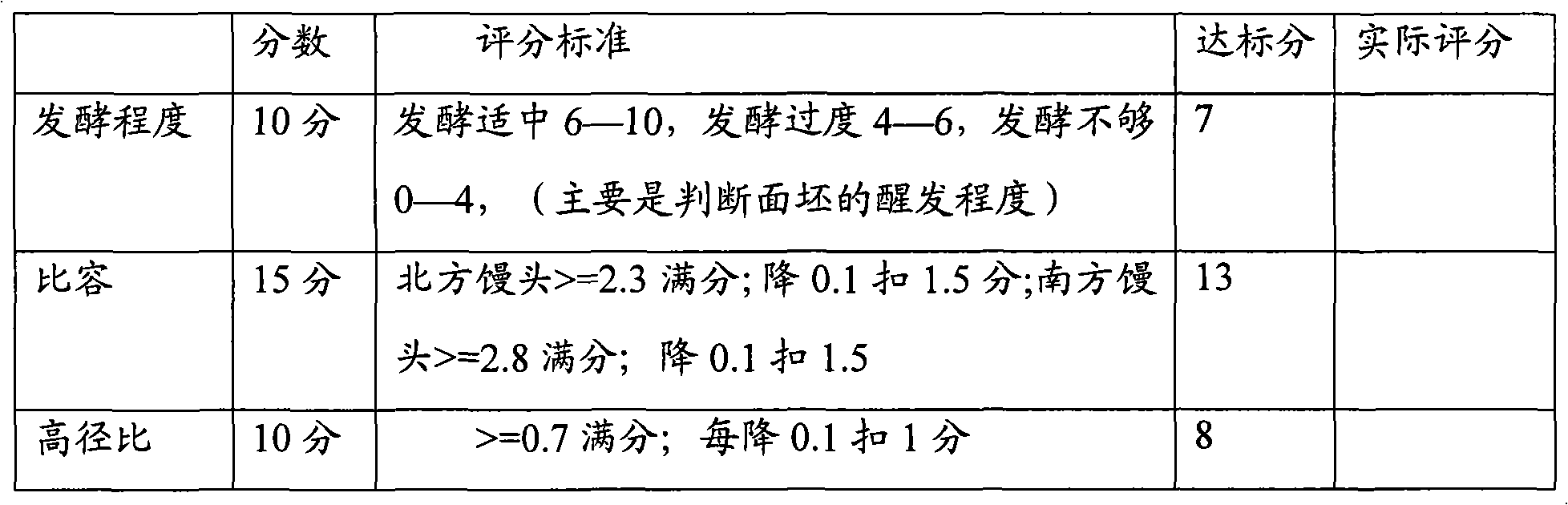

Patents

Literature

1073 results about "Steamed bread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flower-color steamed bread slice and production method thereof

InactiveCN101601418AHighlight substantive featuresSignificant progressDough treatmentDeep-fried productsYeastFlavor

The invention discloses steamed bread slice (dry steamed bread slice) health-care food and a production method thereof. Flour is used as a main raw material, and is added with yeast powder, coarse grain, vegetable powder, dietary fiber, gizzard pepsin powder and flavoring to be prepared into leisure food. The flower-color steamed bread slice product has rich nutrition; various components are scientifically and reasonably compounded; coarse-fine grain and vegetable are matched to accord with the nutrition required by the human body; and the flower-color steamed bread slice product has the characteristics of rich natural color, attractive appearance and unique flavor and mouth feel, meets the demands of various places and various crowds, invigorates the stomach and beautifies, and is favorable for health.

Owner:曹庆荣 +2

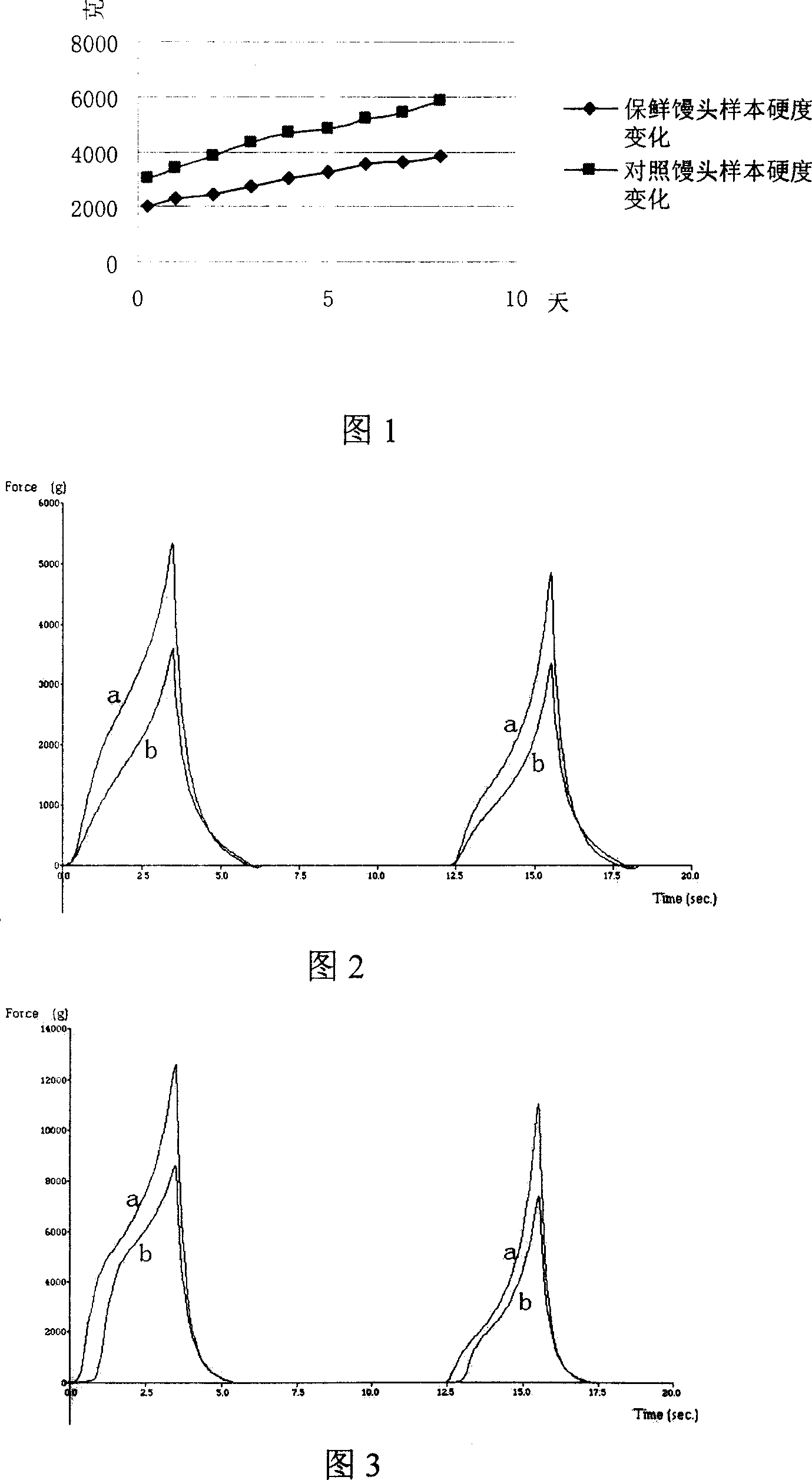

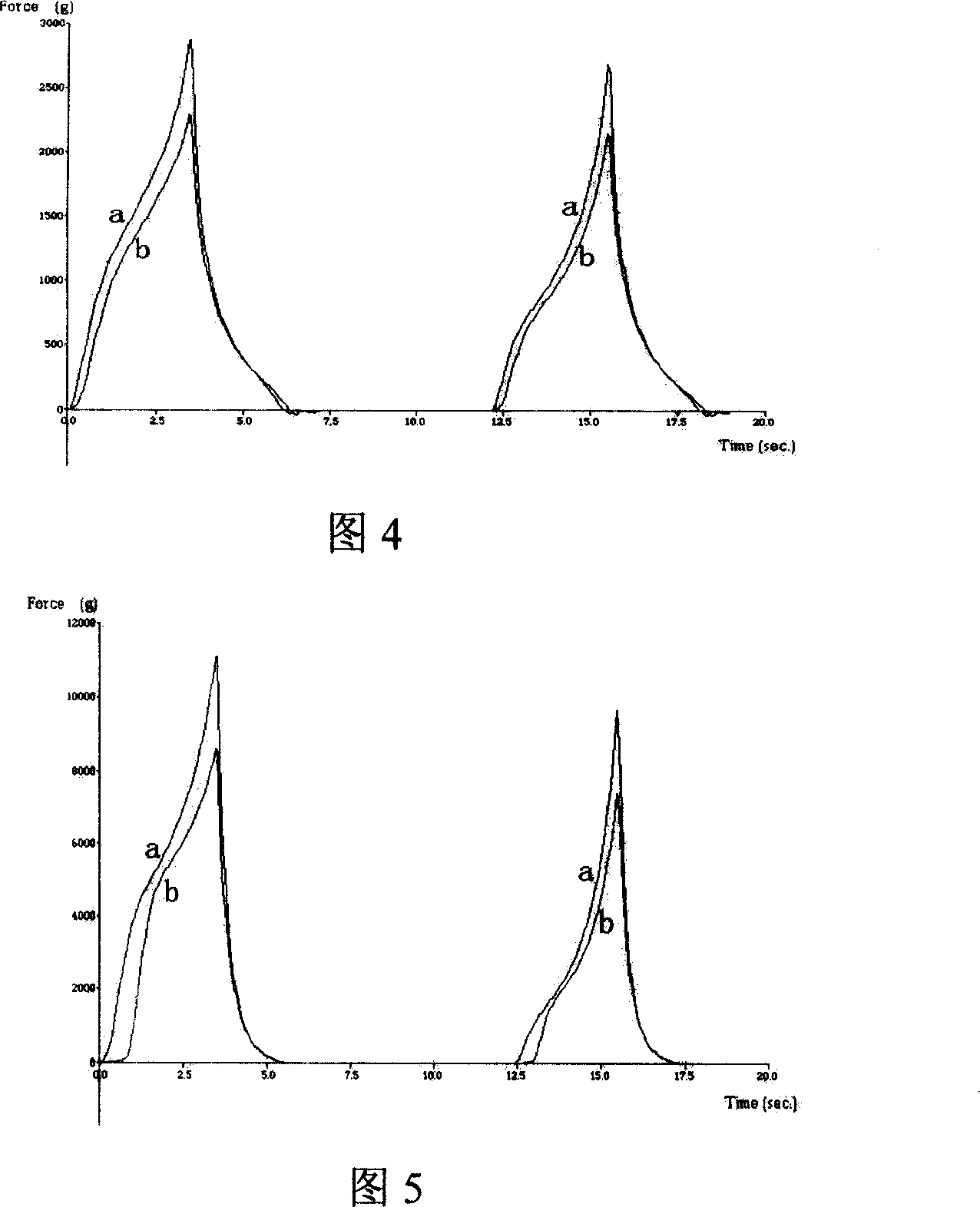

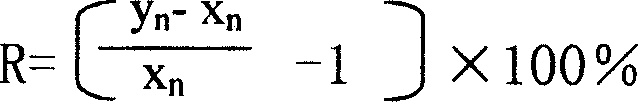

Method of prolonging preservation period of steamed bread

InactiveCN101088341AReduced gelatinization rateIncreased gelatinization rateDough treatmentDough-sheeters/rolling-machines/rolling-pinsGlutenColloid

The present invention belongs to the field of food preserving technology, and is especially method of prolonging preservation period one steamed bread. Compound preserving modifier comprising starch hydrolase 1-7 wt%, hemicellulase 3-7 wt%, lipase 3-7 wt%, emulsifier 40-70 wt%, hydrophilic colloid 15-40 wt%, and coagulation inhibitor 2-6 wt%, is mixed into dough; the dough is pressed and formed into steamed bread blank; and the steamed bread blank is leavened with low temperature supersaturated steam to produce the steamed bread. The steamed bread has improved internal structure, softened core, high antiageing performance and high water content. Its internal cellular gluten structure can limit water escape and delay ageing. At the same time, composite biological mildew inhibitor is sprayed to the surface of steamed bread to inhibit flora growth effectively.

