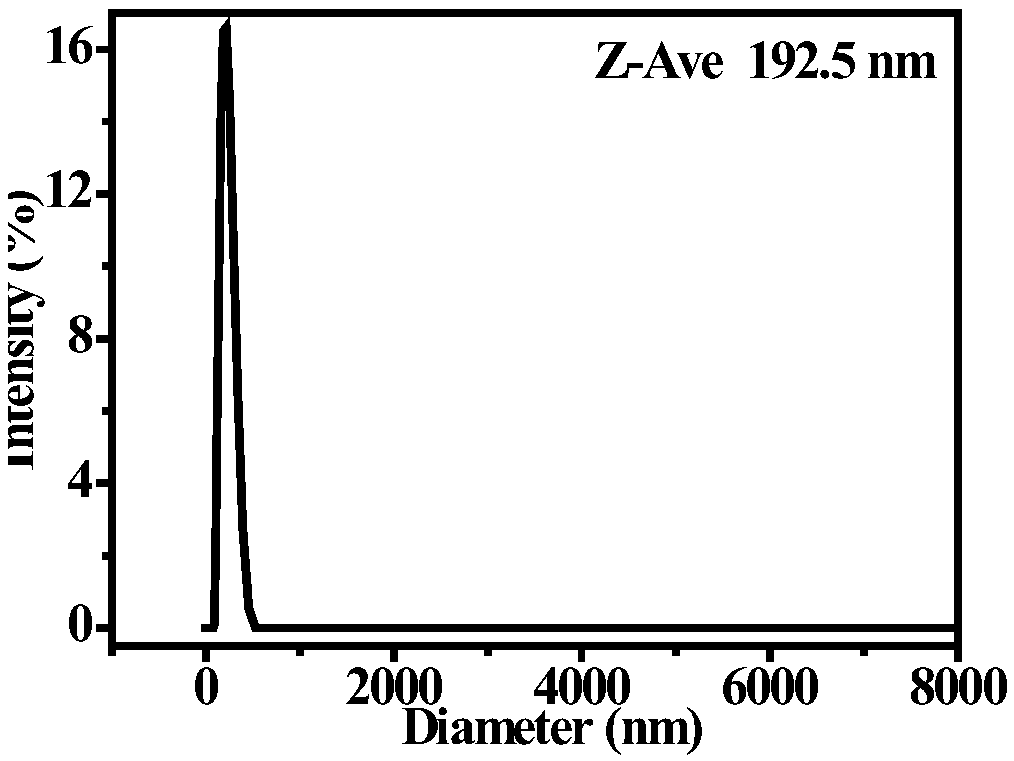

Preparation method of monodisperse hydrophobic poly(trifluoroethyl methacrylate) colloid emulsion

The invention relates to a preparation method of a monodisperse hydrophobic poly(trifluoroethyl methacrylate) colloid emulsion. The method concretely comprises the following steps: washing a trifluoroethyl methacrylate monomer with an alkali solution, and carrying out reduced pressure distillation to obtain refined trifluoroethyl methacrylate; adding an initiator and deionized water into a reactor, and stirring the initiator and deionized water to form a homogeneous system; adding the refined trifluoroethyl methacrylate monomer into the reactor, protecting the obtained reaction system in a protection atmosphere, and uniformly stirring the reaction system by a mechanical stirring device; heating the reactor to carry out a polymerization reaction; and filtering the obtained white product bya gauze to remove gel generated by self-polymerization in order to obtain the flexible monodisperse hydrophobic poly(trifluoroethyl methacrylate) colloid emulsion. Colloid particles prepared through the method have the characteristics of variable colloid size and low monodisperse index. The method has the advantages of fast polymerization rate, strong mixing and heat transferring effect, and no pollution on the surface of the colloid particles.

