Patents

Literature

1434results about "Coke quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

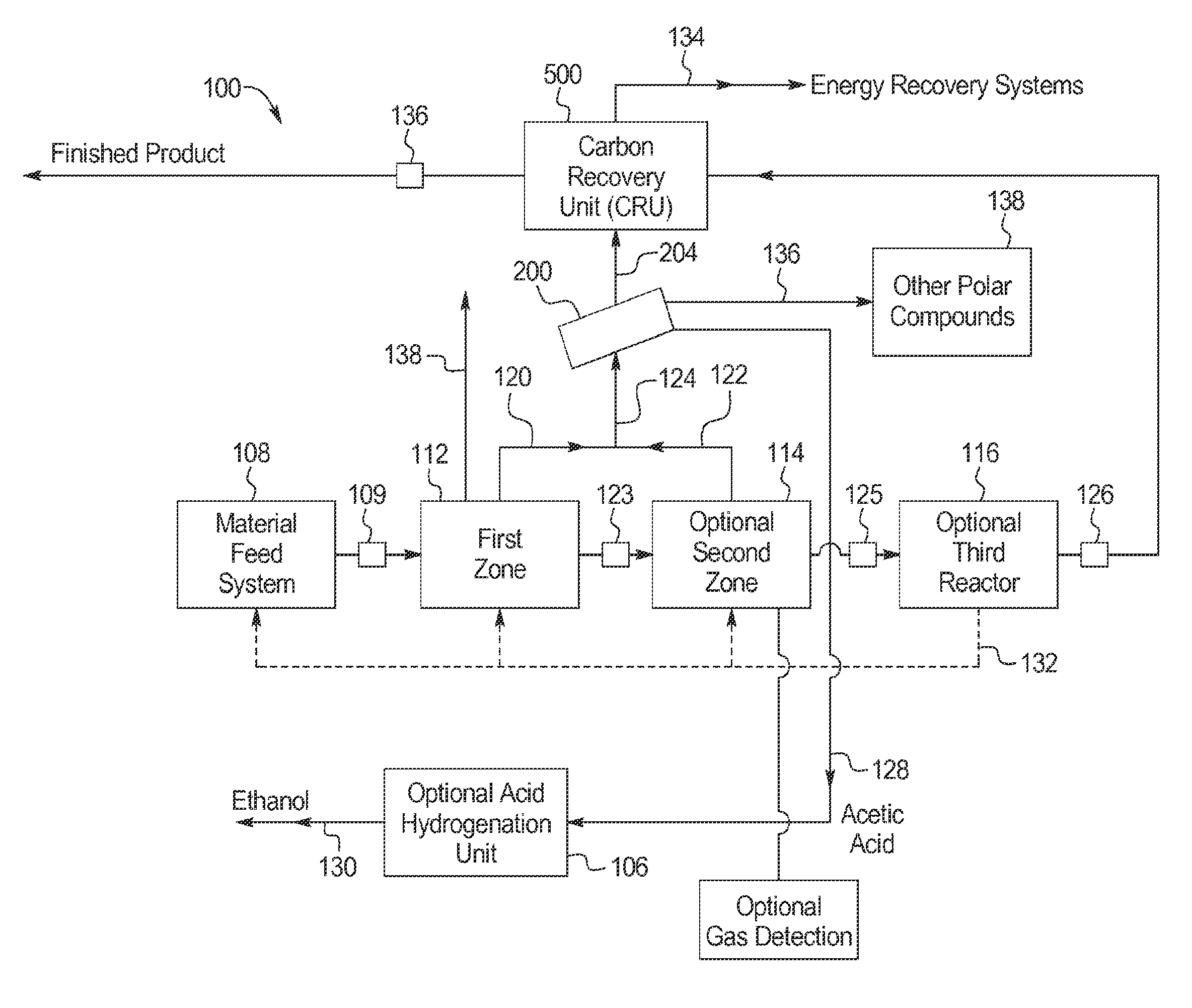

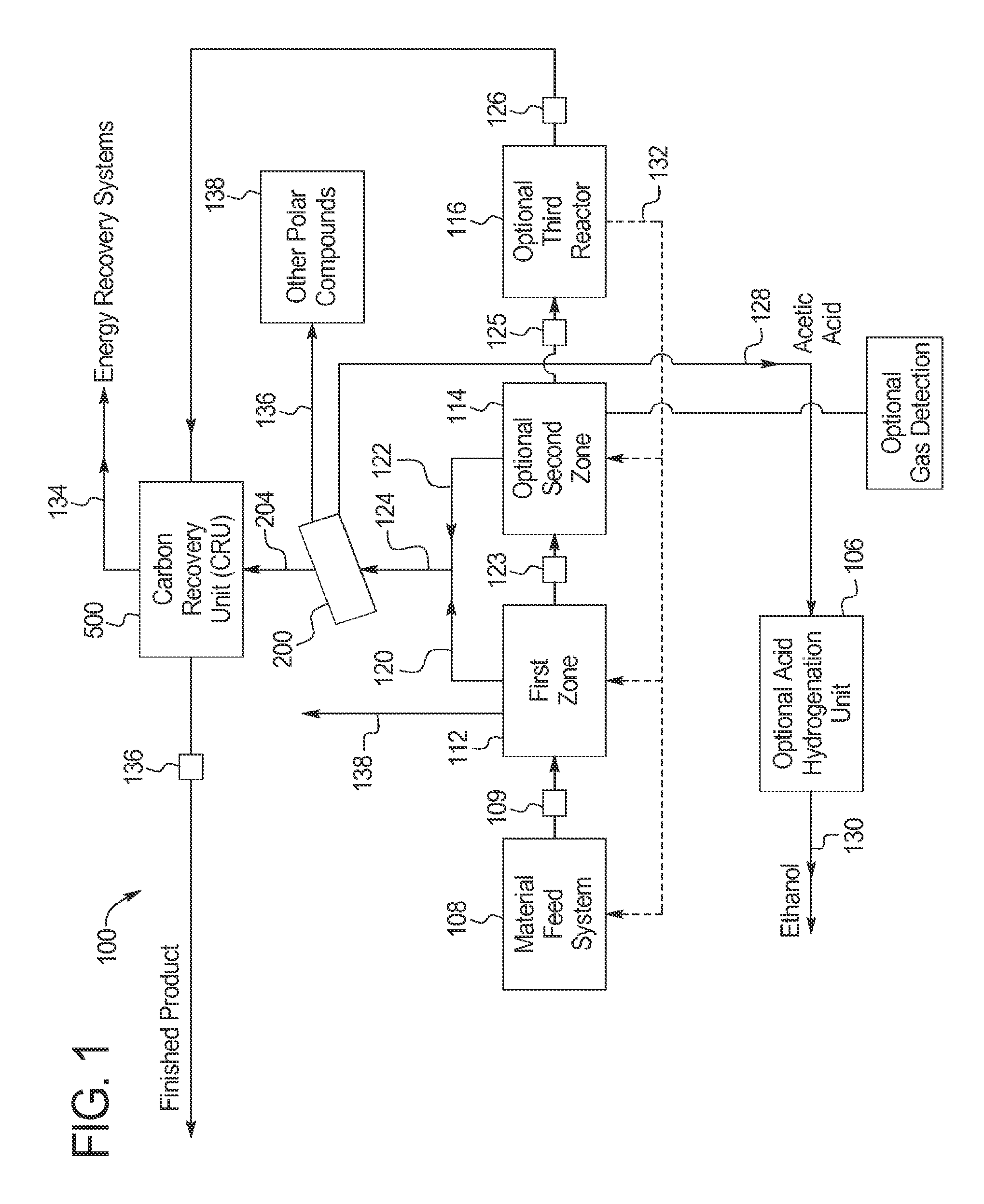

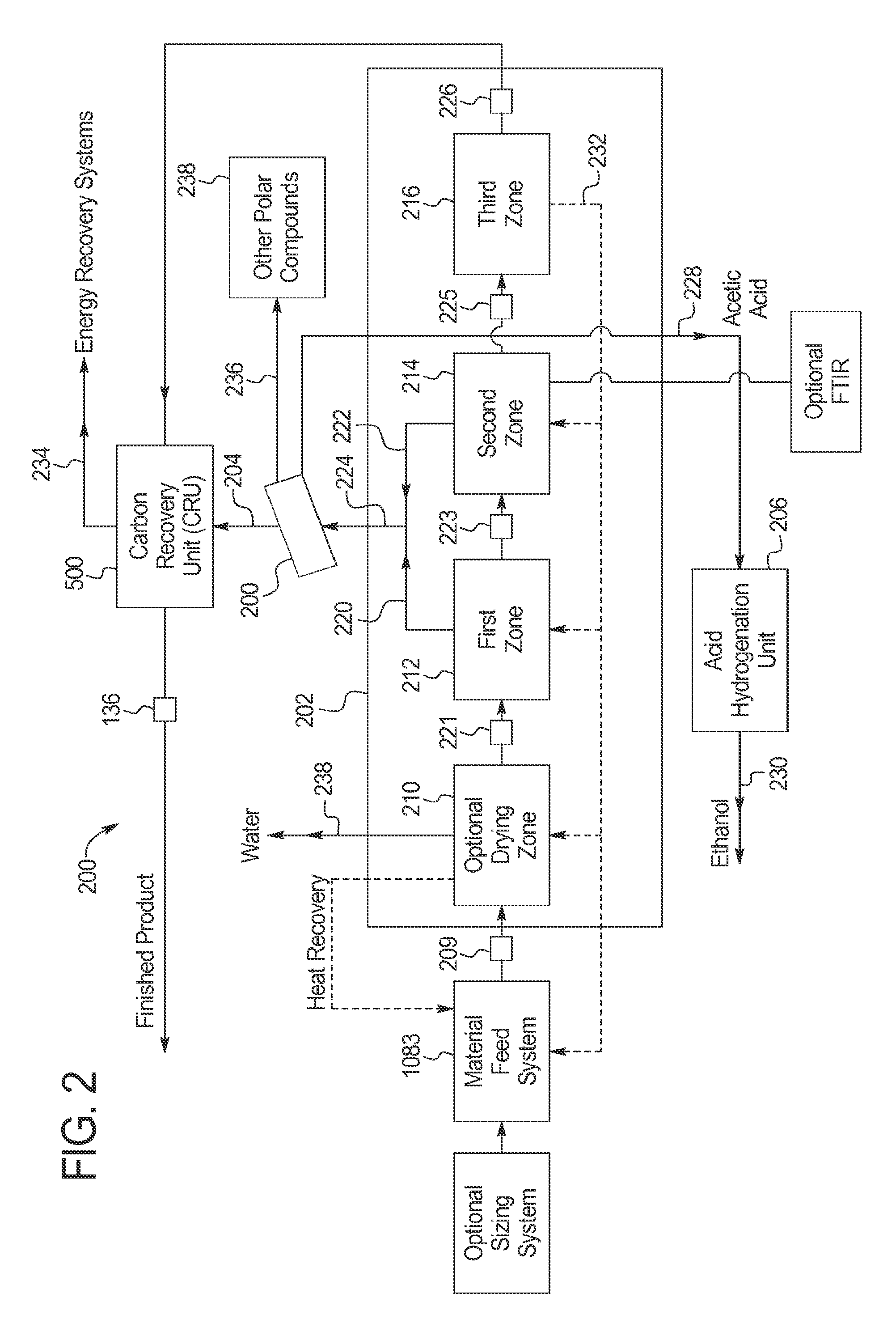

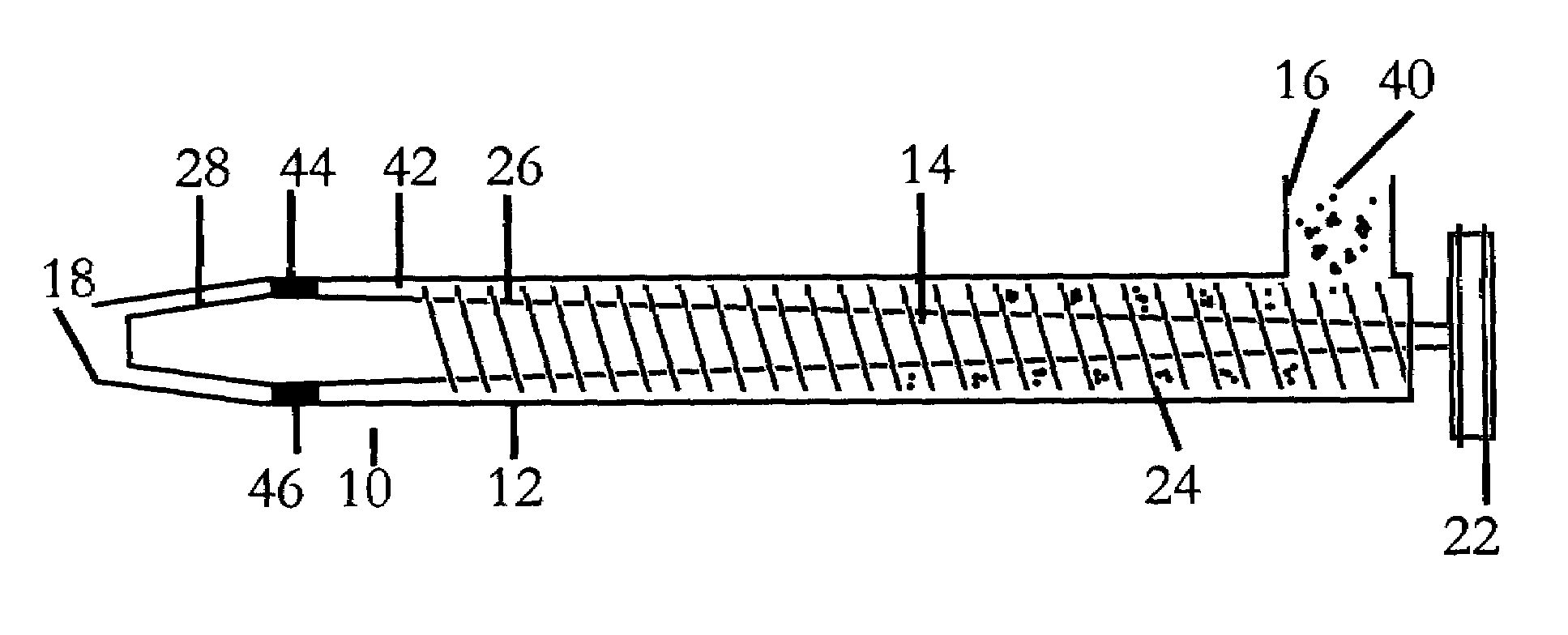

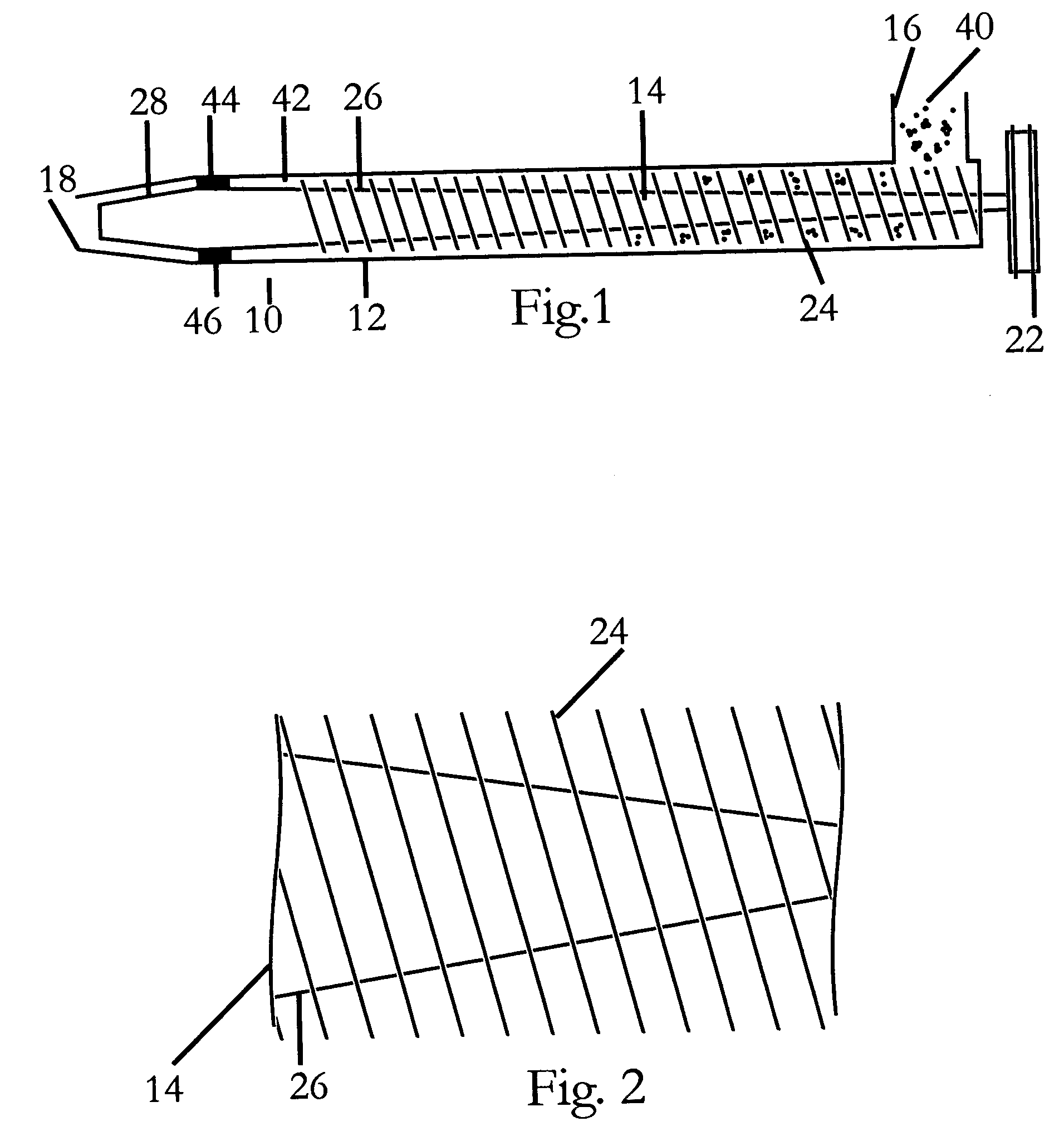

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

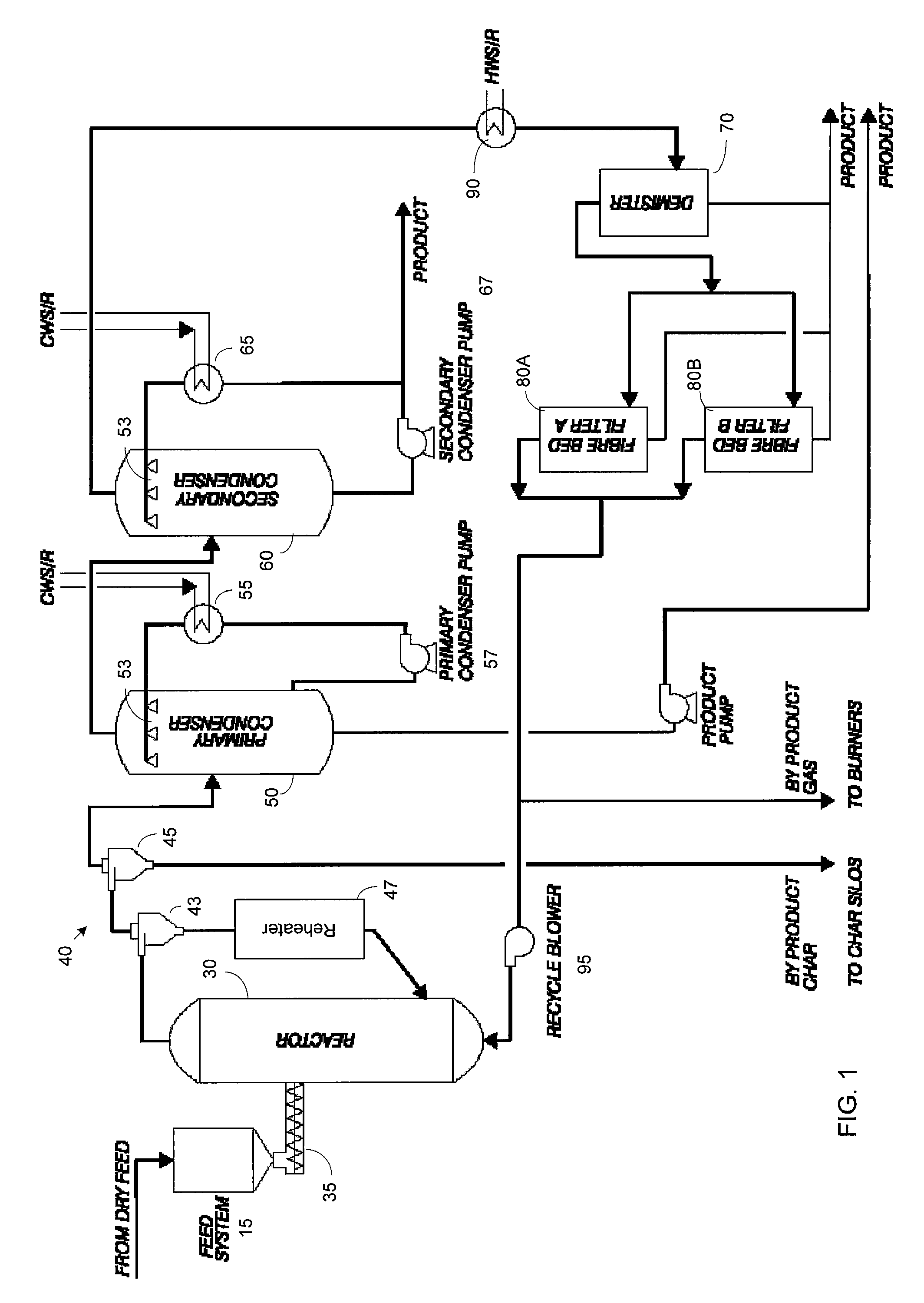

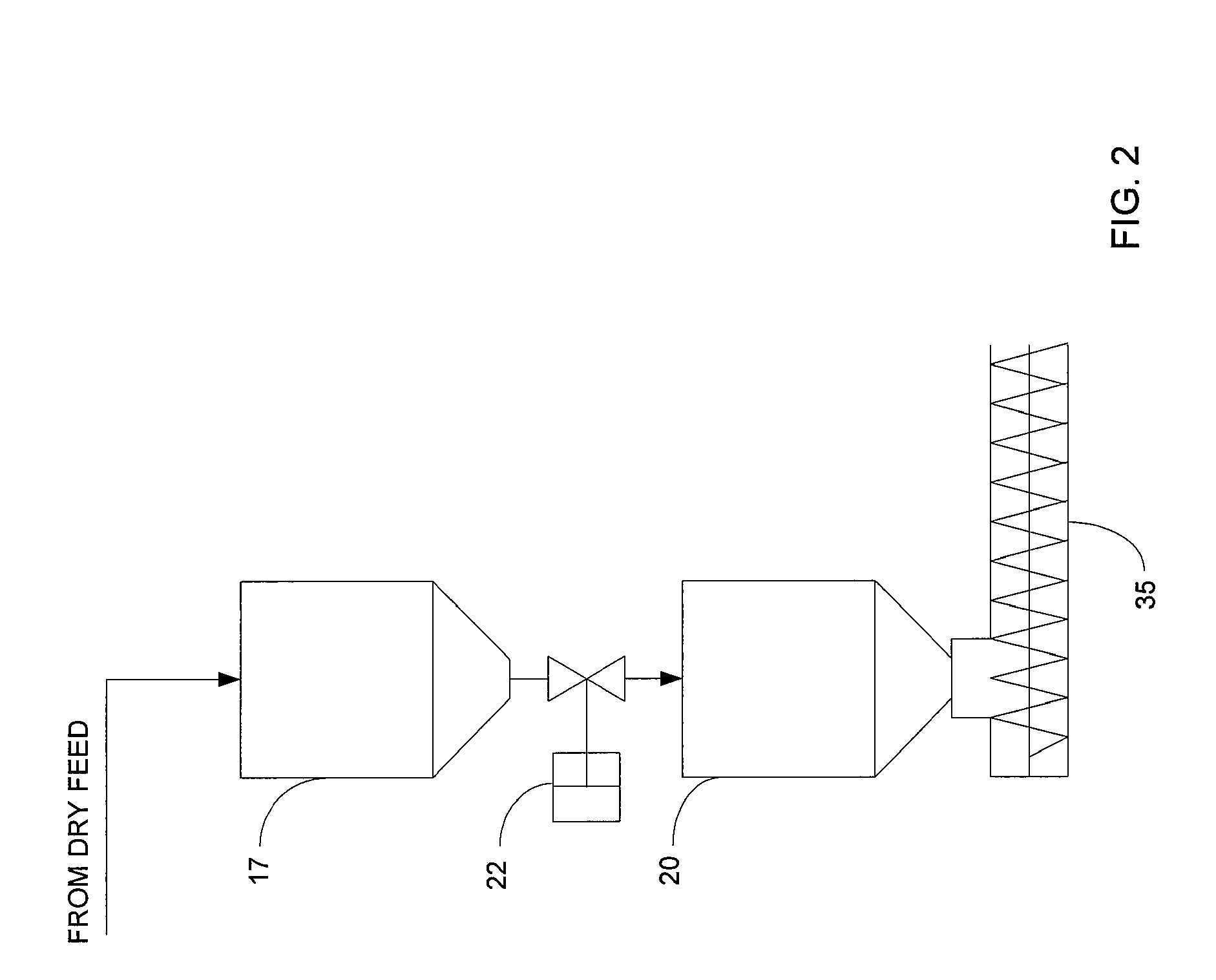

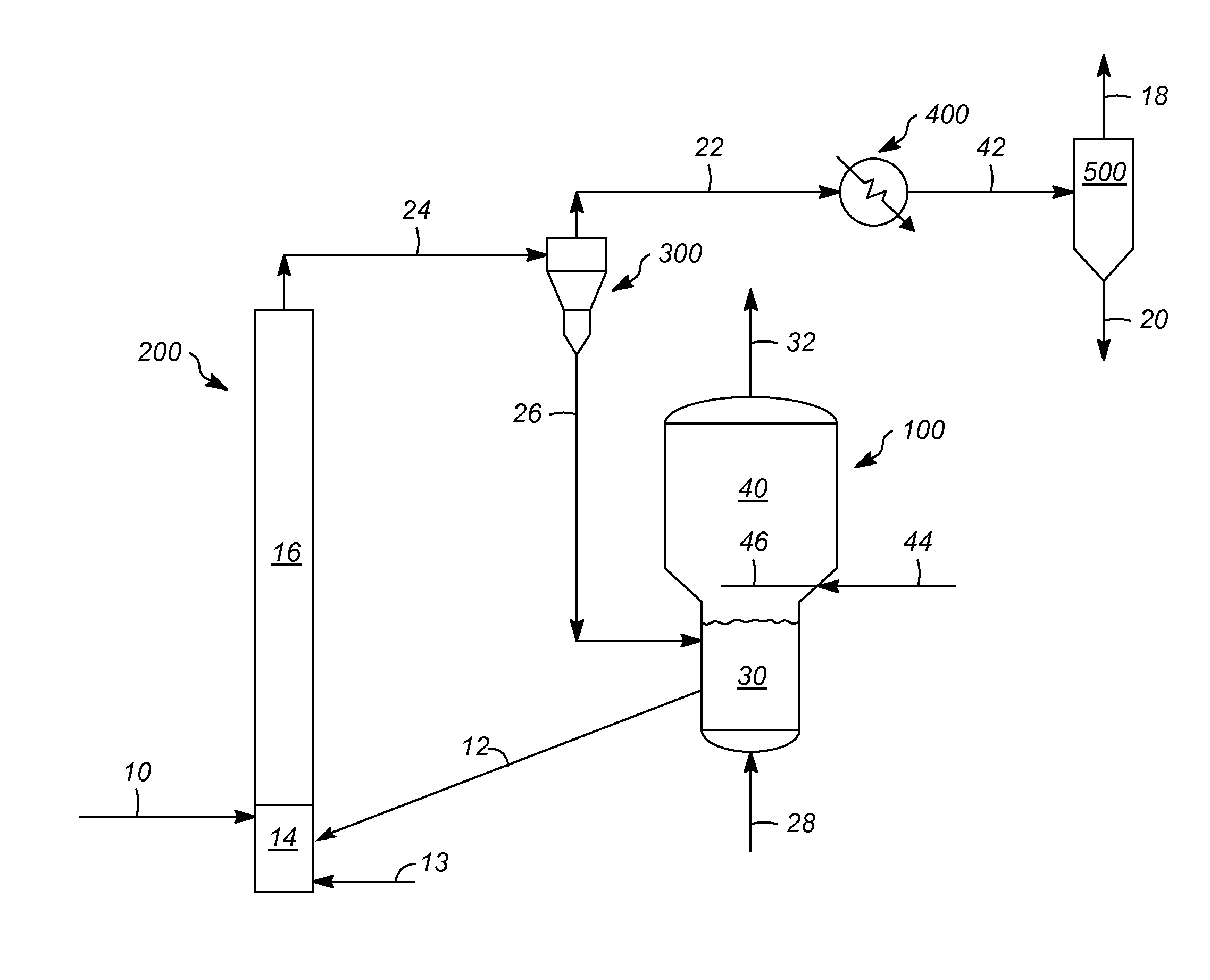

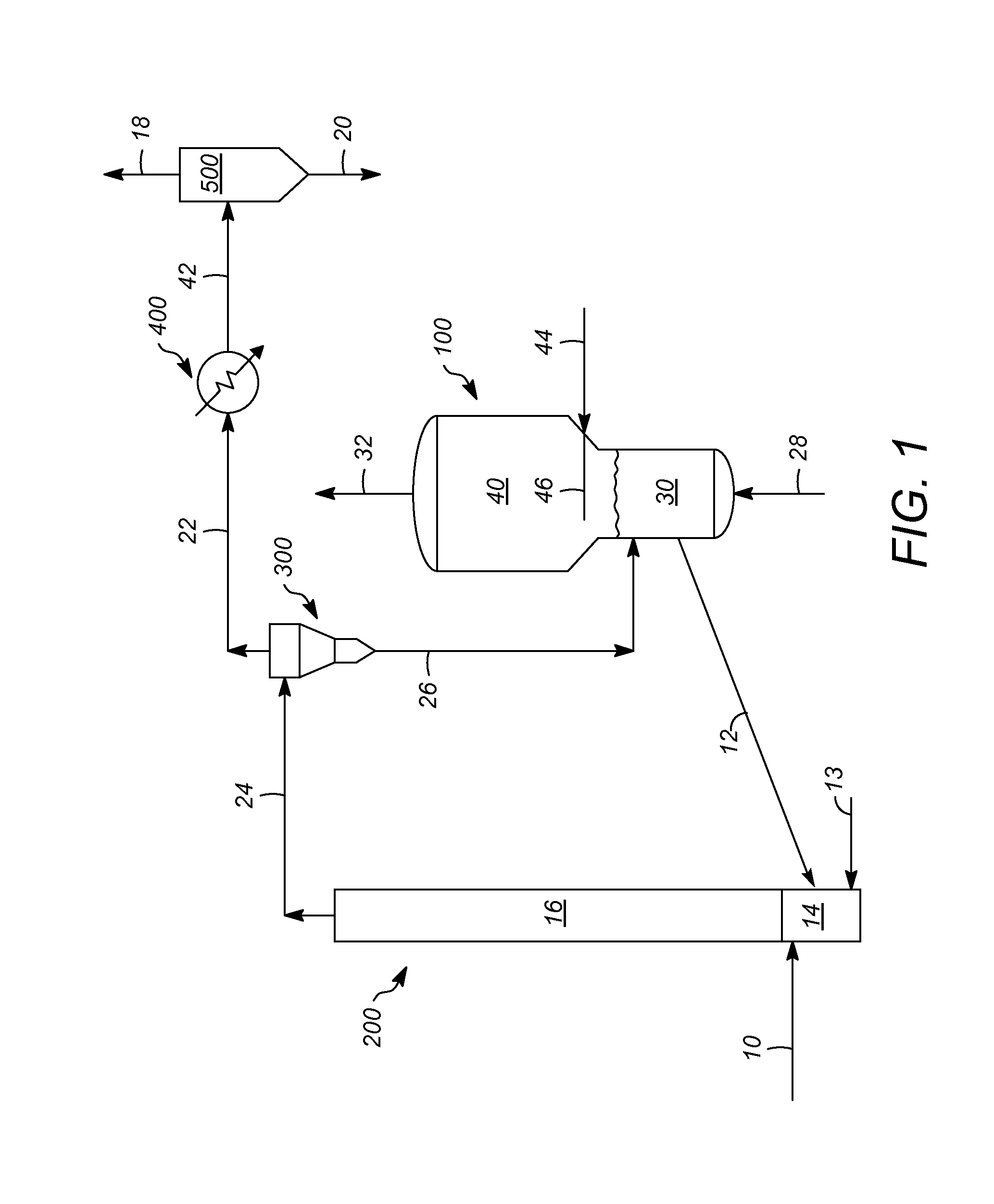

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

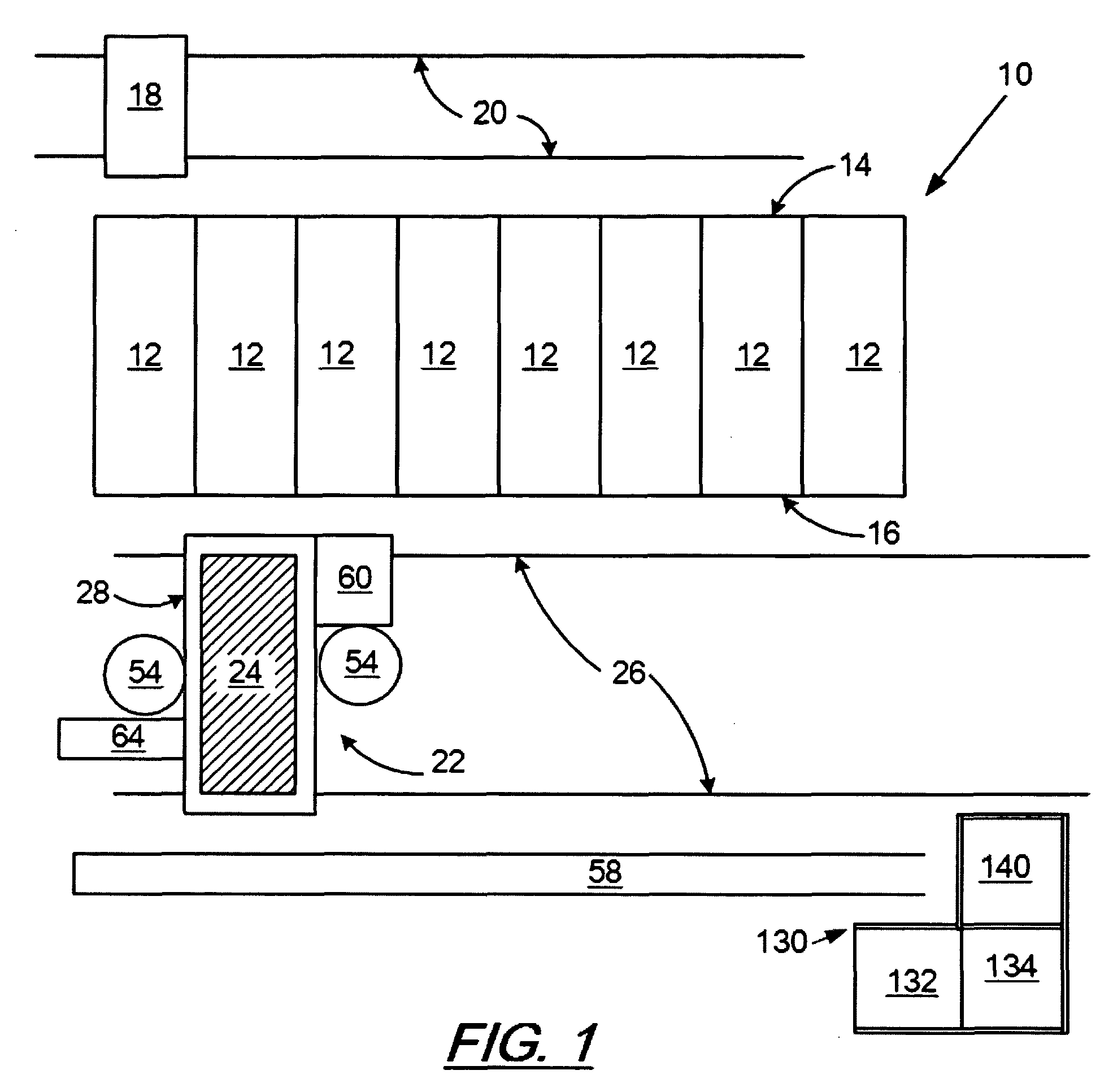

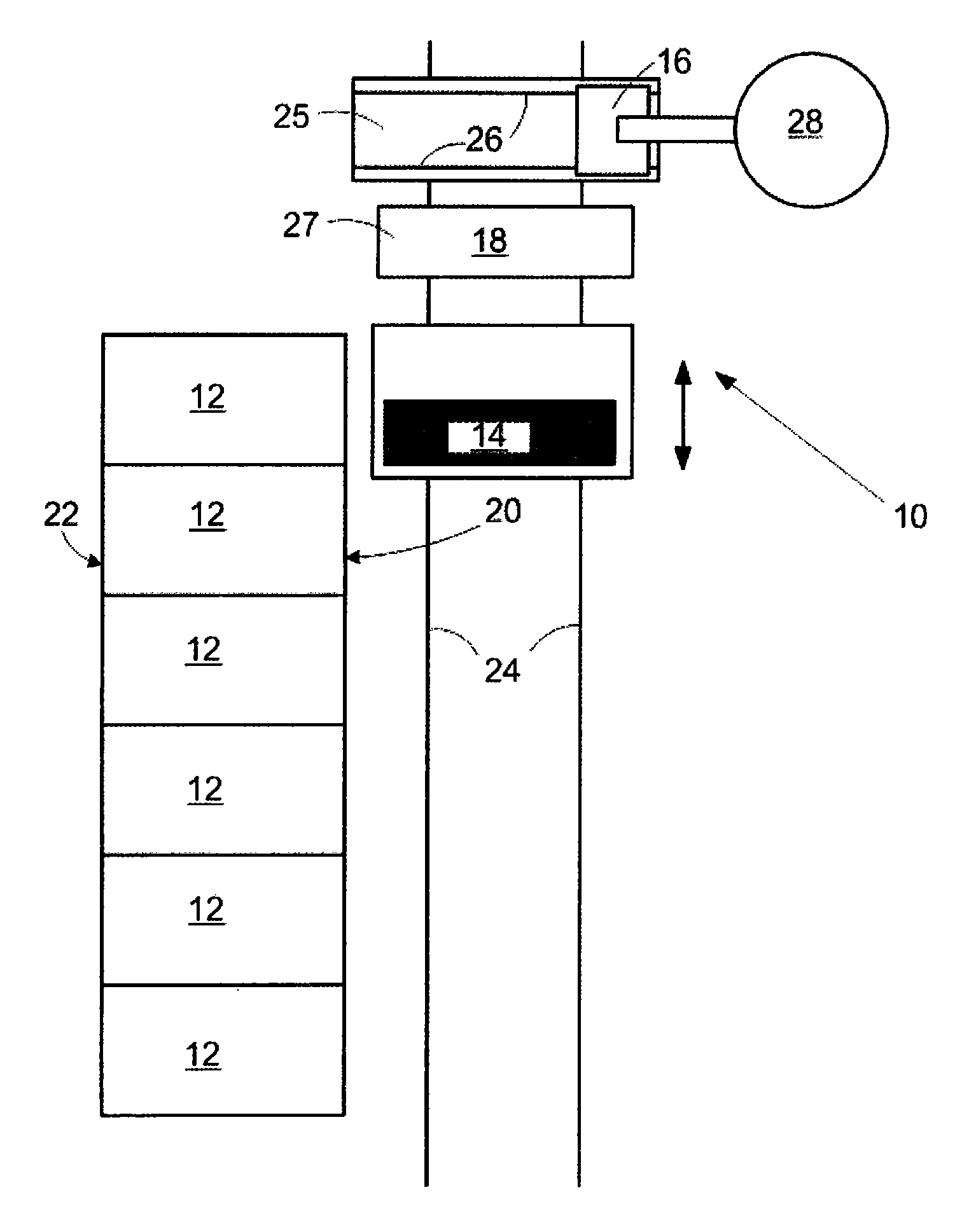

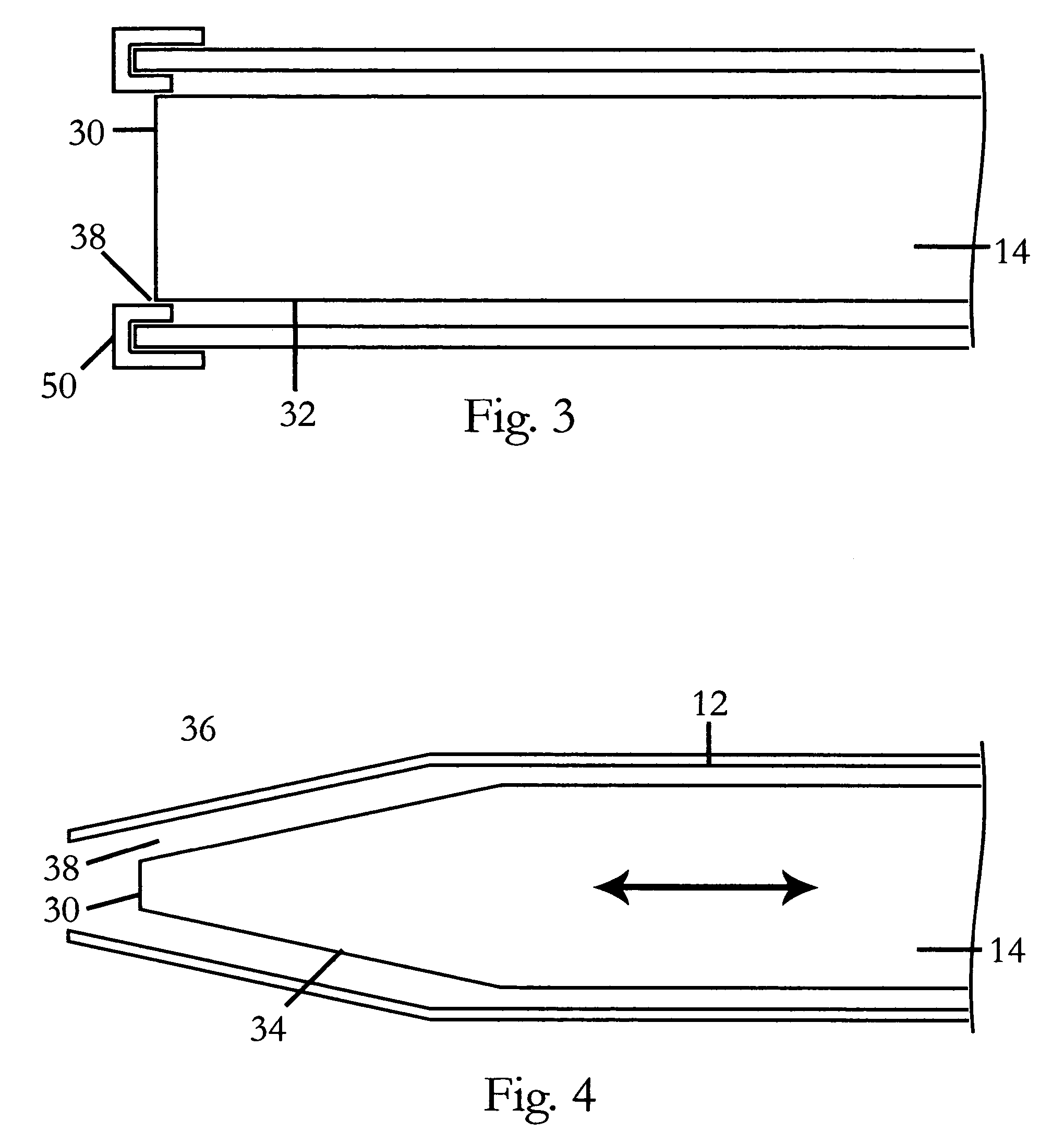

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

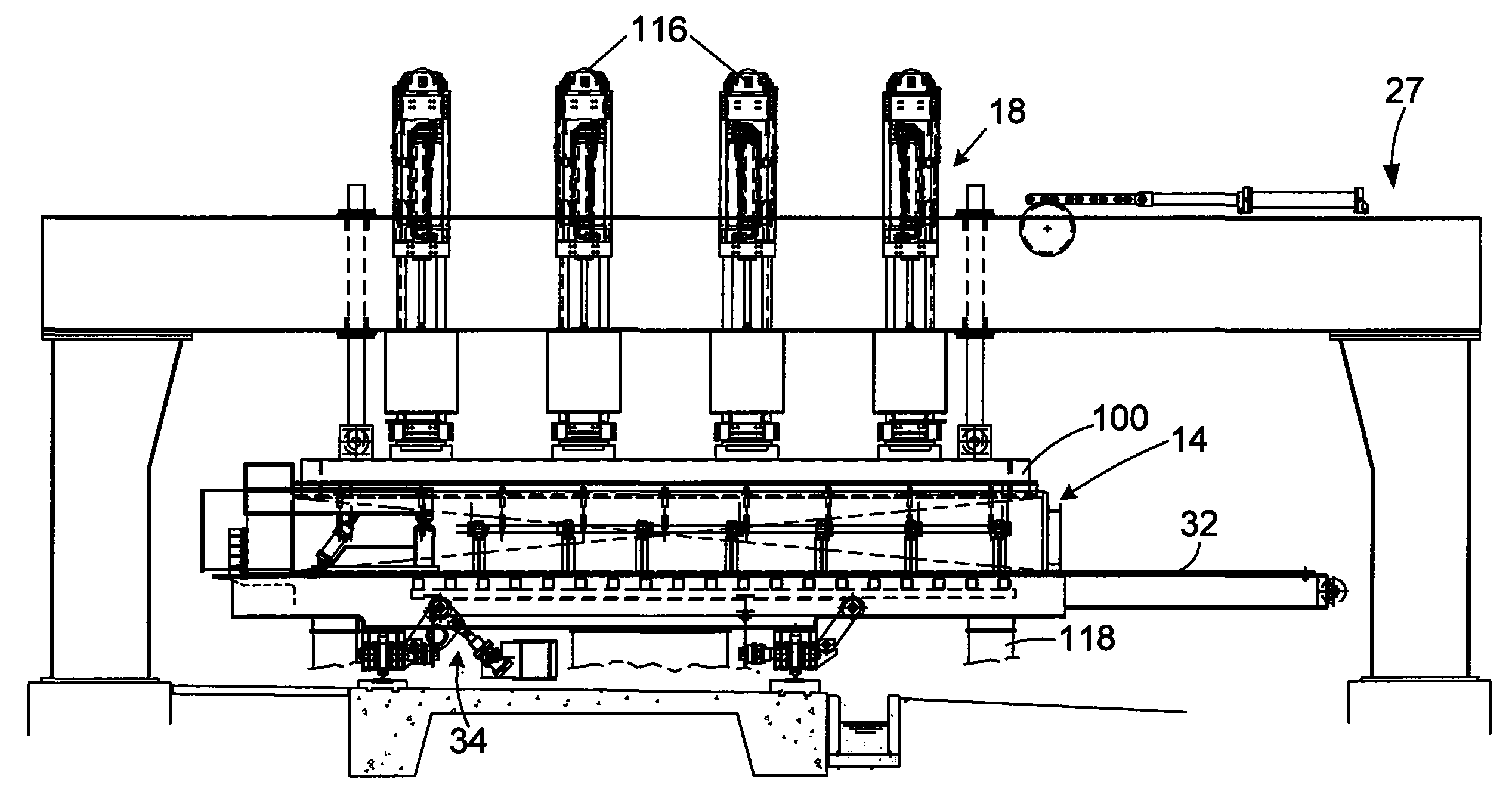

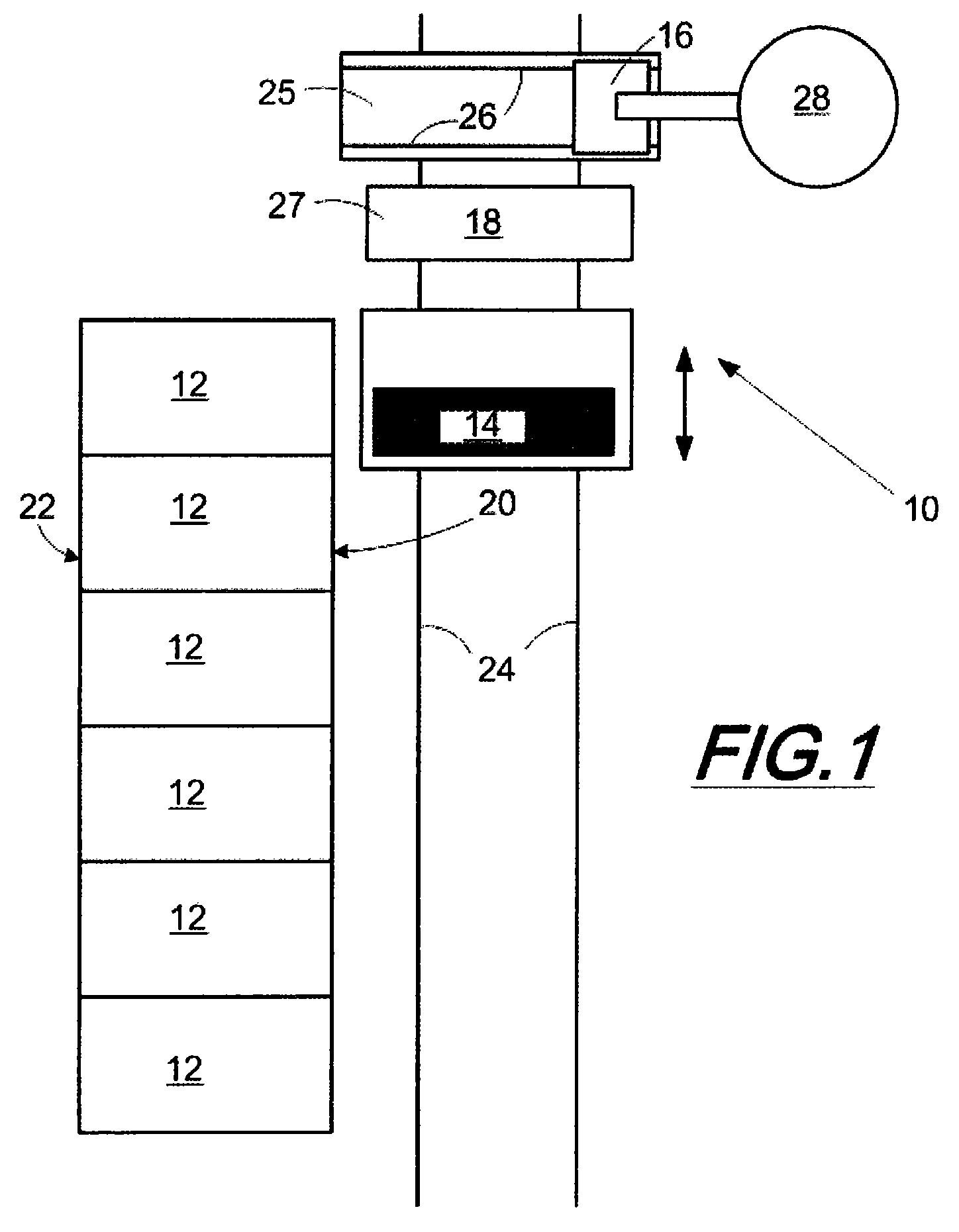

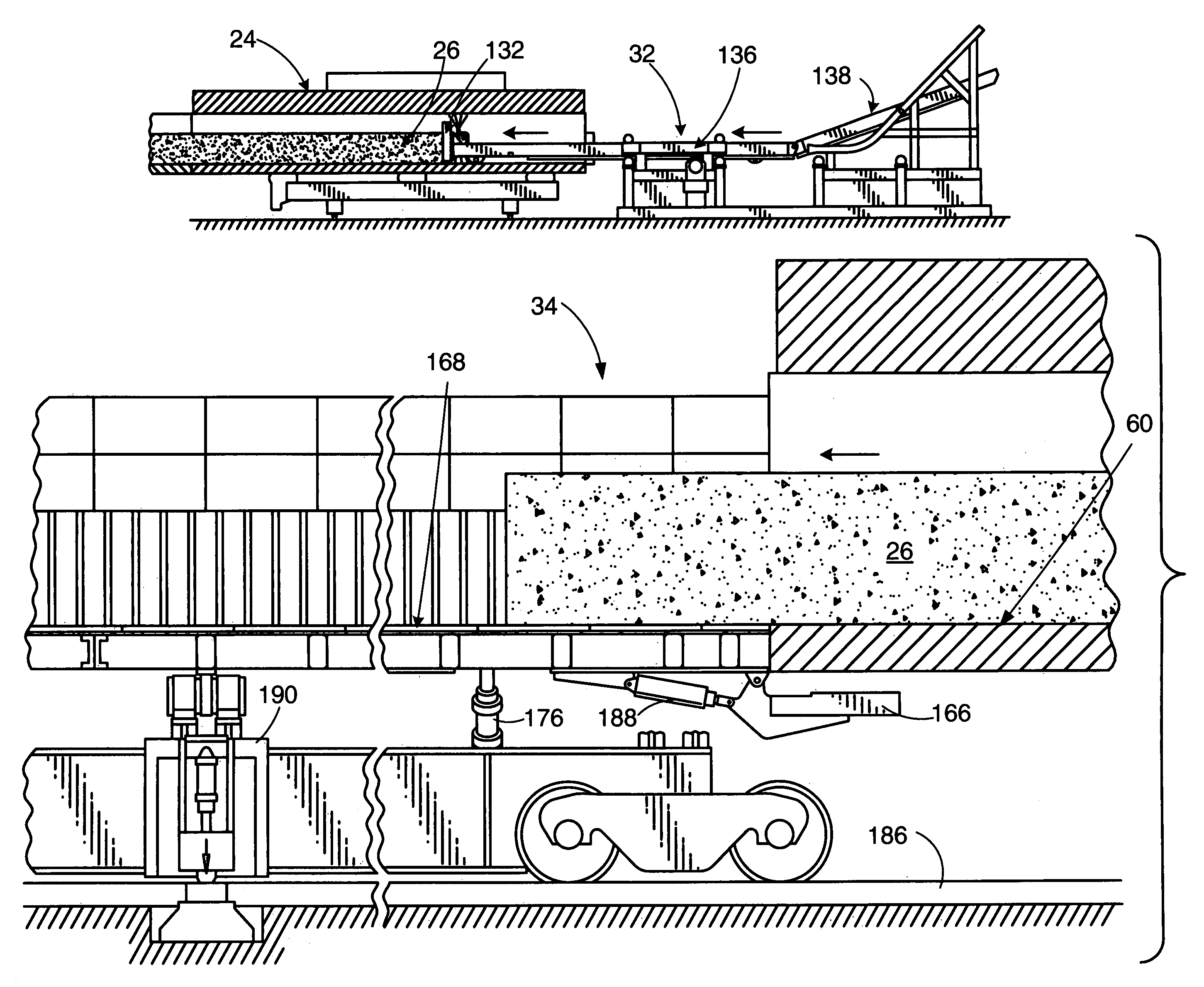

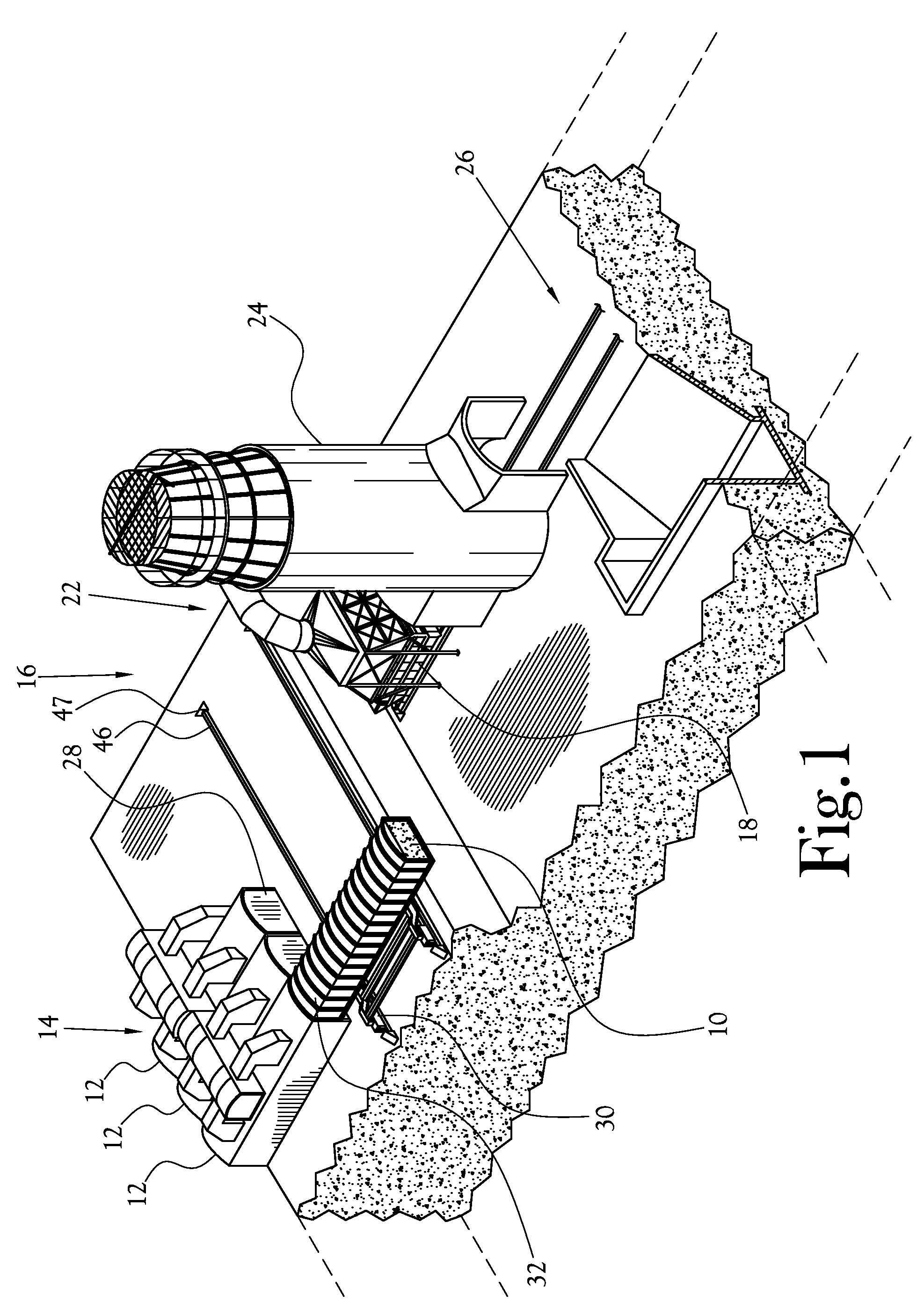

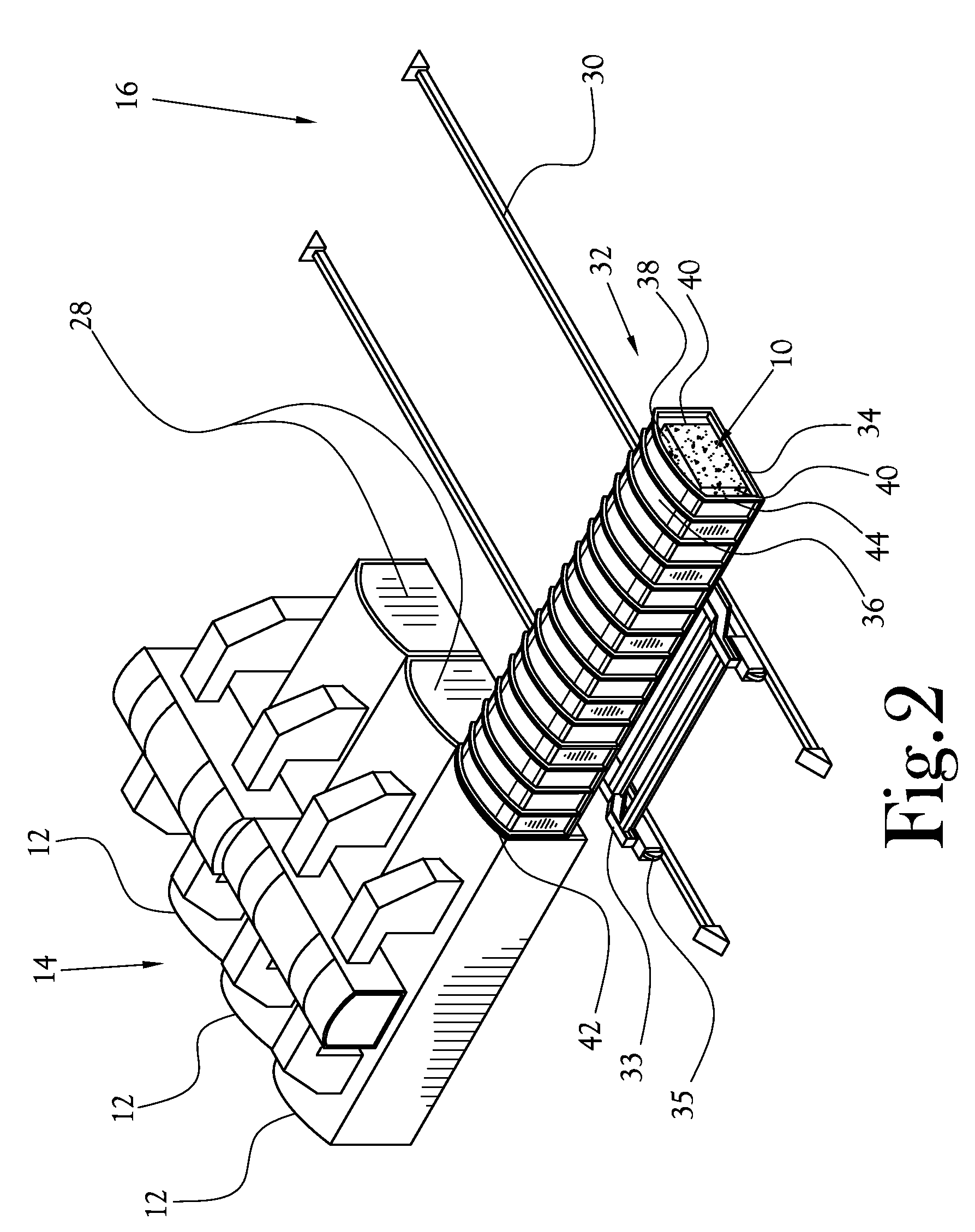

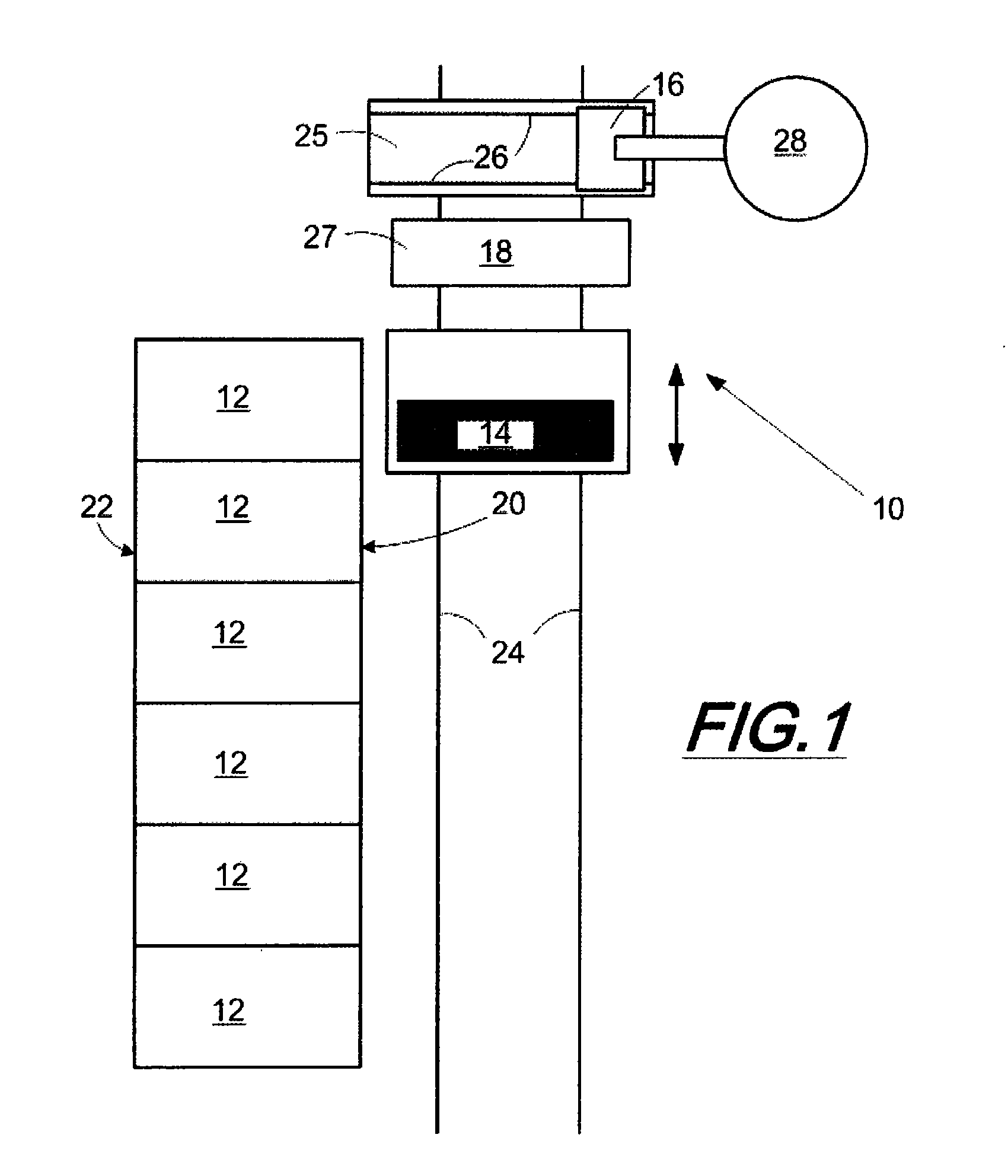

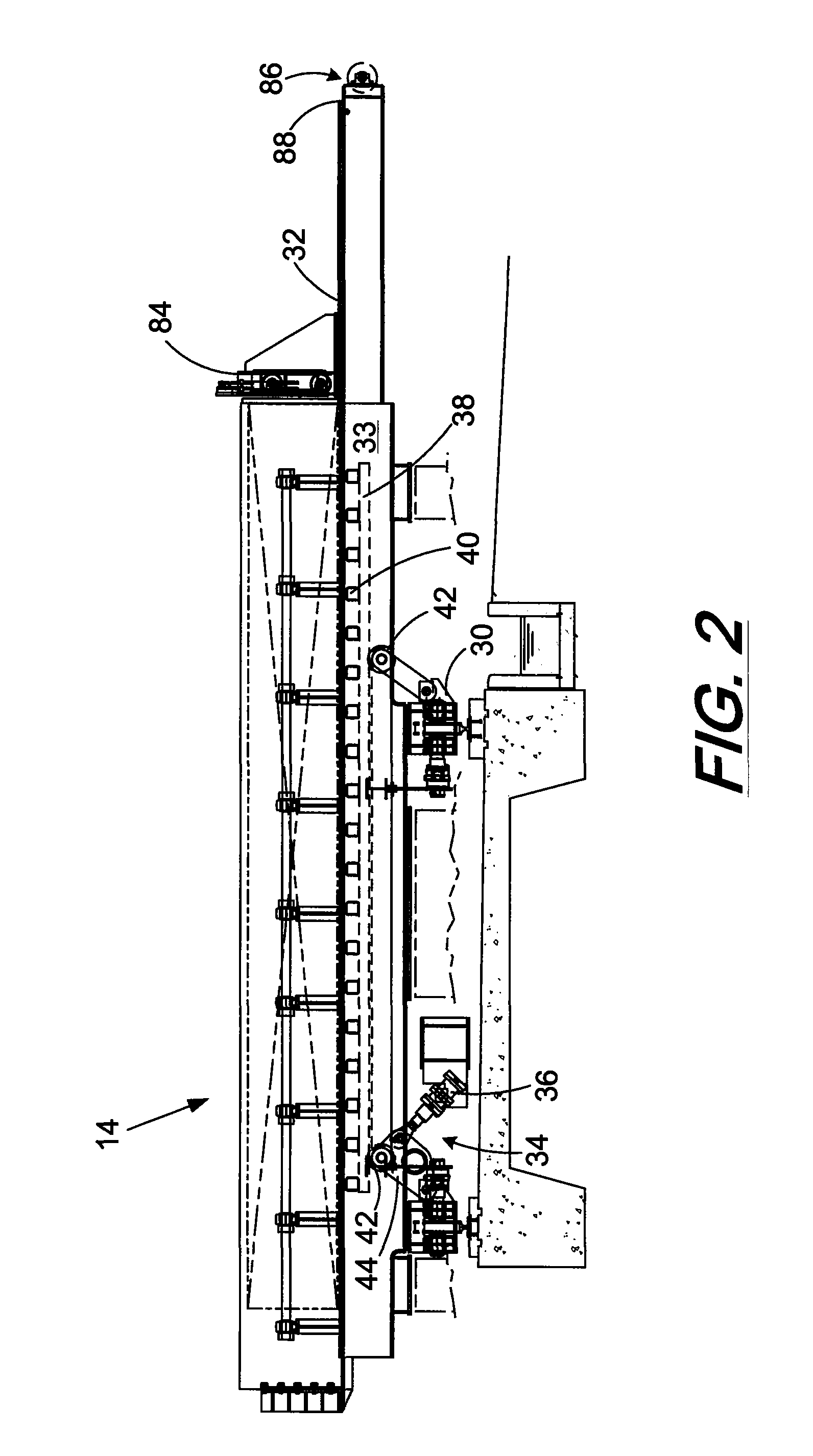

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

Coking furnace capable of recycling heat energy and coking method

InactiveCN102250629AExtend the industrial chainReduce pollutionCoke quenchingGas purification with selectively adsorptive solidsThermal energyCombustion

The invention discloses a coking furnace capable of recycling heat energy, and the coking furnace comprises a furnace body, an exhaust gas recycling system and a raw coal gas treatment system, wherein the furnace body sequentially comprises a coal feeding segment, a rapid coal heating segment, a raw coal gas leading-out segment, a coal carbonization coking segment, a coke quenching and tempering segment, a dry coke quenching segment and a coke discharging segment from top to bottom; the exhaust gas recycling system comprises an exhaust gas leading-out unit, an exhaust gas heat exchanger, a commutator and the like; and the raw coal gas treatment system comprises a raw coal gas leading-out unit. By using the coking furnace disclosed by the invention, continuous coal carbonization coking canbe achieved and the exhaust gas after combustion is used for dry coke quenching in the furnace; pre-dried coal can be quickly heated to 300 DEG C during entering the furnace, the coal is carbonized and coked in the furnace body, and the exhaust gas generated by self-combustion is used for dry coke quenching at the furnace bottom after the exhaust gas is cooled by heat exchange with air, thus continuously producing coke; the pollution is less in the production process; the coal industrial chain is extended, the coking cost is lowered, the coking coal types are broadened, and the product quality is improved; the profit margins are expanded in a large extent; and the maintenance cost is low.