Owner:郑州多福多食品有限公司

Method for improving fermentability and nutritional property of gluten protein-free dough

ActiveCN104146020AImprove fermentation effectImproved ability to hold gasDough treatmentPre-baking dough treatmentNutritive valuesFermentation

The invention provides a method for improving fermentability and nutritional property of gluten protein-free dough. The method includes the steps of 1) activating glutamic acid transaminase, protease A and yeast; 2) peptizing food in water with temperature 50-100 degrees to be evenly mixed with whole flour free of gluten protein, proteins, starches, sugars and salts; 3) adding the activated glutamic acid transaminase and protease A to the mixture for evenly mixing; 4) adding and stirring the activated yeast in the mixture to form the dough; 5) fermenting the mixture within 40-90mins at the temperature of 36-40 degrees and at the humidity of 70-85%. The method is simple and greatly improves the nutritional property and the fermentability of the gluten protein-free dough at the same time. Thus fermentation size of the dough is increased by 1-3 times, contents of vitamin, protein, dietary fiber, mineral elements and the like are remarkably increased, structures and sizes of fermented products such as breads, steamed breads and steamed sponge cakes are improved, and nutritional value of the fermented products is increased.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

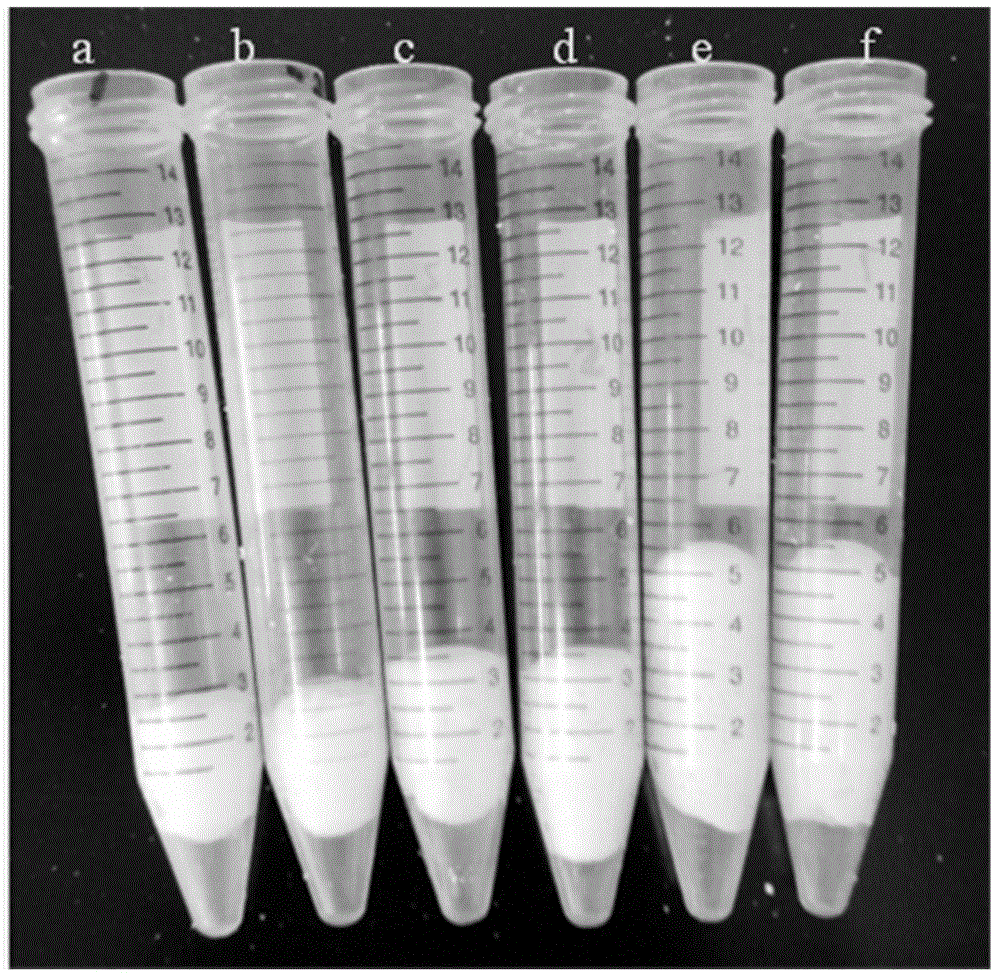

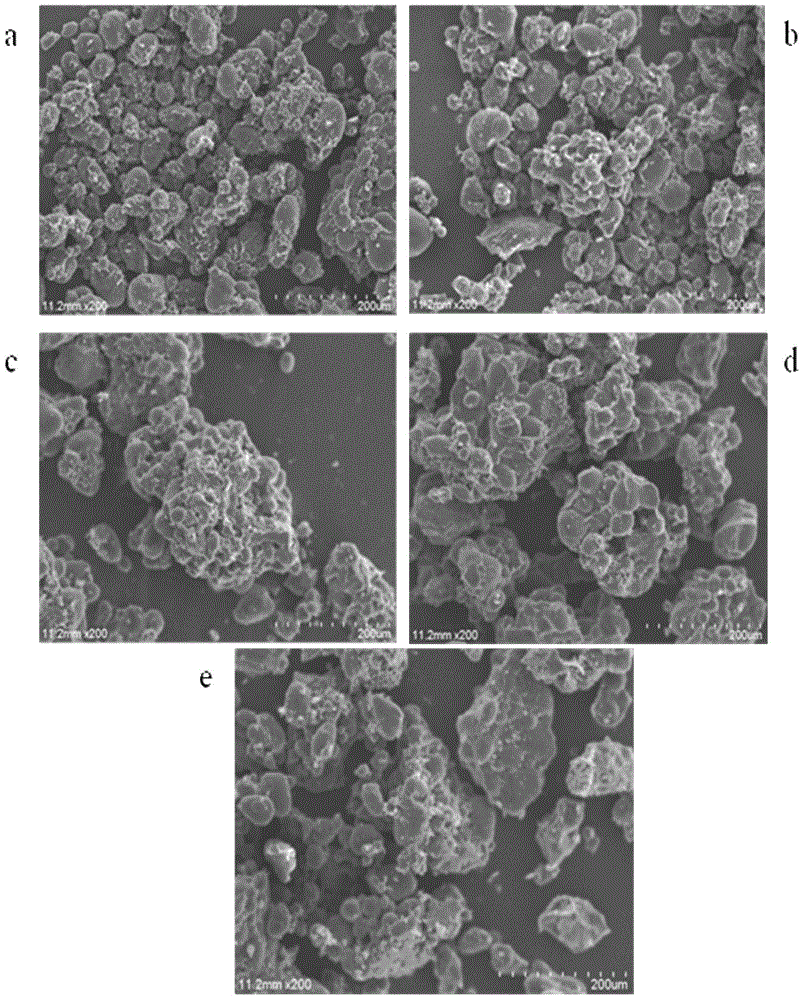

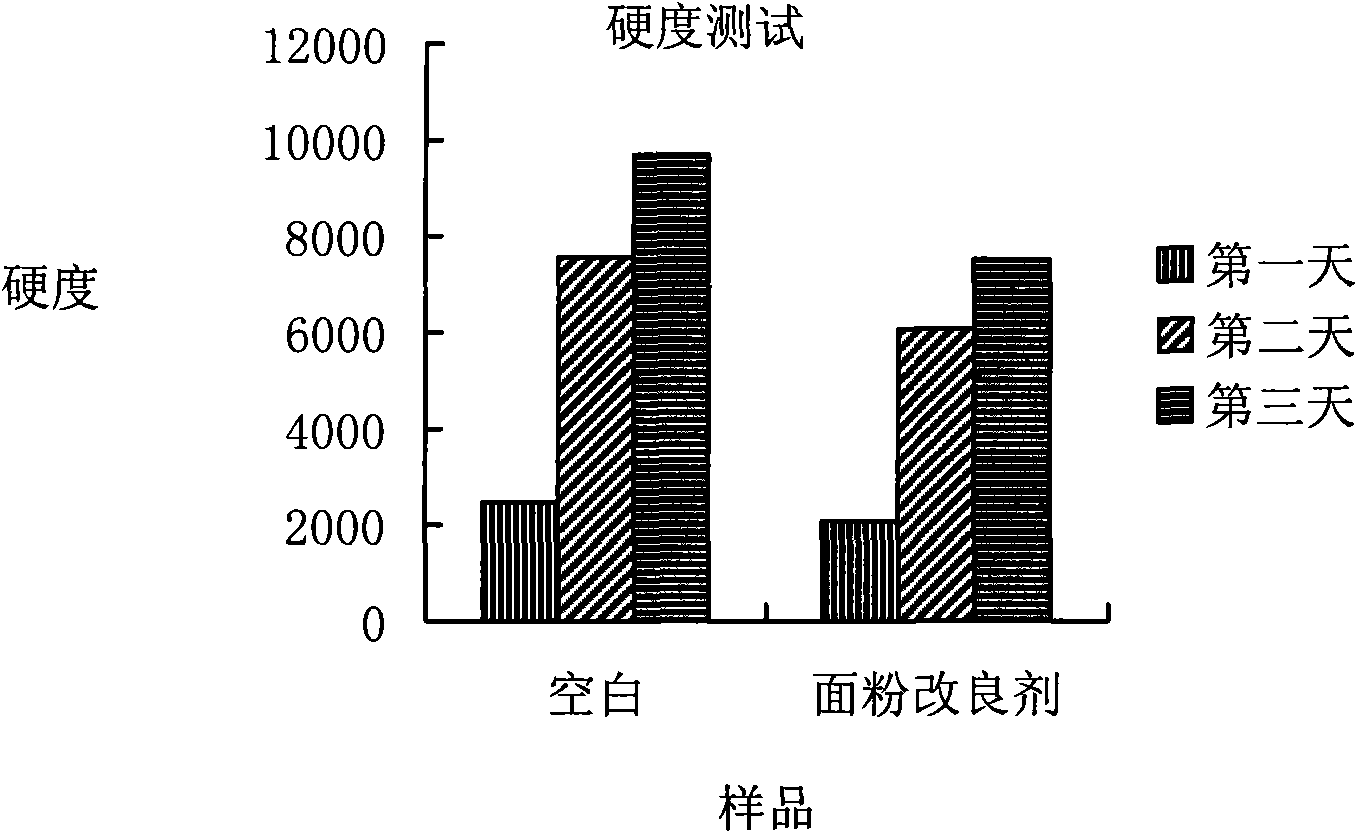

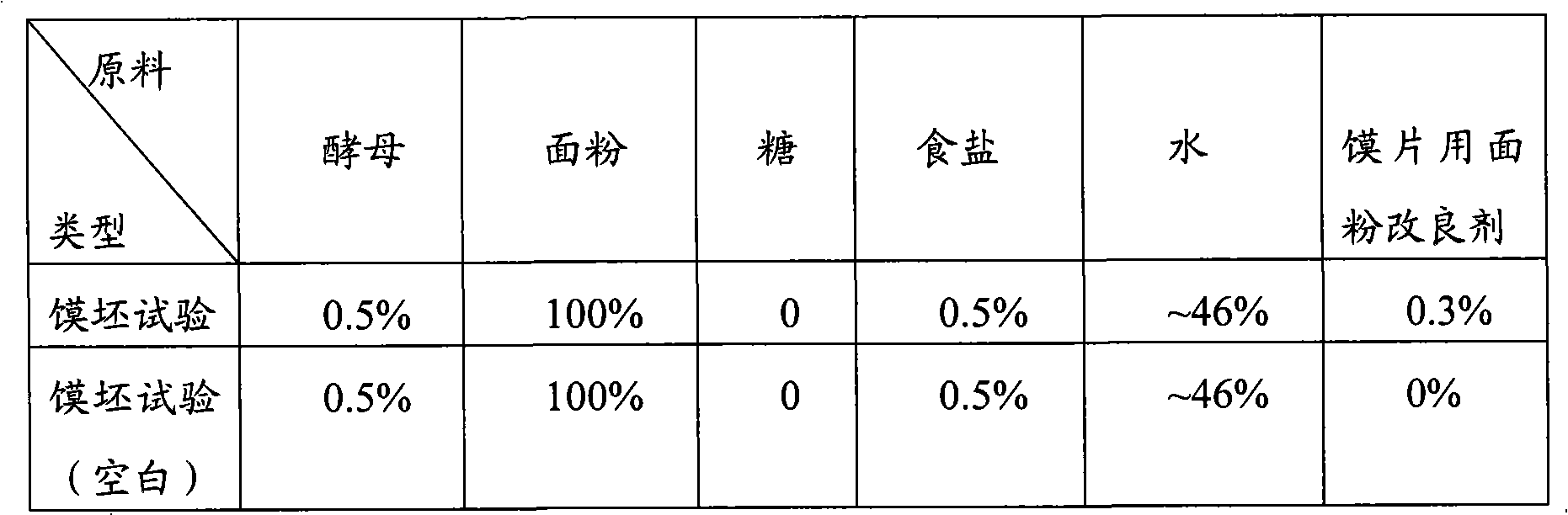

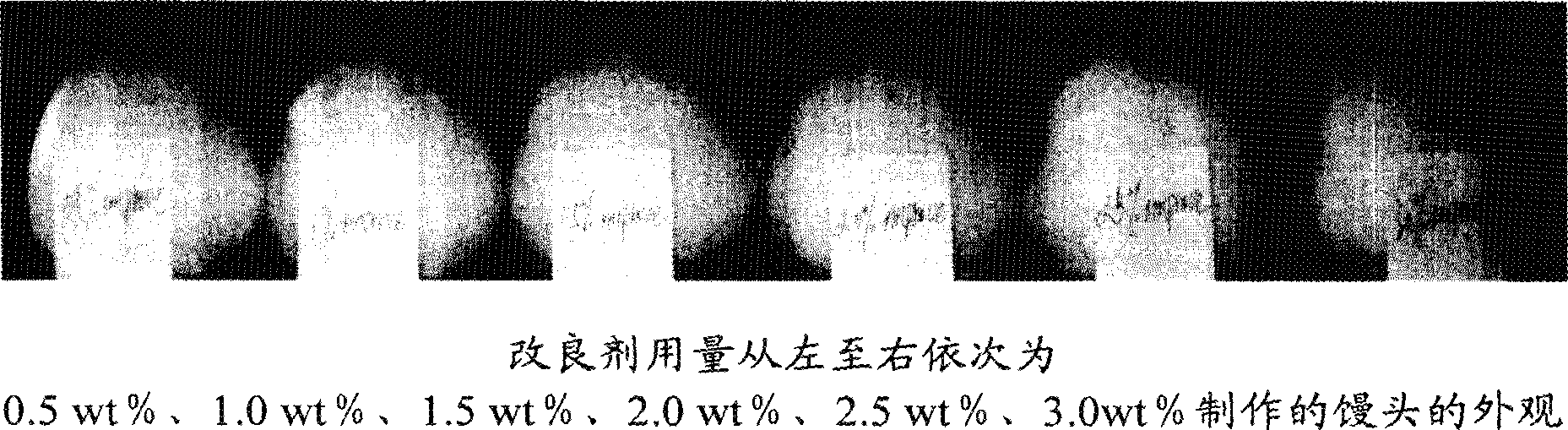

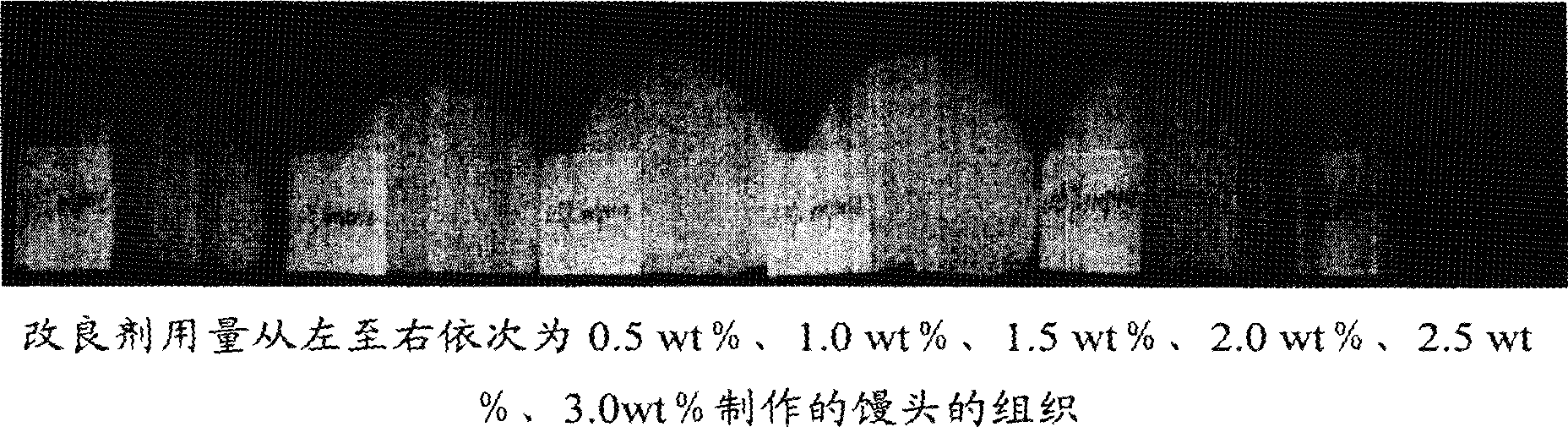

Steamed bread slice making flour modifier and use thereof

InactiveCN101664048AIncrease specific volumeImprove organizational structurePre-baking dough treatmentFood productsSteamed bread

The invention relates to a flour modifier and use thereof, in particular to a steamed bread slice making flour modifier and use thereof. The flour modifier comprises an enzyme preparation, an oxidant,an emulsifier, a swelling agent, a phosphate and starch, can be used for making wheaten food product such as steamed bread and steamed bread slices, improve the structure of steamed bread slices, make the hole in the steamed bread slices more uniform, provide the steamed bread slices with good appearance and improve the crisp degree and yield of the steamed bread slices.

Owner:ANGELYEAST CO LTD

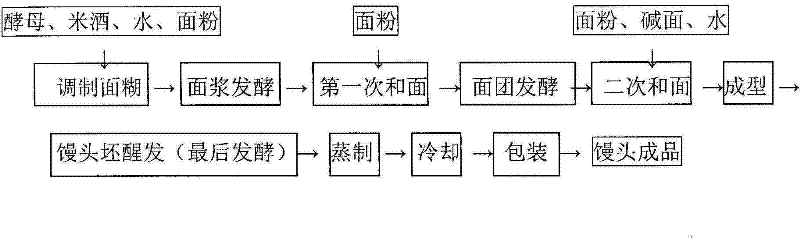

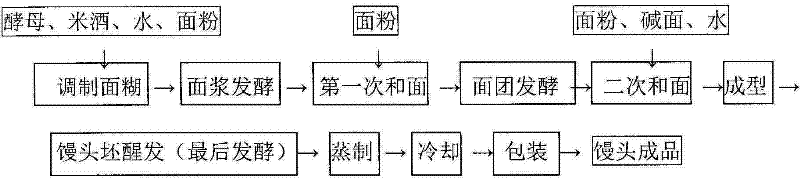

Steamed bun preparation method suitable for industrial production

A steamed bun preparation method suitable for industrial production comprises the following technical steps: 1) fermenting the flour slurry, wherein the flour slurry comprises flour, water, yeast and rice wine; 2) primarily kneading the flour; 3) fermenting the flour dough; 4) secondarily kneading the flour; 5) forming; 6) fermenting the steamed bun billet; and 7) steaming. Compared with prior art, the invention has the following advantages and effects: 1, the technology ferments by the flour slurry so that the strain can be completely activated and propagated; 2, the flour slurry is fermented in a fermenting tank, so the taken area is small; 3, the fermentation of the flour slurry changes the taste and the physical properties of the flour dough, so the flour dough reaches the fermenting taste of the steamed bun levain in short fermenting time, and the fermenting equipment and the area of workshops are reduced; 4, the fermentation of the flour dough effectively adjust the disadvantages that the fermenting force is not stable which caused by continuously supplying the flour slurry; 5, the steamed bun produced by the technology has stable quality and excellent sweet flourbarm, and has unique taste of the traditional steamed bud.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for making steamed breads

The invention relates to a method for making steamed breads, which is characterized by comprising the following steps of: (1) dough making: stirring about 70% of flour, most of water and a pasty dough prepared with a small amount of warm water in advance in a single-shaft S-shaped or crank type dough maker for 5-10 minutes until a dough is unsticky and has elasticity and smooth surfaces, and then putting the dough into a fermenting cylinder, wherein the temperature of the dough requires to be 30 DEG C; (2) fermentation: covering wet cloth on the fermenting cylinder, fermenting for about 3 hours in a fermenting room at the room temperature of 26-28 DEG C and the relative humidity of about 75% until the size of the dough is doubled, the internal honeycomb tissue of the dough is uniform, and the dough has an obvious sour; (3) neutralization, i.e. secondary dough making: putting the fermented dough into the dough maker, gradually adding dissolving water containing soda to neutralize acidity generated by fermentation; and then adding remanent dry flour and water, stirring for 10-15 minutes until the dough is ripe, wherein the soda addition is mastered based on experience, and if the soda addition is appropriate, the dough has a soda flavor and a good mouth feel; (4) formation: accomplishing quantitative cutting and rounding of the dough by adopting a double-roll spiral forming machine, and then placing in boiling drawers (steaming baskets) for fermentation; (5) final fermentation: finally fermenting for 15 minutes at the temperature of 40 DEG C and the relative humidity of about 80%; (6) steaming: steaming in a pot in the traditional method, wherein the dough requires to be placed on the drawers (baskets) when water is boiled, and is well cooked after being steamed for 30-35 minutes on strong fire, or for 25 minutes by using boiler steam for industrial production; and (7) cooling, carrying out air-blast cooling for 5 minutes or naturally cooling and then packaging.