Owner:NANUS NEW MATERIAL

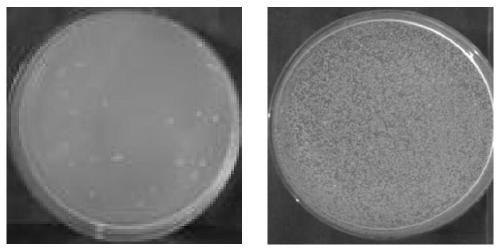

Quaternary ammonium salt type dendritic polythioether modified polymer microsphere

ActiveCN111548526ASignificantly sterilizingImprove stabilityBiocideFungicidesPolymer scienceMicrosphere

The invention discloses a quaternary ammonium salt type dendritic polythioether modified polymer microsphere. The preparation method comprises the following steps: under an ultraviolet light condition, with methoxy polyoxyethylene as a pore-foaming agent and alkyl dithiol, propargyl glycidyl ether and 1,7-octylene as raw materials, synthesizing epoxy microporous polymer spheres by using a sulfydryl-alkyne addition suspension polymerization method; and performing a reaction on the epoxy microporous polymer spheres with excessive organic amine containing unsaturated substituent groups to obtainunsaturated substituent group functionalized porous polymer spheres; then with cysteamine hydrochloride and glycidyl ether containing unsaturated groups as raw materials and methanol as a solvent modifying the surfaces of the epoxy polymer microspheres with dendritic polythioether by adopting multiple iterative reactions alternately performed by a sulfydryl-epoxy addition reaction catalyzed by analkaline compound and a sulfydryl-ene / alkyne addition reaction initiated by free radicals. The quaternary ammonium salt type dendritic polythioether modified porous polymer microsphere prepared by theinvention has bactericidal activity, and does not generate bubbles when being used as a bactericide.

Owner:YANTAI UNIV

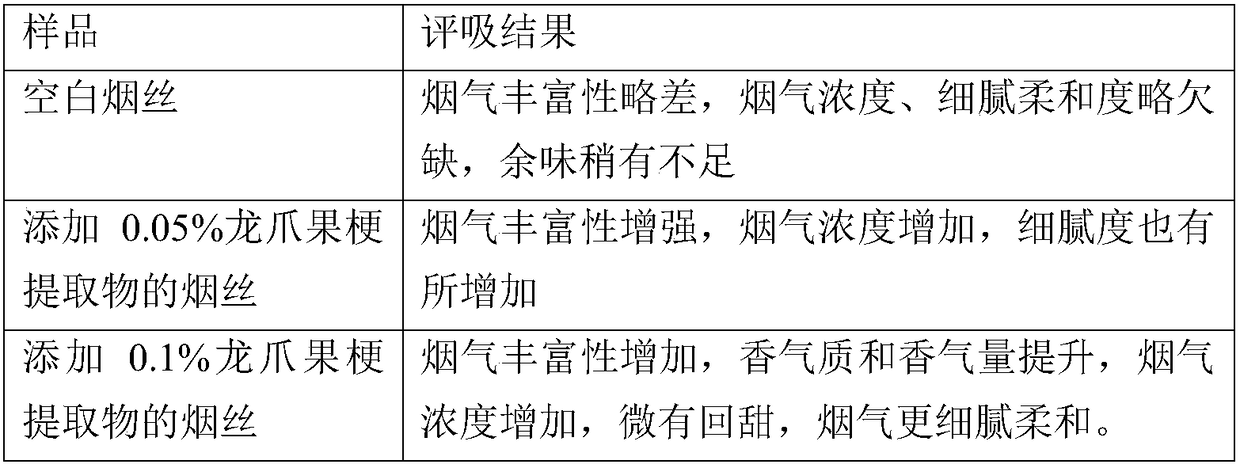

Hovenia acerba fruit stem extract and preparation method and application thereof

ActiveCN108330000AThe preparation method is simple and effectiveNo pollutionTobacco treatmentEssential-oils/perfumesHovenia acerbaAqueous solution

