Patents

Literature

64results about How to "Improve safety production factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

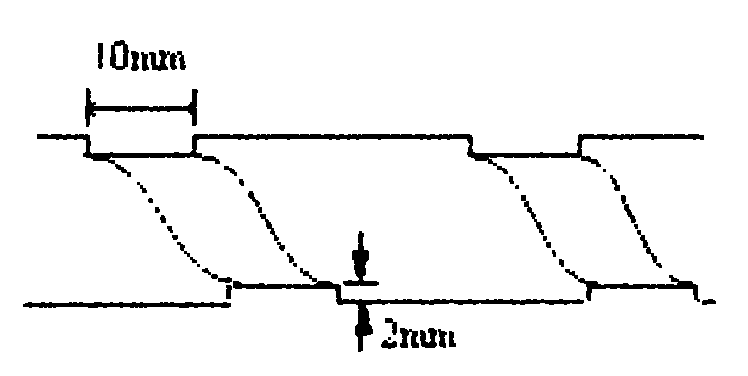

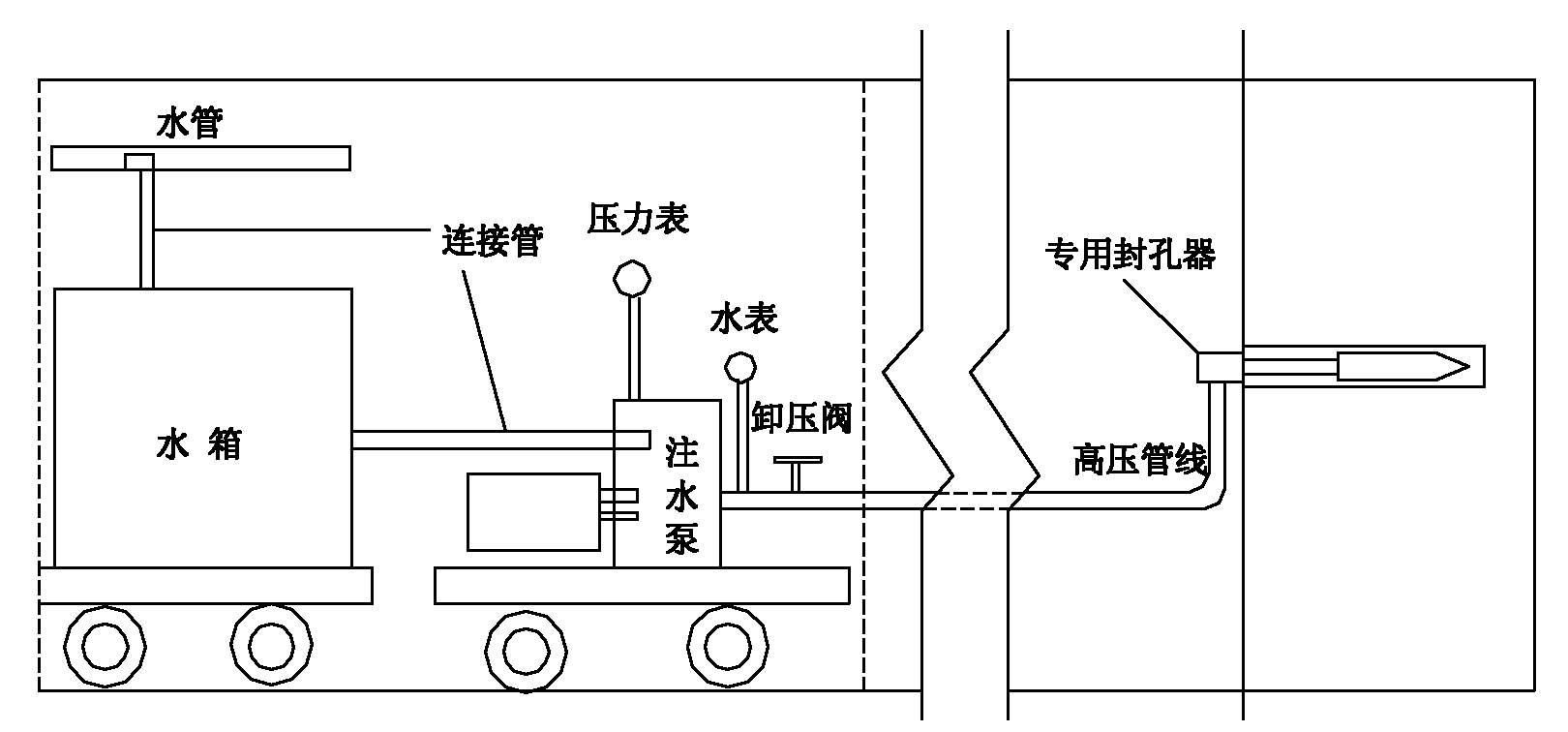

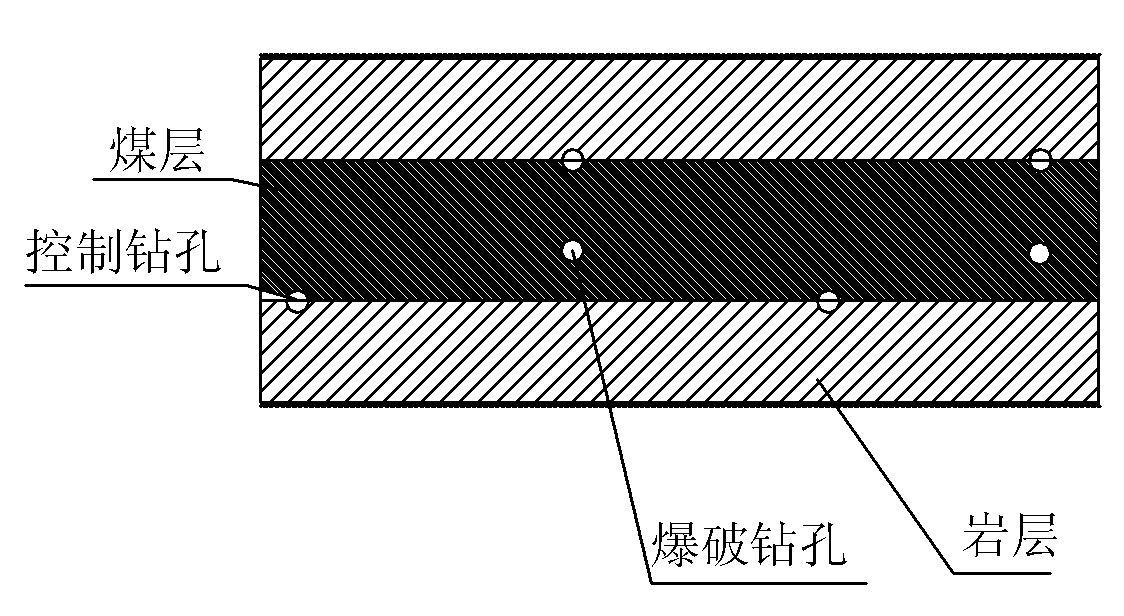

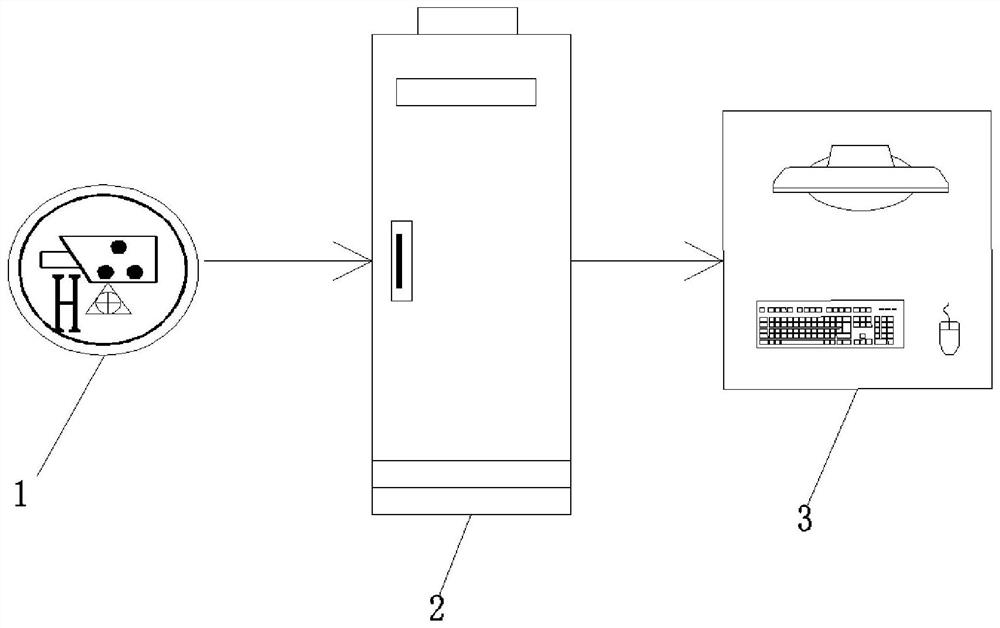

Method for integrated comprehensive management of gas in low-permeability single coal bed

InactiveCN102121395AReduce outstanding riskImprove breathabilityDrilling rodsFluid removalSocial benefitsHydraulic fracturing

The invention relates to a method for integrated comprehensive management of gas in a low-permeability single coal bed, which can effectively solve the problem of comprehensive management and utilization of the gas. A technical scheme of the method comprises the following steps of: firstly, drilling holes, wherein a high-torque drilling machine and a rifle or a trihedral drill stem are used for solving the phenomenon of clamping the drill stem caused by collapsing and jetting of the holes in the hole drilling process; and then, performing hydraulic fracturing permeability improvement on the coal body, drilling holes for pre-split blasting, performing gas drainage, and recycling the drained gas, thereby implementing the integrated management of the gas. With the method provided by the invention, the permeability of the coal body is improved, a pre-draining rate of the gas is improved, and the drained gas is recycled, so that the drilled holes are radically prevented from being blocked in the construction process, the problem of difficulties in draining the gas in the low-permeability coal bed with a drilling tool having insufficient capability in the drilling construction is solved, consequently, outburst risk of the coal and the gas is reduced, outburst accidents of the coal and the gas are reduced and even avoided, and mine production safety and lives of coal mine workers are ensured, so that the method brings great economic and social benefits.