Owner:黄立强

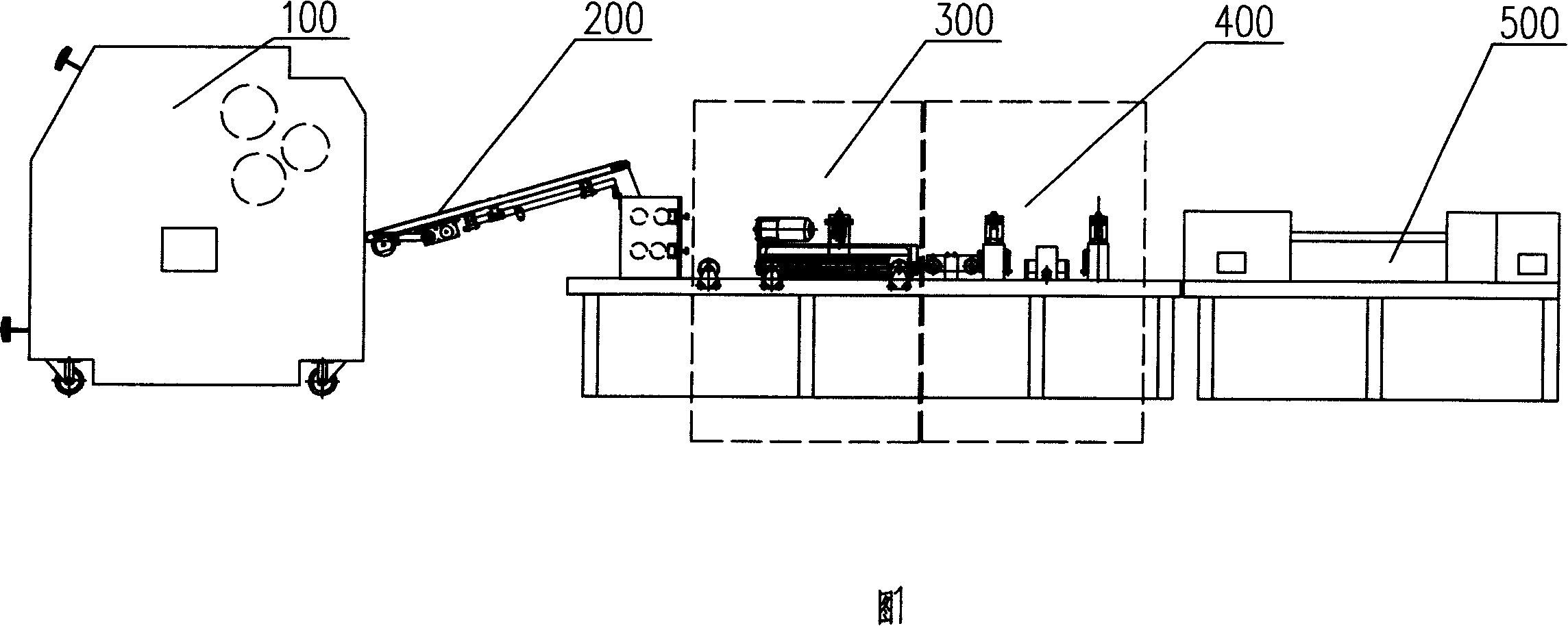

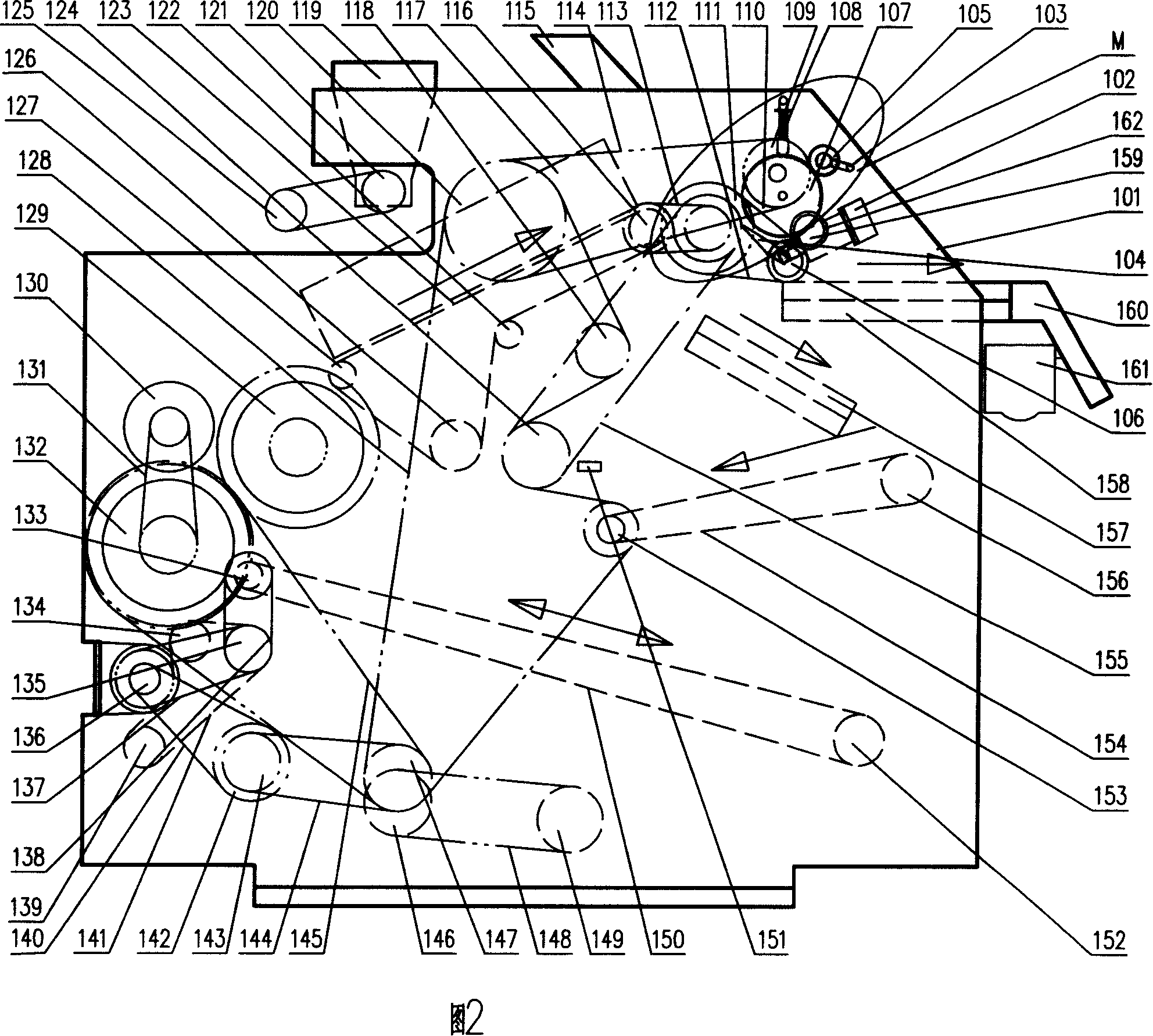

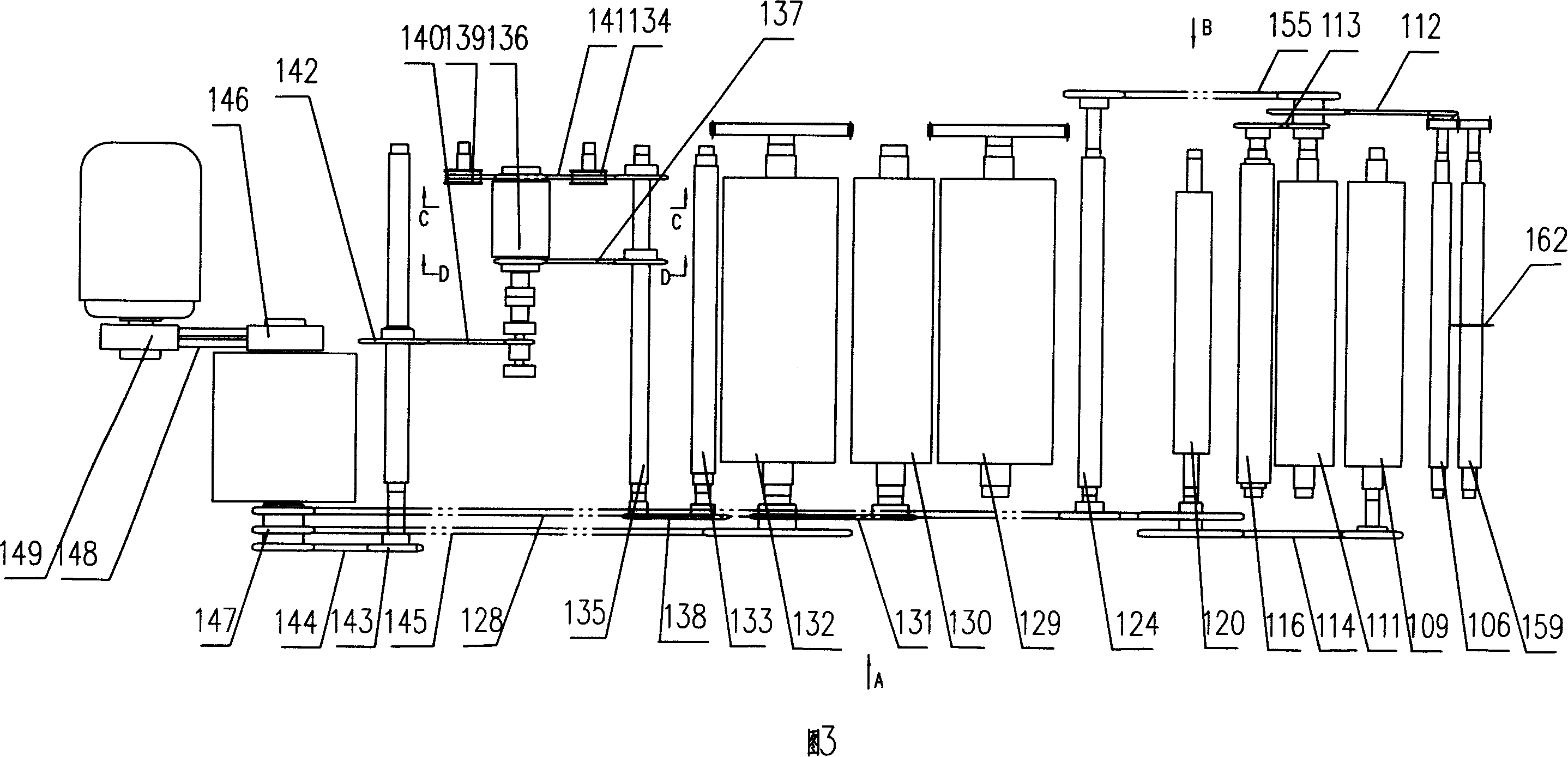

Equipment for producing round steamed bread

ActiveCN101112202AImprove skin brightnessClear internal structureDough-sheeters/rolling-machines/rolling-pinsForming processesFood products

The invention pertains to the technical field of food machinery and relates to producing equipment of round steamed bread. The equipment is provided with the following settings from front to back in sequence: a squash device (100), an incline plane transportation device (200), a winding device (300), a cutting device (400) and a molding device (500). Each device is connected by conveying belt. The squash, winding and cutting devices are added before the molding process. The process steps are as follows: paste is squashed into dough sheet; dough roll is made of the dough sheet through the winding device; then the dough roll is cut, molded to form a clear inner structure layer and improve the brightness of the steamed bread surface and enable the steamed bread to be tasted puckering. The molding process of the invention simulates manual entwisting molding process, which enables the steamed bread inner structure to be difficult to be torn and broken, maintains the sourdough network completely and evenly, has high molding efficiency, and at the same time improves the appearance quality of the dough.

Owner:郑州多福多食品有限公司

Black flour

InactiveCN102405947AFull of nutritionRich in nutrientsDough treatmentNutritional statusModern medicine

The invention discloses black flour. The black flour comprises the following components: black wheat meal, black fragrant rice powder, purple sweet potato whole wheat flour, black millet powder, black bean flour, black sesame powder, black glutinous rice flour, black corn powder and black peanut powder. The invention has the advantages that the flour is rich in nutrition, is rich in Se, melanin and anthocyanin as well as various vitamins, amino acid and mineral elements and also contains certain amount of dietary fiber; especially abundant lysine in the black rice powder can make up the defect that the lysine in common flour is insufficient. Se, melanin and anthocyanin have good antioxidation and free radical eliminating effects, and free radical eliminating capacity by Se is 50-500 times that of vitamin E. Modern medicine thinks that 'black food' is full of nutriments and also has unique effects of tonifying kidney, preventing ageing, benefiting life, preventing and curing illness, hair nourishing and beautifying and the like. Thus, steamed bread and bun produced by adopting the black flour disclosed by the invention can improve nutritional status of the public to a certain extent.

