Patents

Literature

50results about How to "Reduce outstanding risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for integrated comprehensive management of gas in low-permeability single coal bed

InactiveCN102121395AReduce outstanding riskImprove breathabilityDrilling rodsFluid removalSocial benefitsHydraulic fracturing

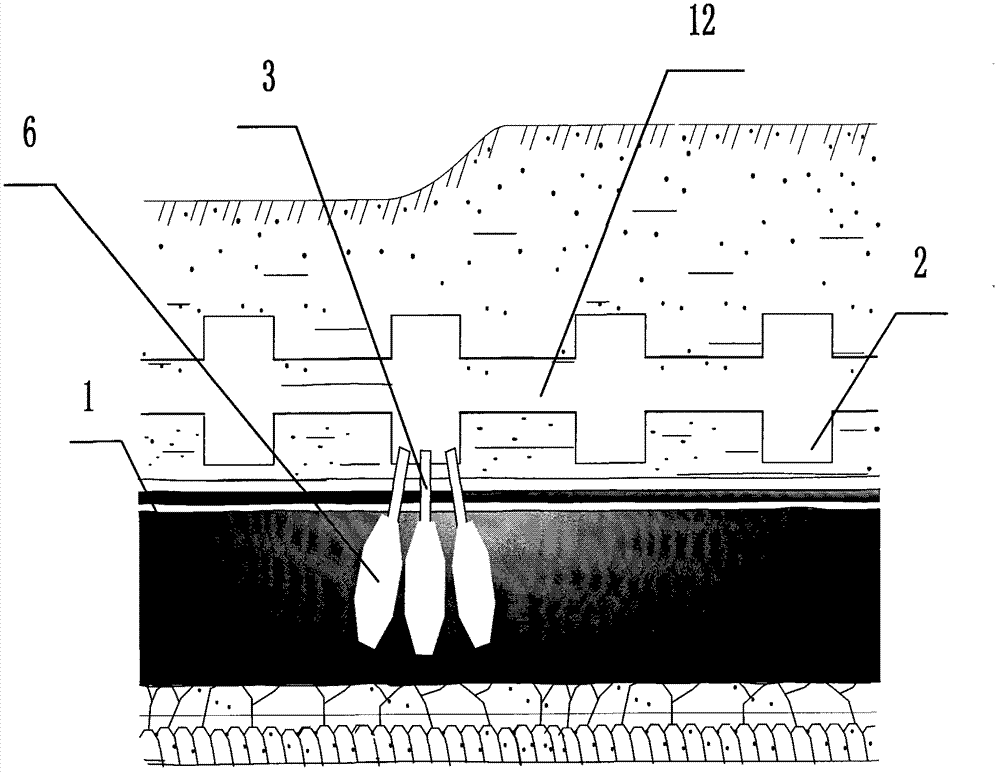

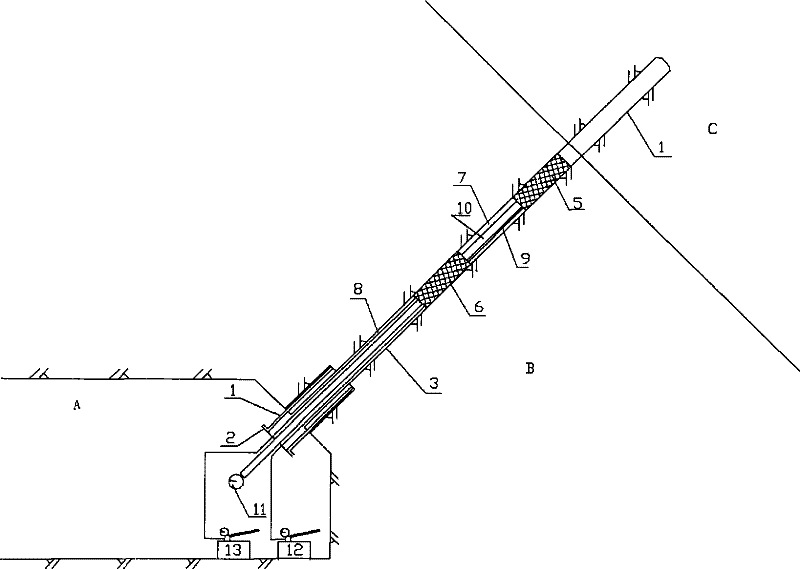

The invention relates to a method for integrated comprehensive management of gas in a low-permeability single coal bed, which can effectively solve the problem of comprehensive management and utilization of the gas. A technical scheme of the method comprises the following steps of: firstly, drilling holes, wherein a high-torque drilling machine and a rifle or a trihedral drill stem are used for solving the phenomenon of clamping the drill stem caused by collapsing and jetting of the holes in the hole drilling process; and then, performing hydraulic fracturing permeability improvement on the coal body, drilling holes for pre-split blasting, performing gas drainage, and recycling the drained gas, thereby implementing the integrated management of the gas. With the method provided by the invention, the permeability of the coal body is improved, a pre-draining rate of the gas is improved, and the drained gas is recycled, so that the drilled holes are radically prevented from being blocked in the construction process, the problem of difficulties in draining the gas in the low-permeability coal bed with a drilling tool having insufficient capability in the drilling construction is solved, consequently, outburst risk of the coal and the gas is reduced, outburst accidents of the coal and the gas are reduced and even avoided, and mine production safety and lives of coal mine workers are ensured, so that the method brings great economic and social benefits.

Owner:平顶山天安煤业股份有限公司十矿

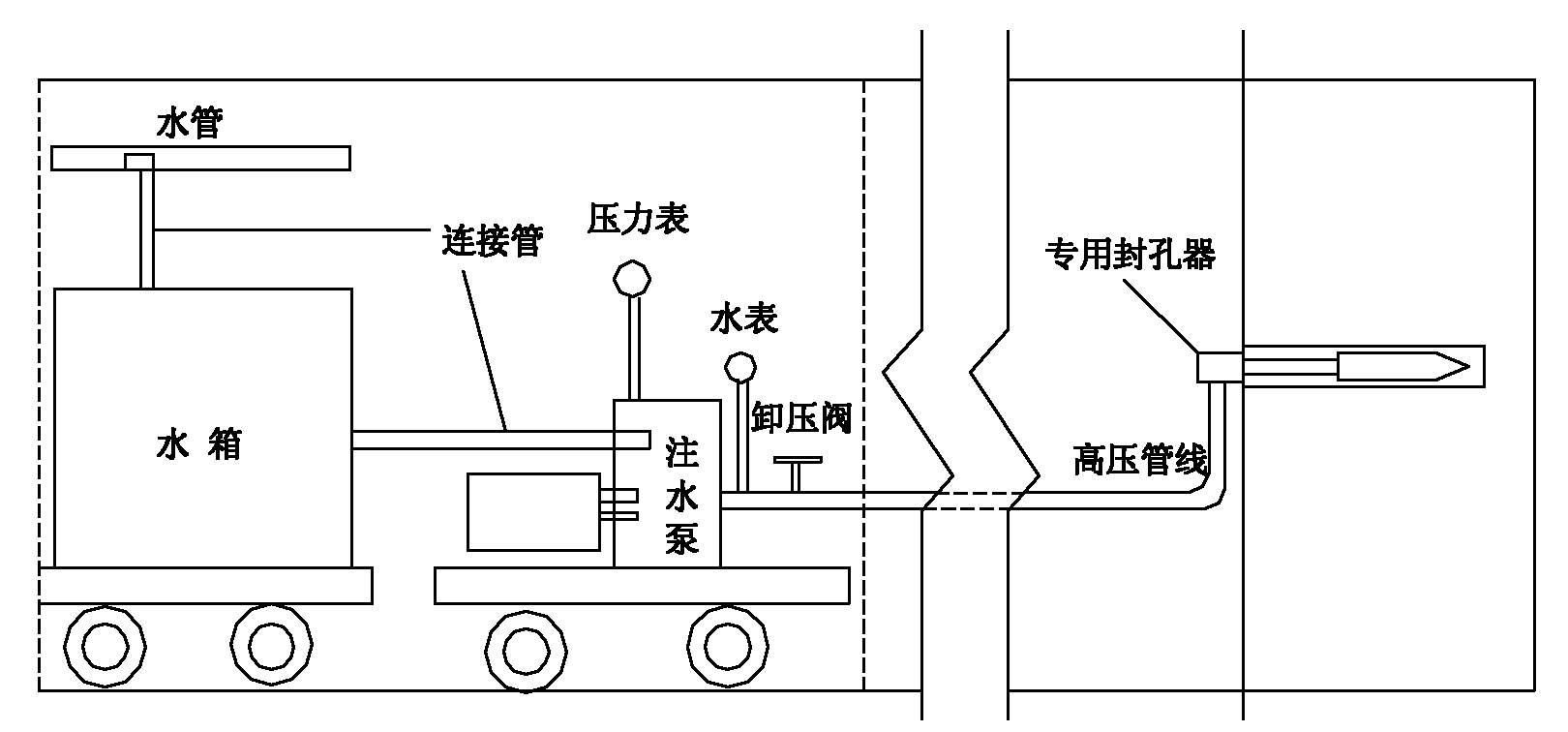

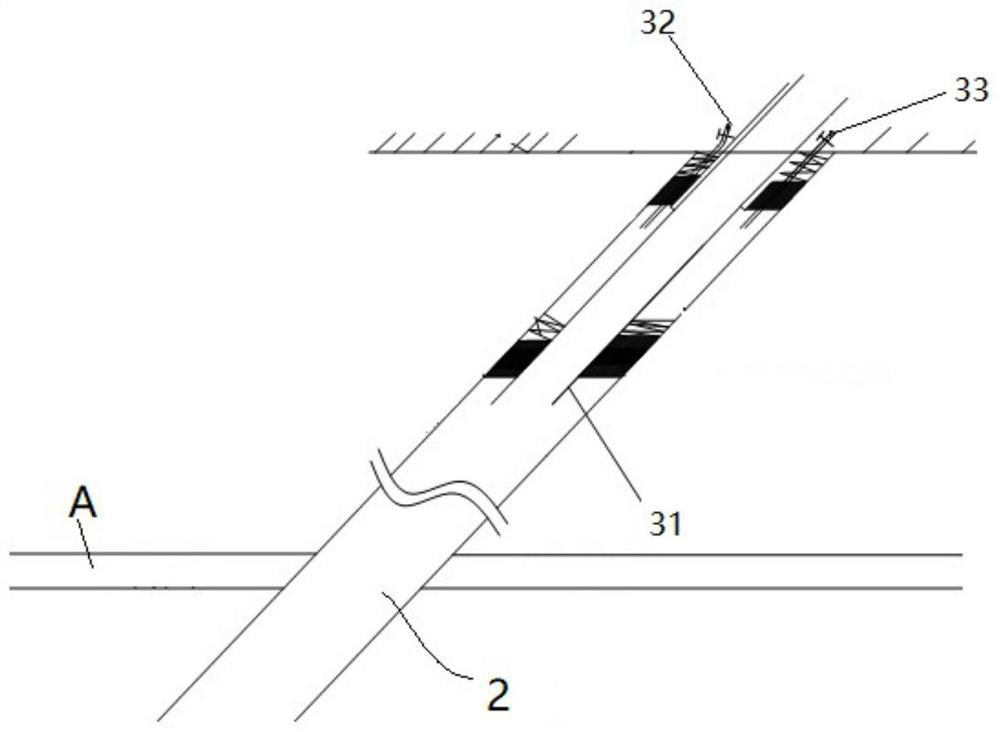

Refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction

InactiveCN102383828AHigh extraction rateRelieve pressureFluid removalGas removalEngineeringHigh pressure water

The invention discloses a refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction. The method comprises the following steps of: gradually and alternately constructing hydraulic fracture holes and gas extraction holes in the coal bed direction in a coal mining working face tunnel, an airway or a tunneling working face, and performing high-pressure water injection and gas extraction; stopping injecting water after the water is injected into the hydraulic fracture holes for 0.5 to 5 hours, and changing gas extraction pipe joints to extract gas; after the hydraulic fracture hole or gas extraction concentration is lower than 5%, changing water injection pipes to perform static pressure water injection; and when the coal mining working face is recovered to the position 5 meters away from the static pressure water injection holes or the tunneled working face is tunneled again, stopping a pump or closing a static pressure water valve to stop water injection. According to the method, refection reduction of the gas-containing coal bed is realized, the gas extraction rate is improved, the gas in the mining space is effectively prevented from exceeding the limit, outburst risks of coal and gas are reduced, and safe and efficient recovery of coal is ensured. The method is simple and good in effect.

