Patents

Literature

149results about How to "Internal stress relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-bending multimode fiber and manufacturing method thereof

ActiveCN101634728AReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

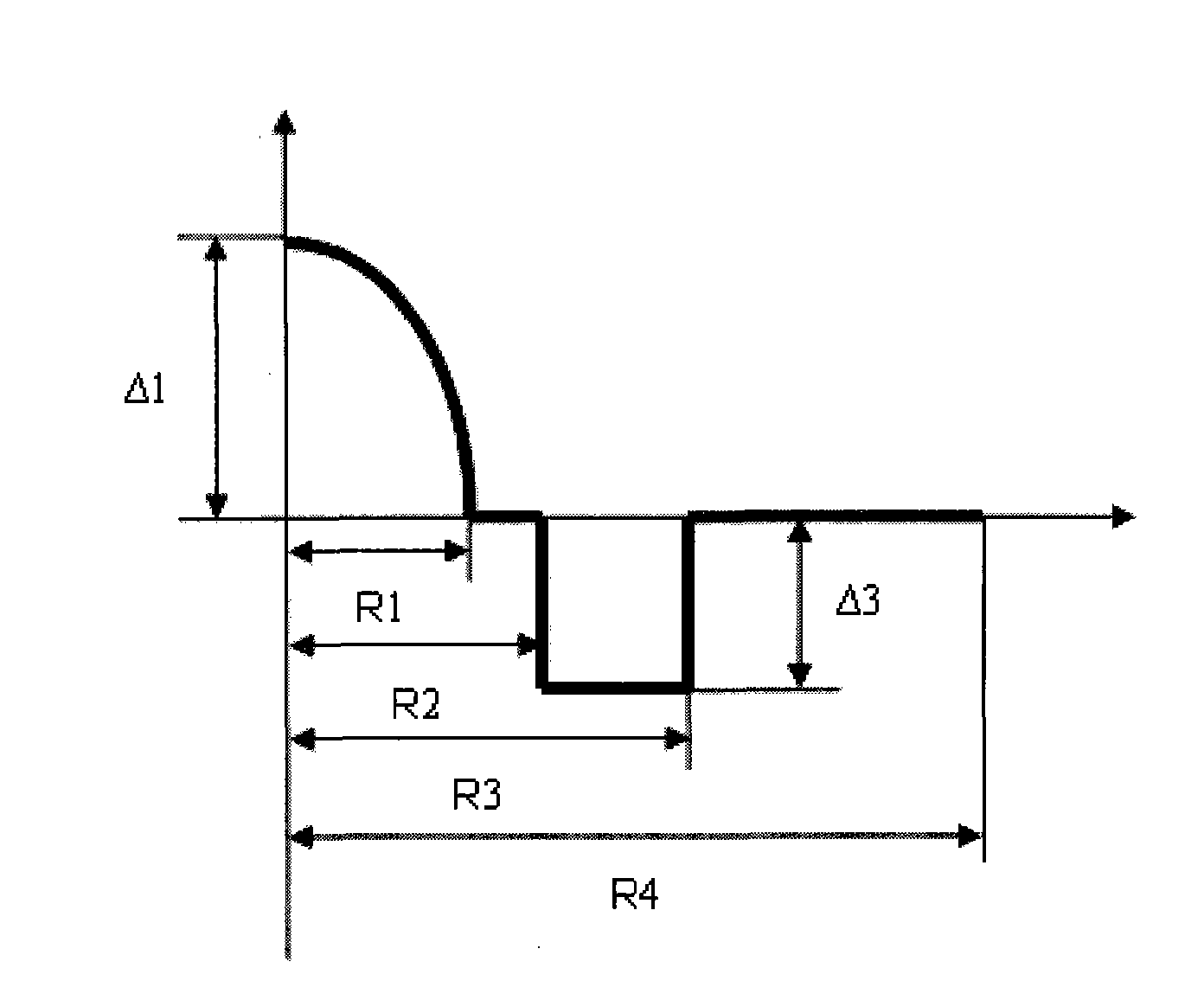

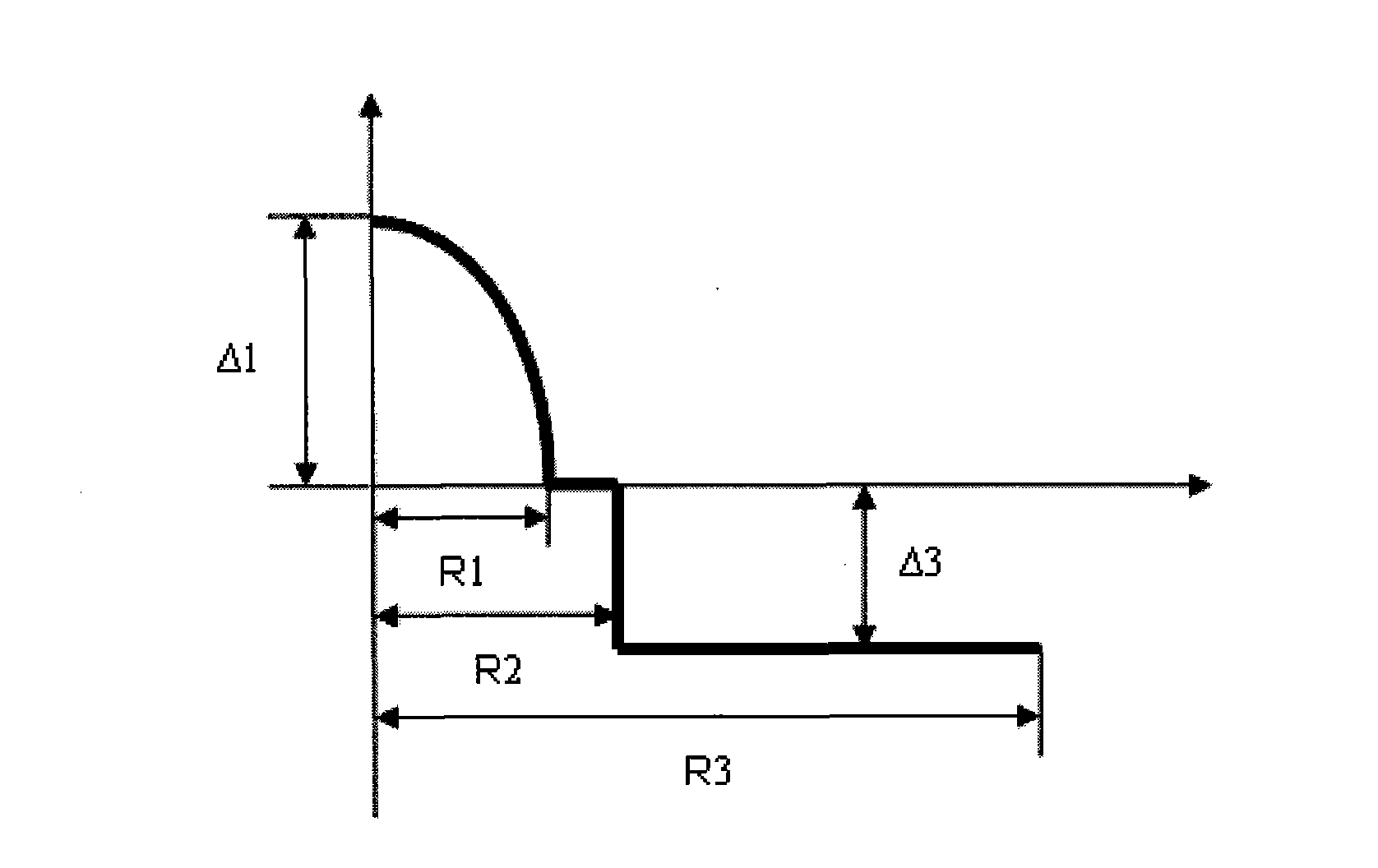

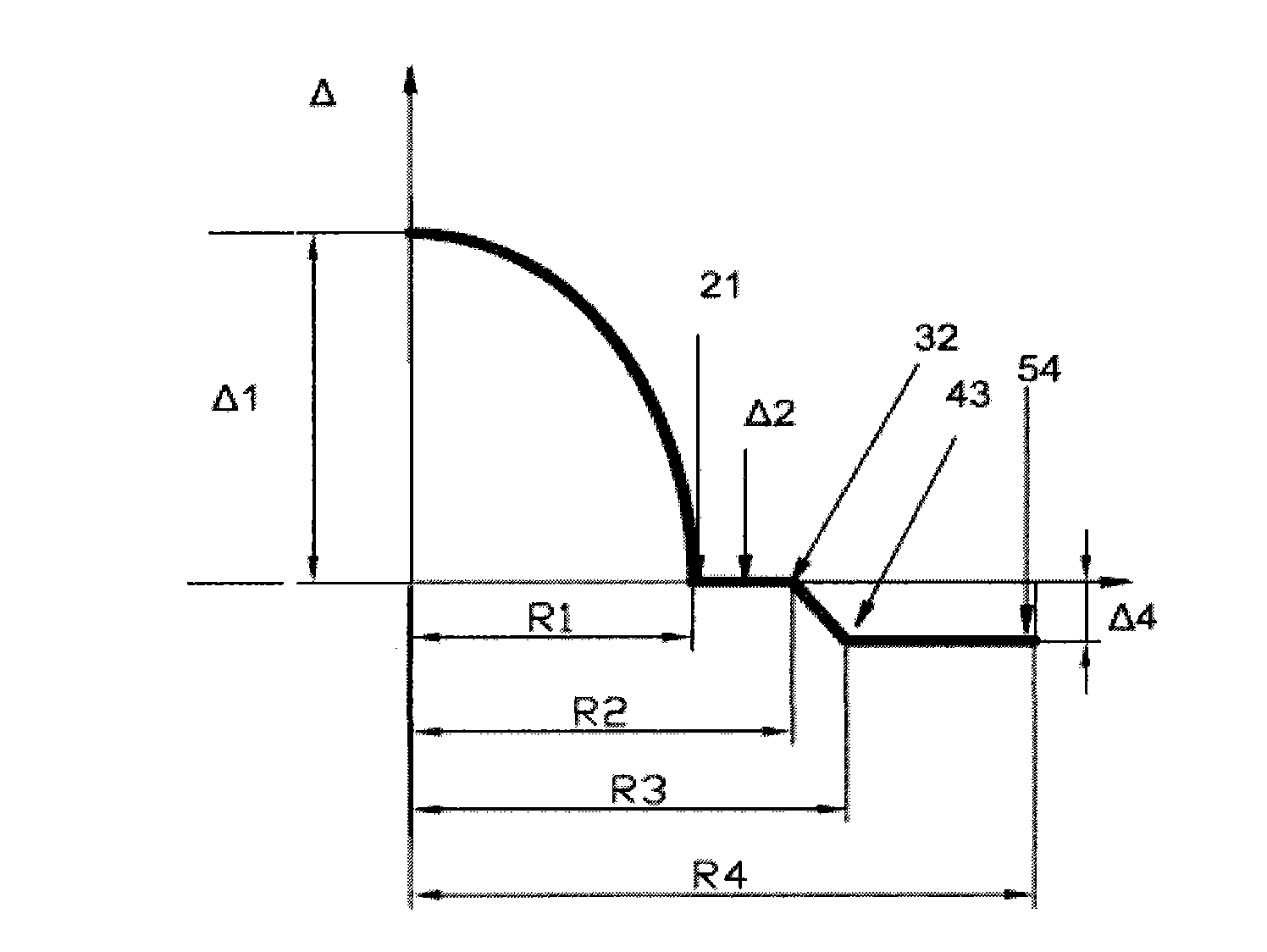

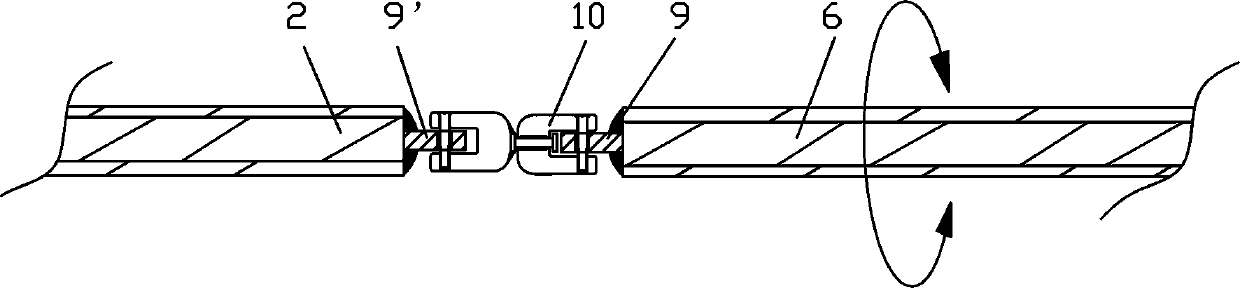

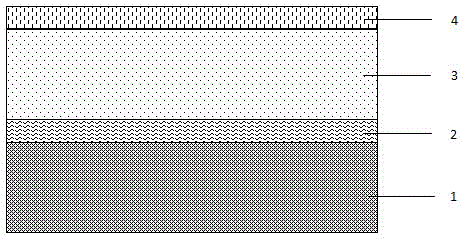

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

Method for replacing crane steel wire ropes

The invention provides a method for replacing crane steel wire ropes. The method comprises the following steps that (a), a lifting hook is seated on the ground, and each of the two sides of the lifting hook is provided with a steel wire rope cylinder of a new steel wire rope; (b), a winch mechanism drives a steel wire rope winding drum to rotate to release old steel wire ropes; (c), two steel wireropes between a steel wire rope balance frame and the lifting hook are cut off, and connecting steel rings are installed on the end surfaces of the old steel wire ropes and the new steel wire ropes;(d), a steel wire rope connecting buckle is used for connecting the new steel wire ropes and the old steel wire ropes, the steel wire rope connecting buckle comprises a fixing buckle and a rotating buckle, the fixing buckle is connected with the new steel wire rope connecting steel ring, and the rotating buckle is connected with the old steel wire rope connecting steel ring; (e), the winch mechanism is driven to enable the old steel wire ropes to pull the new steel wire ropes to pass through a lifting hook pulley, namely a fixed pulley, for a plurality of circulations until the new steel wireropes are pulled to the position of the steel wire rope winding drum; and (f), the steel wire rope connecting buckle is disassembled, the rope head of the new steel wire rope steel ring is cut off, the rope heads of the old steel wires are put down to the ground, at the moment, the old steel wire ropes are completely detached from the winch system, and the new steel wire ropes are guided into thewinch system.