Owner:山西华天新能源发展有限公司

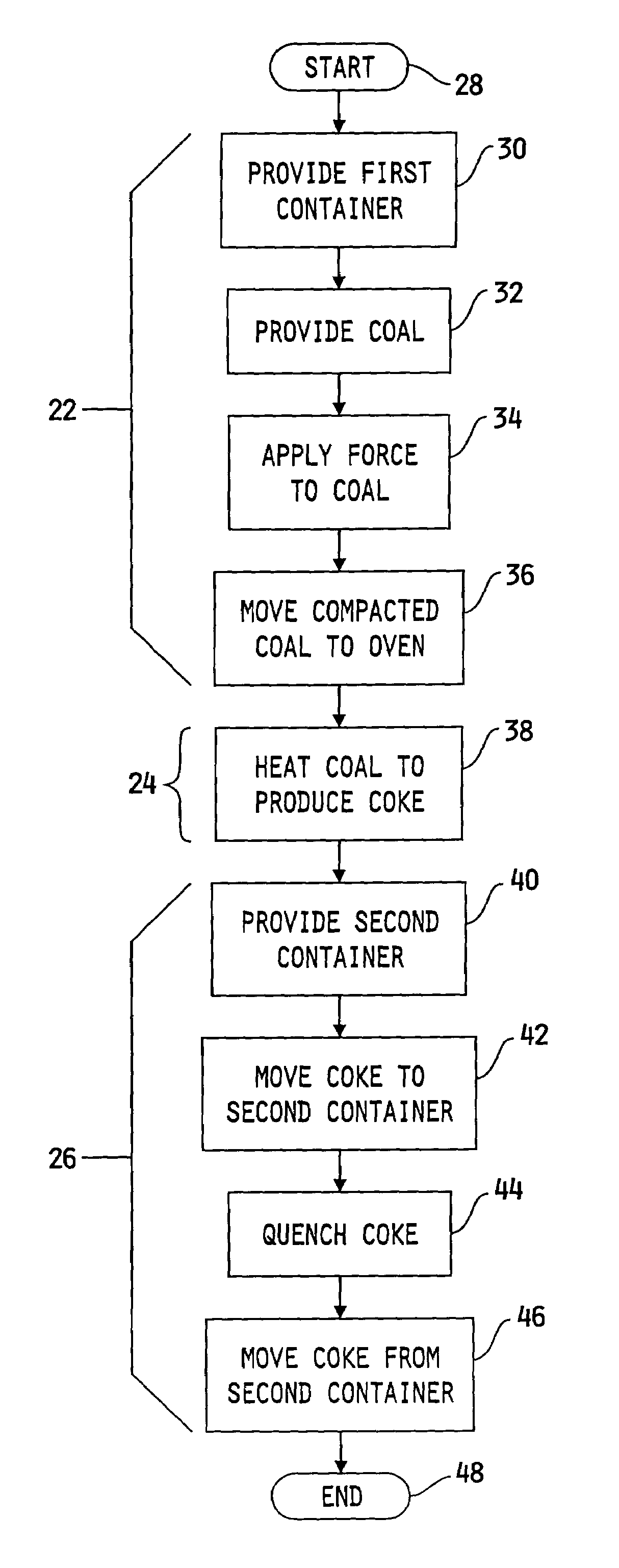

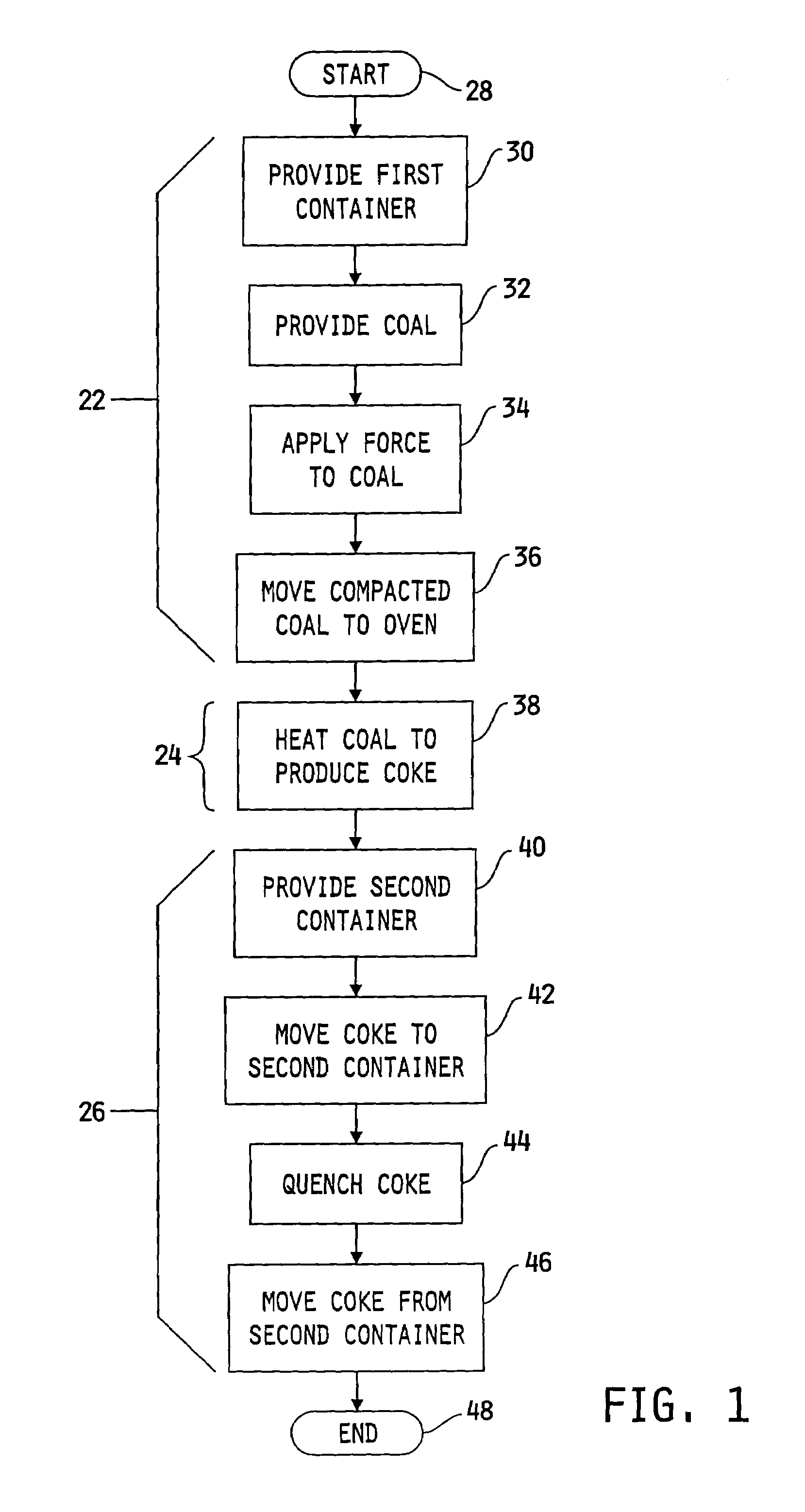

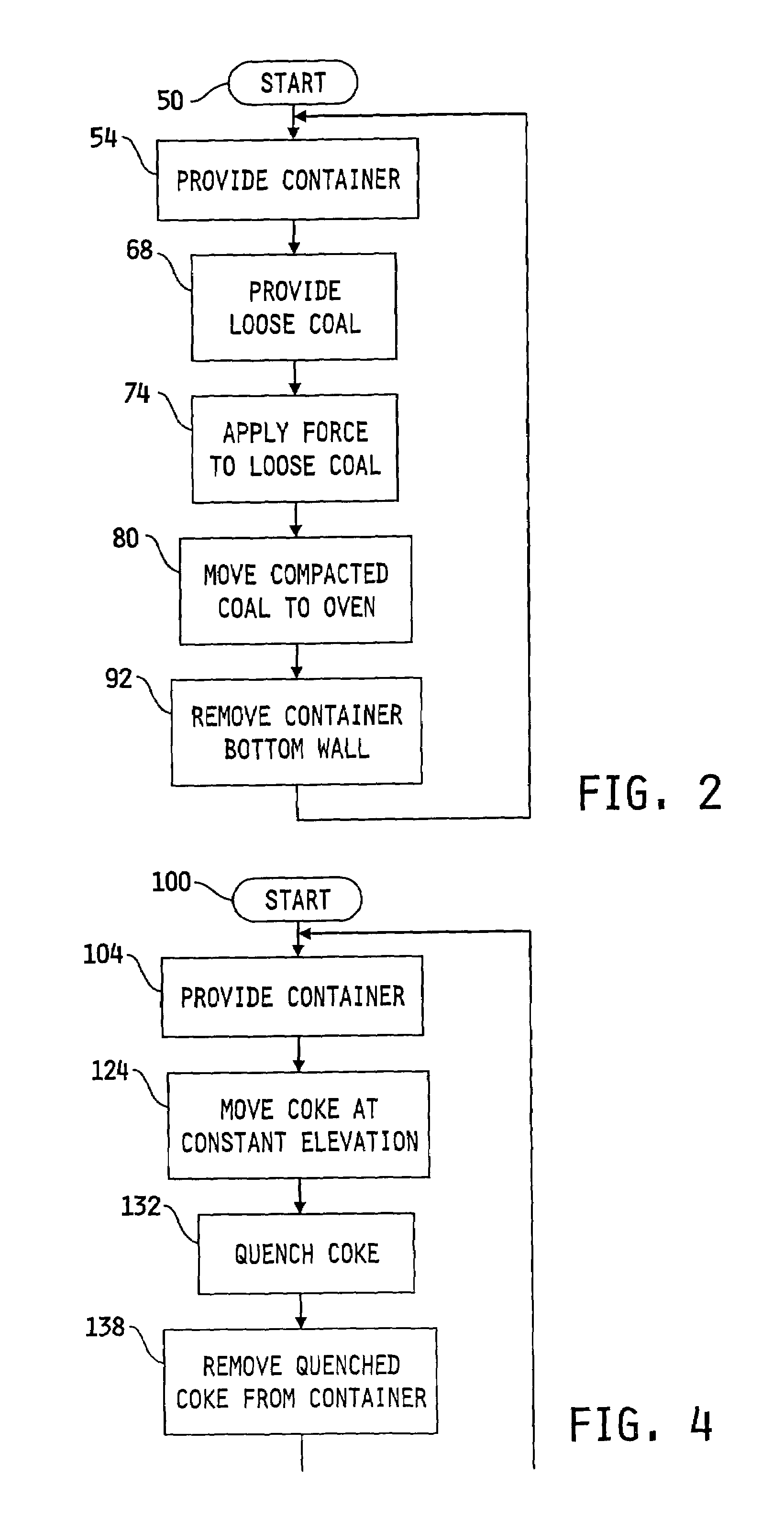

Method for producing blast furnace coke through coal compaction in a non-recovery or heat recovery type oven

A method for producing non-recovery / heat recovery coke may include the steps of providing a container, disposing a volume of loose coal into the container such that a vertical dimension of the volume of loose coal in the container is smaller than a horizontal dimension of the volume of loose coal, applying a force to the coal in the container to produce a volume of compacted coal having a substantially uniform density which is larger than that of the loose coal, disposing the compacted coal into a non-recovery / heat recovery type oven, and heating the compacted coal to produce coke. The method may also include the steps of providing a container, and moving the non-recovery / heat recovery coke mass from the oven at a substantially constant elevation to the container, quenching the coke mass in the container to produce a quenched coke mass, and removing the quenched coke mass from the container.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

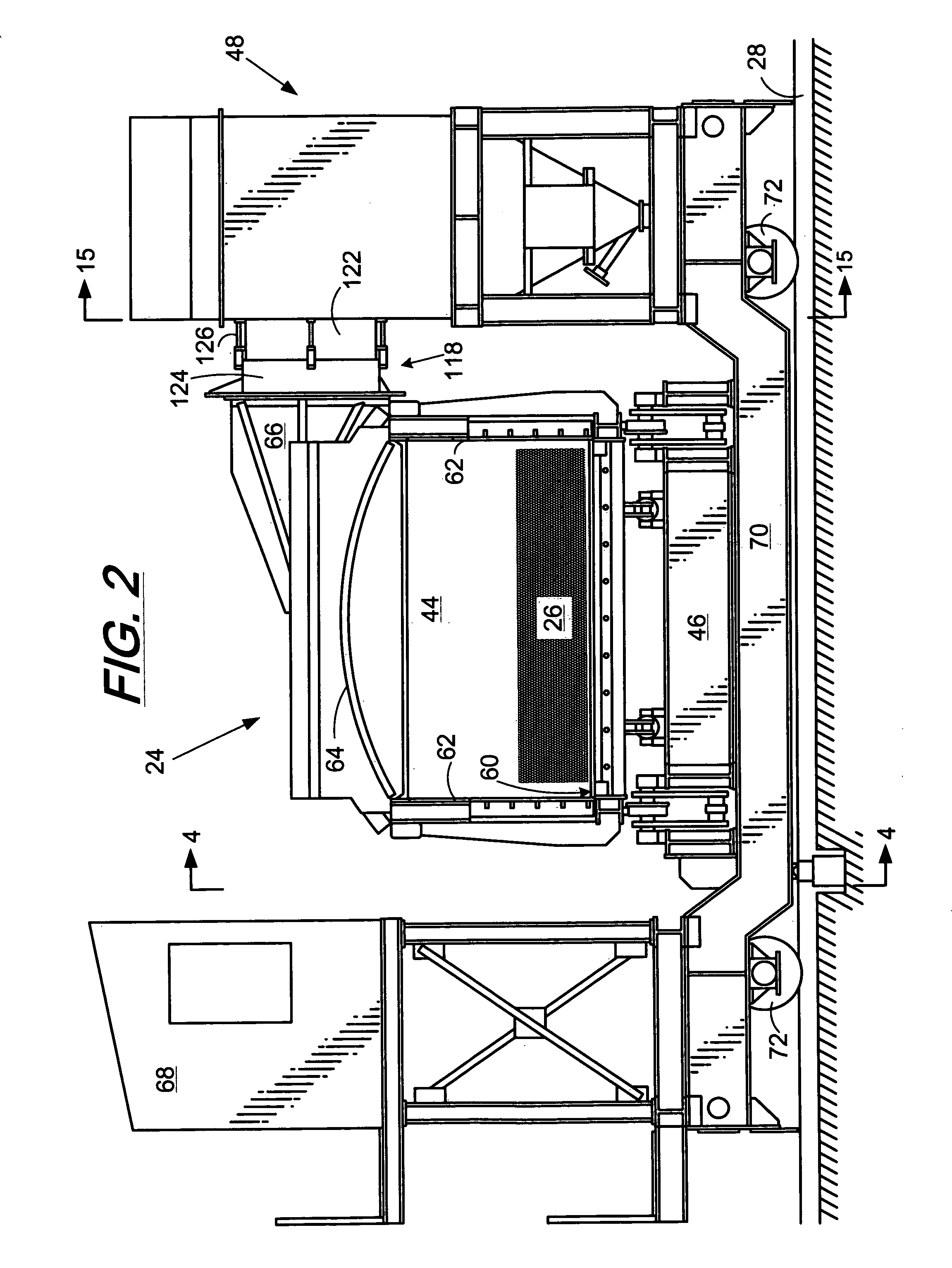

Method and apparatus for producing coke

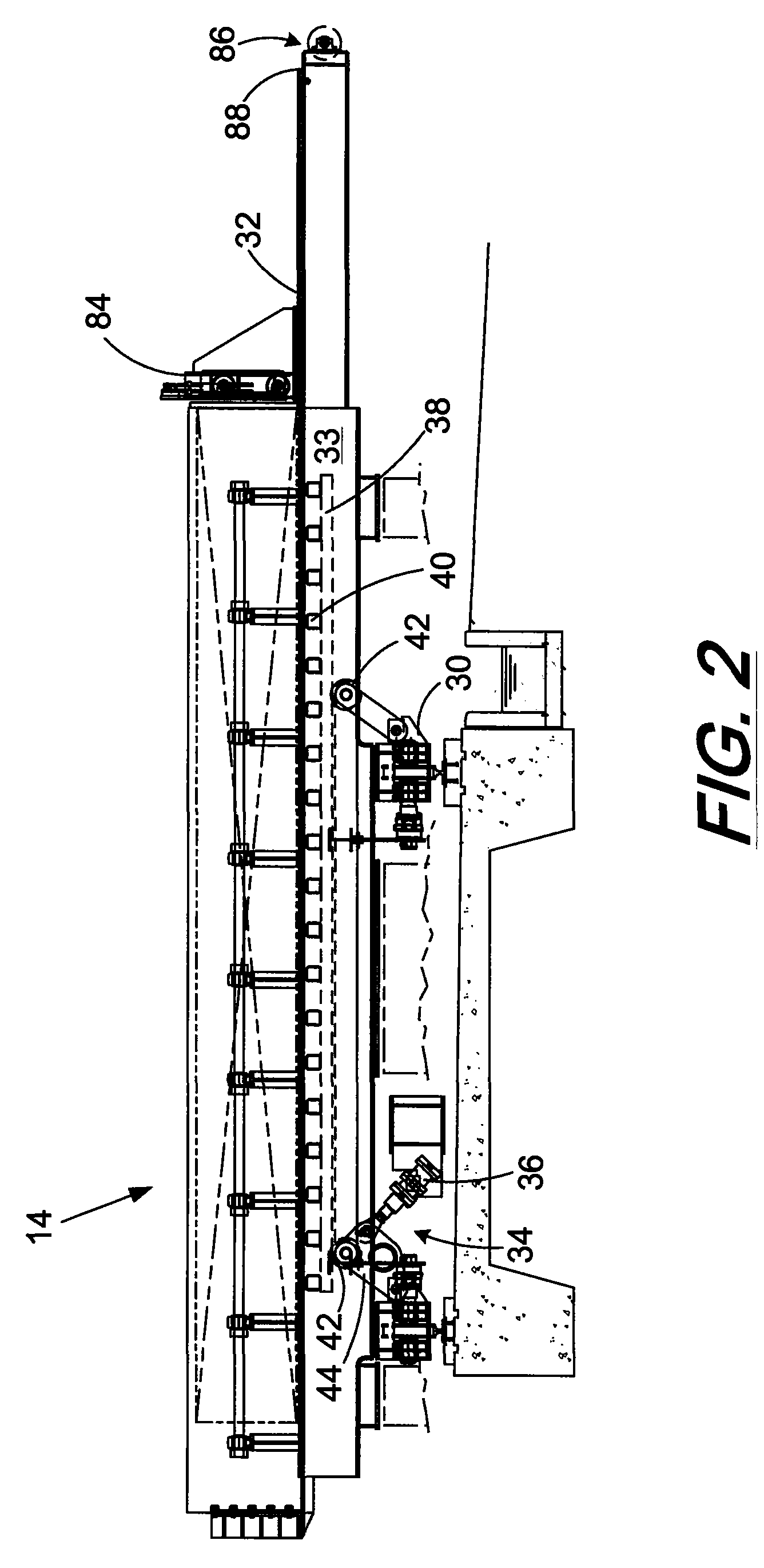

ActiveUS8152970B2Reduce the amount requiredReduce moisture contentSpeed controllerCoke quenchingMetallurgyMetallurgical coke

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

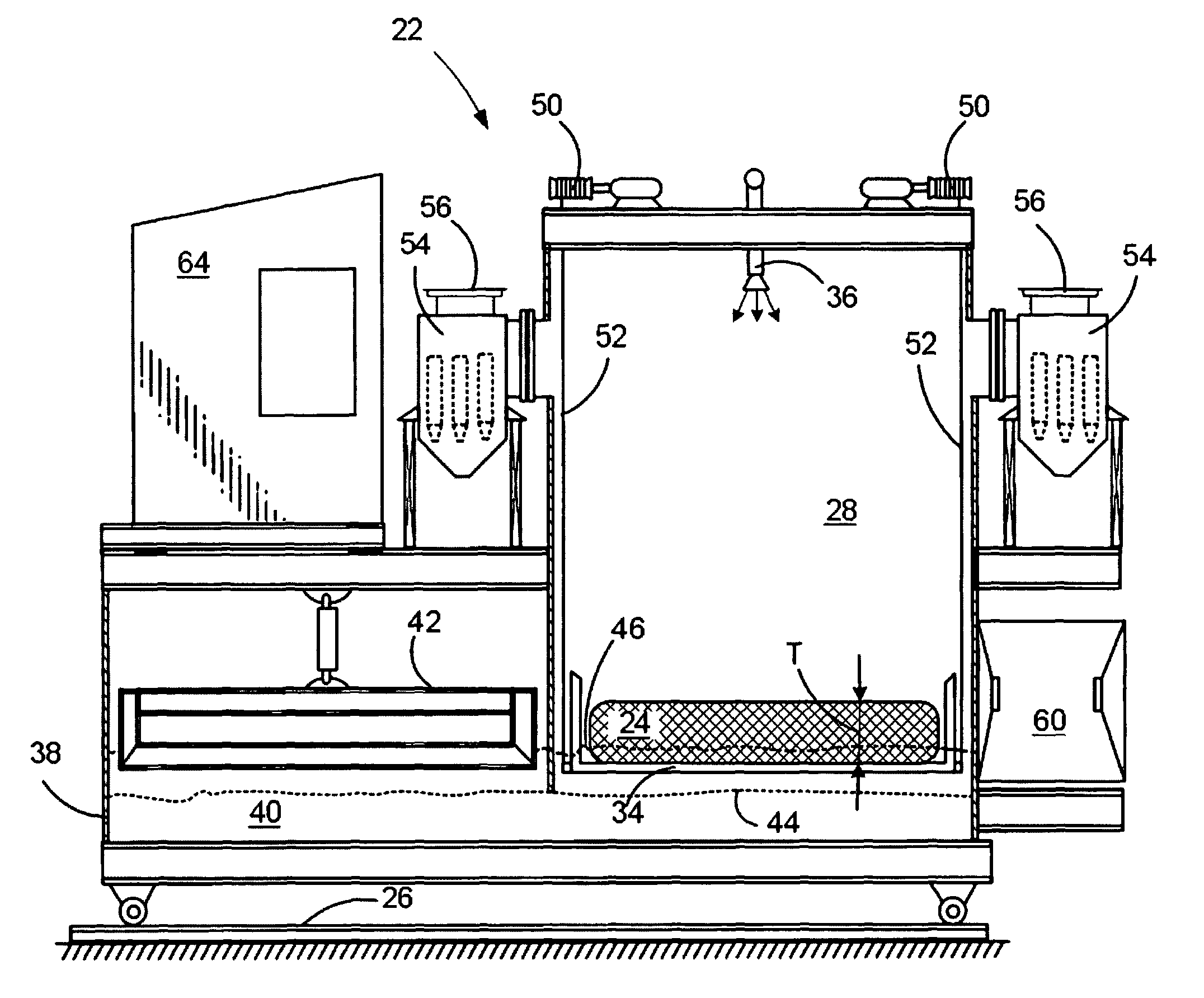

Flat push coke wet quenching apparatus and process

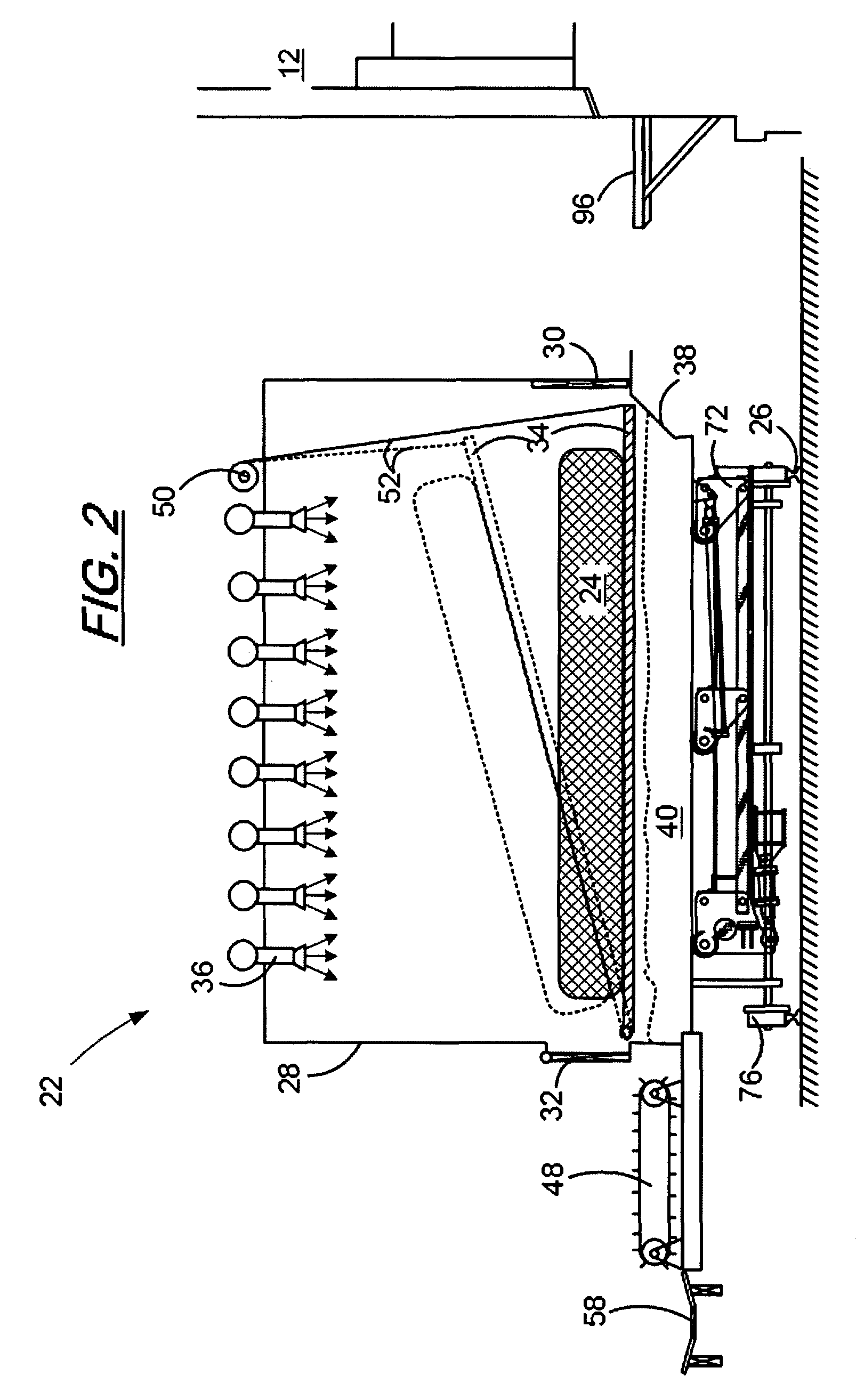

InactiveUS7998316B2Reduce the amount requiredImprove efficiencyCoke quenchingDirect heating destructive distillationCoke ovenWater level

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of incandescent coke onto a substantially planar receiving surface of an enclosed quenching car so that substantially all of the coke from the coking oven is pushed as a unitary slab onto the receiving surface of the quenching car. The slab of incandescent coke is quenched in an enclosed environment within the quenching car with a plurality of water quench nozzles while submerging at least a portion of the slab of incandescent coke by raising a water level in the quenching car. Subsequent to quenching the coke, the planar receiving surface is tilted to an angle sufficient to slide the quenched coke off of the planar receiving surface and onto a product collection conveyer and sufficient to drain water from the quenched coke.

Owner:SUNCOKE TECH & DEV LLC

Process for transporting and quenching coke

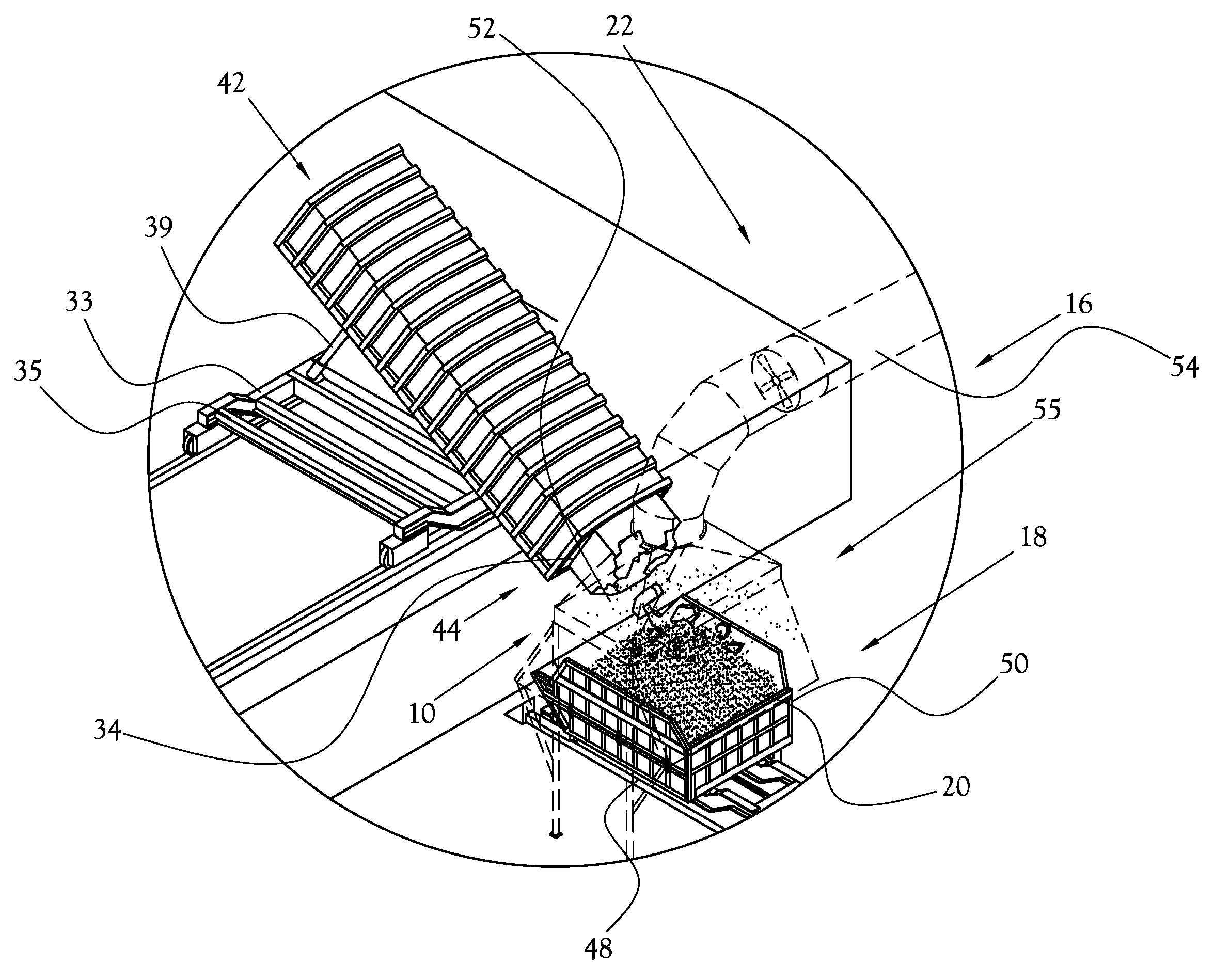

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

High-carbon biogenic reagents and uses thereof

ActiveUS20120285080A1High carbon contentImprove energy efficiencyCoke quenchingCoke oven safety devicesHigh carbonReagent

This invention provides processes and systems for converting biomass into high-carbon biogenic reagents that are suitable for a variety of commercial applications. High carbon biogenic reagents are also provided.

Owner:CARBON TECH HLDG LLC

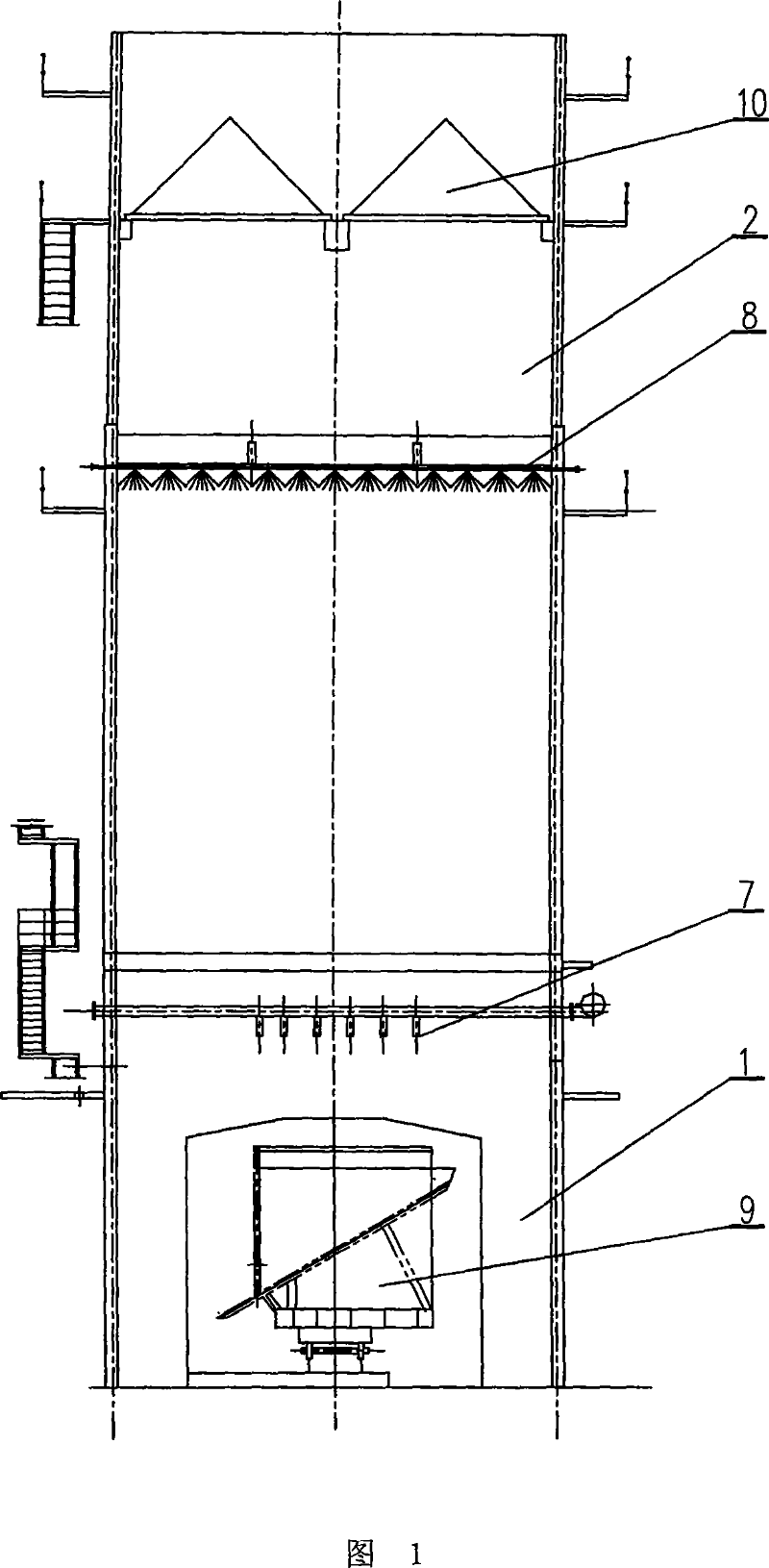

High-effective dust-removing coke quenching tower

ActiveCN101037603AEasy dust removal effectGuaranteed dust removal performanceCoke quenchingSingle stageTower

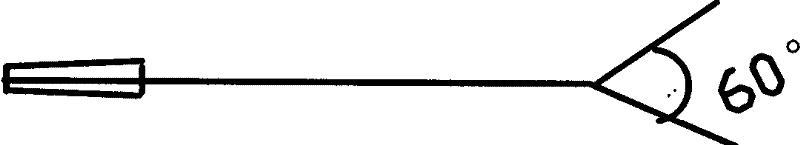

The invention relates to a highly effective dust removal coke quenching machine, which includes a coke quenching injection pipe, a washing and cooling device, and a dust removal device. The dust removal device, which is disposed single-stage or two-stage, includes a structural framework, a dust removal plate, a dust removal pipe and nozzles, wherein the dust removal plate, which is constituted of a heterotypic baffle sheet folded with a certain angle and a dust removal plate support, is disposed on the structural framework and forms angle of 45-60 DEG with horizontal plane; the dust removal pipe is equably equipped with a plurality of nozzles and is arranged parallel with the dust removal plate. Dust content of stream generated at coke quenching process is greatly reduced by water fog washing, cooling, gravitational settling and purifying of baffle plate type dust removal device, amount of coking powder discharged into air of per ton coke is lower than 50g. Moreover, the baffle plate employs industrial plastic, thereby possessing advantages of corrosion resistance, high strength, aging resistance, good dust removal effect, convenient installation and maintance, and easy cleaning.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