Owner:南昌市微小餐饮管理有限公司

Nutrient fortified health-care steamed bread and preparation method

InactiveCN101810270AGreat tasteNutritional diversityDough treatmentFood preparationAdditive ingredientGLYCYRRHIZA EXTRACT

Owner:王福起

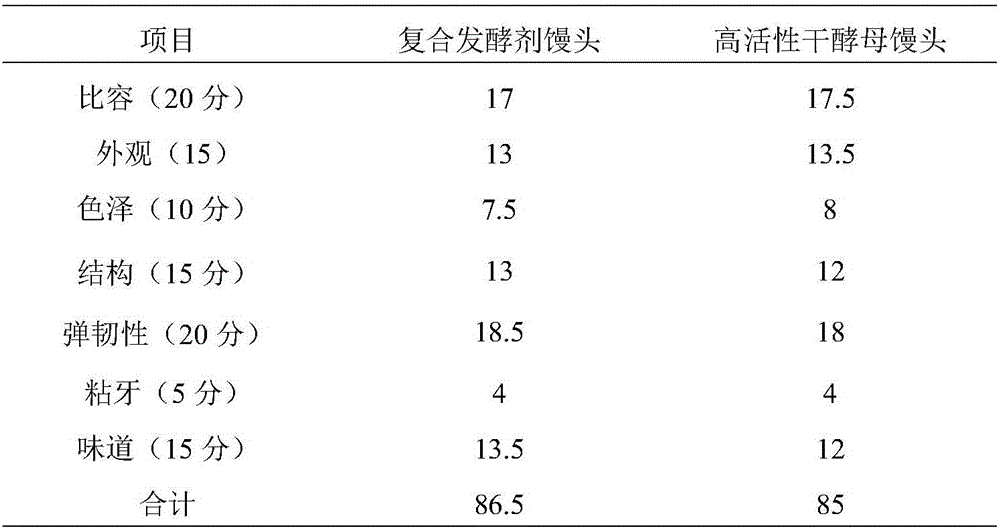

Composite starter for sourdough steamed buns as well as preparation method and steamed buns prepared by virtue of same

The invention relates to a composite starter for sourdough steamed buns. The composite starter is a composition of fermentation strains including saccharomyces cerevisiae, lactobacillus plantarum and lactobacillus brevis, wherein the bacterial number ratio of the saccharomyces cerevisiae to the lactobacillus plantarum to the lactobacillus brevis is (1 to 10): (1 to 5): 1. According to the composite starter for the sourdough steamed buns, which is disclosed by the invention, a strain is separated from the traditional sourdough, and a natural bacterium mixing system of the traditional starter is simulated, thus the traditional unique and abundant flavour can be given to the steamed buns, and the defect of insufficient flavour of the existing starter is made up; and the flavour and taste of the steamed buns can be improved, and the functions of increasing the nutritional value of the steamed buns and prolonging the shelf life of products are further realized due to the existence of lactic acid bacteria. The composite starter disclosed by the invention is simple in production procedures, the microbial inoculum is high in fermentation activity, and the steamed buns are stable in quality.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Direct-throwing type sour dough fermenting agent as well as preparation method and application thereof

The invention relates to a direct-throwing type plant lactobacillus sour dough fermenting agent as well as a preparation method and an application thereof. The preparation method of the direct-throwing type plant lactobacillus sour dough fermenting agent comprises the following steps of: activating plant lactobacillus, preparing the direct-throwing type plant lactobacillus sour dough fermenting agent and the like. The sour dough fermenting agent disclosed by the invention can be used for producing flour foods including breads, steamed breads and the like; the sour dough fermenting agent can be used for delaying the ageing of the foods including the breads and the like, the flavor is very obviously improved and the use is convenient; and the direct-throwing type plant lactobacillus sour dough fermenting agent has a lead reducing function, is very suitable for industrial production and has a very good application prospect.

Owner:JIANGNAN UNIV

Nutrient steamed bun powder pre-mixed with whole-wheat germs and soybeans and preparation method thereof

A nutrient steamed bun powder pre-mixed with whole-wheat germs and soybeans comprises main material and auxiliary material. The main material comprises the following components by weight in percent: 75-85% of wheat basic powder, 7-12% of bran powder, 4-6% of wheat germ meal, 2-5% of air suction powder and 1-3% of soybean meal. The auxiliary material comprises swallow brand high-sugar dry yeast, white granulated sugar and baking powder; and the swallow brand high-sugar dry yeast, the white granulated sugar and the baking powder are 1%, 3% and 1% of the weight of the main material. The flour enhances the nutrient substances which human bodies lack while having all nutrient substances of the wheat grains. The steamed bun powder has good quality, good taste, full fillet and bean fragrance. The shelf life of the product is greatly improved via drying the germs and the bran.

