Steamed bun preparation method suitable for industrial production

A method for making steamed buns, which is applied in the field of steamed buns, can solve the problems of reduced controllability of industrialized production, occupying more equipment and sites, and increased production labor intensity, and achieves reduction of fermentation equipment and workshop area, small footprint, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

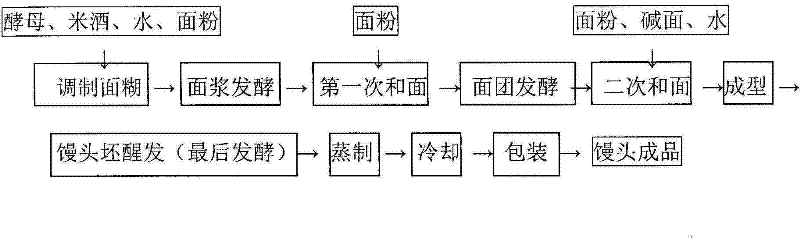

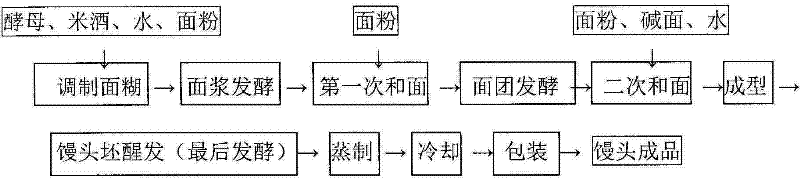

Method used

Image

Examples

example 1

[0029] ① Flour fermentation: Put 10 kg of flour, 18 kg of water, 0.1 kg of yeast, and 0.2 kg of rice wine into a constant temperature fermentation tank with stirring (temperature controlled at 30°C) and mix evenly, and ferment at 30°C for 6 hours under slow stirring;

[0030] ② Kneading the dough for the first time: put 30 kg of flour and all the batter into the dough mixer, stir for 4 minutes, and knead into a uniform dough;

[0031] ③Dough fermentation: Put the reconciled dough in a closed environment at 30°C and 80% relative humidity, and let it ferment for 50 minutes;

[0032] ④Secondary kneading: Put the fermented dough into the dough kneader, add 10 kg of flour, and 0.1 kg of edible alkaline noodles with 1 kg of warm water to dissolve the alkaline water, and stir for 10 minutes;

[0033] ⑤ Forming: The reconciled dough is formed into a round steamed bun blank by a double-roller steamed bread machine, and is shaped by a shaping machine;

[0034] ⑥ Proofing of steamed bun...

example 2

[0037] The difference between this example and Example 1 is that after the batter is fermented in step 1), flour, rice wine and water are added continuously, and the amount added is the same as the first feeding amount, and there is no need to add yeast. Twice and face and dough fermentation process are with example 1. The dough that has been reconciled for the second time is pressed by a continuous kneading press, and then enters the automatic knife-cut steamed bun machine continuously, cuts into square steamed bun blanks, and discharges the blanks on the steaming plate by the automatic discharge machine, enters the continuous steaming and steaming integrated production line, and proofs 50 minutes, steam for 28-35 minutes. Continuous cooling and automatic packaging.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com