The invention provides a hovenia acerba fruit stem extract and a preparation method and application thereof. The preparation method includes: adopting ethanol water or water as an extracting agent forextracting hovenia acerba fruit stems to obtain extract liquid; filtering and separating to obtain supernatant liquid of the extract liquid; concentrating the supernatant liquid to obtain the hoveniaacerba fruit stem extract. The hovenia acerba fruit stem extract is used as a natural tobacco additive to improve smoking quality of tobacco raw materials such as cut stems, slices or tobacco leavesand is capable of enriching and thickening smoke, improving aroma quality and quantity, reducing smoke pungency and dryness to make smoke gentle and delicate, and covering miscellaneous smell.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

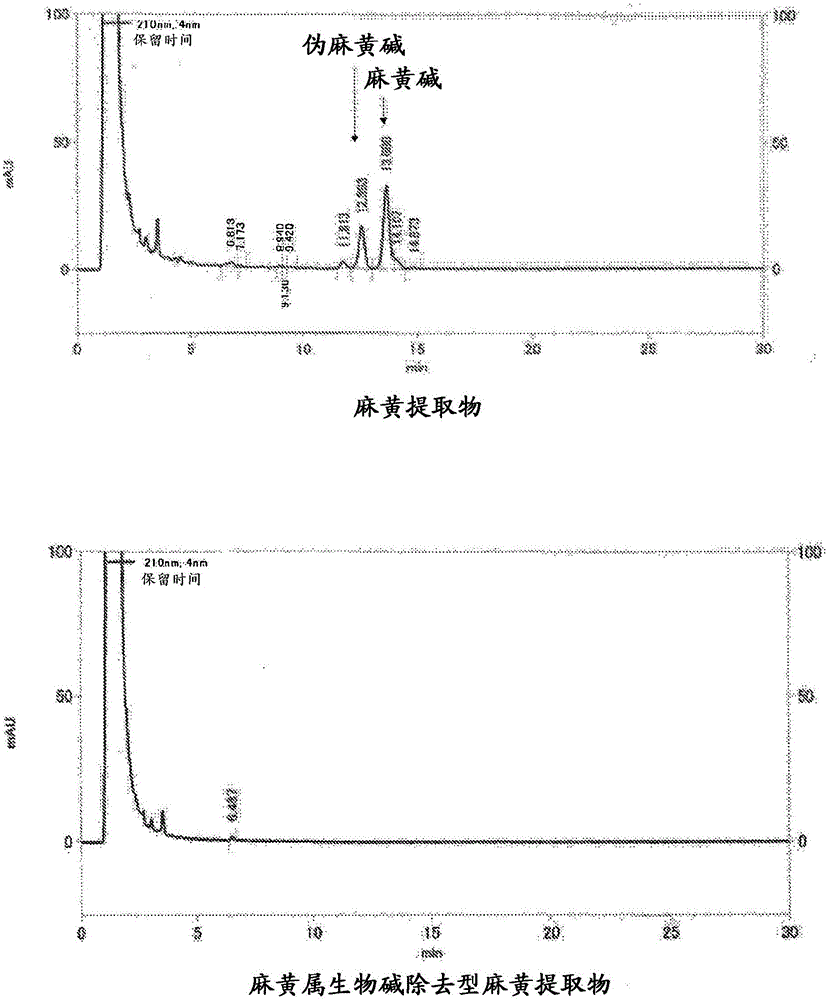

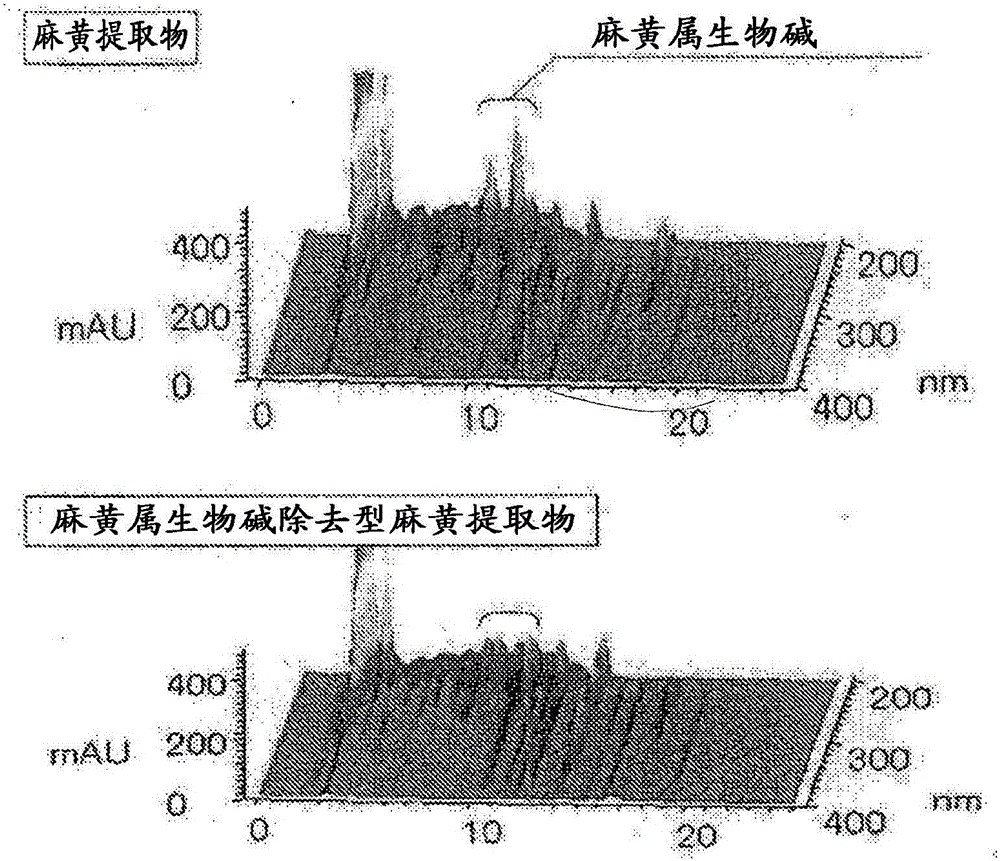

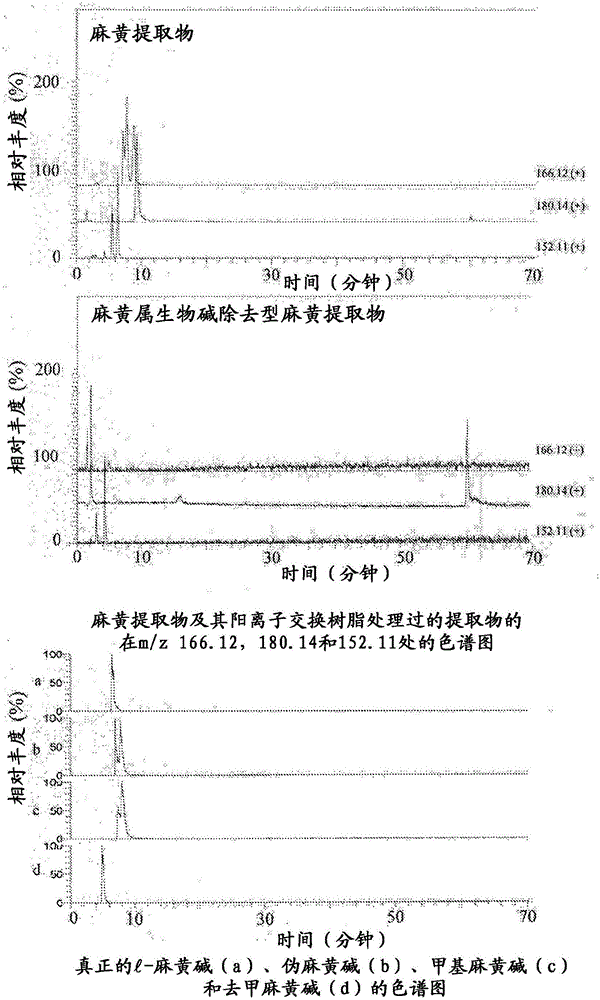

Ephedra extract stripped of ephedrine alkaloids, method for producing same and use of same

ActiveCN105744941AThe preparation method is simple and effectiveInhibition of analgesic effectNervous disorderAntipyreticEphedra Sinica ExtractEphedrine

Provided is an ephedra extract stripped of ephedrine alkaloids, i.e., an ephedra extract from which ephedrine alkaloids have been removed, and a method for producing an ephedra extract stripped of ephedrine alkaloids. Also provided are an antineoplastic / antimetastatic agent, a pain inhibitor, and an anti-influenza virus drug that include said ephedra extract as an active ingredient.

