Patents

Literature

123results about How to "Taste chewy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

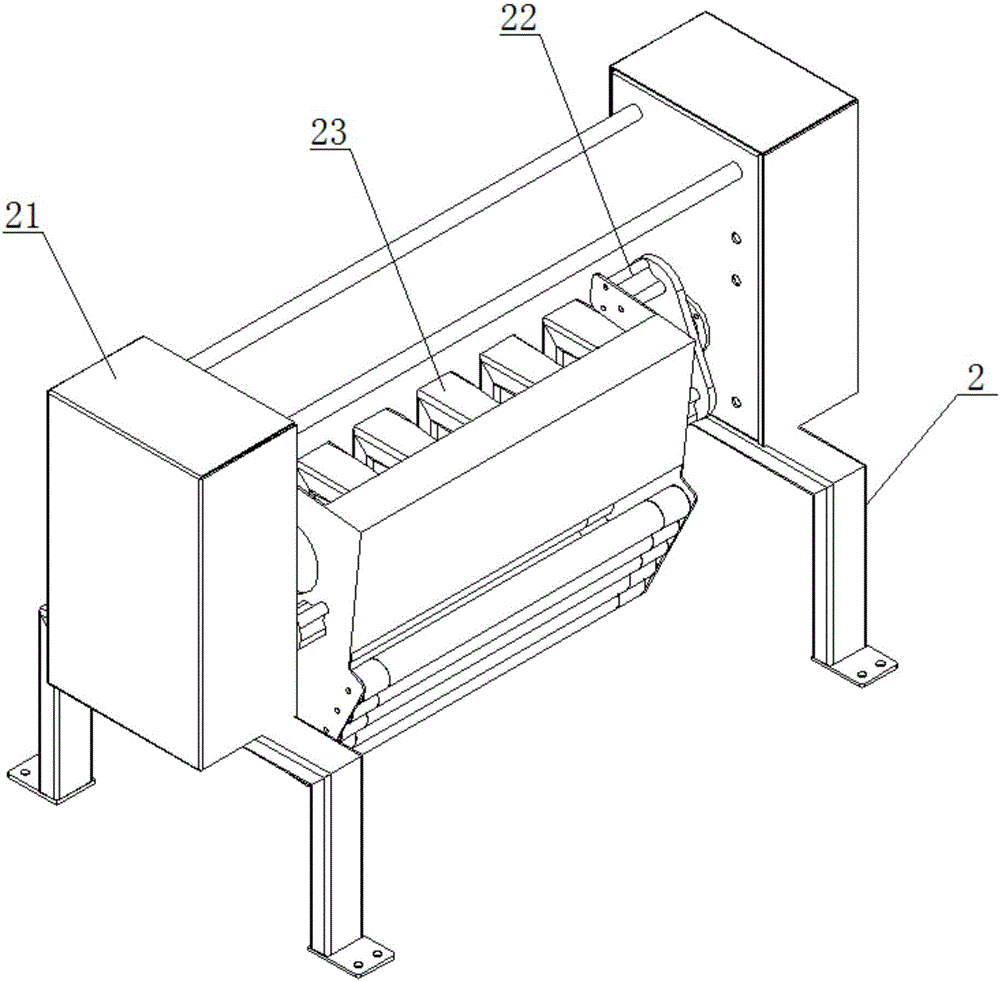

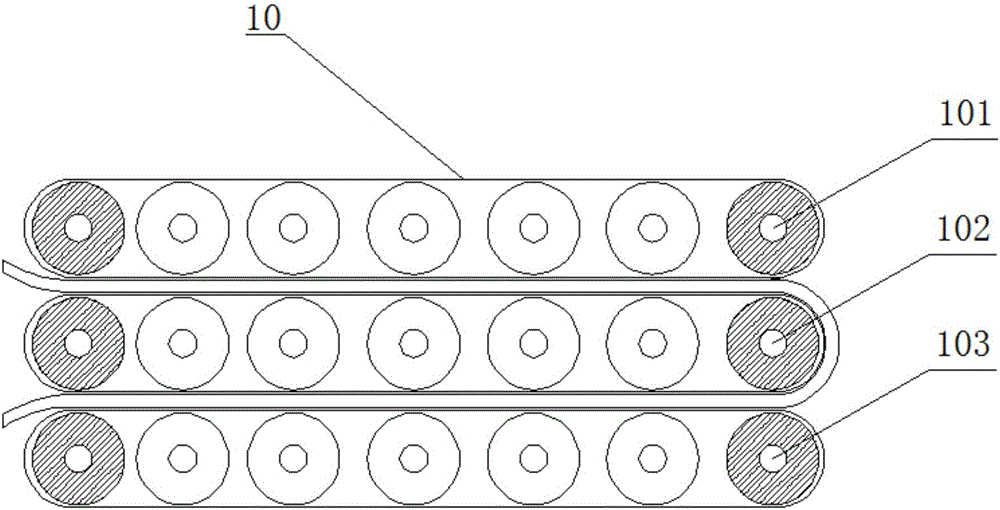

Equipment for producing round steamed bread

ActiveCN101112202AImprove skin brightnessClear internal structureDough-sheeters/rolling-machines/rolling-pinsForming processesFood products