Owner:CHINA UNIV OF MINING & TECH +1

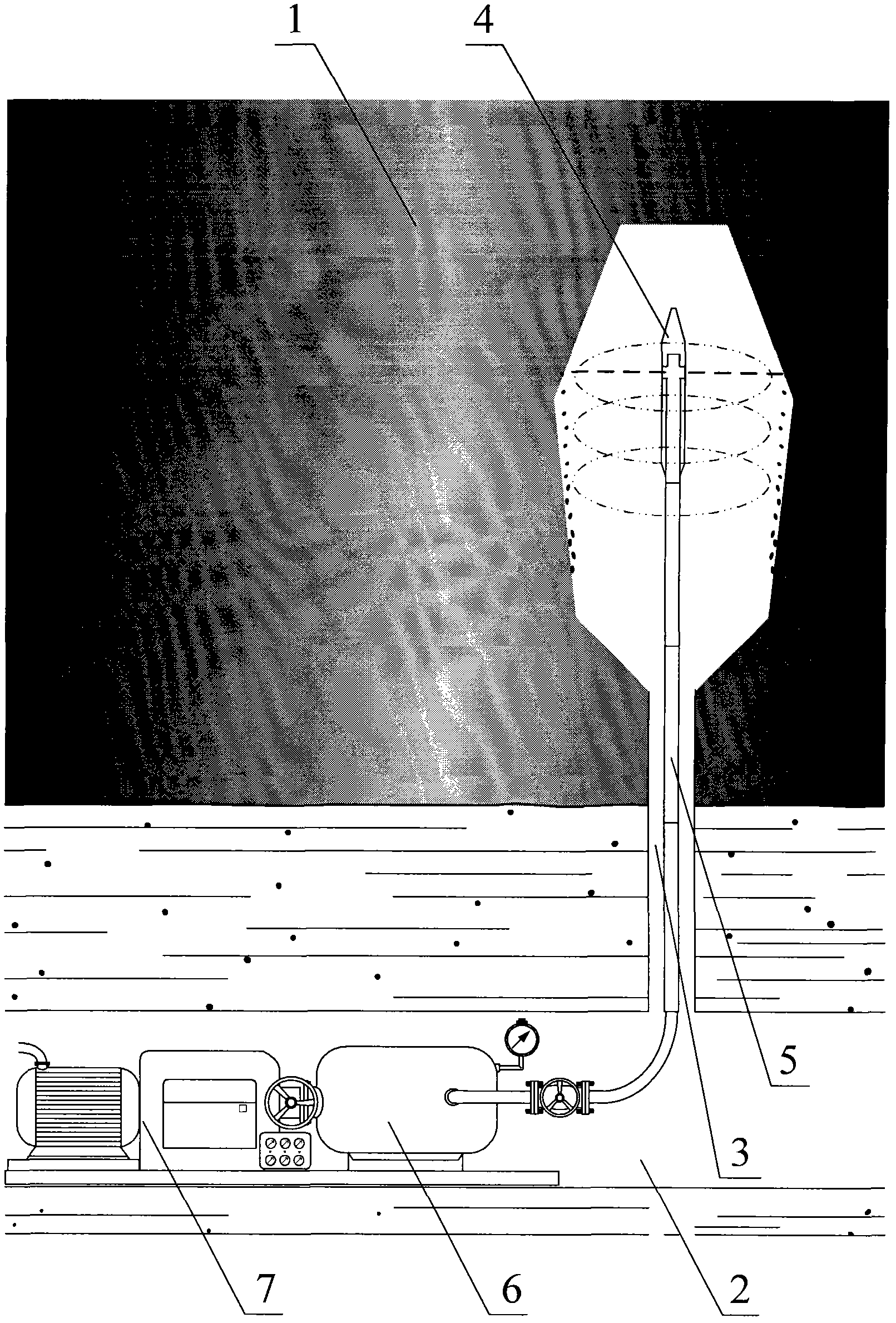

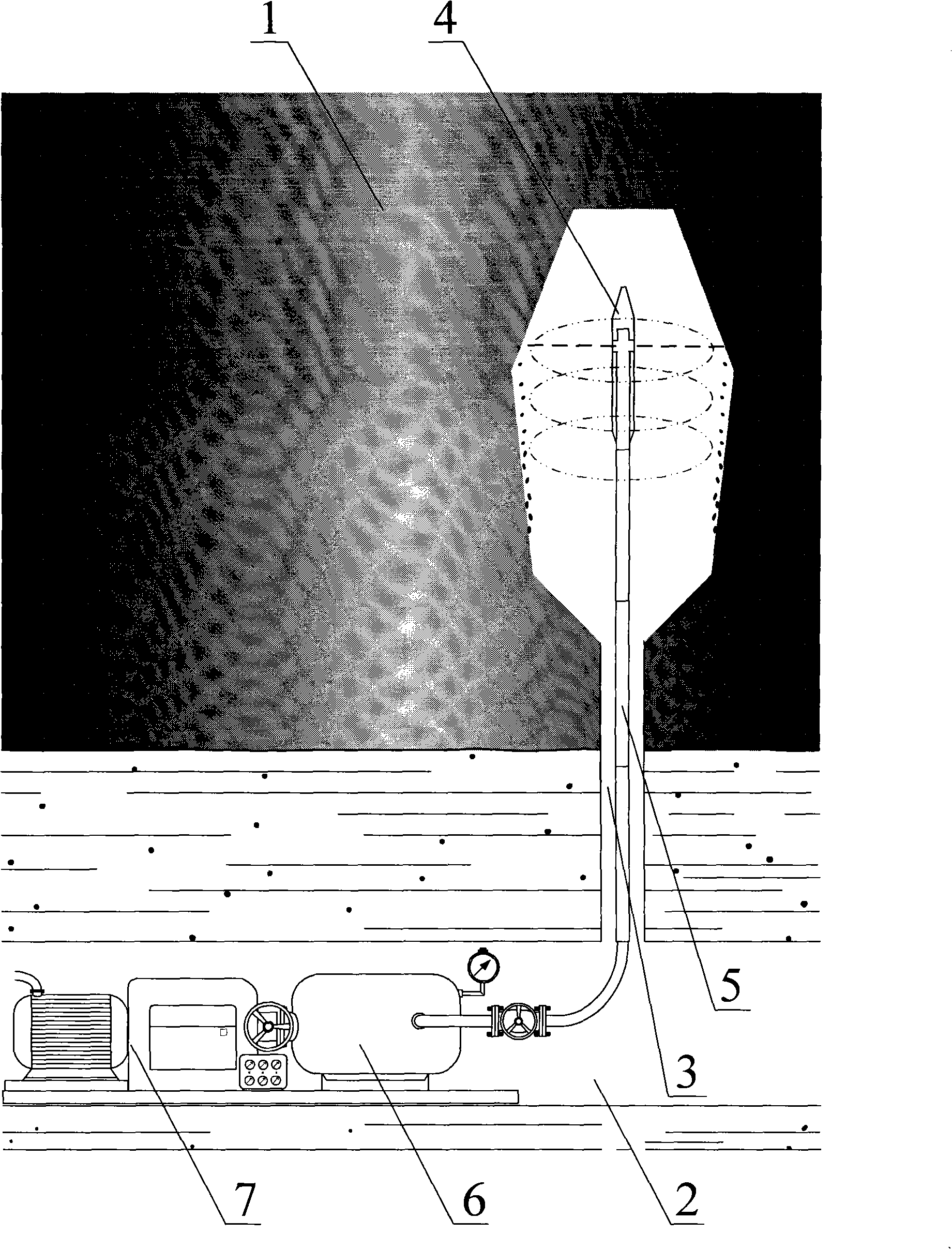

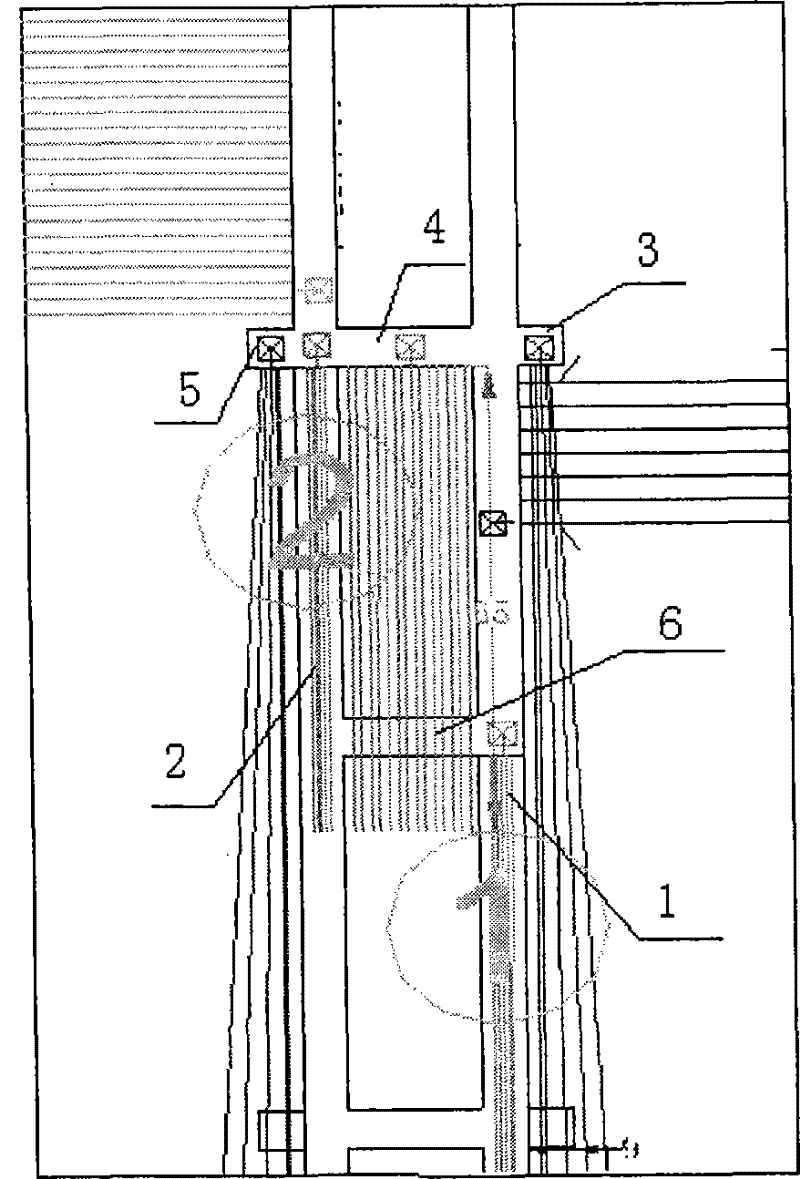

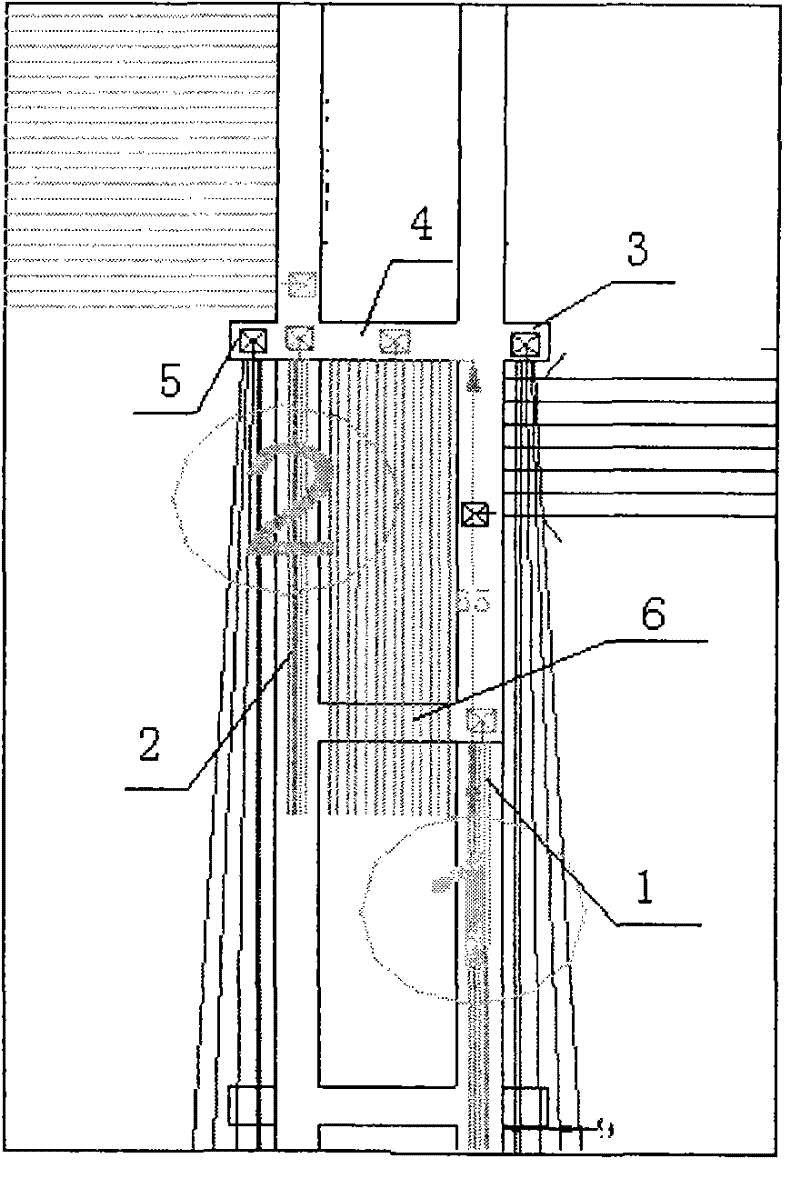

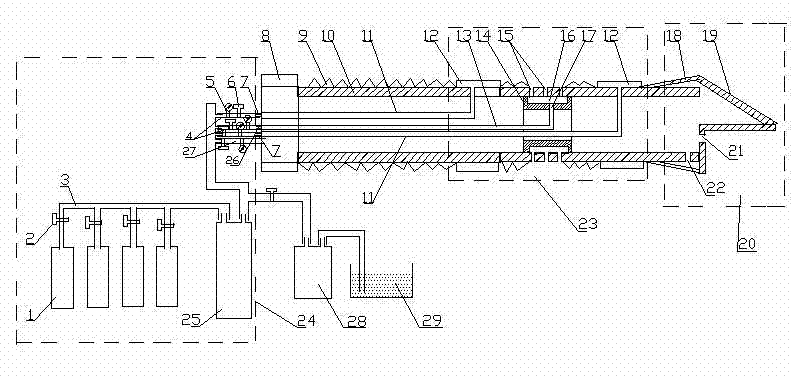

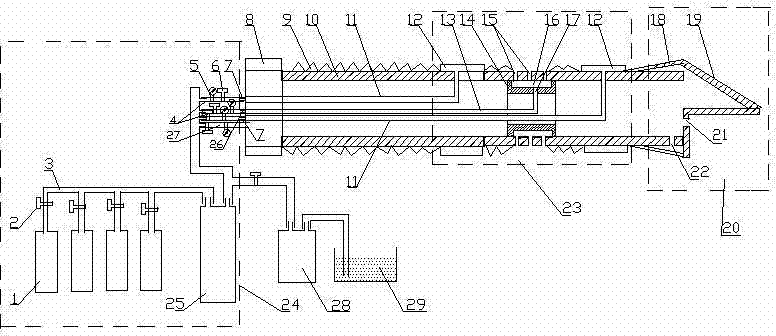

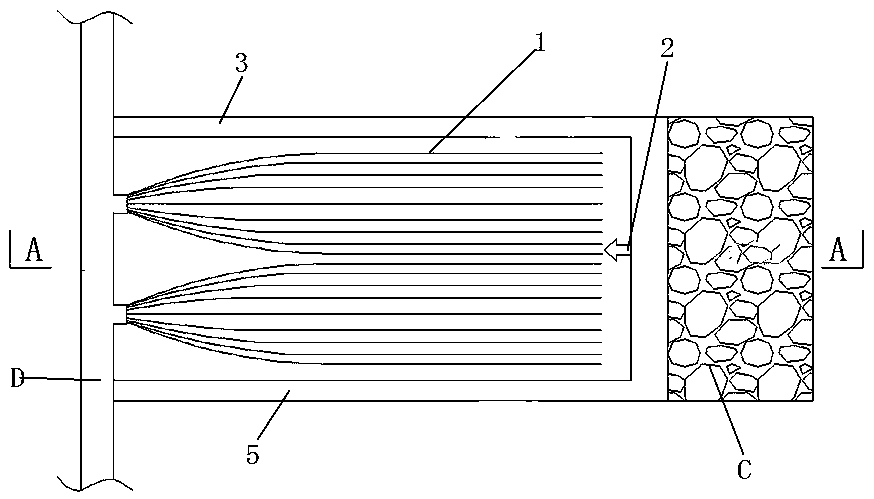

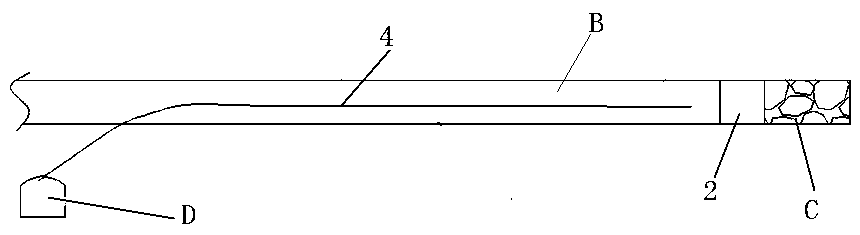

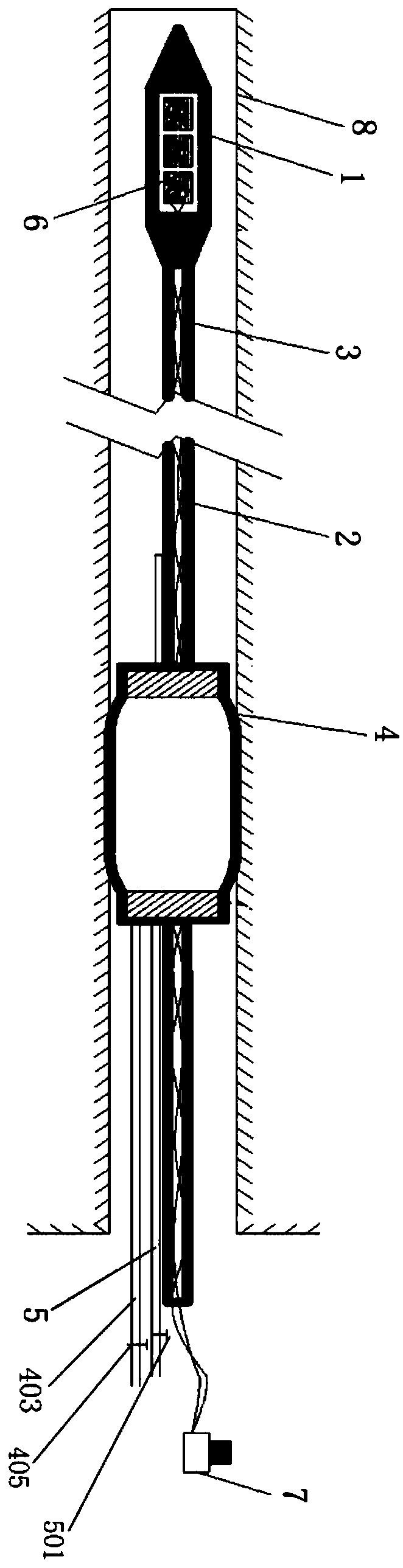

High-pressure gas injection hole-drilling pressure-releasing outburst prevention method

ActiveCN102080525AIncrease the exposed areaImprove breathabilityLiquid/gas jet drillingFluid removalEngineeringHigh pressure