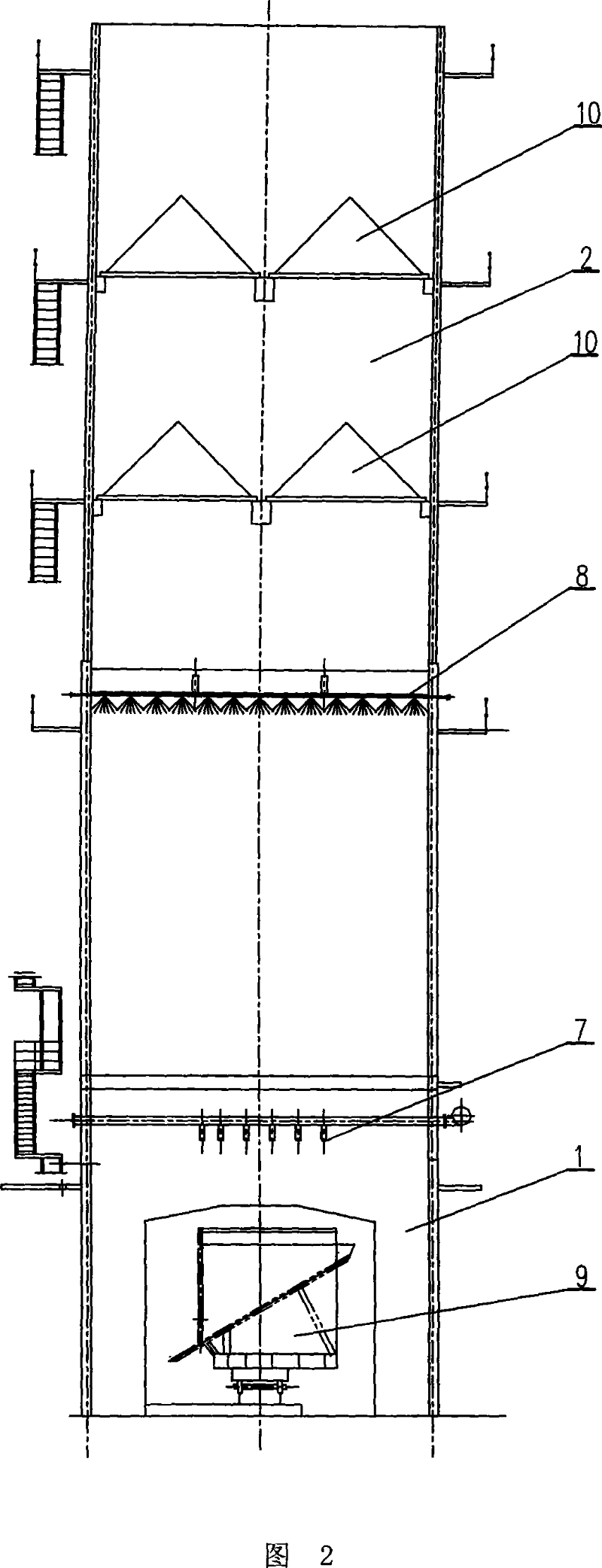

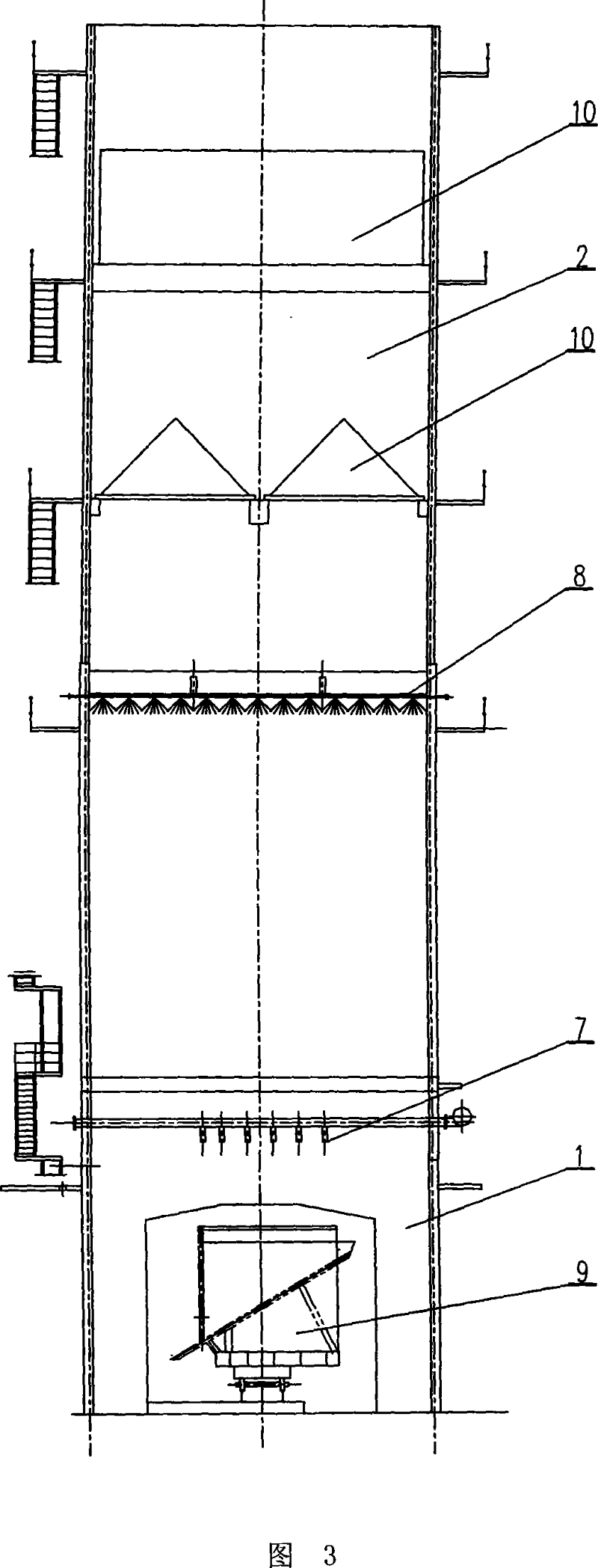

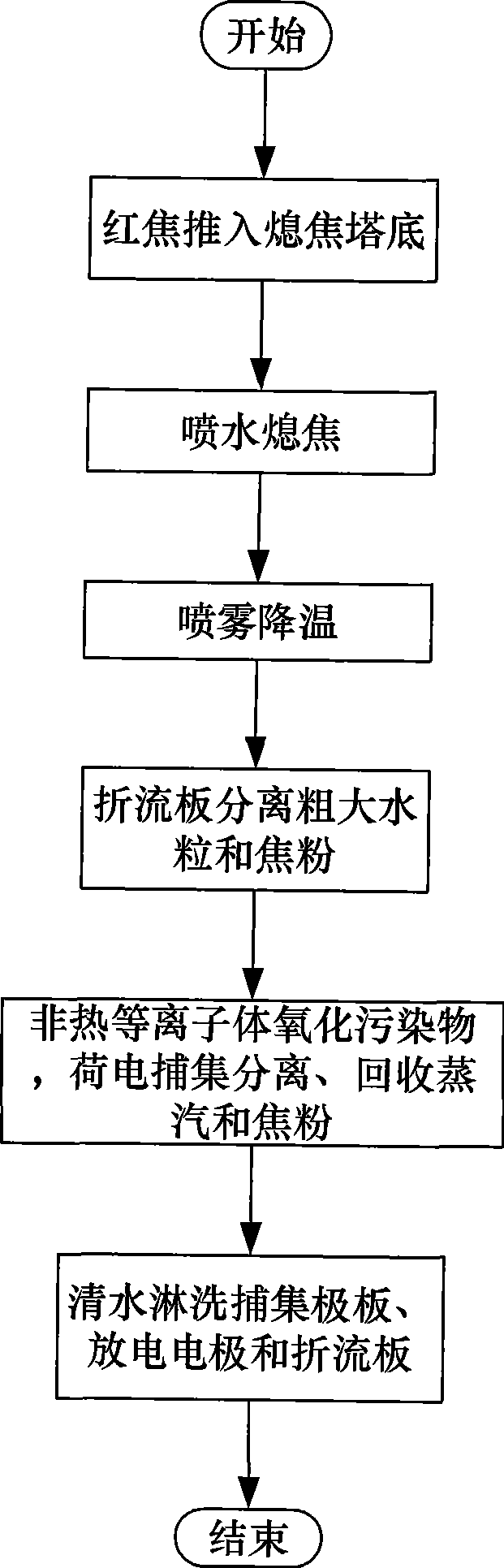

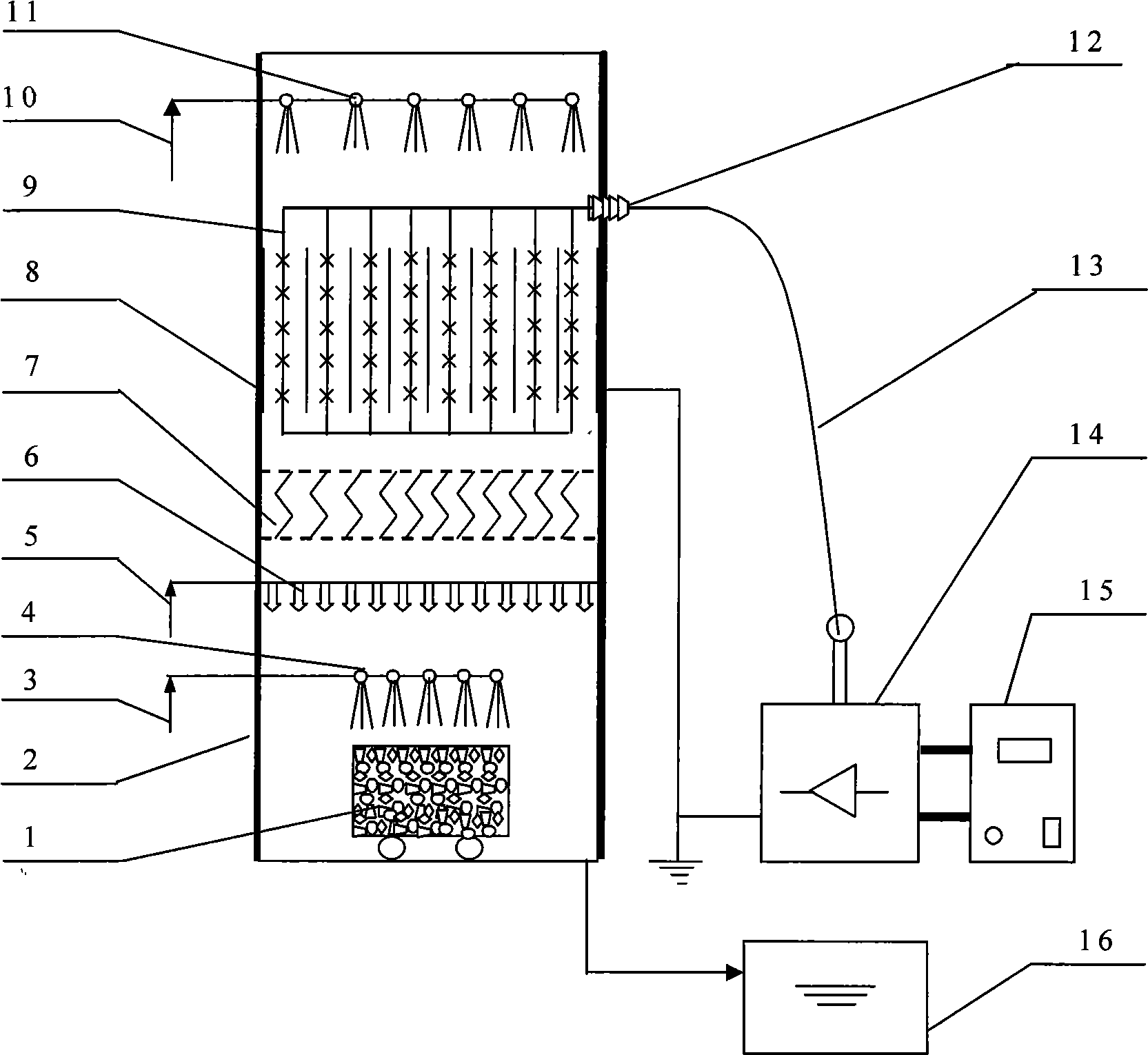

Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

InactiveCN101486017AReduce the amount of pollutantsPrevent diverted emissionsCombination devicesCoke quenchingWater vaporHigh pressure

The invention discloses a method and a device for processing wet quenching coke gas fog on the basis of athermal plasma injection. The method comprises the following steps that: in the ascending process, the hot gas fog generated by wet quenching coke sequentially passes through three processing steps including spray cooling, pre-dedusting on a baffle plate and athermal plasma purification, and is cooled in a spray cooling area; the cooled gas fog enters a pre-dedusting area on the baffle plate where the thicker and bigger water particles and coke powder in the gas fog are separated from the gas fog and impact to the baffle plate under the action of inertia; the remaining gas fog continues to ascend and enter an athermal plasma purification area where organic components, ammonia nitrogen and cyanide in the gas fog are oxidized by the athermal plasma; the water particles and the coke powder are charged and are transferred to a trapping pole plate directionally under the action of a high voltage electric field; and then the gas flow after subjected to the athermal plasma purification area continuous to ascend to the top of a coke quenching tower to be discharged. After the processing steps, the contents of water vapor and the coke powder discharged outside after one ton of coke is produced are controlled to be less than 0.05 ton and 5 grams respectively, and the removal rate of the organic components, the ammonia nitrogen and the cyanide can reach more than 80 percent.

Owner:BEIHANG UNIV

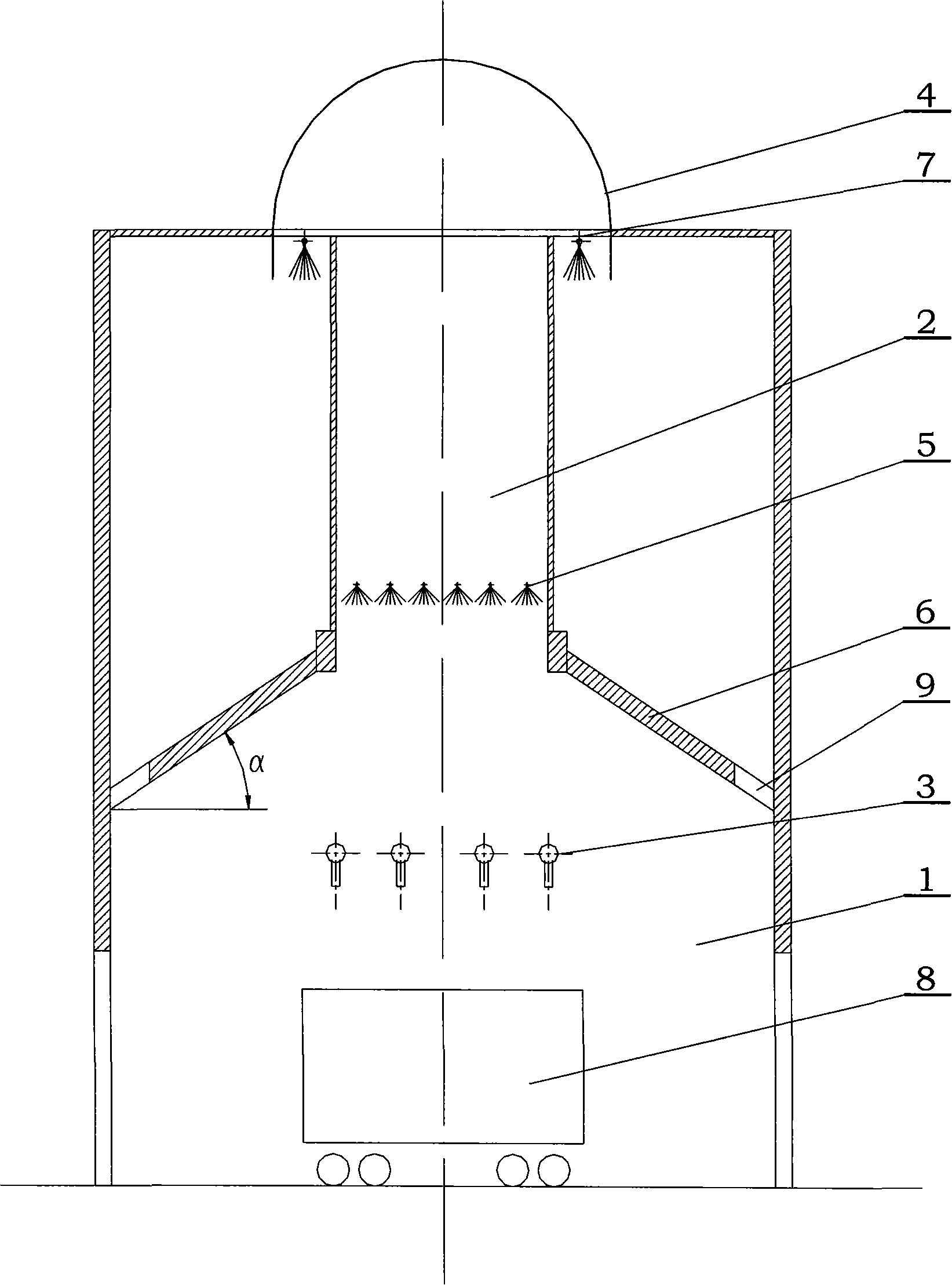

Dome type dust removing coke quenching machine

The invention relates to a dome-like dedusting coke quenching tower, which comprises the following parts: a coke quenching procedure at the bottom and a deduesting procedure at the top, wherein the coke quenching procedure is equipped with a coke quenching injecting pipe; the dedusting procedure is divided into three lattices; the bottom of two side lattices sealed by a tipping plate; the bottom of the tipping plate is equipped with blow-off hole; the included angle alpha of the tipping plate and the horizontal surface is 10-75 degree; the top of the coke quenching injecting pipe and the middle lattice entrance of the dedusting procedure are equipped with a plurality of washing and cooling devices; the top of washing and cooling devices and the top of the coke quenching tower are equipped with dome-like dedusting device which covers the middle lattice and two side lattices of the coke quenching tower dedusting procedure. The invention reduces the dust content after washing the polluting vapor with the water fog, cooling the polluting vapor, settling the polluting vapor gravitively and changing the direction of the gas flowing, which reduces the water consumption.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

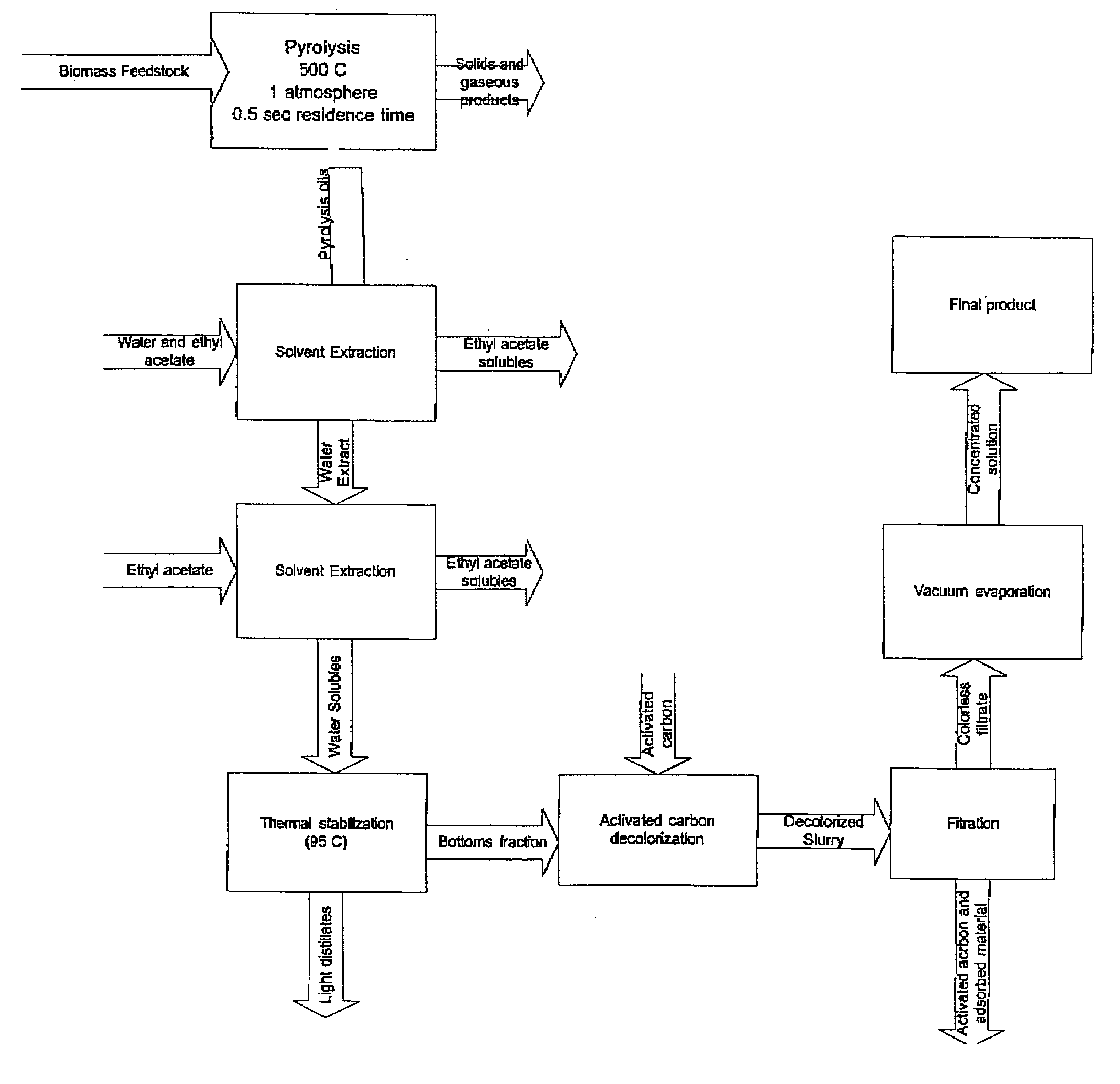

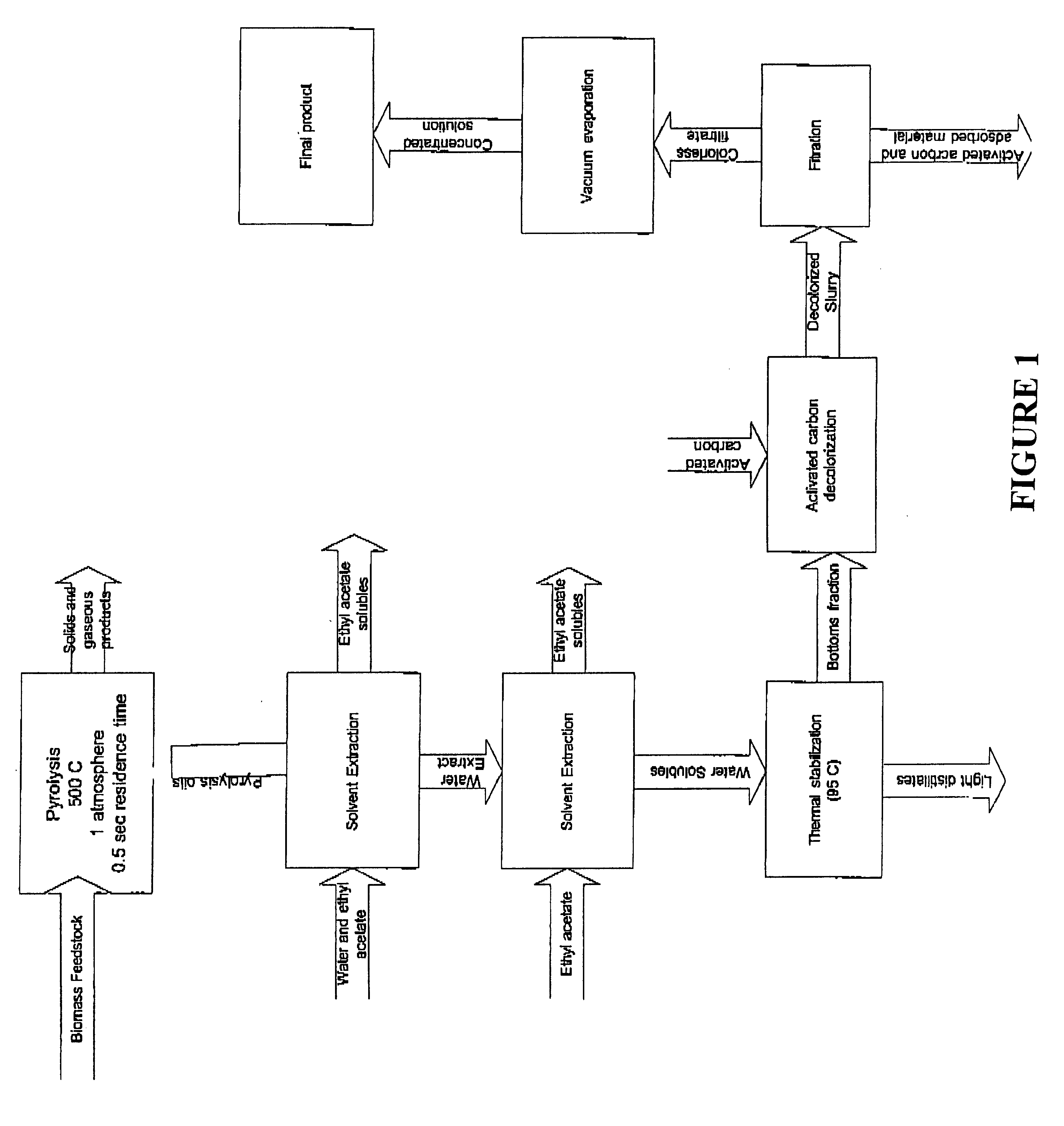

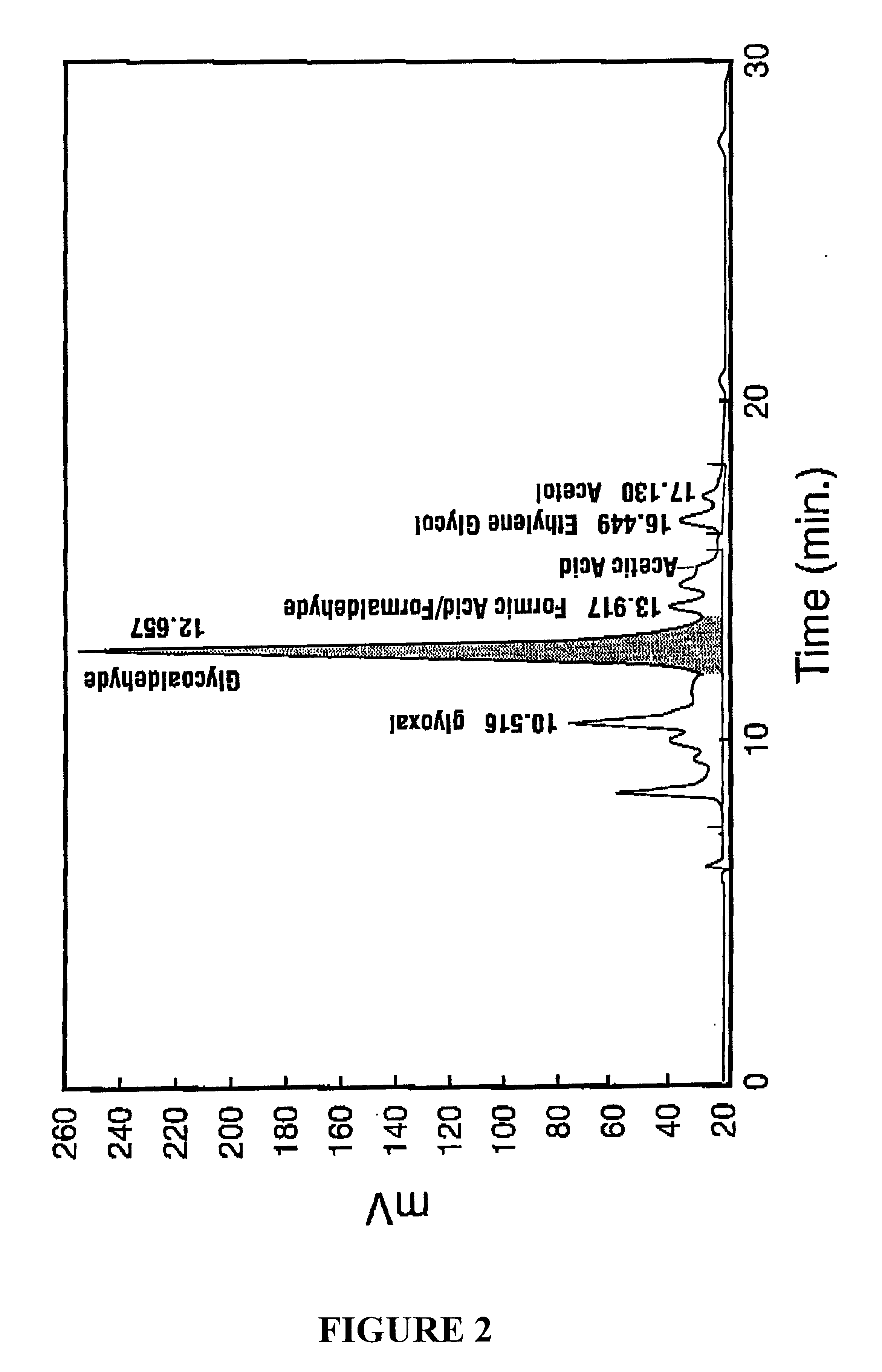

Preparation of brightness stabilization agent for lignin containing pulp from biomass pyrolysis oils

A process for producing a brightness stabilization mixture of water-soluble organic compounds from biomass pyrolysis oils comprising:a) size-reducing biomass material and pyrolyzing the size-reduced biomass material in a fluidized bed reactor;b) separating a char / ash component while maintaining char-pot temperatures to avoid condensation of pyrolysis vapors;c) condensing pyrolysis gases and vapors, and recovering pyrolysis oils by mixing the oils with acetone to obtain an oil-acetone mixture;d) evaporating acetone and recovering pyrolysis oils;e) extracting the pyrolysis oils with water to obtain a water extract;f) slurrying the water extract with carbon while stirring, and filtering the slurry to obtain a colorless filtrate;g) cooling the solution and stabilizing the solution against thermally-induced gelling and solidification by extraction with ethyl acetate to form an aqueous phase lower layer and an organic phase upper layer;h) discarding the upper organic layer and extracting the aqueous layer with ethyl acetate, and discarding the ethyl acetate fraction to obtain a brown-colored solution not susceptible to gelling or solidification upon heating;i) heating the solution to distill off water and other light components and concentrating a bottoms fraction comprising hydroxyacetaldehyde and other non-volatile components having high boiling points; andj) decolorizing the stabilized brown solution with activated carbon to obtain a colorless solution.