Owner:TOKIWA PHYTOCHEM +2

Heat reversible crosslinking polyvinyl chloride (PVC) cable material and preparation method thereof

ActiveCN102924847BImprove thermal stabilityImprove heat resistancePlastic/resin/waxes insulatorsPlasticizerAntioxidant

The invention relates to a heat reversible crosslinking polyvinyl chloride (PVC) cable material and a preparation method thereof. The PVC cable material is prepared by the following components by weight: 100 parts of PVC resin, 2-4 parts of stabilizer, 10-40 parts of plasticizer, 10-50 parts of inorganic filler, 0.5 part to 5 parts of heat reversible crosslinking agent, 0.5 part to 2 parts of lubricant, 0.2 part to 2 parts of antioxidant and 10-30 parts of fire retardant. The preparation method of the PVC cable material includes process steps such as dosing, high speed blending, extrusion pelleting and drying. Compared with the prior art, the cable material has the advantages of adopting a special crosslinking agent capable of generating heat reversible crosslinking to be blended with PVC, utilizing active chlorine on a PVC chain to react to trigger covalence crosslinking of the PVC, improving heat stability and heat resistance of a PVC cable and maintaining prior thermal plasticity.

Owner:内蒙古亿利化学工业有限公司

A method for preparing ultrafine antimony oxides by solution atomization

ActiveCN105858724BSimple processShort manufacturing processAntimony oxides/hydroxides/oxyacidsNonferrous metalSmelting process

The invention discloses a method of using a solution atomization method to prepare superfine Sb oxide. The method comprises the following steps: (1) trivalent Sb is added into a hydrochlric solution to prepare a Sb solution with the molar concentration of 0.05-0.8 mol / L; (2) clean oxidant is used to oxidize the solution obtained in step (1), and a pentavalent Sb solution is obtained; (3) Sb oxide powder is obtained after spray pyrolysis of the pentavalent Sb solution is obtained in step (2). According to the invention, trivalent Sb solution is used as a raw material, superfine Sb oxide powder materials are directly prepared through oxidization and spray pyrolysis, and the technological process is simple. Alternatively, lixivium from the conventional process of using an acid method in antimony smelting is directly used as the raw material. Therefore, the process of preparing the superfine Sb oxide powder materials is shortened; the conventional metallurgical process and the material preparation process are effectively combined; added value of products from conventional non-ferrous metal metallurgy is significantly increased; recycling of hydrochloric acid from lixivium is realized.

