Potato defect detection and recognition system design based on machine vision

A technology of machine vision and defect detection, which is applied in the direction of optical testing defects/defects, instruments, measuring devices, etc. It can solve the problems of slow detection and classification speed, unreachable, low accuracy, etc., to avoid fuzzy judgment and improve algorithm accuracy , the effect of improving speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

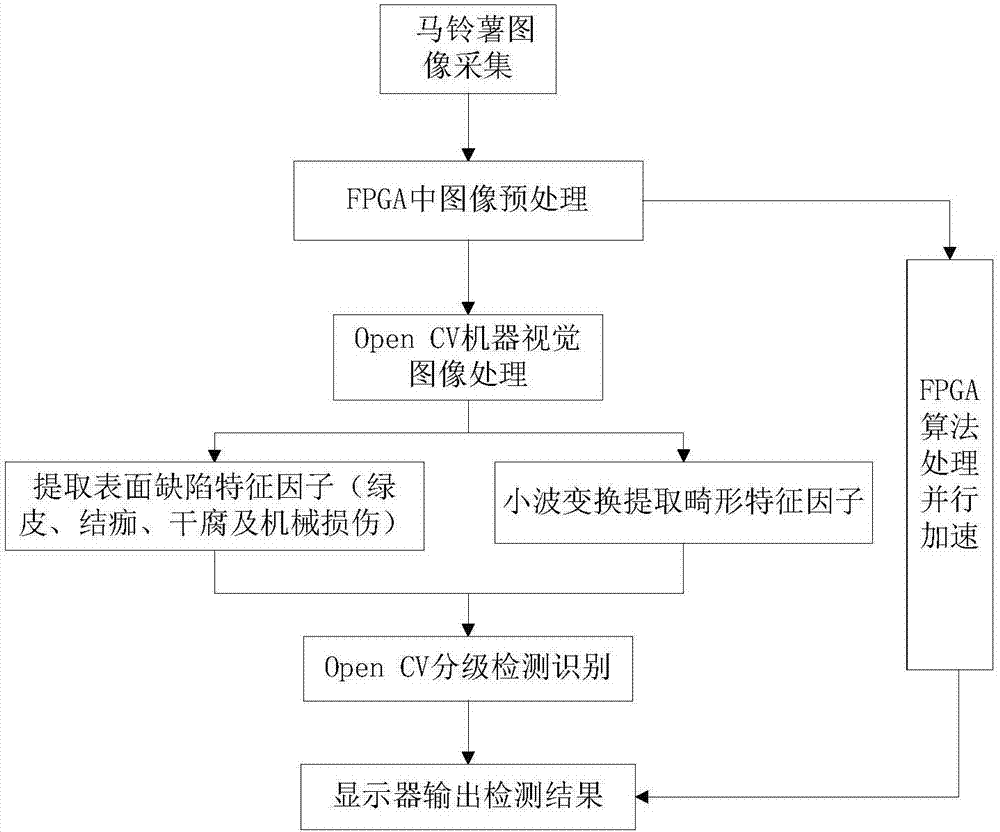

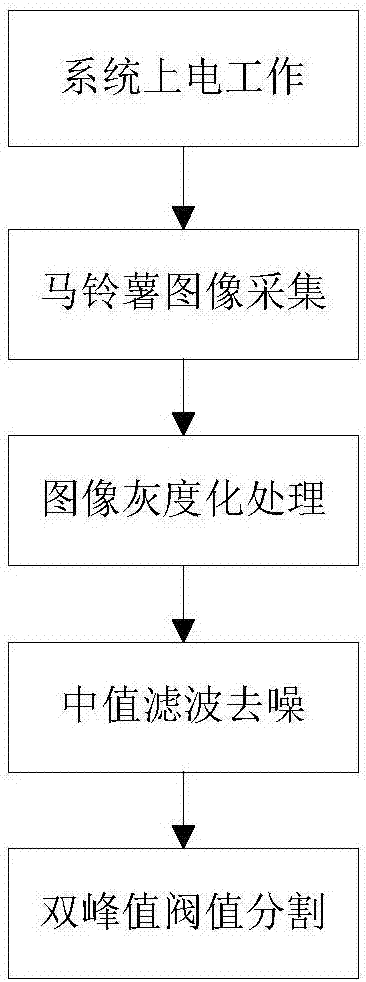

Method used

Image

Examples

Embodiment approach

[0029] The specific implementation method is as follows:

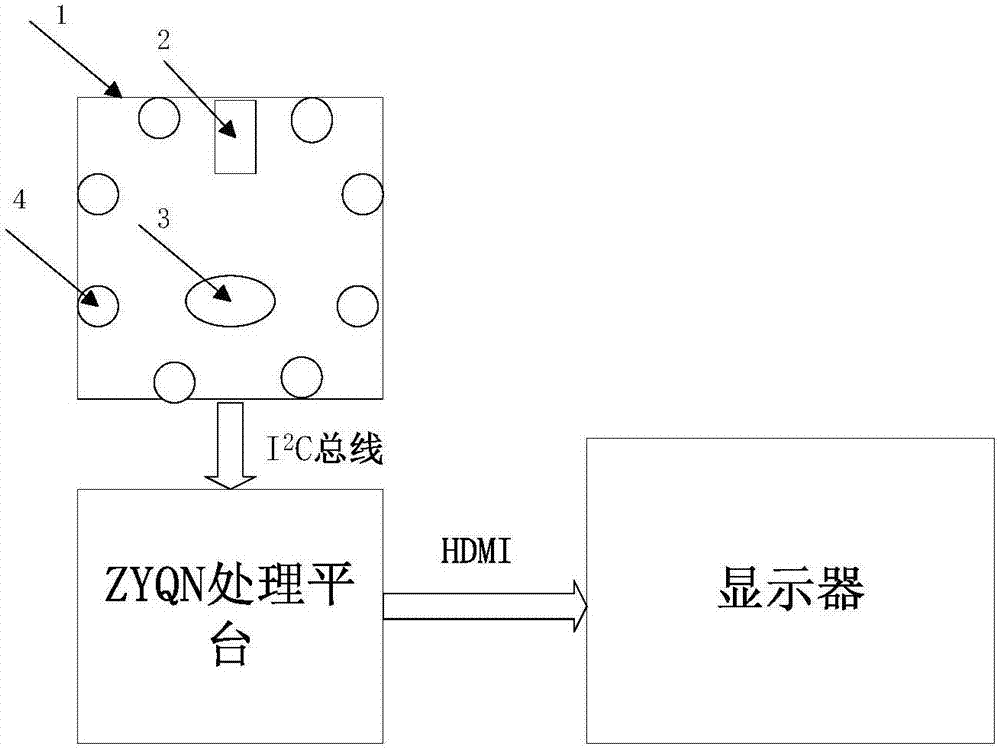

[0030] 1) In a special dark box with shadowless light, such as figure 1 As shown, number 1 indicates the image acquisition box, number 2 indicates the CCD industrial smart camera, number 3 indicates the potato sample, and number 4 indicates the LED light. Install 2 LED lights on each side of the box to ensure the best conditions for image acquisition, and use a CCD industrial smart camera to capture images of potatoes. Combined with Zhang Zhengyou's planar template calibration method to calibrate in the camera, the undistorted and undistorted potato image is obtained. On the plane of the system’s absolute coordinate system Z=0, the model of Zhang Zhengyou’s planar template calibration method is:

[0031] ,

[0032] Among them, A is the internal parameter matrix of the camera, is the rotation and translation matrix. Since the camera has 5 unknown internal parameters, the internal parameter matrix A can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com