Owner:中粮面业(扬州)有限公司

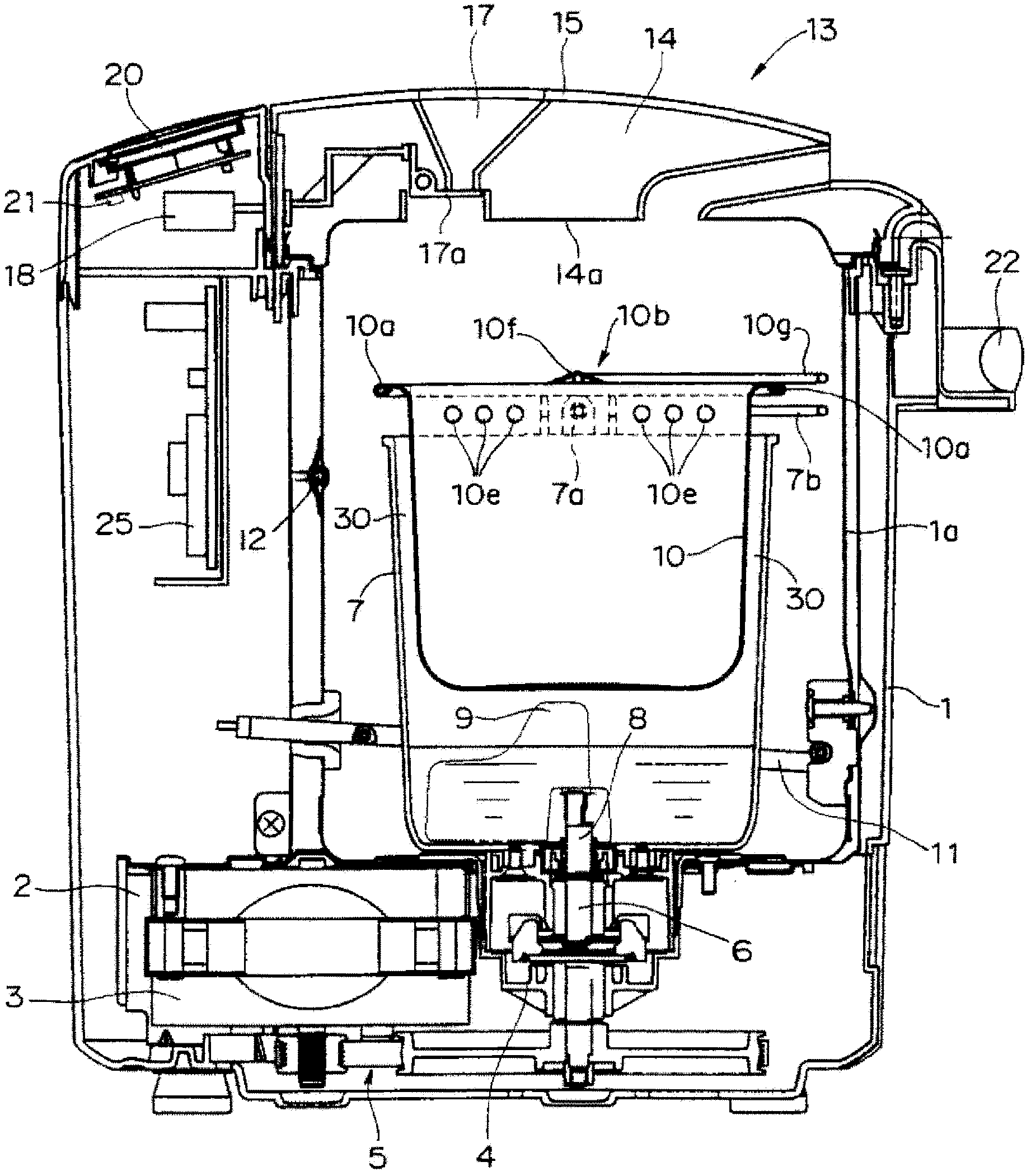

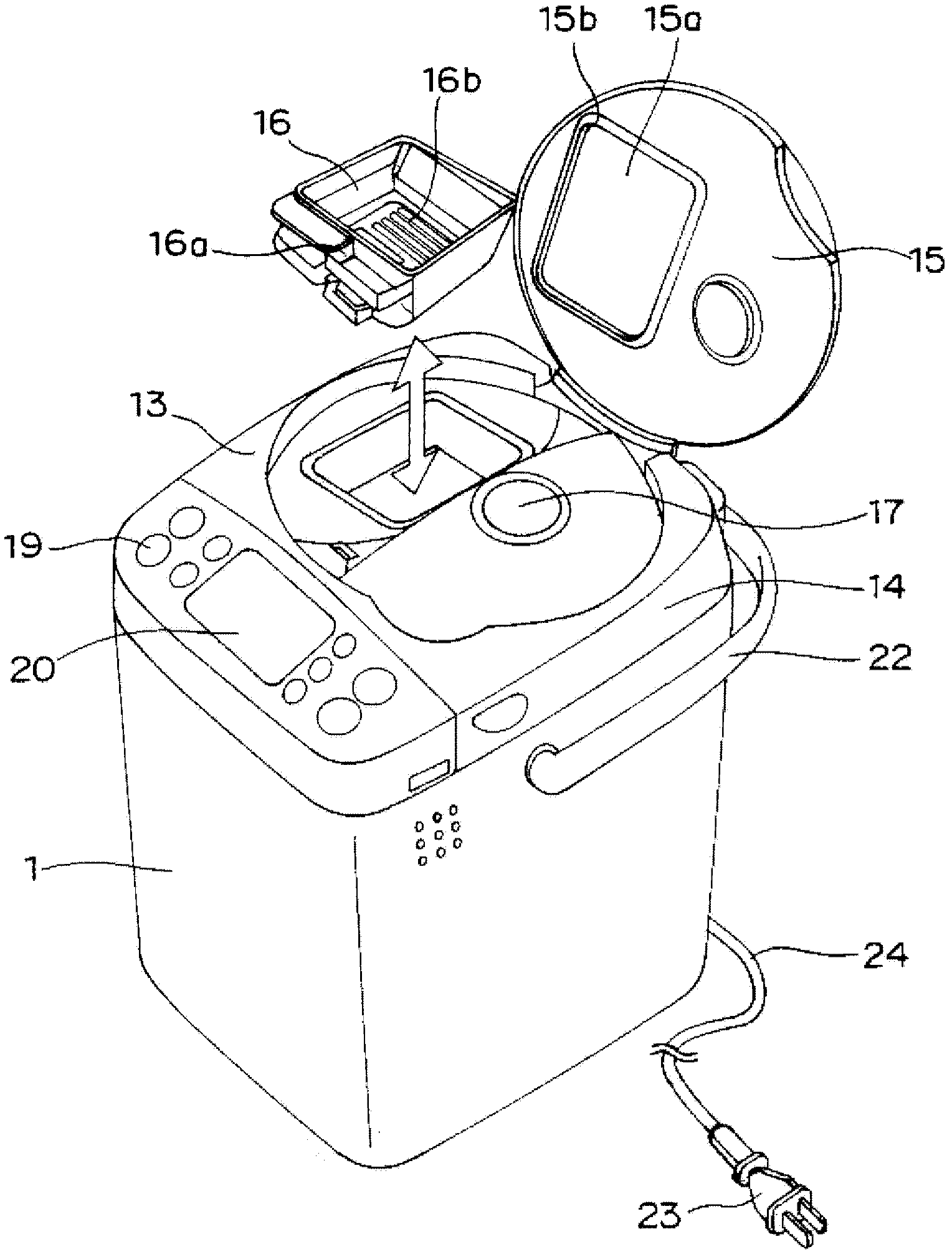

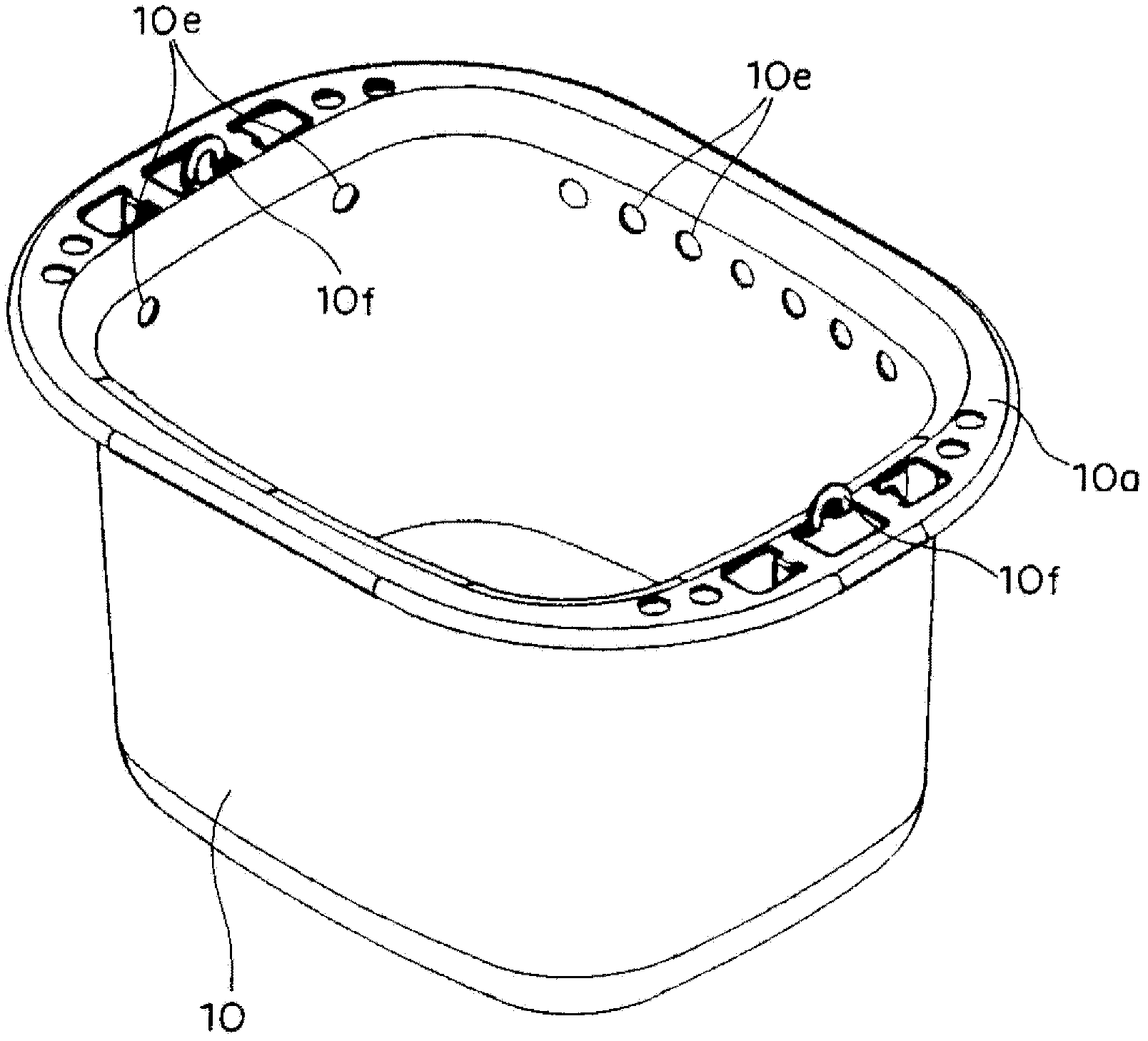

Bread maker with steaming function

InactiveCN102469892AReduce the temperatureEven and uniform heatingSteam cooking vesselsBaking plantsSteam cookingEngineering

Disclosed is a bread maker with a steaming function for making bread such as white bread or steamed bread, wherein not only the inside but also the crust of the bread has a soft texture. The bread maker with a steaming function comprises: a mixing vessel for receiving the ingredients, and a steam-cooking vessel which is smaller in size than the mixing vessel and can receive the ingredients which have been mixed inside the mixing vessel. The bread maker is designed in such a way that when the steam-cooking vessel is supported above the bottom surface of the mixing vessel, a gap for the passage of steam is formed around the whole periphery between the side wall of the steam-cooking vessel and the side wall of the mixing vessel.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

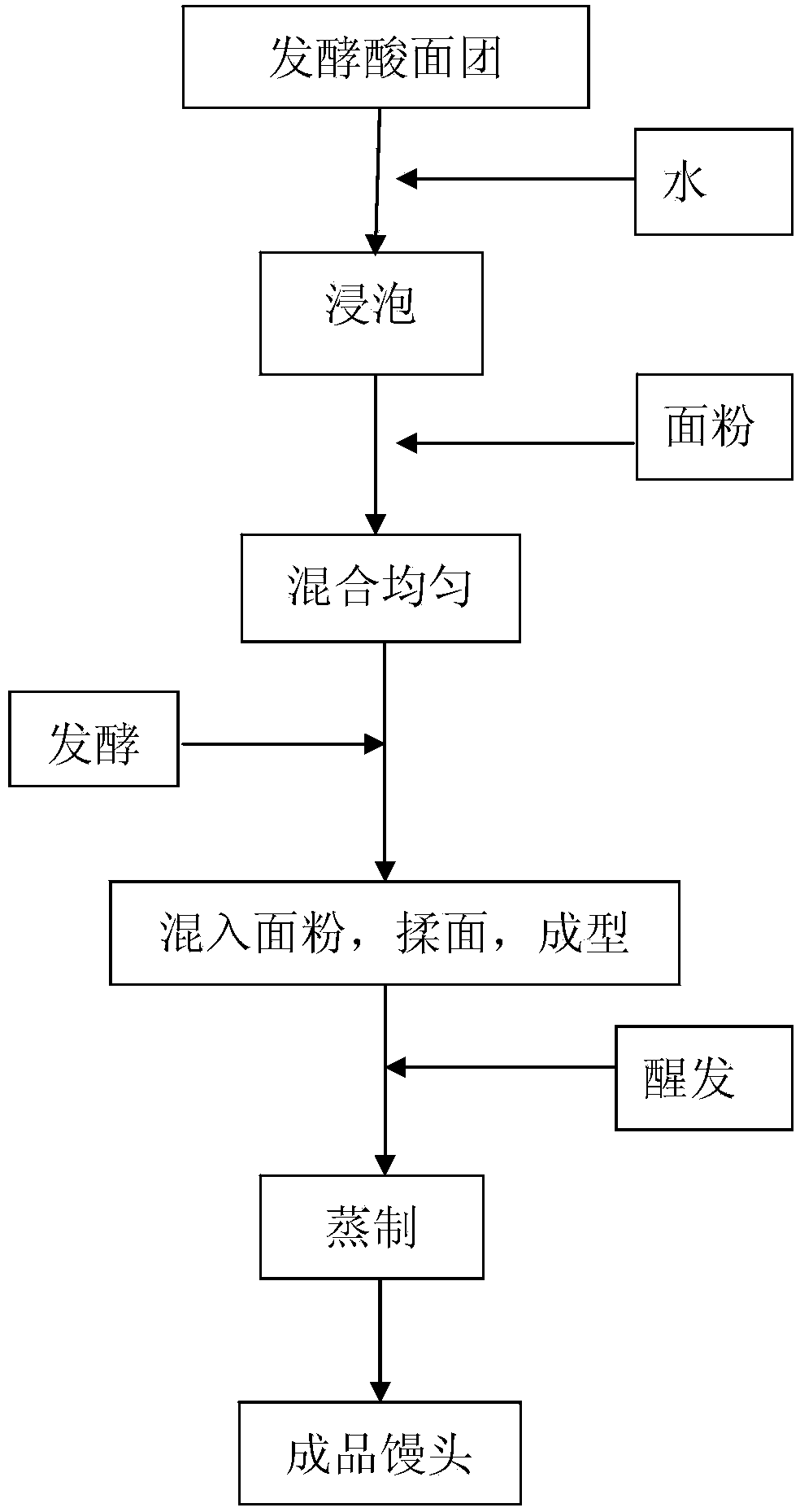

Method for making steamed buns by fermented sour dough

InactiveCN103652601AGreat tasteTissue structure is soft and delicateFood preparationFlavorWheat flour

The invention discloses a method for making steamed buns by fermented sour dough. The method comprises steps as follows: the fermented sour dough is placed in water for soaking, wheat flour is added after soaking, uniform mixing is performed, and the dough is placed for fermentation for 2.5-4 h at the temperature of 28 DEG C to 32 DEG C and at the relative humidity of 70%-80% after the fermentation, the wheat flour and water are added, then dough kneading, segmenting, round kneading and forming are performed, and the dough is leavened for 40-70 min at the temperature of 28 DEG C to 32 DEG C and at the relative humidity of 70%-80%, and after the leavening, the dough is steamed, and finished steamed buns are obtained. The fermented sour dough is taken as a leavening agent to prepare the steamed buns, alkali is not added in a making process, so that the made steamed buns are good in taste, soft and smooth in organizational structure, good in flavor and abundant in nutrition.

Owner:ZHEJIANG UNIV

Whole potato starch preparation technology by freeze drying method

InactiveCN104872583ABiologically activeMaintain vitality and colorFood preparationBiotechnologyPotato starch

The invention provides a whole potato starch preparation technology by a freeze drying method and belongs to the technical field of potato processing. The whole potato starch preparation technology includes the steps of taking fresh potatoes as a raw material, subjecting the potatoes to cleaning, peeling and slicing, soaking the sliced potatoes in color-protecting liquid for color protection, taking out for draining and quick freezing, and placing in a freeze drying bin for freeze drying and dewatering; subjecting the dried and dewatered potatoes to smashing, sieving and packing to obtain whole potato starch. The whole potato starch preparation technology by the freeze drying method has the advantages that activity, color, aroma and taste of the potatoes can be kept in the whole potato starch maximally, and a high-quality product can be obtained, so that the prepared whole potato starch has biological activity in protein, a gluten network structure can be formed by the aid of protein crosslinks during dough kneading, the problem of low processing performance of a potato dough used for processing needles and steamed buns is solved, and the whole potato starch preparation technology is significant to propulsion of making the potatoes as staple food.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Improved noodle food

InactiveCN101467532AGuaranteed intakeAvoid it happening againDough treatmentBlood sugarHealthful food