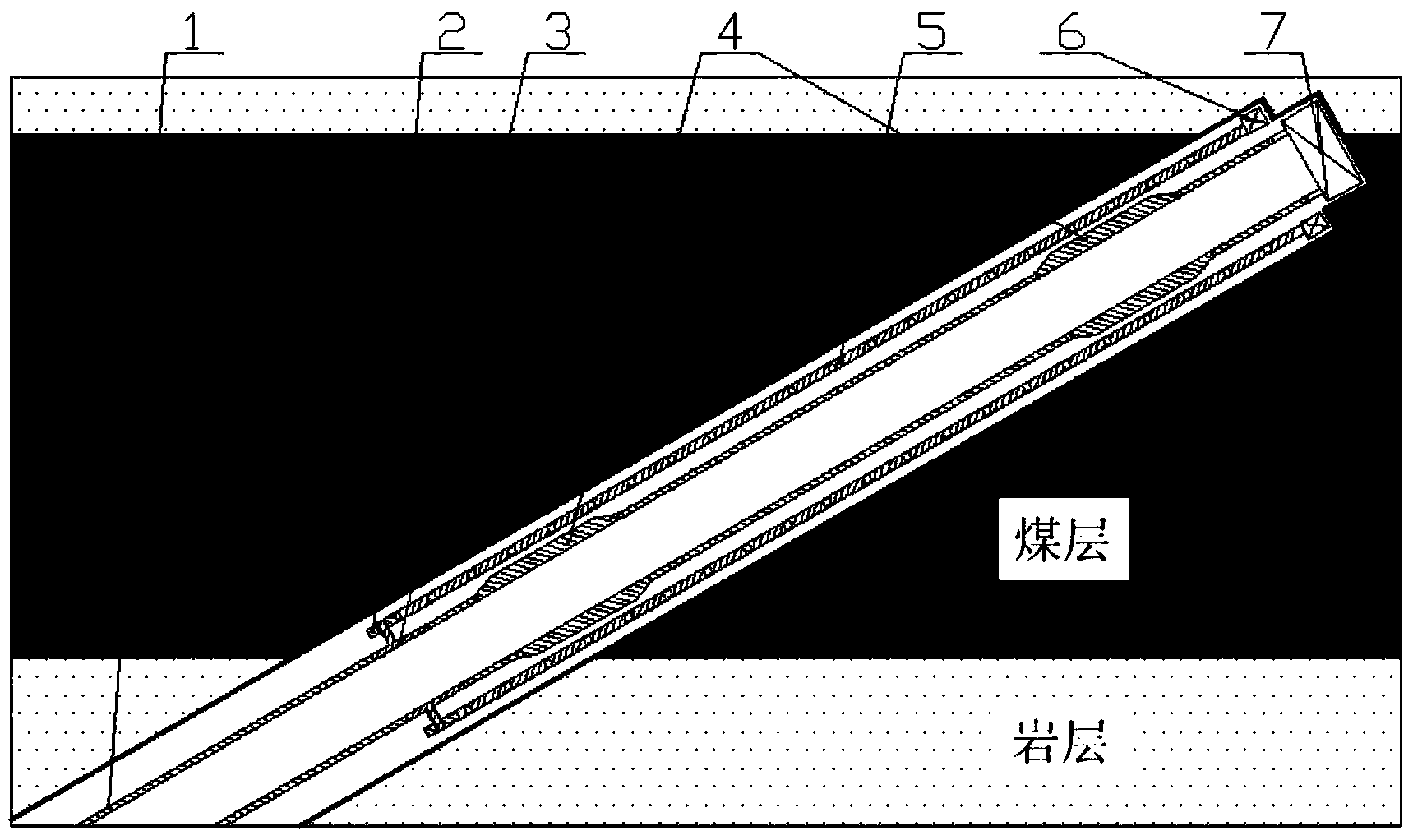

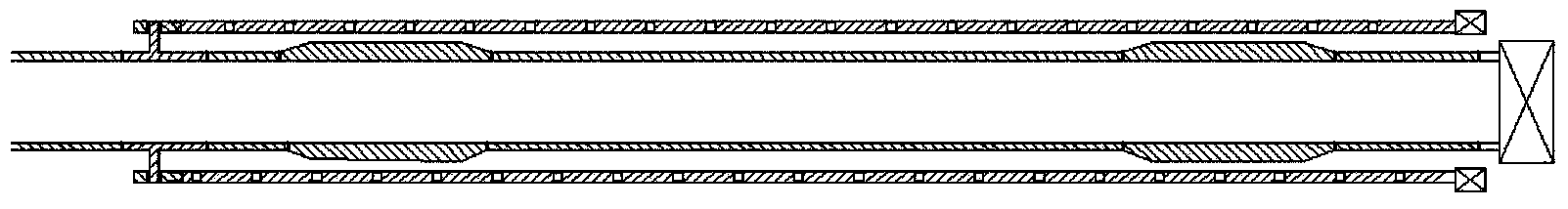

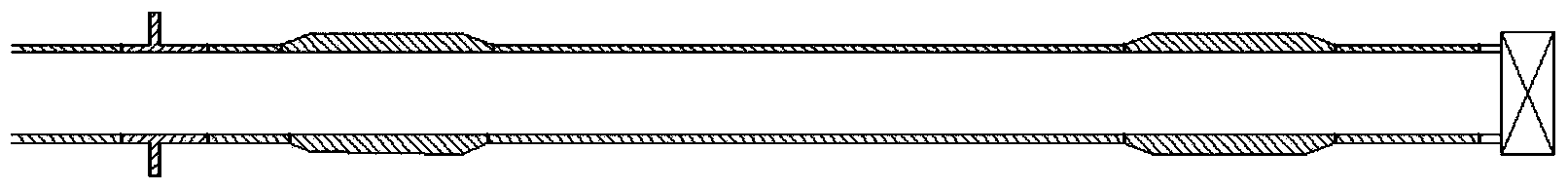

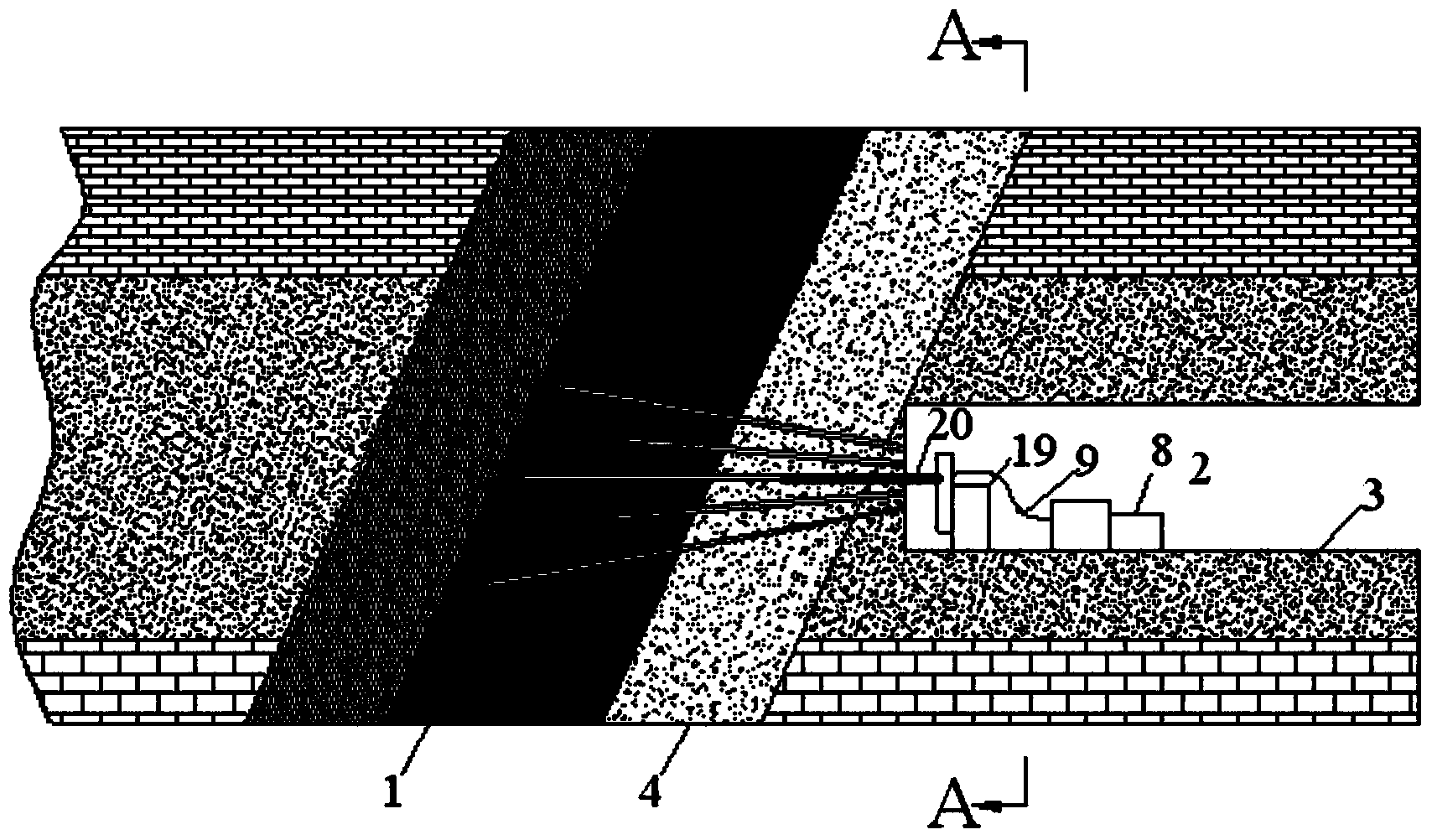

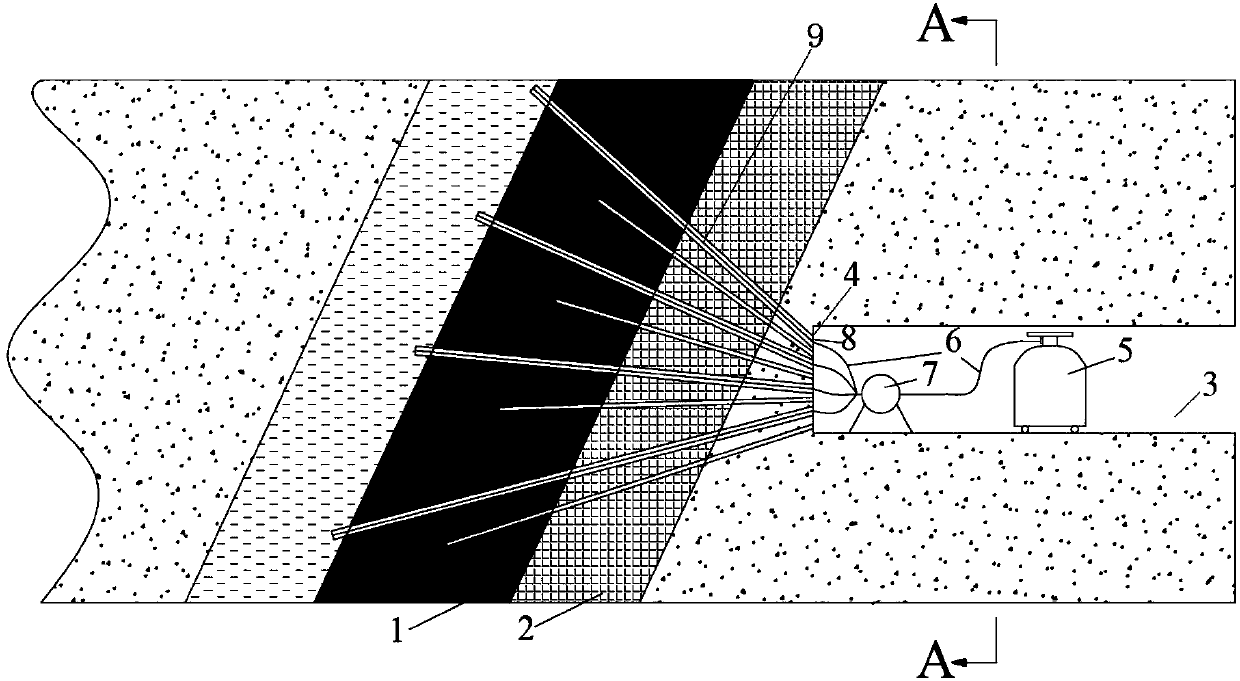

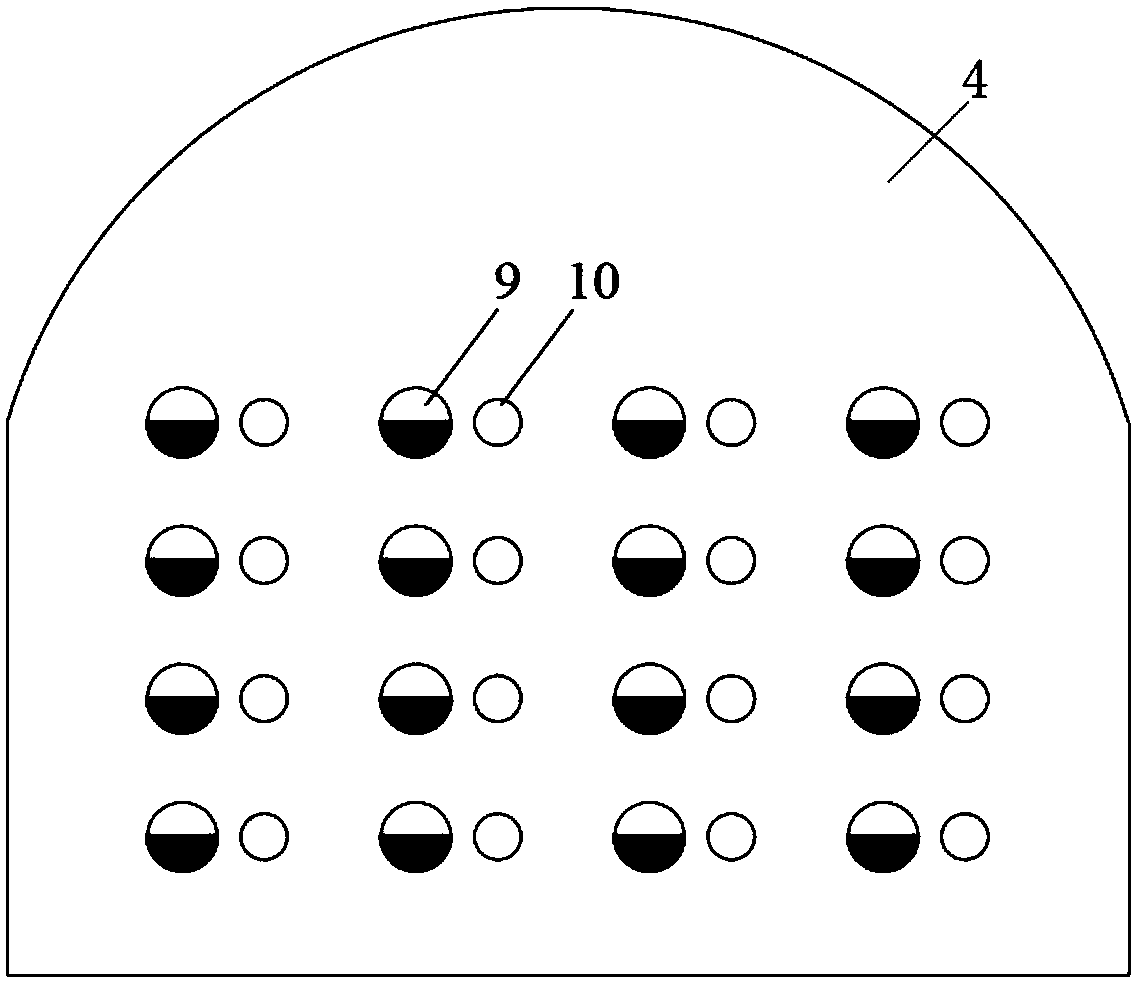

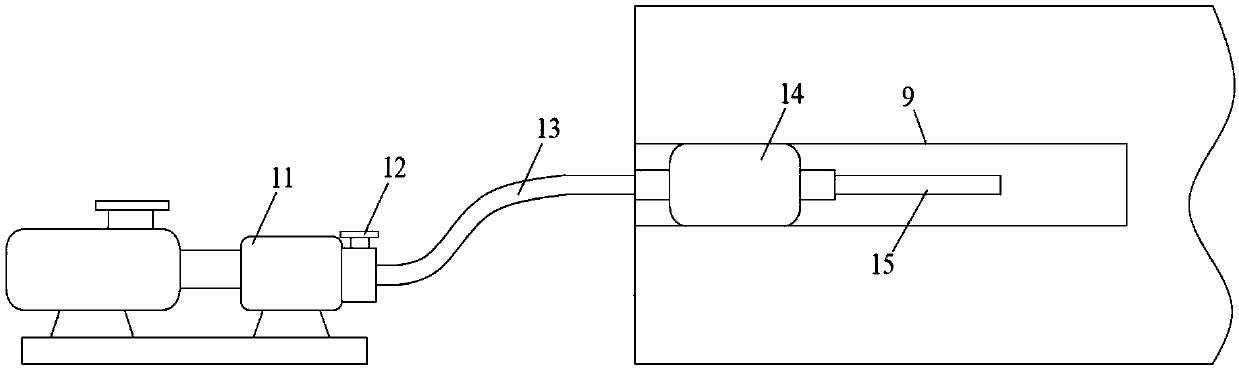

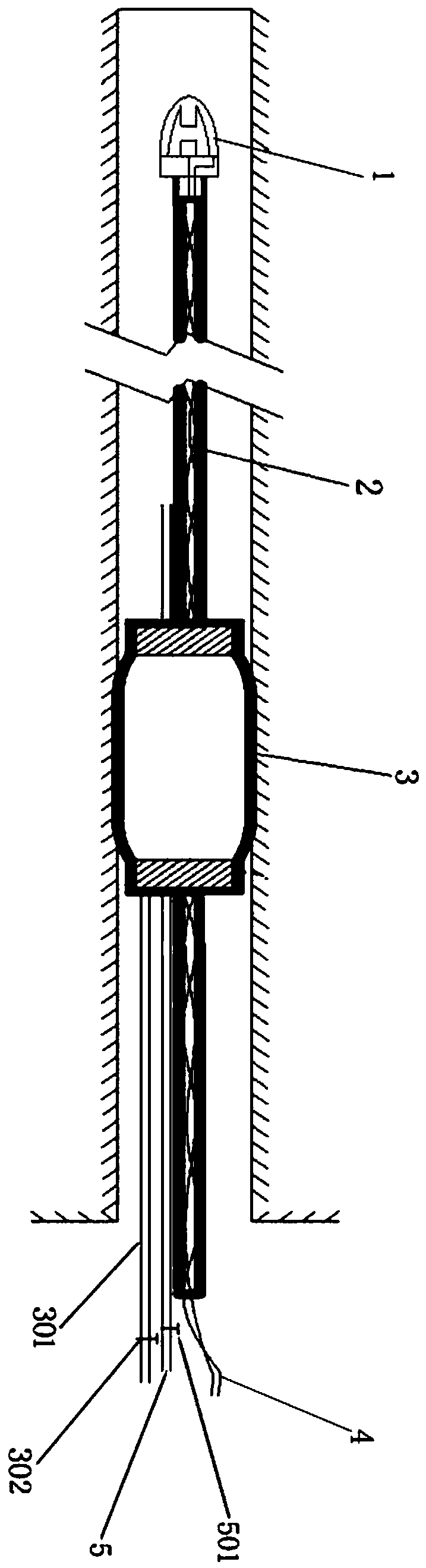

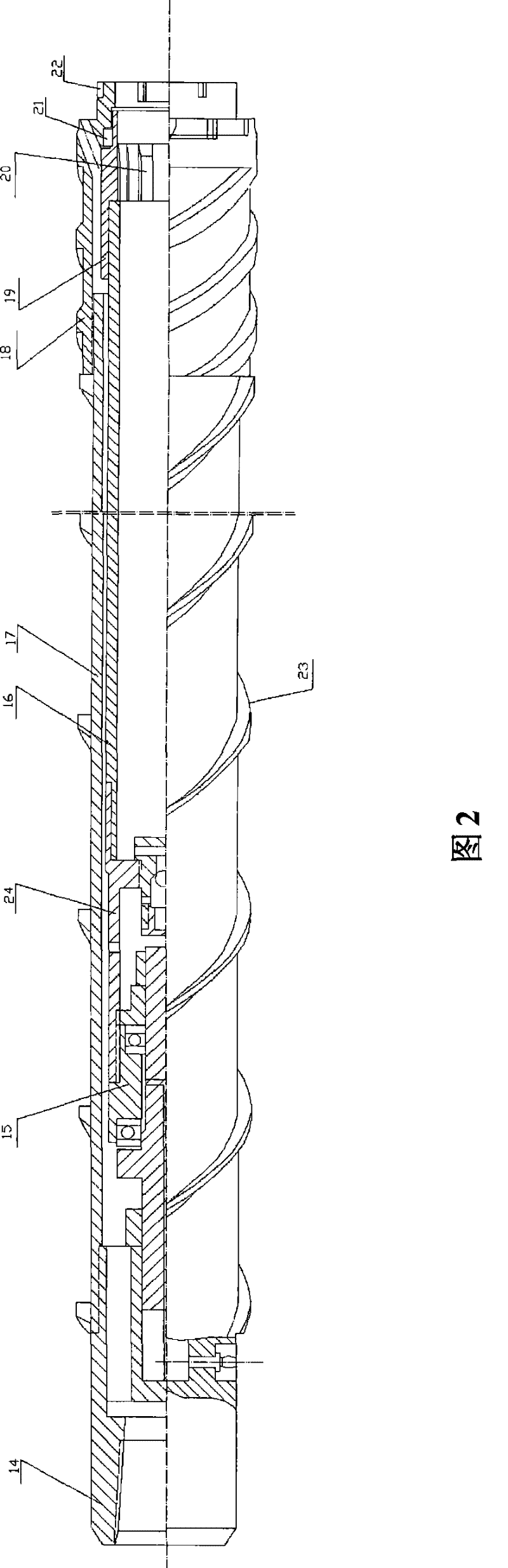

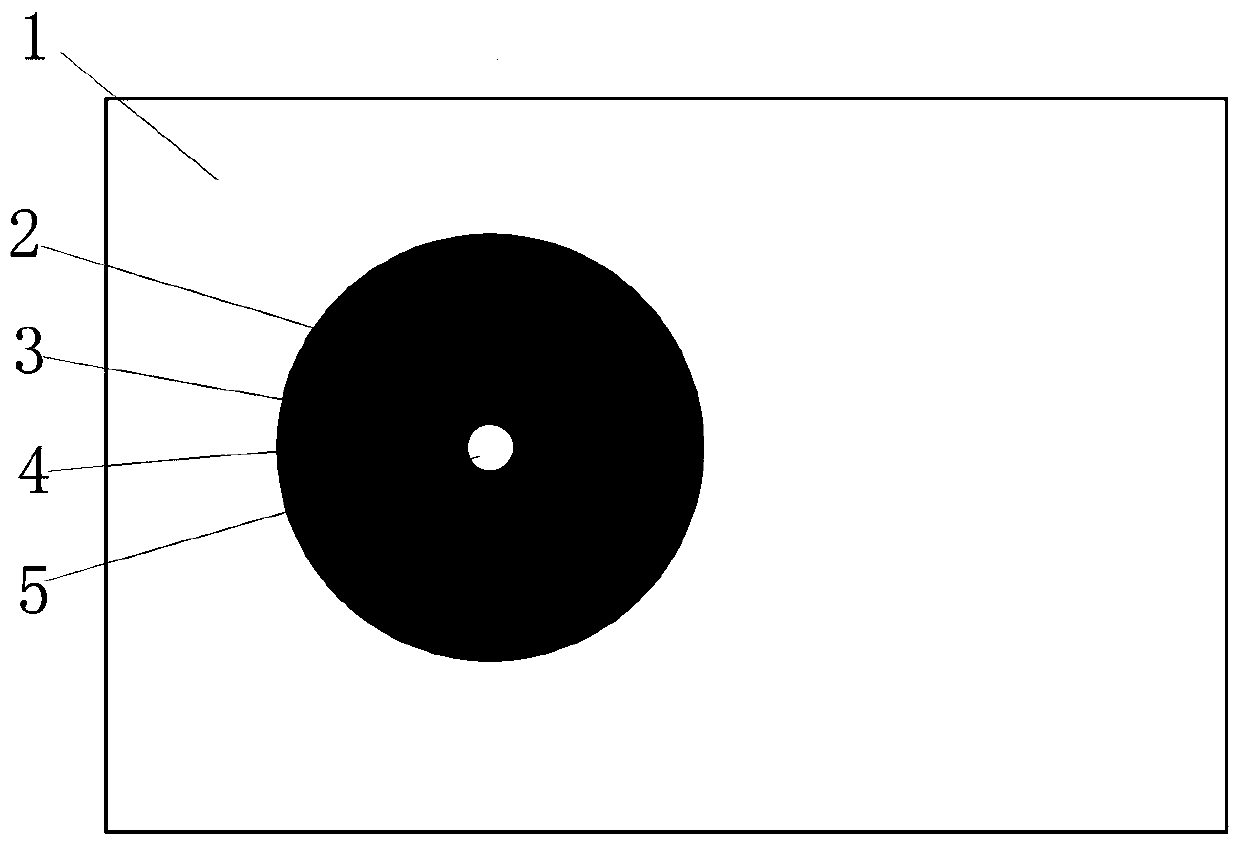

The invention discloses a high-pressure gas injection hole-drilling pressure-releasing outburst prevention method which comprises the steps of: firstly, carrying out common drilling operation in a bottom plate stone drift (2) of a coal bed (1) in front of a coal mining or driving face; after a drill hole (3) enters a design depth of the coal bed, drawing back a drill, sending a jet nozzle (4) anda high-pressure drill rod (5) connected with the jet nozzle into the drill hole, and connecting a high-pressure gas-storing device (6) connected with the tail of the high-pressure drill rod (5) with a high-pressure gas compressing device (7) through a high-pressure tube; starting the high-pressure gas compressing device (7), carrying out near cylinder rotary impacting, cutting and holing on the hole wall of the drill hole in the coal bed (1) by using high-pressure impact wave as a power source through the jet nozzle (4) capable of jetting high-pressure airflow and automatically rotating to ensure that the coal body around the drill hole (3) is gradually crushed and separated from the hole wall to form pressure releasing space and subjected to the pressure balanced permeability increase through ground pressure and gas pressure action. According to the invention, the drainage efficiency of the gas in the coal bed is greatly improved and the outburst damage of the coal bed is reduced.

Owner:河南省迪卡尔机电设备制造有限公司

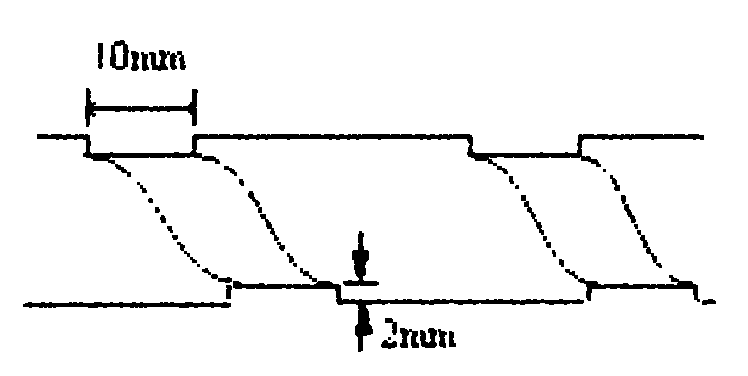

Sieve tube drilling process for outburst coal seam section in underground coal mine

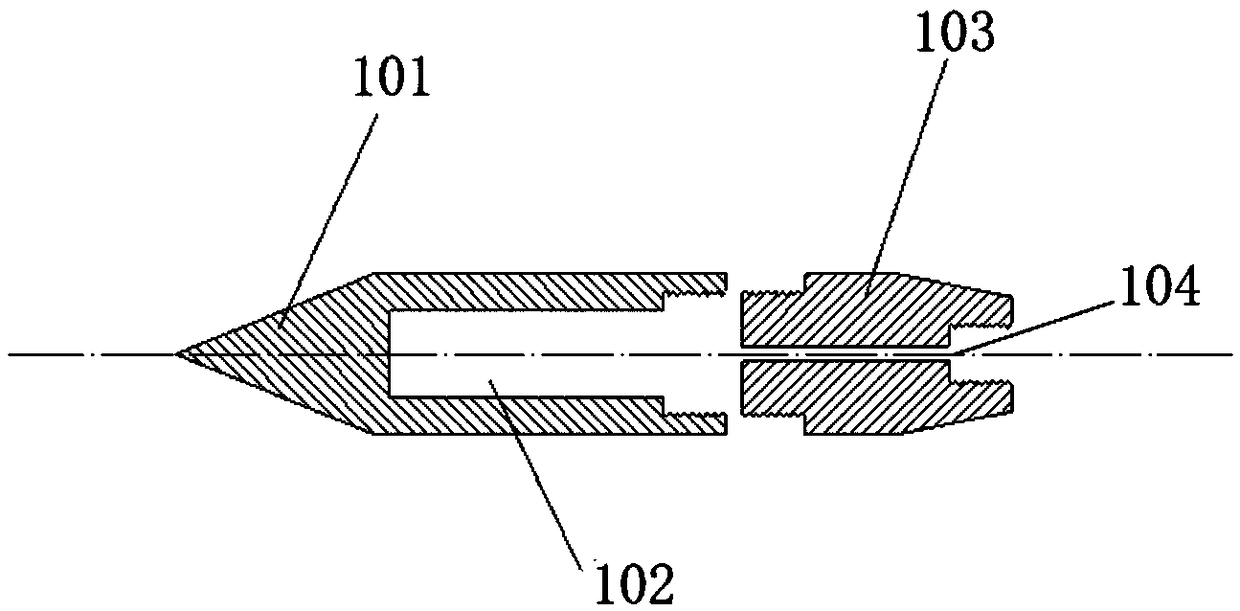

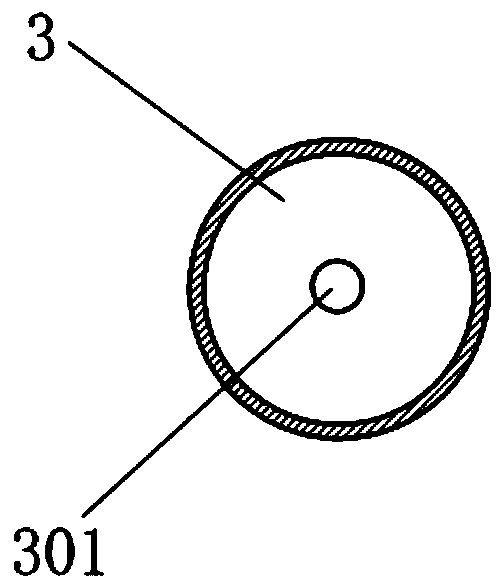

InactiveCN103643893AImprove securityImprove efficiencyDrilling rodsFluid removalTorque transmissionCoal

A sieve tube drilling process for an outburst coal seam section in an underground coal mine comprises the following steps: preparation: calculating the length of the outburst coal seam section; drilling: drilling to the hole drilling depth by a drilling machine, mounting an orifice pipe, sealing holes and fixing the orifice pipe; synchronous drilling: adopting a sieve tube drilling rig combination to drill to the designed hole depth, wherein each sieve tube drilling rig comprises an active drill rod and a sieve opening sleeve surrounding the outer side of the active drill rod, and a torque transmission device is arranged between the rear end of the sieve opening sleeve and the active drill rod; withdrawing the drill rod: rotating the active drill rod in the reverse direction by 1-2 turns to enable a torque transmission male connector to be separated from a torque transmission female connector, withdrawing the active drill rod, and leaving the sieve opening sleeve in the outburst coal seam section. After the drilling is performed to the designed hole depth, the active drill rod is rotated in the reverse direction and withdrawn, the drilling process and the sieve tube lowering process are combined, the safety and the efficiency are improved, the cost is reduced, and the problems in the prior art are solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

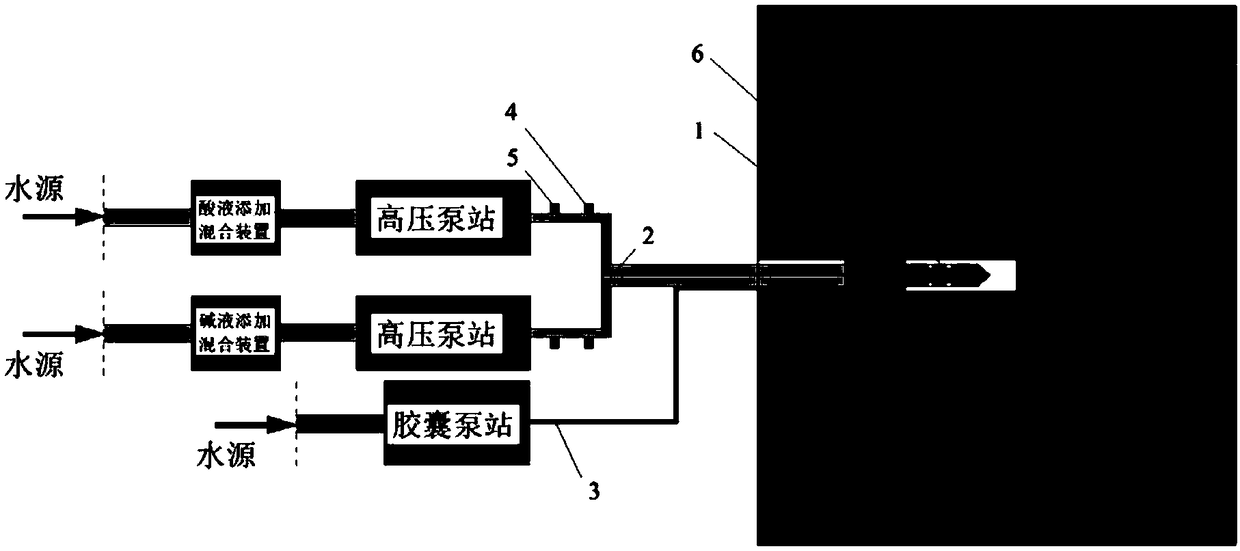

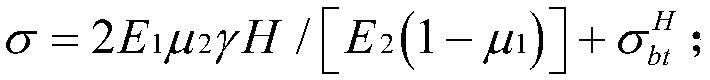

Freezing-type stone door cross-measure coal uncovering method based on hydraulic seam cutting

ActiveCN104213921AImprove flow statusImprove breathabilityUnderground miningSurface miningUltimate tensile strengthCoal

A freezing-type rock cross-measure coal uncovering method based on hydraulic seam cutting is suitable for a rock cross-measure coal uncovering operation in a high-gas outburst coal seam. The method includes following steps: (1) constructing a plurality of water injection holes into a coal uncovering operation surface at a position of the coal uncovering operation surface, wherein a minimum normal distance from the coal seam to the position is not less than 7 m; (2) performing hydraulic seam cutting to the water injection holes through a conventional hydraulic seam cutting technology; (3) when the hydraulic seam cutting is finished, connecting the water injection holes to a gas extraction pipe network to perform gas extraction; (4) when the content of gas in the coal seam is less than 8 m<3> / t, stopping the gas extraction; (5) constructing a freezing holes and a temperature measuring hole respectively at the two sides of the water injection holes; (6) sealing the holes through a capsule hole-sealing device; (7) injecting water into the coal seam through the water injection holes and closing valves when the water injection process is finished to enable the water injected into the coal seam to gradually seep into micro cracks in coal; (8) freezing the coal seam around the water injection holes through a conventional freezing technology to enable free water in the micro cracks in the coal seams to gradually convert from liquid phase into solid phase during the freezing process, so that a strength and an anti-impact performance of the coal are increased and an effect of solidification of the coal seam is achieved; and (9) uncovering the coal seam through a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