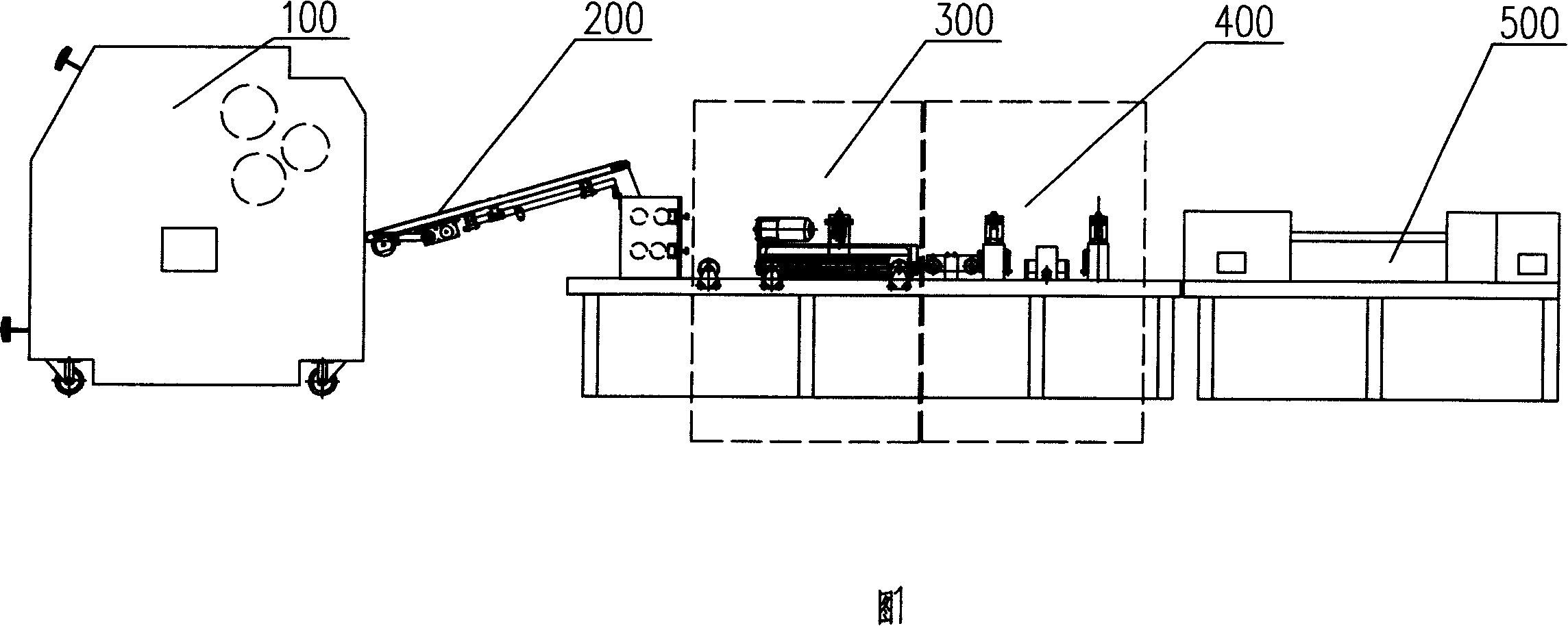

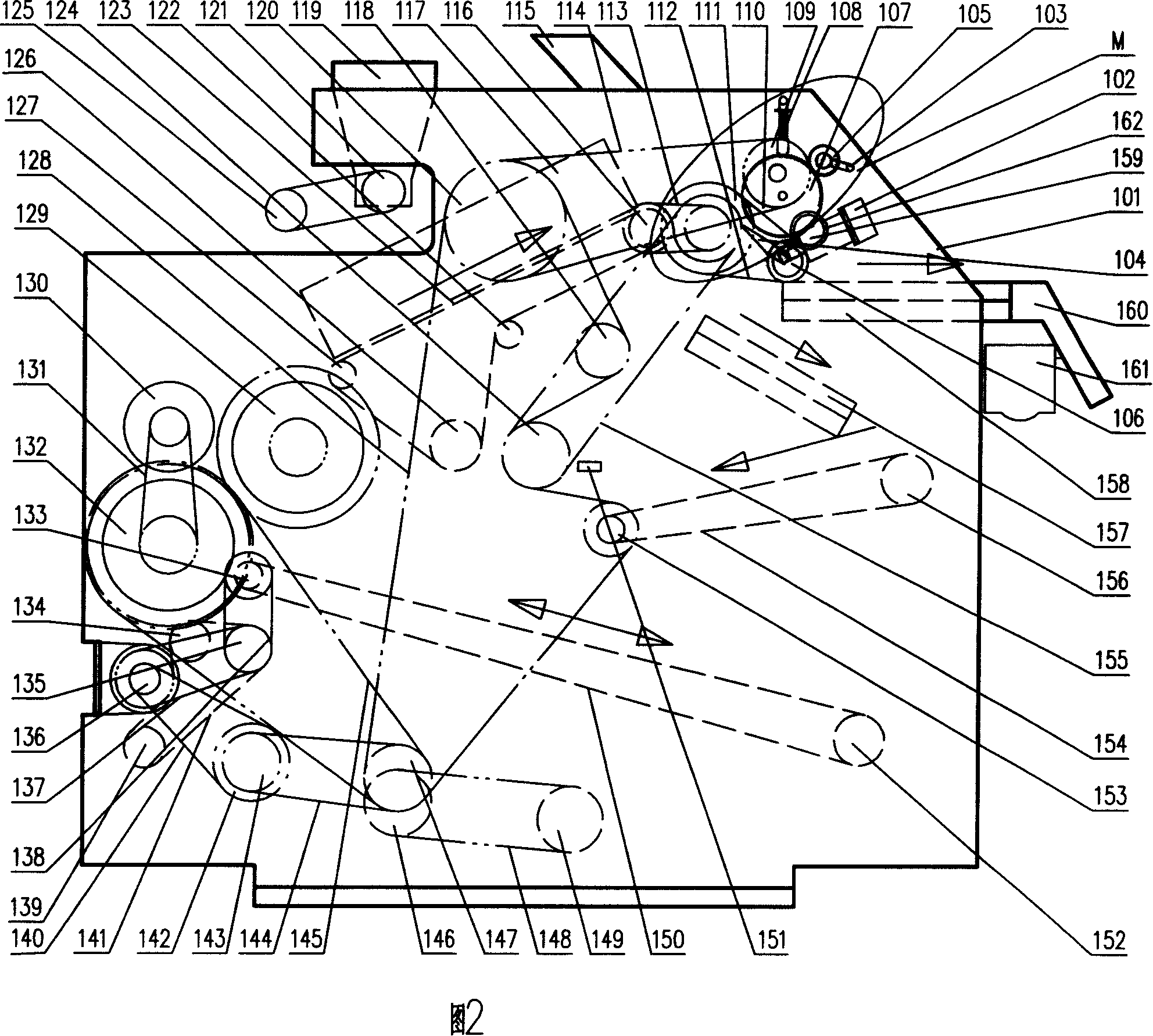

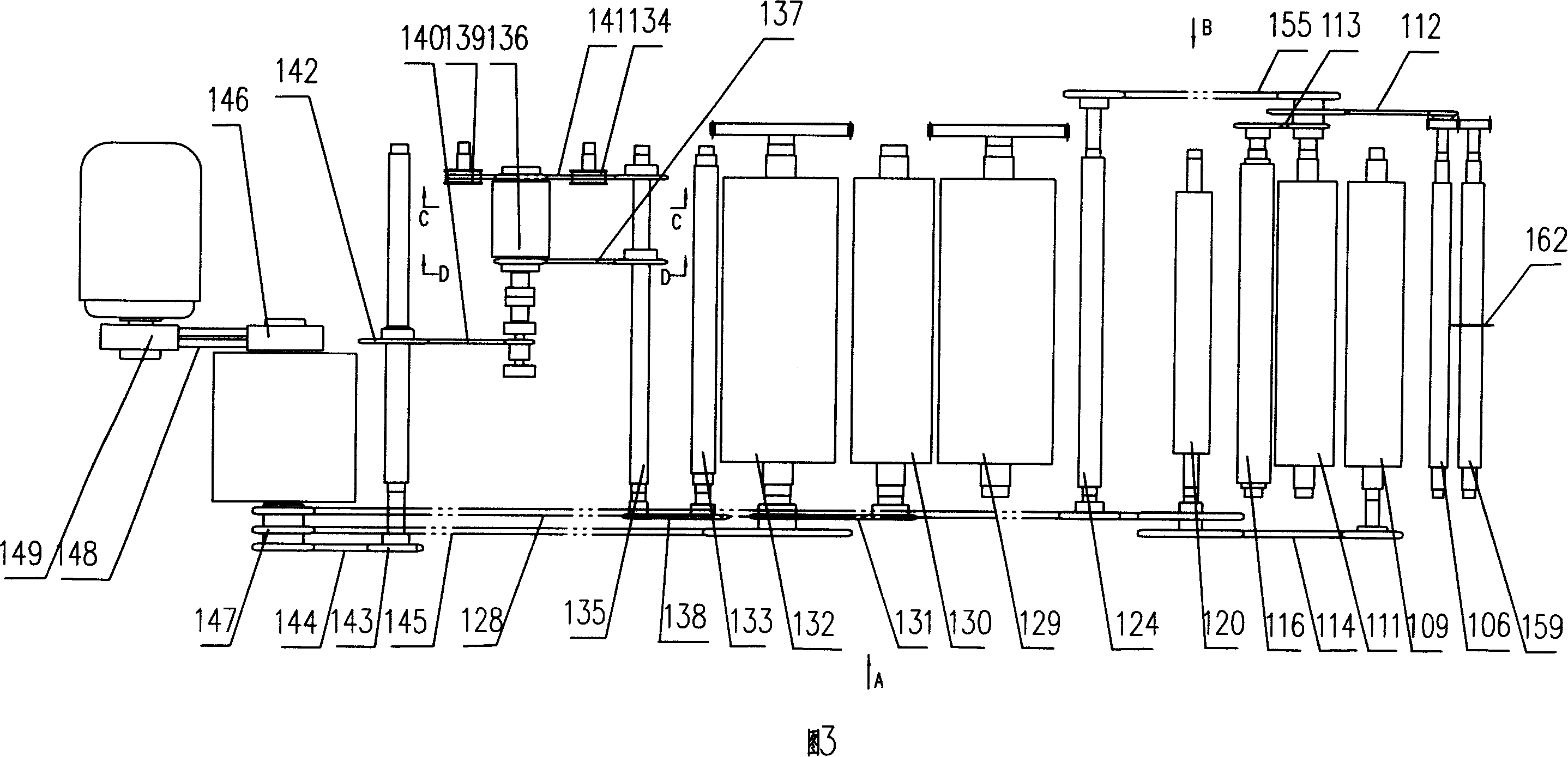

The invention pertains to the technical field of food machinery and relates to producing equipment of round steamed bread. The equipment is provided with the following settings from front to back in sequence: a squash device (100), an incline plane transportation device (200), a winding device (300), a cutting device (400) and a molding device (500). Each device is connected by conveying belt. The squash, winding and cutting devices are added before the molding process. The process steps are as follows: paste is squashed into dough sheet; dough roll is made of the dough sheet through the winding device; then the dough roll is cut, molded to form a clear inner structure layer and improve the brightness of the steamed bread surface and enable the steamed bread to be tasted puckering. The molding process of the invention simulates manual entwisting molding process, which enables the steamed bread inner structure to be difficult to be torn and broken, maintains the sourdough network completely and evenly, has high molding efficiency, and at the same time improves the appearance quality of the dough.

