Patents

Literature

293 results about "Potato processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are processing plants for frozen products and those that are purely dehydration plants. Some operations have facilities for both types of processing. One of the benefits of processing potatoes, aside from convenience to the consumer, is that it gives an opportunity to use the less than perfect potatoes, resulting in less waste.

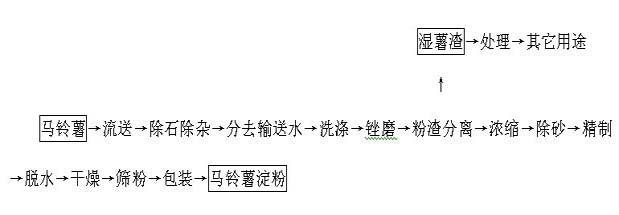

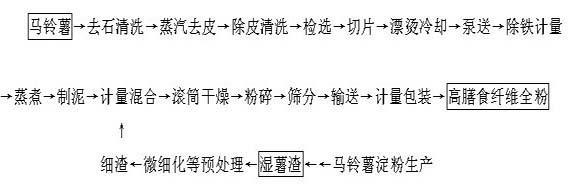

Method for producing potato flake with high dietary fiber content

The invention discloses a method for producing potato flake with high dietary fiber content. The method comprises the following steps: after the byproduct of wet potato residue generated through flour-residue separation during potato starch production is subject to acid base interaction, oxidation or enzymolysis and micronization, the micronized dietary fiber of potato is mixed with mashed potatoes obtained through steaming, boiling and smashing in a certain content ratio, the mixture is dried through a roller dryer, the moisture content in the product is smaller than or equal to 10 percent, and the potato flake rich in dietary fiber is produced after crushing and sieving. The method of the invention is suitable for being implemented in whole potato processing production enterprises, the produced potato flake is rich in an excess amount of dietary fiber and can be used as an auxiliary material for processing other foods, therefore, the economic value of the byproduct of starch production, i.e., wet potato residue is greatly increased, and pollution to the environment is reduced.

Owner:广州华糖食品有限公司 +1

Potato-bread frozen dough and preparation method thereof

InactiveCN102599210AImprove frost resistanceImprove stabilityDough treatmentBaking mixturesNutritive valuesYeast

The invention provides potato-bread frozen dough and a preparation method thereof. The potato-bread frozen dough comprises the following components: potato powder and wheat flour, wherein the weight rate of the potato powder to the wheat flour is (10-40): (90-60). The preparation method comprises the following steps of: mixing the potato powder and the wheat flour, and adding water as well as an appropriate amount of yeast, sugar, salt, butter, eggs and the like into the obtained mixture so as to obtain dough; and then, after carrying out partitioning, forming and pre-fermenting on the dough, freezing the dough and then taking out the dough to carry out packing, and carrying out freezing storage on the dough. The potato-bread frozen dough (the viable count of yeasts in the frozen quality guarantee period is greater than or equal to 107 cfu / g) produced by using the method disclosed by the invention can be subjected to unfreezing, re-fermenting and baking so as to prepare fresh bread as required, and the technique facilitates the production management of bread and the freshness preservation of products; in addition, due to the addition of the potato powder, the nutritive value of bread is improved, the texture and taste of bread are improved, and the comprehensive utilization and development of potato processed by-products are facilitated, thereby having great significance in improving the additional values thereof.

Owner:FUJIAN AGRI & FORESTRY UNIV

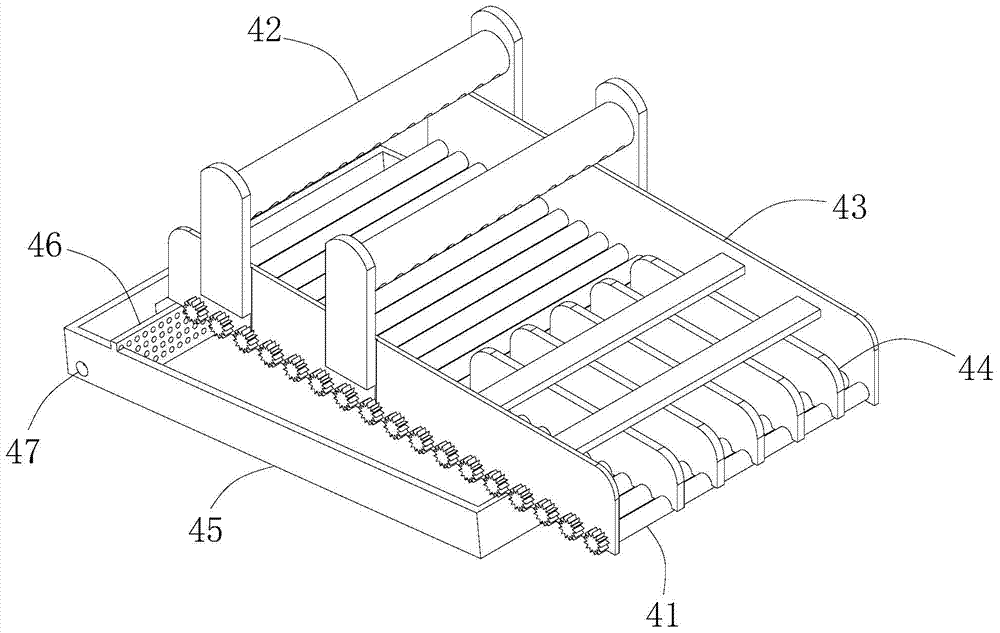

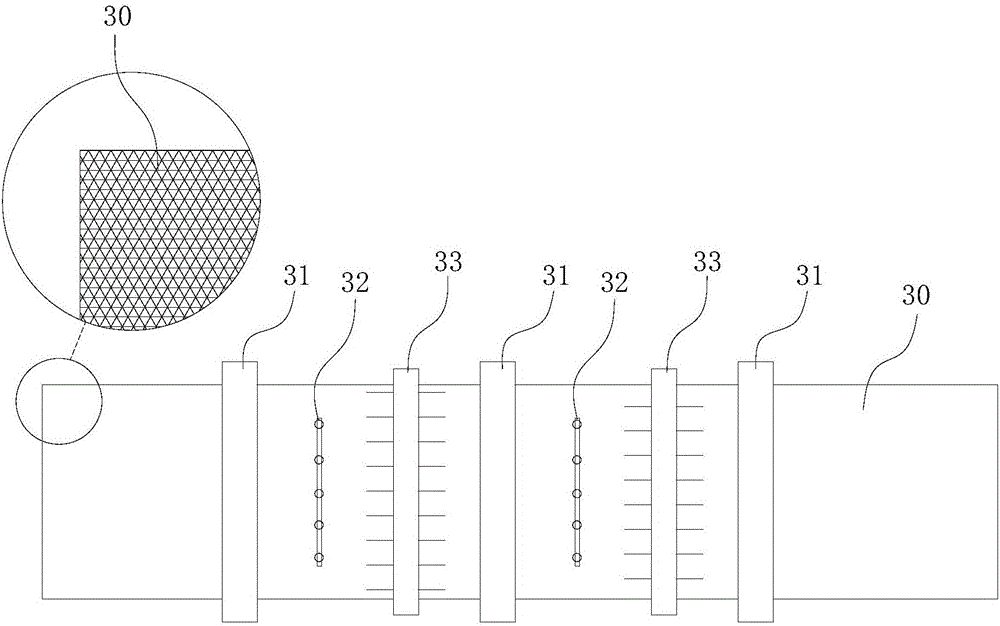

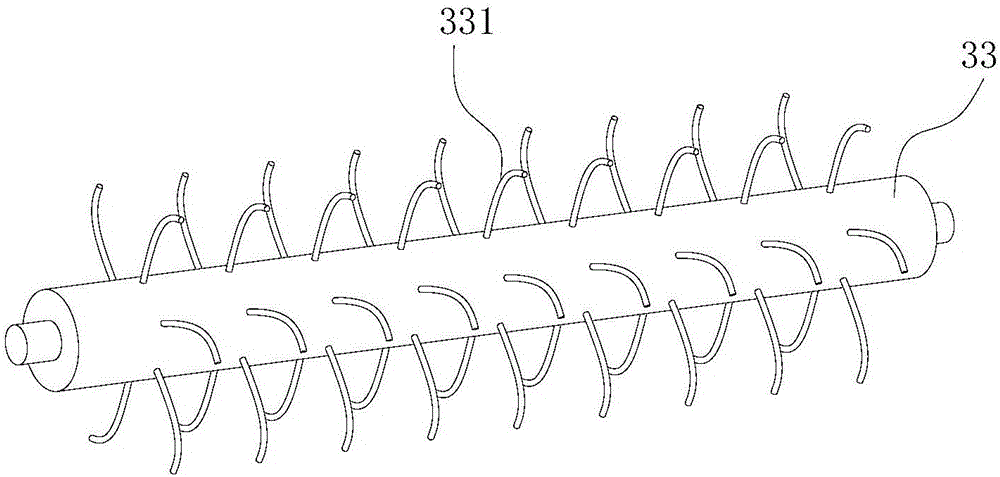

Potato drip-washing and conveying device

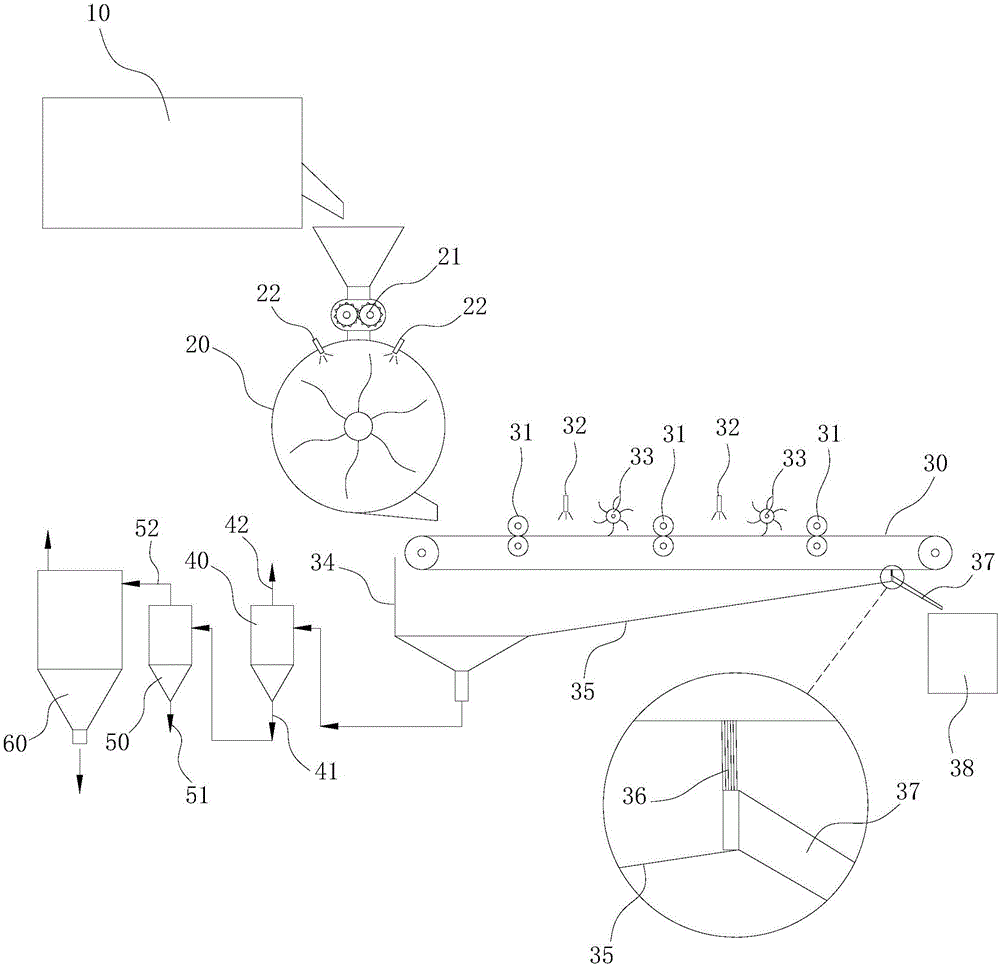

InactiveCN103919242AAchieve separationImprove processing efficiencyConveyor partsFood treatmentWater savingEngineering

The invention discloses a potato drip-washing and conveying device. The potato drip-washing and conveying device comprises a conveying mechanism, wherein a conveying roll is rotatably fixed on a rack; a water spraying mechanism is arranged above the conveying roll; protecting plates are arranged on outer sides of two ends of the conveying roll; a collecting tank for collecting separated potato skins is arranged below the conveying mechanism; the bottom of the collecting tank is inclined; the bottom, which is positioned on one side of a feeding end of the conveying mechanism, of the collecting tank is low; a filter screen is arranged in the collecting tank; and a water outlet is formed in the lowest position of the collecting tank, and is connected with a reservoir through a connecting tube. By using the scheme, potatoes without skins can be cleaned, the potato skins can be separated from the potatoes, and the potato processing efficiency is improved. The potatoes are washed in a dripping manner; and compared with the original cleaning pond, the potato drip-washing and conveying device has the advantages that water can be saved, and the used water can be collected to the reservoir and is used for preliminarily cleaning the potatoes.