The invention provides an improved flour food. The improved flour comprises dietary fiber, whole wheat flour dietary fiber and amylose extracted from corn, potato, sweet potato and rice; the flour can be made into fine dried noodles, dumplings, gruel, bread, pastry, cake, steamed bread and so on. The food has low glycemic index, can satisfy health and nutrition of human body, delay the sugar absorption, effectively control blood sugar in diabetes patients, make the glycolated hemoglobin restore to normal value; the food with low glycemic index can reduce load of pancreatic islet, recover pancreatic islet function, secrete insulin resistance and protect B cell; the food with low glycemic index supplies high-nutrition content natural food to diabetes patients with nutrition utilization obstacle and nutrition deficiency caused by metabolic disorder; the invention is a kind of convenient health food.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Compound steamed-bread preserving modifier

The present invention belongs to the field of food preserving technology, and is especially one kind of compound steamed bread preserving modifier comprising starch hydrolase 1-7 wt%, hemicellulase 3-7 wt%, lipase 3-7 wt%, emulsifier 40-70 wt%, hydrophilic colloid 15-40 wt%, and coagulation inhibitor 2-6 wt%. The compound steamed bread preserving modifier can improve the internal structure of steamed bread, soften core, promote the form of cellular gluten structure, raise the antiageing performance, raise total water content and delay water-losing ageing of steamed bread.

Owner:河南兴泰科技实业有限公司

Hot and spicy sauce of preserved red peppers and preparation method thereof

InactiveCN101396113ASlightly spicySlightly spicy taste slightly spicy, not dry mouth after eatingFood preparationSesamumAdditive ingredient

The invention mainly relates to a table hot and spicy sauce and a preparation method thereof. The hot and spicy sauce, which is made from pickled pepper, is characterized by containing ingredients in terms of part by weight: pickled 18-20 parts of pickled pepper, 40-50 parts of edible oil, 6-7 parts of lobster sauce, 3.5-4.5 parts of black sesame seed, 3.2-8.8 parts of pignut, 4-4.5 parts of soybean, 7.2-8 parts of shallot, and 4.1-5 parts of sufu. The ingredients are prepared into the hot and spicy sauce, which has a slightly hot taste and does not cause people to have a parched mouth or tongue and excessive internal heat, thus being suitable for various people. Besides, the requirements of fresh-keeping and quality guarantying of the hot and spicy sauce can be satisfied without adding any additive, thus overcoming the defect that the fresh-keeping and quality guarantying can only be realized when the additive is added and facilitating eating and storage. The sauce is rich in nutrition, convenient to eat and store, and suitable for public taste; moreover, the sauce can not only used for mixing rice, steamed bread or cold dish, but also be widely used in restaurants, households and on journey.

Owner:邹春涛

Whole wheat flour, raw material formula for whole wheat flour steamed bread, and whole wheat flour steamed bread and making method thereof

The invention relates to a whole wheat flour, a raw material formula for making a whole wheat flour steamed bread, and the whole wheat flour steamed bread and a making method thereof. The whole wheat flour steamed bread provided by the invention is rich in wheat dietary fiber and vitamins and overcomes the problems of a small size, poor taste and hard quality of traditional whole wheat flour steamed breads.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Nutritious powder with functions of reducing lipid and slimming

InactiveCN1931335AEffective fat reductionEffective weight lossPowder deliveryMetabolism disorderLipid formationFood material

The present invention relates to one kind of nutritious powder as both medicine and food with functions of reducing lipid and slimming is prepared with medicinal food materials, including water caltrop 1-3 weight portions, chick pea 1-3 weight portions, coix seed 1-3 weight portions, konjack 1-3 weight portions, cassia seed 1-3 weight portions, and haw 0.5-1.5 weight portions. The nutritious powder may be made into porridge, cake, noodles, instant noodles, steamed bread, etc. for regular eating. It has obvious remitting and treating effect on hyperlipemia and obesity.