Owner:郑州多福多食品有限公司

Purple sweet potato noodles and preparation method thereof

The invention relates to purple sweet potato noodles. The purple sweet potato noodles are prepared from raw materials of whole purple sweet potato flour, high-gluten wheat flour, shelled fresh eggs and the like through the steps of mixing, cooking, tabletting, slitting, drying, cutting and the like. A weight ratio of the whole purple sweet potato flour to the high-gluten wheat flour is 1: (0.65 to 2.35). A use amount of the shelled fresh eggs is 1.8 to 2.2 % of a total weight of the whole purple sweet potato flour and the high-gluten wheat flour. The purple sweet potato noodles maintain inherent nutritive values and healthy effects of purple sweet potatoes. Through addition of fresh eggs, the purple sweet potato noodles is added further with the advantages of good color and flavor, high nutrition, and chewy, tender and smooth taste. The purple sweet potato noodles have a natural color, a flavor and a taste. A preparation method of the purple sweet potato noodles adopts physical processes, and thus the preparation method does not destroy nutrients of purple sweet potato noodles and retains effectively the nutrients and dietary fiber of the purple sweet potato noodles. The raw materials adopted by the preparation method have wide sources. Therefore, the preparation method is suitable for large-scale industrialized production.

Owner:王相军

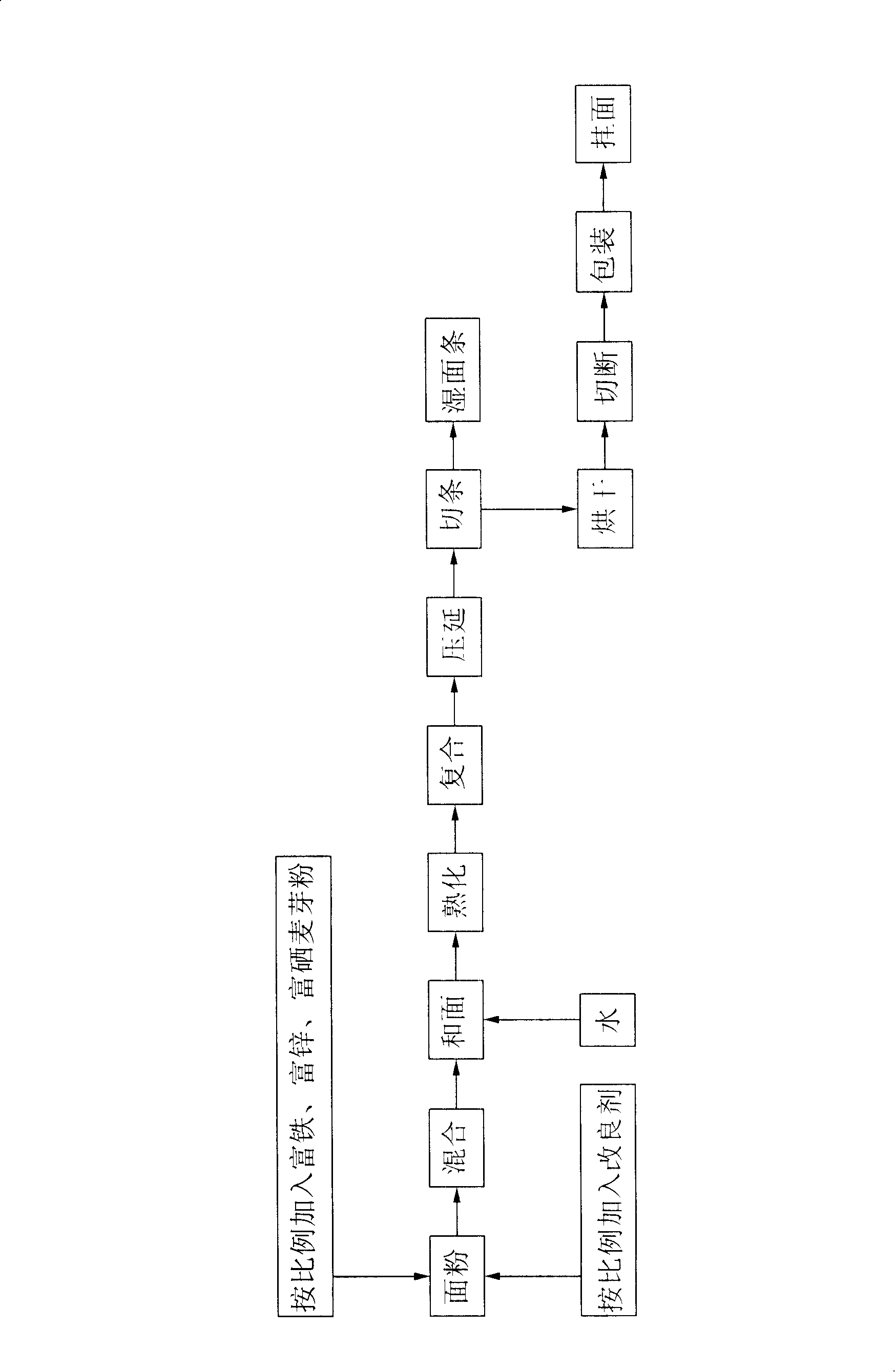

Preparing method of noodle rich in Fe, Zn, and Se and its preparing technique

InactiveCN101199324AHigh nutritional valueMeet needsDough treatmentCultivating equipmentsNutritive valuesZinc

The invention discloses a production process of nourishing noodles rich in iron, zinc and selenium, which includes procedures of flour and water mixing and kneading, slaking, compounding, calendaring and slicing, and rich iron, rich zinc, selenium-enriched wheat malt flour and improver are added in the flour. The nutrient noodles rich in iron, zinc and selenium adopting the technical proposal of the invention have advantages at following aspects that: (1) the noodles have high nutritive value, the noodles have the iron content of 24-32mg / kg, zinc content of 9-12 mg / kg and selenium content of 200-280ug / mg after enhancement, thereby completely meeting the demand of human body. (2) The enhanced iron, zinc and selenium all exist in organic forms with good biological activity, thus greatly being favorable for human body absorption. (3) The noodles are delicate and flexible and tolerable to boiling, and do not stick together. The invention has 92 marks in the perceptive evaluation, and can reach industrial product high quality standards.

Owner:HENAN AGRICULTURAL UNIVERSITY

Processing method of garlic product

The invention relates to a processing method of deodorized, dried garlic and further relates to a processing method of black garlic by the deodorized, dried garlic. The deodorized, dried garlic is made by deodorizing and drying. The defects of fresh garlic such as easiness to sprout, dehydrate, wither and rot in long-term storage and unsuitability for long-term storage are overcome, and processing and eating methods of garlic are broadened. The processing method of the black garlic includes the steps of soaking, cooking, fermenting and drying and is laborsaving, timesaving, cost-saving, high in production efficiency and low in rejection rate. The produced black garlic product is effective to eat and is available delicacy convenient and free for people to eat.

Owner:徐州绿之野生物食品有限公司

Preparation method for instant noodles

InactiveCN103504203AConvenience guaranteedEnsure food safety and healthMulti-step food processesFood preparationReady to eatPreservative

A disclosed preparation method for instant noodles specifically comprises the following steps: 1) boiling: putting fresh noodles into boiling water and boiling the noodles to have gelatinization degree of 45-65%; 2) cutting; 3) mixing with oil: spraying cooked edible oil on the noodles and mixing uniformly; 4) mixing with seasoning: adding the seasoning into the noodles and mixing uniformly; 5) loading boxes with weighed noodles according to product specification demands; and 6) steaming: steaming with a temperature of 97 DEG C-100 DEG C, heating till the central temperature of the noodles reaches 100 DEG C, and keeping the constant temperature for 40 min or more to obtain the instant noodles. According to the method, the fresh noodles are subjected to once independent gelatinization, are successively impregnated with oil, mixed with the seasoning and subjected to secondary gelatinization, and the two-time gelatinization degree and the central temperature of the noodles are controlled for reaching the demands of packaging, fresh-keeping and ready-to-eat property; and no any antiseptics are used, the finished product does not need refrigeration for preservation, and tests prove that the instant noodles can be stored at room temperature for 60 days or more.