Owner:平顶山天安煤业股份有限公司十矿

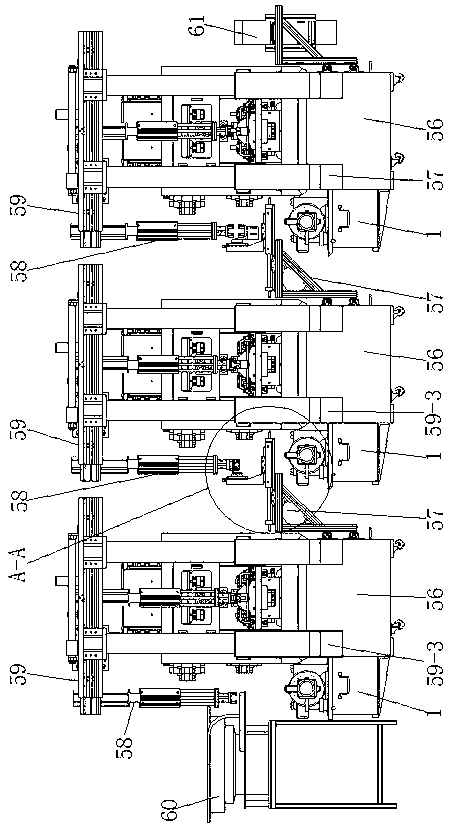

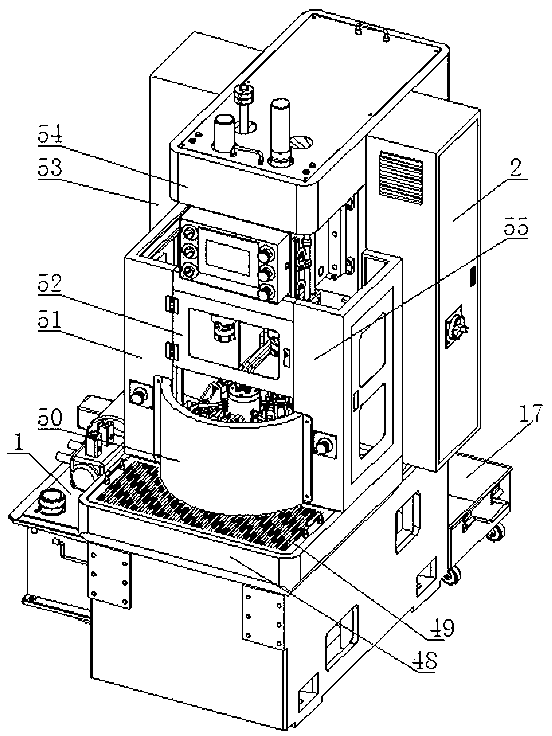

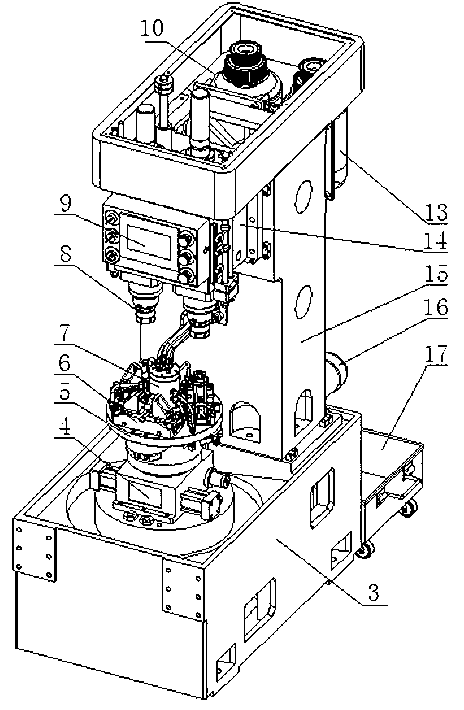

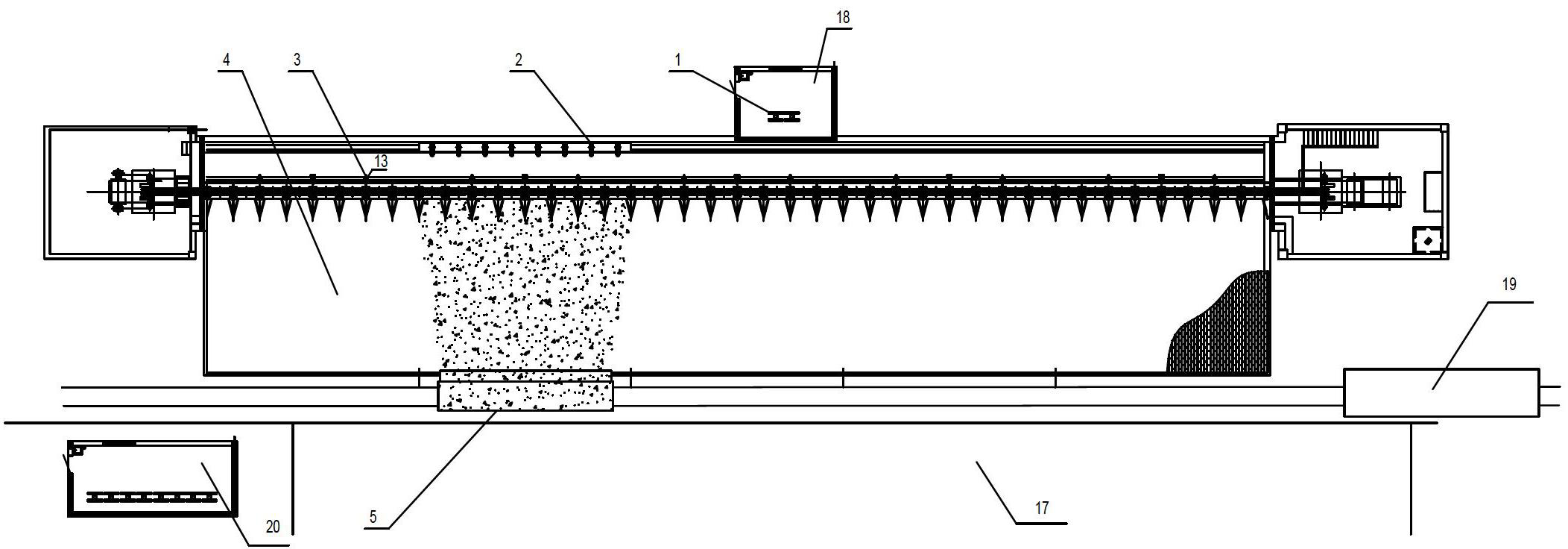

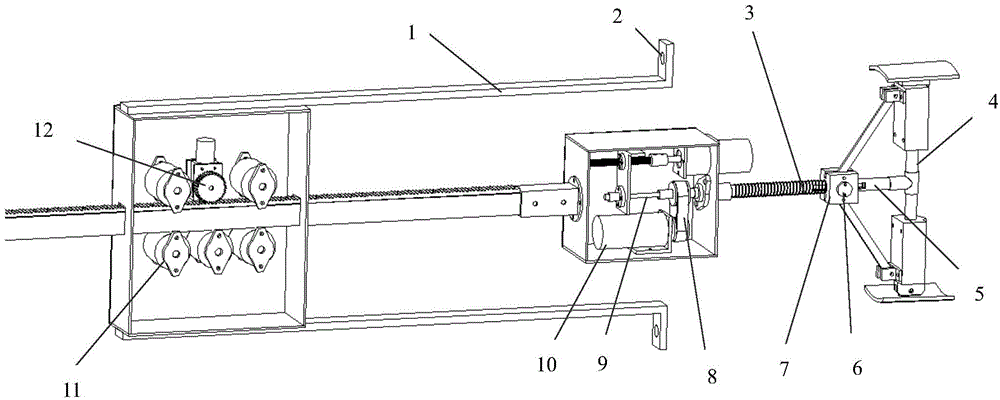

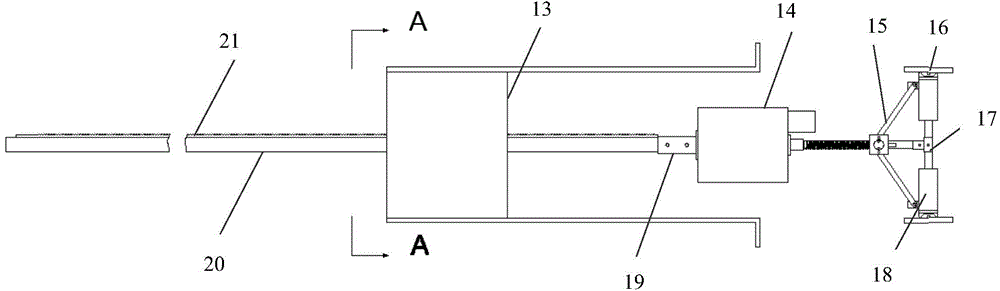

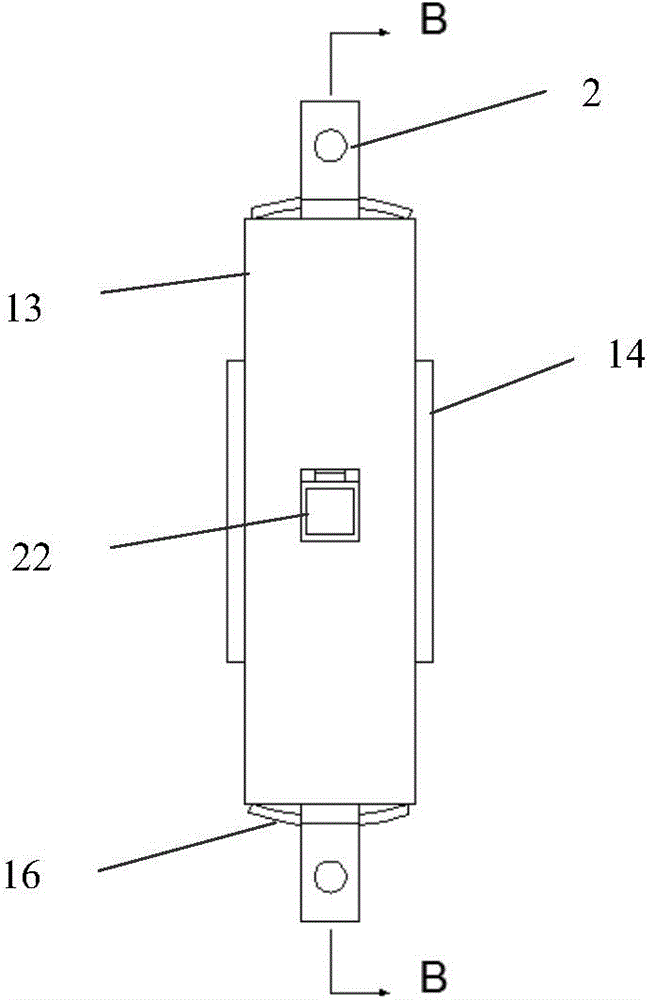

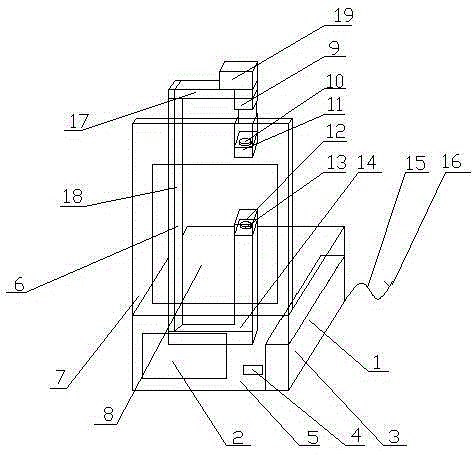

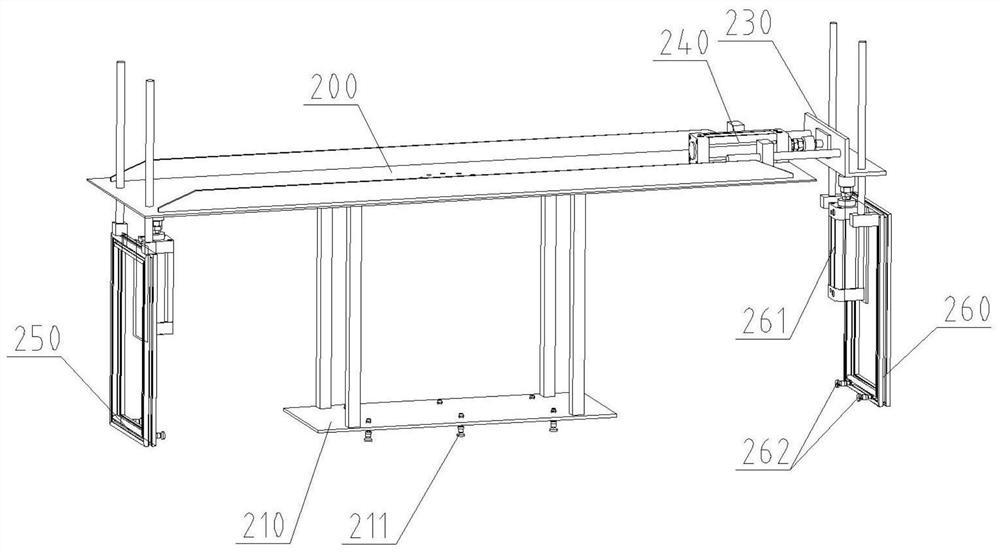

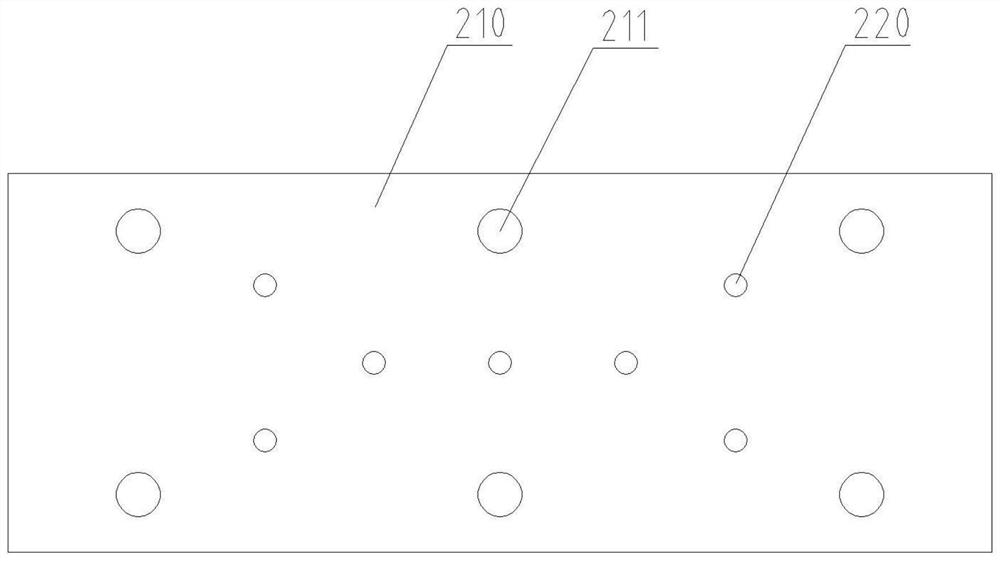

Automatic combination processing production line of double-shaft drilling machines

InactiveCN103341761AReduce allocationReduce labor costsOther manufacturing equipments/toolsLarge fixed membersProduction lineRobotic arm

The invention discloses an automatic combination processing production line of double-shaft drilling machines. The automatic combination processing production line of the double-shaft drilling machines comprises a plurality of double-shaft drilling machines, every two double-shaft drilling machines are connected through a transferring mechanism and a mechanical arm mechanism, a transverse feed mechanism is arranged on each double-shaft drilling machine, the mechanical arm mechanisms are connected with the transverse feed mechanisms, a vibrating type feed plate assembly is arranged on one side of the first double-shaft drilling machine, and a blanking mechanism is arranged on one side of the last double-shaft drilling machine. The production line is formed by conveying automatic feeding and blanking to the double-shaft drilling machines through a transferring mechanisms to carry out processing and combination in three different directions, multiple devices can be controlled by one person, and the automatic combination processing production line of the double-shaft drilling machines has the advantages of being high in producing rate, high in product quality, low in composite cost and the like, and is suitable for processing parts of multiple types on a large scale.

Owner:南安市瑜鼎投资管理有限公司

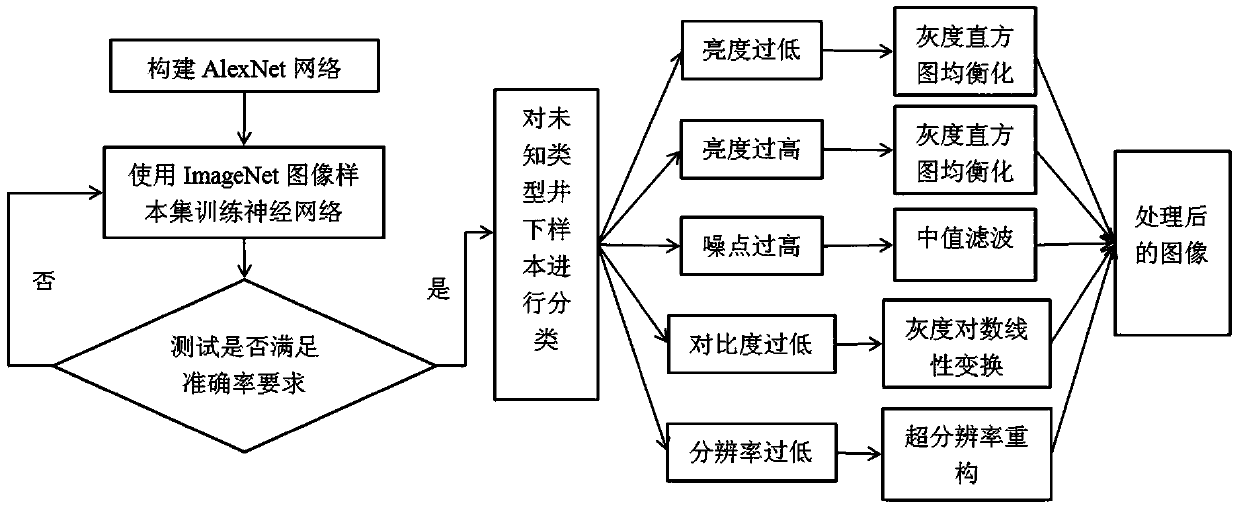

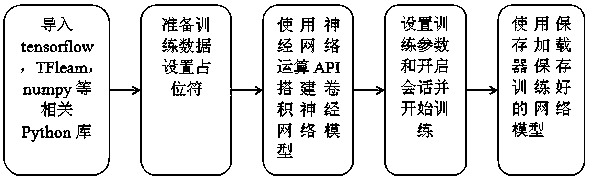

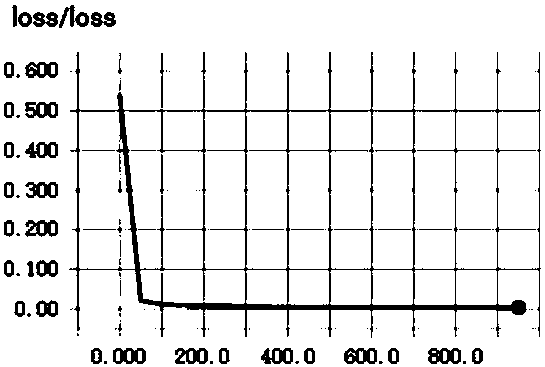

Underground coal mine image processing method based on deep neural network

InactiveCN107730473AEnhancement effect is goodImprove safety production factorImage enhancementImage analysisDisaster areaImaging quality

An underground coal mine image processing method based on a deep neural network comprises the steps of constructing an eight-layer convolutional neural network by use of an AlexNet network structure model, and completing networking training by use of a Tensorflow deep learning training framework; then, realizing training and test for the convolutional neural network subjected to initial training by use of images with five types of image quality including high brightness, low brightness, high noisy point, low contrast ratio and low resolution ratio to obtain a deep convolutional neural networkwhich can realize classification of image quality; and in combination with a mature image processing method at present, respectively adopting different types of image processing methods for images with different types of image quality. According to the underground coal mine image processing method based on the deep neural network, the content is the key problem which needs to be solved by detection visualization of a coal mine disaster area and also provides knowledge reserve and technological base for future large-scale safe mining of deep coal resources in China.