Owner:刘凤斌 +2

Process for the co-manufacture of ingredients for use in foods and beverages using potatoes as starting material

InactiveUS20010041199A1Reduce the amount requiredPrevent enzymatic browningBeer fermentationAlcoholic beverage preparationBiotechnologyFruit juice

Disclosed is a process for the co-manufacture of ingredients having food and beverage applications, using potatoes as starting material. The process comprises six steps. The first step is a cutting and dipping of washed raw potatoes in an anti-oxidant solution. The second step is an extraction of undiluted juice free of starch and fibers from a purée made from the anti-oxidant-dipped raw potatoes. The third step is a concentration and enzymatic treatment of the juice. The fourth step is a heating of the juice to specific temperatures to cause precipitation of proteins and separation of precipitated protein therefrom. The fifth step is a thermal browning of the clear juice. The sixth step is an adjustment of the final pH of the juices of the fourth and fifth steps and a blending of these juices in ratios appropriate for intended use. These six steps yield products which may be used as the main flavor principle in malt-free beer, as a coffee substitute and as a flavor enhancer in savory mixes. They also yield dietary fibers, a concentrated edible protein and non-gelatinized granular starch, thereby increasing revenues derived from potato processing while minimizing liquid waste stream.

Owner:SENSICULTURE FY BIOTECH

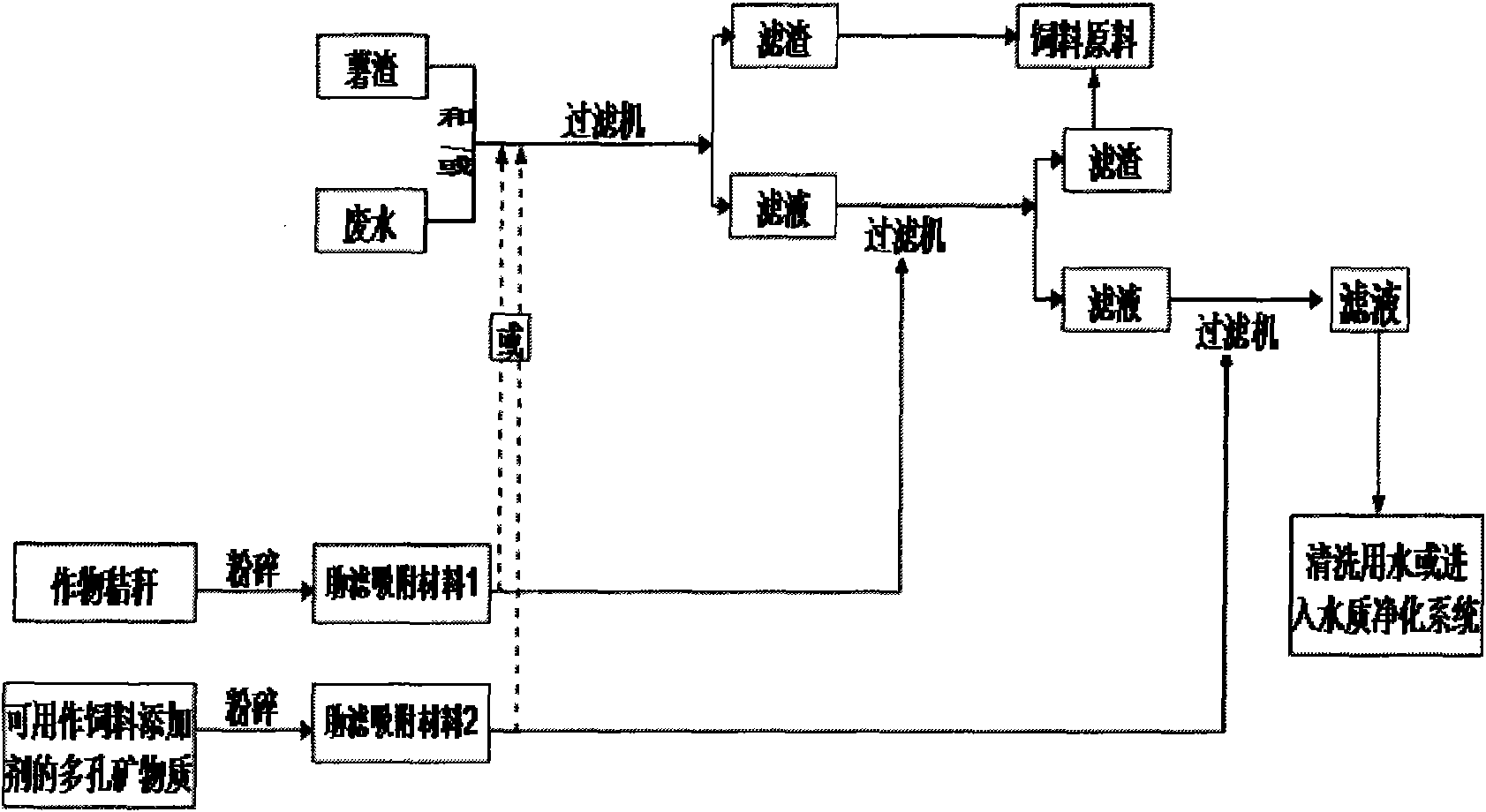

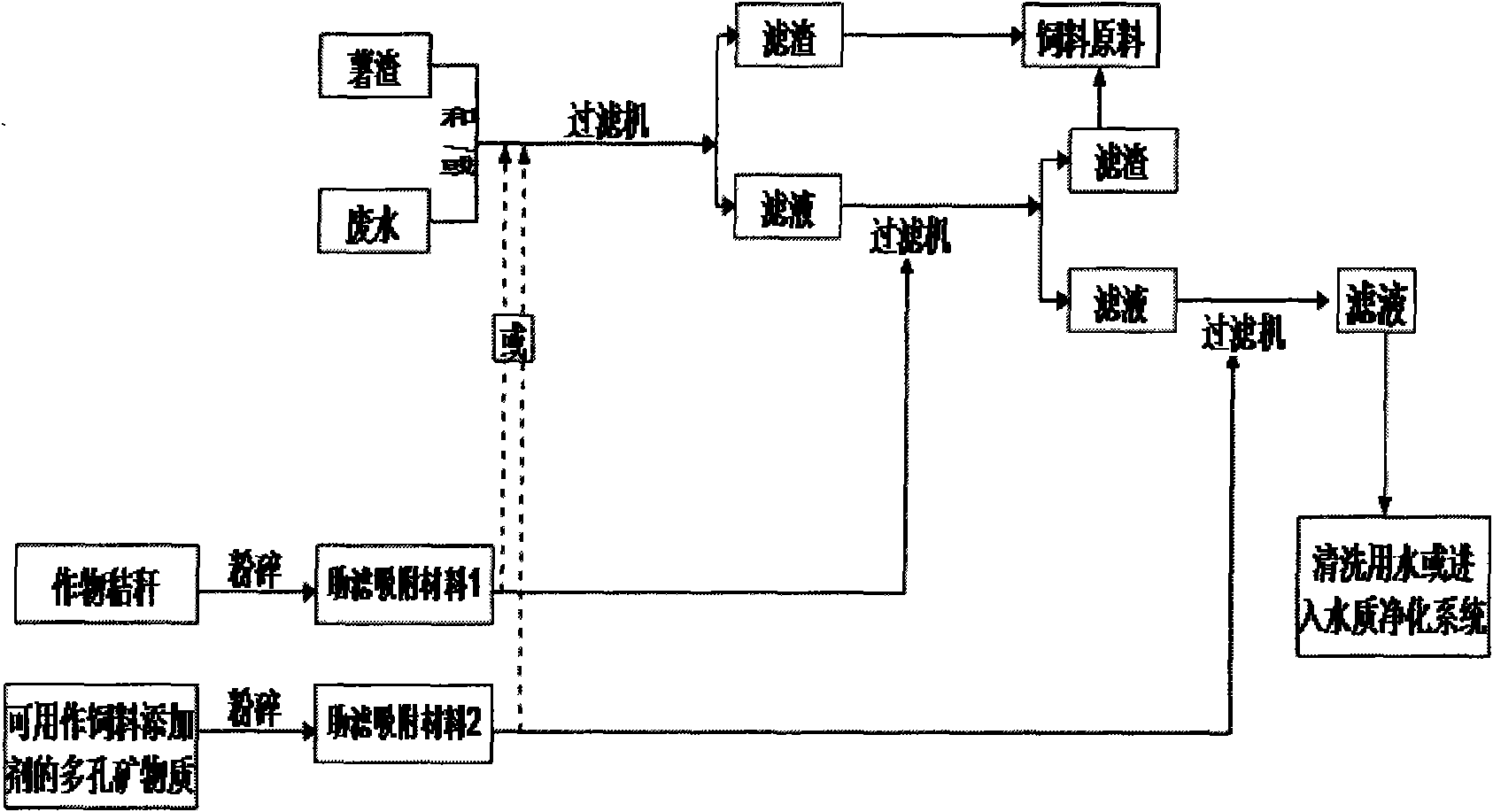

Method for recycling potato residue and waste water in production process of potato starch

InactiveCN101990987AReduce equipment costsLow running costOther chemical processesFood processingSubstance usePotato starch

The invention relates to the field of industrial production of potato starch and provides a method for recycling potato residue and waste water in the production process of potato starch. The method mainly comprises the following steps of: respectively pulverizing crop straws and porous mineral substances used as a feedstuff additive into certain size of particles as filtering-assisted adsorbing materials through a physical method; and carrying out filtering treatment by stages by utilizing the two filtering-assisted adsorbing materials in a process of recycling potato residue and waste water organic matters generated when processing the potato starch. The recycled organic matters, such as small particle starch, protein, polysaccharide, and the like and the filtering-assisted adsorbing materials can be together used as feedstuff materials, and the purpose of purifying the waste water is also achieved; and the purified water can be used as washing water for potato processing directly or through precipitating.

Owner:甘肃省农业科学院农产品贮藏加工研究所

Whole potato starch preparation technology by freeze drying method

InactiveCN104872583ABiologically activeMaintain vitality and colorFood preparationBiotechnologyPotato starch

The invention provides a whole potato starch preparation technology by a freeze drying method and belongs to the technical field of potato processing. The whole potato starch preparation technology includes the steps of taking fresh potatoes as a raw material, subjecting the potatoes to cleaning, peeling and slicing, soaking the sliced potatoes in color-protecting liquid for color protection, taking out for draining and quick freezing, and placing in a freeze drying bin for freeze drying and dewatering; subjecting the dried and dewatered potatoes to smashing, sieving and packing to obtain whole potato starch. The whole potato starch preparation technology by the freeze drying method has the advantages that activity, color, aroma and taste of the potatoes can be kept in the whole potato starch maximally, and a high-quality product can be obtained, so that the prepared whole potato starch has biological activity in protein, a gluten network structure can be formed by the aid of protein crosslinks during dough kneading, the problem of low processing performance of a potato dough used for processing needles and steamed buns is solved, and the whole potato starch preparation technology is significant to propulsion of making the potatoes as staple food.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