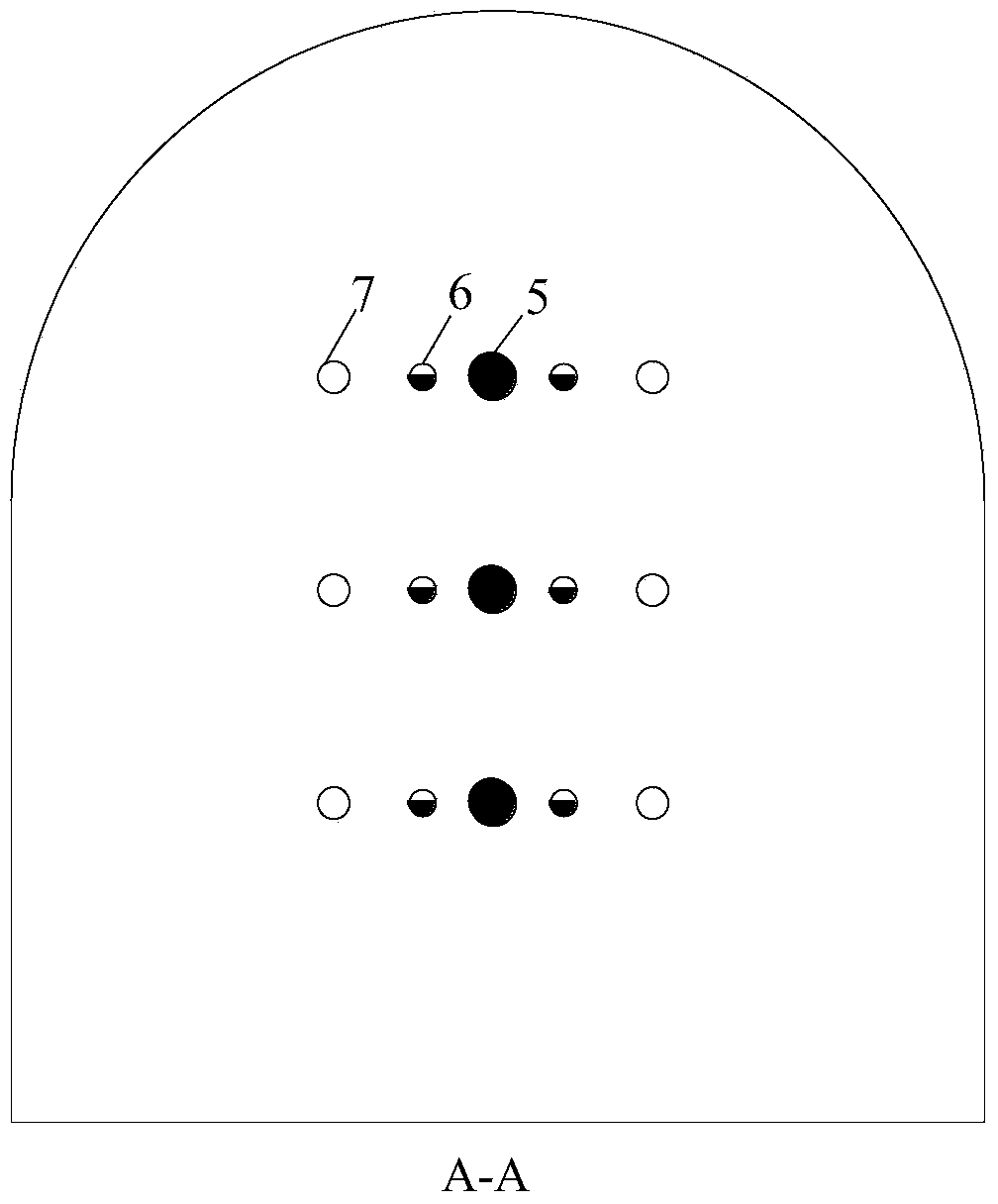

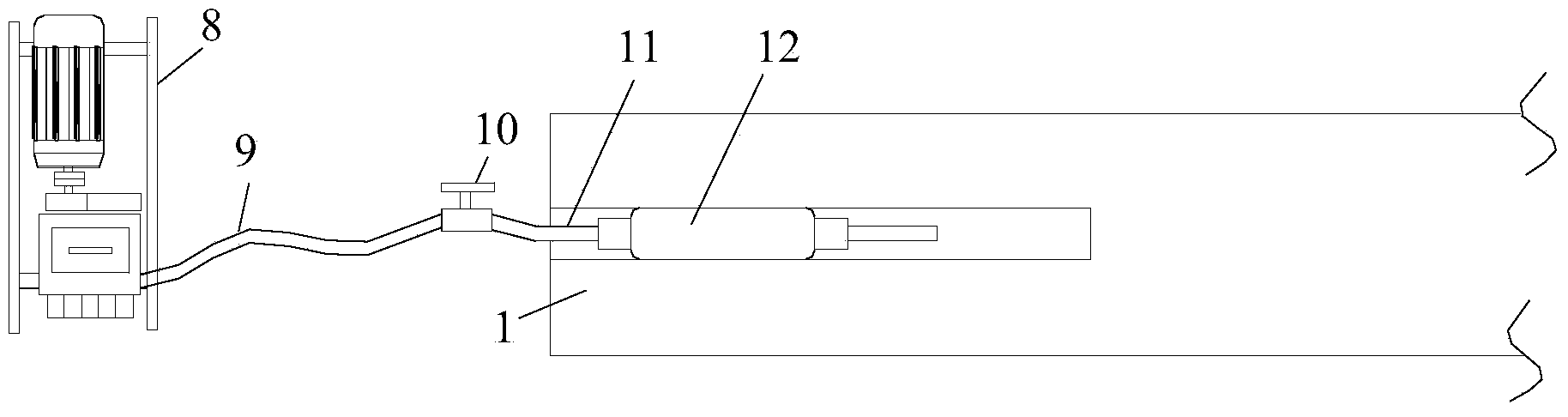

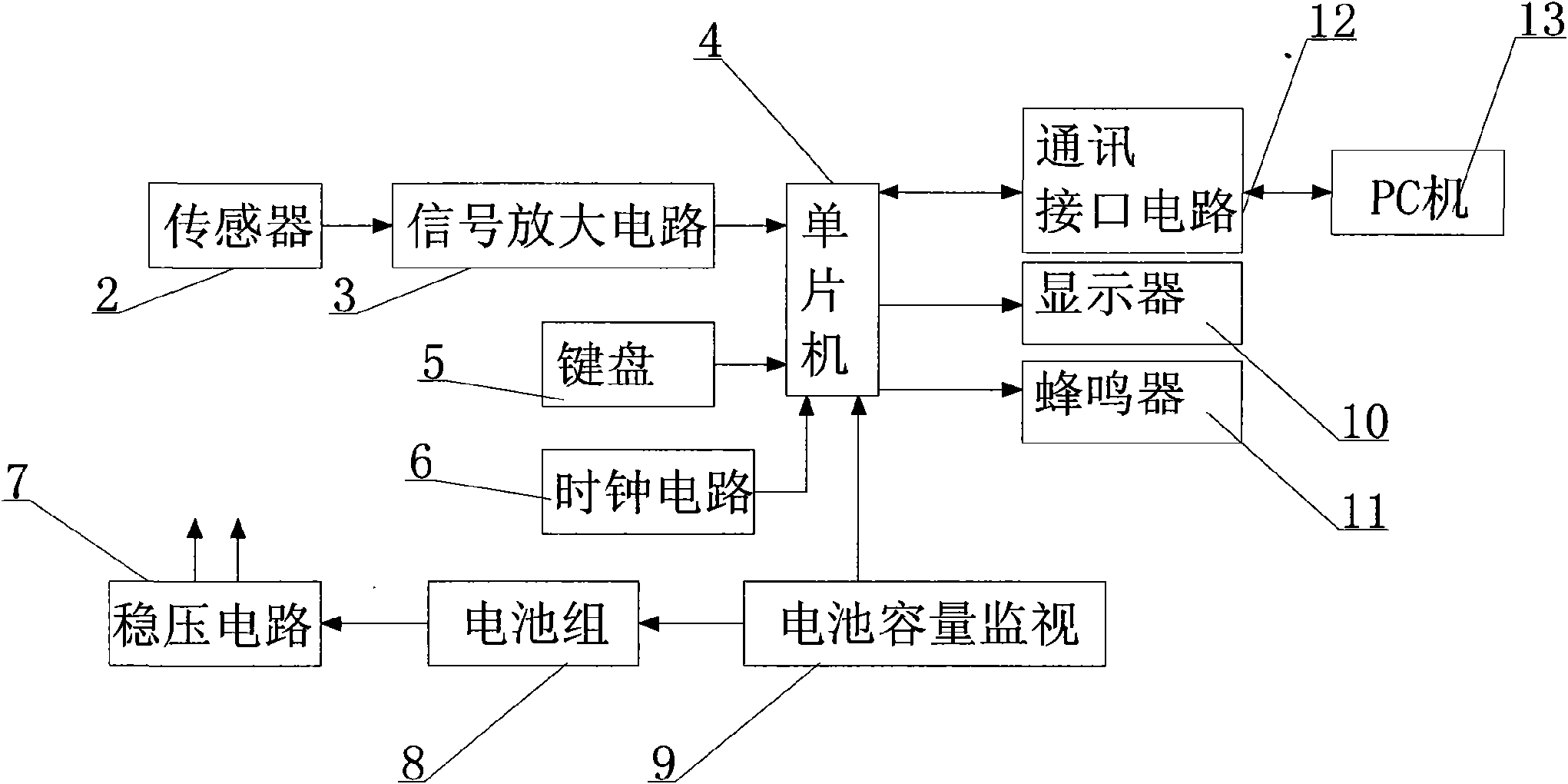

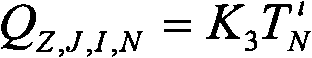

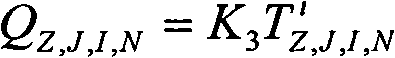

Method for forecasting coal and gas outburst on site

InactiveCN101598033AImprove forecast accuracyAvoid misjudgmentMining devicesGas removalMicrocontrollerDesorption

The invention relates to a method for forecasting coal and gas outburst, which is characterized by comprising the following steps: firstly, measuring a forecasting preliminary index K1 value of coal and gas outburst by a drillings gas desorption index measuring method stipulated by AQ / T1065-2008; secondly, introducing new forecasting judgment index i value, wherein the computational formula is Q=K3T-WL; and in the formula, Q is the total amount of gas desorption of time T, cm / g, T is the time, the minWL is the gas loss of a coal sample before measurement, cm / g, and K3 is a constant; thirdly, measuring i value according to the following steps: 1) placing the coal sample in a coal sample tank; and 2) converting the pressure formed by the gas desorption amount of the coal sample into an electrical signal by a pressure sensor connected with the coal sample tank, sending the electrical signal to an amplifying circuit for signal amplification, then sending the electrical signal to a singlechip, and performing data processing by a least square method to obtain the i value; and fourthly, combining the i value and the K1 value to determine the gas outburst.

Owner:CHONGQING YUKE MINING EQUIP

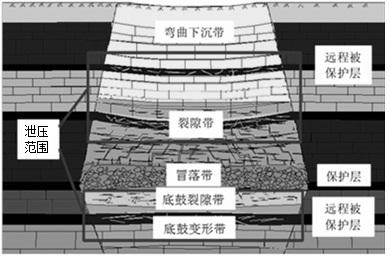

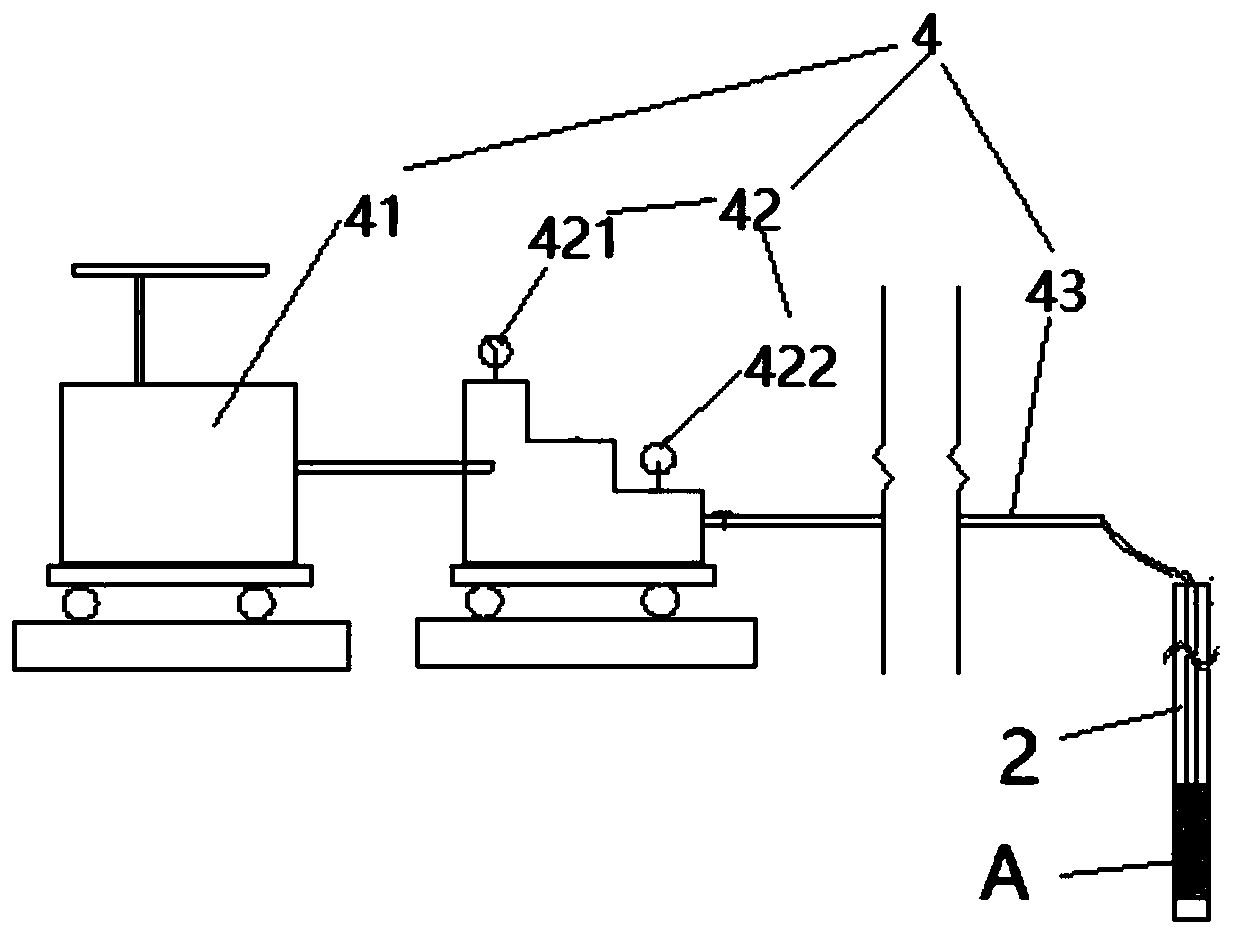

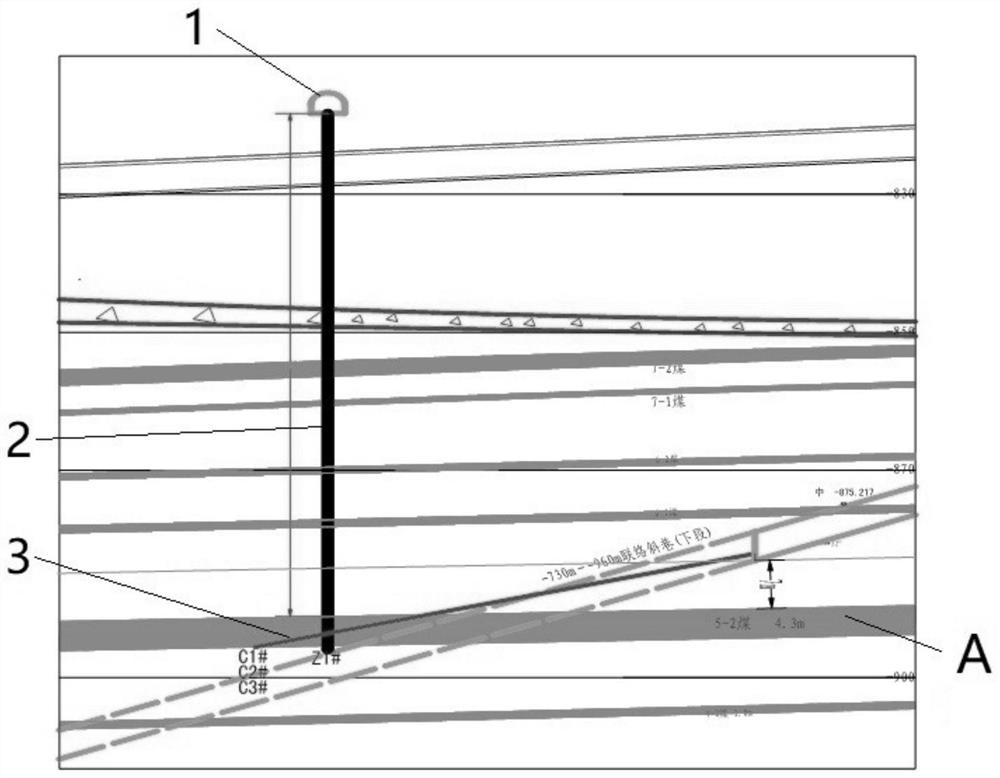

Ground and underground combined coal and coal-bed gas co-mining method for low-permeability coal bed group

ActiveCN111042791AReduce penetrationReduce air contentUnderground miningFluid removalMining engineeringCoal mine methane

The invention discloses a ground and underground combined coal and coal-bed gas co-mining method for a low-permeability coal seam group. The method is applied to a gas outburst mine, a mode that the protective layer mining is combined with the ground gas extraction is used for a coal reservoir with the characteristics of low permeability and low gas content, so that an adjacent coal bed is subjected to rapid pressure relief, coal-bed gas is efficiently and rapidly extracted from the ground, and a co-mining technology system that ground and underground are combined to extract the coal-bed gas and coal and the coal bed gas are extracted while being pumped is provided, so that a highly-located drainage roadway and an end-located drainage roadway are replaced to the maximum extent, the coal mine gas treatment cost is effectively reduced, the ground coal-bed gas well yield is increased, the coal mine gas outburst risk and the gas overrun accident occurrence frequency is reduced, the coal mining efficiency is improved, and the coal mine mining safety and efficiency are realized.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Outburst prevention technique for multiple heading in coal mine

ActiveCN101749017AReduce gas contentReduce outstanding riskUnderground miningSurface miningMedicineMaterial Perforation

The invention relates to a coal roadway heading technology, in particular to an outburst prevention technique for the multiple heading in a coal mine, which solves the problems of unitary outburst prevention measure and low efficiency for the heading working surface of the prior roadway. The technique comprises the following steps: firstly, performing long-distance perforation in front of the working surface to drain gas, predicating the outburst danger of the working surface, executing outburst prevention measures, testing the effect after the outburst prevention measures are implemented, and finally adopting corresponding safety measures to perform heading construction. Compared with the prior art, a measure of long-distance perforation for gas drainage is added before predication, thereby greatly reducing the gas content in the coal ahead of the heading position and the corresponding ground stress, reducing the times of outburst predication index over-standard while reducing the outburst danger of the working surface, saving the time for adopting a local outburst prevention measure, ensuring the fast-pace production of the heading working surface, and improving the production efficiency.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

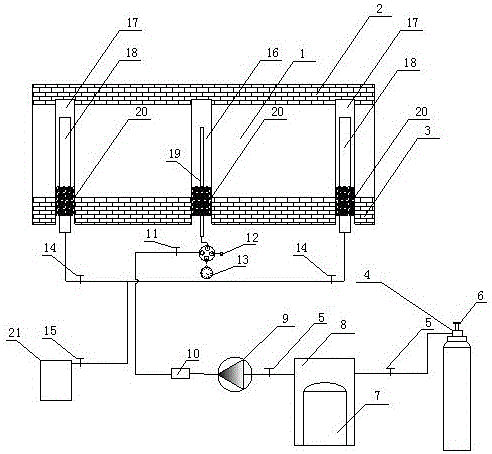

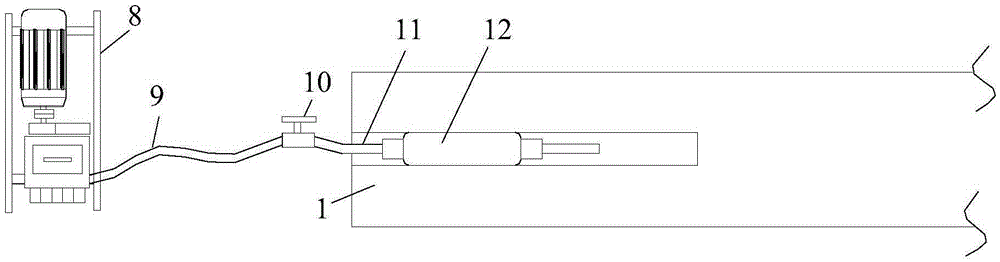

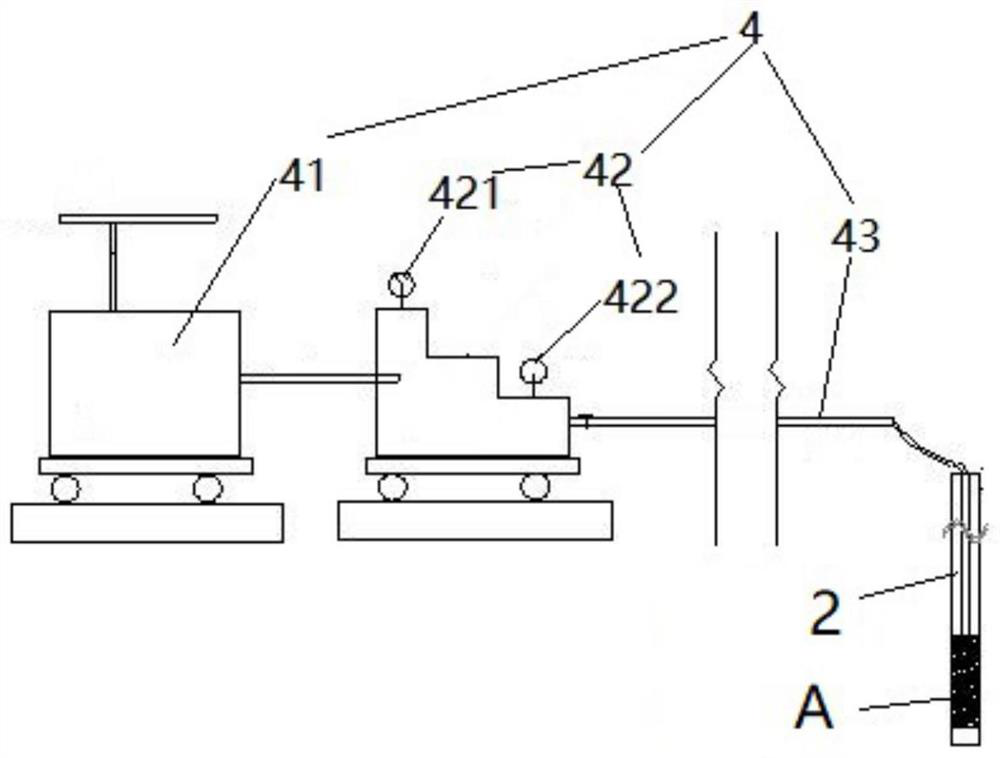

Low permeability coal bed supercritical carbon dioxide anti-reflection system and method

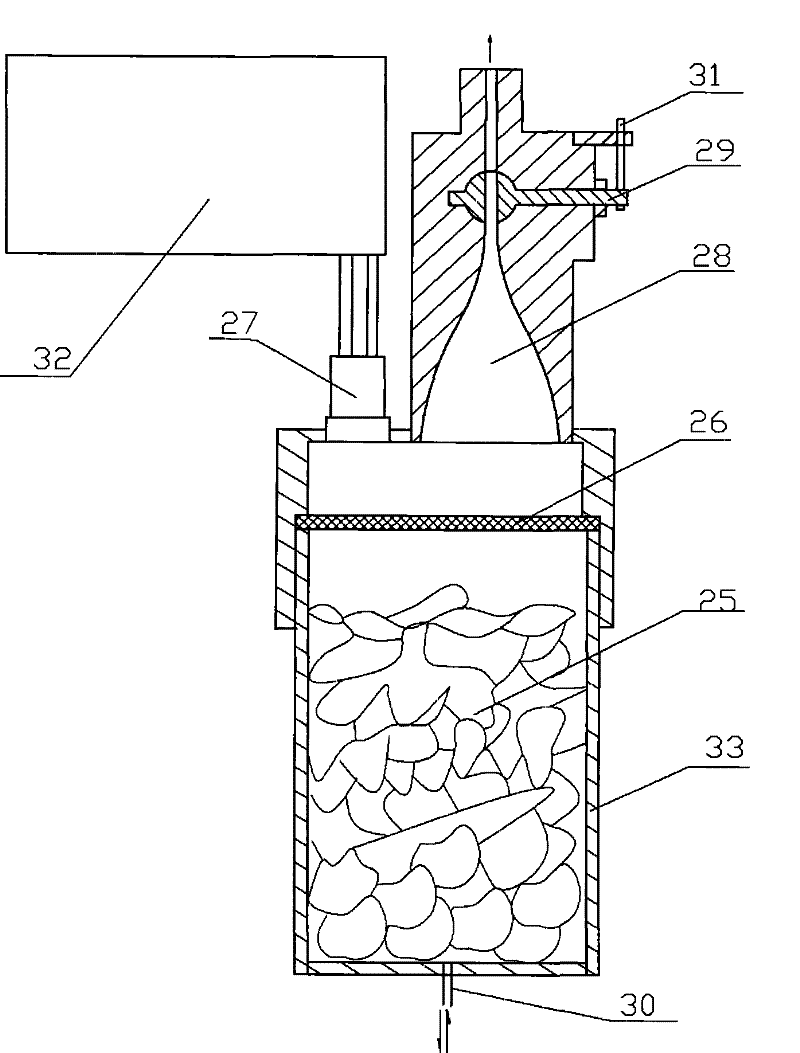

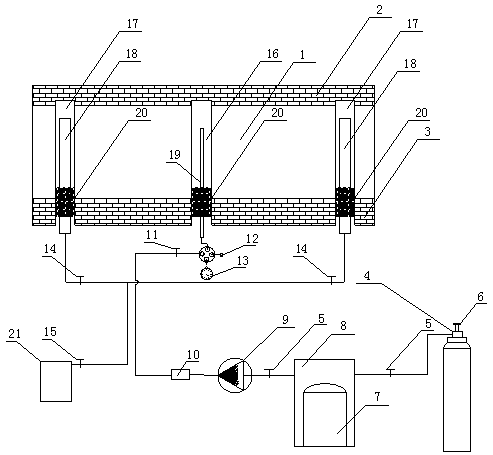

ActiveCN105822341AImprove permeabilityImprove output efficiencyVessel mounting detailsContainer filling methodsInjection pressureFour-way valve

The invention discloses a low permeability coal bed supercritical carbon dioxide anti-reflection system and method. The anti-reflection system comprises an extraction pipe and an injection pipe, wherein the extraction pipe and the injection pipe are sleeved with a hole packer, an extraction device is connected to the outer end of the extraction pipe through an extraction pipeline, and an extraction stop valve and a main extraction stop valve are sequentially arranged between the extraction pipe and the extraction device; an injection stop valve, an injection supercritical carbon dioxide pump, a thermostat and a carbon dioxide gas tank are sequentially connected to the outer end of the injection pipe through an injection pipeline, a high-pressure buffer tank is arranged in the thermostat, and a temperature sensor and a gas injection pressure gauge are connected to a four-way valve. The anti-reflection system is reasonable and simple in structure, convenient to implement, safe and reliable, and capable of improving the permeability of a coal bed greatly. By the adoption of the anti-reflection method, the original pore structure of the coal bed can be changed, the permeability of the coal bed can be improved greatly, coal bed gas output efficiency can be improved, extraction effect can be improved greatly, the outburst danger of the coal bed can be effectively reduced, and safe production of a coal mine can be ensured.