Owner:CHINA UNIV OF MINING & TECH

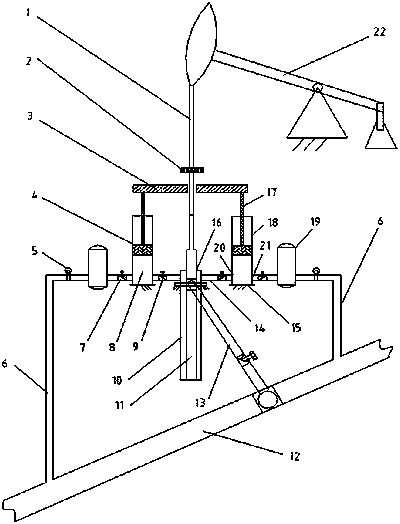

Oil well casing gas collecting device

ActiveCN102747989AAchieve compressionDynamic balance disruptionFluid removalPipeline systemsEconomic benefitsOil transportation

The invention provides an oil well casing gas collecting device. An oil pumping pipe, an oil pumping rod and a casing are arranged in an oil well, the oil pumping rod is connected onto an oil pumping unit, and the oil pumping unit pumps crude oil from the oil pumping pipe and transports the crude oil to an oil transportation pipe. The device comprises a casing connecting pipe, a one-way valve A, a boosting pump, a one-way valve B and an oil pipe connecting pipe. The boosting pump includes a connecting rod, the upper end of the connecting is fixedly connected with a pressure arm, the upper portion of the oil pumping rod is fixedly connected with a pressure button, and the pressure button is located above the pressure arm. When the boosting pump is installed, the connecting rod is parallel to the oil pumping rod, and the pressure arm is intersected with the connecting rod but is not connected with the connecting rod. When the oil pumping rod is lifted up under the driving of the oil pumping unit, casing gas drives a piston, the connecting rod and the pressure arm to move upward under the action of self pressure. When the oil pumping rod moves downward under the action of self gravity, the pressure button presses the pressure arm to drive the connecting rod and the piston to move downward, and compressed casing gas in a compression cylinder enters the oil transportation pipe. By means of the oil well casing gas collecting device, a series of problems including difficulty in traditional oil well casing gas recovering, energy waste, environment pollution, safety hazard and the like are solved. Therefore, the oil well casing gas collecting device has obvious economic benefit and environmental-protection benefit.

Owner:SHANGHAI YIJING ENERGY TECH

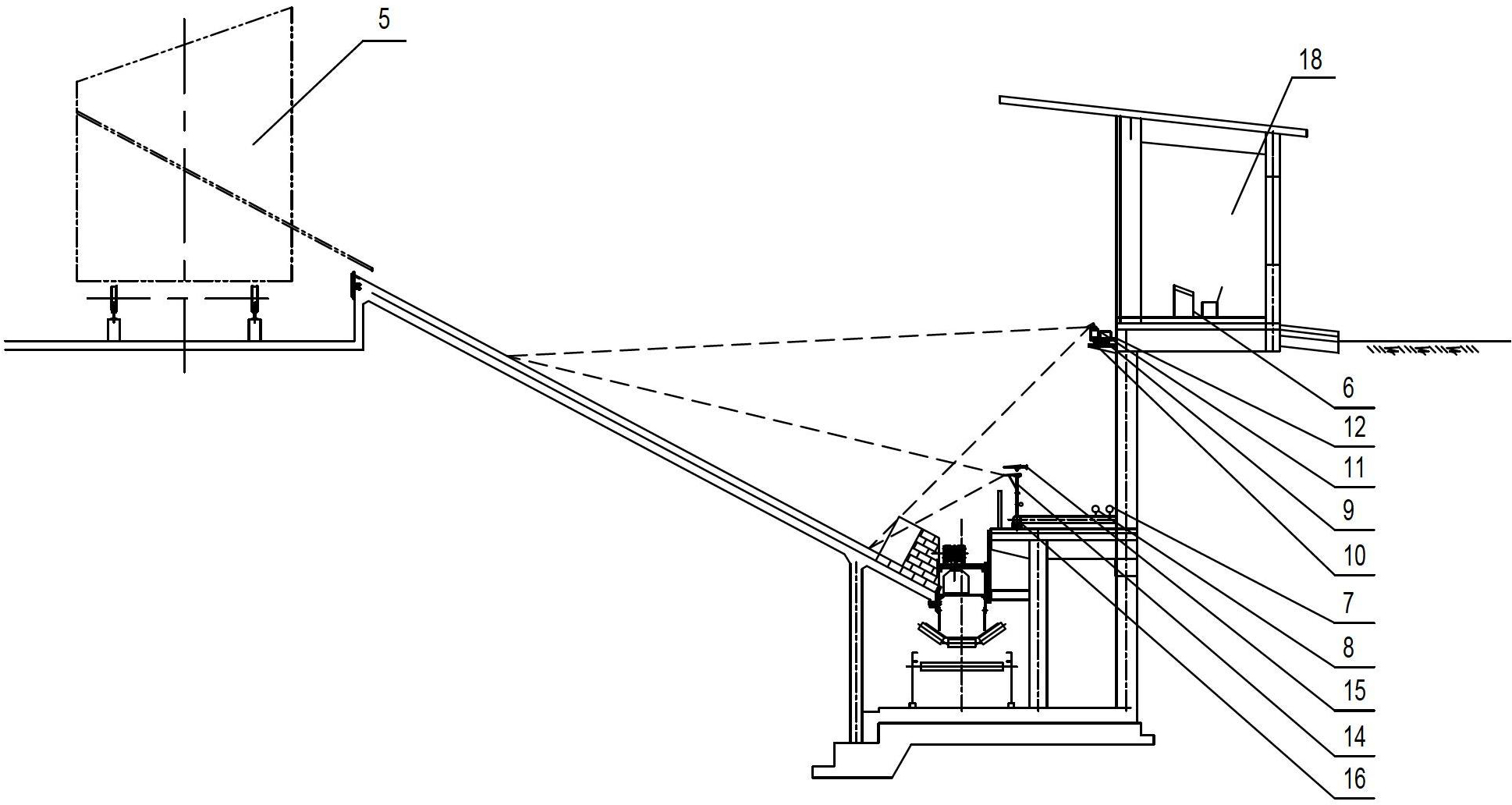

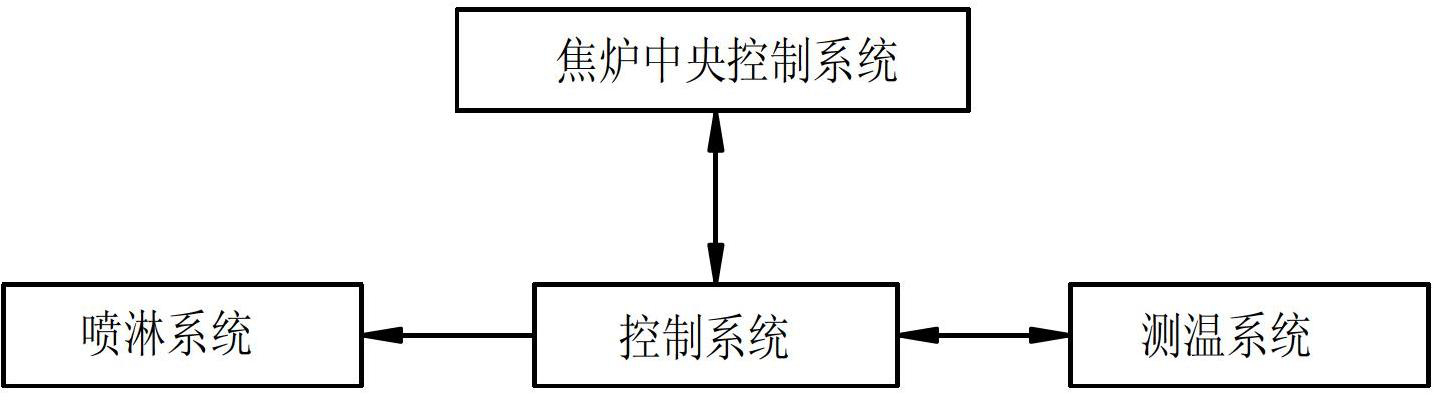

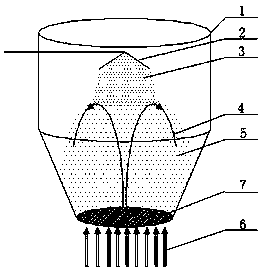

Automatic monitoring and sprinkling coke quenching system for red coke of coke wharf

InactiveCN102660305AIncrease the level of automationAvoid wastingCoke quenchingControl systemEngineering

The invention relates to an automatic monitoring and sprinkling coke quenching system for red cokes of a coke wharf. The automatic monitoring and sprinkling coke quenching system consists of a control system, a temperature measuring system and a spraying system, wherein a coke oven central control system transmits the position of a coke quenching vehicle at a coke placing section of the coke wharf to the control system; the control system instructs the temperature measuring system to perform on-line monitoring on coke put into the coke wharf by the coke quenching vehicle; if the temperature measuring system monitors that overtemperature red cokes are on the coke wharf, the position and an overtemperature value are sent to the control system immediately; the control system sends an instruction to the spraying system according to the positions of the red cokes and the overtemperature value, after the spraying system finishes operating, the temperature measuring system continues to monitor the region, and if other red cokes exist, the control system sends the instruction to the spraying system to perform circulating operation; and if the coke wharf does not have the overtemperature red cokes, the control system waits for the coke oven central control system to send the coke placing instruction of the next oven. By the automatic monitoring and sprinkling coke quenching system, the safety production coefficients and automated level of coking plant areas are improved greatly, and powerful guarantee is provided for the normal production of a coke treatment system.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Oil well casing gas collecting device

ActiveCN102747989BAchieve compressionDynamic balance disruptionFluid removalPipeline systemsEconomic benefitsOil transportation

The invention provides an oil well casing gas collecting device. An oil pumping pipe, an oil pumping rod and a casing are arranged in an oil well, the oil pumping rod is connected onto an oil pumping unit, and the oil pumping unit pumps crude oil from the oil pumping pipe and transports the crude oil to an oil transportation pipe. The device comprises a casing connecting pipe, a one-way valve A, a boosting pump, a one-way valve B and an oil pipe connecting pipe. The boosting pump includes a connecting rod, the upper end of the connecting is fixedly connected with a pressure arm, the upper portion of the oil pumping rod is fixedly connected with a pressure button, and the pressure button is located above the pressure arm. When the boosting pump is installed, the connecting rod is parallel to the oil pumping rod, and the pressure arm is intersected with the connecting rod but is not connected with the connecting rod. When the oil pumping rod is lifted up under the driving of the oil pumping unit, casing gas drives a piston, the connecting rod and the pressure arm to move upward under the action of self pressure. When the oil pumping rod moves downward under the action of self gravity, the pressure button presses the pressure arm to drive the connecting rod and the piston to move downward, and compressed casing gas in a compression cylinder enters the oil transportation pipe. By means of the oil well casing gas collecting device, a series of problems including difficulty in traditional oil well casing gas recovering, energy waste, environment pollution, safety hazard and the like are solved. Therefore, the oil well casing gas collecting device has obvious economic benefit and environmental-protection benefit.

