Oil well casing gas collecting device

A technology of oil well casing and collection device, which is applied in pipeline systems, wellbore/well components, gas/liquid distribution and storage, etc., can solve the problems of environmental pollution, high transportation cost, incomplete collection, etc., and achieve significant environmental benefits , The effect of improving the atmospheric environment and improving the conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

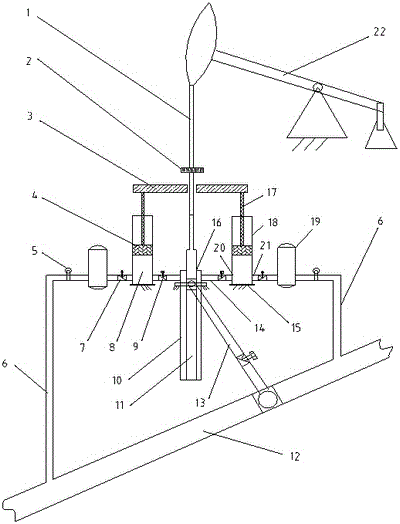

[0026] as attached figure 1 The oil well casing gas collection device shown in the figure is installed on the wellhead 16 of the oil well, and includes two casing connecting pipes 14, which are connected to the casing 10, and two one-way valves A9, two There are 18 booster pumps, two one-way valves B7, and two oil pipe connecting pipes 6 connected to the oil delivery pipe 12. Booster pump 18 contains components such as connecting rod 17, piston 4, cylinder 8, air inlet 20, air outlet 21. Two booster pumps 18 are symmetrically connected on both sides of the casing 10, and the upper ends of the two connecting rods 17 of the two booster pumps 18 are jointly connected with a pressure arm 3, and the pressure arm 3 crosses the sucker rod 1 through. The pressure arm 3 is placed horizontally, which is convenient for the sucker rod 1 and the connecting rod 17 to go up and down vertically, and the power efficiency is higher.

[0027] The casing connecting pipe 14 is connected with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com