Owner:唐先平

Purple sweet potato full-powder steamed bread and processing method thereof

InactiveCN102648753ABoth health benefitsAvoid highly seasonal supplyDough treatmentFood preparationFlavorTriticum turgidum

The invention relates to purple sweet potato full-powder steamed bread and a processing method thereof. The purple sweet potato full-powder steamed bread is prepared by mixing, fermenting and cooking the following components as per parts by weight: 100 parts of wheat flour, 10 to 30 parts of purple sweet potato full powder, 0.6 to 1.0 part of yeast, 6 to 9 parts of granulated sugar and 50 to 70 parts of water. The processing method of the purple sweet potato full-powder steamed bread comprises the following steps: (1) preparing the purple sweet potato full powder; (2) weighing the wheat flour, the purple sweet potato full powder, the yeast, the granulated sugar and the water and preparing yeast solution and granulated solution; and (3) pouring the wheat flour and the purple sweet potato full powder into a flour-mixing machine, adding the yeast solution, stirring uniformly, adding the granulated sugar solution, stirring into dough, fermenting the dough to prepare into raw steamed bread, fermenting, placing into a steamer and steaming. The purple sweet potato full-powder steamed bread has rich nutrients, unique flavor and natural color and luster of the purple sweet potato, and has health-care effects of resisting cancer, preventing constipation, reducing blood pressure, enhancing immunity, prolonging life and the like after long-time use.

Owner:HUNAN AGRICULTURAL UNIV

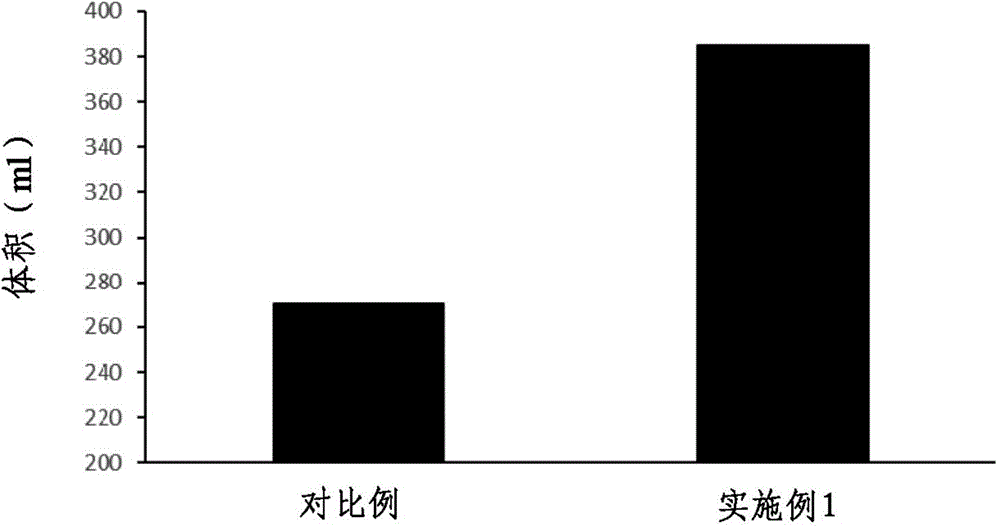

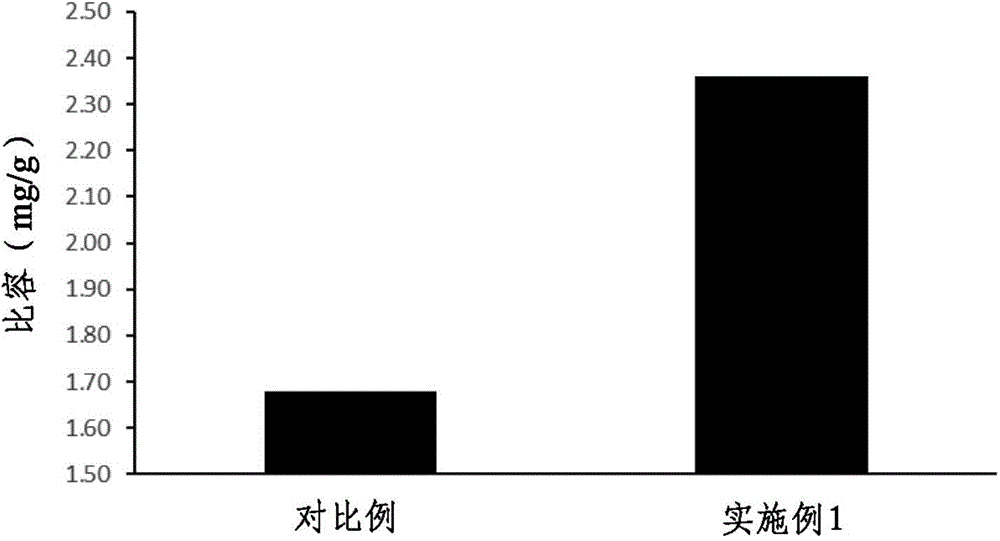

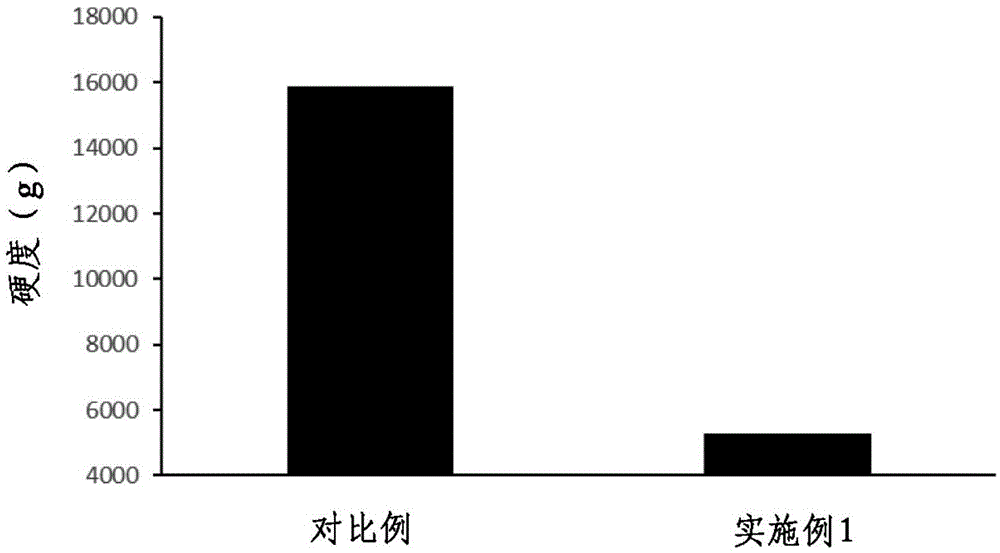

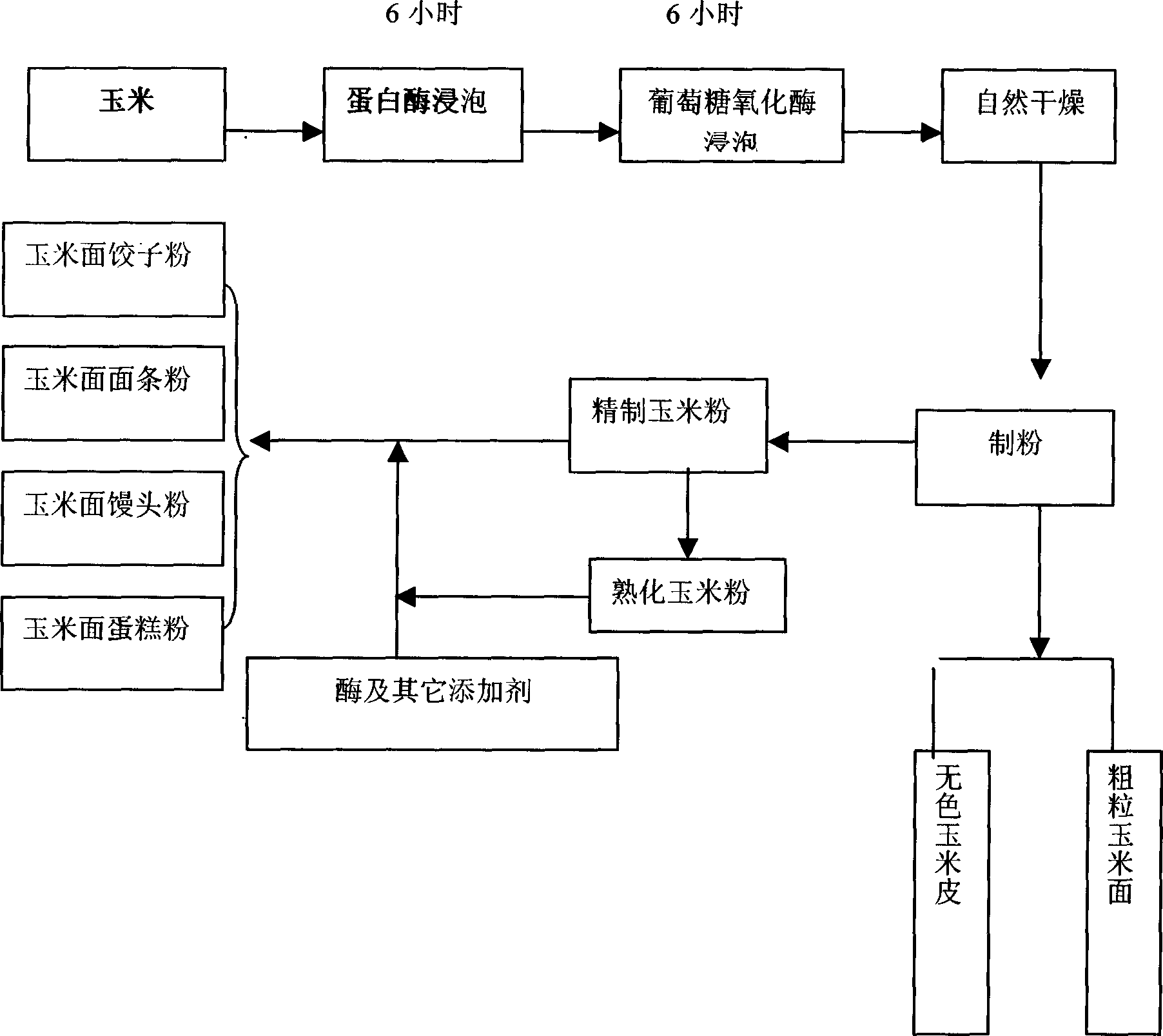

Special-purpose maize flour

The present invention discloses one kind of special corn powder superior to available corn powder, which has poor processing performance, coarse mouth feeling, unbalanced nutrients and other merits. The special corn powder is produced based on the different effects of neutral proteinase, glucose oxidase, alpha-mylase and cellulase on corn or corn powder, and by means of glutelin powder, soybean powder, sodium alginate and guar gum to raise the stiffness and water preserving capability of corn powder and cooking to raise the viscosity of corn powder. The special corn powder is treated with enzyme preparation and natural flour additive while its nutritive components are maintained. The special corn powder may be special dumpling corn powder, special steamed bread corn powder, special self-fermenting steamed bread corn powder, special noodles corn powder, special cake corn powder, etc.

Owner:HEBEI AGRICULTURAL UNIV.