Owner:HENAN POLYTECHNIC UNIV

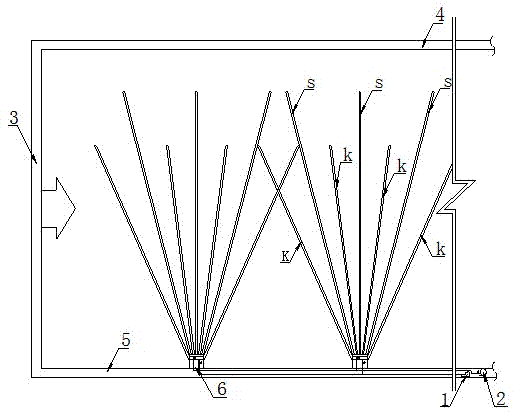

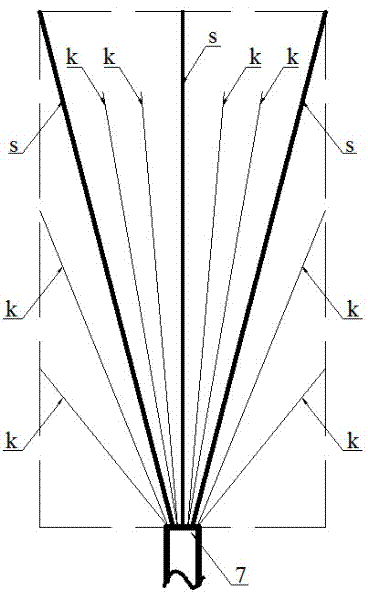

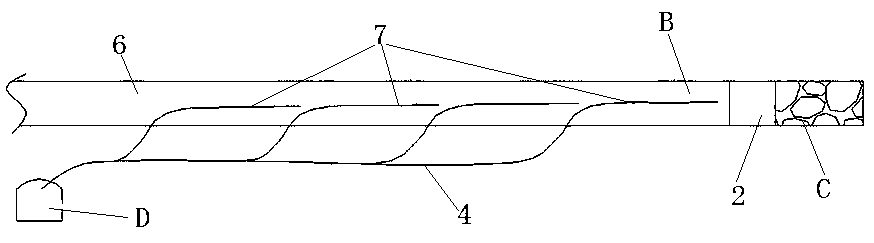

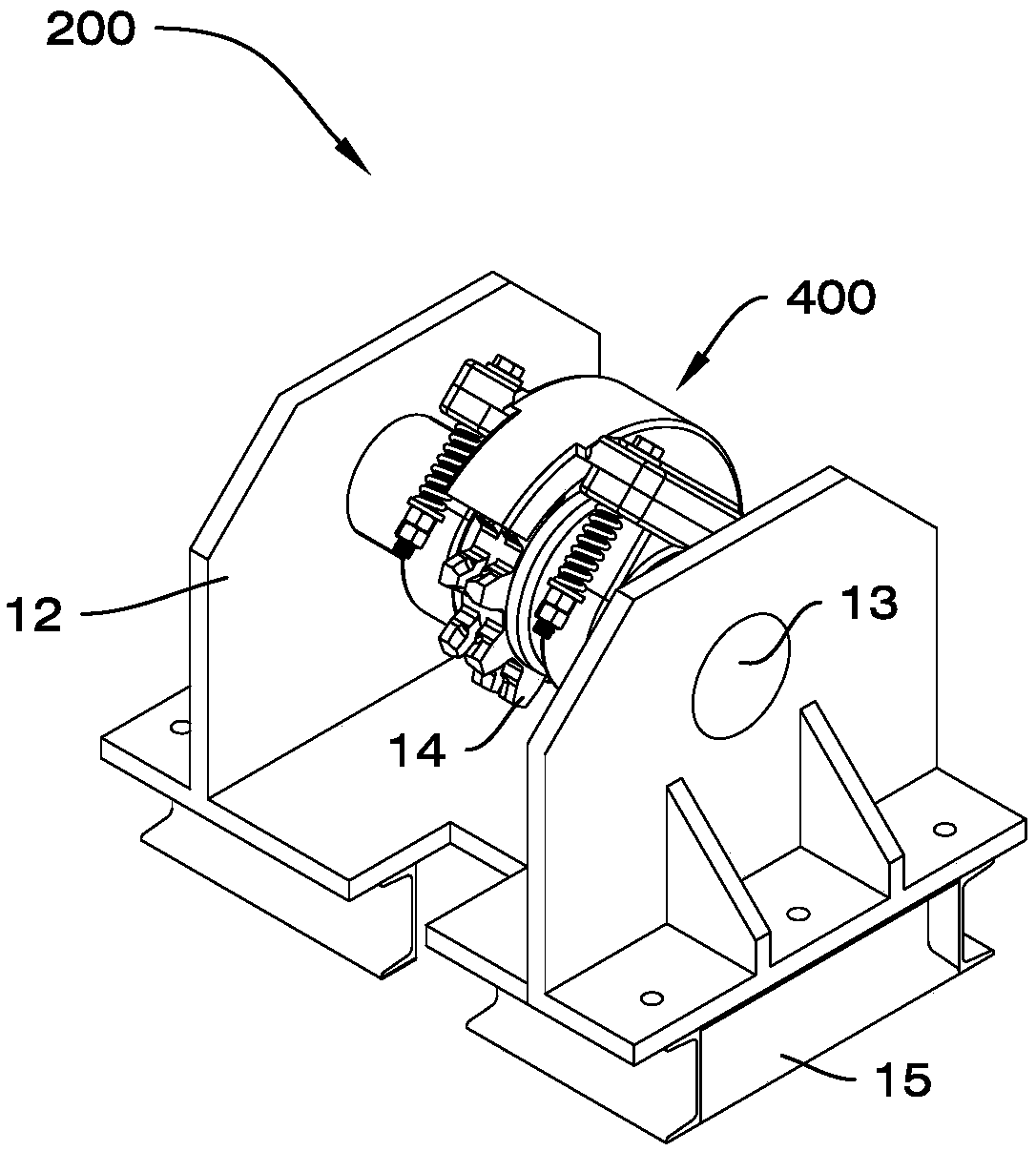

Drilling and anti-permeability integrated device in tectonic coal development area

InactiveCN102261261AImprove breathabilityImprove pumping efficiencyDrill bitsDrilling rodsAir pumpEngineering

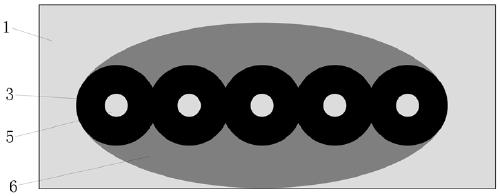

The invention discloses a drilling and reflection reducing integrated device for a tectonic coal development area. The device comprises a drill rod, the rear end of which is connected with a drilling machine; the front end of the drill rod is provided with a drill bit; air bags are wrapped at the outer ring of the rod body of the drill rod at intervals; the rod body of the drill rod between the two adjacent air bags is provided with gas fracturing holes; the air bags and the gas fracturing holes are connected with an air pump through an air bag pipeline and an air pressure pipeline respectively; the air pump is connected with an air tank; a cutting blade encircling the rod body of the drill rod is connected between the rear end of the drill bit and the drill rod; the cutting blade is obliquely arranged, and the tip of the cutting blade is backward; and the cutting blade and the drill bit form a bidirectional drill bit, the drilling direction of which is the front and rear direction. Through the drilling and reflection reducing integrated device for the tectonic coal development area for solving the problems that the drilled holes easily collapse to bury a drill, the reinforcing effect is not ideal and the extraction is difficult and the like during drilling in the tectonic coal development area, the problem of difficulty in forming holes in the tectonic coal is solved, the airpermeability of the coal is improved, the gas drainage efficiency can be improved, outburst of coal and gas is effectively reduced, and safe and efficient production of the coal can be improved.

Owner:HENAN POLYTECHNIC UNIV

Outburst coal seam 'five-fixation' gas treatment method based on directional drilling machine

PendingCN110645040AReduce biasReduce outstanding riskSurveyFluid removalThermodynamicsMonitoring system

The invention provides an outburst coal seam 'five-fixation' gas treatment method based on a directional drilling machine. The outburst coal seam 'five-fixation' gas treatment method based on the directional drilling machine comprises the following steps of (1) evaluating the feasibility of each extraction geological unit adopting the'five-fixation' gas treatment method; (2) directionally drillingeach extraction geological unit; (3) carrying out positioning disturbance in permeability improvement holes, and improving the permeability of a coal bed; (4) sealing the permeability improvement holes and extraction holes; and (5) sampling fixed points in a sealing way for determining gas parameters, quickly extracting gases conveniently, monitoring the gas concentration and the flow on an extraction pipeline in real time through a gas extraction online monitoring system, and furthermore, carrying out real-time statistic and display on the gas extraction amount and the gas amount to be extracted on a displayer through a cloud chart form through system calculation, so that the extraction time of drilling can be accurately controlled, the gas extraction amount and the participated gas content of each drill hole or hole group are displayed with a cloud chart in different colors, and an extraction effect is intuitively reflected.

Owner:郑州慧矿智能科技有限公司

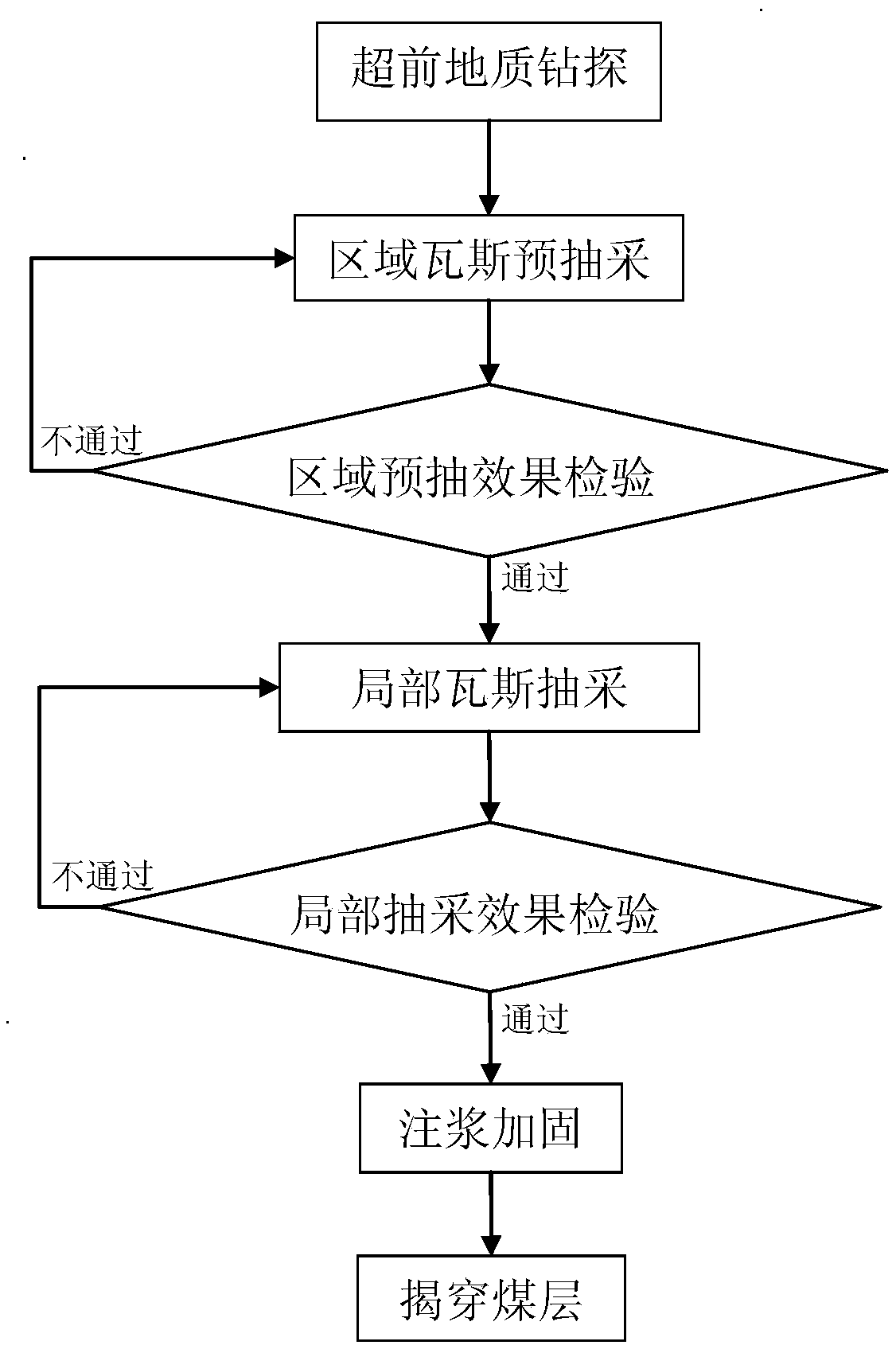

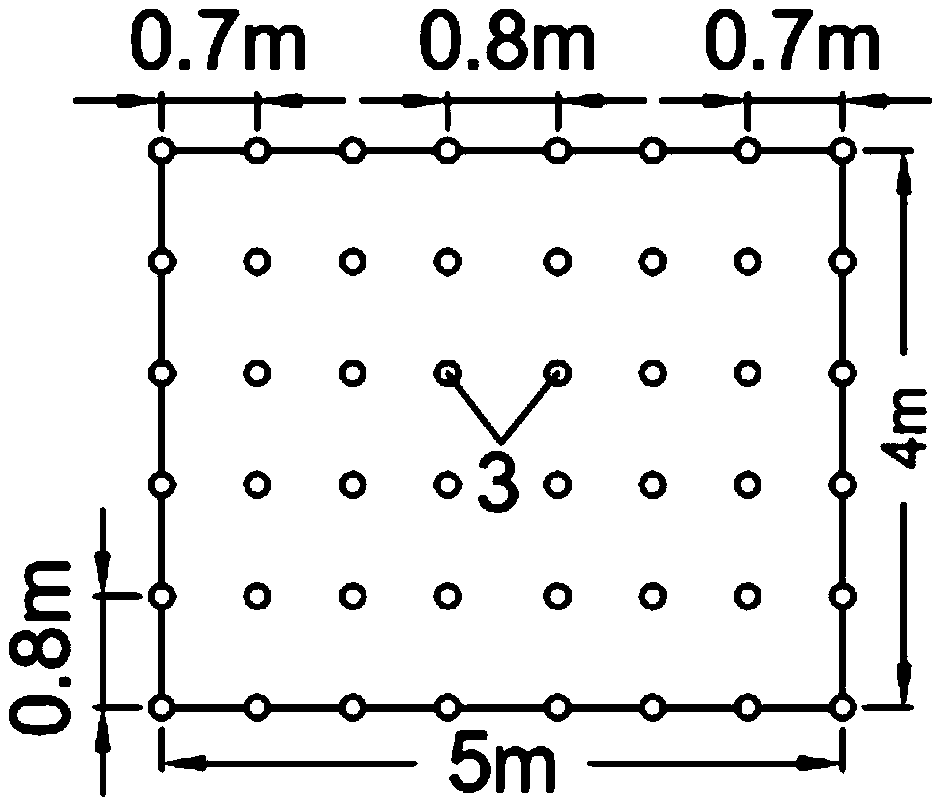

Comprehensive anti-burst construction method for rock cross-cut outburst coal seams

ActiveCN109209293AReduce outstanding riskImprove breathabilityGas removalSealing/packingGeomorphologyCross cut

The invention discloses a comprehensive anti-burst construction method for a rock cross-cut outburst coal seam, and belongs to the field of rock cross-cut coal uncovering in the underground coal mineof mining engineering. The method comprises the steps of 1), construction advanced geological drilling to determine coal seam information; 2) advanced gas pre-draining of regional gas; 3) on-site inspection of gas pre-pumping effect, after meeting the requirements, stopping and continuing cross drifting; 4) when the vertical distance between the cross-cut working surface and the coal seam is 4m, arranging a skeleton drilling hole, installing a steel pipe for protecting the hole, and then sealing the hole with cement mortar to continuously extract the gas in the coal seam; 5) inspection of partial gas-pumping effect, and stopping the local gas-pumping when the requirements are met; 6) grouting reinforcement; and 7) exposing the coal seam. The method is based on a conventional gas pre-pumping and anti-burst measures, and a traditional metal skeleton anti-burst technology is improved. The method is a comprehensive anti-burst construction method for the rock cross-cut outburst coal seam with gas pre-extraction, coal body solidification and advanced support functions.

Owner:LIAONING TECHNICAL UNIVERSITY

Liquid nitrogen freezing-type rock cross-cut coal uncovering method

ActiveCN107605484ASpeed up emissionsIncrease moisture contentUnderground miningSurface miningCross cutSlurry

The invention discloses a liquid nitrogen freezing-type rock cross-cut coal uncovering method. The method comprises the following steps: when the coal uncovering face is close to a safety rock pillar,the coal uncovering face is provided with several freezing boreholes, which pass through the safety rock pillar and the coal seam; the freezing boreholes are injected with water; thermometer holes are arranged at one side of the freezing boreholes, temperature tubes are distributed inside the thermometer holes, and the thermometer holes are sealed; a freezing tube and a slip-casting steel pipe are distributed in each of the freezing boreholes; the freezing boreholes are injected with slurry to fasten the coal body; liquid nitrogen is injected into the freezing tubes and the liquid nitrogen absorbs heat of the coal seam during the gasification process so as to freeze and solidify the coal seam; temperature of the coal seam at the freezing region is monitored by the utilization of the thermometer holes to ensure that the coal seam is fully frozen, and then rock cross-cut is uncovered. The method of the invention has short construction period, is time-saving, has a good solidification effect on the coal seam, and can help raise efficiency and safety of the rock cross-cut coal uncovering operation effectively.

Owner:CHINA UNIV OF MINING & TECH

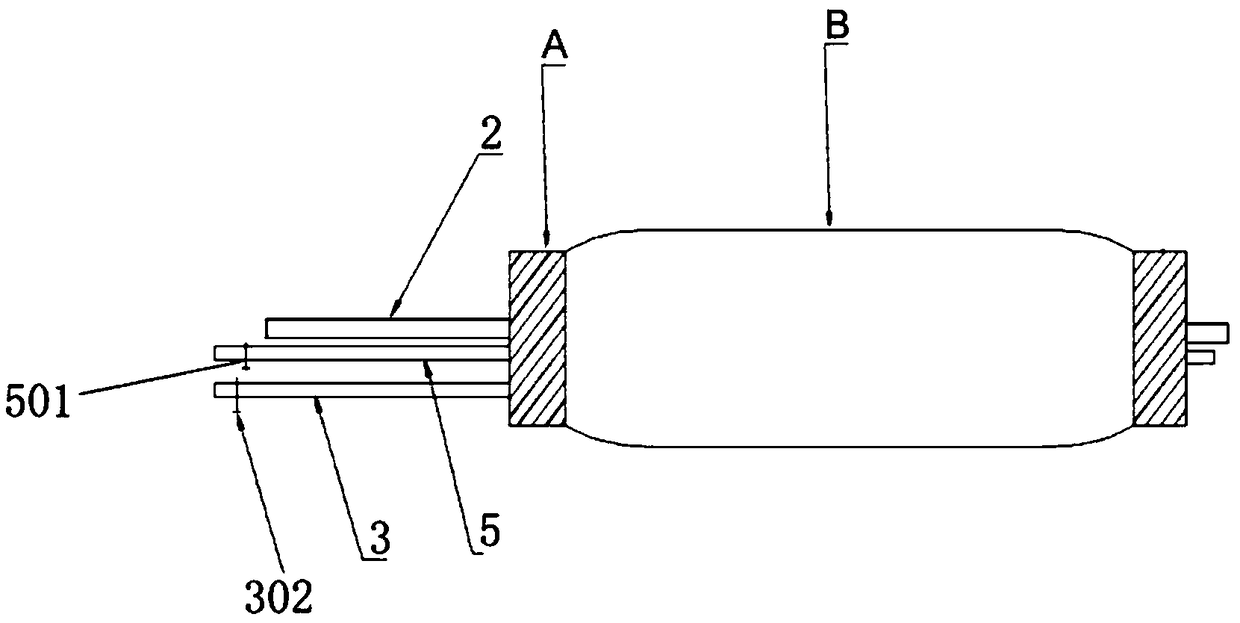

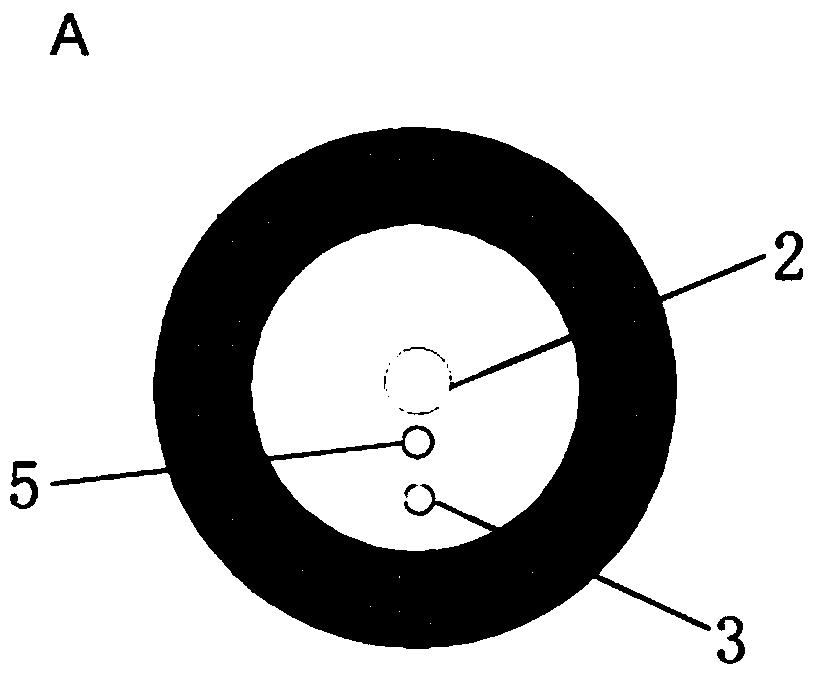

Electric pulse hydraulic fracturing integration device

InactiveCN109138956AIngenious structureRealize integrated operationFluid removalSealing/packingCavitationEngineering

An electric pulse hydraulic fracturing integration device comprises a discharge electrode, a high voltage cable, a line pipe, a high voltage energy storage capacitor, a capsule hole packer, a hole drilling water injection pipe and a capsule water injection pipe. The discharge electrode is fixed to the front end of the line pipe. One end of the high voltage cable is connected to the discharge electrode. The other end of the high voltage cable passes through the line pipe and then is connected to the high voltage energy storage capacitor. The capsule hole packer is strung to the line pipe. The front end of the capsule water injection pipe is extended into the capsule hole packer. The front end of the hole drilling water injection pipe passes through the capsule hole packer. By using the electric pulse hydraulic fracturing integration device, the structure is ingenious, the integration operation of discharge electrode placing, water injection and hole sealing is realized, work efficiencyis high, static pressure water is taken as a medium, an electric pulse generated by the discharge electrode causes the cavitation effect of water so as to continuously amplify fractures in a coal bodyand the water fills the fractures and secondary interstices around a drilling hole, the mechanical property of the coal body is improved, the plasticity of the coal body is increased and an outbursthazard is reduced.

Owner:徐州市三成铸业有限公司

CO2 preparation high-pressure fracturing coal mine gas permeability enhancement and replacement method in coal seam

ActiveCN109458166AImprove the efficiency of crackingPrevent closureFluid removalGas removalHydraulic fracturingHigh pressure

The invention relates to a CO2 preparation high-pressure fracturing coal mine gas permeability enhancement and replacement method in a coal seam, belongs to the technical field of coal mine gas permeability enhancement and replacement, and aims at solving the existing problem of low hydro fracturing efficiency of the coal seam. The method is characterized in that on the one hand, liquid is adoptedto fracture the coal seam through high pressure to increase the coal mine gas permeability of the coal seam, on the other hand, liquid which is injected into coal through high pressure is taken as aCO2 generating agent, a large amount of CO2 gas can be generated in coal seam gaps, the effects of enhancing coal seam coal mine gas permeability, repelling free coal mine gas and replacing absorbed coal mine gas can be achieved, and the purpose of reducing coal mine gas disasters is finally achieved.