Owner:BAOSHAN IRON & STEEL CO LTD

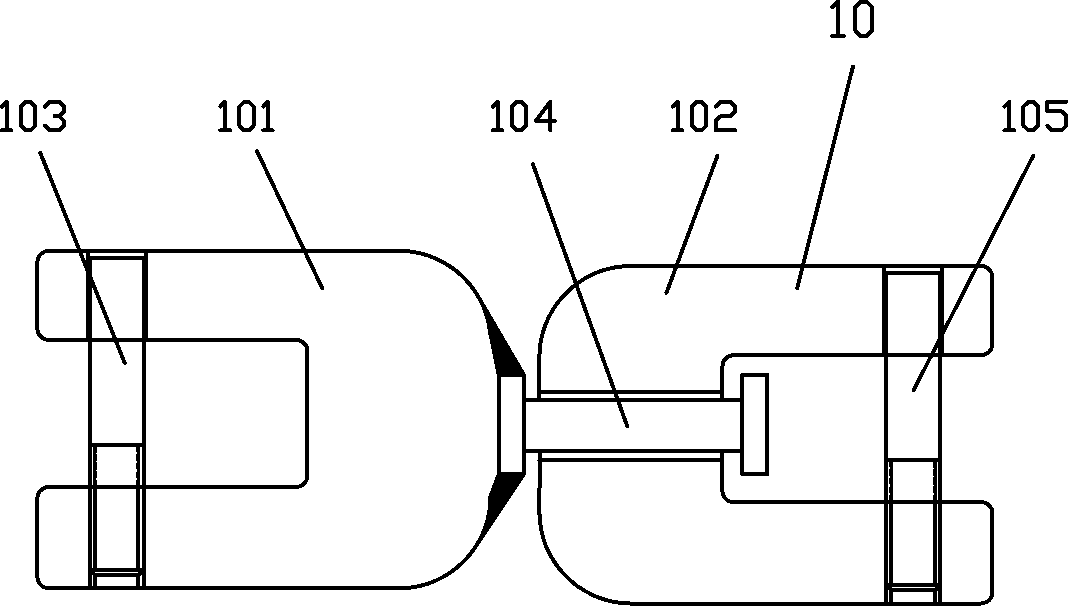

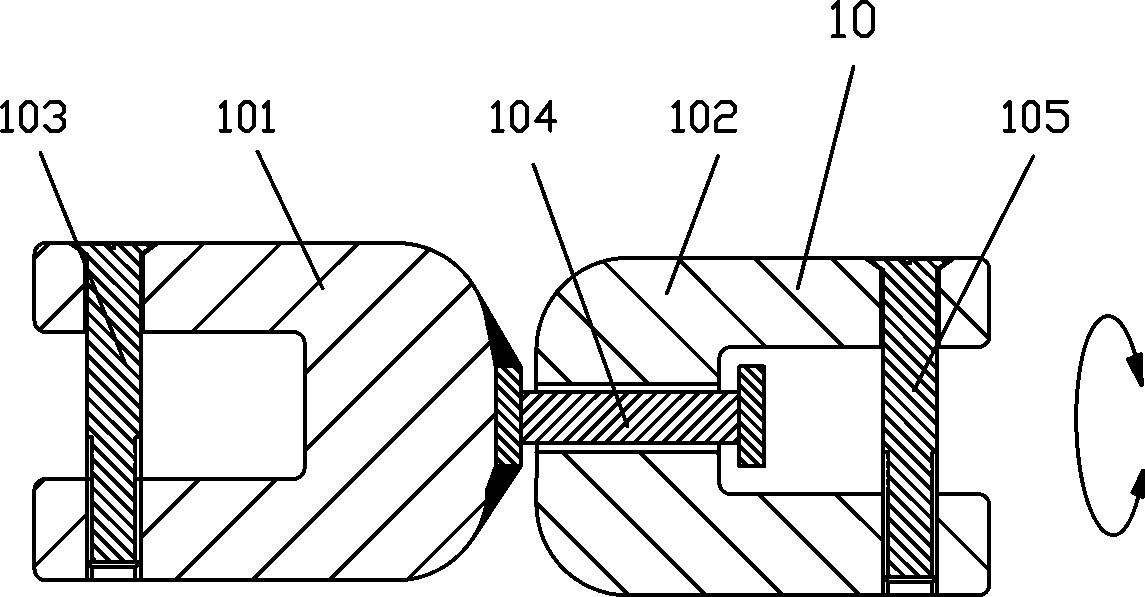

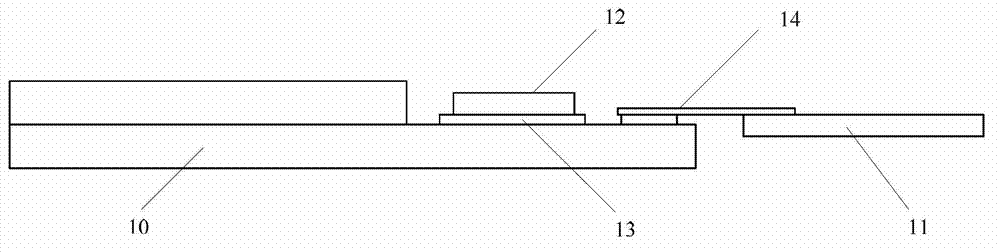

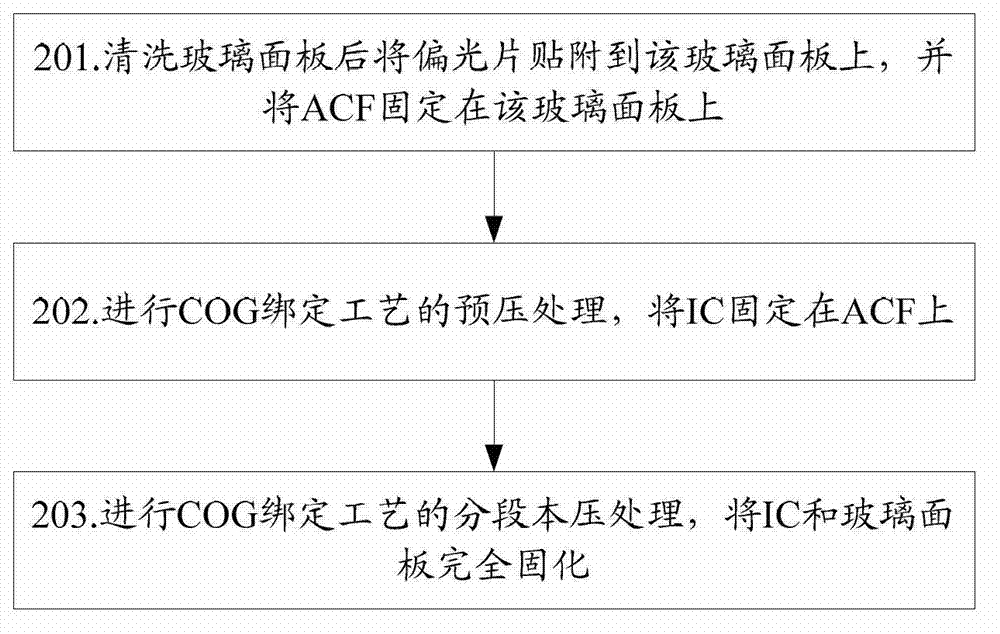

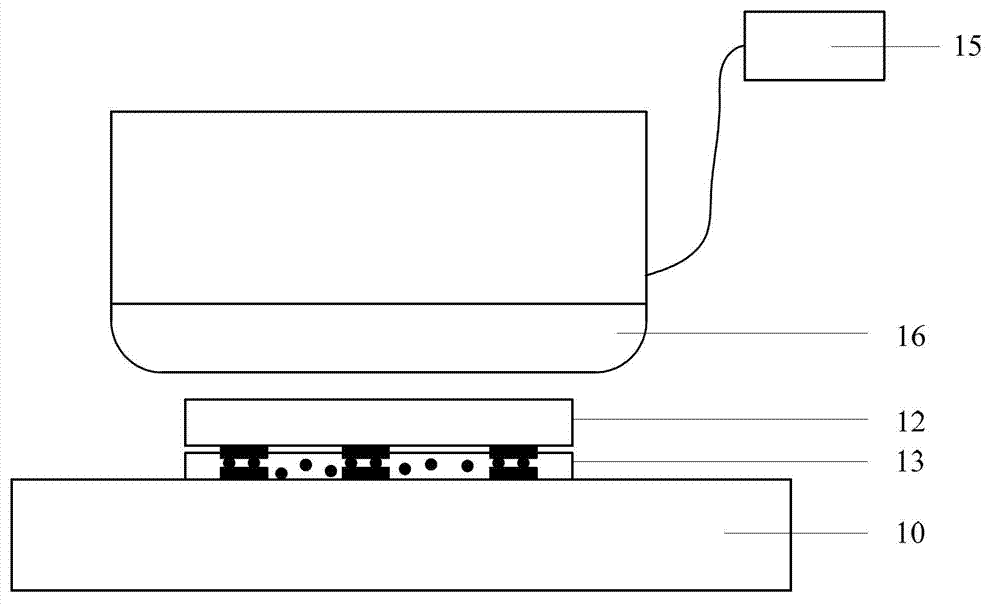

COG (Chip On Glass) bonding method and temperature control device

InactiveCN103592785AInternal stress reliefReduce crackingTemperature control using electric meansNon-linear opticsTemperature controlAnisotropic conductive adhesive

The invention discloses a COG (Chip On Glass) bonding method. The COG bonding method comprises attaching a Polaroid to a glass panel after the glass panel is cleaned and fixing an ACF (Anisotropic Conductive adhesive Film) on the glass panel; performing the pre-bonding treatment of the COG bonding process and fixing an IC (Integrated Circuit) on the ACF; performing the segment main bonding treatment of the COG bonding process and performing the complete curing on the IC and the glass panel. The invention also provides a temperature control device. According to the technical scheme of the COG bonding method and the temperature control device, the process of the COG bonding process is achieved through the segment main bonding process and accordingly the IC and the glass panel can have the same swelling amount and accordingly the badness can be avoided.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

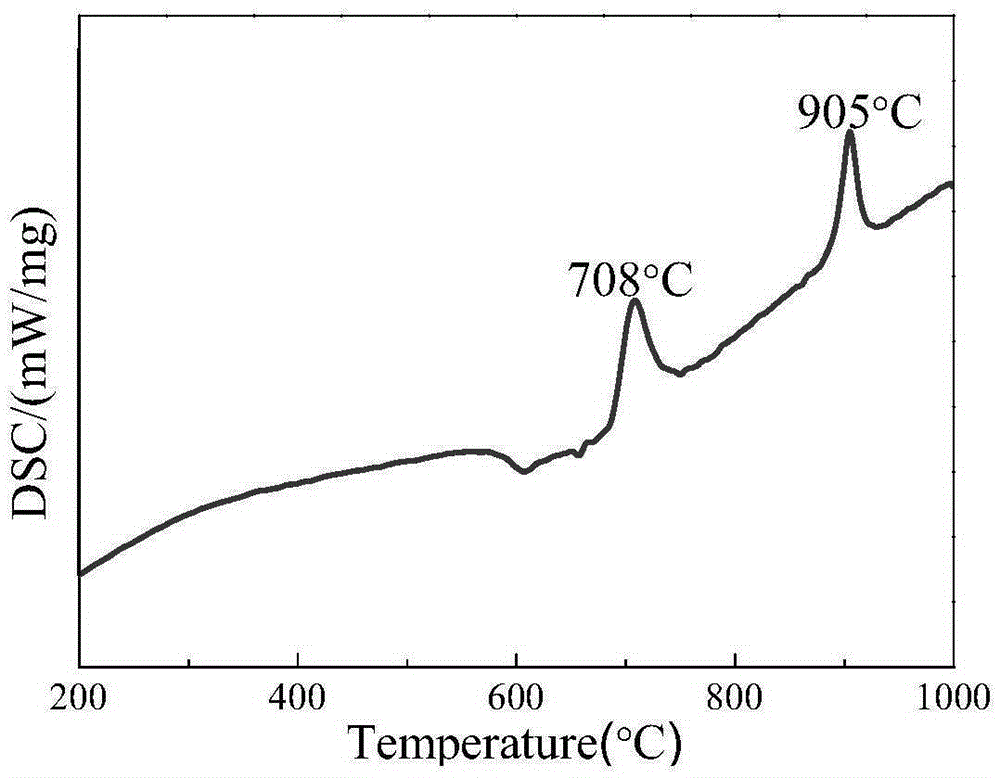

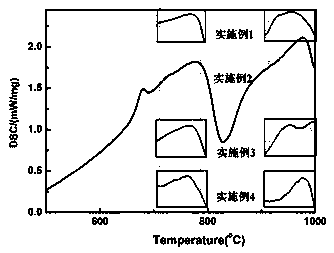

K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and preparation method thereof

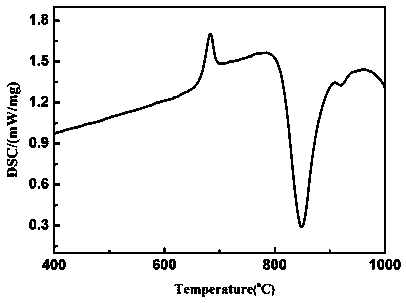

The invention relates to a K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and a preparation method thereof. The method comprises the following steps: mixing K2CO3, Na2CO3, Nb2O5, SiO2, H3BO3 and BaF2 according to a molar ratio of 15:15:30:4.2:(2-5), fusing, molding, annealing, and crystallizing to prepare the material. Alkali metal oxides in raw materials exist in the glass system as a network modifier to destroy the network structure of glass, so the formula of the glass is simplified, the cost is reduced, and the quantity of kinds of precipitated impure phases is fundamentally reduced; a fusion technology is adopted, so the raw materials highly and uniformly react, and the experiment operation is simple; annealing can effectively eliminate internal stress; and segment heat insulation is adopted in the crystallization treatment process, so a crystal phase completely grows, crystal precipitation is thorough, and obtaining of glass ceramic with fine internal crystal grins, high homogenization degree and high energy storage density is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

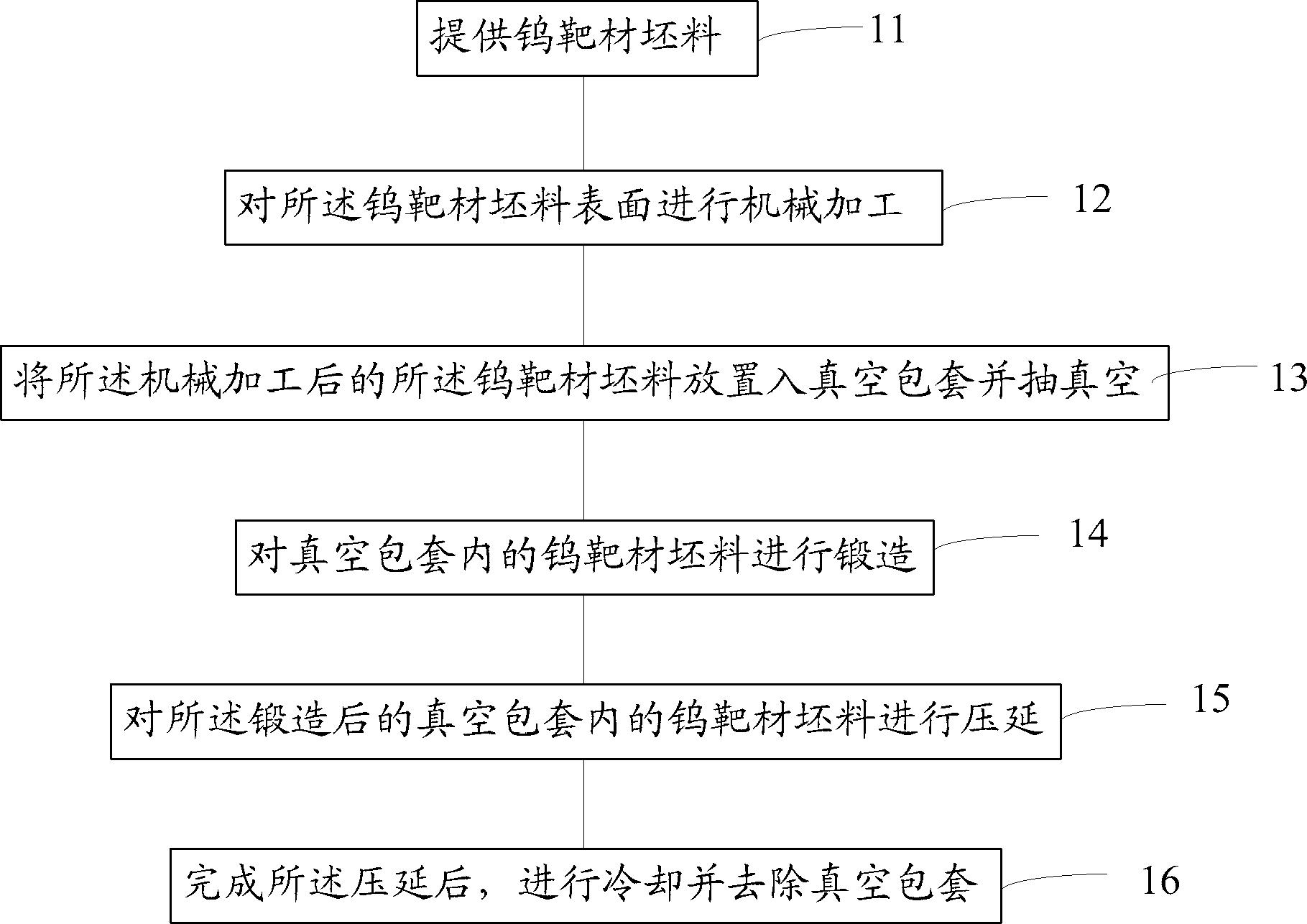

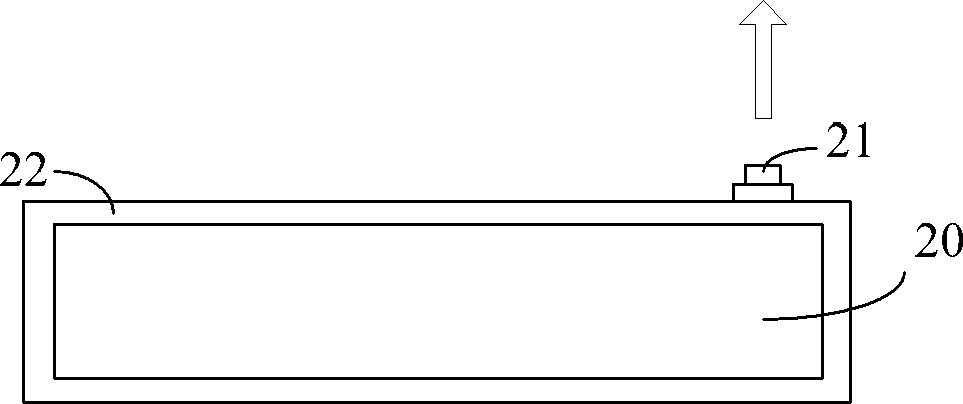

Manufacturing method of tungsten target material

ActiveCN102513789AAvoid crackingUniform structureVacuum evaporation coatingSputtering coatingMachiningTungsten target

A manufacturing method of a tungsten target material includes the steps of providing tungsten target blank, machining the surface of the tungsten target blank, placing the machined tungsten target blank in a vacuum sheath and vacuumizing, forging the tungsten target blank in the vacuum sheath, rolling the forged tungsten target blank in the vacuum sheath, cooling and removing the vacuum sheath after rolling. The manufacturing method of the tungsten target material does not require a mould, resolves the problems that cracks exist in rolling and extending the tungsten target blank and the surface of the tungsten target blank is prone to oxidation, is capable of manufacturing the tungsten target material which has uniform internal organization structure and meets the requirement of a sputtering target material for grain size. In addition, the manufacturing method of the tungsten target material has the advantages of being easy to machine and low in rejection ratio. The manufacturing method is more suitable for manufacturing the large-sized tungsten target material.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