Owner:CENT SOUTH UNIV

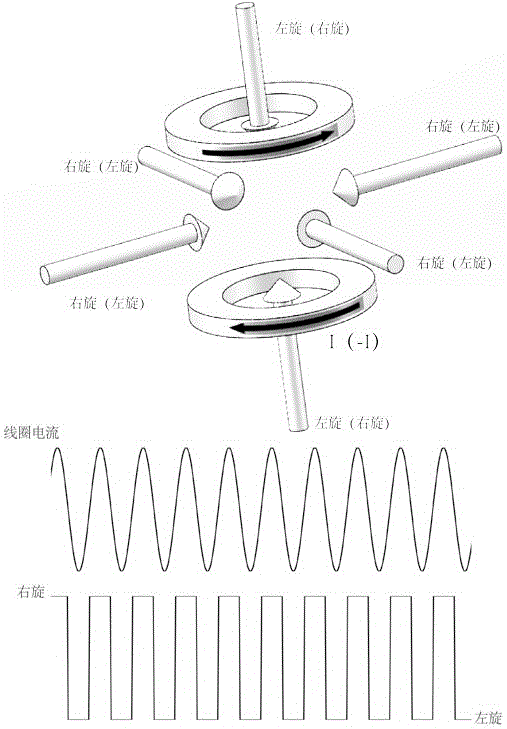

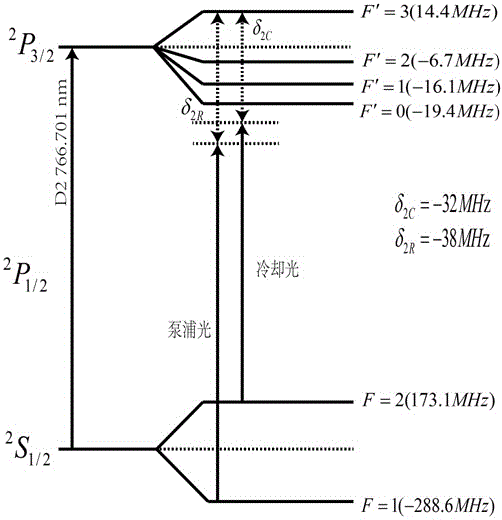

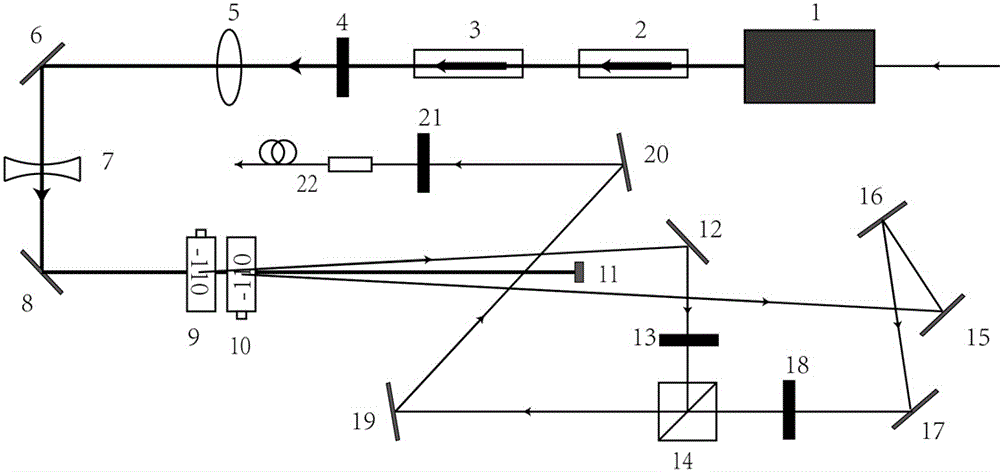

Preparation method of alternating current magneto-optical trap

InactiveCN106653137AThe preparation method is simple and effectiveWide operating frequencyLaser detailsRadiation/particle handlingIonPhysics