Owner:张斌社

Black Jerusalem artichoke food and preparation method thereof

InactiveCN103039915AImprove antioxidant capacityDelicate meatFood preparationFood processingJerusalem artichoke

The invention discloses a black Jerusalem artichoke food and a preparation method thereof, which relates to the field of food processing. The black Jerusalem artichoke food is prepared by fermenting pre-processed Jerusalem artichoke at the temperature of 65-75 DEG C and the humidity of 75-85% for 15 days. According to the invention, the product is delicate in texture and easy to chew, thereby contributing to the eating of the aged and people having bad teeth; and the fermented Jerusalem artichoke is sweet in taste, and tough and chewy, thereby increasing the eating desire of people. The invention is reasonable in process, simple to manufacture, and beneficial to industrial production, and has good market prospects.

Owner:徐州绿之野生物食品有限公司

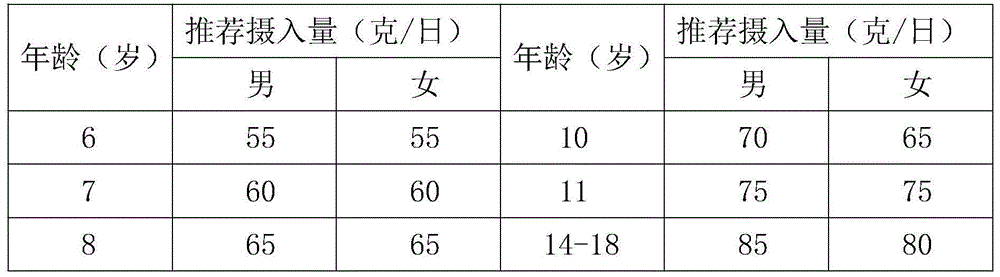

Nutritional noodles for children and production technology thereof

InactiveCN104938944AHigh nutritional valuePromote absorptionFood ingredient functionsFood preparationYolkButter cocoa

The invention discloses nutritional noodles for children. The nutritional noodles are prepared from the following components in parts by weight: 100 parts of flour, 2 parts of corn peptide, 1.5 parts of flavor salt, 5 parts of flavor powder, 2 parts of dry cowhells powder, 2 parts of dry pig skin powder, 0.5 part of dry crucian meat powder, 0.5 part of apple powder, 5 parts of soybean powder, 2 parts of cocoa butter, 1 part of white granulated sugar, 2 parts of tartary buckwheat powder, 1 part of yolk powder, 0.2 part of fresh-water turtle shell powder, 0.5 part of leonurus pollen and a proper amount of water. The nutritional noodles are prepared by stirring and mixing the flour, the corn peptide, the flavor salt, the flavor powder, the dry cowhells powder, the dry pig skin powder, the dry crucian meat powder, the apple powder, the soybean powder, the cocoa butter, the white granulated sugar, the tartary buckwheat powder, the yolk powder, the fresh-water turtle shell powder, the leonurus pollen and the proper amount of water, then performing curing, compounding, rolling and slitting and carrying out drying and packaging. The nutritional noodles are rich in nutrition and do not contain substances harmful to the health and the growth of a human body; furthermore, the raw materials are readily available; the preparation technology is simple, and the cost is low; the nutritional noodles are rich in trace elements necessary to the human body.

Owner:ANHUI FOZILING FLOUR IND

Sanqing noodles and preparation method thereof

The invention relates to Sanqing noodles. The Sanqing noodles are mainly prepared from sweet buckwheat powder serving as the main material, and auxiliary materials including oat powder, tartary buckwheat powder, peameal and konjaku flour; and the raw materials are in parts by weight, as follows: 80 to 90 parts of sweet buckwheat powder, 5 to 11 parts of oat powder, 6 to 14 parts of tartary buckwheat powder, 1 to 5 parts of peameal, and 1 to 7 parts of konjaku flour. The invention also relates to a preparation method of the Sanqing noodles, and the preparation method comprises the following steps of: screening the sweet buckwheat powder and the auxiliary powder to remove impurities; weighing; kneading dough; fermenting; microbulking and extruding in two grades; ageing; drying; cutting to strips; and packaging. According to the preparation method, the raw material and auxiliary materials are pollution-free, any food additives are not added, so that the Sanqing noodles are pure natural coarse cereal foods; the processing process and operation are simple, the production efficiency is high, and the nutritional components of buckwheat are fully remained. As shown in the detection result from the technical section, the Sanqing noodles meet relevant national standard for foods and can be used as the daily diet for patients suffering from hyperlipidemia, hypertension and hyperglycemia according to the food glycemic index evaluation test; and in addition, the Sanqing noodles taste pliable and smooth, have unique flavor and are received by consumers.

Owner:TAIYUAN LIUWEIZHAI IND +1

Spicy jerusalem artichoke black pickle and processing method thereof

InactiveCN103039922AEdible and easy to chewEasy to eatClimate change adaptationFood preparationSide dishOlder people

The invention provides spicy jerusalem artichoke black pickle and a processing method thereof. The spicy jerusalem artichoke black pickle comprises 100 kg of jerusalem artichoke, 6-12 kg of salt, 0.02-0.03 kg of ascorbic acid, 0.35-0.5 kg of pepper, 0.25-0.35 kg of star anise, 0.3-0.5 kg of allspice, 1.5-3 kg of dried red pepper and 0.5-1 kg of white sugar and is prepared by pickling, airing, steam cooking and fermenting. The prepared spicy jerusalem artichoke black pickle is tough and chewy in mouth feel and mellow in taste, has a fragrant, salty, sweet and slightly spicy taste, is particularly applicable to old people and people with bad teeth, is easy to chew, provides a side dish eaten together with rice or bread for people, and has a health-care effect and thus is particularly applicable to diabetics; a processing method of the spicy jerusalem artichoke black pickle is simple in process and applicable to large-scale production, and can form an industry to meet market demands of people; and the spicy jerusalem artichoke black pickle is high in quality, low in price and very popular among customers.

Owner:徐州绿之野生物食品有限公司

Pre-gelatinized noodle flour and production method thereof

ActiveCN101791000ATaste chewyLong shelf lifeDough treatmentPre-baking dough treatmentChemistryMoisture

The invention discloses pre-gelatinized noodle flour and a production method thereof. The production method mainly comprises the following steps: adding special additives in raw flour, mixing, treating for 2-3 seconds with hydrothermal steam of 105 DEG C to obtain gelatinized flour, and dehumidifying the gelatinized flour until the moisture content in the flour is reduced to below 14 percent, thereby obtaining the pre-gelatinized noodle flour. The noodles produced with the pre-gelatinized noodle flour of the invention are white, translucent and pliable, and the shelf life is significantly prolonged. Moreover, the noodles produced with the pre-gelatinized noodle flour can maintain the natural taste after being frozen.