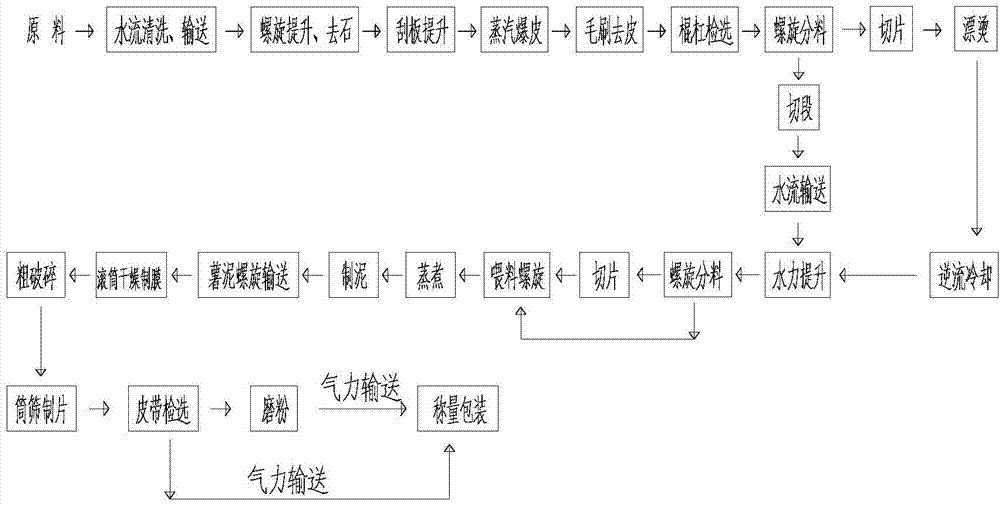

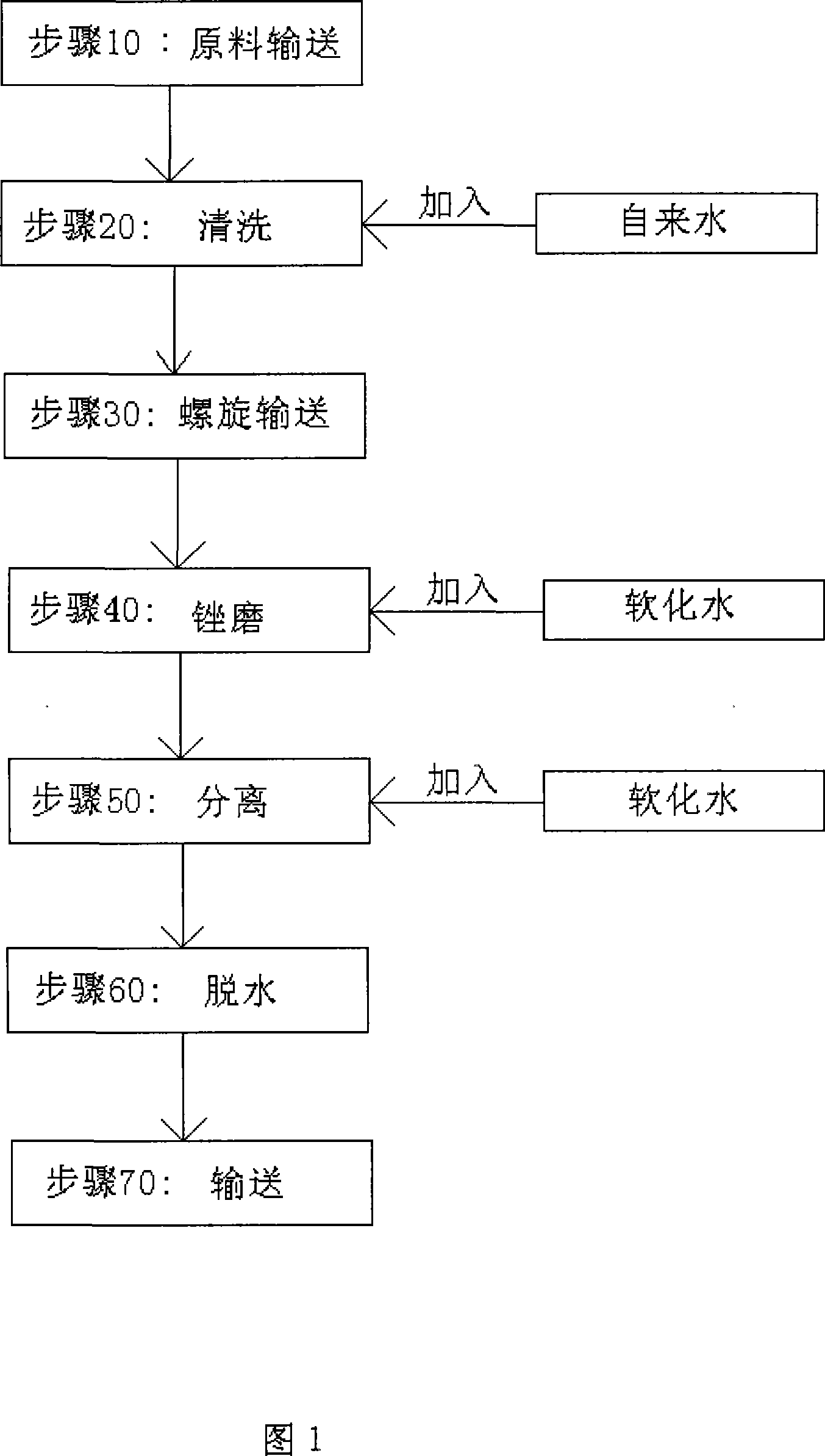

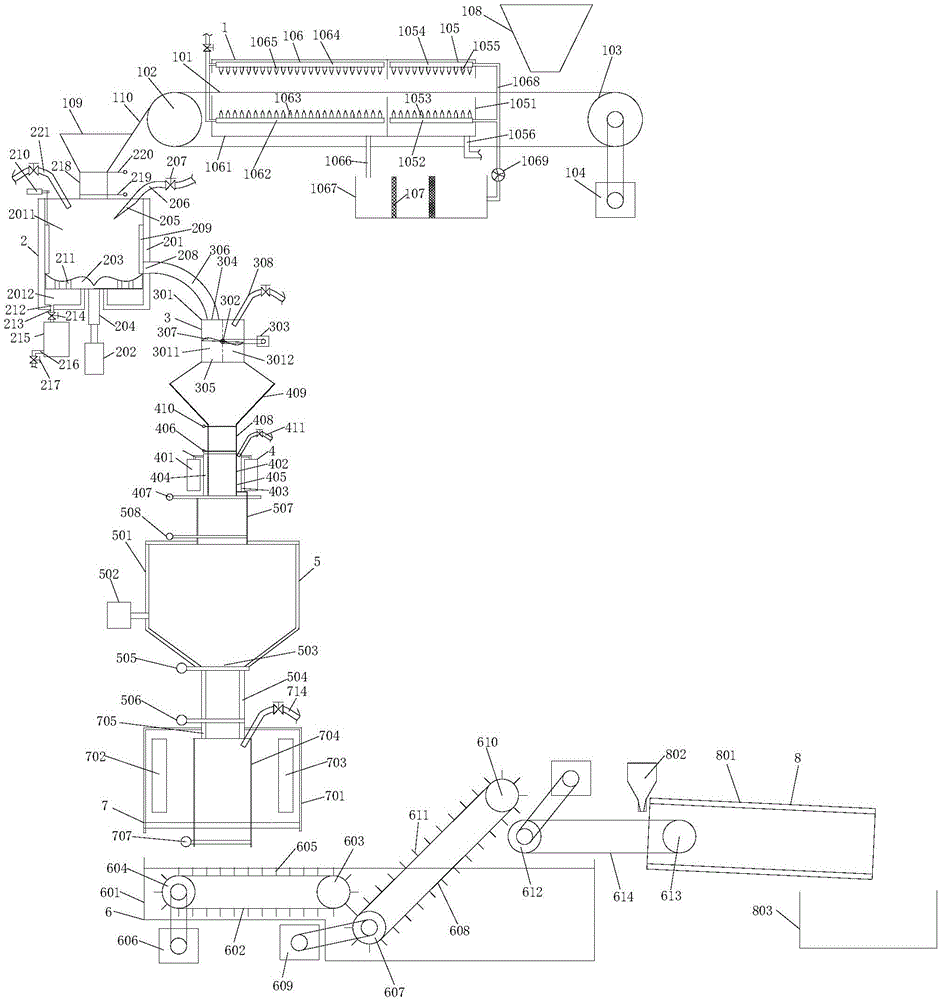

Preparation technology of potato whole powder

The invention discloses a preparation technology of potato whole powder. The preparation technology comprises the steps of conveying a raw material by water flow, and then feeding the raw material to a cleaning and stone-removing procedure and a peeling procedure sequentially; after the raw material is treated by the peeling procedure, cutting the raw material into pieces; and feeding the cut raw material to subsequent working procedures of cooking, mashing, roller drying and film preparation, crushing and packaging sequentially. The raw material of the potato whole powder is one in purple sweet potatoes, sweet potatoes and purple potatoes, and the cut raw material pieces have the length of 70-100 mm; the purple potatoes are sliced after being cut into pieces, and the purple potato slices sequentially enter the subsequent working procedures of cooking, mashing, roller drying and film preparation, crushing and packaging; the purple potato slices have the thickness of 10-30 mm. After the preparation technology is adopted, the generality of the potato processing technology can be improved, and the combination of preparation technologies of different potato materials can be realized; therefore, the utilization rate of a whole powder device and the whole powder quality are improved, and the aims that one machine in a processing enterprise serves multiple purposes, and the products are diversified can be achieved.

Owner:山丹县芋兴粉业有限责任公司

Technology for preparing potato flour by electrothermal forced air drying method

InactiveCN104872582AQuality improvementBiologically activeFood ingredient functionsFood preparationProcess engineeringGluten

The invention provides a technology for preparing potato flour by an electrothermal forced air drying method, and belongs to the technical field of potato processing. The technology includes taking a fresh potato tuber as a raw material, cleaning, peeling and dicing the tuber, soaking the tuber in color protection liquid for color protection, taking out the tuber, draining off water, and putting the tuber in an electrothermal forced air dry box to perform electrothermal forced air drying and dehydrating; smashing, sieving and packaging the tuber to obtain the potato flour. The technology has the advantages that the temperature for electrothermal forced air drying and dehydrating is controlled to be lower than potato albuminous degeneration temperature and starch pasting temperature, so that color, smell and taste of a potato can be kept to the utmost to obtain a high-quality final product; protein of the prepared potato flour has biological activity, and protein crosslinking can be achieved during kneading to form a gluten network structure, so that the processing performance problems in processing of potato paste into noodles and steamed buns are solved, and the technology has a great significance in promotion of potatoes serving as staple food.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Potato shreds, chip, cubes and powder and their production process

The present invention relates to the improved potato processing technology. The technological process includes cutting potato into shreds, chips or cubes, rinsing in cold water, rinsing in hot water, dewatering, stoving and sieving. The potato shreds can be further crushed and mixed with starch and flour to produce potato powder. The technologial process of the present invention has no loss in the nutritive components of potato. The products of the present invention, including potato shreds, chips, cubes and powder can be produced into various kinds of potato food.

Owner:李 新杰

Potato raw flour preparing process by vacuum drying method

The invention provides a potato raw flour preparing process by the vacuum drying method and belongs to the technical field of potato processing. The process includes adopting fresh potatoes as raw material, cleaning, peeling and dicing the potatoes, soaking the potatoes through color protecting liquid to protect color, fetching and draining the potatoes before placing into a vacuum drying box to perform vacuum drying; obtaining the potato raw flour after smashing, filtering and packaging. The color, flavor and taste of potatoes can be remained to the utmost extent, the quality of the obtained potato raw flour is high, the protein has the biological activity, protein crosslink occurs to form a gluten network structure during dough making, the processing performance problem is solved when the potato dough is used for noddle and bread processing, and the significance is provided for promoting potatoes to be staple foods.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sweet potato processing method

The invention belongs to the technical field of food processing and particularly provides a novel processing method of sweet potato. The processing method of the sweet potato has the following steps: 1) the unputrefied and fresh sweet potato is selected and cleaned, removed of pedicels of both sides, and then steamed, peeled, and mashed to sweet potatoes; 2) 1-1.25 kg of edible oil is taken, heated at medium baking temperature to medium well, and then added with 3.5-4.5 kg of white sugar, stirred till the dissolution of the sugar and uniform bubble appears, and adjusted to small fire. 10kg of the sweet potatoes is added to be fully stirred, and 100-200 minutes later, 0.2-0.25kg of white sesameseed fried to slight yellow is added, and then well stirred, finally cooled and packed. The invention has the beneficial effects as follows: the prepared sweet potato has golden red color and sweet and pure taste. Furthermore, the sweet potato is easy to store and does not contain any essence, color agent, and preservative, etc., and can be widely used in fillings of pastry, bread, cake, etc. The sweet with golden red color, natural and sweet taste and robust flavor, can be used as instant snack food, also be added with other foods to form snack foods with various flavors and is suitable for mass consumption.

