Refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction

A technology of hydraulic fracturing and gas drainage, which is applied in the direction of gas discharge, mining fluid, mining equipment, etc., and can solve the problem of unscientific layout and drilling depth of hydraulic fracturing holes and gas drainage holes, gas drainage and outburst elimination The effect cannot be guaranteed, and the gas drainage process cannot be organically combined, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

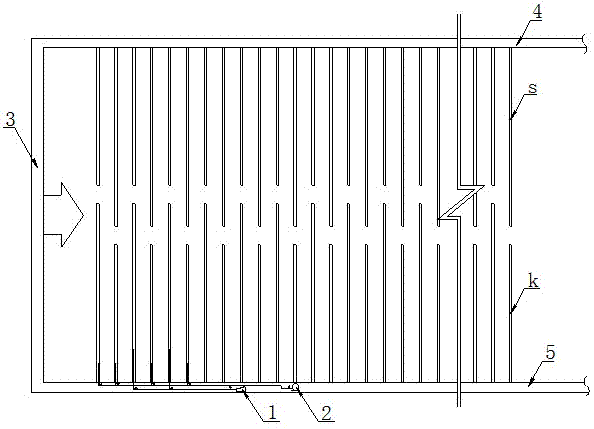

[0018] Embodiment one: if figure 1 As shown, the coal and gas outburst coal seam in the mining face of a certain mine has an average thickness of 4m, a hardness of f=2, and the length of the coal mining face 3 is 206m. Set the gas drainage pump 2 on the ground, and the water injection pump 1 in the air lane 5 of the coal mining face 3; figure 1 The hole positions of hydraulic fracturing holes S and gas drainage holes K are arranged as shown, and the hole positions of hydraulic fracturing holes S and gas drainage holes K can also be set only in one roadway of machine lane 4 or wind lane 5 . Hydraulic fracturing holes S and gas drainage holes K are alternately constructed in the direction of the coal seam according to the set hole position one by one, and the hydraulic fracturing holes S and gas drainage holes are constructed alternately in the direction of the coal seam in the machine lane 4 and wind lane 5 of the coal mining face Holes K are arranged in parallel, and the spac...

Embodiment 2

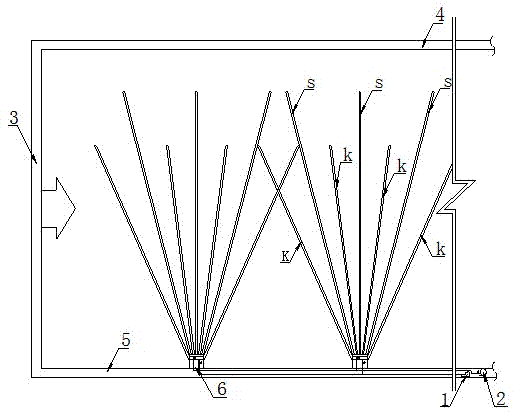

[0019] Embodiment two: if figure 2 As shown, the coal and gas outburst coal seam in the mining face of a certain mine has an average thickness of 2m, a hardness of f=2, and a working face length of 140m. Set the gas drainage pump 2 on the ground, and the water injection pump 1 in the airway 5 of the coal mining face 3; in the airway 5 of the coal mining face, as figure 2 As shown, multiple drilling sites are set up with a distance of 20-100m. Each drilling site is arranged with 1-3 rows of drilling holes. The number of hydraulic fracturing holes S is 1-8, and the number of gas drainage holes K is 1-20. The hydraulic fracturing holes S and the gas drainage holes K that are alternately constructed in each drilling site towards the coal seam are fan-shaped. For example, the interval between the drilling sites is 30m. There are 1 fan-shaped hydraulic fracturing hole S and 4 gas drainage holes K. The hydraulic fracturing hole S is 120m long, and the gas drainage hole K is 95m lo...

Embodiment 3

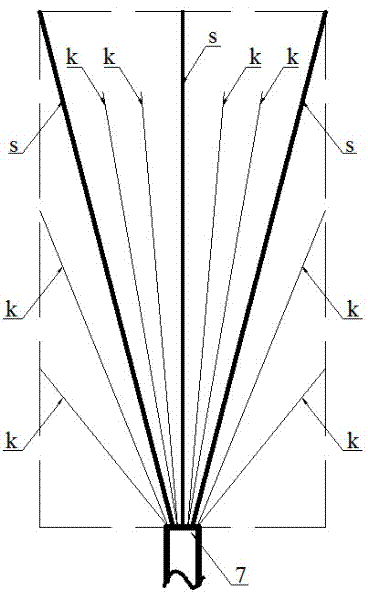

[0020] Embodiment three: as image 3 As shown, the coal and gas outburst coal seam in the tunnel of a certain mine has an average thickness of 3m and a hardness of f=2.5. Set the gas drainage pump on the ground, and the water injection pump in the adjacent roadway of the excavation face 7; set the hydraulic fracturing hole S and the gas drainage hole K in the excavation face 7 in a quincunx shape, and press the design one by one. Alternately construct hydraulic fracturing holes S and gas drainage holes K in the direction of the coal seam at the fixed hole positions, and there are 1 to 4 rows of mechanical fracturing holes S and gas drainage holes K, of which there are 1 to 8 hydraulic fracturing holes S and gas drainage holes There are 1-20 production holes K, and the drilling direction is fan-shaped. The drilling depth of the hydraulic fracturing hole S is 3-80m longer than that of the gas drainage hole K. like image 3 As shown, for example, fan-shaped hydraulic fracturing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com