Owner:青岛品品好食品发展有限公司

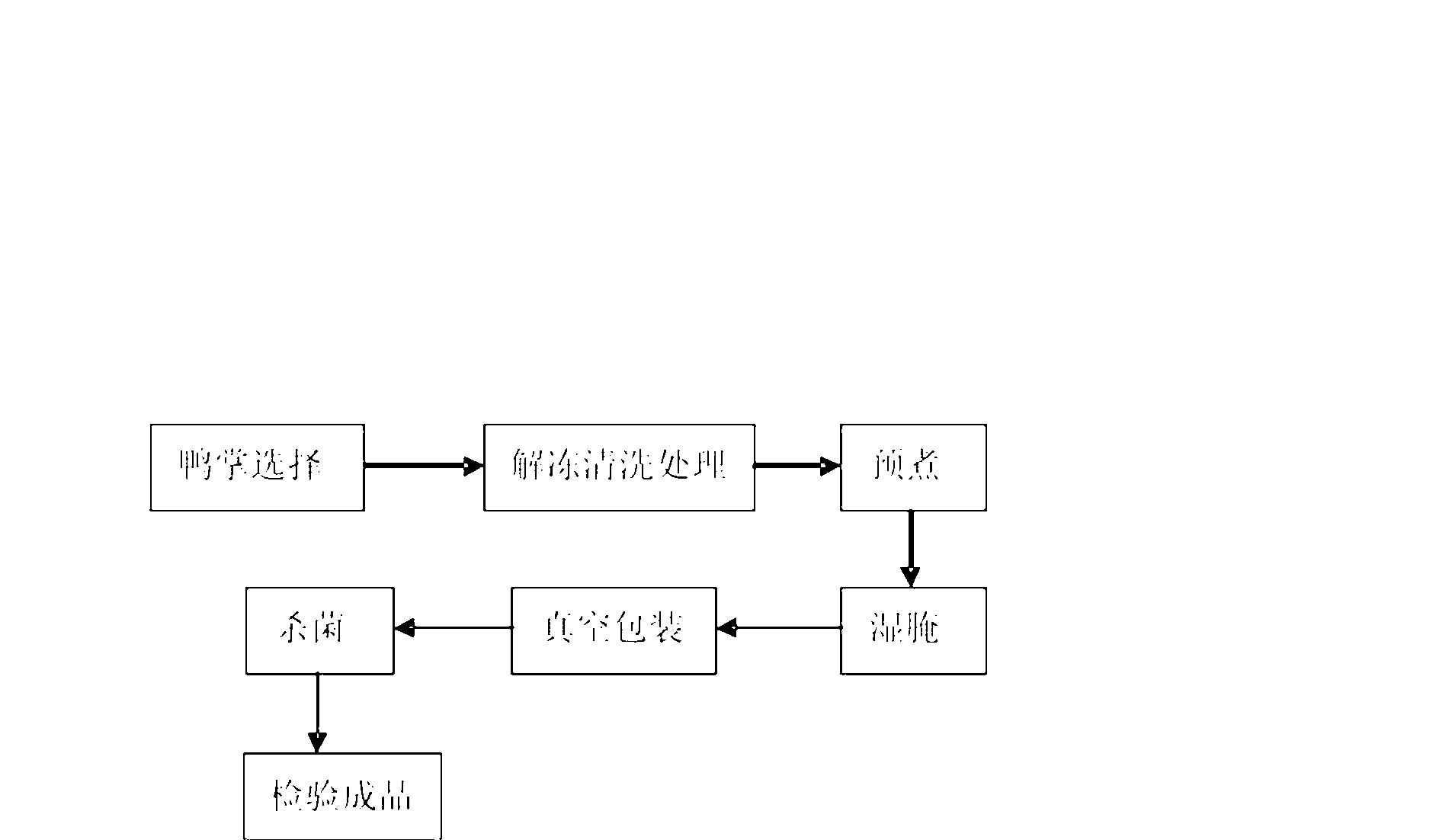

Snack duck feet processing process

The invention relates to a snack duck feet processing process, and discloses a novel processing process of duck feet. A main material comprises examined and qualified frozen duck feet, and auxiliary materials comprise a flavoring A and a spice B. The flavoring A comprises edible salt, white sugar, soy sauce, edible aromatic vinegar, and monosodium glutamate. The spice B comprises aniseed, cinnamon, ginger, fennel, and bay leaf. A process flow comprises the steps of: duck feet selecting, thawing and washing, precooking, wet preserving, vacuum packaging, sterilizing, and finished product examining. The process comprises the steps that: high-quality duck feet are selected and trimmed; the duck feet are washed twice by using clear water, and are dip-dried in a basket; a precooking marinade is prepared by using 100kg boiled water and 10% of edible salt, 5% of soy sauce, 3% of sliced ginger, 0.5% of aniseed, and 1% of cinnamon; the materials are boiled for 30min in a boiling state; a material bag is boiled for 15min with the duck feet, such that the product is uniformly heated, colored, and flavored; when the product is in a sauce-yellow color, the product is fetched, dip-dried, and cooled; a preserving liquid is decocted in a sandwich pot; the duck feet is placed in the preserving liquid, and is preserved for 10min; and vacuum packaging and sterilizing are carried out.

Owner:XUZHOU HUINONG DUCK IND CO LTD

Selenium-rich noodles

InactiveCN102934771AImprove biological activityHigh nutritional valueFood preparationCodonopsis pilosulaPlant Tubers

The present invention relates to selenium-rich noodles, which are characterized by comprising the following dry components, by weight, 0.1-1% of selenium-rich gynostemma pentaphyllum, 0.1-1% of tuber fleeceflower root, 0.1-1% of pilose asiabell root, 0.1-1% of medlar, 2-25% of mung bean, 0.05-0.2% of rhizoma coptidis, 5-15% of corn starch, 5-15% of glutinous rice, 1-5% of common yam rhizome powder, and 80-95% of flour. According to the present invention, selenium-rich gynostemma pentaphyllum and other materials are placed in a pot to carry out decoction to remove residues, the filtrate is added with common yam rhizome powder and flour to knead, and noodles are produced according to the existing noodle production process.

Owner:饶莉

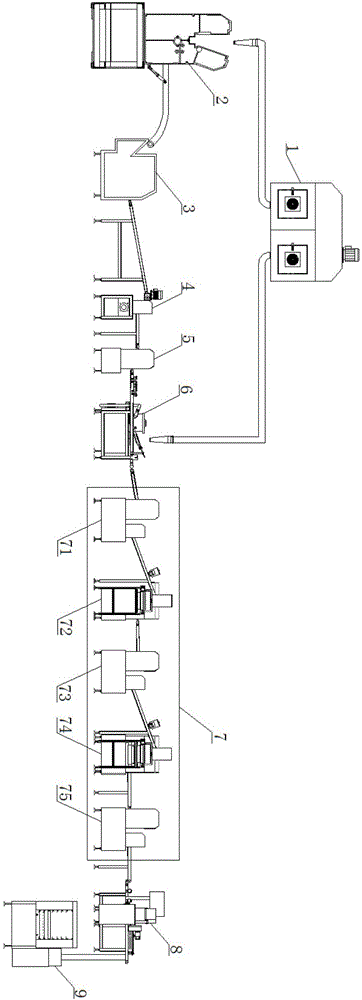

Fresh noodle processing technology and fresh noodle automated production device

InactiveCN106561758AIncrease toughness and cooking resistanceTaste chewyDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusChemistryForming processes

The invention discloses a fresh noodle processing technology and a fresh noodle automated production device. The fresh noodle processing technology comprises the steps of preparing flour mixing water, mixing flour, crushing, tabletting, folding and rolling flour into dough, folding, rolling, cutting and forming, packaging, preserving, and the like. According to the fresh noodle processing technology and the fresh noodle automated production device of the invention, dough is preliminarily processed through a flour mixer, a dough crusher, a compound tablet press and a folding processing device to make the raw material stirred evenly, preliminary rolling and folding are carried out, and then, rolling and folding are carried out repeatedly through folding and rolling devices. Thus, the toughness of noodles is increased in the noodle shaping process, and the same chewiness as handmade noodles is achieved. Moreover, the production device is fully automated, so that the work efficiency and the yield of noodles are improved greatly. There is no manual operation in the intermediate processing link, and thus, the noodles made are cleaner.