Owner:梁平安

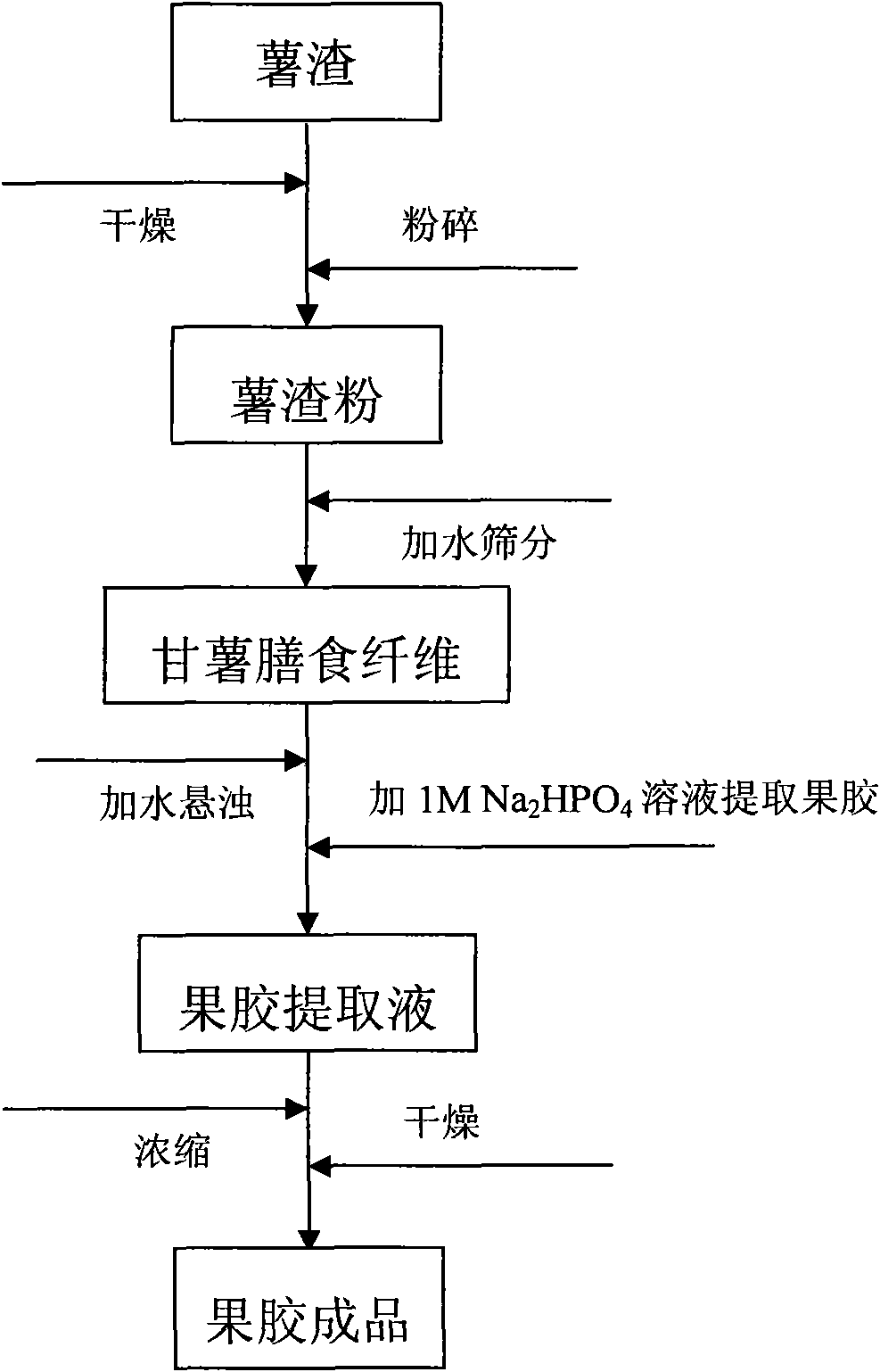

Novel method for extracting pectin from sweet potato dregs

ActiveCN101627825AHigh extraction rateHigh purityOrganic active ingredientsMetabolism disorderFood additiveCentrifugation

The invention discloses a novel method for extracting pectin from sweet potato dregs. The method comprises the following steps of: 1) preparing the sweet potato dregs into a suspension, carrying out physical screening processing on the suspension, and removing most starch to obtain dietary fibers with higher purity; 2) using amylase to carry out enzymolysis on residual small amount of starch in the dietary fibers in step 1), carrying out centrifugation, removing supernate, and collecting sediments; and 3) preparing the sediments obtained in step 2) into the suspension, adding Na2HPO4 solution into the suspension to extract the pectin, carrying out centrifugation after extracting, collecting supernatant, and carrying out concentration and drying to obtain pectin powder. The method can make the extraction ratio of the sweet potato pectin reach 95.87 percent and the purity of pectin products reach 91.28 percent (taking Xu55-2 as a material). The method has the advantages of high extraction ratio, high pectin purity, strong practicality, easy industrialization and the like. The products can be directly used as food additives or pharmaceutical excipients. The method not only can improve the comprehensive economic benefit of potato processing, but also can reduce the environmental pollution caused by accumulation of the potato dregs.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

A kind of purple sweet potato fresh noodles and processing method thereof

The invention discloses a purple sweet potato fresh noodle and a processing method thereof. It is prepared by mixing flour materials and additives. The flour materials are: purple sweet potato whole powder and high-gluten wheat flour mixed powder; the additives are: edible alcohol 3-10% , 0.1-2% propylene glycol, 1-3% sorbitol, 0.3-0.5% disodium dihydrogen pyrophosphate or potassium dihydrogen phosphate, 0.1-0.3% sucrose fatty acid ester or sodium alginate; It is 26-32% by weight. During the processing process, edible alcohol, propylene glycol, and sorbitol are used for combined preservation, and salt, sucrose fatty acid ester or sodium alginate are added to improve the quality of noodles; disodium dihydrogen pyrophosphate or potassium dihydrogen phosphate are used as color-protecting agents. The purple sweet potato fresh noodles provided by the invention have good fresh-keeping effect, stable color, a shelf life of 2 months at normal temperature, light pink soup after the noodles are boiled, and good market prospects.

Owner:河北鲜邦食品有限公司

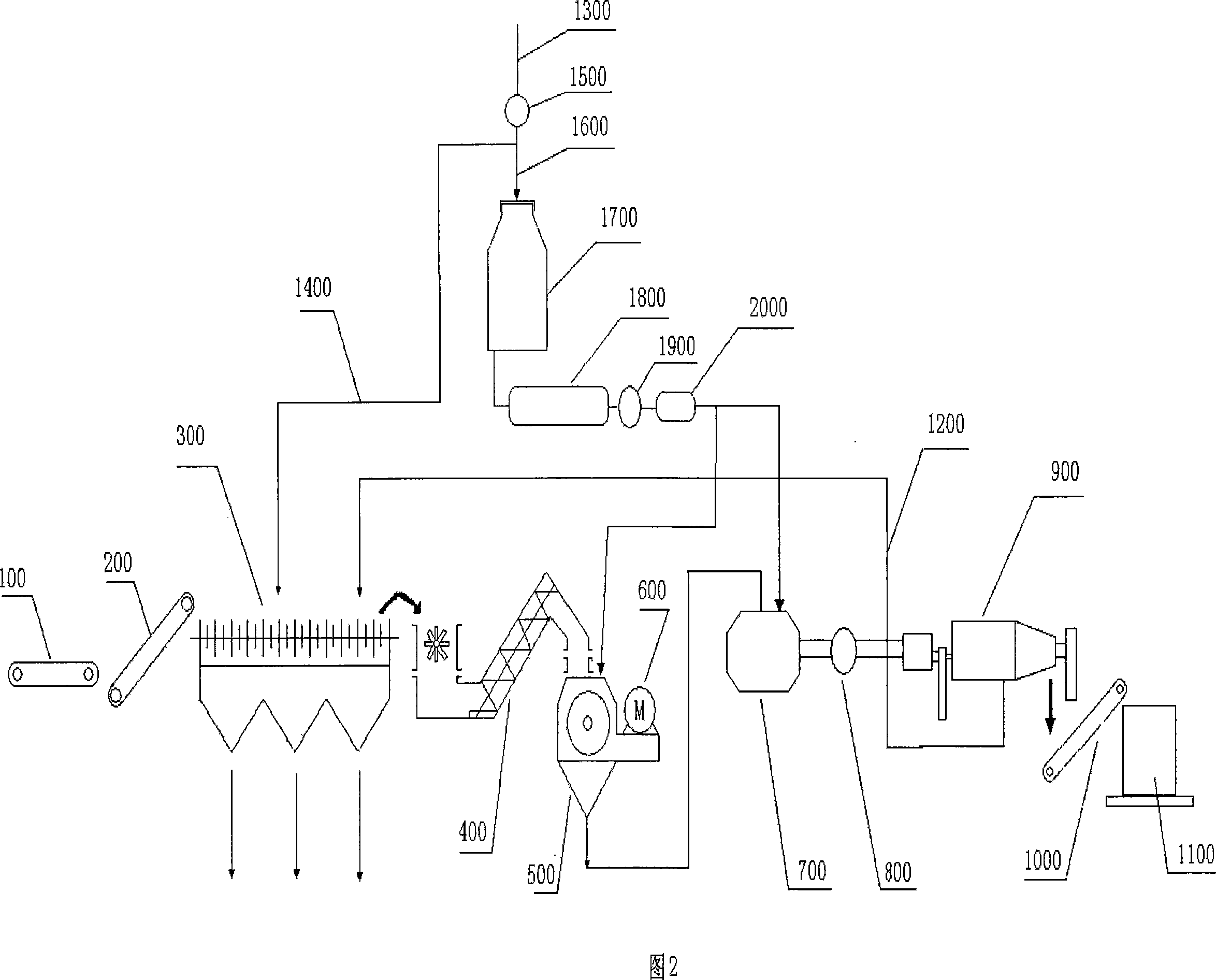

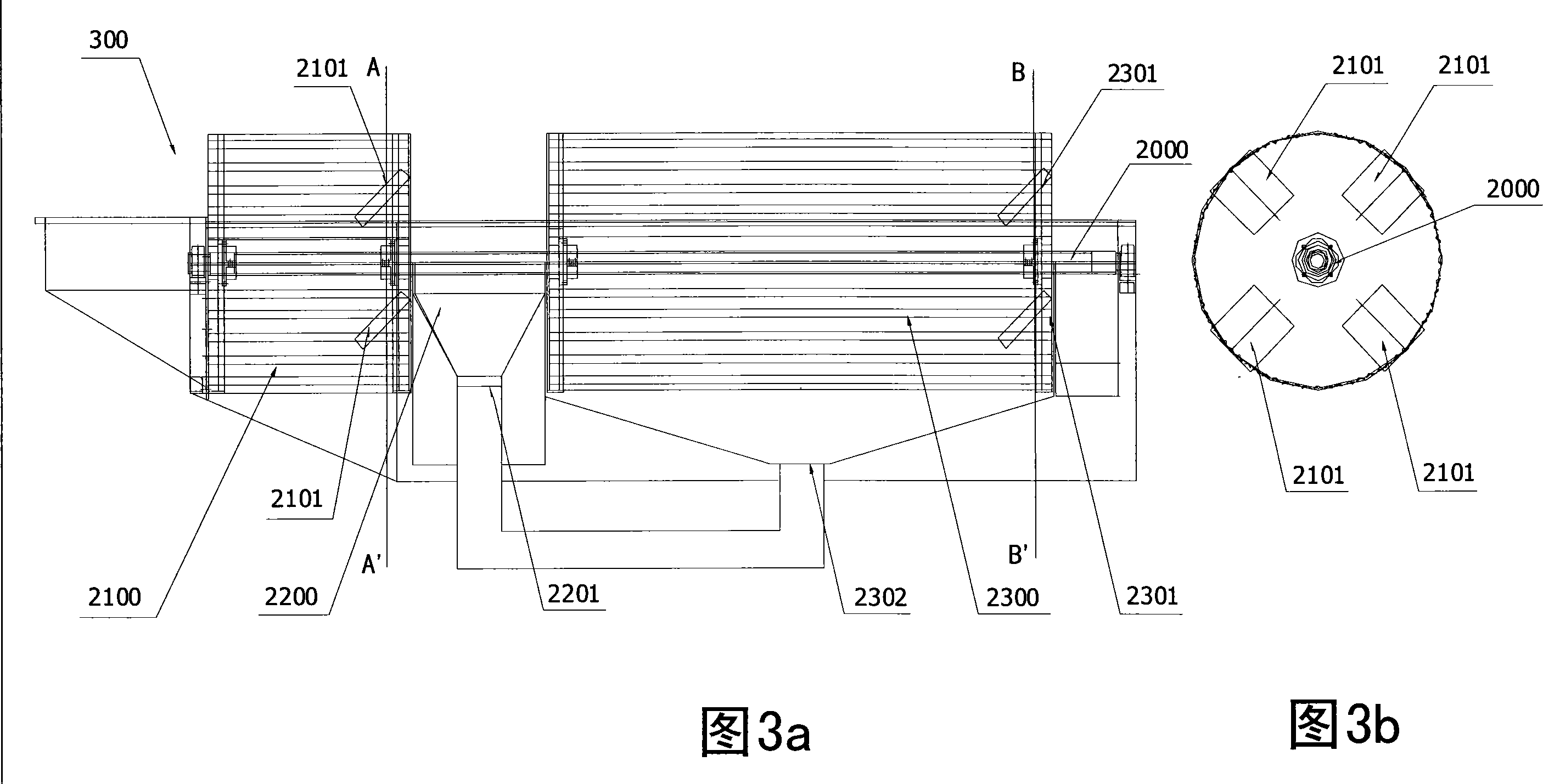

Vehicle mounted potato starch processing system and method

The present invention is vehicular potato starch producing system and process. The vehicular potato starch producing system includes a mill, an impurity separator, a dewatering apparatus, a reflux cleaning machine and a conveyer on at least one vehicle. The reflux cleaning machine includes a dry cleaning drum to eliminate mud from potato, a sand eliminating tank, a reverse cleaning squirrel cage, and a driving shaft. The present invention can realize automatic field potato starch production, and has high production efficiency.

