Automatic combination processing production line of double-shaft drilling machines

An automatic combination and drilling machine technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve difficult to adapt to diversified flexibility and complex shape parts high-efficiency and high-quality processing requirements, short development and production cycle, etc. problems, to achieve the effect of shortening the basic time, improving the safety production factor, and solving the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

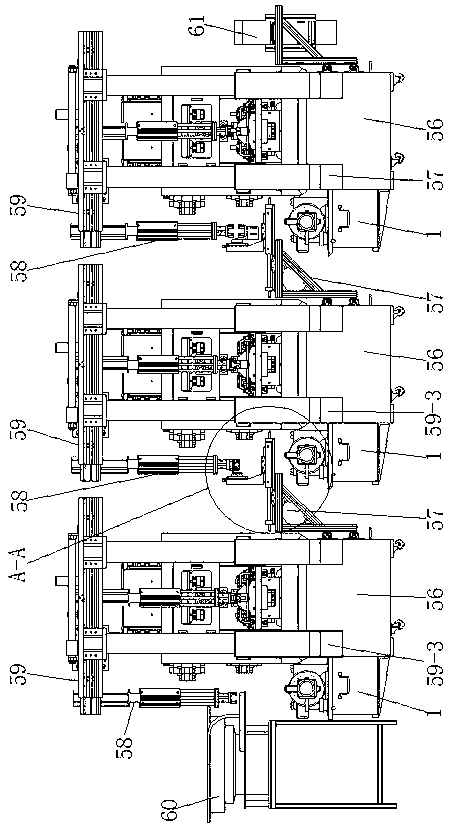

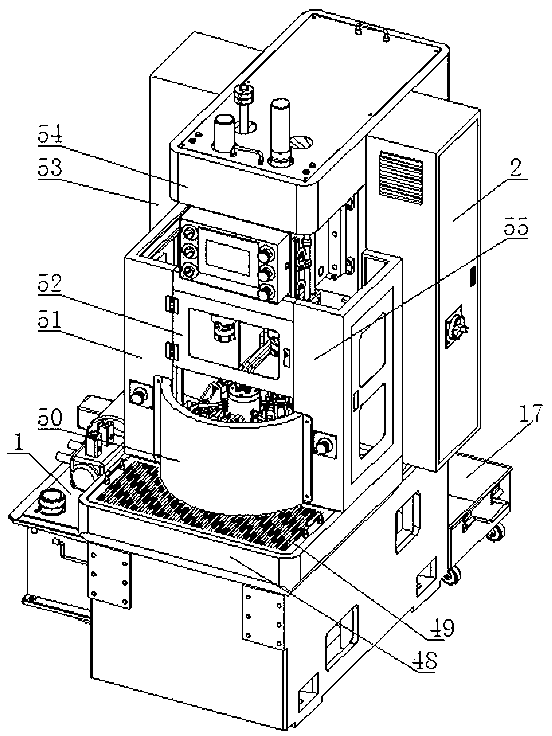

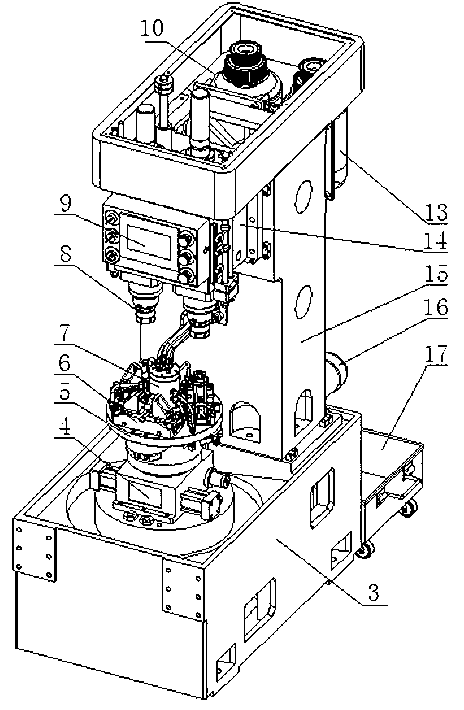

[0039] refer to Figure 1 to Figure 12 As shown, the automatic combined processing production line of the biaxial drilling machine includes a plurality of biaxial drilling machines 56, and every two biaxial drilling machines 56 are connected with the mechanical arm mechanism 58 through the transfer mechanism 57, and each biaxial drilling machine 56 is connected with the mechanical arm mechanism 58. Axle drilling machine 56 is provided with lateral feed mechanism 59, and mechanical arm mechanism 58 is connected with lateral feed mechanism 59. One side of the first dual-axis drilling machine is provided with a vibrating feeding tray assembly 60, and the last station One side of the biaxial drilling machine is provided with a blanking mechanism 61 .

[0040] The transfer mechanism 57 includes a transfer frame 8-2, the transfer frame 8-2 is connected to the biaxial drilling machine 56 through the transfer mounting block 8-1, and the transfer frame 8-2 is also provided with The cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com