Owner:安徽新创智能科技有限公司

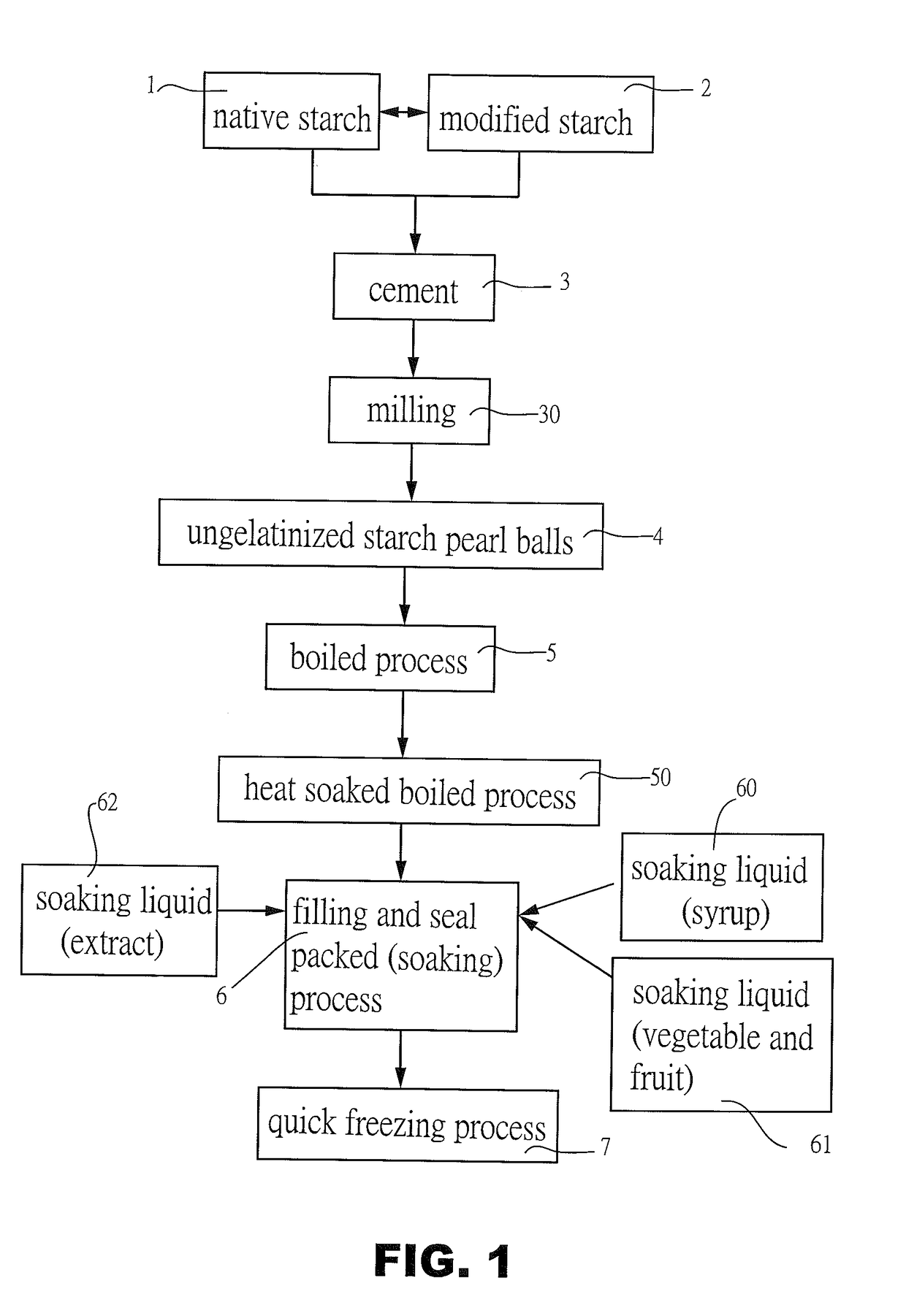

Method for Making Starch Pearl Ball

A method includes provides native starch and modified starch which are mixed to form a body. Then, the body and the cement are treated by a conventional manufacturing method to make ungelatinized starch pearl balls. The ungelatinized starch pearl balls are treated by a boiled process during 5-30 minutes and are then treated by a heat soaked boiled process during 30-150 minutes to form gelatinized starch pearl balls. Then, the gelatinized starch pearl balls and a soaking liquid are filled into a package to perform a vacuum filling and seal packed process, so that the gelatinized starch pearl balls are soaked in the soaking liquid during a few hours. Then, the gelatinized starch pearl balls perform a quick freezing process to prevent the starch pearl balls from becoming aged and hardened. Thus, the starch pearl balls keep a chewy taste and have different flavors.

Owner:CHEN CHIH CHIEH

Sorghum and honeysuckle dietary rice and preparation method thereof

InactiveCN105285721AHigh transparencyAppearance crystal lusterNatural extract food ingredientsFood ingredient functionsPEARCocoa Powders

The invention discloses sorghum and honeysuckle dietary rice. The sorghum and honeysuckle dietary rice is prepared from the following raw materials in parts by weight: 60-70 parts of sorghum, 10-14 parts of walnut kernels, 100-120 parts of brown rice, 30-40 parts of corn cobs, 10-12 parts of honeysuckles, 6-7 parts of lemon grass, 20-30 parts of snow pears, 10-15 parts of sweet oranges, 3-4 parts of mint leaves, 1-2 parts of angelica dahurica, 2-3 parts of radix scutellariae, 1-2 parts of tree peony bark, 2-3 parts of greenish lily seeds, 7-9 parts of cocoa powder, and an appropriate amount of soybean milk. According to the sorghum and honeysuckle dietary rice disclosed by the invention, the brown rice is used as the main material, and the nutrients raw materials, such as the sorghum and the honeysuckles, are added to be reorganized and processed to obtain the dietary rice. The sorghum and honeysuckle dietary rice is sparkling, crystal-clear and bright in appearance, smooth, mellow and full in surfaces, high in transparency, compact in structure, long in shelf time, short in cooking time, good in appearance of rice after being cooked, free from pastiness or deformation, light in fragrance of flowers, tenacious in mouth feel, and moderate in soft and hard degrees. After being eaten for a long term, the sorghum and honeysuckle dietary rice has the efficacies of nourishing the kidney, warming the lung, relieving rigidity of muscles and activating collaterals, regulating the function of the stomach, ventilating, loosening bowel to relieve constipation and the like.

Owner:安徽省谷色天香农业有限责任公司

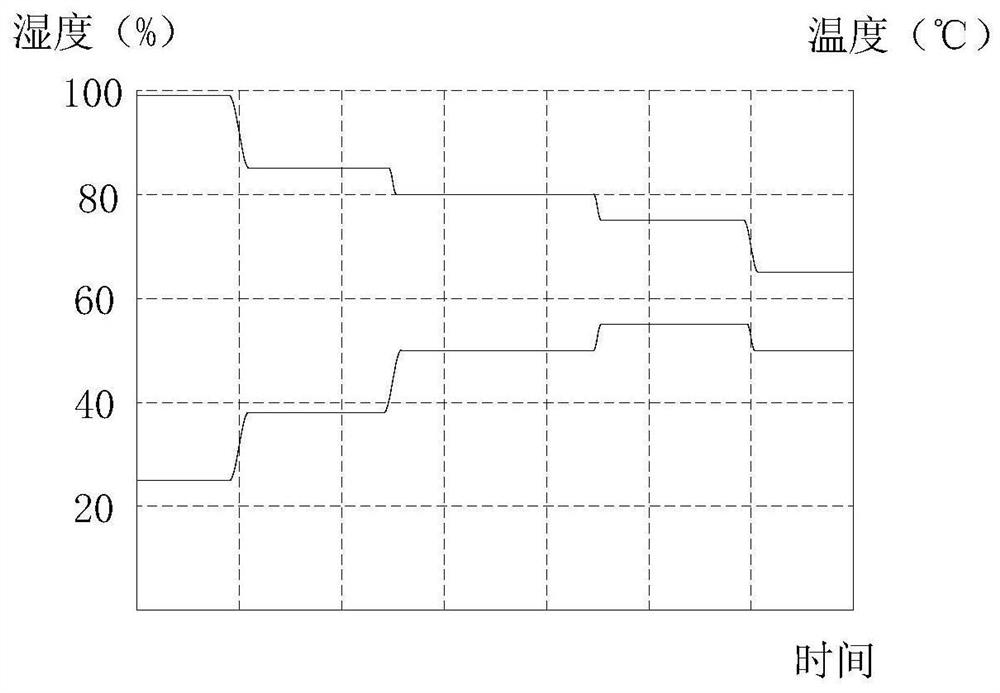

Medium-temperature high-humidity noodle drying process

ActiveCN112414023AIncreased water diffusion resistanceControl humidity gradientDrying gas arrangementsDrying solid materialsSurface moistureEngineering

The invention relates to the technical field of noodle processing, in particular to a medium-temperature high-humidity noodle drying process, which comprises the following steps of: feeding sliced noodles into a drying room for drying in stages, wherein the initial humidity in the drying room is 98 + / -2 percent, the air humidity is sequentially reduced in each stage until the air humidity is finally 65 + / -5 percent, the initial temperature in the drying room is 25 + / -2 DEG C, the temperature in the drying room is firstly sequentially increased to 55+ / -2 DEG C, then the drying temperature at the last stage is reduced to 50+ / -2 DEG C, and the difference value between the internal moisture content and the surface moisture content of the noodles in each stage is smaller than 2 percent; and then sending the noodles out of the drying room so as to be naturally cooled, wherein no film is formed on the surfaces of the noodles when the noodles are taken out of the drying room. According to themedium-temperature high-humidity noodle drying process provided by the invention, through reasonable temperature and humidity control, a drying effect is good, the noodle quality is good, and the noodles are smooth in surface, good in smoothness, high in flexibility, chewy in taste and stable in product quality.