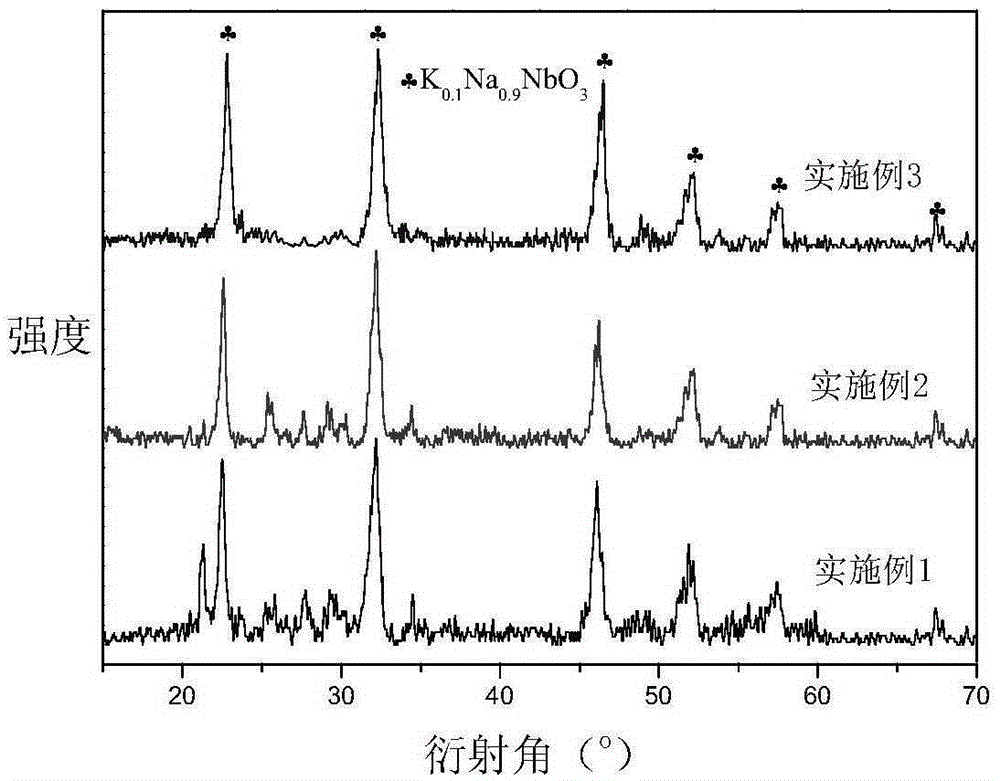

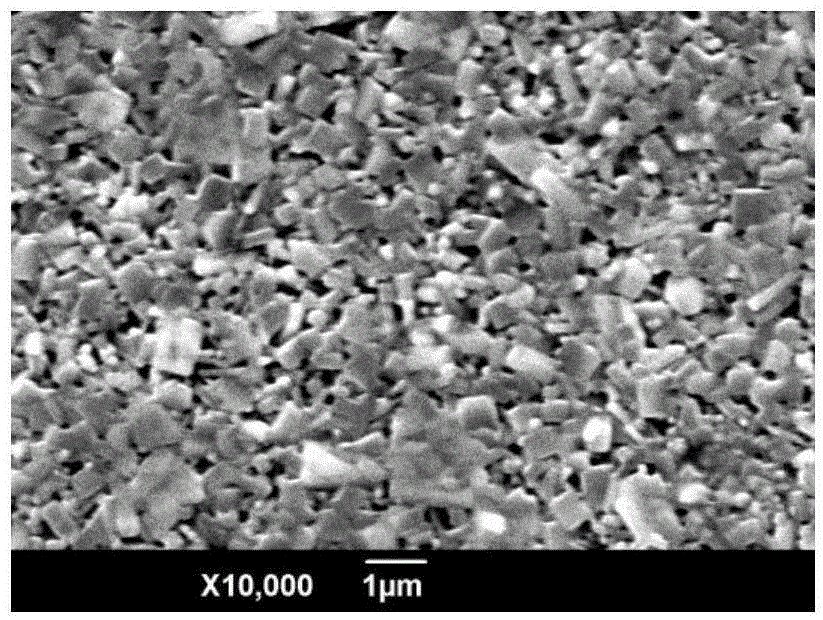

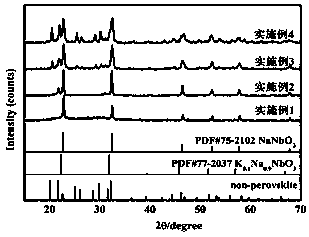

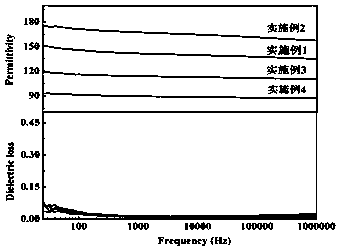

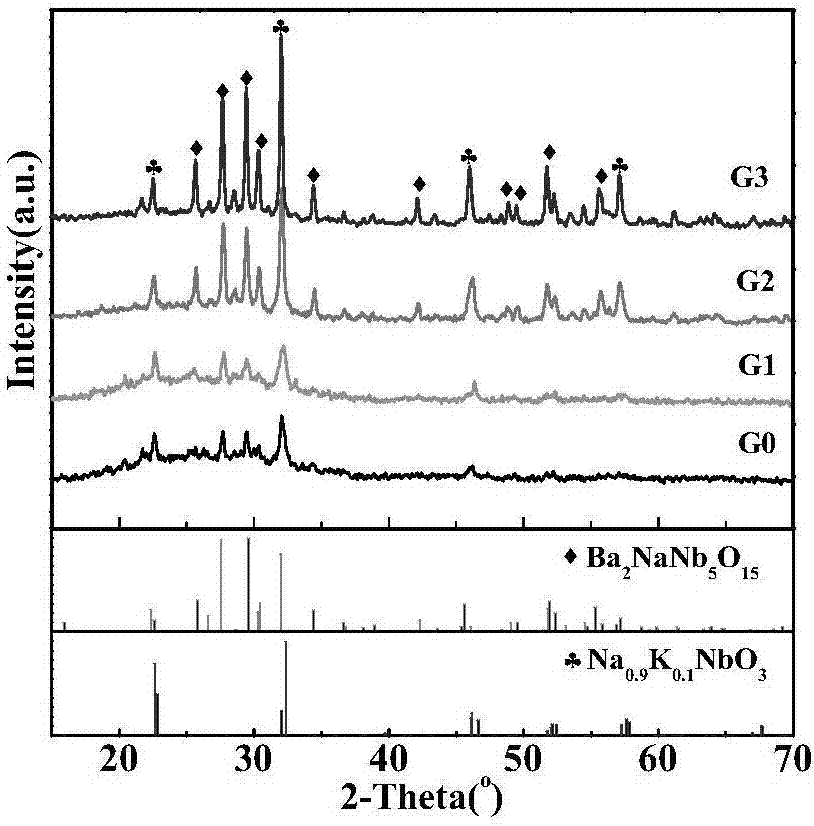

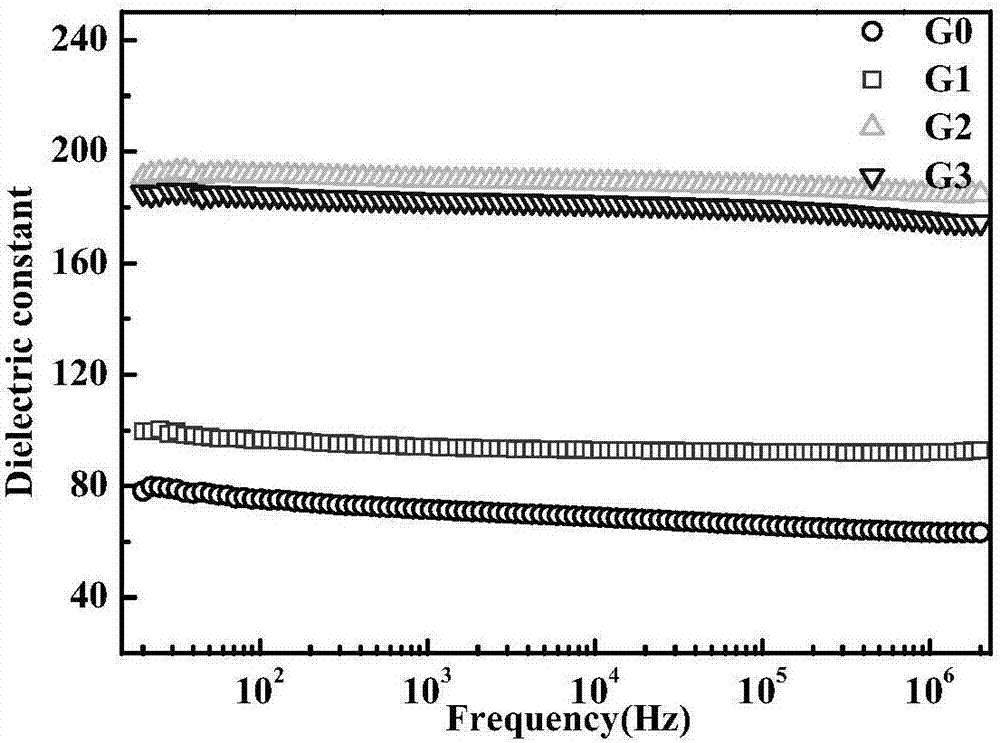

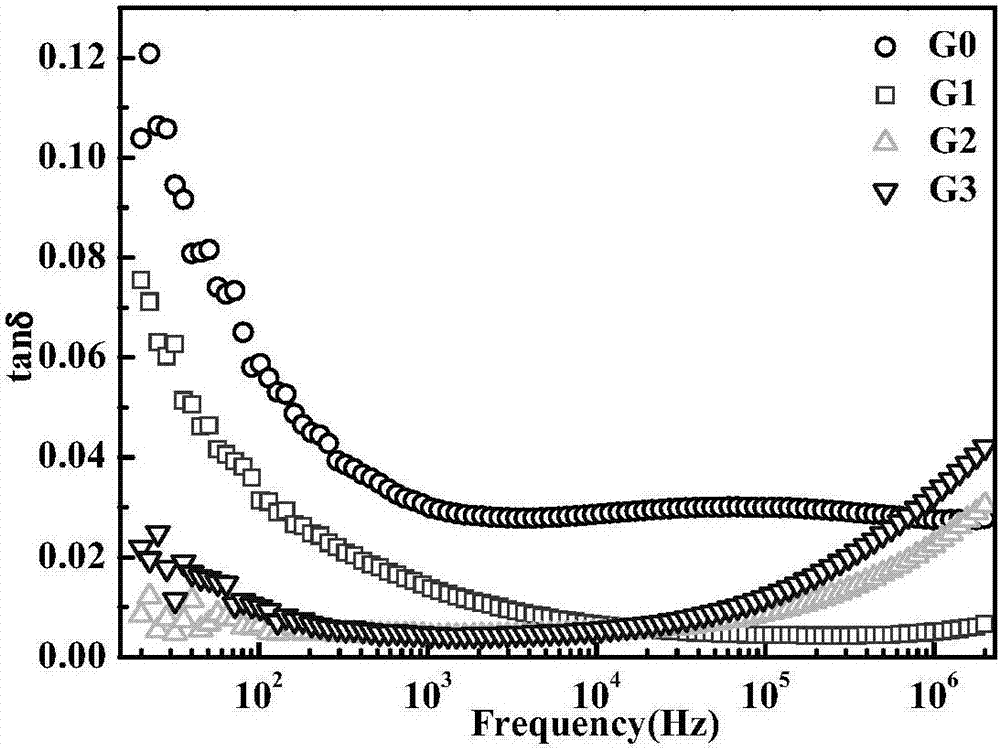

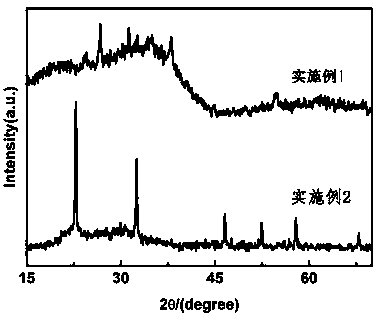

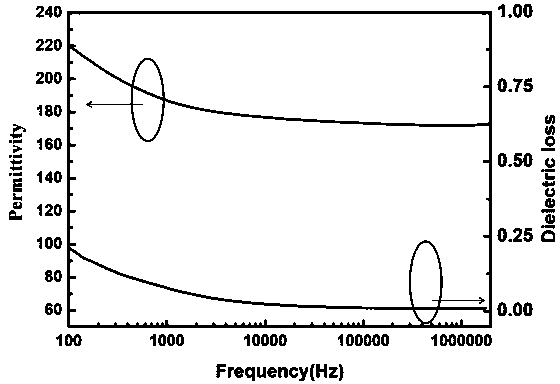

NaNbO3 phase containing Na2O-K2O-Nb2O5-SiO2 low dielectric loss energy storage glass ceramic

The invention relates to a NaNbO3 phase containing Na2O-K2O-Nb2O5-SiO2 low dielectric loss energy storage glass ceramic material, the microcrystal glass material is prepared by mixing a glass phase and a crystal phase, fusing, cooling and molding, annealing, and conducting crystallization heat treatment; wherein the glass phase accounts for 20% according to mole percent, and the balance is the crystal phase; the crystal phase is prepared by heating and fusing Na2CO3, K2CO3 and Nb2O5 at the molar ratio of x:(1-x):1, wherein x is more than or equal to 0.7 and less than or equal to 1. The dielectric loss of the prepared potassium-sodium niobate based energy storage microcrystal glass material is low; the added Na2CO3 not only has an effect on regulating the composition of the crystal phase ofa potassium-sodium niobate system, but also has a certain effect on promoting the crystallization process, the NaNbO3 phase favorable for the high energy storage density is formed, and the high energy storage density glass ceramic material is finally obtained.

Owner:SHAANXI UNIV OF SCI & TECH

Method for repairing lining plate-free flat-head cap of spindle of rolling mill

InactiveCN101890609AGuaranteed automatic controlQuality assuranceRolling mill drivesLaser beam welding apparatusAutomatic controlStress relief

The invention discloses a method for repairing a lining plate-free flat-head cap of a spindle of a rolling mill, which comprises the following steps of: performing stress relief annealing on the lining plate-free flat-head cap to eliminate internal stress, performing induction annealing on a flat potential surface to reduce hardness and tempering the flat potential surface in 2 hours; checking to determine the thickness of a fatigue layer of the flat potential surface and performing dye check to determine that cracks are not generated at all; machining to remove the fatigue layer of the flat potential surface, and performing dye check again to determine that cracks are not generated at all; and performing laser cladding on the flat potential surface by adopting gas-atomized nickel-based alloy powder to ensure that a binding layer of a laser cladding layer and a base body matrix has the mechanical strength of over 90 percent of that of the base body and the hardness of 35HRC, machining the cladding layer into the size matched with that of the spindle of the rolling mill, and performing dye check to determine that the flat potential surface is not damaged. The method can repair failed lining plate-free flat-head cap, recover the effect of the lining plate-free flat-head cap, ensure the automatic control and finished product quality of the rolling mill, reduce maintenance cost, and prolong the service life of the lining plate-free flat-head cap.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

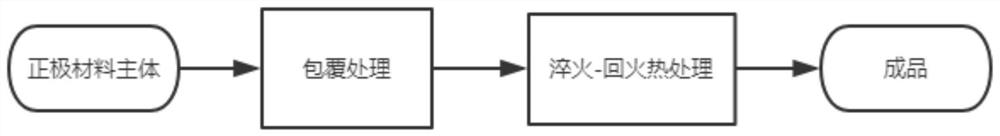

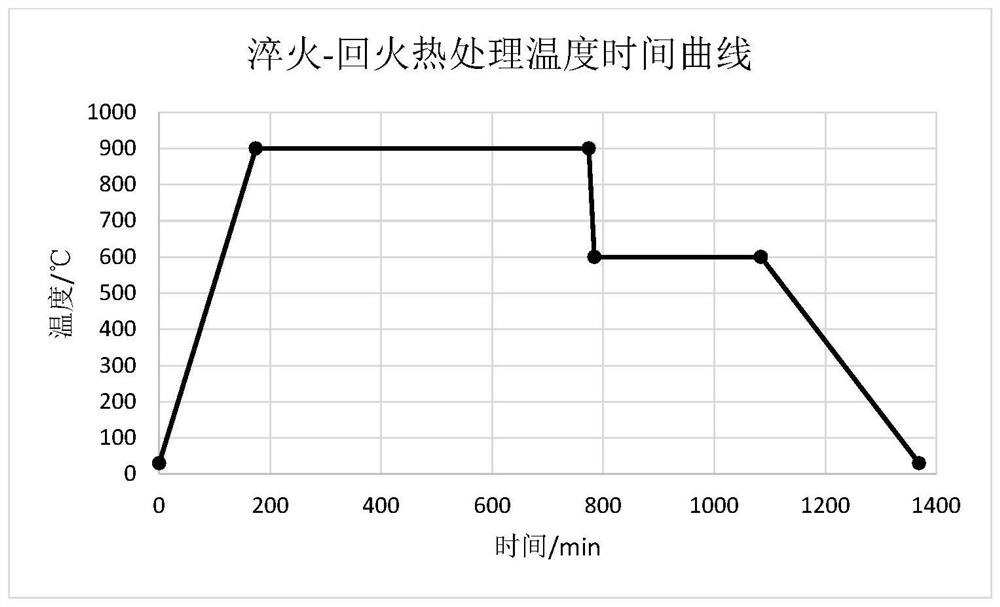

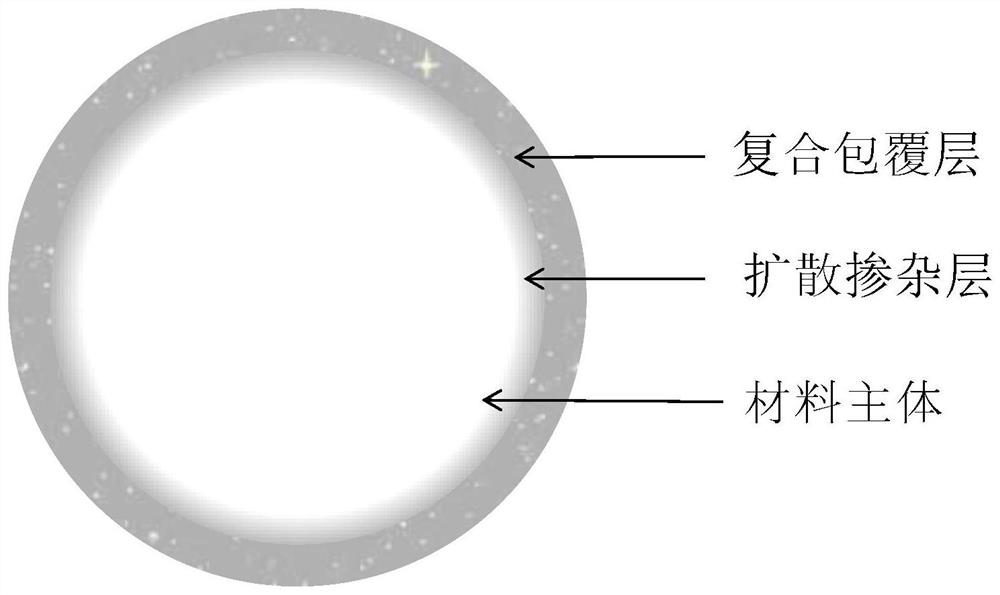

Fluoride/oxide co-coated positive electrode material and preparation method thereof

ActiveCN112151798AGood chemical stabilityImprove electrochemical stabilityElectrode thermal treatmentPositive electrodesIonic diffusionPhysical chemistry

The invention provides a fluoride / oxide co-coated positive electrode material which comprises a positive electrode material main body, a composite coating layer and a diffusion doping layer, and is characterized in that the composite coating layer is a continuous coating film formed by uniformly coating the surface of the positive electrode material main body with oxyfluoride; and the diffusion doping layer is formed by diffusing partial metal element ions in the composite coating layer to the surface layer of the positive electrode material main body. The invention also provides a preparationmethod of the fluoride / oxide co-coated positive electrode material. The positive electrode material provided by the invention has relatively good cycling stability, storage life, high-temperature performance and safety performance under high voltage.