Owner:安徽瑞德华机电设备有限公司

Process for brewing subprostrate sophora wine

The invention discloses a process for brewing subprostrate sophora wine. Subprostrate sophora is used as a raw material, and sweet potatoes are used as a matrix. The subprostrate sophora wine is prepared by the steps including raw material processing, soaking and super-finely crushing, sweet potato processing, raw material mixing, medicine adding, post-fermentation, squeeze filtering, wine mixing and the like. The soaked raw material is crushed and then fermented continuously, so that the utilization ratio of the raw material can be increased, resource waste is reduced, and the finished product of subprostrate sophora wine is more balanced in nutrient substances, mellow in taste and long in aftertaste, and meanwhile, has health efficacy of clearing internal heat for detoxification, relieving swelling and pain, moistening the throat, relieving sore-throat and the like.

Owner:余芳

Processing method for pre-pasting potato granule full powder

The present invention relates to potato processing method, and especially production process of whole gelatinized potato powder. The production process includes the steps of pre-treatment, cutting, scalding, dewatering, crushing, sieving, packing, etc. The present invention powders potato after cutting and semi-cooking, and this results in less breaking of carbon chains, preservation of most cells, less free starch formed and well preservation of vitamins, minerals, amino acids, trace elements, cellulose and other nutritive matters potato contains. The present invention is suitable for potato processing.

Owner:李 新杰

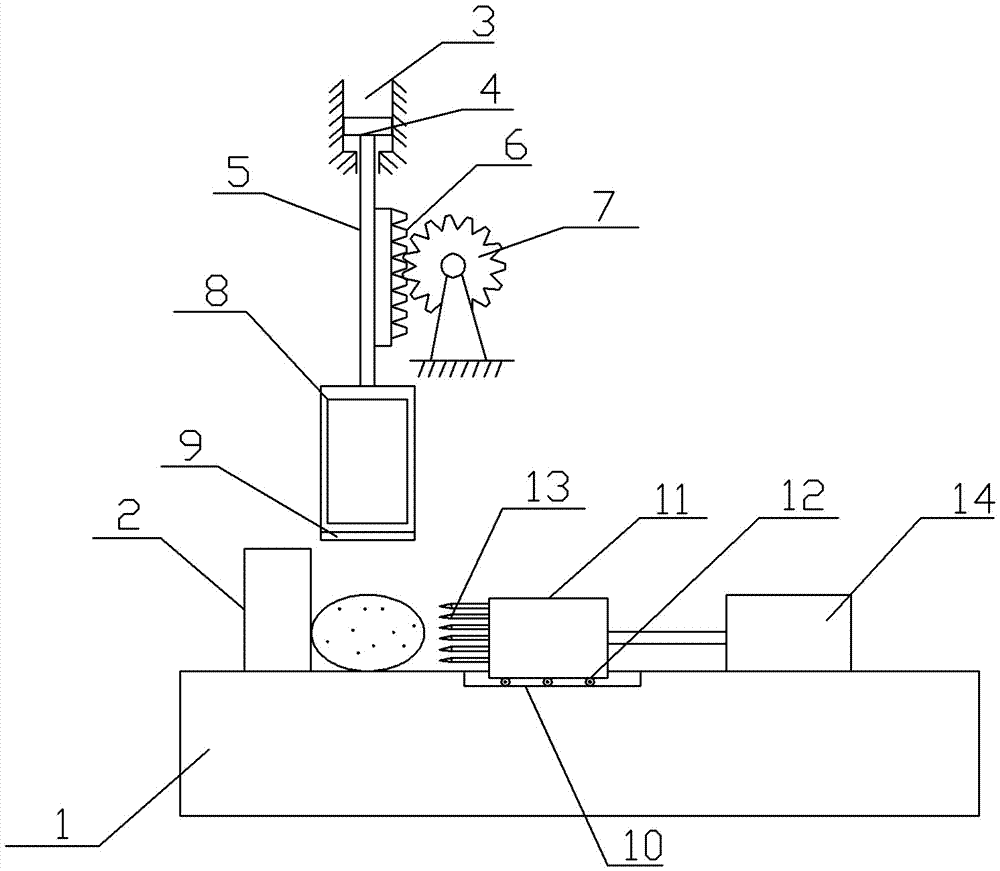

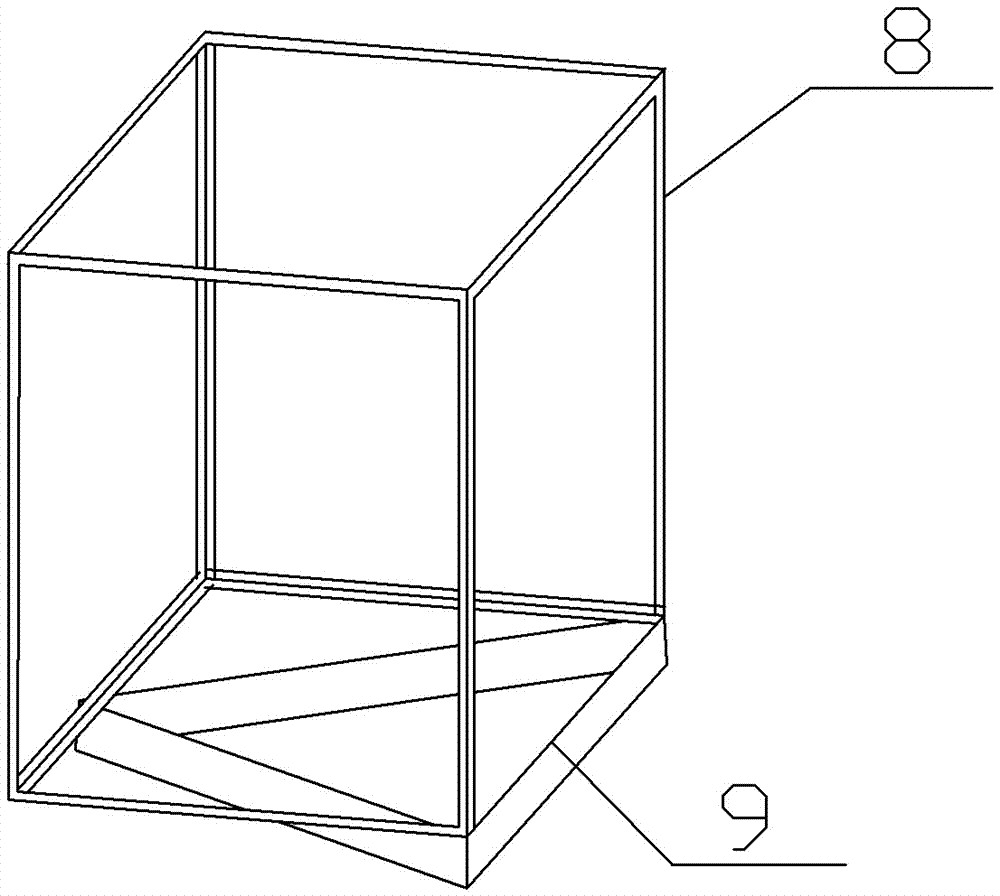

Pattern cutting device for potato

InactiveCN105437283AImprove the efficiency of cut flower processingImprove processing efficiencyMetal working apparatusBlade plateEngineering

The invention belongs to the technical field of potato processing, and discloses a pattern cutting device for a potato. The device comprises a rack on which a horizontal processing platform is arranged, wherein a vertical cutter board is arranged on the processing platform, and a chute is located at the right side of the cutter board; a processing station is formed between the chute and the cutter board; the rack is provided with a rectangular frame above the processing station, and the rectangular frame can move up and down; a plurality of pattern cutters are welded on the bottom surface of the rectangular frame, and all pattern cutters can be spliced to form a pattern to be cut; a cutter holder is arranged in the chute in a rolling fit manner; a plurality of horizontal slicing cutters are arranged at equal intervals from top and bottom on the left sidewall of the cutter holder; the slicing cutters are opposite to the cutter holder and can extend into the rectangular frame; a cylinder is fixed to the right side of the chute in the processing platform, and an output shaft of the cylinder is fixedly connected to the right sidewall of the cutter holder. According to the pattern cutting device for the potato, the pattern cutting and slicing steps can be fully automatically carried out; the pattern cutters and the slicing cutters are used to enable the consistent pattern and uniform thickness of the obtained potato slices, and as a result, the potato pattern cutting processing efficiency can be greatly improved.

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

Processing method and device thereof of potato chips

PendingCN105661411APrevent browningImprove qualityMetal working apparatusFood treatmentChipped potatoesProcess engineering

The invention discloses a processing method and device thereof of potato chips, for preventing brown changes of potatoes in the course of processing. The processing method of the potato chips comprises the following steps of thoroughly cleaning the potatoes, respectively performing peeling treatment, dicing treatment, curing treatment, cooling treatment and microwave heating drying treatment on the potatoes in sealed environment, and then performing deep-frying treatment and seasoning treatment. In the processing course of the potato chips, the contact probability of the potatoes and oxygen is greatly reduced, contact of polyphenol oxidase (PPO) in the potatoes with oxygen in air can be effectively prevented, and oxidation polymerization is avoided; the brown changes of the potatoes can be effectively avoided, so that the produced potato chips can be guaranteed to high in quality, and the processing method and device are suitable for popularization and application in the field of processing technologies of the potatoes.

Owner:XICHANG COLLEGE +1

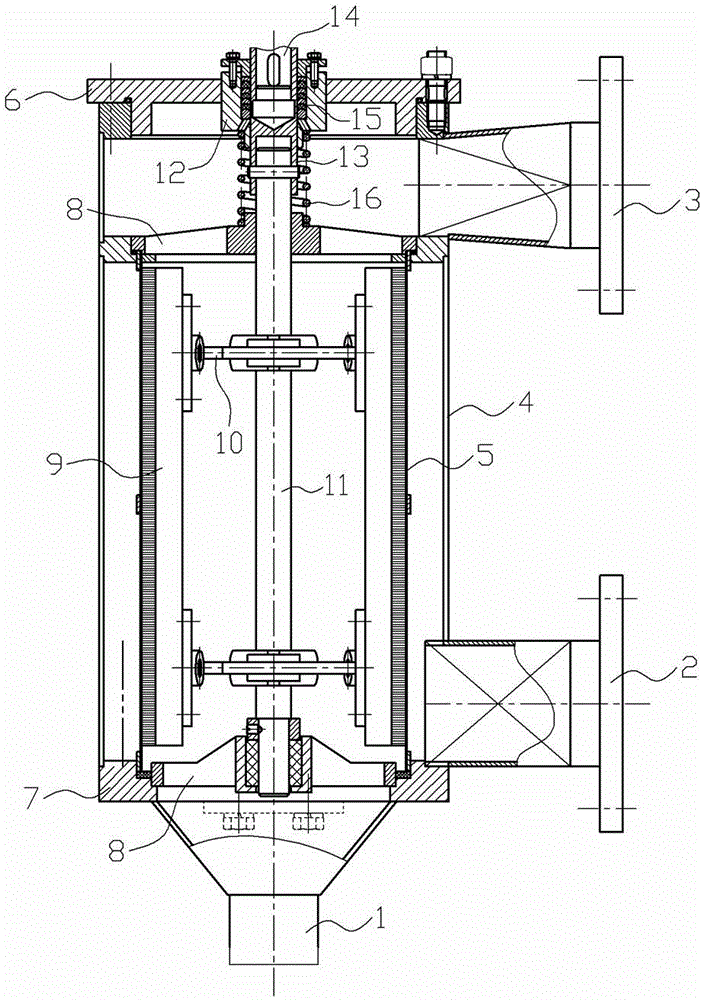

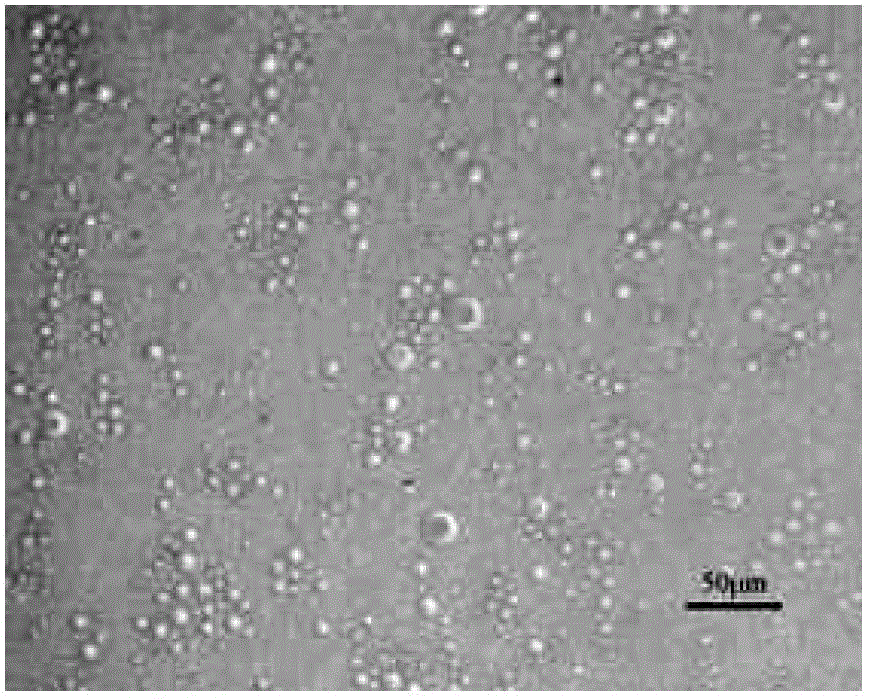

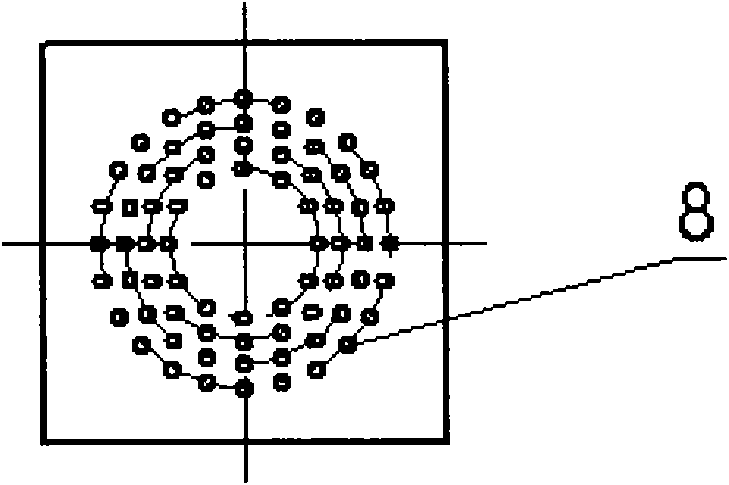

Rotary starch filter

InactiveCN104689618AReasonable structureImprove filtration efficiencyStationary filtering element filtersSlagEngineering