Owner:襄阳丰庆源面业股份有限公司

Garlic noodle

InactiveCN104642923AAntidiarrhealFull of nutritionNatural extract food ingredientsFood ingredient functionsDigestionAllium sativum

The invention discloses a garlic noodle, and belongs to the technical field of food processing. The garlic noodle is prepared from the following raw materials in parts by weight: 25-80 parts of garlic juice, 2-5 parts of ginger juice, 1-5 parts of onion juice, 50-80 parts of wheat meal, 5-15 parts of millet flour, 1-15 parts of black soybean meal, 1-15 parts of cassava starch, 1-15 parts of corn flour, 1.2-3.0 parts of citric acid, 0.1-1.0 part of edible salt and 0.6-1.2 parts of dietary alkali. The garlic noodle disclosed by the invention has the efficacies of resisting and preventing diarrhea, checking diarrhea, helping digestion, lowering blood pressure, enhancing the immunity, regulating the flow of vital energy and reliving a cough; the noodle prepared from a plurality of coarse grain flour, such as wheat meal, millet flour and black soybean meal is abundant in nutrient and good in flavor.

Owner:黄汉森

Method for preparing rice noodles

The invention discloses a process for preparing rice noodles, and belongs to the field of food processing. The process for preparing the rice noodles comprises the following steps: (1) soaking of raw materials; (2) pulping; (3) rice noodle steaming forming; (4) slicing; (5) drying and packaging. Rice is adopted as a raw material for the rice noodles, the flavor and the nutrition of the rice are reserved, and no pigments, edible gum, alum and additives are added; the rice noodles prepared by the method taste chewy, soft and smooth without breakage, agglomeration and sand-dust, and the shelf time is prolonged.

Owner:黔东南佳味源食品有限公司

Highland barley fine dried noodle and preparation method thereof

InactiveCN109567019ARaise the ratioFit for consumptionFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentFlavorBeta-glucan

The invention belongs to the technical field of food processing and specifically relates to a highland barley fine dried noodle and a preparation method thereof. The highland barley fine dried noodleis prepared from the following raw materials by weight percent: 80-90per cent of highland barley flour, 10-15per cent of wheat gluten, 0-1.5per mil of flaxseed gum, 0-0.3per mil of sagebrush gum and 0-0.6per cent of edible salt. Percentage of highland barley flour is high in raw materials; the prepared fine dried noodle has a strong flavor of highland barley flour; the highland barley fine dried noodle is high in content of highland barley beta-glucan and is especially suitable for people accompanied by high blood fat, high blood pressure and high blood sugar; wheat gluten is adopted, so thatductility is excellent when flour is pressed in production process, and the problems of easiness in dispersing, incapability of fishing up and high loss ratio of cooking while cooking the highland barley fine dried noodle can be solved. The invention also provides the preparation method; the highland barley fine dried noodle is prepared through the steps of mixing raw materials, kneading dough, fermenting dough, pressing dough, slitting, drying, and the like; the operation is simple; dosing of the product is simpler and is easy to master; production cost is low; productivity is high; the highland barley fine dried noodle is easy for large-scale production.

Owner:雷在更

Starch lump making process using sweet potato starch

The invention relates to a starch lump making process using sweet potato starch, wherein the process comprises Gordon euryale seed powder preparing, conciliating flour, powder leaking and injection molding.

Owner:董树海

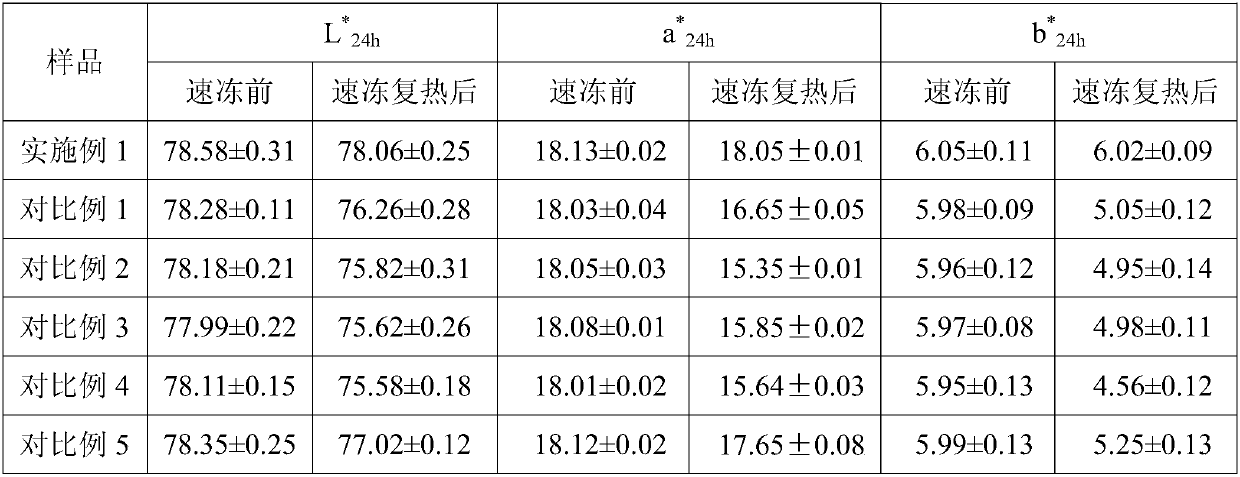

Quick-frozen braised noodle and preparation method thereof

The invention relates to the technical field of food processing, and particularly relates to a quick-frozen braised noodle and a preparation method thereof. According to the quick-frozen braised noodle provided by the invention, wheat-core wheat flour, acetate modified starch and hydroxypropyl distarch phosphate are combined and used as a flour matrix, four components of isolated soy protein, sodium tripolyphosphate, sodium pyrophosphate and sodium polypyrophosphate are contained in a water retention agent; all components in the flour matrix synergistically acts; all the components in the water retention agent synergistically interacts; afterwards, by combining a three-time-awaking noodle preparation process, the water-absorption and water-retention performance of the quick-frozen braisednoodle is promoted; the color and luster stability is promoted; the quick-frozen braised noodle is prevented from generating brown stains in a quick-frozen reheating procedure; the eating quality of the quick-frozen braised noodle is improved. The braised noodle prepared by the preparation method is subpackaged and quick-frozen, is directly reheated by a microwave before being eaten, and is convenient for a consumer to eat and suitable for a busy office worker and the industrialized production of the braised noodle is promoted.

Owner:郑州研霖生物科技有限公司

Konjac-hulless barley noodles

InactiveCN106234999ANutritional scienceSmooth and mellow tasteFood ingredient as anti-caking agentNatural extract food ingredientsFagopyrum tataricumCalcium/Sodium

The invention relates to konjac-hulless barley noodles, which are prepared from the following raw materials by weight: 80-100 parts of wheat powder, 20-30 parts of konjac powder, 20-30 parts of hulless barley powder, 4-8 parts of Fagopyrum tataricum powder, 4-8 parts of oat powder, 2-5 parts of a cucumber juice, 1-4 parts of a tomato juice, 1-3 parts of a spinach juice, 30-45 parts of water, 2-3 parts of edible salt, and 0.08-0.1 part of calcium sodium stearyl lactylate. According to the present invention, the konjac-hulless barley noodles have advantages of nutritional and scientific formula, smooth taste and chewiness, and have a certain effect of blood pressure lowering and human immunity enhancing.

Owner:宜垦(天津)农业制品有限公司

Manufacturing method of rice noodles

The invention relates to the technical field of food, and discloses a manufacturing method of rice noodles. The method comprises the following steps of S1, taking 90 to 100 parts of rice and 20 to 30 parts of sticky rice in parts by mass; uniformly mixing the rice and the sticky rice; performing clean washing; performing soaking for 45 to 60 minutes at the normal temperature; S2, fishing out the rice and the sticky rice; performing still standing for 1 to 2 hours so that the water content of the rice and the sticky rice reach 28 to 30 percent; S3, grinding the rice and the sticky rice subjected to still standing into rice powder by an electric stone mill; sieving the rice powder by sieve holes being 60 meshes to 80 meshes; S4, weighing 15 to 20 mass parts of yam; peeling, cleanly washing and crushing the yam; then, adding the yam powder into water to be uniform stirred for forming yam thick liquid; extracting the yam thick liquid through sieves holes being 60 meshes to 80 meshes; S5, uniformly mixing the rice powder and the yam thick liquid; then, putting the mixture into a material cabin of an extrusion machine; performing gelatinization at the temperature being 100 to 110 DEG C; S6, after the gelatinization, extruding rice noodles; S7, performing aging retrogradation, air drying, sterilization and packaging. The rice noodles manufactured by the method have the advantages that fracture cannot easily occur after the boiling for a long time; the mouthfeel is chewy.