Owner:常州苏锂科技有限责任公司

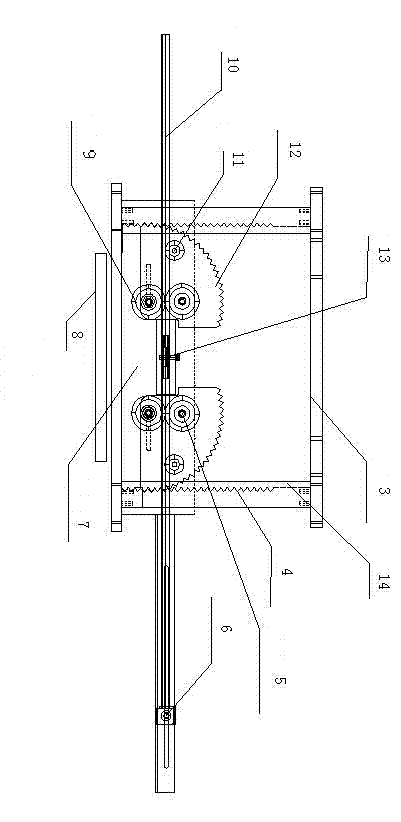

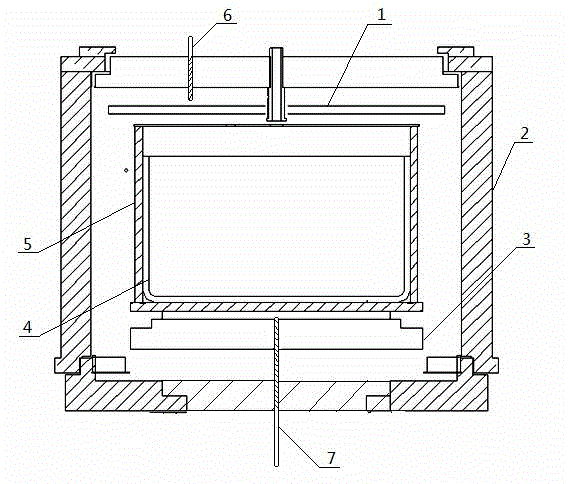

Precise U-shaped bending die for magnesium alloy sectional materials

ActiveCN102950207AGuaranteed uniform speedEnsure balanceShaping toolsMaterials scienceMagnesium alloy

A precise U-shaped bending die for magnesium alloy sectional materials is mainly used for processing the magnesium alloy sectional materials. The die comprises an upper die frame and a lower die plate and is characterized in that the rectangular upper die frame consists of an upper crossbeam plate, a lower crossbeam steel pad and two precisely feeding racks, wherein the upper crossbeam plate and the lower crossbeam steel pad are horizontally arranged, the precisely feeding racks are vertically arranged as vertical sides, and the precisely feeding racks are connected to the upper crossbeam plate and the lower crossbeam steel pad; retaining plates are embedded on the outer sides of the precisely feeding racks, grooves are formed between the precisely feeding racks and the retaining plates, and rotating gear discs can slide in the grooves and are meshed with the precisely feeding racks; and two adjustable support wheels, the rotating gear discs and a retainer are arranged on the lower die plate, and a guide wheel and a molding wheel are arranged on each rotating gear disc. The deformation and breakage problems of magnesium alloy are basically solved. Through the fine adjustment of a wheel gap, the gap accuracy of the sectional materials is increased by 50%, and the defective rate is reduced by 80%.

Owner:山西东银实业有限公司

Synchronous high pressure gas bulging forming method for large size titanium alloy double-layered cone member

The invention relates to a synchronous high pressure gas bulging forming method for a large size titanium alloy curvilinear generatrix double-layered cone member. High pressure thermal gas bulging forming is carried out on a double-layered cone blank at a special temperature, so that the curved shapes between the inner and outer cones are consistent, the fit clearance is small and a follow-up shape correcting step is not needed. The structure property is regulated then through insulating thermal treatment, the dimensional accuracy is prevented from being damaged by thermal treatment after forming, and the shape accuracy and the structure property are regulated integrally.

Owner:HARBIN INST OF TECH

Technology for manufacturing flat enamel-cover copper wire with large width-to-thickness ratio

ActiveCN107240464AHigh aspect ratioLarge aspect ratioFlat/ribbon cablesManufacturing wire harnessesManufacturing technologyCopper wire

The invention belongs to the conductive wire manufacturing field and more particularly, to a technology for manufacturing flat enamel-cover copper wire with a large width-to-thickness ratio. The invention aims to solve the technical problems that the flat enamel-cover copper with a large width-to-thickness ratio manufactured by the existing technology has a low uniformity and poor consistency, which compromises the overall conductivity and cannot meet the manufacturing requirement for the flat enamel-cover copper wire with a large width-to-thickness ratio. The manufacturing technology comprises the following steps: A) releasing and correcting straight the wire; B) squeezing to make a round wire; C) squeezing to make a flat wire I; D) squeezing to make a flat wire II; E) squeezing to make a flat wire III; F) cooling; G) performing ultrasonic cleaning; H) annealing; I) cleaning and baking; J) painting and baking; and K) cooling, attracting and collecting the wires. With the technology proposed by the invention, the manufacturing for a flat enamel-cover copper wire with a large width-to-thickness ratio can be realized easily so that the manufactured flat enamel-cover copper wire has better conductivity and consistency.

Owner:WELL ASCENT ELECTRONIC (GANZHOU) CO LTD

Packaging method for board level fan-out structures

ActiveCN104241153AGuaranteed quality and performanceIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingDeformation ProblemCopper foil

The invention relates to the technical field of electronic packaging, in particular to a packaging method for board level fan-out structures. The method includes the steps of copper foil pressing fit, chip surface mounting, medium layer pressing fit, blind hole manufacturing, circuit manufacturing, installed and welded layer pressing fit, ball attachment, stripping and others. According to the packaging method for the board level fan-out structure, two fan-out packaging structures are symmetrically designed on the upper side and the lower side of a core board, and in the manufacturing process, because the upper end and the lower end of the core board are symmetrically and evenly stressed, and a high-temperature annealing mode is adopted for eliminating internal stress before a first double-layer copper foil structure and a second double-layer copper foil structure are stripped, the problem of warping and other mechanical deformation problems will not occur, and the quality and performance of the fan-out structures are guaranteed. In addition, the packaging method for the board level fan-out structures can be used for manufacturing the two fan-out structures at the same time, and therefore production efficiency is improved.

Owner:北京中科微投资管理有限责任公司

Aluminum profile extrusion technology

InactiveCN107685086AInternal stress reliefNo Extrusion StreaksExtrusion control devicesAluminum extrusionMaterials science

The invention discloses an aluminum profile extrusion process, which is characterized in that the process is as follows: preheating: using a temperature gradient form of heating 85°C / 1 hour, heating the ingot cylinder to 380°C-420°C, according to the product Select the appropriate aluminum rod and put it into the ingot tube, heat the aluminum rod to 450-500°C in the form of 90°C / 1 hour gradient temperature, and keep it warm for 3-5 hours, choose a suitable mold, and heat the flat mold to 460°C ℃-480℃, heat up to 480-500℃ in separate molds, and keep warm for 4-6 hours.

Owner:田静

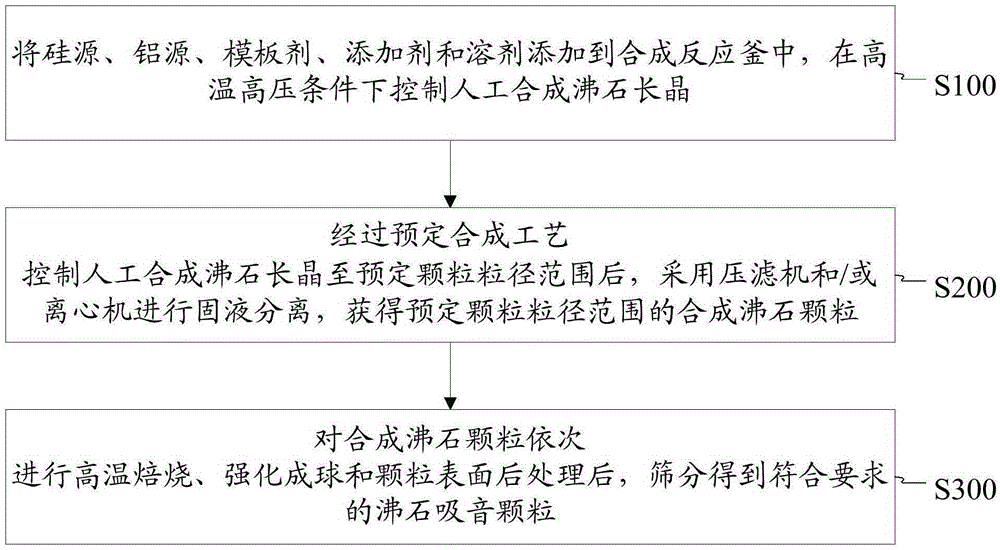

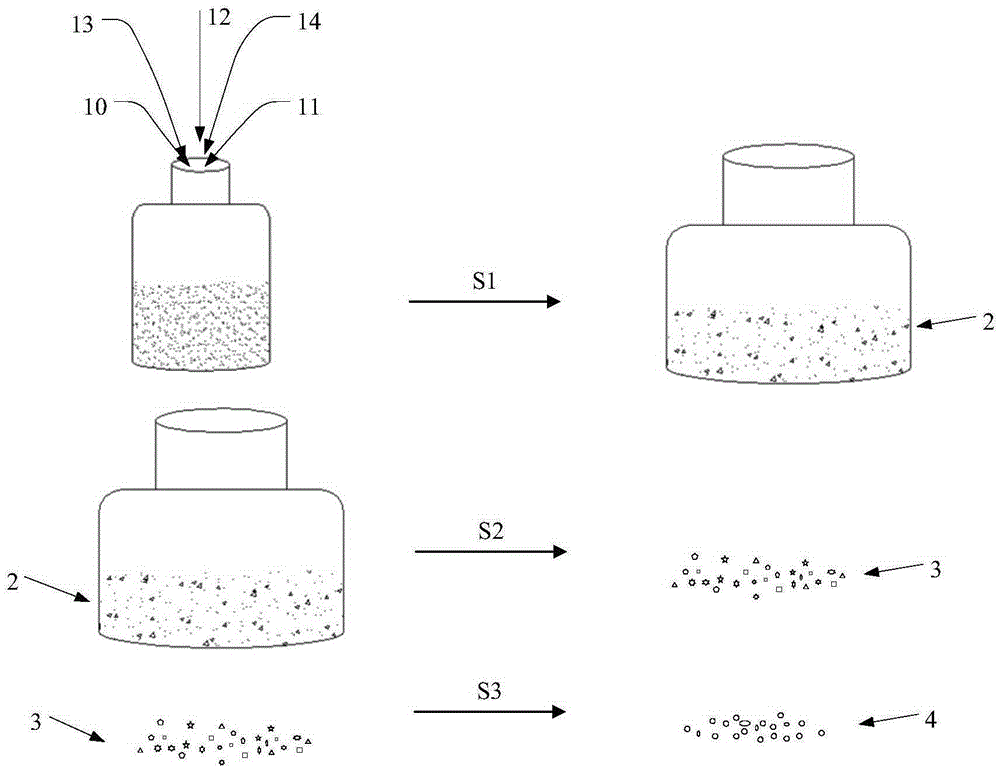

Sound absorption zeolite particle and synthesis and preparation method thereof

ActiveCN105347357AGood mass transfer efficiencyGood sound absorptionCrystalline aluminosilicate zeolitesSolventLoudspeaker

The invention discloses a sound absorption zeolite particle and a synthesis and preparation method thereof. The method comprises the following steps: adding a silicon source, an aluminum source, a template, an additive and a solvent into a synthesis reaction kettle, and controlling artificially synthesized zeolite crystal growth under high temperature and high pressure conditions for a predetermined synthesis time to reach a predetermined particle size range; carrying out solid-liquid separation by using a filter press and / or a centrifuge to obtain molded synthesized zeolite particles; and sequentially carrying out high temperature roasting, reinforcing balling and particle surface post-treatment on the molded synthesized zeolite particles, and screening to obtain the satisfactory sound absorption zeolite particle. The method adopting the above technical scheme does not need secondary molding, so influences of a bonding agent on the zeolite particles are avoided, thereby the sound absorption zeolite particle has good mass transfer and sound absorption effects when being applied in loudspeaker products; and the required zeolite particle is obtained through the high temperature roasting, reinforcing balling and particle surface post-treatment of the molded synthesized zeolite particles.

Owner:GOERTEK INC

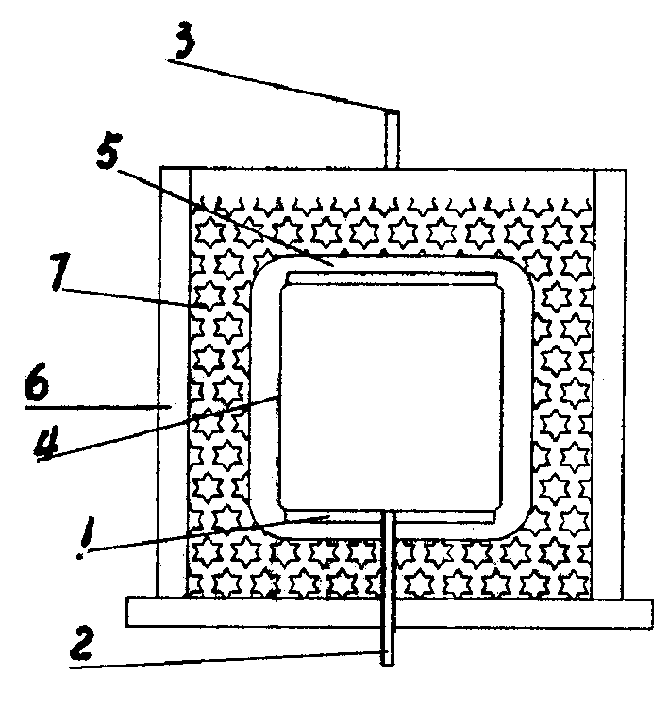

Vacuum infusion process of large winding in soft mold

InactiveCN1469401ASolve the sealing problemMeet the requirements of vacuum pressure impregnationCoils manufactureVacuum pumpingTemperature control

The vacuum impregnation process of large winding in soft mold features the technological process comprising mounting guiding board, glue pouring gate and riser; combining guiding board and winding and coating with self-dissolving sealing belt; painting liquid sulfurized silicone rubber to form sealed cavity; vacuum and leak repairing; mounting outer winding mold, vacuum pumping in winding, depositing sulfurized silicone rubber into between the self-dissolving sealing belt and the outer winding mold and curing to form; winding electrical heating belt outside the outer mold and connecting temperature control instrument; winding heat insulating layer outside the electrical heating belt; and connecting vacuum system to the riser and glue feeding system to the glue pouring gate. The present invention utilizes vacuum bag for sealing mold, and has simple mold design and lowered cost.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and preparation method

The invention relates to a KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and a preparation method. The microcrystalline glass material is prepared from a glass phase and a crystal phase through mixing, fusing, cooling and molding, annealing, carrying out crystallization heat treatment, wherein according to mol percent, the glass phase accounts for 20 percent to 50 percent and the balance is the crystal phase; the crystal phase is composed of K2CO3, Na2CO3, Nb2O5 and BaCO3 at a mol ratio of (3-x) to (3-x) to 6 to 2x and x is more than 0 and less than or equal to 2.5. The KNN-based energy storage microcrystalline glass material prepared by the preparation method has extremely low dielectric loss; BaO is introduced, has the effect of adjusting the composition of the crystal phase of a sodium potassium niobate system and also has a certain promotion effect on a devitrification process and devitrification is accelerated by rare-earth metal ions; the BaO can also generate a pinning effect, and adverse impacts, caused by interface polarization, on breakdown and worsening are weakened; finally, the microcrystalline glass material with a high dielectric constant is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