Owner:SHANGHAI YIJING ENERGY TECH

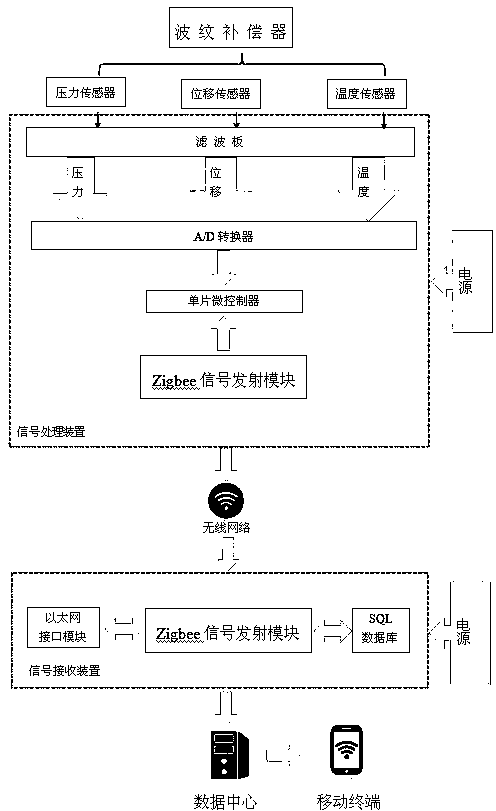

Wireless monitoring system for ripple compensator based on mobile terminal

PendingCN109358554ARealize remote real-time monitoringGet rid of the bondageProgramme controlMeasurement devicesTablet computerThe Internet

The invention discloses a fault monitoring system for a ripple compensator based on a mobile terminal, and relates to a fault monitoring system. The used method comprises several aspects of the collection, transmission, analysis, storage, display and alarm of the data. The method comprises firstly collecting the pressure, displacement and temperature signals of the ripple compensator during operation by a high-performance sensor; secondly, carrying out filtering, converting and the like on the collected signals and sending to a mobile terminal such as a mobile phone or a tablet computer Bluetooth through a wireless network or Bluetooth, so as to display the information on the interface in real time; finally, an alarm is issued when the data is abnormal, thereby reminding the staff to dealin time. Moreover, the system can send the operation state of the ripple compensator to a monitoring host through the Internet, thereby realizing the interconnection of objects and objects, people andthings. Therefore, production accidents caused by the failure of the ripple compensator can be effectively avoided, and the safety production coefficient can be improved.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

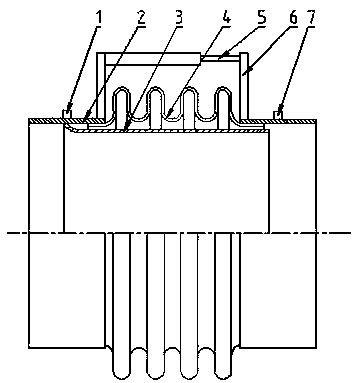

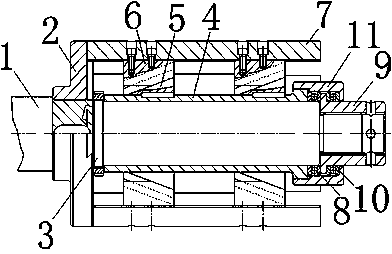

Hand-operated expansion mechanism for unreeling machine for stainless steel strip coil

The invention discloses a hand-operated expansion mechanism for an unreeling machine for a stainless steel strip coil. The mechanism comprises a transmission shaft, a sliding sleeve and a circular arc plate, wherein the sliding sleeve is arranged on the transmission shaft in a sliding manner; a round plate sliding block is arranged at one end of the transmission shaft; a telescopic nut is arranged at the other end of the transmission shaft; the circular arc plate is arranged on the side surface of the round plate sliding block in a sliding manner; a plane thrust ball bearing is arranged between the telescopic nut and the sliding sleeve; a sliding block expansion mechanism is arranged between the sliding sleeve and the circular arc plate; a lower sliding block and the sliding sleeve, an upper sliding block and the circular arc plate are connected through self-locking bolts. The mechanism has the advantages that diameters of a roll head can be adjusted quickly and accurately through the telescopic nut, so as to be suitable for stainless steel strip coils of different specifications; the mechanism is high in universality, simple to operate, and low in labor intensity; the stainless steel strip coil is in stable operation without retraction, so that the safety production ratio is increased greatly.

Owner:WUHU XINLI PIPELINE TECH

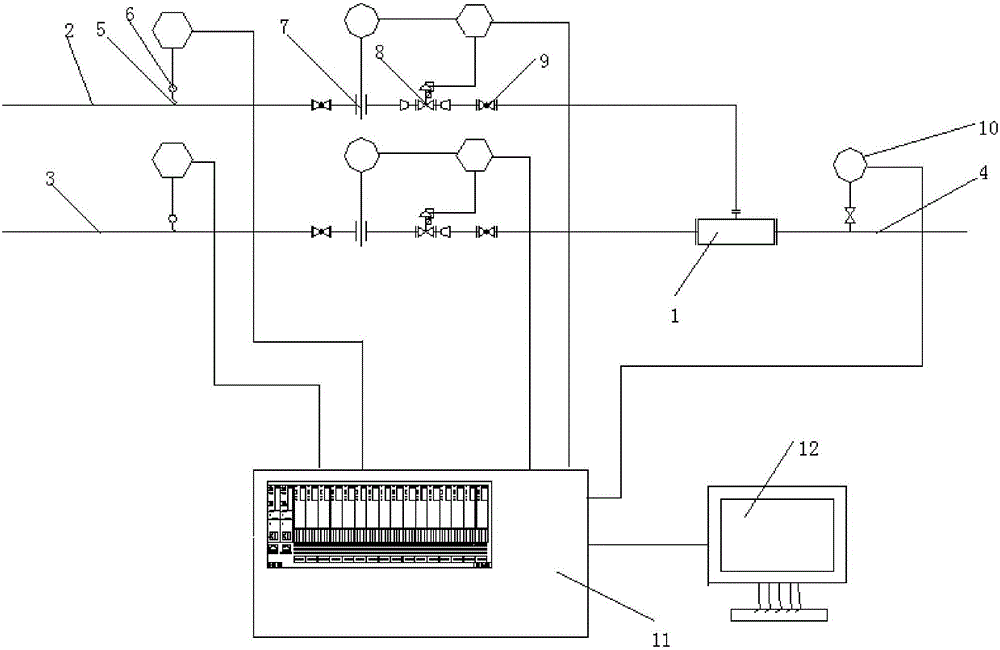

Method for preparing odorless and transparent 107 glue at ordinary pressure

The invention provides a method for producing 107 glue at ordinary pressure. The method comprises the following steps that S1, a raw material is added to a dehydration kettle for dehydration and then added to a polymerization reaction kettle; a catalyst is added under stirring and reacts; S2, a deionized aqueous solution mixed with H3PO4 or AcOH is added to a product obtained by reaction in Step S1 for degradation reaction; and S3, a product obtained in Step S2 is stirred and extruded by a twin-screw glue discharge machine with a vacuum port, wherein the temperature in the twin-screw glue discharge machine is 160-170 DEG C, and the catalyst is KOH, NaOH or LiOH. The method adopts the strong alkaline catalyst, so that the product is more transparent, and no yellowing or fishy smell exists in a produced RTV (room temperature vulcanization) product via testing.

Owner:矽时代材料科技股份有限公司

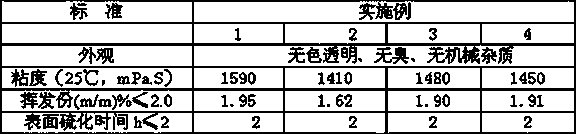

Ultra-thin float glass production line tin bath protective gas intelligent control system

The invention discloses an ultra-thin float glass production line tin bath protective gas intelligent control system. intelligent control system comprises a hydrogen supply pipeline, an oxygen supply pipe and a mixing gas loop; a pressure transmitter, a temperature sensor, a flow transmitter, an electric regulating valve, and a pneumatic intercepting valve are respectively arranged on the hydrogen supply pipeline and the oxygen supply pipeline in order, a gas purity analyzer is arranged in the mixing gas loop; the pressure transmitter, the temperature sensor, the flow transmitter, the electric regulating valve, and the pneumatic intercepting valve and the gas purity analyzer are respectively connected with a PLC controller, and a DCS controller is connected with the PLC controller. According to the invention, the gas purity analyzer is used for accurately analyzing the hydrogen content, safety production coefficient is increased, and the gas flow entering into the tin bath can be accurately controlled through control of PID.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

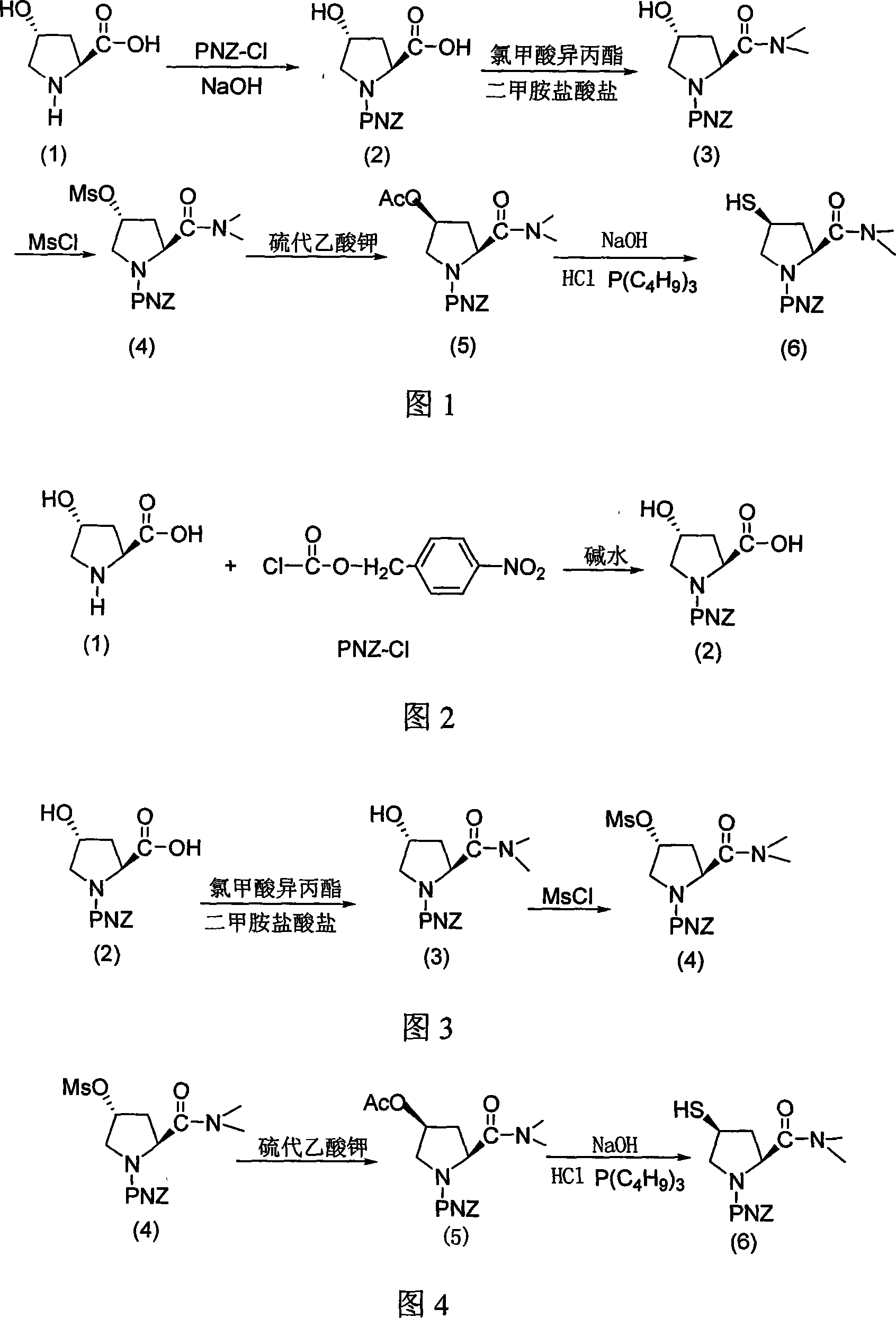

Method for synthesizing meropenem intermediate

InactiveCN101225069ASave man hoursReduce energy consumptionOrganic chemistrySide chainSynthesis methods

The invention provides a synthesis method of a side chain H of a meropenem, which is characterized in that a new radical is introduced respectively for three functional groups of 4R hydroxy L hydroxyproline and a certain spatial configuration is kept. The synthesis method for the side chain H of a meropenem has the advantages of moderate process conditions, stable product quality, and high yield, which is applicable to the industrial production on a large scale.

Owner:TIANJIN JINGYE FINE CHEM

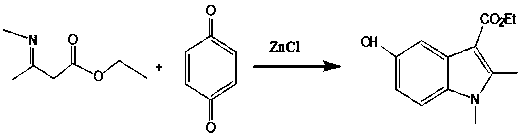

Automatic cleaning device for inner wall of porcelain bottle of high-voltage circuit breaker

An automatic cleaning device for the inner wall of a porcelain bottle of a high-voltage circuit breaker comprises a cleaning mechanism, a rotation control mechanism and a horizontal-movement control mechanism. The rotation control mechanism is used for controlling the cleaning mechanism to rotate, and the horizontal-movement control mechanism is used for controlling the cleaning mechanism to move horizontally. The cleaning mechanism comprises a hollow main shaft, a main slider, an auxiliary slider and a drawing rod. The front end of the hollow main shaft is connected with one end of a sliding rod, the auxiliary slider is arranged at the other end of the sliding rod, the main slider is arranged on the hollow main shaft, and the main slider is connected with the auxiliary slider through a connection rod. The end, far from the hollow main shaft, of the auxiliary slider is provided with a wiping plate used for cleaning the inner wall of the porcelain bottle of the high-voltage circuit breaker. The hollow main shaft is sleeved with a spring. The drawing rod and the hollow main shaft form a front-back moving pair. The rear end of the drawing rod is connected with a telescopic control mechanism enabling the drawing rod to move back and forth. The automatic cleaning device is safe, effective, high in work efficiency and low in cost.

Owner:浙江银福电器有限公司

Suspension type spot welder with protection plate

The invention provides a suspension type spot welder with a protection plate. The suspension type spot welder comprises a spot welder, wherein the spot welder comprises a workbench, a spot welder bracket, an upper electrode, a lower electrode, an upper protection cover and a lower protection cover, wherein the spot welder bracket comprises a support rod, a T-shaped support rod and a connection rod; a protection plate is mounted at the upper end of the workbench; an observation window is formed in the protection plate. Compared with the prior art, the suspension type spot welder with the protection plate has the beneficial effects that the upper protection cover and the lower protection cover are closed when not working, thereby preventing the dust from entering the upper electrode and the lower electrode and avoiding the danger caused by the dust in the spot welding process; a welding part is arranged at the upper end of the lower electrode and is positioned when working; a telescopic hydraulic rod is controlled to rise and fall, thereby driving the upper electrode to weld the welding part; through the protection plate on the workbench, the harm to workers during spot welding is reduced. The suspension type spot welder with the protection plate is simple in structure, convenient to operate and accurate in spot welding; the safety coefficient of production is increased.