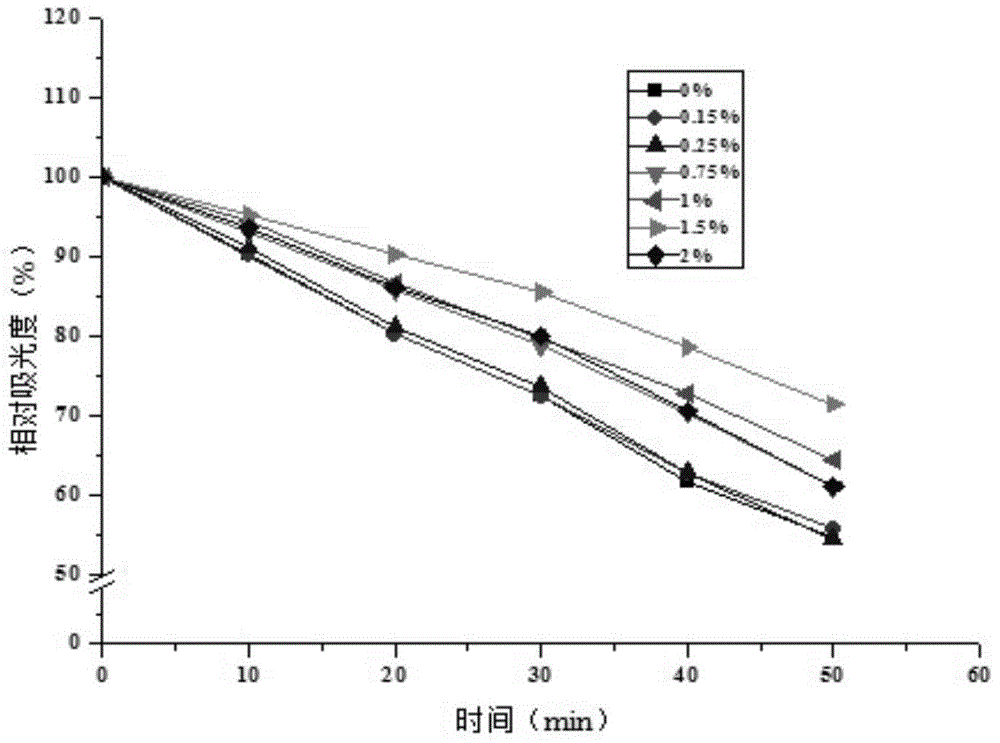

Method for preparing anti-aging steamed bread

InactiveCN103932038APrevent agingExtended shelf lifeFood ingredient as gelling agentFood ingredient for microbe protectionBiotechnologyImmunity

The invention relates to a method for preparing anti-aging steamed bread. The method concretely comprises the following operation steps: (1) preparing an activated yeast solution; (2) modulating paste, namely, mixing and stirring special flour for steamed bread with beta-glucan, and adding the yeast solution to obtain smooth and intact paste; (3) fermenting and molding for the second time; (4) steaming by steam to obtain the steamed bread; (5) packaging and storing, cooling and bagging at room temperature, and storing at room temperature. The method provided by the invention not only is simple and feasible, but also the aging of the steamed bread is inhibited and the shelf life of the steamed bread is prolonged to be over 6 days at the room temperature by the water-retaining property, the gelling property and the antibacterial activity of the beta-glucan. On the other hand, the beta-glucan is a biological response modifier, and has a plurality of physiological active functions of enhancing the immunity of the organism and the like, and the health quality of the anti-aging steamed bread is enhanced.

Owner:HEFEI UNIV OF TECH +1

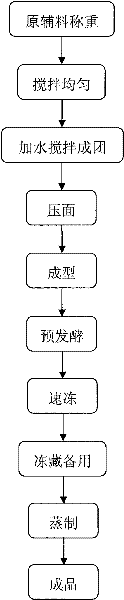

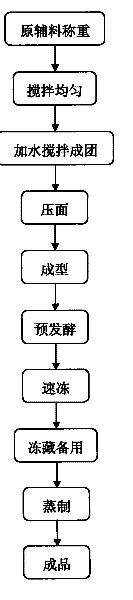

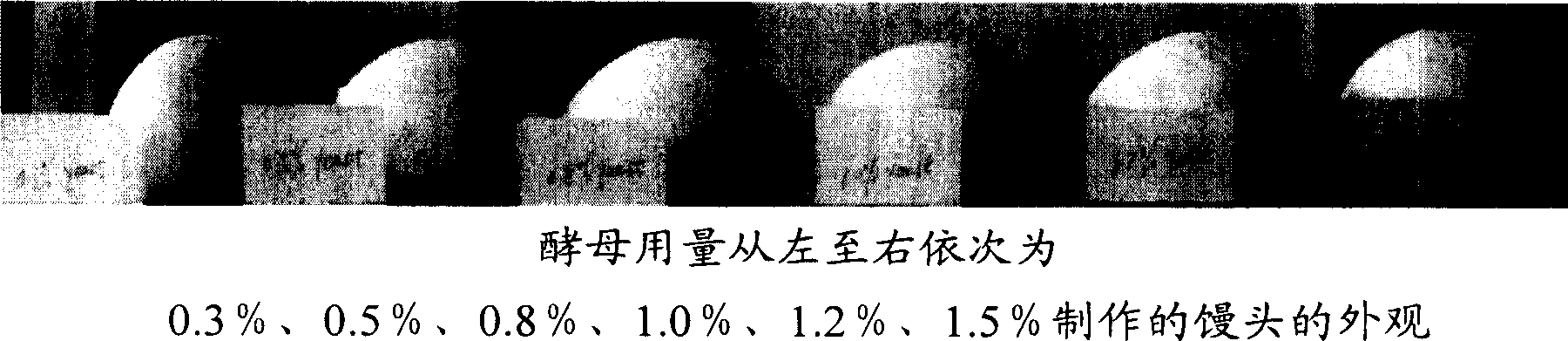

Pre-fermented frozen dough steamed bread and production method thereof

InactiveCN101744181AUniform colorFlat surfaceDough treatmentPre-baking dough treatmentPotato starchGlutaminase

The invention relates to pre-fermented frozen dough steamed bread and a production method thereof, belonging to the technical field of food processing. The production method comprises the following steps: putting flour, Yanshan yeast, non-aluminum baking powder, sugar, shortening, salt, transglutaminase, lipase, xylanase, glucose oxidase, trehalose, ascorbic acid, lecithin, sucrose esters, glycerin, locust bean gum, artemisia gum, carboxymethyl cellulose, guar gum, gluten and wheat starch or corn starch or potato starch or rice starch into a stirring vat, slowly stirring and mixing uniformly, then adding water, and stirring to form dough at a medium speed; pressing the dough, forming, pre-fermented cooling, then quick-freezing, and storing by freezing for standby; and only directly steaming in needing to obtain fresh steamed bread products. The application of the invention overcomes the problem of flavor loss caused by steaming again and keeps the advantages of uniform color, smooth surface, fluffy taste, good flexibility, and the like of steamed bread (steamed stuffed bun) products, and at the same time can improve the standardization, security and convenience of product quality.

Owner:黄卫宁

Improver of self-rising flour, self-rising flour using the improver and steamed food

ActiveCN101396036AImprove performanceImprove qualityDough treatmentPre-baking dough treatmentSodium bicarbonateVitamin C

The invention relates to a self-raising flour modifier and a self-raising flour which uses the modifier, in particular to a self-raising flour modifier, which comprises (on the basis of total weight of the self-raising flour modifier) 28-40% of sodium bicarbonate, 4-7% of disodium dihydrogen pyrophosphate, 4-6% of calcium hydrogen phosphate, 24-28% of calcium biphosphate, 10-20% of glucolactone, 0.01-0.03% of fungal-Alpha-amylase, 0.01-0.02% of glucose oxidase, 0.05-0.10% of xylanase, 0.3-0.45% of vitamin C, 0.5-2% of calcium peroxide, 3-5% of CSL-SSL, 2-6% of gluten and residual quantity of maize starch. The self-raising flour modifier can effectively increase the volume of steamed food such as Chinese steamed bread, steamed and stuffed bun and the like which are made of the self-raising flour, leads the food to have smooth surface, uniform and fine tissue, more delicious taste and no bad flavor. The invention also relates to the self-raising flour and the steaming food which contain the modifier.

Owner:ANGELYEAST CO LTD

Potato steamed bread and preparation method thereof

The invention provides a potato steamed bread. The steamed bread is prepared from the following components in parts by weight: 10-40 parts of potato pulp cornflour, 10-40 parts of potato slag superfine powder, 10-20 parts of potato slag nano powder, 4-12 parts of potato modified starch, 5-12 parts of extruded potato slag powder, 5-13 parts of potato slag microwave processing powder, 0.5-6 parts of potato starch, 0.1-3 parts of food gum, 1-3 parts of protein, 0-1 part of sugar, 0-3 parts of salt, 1-2 parts of yeast and water, wherein the weight ratio of water to other components is (50-70) to 100. The defects existing in common wheat steamed bread are overcome; the potato steamed bread does not contain gluten so as to be suitable for being eaten by people who are allergic to wheat and barley or patients with celiac diseases, is comprehensive in nutritional ingredients, and has a health function.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Production method of wheat flour

The invention relates to a production method of wheat flour, which comprises the following steps: elutriating wheat, soaking the cleaned wheat with water, draining water, covering with wet cloth or a plastic bag with the room temperature being 30 DEG C to 35 DEG C, germinating for 15-18 hours, drying the germinated wheat and grinding in a conventional way to produce flour. When the wheat flour of the invention is used as the raw material of food, no chemical additive is needed, and the wheat flour can ferment without base. Moreover, the wheat flour can reinforce the spleen to promote digestion and harmonize the stomach to regulate the function of the middle-warmer, and the food such as steamed bread, date cake and the like prepared with the wheat flour is crisp, delicious and sweet without any additional sugar, and is good visiting present for visiting relative or friends.

Owner:李玉龙

Technology for preparing potato flour by electrothermal forced air drying method

InactiveCN104872582AQuality improvementBiologically activeFood ingredient functionsFood preparationProcess engineeringGluten

The invention provides a technology for preparing potato flour by an electrothermal forced air drying method, and belongs to the technical field of potato processing. The technology includes taking a fresh potato tuber as a raw material, cleaning, peeling and dicing the tuber, soaking the tuber in color protection liquid for color protection, taking out the tuber, draining off water, and putting the tuber in an electrothermal forced air dry box to perform electrothermal forced air drying and dehydrating; smashing, sieving and packaging the tuber to obtain the potato flour. The technology has the advantages that the temperature for electrothermal forced air drying and dehydrating is controlled to be lower than potato albuminous degeneration temperature and starch pasting temperature, so that color, smell and taste of a potato can be kept to the utmost to obtain a high-quality final product; protein of the prepared potato flour has biological activity, and protein crosslinking can be achieved during kneading to form a gluten network structure, so that the processing performance problems in processing of potato paste into noodles and steamed buns are solved, and the technology has a great significance in promotion of potatoes serving as staple food.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hot flavour mushroom diced meat can

InactiveCN101283812AIncrease added valueActive economyFood preparationMonosodium glutamateVegetable oil

The invention discloses a spicy can containing mushroom and meat cubes and the processing process thereof, which belong to the field of food processing technology. The process comprises following steps: selecting mushroom, protecting color, pre-boiling, frying scented oil, frying, bottling, sterilizing, etc. The materials comprise mushroom 3 to 10 kg, vegetable oil 1.0 to 1.5 kg, Sichuan pepper 50 to 70 g, fennel 40 to 80 g, garlic 50 to 80 g, ginger 50 to 80 g, tomato sauce 70 to 100 g, chili 50 to 150 g, monosodium glutamate 30 to 50 g, salt 0.12 to 0.18 kg, ethyl maltol 0.8 to 0.5 g, beta-cyclodextrin 3 to 5 g, white sesame seeds 0.3 to 0.8 kg, peanut 0.3 to 0.6 kg, white sugar 40 to 70 g, TBHQ 25 to 50 g, and potassium sorbate 6 to 15 g. The invention solves the technical problems that fresh mushroom is difficult to be stored and the conventional mushroom product is likely to lose a great amount of nutrient and umami substances. The can has spicy and delicious taste, unique flavor and abundant nutrient, and can be used for seasoning vegetables, noodles, rice and steamed bread. The can is a necessary product for dietary.

Owner:BEIJING KEWEIHUA FOOD ENG TECH

Technology of producing steamed bread

InactiveCN1413496AShorten the production cycleImprove controllabilityFood preparationSteamed breadProduction cycle

A technology for preparing steamed bread in batches features that after the dough is fermented once and shaped, the raw breads are steamed under 0.2-0.25 MPa. Its advantages are short production period, good appearance and taste, and high quality.

Owner:烟台蓝白食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com