Owner:北京安科兴业科技股份有限公司

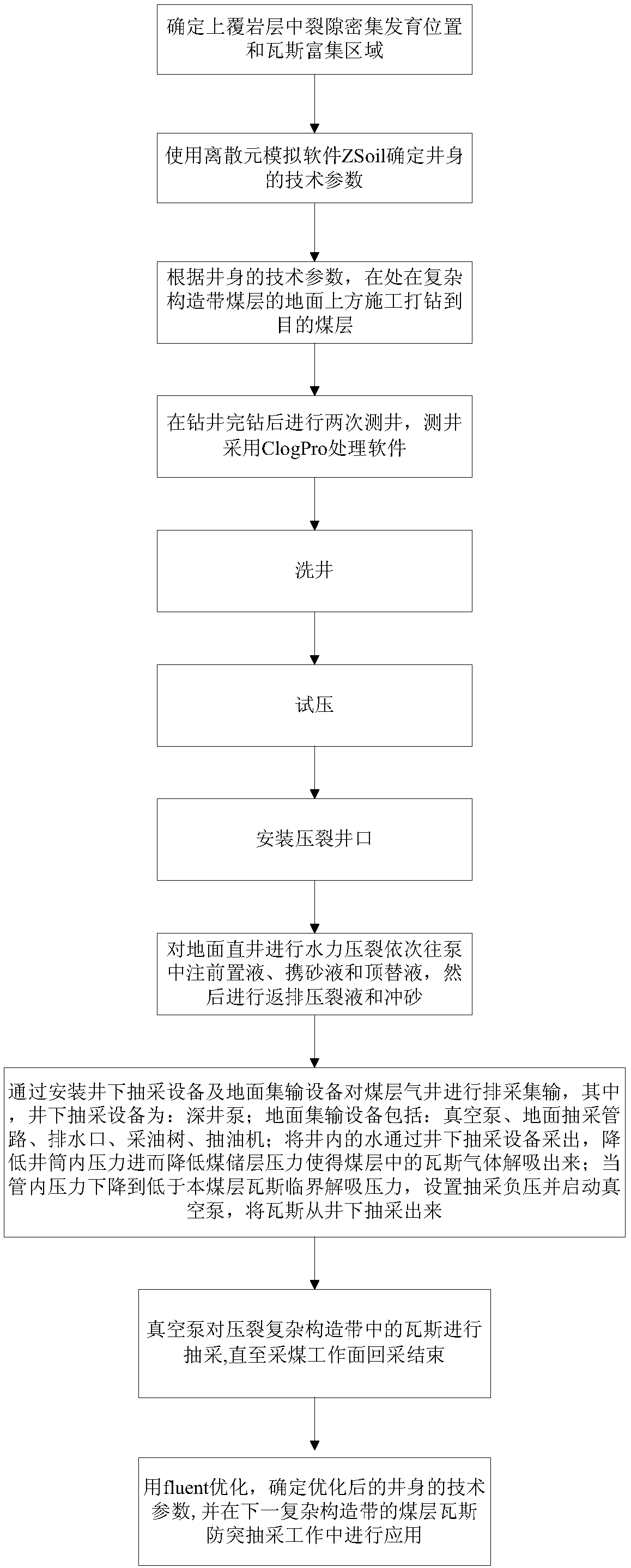

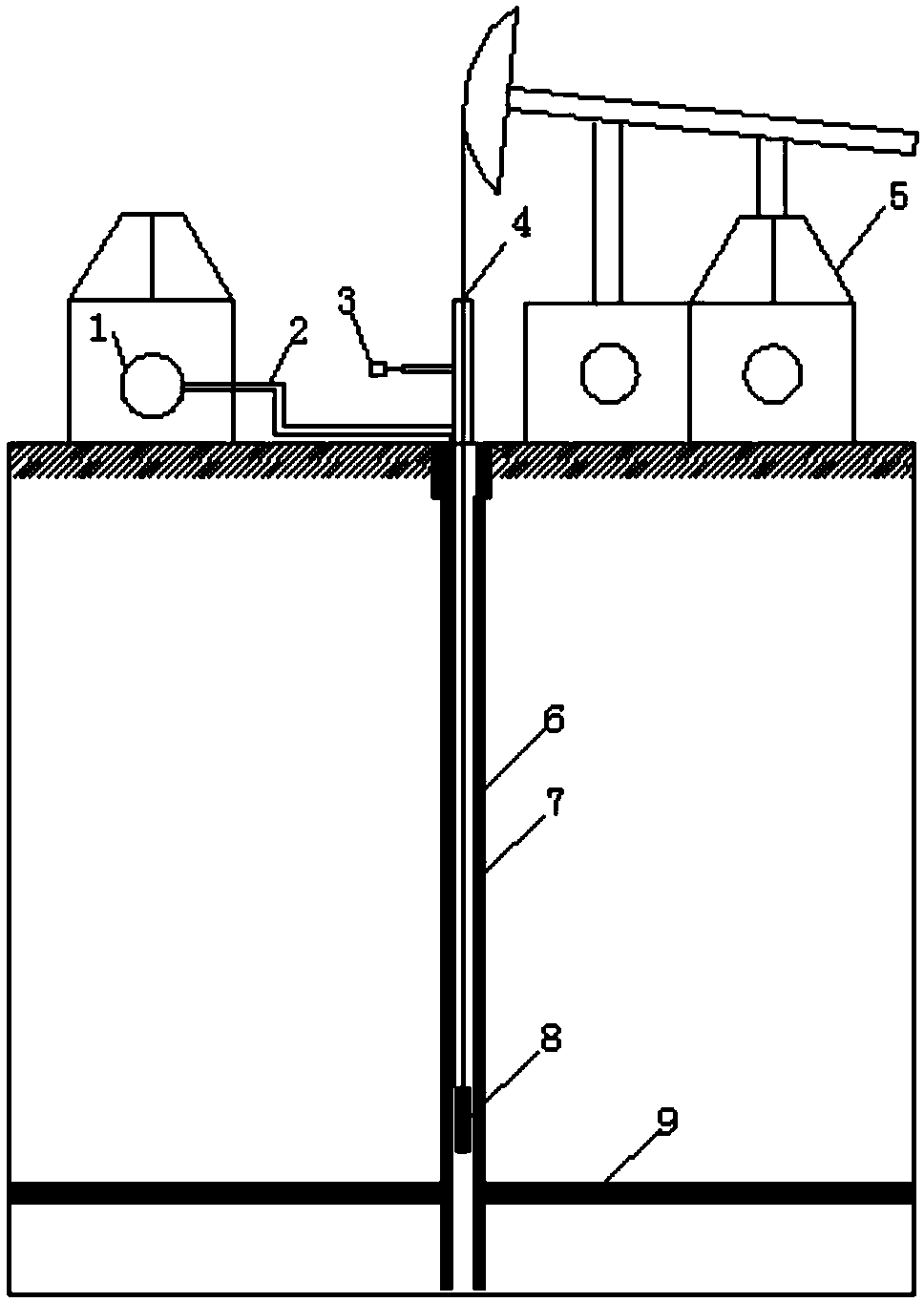

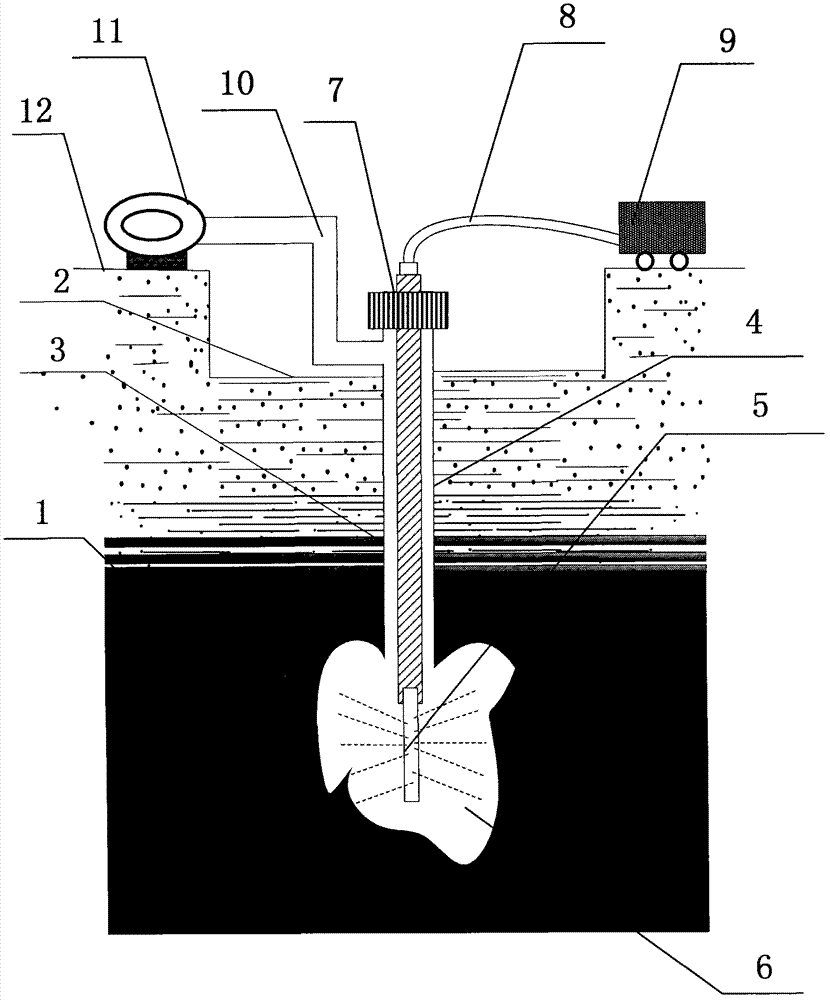

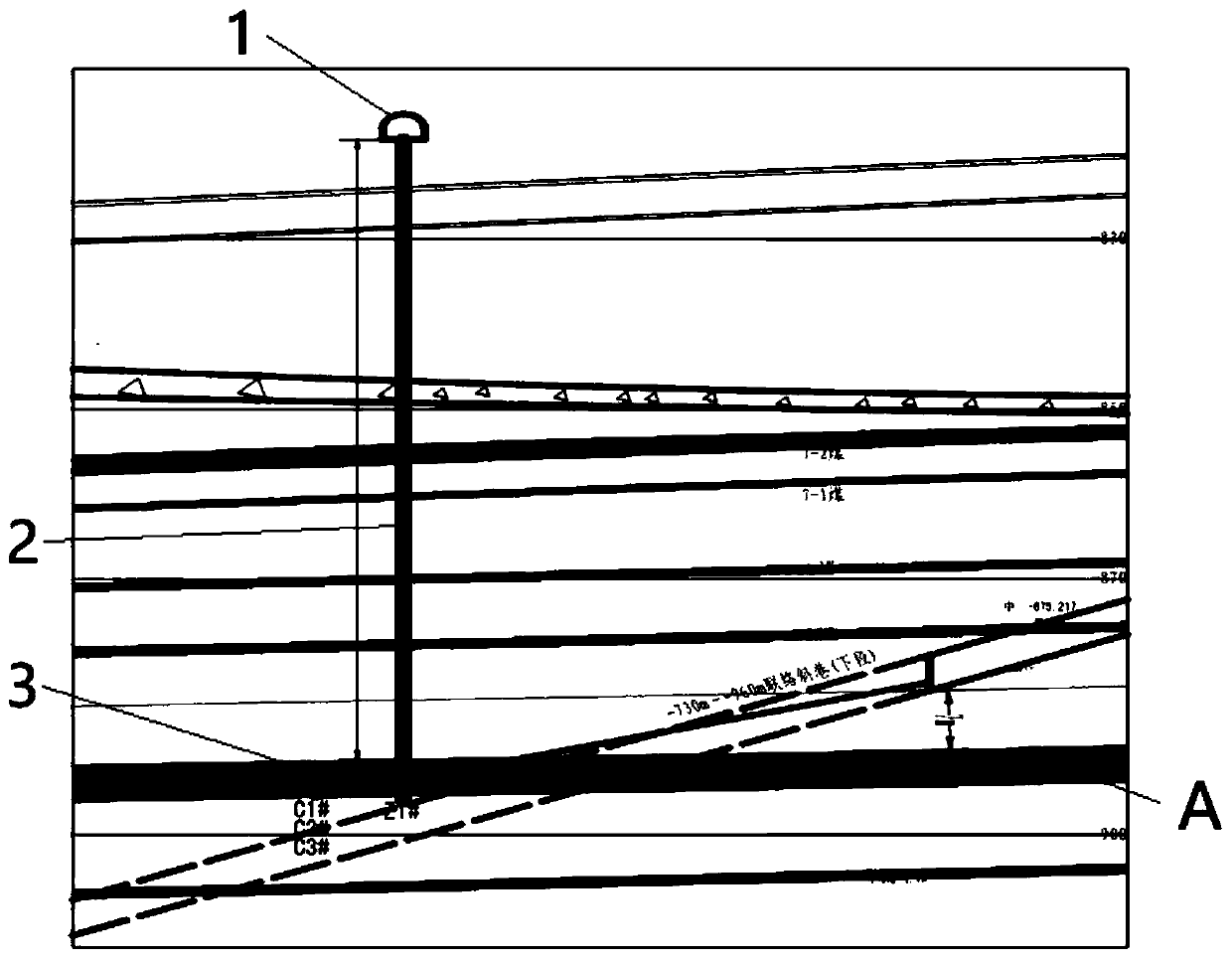

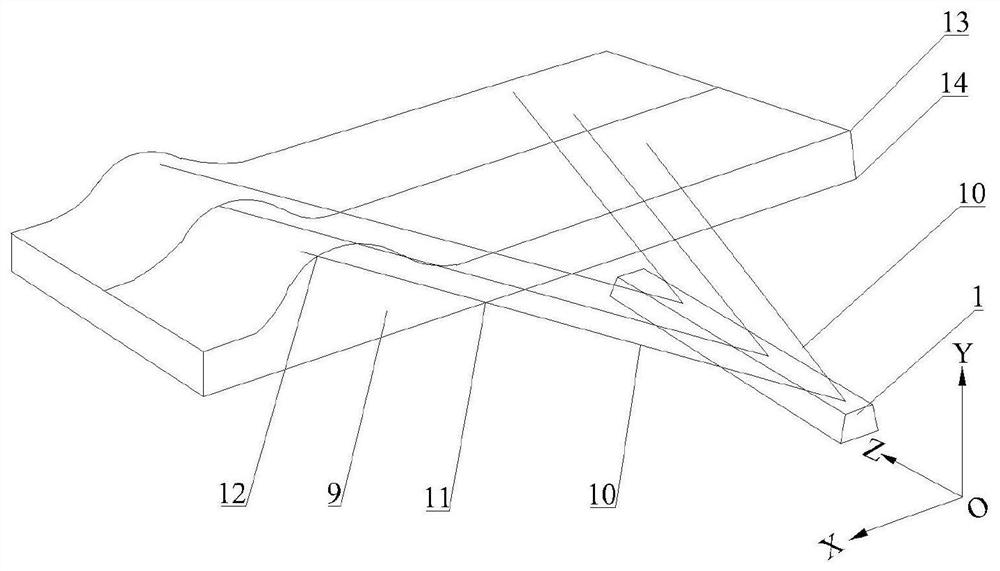

Three-dimensional outburst prevention system and method for gas extraction based on complex structural belt

InactiveCN109611056ASolve the problem of slow excavation speedResolve outstanding situationsSurveyFluid removalEngineeringGeological structure

The invention provides a three-dimensional outburst prevention system and method for gas extraction based on a complex structural belt, and belongs to the technical field of coalbed methane extraction. The system comprises a vacuum pump, a ground extraction pipeline, a water outlet, a Christmas tree, an oil pumping unit and a deep-well pump. Underground extraction equipment and ground gathering and transportation equipment are installed for discharging, extraction, collecting and transporting of a coal bed gas well, water in the well is extracted through the underground extraction equipment, the pressure in a shaft is reduced, and then the pressure of a coal reservoir is reduced, so that gas in the coal bed is desorbed. When the pressure in a pipe is reduced to be lower than a critical gasdesorption pressure of the coal bed, an extraction negative pressure is set and a vacuum pump is started, so that gas is extracted from the underground, and at the moment, the oil pumping unit and the deep-well pump work all the time to extract water in the well and discharge the water through a water outlet. The method solves the problems that the tunneling speed of a complex structural belt coal roadway is low due to the fact that the gas extraction effect through an underground drill hole in a geological structure zone is poor and the extraction standard-reaching time is long.

