Sweet potato crushing and filtering system

A filtration system and sweet potato technology, applied in presses, grain processing, manufacturing tools, etc., can solve the problems of starch slurry residue, waste, high water consumption, etc., achieve the effect of reducing slurry residue and improving starch extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The concrete embodiment that crushing and filtration system of the present invention is applied in sweet potato flour production system is as follows:

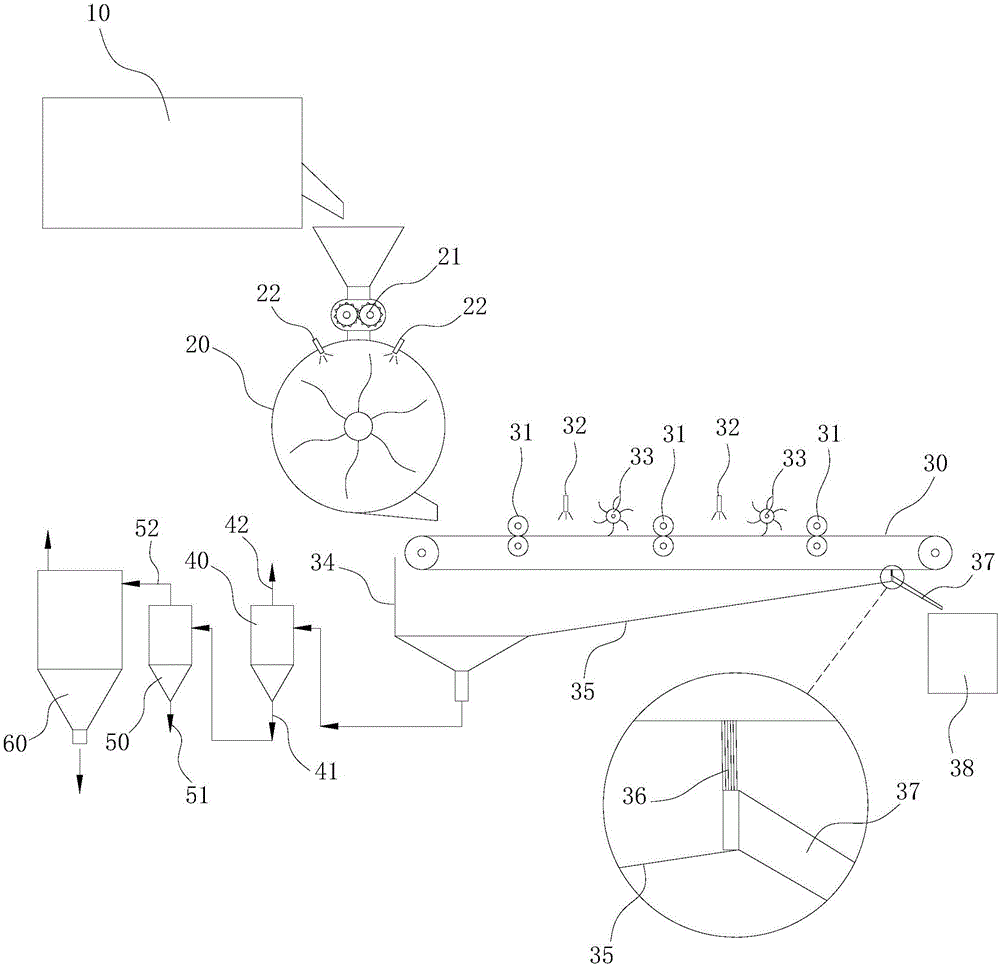

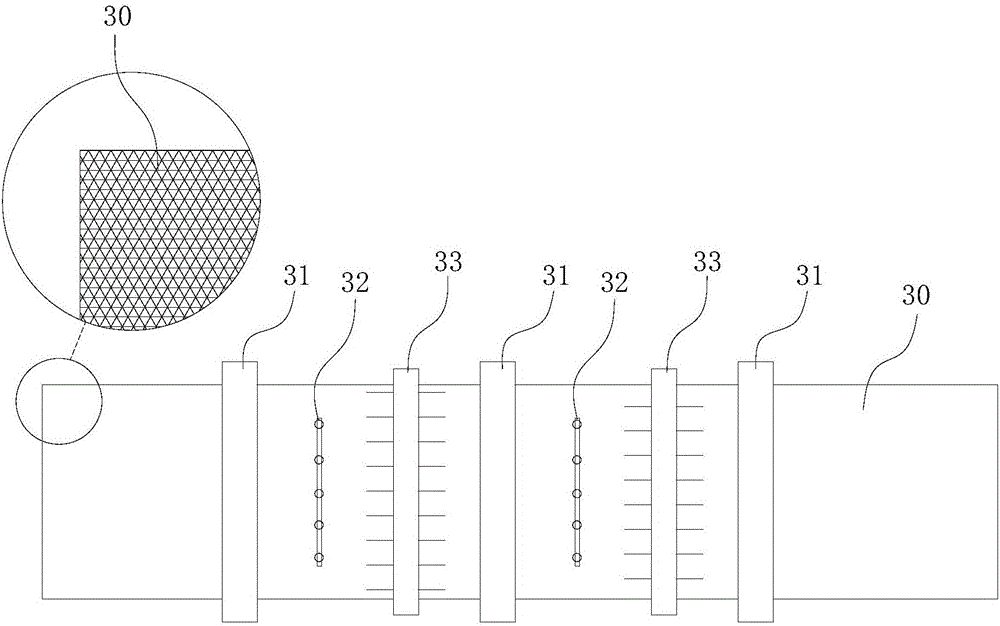

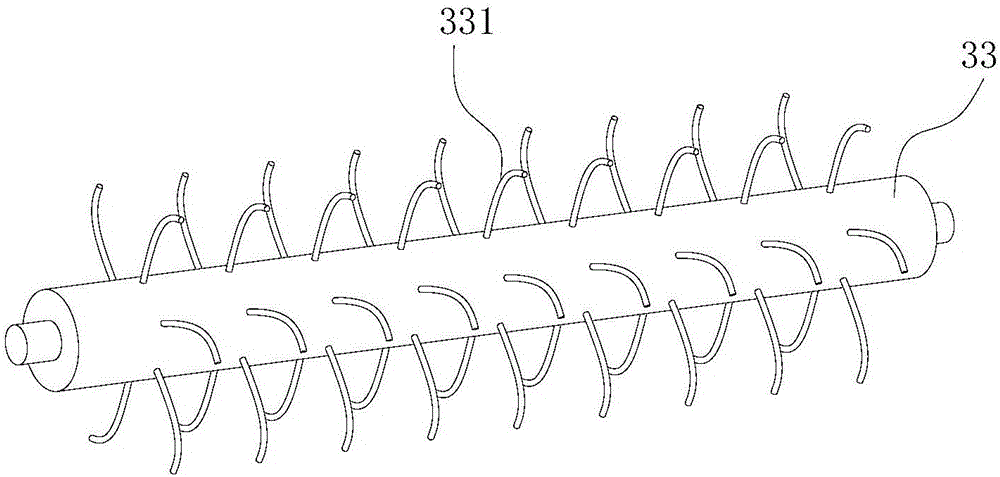

[0018] like figure 1 Shown, a kind of sweet potato flour production system comprises the following devices arranged in order: peeling and cleaning device 10; For crushing sweet potato into a crushing device 20 of slurry; For separating the filter device of potato dregs and slurry; A separation device for separating starch and water in the slurry; a desanding device for removing the sediment in the starch; a dehydration device for removing the water content of the starch slurry into wet starch; the feeding port of the crushing device 20 and peeling and cleaning The discharge port of the device 10 is relatively arranged, and the discharge port of the crushing device 20 is located above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com