The invention relates to food machinery, specifically to a rotary starch filter used for filtering out large particles in fluid. The rotary starch filter comprises a filter cylinder (4) equipped with a feed inlet (1), a discharge outlet (2) and a slag hole (3); a filter screen (5) is arranged in the filter cylinder; the upper and lower ends of the filter cylinder (4) are respectively provided with an upper end cover (6), a lower end cover (7) and a shaft seat (8); the filter screen (5) is placed in the filter cylinder (4), and a ring cavity is formed between the filter screen (5) and the filter cylinder (4); a fur brush (9) closely adhering the interior wall of the filter screen (5) is arranged in the filter screen (5); the fur brush (9) is fixed on a rotating shaft (11) through a brush handle (10); and the rotating shaft (11) is fixed on the shaft seat (8). The rotary starch filter has the advantages of reasonable structure and high filtering efficiency and is applicable to large-scale line production for potato processing.

Owner:NINGAN CEREALS OILS & STARCH MACHINERY MFG

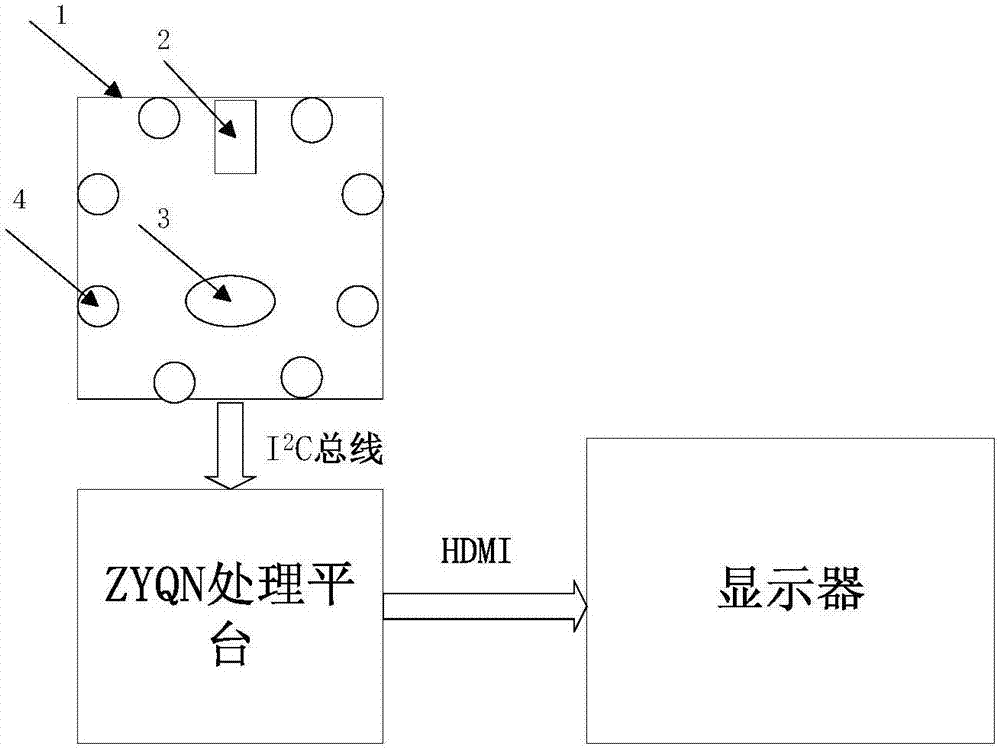

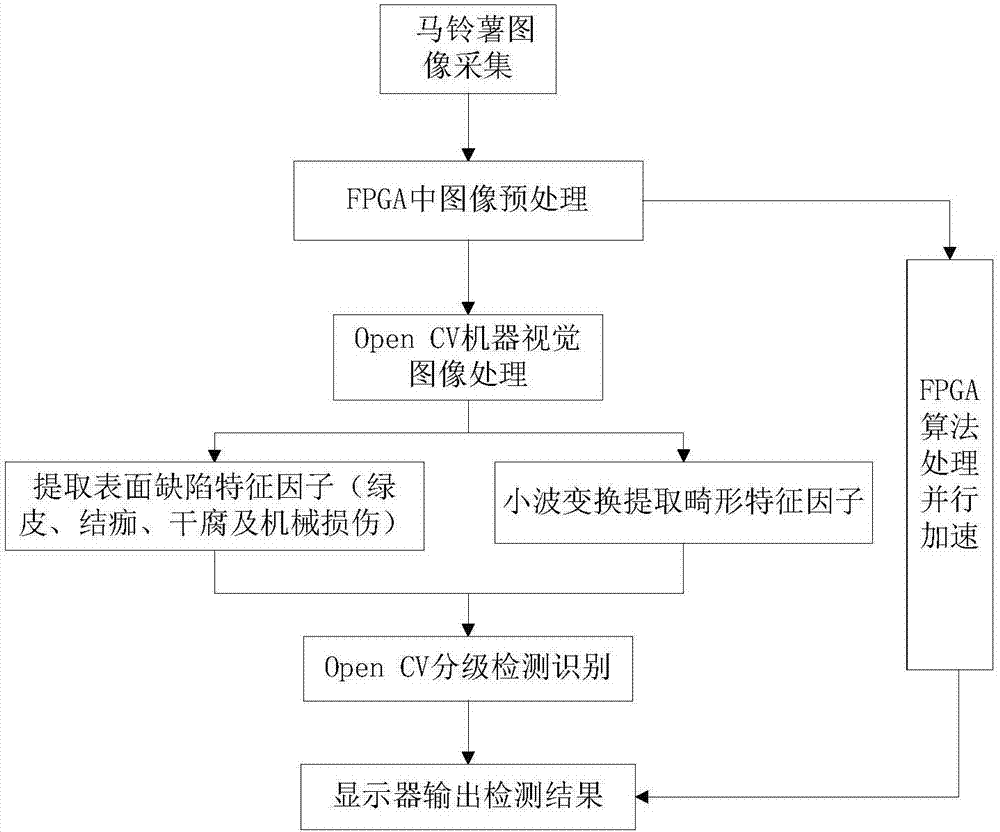

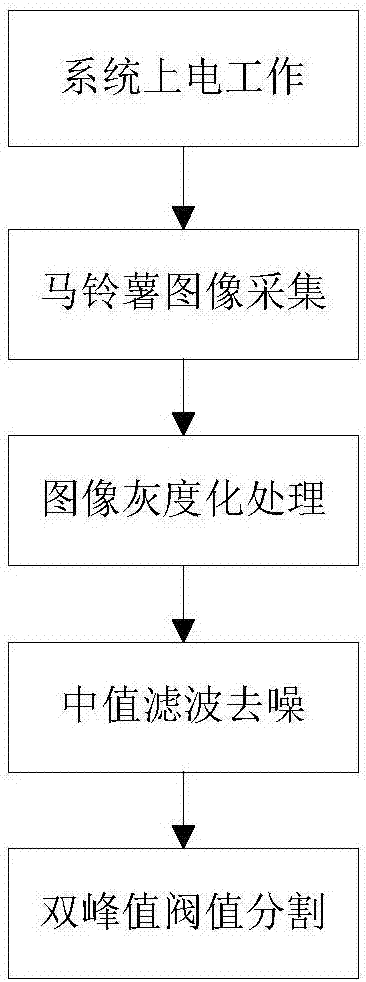

Potato defect detection and recognition system design based on machine vision

InactiveCN106872473AImprove efficiencyHigh precisionOptically investigating flaws/contaminationHardware structureSystems design

The invention discloses a potato defect detection and recognition system design based on machine vision. The potato defect detection and recognition system design is characterized in that defected potatoes are identified and classified on a ZYNQ platform by utilizing a machine vision library Open CV of an embedded Linux system; characteristic factors of the defected potatoes with green peels, dry rot, crust and mechanical damages are extracted and R, G and B discrete degrees of variable defect factors are analyzed to realize detection and recognition of surface defects of the potatoes, and the algorithm precision is greatly improved. Wavelet transform is applied to analysis and detection of potato shapes of the potatoes, and ellipse radiuses of the potatoes are extracted and are subjected to normalization processing; grading is carried out through a RBF (Radial Basis Function) neural network, so that the efficiency and precision of recognizing the defected potatoes by grades are improved; potato images are pre-processed by utilizing an FPGA (Field Programmable Gate Array) and an algorithm in the Open CV is subjected to accelerated processing; a calculation speed and the algorithm efficiency are remarkably improved. A testing result shows that compared with an existing defected potato recognition and classification technology based on software image processing, an image processing algorithm is innovated and optimized by a novel method based on a hardware structure platform, and the processing speed and the algorithm efficiency are greatly improved; theories and experiments show that the design has relatively ideal detection efficiency and speed on the recognition and classification of the defected potatoes in an actual process. The design has very great significance on a potato processing industry.

Owner:CHINA UNIV OF MINING & TECH

Planting method free of plastic film mulching, soil preparation, bedding and ridging for potatoes in circulating mode

ActiveCN103718819AReduce usageReduce labor inputPlant protective coveringsAmmonium compoundsPlastic mulch

The invention discloses a planting method free of plastic film mulching, soil preparation, bedding and ridging for potatoes in a circulating mode. The planting method is characterized by comprising variety selecting, seed potato processing, soil preparation, preheating and moisture regaining, seeding, wheat straw mat covering, fertilization, seedling emerging and freeze protection, seedling management and water management, wherein the soil preparation comprises the steps of ploughing soil in a first year and applying a mixed fertilizer of stable manure and a black ammonium compound fertilizer, preheating and moisture regaining are conducted ten to fifteen days before planting, and after water is sprayed to the soil, the soil is covered with a wheat straw curtain; fertilization comprises a base fertilizer stage and a topdressing stage; seedling emerging and freeze protection are conducted about fifteen days after seeding, the wheat straw curtain is removed to avoid the situation that seedlings cannot expose out of the soil due to the fact that the seedlings are pressed, the seedlings expose out of the soil in about twenty days, seedling freezing should be avoided at the moment, the seedlings can be covered with the wheat straw curtain at night, but it is noticed that the seedlings cannot be heavily pressed, and when the seedlings grow to 10cm, it is unnecessary to avoid seedling freezing. By means of the planting method, labor input is reduced, economic efficiency is improved, meanwhile use of mulching films difficult to degrade is avoided, and therefore the planting method is economical and protects the environment.

Owner:甘肃田地农业科技有限责任公司

Preparation of waste potato residue/palygorskite composite adsorbent and application of adsorbent in treatment of potato starch processing wastewater

InactiveCN102600801ATake advantage ofSolve processing problemsOther chemical processesWater/sewage treatment by sorptionPotato starchSorbent

The invention provides a self-circulation utilization technology for leftovers of potato starch processing. The self-circulation utilization technology comprises the steps of: ultrasonically dispersing palygorskite clay powder and potato residues according to the mass ratio of 1: (0.5-1.5) in water to form slurry; then, transferring the slurry into a hydrothermal reaction kettle, and carrying outcarbonization reaction for 6-48 hours at 120-200 DEG C; and after the carbonization reaction is finished, naturally cooling, washing, drying and crushing the product to obtain a waste potato residue / palygorskite composite adsorbent. Potato starch processing wastewater treated by using the adsorbent can completely reach a discharge standard of water pollutants for starch industry (GB25461-2010) under national regulation. According to the invention, the waste potato residues are fully utilized, the most difficult problem in treating potato processing wastewater at present is solved, and the mutual harmless treatment of the wastes obtained after the potato starch processing is realized, and the technology has a very good popularization value.