Owner:LIAONING TECHNICAL UNIVERSITY

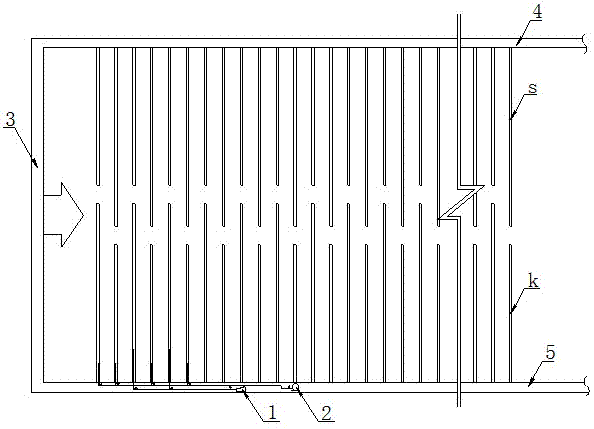

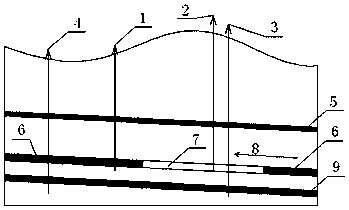

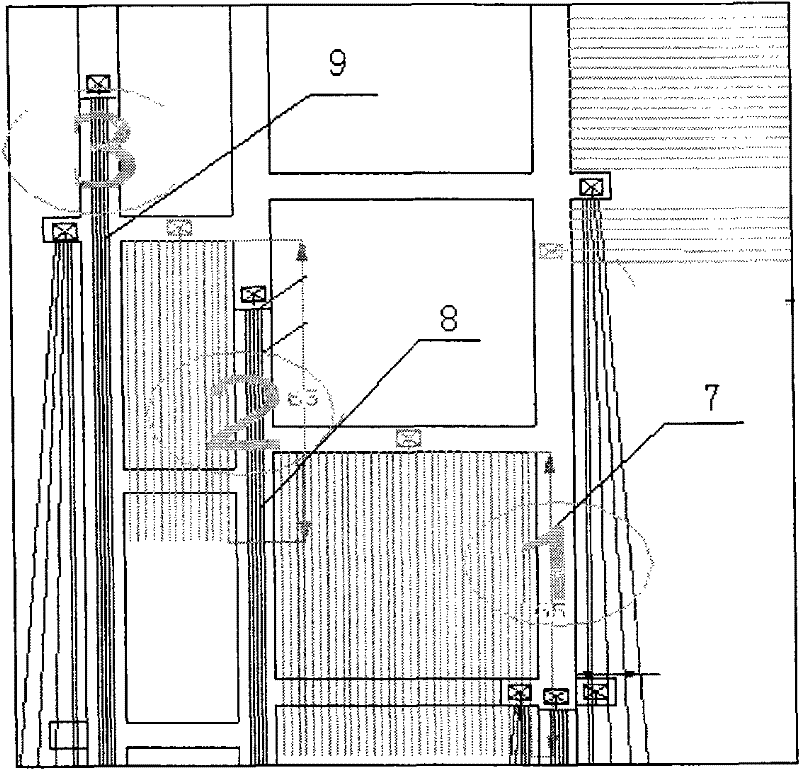

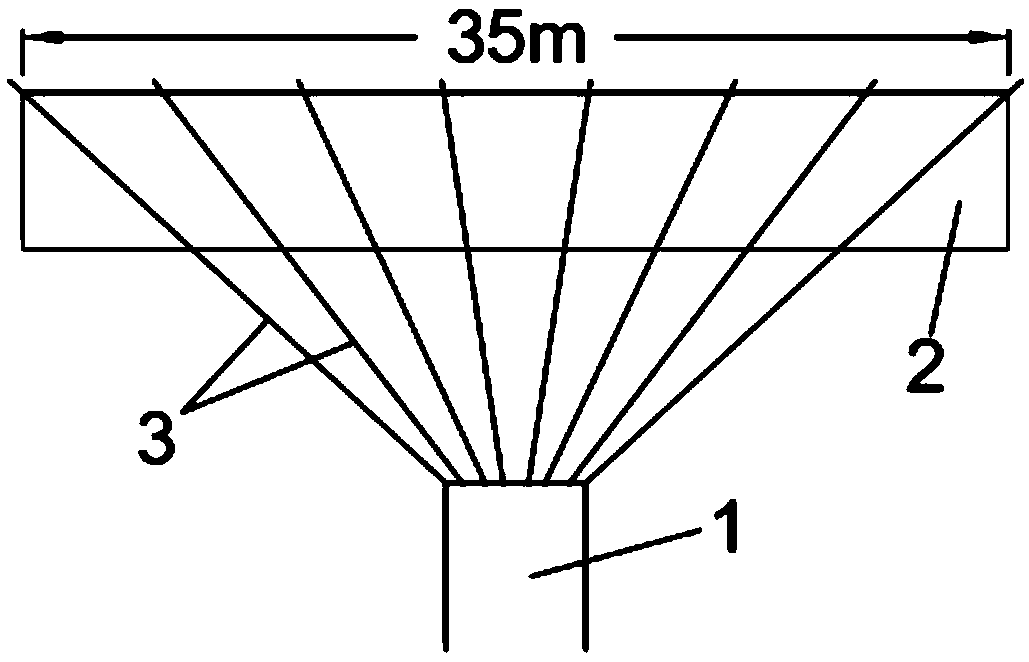

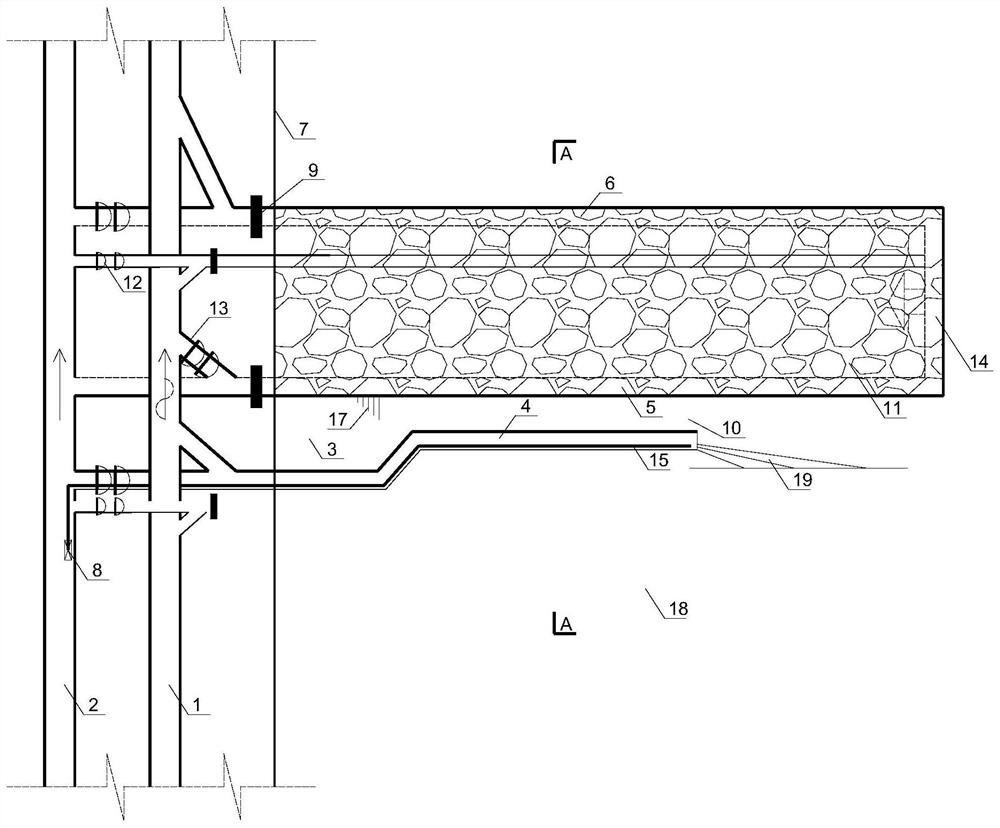

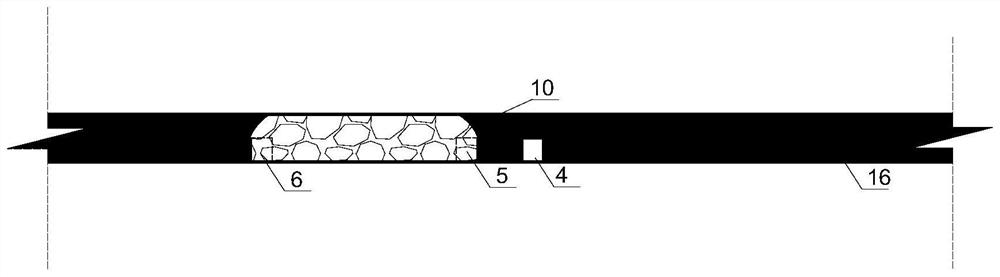

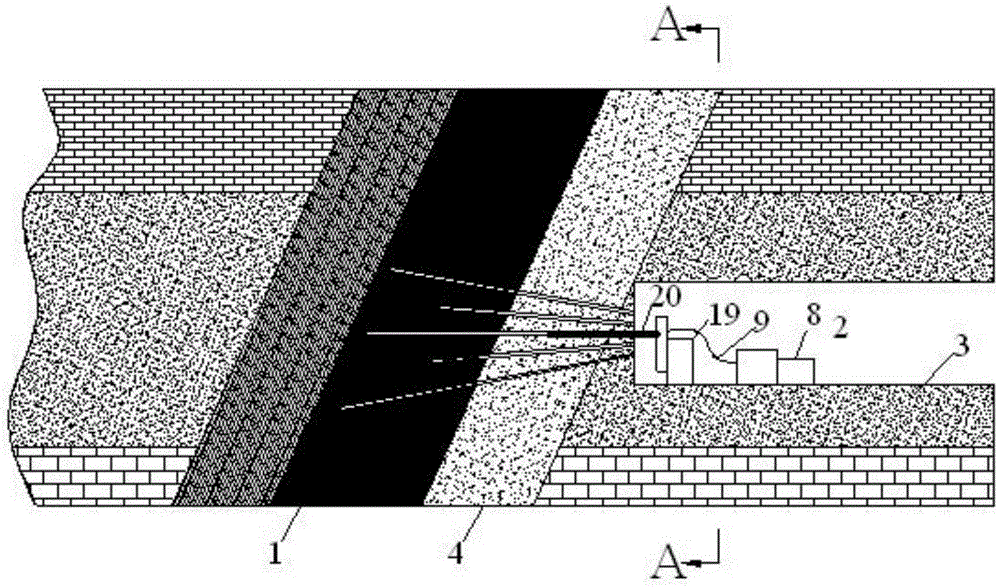

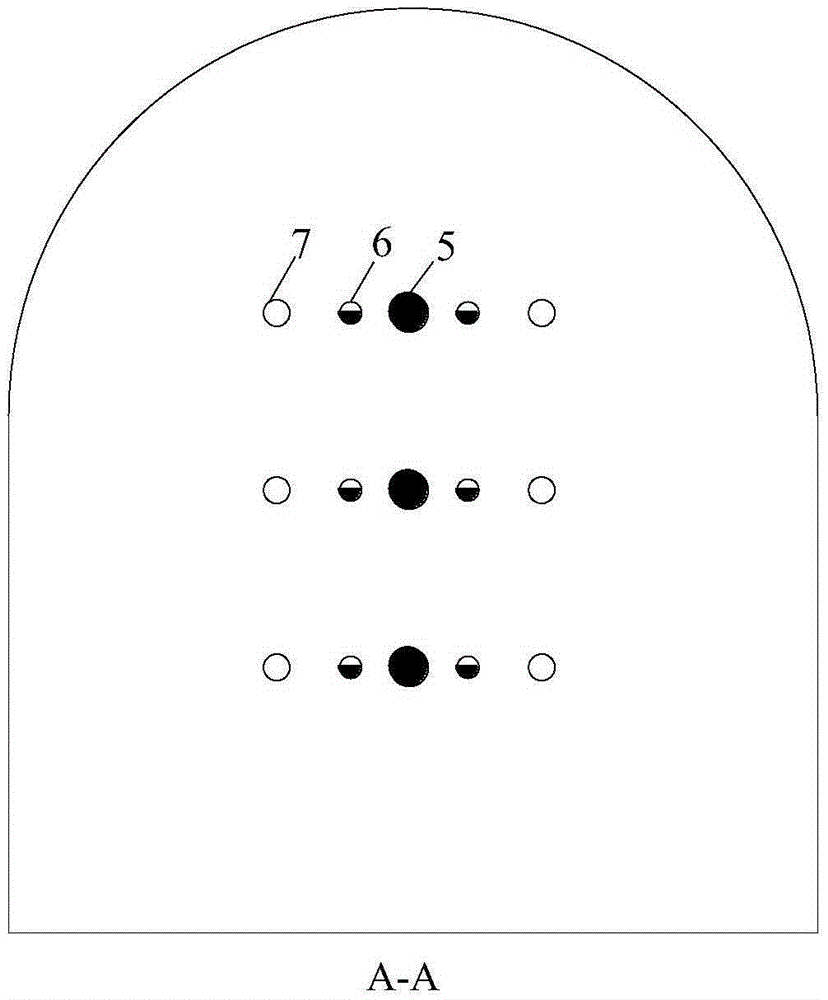

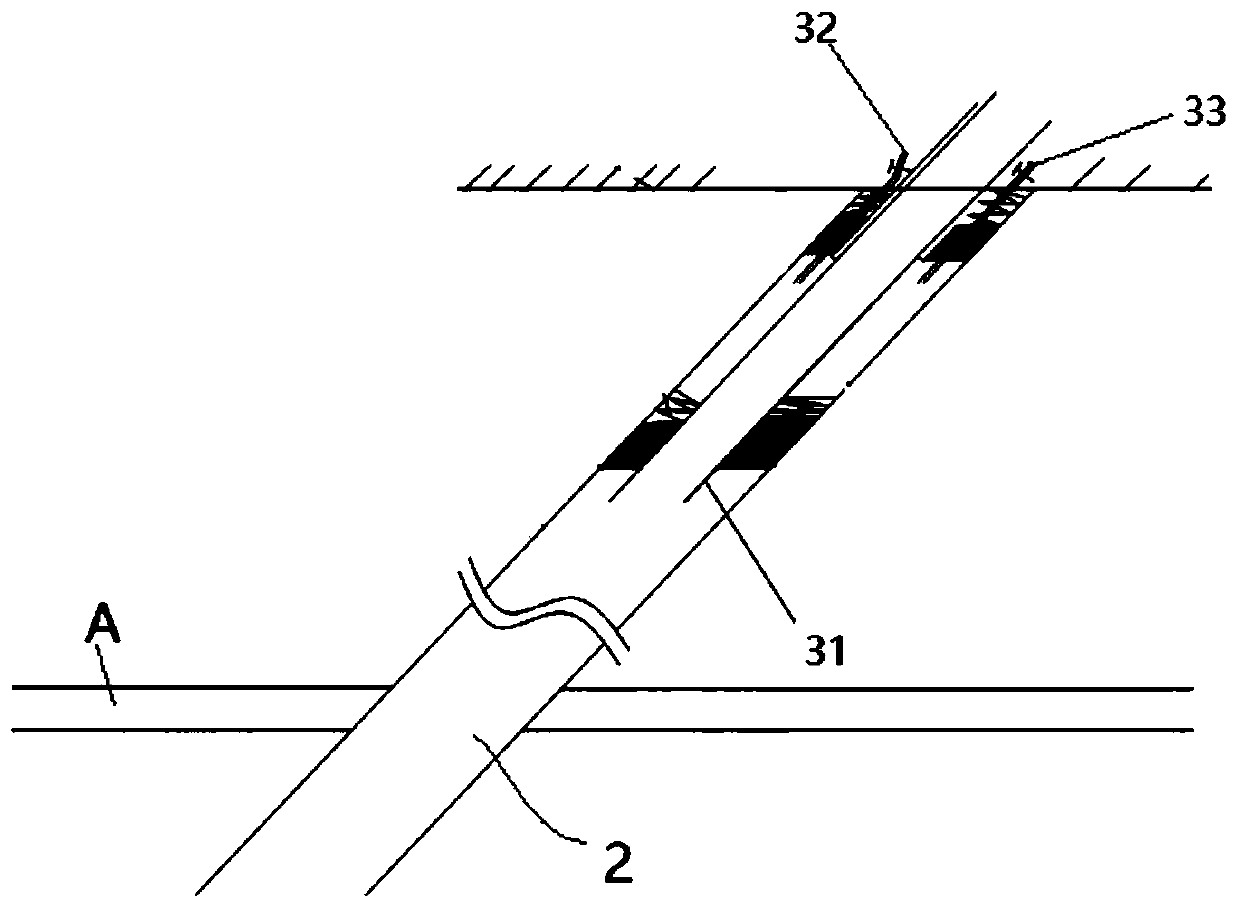

High-pressure hydraulic tunneling, pressure releasing and protrusion removing method for upper drainage roadway

ActiveCN102094668BImprove pumping efficiencyImprove breathabilityLiquid/gas jet drillingGas removalCoal waterWater treatment system

The invention discloses a high-pressure hydraulic drilling, pressure releasing and protrusion removing method for an upper drainage roadway. The method comprises the following steps of: arranging a drilling field (2) in the upper drainage roadway (12) and constructing boreholes with small apertures in a protrusion-preventing area coal bed (1); driving a hydraulic jet device (5) to eject high pressure water so as to form rotational impact by using a drill stem (4), and performing continuous rotational impact drilling on the boreholes (3) until a drilling level meets a designed requirement; meanwhile, collecting a coal-water mixture produced in the hydraulic drilling process and feeding into a coal and water treatment system (11) by using a slurry returning pipeline (11); and when the hydraulic drilling work of all the boreholes is finished, increasing the transmittance of a coal body under uniform pressure under the action of ground pressure and gas pressure, and draining gas from a pressure releasing coal bed (1) by the conventional method. By the method, the number of the boreholes (3) is greatly reduced, the pressure releasing space (6) of the coal bed (1) is expanded, and the gas drainage efficiency is improved; and by injecting the high pressure water, dust is effectively restrained, the protrusion danger of the coal bed is lowered, and underground operation environment is improved.

Owner:ZHENGZHOU UNIV

Gas prevention and control method for gob-side entry self-pressure-relief outburst-elimination rapid tunneling

ActiveCN112343647AReduced number of extraction boreholesIncrease extraction concentrationSurveyGas removalMining engineeringEngineering

The invention provides a gas prevention and control method for gob-side entry self-pressure-relief outburst-elimination rapid tunneling, and relates to the technical field of mine gas prevention and control. According to the gas prevention and control method, a pressure relief zone area, which is close to a coal body, of a upper section stope face is accurately determined, so that roadway tunneling in the pressure relief zone area is guaranteed; additionally, the outburst of gas of a coal seam on the inner side of a roadway is eliminated, the number of gas extraction drill holes is reduced, the work amount of the drill holes is reduced, the tunneling speed of the outburst coal seam is obviously increased, and the outburst risk in a tunneling process is greatly reduced; in the roadway tunneling process, the range of the pressure relief zone area is further enlarged, the gas extraction concentration and the extraction amount of the gas extraction drill holes are increased to a certain degree, the gas extraction time is shortened, and the gas pressure and content of the coal seam are rapidly reduced; and plugging materials are used for guniting and plugging the coal wall of the outerside of the roadway, and a damaged fracture gas seepage channel is effectively plugged, so that the inrush of goaf gas is reduced, and the concentration of return current gas is prevented from exceeding the limit.

Owner:CCTEG CHINA COAL RES INST

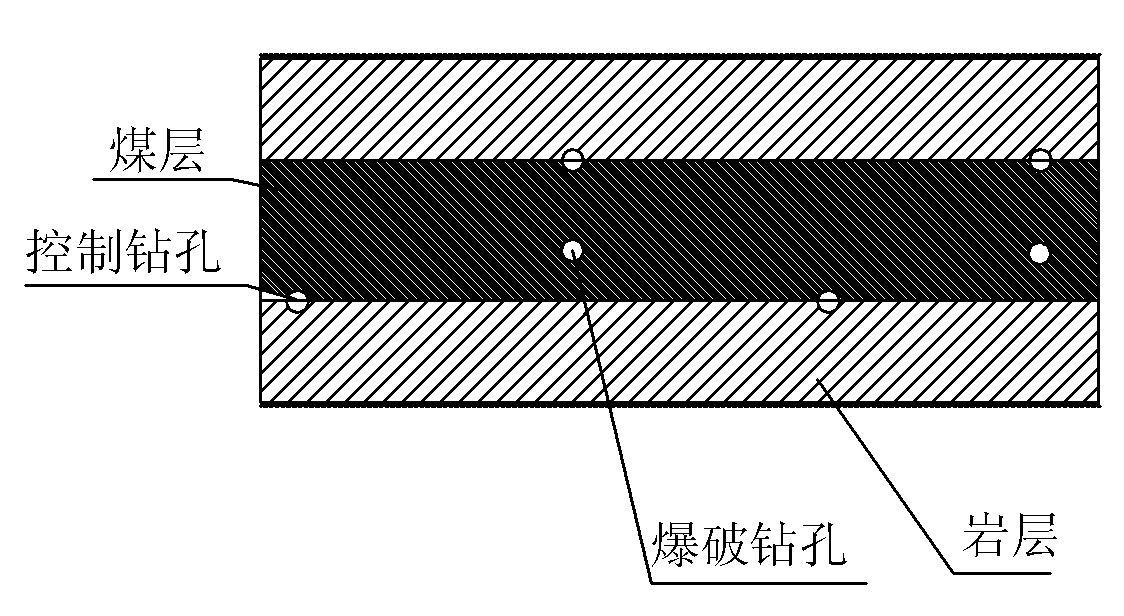

Deep-hole loosening hydraulic pressure-relief integrated blasting method and device

A deep-hole loosening hydraulic pressure-relief integrated blasting device comprises a blasting cartridge, an explosive line, an explosive feeding pipe, a capsule hole-sealing device and a drilling water injection pipe. The front section of the blasting cartridge is conical, the middle section of the blasting cartridge is hollow, explosive is placed in the middle section of the blasting cartridge,an explosive line extending hole is formed in the middle of the tail section of the blasting cartridge, a hollow pipeline is arranged in the middle of the explosive feeding pipe, and the capsule hole-sealing device is arranged on the explosive feeding pipe in a bunched mode. The explosive line passes through the explosive line extending hole and the hollow pipeline to extend out of the tail end of the explosive feeding pipe. During blasting, the deep-hole loosening hydraulic pressure-relief integrated blasting device is put into a drilled hole, the capsule hole-sealing device seals the hole,static pressure water is injected into the drilled hole, then the blasting cartridge is detonated, and finally, the static pressure water is injected into the drilled hole again. According to the deep-hole loosening hydraulic pressure-relief integrated blasting device, integration of explosive placing, hole sealing, water injection and blasting is achieved, and the operation efficiency is high.

Owner:CHINA UNIV OF MINING & TECH

Freezing Shimen Uncovering Coal Method Based on Hydraulic Slit

ActiveCN104213921BImprove flow statusImprove breathabilityUnderground miningSurface miningLiquid stateCross cut

Owner:CHINA UNIV OF MINING & TECH

Rock cross-cut coal uncovering high-pressure hydraulic flushing comprehensive permeability enhancement method

ActiveCN111197497AExtended service lifeIncrease the punching water flow, punching pressure and anti-reflection rangeLiquid/gas jet drillingFluid removalPetrologyCoal

The invention discloses a rock cross-cut coal uncovering high-pressure hydraulic flushing comprehensive permeability enhancement method. The rock cross-cut coal uncovering high-pressure hydraulic flushing comprehensive permeability enhancement method comprises the steps that an auxiliary roadway is constructed; vertical drilling holes are constructed downward in the auxiliary roadway, and the endpoint of the vertical drilling holes is located under a coal seam floor to be uncovered; the vertical drilling holes are subjected to hole sealing and cementing; three drilling holes are constructed on a driving face of a coal uncovering working face, one of the three drilling holes is a slagging drilling hole penetrating through the vertical drilling holes, the other two drilling holes are located on two sides of the vertical drilling holes respectively, and grouting and hole sealing are performed on the three drilling holes; a pressure flushing system communicates with the vertical drillingholes to carry out water supply pressure flushing; static pressure water flushing and high pressure water injection pressure flushing are adopted sequentially; and after the hydraulic pressure flushing operation is completed, a plurality of outburst prevention measure holes are constructed. The rock cross-cut coal uncovering high-pressure hydraulic flushing comprehensive permeability enhancement method has the beneficial effects that the flushing water flow rate and flushing pressure and penetration enhancement range are increased, by adopting hydraulic flushing measures combining the static pressure water flushing with the high pressure water pressure flushing, the extraction effect of a coal seam with complex geological conditions, deep burial depth, high gas pressure and poor permeability can be effectively improved, and the benefit of permeability enhancement is realized.

Owner:HUAINAN MINING IND GRP

Fast prediction method for crossdrift and pitshaft coal uncovering burst fatalness

InactiveCN101344514BAccurate measurementAccurately determineGeological measurementsMaterial analysisUltimate tensile strengthCoring

The invention discloses a quick prediction method of protrusion danger in the crossdrift and pitshaft coal uncovering, implements quick gas pressure measurement of a coal bed in front of a working face of a crossdrift or a pitshaft by rock strata grouting and rock strata densification, and collects a complete coal core of the coal bed with a coring device, thus determining the position of a soft bed and obtaining a coal sample in the soft bed, and after the collecting of the complete coal core is finished, a thermometer is sent into the coal bed through a coring pore and taken out after occluded for half an hour, the temperature of the coal bed is read, an initially released gas dilatation energy index Wp of the collected coal sample in the soft bed of the coal core is measured, and whether the protrusion is generated when uncovering the coal bed of the crossdrift or the pitshaft and protrusion intensity are determined by comparing the measured initially released gas dilatation energyindex Wp with existing critical values of weak protrusion and strong protrusion. The quick prediction method of the protrusion danger in the crossdrift and pitshaft coal uncovering has short prediction time, can finish in about 3 to 5 days, and has accurate prediction, convenient operation, good effects and wide practicability.

Owner:CHINA UNIV OF MINING & TECH

Comprehensive Permeability Enhancement Method for Shimen Uncovering Coal by High Pressure Hydraulic Punching

ActiveCN111197497BImprove the extraction effectReduce outstanding riskLiquid/gas jet drillingFluid removalPunchingSlag

Owner:HUAINAN MINING IND GRP

The Method of Utilizing Microorganisms to Control Coal Mine Gas

ActiveCN110017163BReduce concentrationReduce operating costsGas treatmentMethane captureMicroorganismProcess engineering

The invention provides a method for controlling coal mine gas by using microorganisms, which uses microorganisms capable of degrading methane to eliminate gas in coal mines. Specifically, the microorganism capable of degrading methane is Methylophilus methylotrophus. The method of the present invention changes the borehole water injection in the conventional coal mine mining into the culture solution of microorganisms that can degrade methane, degrades the gas in the coal body, reduces the gas concentration, makes it unnecessary to perform gas drainage and discharge operations, and significantly reduces manpower consumption. , reduce operating costs and improve mining safety.

Owner:XINWEN MINING GROUP

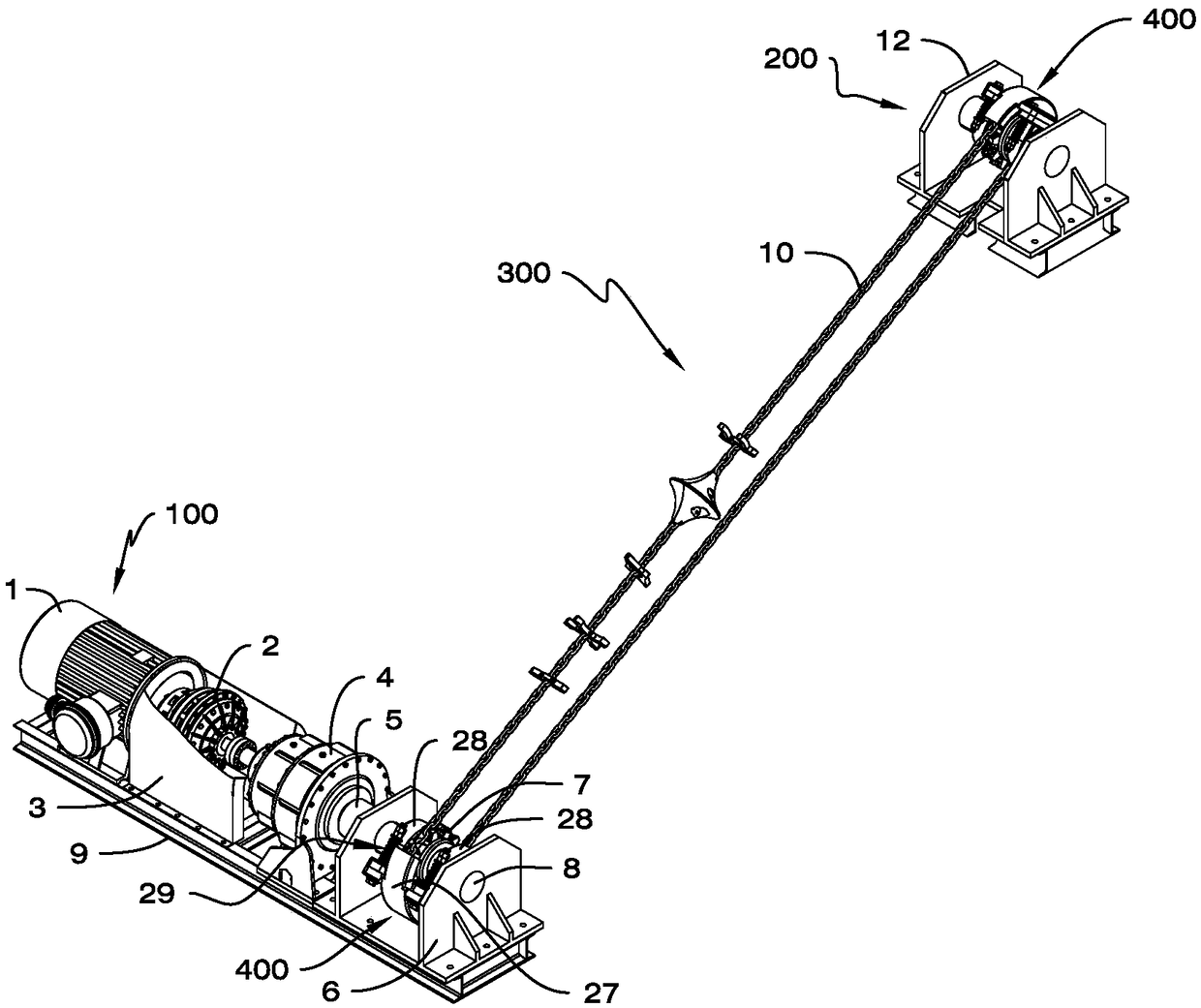

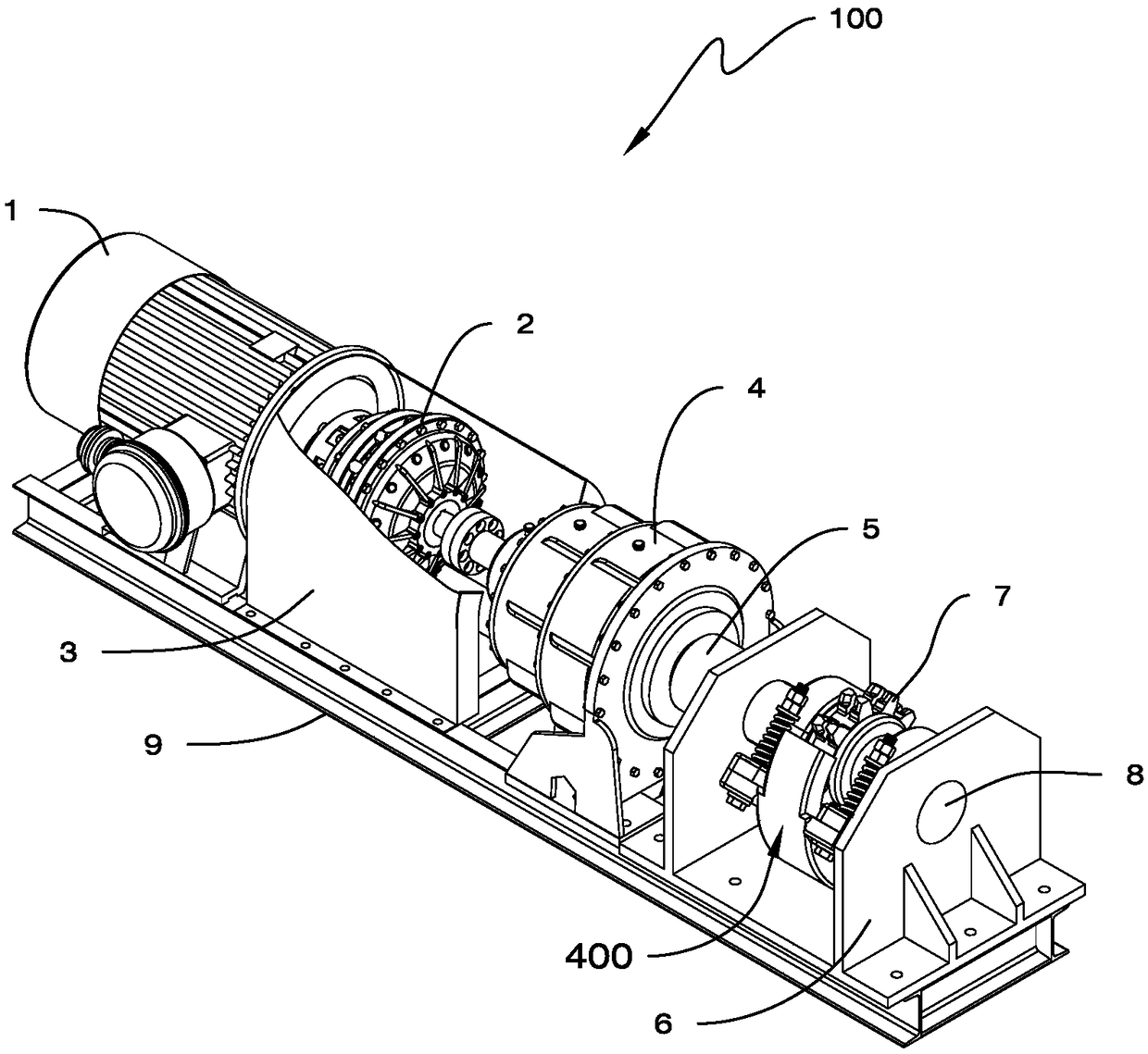

Coal raking machine and coal mining method utilizing coal raking machine

PendingCN108979633AEasy to operateNo human intervention requiredPropulsionMechanical engineeringStart up

The invention relates to a coal raking machine and a coal mining method utilizing the coal raking machine. The coal raking machine comprises a driving part, a driven part and a transmission link part,wherein the transmission link part comprises an annular transmission chain which is detachably mounted at a raking head, and the two ends of the annular transmission chain are separately engaged withchain wheels of the driving and driven parts so as to achieve circulating reciprocating movement. During coal mining, interior of upper and lower gate roads is subjected to loosening-borehole-drilledexplosive-loaded blasting towards a coal bed of a working surface, thus, coal mass can fall into slotted holes, then, the driving part is started up, coal self-slides into or is driven to slide intothe lower gate road through the raking head and enters a scraper reloader for being conveyed away, then, the coal raking machine and the reloader are closed down, and the coal raking machine moves forwards under the drive of a hydraulic support for carrying out next circulating mining. The coal raking machine and the coal mining method utilizing the coal raking machine have the aims that the structure is simple, the operation is convenient, large-scale equipment is not required to be arranged in the working surface, and the unmanned mining of a working surface of a pitching coal bed can be achieved.