The present invention belongs to the atom and molecule optics technology field, and concretely discloses a preparation method of an alternating current magneto-optical trap. Sinusoidal signals are employed to modulate the inverted Helmholtz coil current to generate an alternating magnetic field. Two acoustic optical modulators disposed back to back, a half-wave plate and a polarization beam splitter are employed to realize the rapid conversion of the laser trapping polarization configuration. The raid switching laser features of the acoustic optical modulators are employed to realize the laser beam polarization configuration switching of more than 10MHz and coordinate with a direct current and radio-frequency circuit to realize the magneto-optical trap from a quasi state (DC) to 10MHz polarization / magnetic field switching frequency. The preparation method of the alternating current magneto-optical trap is simple and efficient and wide in work frequency, can satisfy the technical requirement of each aspect such as the ultracold ion preparation and molecule cooling, and can be widely applied to the quantum optics field in the cold molecule and the nonmagnetic condition.

Owner:FUDAN UNIV

Bending-resistant multi-mode fiber

ActiveCN101840023BAvoid internal stressReduce macrobending additive attenuationGlass optical fibreOptical fibre with multilayer core/claddingFiberRefractive index

The invention relates to a bending-resistant multi-mode fiber used in an access network or a miniature optical device. The bending-resistant multi-mode fiber comprises an optical fiber and a coating coated on the outer surface of the optical fiber, wherein the fiber consists of a quartz glass core layer which has a section structure with a parabolic shape or step-type refraction index and a quartz glass cladding which surrounds the core layer. The optical fiber is characterized in that: the core layer has a diameter of between 20 and 200 mu m and consists of a germanium-and-fluorine-doped quartz glass material; and double solidified polymer coatings are coated out of the cladding, wherein an inner coating coated on the outer surface of the cladding is a low-refraction index flexible polymer coating while an outer coating is a high-Young's modulus polymer coating. Because of the design of the low-refraction index inner coating, an internal stress of the optical fiber is avoided, the mechanical performance of the optical fiber is greatly improved, and the use performance and the service life of the optical fiber working in a small-radius bending state are ensured. The bending-resistant multi-mode fiber has high bending-resistant performance; and at a wavelength of 850 nm, the additional attenuation of the bending caused by winding 1 circle with a bending radius of 10 mm is less than or equal to 0.15 dB. The bending-resistant multi-mode fiber has the characteristic of simple, convenient and effective manufacturing method, and is suitable for large-scale production.

Owner:EVERPRO TECH COMPANY

A seven-core small-diameter single-mode optical fiber and its manufacturing method

ActiveCN109061793BImprove waveguide transmission conditionsReduce additional lossOptical fibre with multilayer core/claddingGlass fibre drawing apparatusEngineeringExternal cladding

The invention relates to a seven-core small-diameter single mode fiber. The seven-core small-diameter single mode fiber comprises seven single-mode fibers having the same core cladding structure, wherein the seven fibers combined together closely, one fiber located at the center of the fibers, and the other six fibers surround the periphery of the center fiber; the single-mode fiber comprises a core layer and a cladding layer, the cladding layer comprises an inner cladding layer, a sunken cladding layer and an external cladding layer from the inside to the outside, radius r4 of the external cladding layer is 20-25 microns, ratio r4 / r1 of the radius of the external cladding layer to the radius of the core layer is 5.1-5.5, ratio r4 / r2 of the radius of the external cladding layer to the radius of the inner cladding layer is 2.4-2.8, and ratio r4 / r3 of the radius of the external cladding layer to the radius of the sunken cladding layer is 1.6-2.0. With the fiber provided by the invention,external diameter of the multi-core fiber is reduced greatly, and communication capacity density of unit cross section of the fiber is improved remarkably; consequently, space resource for paving pipelines is reduced; meanwhile, signal crosstalk influence among different fiber units is eliminated. The fiber provided by the invention has excellent comprehensive performance parameters, such as wavelength, mode field, attenuation and chromatic dispersion, in application wavebands, has microbending loss which is small enough. The fiber provided by the invention can be produced through a simple and convenient manufacturing method and needs low manufacturing cost.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com