Owner:MIDWEST RES INST

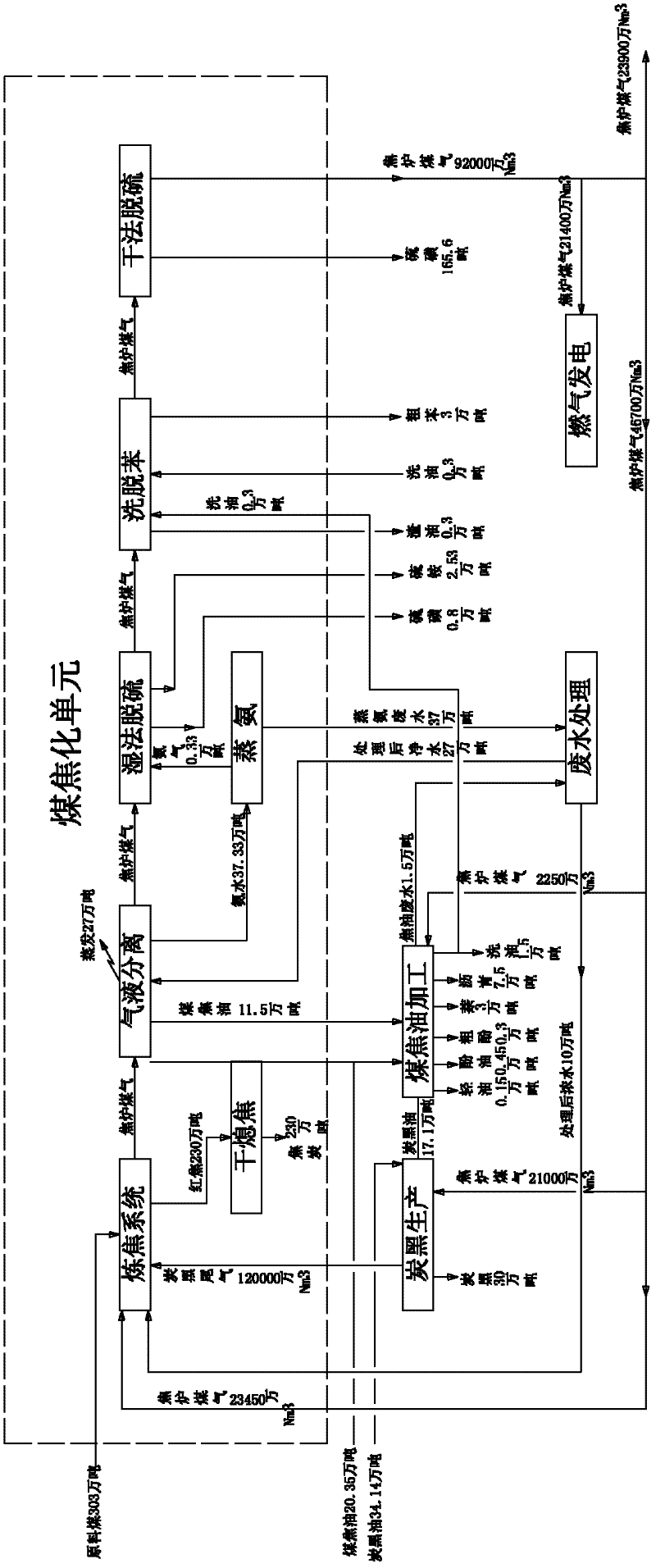

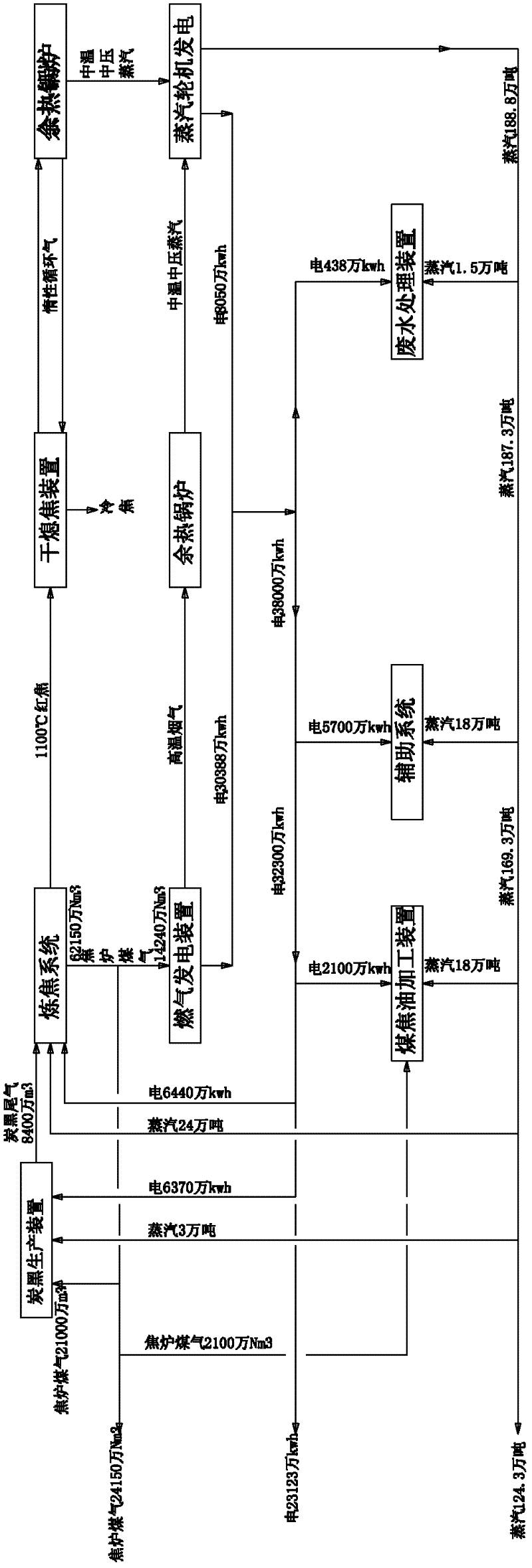

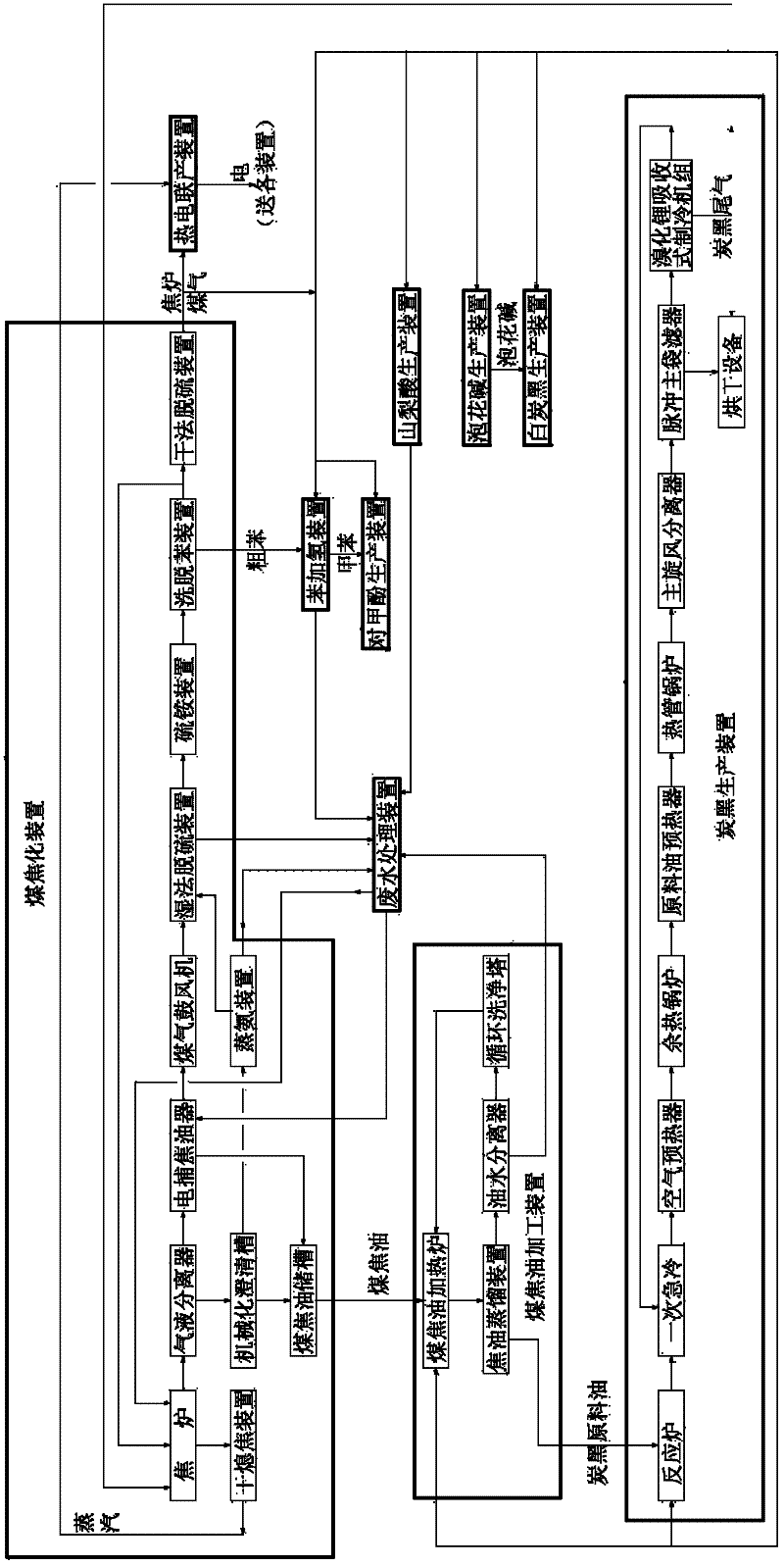

Green circular economy technology with coal coking as the main part

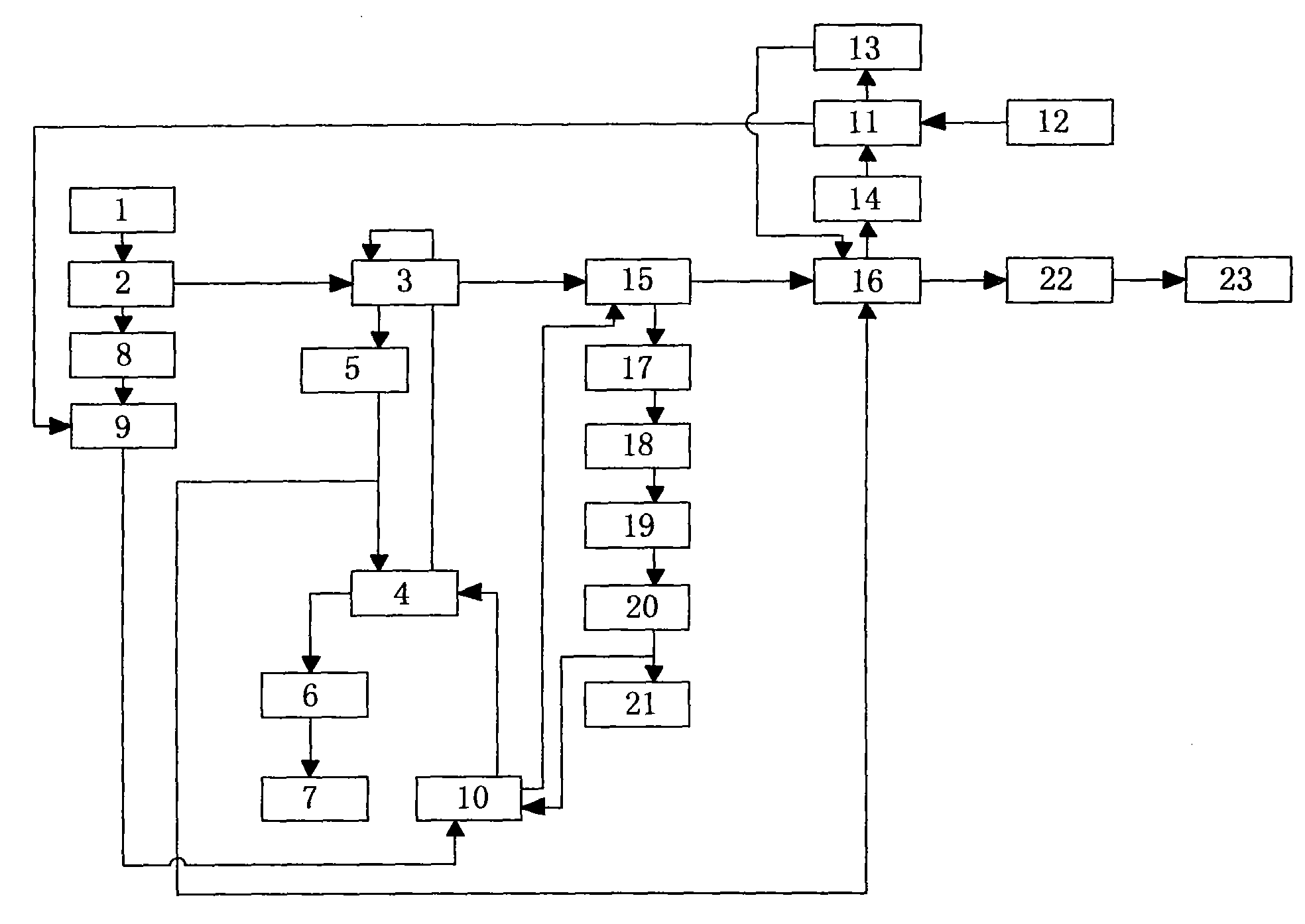

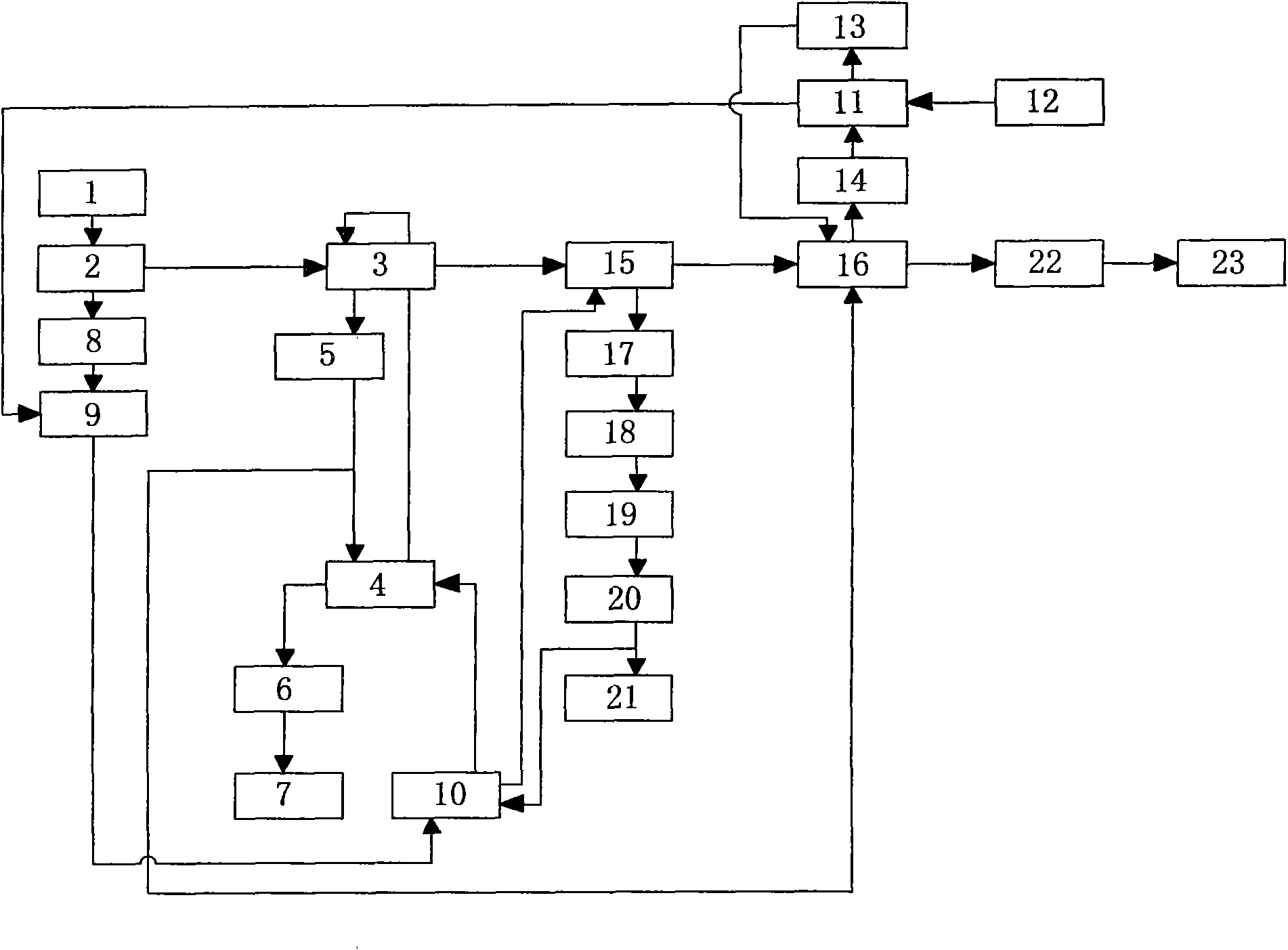

ActiveCN102229806AHigh aromatic contentQuality improvementPigmenting treatmentCoke quenchingCogenerationEngineering

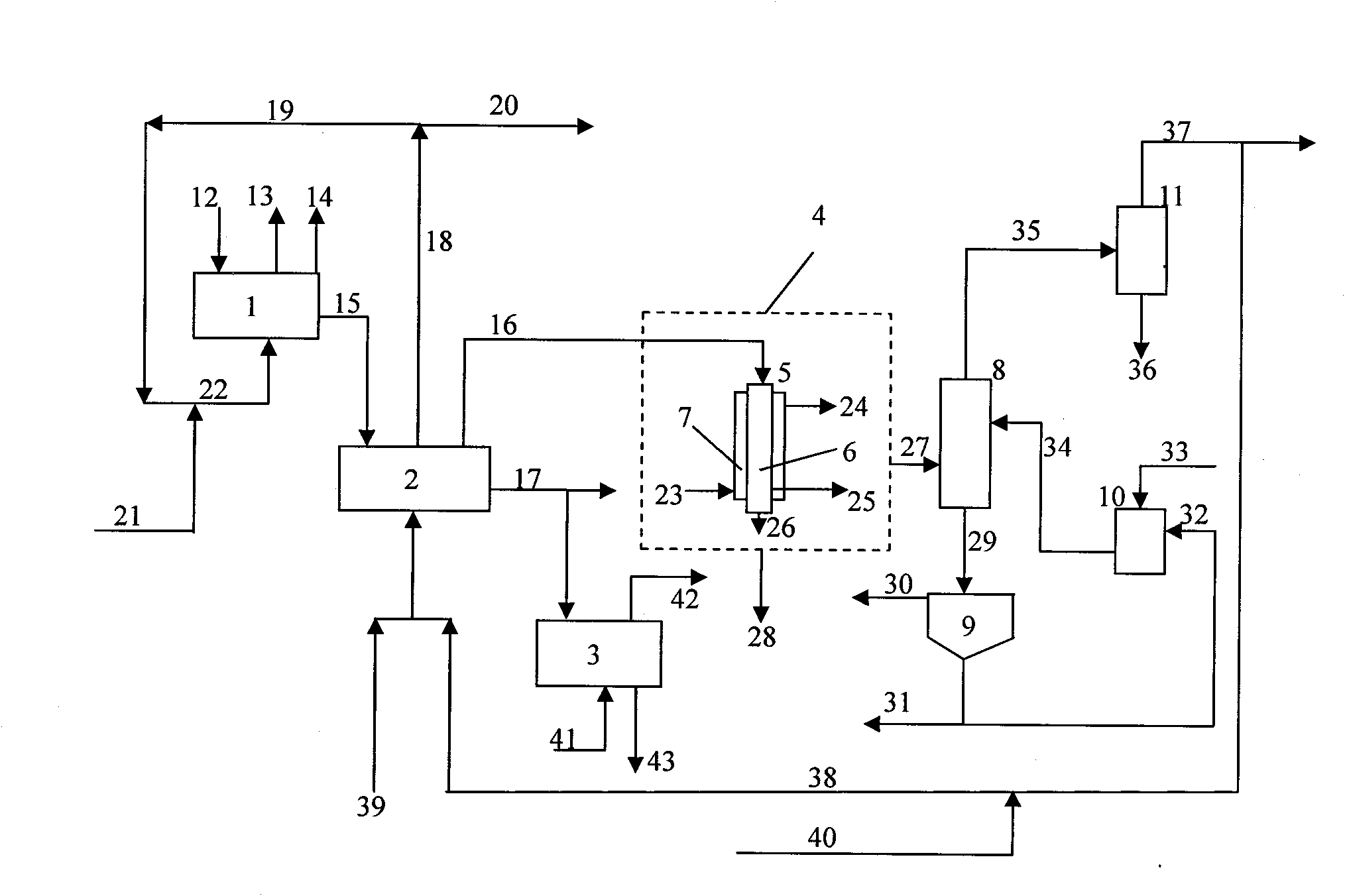

The invention provides a green circular economy technology with coal coking as the main part. The technical scheme of the technology is as follows: a coal coking part, a coal tar processing part, a carbon black part and a part of combined power and thermoelectricity generation by coke oven gas are organically combined to form the relationship of industrial metabolism, symbiosis and coupling; suchmeasures as differentially utilizing tail gas of carbon black, recovering energy of coke drying quenching, reducing, recycling and changing the three wastes into resources, etc., enable resources to be saved, production cost to be reduced and pollution to be lessened; therefore, economic benefits of coal coking enterprises are maximized and the green circular economy technology is realized indeed. The invention also provides an apparatus for realizing the green circular economy technology with coal coking as the main part.

Owner:JINNENG SCI & TECH

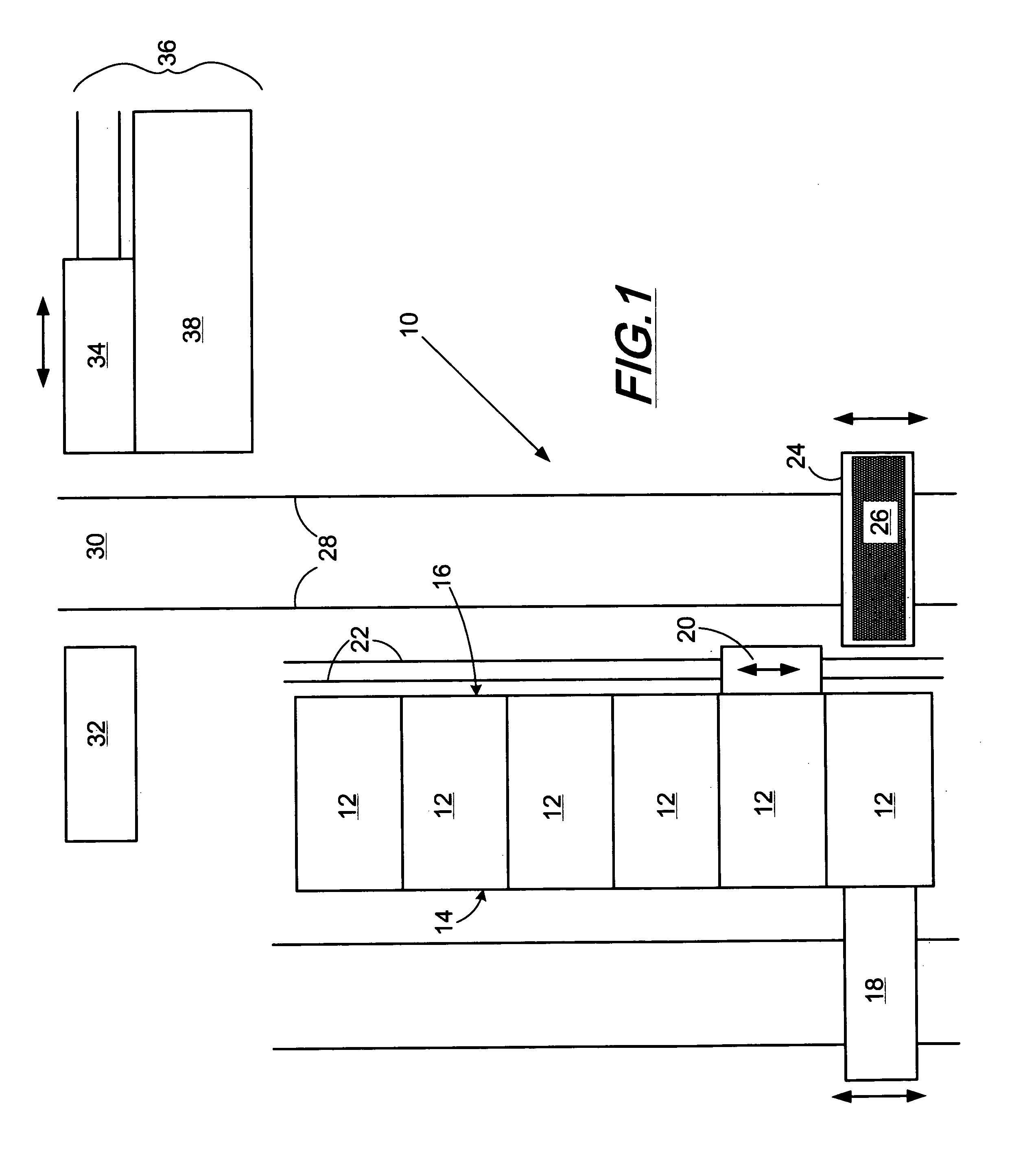

Method and apparatus for compacting coal for a coal coking process

InactiveUS20070289861A1Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsCoke ovenEngineering

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

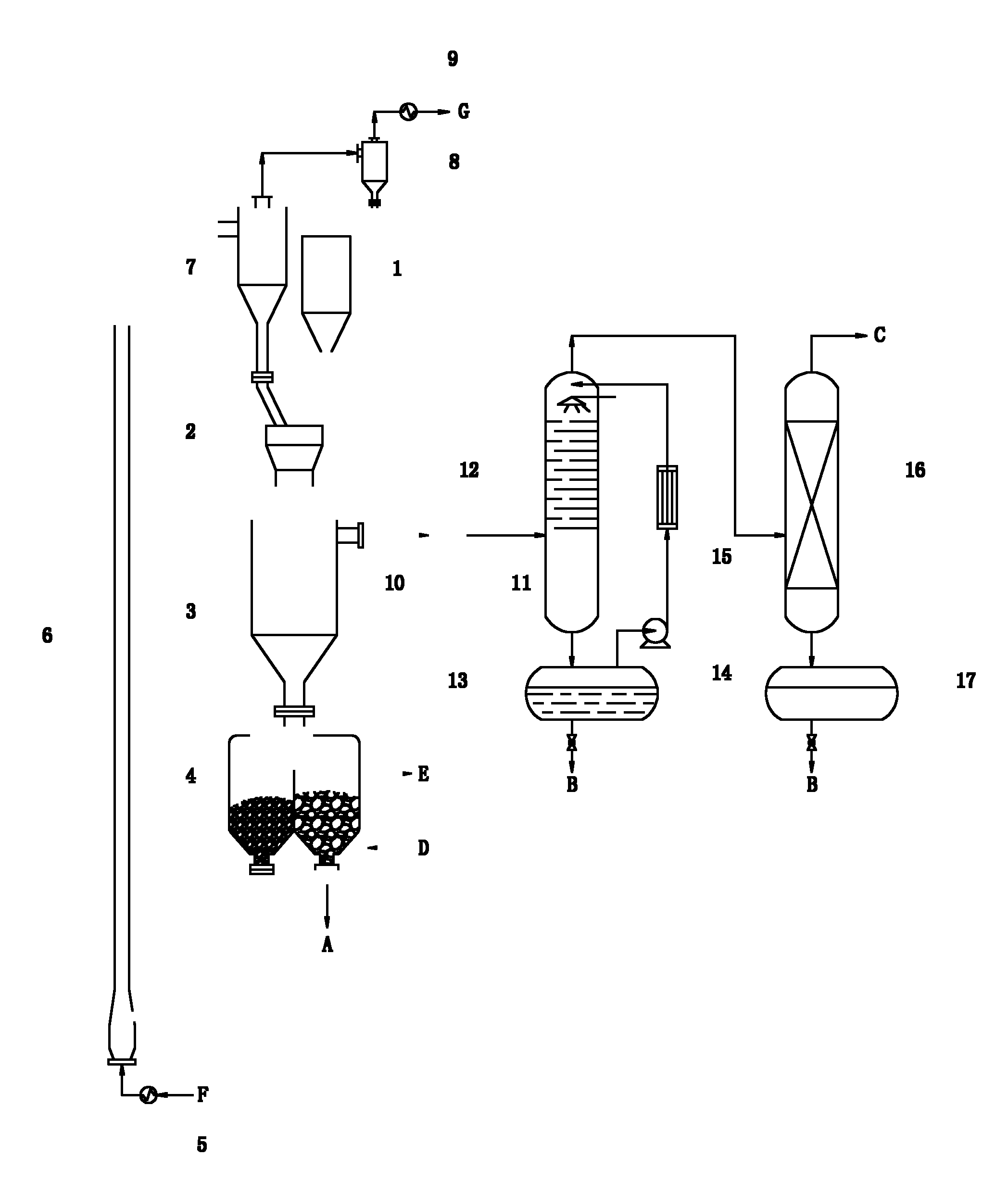

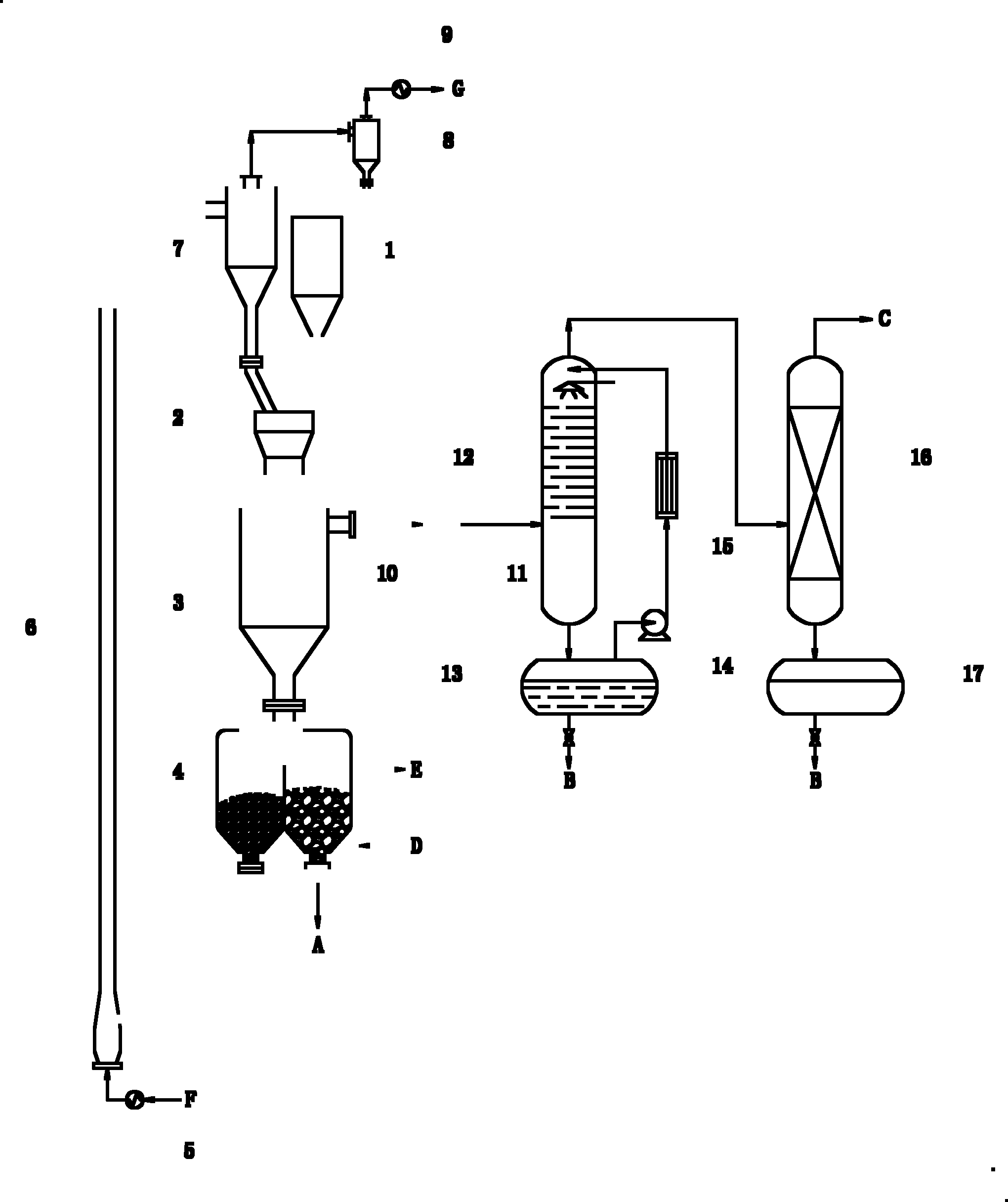

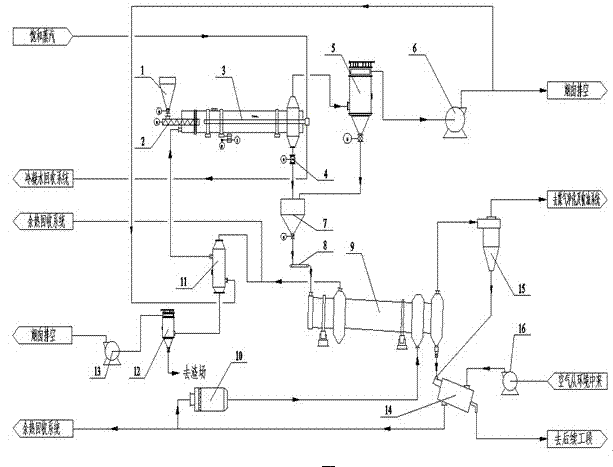

High-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as heat-carrying medium

InactiveCN101812310AReduce in quantityEfficient use ofCoke quenchingChemical industryEconomic benefitsTar

The invention relates to a low-temperature dry distillation process for coal, in particular to a high-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as a heat-carrying medium. The process comprises a coal-preparing flow, a drying flow, a dry distillation flow, a heat source flow, a coal gas and tar processing flow and a semicoke cooling transfer flow; in the process, vapor self-generated by a drying tower is used as a drying medium, the coal gas of a generator is taken as a heat source to heat the self-generated dry distillation coal gas, and serves as a dry distillation medium, and the coal gas of the generator is used as fuel of a hot air furnace; the dry distillation semicoke is cooled in a cooling mode of drying fume exhaust plus semi water spraying; and condensation water is used for coke-quenching water, a gasifier of the coal gas of the generator and a tar cooling agent. The process has the advantages of producing high-index dry coal and dry semicoke, high-heating value coal gas and high-quality tar, having a flawless and high-efficiency energy recycling system, not using outside nature water, hardly discharging water to the outside, saving huge cost for sewage treatment, creating the maximum economic benefits for customers and having quite strong competitive power on economy, technology and market.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

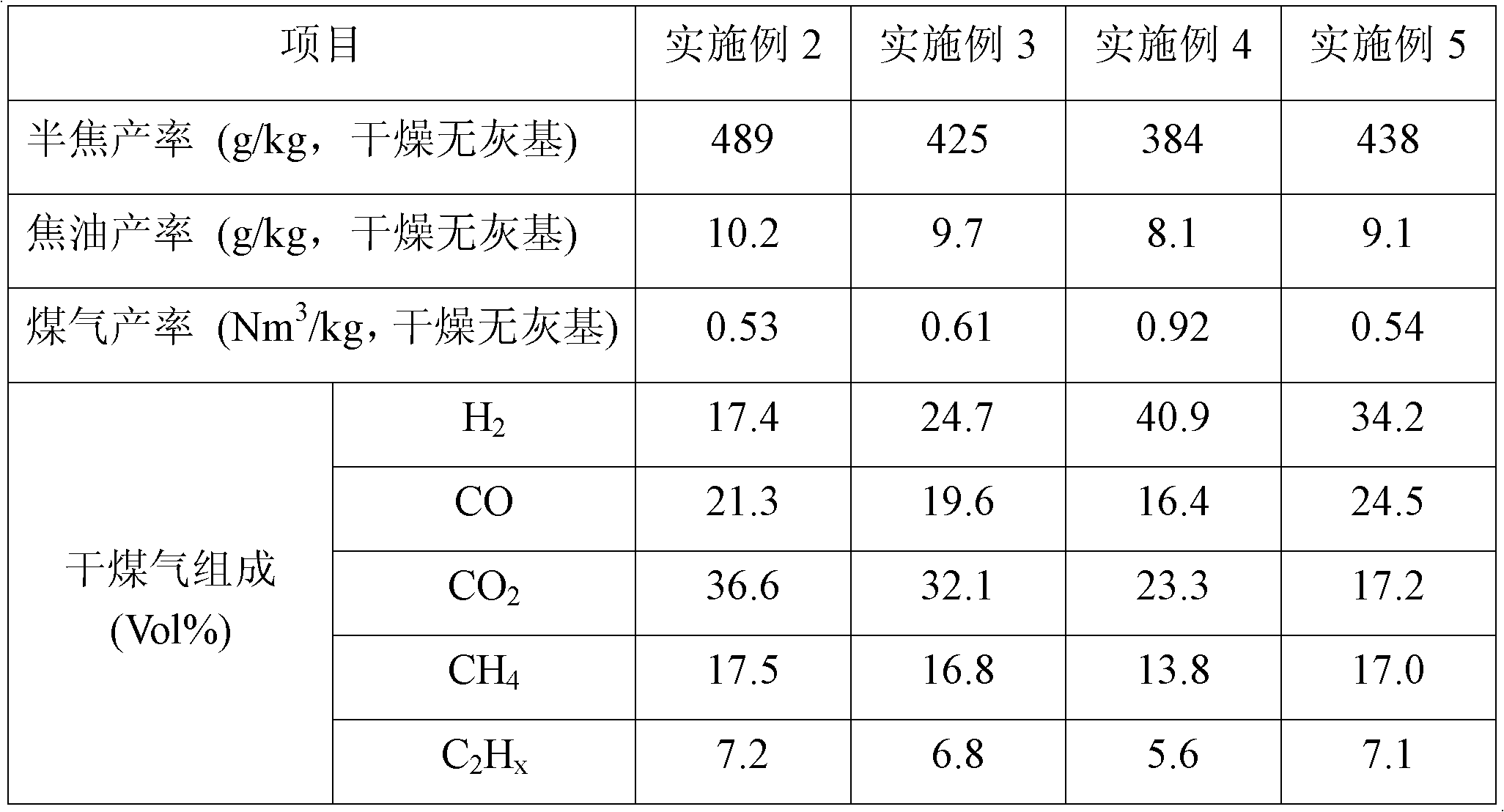

Low-coalification degree pulverized coal pyrolysis method and product prepared through the same

ActiveCN101880540AAlleviate the difficulty of efficient utilizationAlleviate the problem of secondary pyrolysisCoke quenchingSpecial form destructive distillationCoal pyrolysisCoal tar

The invention relates to a low-coalification degree pulverized coal pyrolysis method and a product prepared through the same. The method comprises the following four steps: low-coalification degree pulverized coal pre-drying, low-coalification degree pulverized coal pyrolysis reaction, gas cooling and tar recovery, and hot semi-coke cooling. The method is applicable to heat treatment to low-coalification degree pulverized coal resources so as to obtain high-quality pyrolysis gas and tar products, wherein the gas contains low inert component content, tar contains high light component content and low dust content, and semi-coke products with wide purposes are obtained. The process method is characterized by high comprehensive utilization rate of energy, large amount of treated material, lowdevice investment, easy industrialization realization, environmental friendliness and the like while improving the raw material utilization efficiency.

Owner:XIAN ORIGIN CHEM TECH

Device and method for cooling coke

InactiveCN101705101AQuality improvementIncrease productionCoke quenchingCombustible gas productionWater vaporEngineering

The invention discloses a device and a method for cooling coke. The device consists of a prestorage section, a vapor cooling section, a transitional section, a physically cooling section and a discharge section, wherein the upper prestorage section and the vapor cooling section are communicated by a vaporization gas collection channel; the middle transitional section and the physically cooling section are communicated by high-temperature coolant collection channel; a rotary discharge valve of the discharge second is immersed in liquid-sealed coke quenching tank; and a coke conveying device is arranged in the liquid-sealed coke quenching tank or a belt conveyor is arranged at the outlet of the discharge valve to convey the coke to the outside. The method for cooling the coke by vapor and coke oven gases comprises: introducing the vapor into the vapor cooling section; performing vaporization and generating synthesis gases; and introducing the coke oven gases into the physically cooling section to allow the coke oven gases to absorb the sensible heat of the coke and perform physical heat exchange with the coke. The device and the method have the advantages of reducing circulating gas volume, recovering the sensible heat of high-temperature coke, generating water gas and fully utilizing resources.

Owner:TAIYUAN UNIV OF TECH

Method for preparing semicoke, empyreumatic oil and coal gas by pyrolyzing coal

InactiveCN102010728AIncrease production capacityFast heatingCoke quenchingDirect heating destructive distillationHeat carrierTar

The invention discloses a method for preparing semicoke, empyreumatic oil and coal gas by pyrolyzing coal. The method is characterized in that a heating mode of solid thermal carriers is adopted in the pyrolysis process; the semicoke generated in the pyrolysis process and large-particle semicoke in a heat carrier mixture are separated as products by a size grading method, and the empyreumatic oiland coal gas with a medium heat value are produced as byproducts, wherein a pyrolysis system mainly comprises a heat carrier storage bin, a mixer, a pyrolysis reactor, a solid grading separator and araising pipe burning reactor. In the invention, the heating rate of coal is improved, the destructive distillation time is shortened, the single burner production capacity is improved, and the coal of combination grain is taken as production raw materials, the raw material adaptability and the utilization factor are high and the method provided by the invention is suitable for various lignite andbitumite.