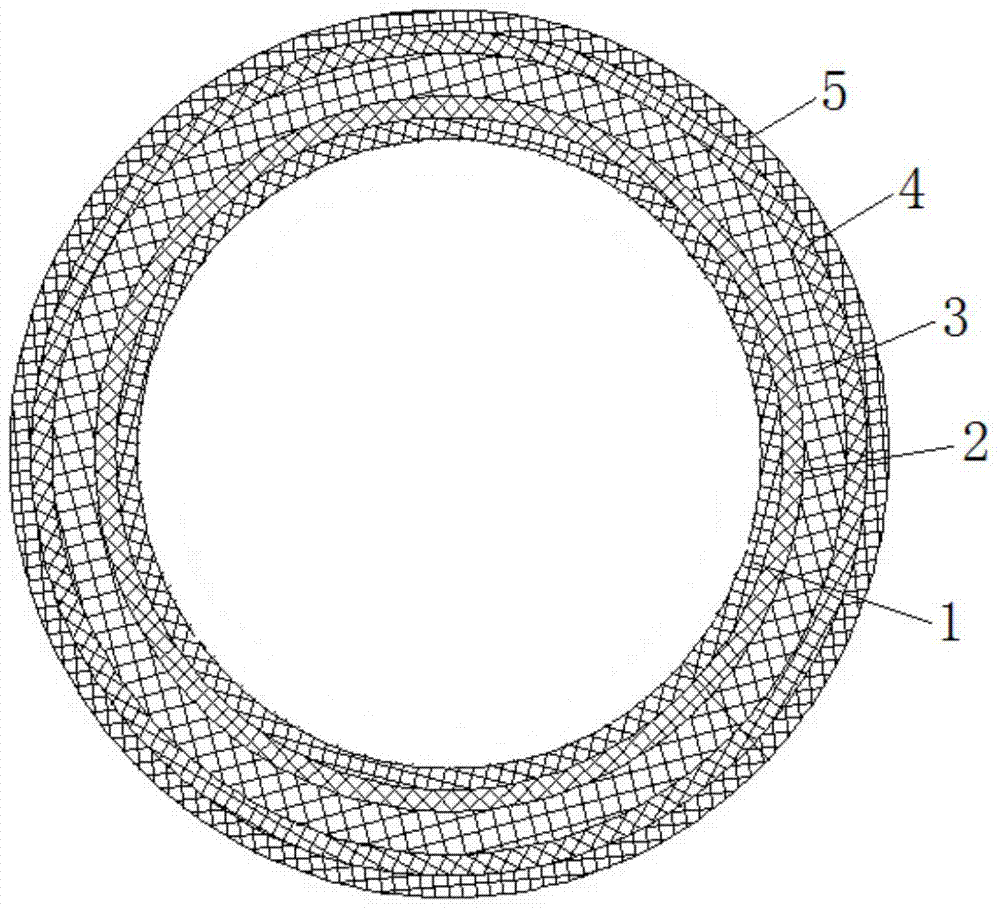

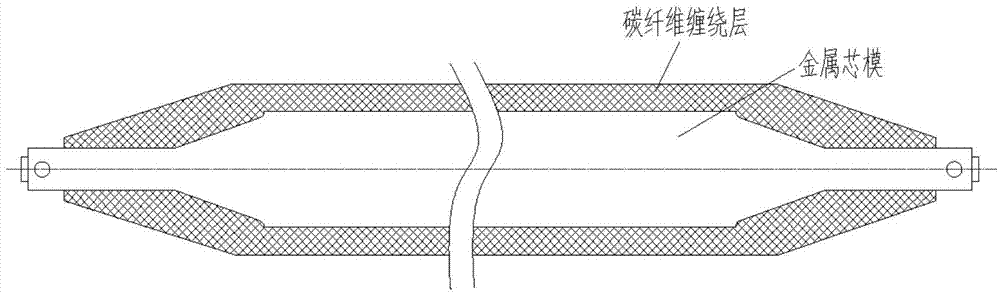

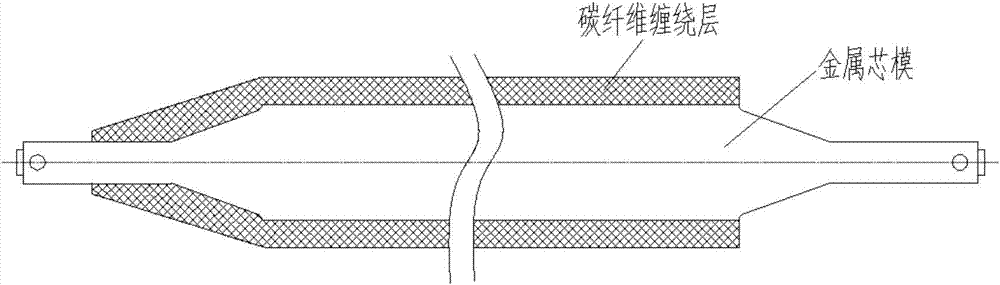

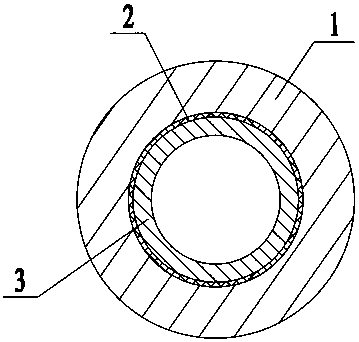

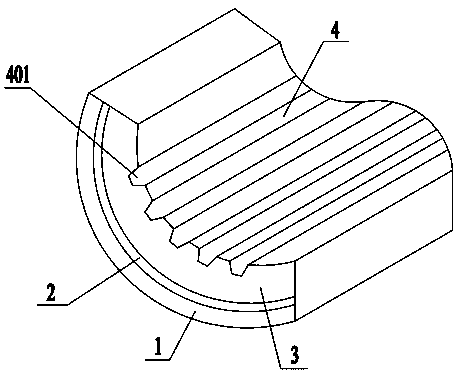

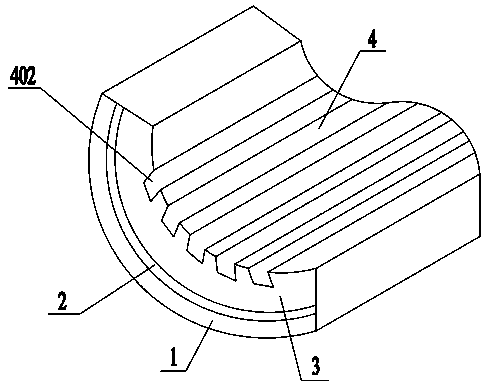

Method for preparing carbon fiber guide wheel for cutting silicon chips and carbon fiber guide wheel

ActiveCN103878985ASimple manufacturing processShorten the production cycleFine working devicesYarnFiber

The invention discloses a method for preparing a carbon fiber guide wheel for cutting silicon chips and the carbon fiber guide wheel, and belongs to the field of silicon chip processing equipment. The preparation method comprises the following steps: (1) heating resin in a drying oven for 1-2 hours, adding a curing agent, and uniformly stirring in vacuum at a high speed; (2) preheating a metal core mold for 1-2 hours, and lifting the metal core mold on a three-dimensional winding machine for fixation; (3) performing a layer paving design; (4) winding to form the winding angles of carbon fiber yarns layer by layer according to a sequence from the interior to exterior; (5) performing stepped heating and cutting on the metal core mold wound with carbon fibers; and (6) accurately grinding cured carbon fiber tubes to a specified guide wheel size, and performing fixed-length cutting, so as to obtain a carbon fiber guide wheel roller. The carbon fiber guide wheel is manufactured by one-step winding, one-step curing and one-step outer surface machining, the manufacturing process is simplified, the production period is greatly shortened, and the easy layering risk due to repeated winding is reduced. Moreover, the manufactured guide wheel is high in strength, stable in quality and low in cost.

Owner:常州神鹰碳塑复合材料有限公司

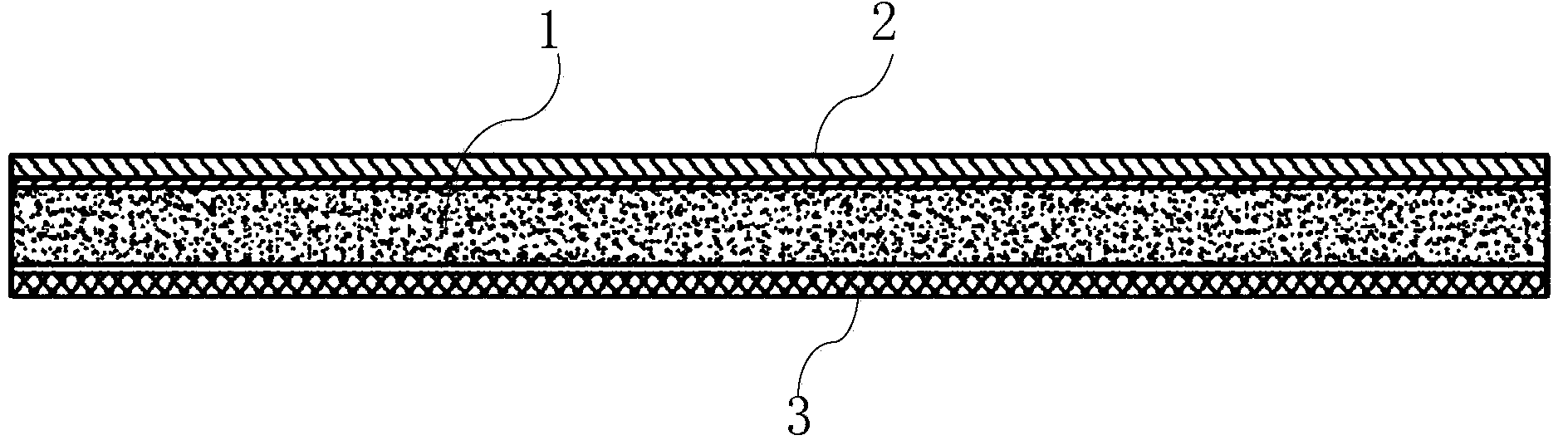

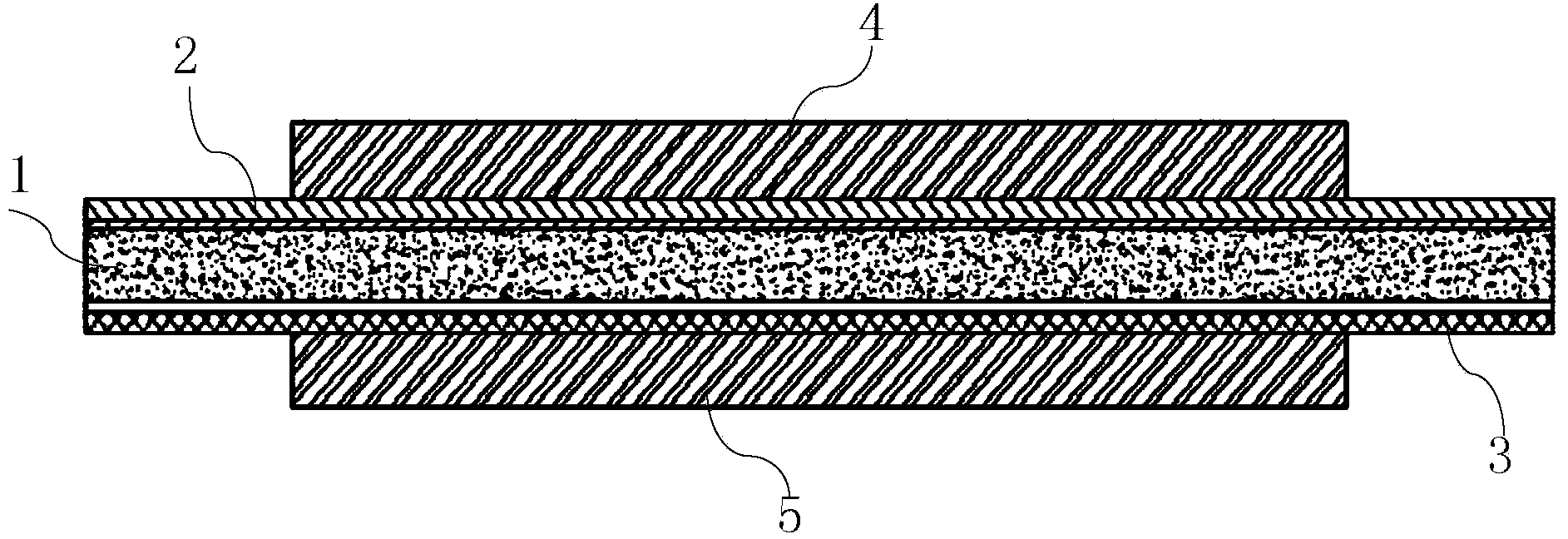

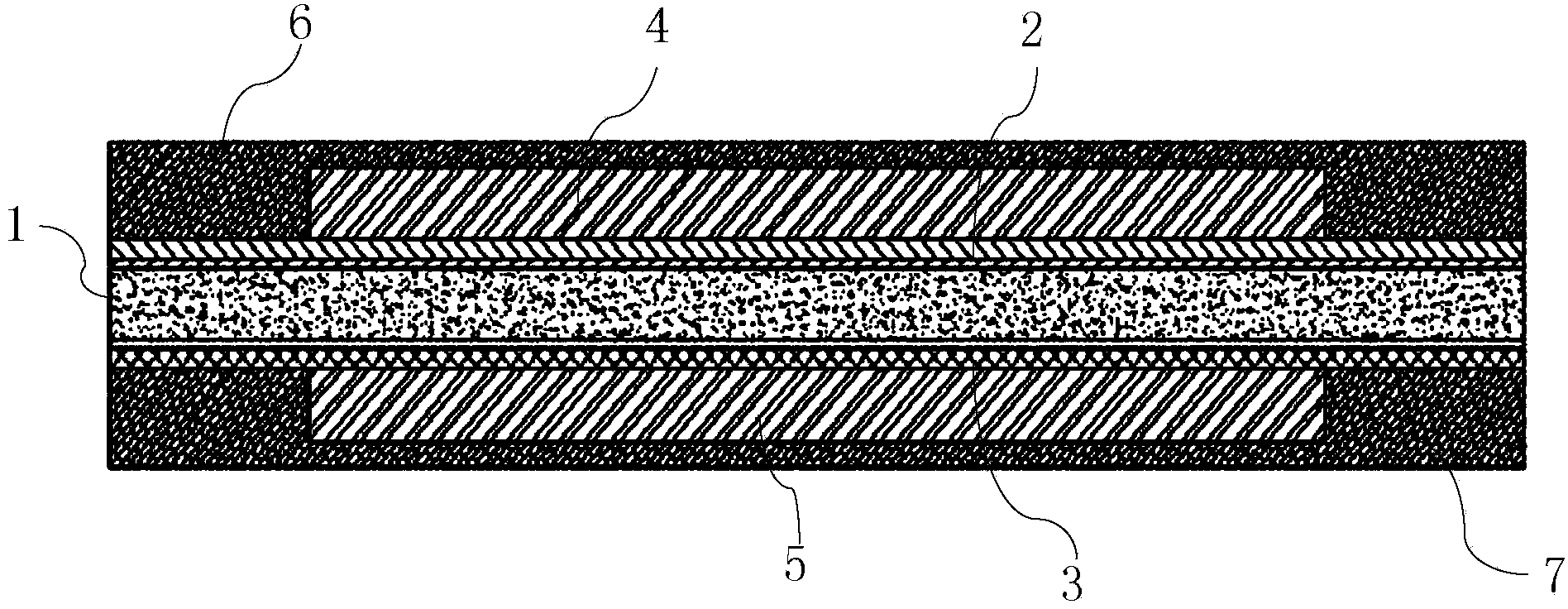

Copper-based bearing pad with toughening interlayer and preparation method of copper-based bearing pad

InactiveCN107747592AIncrease the carrying areaImprove bearing capacityShaftsBearing componentsAlloyToughening

A copper-based bearing pad with a toughened intermediate layer and a preparation method thereof. The bearing pad includes a copper shell, a toughened intermediate layer and a tin-based bearing alloy layer. The preparation method of the bearing pad includes: preparing a copper shell and a tin-based bearing alloy; The surface of the copper shell is degreased, mechanically sandblasted and roughened, cleaned with lye to remove surface oil stains and oxide films, cleaned with absolute ethanol, and then activated with acid to activate the surface of the copper shell; on the inner surface of the treated copper shell Form a toughened intermediate layer with a thickness of 30-100 μm, the composition of the toughened intermediate layer is pure nickel; cast a tin-based bearing alloy layer on the toughened intermediate layer, and set uniform grooves on the inner wall of the tin-based bearing alloy layer , the depth of the groove is 1 / 5~1 / 3 of the thickness of the tin-based bearing alloy; finally, cryogenic treatment is carried out on the bearing bush. The present invention avoids the generation of Cu6Sn5 brittle phase from reaction at the joint surface of the tin-based bearing alloy and the copper shell by setting the toughening intermediate layer, thereby improving the bonding strength between the tin-based bearing alloy and the copper shell.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