Owner:CHONGQING LAM WELDING EQUIP

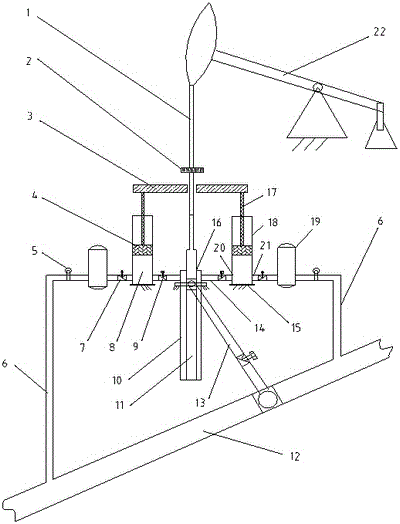

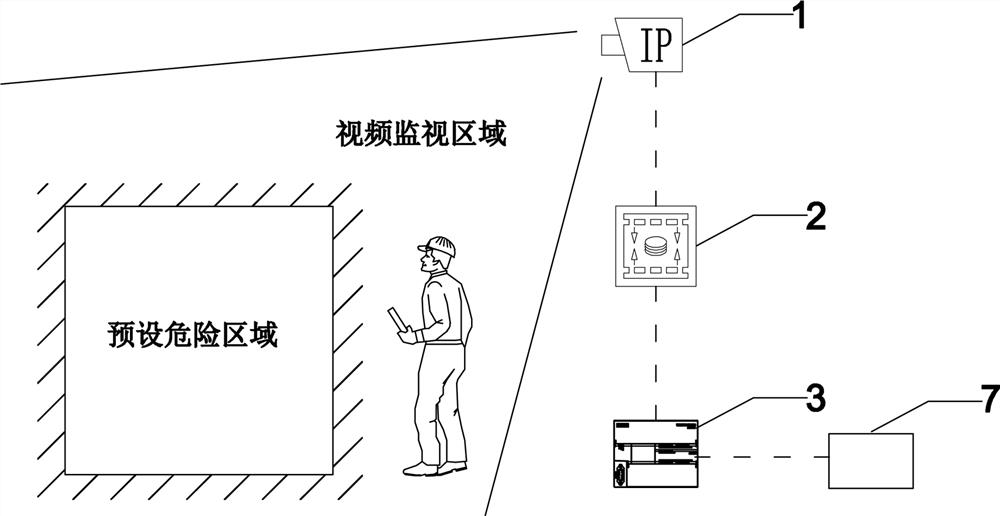

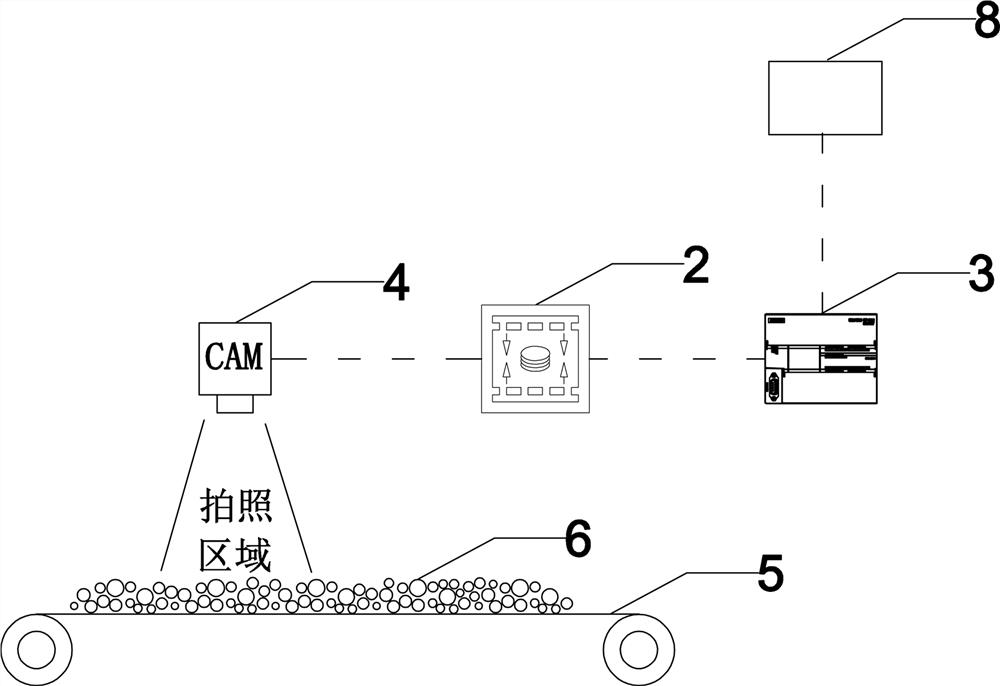

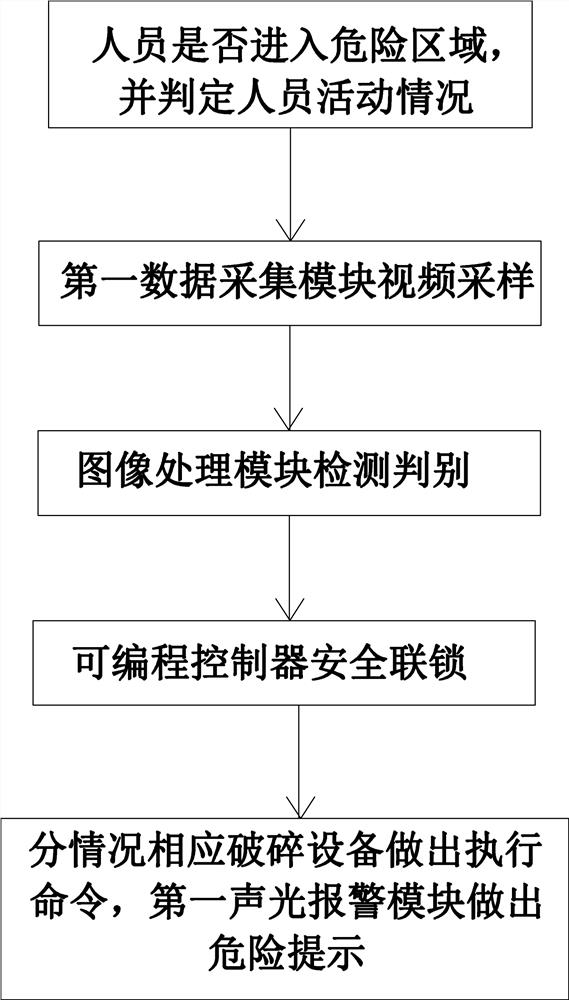

Unattended system and method for aggregate crushing equipment

ActiveCN111804421AImprove the safety production environmentImprove safety production factorGrain treatmentsImage manipulationVisual perception

The invention discloses an unattended system and method for aggregate crushing equipment. The system comprises a dangerous area monitoring part, a discharge size monitoring part, an image processing module and a programmable controller. The method comprises the steps of determining and warning a production dangerous area of the crushing equipment, and performing online detection on the qualified rate of the product size after being crushed. The unattended system comprises safety protection and visual detection, the conditional decision of the safe operation of the equipment is reinforced, thevisual detection technique is introduced, and the detectability of the safe operation and intermediate products of the equipment is increased; the safety of the equipment environment is combined witha production automation control system, so that the safety production coefficient of a production line is increased, and the product detection is implemented in advance; and the safety production environment can be effectively increased, the detection function is realized in advance, and the product online detection is introduced in advance.

Owner:洛阳耐锐机械设备有限公司

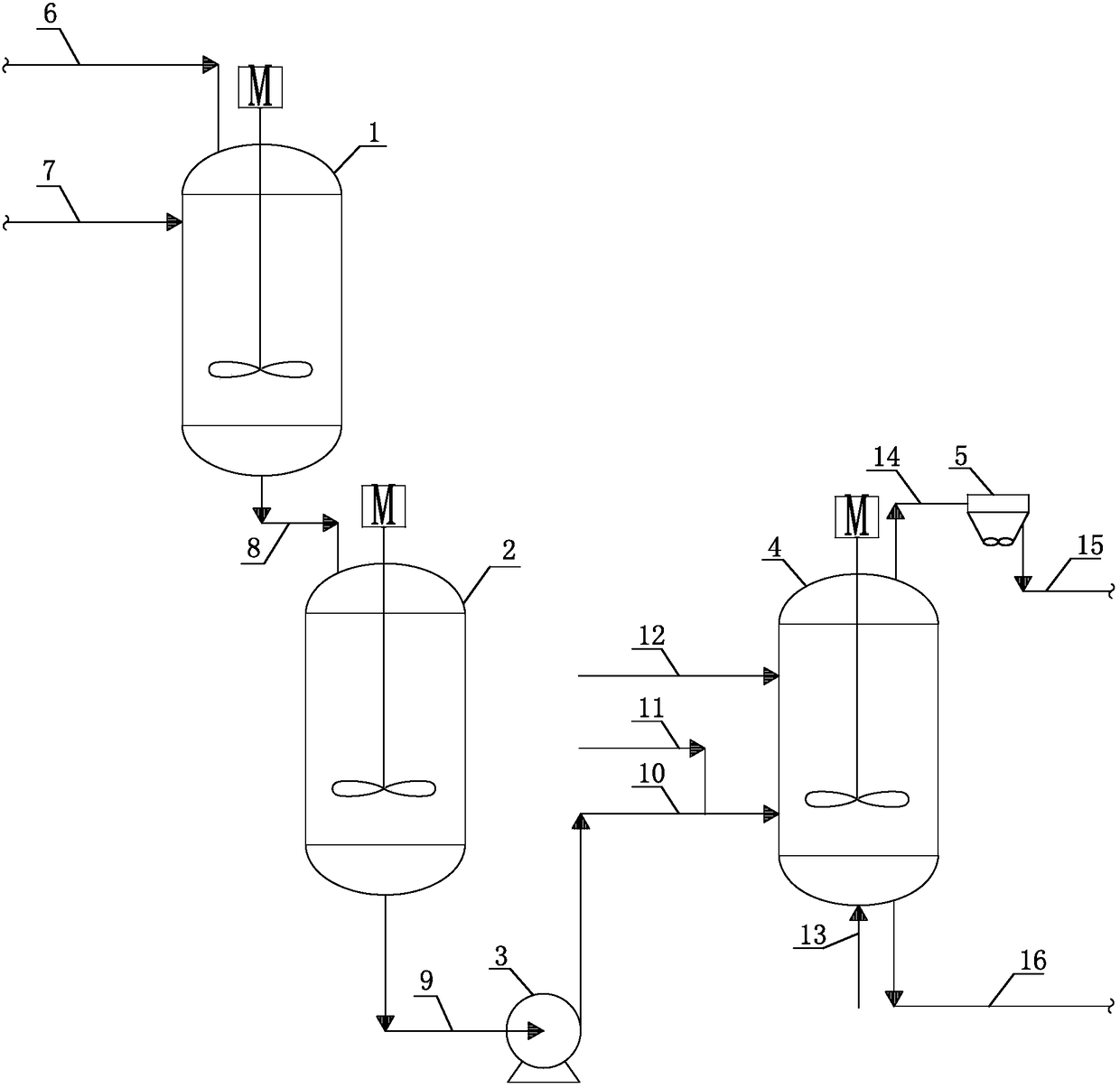

Steam stripping agent system for removing solvent in halogenated butyl rubber

The invention relates to a steam stripping agent system for removing a solvent in halogenated butyl rubber, and belongs to the technical field of petroleum chemical engineering. The steam stripping agent system comprises a steam stripping agent preparation tank, a steam stripping agent buffer tank, a steam stripping agent conveying pump, a halogenation flash tank and an air cooler, wherein the steam stripping agent preparation tank is communicated with the steam stripping agent buffer tank through a tank communication line; the steam stripping agent buffer tank is communicated with the steam stripping agent conveying pump through a tank-pump communicating line; the steam stripping agent conveying pump is communicated with the halogenation flash tank through a second material inlet pipe; the halogenation flash tank is communicated with the air cooler through a vapor phase conveying pipe. By adopting the technique, the steam stripping agent system has the advantages that the amount of residual solvent carried in rubber particles is reduced, the influence to the environment by the exhausted solvent gas in the post-treatment procedure is reduced, the safety production coefficient is improved, and the wall-hanging condition of rubber liquid in the halogenation flash tank is relieved; the purposes of improving the operation property of the device and the product property, decreasingmaterial consumption and reducing pollution to environment are realized.

