Automatic monitoring and sprinkling coke quenching system for red coke of coke wharf

An automatic monitoring and red coke technology, which is applied in coke ovens, coke cooling, petroleum industry, etc., to avoid accidents, improve automation level, and optimize the quenching tower sprinkler system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

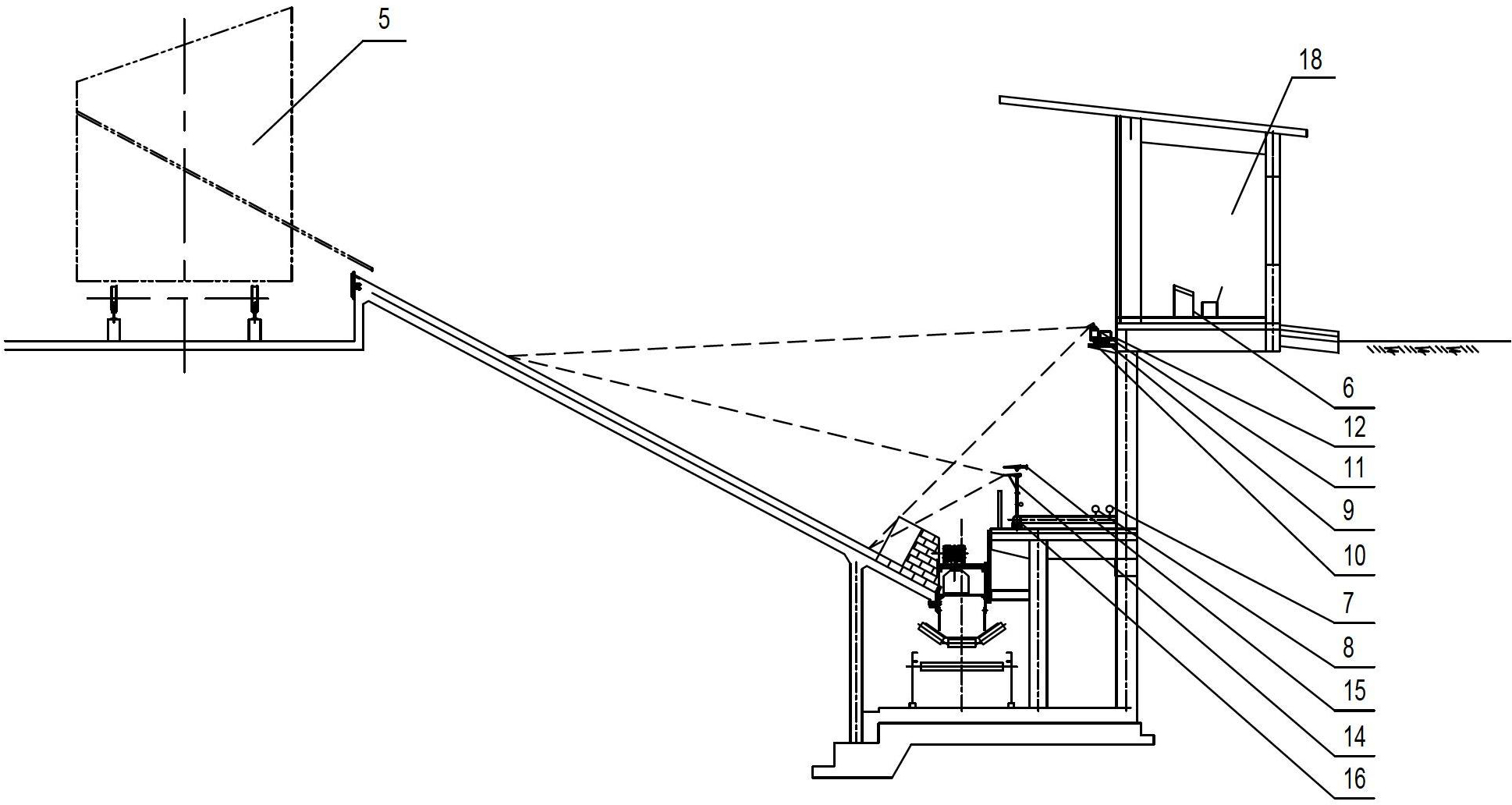

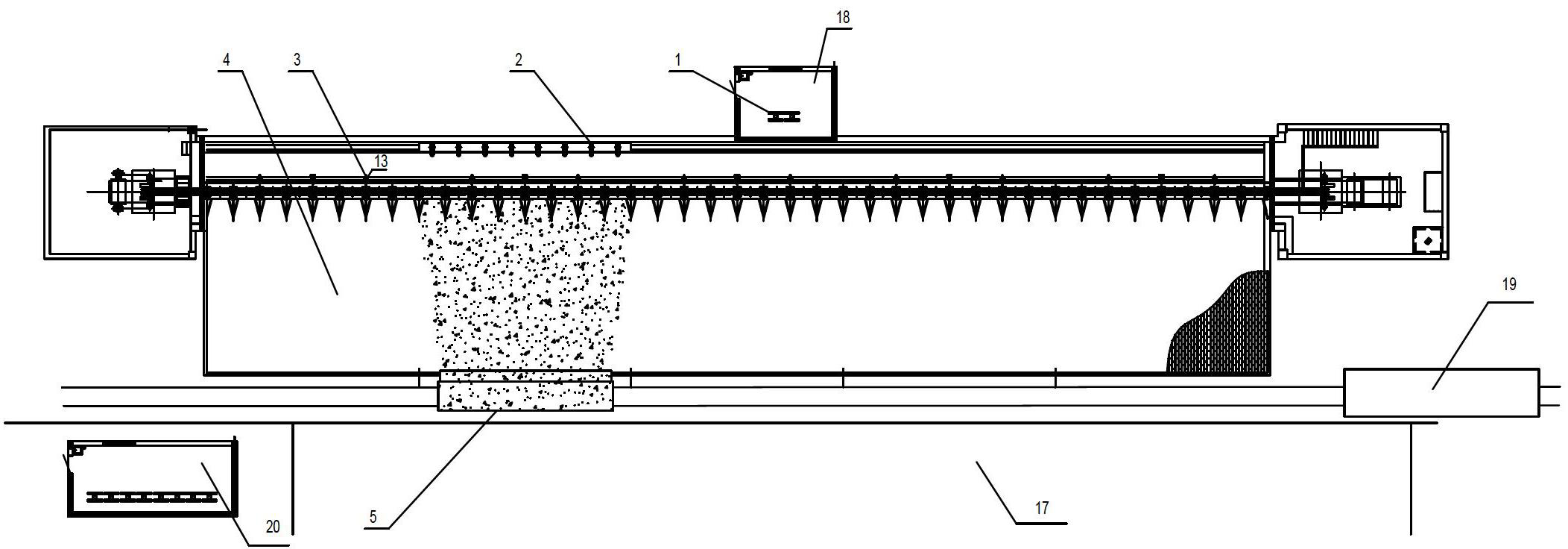

[0023] The composition and operation process of the coke platform red coke automatic monitoring and water sprinkling coke quenching system of the present invention will be described in detail below in conjunction with the accompanying drawings.

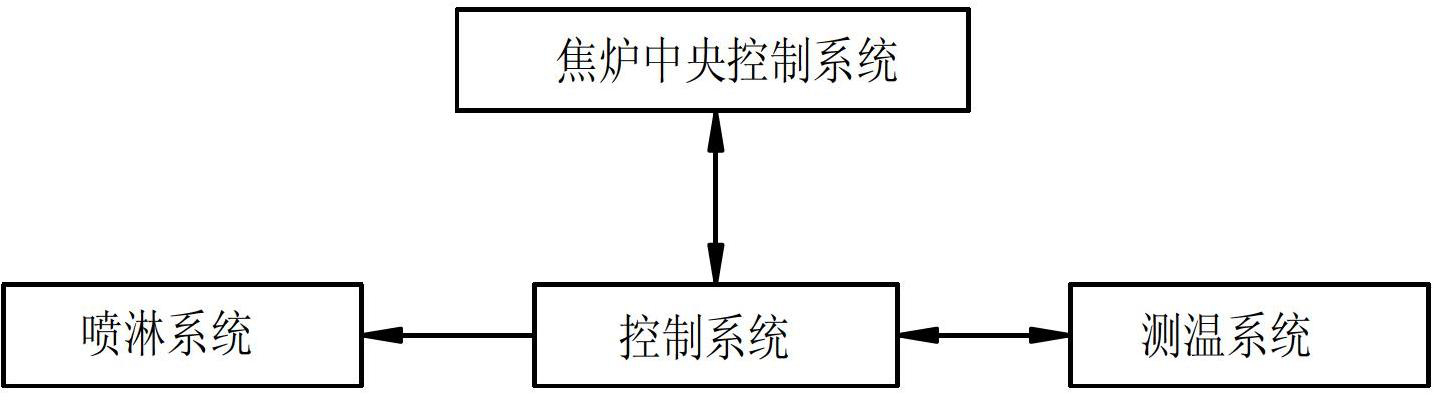

[0024] See figure 1 , figure 2 , image 3 , taking the 60-meter coke platform 4 as an example, the coke platform red coke automatic monitoring and sprinkling coke quenching system of the present invention is composed of a control system 1, a temperature measurement system 2 and a spray system 3. Three parts. Among them, the control system 1 is composed of a touch screen operating console 6, a water pressure gauge 7 and a flow meter 8, and the temperature measurement system 2 is composed of a temperature measuring car 9, a temperature measuring car track 10, an infrared temperature detector 11 and a safety slide. Contact line 12 is formed, and sprinkler system 3 is to be made up of main engine part by electric butterfly valve 13, au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com