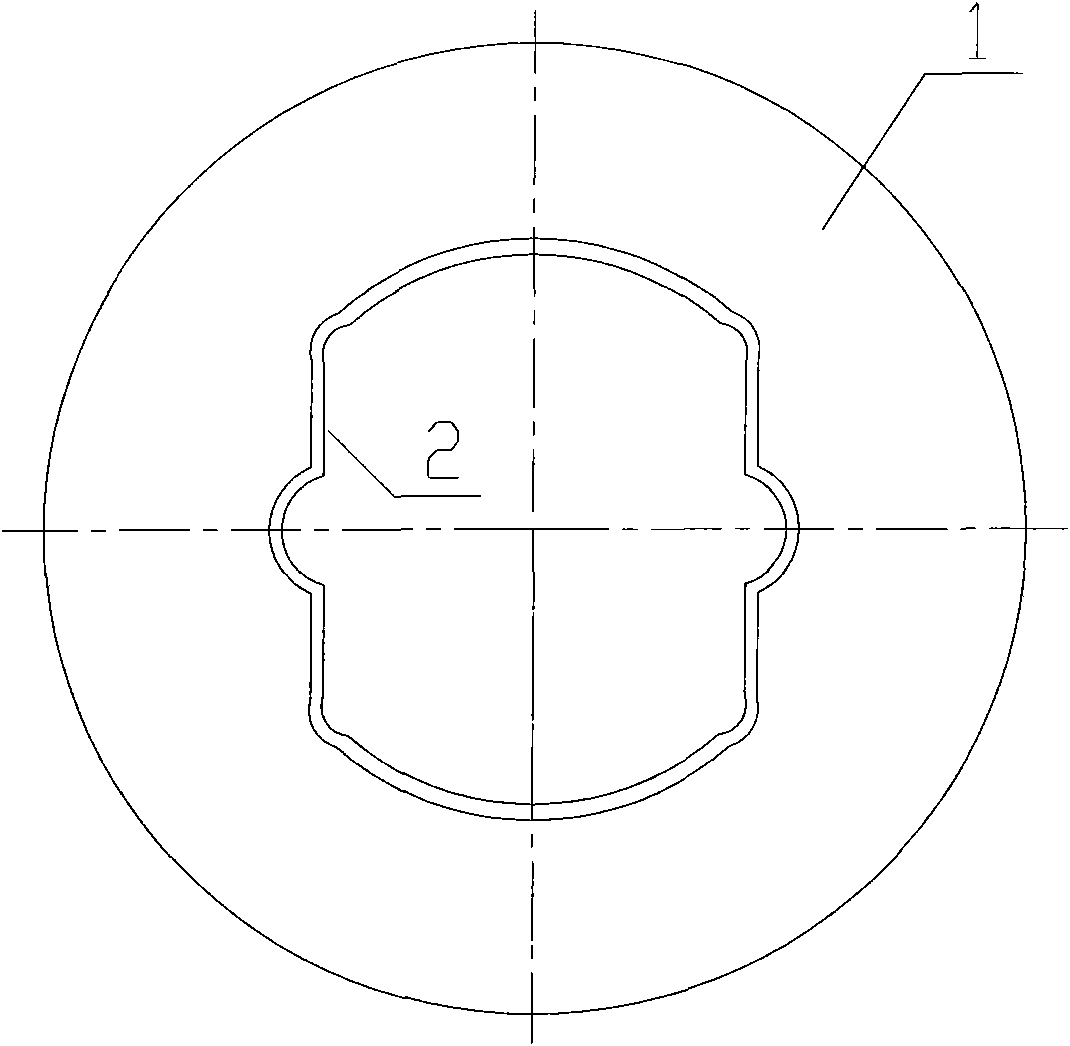

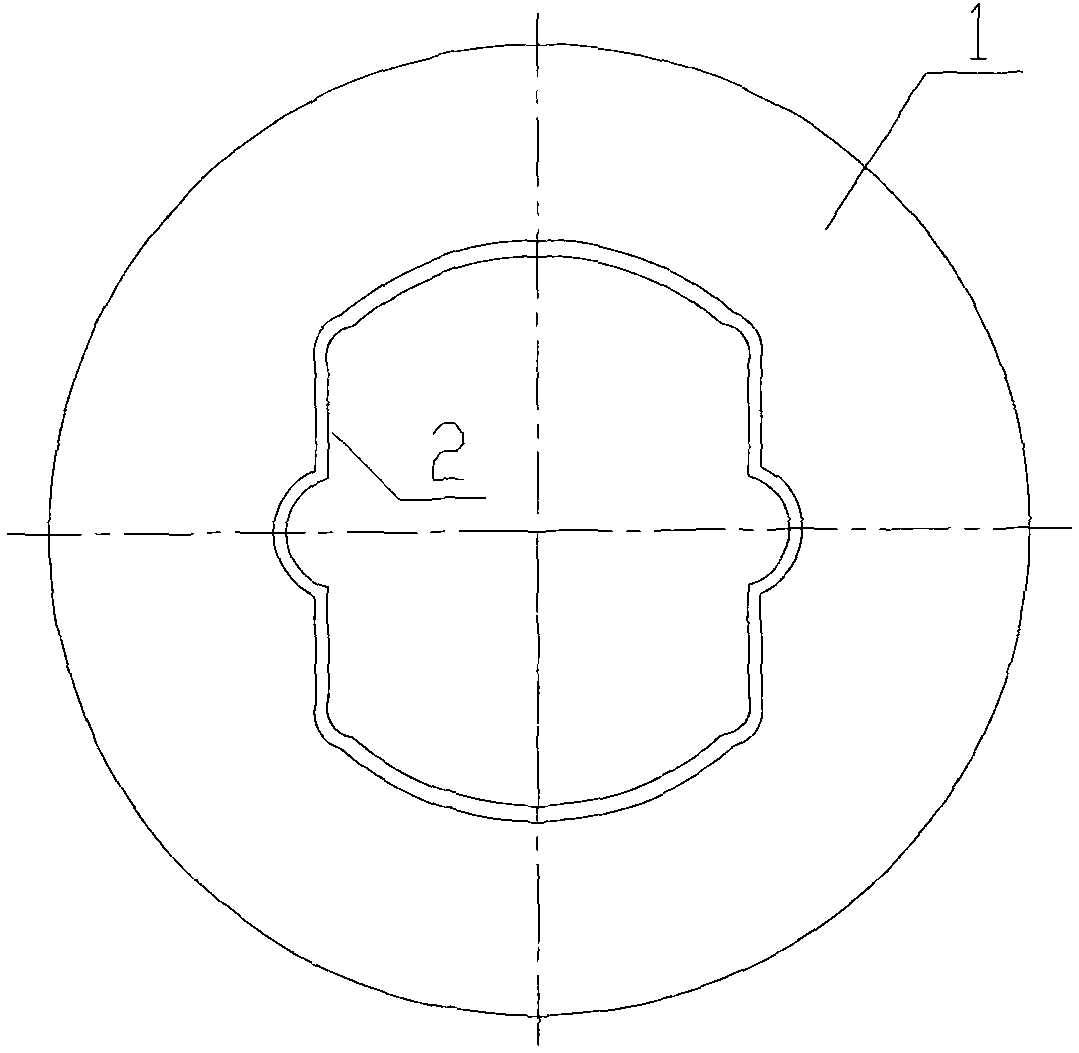

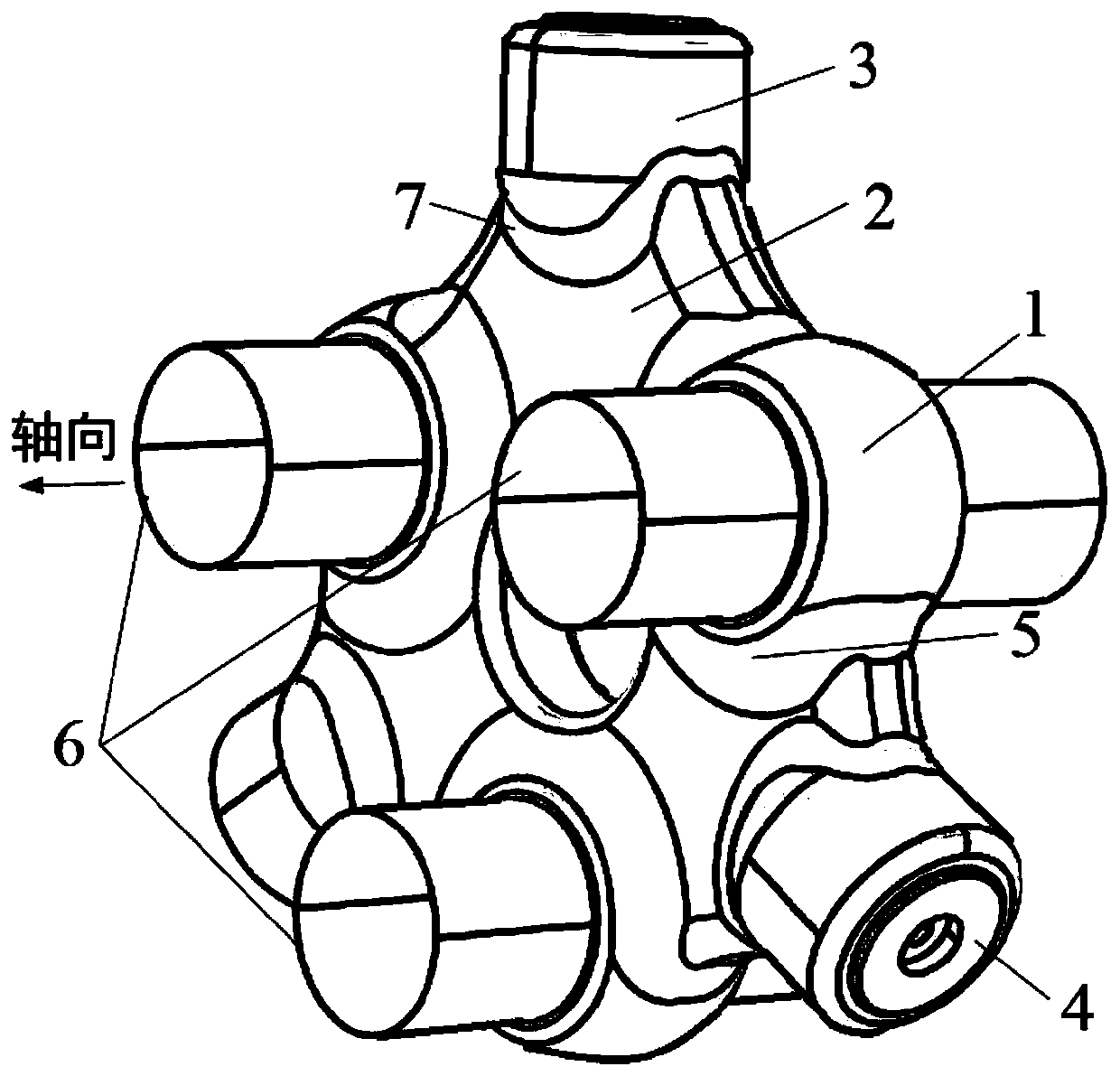

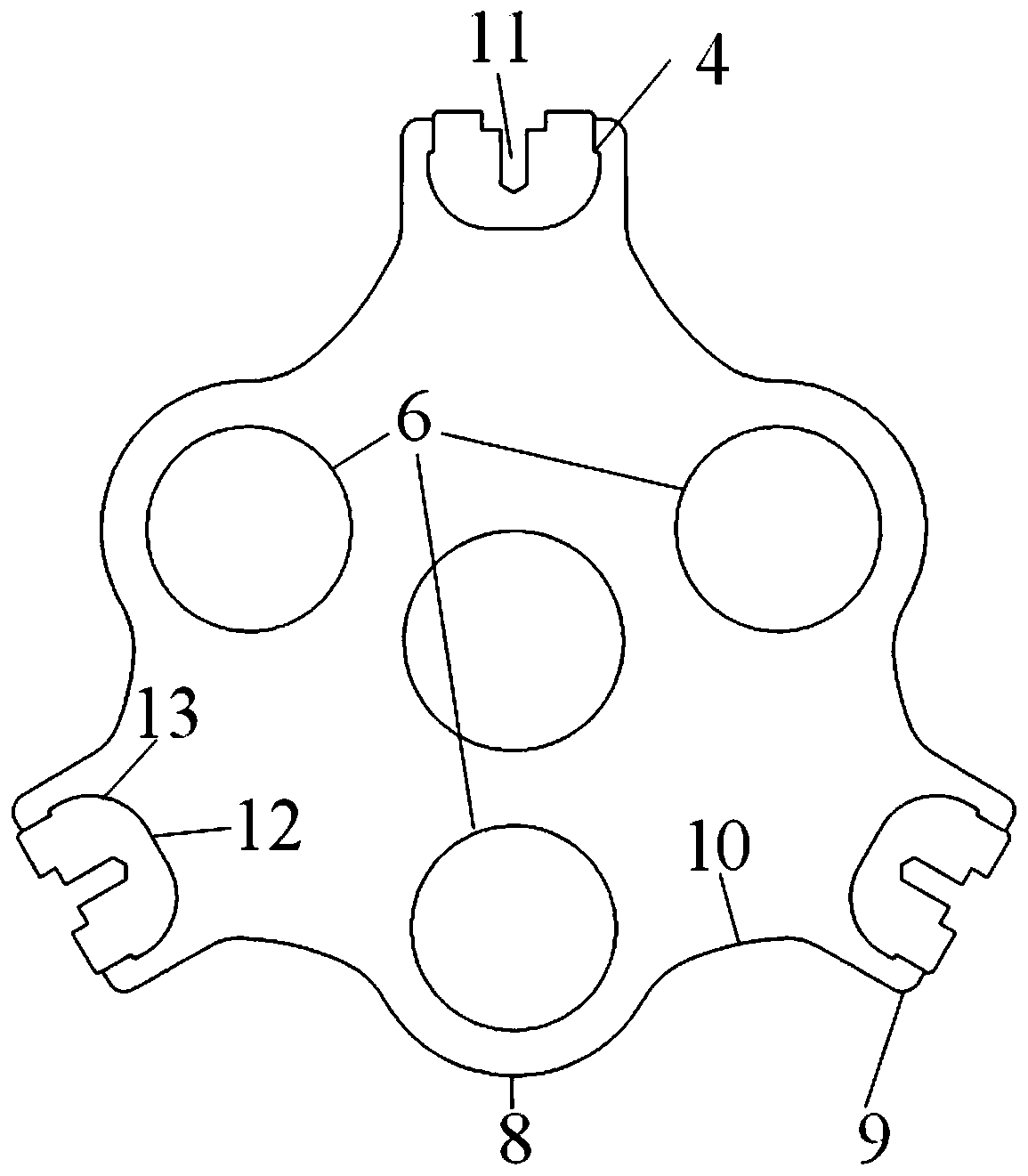

Three-phase three-post insulator for three-phase common box type compact GIS/GIL

PendingCN111370188AGently enveloped outer contourImprove capacitance distributionSupporting insulatorsElectrical conductorEngineering

The invention discloses a three-phase three-post insulator for a three-phase common box type compact GIS / GIL. The insulator comprises an insulator belly part, and conductor coating areas and supporting legs which are arranged on the insulator belly part, wherein the conductor coating areas and the supporting legs are distributed at intervals in the circumferential direction of the insulator bellypart, metal inserts are arranged in the supporting legs, the axial width of the conductor coating area is greater than the axial thickness of the insulator belly part, the conductor coating area and the insulator belly part are in smooth transition through a first chamfer, the width of the supporting leg is larger than the thickness of the insulator belly part in the axial direction, the supporting leg and the insulator belly part are in smooth transition through a second chamfer, the portion, located between the supporting leg and the conductor coating area, of the insulator belly part is insmooth transition through a first arc section, and the first arc section is a concave arc section. According to the three-phase three-post insulator, the surface synthesis field intensity, the tangential field intensity and the metal insert surface field intensity can be greatly reduced, and the control value requirement in engineering is met, so that the stability of the insulator under long-termoperation is improved.

Owner:XI AN JIAOTONG UNIV

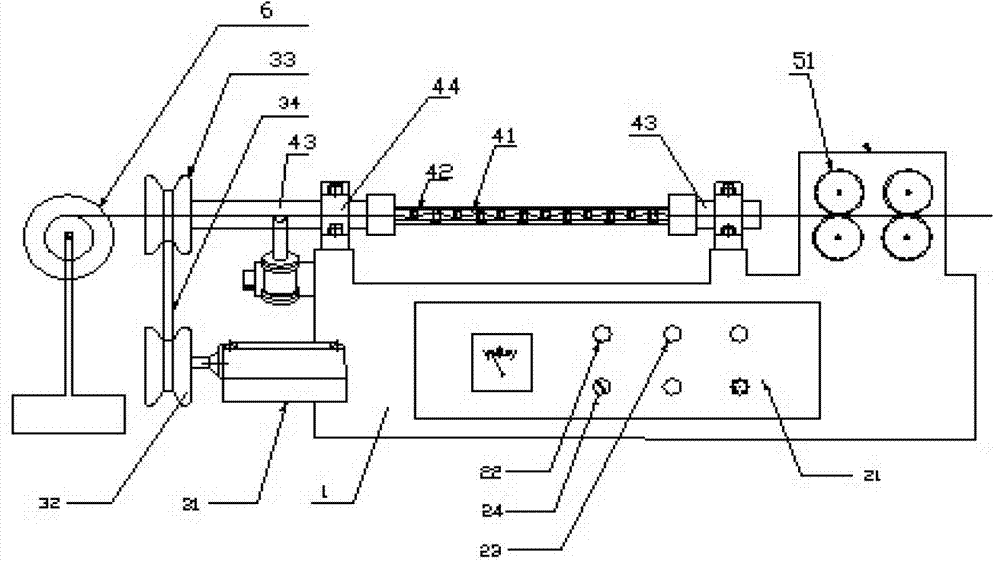

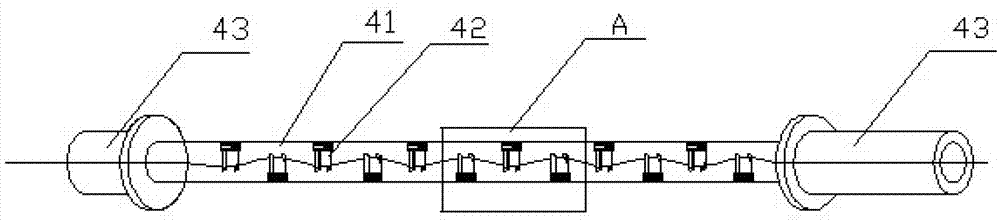

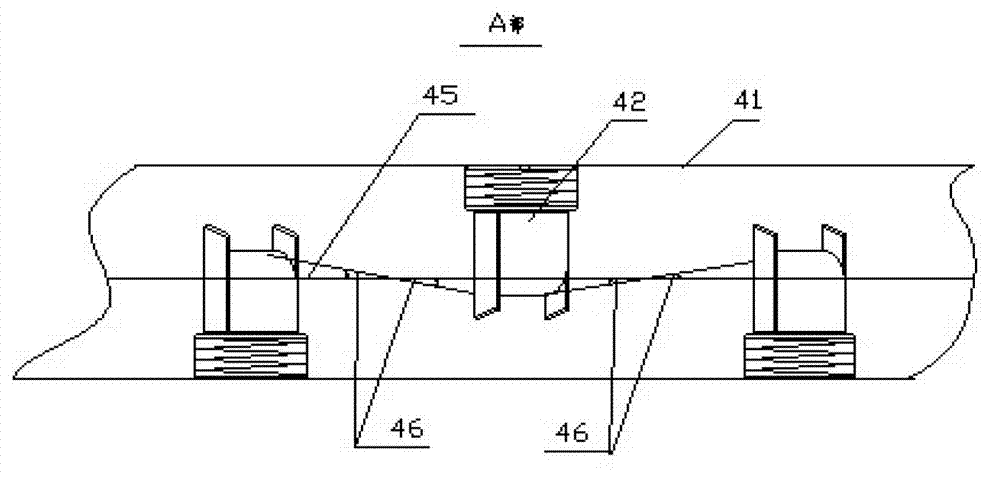

Machine for straightening metal threads

The invention discloses a machine for straightening metal threads. The machine comprises a rack, an operation control mechanism, a transmission mechanism, front straightening mechanism and a back straightening guide mechanism. The machine for straightening the metal threads is characterized in that the front straightening mechanism comprises a rotary drum and a straightening wheel; the straightening wheel is provided with a straightening rod; one end of the straightening rod is in a threaded rod shape; the other end face of the straightening rod is an arc surface; a plurality of screw holes are arranged in the straight line on the two side walls of the rotary drum symmetrical about the axial centerline of the rotary drum; the screw holes are in stagger arrangement at equal intervals; the threaded rod of the straightening rod and the rotary drum are in screwed connection; a plurality of straightening rods are in staggered and embedding arrangement at equal intervals; the end face of the arc surface of the straightening rod is beyond the axial centerline of the rotary drum; and the degrees of the included angles formed by the intersections of the tangency point lines of all adjacent straightening rod arc surfaces and the axial centerline of the rotary drum are equal. The machine for straightening the metal threads has the advantage that the adjustment of the depth or the angle of the straightening rod in the rotary drum is achieved by screwing and unscrewing the straightening rod, so that the application ranges of fine metal threads needing to be straightened are widened.