Owner:临泽县奋君矿业有限公司

Method for filtering and recovering solids from potato process water

InactiveUS7465398B1Improve production yieldMembranesJuice extractionProcess engineeringPotato processing

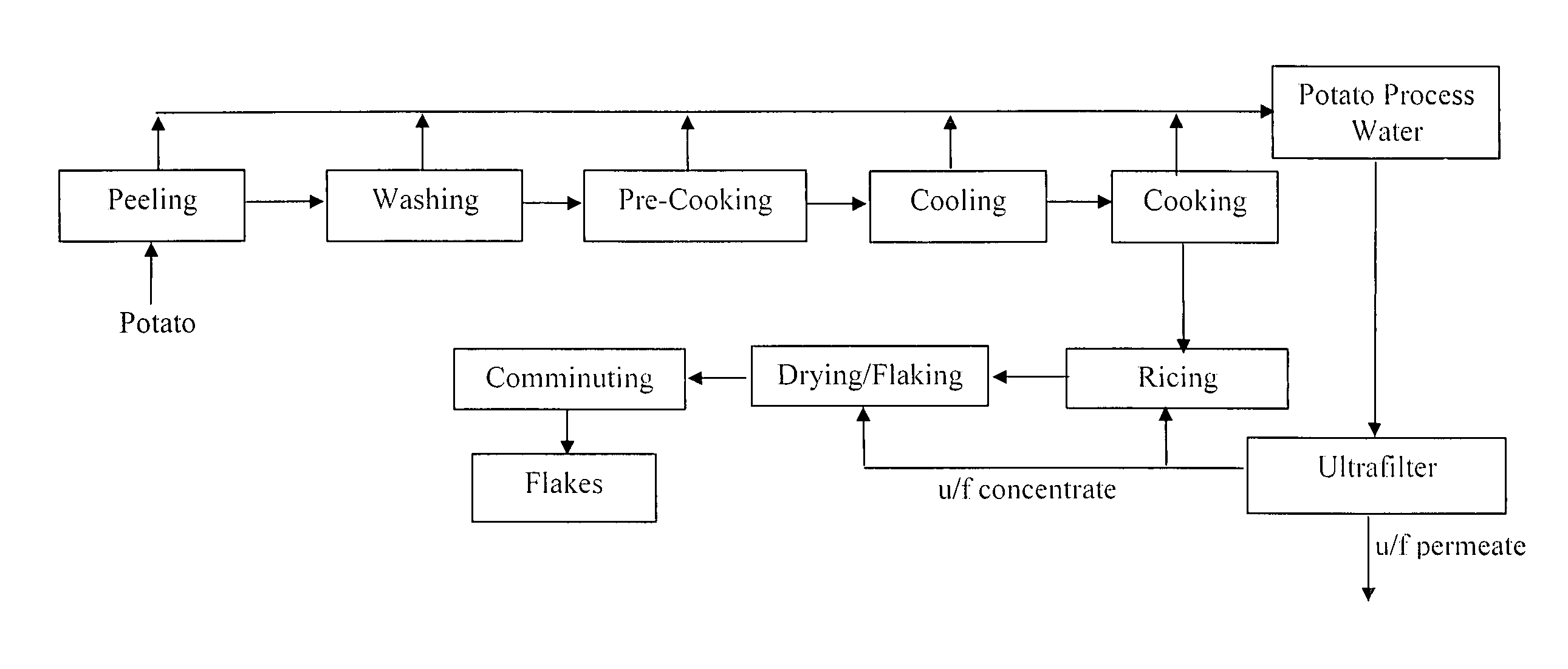

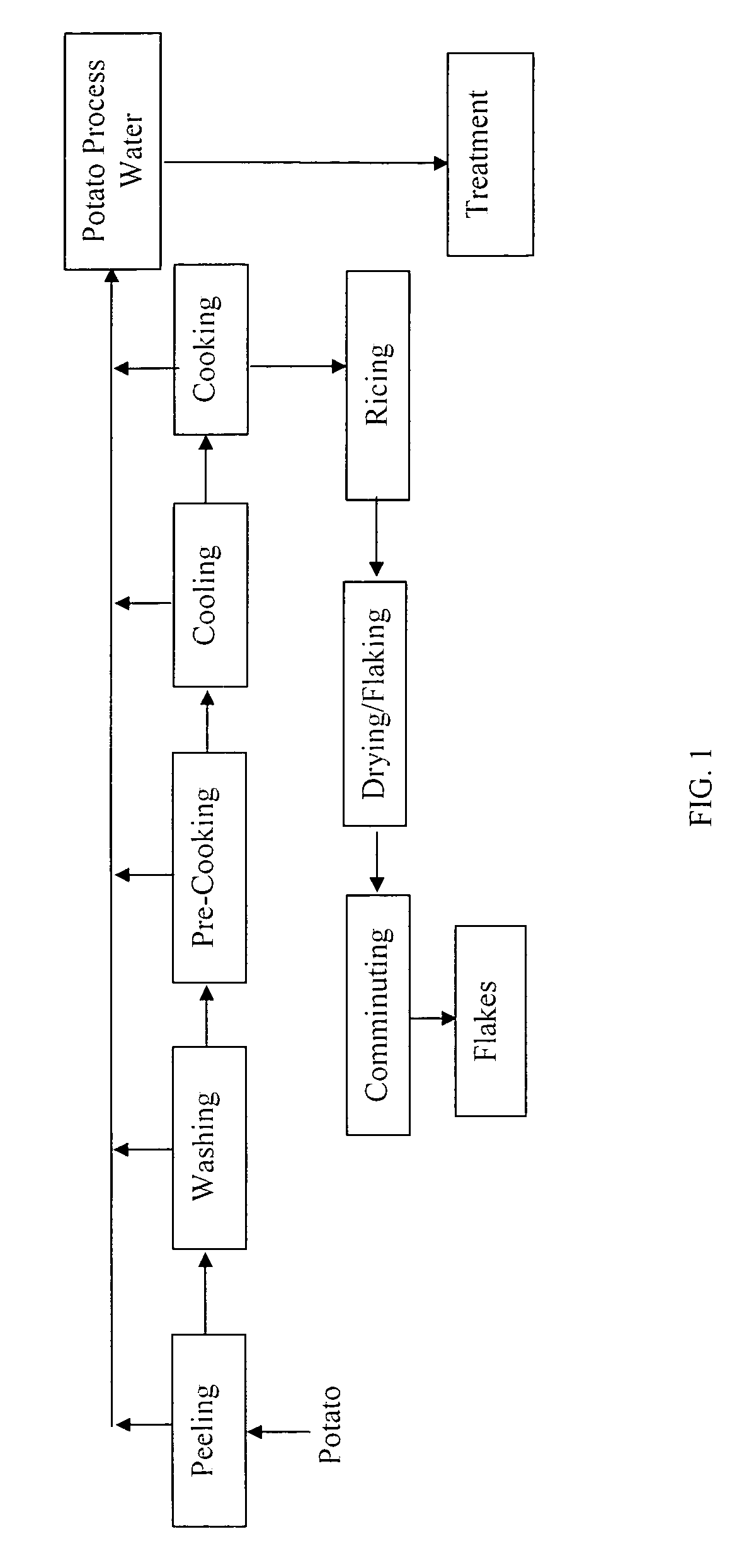

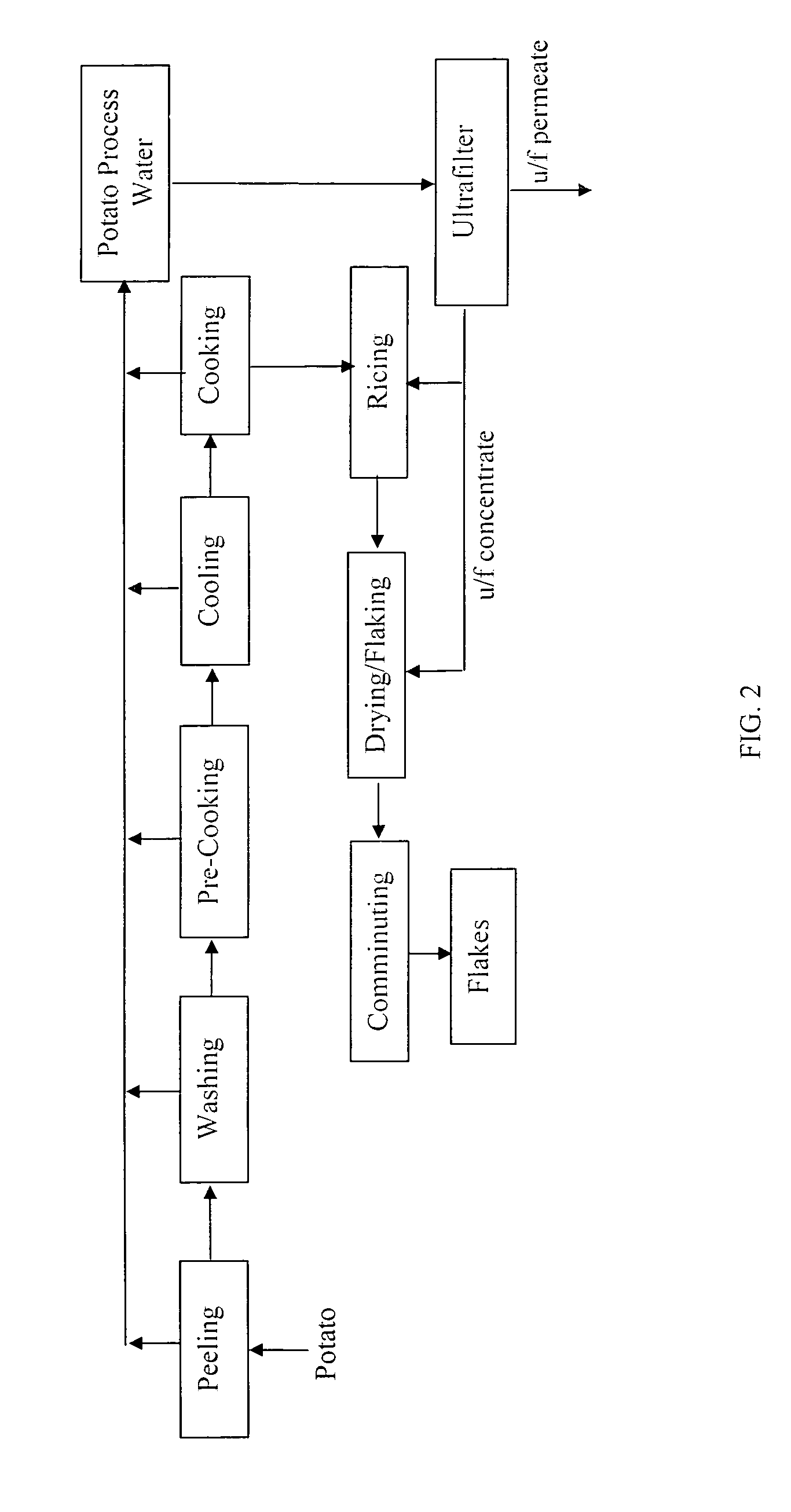

A method for filtering and recovering solids from potato process water that results in a product containing a portion of the solids from the potato process water is presented. In general, the method involves providing a plurality of vessels wherein a step in a manufacturing process takes place in each vessel and wherein at least one step in the manufacturing process produces a potato process water having solids. The potato process water is passed through at least one ultrafilter wherein each ultrafilter produces an ultrafilter (u / f) permeate stream and a u / f concentrate stream. The u / f concentrate stream is collected and reintroduced into at least one vessel in the manufacturing process producing a product containing a portion of the solids from the potato process water. The final characteristics of the product remain essentially unchanged.

Owner:DELTA T

Method for preparing edible mushroom culture medium from potato residue

InactiveCN104557258AFully realize the potential valuePrevent acid fermentationCalcareous fertilisersOrganic fertilisersCompostMoisture

The invention discloses a method for preparing an edible mushroom culture medium from potato residue. The method comprises the following steps: removing rotted potato residue, spreading the potato residue on an iron net and dehydrating, enhancing the ventilation force so that the moisture content of the potato residue is evaporated, and grinding and sieving the air-dried potato residue; evenly mixing 15-20 parts of potato reside, 10-15 parts of saw dust, 4-5 parts of soybean cake powder, 62-66 parts of straw powder and 1-2 parts of gypsum, and adding water until the moisture content is 60-62% and then stirring evenly; bagging and sterilizing, thereby obtaining the edible mushroom culture medium. According to the method, the leftovers of agricultural and forestry products are taken as the major compost needed by cultivating the edible mushrooms, so that the edible mushroom culture cost is reduced; especially, the dosage of the potato residue and other raw materials is optimized so that the biological conversion rate can be increased and the potential value of the potato residue can be developed thoroughly; besides, the environmental pollution caused by the waste potato residue in the potato processing process is solved, the agricultural product processing industry chain is expanded, excellent ecological benefit is generated and considerable economic benefit is generated.