Owner:SHANDONG QILU PETROCHEM ENG

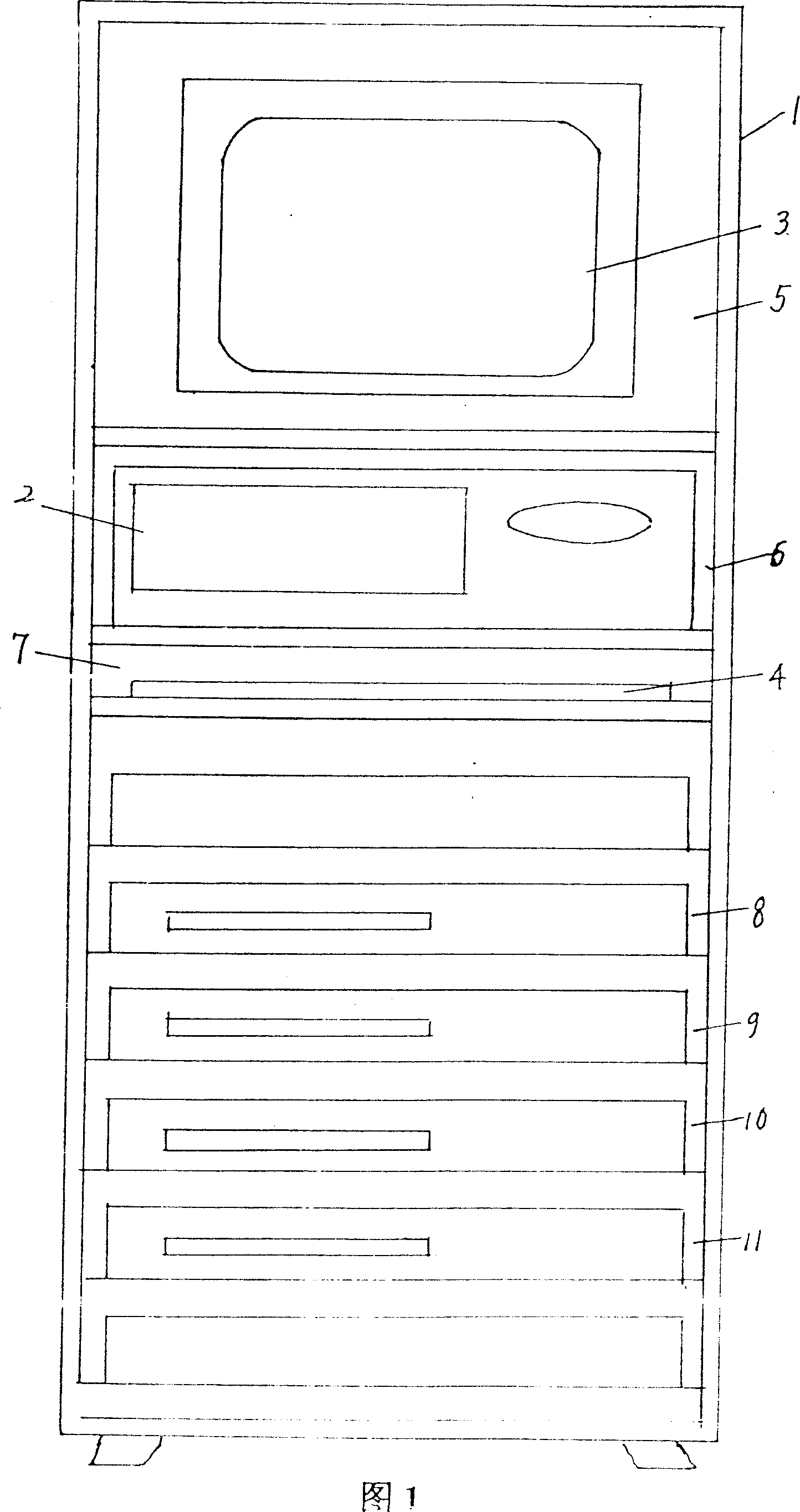

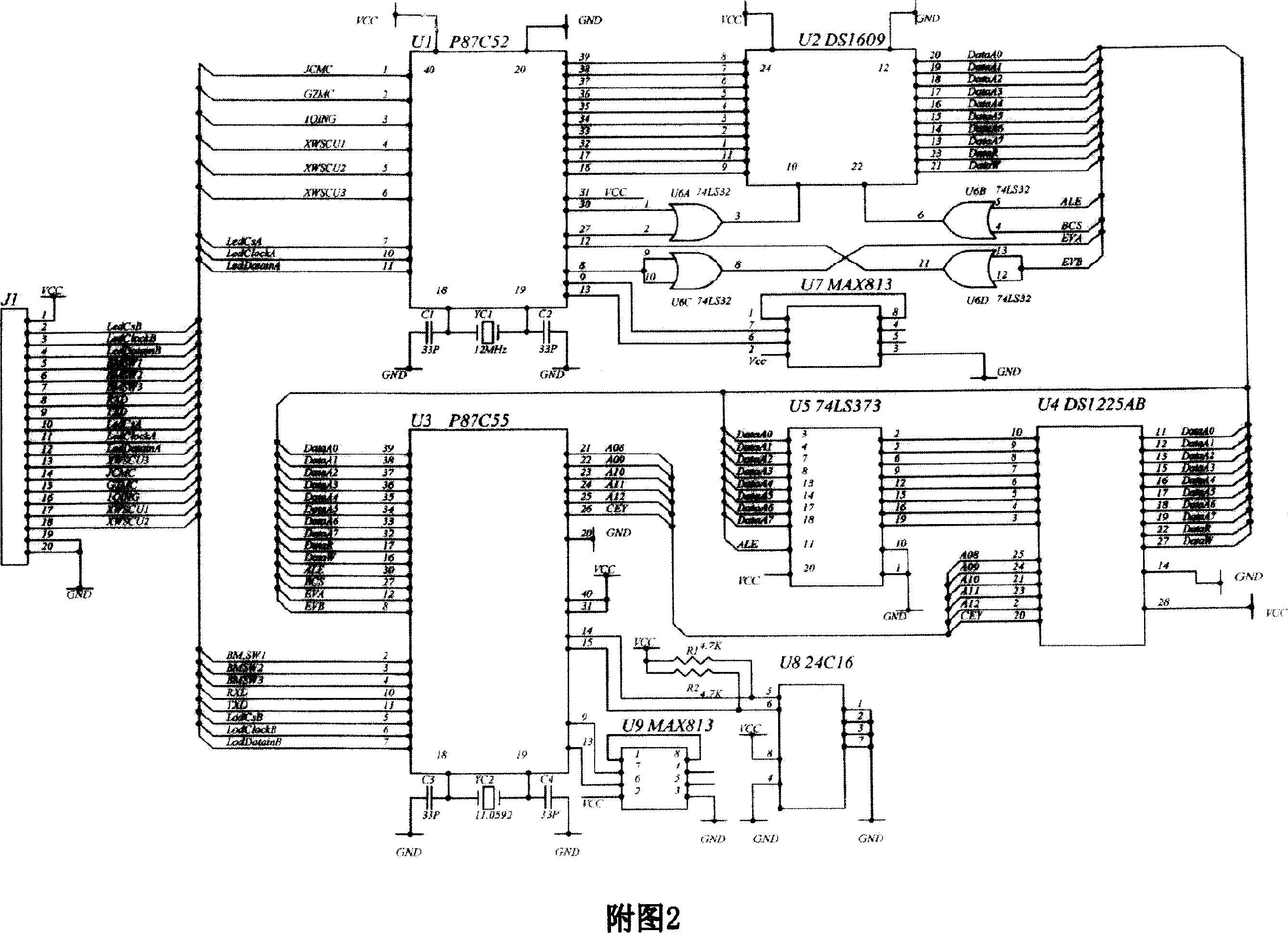

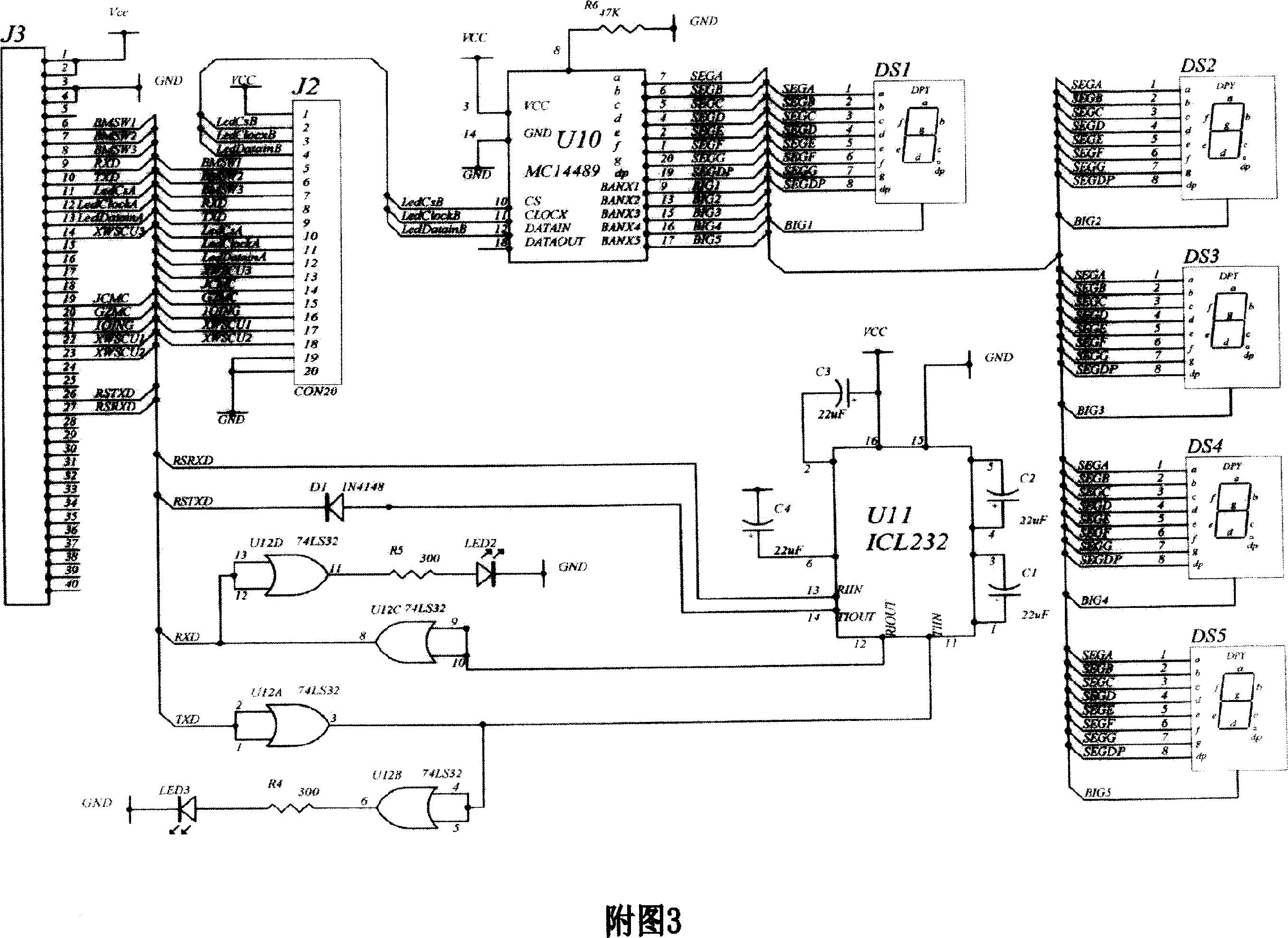

Limit controller of flame cutting vehicle

InactiveCN1971464AFully automatedReduce labor intensityAC motor controlComputer controlComputer moduleEngineering

A flame cutting vehicle block includes rack, host machine, monitor, keyboard and mouse, control component that characterized in that said control component comprises four similar flow control modules of the circuit unit, the four similar flow control modules are connected with serial port of computer by cable, and connected with on-site variable-frequency control by connector, every flow control module includes work detecting control circuit, length display communication control circuit and variable-frequency control frequency display and outgoing control circuit, the four flow control modules are mounted in the rack. The invention can limit control four flow flame cutting vehicles at the same time with high accuracy and distance, the production capability, production efficiency, product quality and economic profit can be increased greatly. Otherwise, coefficient of safety is high, operation is simple, and labor intensity of workers can be lightened.

Owner:毕鹏飞

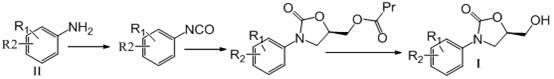

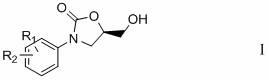

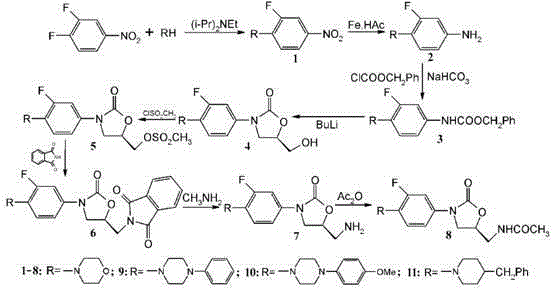

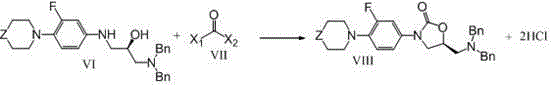

Preparation method of 3-substituted phenyl-5-hydroxymethyloxazolidine-2-ketone

ActiveCN102321042AAvoid harsh reaction conditionsIncrease profitOrganic chemistryBulk chemical productionBiochemical engineeringKetone

The invention discloses a preparation method of 3-substituted phenyl-5-hydroxymethyloxazolidine-2-ketone. The preparation method comprises the following steps: carrying out condensation reaction on substituted aniline which is used as a starting material and 3-sustituted-1,2-propanediol so as to synthesize an intermediate (R)-(+)-3-substituted phenylamino-1,2-propanediol; and preparing 3-substituted phenyl-5-hydroxymethyloxazolidine-2-ketone through two-step reaction, wherein the obtained product 3-substituted phenyl-5-hydroxymethyloxazolidine-2-ketone is an important intermediate used for commercially producing oxazolidinone antibacterial agents. The method for preparing 3-substituted phenyl-5-hydroxymethyloxazolidine-2-ketone through two-step reaction has the characteristics of less steps, cheap and available raw materials, mild reaction conditions and the like, and is simple to operate; and by using the method in the invention, production efficiency is improved, production energy consumption is reduced, safe production coefficient is improved, production cost is reduced, environment pollution is reduced, thus the method in the invention is an environmentally-friendly low-carbon green synthesis method.

Owner:SUZHOU JINGYE MEDICINE & CHEM

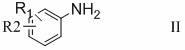

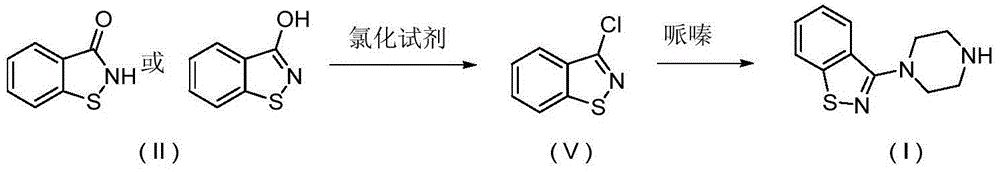

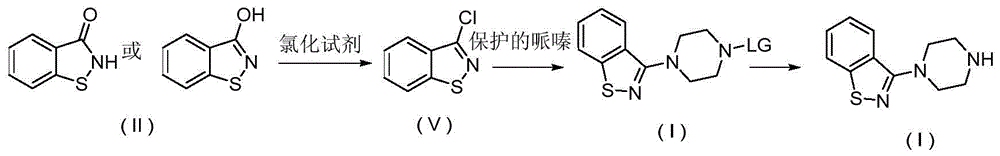

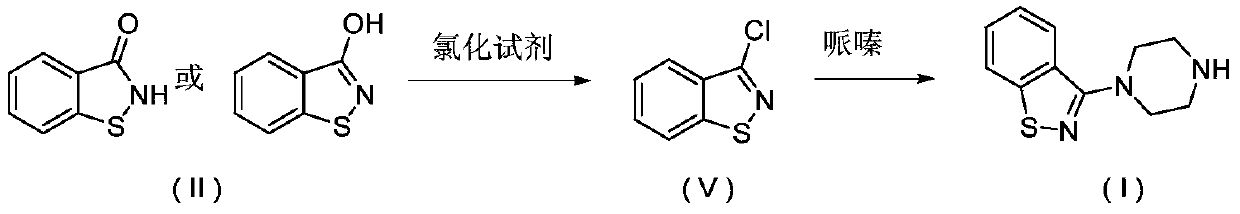

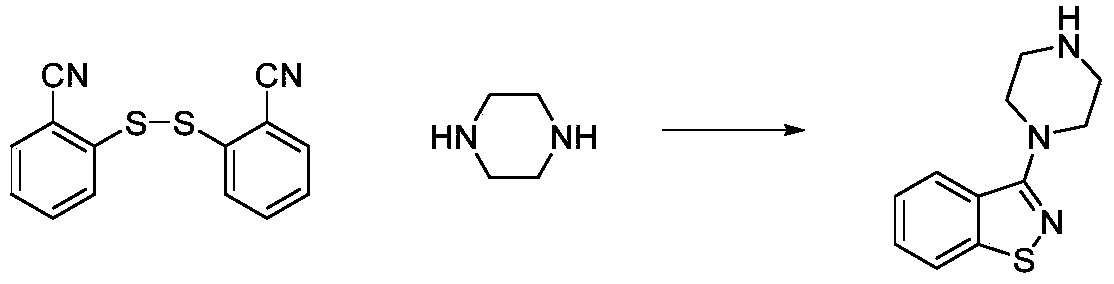

Ziprasidone key intermediate preparation method

The present invention relates to a ziprasidone key intermediate preparation method, wherein benzo[d]isothiazole-3-ol (or one) is adopted as a raw material, and reacts with a substituted sulfonyl chloride or anhydride under an alkaline condition to obtain benzo[d]isothiazole-3-substituted sulfonate, and the benzo[d]isothiazole-3-substituted sulfonate reacts with piperazine to prepare the ziprasidone key intermediate 3-(1-piperazinyl)-1,2-benzoisothiazole. The method of the present invention has characteristics of simple operation, easily available raw materials, less byproducts, simple post-treatment, less industrial three-waste and the like, and is especially suitable for industrial production.