Owner:宁波保税区安杰脉德医疗器械有限公司

Full-power control ingot casting process for polycrystalline silicon ingot furnace

InactiveCN104480527APromote growthInternal stress reliefPolycrystalline material growthSingle crystal growth detailsIngot castingTemperature difference

The invention discloses a full-power control ingot casting process for a polycrystalline silicon ingot furnace, and relates to the technical field of photovoltaic manufacturing. According to the full-power control ingot casting process, five procedures of heating, melting, crystal growth, annealing and cooling in the ingot casting process are completed through power and time control completely, the ending of the heating procedure and the ending of the melting procedure are respectively alarmed when preset temperatures of a first thermocouple above a heater and a second thermocouple below a quartz crucible are reached, each procedure comprises multiple steps for controlling the power and the time, and finally a finished product is prepared. By adopting the full-power control ingot casting process, a stable heat source can be provided, the temperature difference of upper and lower temperature gradients can be effectively reduced when silicon ingots grow, the process control is more reasonable, the internal stress of the silicon ingots can be effectively eliminated, the fluctuation of a thermal field can be reduced to a maximum extent, crystal growth of the silicon ingots is relatively facilitated, and the quality of the silicon ingots is improved.

Owner:HENGSHUI YINGLI NEW ENERGY

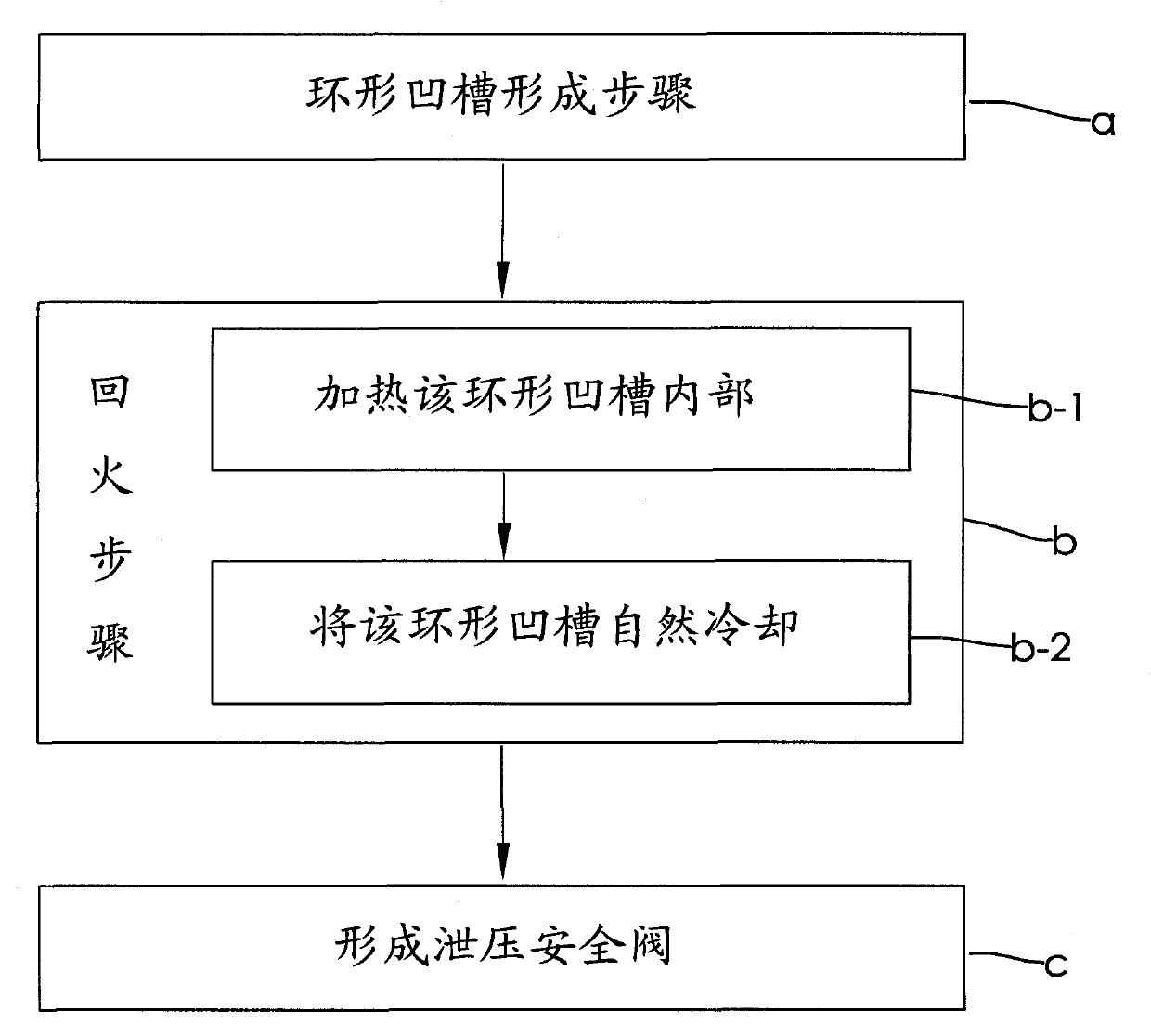

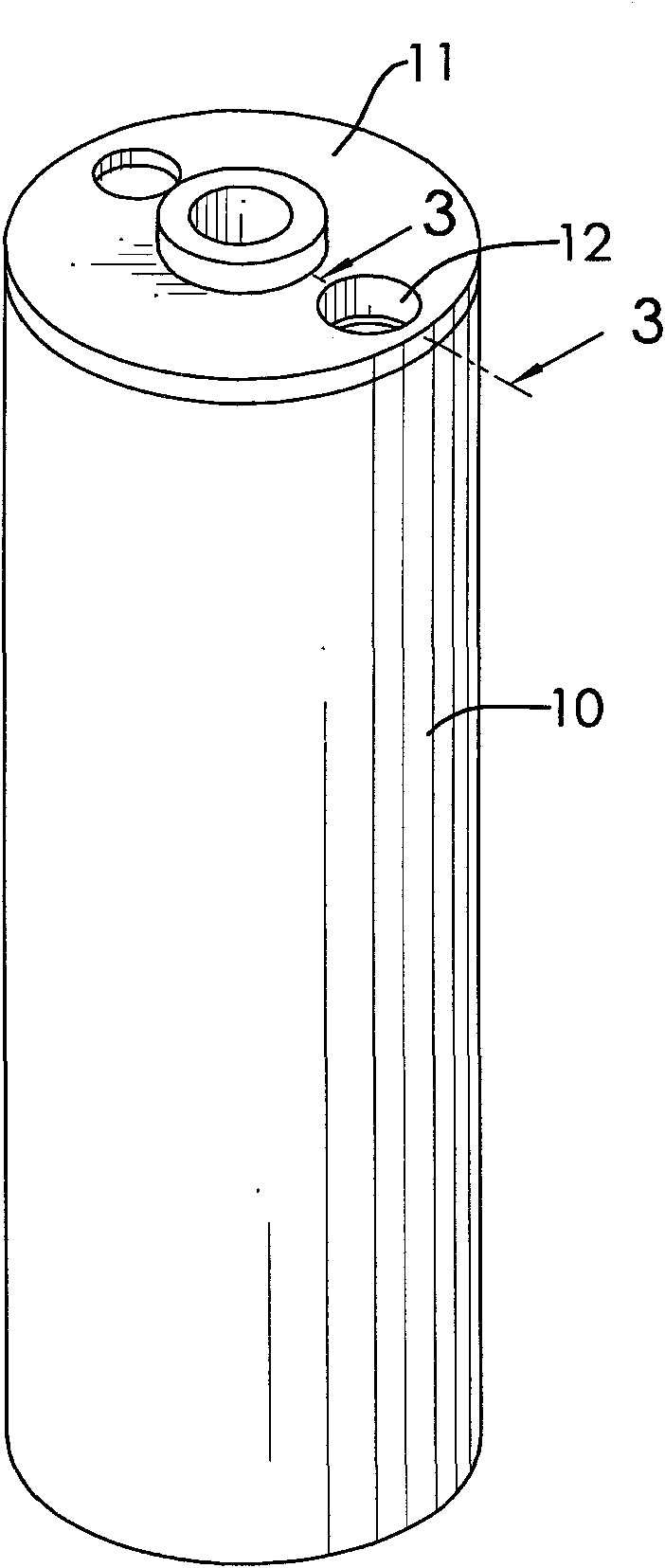

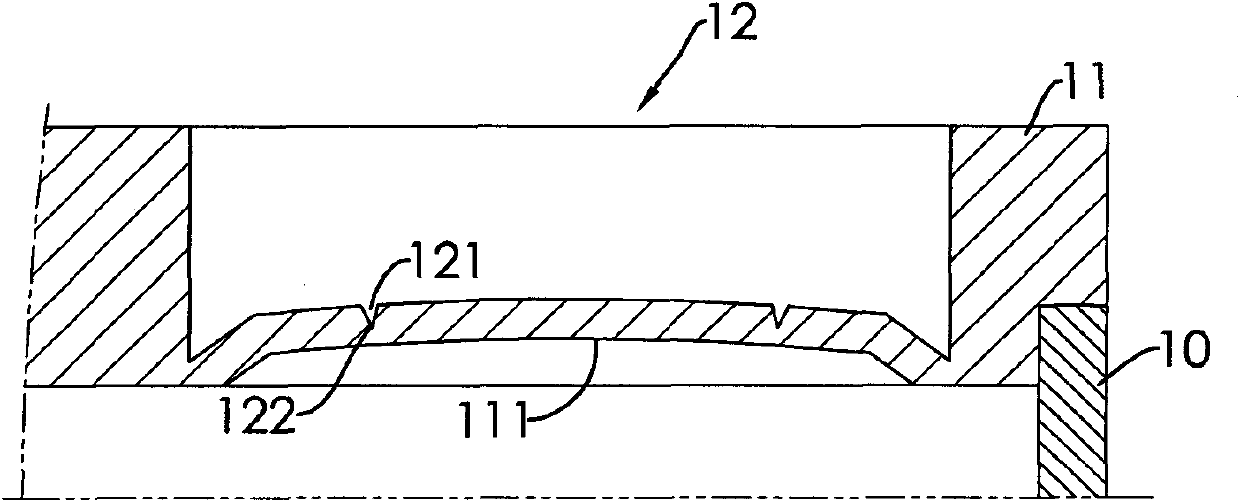

Safety relief valve of lithium battery cover body and manufacturing method of same

The invention relates to a safety relief valve of a lithium battery cover body and a manufacturing method of the same. The manufacturing method for the safety relief valve of the lithium battery cover body comprises the following steps of: arranging an annular groove (explosive groove) in the lithium battery cover body, wherein the lithium battery cover body is made of aluminum alloy; heating the inner part of the annular groove to enable the temperature of the inner part of the annular groove to reach 200-500 DEG C; and cooling the annular groove to form the safety relief valve on the lithium battery cover body. As the aluminum alloy is heated to a proper temperature, the internal stress of the safety relief valve can be eliminated, the hardness of materials is reduced, uniform strength of the materials is realized, brittle ruptures caused by processing and hardening are reduced, and therefore, the purpose of increasing yield is achieved.

Owner:RESIN ENTERPRISE

Vinyl ester resin heavy mortar floor

ActiveCN104652778AReduce curing heatSolve problems that cannot meet the requirements of heavy industrial production floor applicationsFlooringFiberIsolation layer

The invention provides a vinyl ester resin heavy mortar floor which consists of a priming coat, a vinyl ester resin mortar layer and a finish coat layer, wherein the vinyl ester resin mortar layer is directly paved on the priming coat, and an FRP (Fiber Reinforced Plastic) isolation layer is not needed to be manufactured; the once paving thickness of the vinyl ester resin mortar layer is 30-100mm, and the whole vinyl ester resin mortar layer is seamless; the vinyl ester resin mortar layer is prepared from the following raw materials in parts by weight: 1000-1200 parts of quartz sand aggregate, 100-120 parts of vinyl ester resin, 2-3 parts of methyl ethyl ketone peroxide, 1-1.5 parts of cumene hydroperoxide and 1-2 parts of cobalt iso-octoate. The vinyl ester resin heavy mortar floor has the characteristics of high mechanical strength, good load-carrying property, integrally seamless property, excellent anti-permeation property, excellent corrosion resistance property, high construction efficiency and the like, is especially applicable to regions with frequency rolling of heavy machinery, heavy high-altitude falling impact and corrosion caused by the continuous soaking of acid, alkali and saline solutions with relatively high concentrations.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

NaNbO3-based Na2O-Nb2O5-SiO2 high-dielectric-constant energy-storage glass ceramic and preparation method

InactiveCN109626828AReduce porosityLow dielectric lossGlass shaping apparatusElectricityDielectric loss

The invention relates to a NaNbO3-based Na2O-Nb2O5-SiO2 high-dielectric-constant energy-storage glass ceramic and a preparation method of the glass ceramic. The glass ceramic material is prepared through the steps that a glass phase and a crystal phase are subjected to mixing, fusion, cooling formation, annealing and heat treatment for crystallization, wherein the glass phase accounts for, by mole, 0.1%, and the balance is the crystal phase; the crystal phase is formed by heating and fusing Na2CO3 and Nb2O5 in a mole ratio of 1:1. The NaNbO3-based energy-storage glass ceramic mateiral is low in dielectric loss; due to the addition of the NaCO3, the composition of the crystal phase of the potassium-sodium niobate system can be adjusted, moreover, a certain of promoting effect on the crystallization process is achieved, the NaNbO3 phase high in storage energy density is easily formed, and finally, the high-storage-energy-density glass ceramic material is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