Owner:GANSU ZHENGYANG FOOD

Sweet potato crushing and filtering system

ActiveCN106269175AHigh extraction rateReduce slurry residueGrain treatmentsPressesFilter systemEngineering

The invention belongs to the technical field of sweet potato processing, and specifically relates to a sweet potato crushing and filtering system. The sweet potato crushing and filtering system comprises a crushing device used for crushing sweet potatoes into pulp and a filtering device used for separating sweet potato dregs and the pulp. The sweet potato dregs are squeezed by means of compression rollers and fully dehydrated, pressured is circularly applied on the sweet potato dregs while the sweet potato dregs are washed repeatedly, pulp remaining in the sweet potato dregs is effectively reduced, and the starch extraction ratio is increased.

Owner:岳西神农氏农业科技有限公司 +1

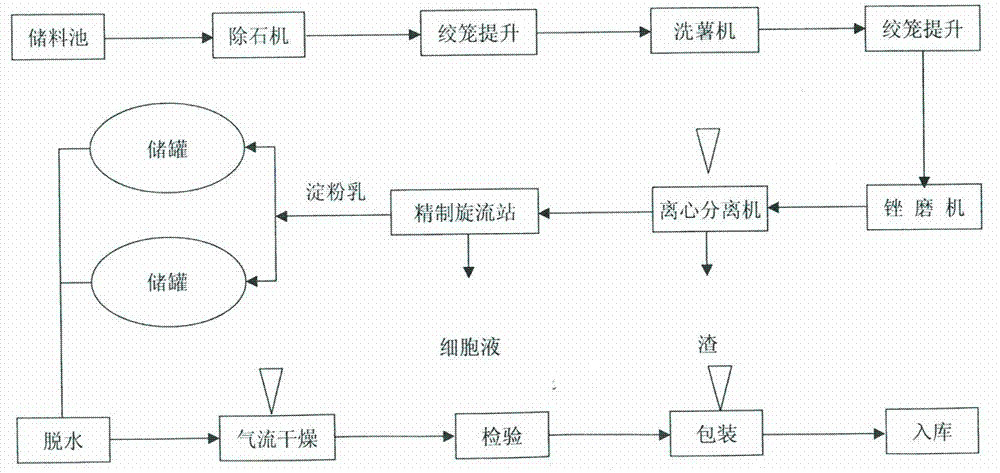

Potato starch production technology

The invention discloses a potato starch production technology, and belongs to the technical field of potato processing. The potato starch production technology comprises the following steps: 1, carrying out dry screening of fresh potatoes, removing impurities, storing the potatoes in a material storage pool, conveying the potatoes to a derocker under the action of a water flow, lifting the potatoes to a potato cleaning machine by a stranding cage, and thoroughly cleaning the potatoes; 2, lifting or spirally conveying the thoroughly-cleaned potatoes to a grinding machine by the stranding cage, mixing the prepared paste with water, separating through a centrifuge, and inputting to a refining cyclone station; and 3, dehydrating the material output from the refining cyclone station, carrying out air drying, and screening to obtain potato starch. The potato starch production technology has the advantages of simplicity, low cost, no addition of any additives, good quality, and great market value.

Owner:WUZHAI COUNTY RUNZE STARCH IND CO LTD

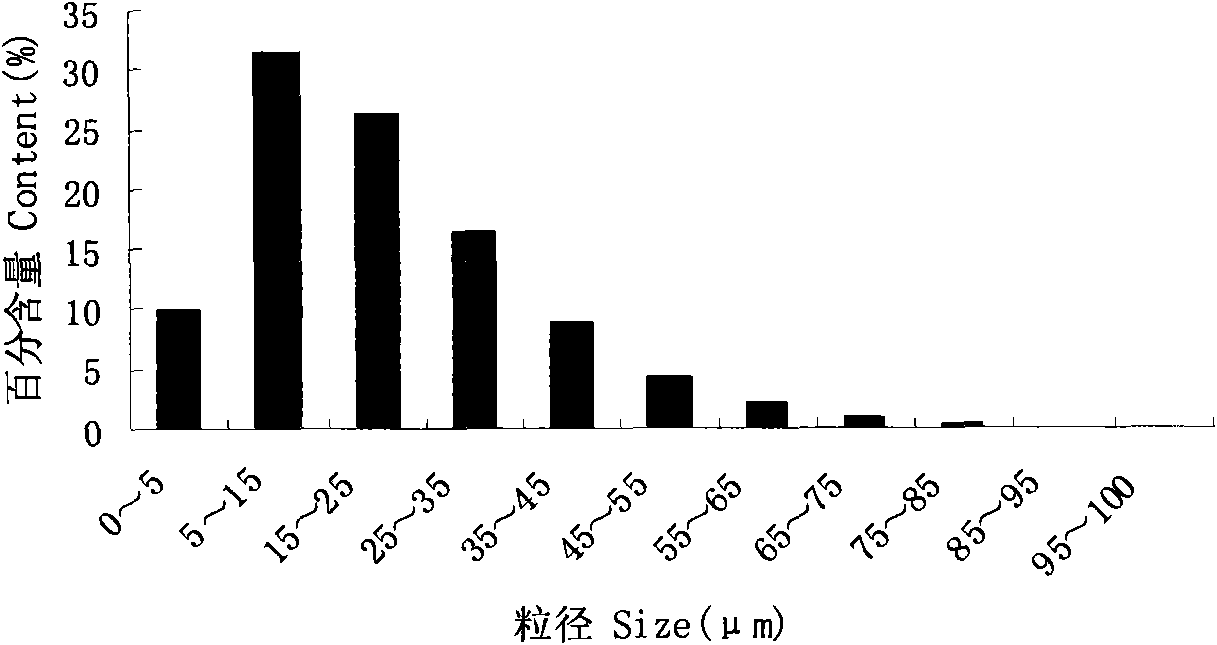

Method for preparing high-stable sweet potato pectin emulsion

The invention relates to a method for preparing a high-stable sweet potato pectin emulsion. A raw material of sweet potato residue in starch production is carried out with an enzymolysis process in a water bath. A sweet potato pectin is obtained by adding water to produce suspension, adjusting the pH value of the suspension, carrying out extraction by shaking the suspension in water bath, carrying out centrifugation, carrying out concentration with an ultrafiltration membrane, precipitating with absolute ethanol, carrying out centrifugation, washing precipitation, and freeze-drying. A sweet potato pectin solution is obtained by mixing the sweet potato pectin with distilled water, adjusting the pH value of the mixture, stirring the mixture at the room temperature, and keeping the mixture stand for 24h. The sweet potato pectin emulsion which is distributed evenly is obtained by homogenizing the sweet potato pectin solution and soybean oil with a high pressure homogenizer for 2 min. The method in the invention is waste utilization, wherein the raw materials come from a variety of sources, and production processes are simple and feasible. Particle size of the prepared sweet potato emulsion is less than or equals to 8.05 mu m. After laid aside for 7d, the emulsion has an emulsifying stability which is more than or equals to 80%. The emulsion can be used as emulsions or emulsifying stabilizer that is used in food and pharmaceutical industries in a large scale. The method of the invention greatly improves degrees of comprehensively utilizing by-products in sweet potato starch processing, and increases economic benefits of sweet potato processing.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Method for processing reversed steaming sweet potato

InactiveCN101461418AMaintain nutrientsMaintain propertiesFood preparationFruits/vegetable preservation by dehydrationFlavorHigh pressure

The invention relates to an inverted steamed sweet potato processing method, belonging to the agricultural product deep processing field. The inverted steamed sweet potato processing steps compris: choosing material and cleaning-> peeling-> slivering-> boiling by water-> draining-> first dehydrating-> steaming to soft-> second dehydrating-> re-steaming-> third dehydrating-> packaging-> sterilizing-> cooling-> inspecting-> finishing and warehousing; the method can be implemented by using modern technology and mechanized equipment, and the sterilization treatment is concerned in each step according to the fence principle. The invention overcomes the insufficient of product quality and flavor changeable in high pressure sterilization and not thoroughly in pasteurizing sterilization; keeps the nutrient compositions and peculiar flavor of sweet potato better; avoids the loss caused by fresh sweet potato storage; has a strong practicality, and is one of the domestic ideal methods for sweet potato deep processing.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

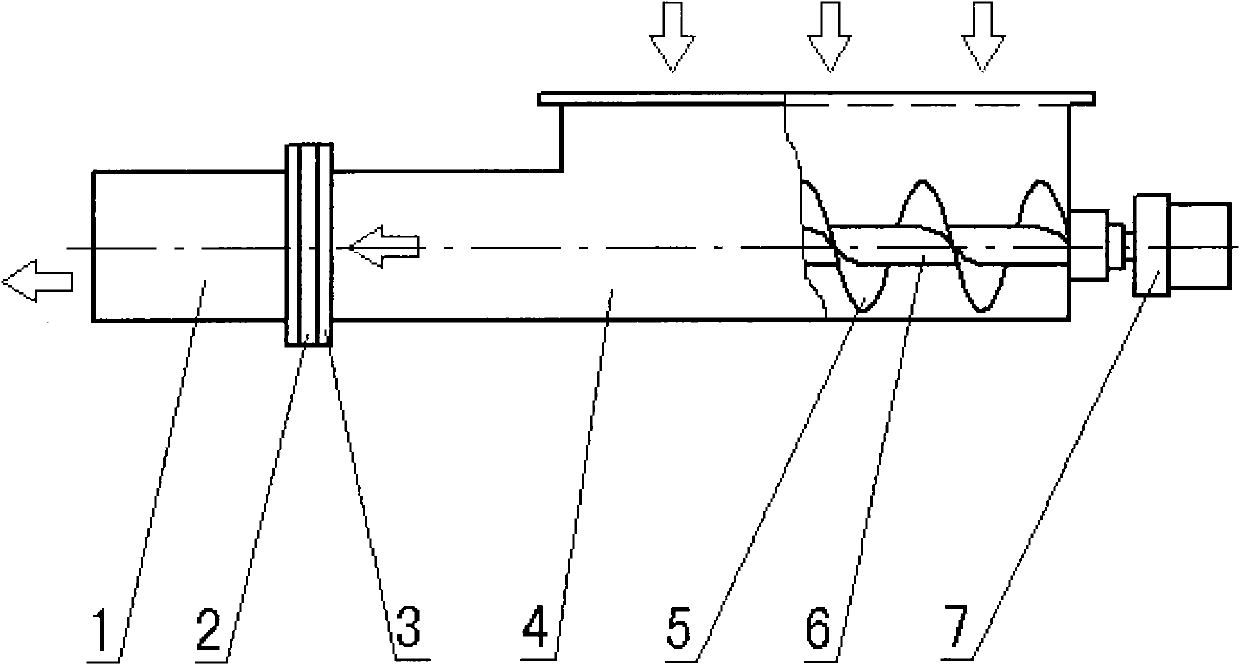

Potato masher

The invention relates to a potato masher which comprises a main shaft, a material propeller, a shell, a shell flange, a mashing board, a material discharging barrel and a transmission device, wherein the main shaft driven by the transmission device is arranged in the shell, the material propeller is fixedly arranged on the outer periphery of the main shaft, the mashing board is arranged in a rectangular socket at a connection part between the shell flange and the material discharging barrel, a material discharging through hole is arranged on the mashing board, and a material discharging shield is of a cylindrical thin-wall structure which is through in axial direction. When applied to a potato production line, the potato masher can quickly, safely, sanitarily and continuously mash steamed and boiled potatoes into potato mash reaching quality requirement; in addition, the potato masher has simple structure and can operate reliably.

Owner:东台市食品机械厂有限公司

Preparation method of frozen baked sweet potatoes

InactiveCN108175057AEasy to eatKeep the inherent aromaFood freezingFruit and vegetables preservationCooking & bakingFlavor

The invention discloses a preparation method of frozen baked sweet potatoes. The method comprises operation steps as follows: screening, cleaning, baking, quick freezing, packaging, frozen storage anddelivery, wherein in the baking step, a large hot air revolving furnace baking technology is adopted, the baking temperature is 200-250 DEG C, the rotating speed is 20-40 r / min and the baking time is30-90 min; in the freezing step, a liquid nitrogen dispersion refrigeration technology is adopted, and the baked sweet potatoes are quickly frozen at the temperature of subzero 100 DEG C to subzero 50 DEG C for 5-20 min. The invention provides the frozen sweet potatoes and the preparation method thereof. No materials are added, the original taste and flavor of the sweet potatoes are guaranteed, and rich minerals and vitamins contained in the sweet potatoes are not damaged and affected; the baked sweet potato processing technology adopts constant-temperature baking and liquid nitrogen quick cooling modes in the baking and quick freezing processes, retrogradation after starch granule gelatinization of the sweet potatoes is effectively inhibited, the inherent fragrance and taste of the bakedsweet potatoes are kept to the greatest extent, and the product tastes purer and is easier to digest.

Owner:南通瑞隆农产品开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com