Special-purpose maize flour

A technology of corn flour and amylase, applied in the field of special corn flour, can solve the problems of rough taste, nutrient imbalance, and many nutrient losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

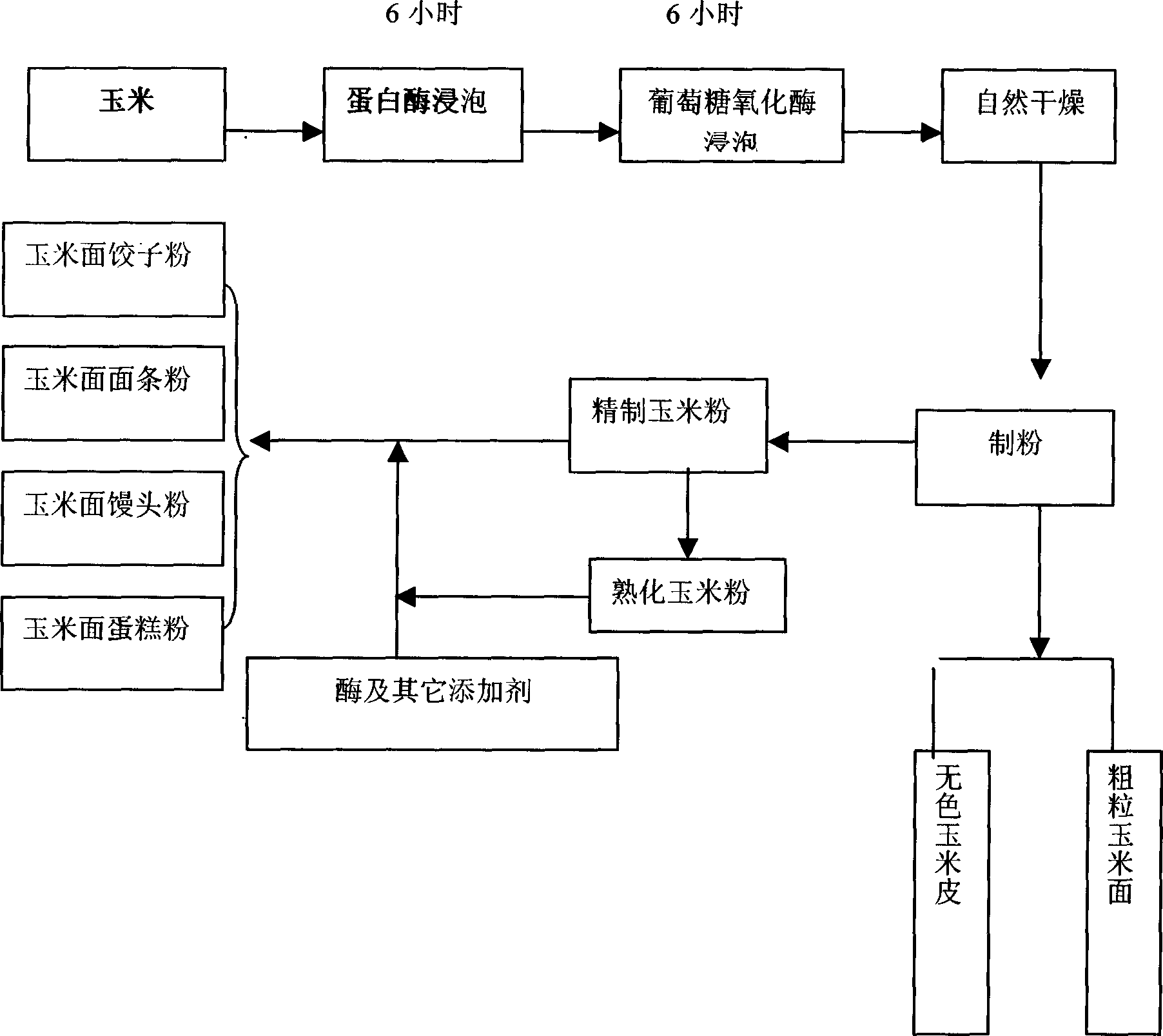

[0082] Example 1 Preparation of Refined Corn Flour

[0083] The ratio of 1000ppm neutral protease aqueous solution to corn is 2: 1, soak at 42°C for 6 hours, then wash with clean water, soak at 35°C with 1000ppm glucose oxidase for 6 hours, wash and dry, and the water content of the grain is 18%; then Mill the treated corn without peeling and germ, and pass the prepared corn flour through a CB39 sieve to obtain refined corn flour, coarse corn flour, and colorless corn hulls. The weight ratio of the three is 89:9:2.

Embodiment 2

[0084] Example 2 Special corn flour for dumplings

[0085] Composition: Refined corn flour 92, gluten flour 8, guar gum 0.6, sodium alginate 0.5, cellulase 0.00015, glucose oxidase 0.0001 (expressed by weight ratio).

[0086] Preparation: Mix refined corn flour, gluten flour, guar gum, sodium alginate, cellulase, and glucose oxidase in the dough mixer in the above ratio.

Embodiment 3

[0087] Example 3 Special corn flour for steamed bread

[0088] Composition: Refined corn flour 84, cooked corn flour 8, gluten flour 8, sodium alginate 0.05, cellulase 0.00015, amylase 0.0001 (expressed by weight ratio).

[0089] Preparation: Mix refined corn flour, gluten flour, mature corn flour, sodium alginate, cellulase, and amylase in the dough mixer according to the above ratio, and pack them into bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com