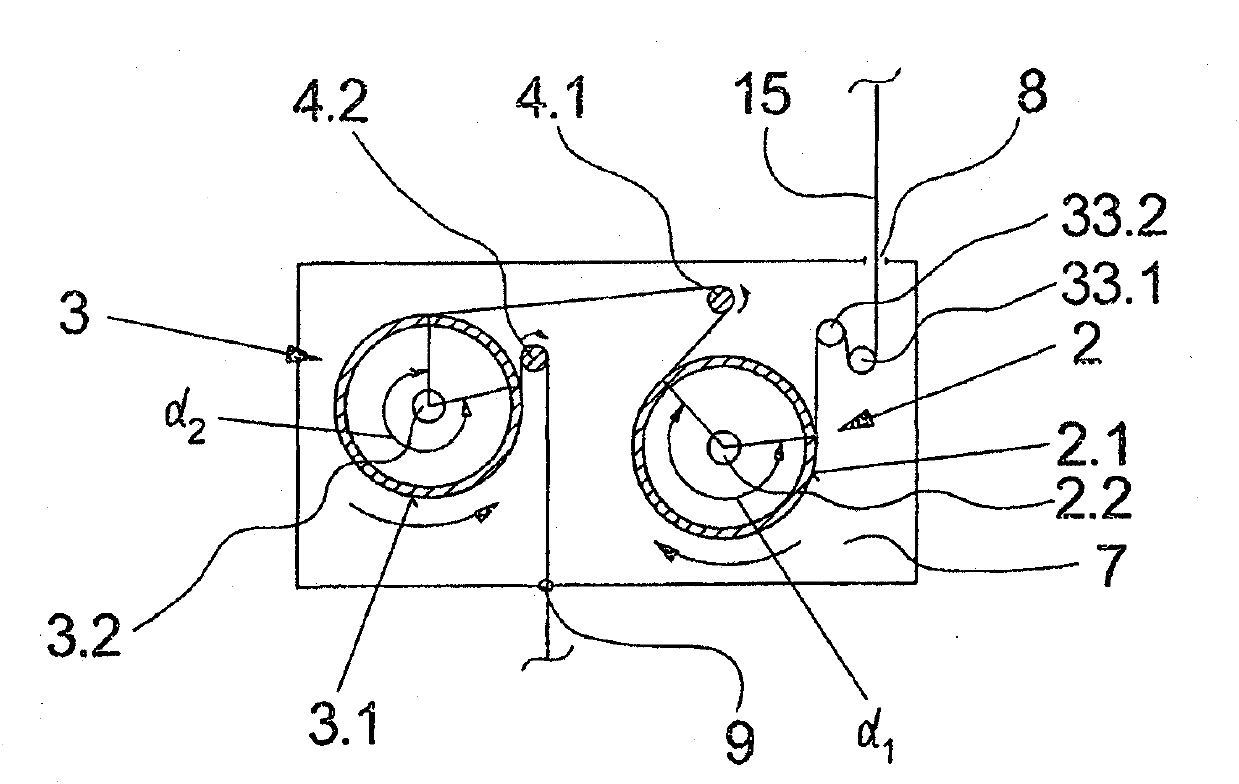

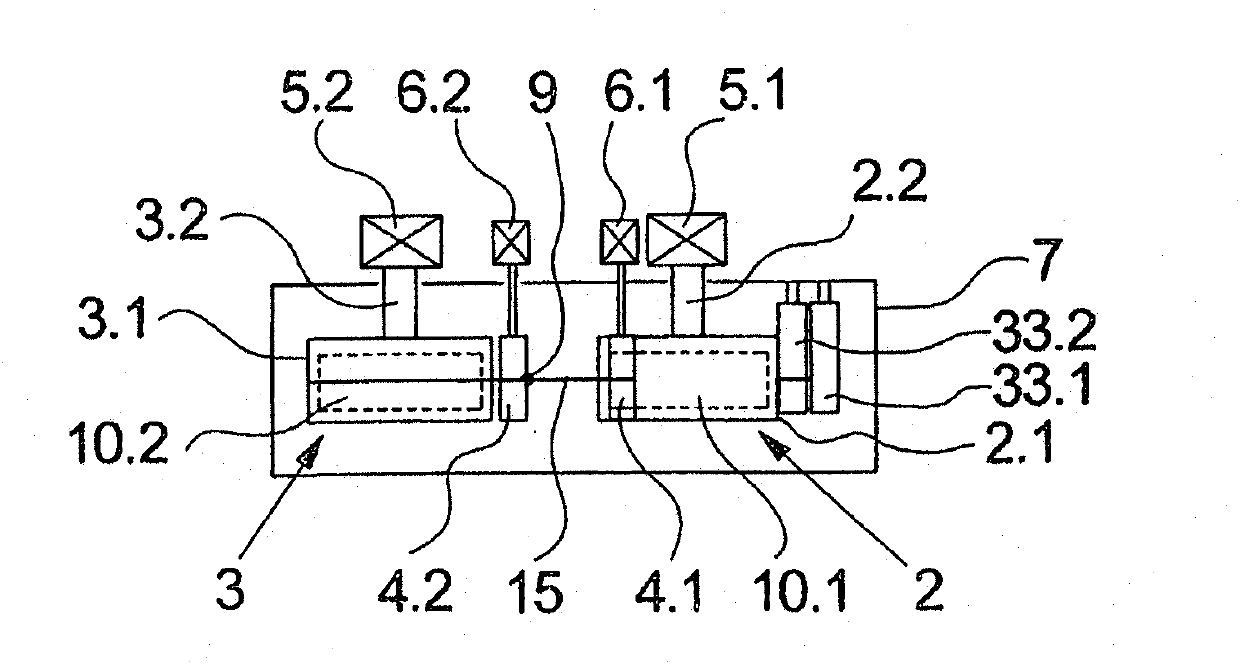

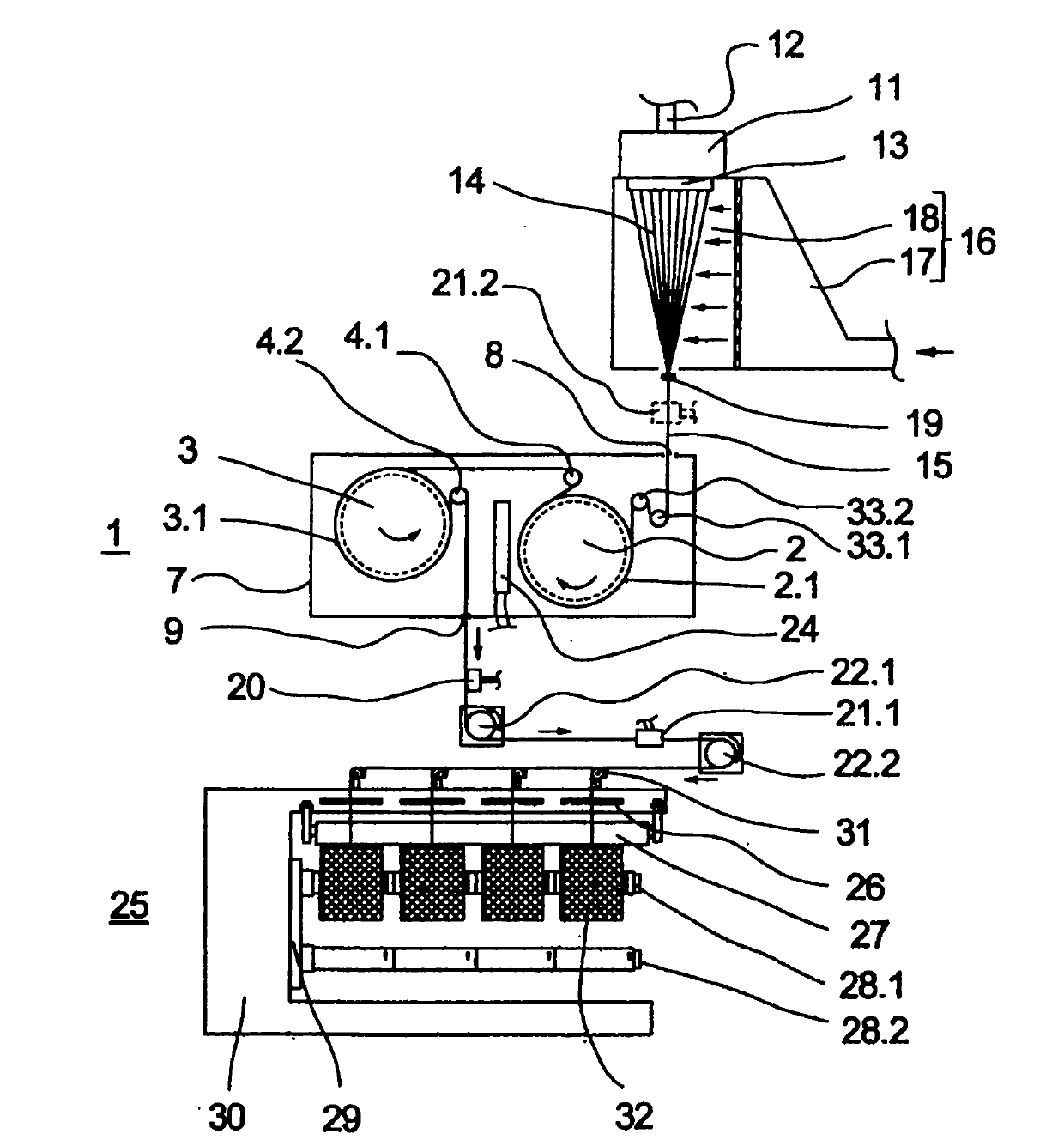

Method for taking up and drawing a multifilament during melt-spinning, and apparatus for carrying out said method

InactiveCN102016139AFull stressEnough tensionArtificial thread manufacturing machinesFilament manufacturePolymer scienceMelt spinning

The invention relates to a method and an apparatus for taking up and drawing a multifilament during melt-spinning. In said method and apparatus, the multifilament is guided on driven guiding sleeves of several godets, at least partially going therearound. Several guiding sleeves are heated. One of the guiding sleeves is driven at a circumferential speed exceeding 1,500 m / min so as to take up the multifilament, while at least one guiding sleeve located downstream is driven at least at twice said circumferential speed so as to draw the multifilament. In order to sufficiently heat the multifilament as the same goes around the guiding sleeves once and generate a sufficient tensile force on the multifilament, the multifilament is guided on the guiding sleeve that is driven for taking up the multifilament such that the multifilament and the guiding sleeve are in uninterrupted contact for a minimum length of 650 mm, the guiding sleeve being heated to a surface temperature ranging from 80 DEG C to 200 DEG C.

Owner:OERLIKON TEXTILE GMBH & CO KG

Medium chromium alloy wear-resisting steel ball and preparation method thereof

InactiveCN107739985AHigh hardnessImprove toughnessFurnace typesHeat treatment furnacesSteel ballWear resistance

The invention discloses a medium chromium alloy wear-resisting steel ball and a preparation method thereof and relates to the technical field of wear-resisting materials. The chemical components of the medium chromium alloy wear-resisting steel ball comprise, by weight, 1.5-1.9% of C, 0.9-1.2% of Si, 0.7-1.0% of Mn, 5.5-7.0% of Cr, 0.3-0.5% of Mo, 0.08-0.20% of Ti, 0.1-0.2% of Cu, 0.02-0.05% of Nb, 0.06-0.08% of Al, 0.02-0.05% of Hf, 0.05-0.1% of B, 0-0.05% of P, 0-0.04% of S, and the balance Fe and inevitable impurities. The chemical components and contents thereof of the medium chromium alloy wear-resisting steel ball are reasonably optimized, the synergy is enhanced, the strength, hardness and toughness of the medium chromium alloy are improved remarkably, the prepared wear-resisting steel ball is excellent in comprehensive mechanical performance, the good impact energy is achieved while the effect that the high hardness HRC is greater than or equal to 61 is ensured, and wear resistance and corrosion resistance are good.

Owner:TONGLING MINGCHENG FOUNDRY

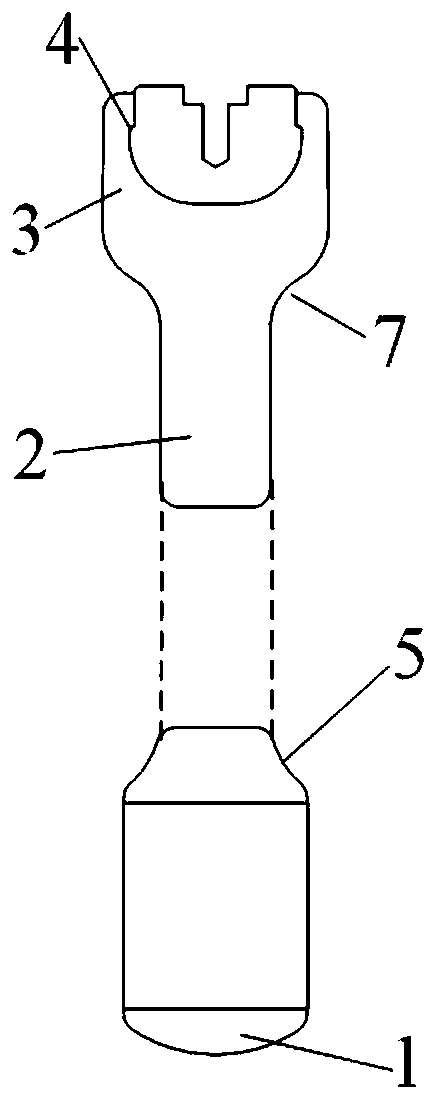

Manufacturing method of track pin sleeve of bulldozer

InactiveCN102275066AIncrease profitReduce manufacturing costHeat treatment process controlRoom temperatureQuenching

A manufacturing method of a bulldozer crawler pin bushing is realized by adopting the following steps: (1) cutting material, intercepting a bar; (2) upsetting, reverse extrusion and punching; (3) annealing and cooling at room temperature; (4) Shot blasting; (5) Rough turning shape; (6) Overall quenching and tempering; (7) Carburizing; (8) Finish turning the outer circle and end face. The invention has high utilization rate of raw materials and low production cost. Since the raw material is heated and annealed again, the internal stress of the raw material is eliminated, and the grain size grade of the pin sleeve is improved, so the invention can improve the structural performance of the pin sleeve and prolong the service life.

Owner:SHANTUI CONSTR MASCH CO LTD

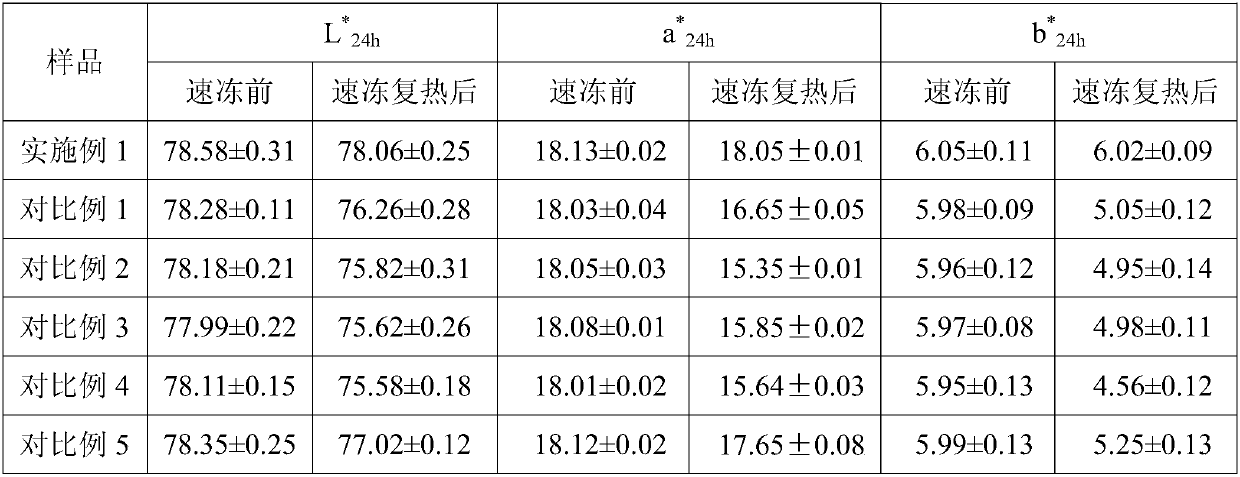

Quick-frozen braised noodle and preparation method thereof

The invention relates to the technical field of food processing, and particularly relates to a quick-frozen braised noodle and a preparation method thereof. According to the quick-frozen braised noodle provided by the invention, wheat-core wheat flour, acetate modified starch and hydroxypropyl distarch phosphate are combined and used as a flour matrix, four components of isolated soy protein, sodium tripolyphosphate, sodium pyrophosphate and sodium polypyrophosphate are contained in a water retention agent; all components in the flour matrix synergistically acts; all the components in the water retention agent synergistically interacts; afterwards, by combining a three-time-awaking noodle preparation process, the water-absorption and water-retention performance of the quick-frozen braisednoodle is promoted; the color and luster stability is promoted; the quick-frozen braised noodle is prevented from generating brown stains in a quick-frozen reheating procedure; the eating quality of the quick-frozen braised noodle is improved. The braised noodle prepared by the preparation method is subpackaged and quick-frozen, is directly reheated by a microwave before being eaten, and is convenient for a consumer to eat and suitable for a busy office worker and the industrialized production of the braised noodle is promoted.

Owner:郑州研霖生物科技有限公司

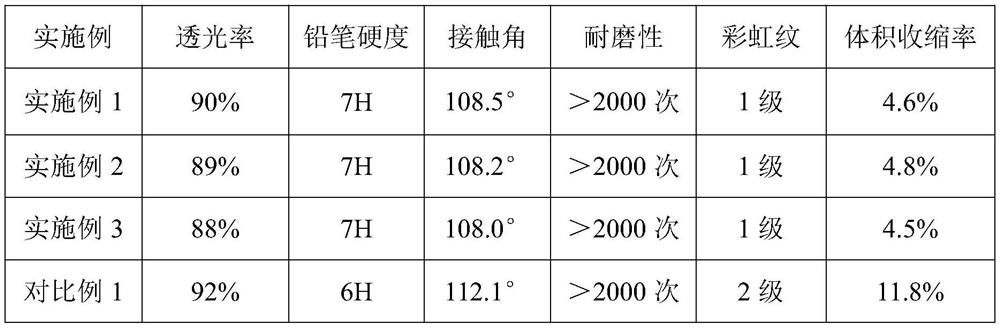

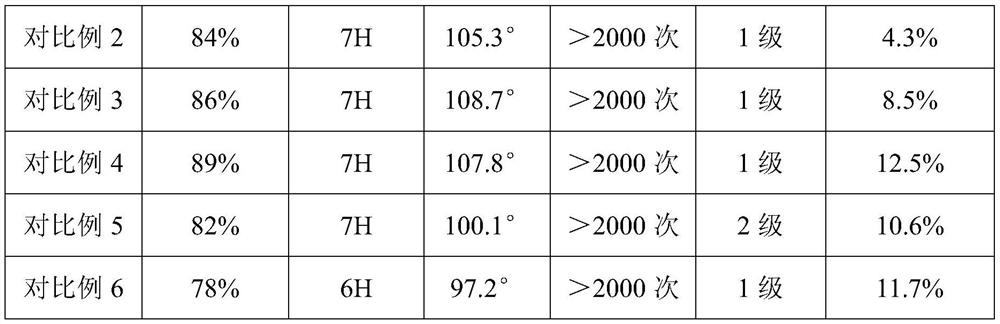

Wear-resistant antifouling hardened film and preparation method thereof

ActiveCN114316333AReduce internal stressInternal stress reliefPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceAcrylate ester

The invention discloses a wear-resistant antifouling hardened film and a preparation method thereof. The preparation method of the wear-resistant antifouling hardened film comprises the following steps: step 1, ultrasonically dispersing an acrylate monomer in a solvent, and adding nano titanium dioxide; sequentially adding octavinyl silsesquioxane, a photoinitiator and photosensitive resin, and stirring and homogenizing; a hardened coating liquid is obtained; step 2, irradiating one side of the transparent base film for 15-18 minutes by using an ultraviolet lamp; hardening coating liquid is evenly coated, and under an ultraviolet lamp, low illumination intensity is set, and irradiation is conducted for 5-8 minutes; setting high illumination intensity to irradiate for 2-4 minutes; and curing overnight at a certain temperature to obtain the wear-resistant antifouling hardened film. The preparation method has the beneficial effects that by limiting the acrylate monomer, a mercaptan click reaction in the hardened coating liquid is utilized to enhance the refractive index, and the addition amount of titanium dioxide is reduced on the basis of inhibiting rainbow lines; and octavinyl silsesquioxane is utilized to reduce volume shrinkage.

Owner:YILIKIM NEW MATERIALS CO LTD

Method for solving chemical milling deformation of domestic un-prestretched sheets

InactiveCN102392117ASolve the problem of chemical milling deformationInternal stress reliefFurnace typesHeat treatment furnacesInternal stressQuenching

The present invention relates to a method for solving chemical milling deformation of domestic un-prestretched sheets, which includes the following steps: 1, applying oil to a sheet before quenching; 2, quenching the sheet according to thermal treatment regulations; 3, in the state of quenching, horizontally stretching the sheet to eliminate the internal stress of materials; and 4, finishing subsequent formation and chemical milling procedures according to the drawing. The method can eliminate the internal stress of process un-prestretched sheets, solve the problem of serious chemical milling deformation, reduce the labor intensity of workers and improve the making quality of large-sized enveloped parts.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com