Owner:香格里拉市穗源食品有限公司

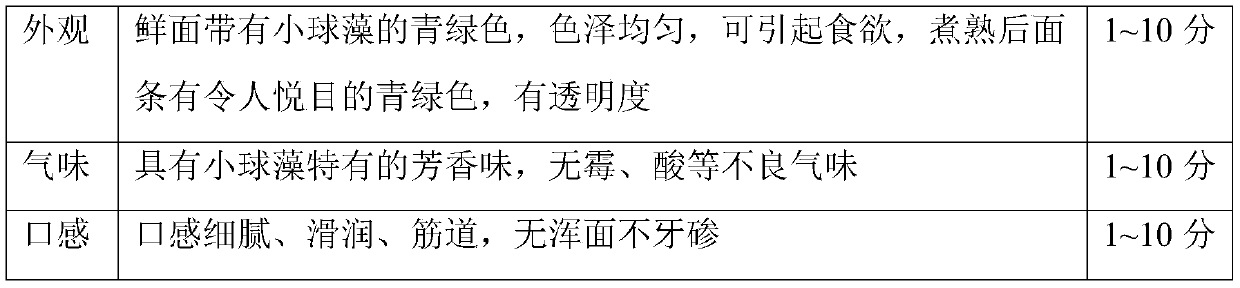

Chlorella pyrenoidosa fine dried noodles and preparation method thereof

ActiveCN109938267ANutritional balanceGood color and fragranceClimate change adaptationFood scienceAdditive ingredientCellulase

The invention discloses chlorella pyrenoidosa fine dried noodles and a preparation method thereof. The fine dried noodles are prepared from 100 parts of wheat meal, 5-10 parts of chlorella pyrenoidosapowder, 2-3 parts of glucose oxidase, 1-3 parts of cellulase, 5-8 parts of corn starch, 3-5 parts of cassava starch, 7-10 parts of xanthan gum, 1-3 parts of sodium alginate, 2-5 parts of salt and 28-40 parts of water. The chlorella pyrenoidosa fine dried noodles prepared through the preparation method have the advantages that the cooked noodle breaking rate is reduced to 0, the cuisine loss rateis reduced to 0.7%, fresh noodles have blue green of chlorella and uniform color and luster, and can whet appetite, the cooked noodles have the pleasing blue green, transparency, unique aroma of the chlorella, no moldy, sour or other unpleasant odors, fine, smooth, tough and chewy taste and no turbid soup, and is not tooth-cracking, the sensory score reaches 27.2-29.4, the sensory evaluation is excellent, and the noodles are a flour-made food which is not only nutritious but also delicious.

Owner:海南绿康安健康生物科技有限公司

Chenopodium quinoa willd half-dried noodles with high lysine content and preparation method

InactiveCN106858319AImprove processing qualityImprove developmentFood ingredient as colourFood ingredient as flavour affecting agentFood additiveFlax fiber

The invention relates to chenopodium quinoa willd half-dried noodles with high lysine content. The chenopodium quinoa willd half-dried noodles are made from the following raw materials in percentage by weight: 20-30% of chenopodium quinoa willd flour, 5-15% of dietary flax fiber flour and 55-75% of high-gluten wheat flour. The chenopodium quinoa willd half-dried noodles disclosed by the invention have the advantages of being simple in technology, free from food additives and high in lysine content.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Rivier giantarum noodles

The invention relates to rivier giantarum noodles. The rivier giantarum noodles are prepared from the following raw materials in parts by weight: 80-100 parts of wheat flour, 20-30 parts of rivier giantarum flour, 4-8 parts of pumpkin flour, 4-8 parts of maize flour, 0.1-0.3 part of lemon flour, 30-45 parts of water, 2-3 parts of common salt and 0.08-0.1 part of sodium-calcium stearyl lactylate. According to the rivier giantarum noodles, the formula is nutritional and scientific, and the taste is smooth, mellow and chewy; the rivier giantarum noodles have certain effects of lowering blood pressure and enhancing human immunity.

Owner:宜垦(天津)农业制品有限公司

Polypeptide cold noodle and production process thereof

InactiveCN104905142AHigh nutritional valuePromote absorptionFood ingredient functionsFood preparationMonopterusTrace element

The present invention discloses a polypeptide cold noodle which is characterized by being prepared by the following components in parts by weight: 90-150 parts of flour, 1-5 parts of corn peptide, 1-2 parts of flavored salt, 4-6 parts of flavored powder, 1.5-2.5 parts of dried donkey white blood powder, 1-2 parts of monopterus albus bone meal, 0.4-0.6 parts of dried serpent-head meat intestine powder, and an appropriate amount of soup-stock; and the polypeptide cold noodle is prepared by the following steps: the flour, corn peptide, flavored salt, flavored powder, dried donkey white blood powder, monopterus albus bone meal and dried serpent-head meat intestine powder are mixed with the appropriate amount of soup-stock, the dough is kneaded, cured, compounded, rolled strip cut, oven-dried and packaged. The polypeptide cold noodle is nutritious, does not contain harmful substances to human health and growth, has wide sources of raw materials, simple preparation process and low cost, and a variety of human body essential trace elements are added.

Owner:ANHUI FOZILING FLOUR IND

Preparation method of mung bean rice noodles

InactiveCN106071886AMeet food health and nutrition requirementsIncrease elasticityFood scienceFlavorPigment

The invention discloses a preparation method of mung bean rice noodles, and belongs to the field of food processing. The preparation process of the mung bean rice noodles includes the first step of raw material soaking, the second step of mixing and paste grinding, the third step of noodle steaming and forming, the fourth step of slitting, and the fifth step of drying and packaging. Mung beans and rice serve as raw materials of the rice noodles, the original taste and flavor of mung beans are maintained, and the mung bean rice noodles contain no pigment or edible gum or alum or additive; besides, the mung bean rice noodles prepared with the method taste chewy, soft and smooth, do not break or cake and are free of dust, and the preservation time of the mung bean rice noodles is prolonged.

Owner:黔东南佳味源食品有限公司

Polypeptide spaghetti and preparation technology thereof

InactiveCN105249189AHigh nutritional valueMeet needsNatural extract food ingredientsPolysaccharide/gum food ingredientsFlavorWheat germ

A polypeptide spaghetti is characterized in that the spaghetti is prepared from wheat flour 75-85 kg, seasoning salt 0.03-0.06 kg, water 18-22 kg, purple sweet potato leaf powder 4-6 kg, Chinese yam polysaccharide 5-10 g, corn peptide 20-80 g, clove extract 40-60 g, rape flower extract 40-60 g, puffed wheat germ powder 1-3 kg, flavor powder 2-4 kg, multivitamin 10-15 g, selenium yeast powder 5-10 g, and alginic acid 6-15 g. The spaghetti has rich nutrition, is without the harmful material for the health and growth of human, and has wide raw material source, simple preparation technology, low cost. Moreover, the spaghetti adds a plurality of necessary trace elements for human body.

Owner:田金举

Pork-chicken composite roasted sausage

The invention discloses a pork-chicken composite roasted sausage. The pork-chicken composite roasted sausage comprises, by mass, 35-70 parts of pork, 10-20 parts of chicken, 5-10 parts of lard, 35-70 parts of ice water, 7.5-15 parts of corn starch, 1.5-3 parts of table salt, 1.5-3 parts of soybean protein isolate, 1.5-3 parts of a curing agent MAPEAK 2.0, 0.75-1.5 parts of white sugar, 0.25-0.5 parts of MF006 liquid pork essence, 0.3-0.6 parts of monosodium glutamate, 0.25-0.5 parts of MAGEL-TA carragheenan, 0.6-1.2 parts of MS104 roasted sausage perfume, 0.075-0.15 parts of a monascus red pigment liquid and 0.004-0.008 parts of sodium nitrite. The pork-chicken composite roasted sausage comprises pork and chicken according to a certain ratio, has a tough, non-greasy and moderately salty taste and is suitable for various people.

Owner:QINGDAO XIUXIAN FOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com