Owner:北京安科兴业科技股份有限公司

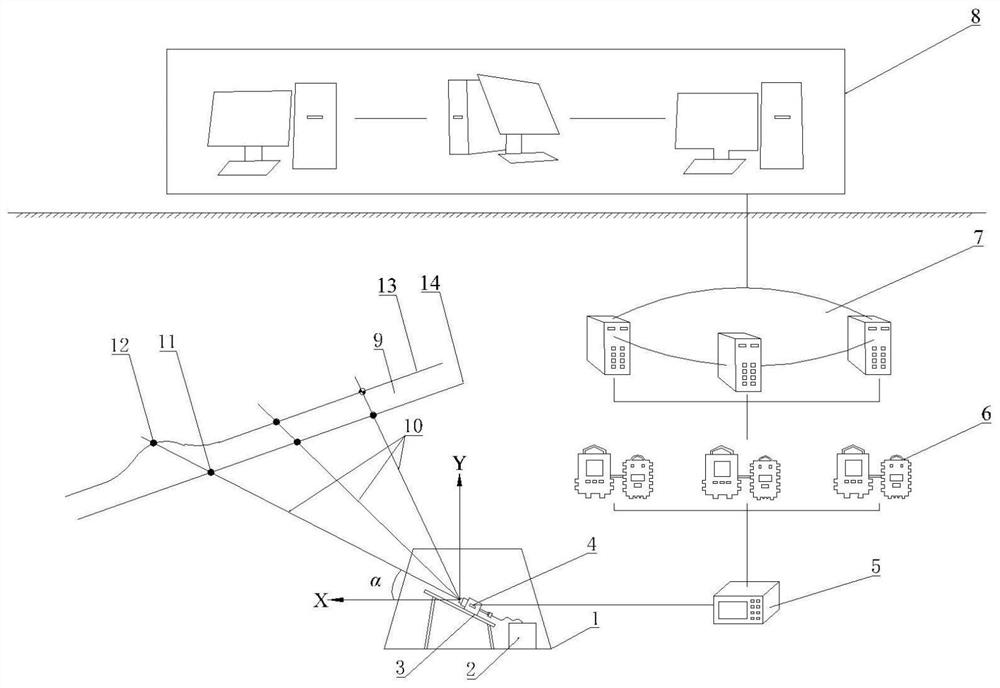

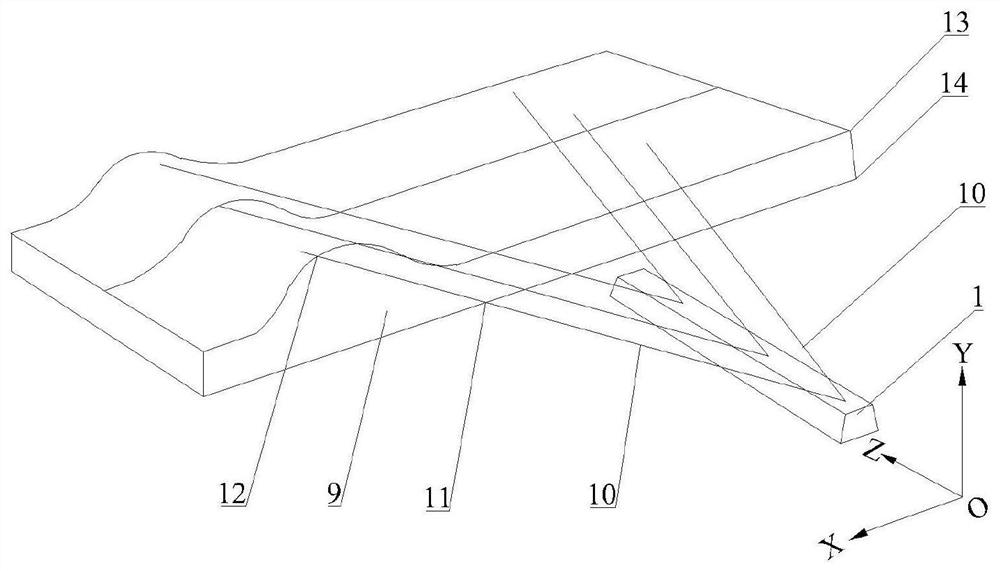

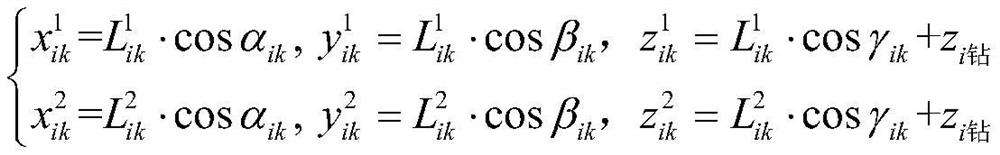

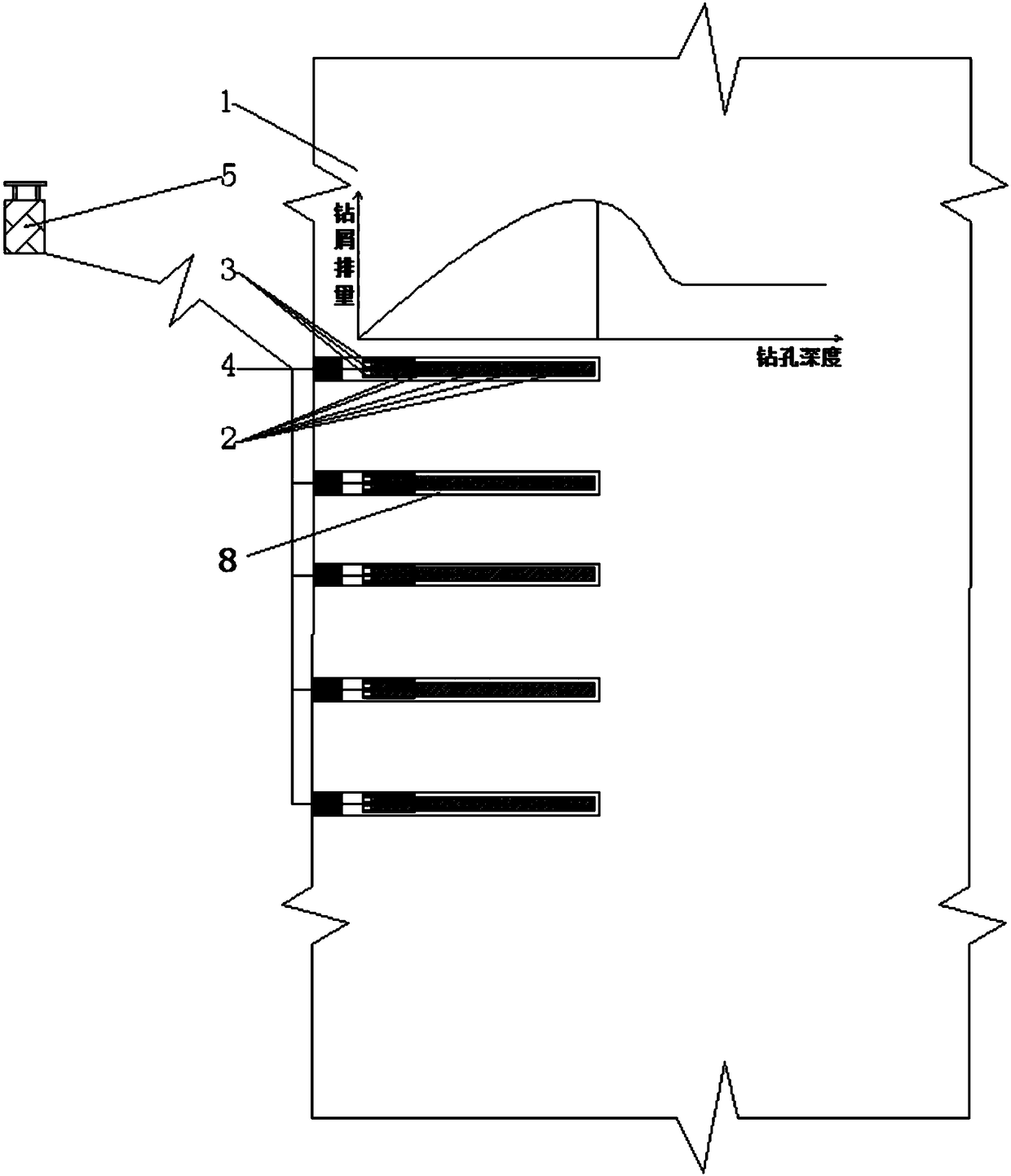

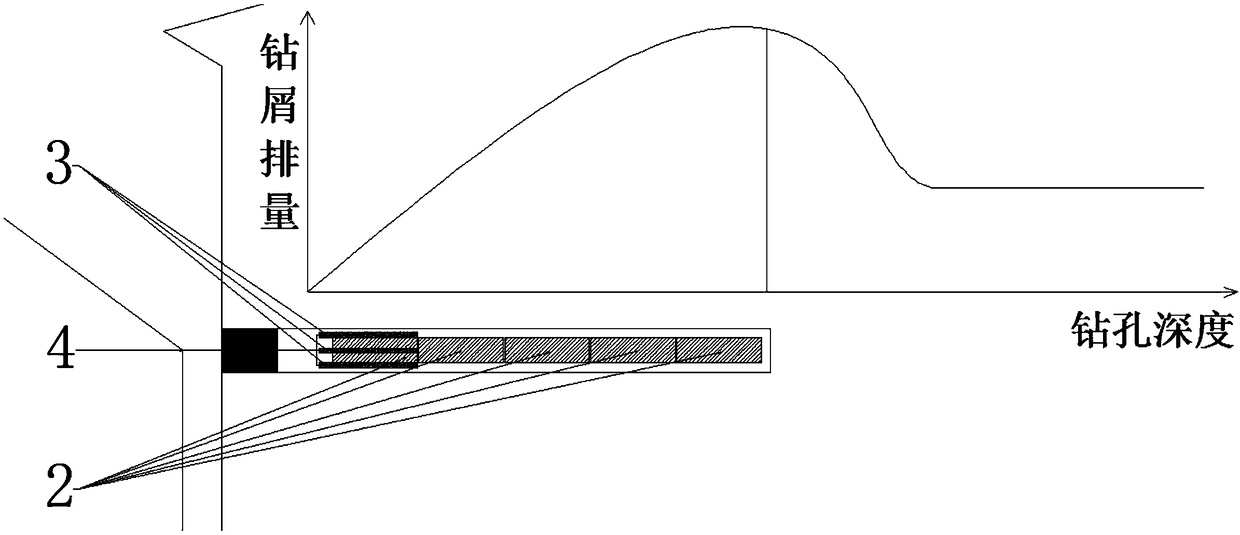

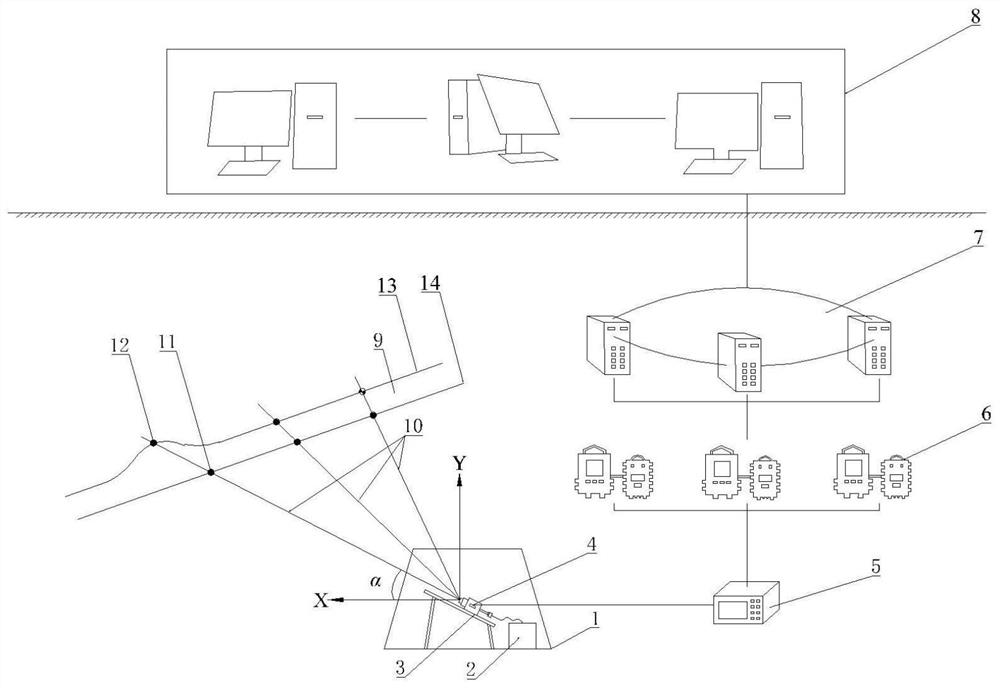

Intelligent detection device and method for coal seam occurrence distribution in regional gas control process

ActiveCN113006858AReduce outstanding riskOvercoming the large amount of constructionMining devicesGas removalThermodynamicsData acquisition

The invention discloses an intelligent detection device and method for coal seam occurrence distribution in a regional gas control process. The equipment comprises a hydraulic drilling system, a data acquisition system and a data transmission system. The method comprises the following steps of: acquiring while-drilling information in real time by utilizing the data acquisition system, and determining drilling specific work and a distance between a drill bit and a drilling machine; judging relative positions of the drill bit entering and penetrating through a coal seam according to difference characteristics of the drilling specific work; then, changing the position of the drilling machine and a construction angle according to the requirements of a coal roadway tunneling regional gas control project, and repeating the steps to obtain multiple groups of relative position information; and finally, respectively drawing interfaces between the coal seam and a top plate and between the coal seam and a bottom plate based on a cubic spline interpolation method. According to the intelligent detection device and method disclosed by the invention, a drilling technology is combined with the regional gas control project, so that the problems of large construction amount, limited test range and the like of the drilling technology are solved.

Owner:CHINA UNIV OF MINING & TECH

Anti-outburst method of pressure-relief and anti-reflection type bedding drainage for single coal seam protective layer in coal mine

InactiveCN109026132BImprove breathabilityShorten the sampling periodGas removalMining engineeringCoal mine methane

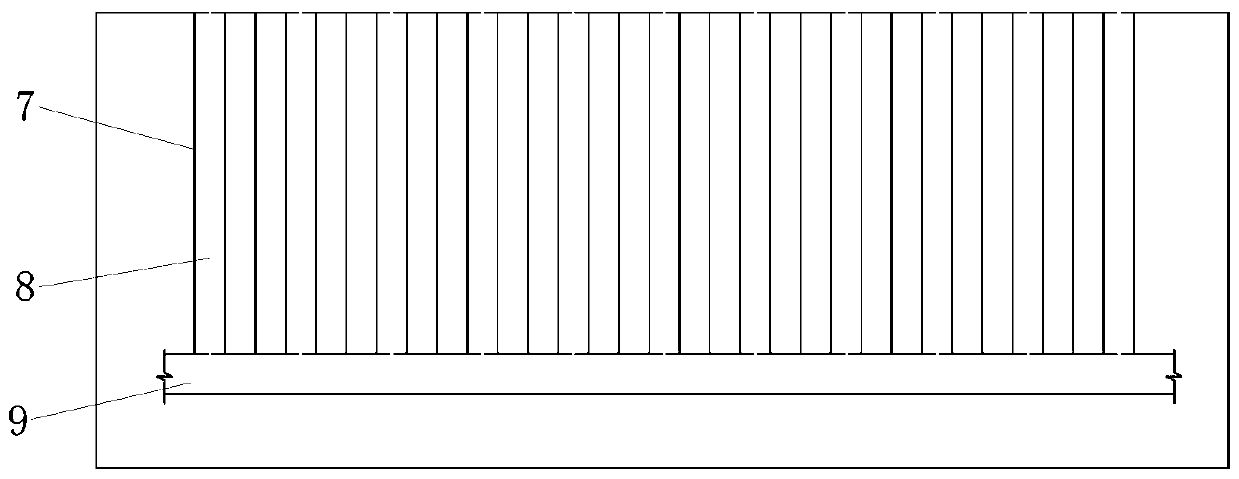

The invention belongs to the technical field of coal mine gas extraction, and particularly relates to an anti-outburst method for coal mine single coal seam protective layer pressure relief and permeability-increasing type sequential layer extraction, which comprises the following steps of: firstly, carrying out sequential layer drilling construction at the lower part of the coal wall of a tunneland vertical to the coal wall of the tunnel, forming a linear pressure relief drilling hole at the lower part of the coal wall of the tunnel, wherein the influence regions of the adjacent pressure relief drilling holes are connected with each other to form an arched shed effect pressure relief region; then, carrying out the construction of the gas extraction drilling at the upper part of the coalwall of the tunnel. According to the invention, the technical problem of sequential drilling pre-extraction coal seam gas pressure relief is effectively solved, by arranging linear dense pressure relief drilling holes at the lower part of the coal seam, the arched shed effect pressure relief region is generated, the conduction of vertical ground stress in the coal seam is effectively cut down, thecoal stress and gas gravity are redistribute, the air permeability of the coal seam can be well improved, the extraction standard period can be effectively shortened, the treatment practice of the working face can be shortened, the improvement of the gas treatment is enhanced, the safety of the mining of the coal mine can be improved, and the effect and efficiency of gas extraction can be improved.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

A low-permeability coal seam supercritical carbon dioxide permeability enhancement system and method

ActiveCN105822341BImprove permeabilityImprove output efficiencyVessel mounting detailsContainer filling methodsInjection pressureFour-way valve

The invention discloses a low permeability coal bed supercritical carbon dioxide anti-reflection system and method. The anti-reflection system comprises an extraction pipe and an injection pipe, wherein the extraction pipe and the injection pipe are sleeved with a hole packer, an extraction device is connected to the outer end of the extraction pipe through an extraction pipeline, and an extraction stop valve and a main extraction stop valve are sequentially arranged between the extraction pipe and the extraction device; an injection stop valve, an injection supercritical carbon dioxide pump, a thermostat and a carbon dioxide gas tank are sequentially connected to the outer end of the injection pipe through an injection pipeline, a high-pressure buffer tank is arranged in the thermostat, and a temperature sensor and a gas injection pressure gauge are connected to a four-way valve. The anti-reflection system is reasonable and simple in structure, convenient to implement, safe and reliable, and capable of improving the permeability of a coal bed greatly. By the adoption of the anti-reflection method, the original pore structure of the coal bed can be changed, the permeability of the coal bed can be improved greatly, coal bed gas output efficiency can be improved, extraction effect can be improved greatly, the outburst danger of the coal bed can be effectively reduced, and safe production of a coal mine can be ensured.

Owner:HENAN POLYTECHNIC UNIV

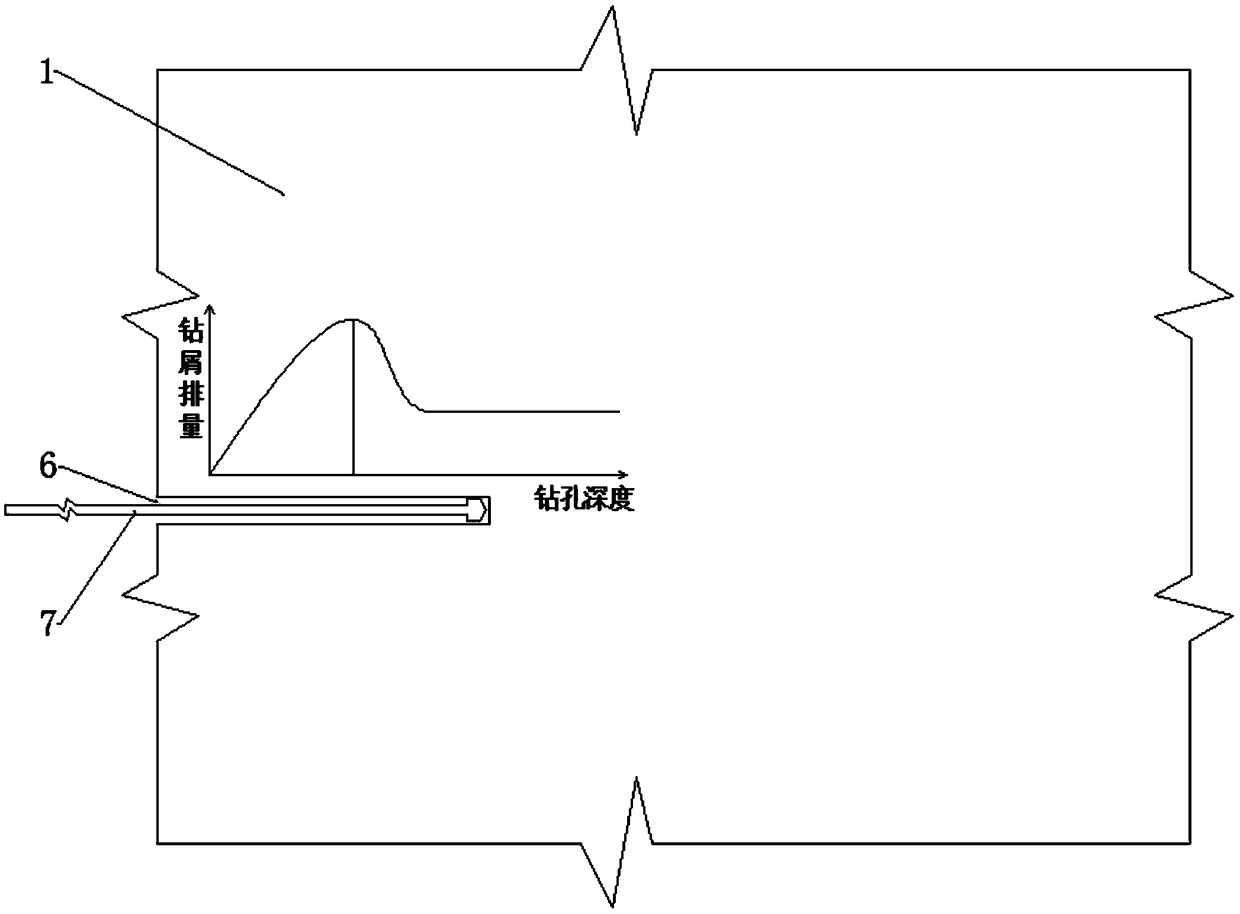

Method for deep hole blasting in coal face

A method for deep-hole blasting in coal face includes such steps as constructing test hole in coal face, testing drilling cuttings discharge during drill pipe drill operation, and taking the depth X at the maximum cuttings discharge as the position of leading stress peak in coal face, setting the drill cuttings discharge depth X at the top of drill cuttings discharge, and setting the drill cuttings discharge depth X at the bottom of drill pipe drill operation. B, the blasting hole is arranged parallel to the test hole, and the hole depth of the blasting hole is X determined in the step a; (c)load a plurality of explosive rolls and detonator into a detonation cylinder; (d) feed that detonator into the bottom of the hole according to the conventional charge method, lead out the gun line, and sealing the hole at the position of the hole; E, in accordance with b-(d) sequentially construct other blasting hole on that working surface and loading explosives; F. The connected gun line is mounted on the detonator, and the detonation is carried out by conventional method. The invention sets the blasting hole depth according to the working face stress peak position, and after the working face deep hole blasting, the stress peak position is pushed to the rear of the working face, so as to reduce the coal and gas outburst risk in the mining process of the working face.

Owner:CHINA UNIV OF MINING & TECH

Coal seam occurrence and distribution intelligent detection equipment and method in the process of regional gas control

ActiveCN113006858BReduce outstanding riskAvoid it happening againMining devicesGas removalThermodynamicsData acquisition

The invention discloses an intelligent detection equipment and method for the occurrence and distribution of coal seams in the regional gas control process. The equipment includes a hydraulic drilling system, a data acquisition system and a data transmission system. The method uses the data acquisition system to collect real-time information while drilling, and determines the specific power of drilling and the distance between the drill bit and the drilling machine; according to the difference characteristics of the specific power of drilling, the relative position of the drill bit entering and passing through the coal seam is determined; then, According to the requirements of the gas control project in the coal roadway excavation area, the location of the drilling rig and the construction angle are changed, and the above steps are repeated to obtain multiple sets of relative position information; finally, based on the cubic spline interpolation method, the interfaces between the coal seam and the roof and floor are drawn respectively. The invention combines the drilling technology with the regional gas control project, and overcomes the problems of large construction volume and limited testing range of the drilling technology.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com