Owner:DALIAN UNIV OF TECH

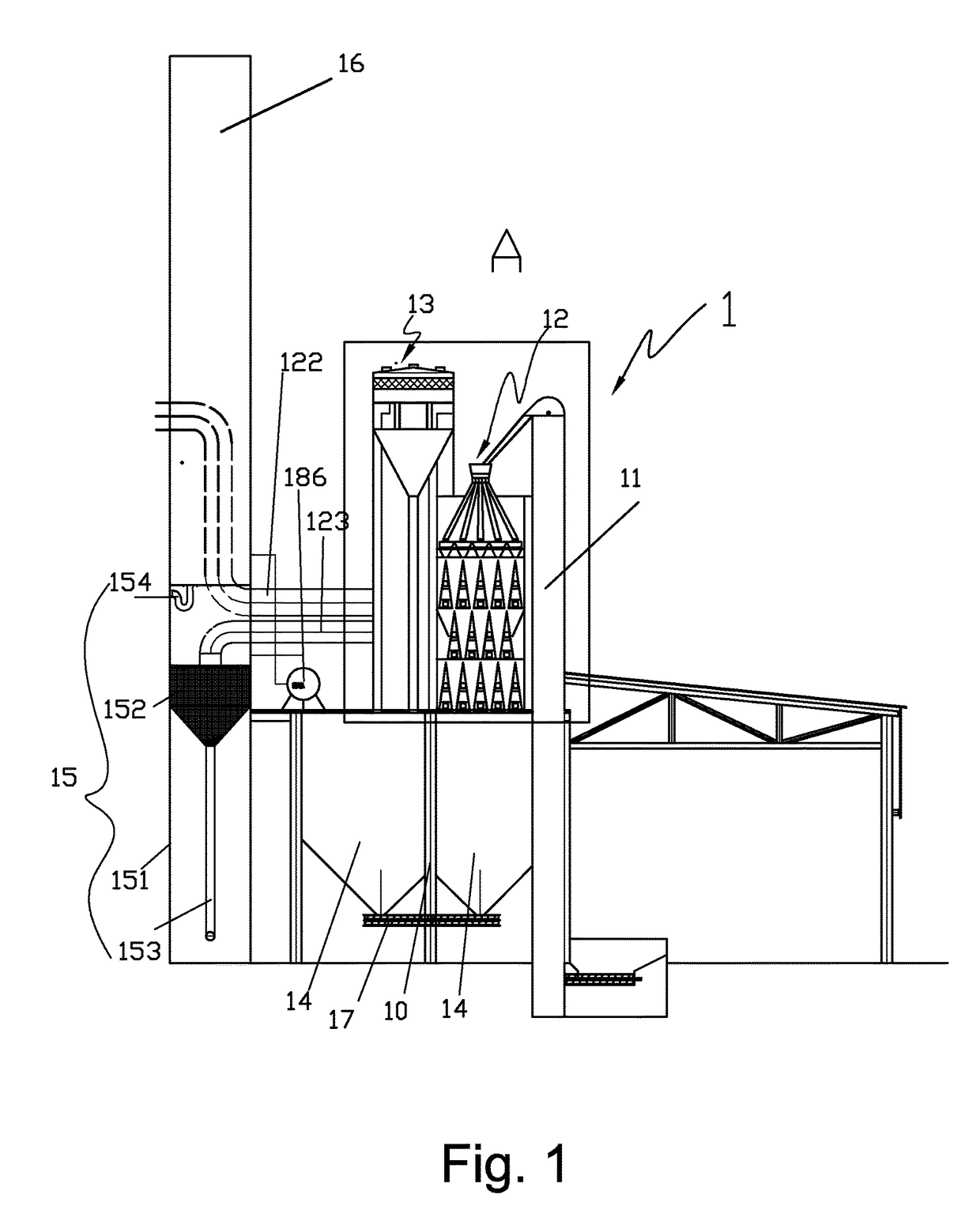

Device for manufacturing biological carbon

InactiveCN102443404ALow costNo pollution in the processCoke quenchingBiofuelsCombustion chamberCooling tower

The invention relates to a device for manufacturing biological carbon. A pre-heating chamber is positioned in a smoke gas chamber, both ends of the pre-heating chamber are respectively connected with a material outlet rolling tube and a material inlet roller, the other end of the material outlet rolling tube is connected with a middle material cabin, the lower part of the middle material cabin is connected with a material inlet chamber, the other end of the material inlet rolling tube is connected with a gas collection chamber, a mixed gas outlet of the gas collection chamber is connected with a gas inlet of a spraying washing cooling tower, a dry distillation chamber is positioned in a combustion chamber, both ends of the dry distillation chamber are respectively connected with a front rolling tube and a back rolling tube, the other end of the front rolling tube is connected with the material inlet chamber, the other end of the back rolling tube is connected with the material outlet chamber, a cooling chamber is connected under the material outlet chamber, a mixed gas outlet of the material outlet chamber is connected with a gas inlet of the spraying washing cooling tower, an external fuel combustion device and a non-condensed combustible gas combustion device are arranged in a position in the combustion chamber positioned at the lower part of the dry distillation chamber, and a hot smoke gas pipeline is arranged between the top of the combustion chamber and the bottom of the hot smoke gas chamber. The device for manufacturing the biological carbon provided by the invention can be used for industrially manufacturing the biological carbon in a pollution-free way at low cost.

Owner:张大伟 +1

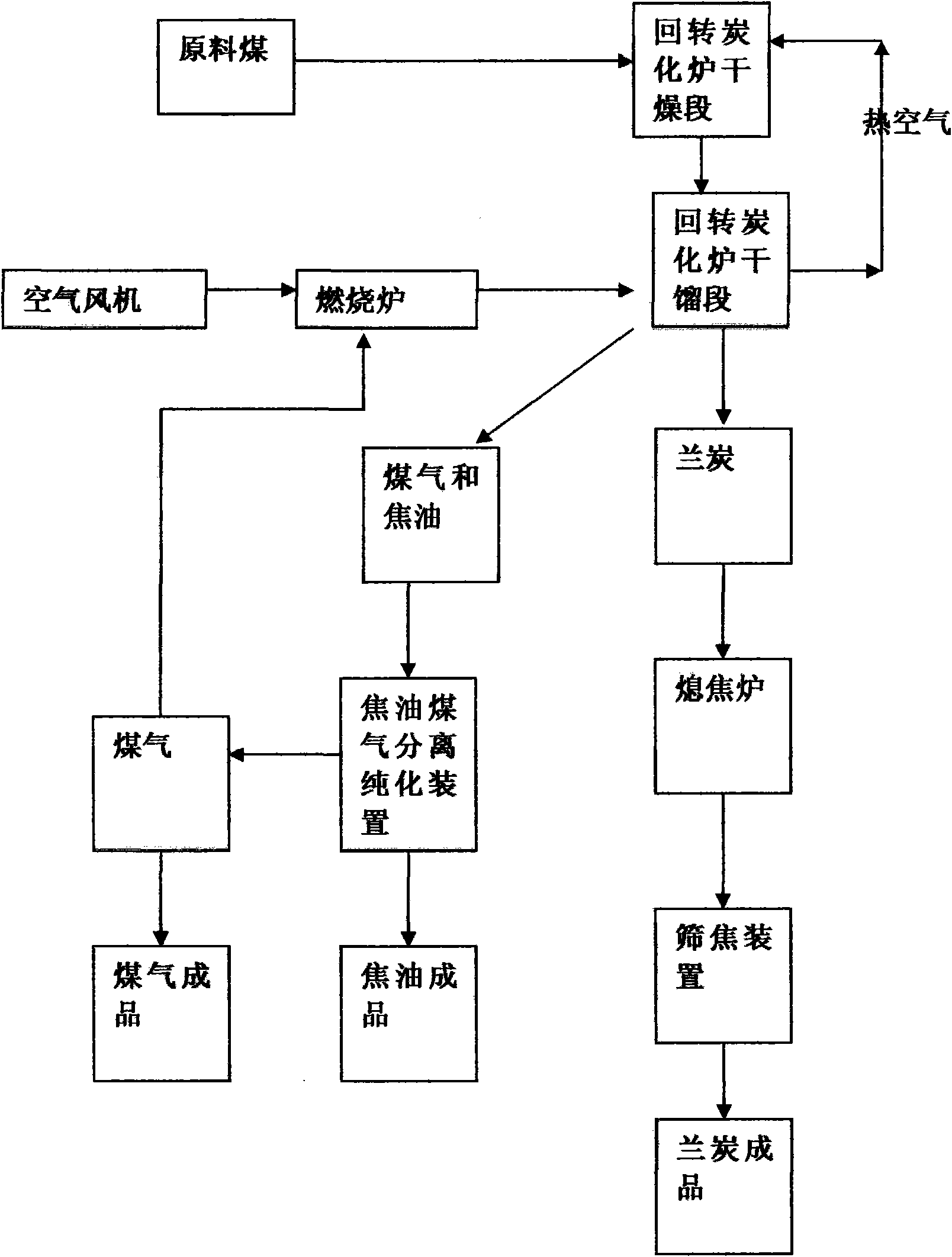

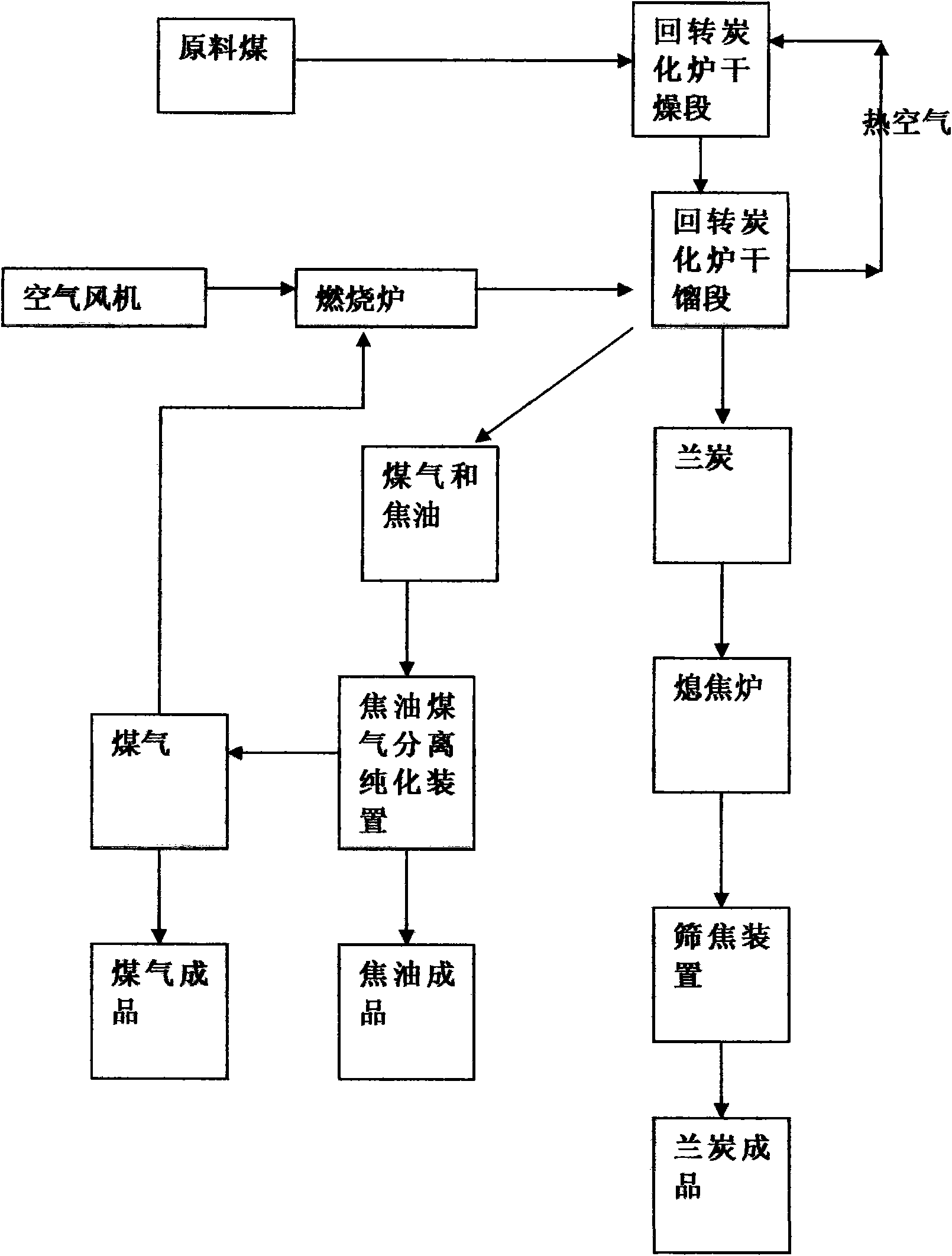

Method for preparing carbocoal by thermally cracking raw coal with external-heat horizontal rotary charring furnace

ActiveCN101805625ASmall granularityIncrease profitCoke quenchingIndirect heating destructive distillationGranularityTar

The invention provides a method for preparing carbocoal by thermally cracking raw coal with an external-heat horizontal rotary charring furnace. The method comprises the following steps of: drying and desorbing the raw coal in a drying section of the rotary charring furnace at the temperature of between 100 and 300 DEG C; delivering the dried raw coal into a dry distillation section of the rotarycharring furnace; thermally cracking the raw coal for 1 to 5 hours at the temperature of between 500 and 700 DEG C of materials; obtaining the carbocoal, tar and coal gas after the thermal cracking; allowing the generated carbocoal to pass through a coke quenching furnace and a coke sieving device to obtain a carbocoal finished product; and allowing the generated tar and coal gas to pass through a coal gas separating and purifying device to obtain a high-quality tar finished product and a high-calorific-value coal gas finished product. The method can reduce the granularity of the raw coal, improve the utilization rate of the raw coal, additionally improve the calorific value of the coal gas and greatly improve the utilization value of the coal gas. The method improves the quality of the carbocoal, saves energy resources and reduces harmful gas by adopting a dry coke quenching and continuous decoking method. The method has the advantages of single reactant in the technical process and no discharge of waste gas, waste water or waste residue, and belongs to a project of environmental protection.

Owner:西安三瑞非常规能源开发有限公司

Wood gasification apparatus

A wood gasification apparatus in which cellulosic material is transported by an auger through a housing and heated to vaporize at least a portion of the cellulosic material by frictional heating. The auger and housing define a spiral void through which the cellulosic material is propelled from the inlet to the outlet, and which continually decreases in volume from the inlet to the outlet. The ever decreasing volume of the void increases the pressure on the cellulosic material and maximizes the frictional heating until the material reaches a vaporization temperature.

Owner:BIO GAS TECH

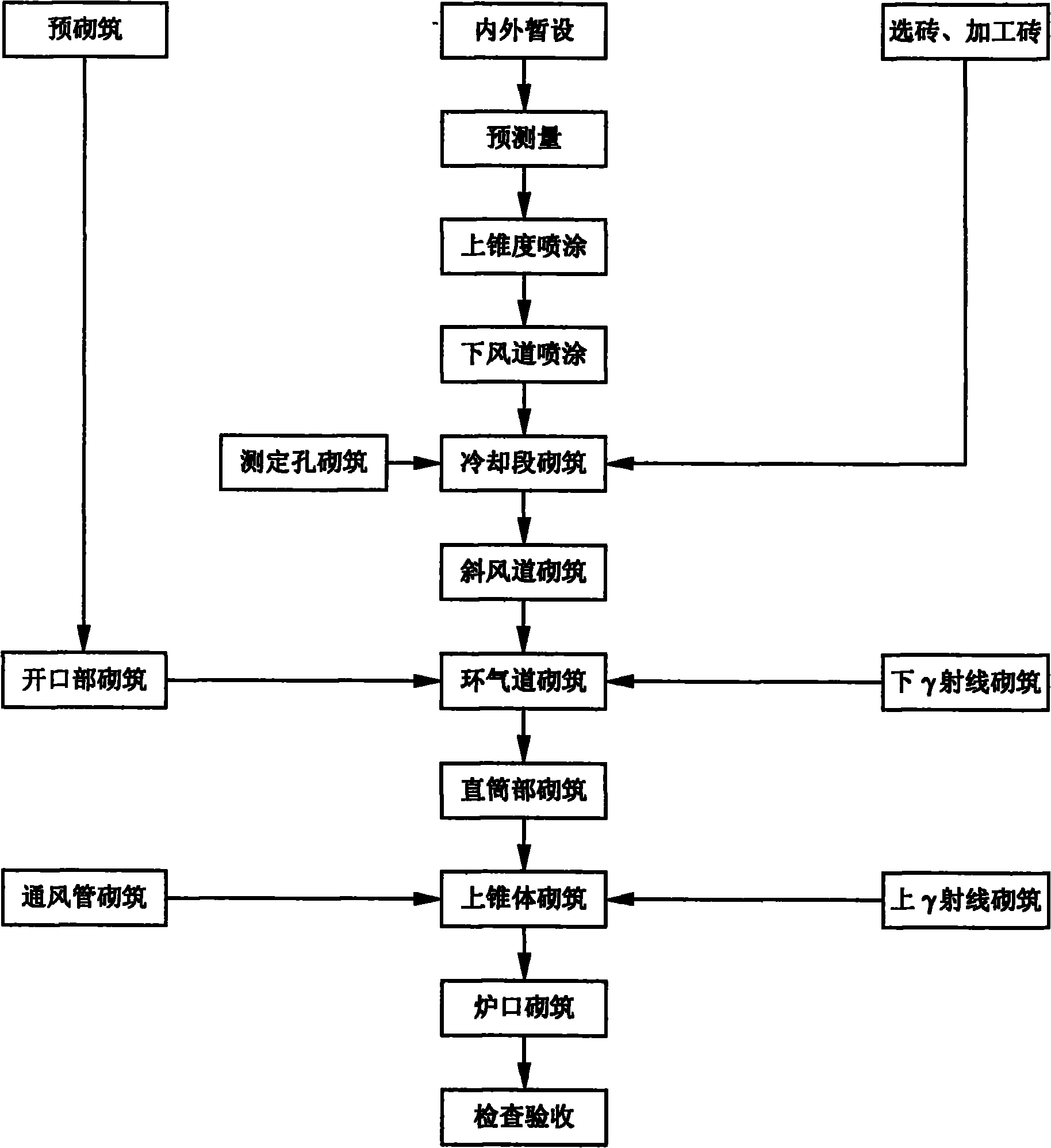

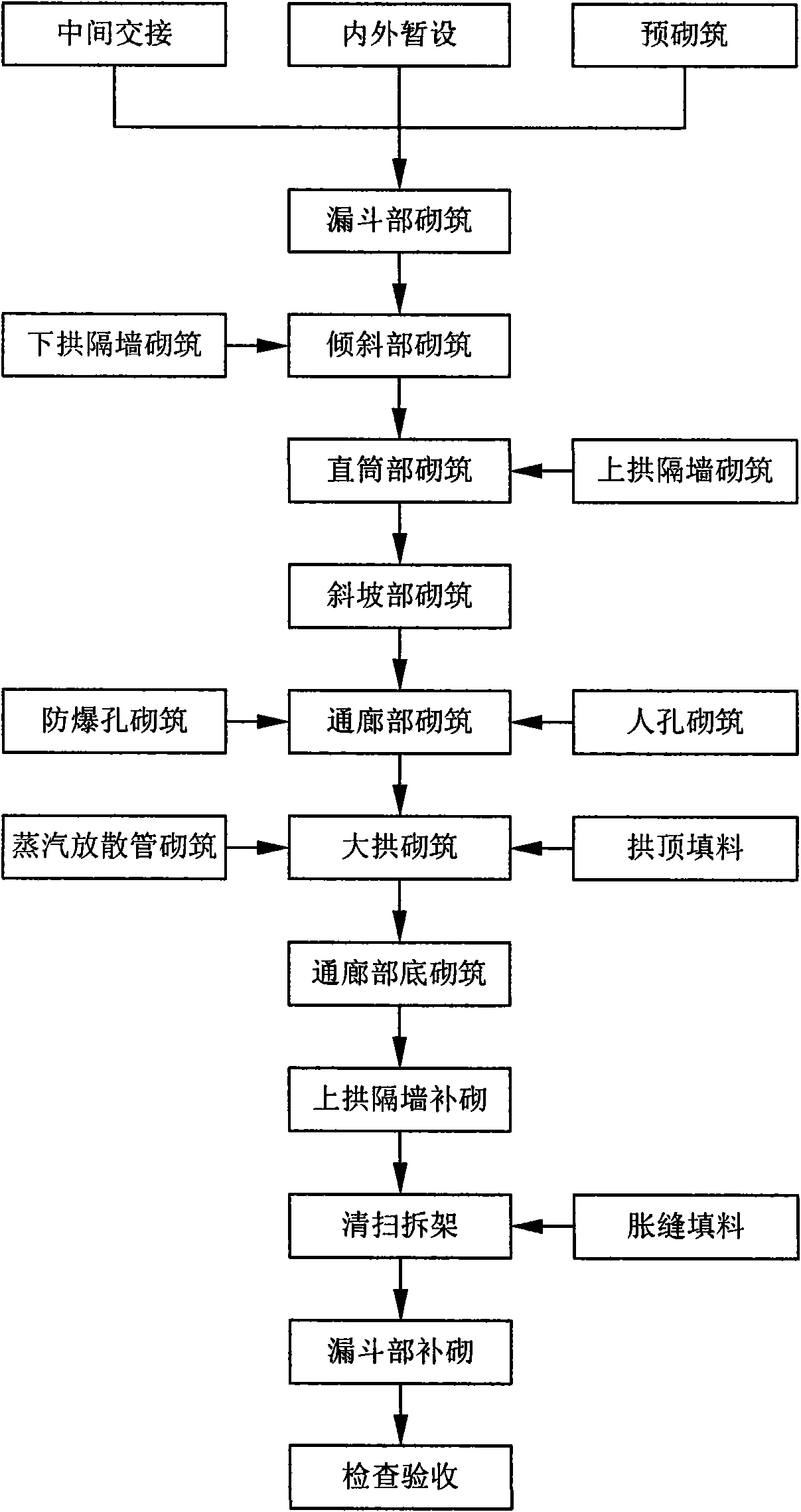

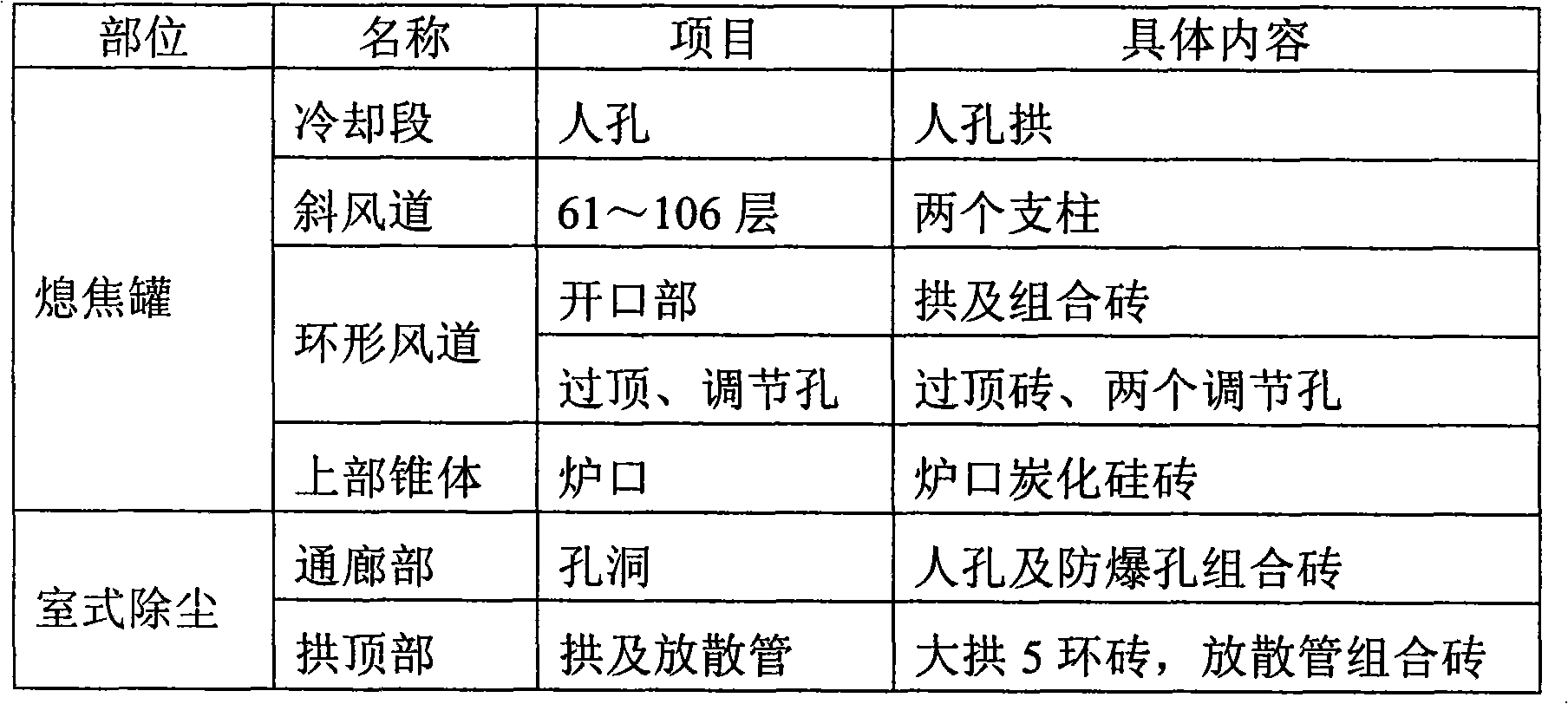

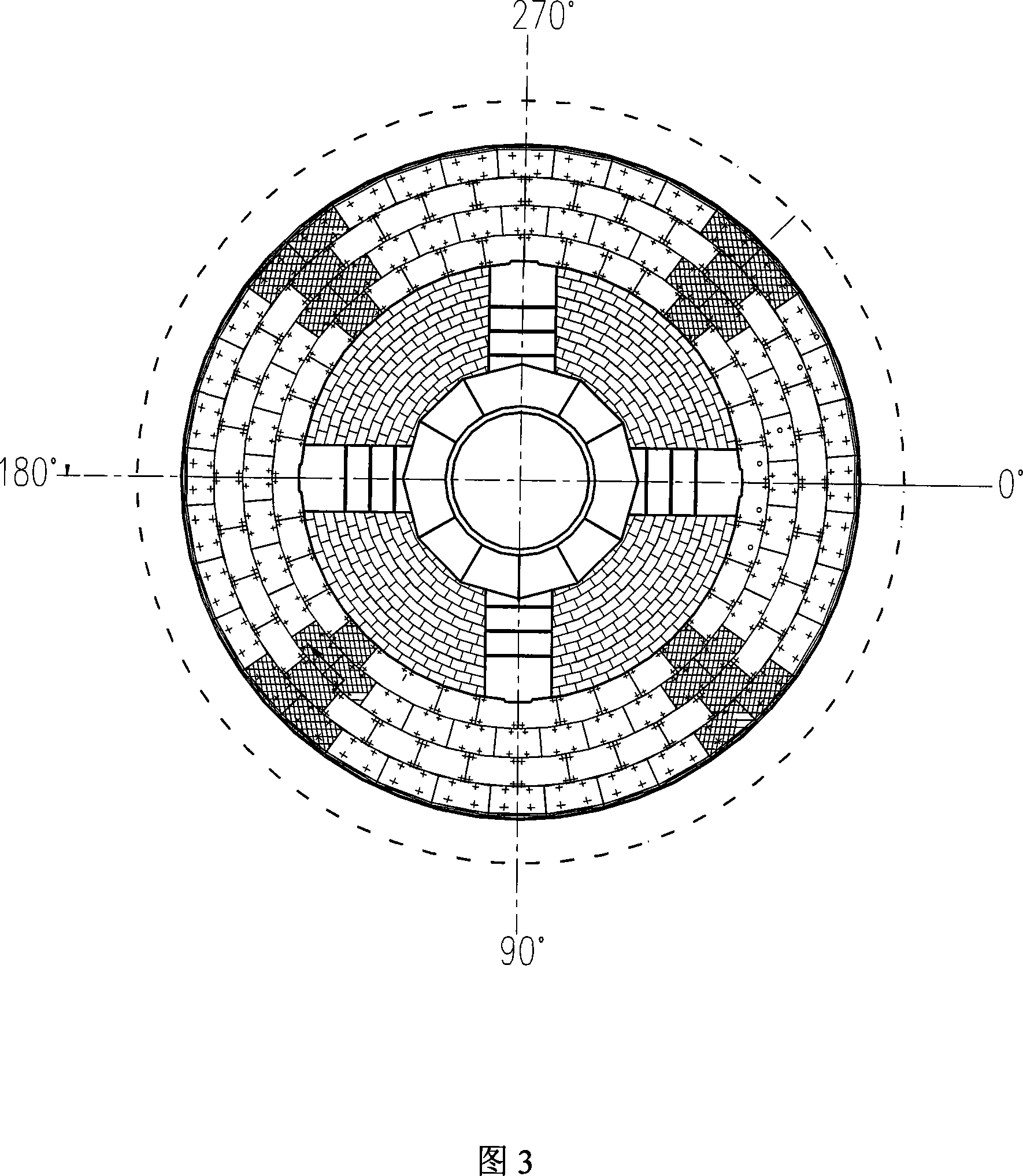

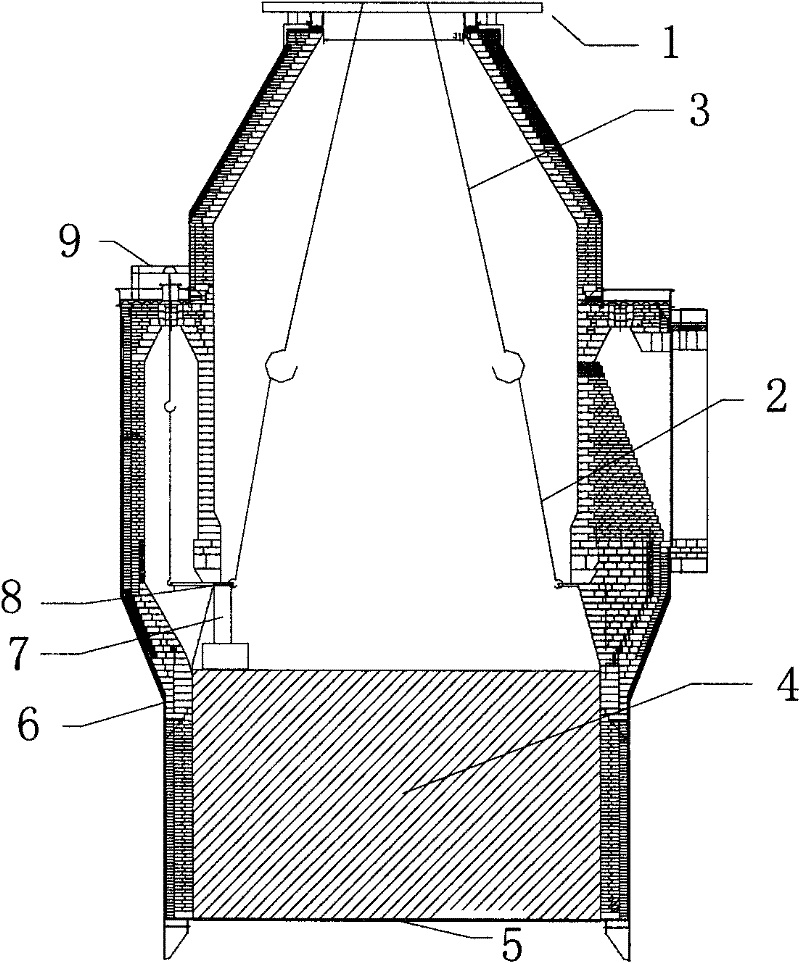

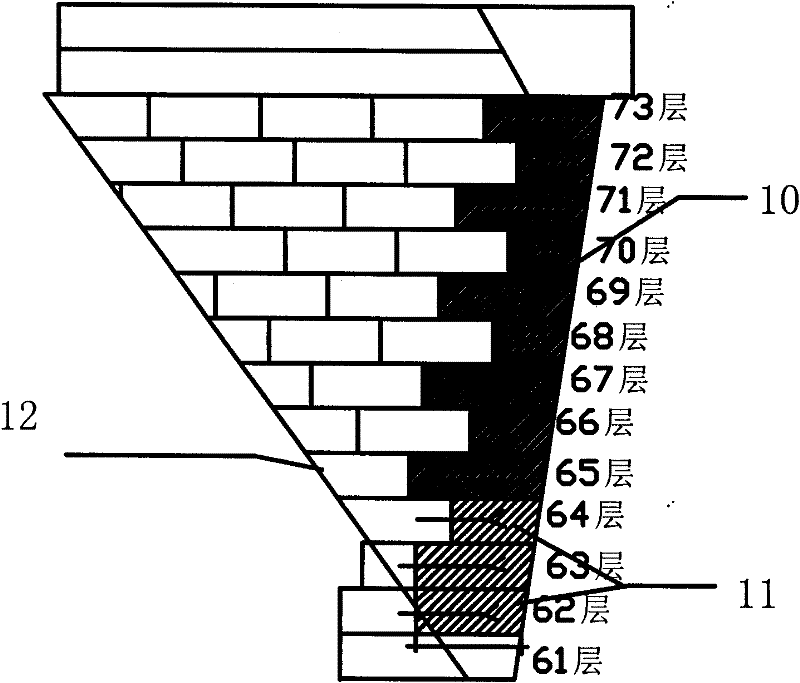

Dry quenching laying method

ActiveCN101928575AImprove construction efficiencyCoke quenchingCoke oven brickworkQuenchingMaterials science

The invention relates to the field of metallurgical equipment construction, in particular to a dry quenching laying method. The dry quenching laying method comprises the following steps of: quenching jar pre-laying, primary deduster pe-laying, quenching jar furnace building construction and primary deduster furnace building construction, wherein the quenching jar furnace building construction comprises the following steps of: 1. construction of cooling sections from the first layer to the 54th layer; 2. construction of inclined wind channels from the 55th layer to the 81st layer; 3. construction of inclined wind channels from the 82nd layer to the 114th layer; and 4. construction of prestoring section from the 115th layer to the 179th layer; and the primary deduster furnace construction comprises the following steps of: 1. setting out; 2. inclined part construction; 3. straight cylinder part construction; 4. vestibule part construction; 5. vault construction; and 6. compandor construction. The dry quenching laying method passes the installation and detection standard of strict design specifications, has the advantage of high laying operation efficiency, is safe and reliable.