Owner:SHANGHAI TIANCI BIOLOGICAL VALLEY BIOLOGICAL ENG

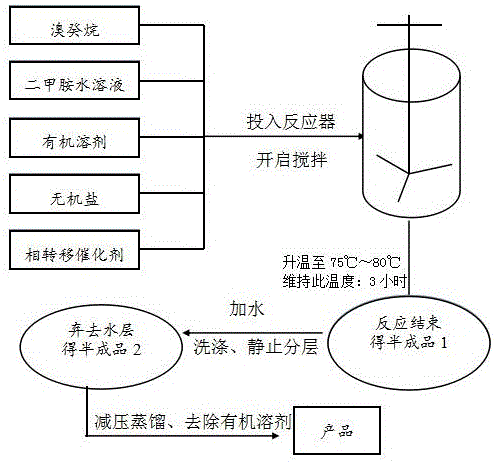

Preparation method of brominated double long chain quaternary ammonium bactericide crude drugs for livestock

InactiveCN106366001ALow reaction temperatureLow requirements for production equipmentOrganic compound preparationChemical recyclingSURFACTANT BLENDCrude drug

The invention discloses a preparation method of brominated double long chain quaternary ammonium bactericide crude drugs for livestock. The preparation method uses bromoalkane and a dimethylamine agueous solution as starting material, completes synthesis of the target product at 80 DEG C under normal pressure status through action of a catalyst, and thereby solves the problems that requirements for production equipment are high and security risk is high when methyl bromide is used; uses a home-made high molecular surfactant as the catalyst, recycles the catalyst, and thereby reduces production cost; can be widely used in breeding environment disinfection, utensil disinfection and aquaculture water disinfection.

Owner:四川创美克科技有限公司

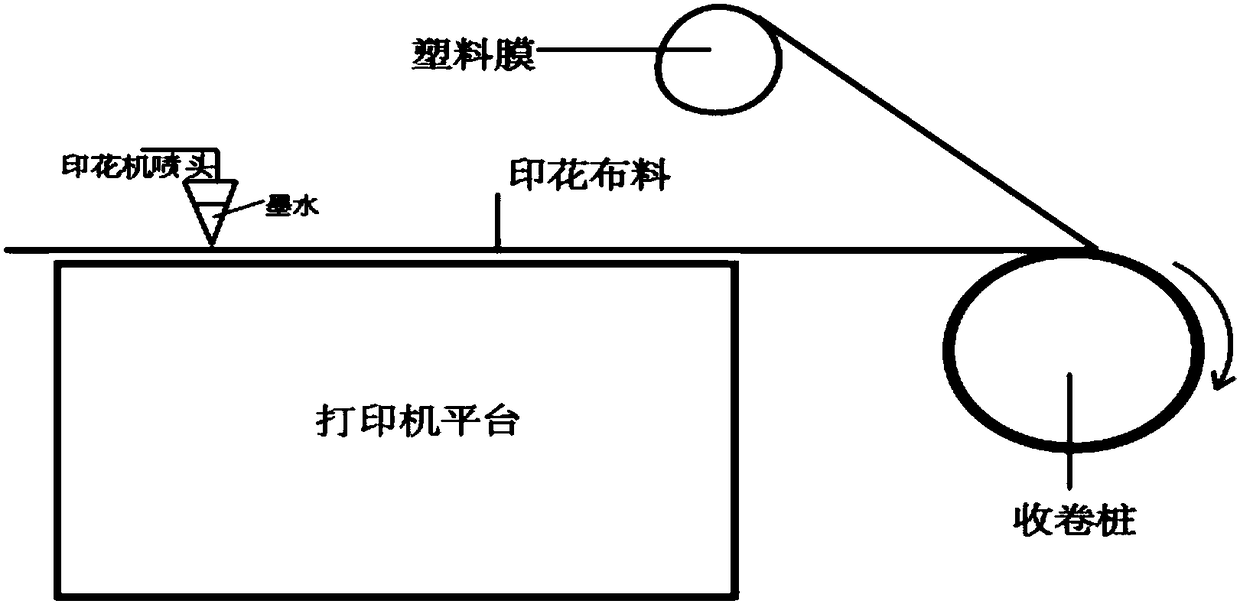

A kind of cellulose fiber cold fixation color digital printing method

InactiveCN106283757BLow costReduce total timeDyeing processVegetal fibresRoom temperatureEngineering

The invention discloses a cold color-fixing digital printing method for cellulosic fibers, which comprises the following steps: (1) selecting of a reactive dye ink; (2) preparation for cloth conditioning: subjecting cellulosic fiber cloth to a double-nip-double-dip process by means of a padder containing a padding solution with pick-up controlled in a range of 75-80%; (3) digital printing: printing patterns on the cloth that is previously treated in step (2) by using the selected reactive dye ink by means of a digital printing material; (4) cold color fixation: simultaneously rolling the pattern printed cloth with a layer of plastic film, and placing the roll at room temperature for 5-6 hours, thereby completing the color fixation. The cold color-fixing digital printing method for cellulosic fibers is simple and convenient in operation of process, high in flexibility, high in efficiency and low in cost with effects of energy conservation and emission reduction.

Owner:浙江彩伦数码科技有限公司

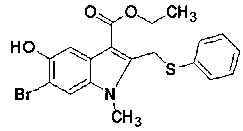

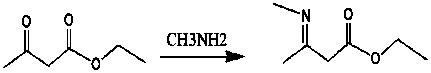

Preparation method of arbidol intermediate

ActiveCN111269168ASimple and fast operationHigh yieldOrganic chemistryCarboxylic acidMethyl palmoxirate

The invention discloses a preparation method of an arbidol intermediate. Ethyl acetoacetate, monomethylamine and p-benzoquinone used as initial raw materials undergo methylation, cyclization, acetylation, bromination and benzene vulcanization to prepare the target compound ethyl 5-hydroxy-6-bromo-2-phenylthiomethyl-1-methylindole-3-carboxylate. The preparation method of the arbidol intermediate issimple and convenient to operate, cheap and easily available in raw materials, high in yield, low in cost, good in quality, environment-friendly, mild in reaction condition, high in safety productioncoefficient and suitable for large-scale industrial production.

Owner:SUZHOU JINGYE MEDICINE & CHEM

Roll vacuum heat treatment cleaning equipment

Owner:SHANDONG HONGMIN ROLLER MOLD

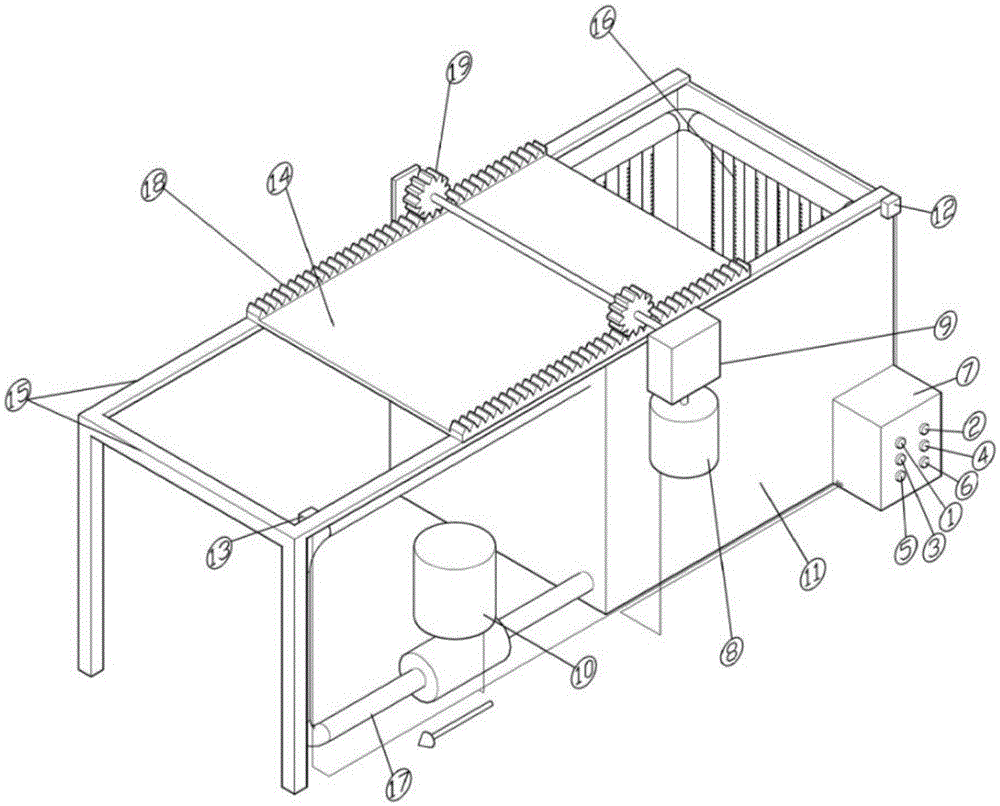

Fan outer packing boxing system and control method thereof

PendingCN112193534AHigh motion positioning accuracyAvoid damagePackaging automatic controlIndividual articlesCartonStructural engineering

The invention relates to the field of fan production equipment, in particular to a fan outer packing boxing system and a control method thereof. The fan outer packing boxing system comprises a robot module, a material frame, an inclined positioning table, a secondary positioning table and a conveying line, wherein the material frame, the inclined positioning table, the secondary positioning tableand the conveying line are arranged around the robot module, the material frame is provided with a positioning structure, and the conveying line is provided with a left centering module and a right centering module. According to the fan outer packing boxing system and the control method thereof, boxing is carried out by a robot, so that the working efficiency is improved, and the labor cost is saved; and the positioning precision of the action of the robot is high, so that the phenomenon that a carton is damaged during manual operation is avoided, and the utilization rate of the carton and thebeauty of the appearance of a fan are guaranteed.

Owner:青岛星华智能装备有限公司

Method for reducing dehydrolincomycin in lincomycin hydrochloride

InactiveCN108409812AEasy to recycleNo solid waste generatedSugar derivativesSugar derivatives preparationHydrogenation reactionLincomycin Hydrochloride

The invention discloses a method for reducing dehydrolincomycin in lincomycin hydrochloride, and the method comprises the following steps: S1, dissolving lincomycin hydrochloride in purified water with the weight of 2 to 4 times of the weight of the lincomycin hydrochloride to obtain an aqueous solution; S2, adding a Raney nickel catalyst with the weight of 1 / 10 of the weight of the lincomycin hydrochloride to the aqueous solution of the step S1; S3, introducing hydrogen into the aqueous solution of the step S2 for reaction for 6-8h to obtain a reaction liquid; S4, filtering the reaction liquid to filter out the Raney nickel catalyst to obtain a filtrate; S5, using purified water to wash the reaction liquid attached to the surface of the Raney nickel catalyst away to obtain a washing liquid; and S6, combining the filtrate and the washing liquid, and crystallizing to obtain the lincomycin hydrochloride; the method adopts the Raney nickel catalyst for hydrogenation reaction, the cost issuccessfully reduced, and the method is suitable for industrial production; the hydrogenation reaction is carried out under normal pressure, and the safety production coefficient is improved.

Owner:XINYU PHARM CO LTD

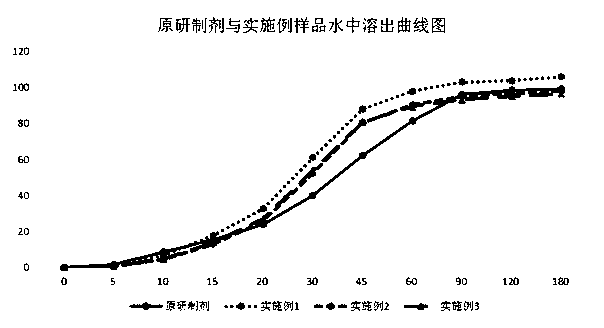

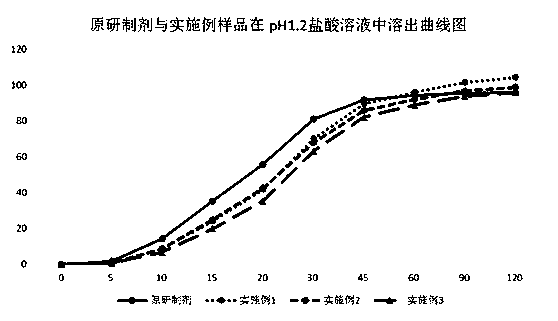

Indapamide capsule preparation method

ActiveCN110123775AGood molding effectNot easy to cause pollutionOrganic active ingredientsGranular deliveryHard CapsuleMedicine

The invention relates to an indapamide capsule preparation method. The method includes steps: preparing granulation liquid, performing top-spraying one-step granulation with a fluidized bed, screeningdried granules, well mixing with a lubricant, and finally filling the granules in hard capsule shells to obtain indapamide capsules. The method has advantages that process steps are reduced, preparation time is shortened, airtight equipment is adopted for preparation in a whole production process, and accordingly pollution to the environment and operating personnel can be avoided, and productionefficiency is remarkably improved; air inlet temperature is 70 DEG C or below, and the method is low in potential safety hazards in production and suitable for industrial production and has advantagesof low energy consumption, high safety production coefficient and the like; problems of poor mixing uniformity and nonuniformity in release in a wet granulation process are solved, high granule formability and high controllability of process parameters in the production process are realized, influences of manual operation are reduced, medicine quality stability is improved, and the problem of content uniformity disqualification or low dissolution rate of products is solved.

