Preparation technology of potato whole powder

A production process, potato powder technology, applied in the field of potato processing, can solve the problems of increasing the cut section, loss of anthocyanins and natural pigments, and failure to maintain the properties of raw materials, so as to achieve the effect of reducing loss and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

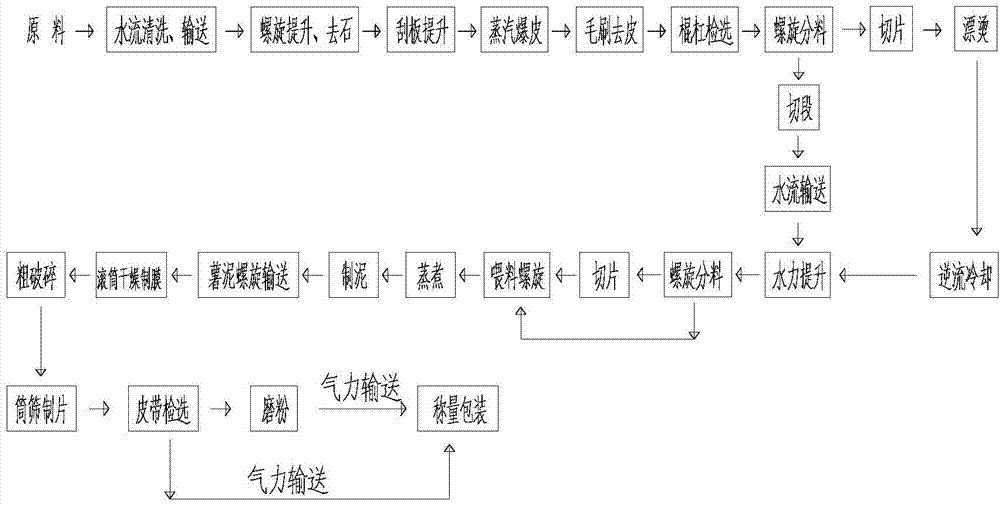

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The invention provides a production process of whole potato powder, which combines four different raw materials to produce whole powder, processes different raw materials through different processes, and obtains four kinds of whole powder products, realizing the multi-purpose and diverse products of processing enterprises. desire to transform.

[0022] Process flow of the present invention such as figure 1 As shown, a ditch is built on the ground of the raw material warehouse, which is connected to the spiral stone removal elevator in the production workshop, and the raw materials are transported to the entrance of the spiral stone removal elevator by using circulating water flow. During the conveying process, the water flow ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com