Owner:MCC5 GROUP CORP SHANGHAI

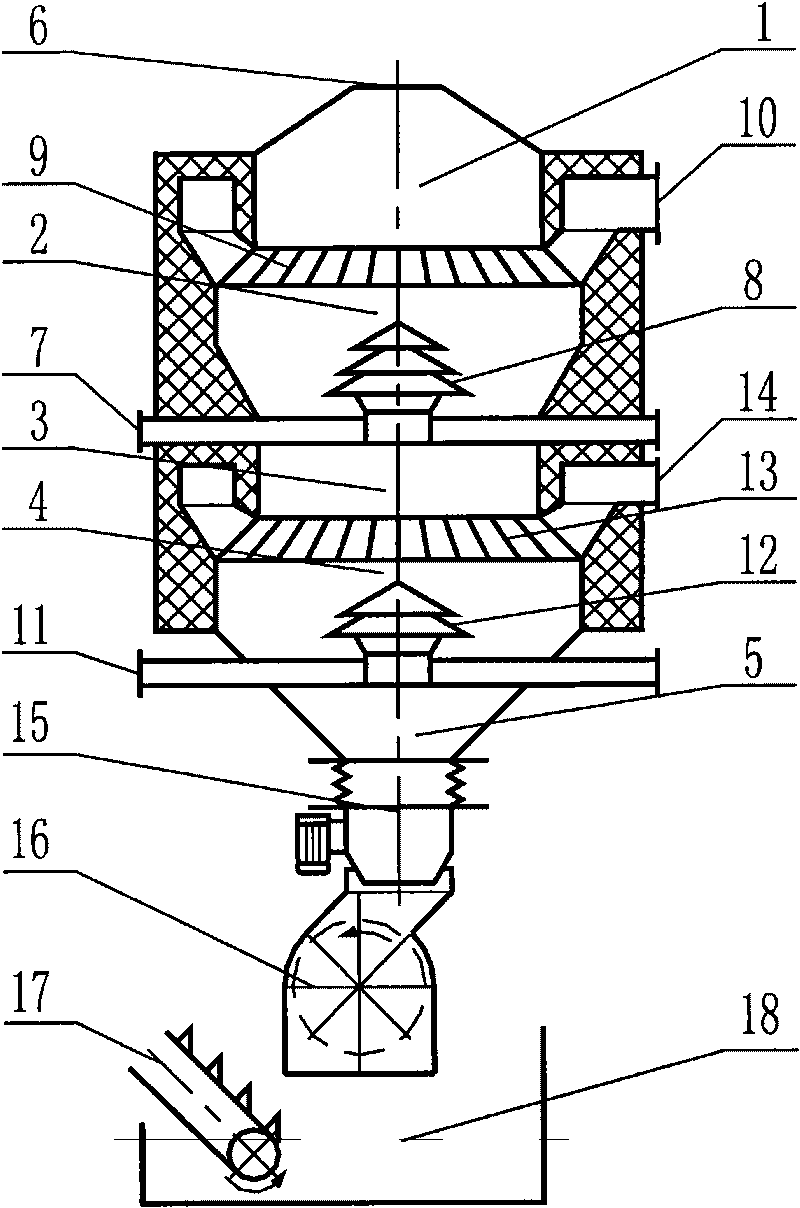

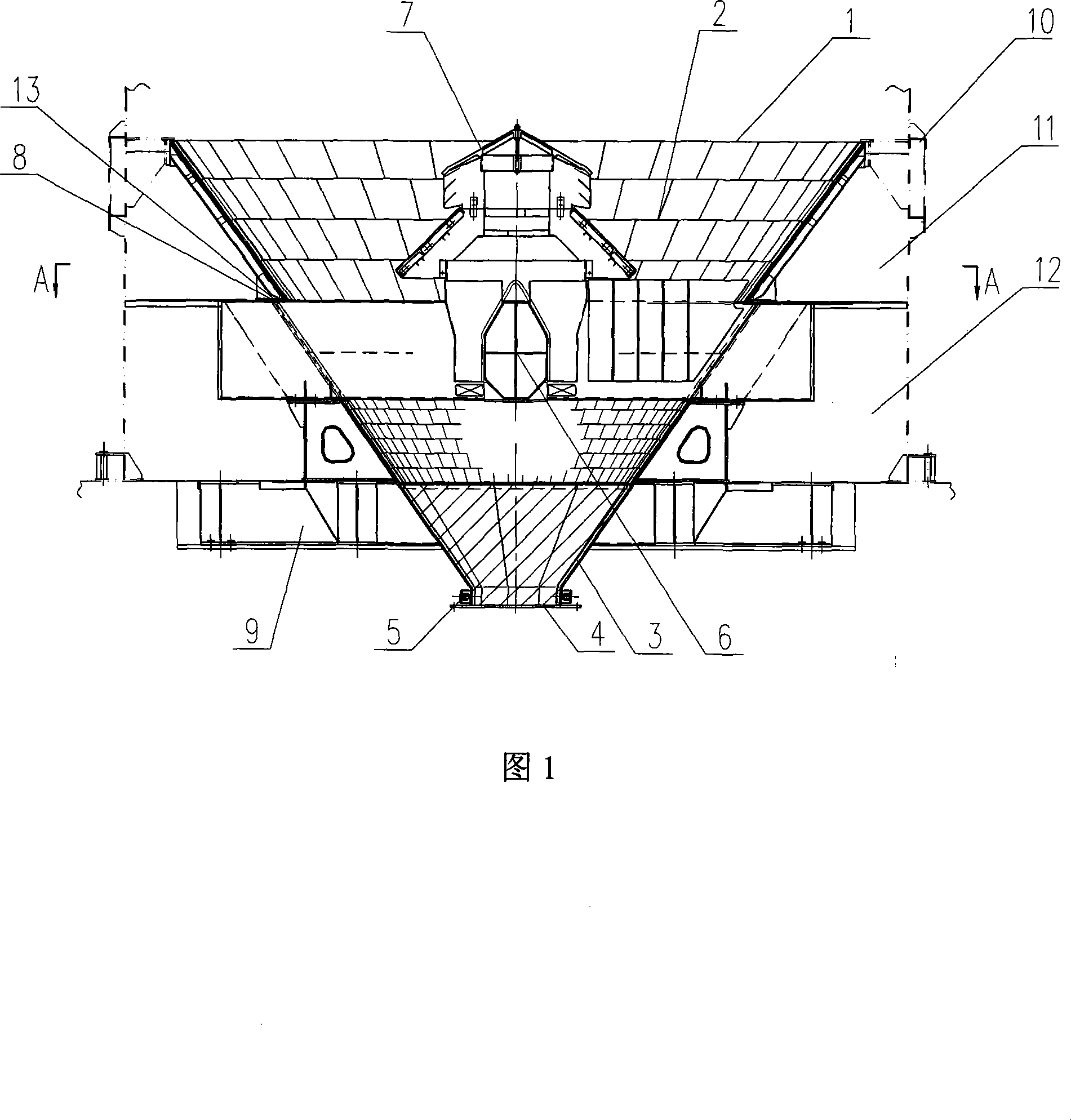

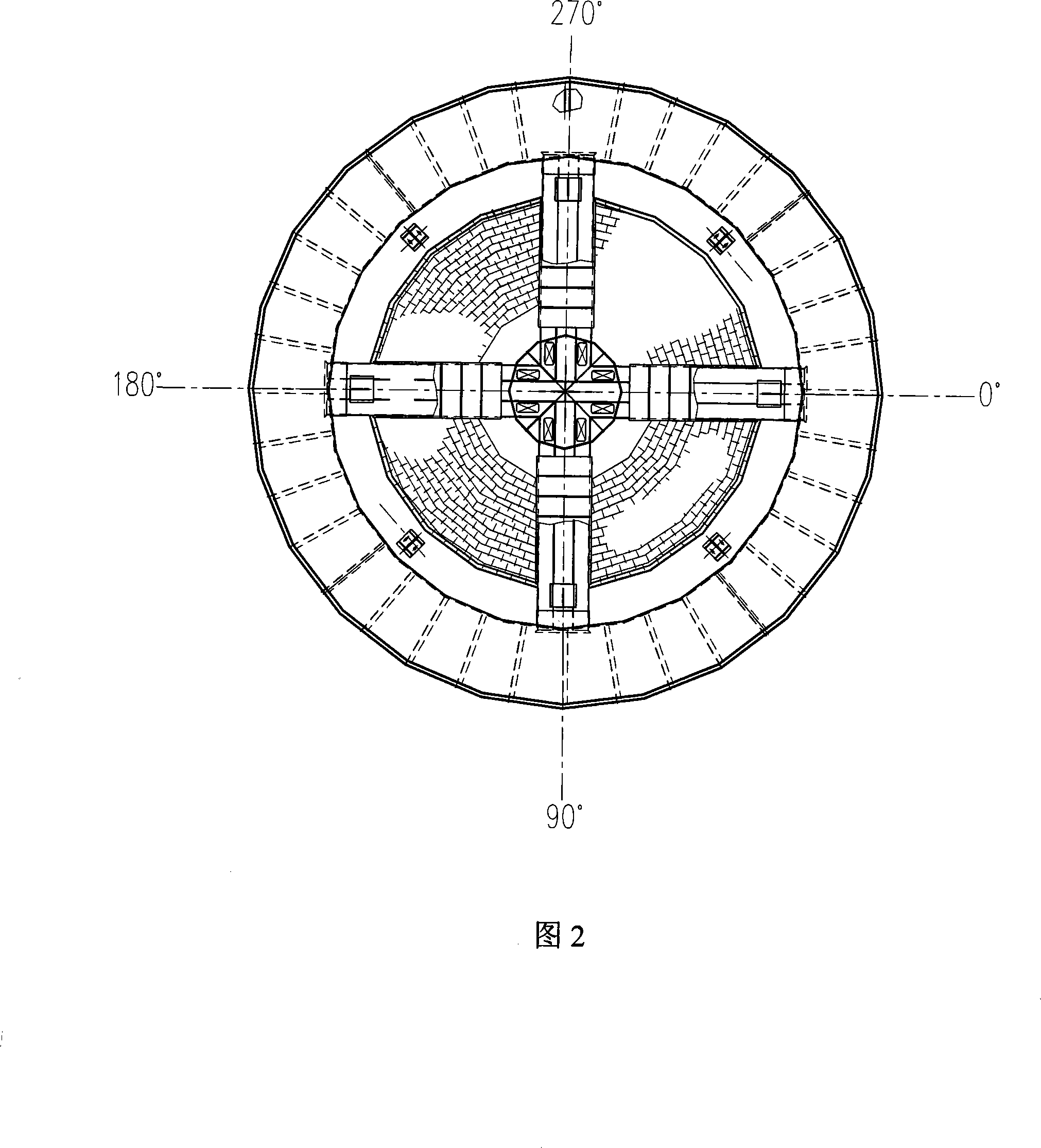

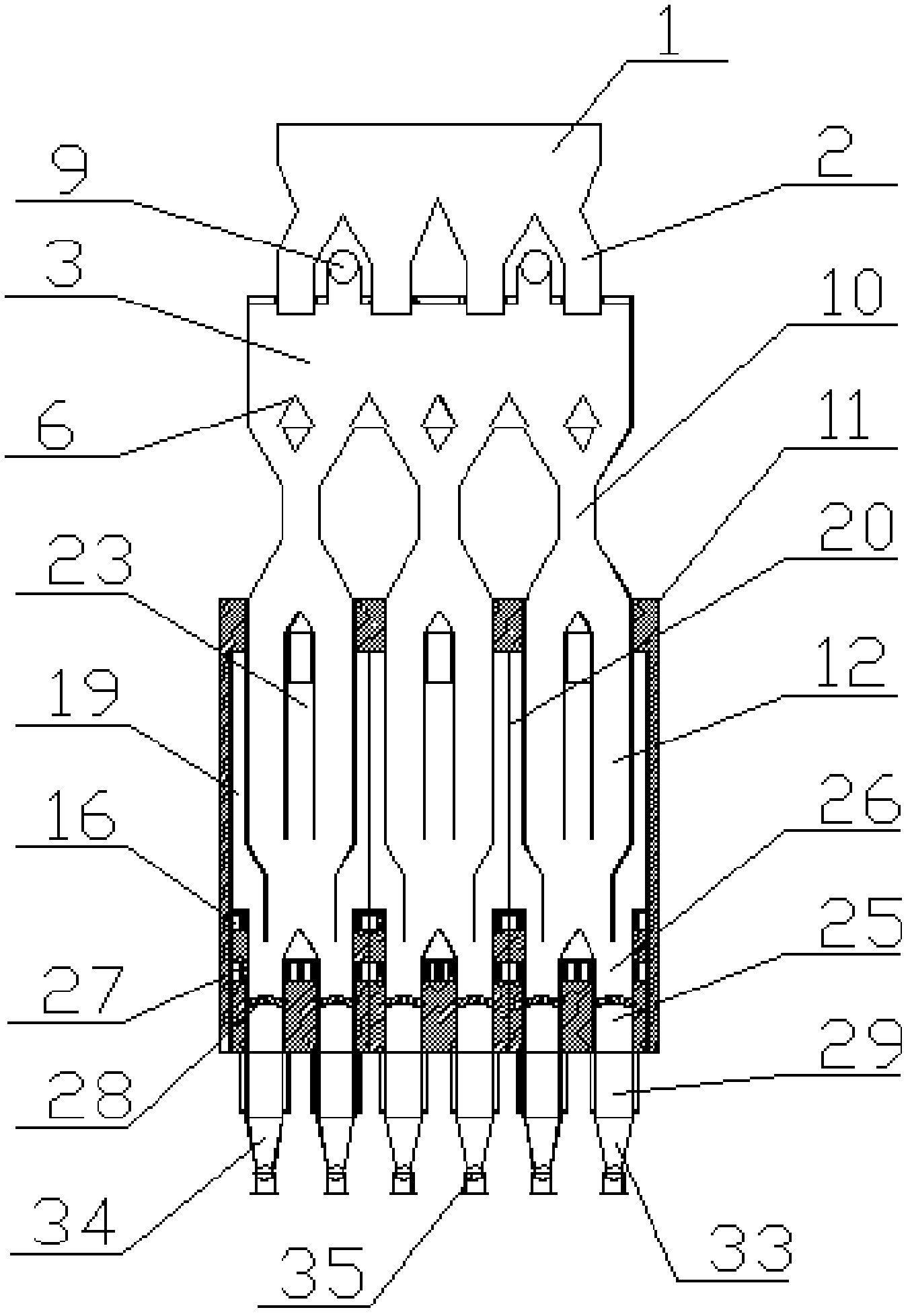

Special-purpose gas supplying device for coke dry quenching unit

The invention relates to an air supply facility specially used for a dry out furnace. The facility is composed of an upper cone funnel, a lower cone funnel, a dry out furnace casing body, a ring-shaped air channel, a cross air channel, and a central windshield, wherein the upper cone funnel and the lower cone funnel are sleeved and inserted with each other, the ring-shaped air channel is composed of an annular gap which is formed by a sleeve and inserting ledge, and the cross air channel is positioned on the upper portion of the lower cone funnel and is horizontally arranged, the centre of the cross air channel coincides with the centre of the dry out furnace and extends upwards and is communicated with the central windshield which is arranged on the cone funnel, the facility employs a combining air supply form of that peripheral air rings supply air from outside in and the central windshield supplies air from inside out on the upper portion of the furnace body. The facility can effectively resolve the problem that the cooling cycle air entering the dry out furnace is uniformly distributed in the periphery direction of the dry out furnace, which is favorable for achieving uniform cooling of the coke in the furnace, thereby improving the cooling property of the dry out furnace, increasing the cooling efficiency of the dry out furnace, and reducing the dry out time of the coke in the dry out furnace.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

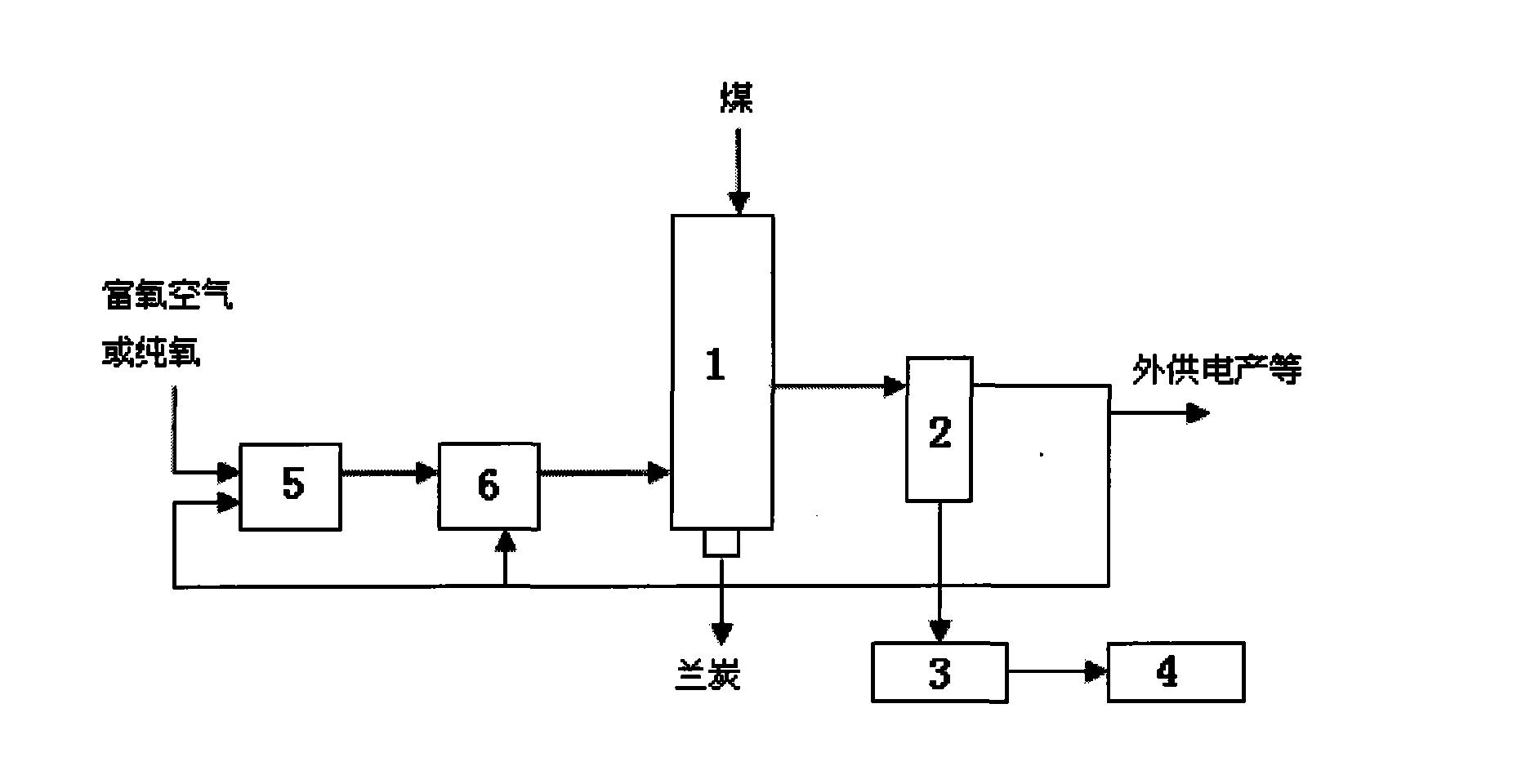

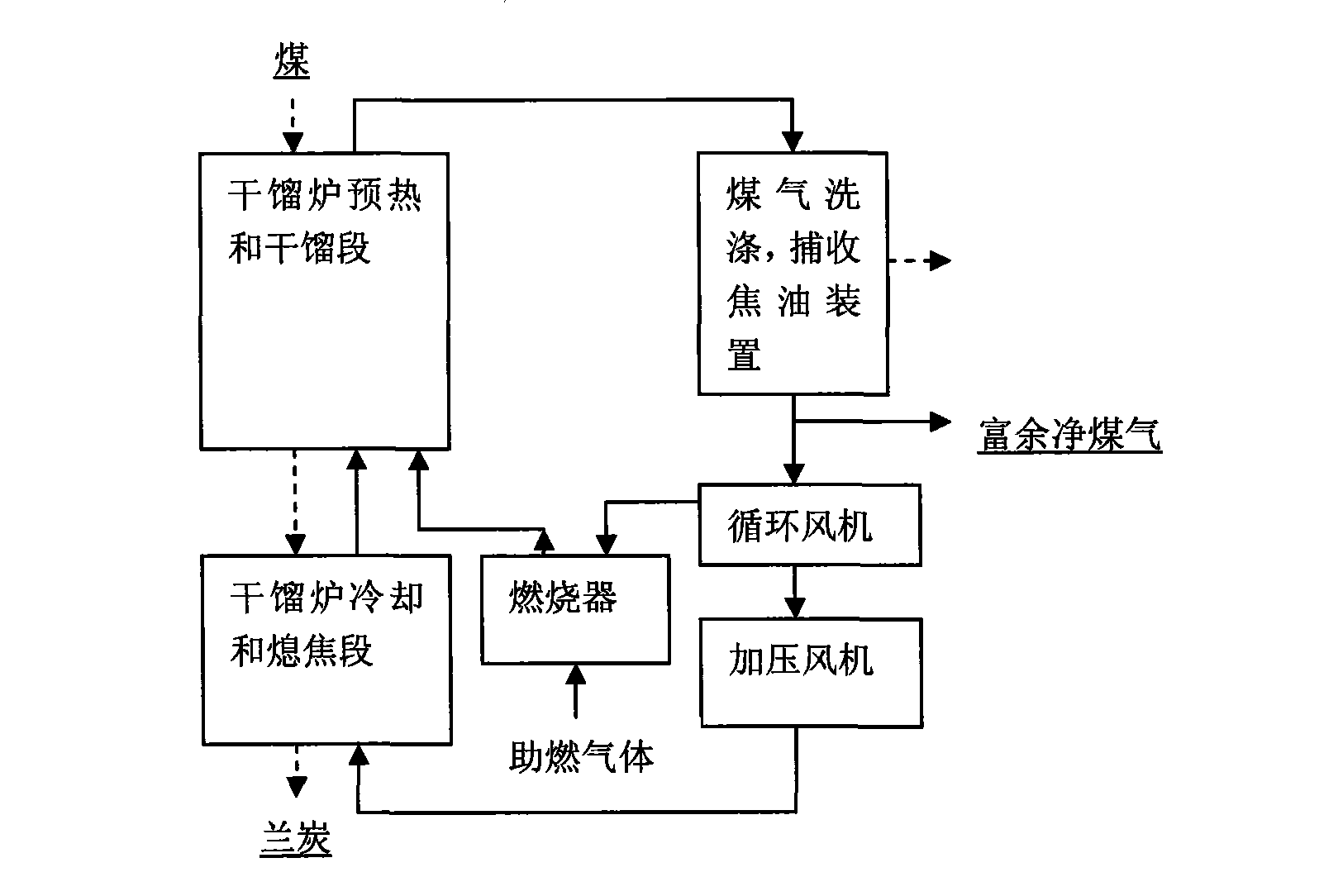

Method for coke dry quenching by coal internal heat smouldering

InactiveCN101514291ATake advantage ofImprove heat utilization efficiencyCoke quenchingIndirect heating destructive distillationCarbonizationQuenching

The invention discloses a method coke dry quenching by coal internal heat smouldering. In the method, high temperature carbonized coal gas produced by carbonized dry quenched coke is made into cool coal gas by washing and collecting tar; after the cool coal gas passes a circulating fan, part of the coal gas is introduced into a burner to be synthesized with high temperature waste gas into high temperature mixed gas satisfying the coal smouldering requirement; the high temperature mixed gas enters into a carbonization section of a coke oven to be used as a carbonization heat source; the other part of pure coal gas passing the circulating fan is introduced to a coke quenching and cooling section of a carbonization furnace by a booster fan to be used as an inertia medium of Ramsbottom coke and quenched coke; the cool coal gas passing the coke quenching and cooling section of the carbonization furnace absorbs the heat and then passes the carbonization section of the coke oven to carry out nonoxidation heating or weak-oxidation heating towards the coal together with the carbonization heat source to realize combustion-free circulation. The method simplifies the coke dry quenching technology, reduces the water content of the Ramsbottom coke, uses the heat of the Ramsbottom coke before coke quenching effectively, improves the utilization rate of the pure coal gas, reduces the use of combustion-supporting gas and accordingly reduces the energy consumption of the burner.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

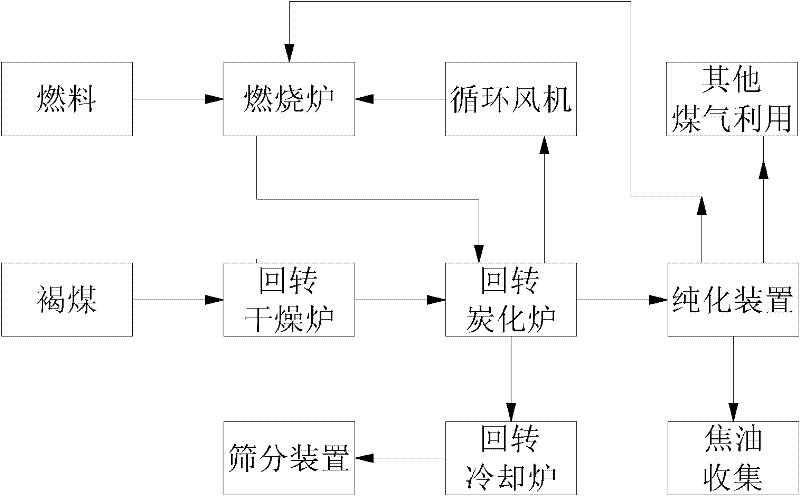

Method for improving quality of brown coal with externally heated rotary furnace

InactiveCN102250633AIncrease profitHigh value availableCoke quenchingChemical industryBrown coalCombustion