Owner:珠海润都制药股份有限公司

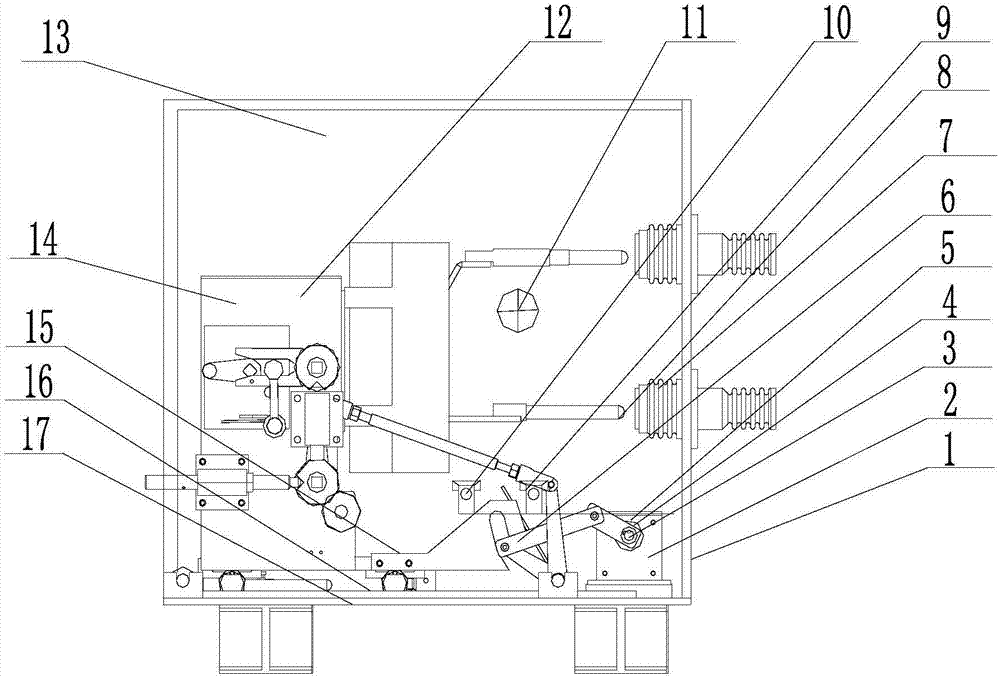

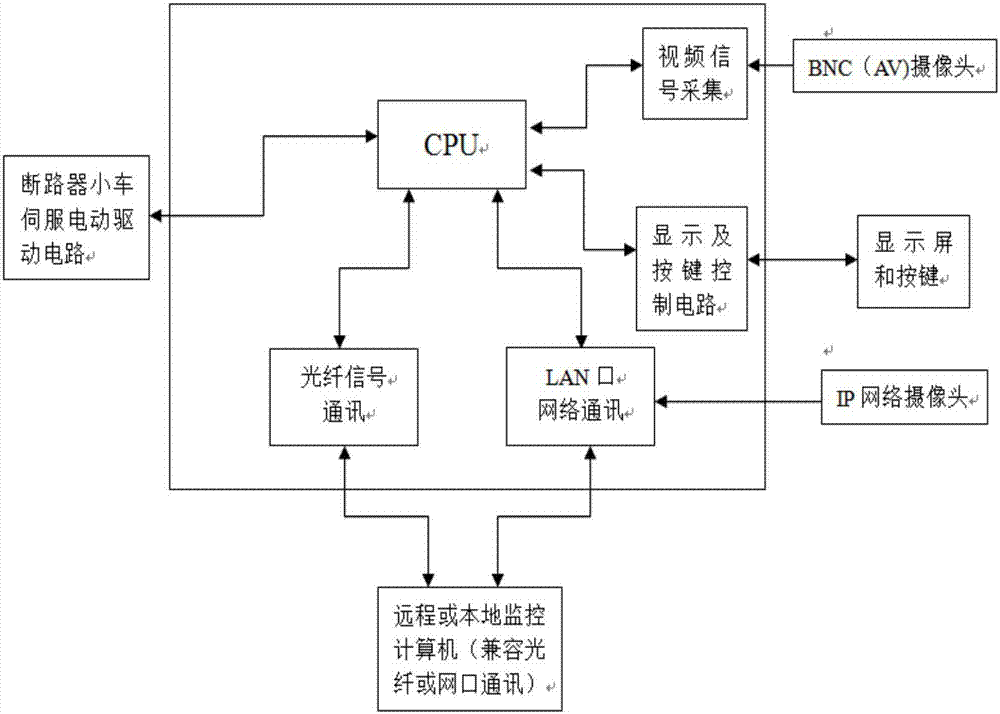

Remote operation device for visualized power distribution cabinet circuit breaker trolley

InactiveCN107508379ARealize remote visual operationImprove the level of digital managementCircuit arrangementsInformation technology support systemElectromagnetic clutchDigitization

The invention aims to provide a remote operation device for a visualized power distribution cabinet circuit breaker trolley, which comprises a circuit breaker and a main controller module, wherein the circuit breaker is provided with an electromagnetic clutch apparatus, a side plate of the circuit breaker is provided with a camera, a switching-on position and a switching-off position of the side plate are respectively provided with a switching-on sensor and a switching-off sensor, a pedestal of the circuit breaker is provided with a fixed guide rail, the fixed guide rail is provided with a circuit breaker trolley bottom plate, the pedestal at one end of the fixed guide rail is provided with a vertical fixed plate and a motor, and the motor, the camera, the switching-on sensor and the switching-off sensor are connected with the main controller module. The remote operation device can achieve remote operations, thereby achieving remote visualized operations of a coal mine power distribution apparatus, greatly improving the digitalized management level and high-efficiency and safe production of a coal mine, guaranteeing the personal safety and improving the safety production coefficient.

Owner:HEFEI HONGGUANG ELECTRIC CO LTD

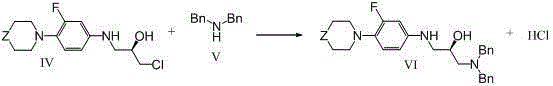

The preparation method of 3-substituted phenyl-5-aminomethyl oxazolidin-2-one

The invention discloses a preparation method of 3-substituted phenyl-5-(aminomethyl) oxazolidin-2-one. The preparation method comprises the following steps of: enabling substituted aniline to react with (R)-chloro-epoxy propane to get (R)-3-substituted phenylamino-2-hydroxy-chloropropane, further reacting with dibenzyl amine to get (R)-3-substituted phenylamino-1-dibenzyl amino-2-propanol, cyclizing to get (S)-3-substituted phenyl-5-dibenzyl aminomethyl oxazolidin-2-one and finally performing hydrogenation and debenzylation to get (S)-substituted phenyl-5-(aminomethyl) oxazolidin-2-one. A compound obtained by the method disclosed by the invention is of an important intermediate for commercial production of oxazolidinone type antibacterial agents. The method for preparing the 3-substituted phenyl-5-(aminomethyl) oxazolidin-2-one through four-step reaction has the characteristics of few steps, simple operation, low cost and easiness in obtainment of raw materials, mild reaction conditions and the like; and by adopting the method, the production efficiency can be improved, the production energy consumption can be reduced, a safety production coefficient can be further improved, environmental pollution can be reduced, and the preparation method is of an environment-friendly and low-carbon green synthesis method.

Owner:SUZHOU JINGYE MEDICINE & CHEM

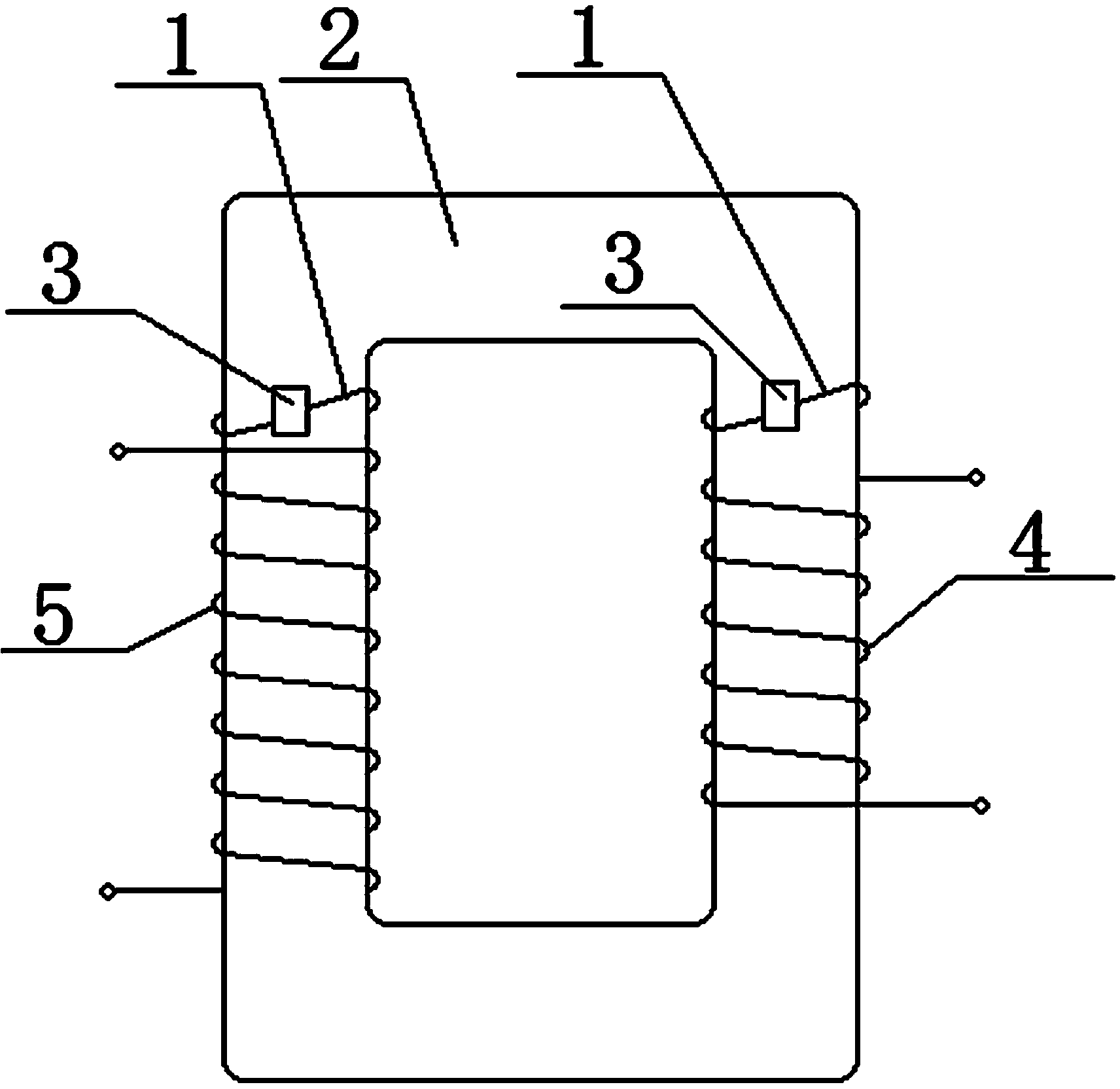

Transformer voltage wireless measurement device

InactiveCN104297600AReduce cost of measurementLow costTransmission systemsCurrent/voltage measurementTelecommunicationsTransformer

The invention provides a transformer voltage wireless measurement device, belongs to the technical field of power transformation, and mainly solves the problems that the cost and the loss are high and potential safety hazards exist to operating personnel when a mutual inductor is used for measurement in the prior art. The transformer voltage wireless measurement device comprises a transformer magnetic circuit and is characterized by further comprising a voltage sampling device, and the voltage sampling device comprises a solitary turn coil, an analog-digital conversion device and a wireless transmitter; the magnetic circuit is wound with the solitary turn coil, the solitary turn coil is close to a tested primary side or auxiliary side coil, the analog-digital conversion device is connected between two ends of the solitary turn coil, an output end of the analog-digital conversion device is connected with the wireless transmitter, and an induction voltage value in the solitary turn coil is transmitted to a receiving device through the wireless transmitter.

Owner:STATE GRID CORP OF CHINA +2

A kind of preparation method of ziprasidone key intermediate

The present invention relates to a ziprasidone key intermediate preparation method, wherein benzo[d]isothiazole-3-ol (or one) is adopted as a raw material, and reacts with a substituted sulfonyl chloride or anhydride under an alkaline condition to obtain benzo[d]isothiazole-3-substituted sulfonate, and the benzo[d]isothiazole-3-substituted sulfonate reacts with piperazine to prepare the ziprasidone key intermediate 3-(1-piperazinyl)-1,2-benzoisothiazole. The method of the present invention has characteristics of simple operation, easily available raw materials, less byproducts, simple post-treatment, less industrial three-waste and the like, and is especially suitable for industrial production.

Owner:SHANGHAI TIANCI BIOLOGICAL VALLEY BIOLOGICAL ENG

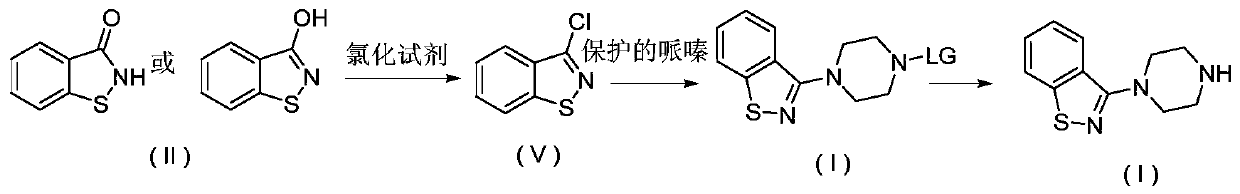

Non-contact three-dimensional thermal displacement detection system and application thereof

PendingCN114018158AImprove the level of intelligenceImprove safety production factorUsing optical meansVision processingVisual perception

The invention provides a non-contact three-dimensional thermal displacement detection system and application thereof. The non-contact three-dimensional thermal displacement detection system comprises a binocular camera, a laser range finder, a visual processing cabinet and a computer control system, and the binocular camera and the laser range finder conduct signal collection on displacement; and then the collected signals are transmitted to the visual processing cabinet, and the visual processing cabinet transmits the signals to the computer control system. The embodiment of the invention provides a non-contact three-dimensional thermal displacement detection system and application thereof, the non-contact three-dimensional thermal displacement detection system provided by the invention adopts an artificial intelligence technology, realizes a measurement mode of parameters such as boiler expansion amount and pipeline displacement amount, can perform automatic early warning on safe operation of equipment, improves the intelligent level of the power plant, improves the safety production coefficient of the power plant, gains economic benefits for the power plant, and guides digital construction and intelligent operation of the power plant.

Owner:CHINA DATANG TECH & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com