Owner:西安三瑞实业有限公司

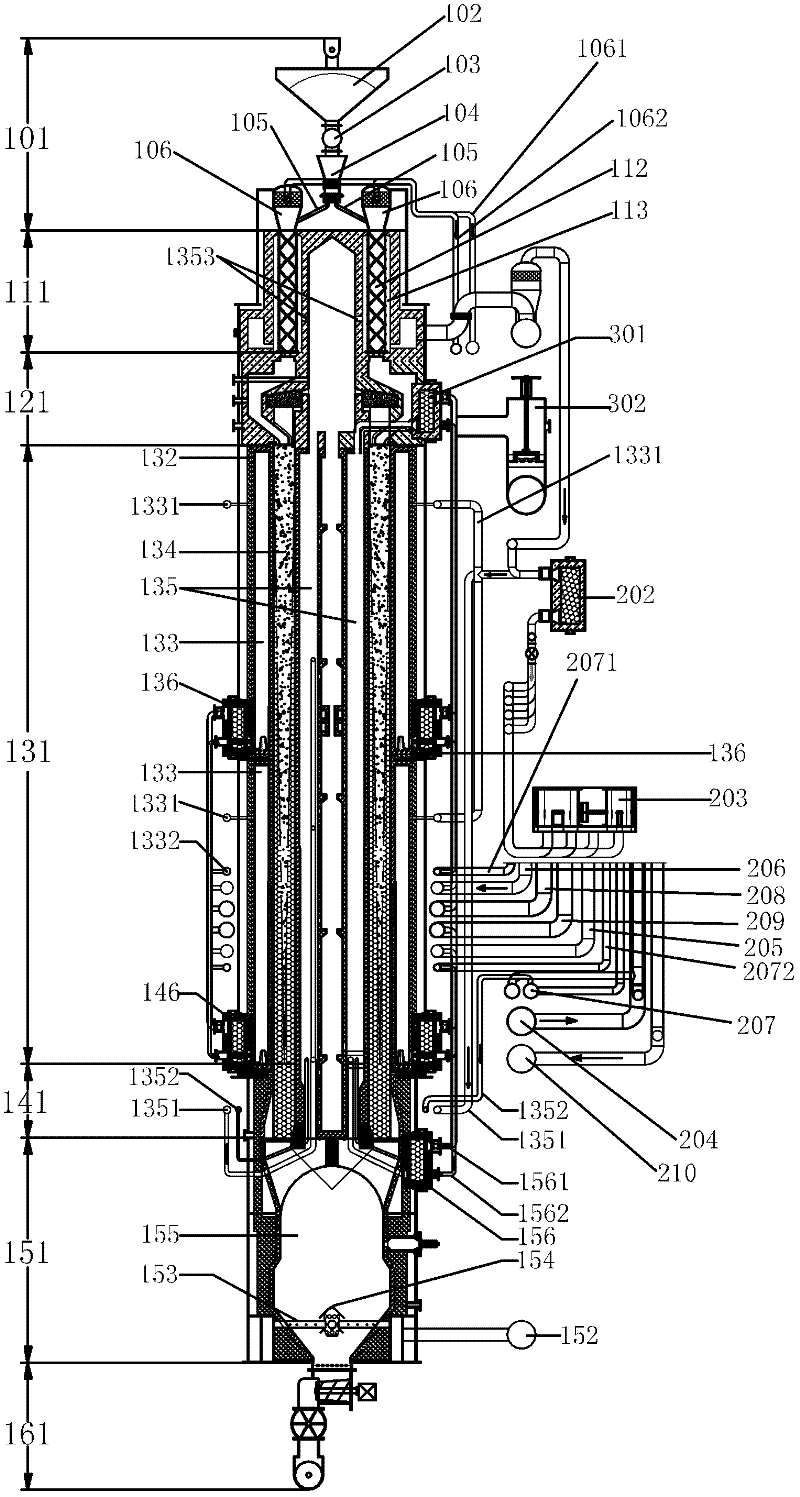

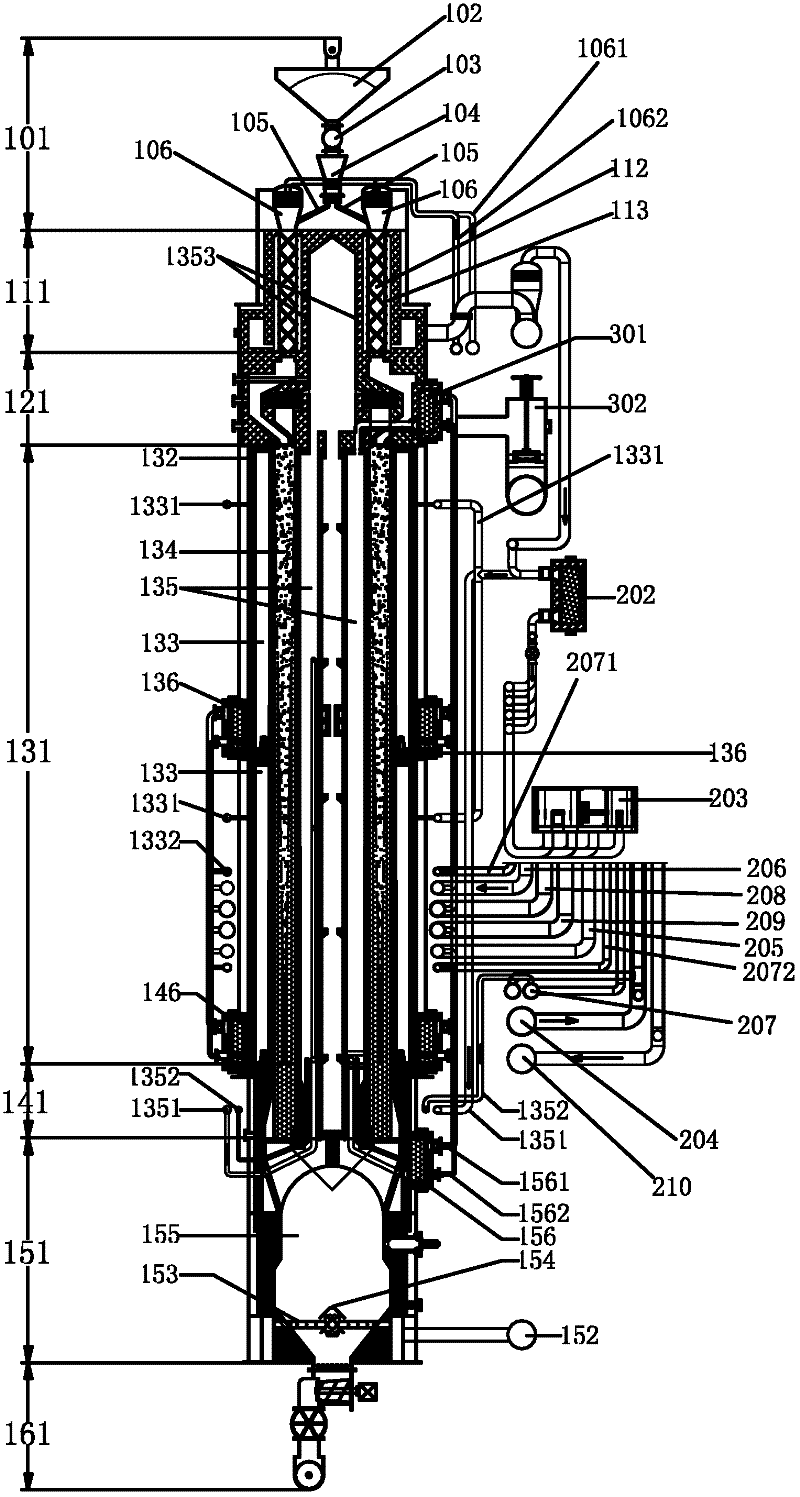

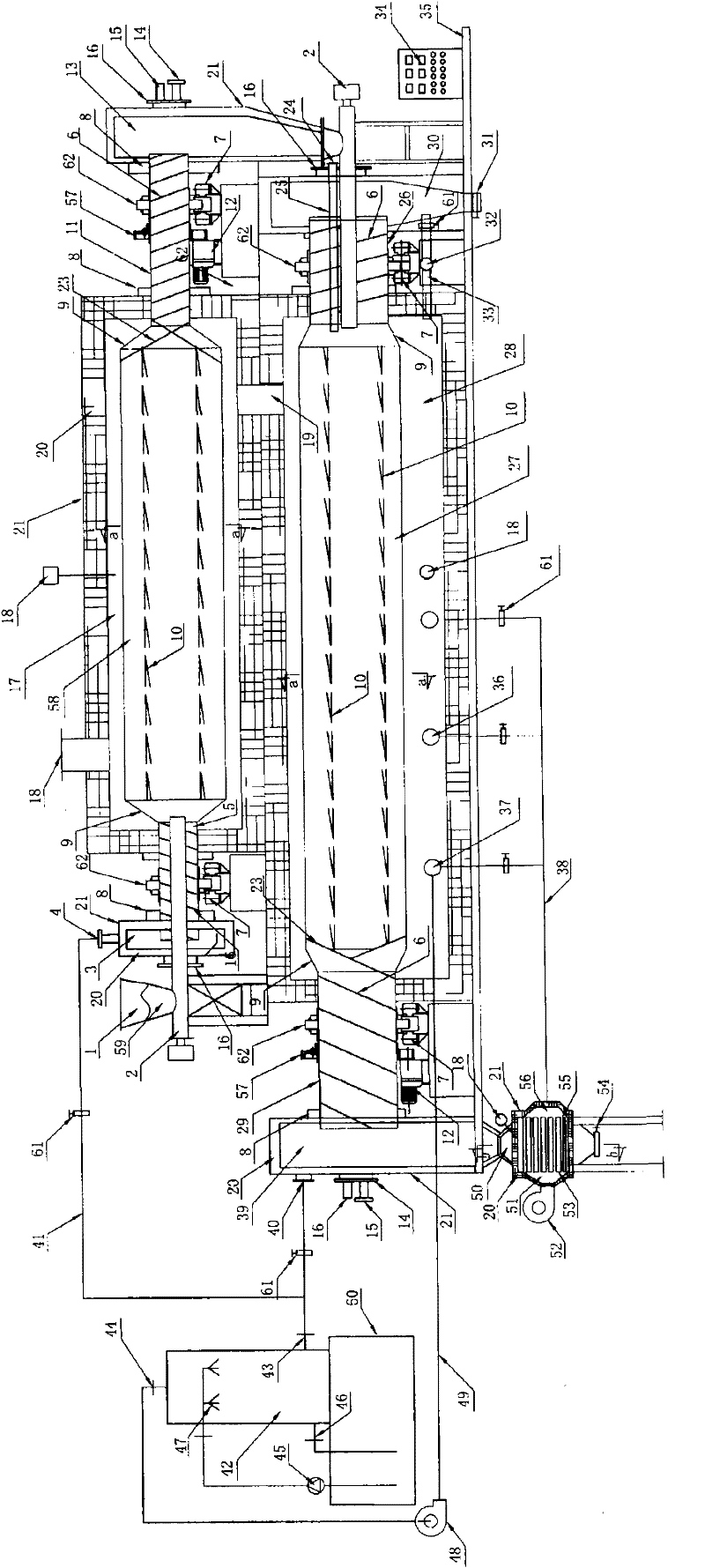

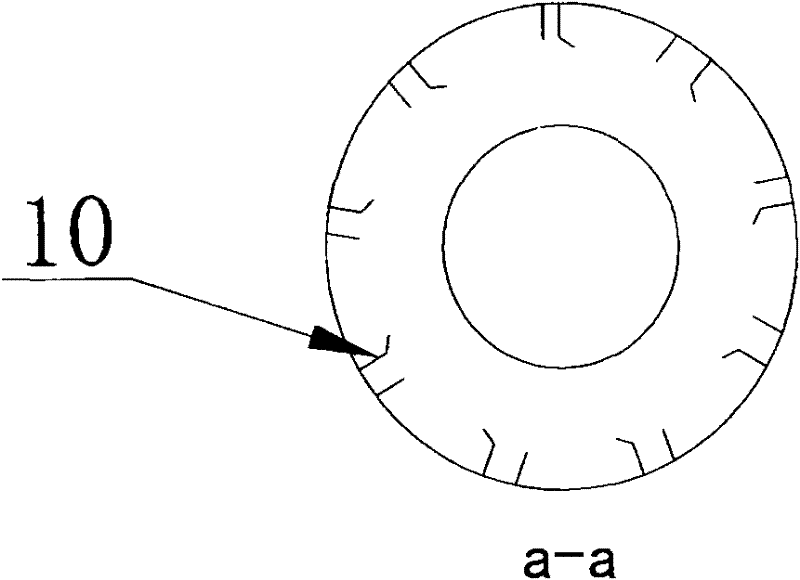

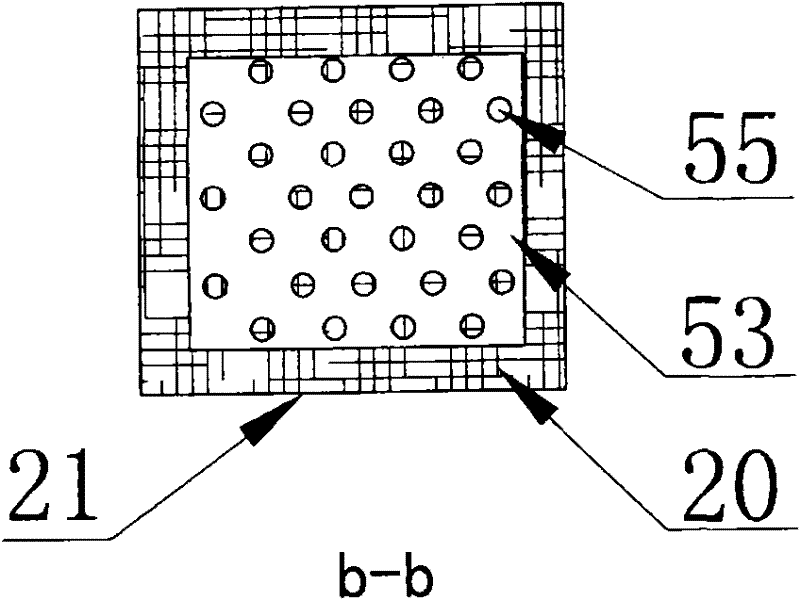

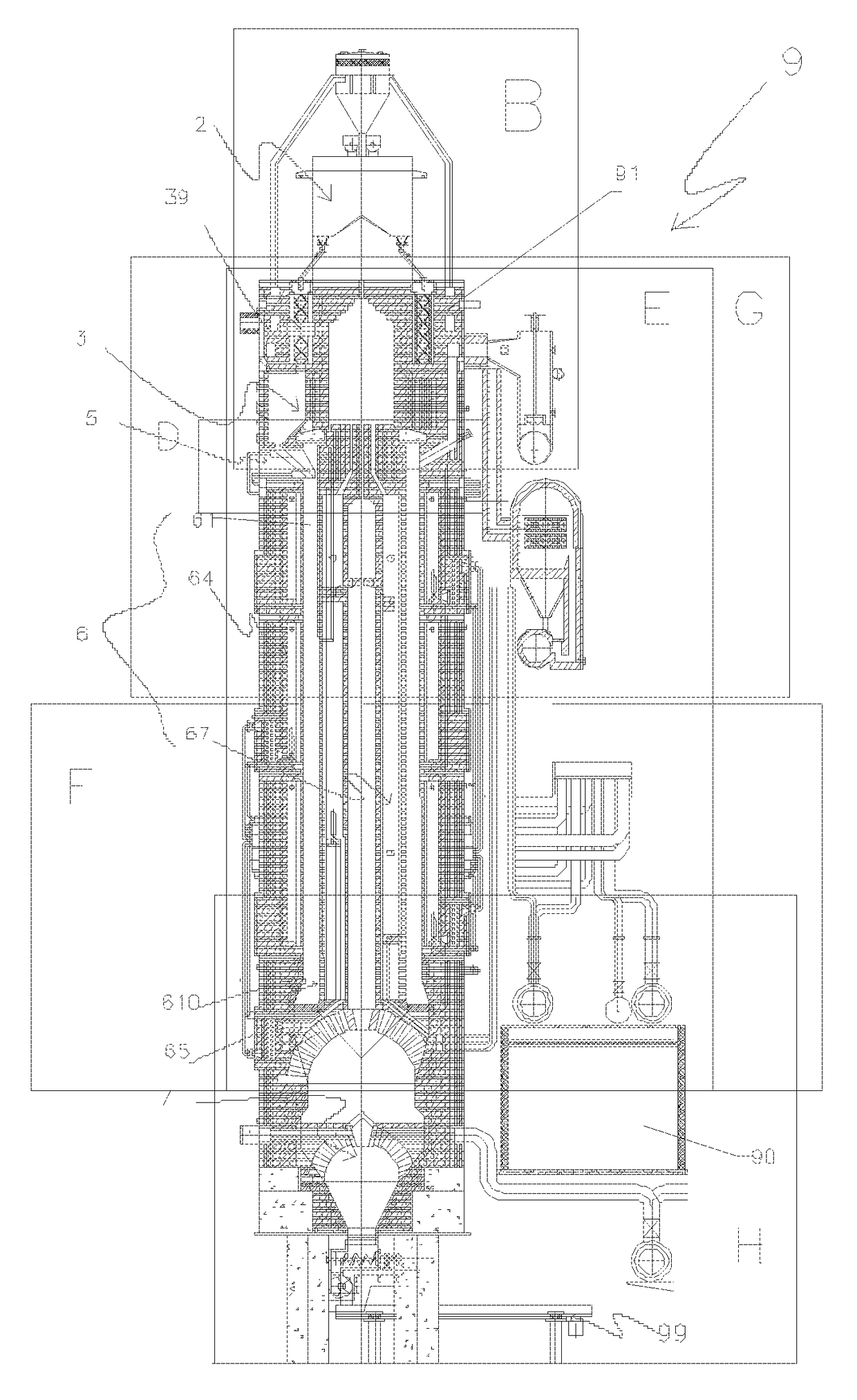

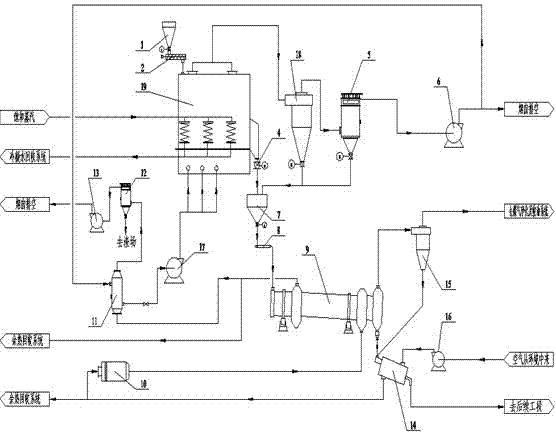

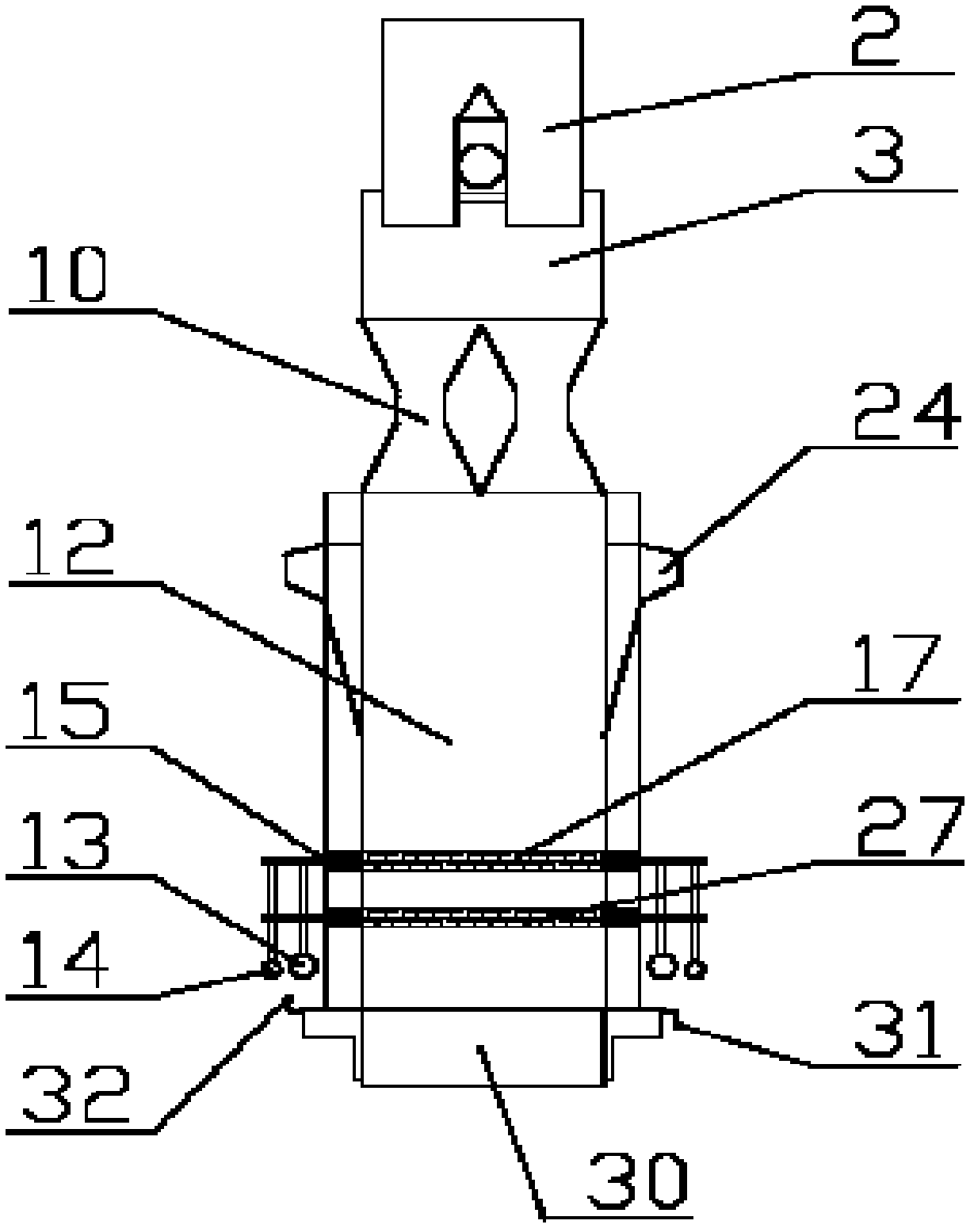

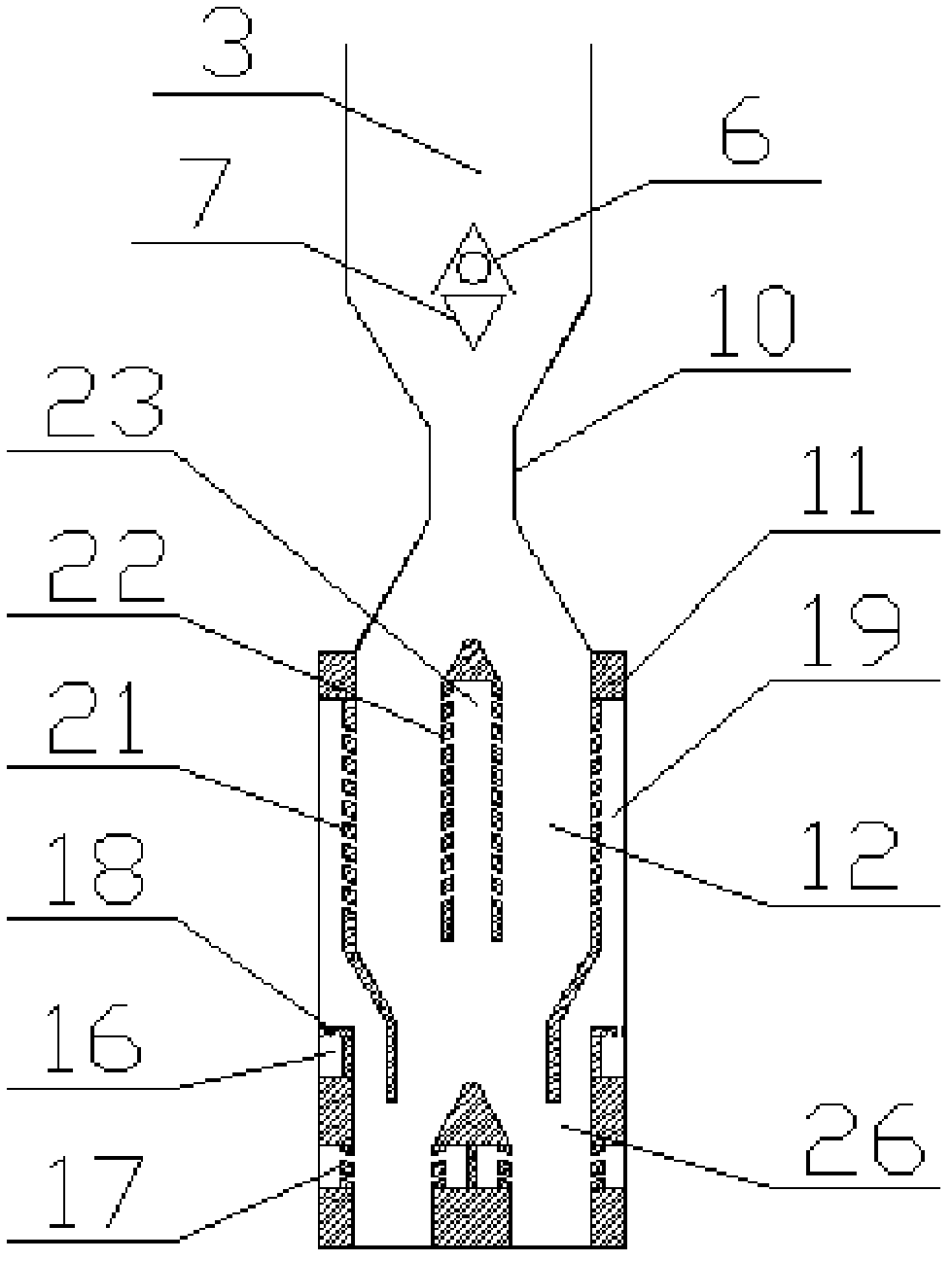

Thermal cycle continuous automated coal pyrolyzing furnace

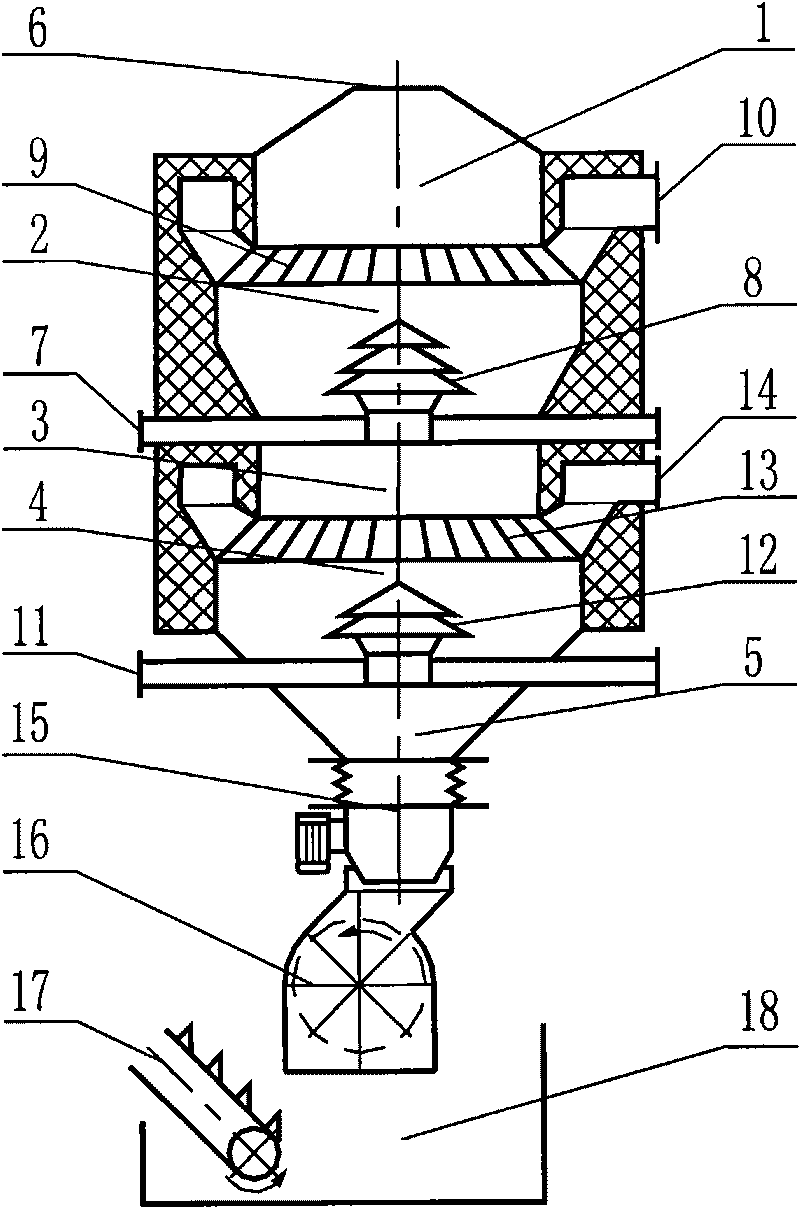

InactiveUS10047296B2Improve efficiencyReduce coking costCoke quenchingCombustible gas coke oven heatingProcess engineeringGas heating

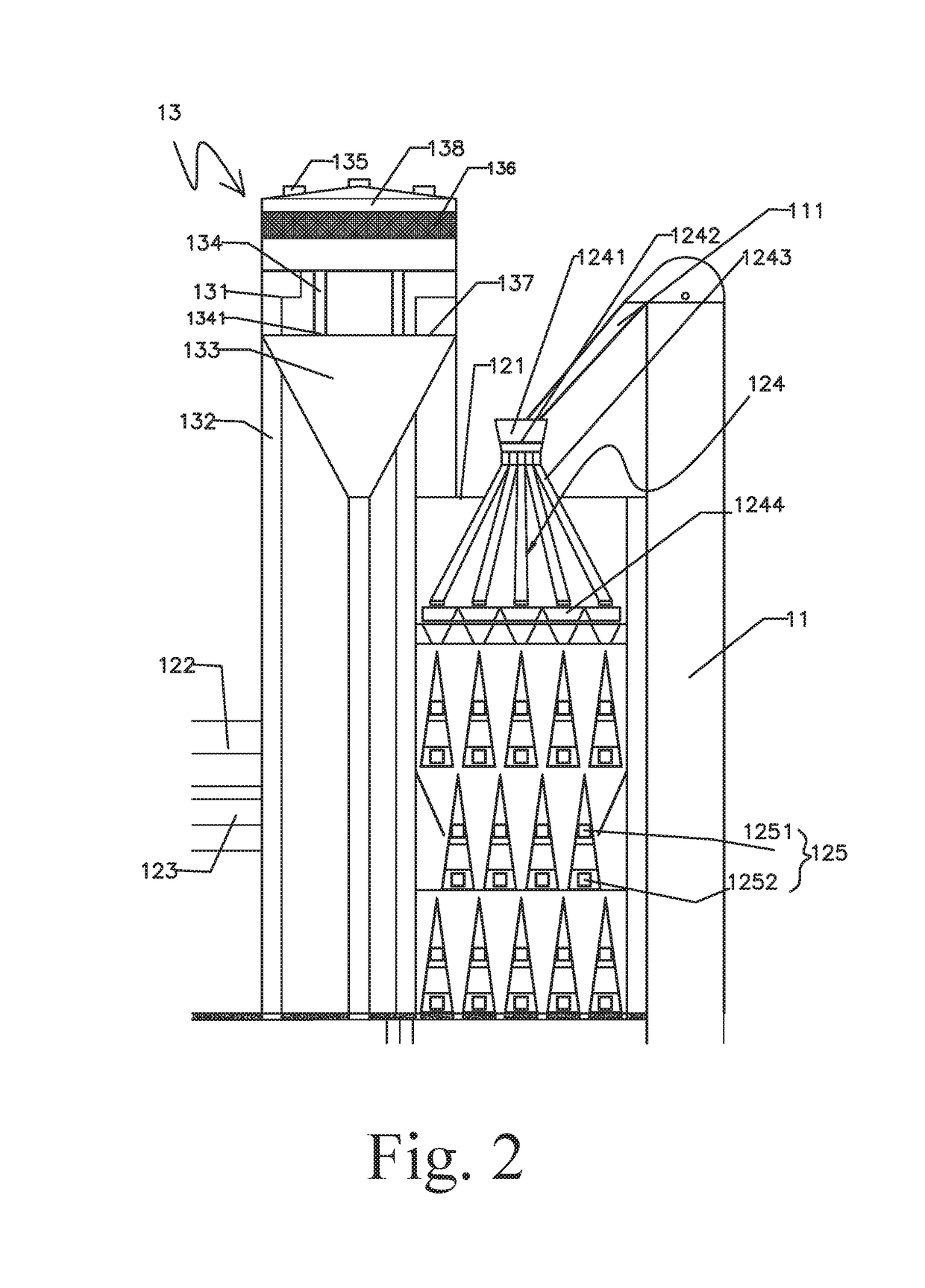

A thermal cycle continuous automated coal pyrolyzing furnace, includes a furnace body, a coal feeding device, a preheating device, an inputting coal regulating bunker, an inputting coal cooling device, a coal pyrolyzation coking device, a coke modification device, a dry quenching device and a raw gas exporting device; wherein the coal feeding device, the pre-heating device, the inputting coal regulating bunker, the inputting coal cooling device, the coal pyrolyzation coking device, the coke modification device, the dry quenching device and the raw gas exporting device are all integrated on the furnace body; the coal pyrolyzation coking device includes a coking chamber, an external combustion gas heating device, an internal combustion gas heating device and a flame path bow. Utilizing the coal pyrolyzing furnace is capable of achieving continuously quenching, so as to improve quenching efficiency and decrease quenching cost.

Owner:SHANXI XINLI ENERGY TECH

Heat removal and recovery in biomass pyrolysis

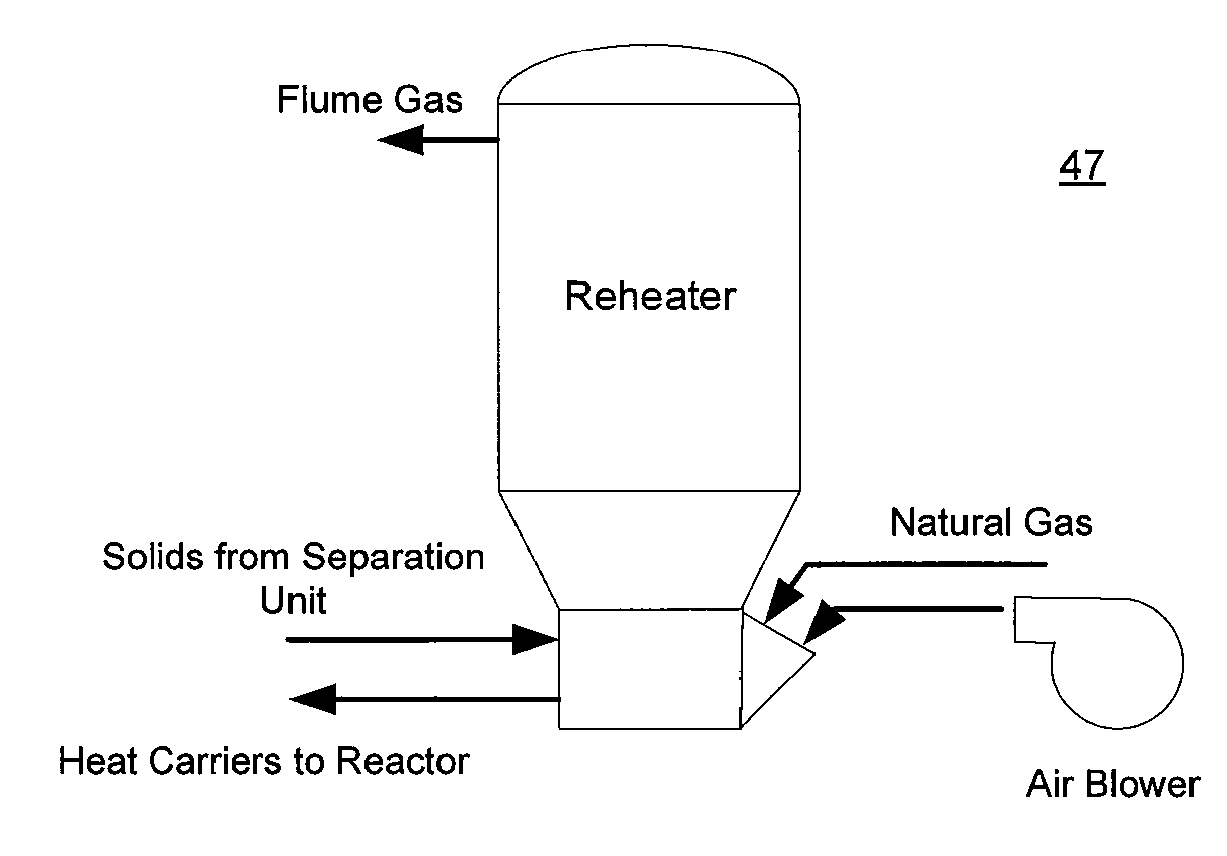

ActiveUS20120214113A1Easy to controlImprove operational flexibilityCoke quenchingDirect heating destructive distillationHeat carrierBiomass

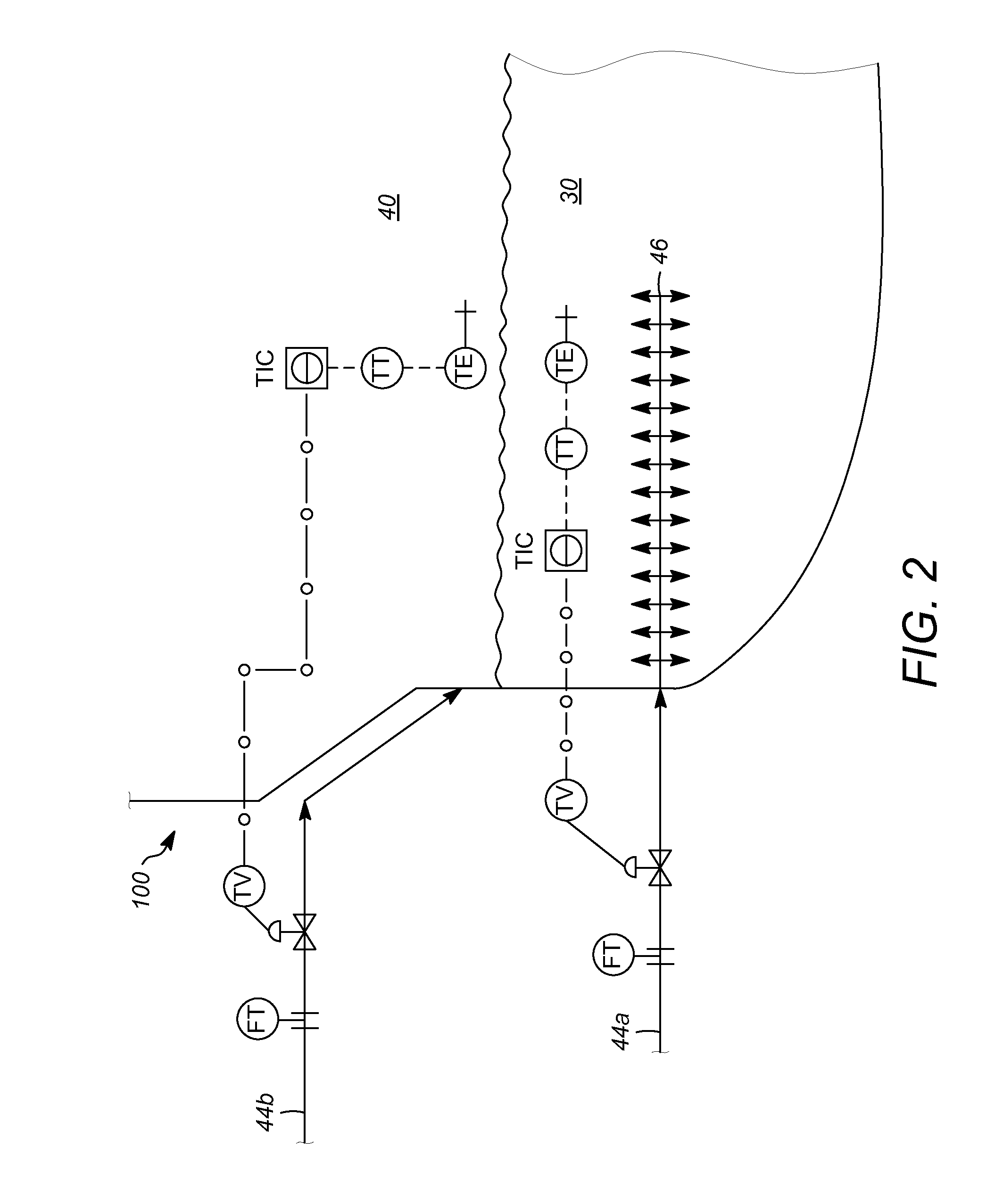

Pyrolysis methods and apparatuses that allow effective heat removal, for example when necessary to achieve a desired throughput or process a desired type of biomass, are disclosed. According to representative methods, the use of a quench medium (e.g., water), either as a primary or a secondary type of heat removal, allows greater control of process temperatures, particularly in the reheater where char, as a solid byproduct of pyrolysis, is combusted. Quench medium may be distributed to one or more locations within the reheater vessel, such as above and / or within a dense phase bed of fluidized particles of a solid heat carrier (e.g., sand) to better control heat removal.

Owner:ENSYN RENEWABLES

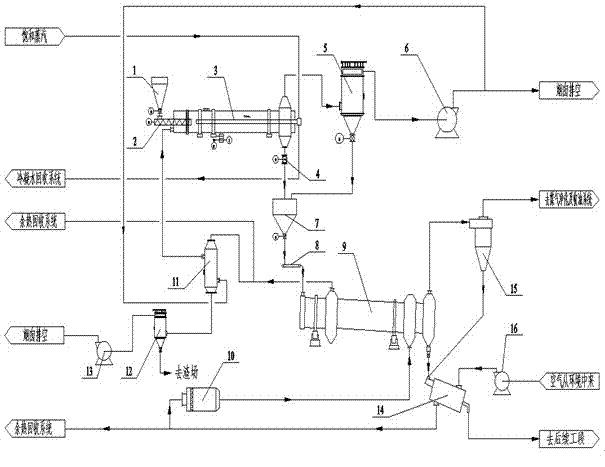

Drying and dry distillation combined quality improving process and system for low rank coal

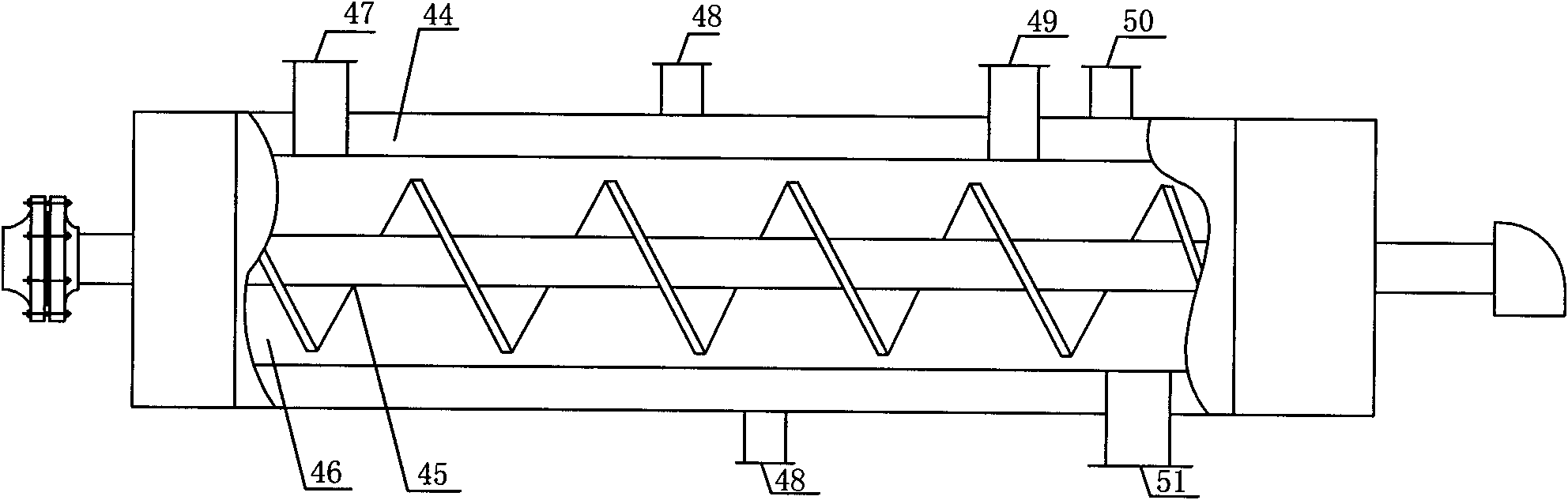

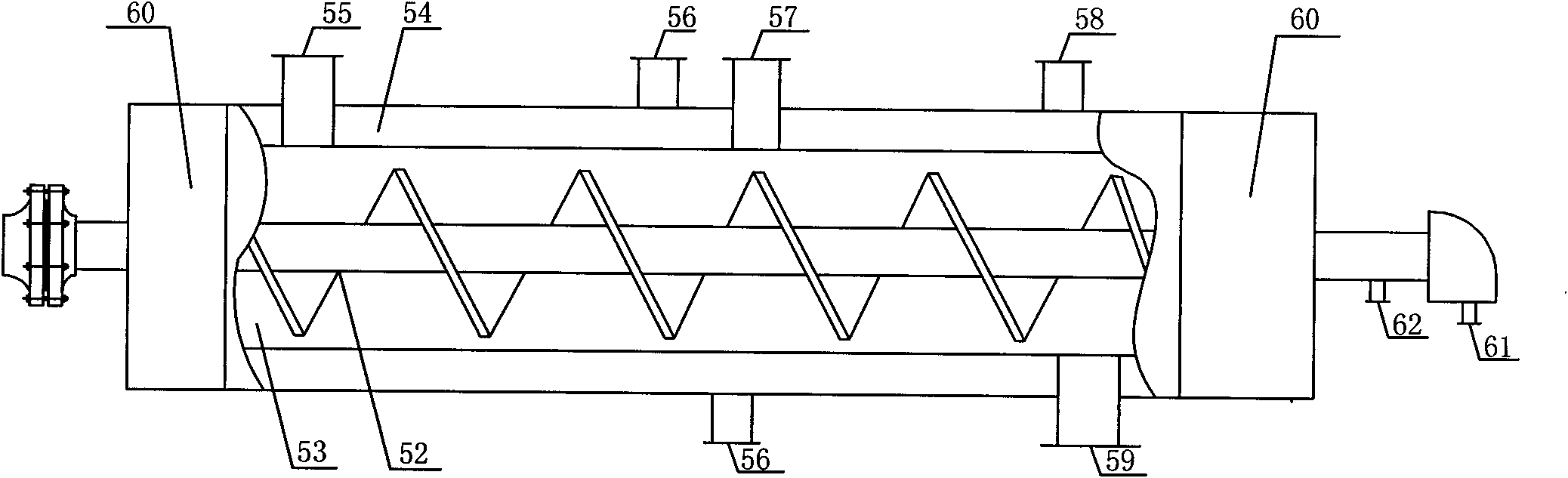

The invention discloses a drying and dry distillation combined quality improving process and a drying and dry distillation combined quality improving system for low rank coal, which are used for overcoming the defects existing in the prior art and are particularly suitable for drying and dry distillation combined quality improvement of brown coal with high water content or other low rank coal such as long flame coal, non-caking coal or weakly caking coal, gas coal and the like. In the process, a combined quality improving method in which a steam revolving drier for drying and a multi-pipe revolving low-temperature dry distiller for dry distillation are provided is adopted, so that the problems of large coking wastewater handling capacity, large coal gas handling capacity and the like existing in a pure dry distillation process are solved. The drying and multi-pipe revolving low-temperature dry distillation combined quality improving process provided by the invention has the advantages of high energy utilization ratio, safe and stable systems, small dry distillation gas handling capacity, small coking wastewater handling capacity, high tar yield, high coal gas heat value and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Gas heat carrier low-temperature pyrolyzing furnace and gas heat carrier low-temperature pyrolyzing method

InactiveCN102676187AImprove heat utilization efficiencyReduce contact timeCoke quenchingDirect heating destructive distillationHeat carrierBrick

The invention discloses a gas heat carrier low-temperature pyrolyzing furnace and a gas heat carrier low-temperature pyrolyzing method. High-moisture materials are subjected to drying preprocessing in the pyrolyzing furnace by means of a gas heat carrier convection drying method, and hot gas is uniformly distributed in a drying section under the action of a gas distribution umbrella. Dried materials enter a dry distillation area where gas heat carriers transversely penetrate through materials, and exchange heat with the gas heat carriers prior to heating to enable low-temperature pyrolytic reaction. Gas in the furnace is formed by mixing lower coke quenching coal gas with hot flue gas in a combustion area, enters a flame path, then flows across a material layer from a flame path lattice wall to a gas collection lattice wall to enter a gas collection chamber, and is finally led out of the furnace through a gas collection passage formed by double-faced gas collection lattice walls and gas collection chamber gas distribution bricks. Pyrolyzed product hot semi-cokes enter a combined dry quenching device to be cooled and pass through a coal gas quenching area and a water-cooling heat exchange area sequentially. A guide chute on the lower portion of the furnace is connected with a discharger and a conveyor, and semi-cokes are uniformly led out and conveyed to a semi-coke storage yard under the action of the discharger and the conveyor.

Owner:北京德天御投资管理有限责任公司

Coke dry quenching slope air course supporting brick overhaul construction process

ActiveCN102191066AExtended service lifeShorten maintenance periodCoke quenchingBrickArchitectural engineering

The invention discloses a coke dry quenching slope air course supporting brick overhaul construction process, which comprises the following steps: a) mounting a suspended ceiling supporting device; b) removing part of refractory bricks of a pillar of the slope air course; c) mounting an piece for anchoring the root part of the pillar of the oblique air course; d) providing castable and making castable prefabricated bricks; e) constructing the castable and building the castable prefabricated bricks; and f) removing the ceiling supporting device. The coke dry quenching slope air course supporting brick overhaul construction process has the advantages of prolonging the service life of the supporting part of the slope air course, reducing overhaul construction period, reducing maintenance cost and saving production cost.

Owner:CHINA MCC5 GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com